Page 1

RC Pure IP

TM

multi-technology

reader controller

User guide

Page 2

FCC Statement

Model FCC ID IC ID

RC11

RC15

RCK15

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause

undesired operation.

Changes or modifications not expressly approved by the party responsible for compliance could void

the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

(1) Reorient or relocate the receiving antenna.

(2) Increase the separation between the equipment and receiver.

(3) Connect the equipment to an outlet on a circuit different from that to which the receiver is

connected.

(4) Consult the dealer or an experienced radio/TV technician for help.

XPB-RC11 8053B-RC11

XPB-RC15 8053B-RC15

This device complies with RSS-210 of Industry Canada.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause

undesired operation.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio

exempts de licence.L’exploitation est autorisée aux deux conditions suivantes:

(1) l’appareil ne doit pas produire de brouillage, et

(2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d’en compromettre le fonctionnement.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

For RF Safety and per FCC and Industry Canada regulations, the product should never be

installed within 8-inches (20cm) of typical people locations.

U.S. Patent Nos.

7,775,429

8,662,386

9,153,083

9,336,633

7,676,839

U.S. Application No.

14/019,924

Page 3

Contents

ii FCC Statement

iv Contact information

iv Warnings and cautions

5 Before you begin

5 General requirements

6 Reader controller specifications

7 Installation location guidelines

9 Reader controller reset button

10 Wiring

10 Powering the reader controllers

11 Door wiring

13 Lock wiring using PoE

13 Door sensor wiring

14 Advanced Security Module (ASM) wiring

15 Configuring communications

15 Reader controllers to host soware

16 Appendix A: Power options

16 PoE Power Budget Calculations

17 Additional power options

18 Dual power sources

19 Appendix B: Additional wiring considerations

19 ASM LED status index

19 Wiring two readers to one lock

20 Managing inductive load challenges

21 PoE: Magnetic lock, ASM and PIR

22 Appendix C: UL Disclaimers

iii • Schlage • Reader controller

Page 4

Contact information

If you need assistance, contact technical support at:

1-877-671-7011

www.allegion.com/us

MIFARE® and DESFire™ are registered trademarks of NXP B.V.

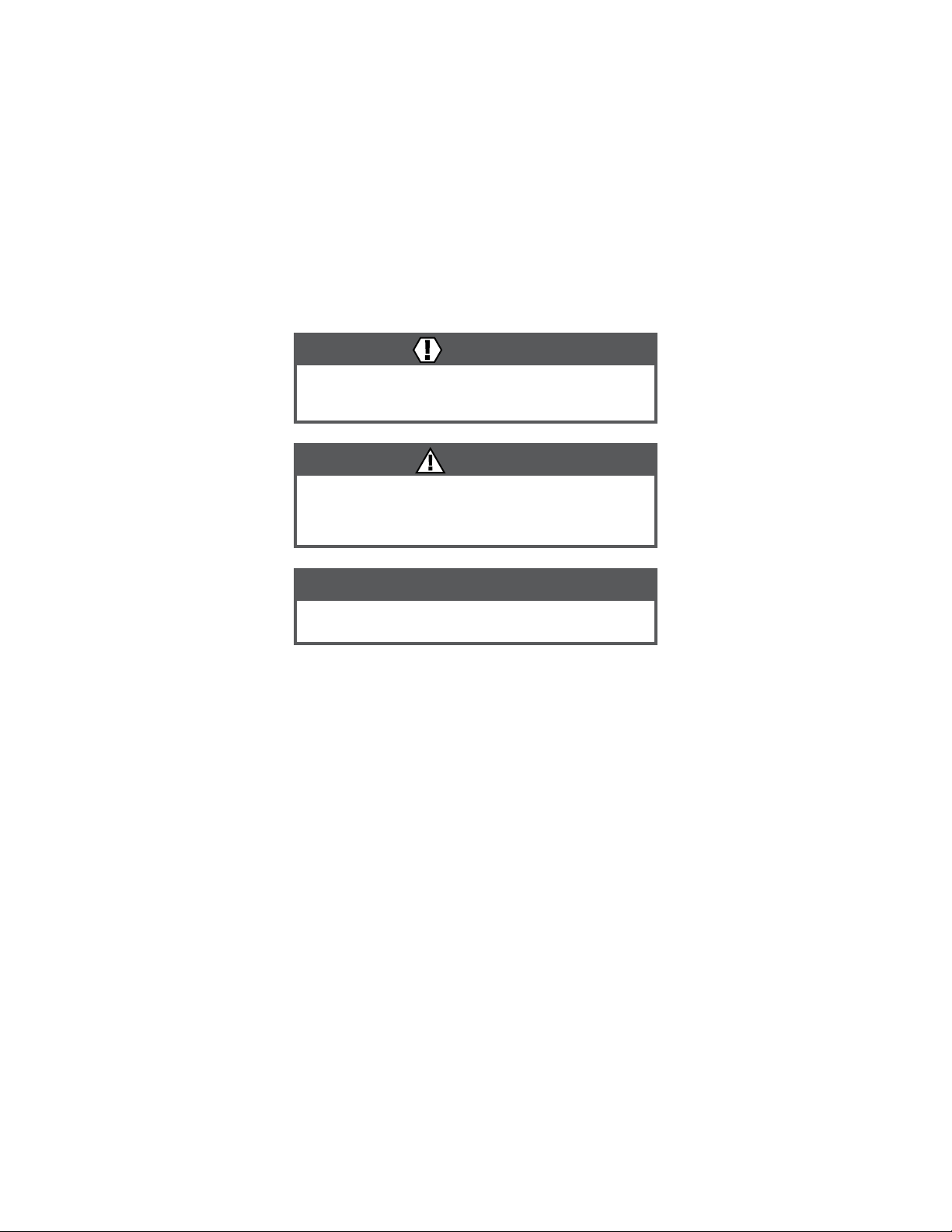

Warnings and cautions

WARNING

Warnings indicate potentially hazardous conditions,

which if not avoided or corrected, may cause death or

Cautions indicate potentially hazardous conditions,

which if not avoided or corrected, may cause minor or

moderate injury. Cautions may also warn against

Notices indicate a condition that may cause equipment

serious injury.

CAUTION

unsafe practices.

NOTICE

or property damage only.

iv • Schlage • Reader controller

Page 5

Before you begin

This guide discusses each wiring process separately. Understanding all of these processes makes a project much simpler and

helps guarantee success. To install a Reader Controller unit, you must complete four key tasks:

1. Mount the Reader Controller in the appropriate location. Recommended locations and wiring methods shall be in

accordance with 1) the National Electrical Code, {ANSI/NFPA 70}; 2) International Building Code {IBC}, and 3) Americans

with Disabilities Act {ADA}.

2. Supply power to the Reader Controller. This may be accomplished with power being provided on the Ethernet data cable

(Power over Ethernet [PoE / PoE+ / IEEE 802.3af]) or through an external DC power source (12VDC). When powering from

PoE or PoE+, in order for the system to be UL294 V7 compliant, the Power Sourcing Equipment (PSE) injector or end point

must be compliant to UL294 or UL294B standards.

3. Wire the unit to the door’s locks and other components for physical access control.

4. Connect the unit to the data network for communication with the host access control system.

The Reader Controller complies with UL 294 V6 and is rated for the following performance levels:

Standby power Level I

Endurance Level IV

Line Security Level I

Destructive Attack Level I (ASM required)

General requirements

• If PoE is not being used, then use only UL-listed, access control, power-limited power supplies with an ‘AC on’ indicator light

clearly visible on the enclosure. Power supplies should provide at least four hours of standby power.

• Never connect power supplies to a switch-controlled receptacle.

• Install the Schlage system in accordance with the National Electrical Code NFPA 70, IBC, and ADA requirements, or the

Canadian Electrical Code, C22.1-02. (Local authority has jurisdiction.)

• Use only UL-listed wire or cabling recognized suitable for Schlage power supply and data communications, in accordance

with the National Electrical Code.

• Where possible, separate Schlage equipment and cabling from sources of electromagnetic interference (EMI). Where this is

not possible, take other steps to reduce the effect of EMI on cabling or equipment.

• Protect input and output terminals adequately from transient signals. Also, connect these terminals to power-limited

circuitry.

• The readers are UL Listed for standalone operation only. Reference to operation with the server have not been investigated

by UL.

• Operation with the ASM has not been investigated by UL.

• Accessories connected to the readers shall be UL Listed.

• The reader controllers are intended to be used with the building’s communication system and not intended for direct

outside connection.

• All input/output wiring shall employ earth grounded shielded cable. The maximum wiring distance is 30 m, same room.

• The minimum conductor gauge permitted to connect between the PSE or power injector and the device shall be 26 AWG

(0.13 mm2) for patch cords; 24 AWG (0.21 mm2) for horizontal or riser cable.

• Premise network equipment shall be UL Listed for compliance with UL60950-1 or UL62368-1.

• Intended for Alternative A PoE sources. NEC, Class 3 wiring methods shall be followed.

• Compliance to ULC-S319, Electronic Access Control Systems, would be invalidated through the use of any add-on,

expansion, memory or other module manufactured or supplied by the manufacturer or manufacturer’s representative.

• In POE applications, installation shall be in accordance with Article 725.121, Power Sources for Class 2 and Class 3 circuits.

5 • Schlage • Reader controller

Page 6

Before you begin | Reader controller specifications

Reader controller specifications

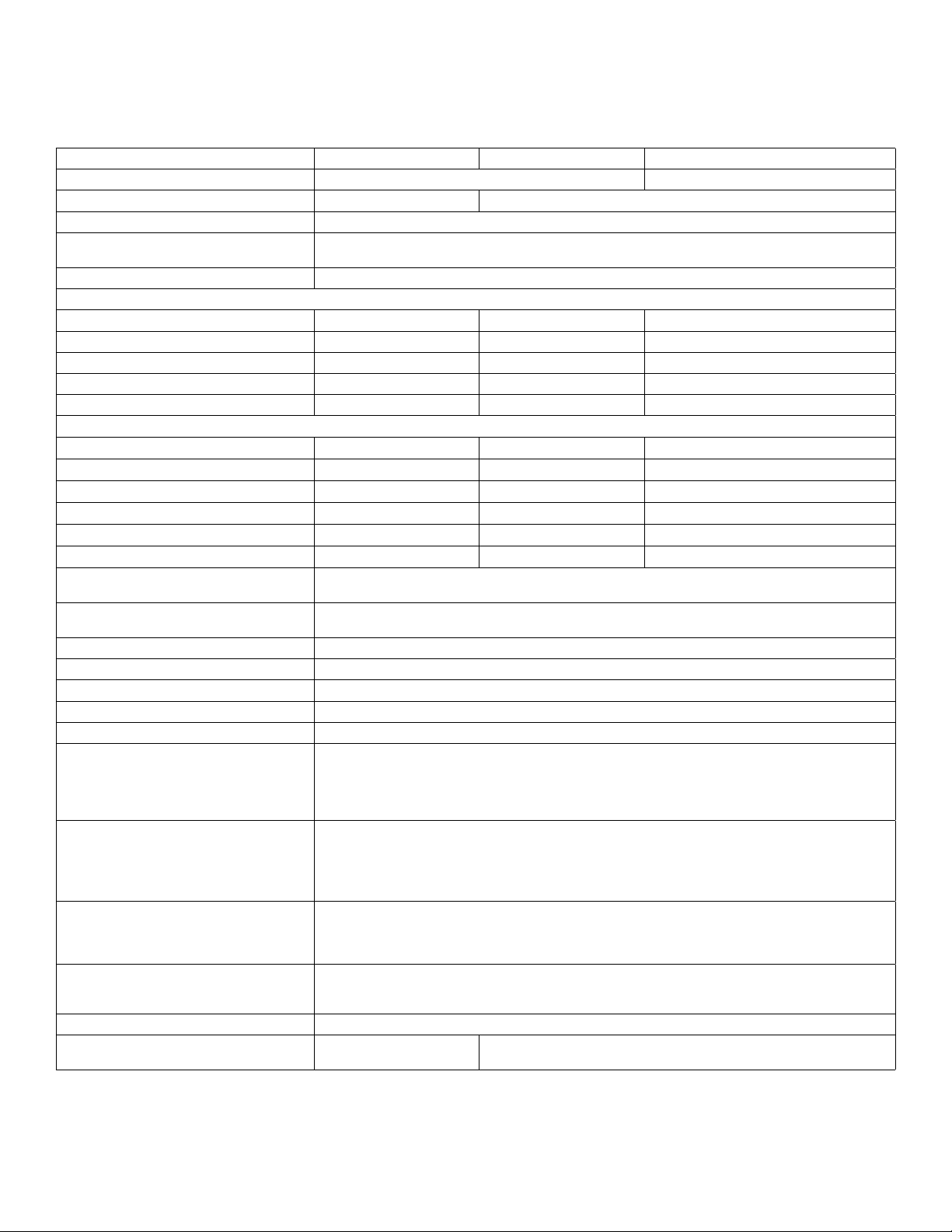

Model RC11 RC15 RCK15

Reader controller Type Mobile enabled multi-technology Mobile enabled multi-tech w/keypad

Mounting Style Mullion Single Gang

Standards ISO 14443A, ISO 15693

Certifications FCC Certification, IC Certification, UL 294/cUL Listed, RED Directive, CE Mark, IP65, REACH,

Frequency 2.4 GHz, 13.56 MHz and 125 kHz

Technology Supported (See Appendix C: UL Disclaimers on page 22.)

CSN

Proximity

Smart

Mobile (NFC)

Mobile (Bluetooth)

Read Range

Prox FSK

Prox ASK

MIFARE Classic EV1

MIFARE Plus

MIFARE DESFire EV1

MIFARE DESFire EV2

Schlage Mobile Credential

(Bluetooth) (short range-standard)

Schlage Mobile Credential

(Bluetooth) (long range-optional)

Users 64,000

Audits 5,000

Schedules 32

Holidays 32

Auto Events 448

Communication Standards 10/100 Mbps, Half or Full Duplex

Power Options Power Over Ethernet (PoE/PoE+), (IEEE 802.3af/at)

Outputs Locking mechanism: 600 mA @ 12VDC max

Signal Inputs Door Position Switch (DPS)

Operating Temperature -31°F (-40°C) to 151°F (66°C)

Dimensions 5.94” x 1.77” x 1”

Bluetooth SIG, RoHS3

Up to 1.75" (4.4 cm) Up to 4.0" (10.1 cm) Up to 4.0" (10.1 cm)

Up to 1.5" (3.8 cm) Up to 3.25" (8.2 cm) Up to 3.25" (8.2 cm)

Up to 1.75" (4.4 cm) Up to 2.0" (5.1 cm) Up to 2.0" (5.1 cm)

Up to 0.25" (0.6 cm) Up to 1.25" (3.2 cm) Up to 1.25" (3.2 cm)

Up to 0.5" (1.3 cm) Up to 1.5" (3.8 cm) Up to 1.5" (3.8 cm)

Up to 1.5" (3.8 cm) Up to 2.0" (5.1 cm) Up to 2.0" (5.1 cm)

5’ (1.5 m)

30’ (9.1 m)

Ethernet, WebSockets, Standard Cat5e or better Cable

DHCP Addressing Supported

Transport Layer Security (TLS) version 1.2

Advanced Encryption Standard (AES), 256-bit

DC Power: 12VDC +/- 10% at 300 mA

Î PLEASE NOTE: 300 mA current rating does not include locking mechanism

current. Consult your product documentation.

Advanced Security Module Outputs

RS-485 (future use)

2x General Purpose Outputs (TTL logic levels at ± 24mA)

Request to Exit (REX)

Auxiliary Input (AUX)

5.13” x 3.25” x 1” (130 x 83 x 25 mm)

(150 x 45 x 25 mm)

6 • Schlage • Reader controller

Page 7

Before you begin | Installation location guidelines

Installation location guidelines

When selecting the location where you are going to mount the Reader Controller, a few guidelines should be observed.

1. In humid environments, a drip-loop should be formed in the Reader Controller’s cables, before the cables enter the unit.

2. The Reader Controller should be protected from extreme heat and sunlight. It is rated for conditions up to 151 F. A direct

southern exposure, in the Southwest area of the United States may exceed these ratings.

3. The cables extending from the back of the Reader Controller’s field wiring cable is available in a two standard lengths (10'

or 25' [3 m or 7.62 m]). The door wiring must terminate within that distance or less than 98' (30m) from the Reader

Controller.

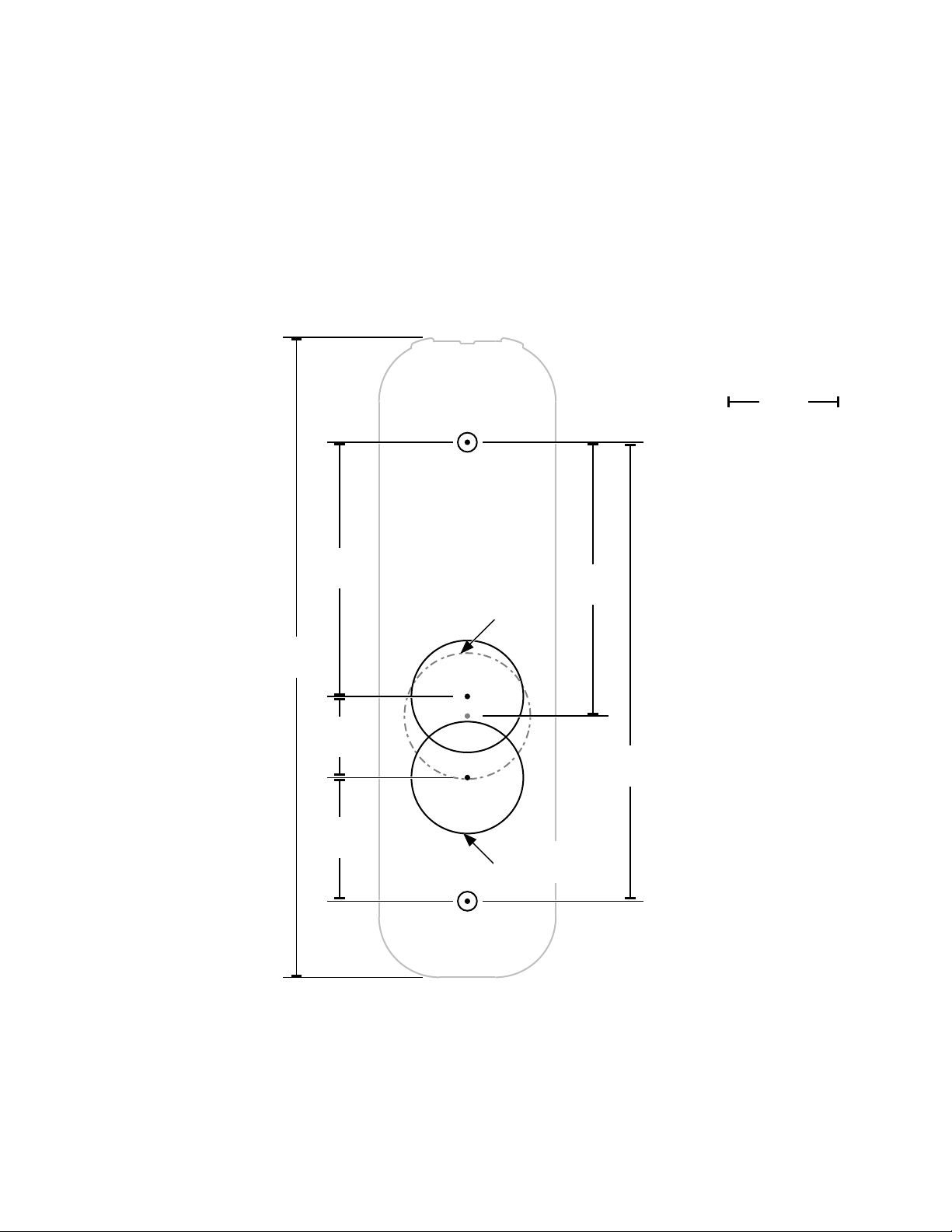

4. The wall mounting templates are shown in Figure 1.1: RC11 Mounting and Figure 1.2: RC15/RCK15 Mounting.

5. The selected location should meet ADA requirements. Check local regulations for more information.

Template to scale. Check

scaling when printing.

1"

(25.4)

Figure 1.1: RC11 Mounting

5 ²³"

(145.256)

2 "

(40.481)

²³"

(18.415)

1 ³"

(27.940)

Alternate hole

1 ¹" (28.575)

1" (25.400)

2 places

2 "

(62.128)

4 ³"

(101.600)

mm in

parenthesis

7 • Schlage • Reader controller

Page 8

Before you begin | Installation location guidelines

Template to scale. Check

scaling when printing.

1"

(25.4)

1 "

(39.688)

²²"

(19.05)

4 "

(125.412)

Figure 1.2: RC15/RCK15 Mounting

Alternate hole

1 ¹" (28.575)

1" (25.400)

2 places

1 ³"

(44.450)

3 "

(82.550)

mm in

parenthesis

8 • Schlage • Reader controller

Page 9

Before you begin | Reader controller reset button

Reader controller reset button

The reset button is located on the back of the Reader

Controller. It can be used for two different types of

resets.

Î The Reader Controller must be connected to the

network before initiating reset.

Network reset

Press and hold the reset button until one green LED

flash and one short beep, (approx. five secs.) then

release. Successful network reset is indicated by one

LED flash and one short beep. A network reset

reestablishes the network connection using the current

network settings. The certificate file and domain

routing information is reestablished prior to reforming

the connection to the host access control system.

reset button

Figure 1.3: Reset button locations

Table 1.1: Reader reset indications

Factory default reset

Press and hold the reset button until two green LED

flashes and two beeps (approx. 10 secs.), then release.

Successful factory default reset is indicated by a long

steady green light and long beep. A Factory Default

Reset (FDR) will return the Reader Controller settings

to the original settings as shipped from the factory.

Removes configurations, databases, and requires the

lock to be re-captured. A FDR will not remove the device from your ENGAGE account.

Actions Lights Beeps

Factory Default Reset (FDR) initiated 2x green short 2x short

Network reset initiated 1x green short 1x short

Reset complete 1x green long 1x long

Reset failed 2x red long 2x long

9 • Schlage • Reader controller

Page 10

Wiring

Powering the reader controllers

• A direct connection to a power source is required.

• Reader controllers can be powered with 12 volts DC or PoE (IEEE 802.3af) power and the supply must be regulated.

NOTICE

Never connect 24VDC to the Reader Controller. 24V will

damage the device and will void the unit’s warranty.

Power over ethernet (PoE) option

PoE allows one cable to supply data and

power to the Reader Controller, which in

turn can then supply 12VDC to the door’s

electronic lock.

If your network switches do not support

PoE, then a PoE Injector can be used to

augment the switch’s output with PoE

power. A PoE injector is normally located

close to your existing network hub/

switch, and the PoE Injector itself is

plugged directly into a standard AC

outlet, or for extra reliability, a UPS with

battery backup.

A standard CAT5/6 cable is then run

between the PoE source (Injector or

switch) and the Reader Controller which

will be located right next to the door. The

CAT5/6 cable can be up to 100 Meters

(328 feet) long, including all patch cables

and patch panels.

Host server

IP network

data

PoE network

switch

Reader Controller

data &

PoE

ASM

latch

Supplying 12 VDC to door

components from the PoE

powered Reader Controller

When the Reader Controller is powered

by PoE, the reader can supply 0.6 amps

@12 VDC power for external components.

This DC power is available via two field

wiring wires.

The red field wiring is typically used to control the door’s lock. The red wire’s 12VDC output will be activated/deactivated when

the reader is operating the door’s lock. This connection has a built-in current limiting feature to prevent the lock from consuming

too much power.

The orange field wiring provides a source of continuously-available 12VDC power for other desired devices.

10 • Schlage • Reader controller

Figure 2.1: Overview of how to use

PoE to power both the Reader

Controller and an electronic

locking mechanism

Page 11

Wiring | Door wiring

Door wiring

Î Door wiring should be done before power is connected to every Reader Controller.

Example devices:

• Electronic door latch

• Request to exit (REX) devices like a REX button or motion detector

• Door sensors

• Figure 2.2: Typical configuration of equipment at the door

Reader controller control-leads

Field wiring consists of 12 wire leads (22AWG) which are used to connect to the various components at the door location. Most

installations do not require the use of all the leads. The usage of each available lead is shown in Figure 2.3: Reader controller

field wiring color codes.

The controllers have a lock-control circuit. This circuit provides conditioned 12VDC power up to 600mA and can be directly

connected to the electronic lock to unlock the door when a valid credential is presented.

The usage of each lead will be detailed in the next few pages.

Î Field wiring cable length must remain under 98' (30 m).

door

sensor

Lock Relay

DPS

REX

REX

button

reader/

controller

latch

Figure 2.2: Typical configuration of equipment at the door

RS-485 A

RS-485 B

V-Line-P

AUX Input

ASM C

Reader controller

ASM D

TTL1

TTL2

Ground

Figure 2.3: Reader controller field wiring color codes

11 • Schlage • Reader controller

Page 12

Wiring | Door wiring

Table 2.1: Input/Output Descriptions

Name I/O Pin Wire Color Description

Lock Lock Relay Output 1 Red The dry lock relay is capable of switching up to 600 mA resistive

DPS Door Position

Switch

REX Request to Exit Input 3 Green When the switch activates, the RC will audit the event and activate

RS-485 A RS-485 Data A Both 4 Pink Future intent RS-485 Data A communication.

RS-485 B RS-485 Data B Both 5 Yellow/

V-Line-P 12V Input/Output Either 6 Orange 12 VDC input. When POE powered, 12 Vdc output at 100mA max.

AUX Auxiliary Input Input 7 Gray When the switch activates, the RC will audit the event and activate

ASM D Advanced Security

Module Data

ASM C Advanced Security

Module Clock

TTL1 Generic Logic

Output 1

TTL2 Generic Logic

Output 2

Ground Ground Ground 12 Black Electrical ground for the RC.

Input 2 Blue When a DPS is installed, the RC will trigger an alert, forced door or

Black

Output 8 Yellow Advanced Security Module data communications.*

Output 9 White Advanced Security Module clock communications.*

Output 10 Purple Generic output at TTL voltage levels. Capable of sinking or

Output 11 Brown Generic output at TTL voltage levels. Capable of sinking or

load at 12 VDC.

propped door, and can be configured to activate the TTL output(s).

the Lock Relay, and/or TTL(s) if configured. REX can be configured

active high or active low through configuration settings.

Future intent RS-485 Data B communication.

the Lock Relay, and/or TTL(s) if configured. AUX can be configured

active high or active low through configuration settings.

sourcing up to 24 mA. TTL can be configured to activate based on

various sources including the lock relay, REX, AUX, and DPS. TTL

can be configured active high or active low through configuration

settings.

sourcing up to 24 mA. TTL can be configured to activate based on

various sources including the lock relay, REX, AUX, and DPS. TTL

can be configured active high or active low through configuration

settings.

* Not investigated by UL.

12 • Schlage • Reader controller

Page 13

Wiring | Lock wiring using PoE

Lock wiring using PoE

The Reader Controller supports a simplified configuration when PoE is

being used to supply the lock’s power.

1. Connect the red wire on the Reader Controller to the positive lead

of the electric lock. See Figure 2.4: Typical fail-secure door lock

wiring

2. Connect the negative lead of the lock to the black wire on the

Reader Controller.

3. See Managing inductive load challenges on page 20 for more

info regarding the use of the BackEMF diode.

Door sensor wiring

Connecting the Reader Controller to a door sensor allows the host

access control system to detect if the door is ajar. Then the host access

control system can create alarms based on the door’s state.

First, connect one terminal of the door sensor to the reader's blue wire.

Then connect the door sensor's other terminal to the Reader

Controller's common ground wire (black).

BackEMF

Protection Diode

Figure 2.4: Typical fail-secure door lock wiring

Lock and strike

Door sensor

(normally closed)

Figure 2.5: Door sensor wiring

13 • Schlage • Reader controller

Page 14

Wiring | Advanced Security Module (ASM) wiring

Advanced Security Module (ASM) wiring

The Reader Controller has an optional ASM,

which allows you to isolate the door’s lock

control circuitry on the secure side of the

building.

The ASM contains a form-C relay with

dry-contacts that are rated for 3 amps of current

@ 30 Volts. It can also be used in cases where

the Reader Controller is switching an externally

supplied voltage or an external control signal.

Examples of such usages include operating a

24VDC lock, or switching a logic signal for a

garage door opener.

Two methods of connecting the ASM are shown.

Figure 2.6: ASM with Reader Controller

supplying PoE power shows powering both the

lock and the ASM with the Reader controller’s

PoE power. Figure 2.7: ASM with lock running

on 24V external power shows powering the

ASM with the Reader controller’s PoE power

output, and the lock with an external 24 volt

power supply.

Figure 2.6: ASM with Reader Controller supplying PoE power

BackEMF

Protection Diode

Jumper

ASM

Relay

+ 12V

Door lock

(fail secure)

ASM Wire Conductor Preparation:

Factory-installed jumer

has been removed

Strip back the wire insulation: 0.25" to 0.281" (6

mm to 7 mm).

Acceptable single conductor sizes: 26 gauge to

15 gauge

Acceptable two conductors sizes: 26 gauge to 15

gauge

ASM

Relay

Î Note for multi-stranded conductors: Avoid

allowing any stray wire strands from

contacting the adjacent terminal block

connection.

Twist the multi-strands together prior to

insertion. Lightly solder-tinning the exposed wire

can help prevent stray strands.

(fail secure)

Figure 2.7: ASM with lock running on 24V external power

Table 2.2: ASM wiring

Reader Side Connection Lock Side Connection

Label Wire Label PoE Power (Figure 2.6) 24V Power (Figure 2.7)

A

B

C

D

Orange (12 V input power)

Black (ground)

Yellow

White

1

2

3

4

5

12V output power not used (factory-installed jumper removed)

Power ground not used

ASM common contact

ASM normally closed (NC) contact (fail-safe lock)

ASM normally open (NO) contact (fail-secure lock)

Door lock

+

24 VDC

-

BackEMF

Protection Diode

14 • Schlage • Reader controller

Page 15

Configuring communications

The Reader Controller can communicate with a variety of access control soware platforms. Contact your sales associate for a

complete list. The reader controllers communicate over the network to the host system. Below are best practices on this

configuration.

Reader controllers to host soware

Î Many other Ethernet network topology permutations exist. This is the most common Ethernet configuration used by

Schlage customers.

This is the simplest type of network connection. The Reader Controller is an IOT-style device that requires minimal network

configuration to function. The physical access control partner’s host system provides a cloud instance of the host soware. The

reader controllers must be configured to connect to host soware. The ENGAGE Mobile Application provides the interface to

capture and commission a unit with the initial configurations required to connect to the host soware. The following

configurations are needed to direct the Reader Controller to connect to the host soware:

Î Notice: Prior to capturing and commissioning, the reader controlled must be fully installed in its intended location

(including cover).

• WebSocket Server URL

• Certificate Authority Server URL

Addressing: The recommended best-practices is to let the local network’s DHCP service assign the IP Address to each reader.

As an alternate, you can manually assign the reader’s IP Address. To allow the reader to successfully reach the host soware,

the following setting are required:

• Static IP Address that is valid on the local subnetwork

• IP Address of the local subnetwork’s gateway.

• Subnet Mask

• DNS server’s IP Address

• Alternate DNS server’s IP Address

Here are a couple guidelines to follow to assure that your network’s configuration will support the Schlage access system.

• The Reader Controller is a standard “network appliance.” Standard TCP/IP networking rules apply.

• DHCP Configuration

• If the reader controllers are to be le on DHCP it is strongly recommended to use reservations, so the IP address does

not need to be renewed.

• Network Configuration

• A common best-practice is to place the reader controllers in a dedicated subnet

• The PoE switch should have enough power to run all ports and account for in rush. (IE. A switch restart which would

cause all readers to restart.)

15 • Schlage • Reader controller

Page 16

Appendix A: Power options

PoE Power Budget Calculations

When planning an installation using PoE, you need to validate that the PoE source (PoE Injector or PoE equipped Network

Switch) supplying the PoE power is sized properly for all the attached PoE devices. To do this, you total up the power draw (in

watts) of the PoE connections, and compare that total power draw to the rated capacity of the PoE source.

When the Reader Controller is dual powered there may be an increased number of power audits. If the 12VDC regulated power

supply voltage fluctuates above 12.1VDC the Reader Controller will transition from the PoE source to the DC power supply,

resulting in an audit.

Likewise when the DC power supply drops below 12.1VDC the Reader Controller will transition from the DC power supply to the

PSE, resulting in another audit.

Table 4.1: Expected PoE power draws of the reader controllers

Door Location Configuration PoE Power Requirement *

Reader controller 2.65 W

Reader controller with Electronic Lock (300 mA @ 12V) 6.26 W

Reader controller with Electronic Lock (600 mA @ 12V) 9.85 W

* Ethernet cabling power losses not included. Losses range from being negligible for short Cat5/6

cables, up to about 16% for 100 meter Cat5/6 cables.

To meet the Reader Controller’s variable PoE power requirements, the Reader Controller will classify itself with the PoE source

as a “Class 0” PoE device. The power usage of a Class 0 device can range between 0.4 to 13.0 watts at the device (up to 15.4

watts from the PoE source).

Some network PoE equipment will budget and allocate it’s distribution of PoE power based upon the maximum power usage of

the each attached device’s classification. If your network equipment uses this power provisioning technique, then you should

budget 15.4 watts for each Reader Controller. Such network PoE Equipment may allow you to manually configure the amount of

power that should be allocated to each device. Configuring the PoE equipment for an allocation of 3.0 watts or 11.0 watts per

connection would be appropriate. When powering from PoE or PoE+, in order for the system to be UL294 V7 compliant, the PoE

injector or end point must be compliant to UL294 or UL294B standards.

Using PoE over longer cable distances:

The Reader Controller can be powered via PoE on cable runs up to 328' (100 m) long (the standard Ethernet cable limit).

For Reader Controller locations that have longer cable runs (> 164' [50 m]), extra care should be given to the planning and

installation of the network cabling. The PoE power delivery system will running at about 80% of the allowable capacity, when

powering a 600mA lock over a 100 meter cable run.

For these long cable run installations, here are some items to focus on:

• Cabling:

• Use high-quality Ethernet cabling (Cat 5e or Cat6). Please note that the power loss over a Cat 6 cable is about 30%

less than the power loss on a Cat5e cable

• Cable Length. The 100 meter limit needs to include any patch cords and patch panels.

• Follow IEEE/TIA installation best practices.

• PoE Source

• The PoE Source (PoE Network switch or PoE Injector) meets the IEEE 802.3af standard.

• The PoE Source is properly sized to supply 15.4 watts/port. (Cabling power loses can be up to 2.5 watts/cable)

16 • Schlage • Reader controller

Page 17

Appendix A: Power options | Additional power options

Additional power options

Most installations will use PoE for the Reader Controller and door locks to control a door using a single, standard network cable.

There are many additional options available if the door location requires more power than a standard PoE-powered Reader

Controller can provide.

The different options require different configurations of the supporting equipment and/or building wiring. Table 4.2: Power

option configurations and Figure 4.1: Power options describes some of these power options.

Table 4.2: Power option configurations

Power Source Switchable

PoE (802.3af) 0.60 amps

PoE (802.3af) 0.55 amps

DC Power Supply 12

VDC

PoE Plus (802.3at) 1.8 amps

High-Powered PoE

(non-standard)

Example: PoE

Injector PowerDsine

PD-9501G

Power

(Max)

(12VDC)

(12VDC)

3.0 amps

(12VDC)

(Approx)

(12VDC)

3.0 amps

(12VDC)

Equipment at the

Door

Reader controller Reader controller’s

Reader controller

ASM

Reader controller

ASM

Reader controller

ASM

PoE Splitter

Example: PoE

Splitter PowerDsine

PD-AS-701/12

Reader controller

ASM

PoE Splitter

Example: PoE

Splitter PowerDsine

PD-AS-951/12-24

Limiting Factor Dia.

available PoE

Output

Reader controller’s

available PoE

Output {minus} the

power required by

the ASM

Rating of ASM’s lock

relay (12VDC

required by ASM’s

internal circuitry)

Rating of PoE

Splitter {minus}

power required to

operate Reader

Controller & ASM

Rating of ASM’s lock

relay

Equipment closet

PoE switch

A

B

C

or injector

0.60 A

Door location

Equipment closet

D

E

PoE switch or

injector

A

B

ASM

Door location0.55 A

Equipment closet

Switch

DC power

supply

Figure 4.1: Power options

17 • Schlage • Reader controller

C

ASM

Door location3.00 A

Equipment closet

High-powered PoE

switch or injector

(IEEE 802.3at)

D

ASM

PoE

Splitter

Door location1.80 A

Equipment closet

Switch

Proprietary

PoE Injector

Proprietary

PoE Splitter

E

ASM

Door location3.00 A

Page 18

Appendix A: Power options | Dual power sources

Dual power sources

Typical Reader Controller install

with:

• Redundant power supplies

• Input power: PoE

• Input power: 12VDC

Solution highlights

• Improve the ACS fault-tolerance

design by supplying the Reader

Controller with electrical power

from two independent power

sources.

• With this design, if the Reader

Controller's connection to the

PoE nework switch is lost, the

Reader Controller will

automatically begin to draw its

power from the DC power

source.

Installation tips

• Schottky Diode:

• Manufacturer: Vishay/

General Semiconductor

• P/N: SB560-E3/54 or equivalent

• Install the BackEMF diode

• Red wire will provide the lock with +12VDC

Figure 4.2: Dual power sources wiring

BackEMF

protection

diode

Lock strike

Pigtail

PoE equipped network switch

Cat 5

with PoE

Back-flow protection

diode (Schottky)

power supply

Additional reader

controllers

12VDC

regulated

+

-

18 • Schlage • Reader controller

Page 19

Appendix B: Additional wiring considerations

ASM LED status index

The ASM has two status LEDs

Power LED:

Located on the side towards the Reader Controller’s field wiring.

A Red LED indicates 12VDC power is being supplied to the ASM.

Communication Status LED:

Located on the side towards the Lock wiring.

LED status meaning are described in the table below.

Reader

controller

Locked

Off Green Normal Operation

Flash Amber Flash Amber No Operation Yellow wire may be disconnected

Off Flash Amber No Operation White wire may be disconnected

Off Flash Amber No Operation Invalid encryption key received from Reader Controller

Off Off No Operation If PowerCycle of Reader Controller allows for one or more lock

Reader

controller

Unlocked

Lock State when

Reader controller

is unlocked

Description or Item to Check

operations,and then the lock stops operating, then the BackEMF diode may

not be installed correctly.

Wiring two readers to one lock

If you are wiring both sides of the door to control IN and OUT access, then

you will have the special condition of wiring two reader controllers to a

single locking mechanism.

The “Inside” Reader Controller controls the door, and is wired to the door’s

components, such as the lock and door-sense switch. Use the following

steps to cause the “outside” Reader Controller to activate the REX input on

the “Inside” Reader Controller.

Steps

Î Figure 5.1: Two readers to one lock wiring

1. Wire the “Inside” reader normally

2. Connect an ASM to the “Outside” reader

3. Connect the “Inside” reader’s REX input to the “NO” terminal of the

ASM.

4. Connect the “Inside” reader’s black wire to the Common terminal of the

ASM.

5. If the door also has a REX device, wire the REX device “in parallel” to

the ASM.

Programming

“Inside” Reader Controller must be programmed to activate the lock upon a

REX input event.

remaining

to remaining door

Figure 5.1: Two readers to one lock wiring

Inside Outside

ASM

Relay

wires

optional input REX

switch or relay

components

(dry contact)

ASM

control

19 • Schlage • Reader controller

Page 20

Appendix B: Additional wiring considerations | Managing inductive load challenges

Managing inductive load challenges

Most door latches use a relay coil that powers up and

down, when the door is unlocked and locked. When

this happens, a pulse of electrical energy is produced

by the lock’s coil. This pulse is called back EMF, and

can interfere with the reader’s operation.

Switching off a typical 12 VDC relay coil can produce

a back EMF pulse of 300 volts or more. If this voltage

pulse is allowed to flow back into the reader, it can

cause the reader to “brown out” and the reader will

reboot.

Figure 5.2: Inductive load control (two options

shown) shows a solution. You can virtually eliminate

back EMF by installing a transient suppression

device (diode). Each Reader Controller is supplied

with a diode assembly, which simplifies the

installation process. A standard diode, from any

electronic supply store, can also be used. Always

check that the diode is correctly rated for the circuit

voltage. For optimum performance, the diode should

be installed at the lock or close to the lock. Standard

diodes have a stripe-band marking on one side. That

side of the diode should be connected to the “+” wire

of the lock circuit.

Diode

assembly

(+DC)

(-DC)

Protect the Digital Output

Which type of transient suppressor should you

install? This depends mainly on the type of inductive

load being switched. Some locks have Back EMF

protection built into the lock itself.

For Back EMF in low voltage DC applications, a

1N4007 diode will suce.

However, for protection against other transient

voltages (i.e. lightning), we recommend using a

fast-switching transient voltage suppressor.

Standard diode

(1N4007 or

equivalent)

Figure 5.2: Inductive load control (two options shown)

(+DC)

(-DC)

20 • Schlage • Reader controller

Page 21

Appendix B: Additional wiring considerations | PoE: Magnetic lock, ASM and PIR

PoE: Magnetic lock, ASM and PIR

Typical Reader Controller install with:

• Magnetic lock

• ASM

• PIR motion detector

• In-rush supressor

• Door open sensor

• PoE splitter

• Input power

• PoE to the PoE splitter

• 12VDC from splitter to components

Installation tips

• PoE splitter and fuse isolated the magnetic

lock's power source to the inside of the

facility

• See Advanced Security Module (ASM)

wiring on page 14 for more information.

• Splitter 12V to ASM power input and

ASM relay common contact

• ACC-IRS-4700 - Red wire goes to the 12V

supply (PoE splitter)

• 0.5 Amp fast-acting fuse: Littelfuse PN:

0208.500MXP or equivalent

• In-line fuse- holder: Littelfuse PN: 150274 or

equivalent

Cat 5

w/o PoE

Inside facility

PoE equipped network switch

Cat 5

w/ PoE

PoE

splitter

0.5 A

fast-acting fuse

ASM

PIR motion

detector

(REX)

In-rush suppressor

PN: ACC-IRS-4700

(+)

(-)

12VDC

(2 wires)

Gnd

(1 wire)

21 • Schlage • Reader controller

Door sense

switch

Magnetic

lock

Page 22

Appendix C: UL Disclaimers

• Electronic credential transmission technology: Bluetooth (BGM111) Version 02.11.01.241, 01.08.04, 01-1.6.0 or greater.

• Reader controller main firmware version 1.1.46 or greater and bootloader version 11.04.00 or greater.

• Wireless electronic credential application: Schlage Mobile Access version 1.0.0 or greater.

The access control system shall have the means to distinguish between the type of credential used via code or description (i.e.

authentication/digital signature keys received from a physical card vs. authentication/digital signature keys received from a

wireless electronic credential).

When provided, minimum data encryption/authentication techniques shall be employed in accordance with paragraph 64.3.2 in

the UL 294 standard.

The wireless electronic credential was only used as an alternate means for transmitting the user data typically found on a

physical credential to the reader interface. The wireless electronic device shall not be capable of command, control,

programming, or any other system manipulation.

The wireless electronic device shall only be used in the same manner as a physical credential, transmitting user data to the

reader interface within close proximity, as indicated by the manufacturer.

22 • Schlage • Reader controller

Page 23

About Allegion

Allegion (NYSE: ALLE) is a global pioneer in seamless access, with leading

brands like CISA

Focusing on security around the door and adjacent areas, Allegion secures

people and assets with a range of solutions for homes, businesses, schools

and institutions. Allegion had $2.9 billion in revenue in 2019 and sells

products in almost 130 countries.

For more, visit www.allegion.com

®

, Interflex®, LCN®, Schlage®, SimonsVoss® and Von Duprin®.

© 2020 Allegion

013562013563, Rev. 09/20

www.allegion.com/us

Loading...

Loading...