Page 1

Allegion

LCN Benchmark® AU9100 Series

Low Energy Operators

Installation Manual

LCN Low Energy Operators should

be installed in accordance with the

current Allegion LCN installation

instructions.

Commissioning and Servicing of

installed units must be carried out by

an Allegion Approved, Authorised

Technician

16-20 Third Ave, Sunshine, Vic, 3020

Tel: 1800 098 094

Email: auinfo@allegion.com

Page 1 of 20 December 2014 Ver 4

Page 2

1 GENERAL ............................................................................................................................................ 2

2 REPLACEMENT PARTS AND SYSTEM COMPONENTS .............................................................. 3

3 PRE-INSTALLATION SITE AND PRODUCT CHECK .................................................................... 4

4 OPERATOR INSTALLATION ............................................................................................................ 5

5 WIRING ................................................................................................................................................ 7

6 ARM AND COVER INSTALLATION ................................................................................................ 8

7 OPERATIONAL CHECK................................................................................................................... 10

8 OPERATOR ADJUSTMENT ............................................................................................................. 11

9 RELEASE FOR SERVICE ................................................................................................................. 13

10 LCN AU9100 (Briton 2500) V4 SOFTWARE .................................................................................... 14

1 GENERAL

The LCN Benchmark® 9100 Series is an automatic electromechanical swing door operator for use on

hinged, centre pivoted, and offset pivoted doors. The controller is a microprocessor based system, tracking the

door position at any time during the cycle. When activated the Benchmark® 9100 drives the door to the full

open position creating the potential energy in the spring. When closing the electrical power is reduced and the

door closes by controlling the potential energy release in the spring force. The activating circuit opens the

door from any position on the closing swing. During power failure the Benchmark® 9100 acts as a manual

door closer (size 3). Door opening and closing cycles, including opening speed, back check speed, hold open

time delay, closing speed, and latch position are all adjustable.

WARNING

Always disconnect main power to the operator prior

to servicing or cleaning

Warning

Swing door operator Swing door operator

Pull arm and track assembly Push arm assembly

LCE65006 LCE65007

Page 2 of 20 December 2014 Ver 4

Page 3

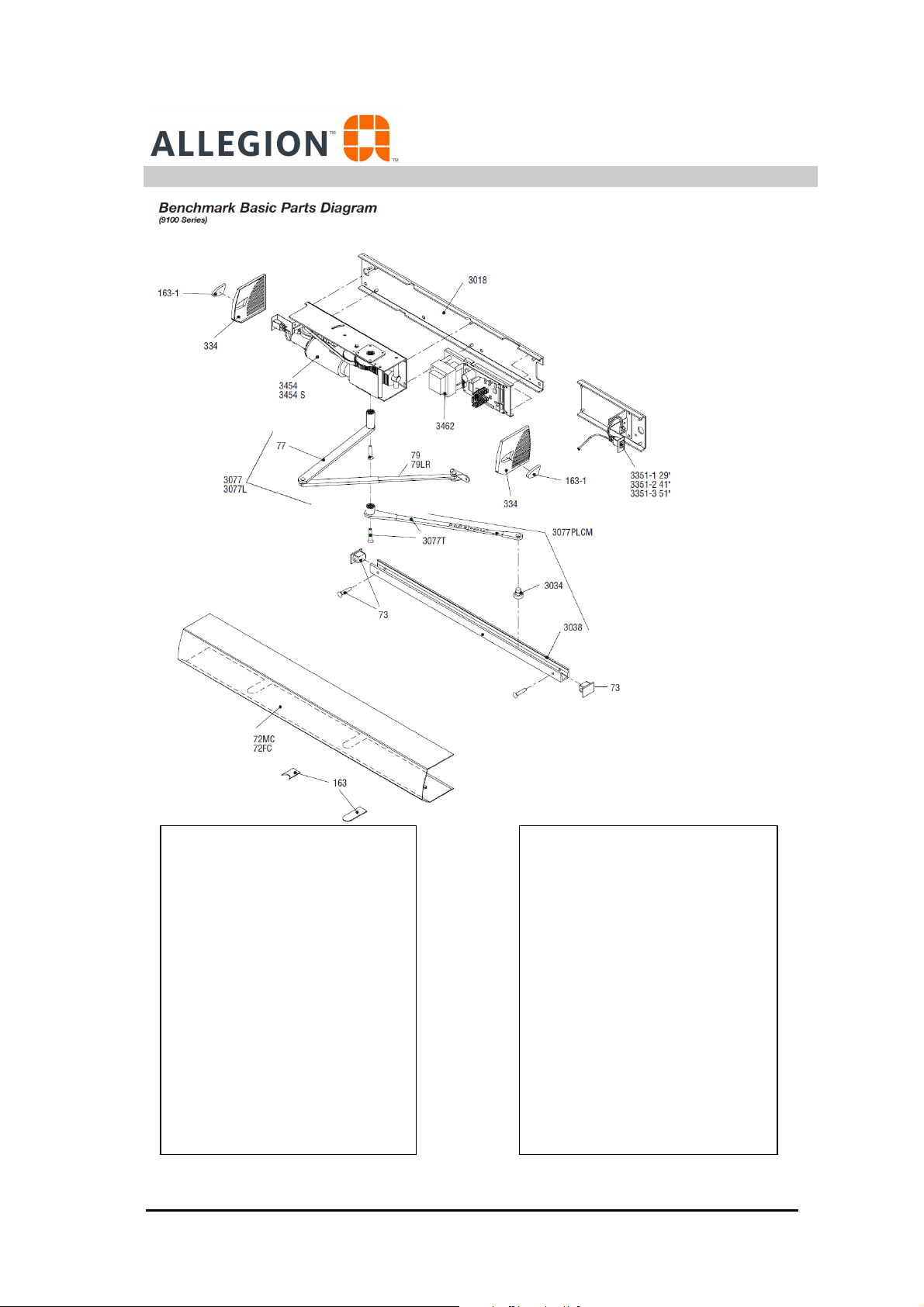

9140 Series

9130 Series

2 REPLACEMENT PARTS AND SYSTEM COMPONENTS

9130-3077T................................Standard Arm

9130-3077PLCM..........Standard Arm w/Track

9130-3038................................................Track

9130-72MC*..................................Metal Cover

9130-72FC* ............................Full Metal Cover

9130-MS........................................Screw Pack

9130-73.....................................Track End Cap

9130-163.......................................Cover Insert

9130-163-1 ....................Cover End Cap Insert

9130-334 .................................Cover End Cap

9130-360.........................................24v SO Kit

9130-3018............................Mounting Bracket

9130-3155 ..........................................Label Kit

9130-3034 .....................................Track Roller

9130-3351-1......................Switch Bracket 29"

9130-3351-2......................Switch Bracket 41"

9130-3351-3......................Switch Bracket 51"

9130-3454 ...............Motor Gearbox Assembly

9130-3454S...Motor Gearbox Assembly w/Switch

9130-3462SC ................Standard Control Box

9130-3498-2A..............A/C Power Cable - 29"

9130-3498-2B .............A/C Power Cable - 42"

9130-3498-2C .............A/C Power Cable - 52"

- (ANCLR or ANDKB only)

9140-3077 ....................................Regular Arm

9140-3077L.......................................Long Arm

9140-72MC*..................................Metal Cover

9140-72FC* ............................Full Metal Cover

9140-MS........................................Screw Pack

9140-77.............................................Main Arm

9140-79......................................................Rod

9140-79LR........................................Long Rod

9140-163.......................................Cover Insert

9140-163-1 ....................Cover End Cap Insert

9140-334 .................................Cover End Cap

9140-360.........................................24v SO Kit

9140-3018............................Mounting Bracket

9140-3155 ..........................................Label Kit

9140-3351-1......................Switch Bracket 29"

9140-3351-2......................Switch Bracket 41"

9140-3351-3......................Switch Bracket 51"

9140-3454 ...............Motor Gearbox Assembly

9140-3454S.............Motor Gearbox Assembly

........................................................w/Switch

9140-3462SC ................Standard Control Box

9140-3498-2A..............A/C Power Cable - 29"

9140-3498-2B .............A/C Power Cable - 42"

9140-3498-2C .............A/C Power Cable - 52"

- (ANCLR or ANDKB only)

Page 3 of 20 December 2014 Ver 4

Page 4

3 PRE-INSTALLATION SITE AND PRODUCT CHECK

3.1 Check that the product model is correct for the required application

3.2 Check that all parts listed for the installation are received

3.3 Check architectural drawings and final approved shop drawings for position of frame and structural

openings

3.4 Check header and frame dimensions and required clearances

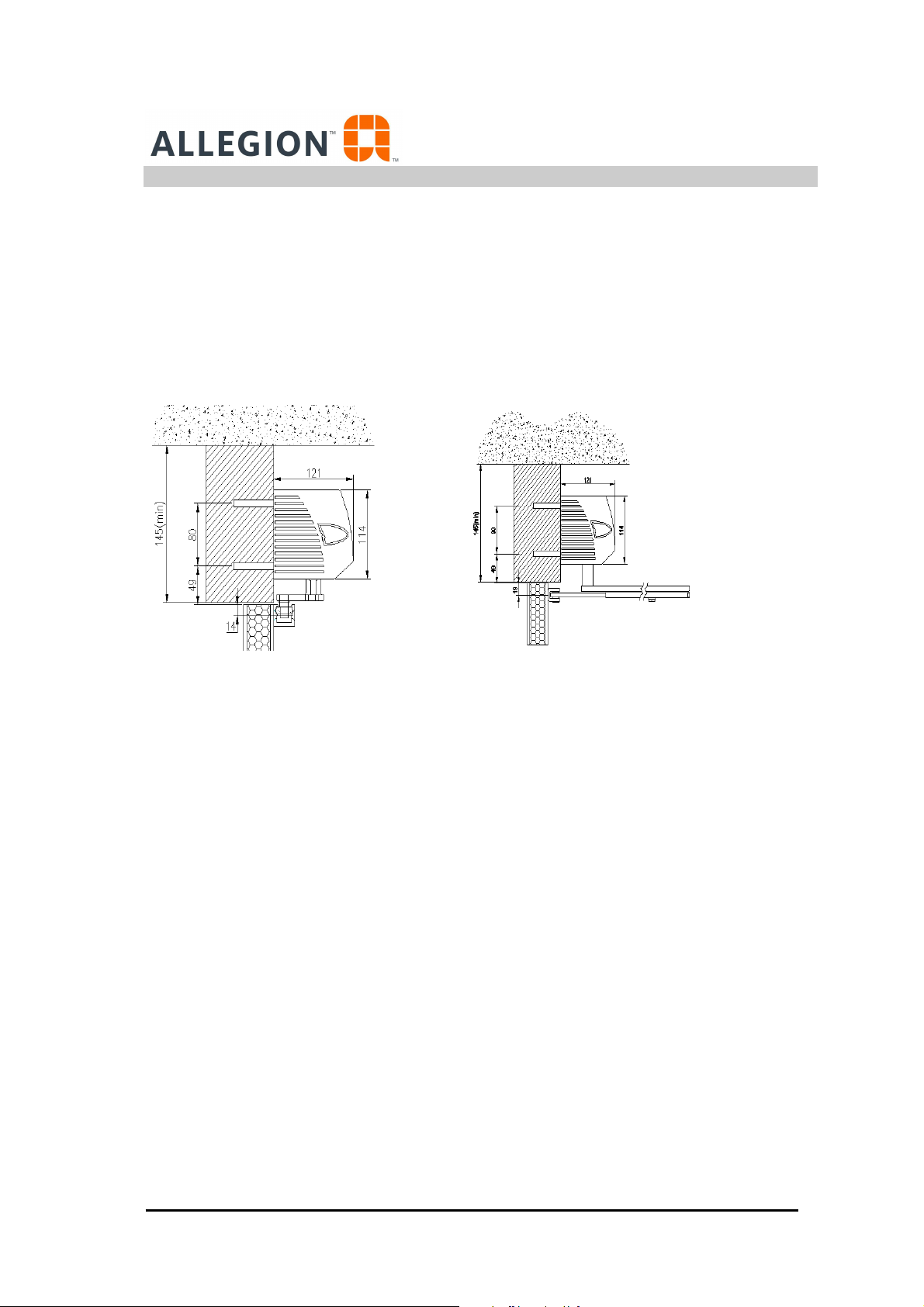

Clearances for pull system Clearances for push system

3.5 Ensure door weight is less than 90Kgs. For heavier doors consult supplier

3.6 Check that a 240 Volt, single phase, 60 Hz, fused supply (5 amp fuse maximum) is available at

the side of the jamb within approximately 1 Meter of the header. Approved type conduit is

recommended for 240V systems

3.7 If an electric lock is to be connected to the system, the maximum current draw is 2 Amps. The

switching relay contact is a maximum resistive current of 2 Amps.

3.8 The supply must be a dedicated circuit from the main circuit breaker panel and must not be connected

into building lighting circuit with fluorescent lights

Page 4 of 20 December 2014 Ver 4

Page 5

4 OPERATOR INSTALLATION

4.1 Remove control box from mounting bracket, then remove Motor/Gearbox from bracket

4.2 Prepare header frame Pull system …………………See Page 5

Push system…………………See Page 6

NOTE

NOTE

For push units with a reveal greater than 150 mm refer

to installation sheet included in the extended arm

Packaging.

4.3 Install operator-mounting bracket on the header/frame.

4.4 Install motor/gearbox on operator mounting bracket, then install control box on bracket Go to wiring

page 7

Pull System

Framed Header and Door Preparation

Page 5 of 20 December 2014 Ver 4

Page 6

REVEAL

Butt Hung/Offset Pivot

Centre Pivot

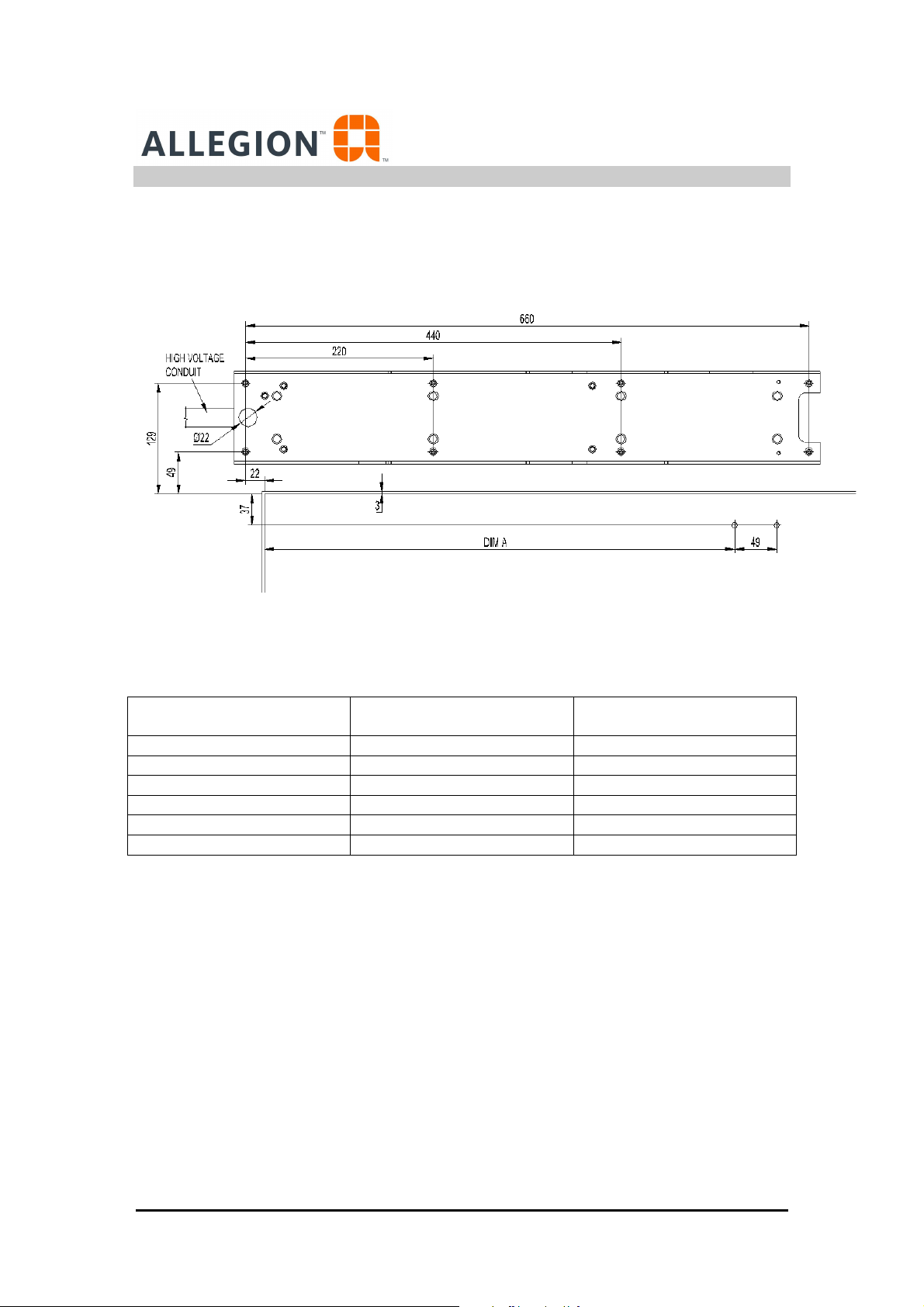

25. 559 686

51 533 660

76 508 635

102 483 610

127 457 584

152 457 584

OPERATOR INSTALLATION (Cont)

Push System

Framed Header and Door Preparation

DIM A

DIM A

Page 6 of 20 December 2014 Ver 4

Page 7

•

Make sure all wires are properly dressed and secured to prevent interference

5 WIRING

C

CAUTION

• Route all wiring away from moving parts, sharp edges, and heat sources

• Use copper conductors only

• Do not modify the factory wiring or connect into existing electrical circuits or

devices

AUTION

5.1 Refer to the appropriate wiring diagram for the standard control box (Page 22) or the

diagram supplied for custom applications. And connect the following cables

• Ground cable (Ground the operator properly with the earth from main

supply

• Hall effect Cable (do not wrap the hall effect cable around the motor cable)

• Motor power cable (do not wrap the motor cable around the hall effect

cable)

• Control box power cable

5.2 Connect Activate, Safety, Key switch, and lock accessories as needed. Refer to the

accessory instruction/s for any accessories used. Do not connect any remote activating

device to the door unless it is located within line of sight of the door

5.3 When wiring is complete go to “Arm and cover installation” on page 8

Page 7 of 20 December 2014 Ver 4

Page 8

Keep hands, clothing, wires, t

ools, ETC away from the

6 ARM AND COVER INSTALLATION

WA

WARNING

•

operator motor when the operator is turned on

RNING

6.1 Make sure the operator power switch is turned OFF

6.2 Install a jumper across the control box MAIN ACT T28 and COMMON T27

6.3 Turn the operator power switch on. The operator motor will activate and drive to the full

open position.

6.4 Attach the arm to the operator spindle loosely with the 8-mm socket head screw (for push

systems ensure adjusting boss is inserted correctly).

6.5 Attach the arm to the door

6.5.1 For push systems attach the push arm shoe to the door

Page 8 of 20 December 2014 Ver 4

Page 9

6.5.2 For pull systems, slide the pull arm roller into the track, insert a track cap

on each end of the track, and attach the track to the door.

6.6 Adjust the arm

6.6.1 For pull systems, remove the locking screw from the arm

6.6.2 For the push system remove the locking screw from the arm

Pull Arm Push Arm

ARM AND COVER INSTALLATION (Cont)

Pull Arm

6.7 Keep the door in the full open position and adjust the arm length as necessary to align the door at 90

degrees from closed. When the arm is adjusted to the correct length, tighten up the 8mm socket head

screw that secures the arm to the operator spindle and ensure this is secure, then tighten the arm

locking screw

6.8 Turn off the power operator switch. The door closes

6.9 Remove the jumper from the control box T27, T28

6.10 Test the operator (See operational check” on page 11) and continue with step 6. 10

6.11 Adjust the operator as required( see “Operator Adjustment” on page 12) and continue with

step

6.12 Snap optional end cap insert (from screw bag) into the end cap opposite the on/off switch.

6.13 Install the cover assembly on the operator

6.14 Release the operator for service ( see “Release for Service” on page 14)

Page 9 of 20 December 2014 Ver 4

Page 10

7 OPERATIONAL CHECK

7.1 Set the Key switch to Auto (1 Way) and turn on the operator power switch

7.2 Activate the operator using the activation device, the operator will perform one sizing cycle

Sizing cycle: Occurs after a legitimate activation signal is received, after power has been turned on. During

the size cycle, the door opens and closes one time.

7.2.1 If the door does not open at all during sizing cycle

7.2.2 Check door for binding

7.2.3 If an electromechanical lock is being used, check that the lock disengages before the operator opens

the door.

7.2.4 Check fuses, Circuit breakers, and connections.

7.2.5 Adjust the operator and check door operation (See “Operator Adjustment on page xx)

Opening speed 75%

Back check speed 75%

Hold open time delay Minimum

Latch position Maximum

Closing speed 50%

SW1, 2, 3, 4 OFF

If the door does not open fully during size cycle

c

heck the door for binds

Increase the back check speed slightly and check door operation continue increasing back

check speed until door opens fully

7.3 If the door slams open decrease the back check speed slightly and check door operation. Continue

decreasing back check speed until the door opens without slamming

7.4 After the sizing cycle is complete and the door is closed, apply a maintained activation signal and

check that the door remains open while the signal is applied.

7.5 If a door safety device is being used:

7.6 Door open safety

When the door is in the closed position activate the safety device, then try to activate the

door the door should remain closed.

Activate the door, as the door is opening activate the safety device the door should stop, and

then slowly drive to the full open position.

7.7 Door close safety

Activate the door then maintain activation of the safety device, the door should open and

remain open.

As the door is closing, activate the safety device, the door should re-open to the open

position, time out and then close.

7.8 When the door is operating properly, continue with step 6.10 on page 9

Page 10 of 20 December 2014 Ver 4

Page 11

NOTE

Safety

P8 Controls the angle during the

Closer to open

Further from

8 OPERATOR ADJUSTMENT

See table below and diagrams on page 18 for operator feature adjustment. After adjustment, cycle the door

several times and check for proper operation, then continue with step 6.11 on page 9.

N

Adjust operator for the slowest operation practical in accordance with the latest

AS_5007 standards for powered doors for pedestrian access and egress.

Opening speed 5 sec’s or more Closing speed 3 sec’s or more

OTE

Features Control Description Anti-Clockwise Clockwise

Opening

Speed

Back Check

Speed

Hold Open

Time Delay

Auto

Reverse

setting

Latch

Position

Closing

Speed

Safety

Opening

Angle

P1 Controls opening speed of door Slower Faster

P2 Controls speed of door near full

open position to prevent door

slamming open

P3 Controls length of time door

remains in the full open

position 1 to 30Sec

P4 Sets pressure required on door

opening before door stops

P5 Determines distance at which

the door begins to decelerate to

full closed position to prevent

door slamming

P6 Controls closing speed of door Slower Faster

P7 Controls the angle during the

open cycle that safety operates

Slower Faster

Less time

1 Sec

Less Pressure

required

Less Latch More Latch

Closer to closed

position

`More Time

30 Sec’s

More

Pressure

Required

Further from

closed

position

Closing

Angle

Delayed

Activation

Push And Go SW2 When switched on, pushing the door

Power boost

On or OFF

Power boost

continuous

or 5 Sec’s

SW1

SW3 Enables or disables Power Boost

SW4 Enables power boost to operate

close cycle that safety operates

open by 5 degrees causes

the operator to open for the

remainder of the open cycle

which gives a force in the closed

direction when the door is closed.

Used for high wind

situations

continuously or for 5 Sec’s only after

door closes.

position

open

position

Page 11 of 20 December 2014 Ver 4

Page 12

OPERATOR ADJUSTMENT (Cont)

Page 12 of 20 December 2014 Ver 4

Page 13

IMPORTANT

9 RELEASE FOR SERVICE

9.1 Remove all tools, installation equipment, and debris from the vicinity of the door.

9.2 Install all safety, traffic control, and instruction labels on the door as required by the latest

AS_5007 Standard. Failure to do this leaves the installer LIABLE for any accident that

might occur. This must be done.

9.3 Verbally instruct the owner or person in charge of the proper operation of the door.

9.4 Instruct the owner or person in charge to routinely inspect the door for the following

• Occasional damage

• Developing problems

• Minor preventative maintenance

9.5 Instruct the owner or people in charge who and where to call for service and maintenance

when required.

IMPORT

Make sure to install all safety, traffic control and

instruction decals on the door as required

ANT

Page 13 of 20 December 2014 Ver 4

Page 14

10 LCN AU9100 (Briton 2500) V4 SOFTWARE

10.1. OPERATION .................................................................................................... 15

10.1.1. Sizing ............................................................................................................ 15

10.1.2. Auto Reverse on open ................................................................................... 15

10.1.3. Standard operation ........................................................................................ 15

10.2. FUNCTION SELECTION................................................................................ 16

10.2.1. Standard (0) ................................................................................................... 16

10.2.2. Lock in OFF Only (1) ................................................................................... 16

10.2.3. Lock in 1 Way Only (2) ................................................................................ 16

10.2.4. PNG in OFF (3) ............................................................................................ 16

10.2.5. Door closes and Unlocks in Fire Alarm (4) .................................................. 16

10.3. FUNCTION CHART ........................................................................................ 17

10.4. CONTROL BOX SETUP ................................................................................. 18

10.5. LCN AU9100 (Briton 2500) ii WIRING .......................................................... 19

Page 14 of 20 December 2014 Ver 4

Page 15

10.1 OPERATION

10.1.1 Sizing

From start up (size) the door will activate from morning entry (24Hrs,T9,

T10) regardless of key switch position, 1 Way input (T27,T28) with key

switch in one way. 2 Way input (22, T23) with key switch in two way, or

key switch Hold Open. The first movement will be in the open direction

- The speed of the sizing cycle is automatic and cannot be set from a

potentiometer the door drives opened to the full open position where the

system sets the counter to full open. The door closes at close speed then

latch up to closed position where the system sets the counter for closed

position. From these two parameters opened and closed position the

system calculates all the other parameters it requires for normal

operation i.e. latch position back check position etc.

• Notes

If the encoder is connected for opposite direction or faulty or

disconnected the door will operate erratically continuously opening ½

way closing latching and re-opening. This will continue to occur until

power is switched off

10.1.2 Auto Reverse on open

The auto reverse open is set from the backcheck position pot. This sets

the level of current required to trip the door as it is opening.

Normal operation

Key switch, activation, morning entry/fire alarm, locking, and safety.

10.1.3 Standard operation

Upon a legitimate activation signal the door accelerates up to open speed,

monitoring the current load on the drive output. (If the current reaches a

level above the set datum the door will stop and close). The door travels at

the set speed (Potentiometer setting) until it reaches the set backcheck

position, where the speed (Potentiometer setting) is decreased to back

check speed. When the door stops at hold open position the system sets the

hold open speed and holds the door open until activation and or timer is

cleared. The door will then close at close speed, (Potentiometer setting) up

to latch position (Potentiometer setting). Where the speed is decreased by

driving the motor in the open direction (fixed setting), the power is set

such that the spring will overcome this power and continue to allow the

door to close up to the closed position. During the open cycle the safe

opening (T1, T2) is active and the Safety side Adj Pot sets the angle at

which the sensor is redundant, this can be set from Closed up to back

check position. During the closing cycle the safe closing (T5, T6) is active

and the Activate side Adj pot sets the angle the sensor is redundant, this

can be set from Opened up to a few degrees of closed position.

Page 15 of 20 December 2014 Ver 4

Page 16

General

24Hr operates the door regardless of key switch position the door will drive open and

remain in the open position as long as the contact is made (Program 4 is the exception)

Key switch position OFF no activation or safety operates. Electric lock operates when

door closed dependant upon function selection Electric lock operation is set from the

function selector the time delay is fixed

Key switch Position 1 Way the activation from internal Activate (T27, T28) safety

operates. Electric lock operates when door closed dependant upon function selection

Key switch Position 2 way the activation from internal Activate (T27, T28) and external

Activation (T22, T23) safety operates. Electric lock does not operate when door closed

Key Switch H.O The door operates to the open position and remains in the open position

safety is by passed (If safety activated the door will open slowly)

10.2 FUNCTION SELECTION

10.2.1 Standard (0)

Operates as a standard door with electric lock operating in OFF and 1 WAY

Eyetech Activation T5, T6 (Closing Cycle)

Eyetech Safety T1, T2 (Opening Cycle)

F/A T9, T10

1 Way T27, T28

2 Way T22, T23

Door open T14

Key switch off T12

T8 Not Used

10.2.2 Lock in OFF Only (1)

Operates as a standard door with electric lock operating in OFF only.

This selection will give a fast activation in Auto or 1 Way from closed as

there is no delay for lock operation.

10.2.3 Lock in 1 Way Only (2)

Operates as a standard door with electric lock operating in 1 Way only

10.2.4 PNG in OFF (3)

Operates as a standard with Push & Go operating in key switch OFF

10.2.5 Door closes and Unlocks in Fire Alarm (4)

Operates as a standard Fire Alarm Normally closed if open circuit door

closes and will remain Unlocked

Page 16 of 20 December 2014 Ver 4

Page 17

10.3 FUNCTION CHART

Standard

0

Locking in OFF only

1

Locking Auto only

2

Standard PNG in OFF

3

Fire Alarm to close door

4

Program BCD Operation

Eyetech Act T1,T2 Eyetech Saf T5,T6

F/A T9,T10 1 Way T27,T28

Door open T14

Key switch off T12

2 Way T22,T23

T8 Not Used

As Std

Door locks in OFF Only

As Std

Door Locks in AUTO Only

As Std PNG operates in key switch OFF

As Std

Normally closed

(Breakout)

F/A T9,T10 Normally closed

Door closes and remains unlocked

5

6

7

8

9

A

B

C

D

E

F

Page 17 of 20 December 2014 Ver 4

Page 18

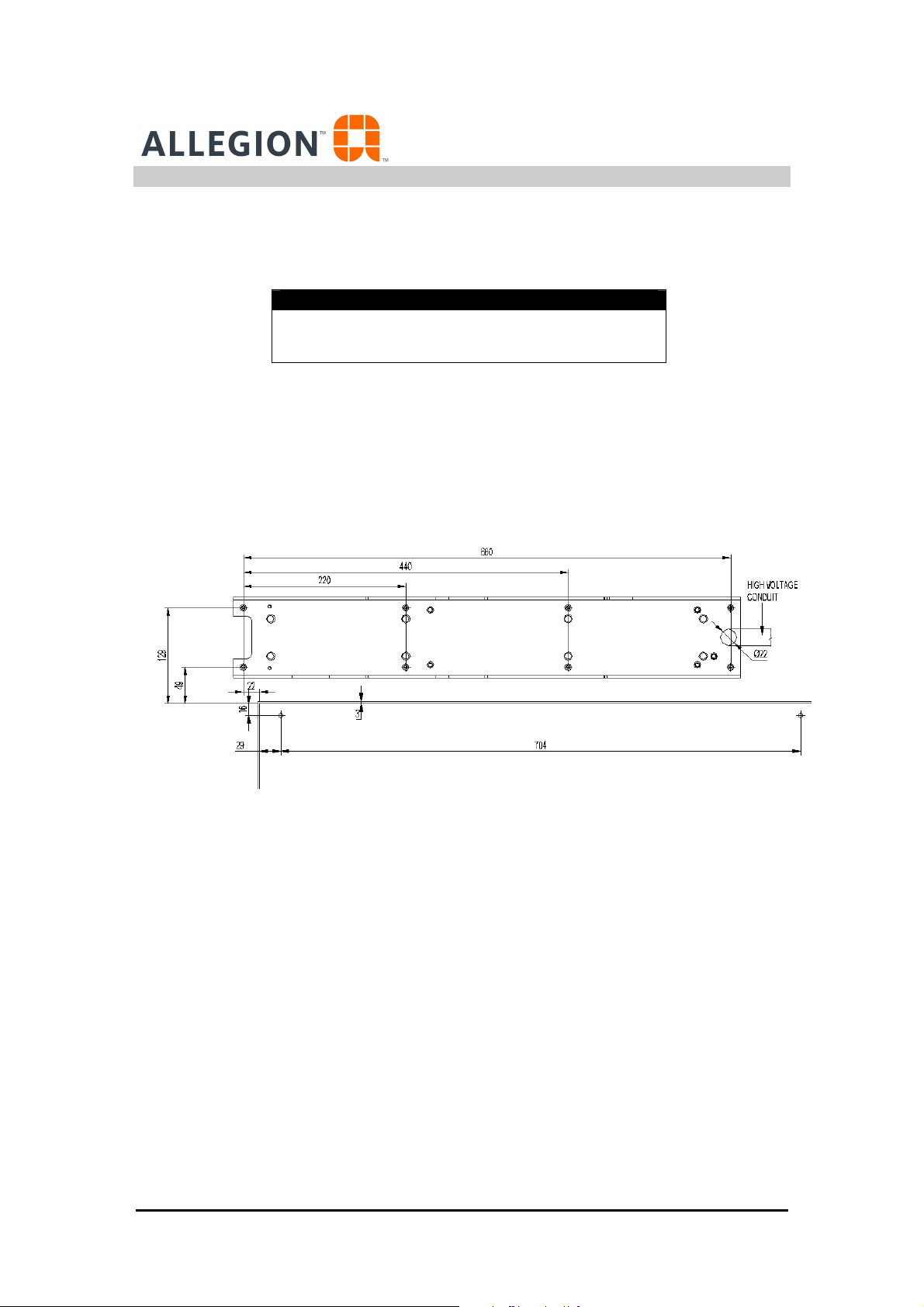

10.4 CONTROL BOX SETUP

Page 18 of 20 December 2014 Ver 4

Page 19

10.5 LCN AU9100 (Briton 2500) ii WIRING

Page 19 of 20 December 2014 Ver 4

Page 20

10.6 LCN AU9100 (Briton 2500) ii Terminal Block

Page 20 of 20 December 2014 Ver 4

Loading...

Loading...