查询2526供应商

USB DUAL POWER CONTROL SWITCHES

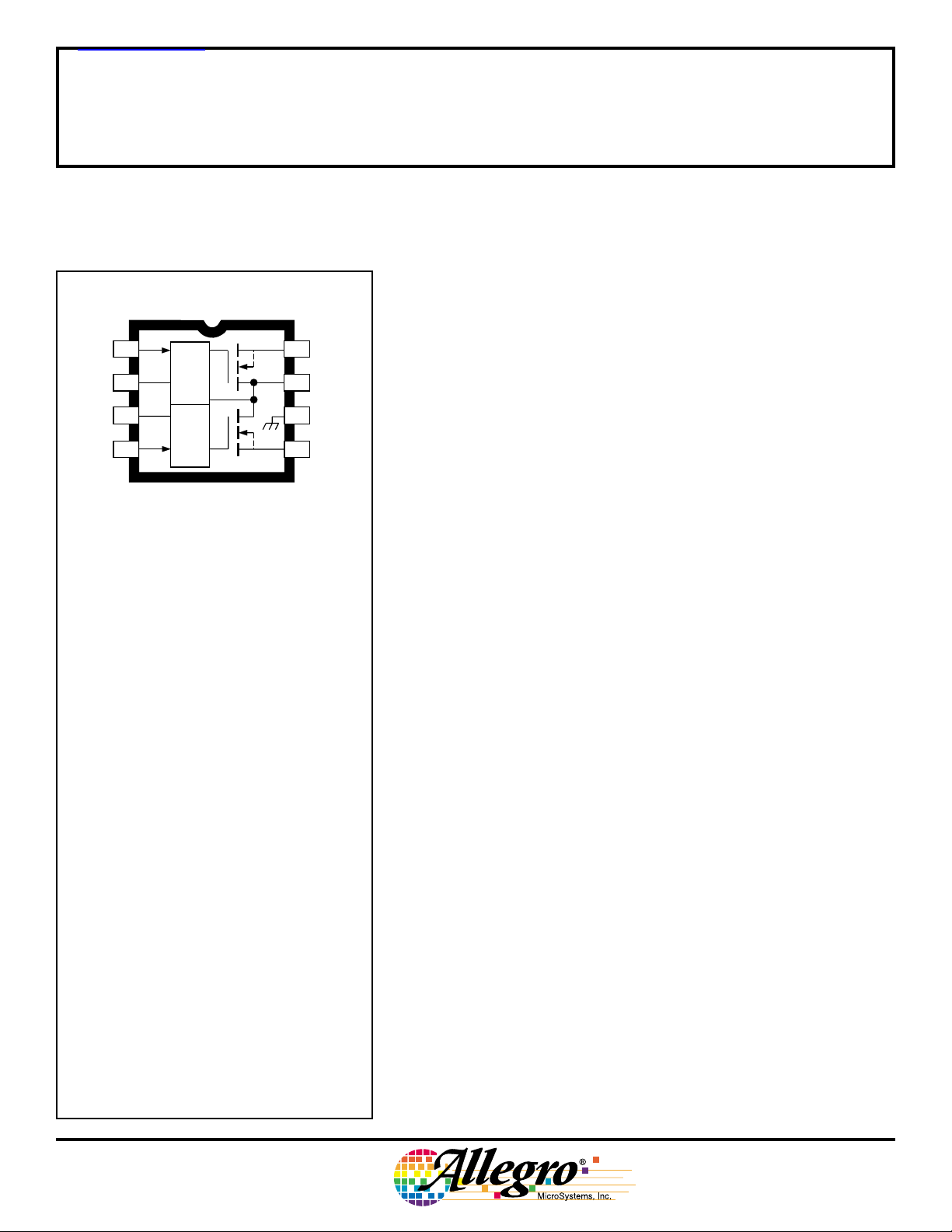

A2526EM

EN

FLG

FLG

EN

Note that the A2526EM (DIP) and the

A2526EL (SOIC) are electrically identical and

share a common terminal number assignment.

1

A

2

A

3

B

45

B

GATE

CONTROL

GATE

CONTROL

ADVANCE INFORMATION

(subject to change without notice)

March 5, 1999

ABSOLUTE MAXIMUM RATINGS

Supply Voltage, V

Output Voltage, V

Output Current,

I

................. Internally Limited

OUT

ENABLE Voltage Range,

......................... –0.3 V to 10 V

V

EN

Fault Flag Voltage, V

Fault Flag Current, I

Package Power Dissipation,

................................. See Graph

P

D

Operating Temperature Range,

......................... -40°C to +85°C

T

A

Junction Temperature, T

Storage Temperature Range,

T

........................... -65°C to 150°C

S

* Fault conditions that produce excessive

junction temperature will activate device

thermal shutdown circuitry. These conditions

can be tolerated but should be avoided.

..................... 6.0 V

IN

................... 6.0 V

OUT

FLG

............. 50 mA

FLG

J

8

OUT

7

IN

GND

6

OUT

Dwg. PP-070-2

.............. 8.0 V

....... +150°C*

2526

AND

Data Sheet

27447.2

2536

The A2526EL/M and A2536EL/M are integrated high-side dual

power switches, optimized for self-powered and bus-powered Universal Serial Bus (USB) applications. Few external components are

A

B

necessary to satisfy USB requirements. The A2526EL/EM ENABLE

inputs are active high; the A2536EL/EM are active low.

All devices are ideally suited for USB applications. Each switch

channel supplies up to 500 mA as required by USB peripheral devices.

In addition, the switch’s low on-resistance permits achieving the USB

voltage-drop requirements. Fault current is limited to typically

750 mA, satisfying the UL 25 VA safety requirements, and a flag

output is available to indicate a fault condition to the local USB

controller. Momentary voltage drops that may occur on the upstream

port when the switch is enabled in bus-powered applications is eliminated by a “soft start” feature.

Additional features include thermal shutdown to prevent catastrophic

switch failure from high-current loads, undervoltage lockout to ensure

that the device remains OFF unless there is a valid input voltage

present, and 3.3 V and 5 V logic-compatible enable inputs.

These switches are provided in 8-pin mini-DIP (suffix ‘M’) and

8-lead SOIC (suffix ‘L’) packages.

Features

■ 2.7 V to 5.8 V Input

■ Up to 500 mA Continuous Load Current per Port

■ 140 mΩ Maximum ON-Resistance

■ 1.25 A Maximum Short-Circuit Current Limit

■ Individual Open-Drain Fault Flag Outputs

■ 110 µA Typical ON-State Supply Current

■ 1 µA Typical OFF-State Supply Current

■ Outputs Can be Forced Higher Than Input (off-state)

■ Thermal Shutdown

■ 2.4 V Typical Undervoltage Lockout

■ 1 ms Turn On (soft-start) and Fast Turn Off

■ Active-High or Active-Low Enable Versions

■ Improved Replacements for MIC2526-1 and MIC2526-2

Applications

■ USB Hosts and Self-Powered Hubs

■ USB Bus-Powered Hubs

■ Hot Plug-In Power Supplies

■ Battery-Charger Circuits

2526

AND

2536

USB

DUAL POWER CONTROL

SWITCHES

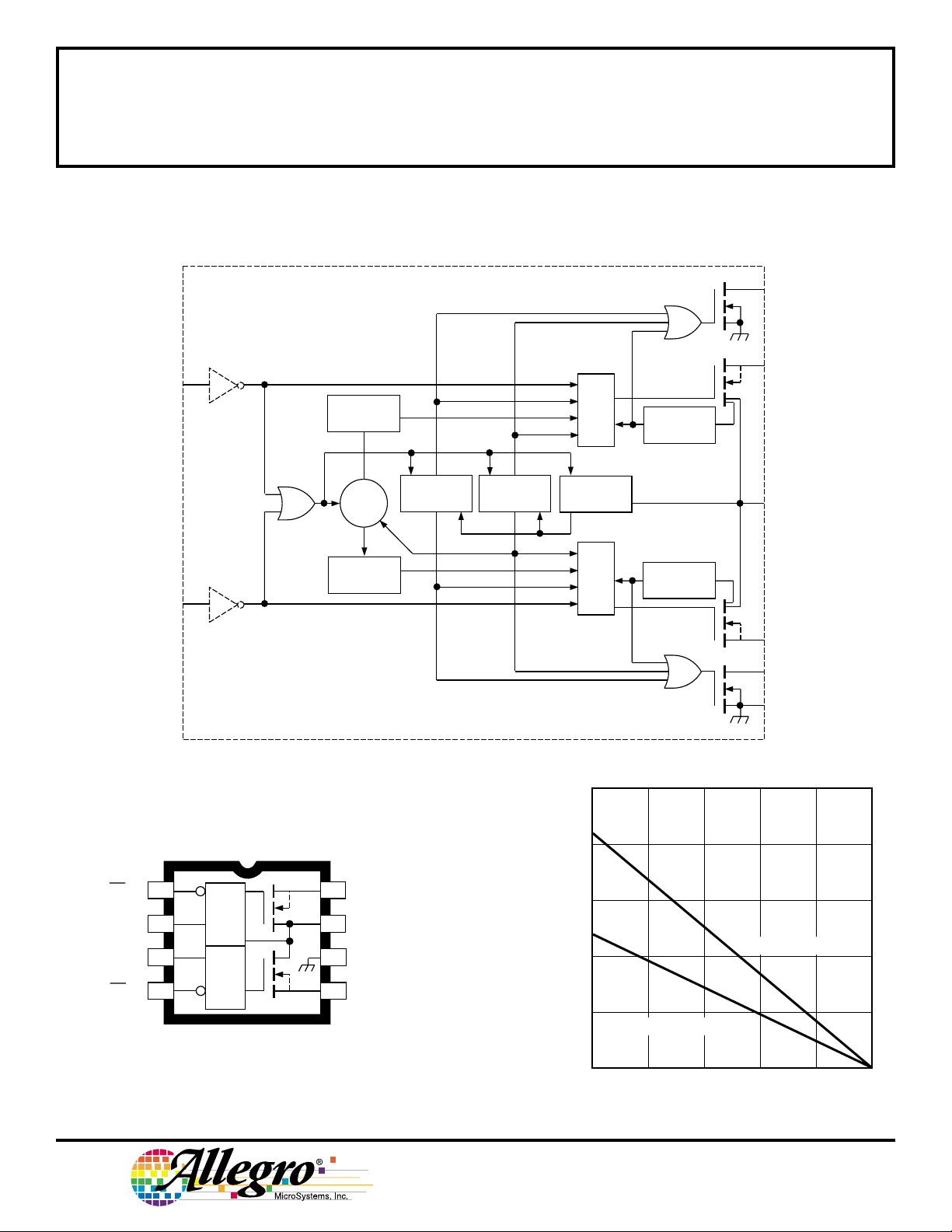

FUNCTIONAL BLOCK DIAGRAM

FLG

A

EN

EN

A2536 ONLY

A

A2536 ONLY

B

CHARGE

PUMP

OSC

CHARGE

PUMP

TSD

UVLO

1.2 V

REF.

2.5

GATE

CONTROL

GATE

CONTROL

CURRENT

LIMIT

CURRENT

LIMIT

OUT

IN

OUT

FLG

GND

Dwg. FP-049-1

A

B

B

A2536EM

EN

FLG

FLG

EN

1

A

2

A

3

B

45

B

GATE

CONTROL

GATE

CONTROL

Note that the A2536EM (DIP) and the

A2536EL (SOIC) are electrically identical and

share a common terminal number assignment.

8

OUT

IN

7

GND

6

OUT

Dwg. PP-070-3

2.0

A

B

1.5

1.0

0.5

0

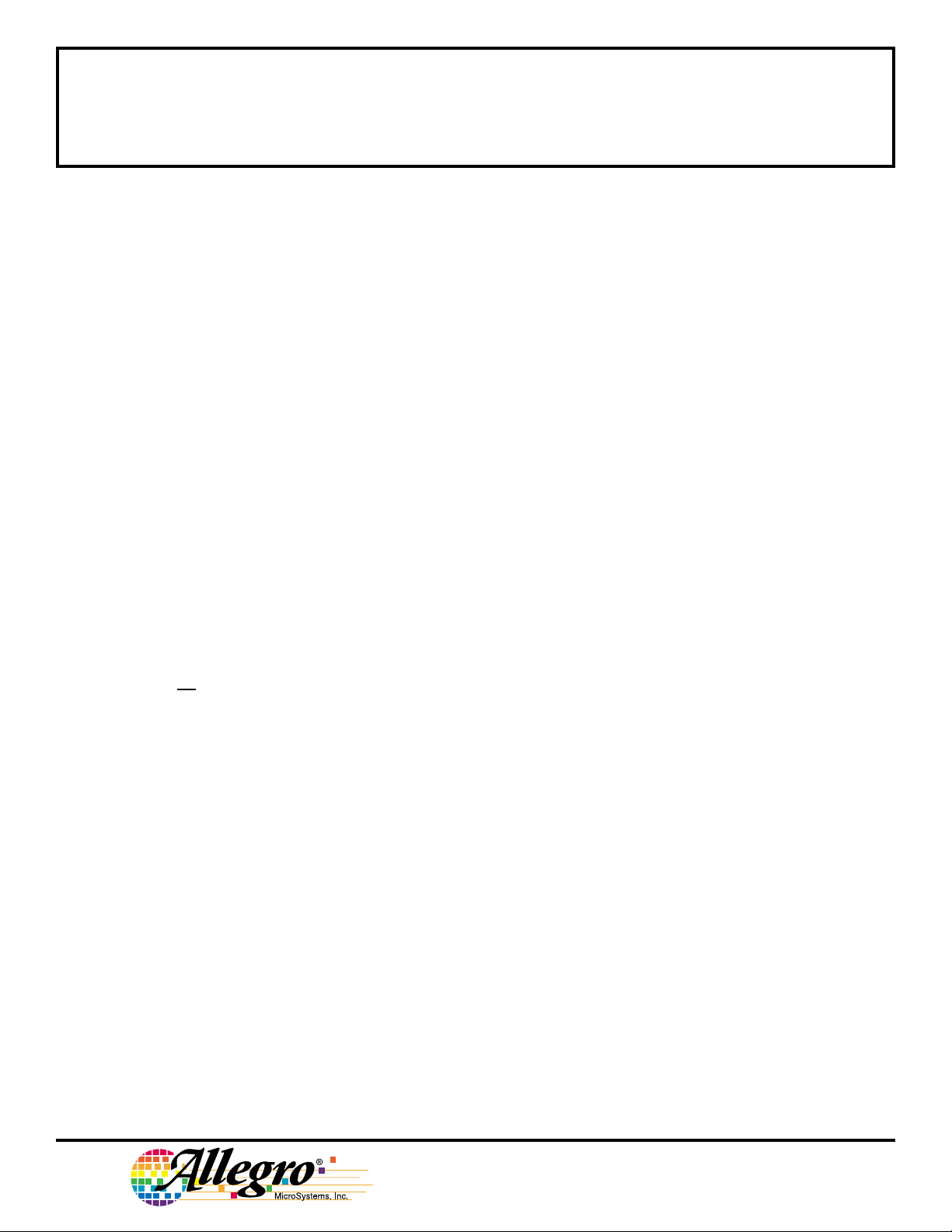

ALLOWABLE PACKAGE POWER DISSIPATION IN WATTS

SUFFIX 'L', R

25

50 75 100 125 150

AMBIENT TEMPERATURE IN °C

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1999, Allegro MicroSystems, Inc.

θJA

= 108°C/W

SUFFIX 'M', R

θJA

= 60°C/W

Dwg. GP-009-2

2526

AND

2536

USB

DUAL POWER CONTROL

SWITCHES

Electrical Characteristics at T

= 25°C, V

A

= 5 V (unless otherwise noted).

IN

Limits

Parameter Test Conditions Min Typ Max Units

Operating Voltage Range V

IN

Switch Resistance VIN = 5 V, I

= 500 mA – 100 140 mΩ

OUT

2.7 – 5.8 V

VIN = 3.3 V, IOUT = 500 mA – 100 140 mΩ

Output Leakage Current Each output (output disabled), VIN = 5 V, V

= 0 – – 10 µA

OUT

Maximum Load Current Each output 500 – – mA

Short-Circuit Current Limit Each output (enable into load), V

Current-Limit Threshold Ramped load applied to enabled output, V

= 4 V 0.5 – 1.25 A

OUT

≤ 4 V – 1.6 – A

OUT

ENABLE Input Threshold Low-to-high transition – 2.1 2.4 V

High-to-low transition 0.8 1.9 – V

ENABLE Input Hysteresis – 0.2 – V

ENABLE Input Current V

= 0 V to 5.5 V – ±0.01 ±1.0 µA

EN

ENABLE Input Cap. – 1.0 – pF

Output Turn-On Delay R

Output Turn-On Rise Time R

Output Turnoff Delay R

Output Turnoff Fall Time R

Error Flag Output VIN = 5 V, I

Resistance

Error Flag Off Current V

= 10Ω, each output – 0.5 – ms

L

= 10Ω each output – 1.0 – ms

L

= 10Ω each output – 1.0 – µs

L

= 10Ω each output – 1.0 – µs

L

= 10 mA – 10 – Ω

L

VIN = 3.3 V, I

= 5 V – 0.01 – µA

FLG

= 10 mA – 15 – Ω

L

Supply Current Both switches OFF (see note), OUT = open – 0.75 5.0 µA

Both switches ON (see note), OUT = open – 110 160 µA

UVLO Threshold Increasing V

Decreasing V

Over-Temperature Increasing T

Shutdown Threshold

Decreasing T

IN

IN

J

J

– 2.5 – V

– 2.3 – V

– 165 – °C

– 155 – °C

Note — OFF is ≤ 0.8 V and ON is ≥ 2.4 V (active high) for the A2526EL/EM. OFF is ≥ 2.4 V and ON is ≤ 0.8 V (active low) for

the A2536EL/EM.

2526

AND

2536

USB

DUAL POWER CONTROL

SWITCHES

FUNCTIONAL DESCRIPTION

Power switch

The power switch is an N-channel MOSFET with a maximum

on-state resistance of 140 mΩ (VIN = 5 V). Configured as a

high-side switch, the power switch prevents current flow in

either direction if disabled. The drain body diode is disconnected from the source when the switch is OFF allowing the

output voltage to exceed the input voltage without causing

current conduction. The power switch supplies a minimum of

500 mA per switch.

Charge pump

An internal charge pump supplies power to the driver circuit

and provides the necessary voltage to pull the gate of the

MOSFET above the source. The charge pump operates from

input voltages as low as 2.7 V. The charge pump is limited to

2.5 µA to establish a controlled turn on time of typically 1 ms.

Driver

The driver controls the gate voltage of the power switch. To

limit large current surges and reduce the associated electromagnetic interference (EMI) produced, the driver incorporates

circuitry that controls the rise times and fall times of the output

voltage. The rise time is typically 1 ms.

ENABLE (EN or EN)

Fault Flag (FLG)

This open drain output is asserted (active low) when an

overcurrent or over temperature condition is encountered. The

output will remain asserted until the overcurrent or over

temperature condition is removed.

Current sense

A sense FET monitors the current supplied to the load. The

sense FET measures current more efficiently than conventional

resistance methods. When an overload or short circuit is

encountered, the current-sense circuitry sends a control signal to

the driver. The driver in turn reduces the gate voltage and

drives the power FET into its saturation region, which switches

the output into a constant-current mode and holds the current

constant while varying the voltage on the load.

Thermal sense

An internal thermal-sense circuit shuts off the power switch

when the junction temperature rises to approximately 165°C.

Hysteresis is built into the thermal sense circuit. After the

device has cooled approximately 10°C, the switch turns back

ON. The switch continues to cycle off and on until the fault is

removed.

Undervoltage lockout

The logic enable disables the power switch and the bias for the

charge pump, driver, and other circuitry to reduce the supply

current to less than 5 µA maximum when a logic high is present

on EN (A2526) or a logic low is present (A2536). The proper

logic level restores bias to the drive and control circuits and

turns the power ON. The enable input is a compatible with both

TTL and CMOS logic levels.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

A voltage-sense circuit monitors the input voltage. When the

input voltage is approximately 2 V, a control signal turns OFF

the power switch.

DUAL POWER CONTROL

APPLICATIONS INFORMATION

2526

AND

2536

USB

SWITCHES

Overcurrent

A sense FET is employed for overcurrent conditions. Unlike

current-sense resistors, sense FETs do not increase the series

resistance of the current path. When an overcurrent condition is

detected, the device maintains a constant output current and

reduces the output voltage accordingly. Complete shutdown

occurs only if the fault is present long enough to activate

thermal limiting.

Three possible overload conditions can occur. In the first

condition, the output has been shorted before the device is

enabled or between VIN has been applied. The device senses

the short and immediately switches into a constant-current

output.

In the second condition, the short occurs while the device is

enabled. At the instant the short occurs, very high currents may

flow for a short time before the current-limit circuit can react .

After the current-limit circuit has tripped (reached the

overcurrent trip threshold) the device switches into constantcurrent mode.

In the third condition, the load has been gradually increased

beyond the recommended operating current. The current is

permitted to rise until the current-limit threshold is reached or

until the thermal limit of the device is exceeded. The device is

capable of delivering current up to the current-limit threshold

without damage. Once the threshold has been reached, the

device switches into its constant-current mode.

Fault Flag (FLG)

The FLG open-drain output is asserted (active low) when an

overcurrent or over-temperature condition is encountered. The

output will remain asserted until the overcurrent or overtemperature condition is removed. Connecting a heavy

capacitive load to an enabled device can cause momentary false

over-current reporting from the inrush current flowing through

the device, charging the downstream capacitor. An RC filter

can be connected to the terminal to reduce false overcurrent

reporting. Using low-ESR electrolytic capacitors on the output

lowers the inrush current flow through the device during hotplug events by providing a low impedance energy source,

thereby reducing erroneous overcurrent reporting.

Power dissipation and junction temperature

The low on-resistance of the n-channel MOSFET allows small

surface-mount packages, such as an SOIC, to pass large

currents. The thermal resistance of these packages are high

compared to those of power packages; it is good design practice

to check power dissipation and junction temperature. The first

step is to find r

ture. Next, calculate the power dissipation using:

PD = r

DS(on)

Finally, calculate the junction temperature:

TJ = PD x R

where:

TA = ambient temperature °C

R

= thermal resistance (

θJA

Thermal protection

Thermal protection prevents damage to the IC when heavyoverload or short-circuit faults are present for extended periods

of time. The faults force these devices into constant-current

mode, which causes the voltage across the high-side switch to

increase; under short-circuit conditions, the voltage across the

switch is equal to the input voltage. The increased dissipation

causes the junction temperature to rise to high levels. The

protection circuit senses the junction temperature of the switch

and shuts it OFF. Hysteresis is built into the thermal sense

circuit, and after the device has cooled approximately 20°, the

switch turns back ON. The switch continues to cycle in this

manner until the load fault or input power is removed.

Undervoltage lock-out (UVLO)

An undervoltage lockout ensures that the power switch is in the

OFF state at power up. Whenever the input voltage falls below

approximately 2 V, the power switch will be quickly turned

OFF. This facilitates the design of hot-insertion systems where

it is not possible to turn OFF the power switch before input

power is removed. The UVLO will also keep the switch from

being turned ON until the power supply has reached at least

2 V, even if the switch is enabled. Upon reinsertion, the power

switch will be turned ON, with a controlled rise time to reduce

EMI and voltage overshoots.

Power supply considerations

A 0.1 µF ceramic bypass capacitor between IN and GND, close

to the device, is recommended. Placing a high-value electrolytic capacitor on the output terminals is also desirable when the

output load is heavy. The capacitor reduces power supply

transients that may cause ringing on the input. Also, bypassing

the output with a 0.01 µF to 0.1 µF ceramic capacitor improves

the immunity of the device to short-circuit transients.

at the input voltage and operating tempera-

DS(on)

2

x I

+ T

θJA

A

SOIC = 108°C/W, DIP = 60°C/W

).

2526

AND

2536

USB

DUAL POWER CONTROL

SWITCHES

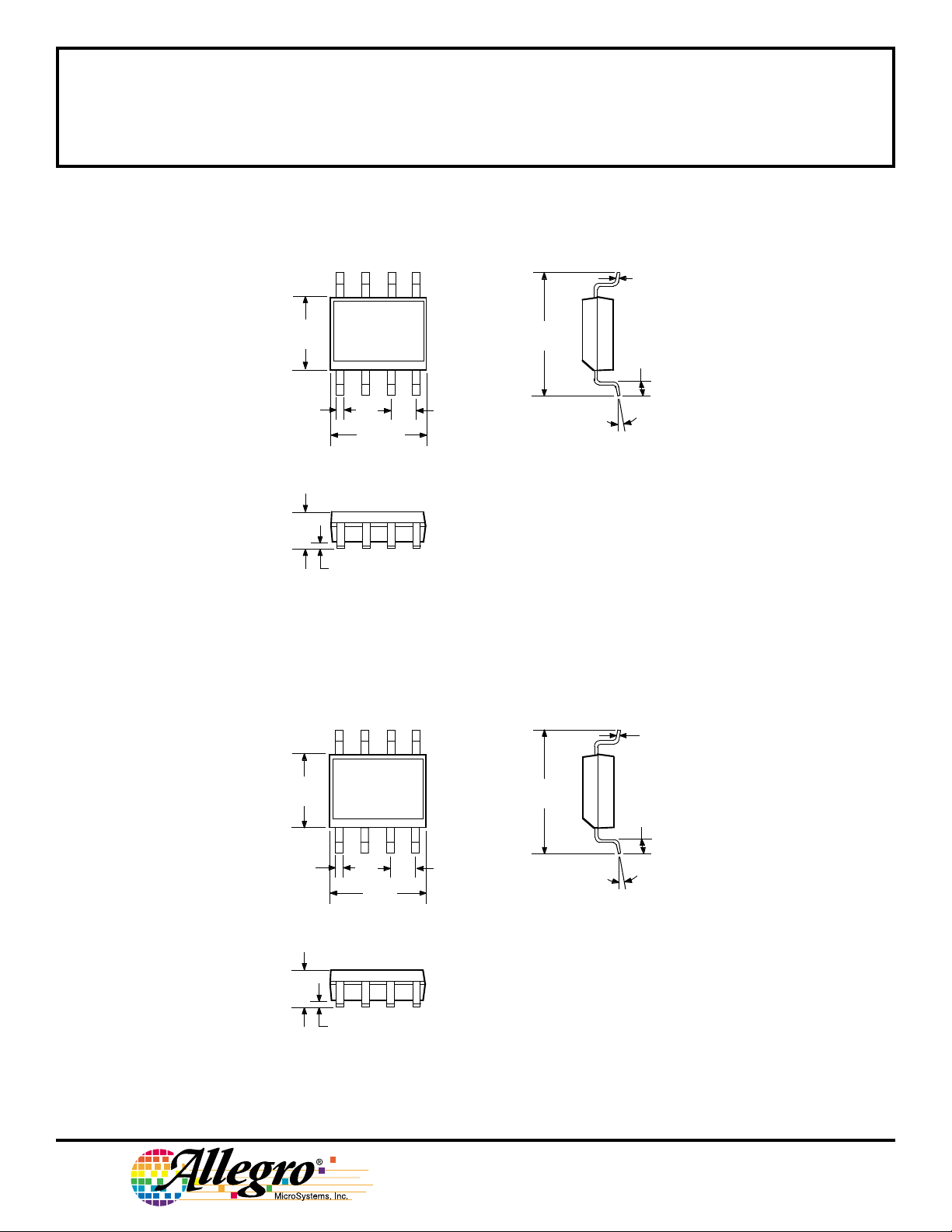

A2526EL and A2536EL

Dimensions in Inches

(for reference only)

0.1574

0.1497

0.020

0.013

0.0688

0.0532

8

1

0.1968

0.1890

0.0040

0.2440

0.2284

0.050

BSC

MIN.

Dimensions in Millimeters

(controlling dimensions)

0.0098

0.0075

0.050

0.016

0° TO 8°

Dwg. MA-007-8 in

8

4.00

3.80

0.51

1

0.33

1.75

1.35

0.10

NOTES: 1. Lead spacing tolerance is non-cumulative.

2. Exact body and lead configuration at vendor’s option within limits shown.

6.20

5.80

1.27

5.00

BSC

4.80

MIN.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

0° TO 8°

Dwg. MA-007-8 mm

0.25

0.19

1.27

0.40

0.280

0.240

A2526EM and A2536EM

Dimensions in Inches

(controlling dimensions)

0.014

58

0.008

2526

AND

2536

USB

DUAL POWER CONTROL

SWITCHES

0.430

MAX

0.300

BSC

0.210

MAX

7.11

6.10

0.015

MIN

1

0.070

0.045

8

1

1.77

1.15

0.022

0.014

0.400

0.355

10.16

9.02

4

0.005

MIN

0.150

0.115

0.100

BSC

Dimensions in Millimeters

(for reference only)

5

4

0.13

MIN

0.355

0.204

Dwg. MA-001-8A in

10.92

MAX

7.62

BSC

5.33

MAX

0.39

MIN

0.558

0.356

2.54

BSC

3.81

2.93

NOTES: 1. Leads 1, 4, 5, and 8 may be half leads at vendor’s option.

2. Lead thickness is measured at seating plane or below.

3. Lead spacing tolerance is non-cumulative.

4. Exact body and lead configuration at vendor’s option within limits shown.

Dwg. MA-001-8A mm

2526

AND

2536

USB

DUAL POWER CONTROL

SWITCHES

Allegro MicroSystems, Inc. reserves the right to make,

from time to time, such departures from the detail specifications as may be required to permit improvements in the

design of its products.

The information included herein is believed to be

accurate and reliable. However, Allegro MicroSystems, Inc.

assumes no responsibility for its use; nor for any infringements of patents or other rights of third parties which may

result from its use.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...