Page 1

MA-Series

Service manual

Page 2

Page 3

Contents

4 Introduction

5 Lock assembly drawing index

8 Lock assemblies

9 MA101 - Passage or closet latch

10 MA161 - Exit or connecting room latch

11 MA301 - Privacy lock

12 MA311 - Privacy, bedroom/bath lock

13 MA321 - Privacy lock

14 MA371 - Store door lock

15 MA381 - Apartment, exit lock

16 MA411 - Asylum or institutional lock

17 MA431 - Classroom security lock with deadbolt

18 MA441 - Classroom security lock

19 MA451 - Hotel guest lock

20 MA521 - Entry/oce lock

21 MA531 - Apartment corridor door lock

22 MA541 - Entry/oce lock

23 MA551 - Holdback lock

24 MA561 - Classroom lock

25 MA571 - Dormitory or exit lock

26 MA581 - Storeroom lock

27 MA621 - Apartment corridor lock

28 MA641 - Dormitory lock

29 MA851 - Electrified fail safe (EL) - 12 or 24V, with or

without RX

30 MA881 - Electrified fail secure (EU) - 12 or 24V, with or

without RX

31 MA911 - Classroom dead lock

32 MA921 - Dead lock outside only

33 MA931 - Dead lock inside and outside

34 MA941 - Dead lock with inside turn

35 MA12 - Single dummy

36 MA18 - Double dummy

37 Parts and accessories

37 Lever and knob designs

37 Screw packs

39 Cams

40 Cylinders

40 Mortise, rim, and cam lock for standard cylinders

40 Strikes

41 Cylinder collars

41 Escutcheon trim rings

41 Sectional trim rings

42 Trim rings and collars

43 Electrified locks

44 Ordering procedures

44 Finishes

45 Door handing

Page 4

Introduction

Introduction

This manual contains a complete listing of parts and assemblies for MA-Series mortise locks manufactured by Falcon Lock

Company. This edition lists components of MA-Series locks manufactured aer February, 2011. All lock case covers are

labeled with dates to identify year of manufacture. Example: 2311 = the 23rd week of 2011.

Exploded views of each lock function and trim assembly are provided with accompanying charts to identify parts for

replacement purposes. Exploded views of trim are shown with parts for standard size doors. In addition, this manual provides

lock trim ordering procedures, cylinder length charts by door range, and all auxiliary components of the MA-Series mortise

locks.

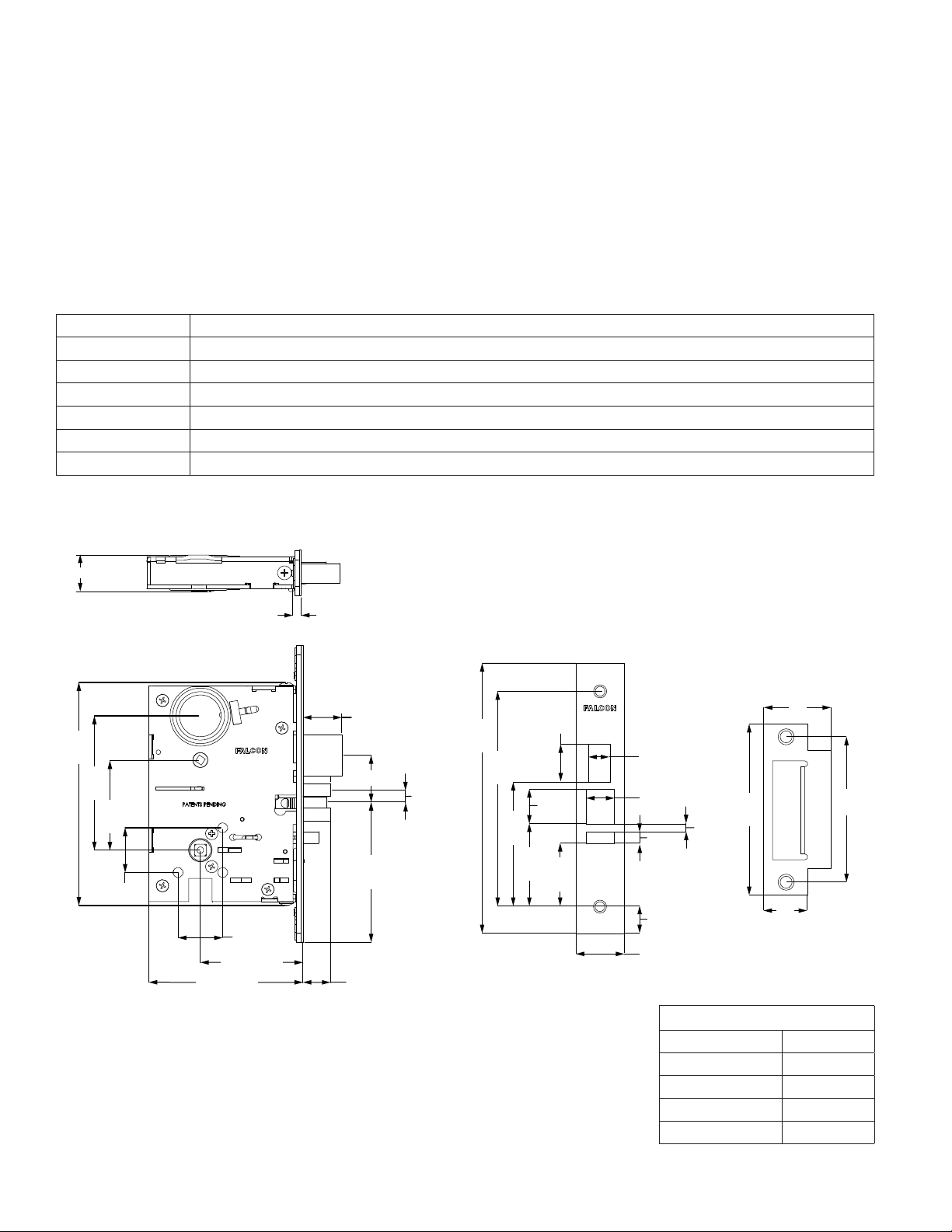

Standard features*

Certifications ANSI A156 .13, Series 1000, Grade 1 Operation and Security, UL Listed for 3-hour fire door

Latch 2-piece brass mechanical anti-friction bolt, ³⁄v” projection

Strike 1Z⁄v” x 4M⁄,”, ANSI, Square corner, with dust box

Cylinder 6-Pin solid brass, keyed 5-pin, Falcon G keyway, keyed different (KD)

Door Range 1³⁄v” – 1M⁄,” standard

Keys Two, nickel silver cut keys per lock, Falcon G keyway

Backset 2³⁄v”

* Locks are furnished with standard features unless otherwise specified.

Lock case dimensions

1” (25)

6”

(152)

3³⁹⁄₆₄”

(92)

2²⁷⁄₆₄”

(62)

1³⁄₁₆” (30)

Lock

1³⁄₁₆” (30)

2³⁄₄” (70)

4⁵⁄₃₂” (106)

¹⁄₄” (6)

1” (25)

1¹⁷⁄₆₄” (32)

3⁴⁹⁄₆₄”

(96)

³⁄₄” (19)

²³⁄₁₀₀”

(6)

8”

(203)

6³⁄₈”

(162)

3²¹⁄₃₂”

Faceplate

(93)

2⁷⁄₁₆”

(62)

1⁹⁄₆₄”

1¹⁄₃₂”

(26)

1²⁷⁄₃₂”

(29)

(47)

⁹⁄₁₆” (14)

⁴⁵⁄₆₄” (18)

¹¹⁄₃₂”

(9)

²⁵⁄₃₂” (20)

1¹⁄₄” (32)

¹⁄₄” (6)

4⁷⁄₈”

(124)

A

4¹⁄₈”

(105)

1¹⁄₄”

(32)

Strike

4 • Falcon • MA-Series service manual

Strike

(A) Door thickness Lip size

1³⁄v” - 1M⁄,” 1Z⁄v” (32 mm)

2” - 2Z⁄,” 1M⁄zn” (37 mm)

2Z⁄v” - 2³⁄,” 1>⁄zn” (40 mm)

2Z⁄x” - 2B⁄,” 1ZZ⁄zn” (43 mm)

Page 5

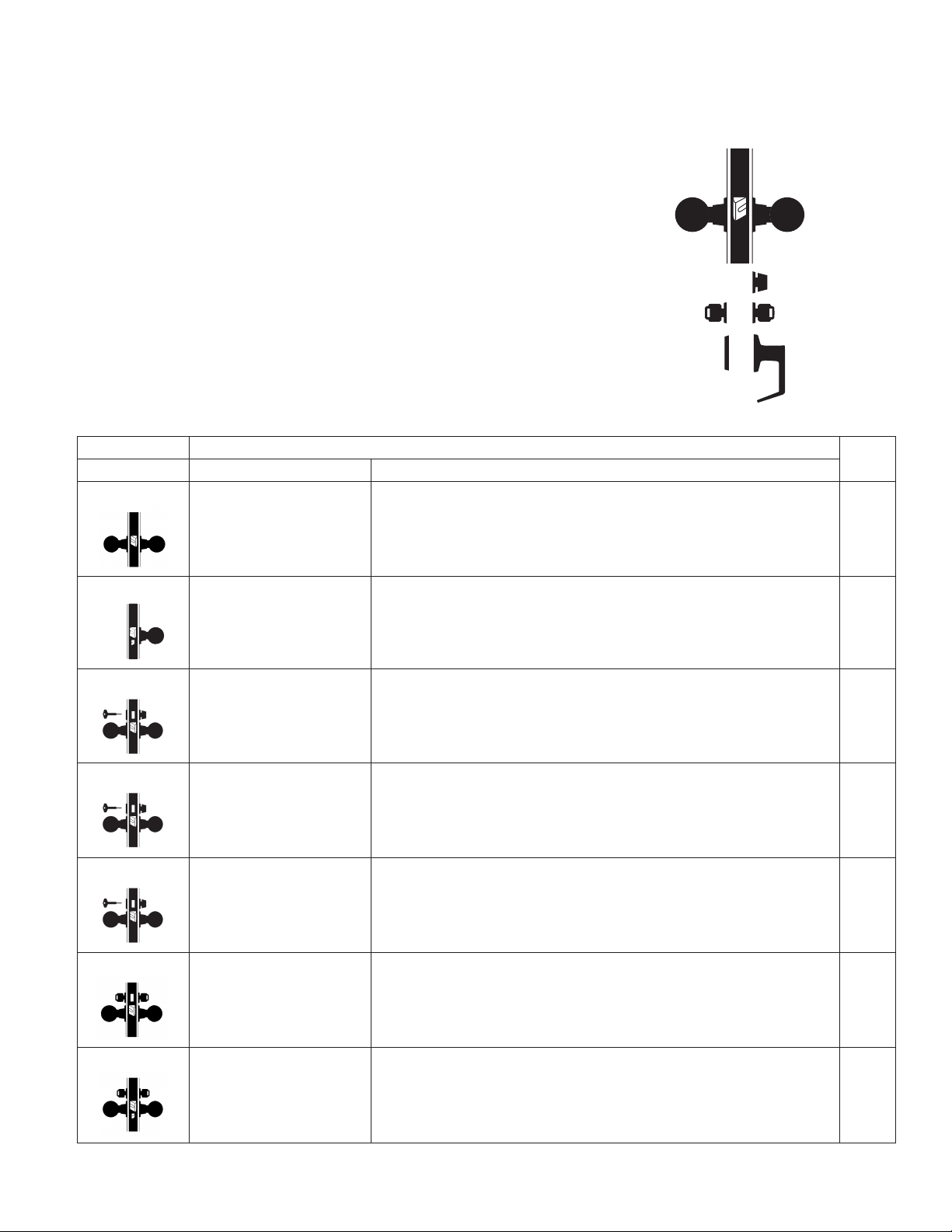

Lock assembly drawing index

Lock assembly drawing index

The lock assembly drawing index provides visual representations and textual

descriptions of available functions. Page numbers for full trim and chassis

drawings are referenced.

To order Falcon MA-Series locksets, please consult page 44 for ordering

information and assistance.

Note: If a special function is required and not listed here, please contact the

factory for assistance.

Knob

Thumb turn

Key

Blank Plate

Function ANSI A156.13, 2005 Page

Falcon ANSI Description Function

MA101 F01 Passage/closet latchset Latch bolt by knob/levers at all times. 9

MA161 F31 Connecting room/exit latch Latch bolt operated by knob/lever from inside. No trim outside. Auxiliary dead latch. 10

MA301 F02 Privacy lock Latch bolt by knobs/levers either side, dead bolt by turn inside or emergency release

outside.

Key

Lever

11

MA311 F19 Privacy, bedroom or bath lock Latch bolt by knobs/levers. Deadbolt by turn from inside and emergency release

outside. Rotating inside knob/lever retracts both bolts.

MA321 F22 Privacy lock Latch bolt operated by knob/lever from either side except when outside knob/lever

is locked by inside thumb turn. Operating inside knob/lever, closing door or

operating outside emergency release unlocks outside knob/lever.

MA371 F14 Store door lock Latch bolt by knobs/levers. Deadbolt by key from either side. 14

MA381 F09 Apartment, exit lock Latch bolt operated by knob/lever from either side, except when outside knob/lever

is locked by key from inside. When outside knob/lever is locked, latch bolt is

retracted by key from outside or by operating inside lever. Auxiliary dead latch.

Falcon • MA-Series service manual • 5

12

13

15

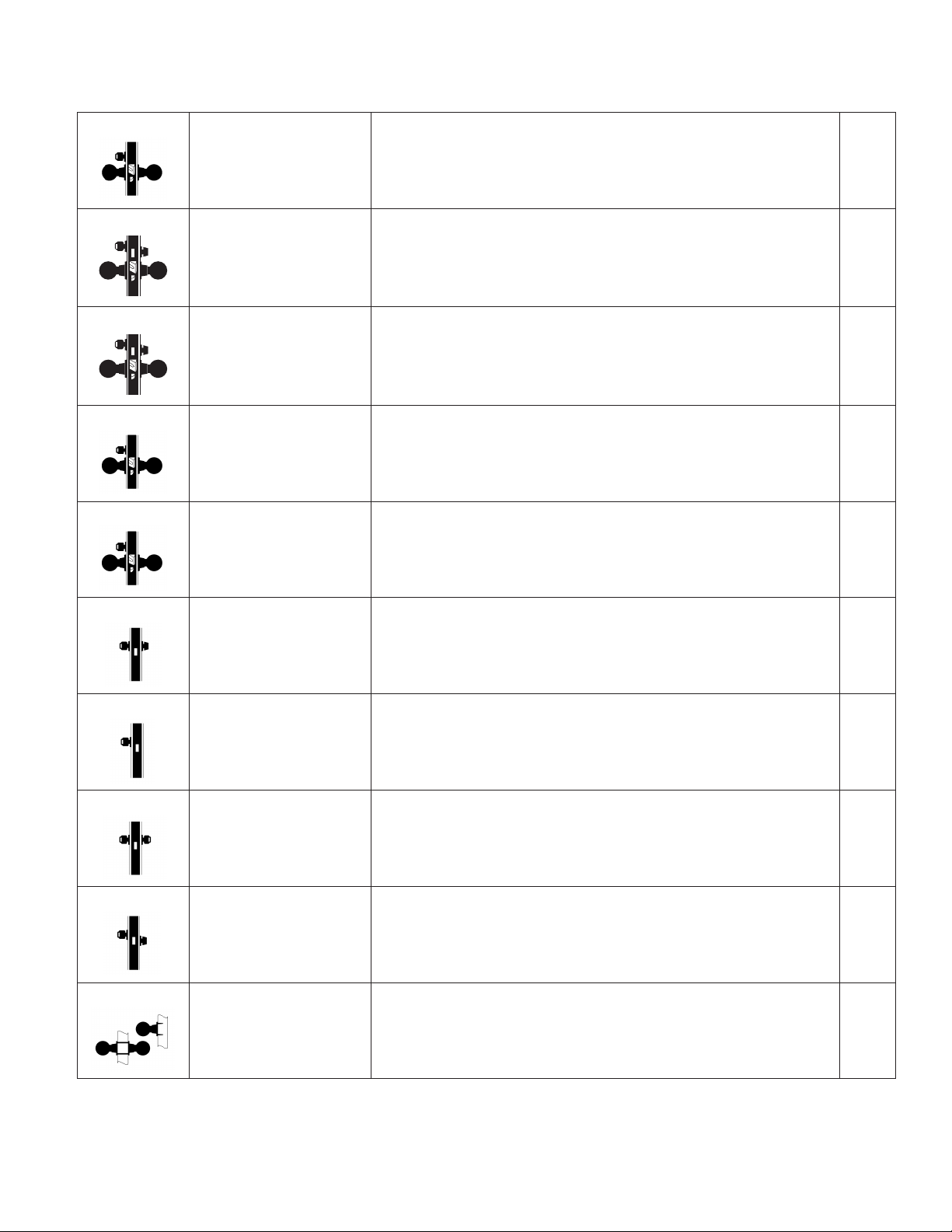

Page 6

Lock assembly drawing index

MA411 F30 Asylum lock Latch bolt operated by key from either side. Both knobs/levers always inoperative.

MA431 F34 Classroom security lock with

deadbolt

MA441 F32 Classroom security lock Latch bolt operated by knob/lever from either side except when outside knob/lever

MA451 F15 Hotel/guest lock Latch bolt operated by key from outside or by operating inside knob/lever. Outside

MA521 F04 Entry/oce lock Latch bolt operated by knob/lever from either side except when outside knob/lever

Auxiliary dead latch.

Latch bolt operated by knob/lever from either side except when outside knob/lever

is locked from inside or outside by key. Dead bolt retracted by key from inside or

outside. Operating inside knob/lever retracts both bolts and unlocks outside. Latch

bolt dead locked when dead bolt is thrown.

is locked from inside or outside by key. When outside knob/lever is locked, latch bolt

is retracted by key from inside or outside or by operating inside knob/lever. Auxiliary

dead latch.

knob/lever is always inoperative. Dead bolt projected by turn from inside and all

keys except emergency key are shut out. Operating inside knob/lever retracts both

bolts. Auxiliary dead latch.

is made inoperative by buttons in face. When outside knob/lever is locked, latch bolt

is retracted by key from outside or by operating inside knob/lever. Auxiliary dead

latch.

When dead bolt is retracted, knob/lever is unlocked by buttons in face.

16

17

18

19

20

MA531 F20 Apartment corridor door lock Latch bolt operated by knob/lever from either side, except when outside knob/lever

is made inoperative by buttons in face. Dead bolt operated by key outside or turn

inside. Key outside operates both bolts. Operating inside knob/lever retracts both

bolts and outside remains locked.

Latch bolt is deadlocked when outside knob/lever is made inoperative or when the

dead bolt is projected. When dead bolt is retracted, knob/lever is unlocked by

buttons in face.

MA541 F21 Entry/oce lock Latch bolt by knobs/levers either side. Deadbolt by key outside or turn inside. 22

MA551 F06 Holdback lock Latch bolt operated by lever from either side except when outside lever is locked

from outside by key. Latch bolt can be locked in a retracted position by key. When

outside lever is locked, latch bolt is retracted by key from outside or by operating

inside lever unless latch bolt has been locked in a retracted position. Auxiliary dead

latch.

Note: Chassis is handed.

MA561 F05 Classroom lock Latch bolt operated by knob/lever from either side except when outside knob/lever

is locked by key. WHen outside knob/lever is locked, latchbolt is retracted by key

from outside or by operating inside knob/lever. Auxiliary latch deadlocks latch bolt

when door is closed. Inside knob/lever always free for immediate use.

MA571 F13 Dormitory or exit lock Latch bolt operated by knob/lever from either side. Dead bolt projected by key from

outside and turn from inside. Operating inside knob/lever retracts both bolts and

unlocks outside.

21

23

24

25

6 • Falcon • MA-Series service manual

Page 7

Lock assembly drawing index

MA581 F07 Storeroom lock Latch bolt operated by key from outside or by operating inside knob/lever. Otuside

MA621 F08/F10 Front door/apartment corridor Latch bolt is operated by knob/lever from either side except when outside knob/

MA641 - Dormitory lock Latch bolt by knob/lever inside and key outside. Inside knob/lever free. Outside

MA851 - Storeroom - Fail safe (EL),

with or without RX

MA881 - Storeroom - Fail secure (EU),

with or without RX

knob/lever is always inoperative. Auxiliary dead latch.

lever is made inoperative by buttons in face. Dead bolt is operated by turn inside.

Key outside operates both bolts.

knob/lever rigid. Dead bolt by key outside or thumb turn inside. Rotating inside

knob/lever retracts both bolts. Deadlocking latch.

Latch bolt operated by knob/lever from either side except when outside knob/lever

is electrically locked. When outside knob/lever is locked, latch bolt retracted by key

in cylinder outside. Deadlocking latch. Inside knob/lever is always free for

immediate egress.

Specify 12 or 24 V DC.

Latch bolt operated by knob/lever from inside except when outside knob/lever is

electrically unlocked, then latch bolt from either side. When locked, key in outside

cylinder outside retracts latch bolt. Deadlocking latch. Inside knob/lever is always

free for immediate egress.

Specify 12 or 24 V DC.

26

27

28

29

30

MA911 F29 Classroom deadlock Key from outside operates deadbolt. Turn from inside retracts but does not project

dead bolt.

MA921 F18 Deadlock outside only Deadbolt by key outside only. 32

MA931 F16 Deadlock inside and outside Deadbolt by key from either side. 33

MA941 F17 Deadlock with inside turn Deadbolt by key outside or turn inside. 34

MA12/MA18 - Dummy trim Single or double available.

SIngle (MA12).

Double (MA18).

31

35

36

Falcon • MA-Series service manual • 7

Page 8

Lock assemblies

9 MA101 - Passage or closet latch

10 MA161 - Exit or connecting room latch

11 MA301 - Privacy lock

12 MA311 - Privacy, bedroom/bath lock

13 MA321 - Privacy lock

14 MA371 - Store door lock

15 MA381 - Apartment, exit lock

16 MA411 - Asylum or institutional lock

17 MA431 - Classroom security lock with deadbolt

18 MA441 - Classroom security lock

19 MA451 - Hotel guest lock

20 MA521 - Entry/oce lock

21 MA531 - Apartment corridor door lock

22 MA541 - Entry/oce lock

23 MA551 - Holdback lock

24 MA561 - Classroom lock

25 MA571 - Dormitory or exit lock

26 MA581 - Storeroom lock

27 MA621 - Apartment corridor lock

28 MA641 - Dormitory lock

29 MA851 - Electrified fail safe (EL) - 12 or 24V, with or

without RX

30 MA881 - Electrified fail secure (EU) - 12 or 24V, with or

without RX

31 MA911 - Classroom dead lock

32 MA921 - Dead lock outside only

33 MA931 - Dead lock inside and outside

34 MA941 - Dead lock with inside turn

35 MA12 - Single dummy

36 MA18 - Double dummy

8 • Falcon • MA-Series service manual

Page 9

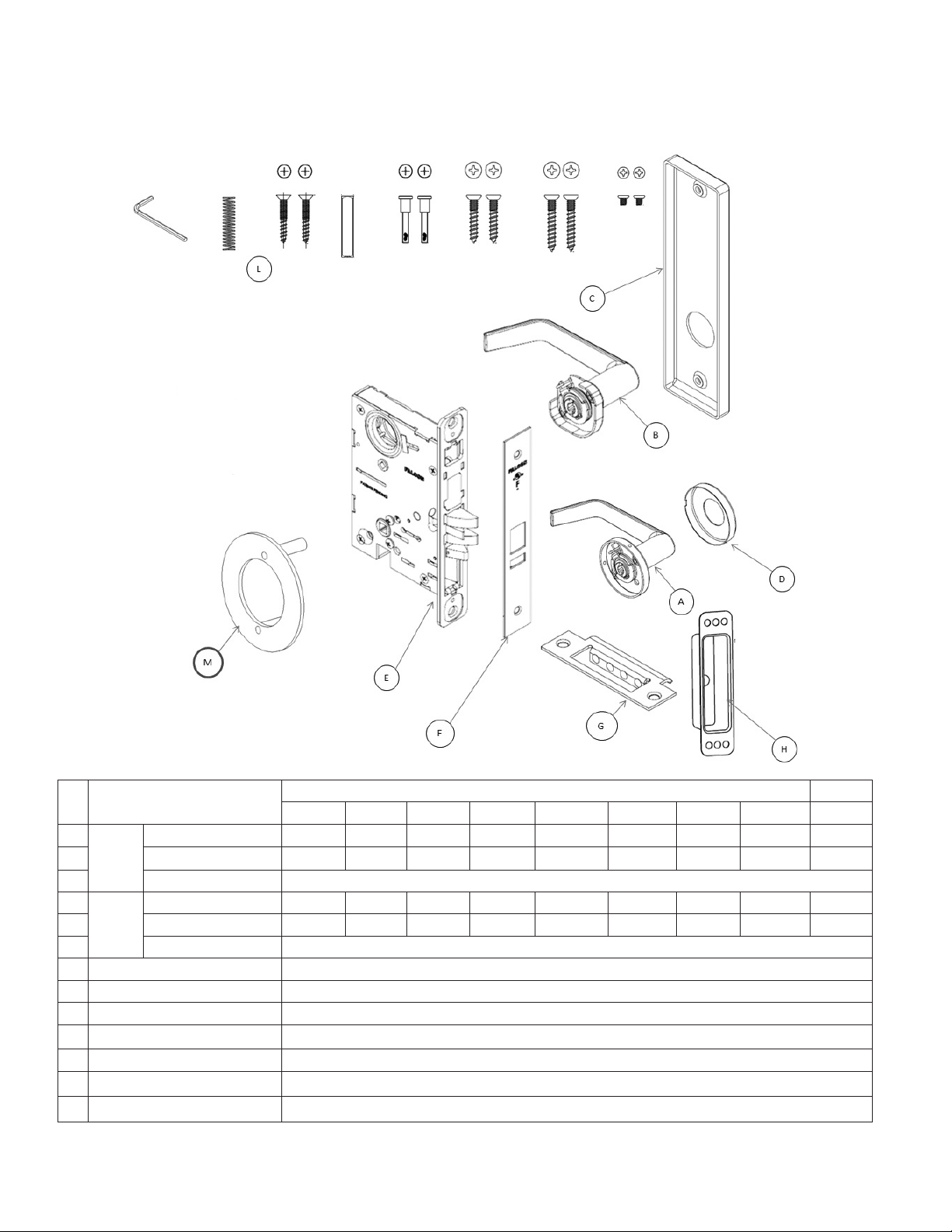

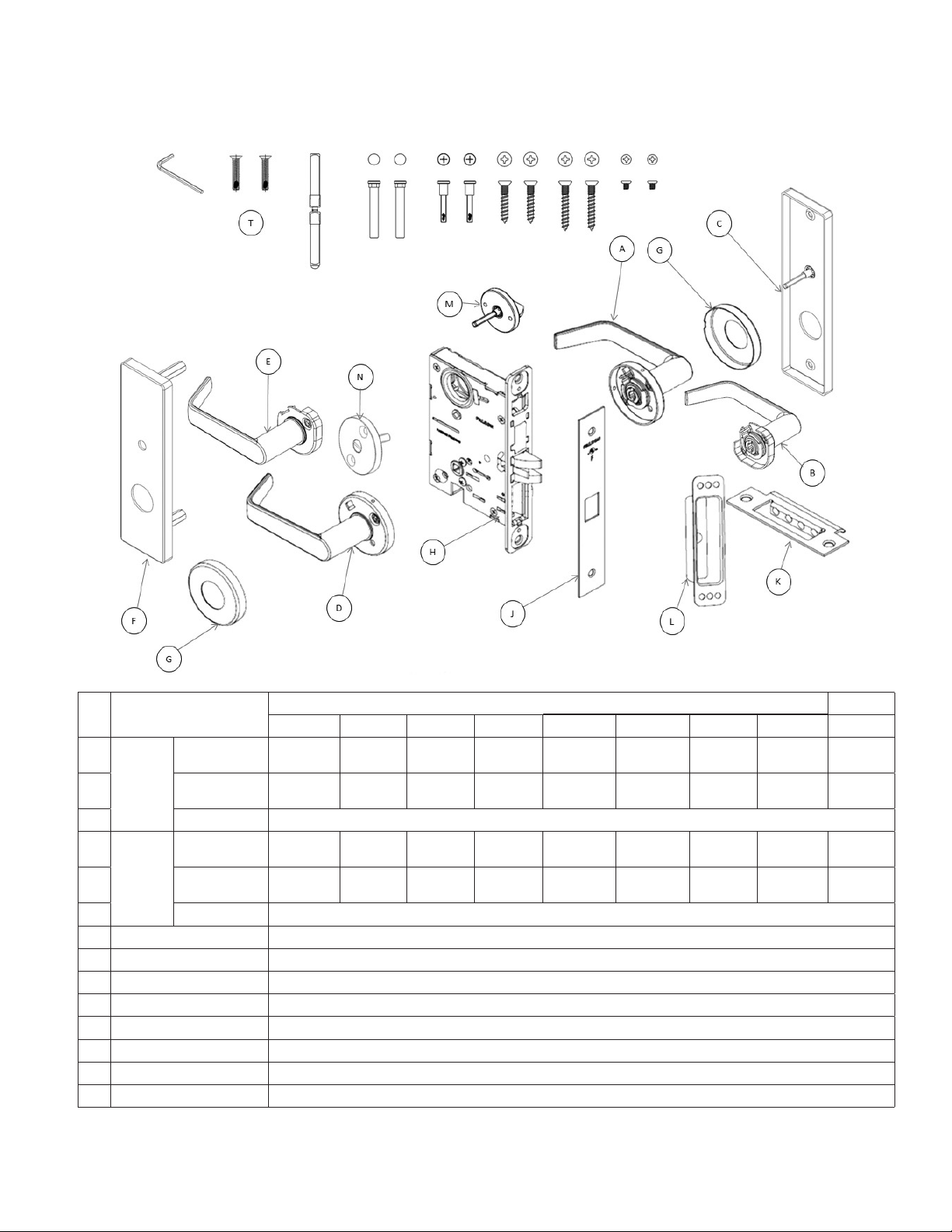

Lock assemblies

MA101 - Passage or closet latch

Ltr. Description

A Inside

trim

B Knob/lever

C Escutcheon E77012-IP

D Outside

trim

E Knob/lever

F Escutcheon AE77012-0P

G Rose (2) S76012

H Assembly, lock unit A7801

J Faceplate S77801

K Strike assembly A8737-X

L Strike box PE1396

P Screw pack See page 37

Knob/lever

sectional

escutcheon

Knob/lever

sectional

escutcheon

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

Falcon • MA-Series service manual • 9

Page 10

Lock assemblies

MA161 - Exit or connecting room latch

Ltr. Description

A

Inside

B

trim

C Escutcheon E77012-IP

Outside

- Knob/lever escutcheon N /A N /A N/A N/A N/A N/A N/A N/A N/A

trim

- Escutcheon N/A

D Rose S76012

E Assembly, lock unit A7831

F Faceplate S77805

Strike assembly

G

H Strike box PE1396

Screw pack

L

M Plate for use with no outside trim

10 • Falcon • MA-Series service manual

Knob/lever sectional

Knob/lever escutcheon

Knob/lever sectional N/A N/A N/A N /A N/A N/A N/A N/A N/A

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

AS76280 AS76526 AS76029 AS76140

AE77280 AE77526 AE77029 AE77140

A8737-X

See page 37

AS5813

AS76310 AS76321 AS76360 AS76760

AE77310 AE77321 AE77360 AE77760

AS76100

AE77100

Page 11

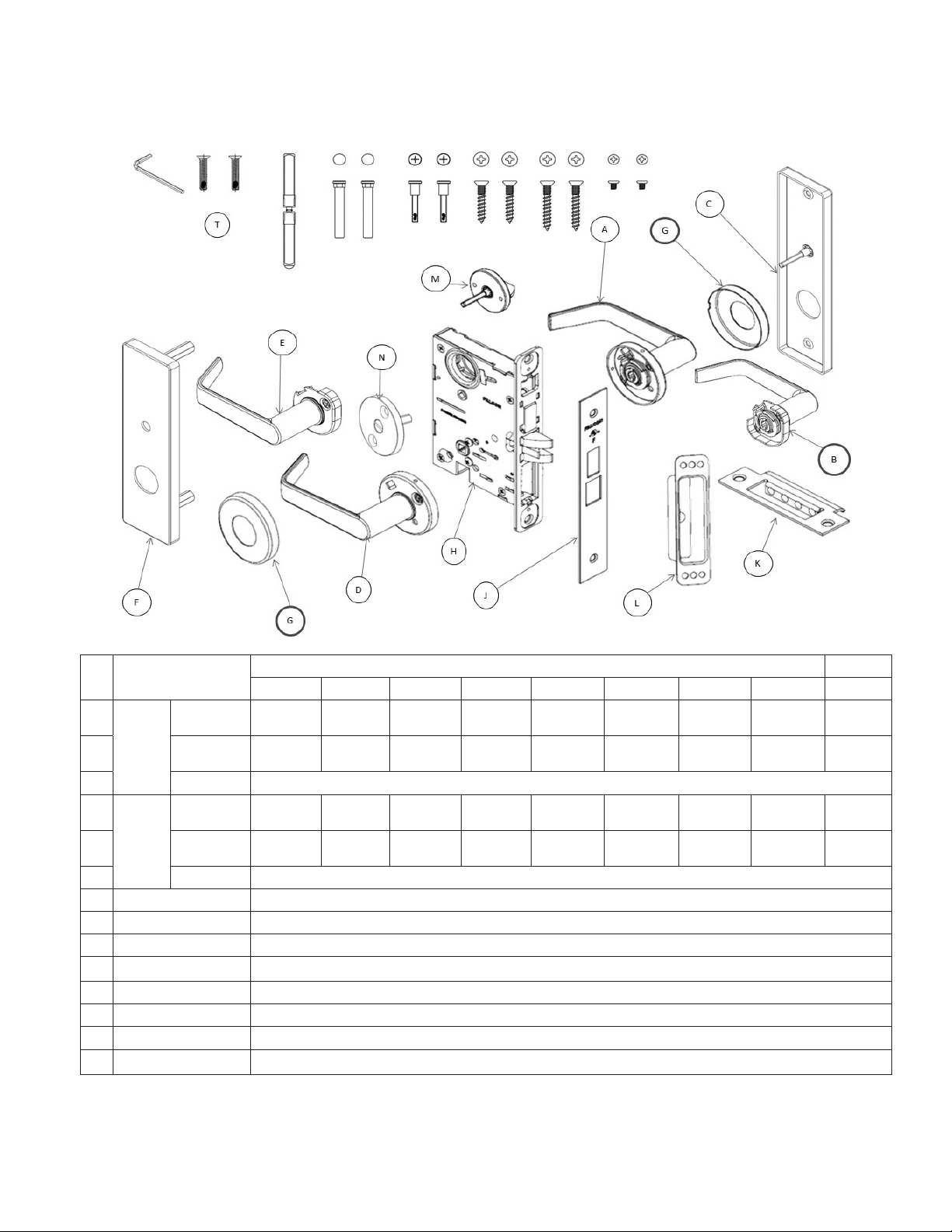

Lock assemblies

MA301 - Privacy lock

Ltr. Description

A Inside

trim

B Knob/lever

C Escutcheon AE77012-IT

D Outside

trim

E Knob/lever

F Escutcheon AE77012-OT

G Rose (2) S76012

H Assembly, lock unit A7802

J Faceplate S77819

K Strike assembly A8737-X

L Strike box PE1396

M Thumb turn AS75319

N Emergency turn AS76853

T Screw pack See page 37

Knob/lever

sectional

escutcheon

Knob/lever

sectional

escutcheon

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

Falcon • MA-Series service manual • 11

Page 12

Lock assemblies

MA311 - Privacy, bedroom/bath lock

Ltr. Description

A Inside

trim

B Knob/lever

C Escutcheon AE77012-IT

D Outside

trim

E Knob/lever

F Escutcheon AE77012-OT

G Rose (2) S76012

H Assembly, lock unit A7819

J Faceplate S77819

K Strike assembly A8737-X

L Strike box PE1396

M Thumb turn AS75319

N Emergency turn AS76853

T Screw pack See page 37

Knob/lever

sectional

escutcheon

Knob/lever

sectional

escutcheon

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

12 • Falcon • MA-Series service manual

Page 13

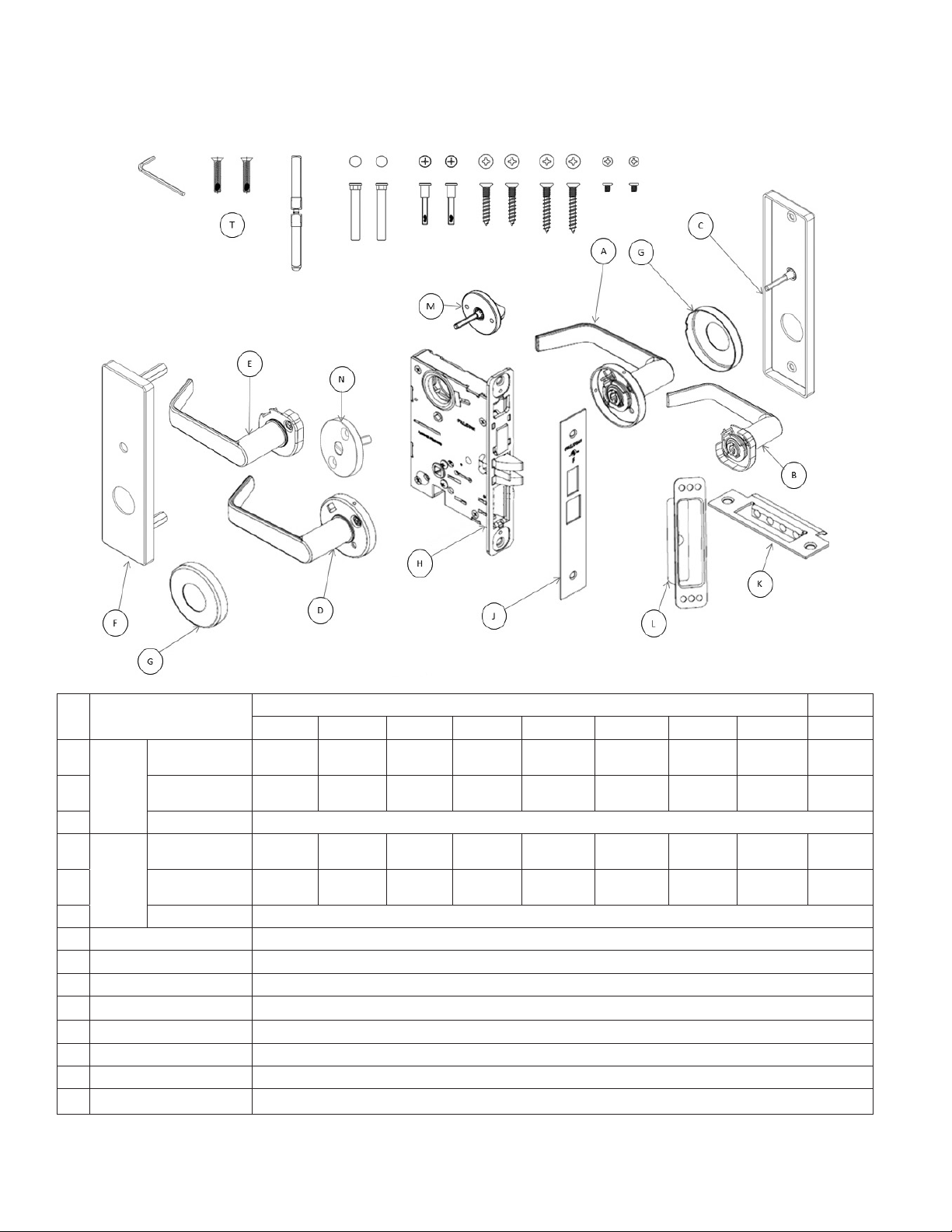

Lock assemblies

MA321 - Privacy lock

Ltr. Description

A

Inside

trim

B

C Escutcheon AE77012-IT

D

Outside

trim

E

F Escutcheon AE77012-OT

G Rose (2) S76012

H Assembly, lock unit A7822

J Faceplate S77801

K Strike assembly A8737-X

L Strike box PE1396

M Thumb turn AS75319

N Emergency turn AS76853

T Screw pack See page 37

Knob/lever

sectional

Knob/lever

escutcheon

Knob/lever

sectional

Knob/lever

escutcheon

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

Falcon • MA-Series service manual • 13

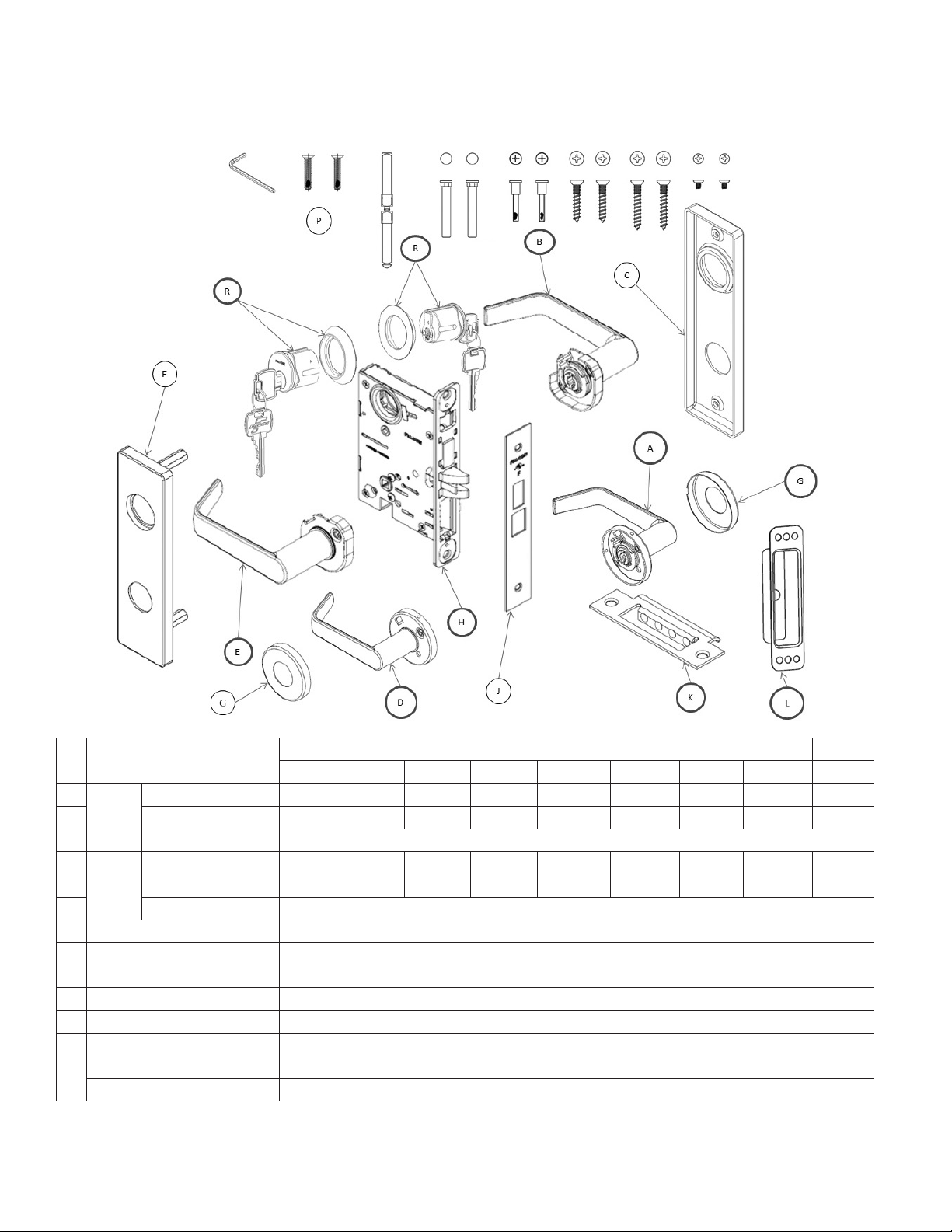

Page 14

Lock assemblies

MA371 - Store door lock

SFIC not shown

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

C Escutcheon E77012-IC

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7814

J Faceplate S77819

K Strike assembly A8737-X

L Strike box PE1396

P Screw pack See page 37

R Cylinder, conventional (2) Q005-064

Cylinder, SFIC (2) Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

14 • Falcon • MA-Series service manual

Page 15

Lock assemblies

MA381 - Apartment, exit lock

SFIC not shown

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

C Escutcheon E77012-IC

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7809

J Faceplate S77805

K Strike assembly A8737-X

L Strike box PE1396

P Screw pack See page 37

R Cylinder, conventional (2) Q005-064

Cylinder, SFIC (2) Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

Falcon • MA-Series service manual • 15

Page 16

Lock assemblies

MA411 - Asylum or institutional lock

SFIC not shown

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

C Escutcheon E77012-IC

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7814

J Faceplate S77819

K Strike assembly A8737-X

L Strike box PE1396

P Screw pack See page 37

Cylinder, conventional (2) Q005-064

R

Cylinder, SFIC (2) Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

16 • Falcon • MA-Series service manual

Page 17

Lock assemblies

MA431 - Classroom security lock with deadbolt

SFIC not shown

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

C Escutcheon E77012-IC

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7813

J Faceplate S77819

K Strike assembly A8737-X

L Strike box PE1396

R Screw pack See page 37

T Cylinder, conventional (2) Q005-064

Cylinder, SFIC (2) Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

Falcon • MA-Series service manual • 17

Page 18

Lock assemblies

MA441 - Classroom security lock

SFIC not shown

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

C Escutcheon E77012-IC

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7805

J Faceplate S77805

K Strike assembly A8737-X

L Strike box PE1396

P Screw pack See page 37

Cylinder, conventional (2) Q005-064

R

Cylinder, SFIC (2) Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

18 • Falcon • MA-Series service manual

Page 19

Lock assemblies

MA451 - Hotel guest lock

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

C Escutcheon AE77012-IT

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7815

J Faceplate S77815

K Strike assembly A8737-X

L Strike box PE1396

M Thumb turn AS76319

R Screw pack See page 37

T Cylinder, conventional Q005-064

Cylinder, SFIC Q008-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

Falcon • MA-Series service manual • 19

Page 20

Lock assemblies

MA521 - Entry/oce lock

SFIC not shown

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

C Escutcheon E77012-IP

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7804

J Faceplate S77804

K Strike assembly A8737-X

L Strike box PE1396

P Screw pack See page 37

R Cylinder, conventional Q005-064

Cylinder, SFIC Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

20 • Falcon • MA-Series service manual

Page 21

Lock assemblies

MA531 - Apartment corridor door lock

SFIC not shown

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

C Escutcheon AE77012-IT

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7820

J Faceplate S77820

K Strike assembly A8737-X

L Strike box PE1396

M Thumb turn AS76319

R Screw pack See page 37

T Cylinder, conventional Q005-064

Cylinder, SFIC Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

Falcon • MA-Series service manual • 21

Page 22

Lock assemblies

MA541 - Entry/oce lock

Ltr. Description

A Inside

trim

B Knob/lever

C Escutcheon AE77012-IT

D Outside

trim

E Knob/lever

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7820

J Faceplate S77820

K Strike assembly A8737-X

L Strike box PE1396

M Thumb turn AS76319

R Screw pack See page 37

T Cylinder, conventional Q005-064

Cylinder, SFIC Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

escutcheon

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

escutcheon

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

SFIC not shown

22 • Falcon • MA-Series service manual

Page 23

Lock assemblies

MA551 - Holdback lock

SFIC not shown

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

C Escutcheon E77012-IP

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7806

J Faceplate S77805

K Strike assembly A8737-X

L Strike box PE1396

P Handing instruction sheet Q513-069

R Screw pack See page 37

T Cylinder, conventional Q005-064

Cylinder, SFIC Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

Falcon • MA-Series service manual • 23

Page 24

Lock assemblies

MA561 - Classroom lock

SFIC not shown

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

C Escutcheon E77012-IP

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7805

J Faceplate S77805

K Strike assembly A8737-X

L Strike box PE1396

P Screw pack See page 37

R Cylinder, conventional Q005-064

Cylinder, SFIC Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

24 • Falcon • MA-Series service manual

Page 25

Lock assemblies

MA571 - Dormitory or exit lock

SFIC not shown

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

C Escutcheon AE77012-IT

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7813

J Faceplate S77819

K Strike assembly A8737-X

L Strike box PE1396

M Thumb turn AS76319

R Screw pack See page 37

T Cylinder, conventional Q005-064

Cylinder, SFIC Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

Falcon • MA-Series service manual • 25

Page 26

Lock assemblies

MA581 - Storeroom lock

SFIC not shown

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

C Escutcheon E77012-IP

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7807

J Faceplate S77805

K Strike assembly A8737-X

L Strike box PE1396

P Screw pack See page 37

R Cylinder, conventional Q005-064

Cylinder, SFIC Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

26 • Falcon • MA-Series service manual

Page 27

Lock assemblies

MA621 - Apartment corridor lock

SFIC not shown

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

C Escutcheon AE77012-IT

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7808

J Faceplate S77811

K Strike assembly A8737-X

L Strike box PE1396

M Thumb turn AS76319

R Screw pack See page 37

T Cylinder, conventional Q005-064

Cylinder, SFIC Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

Falcon • MA-Series service manual • 27

Page 28

Lock assemblies

MA641 - Dormitory lock

SFIC not shown

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

C Escutcheon AE77012-IT

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7815

J Faceplate S77815

K Strike assembly A8737-X

L Strike box PE1396

M Thumb turn AS76319

R Screw pack See page 37

Cylinder, conventional Q005-064

T

Cylinder, SFIC Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

28 • Falcon • MA-Series service manual

Page 29

Lock assemblies

MA851 - Electrified fail safe (EL) - 12 or 24V, with or without RX

SFIC not shown

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321

C Escutcheon E77012-IP

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7851-12, A7851-12RX, A7851-24, A7851-24RX

J Faceplate S77805

K Strike assembly A8737-X

L Strike box PE1396

P Screw pack See page 37

R Cylinder, conventional Q005-064

Cylinder, SFIC Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

AS76360 AS76760

AE77360 AE77760

AS76360 AS76760

AE77360 AE77760

Falcon • MA-Series service manual • 29

AS76100

AE77100

AS76100

AE77100

Page 30

Lock assemblies

MA881 - Electrified fail secure (EU) - 12 or 24V, with or without RX

SFIC not shown

Ltr. Description

A Inside

trim

B Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

C Escutcheon E77012-IP

D Outside

trim

E Knob/lever escutcheon AE77280 AE77526 AE77029 AE77140 AE77310 AE77321 AE77360 AE77760 AE77100

F Escutcheon AE77012-OC

G Rose (2) S76012

H Assembly, lock unit A7881-12, A7881-12RX, A7881-24, A7881-24RX

J Faceplate S77805

K Strike assembly A8737-X

L Strike box PE1396

R Screw pack See page 37

T Cylinder, conventional Q005-064

Cylinder, SFIC Q005-065

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Knob/lever sectional AS76280 AS76526 AS76029 AS76140 AS76310 AS76321 AS76360 AS76760 AS76100

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

30 • Falcon • MA-Series service manual

Page 31

Lock assemblies

MA911 - Classroom dead lock

SFIC not shown

Ltr. Description

- Inside

trim

- Knob/lever escutcheon N/R N/R N/R N/R N/R N/R N/R N/R N/R

A Escutcheon AE77012-IE

- Outside

trim

- Knob/lever escutcheon N/R N/R N/R N/R N/R N/R N/R N/R N/R

B Escutcheon AE77012-OK

C Assembly, lock unit A7829

D Faceplate S77816

E Strike assembly A8737-X

F Strike box PE1396

G Thumb turn AS76319

K Screw pack See page 37

L Cylinder, conventional Q005-064

Cylinder, SFIC Q005-065

Knob/lever sectional N/R N/R N/R N/R N/R N/R N/R N/R N/R

Knob/lever sectional N/R N/R N/R N/R N/R N/R N/R N/R N/R

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

Falcon • MA-Series service manual • 31

Page 32

Lock assemblies

MA921 - Dead lock outside only

Ltr. Description

- Inside

trim

- Knob/lever

A Escutcheon E77012-IB

- Outside

trim

- Knob/lever

B Escutcheon AE77012-OK

C Assembly, lock unit A7816

D Faceplate S77816

E Strike assembly A8737-X

F Strike box PE1396

J Screw pack See page 37

K Cylinder, conventional Q005-064

Cylinder, SFIC Q005-065

Knob/lever

sectional

escutcheon

Knob/lever

sectional

escutcheon

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

N/R N/R N/R N/R N/R N/R N/R N/R N/R

N/R N/R N/R N/R N/R N/R N/R N/R N/R

N/R N/R N/R N/R N/R N/R N/R N/R N/R

N/R N/R N/R N/R N/R N/R N/R N/R N/R

32 • Falcon • MA-Series service manual

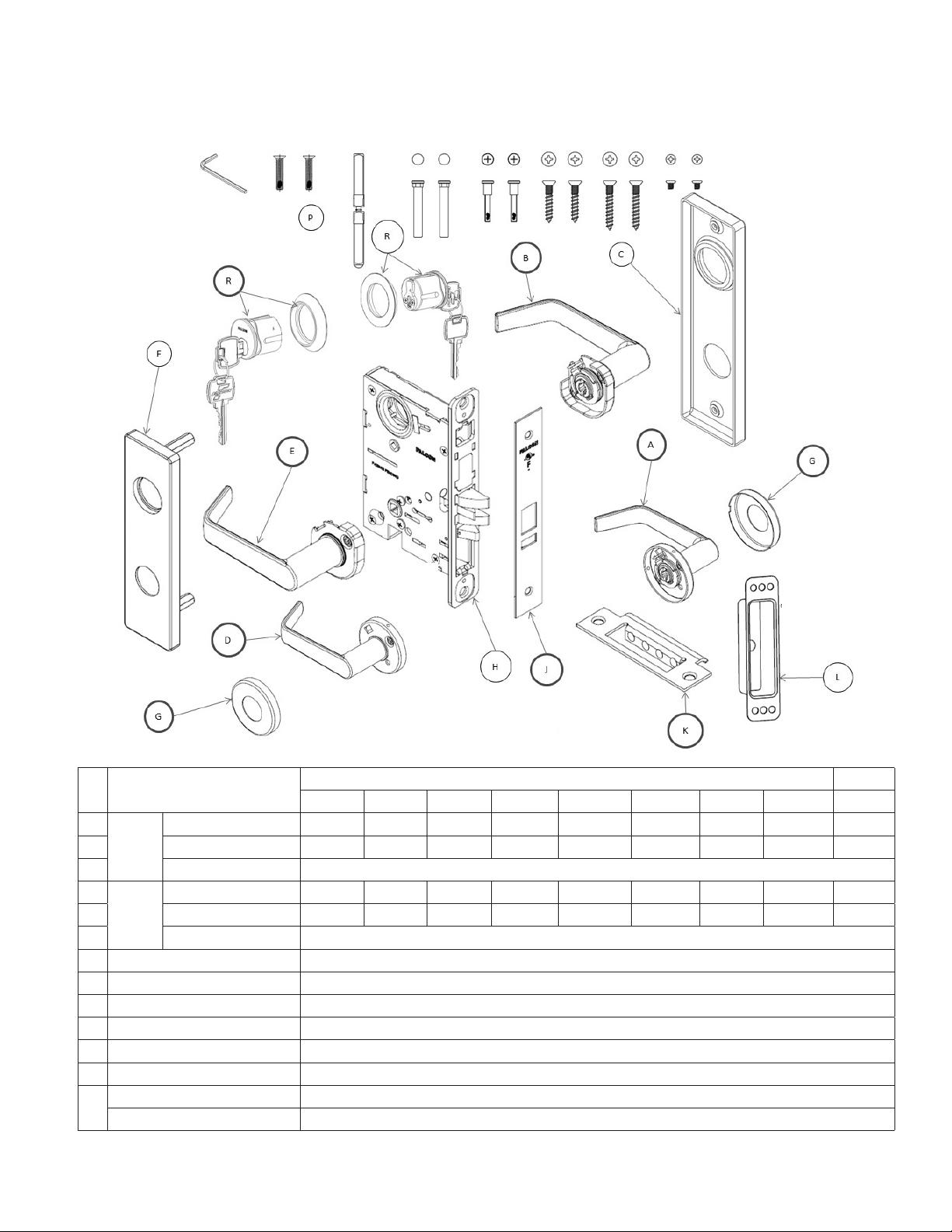

Page 33

Lock assemblies

MA931 - Dead lock inside and outside

Ltr. Description

- Inside

trim

- Knob/lever

A Escutcheon E77012-IK

- Outside

trim

- Knob/lever

B Escutcheon AE77012-OK

C Assembly, lock unit A7816

D Faceplate S77816

E Strike assembly A8737-X

F Strike box PE1396

J Screw pack See page 37

K Cylinder, conventional (2) Q005-064

Cylinder, SFIC (2) Q005-065

Knob/lever

sectional

escutcheon

Knob/lever

sectional

escutcheon

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

N/R N/R N/R N/R N/R N/R N/R N/R N/R

N/R N/R N/R N/R N/R N/R N/R N/R N/R

N/R N/R N/R N/R N/R N/R N/R N/R N/R

N/R N/R N/R N/R N/R N/R N/R N/R N/R

SFIC not shown

Falcon • MA-Series service manual • 33

Page 34

Lock assemblies

MA941 - Dead lock with inside turn

SFIC not shown

Ltr. Description

- Inside

trim

- Knob/lever escutcheon N/R N/R N/R N/R N/R N/R N/R N/R N/R

A Escutcheon E77012-IK

- Outside

trim

- Knob/lever escutcheon N/R N/R N/R N/R N/R N/R N/R N/R N/R

B Escutcheon AE77012-OK

C Assembly, lock unit A7816

D Faceplate S77816

E Strike assembly A8737-X

F Strike box PE1396

J Screw pack See page 37

K Cylinder, conventional (2) Q005-064

Cylinder, SFIC (2) Q005-065

Knob/lever sectional N/R N/R N/R N/R N/R N/R N/R N/R N/R

Knob/lever sectional N/R N/R N/R N/R N/R N/R N/R N/R N/R

Levers Knobs

Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

34 • Falcon • MA-Series service manual

Page 35

Lock assemblies

MA12 - Single dummy

Knobs/Levers on

One Side Fixed

Ltr.

Description Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

A Trim Knob/lever

B Knob/lever

C Escutcheon E77012-IP

D Rose S76012

F Screw pack S76331

sectional

escutcheon

Torx screw pack

(optional)

Levers Knobs

AS76280-D AS76526-D AS76029-D AS76140-D AS76310 AS76321 AS76360 AS76760 AS76100-D

AE77280-D AE77526-D AE77029-D AE77140-D AE77310 AE77321 AE77360 AE77760 AE77100-D

E77308

Falcon • MA-Series service manual • 35

Page 36

Lock assemblies

MA18 - Double dummy

Knobs/Levers on

Both Sides Fixed

Ltr.

Description Dane Sutro Avalon Quantum Boardwalk Broadway Latitude Longitude Hana

A Inside

trim

B Knob/lever

C Escutcheon E77012-IP

D Outside

trim

E Knob/lever

F Escutcheon AE77012-0P

G Rose (2) S76012

K Screw pack See page 37

Knob/lever

sectional

escutcheon

Knob/lever

sectional

escutcheon

Levers Knobs

AS76280-D AS76526-D AS76029-D AS76140-D AS76310 AS76321 AS76360 AS76760 AS76100-D

AE77280-D AE77526-D AE77029-D AE77140-D AE77310 AE77321 AE77360 AE77760 AE77100-D

AS76280-D AS76526-D AS76029-D AS76140-D AS76310 AS76321 AS76360 AS76760 AS76100-D

AE77280-D AE77526-D AE77029-D AE77140-D AE77310 AE77321 AE77360 AE77760 AE77100-D

36 • Falcon • MA-Series service manual

Page 37

Parts and accessories

Parts and accessories

Lever and knob designs

Gala

AG (Avalon-Gala)

BOG (Boardwalk-Gala)

Napa

AN (Avalon-Napa)

BON (Boardwalk-Napa)

DG (Dane-Gala)

BRG (Broadway-Gala)

DN (Dane-Napa)

BRN (Broadway-Napa)

QG (Quantum-Gala)

LTG (Latitude-Gala)

QN (Quantum-Napa)

LTN (Latitude-Napa)

SG (Sutro-Gala)

LGG (Longitude-Gala)

SN (Sutro-Napa)

LGN (Longitude-Napa)

HG (Hana-Gala)

HN (Hana-Napa)

Screw packs

Part No. Description Use

S76300 #8-32 x Z⁄v” L machine screw 1 ³⁄,”-1M⁄,” door

#12-12 / #12-24 x 1Z⁄x” L wood/machine

combination screw

#12-12 / #12-24 x 1Z⁄v” L wood/machine

combination screw

#8-32 x 1Z⁄v” L mounting screw

ø Z⁄v” x 1ZZ⁄zn” L post

B⁄zn” x 1>⁄zn” L x 2 pcs STD spindle assembly

³⁄cx” Allen wrench

thickness,

sectional trim

with levers

Part No. Description Use

S76301 #8-32 x Z⁄v” L machine screw Over 1M⁄,”-2Z⁄x”

#12-12 / #12-24 x 1Z⁄x” L wood/machine

combination screw

#12-12 / #12-24 x 1Z⁄v” L wood/machine

combination screw

#8-32 x 1Z⁄x” L mounting screw

ø Z⁄v” x 2Z⁄v” L post

B⁄zn” x 1M⁄,” L x 2 pcs EXT spindle assembly

³⁄cx” Allen wrench

Falcon • MA-Series service manual • 37

door thickness,

sectional trim

with levers

Page 38

Parts and accessories

Part No. Description Use

S76302 #8-32 x Z⁄v” L machine dcrew 1³⁄,” -1M⁄,” door

#12-12 / #12-24 x 1Z⁄x” L wood/machine

combination screw

#12-12 / #12-24 x 1Z⁄v” L wood/machine

combination screw

#8-32 x 1Z⁄v” L mounting screw

ø Z⁄v” x 1ZZ⁄zn” L post

B⁄zn” x 1Z⁄v” L x 2 pcs STD spindle assembly

³⁄cx” Allen wrench

S76303 #8-32 x Z⁄v” L machine screw Over 1M⁄,”-2Z⁄x”

#12-12 / #12-24 x 1Z⁄x” L wood/machine

combination screw

#12-12 / #12-24 x 1Z⁄v” L wood/machine

combination screw

#8-32 x 1Z⁄x” L mounting screw

ø Z⁄v” x 2Z⁄v” L post

B⁄zn” x 1>⁄zn” L x 2 pcs EXT spindle assembly

³⁄cx” Allen wrench

S76306 #8-32 x Z⁄v” L Torx� head machine screw Torx screw

#12-12 / #12-24 x 1Z⁄x” L Torx head

wood/machine combination screw

S76307 #8-32 x Z⁄v” L Torx head machine screw Torx screw

#12-12 / #12-24 x 1Z⁄x” L Torx head

wood/machine combination screw

#6 x Z⁄x” Torx head sheet metal screw

S76331 #8-32 x Z⁄v” L machine screw Single dummy

#12-12 / #12-24 x 1Z⁄x” L wood/machine

combination screw

#12-12 / #12-24 x 1Z⁄v” L wood/machine

combination screw

#8-32 x 1Z⁄v” L mounting screw

B⁄zn” x 1>⁄zn” L STD spindle

ø 0.027” Wire, OD; ø B⁄zn” x 1³⁄,” L spring

³⁄cx” Allen wrench

E77300 #8-32 x Z⁄v” L machine screw 1³⁄,”-1M⁄,” door

#12-12 / #12-24 x 1Z⁄x” wood/machine

combination screw

#12-12 / #12-24 x 1Z⁄v” L wood/machine

combination screw

#8-32 x 1Z⁄v” L mounting screw

ø Z⁄v” x 1ZZ⁄zn” L post

B⁄zn” x 1>⁄zn” L x 2 pcs STD spindle assembly

#10-24 x 1Z⁄v” machine screw

³⁄cx” Allen wrench

E77301 #8-32 x Z⁄v” L machine screw Over 1M⁄,”-2Z⁄x”

#12-12 / #12-24 x 1Z⁄x” L wood/machine

combination screw

#12-12 / #12-24 x 1Z⁄v” L wood/machine

combination screw

#8-32 x 1Z⁄x” L mounting screw

ø Z⁄v” x 2Z⁄v” L post

B⁄zn” x 1M⁄,” L x 2 pcs EXT spindle assembly

#10-24 x 2” machine screw

³⁄cx” Allen wrench

thickness,

sectional trim

with knobs

door thickness,

sectional trim

with knobs

pack, sectional

trim, no turn

pack, sectional

trim, with turn

thickness,

escutcheon

trim with levers

door thickness,

escutcheon

trim with levers

Part No. Description Use

E77302 #8-32 x Z⁄v” L machine screw 1³⁄,”-1M⁄,” door

#12-12 / #12-24 x 1Z⁄x” L wood/machine

combination screw

#12-12 / #12-24 x 1Z⁄v” L wood/machine

combination screw

#8-32 x 1Z⁄v” L mounting screw

ø Z⁄v” x 1ZZ⁄zn” L post

B⁄zn” x 1Z⁄v” L x 2 pcs STD knob spindle

assembly

#10-24 x 1Z⁄v” L machine screw

³⁄cx” Allen wrench

E77303 #8-32 x Z⁄v” L machine screw Over 1M⁄,”-2Z⁄x”

#12-12 / #12-24 x 1Z⁄x” L wood/machine

combination screw

#12-12 / #12-24 x 1Z⁄v” L wood/machine

combination screw

#8-32 x 1Z⁄x” L trim screw

ø Z⁄v” x 1ZZ⁄zn” L Post

B⁄zn” x 1>⁄zn” L x 2 pcs EXT spindle assembly

#10-24 x 2” L machine screw

³⁄cx” Allen wrench

E77306 #8-32 x Z⁄v” L Torx head machine screw 1 ³⁄,”-1M⁄,” door

#12-12 / #12-24 x 1Z⁄x” L Torx head

wood/machine combination screw

#10-24 x 1Z⁄v” L Torx head, machine screw

E77307 #8-32 x Z⁄v” L Torx head machine screw Over 1M⁄,”-2Z⁄x”

#12-12 / #12-24 x 1Z⁄x” L Torx head

wood/machine combination screw

#10-24 x 2” L Torx head machine screw

E77308 #8-32 x Z⁄v” L Torx head machine screw Torx screw

#12-12 / #12-24 x 1Z⁄x” L Torx head

wood/machine screw

#10-24 / #10 x 1Z⁄v” L Torx head

wood/machine screw

E77331 #8-32 x Z⁄v” L machine screw Escutcheon

#12-12 / #12-24 x 1Z⁄x” L wood/machine

combination screw

#12-12/#12-24 x 1Z⁄v” L wood/machine

combination screw

#8-32 x 1Z⁄v” L mounting screw

B⁄zn” x 1>⁄zn” L STD spindle

#10-24 / #10 x 1Z⁄v” L wood/machine

combination screw

ø 0.027 Wire, ø B⁄zn” O.D. x 1³⁄,” L spring

³⁄cx” Allen wrench

Available in finishes 606, 613, 630.

Non Torx screw packs contain armor front screws, strike screws, trim

screws, mortise screws, spindle, and mounting posts.

Torx screw packs contain armor front, strike, and trim screws only.

thickness,

escutcheon

trim with knob

door thickness,

escutcheon

trim with knob

thickness Torx

screw pack,

escutcheon

trim, standard

door thickness

door thickness

Torx screw

pack,

escutcheon

trim, extended

door thickness

pack, rose

escutcheon

connection

door

connecting

door

38 • Falcon • MA-Series service manual

Page 39

Parts and accessories

Cams

Cams for Falcon mortise cylinders (except MA381 function)

The Falcon MA-Series requires a different cam for keyed functions than its predecessor, the Falcon M Series. All keyed

functions except the MA381 function use a single cam for all standard cylinders and a single cam for all interchangeable

core cylinders.

Door handing Cam part number Outside Inside For cylinder

All 5622-STD (F1) MA371, MA411, MA431, MA441, MA451, MA521, MA531, MA541,

MA551, MA561, MA571, MA581, MA621, MA641, MA851, MA881,

MA911, MA921, MA931, MA941

All 5622-IC (F2) MA371, MA411, MA431, MA441, MA451, MA521, MA531, MA541,

MA551, MA561, MA571, MA581, MA621, MA641, MA851, MA881,

MA911, MA921, MA931, MA941

5622-STD (F1) 5622-IC (F2)

MA371, MA411, MA431,

MA441, MA931

MA371, MA411, MA431,

MA441, MA931

Standard

Interchangeable

core

Cams for Falcon mortise cylinders, MA381 function only

The Falcon MA381 function uses unique cams. Different cams are required depending on the handing of the lock.

Complete cylinders can also be ordered for the MA381 function that include the correct cam (handing must be specified

when ordering cylinders for the MA381). See current Falcon Price Book for details.

Cylinder Door handing Outside cylinder cam part number Inside cylinder cam part number

Standard RH/RHR 5621-STD (R4) 5620-STD (R3)

LH/LHR 5621-STD (L4) 5620-STD (L3)

Interchangeable core RH/RHR 5621-IC (R4) 5620-IC (R3)

LH/LHR 5621-IC (L4) 5620-IC (L3)

MA381 Standard cylinder, outside MA381 Standard cylinder, inside

5621-STD (R4)

R4

MA381 Interchangeable core cylinder, outside MA381 Interchangeable core cylinder, inside

5621-IC (R4)

5621-STD (L4)

L4

5621-IC (L4)

5620-STD (R3)

R

5620-IC (R3)

5620-STD (L3)

5620-IC (R3)

R4

L4

R

Cams for Schlage cylinders

The Schlage Classic cylinders (C, E, and CE keyways) will also operate the Falcon MA-Series locks using the 5622-STD cam.

Falcon • MA-Series service manual • 39

Page 40

Cylinders

Cylinders

Mortise, rim, and cam lock for standard cylinders

Mortise cylinder

900 Series cylinders are furnished

with #4 straight cam, and 250

Series are furnished with #1

cloverleaf cam unless otherwise

specified.

See table for product numbers.

See page 39 for optional cams

and page 42 for collars.

Specify finish: 605, 606, 612, 613,

626, 629, 630

Thumbturn cylinder

Furnished with #4 straight cam,

except 970 Series furnished

with #1 cloverleaf cam unless

otherwise specified.

See table for product numbers.

See page 39 for optional

cams and page 42 for

collars.

Specify finish: 605, 606, 612,

613, 626, 629, 630

Dummy cylinder

Used to plug hole in door where

lock remains but cylinder

operation is no longer needed.

984 1”

985 1Z⁄,”

Specify finish: 605, 606, 612, 613,

626, 629, 630

Keyed mortise cylinders

Number Length Pins Application

985 1Z⁄,” 5 or 6 Generic

986 1Z⁄v” 5 or 6 Generic

987 1³⁄,” 6 or 7 Generic

988 1Z⁄x” 6 or 7 Generic

990 1³⁄v” 6 or 7 Generic

992 2” 6 or 7 Generic

250 1Z⁄,” 6 M451 hotel function

251 1Z⁄v” 6 M451 hotel function

252 1³⁄,” 6 M451 hotel function

253 1³⁄,” 7 M451 hotel function

Thumbturn mortise cylinders

Number Length Pins Application

985T 1Z⁄,” - Generic

986T 1Z⁄v” - Generic

973 1Z⁄,” - M911 classroom thumbturn, RH

(CCW)

974 1Z⁄,” - M911 classroom thumbturn, LH

(CW)

Specify cylinder number, keyway, and finish when ordering.

Strikes

Strike Lip length (x) Lip

A8737-1 1Z⁄v” Curved lip

A8737-2 1M⁄zn” Curved lip

A8737-3 1>⁄zn” Curved lip

A8737-4 1ZZ⁄zn” Curved lip

A8737-5 M⁄,” Straight lip

40 • Falcon • MA-Series service manual

Lip

Length

(x)

Page 41

Cylinders

Cylinder collars

Standard collars for cylinders ordered separately

Length Cylinder Non-AR cams AR cam

1” 984D A08794-000 -

1Z⁄,” 250, 965, 966, 973, 974, 985 Series A08794-000 008876-002

1Z⁄v” 251, 986 Series A08794-001 008876-003

1³⁄,” 252, 253, 987, C987, C997 A08794-002 008876-004

Longer C260 Series, (C)988, (C)990, (C)992 A08794-000 008876-000

Escutcheon trim rings

Door

thickness

1Z⁄x” Single cylinder - A08790-000 A08790-001 A08790-002

1Z⁄x” Double cylinder A08790-000 - - -

1³⁄v” Single cylinder - - A08790-000 A08790-001

1³⁄v” Double cylinder - A08790-000 A08790-001 A08790-002

2” Single cylinder - - A08790-000 A08790-001

2” Double cylinder - - A08790-000 A08790-001

2Z⁄v” Single cylinder - - - A08790-000

2Z⁄v” Double cylinder - - - -

2Z⁄x” Single cylinder - - - -

2Z⁄x” Double cylinder - - -

Function 985

1Z\,”

986

1Z\v”

(C) 987

1C\,”

(C) 988

1Z\x”

-

Sectional trim rings

Door

thickness

1Z⁄x” Single cylinder A08794-001 A08794-002 - -

1Z⁄x” Double cylinder A08794-002 A08794-003 - -

1³⁄v” Single cylinder A08794-000 A08794-001 - -

1³⁄v” Double cylinder A08794-001 A08794-002 A08794-002 -

2” Single cylinder - A08794-000 A08794-001 A08794-002

2” Double cylinder A08794-000 A08794-001 A08794-002 A08794-003

2Z⁄v” Single cylinder - - A08794-000 A08794-001

2Z⁄v” Double cylinder - A08794-000 A08794-001 A08794-002

2Z⁄x” Single cylinder - - - A08794-000

2Z⁄x” Double cylinder - - A08794-000 A08794-001

Specify part number and finish when ordering. (e.g. A08790-000-626). See current Falcon Price Book for available finishes.

Function 985

1Z\,”

986

1Z\v”

(C) 987

1C\,”

(C) 988

1Z\x”

Falcon • MA-Series service manual • 41

Page 42

Cylinders

Trim rings and collars

Dim. A Dim. B Part No.

³⁄cx” >⁄cx” A08790-000

A

B

B

A

Blocking rings

M⁄cx” 1³⁄cx” A08790-001

ZZ⁄cx” 1M⁄cx” A08790-002

ZB⁄cx” XZ⁄cx” A08790-003

V³⁄nv” BB⁄nv” A08790-004

³⁄cx” >⁄cx” A08794-000

M⁄cx” 1³⁄cx” A08794-001

A

ZZ⁄cx” 1M⁄cx” A08794-002

ZB⁄cx” XZ⁄cx” A08794-003

Z⁄,” - 008876-000

³⁄zn” - 008876-005

Z⁄v” - 008876-001

³⁄,” - 008876-002

Z⁄x” - 008876-003

B⁄,” - 008876-004

Wave washer included.

To order separately,

specify 008789-001-60.

Specify part number and finish when ordering. (e.g. A08790-000-626). See current Falcon Price Book for available finishes.

42 • Falcon • MA-Series service manual

Page 43

Electrified locks

Electrified locks

All MA851 and MA881 locks feature automatic detection and

operation with 12V or 24V DC. Locks are furnished with

Allegion Connect molex connector with 3-inch lead. Allegion

Connect system allows rapid installation of locks when used

with Allegion Connect harnesses and hinges. The molex

connector can be cut off to allow for installation by splicing.

It is recommended that all wiring be done by a licensed

electrician familiar with the supporting equipment.

MA851 EL, Electrically locked (fail safe)

Outside trim is continuously locked electrically. The latchbolt

is retracted by a key outside or by the knob/lever inside. Switch

or power failure allows the outside knob/lever to retract the

latchbolt.

MA881 EU, Electrically unlocked (fail secure)

Outside trim is unlocked electrically. Duringt switch or power

failure, the latchbolt is retracted only by a key outside, or by

knob/lever inside. Outside knob/lever will not retract latchbolt

during switch or power failure.

Typical Installation:

All installations should be in accordance with local electrical

codes and National Electrical Code NFPA #70.

It is recommended that each lock have its own 12 or 24 volt

transformer. Be sure to select the proper transformer for the

lock.

Two or more locks may be operated in parallel from a single

transformer provided it has the necessary current rating.

DO NOT connect locks in series from a higher voltage rated

transformer. Damage to locks may occur if they connect to a

supply circuit that also contains electromagnetic devices.

The transient voltage must be suppressed at the equipment

producing them before connecting the locks to a circuit.

A varistor rate at 35 volts (at peak current) may be used for

transient voltage protection.

IMPORTANT: Cable must be routed and tucked to fit. Ensure

that no wires are exposed or pinched during positioning.

1. Prepare mortise pocket in door per template. Access for

the wiring to be per installer’s requirements. It is

recommended that an access channel is bored to provide

contact from the electric transfer hinge or other means of

transfer to the mortise pocket.

2. Connect wires as necessary (some options may not be

used), and slip the mortise into the prepared pocket in the

door. Take care to ensure wires are not pinched or

damaged.

3. Always ensure door operates properly before locking!

Solenoid operated lock

* (not furnished)

Solenoid (Electrically

Locking/Unlocking)

12V DC - Black wires /

24V DC - White wires

RX Switch

Normally open - Green wire

Common RX switch

Common - Orange wire

Rectifier*

Door

connector*

Install varistor

here if used*

Switch*

Operating Temperature: Max +151° F (+ 66° C), Min. -31° F (-0.5° C)

Voltage: 12V DC +/- 10% 24V DC +/- 10%

Operating Current: 0.42 A 0.21 A

Holding Current: 0.135 A

12 or 24V AC

Electrical requirements

110V AC

Transformer*

Falcon • MA-Series service manual • 43

Page 44

Ordering procedures

Ordering procedures

For correct ordering, and to ensure no delays in shipment of your order, the following descriptive data must be listed in the

sequence shown. Necessary information can be found in other parts of this manual. The example below shows an order for

16 each MA locksets in the 521 Entry function, DG (Dane-Gala) trim design in a 626 (satin chrome) finish, 8 RH (right hand)

and 8 LH (le hand) to accommodate doors 1³⁄v” thick with AA1-AA16 keying.

Quantity: Indicate the quantity required.

Catalog number: Select catalog number.

Trim design: Indicate letter of knob or lever design followed

by letter of rose or escutcheon design.

Example: DG-D for Dane lever followed by G for Gala rose.

Finish: When the finish is the same for the outside and

inside trim, it is shown once (626). For split finishes, the

outside is designated first, then the inside (626 x 625).

Latch: Two-piece mechanical anti-friction standard.

All catalog numbers shown in this manual indicated

2³⁄v” backset.

Strike: 4M⁄,” x 1Z⁄v” x 1Z⁄v” lip-to-center with curved lip

standard. Optional strikes with shorter or longer lip lengths

available.

Cylinder type: For 6-pin, add 6-Pin. For 7-pin, add 7-pin.

Door hand: See chart.

Keying detail: We suggest using the standard terms

developed by the A.H.C. (consult factory).

Example: AA1 - Grand master keyed, Master keyed, change

key 1.

Interchangeable core: To order product capable of

accepting an interchangeable core, add “B” less SFIC (for

interchangeable core). To order product with an

interchangeable core, add “SFIC” (with interchangeable

core). Ex: “G” with Falcon SFIC core.

Keyway: “G” is standard on regular cylinders, “A” is standard

on interchangeable cores. Other keyways available. See

current Falcon Price Book for details.

Additional keys: Note the total number of keys required.

Large bow keys: Add - “with large bow keys”.

Example

Qty. Catalog

Number

8 MA521P DG 626 STD STD 6-PIN X AA1-AA8 1³⁄v” DR

8 MA521P DG 626 STD STD 6-PIN X AA9-AA16 1³⁄v” DR

Trim

Design

Finish Latch Strike Cylinder Door Hand Detail

RH LH RHR LHR

Finishes

Falcon offers several finish choices to compliment the design elements of most any project. Falcon applies the best

available protective plating or coating to the surface of our products to minimize the exposure to weather, pollution,

perspiration, extremes of climate, frequency of us and other factors. Please consult with us if your building is subjected to

chemical or corrosive conditions, as some finishes would not be recommended for these areas. Falcon recommends chrome

plated or stainless steel finishes for high corrosive environments.

Finish codes and descriptions

Code Description Code Description

605 (US 3) Bright brass, clear coated 625 (US 26) Bright chromium plated, no coating

606 (US 4) Satin brass, clear coated 626 (US 26D) Satin chromium plated, no coating

613 (US 10B) Oil rubbed bronze, no coating 630 (US 32D) Satin stainless steel, no coating

619 (US 15) Satin nickel, clear coated 643e (US 11) Aged bronze

622 (US 19) Matte black

44 • Falcon • MA-Series service manual

Page 45

Door handing

Door handing

The hand of a door refers to the position of the lock relative to the side and direction of the door hinge.

There are four possible “handings” based on whether the hinge is on the right or le side of the door and whether the door

swings to the inside or outside.

LH

Left Hand

LRB

Left Hand

Reverse Bevel

INSIDE

OUTSIDE

INSIDE

OUTSIDE

Reverse Bevel

RH

Right Hand

RRB

Right Hand

Changing the lock hand

1. Remove latch bolt screw.

2. Remove latch bolt and rotate 180°.

3. Reinstall latch bolt and screw.

4. Move handing screws to opposite side. Handing screws must be located on the non-locking side.

1

2 3

4

180°

Falcon • MA-Series service manual • 45

Page 46

46 • Falcon • MA-Series service manual

Page 47

Page 48

About Allegion

Allegion (NYSE: ALLE) creates peace of mind by pioneering safety and security.

As a $2 billion provider of security solutions for homes and businesses, Allegion

employs more than 9,000 people and sells products in more than 130 countries

across the world. Allegion comprises 25 global brands, including strategic

brands CISA®, Interflex®, LCN®, Schlage® and Von Duprin®.

For more, visit www.allegion.com.

© 2020 Allegion

106694, Rev. 07/20

www.allegion.com/us

Loading...

Loading...