*829767-00*

LP150, LP250

829767-00

Power Supply

LP150B, LP250B

Installation Instructions

LP250RDB4

The LP150/LP250 is a power-limited power supply and battery charger that will convert 120 VAC / 60Hz input into eld-selectable 12 VDC

or 24 VDC Class 2 rated outputs (one continuous, one switchable). It is intended for use in applications with UL listing requirements (see

specications below for specic listings).

This instruction covers:

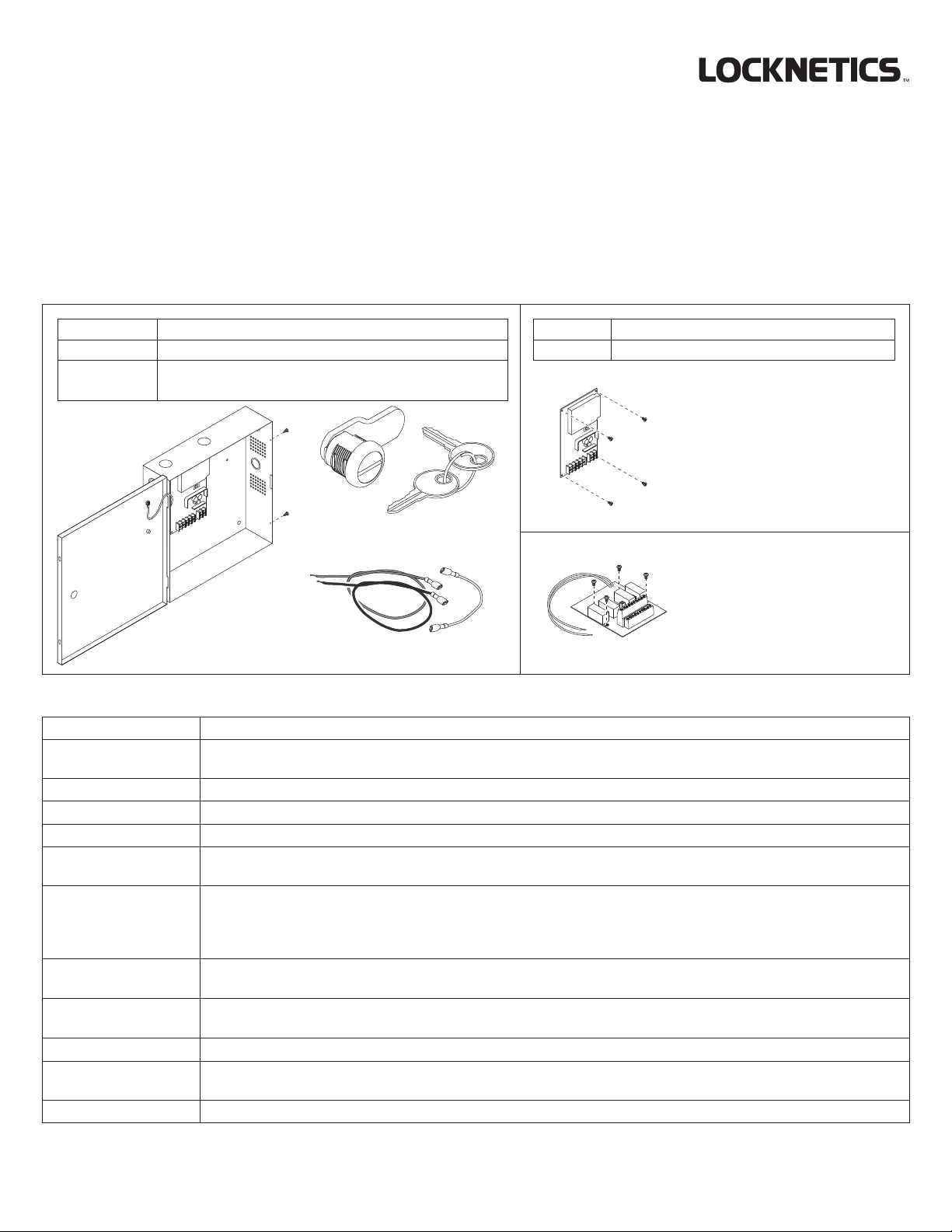

LP150 PS cabinet + board (1.5A), battery wire kit, keylock

LP250 PS cabinet + board (2.5A), battery wire kit, keylock

LP250RDB4 PS cabinet + board (2.5A), battery wire kit, keylock,

RDB4 board *

Keylock

LP150B PS board only (1.5A), 4 mounting screws

LP250B PS board only (2.5A), 4 mounting screws

PS board

RDB4 board included

PS150/250

Power Supply

Enclosure

with hinged cover

+ Board

Battery Wire Kit

*

RDB4

with LP250RDB4 only

and is covered in

separate instruction

PS150/250 Specications:

Input LP150: 120 VAC, 1A, 60Hz LP250: 120 VAC, 1.2A, 60Hz

Output LP150: 12 VDC (13.2V nominal) or 24 VDC (26.4V nominal), 1.5A, Class 2 rated

LP250 (LP250RDB4): 12 VDC (13.2V nominal) or 24 VDC (26.4V nominal), 2.5A, Class 2 rated

Output Protection DC OUT and CONTROL OUT are protected from overload or shorts via self-resetting electronic protection circuit

Battery Protection PTC

Environment 32°-120° F (0°- 49° C), up to 85% relative humidity, indoor use only, protected area

Compliance UL294, UL603, Access control performance levels: Attack: I, Line security: I, Endurance: IV, Standby power: III

(LP150) and II (LP250/LP250RDB4), CSA22.2 NO. 205, CSFM, FCC

Battery Backup Requires 12V, 7AH max. rechargeable sealed lead acid battery: (1) for 12V, (2) for 24V output.

Battery maximum dimensions: 3-3/4” H x 6” W x 3” D

See typical backup times in Section 2

See Section 8 for maintenance of battery

Control Input / Output Input: Normally closed, requires dry contact rated at 24 VDC, 10mA

Output: Powered NC/NO contacts rated at 24 VDC, 2.5A

AC Status Indicator: Green LED

Relay contacts: NO/NC contacts rated at 24 VDC, 1A

DC Output Status Indicator: Red LED

Battery Status Indicator: Red LED

Relay contacts: NO/NC contacts rated at 24 VDC, 1A

Enclosure 13” H x 12-5/8” W x 3-1/4” D (8 knockouts, 1/2” or 3/4”)

Denitions:

Normally closed contacts (NC)

Normally open contacts (NO)

FSE - Fail secure (needs power to unlock)

FACP - Fire Alarm Control Panel

ACC - Access Control Contacts

FS - Fail safe (needs power to lock)

See Section 10 for an explanation

of the Warnings and Cautions

used in this booklet.

1 Installation Overview

Wiring methods shall be applied in accordance with the National Electric Code/NFPA 70/NFPA 72/ANSI, and with all local codes and

authorities having jurisdiction.

WARNING

To avoid risk of electric shock, turn off AC power before

installing or servicing LP150/LP250 power supply.

1. Mount unit in a protected area per Section 2.

2. Select voltage (12 or 24 VDC) per Section 3.

3. Connect AC power per Section 3.

• Connect the earth ground to the green/yellow cabinet wire and line (L) and neutral (N) to the appropriate terminals on the AC

terminal block.

Measure output voltage before connecting devices to prevent damage.

4. Disconnect AC power and nish all wiring per Sections 4 and 6.

5. Install battery backup (if required) per Sections 2 and 3.

If AC input goes o and battery backup is not being used, all devices connected to the power supply will be unpowered.

6. AC status may be required for Battery Backup systems (Section 3).

7. Secure cover with screws or keylock when complete per Section 7.

8. For maintenance and troubleshooting, see Sections 8 and 9.

2

2 Mounting

CAUTION

Product intended for indoor use only and within

the temperature range specified. Mount unit in a

protected area. Do not install in locations with

exposure to rain or water.

Enclosure mounting

screws not provided

Mounting Hole

Dimensions

10¹⁵⁄₁₆"

11¹⁄₈"

Enclosure

Dimensions

12⁵⁄₈"

Mount

in upright

position

13"

Cover not shown

for clarity

Battery mounting

to be as shown

3¹⁄₄"

Battery Backup

Time

BACKUP TIME (HOURS)LOAD

CURRENT

(AMPS)

0.2

0.5

1.5

2.5

LP150

19

11

2

LP250

19

11

2

1.25

Calculated battery backup time based

on charging time of 48 hours at a

temperature of 77° F (25° C).

3

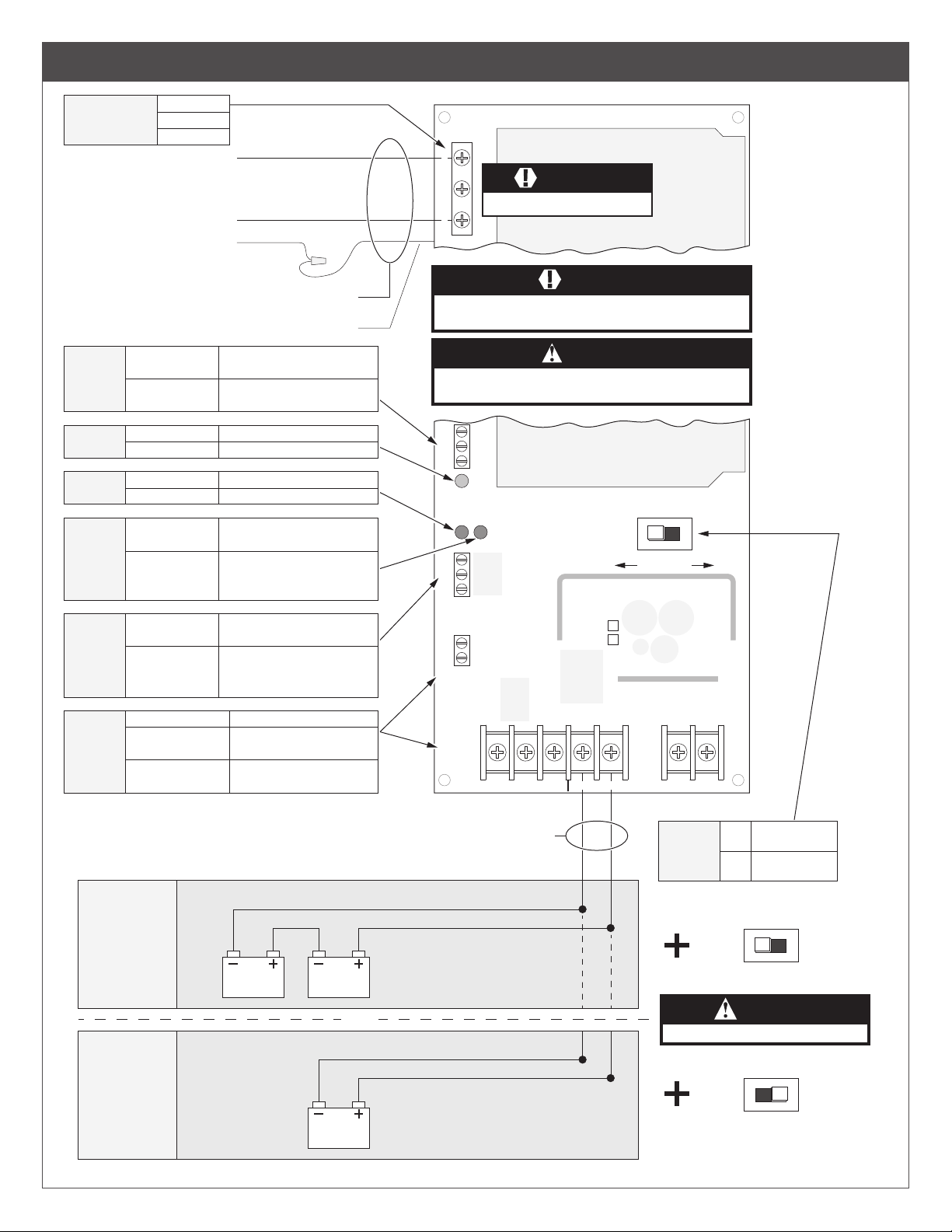

3 Power Supply Board - Features and Operation

120VAC, 60Hz

input voltage

AC

STATUS

120VAC

green LED

DC

red LED

BAT

red LED

BAT

STATUS

L: Line, hot

G: Ground

N: Neutral

NC to C: open

NO to C: closed

NC to C: closed

NO to C: open

off

on

off

on

off

on

NC to C: open

NO to C: closed

NC to C: closed

NO to C: open

Hot

Neutral

Earth Ground

Non power-limited, Class 1

Green/Yellow

120VAC NOT present on input

120VAC present on input

120VAC NOT present on input

120VAC present on input

DC output off or shorted/overload

DC output on (12 or 24V)

Battery not connected or

battery low

Battery connected and

charging or providing battery

backup

Battery not connected or

battery low

Battery connected and

charging or providing battery

backup

120VAC

L

G

N

WARNING

Must be connected via rigid conduit.

WARNING

Keep power-limited wiring separate from non power-limited wiring.

Minimum 1/4" spacing must be provided.

CAUTION

When installing, route field wiring away from sharp projections, corners, and

NC

C

NO

AC STATUS

NC

C

NO

BAT STATUS

IN

C

CONTROL IN

internal components. Deburr all conduit fittings.

BATDC

24V 12V

LP150

LP250

CONTROL

4

CONTROL OUT

NC to DC-: 0V

NO to DC-: DC+ out

NC to DC-: DC+ out

NO to DC-: 0V

24VDC

BATTERY

CONFIGURATION

12VDC

BATTERY

CONFIGURATION

CONTROL IN

IN to C: open contacts

IN to C: closed contacts

Black

Yellow

12V

BATTERY

BATTERY

BATTERY

12V

12V

OR

CONTROL

OUT

Red

Black

Red

NO DC- DC- DC+NC

Non powerlimited

BAT- BAT+

DC

OUT

DC

OUTPUT

VOLTAGE

SELECT

Switch moved to

24V

left position

Switch moved to

12V

right position

24V

CAUTION

Confirm polarity to avoid damage to unit.

12V

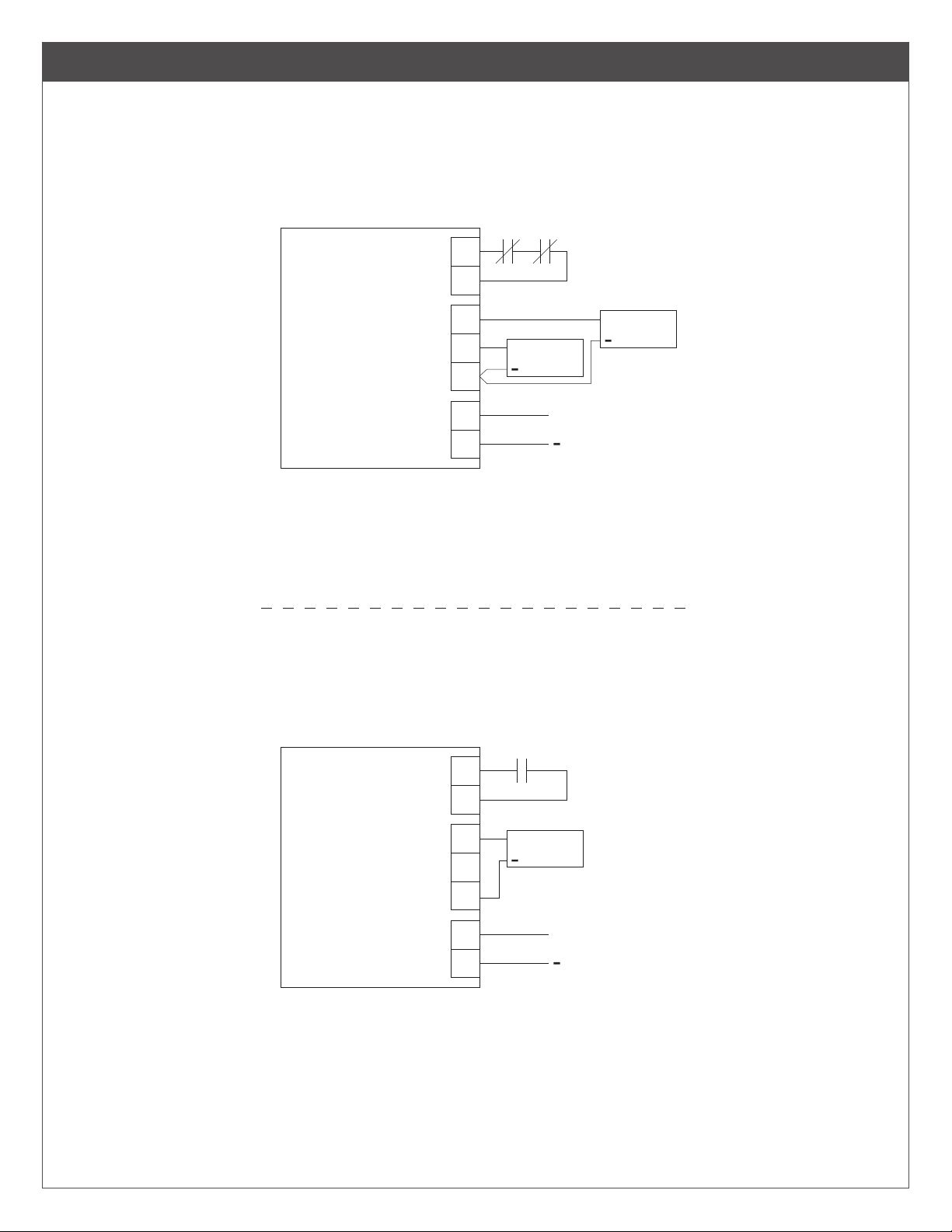

4 Typical Wiring

FS & FSE device connected to

PS board with FACP override

FACPACC

CONTROL

IN

IN

C

NC

LP150/250

Operation:

1. CONTROL IN controls the operation of devices connected to the NO

or NC terminals.

2. Opening of the FACP contacts will unpower the CONTROL OUT NC

contacts and power the NO contacts.

3. DC OUT is always powered regardless of the state of the FACP

contacts.

CONTROL

OUT

DC

OUT

NO

DC-

DC+

DC-

+

E-STRIKE

FSE

+

FSE device using open input

control contacts

ACC

CONTROL

IN

IN

C

+

MAGLOCK

CONTINUOUS

DC OUTPUT

FS

NC

LP150/250

Operation:

1. CONTROL IN controls the operation of the strike connected to the

NC terminal.

2. Closing the ACC contacts will apply power to the FSE strike to unlock it.

CONTROL

OUT

DC

OUT

NO

DC-

DC+

DC-

+

E-STRIKE

FSE

+

CONTINUOUS

DC OUTPUT

5

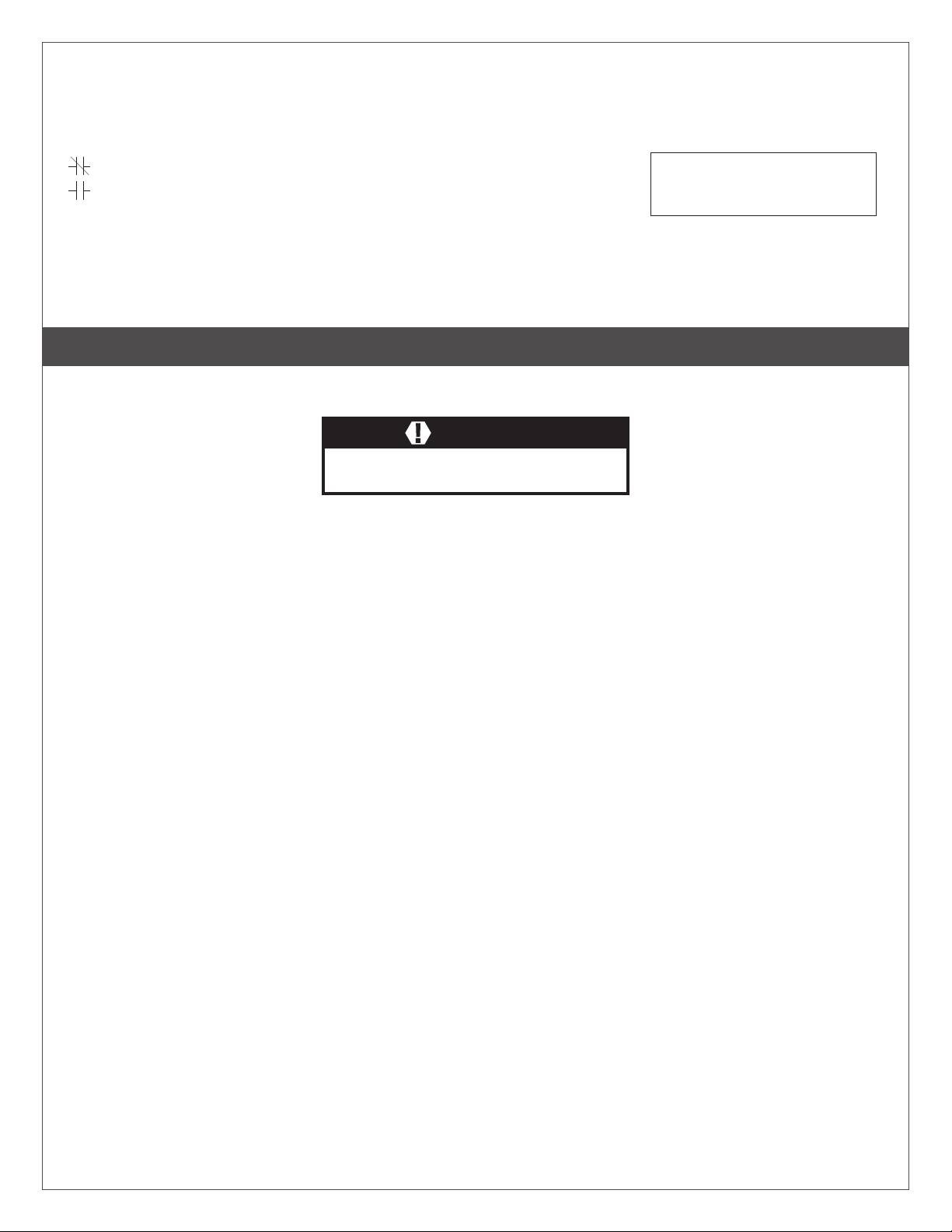

5 PS150B and PS250B Installation

Enclosure cutaway

shown for clarity

Interior of

enclosure

6-32 x 1/4" (4)

6 Wire run lengths

• Use the following table to estimate the gauge of wire required for the application.

• Wire length based on 15% voltage drop at 12 or 24V using stranded copper wire.

• The wire gauge listed is a minimum. The gauge can be increased if desired.

• Distance = total one way wiring distance between power supply and powered device (includes both power wires).

• For UL installations, the minimum permissible wire size to be used shall not be less than 22AWG.

DISTANCE

(FEET)

100

200

300

400

22

22

20

20

22

18

16

16

18

16

14

14

WIRE GAUGE (AWG)

16

14

12

14

12

22

22

22

22

22

22

20

18

22

18

16

16

20

16

14

14

18

14

12

12

500

6

18

0.2

14

0.5

12

1.0

1.5

LOAD CURRENT AT 12V

(AMPS)

2.5

22

0.2

18

0.5

14

1.0

12

1.5

LOAD CURRENT AT 24V

(AMPS)

2.5

7 Secure enclosure door

If No Keylock

Enclosure will be secured with 2

screws as shown (done as last step)

If Keylock

Remove knockout and insert key cylinder and secure with nut as shown

a b

exterior of door

#6 x 3/8" (2)

AC Status

indicator

c

interior of door

7

8 Maintenance

Unit should be tested at least once a year for proper operation as follows:

Voltage Output:

• Verify the proper DC output voltage by measuring the DC+ and DC- terminals.

Fire Alarm Release (if used):

• Verify proper operation by opening the wiring to the CONTROL IN input. Conrm that the locks controlled by the CONTROL

OUT output unlocked properly.

Battery (if used):

• Verify the proper charge voltage (between 26.3 - 26.5 VDC) on the battery terminals by measuring the BAT+ and BATterminals.

• Batteries should be changed every 4 years. Record date of install inside the cabinet to track time of service.

9 Troubleshooting

Refer to Section 3 for LED status of the AC input, DC output, and Battery to determine the cause for any abnormal condition. Each LED

has the denition of its ON or OFF state.

10 Warnings and Cautions

Warnings look like this:

Cautions look like this:

Notices look like this:

Directions look like this:

WARNING

Warnings indicate potentially hazardous conditions, which if not

avoided or corrected, may cause death or serious injury.

CAUTION

Cautions indicate potentially hazardous conditions, which if

not avoided or corrected, may cause minor or moderate injury.

Cautions may also warn against unsafe practices.

Notices indicate a condition that may cause

equipment or property damage only.

Directions identify a step that may or may not

apply to your product configuration. It also may

direct you to another part of the instruction.

8

LP150, LP250

Bloc d’alimentation

LP150B, LP250B

Instructions d’installation

LP250RDB4

Le LP150/LP250 est un bloc d’alimentation limitée en puissance et un chargeur de batterie qui convertissent l’alimentation de 120 V/60

Hz en puissance nominale de classe 2 de 12 ou 24 VCC sélectionnables sur site (continue et commutable). Il est destiné à être utilisé

dans des applications répondant aux exigences UL (voir les spécications ci-dessous pour une liste spécique).

Ces instructions couvrent :

LP150 Armoire électrique + tableau (1,5 A), ensemble de

câblage pour batterie, verrou à clé

LP250 Armoire électrique + tableau (2,5 A), ensemble de

câblage pour batterie, verrou à clé

LP250RDB4 Armoire électrique + tableau (1,5 A), ensemble de

câblage pour batterie, verrou à clé, carte RDB4 *

Verrou à clé

Armoire électrique

PS150/250 avec couvercle

à charnière + tableau

Ensemble de câblage

pour batterie

LP150B Armoire électrique seulement (1,5 A), 4 vis

LP250B Armoire électrique seulement (2,5 A), 4 vis

Armoire électrique

* La carte RDB4 est

fournie avec LP250RDB4

RDB4

uniquement. Elle est

couverte dans des

instructions séparées

Caractéristiques techniques des PS150/250 :

Entrée LP150: 120 V, 1 A, 60 Hz LP250: 120 V, 1,2A, 60 Hz

Sortie LP150 : 12 V (13,2 V nominal) ou 24 V (26,4 V nominal), 1,5 A, classe 2

LP250 (LP250RDB4): 12 V (13,2V nominal) ou 24 V (26,4V nominal), 2,5A, classe 2

Protection de sortie Les ports DC OUT et CONTROL OUT sont protégés contre les surcharges et les courts-circuits grâce à un

circuit de protection électronique à réamorçage automatique

Protection de la

batterie

Environnement 32 ° - 120 ° F (0 ° - 49 ° C), humidité relative jusqu’à 85%, utilisation à l’intérieur uniquement, zone protégée

Conformité UL294, UL603, Niveau de performance: Attaque destructive : niveau I, protection des lignes : niveau I,

Batterie de secours Nécessite 12 V, 7 AH max. batterie plomb-acide scellée rechargeable : (1) pour 12 V, (2) pour une sortie 24 V.

Contrôle de l’entrée/

sortie

État CA Indicateur : LED vert

Etat de la sortie CC Indicateur : LED rouge

État de la batterie Indicator: Red LED

Enceinte 13 po x 12-5/8 po x 3-1/4 po (8 entrées, 1/2 po ou 3/4 po)

PTC

Puissance en veille : niveau III, Résistance: niveau IV, (LP150) and II (LP250/LP250RDB4), CSA22.2 NO.205,

CSFM, FCC

Dimensions maximales de la batterie : 3-3/4 po x 6 po x 3 po

Voir les temps de sauvegarde typiques dans la section 2

Voir la section 8 pour l’entretien de la batterie

Entrée: normalement fermée, nécessite un contact sec de 24 V, 10 mA

Sortie : normalement fermé/ouvert alimenté pour 24 V, 2,5 A

Contacts de relais : normalement ouvert/fermé à 24 V, 1 A

Contacts de relais : normalement ouvert/fermé à 24 V, 1 A

9

Dénitions :

Contacts normalement fermés (NC)

Contacts normalement ouverts (NO)

FSE - Sécurité intégrée (besoin d'alimentation

pour déverrouiller)

FACP - Panneau de contrôle d'alarme

incendie

ACC - Contacts de contrôle d'accès

FS - Sûreté intégrée (besoin d'alimentation

pour verrouiller)

Voir la section 10 pour

une explication des

avertissements et mises

en garde utilisés dans

cette brochure.

1 Aperçu de l’installation

Les méthodes de câblage doivent être appliquées conformément au Code Électrique National/NFPA 70/NFPA 72/ANSI, ainsi qu’aux

codes et autorités locales compétents.

ATTENTION

Pour éviter tout risque de décharge électrique, mettez l’appareil hors

tension avant d’installer ou de réparer l’alimentation LP150/LP250.

1. Installez l’appareil dans une zone protégée conformément à la section 2.

2. Sélectionnez la tension (12 ou 24 V) selon la section 3.

3. Branchez l’alimentation CA conformément à la Section 3.

• Connectez la mise à la terre au l vert/jaune de l’armoire et la ligne (L) et le neutre (N) aux bornes appropriées du bornier CA.

Mesurez la tension de sortie avant de connecter des appareils pour éviter tout dommage.

4. Débranchez l’alimentation CA et terminez tout le câblage conformément aux sections 4 et 6.

5. Installez une batterie de secours (si nécessaire) conformément aux sections 2 et 3.

Si l’entrée CA est désactivée et la batterie de secours n’est pas utilisée, tous les périphériques connectés à l’alimentation ne seront

plus alimentés.

6. L’état de l’alimentation peut être nécessaire pour les systèmes à batterie de secours (section 3).

7. Fixez le couvercle avec des vis ou un verrou à clé lorsque vous avez terminé, conformément à la section 7.

8. Pour la maintenance et le dépannage, voir les sections 8 et 9.

10

2 Installation

MISE EN GARDE

Le produit destiné à une utilisation en intérieur

uniquement et dans la plage de température spécifiée.

Installez l'unité dans une zone protégée. Ne l'installez

pas dans des endroits exposés à la pluie ou à l'eau.

trou d'installation

Vis d'installation du

boîtier non fournies

Dimensions du

10-15/16 po

11-1/8 po

Dimensions de

l'armoire

12-5/8 po

Installez

en

position

verticale

13 po

Couverture non

illustrée pour plus

de clarté

L'installation de la batterie

doit être comme indiquée

3-1/4

po

Temps de sauvegarde

de la batterie

TEMPS DE SAUVEGARDE (HEURES)COURANT DE

CHARGE

(AMPS)

0.2

0.5

1.5

LP150

19

11

2

2.5

Le temps de sauvegarde calculer de la

batterie basé sur un temps de charge de 48

heures à une température de 77 ° F (25 ° C).

LP250

19

11

2

1.25

11

3 Tableau d’alimentation - Caractéristiques et fonctionnement

120 V, tension

d'entrée 60 Hz

L: Ligne, alimentée

G: Mise à la terre

N: Neutre

Normalement fermé à C : ouvert

ÉTAT

Normalement ouvert à C : fermé

CA

Normalement ouvert à C : fermé

Normalement ouvert à C : ouvert

120 V ligne

désactivé

verte

LED rouge CCdésactivé

désactivé

LED rouge

BAT

Normalement fermé à C : ouvert

ÉTAT

Normalement ouvert à C : fermé

DE LA

BATTERIE

Normalement ouvert à C : fermé

Normalement ouvert à C : ouvert

SORTIE DES CONTRÔLES

Normalement fermé à DC : 0 V

CONTRÔLE

NO À CC : CC + sortie

Normalement fermé à DC: CC + sortie

Normalement fermé à DC : 0 V

Alimentée

Neutre

Mise à la terre

Non limité en puissance, classe 1

120 V NON présent à l'entrée

activé

120 V présent à l'entrée

Sortie CC désactivée ou en

court-circuit / surcharge

activé

Sortie DC activée (12 ou 24V)

Batterie non connectée ou

batterie faible

Batterie connectée et en

activé

charge ou fournissant une

batterie de secours

Vert/jaune

120 V NON présent à

l'entrée

120 V présent à l'entrée

Batterie non

connectée ou

batterie faible

Batterie connectée

et en charge ou

fournissant une

batterie de secours

ENTRÉE DES CONTRÔLES

ENTRÉE à C : contacts ouverts

ENTRÉE à C : contacts fermés

120VAC

L

G

N

ATTENTION

Doit être connecté via un conduit ridige.

ATTENTION

Gardez le câblage limité en puissance séparé du câblage non limité en

puissance. Un espacement minimum de 1/4 po doit être fourni.

MISE EN GARDE

Lors de l'installation, éloignez le câblage des projections, des angles et des

composants internes pointus. Ebavurer tous les raccords de conduit.

NC

C

NO

AC STATUS

BATDC

NC

C

NO

BAT STATUS

IN

C

CONTROL IN

CONTROL

OUT

NO DC- DC- DC+NC

Non limité en

puissance

LP150

LP250

BAT- BAT+

24V 12V

SÉLECTION

DE TENSION

DE SORTIE

CC

DC

OUT

Commutateur

24V

déplacé à gauche

Commutateur

12V

déplacé à droite

12

CONFIGURATION

DE LA BATTERIE

24 V

CONFIGURATION

DE LA BATTERIE

12 V

12V

BATTERIE

Noir

Jaune

12V

BATTERIE

OU

12V

BATTERIE

Rouge

Noir

Rouge

24V

MISE EN GARDE

Confirmez la polarité pour éviter

d'endommager l'appareil.

12V

4 Câblage typique

Dispositif FS et FSE connecté à la

carte PS avec neutralisation FACP

FACPACC

ENTRÉE DES

CONTRÔLES

IN

C

NC

LP150/250

Opération :

1. CONTROL IN contrôle le fonctionnement des appareils connectés

aux bornes NO ou NC.

2. L’ouverture des contacts FACP désactive les contacts CONTROL

OUT NC et alimente les contacts NO.

3. DC OUT est toujours alimenté, quel que soit l'état des contacts du

FACP.

SORTIE DES

CONTRÔLES

SORTIE

CC

NO

DC-

DC+

DC-

+

GÂCHE

ÉLECTRIQUE FSE

+

SORTIE CC

CONTINUE

Dispositif FSE utilisant des contacts

de contrôle d'entrée ouverts

ACC

ENTRÉE DES

CONTRÔLES

IN

C

+

MAGLOCK

FS

NC

LP150/250

Opération :

1. CONTROL IN contrôle le fonctionnement de la gâche connectée à la

borne NC.

2. La fermeture des contacts de l'ACC alimentera la frappe FSE pour la

déverrouiller.

SORTIE DES

CONTRÔLES

SORTIE

CC

NO

DC-

DC+

DC-

+

GÂCHE

ÉLECTRIQUE FSE

+

SORTIE CC

CONTINUE

13

5 Installation de PS150B et PS250B

Vue en coupe du

boîtier pour plus de

clarté

Intérieur de

l'enceinte

6-32 x 1/4 po (4)

6 Longueurs de l

• Utilisez le tableau suivant pour estimer le calibre de l requis pour l’application.

• Longueur de l basée sur une chute de tension de 15 % à 12 ou 24 V avec un l de cuivre toronné..

• Le calibre de l indiqué est un minimum. La jauge peut être augmentée si vous le souhaitez.

• Distance = distance totale de câblage unidirectionnel entre l’alimentation et le périphérique alimenté (inclut les deux câbles

d’alimentation).

• Pour les installations UL, la taille de câble minimum permis à utiliser ne doit pas être inférieure à 22 AWG.

DISTANCE

(PIEDS)

100

200

300

400

22

22

20

20

22

18

16

16

18

16

14

14

JAUGE DE FIL (AWG)

16

14

12

14

12

22

22

22

22

22

22

20

18

22

18

16

16

20

16

14

14

18

14

12

12

14

500

18

0.2

14

0.5

12

1.0

COURANT DE CHARGE À 12V

(AMPÈRES)

1.5

2.5

22

0.2

18

0.5

14

1.0

COURANT DE CHARGE À 24V

(AMPÈRES)

12

1.5

2.5

7 Porte sécurisée

Si pas de serrure

Le boîtier sera fixé avec 2 vis

comme indiqué (à la dernière étape)

Si une serrure est présente

Retirez la découpe, insérez le barillet et fixez-le avec l'écrou comme indiqué

a b

extérieur de la

porte

# 6 x 3/8 po (2)

Indicateur

d'état CA

c

intérieur de la

porte

15

8 Entretien

L’unité doit être testée au moins une fois par an pour vérier son bon fonctionnement, comme suit:

Tension de sortie:

• Vériez la tension de sortie CC appropriée en mesurant les bornes DC + et DC-.

Déclenchement d’alarme incendie (si utilisé):

• Vériez le bon fonctionnement en ouvrant le câblage de l’entrée CONTROL IN. Conrmez que les serrures contrôlées par le

CONTROL Sortie sortie déverrouillée correctement.

Batterie (si utilisée):

• Vériez la tension de charge appropriée (entre 26,3 et 26,5 V) aux bornes de la batterie en mesurant les bornes BAT + et

BAT-.

• Les piles doivent être remplacées tous les 4 ans. Notez la date d’installation à l’intérieur de l’armoire pour suivre l’heure de

réparation.

9 Dépannage

Reportez-vous à la section 3 pour connaître l’état des voyants de l’entrée CA, de la sortie CC et de la batterie an de déterminer la cause

de toute condition anormale. Chaque voyant a la dénition de son état ON ou OFF.

10 Avertissements et mises en garde

Les avertissements

ressemblent à ceci :

Les mises en garde

ressemblent à ceci :

Les avis ressemblent

à ceci :

Les instructions

ressemblent à ceci :

AVERTISSEMENT

Les avertissements indiquent des conditions potentiellement

dangereuses qui, si elles ne sont pas évitées ou corrigées, peuvent

provoquer des blessures graves, voire mortelles.

MISE EN GARDE

Les mises en garde indiquent des conditions potentiellement

dangereuses qui, si elles ne sont pas évitées ou corrigées,

peuvent causer des blessures mineures ou modérées. Les

mises en garde peuvent également mettre en garde contre les

pratiques dangereuses.

Les avis indiquent une condition pouvant

uniquement causer des dommages

matériels.

Les instructions identifient une étape qui peut

ou non s'appliquer à la configuration de votre

produit. Cela peut également vous diriger vers

une autre partie de l'instruction.

16

Customer Service

1-877-671-7011 www.allegion.com/us

Canada

1-800-900-4734 www.allegion.ca

© Allegion 2019

Printed in Taiwan

829767-00 Rev. 06/19-b

Loading...

Loading...