Page 1

*941079-00*

941079-00

Maintenance Kit

Page 2

Page: TOC-1

Table of Contents

Description: Page Number:

Pictorial Index to Parts (immediatey follows “Table of Contents”) .............................PIP-1, PIP-2

1. Center Case Parts

Insert-98/99 One Piece Cover .........................................................................................1-1

NL Drive Screw-98/99 Device ..........................................................................................1-2

Control Link Pin-Touch Bar Device .................................................................................1-2

Tailpiece Guide .............................................................................................................. 1-3

2. Dogging Assembly Parts

Hex Dogging Replacement Kit ........................................................................................2-1

Hex Dogging Shaft .........................................................................................................2-1

Dogging Adapter Spring .................................................................................................. 2-2

Dogging Spring ................................................................................................................2-3

Cylinder Dog Actuator .....................................................................................................2-4

CD Dogging Plug ..............................................................................................................2-4

3. Mechanism Case Parts

Mechanism Case Mounting Bracket ..............................................................................3-1

Anti-Rattle Spring-33/35/98/99 ....................................................................................... 3-2

Cover Plate

Shock Absorber and Holder Assembly..........................................................................3-3

Pushbar Guide (front) ......................................................................................................3-4

Pushbar Guide (rear)......................................................................................................

Stop ............................................................................................................ 3-2

3-5

4. Vertical Rod Parts

Rod Extension Connector ................................................................................................ 4-1

Extension Rod Drill Template-2227/98/9927 ................................................................... 4-1

98/9927 Rod Guide Assembly........................................................................................4-2

1/8 x 7/16 Roll Pin ...........................................................................................................4-2

5. Surface Vertical Latch Parts

299 Strike Shim ...............................................................................................................5-1

Shim-264/299F/499F Strike ............................................................................................ 5-1

Bolt Return Spring ..........................................................................................................5-2

98/9927 Auxiliary Bolt Spring .........................................................................................5-3

Page 3

Page: TOC-2

Table of Contents (continued)

Description: Page Number:

6. Concealed Vertical Latch Parts

Ratchet Lever Spring..................................................................................................... 6-1

#10 External Tooth Lock Washer ................................................................................6-2

Compression Spring-33/3547....................................................................................... 6-2

7. Mounting Hardware, Screws, and Retaining Rings

325 Sex Bolt Assembly ................................................................................................. 7-1

425 Sex Bolt Assembly ................................................................................................. 7-1

10-12 x 10-24 x 1 PTHCS ............................................................................................ 7-2

10-24 x 3/4 PPHMS ..................................................................................................... 7-2

10-24 x 1 PPHMS ......................................................................................................... 7-3

8-32 x 1/4 UFPHMS .................................................................................................... 7-3

10-24 x 3/4 UFPHMS ................................................................................................... 7-4

1/4-20 x 3/4 UFPHMS ................................................................................................. 7-4

8-18 x 1/2 UFPHSMS .................................................................................................. 7-5

12-24 Mechanism Case Screw.................................................................................... 7-5

Truarc Retaining Ring T5304-18

10-32 x 1/4 UFPHMS with Nylock ................................................................................ 7-7

10-24 x 3/4 FPHMS ..................................................................................................... 7-7

.................................................................................... 7-6

8. Trim Parts

Shear Pin ..................................................................................................................... 8-1

Cylinder Retaining Cup................................................................................................ 8-2

992L Lift Spring ............................................................................................................ 8-2

Hex Stud-994/996 Trim................................................................................................ 8-3

1/4-20 Hex AStud ........................................................................................................ 8-3

10-24 x 1 3/8 PPHMS .................................................................................................. 8-4

Truarc Retaining Ring 5160-42 ................................................................................... 8-4

Wave Spring Washer................................................................................................... 8-5

1/4-20 x 5/8 Socket Set Screw ..................................................................................... 8-6

Appendix A: Device Lubrication

Appendix B: Latch Lubrication

Index by Part Number...................................................................................................IPN-1, IPN-2

............................................................................................... A-1

................................................................................................ B-1

Page 4

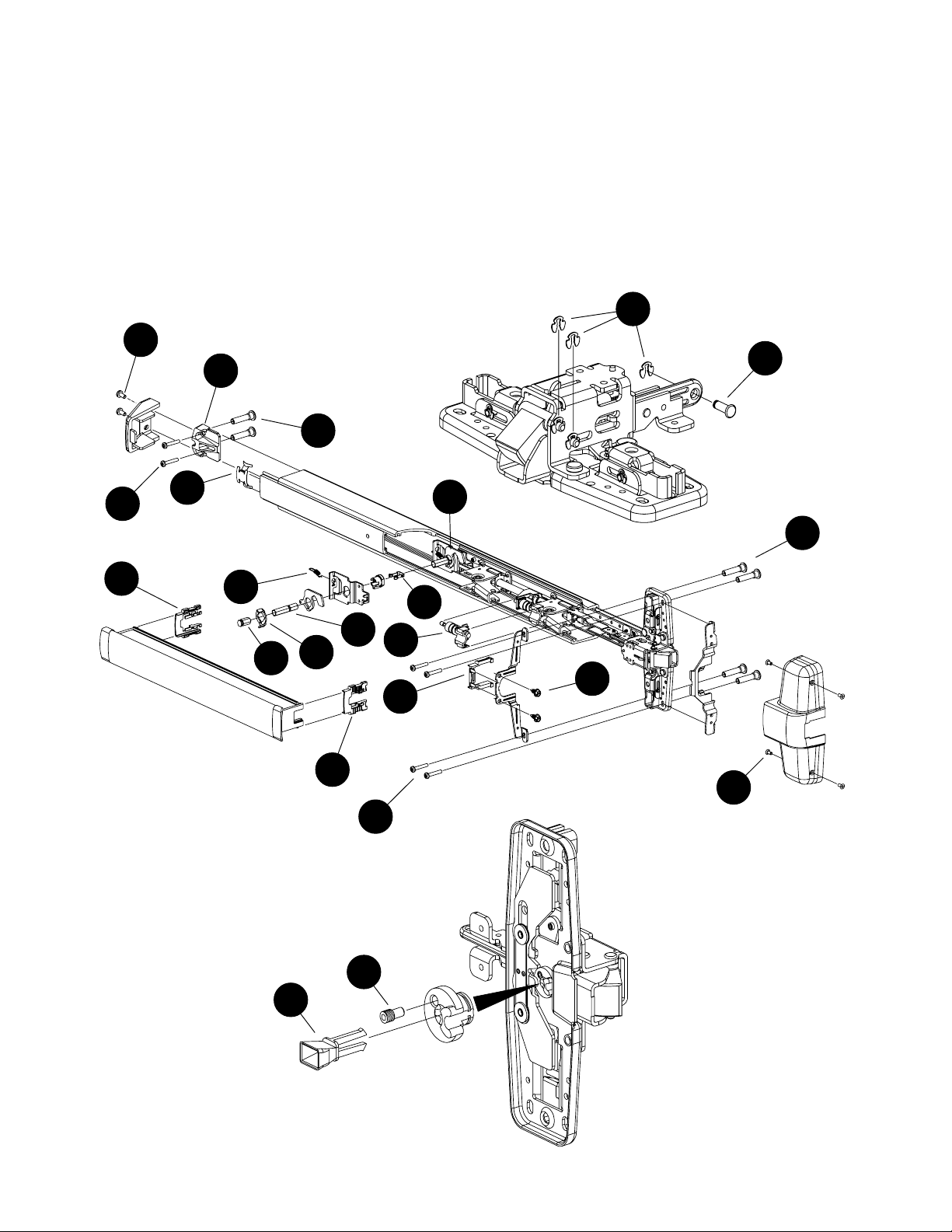

Pictorial Index to Parts

The number in each circle below is the page where information on the part is

found. Use the “Table of Contents” to find items by part description. Use the

“Index by Part Number” in the back of the manual to find items by part number.

7-6

3-1

3-1

7-1

Page: PIP-1

1-2

7-2

3-5

3-2

2-3

2-4

2-4

3-4

2-1

2-1

7-1

2-2

3-4

7-5

3-3

7-5

7-3

1-3

1-2

Page 5

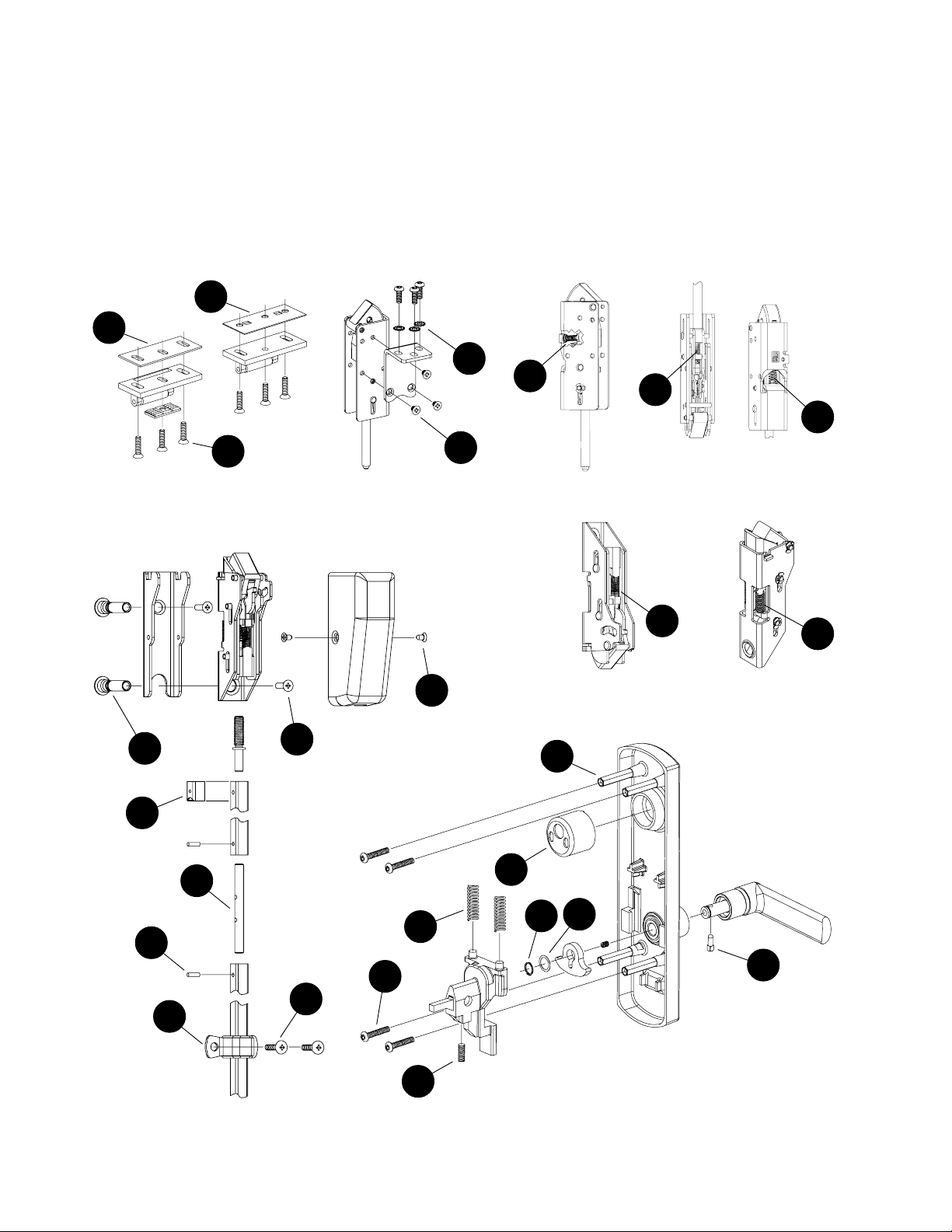

5-1

Page: PIP-2

Pictorial Index to Parts (continued)

The number in each circle below is the page where information on the part is

found. Use the “Table of Contents” to find items by part description. Use the

“Index by Part Number” in the back of the manual to find items by part number.

5-1

6-2

299

7-7

6-1

Spring

299F

7-7

5-2

Spring

6-2

Spring

7-1

4-1

4-2

4-2

4-1

7-4

7-2

8-4

7-3

8-2

8-2

8-4

8-3

8-5

5-2

Spring

5-3

Spring

8-1

8-6

Page 6

This page is intentionally left blank.

Page: 1-1

Page 7

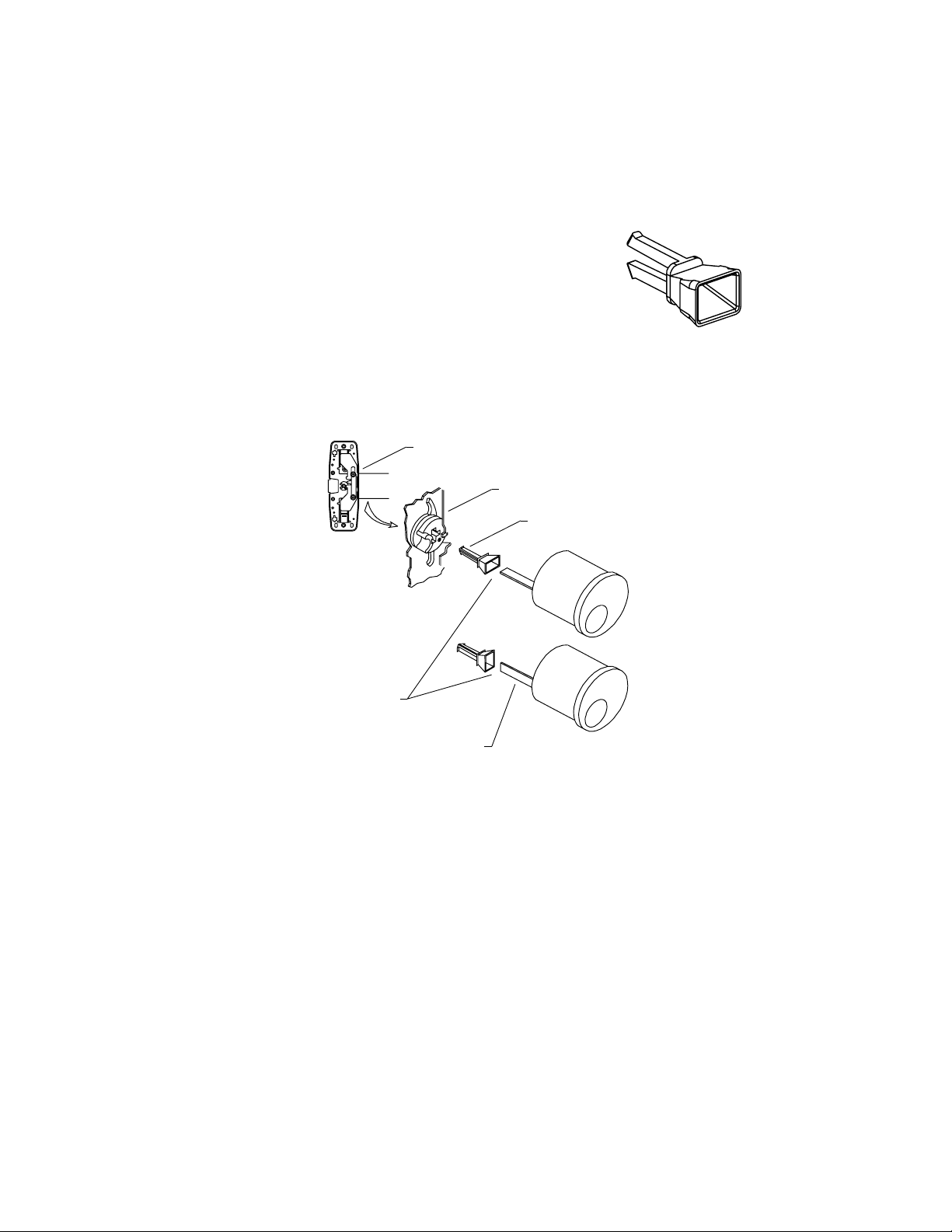

Page: 1-2

1. Center Case Parts

Part Name: NL Drive Screw-98/99 Device Kit Location: Bottom drawer #6

Part Number: 970441-89 unit; 090074-00 bulk, 10/pkg.

Use: 98/99 and 22 devices; BE, EO, DT, NL,

and Rigid applications only

Installation: Use Phillips head screwdriver to turn cam so trim lock slide is in full up position

for RHR or LHR application. Install drive screw in cam using 5/64” hex wrench.

Cam

Cam

RHR LHR

Trim lock slide

in RHR full up

position

Drive

screw

Drive

screw

Part Name: Control Link Pin-Touch Bar Device Kit Location: Top drawer #8

Part Number: 090031-00 bulk, 10/pkg.

Use: 98/99, 33/35, and 22 devices

Installation: Align holes of main control link and control linkage. Insert control link pin.

Main control link

Trim lock slide

in LHR full up

position

Control linkage

Control link pin

Page 8

Page: 1-3

1. Center Case Parts

Part Name: Tailpiece Guide Kit Location: Top drawer #18

Part Number: 050156-00 bulk, 10/pkg.

Use: 98/99 and 22 device keyed (rim cylinder)

trim applications

Installation: Snap pronged end of tailpiece guide into cross-slot of master cylinder cam on

underside of center case. Guide cylinder tailpiece into funnel portion of

tailpiece guide when installing trim.

Underside of center case (99 device shown)

Master cylinder cam

Tailpiece guide

Orient tailpiece guide

to match tailpiece

orientation

Cylinder

tailpiece

Page 9

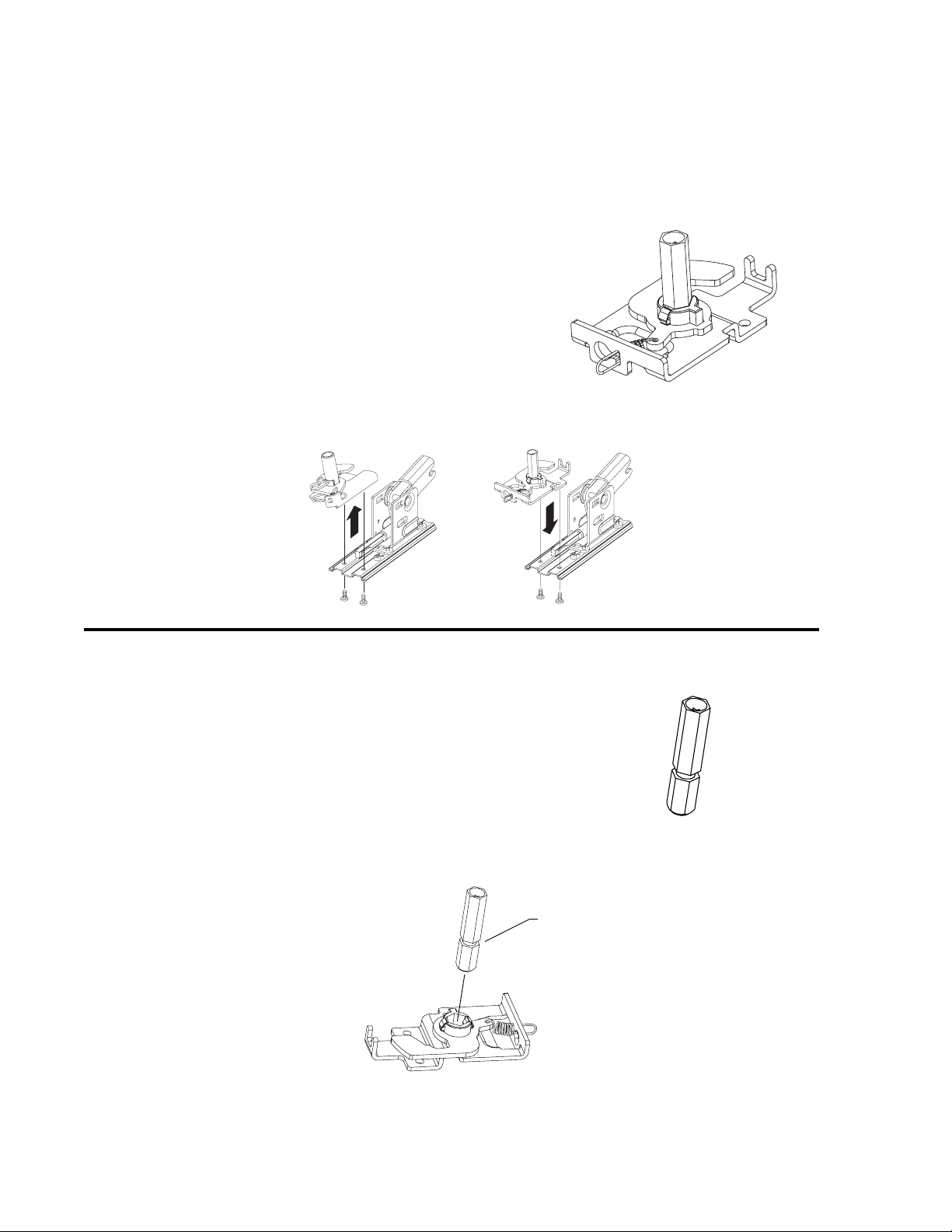

Page: 2-1

2. Dogging Assembly Parts

Part Name: Hex Dogging Replacement Kit Kit Location: Top compartment

Part Number: 15-445-00

Use: To replace existing dogging assemblies

Installation: Remove old dogging assembly, replace with new dogging assembly, and secure

with 2 screws.

Part Name: Hex Dogging Shaft Kit Location: Bottom drawer #5

Part Number: 090040-00 bulk, 2/pkg.

Use: 98/99, 33/35, and 22 dogging assemblies

made after Aug. 1997

Installation: Insert end of shaft that is closest to groove into dogging adapter. Push down

until shaft snaps into place.

Groove

Page 10

Page: 2-2

2. Dogging Assembly Parts

Part Name: Dogging Adapter Spring Kit Location: Bottom drawer #2

Part Number: 090042-00 bulk, 2/pkg.

Use: 98/99, 33/35, and 22 dogging assemblies

made after Aug. 1997

Installation: Pinch legs of spring together and insert into dogging adapter so legs of spring

align with grooves in dogging adapter (A). Insert dogging adapter with spring

through bottom of dogging plate (B). Snap dogging hook over protruding end of

dogging adapter and legs of spring (C). Spring holds dogging adapter, dogging

plate, and dogging hook together (D).

Dogging

adapter

Groove

Dogging

plate

Groove

Dogging

hook

A

C

B

D

Page 11

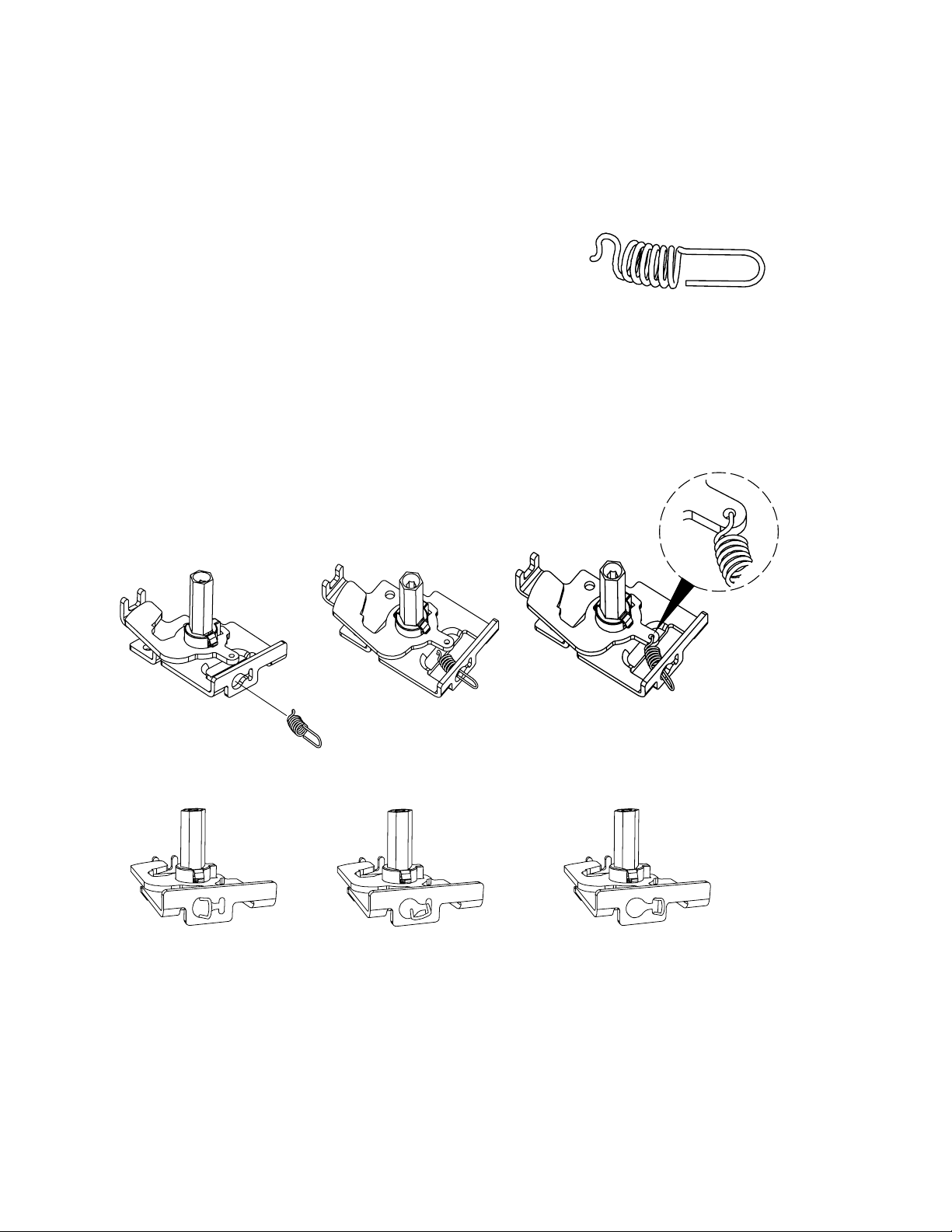

Page: 2-3

2. Dogging Assembly Parts

Part Name: Dogging Spring Kit Location: Bottom drawer #3

Part Number: 090041-00 bulk, 2/pkg.

Use: 98/99, 33/35, and 22 dogging assemblies

made after Aug. 1997

Installation: Hold loop of spring and insert spring through large hole in end of dogging plate

(A and B). Hook short end of spring into hole in dogging hook from top of

dogging hook (C). Slide loop of spring from large hole (D) into smaller hole in

end of dogging plate (E) and align loop vertically (F).

A

D

B

E

C

F

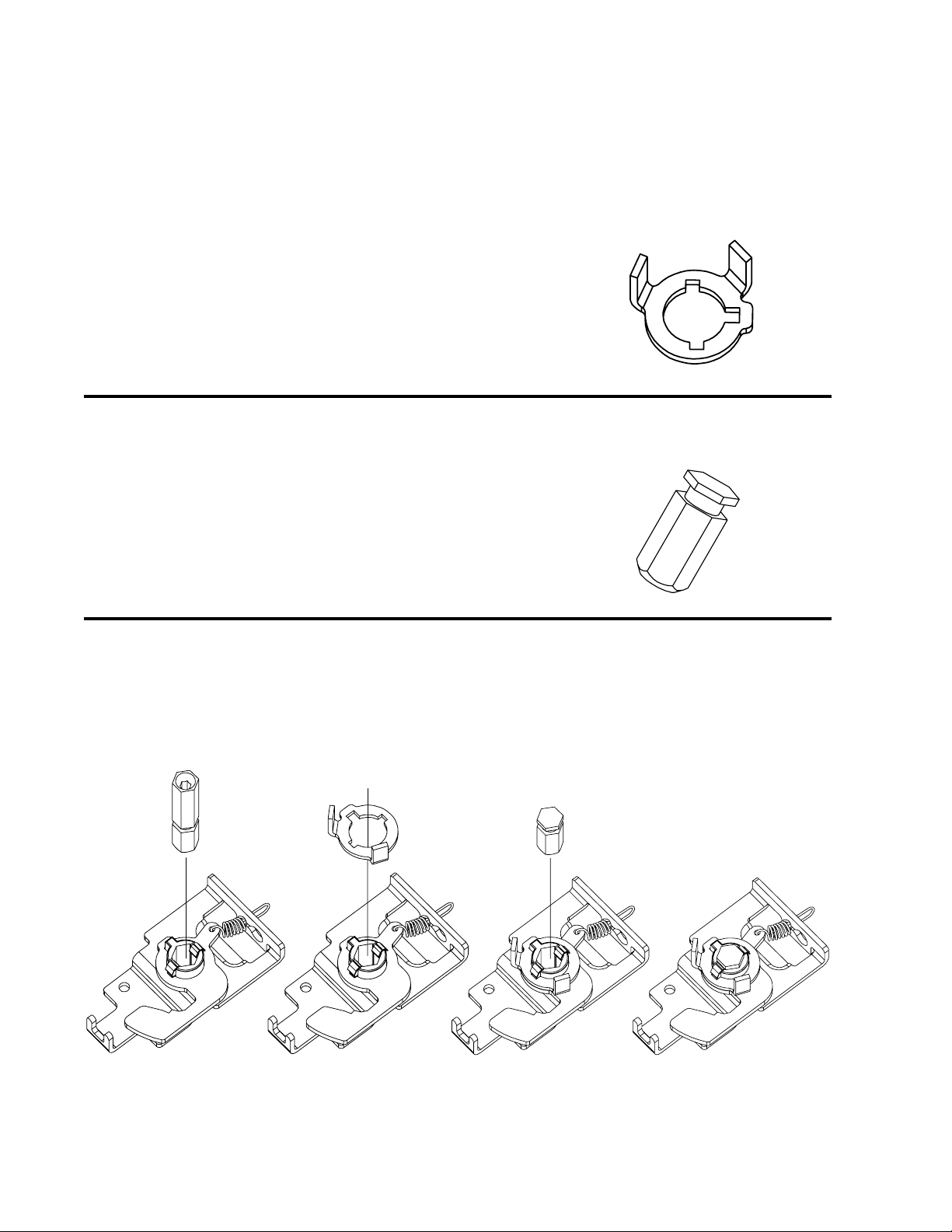

Page 12

Page: 2-4

2. Dogging Assembly Parts

Part Name: Cylinder Dog Actuator Kit Location: Bottom drawer #4

Part Number: 090045-00 bulk, 2/pkg.

Use: 98/99 and 33/35 cylinder dogging assemblies

Part Name: CD Dogging Plug Kit Location: Bottom drawer #11

Part Number: 090046-00 bulk, 2/pkg.

Use: 98/99 and 33/35 cylinder dogging assemblies

made after Sept. 1997

Installation: 1. Pull hex dogging shaft out of dogging adapter (A).

2. Snap cylinder dog actuator into place over dogging adapter spring and

dogging adapter (B).

3. Insert CD dogging plug into hex hole in dogging adapter (C) and press until

dogging adapter spring snaps into top groove of CD dogging plug (D).

B CA

D

Page 13

Page: 3-1

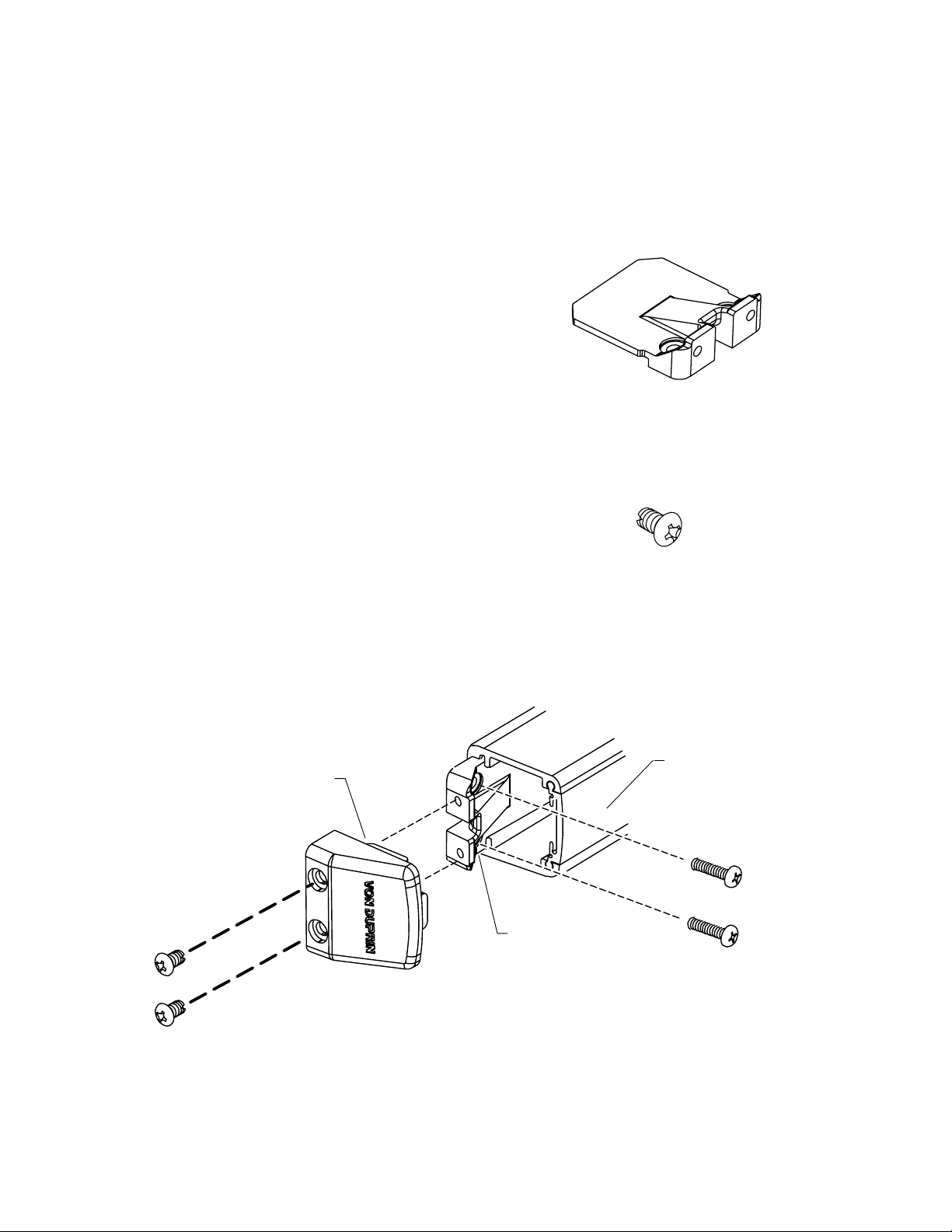

3. Mechanism Case Parts

Part Name: Mechanism Case Mounting Bracket Kit Location: Top compartment

Part Number: 050524-00 (unit)

Use: 98/99 and 33/35 devices

Part Name: End Cap Screw Package Kit Location: Middle 13

Part Number: 900597-00 bulk, 2/pkg.

Use: 98/99 and 33/35 devices

Installation: Slide bracket into mechanism case making sure that Face A is flush against

cover plate. Secure bracket to door. Attach mechanism end cap to bracket (end cap covers

bracket).

Cover plate

Mechanism end cap

Bracket fits

under lip inside

mechanism case

Page 14

Page: 3-2

3. Mechanism Case Parts

Part Name: Anti-Rattle Spring-33/35/98/99 Kit Location: Top drawer #11

Part Number: 090036-00 bulk, 10/pkg.

Use: 98/99 and 33/35 devices

Installation: Without spring, slide cover plate into mechanism case until flush (A and B).

Insert front tabs on spring into channel in underside of cover plate (B). Push

spring in and make sure rear tabs also engage channel. Continue pushing spring

in until vertical tabs on back of spring are flush with end of cover plate (C).

CBA

2”

Minimum

Anti-rattle

clip

Page 15

Page: 3-3

3. Mechanism Case Parts

Part Name: Shock Absorber and Holder Assembly Kit Location: Top drawer #17

Part Number: 050491-00 unit

Use: 98/99 and 33/35 devices

Installation: Place tip of plunger against action rod stop (A). Press in until plunger is fully

retracted (B). Rotate shock absorber and holder so tabs slide over top of open

guide base (C). Push down so tabs snap into cutouts (C and D).

Action

rod stop

Plunger

Tab

Cutout

Open guide

base

A

C

B

D

Page 16

Page: 3-4

3. Mechanism Case Parts

Part Name: Pushbar Guide (front) Kit Location: Middle drawer #12

Part Number: 090049-00 bulk, 10/pkg.

Use: 98/99 and 33/35 devices

Installation: Remove pushbar from mechanism case. Slide pushbar guide onto front of

pushbar. Hold pushbar guide on pushbar and install pushbar on bellcranks.

Slide base plate into mechanism case.

Also replaces older style pushbar guide (part number 971065-00). To replace,

slide mechanism case away from center case. Remove cover mounting bracket

from center case. Unhook older style pushbar guide from cover mounting

bracket and discard. Replace cover mounting bracket. Install new pushbar guide.

Older style pushbar guide

(part number 971065-00)

Cover mounting

bracket

Page 17

Page: 3-5

3. Mechanism Case Parts

Part Name: Pushbar Guide (rear) Kit Location: Middle drawer #12

Part Number: 090049-00 bulk, 10/pkg.

Use: 98/99 and 33/35 devices

Installation: Remove pushbar from mechanism case. Slide guide onto back of pushbar.

Hold guide on pushbar and install pushbar on bellcranks. Slide base plate into

mechanism case.

!

This pushbar guide replaces the older style pushbar

guide (part number 971066-00) shown below.

NOTE

Page 18

Page: 4-1

4. Vertical Rod Parts

Part Name: Rod Extension Connector Kit Location: Top drawer #14

Part Number: 090075-00 bulk, 4/pkg.

Use: 98/9927 and 33/3527 devices on doors

taller than 7 feet

Installation: Drive out roll pin (963935-89) and remove latch case rod connector from latch

end of existing rod (A). Insert rod extension connector into latch end of existing

rod and either end of extension rod and secure with roll pins (B). Insert latch

case rod connector into latch end of extension rod and secure with roll pin (C).

A

Latch case rod

connector

Roll pin

Part Name: Extension Rod Drill Template-2227/98/9927 Kit Location:Top drawer #7

Part Number: 969298-89 unit

Use: To locate roll pin hole on 98/9927,

33/3527, and 2227 vertical rods

Installation: Slide template on rod until bottom of rod and bottom of template are flush. Drill

1/8” diameter hole through hole in template.

B

Rod extension

connector

C

Align bottom of template and

bottom of rod before drilling

Page 19

Page: 4-2

4. Vertical Rod Parts

Part Name: 98/9927 Rod Guide Assembly Kit Location: Bottom drawer #14

Part Number: 112063-32 unit

Use: 98/9927 and 2227 devices made after 1993

!

112063-32 finish is stainless.

Other finishes available.

Installation: Slide over rod after rods have been adjusted. Place half way between device

center case and latch. Secure to door with screws.

Part Name: 1/8 x 7/16 Roll Pin Kit Location: Top drawer #10

Part Number: 090054-00 bulk, 10/pkg.

Use: 98/9927 and 33/3527 vertical rods

NOTE

Installation: Line up holes in rod and latch case rod connector (A) or in rod and rod

extension connector (B) and drive roll pin through hole.

BA

Page 20

Page: 5-1

5. Surface Vertical Latch Parts

Part Name: 299 Strike Shim Kit Location: Top drawer #16

Part Number: 970321-89 unit

Use: 299 strikes to decrease spacing between

strike and latch

Installation: Position shim as shown. Prepare center hole per chart.

Metal Frame

Prep: #25 drill and #10-24 tap

Screw: 10-24 x 3/4 FPHMS

Wood Frame

Prep: 1/8” pilot drill x 1” deep

Screw: 10 x 1 1/2 FPHWS

Part Name: Shim-264/299F/499F Strike Kit Location: Bottom drawer #15

Part Number: 945521-89 unit

Use: 264, 299F, and 499F strikes to decrease

spacing between strike and latch

Installation: Position shim with teeth facing strike and closest to strike roller. Mate teeth with

notches in bottom of strike. Prepare center hole per chart.

Teeth

Prep: #25 drill and #10-24 tap

Screw: 10-24 x 3/4 FPHMS

Prep: 1/8” pilot drill x 1” deep

Screw: 10 x 1 1/2 FPHWS

Metal Frame

Wood Frame

Page 21

Page: 5-2

5. Surface Vertical Latch Parts

Part Name: Bolt Return Spring Kit Location: Bottom drawer #9

Part Number: 090065-00 bulk, 10/pkg.

Use: 98/9927/27-F and 2227/27-F top and bottom latches

98/9947/47-F and 33/3547/47-F bottom latches

Installation: For 98/9947/47-F and 33/3547/47-F latch, remove Truarc retaining ring, latch

pin, and rod connecting screw for accessibility. Replace after installing spring.

98/9947/47-F and 33/3547/47-F Bottom Latch

Rod

connecting

screw

Latch pin

Truarc

retaining

ring

Spring fits

behind latch

bolt axle

Latch bolt

axle

Rear view. Spring

fits behind latch

bolt axle.

Front view. Latch

case not shown

98/9927/27-F and 2227/27-F Top and Bottom Latches

(98/9927/27-F Top Latch Shown)

Rod

connector

tang

Bolt linkage tang

(spring fits over both

legs of tang)

for clarity.

Page 22

Page: 5-3

5. Surface Vertical Latch Parts

Part Name: 98/9927 Auxiliary Bolt Spring Kit Location: Top drawer #5

Part Number: 090076-00 bulk, 10/pkg.

Use: 98/9927 and 2227 top latches

Installation: Place one end of spring over over auxiliary bolt tang. Compress spring and

place free end of spring over latch case housing tang.

Auxiliary

bolt tang

Latch case

housing tang

Page 23

Page: 6-1

6. Concealed Vertical Latch Parts

Part Name: Ratchet Lever Spring Kit Location: Middle drawer #7

Part Number: 090069-00 bulk, 2/pkg.

Use: 98/9947/47-F and 33/3547/47-F top latches

Installation: Place small end of spring over ratchet lever tang. Place large end of spring over

pin in latch case.

Location of spring

Ratchet

lever tang

Pin

Page 24

Page: 6-2

6. Concealed Vertical Latch Parts

Part Name: #10 External Tooth Lock Washer Kit Location: Top drawer #3

Part Number: PKGSRV.1007 bulk, 10/pkg.

Use: To secure 98/9947 and 33/3547

latch mounting bracket

Installation: Use washer with screws that attach latch mounting bracket to door.

Part Name: Compression Spring-33/3547 Kit Location: Middle drawer #3

Part Number: 090066-00 bulk, 10/pkg.

Use: 98/9947 and 33/3547 top latch

Installation: Place small end of spring on latch bolt linkage tang, other end on latch case tang.

Latch bolt

linkage tang

(inside latch

case)

Latch case

tang

Spring Location

Latch case shown cut away for clarity

Page 25

Page: 7-1

7. Mounting Hardware, Screws, and Retaining Rings

Part Name: 325 Sex Bolt Assembly Kit Location: Top drawer #4

Part Number: 034902-32 bulk, 2/pkg.

Use: For mounting 98/99, 33A/35A, and 22 latches

and latch mounting brackets made after Nov. 1998

Installation: Drill mounting holes per template supplied with device, 13/32” diameter

outside, 5/16” diameter inside. Hammer sex bolt through 13/32” diameter hole.

#325 sex bolt takes 1/4-20 thread screw.

Part Name: 425 Sex Bolt Assembly Kit Location: Top drawer #49

Part Number: 034302-32 bulk, 2/pkg.

Use: For mounting 98/99 and 22 device surface

latches and latch mounting brackets made

before Nov. 1998; for mounting 98/99, 33/35,

and 22 device end cap brackets and center cases

(EO applications)

Installation: Drill mounting holes per template supplied with device, 13/32” diameter

outside, 1/4“diameter inside. Hammer sex bolt through 13/32” diameter hole.

#425 sex bolt takes 10-20 thread screw. (See diagram above)

Page 26

Page: 7-2

7. Mounting Hardware, Screws, and Retaining Rings

Part Name: 10-12 x 10-24 x 1 PTHCS Kit Location: Top drawer #13

Part Number: 900919-00 bulk, 2/pkg.

Use: 98/9927 and 2227 device rod guide assembly

Installation: Use screws to mount 9927 rod guide assembly to door. For wood door, drill

1/8” diameter pilot holes. For metal door, use #25 drill and #10-24 tap.

Part Name: 10-24 x 3/4 PPHMS Kit Location: Middle drawer #2

Part Number: PKGSRV.1015 bulk, 10/pkg.

Use: 98/99, 33/35, and 22 device mechanism

case mounting brackets

Installation: Use screws to mount 98/99, 33/35, and 22 device mechanism case mounting

brackets to door. For metal door surface mount, prepare door with #25 drill and

#10-24 tap. Screws also can be used with #425 sex bolts on 1 3/4” door.

98/99 and 33/35 device

mechanism case bracket

22 device

mechanism case bracket

Page 27

Page: 7-3

7. Mounting Hardware, Screws, and Retaining Rings

Part Name: 10-24 x 1 PPHMS Kit Location: Middle drawer #9

Part Number: PKGSRV.1016 bulk, 20/pkg.

Use: 98/99, 33/35, and 22 device center cases

Installation: Use screws to mount 98/99, 33/35, and 22 device center cases to 1 3/4”

hollow metal doors. For surface mount, prepare door with #25 drill and #10-24

tap. Also can be used for through-mounting to trim and with #425 sex bolts.

98/9927 center case shown

Part Name: 8-32 x 1/4 UFPHMS Kit Location: Top drawer #6

Part Number: PKGSRV.1018 bulk, 20/pkg.

Use: 98/9927 and 33/3527 latch case covers

Installation: Place latch case cover over latch case and secure with two screws.

Page 28

Page: 7-4

7. Mounting Hardware, Screws, and Retaining Rings

Part Name: 10-24 x 3/4 UFPHMS Kit Location: Top drawer #1

Part Number: PKGSRV.1019 bulk, 10/pkg.

Use: 98/9927 and 2227 latches and latch mounting

brackets made before Nov. 1998

Installation: Use with #425 sex bolts. Drill mounting holes per template supplied with

device, 13/32” diameter outside, 1/4” diameter inside. Hammer sex bolt

through 13/32” diameter hole.

Part Name: 1/4-20 x 3/4 UFPHMS Kit Location: Bottom drawer #7

Part Number: PKGSRV.1020 bulk, 10/pkg.

Use: 98/9927 and 2227 latches and latch mounting

brackets made after Nov. 1998

Installation: Use with #425 sex bolts. Drill mounting holes per template supplied with

device, 13/32” diameter outside, 1/4” diameter inside. Hammer sex bolt

through 13/32” diameter hole. (See diagram above.)

Page 29

Page: 7-5

7. Mounting Hardware, Screws, and Retaining Rings

Part Name: 8-18 x 3/8 UFPHSMS Kit Location: Middle drawer #11

Part Number: 900892-32 bulk, 4/pkg.

Use: 98/99 center case cover

!

900892-32 finish is chrome.

Other finishes available.

NOTE

Installation: Secure center case cover with four screws.

Part Name: 12-24 Mechanism Case Screw Kit Location: Bottom drawer #12

Part Number: 090073-00 bulk, 10/pkg.

Use: 98/99 and 33/35 devices; secures center case

cover mounting bracket to mechanism case

Installation: Remove two pine tree clips and replace with screws.

98/99 device shown

Page 30

Page: 7-6

7. Mounting Hardware, Screws, and Retaining Rings

Part Name: Truarc Retaining Ring T5304-18 Kit Location: Top drawer #2

Part Number: 090107-00 bulk, 10/pkg.

Use: 98/99 and 22 rim latch bolt axle

98/9927 and 98/9947 center case

Installation: Use flat blade screwdriver to push ring over groove in pin so ring snaps in place.

98/99 and 22 rim

latch bolt axle (98/99 shown)

98/9927 and 98/9947

center case

Page 31

Page: 7-7

7. Mounting Hardware, Screws, and Retaining Rings

Part Name: 10-32 x 1/4 UFPHMS with Nylock Kit Location: Bottom drawer #1

Part Number: 090059-00 bulk, 6/pkg.

Use: 98/9947 and 33/3547 top and bottom

latch mounting brackets

Installation: Use screws to secure latch mounting brackets to latches.

Part Name: 10-24 x 3/4 FPHMS Kit Location: Bottom drawer #8

Part Number: PKGSRV.1023 bulk, 10/pkg.

Use: 299 strike

Installation: Prepare mounting holes per template supplied with device using #25 drill and

#10-24 tap.

Page 32

Page: 8-1

8. Trim Parts

Part Name: Shear Pin Kit Location: Middle drawer #10

Part Number: PKGSRV.1010 bulk, 50/pkg.

Use: 991, 992, and 994 trim made after Jan. 1993

Installation: This procedure is for 992L R&V trim. For other trim, see trim instructions.

1. Remove trim from door.

2. Remove two lift springs (A).

3. Push slider up, then pull out (B).

4. Use retaining ring pliers to remove retaining ring (C).

5. Remove washer and cam (D).

6. Loosen set screw with 3/32” hex wrench and remove broken shear pin (E).

7. Place lever in desired position, RHR or LHR (F).

8. Insert new shear pin with head pointed down and tighten shear pin set screw.

9. Install cam. “R” faces out for RHR door, “L” faces out for LHR door (G).

10. Install washer, retaining ring, slider, and two lift springs.

A B C D

Set screw

in end of

shaft

R

RHR

LHR

RHR LHR

GFE

L

Page 33

Page: 8-2

8. Trim Parts

Part Name: Cylinder Retaining Cup Kit Location: Top drawer #15

Part Number: 968201-89 unit

Use: 880, 990, 991, 992, and 994 trim with rim cylinders

Installation: With trim off door, insert cylinder through trim. Install cylinder retaining cup

over trim so tabs on cylinder retaining cup align with notches on trim. Secure

cylinder retaining cup to cylinder with screws.

Part Name: 992/994 Lift Spring Kit Location: Bottom drawer #13

Part Number: 971573-00 unit; PKGSRV.1011 bulk, 20/pkg.

Use: 992/994 trim

Installation: See pictures below for 992 and 994 spring installation.

992

994

Page 34

Page: 8-3

8. Trim Parts

Part Name: Hex Stud-994/996 Trim Kit Location: Top drawer #4

Part Number: 971585-89 unit

Use: 994 and 996 trim

Installation: Screw stud into trim housing. Do not over-tighten.

Part Name: 1/4-20 Hex Stud Kit Location: Middle drawer #5

Part Number: 971440-89 unit; PKGSRV.1012 bulk, 10/pkg.

Use: 991 and 992 trim made after March 1997

Installation: Screw stud into trim housing. Do not over-tighten.

Page 35

Page: 8-4

8. Trim Parts

Part Name: 10-24 x 1 3/8 PPHMS Kit Location: Top drawer #12

Part Number: PKGSRV.1022 bulk, 10/pkg.

Use: To mount 991 and 992 trim on 1 3/4” doors

Installation: Bolt through device and door to hex studs on trim.

Part Name: Truarc Retaining Ring 5160-42 Kit Location: Middle drawer #6

Part Number: 964285-00 unit; PKGSRV.1013 bulk, 10/pkg.

Use: To secure cam on 991 and 992 trim

Installation: Use retaining ring pliers to open retaining ring. Slip ring over shaft and

position ring in groove in shaft.

Page 36

Page: 8-5

8. Trim Parts

Part Name: Wave Spring Washer Kit Location: Middle drawer #1

Part Number: 090103-00 bulk, 10/pkg.

Use: Used on 992 and 370 series controls to eliminate

excessive lever movement perpendicular to the

face of the door

Installation: This procdure is for 992L R&V trim. For other trim, see trim instructions.

1. Remove trim from door.

2. Remove two lift springs (A).

3. Push slider up, then pull out (B).

4. Use retaining ring pliers to remove retaining ring (C).

5. Replace or install washer (D).

6. Install retaining ring, slider, and two lift springs.

BA

DC

Page 37

Page: 8-6

8. Trim Parts

Part Name: 1/4-20 x 5/8 Socket Set Screw Kit Location: Bottom drawer #10

Part Number: 964353-76 unit

Use: 992 trim

Installation: Loosen or remove set screw. Slide the R&V finger in or out to align the mark for

the door thickness with the surface indicated. When aligned, tighten the set

screw with a 1/8” hex wrench.

Align mark with this

Alignment

marks

surface

1-3/4

2-1/4

2

R & V finger

Set screw

Page 38

Page: A-1

Appendix A: Device Lubrication

Devices are lubricated before delivery. Additional periodic lubrication will increase device life

by inhibiting excessive wear of moving parts. Lubricate every four months with Duralube or

equivalent . Recommended surfaces for lubrication are shown in the diagrams below.

Lubricate indicated surfaces on both sides of device.

CAUTION

!

Use only Duralube or

equivalent for

lubrication.

Contact point

between bellcrank

and open guide base

Inside

bellcrank

notches

Under

dogging

hook

Bellcrank

rivet

Action rod spring

and action rod

(this end only)

Contact points

between housing

rivet, bellcrank, and

center case housing

Contact point

between bellcrank

and open guide base

Bellcrank arm

(through slot in

open guide base)

Inside

bellcrank

notches

Bellcrank

rivet

Outside ends

of latch pin

Contact points

between rod links

and chassis

Outside ends of

latch bolt pin

Slot in trim

lock tumbler

(both ends)

Contact points

between main

control link and

center case housing

Under master

cylinder cam

Page 39

Page: B-1

Appendix B: Latch Lubrication

Latches are lubricated before delivery. Additional periodic lubrication will increase latch life

by inhibiting excessive wear of moving parts. Lubricate every four months with Duralube or

equivalent . Recommended surfaces for lubrication are marked with in the diagrams below.

CAUTION

!

Use only Duralube or

equivalent for

lubrication.

Surface latch, top

Surface latch, bottom

(front of latch)

Concealed latch, top

Concealed latch, bottom

(back of latch)

mottob ,hctal ecafruSpot ,hctal namlluP

Page 40

Page: IPN-1

Index by Part Number

Part Num rebmuN egaPnoitpircseD traPreb

034302-32 (bulk) 425 Sex Bolt Assembly ...................................................................7-1

034902-32 (bulk) 325 Sex Bolt Assembly ...................................................................7-1

050156-00 (bulk) Tailpiece Guide ............................................................................... 1-3

050491-00 (unit) Shock Absorber and Holder Assembly ............................................3-3

050524-00 (unit) Mechanism Case Mounting Bracket

090031-00 (bulk) Control Link Pin-Touch Bar Device ................................................. 1-2

090036-00 (bulk) Anti-Rattle Spring-33/35/98/99 ......................................................... 3-2

090040-00 (bulk) Hex Dogging Shaft ........................................................................... 2-1

090041-00 (bulk) Dogging Spring................................................................................ 2-3

090042-00 (bulk) Dogging Adapter Spring.................................................................. 2-2

090045-00 (bulk) Cylinder Dog Actuator ....................................................................2-4

090046-00 (bulk) CD Dogging Plug ............................................................................2-4

090049-00 (bulk) Pushbar Guide (front) ...................................................................... 3-4

090049-00 (bulk) Pushbar Guide (rear) .......................................................................3-5

090054-00 (bulk) 1/8 x 7/16 Roll Pin ...........................................................................4-2

090059-00 (bulk) 10-32 x 1/4 UFPHMS with Nylock ...................................................7-7

090065-00 (bulk) Bolt Return Spring ..........................................................................5-2

090066-00 (bulk) Compression Spring-33/3547............................................................ 6-2

090069-00 (bulk) Ratchet Lever Spring .......................................................................6-1

090073-00 (bulk) 12-24 Mechanism Case Screw ....................................................... 7-5

090074-00 (bulk) NL Drive Screw-98/99 Device..........................................................

090075-00 (bulk) Rod Extension Connector ................................................................ 4-1

090076-00 (bulk) 98/9927 Auxiliary Bolt Spring ..........................................................5-3

090103-00 (bulk) Wave Spring Washer ...................................................................... 8-5

090107-00 (bulk) Truarc Retaining Ring T5304-18........................................................ 7-6

112063-32 (unit) 98/9927 Rod Guide Assembly (stainless) ....................................... 4-2

15-445-00 (unit) Hex Dogging Replacement Kit........................................................... 2-1

900892-00 (bulk) 8-18 x 3/8 UFPHSMS (chrome)......................................................... 7-5

900919-00 (bulk) 10-12 x 10-24 x 1 PTHCS............................................................... 7-2

900597-00 (bulk) End Cap Mounting Screw................................................................ 3-1

945521-89 (unit) Shim-264/299F/499F Strike ............................................................. 5-1

964285-00 (unit) Truarc Retaining Ring 5160-42.......................................................... 8-4

964353-76 (unit) 1/4-20 x 5/8 Socket Set Screw........................................................... 8-6

968201-89 (unit) Cylinder Retaining Cup.................................................................... 8-2

969298-89 (unit) Extension Rod Drill Template-2227/98/9927..................................... 4-1

971585-89 (unit) Hex Stud-994/996 Trim................................................................... 8-3

970321-89 (unit) 299 Strike Shim ..............................................................................5-1

970441-89 (unit) NL Drive Screw-98/99 Device...........................................................1-2

971440-89 (unit) 1/4-20 Hex Stud.............................................................................. 8-3

............................................ 3-1

. 1-2

Page 41

Page: IPN-2

Index by Part Number (continued)

Part Numb rebmuN egaPnoitpircseD traPre

971573-00 (unit) 992L Lift Spring .......................................................... 8-2

PKGSRV.1007 (bulk) #10 External Tooth Lock Washer ............................... 6-2

PKGSRV.1010 (bulk) Shear Pin ....................................................................8-1

PKGSRV.1011 (bulk) 992L Lift Spring ..........................................................8-2

PKGSRV.1012 (bulk) 1/4-20 Hex Stud .........................................................8-3

PKGSRV.1013 (bulk) Truarc Retaining Ring 5160-42......................................8-4

PKGSRV.1015 (bulk) 10-24 x 3/4 PPHMS ...................................................7-2

PKGSRV.1016 (bulk) 10-24 x 1 PPHMS ......................................................7-3

PKGSRV.1018 (bulk) 8-32 x 1/4 UFPHMS ...................................................7-3

PKGSRV.1019 (bulk) 10-24 x

PKGSRV.1020 (bulk) 1/4-20 x

PKGSRV.1022 (bulk) 10-24 x 1 3/8 PPHMS ................................................8-4

PKGSRV.1023 (bulk) 10-24 x 3/4 FPHMS .................................................. 7-7

3/4 UFPHMS ................................................7-4

3/4 UFPHMS............................................... 7-4

Customer Service

1-877-671-7011 www.allegion.com/us

© Allegion 2019

Printed in U.S.A.

941079-00 Rev. 09/19-c

Loading...

Loading...