Page 1

*911066-00*

911066-00

Concealed Vertical Rod Exit Device

for Metal Doors

5547EO, 5547DT,

5547L, 5547NL,

1 Check handing of device. Reverse if necessary.

Installation Instructions

& 5547TL

b b

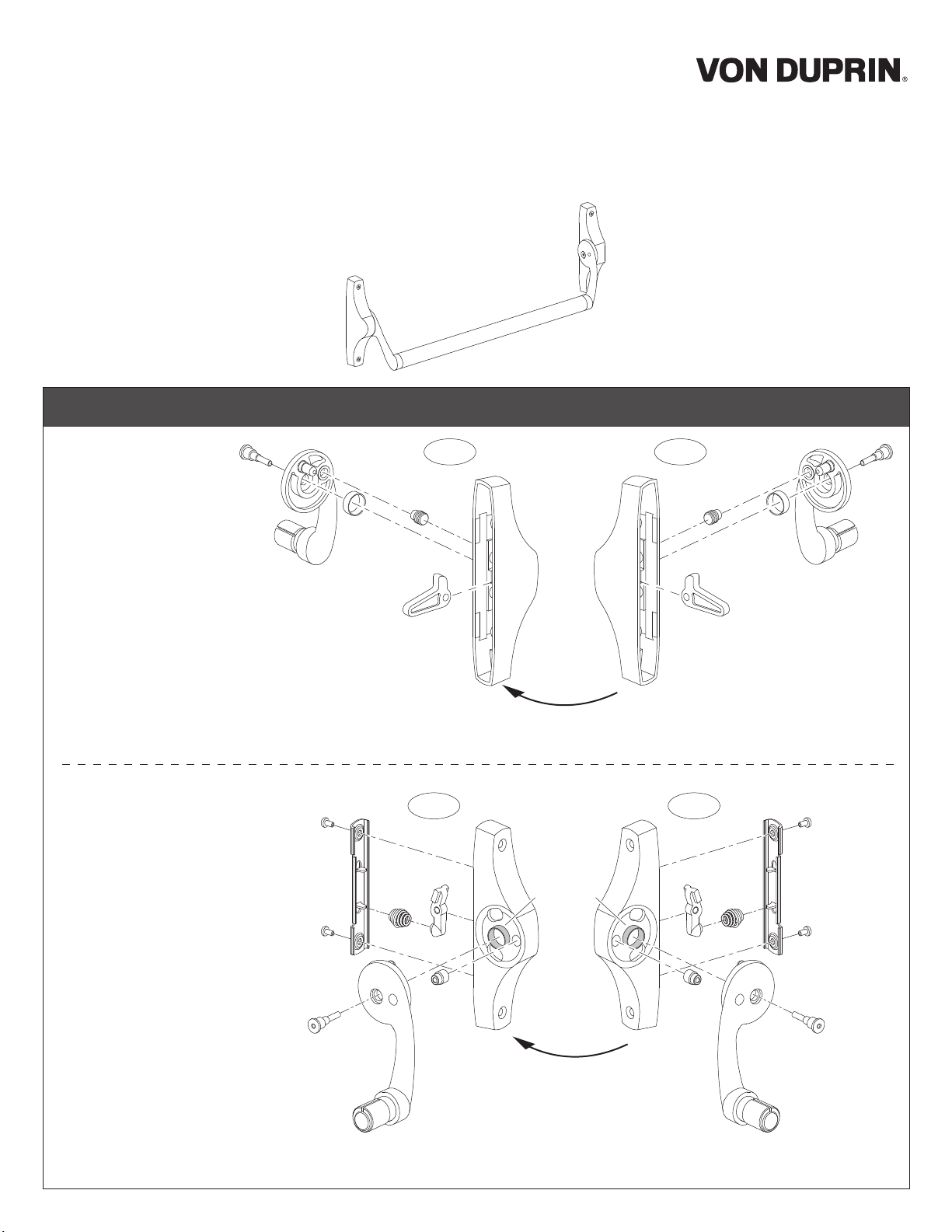

REVERSING PROCEDURE

FOR LOCK STILE CASE

Invert the case and

reassemble in order shown

(a thru d) with opposite hand

lever arm from hinge case.

REVERSING PROCEDURE

FOR HINGE STILE CASE

Disassemble hinge stile case,

rotate parts as shown with spring

always at the bottom. Reassemble

in order shown (a thru d) with

opposite hand lever arm from

center case.

LH lever

arm

LHR

RHR

a a

Lock Stile Case

LHR

Bushing

RHR

aa

RH lever

arm

dd

cc

RH lever

arm

When exchanging parts, be certain that one bushing remains on the hub of each case.

Hinge Stile Case

bb

LH lever

arm

Page 2

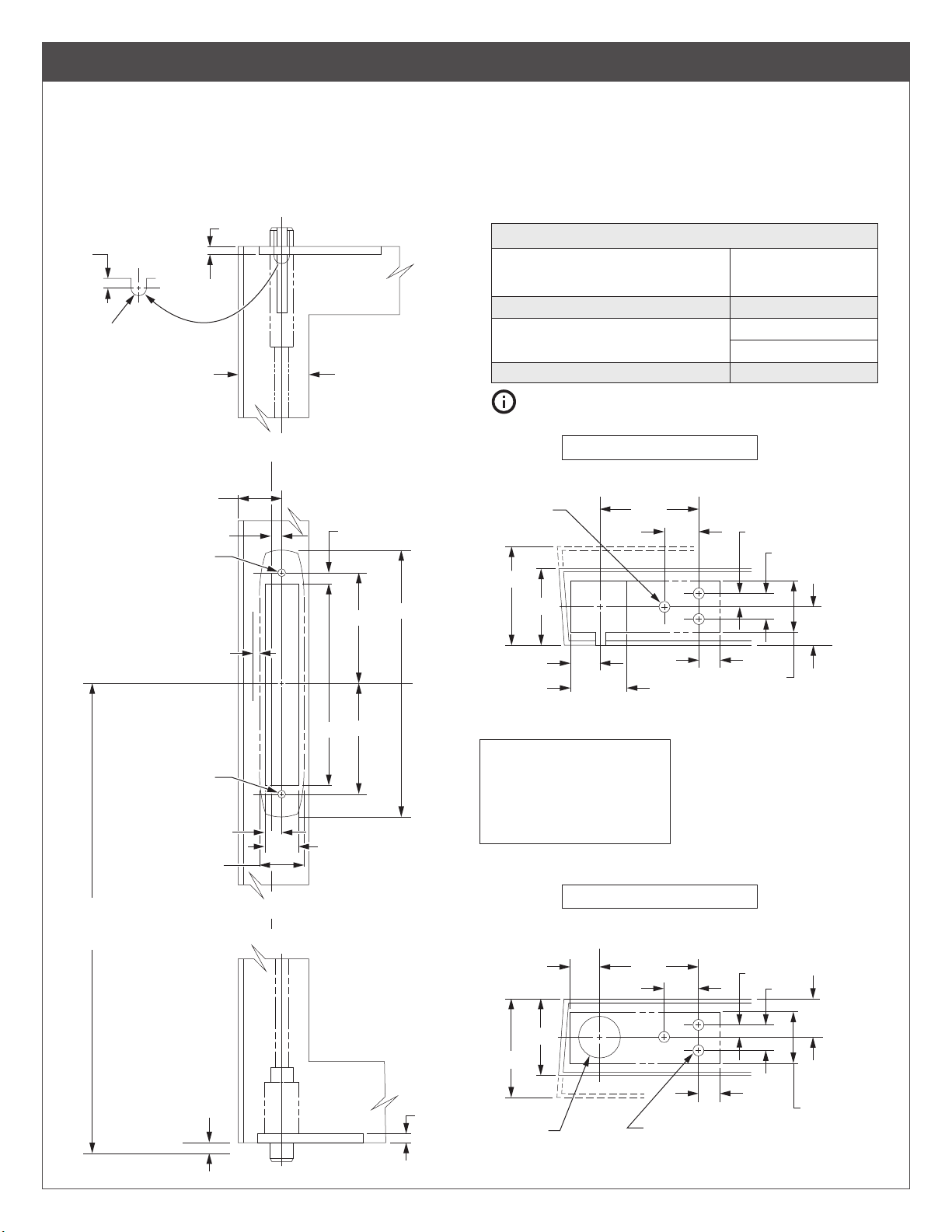

2 Prepare door.

This device is for metal door only.

a. Tape door template (page 4) to inside face of lock stile according to handing. Be sure vertical centerline of device on template

is parallel to edge of door and backset is as shown in schedule below. Be sure horizontal centerline of device is 39-13/16” from

nished oor.

b. Prepare door as shown.

c. Prepare door for top and bottom bolt guides. See Figures 1 and 2 below.

d. If door requires trim, make additional preparations per trim template.

¹⁄₄"

⁷⁄₃₂" R

"A" or "B" - See

page 4 template

for correct hole

See

backset

schedule

preparation

³⁄₁₆" Min. to

edge of stop

¹⁄₄"

⁷⁄₃₂"

1³⁄₄" Min. stile

width

X

Device & Latch Bolt

C

L

¹⁄₄"

3"

7¹⁄₄"

C

L

Device

DEVICE INSTALLATION SCHEDULE

Installation

Flush hollow metal door

Minimum 1-3/4" to 2-1/2" door stile

Stiles wider than 2-1/2"

Stop height of 1/2" minimum required.

FIG. 1 (TOP PREP)

Device & Latch Bolt

C

L

#12-24 Tap

3 holes

2¹⁄₄"

1³⁄₄"

⁵⁄₈"

1¹⁄₄" Typ.

2⁷⁄₃₂"

³⁄₄"

Backset

from high side

of bevel

2-1/2"

Single Door 1-9/32"

Double Door 1-5/32"

1/2 of stile

¹⁹⁄₆₄"

¹⁹⁄₃₂"

¹⁄₂"

1¹⁄₈"

⁷⁄₈"

C

L

Latch

Bolt

2

"A" or "B" - See

page 4 template

for correct hole

preparation

39¹³⁄₁₆"

to finished

floor

¹⁄₄" max undercut

¹⁵⁄₃₂"

1³⁄₁₆"

or threshold

needed

5¹⁄₂"

¹⁵⁄₁₆"

of trim if required

C

L

X

3"

⁷⁄₃₂"

METAL DOOR

APPLICATION

Inside face of lock stile

LHR shown, RHR opposite

FIG. 2 (BOTTOM PREP)

Device & Latch Bolt

C

L

⁵⁄₈"

1³⁄₄"

2¹⁄₄"

¹⁵⁄₁₆" Dia.

2⁷⁄₃₂"

#12-24 Tap

3 holes

³⁄₄"

¹⁄₂"

¹⁹⁄₆₄"

¹⁹⁄₃₂"

⁷⁄₈"

1¹⁄₈"

C

L

Latch

Bolt

Page 3

THIS PAGE

INTENTIONALLY

BLANK

3

Page 4

DEVICE INSTALLATION SCHEDULE

Installation

Flush hollow metal door

Minimum 1-3/4" to 2-1/2" door stile

Stiles wider than 2-1/2"

Backset

from high side

of bevel

2-1/2"

Single Door 1-9/32"

Double Door 1-5/32"

1/2 of stile

DEVICE

BACKSET

(SEE SCHEDULE)

C

L

BACKSET

(SEE SCHEDULE)

Actual Size

1"

Do Not Scale

Stop height of 1/2" minimum required.

SCREW CHART

Check door material and metal thickness

For correct hole preparation

A B

Aluminum Doors

Unreinforced Hollow Metal Doors

7/32" Dia.

2 holes for sex bolt head

DEVICE

C

L

Reinforced

Hollow Metal Doors

1/4-28 Tap

2 holes for hex stud

XX

RHRLHR

EDGE OF

STOP

(Single door

application

only)

3/16" MIN.MIN. 3/16"

TO FINISHED

4

39¹³⁄₁₆"

FLOOR

EDGE OF

STOP

(Single door

application

only)

IF REQUIRED

OF TRIM

LHR DOOR

C

L

XX

OF TRIM

IF REQUIRED

C

L

RHR DOOR

Page 5

THIS PAGE

INTENTIONALLY

BLANK

5

Page 6

3 Install rod control assembly.

Blind fastener package

Conrm orientation before installing. “Top” and “Bottom” of each assembly is marked with a label. Spring is at the bottom.

A B

ALUMINUM DOOR

UNREINFORCED

HOLLOW METAL DOOR

a. Check metal thickness of door. If 1/8" or less, using blind fastener package,

place a washer under the sex bolt. If metal thickness is greater than 1/8",

omit the washer.

b. Remove burrs and insert sex bolt head into 7/32" diameter hole from interior

of door thru rod control cutout.

c. Thread sex bolt anchor on sex bolt head and tighten.

d. Remove sex bolt anchor and install rod control assembly with spring towards

bottom of door.

e. Replace sex bolt anchors.

Sex bolt

anchor (2)

Use washer for

1/8" or less

thickness only

REINFORCED

HOLLOW METAL DOOR

a. Check for reinforcing. If not reinforced, follow procedure

for aluminum doors. If reinforced, continue with steps b,

c, and d below.

b. Tap 1/4-28 thread for hex stud.

c. Install rod control assembly with spring towards bottom

of door.

d. Using blind fastener package, install hex studs.

Hex stud (2)

#12 S.A.E. washer (2)

Sex bolt head (2)

Sex bolt

anchor (2)

Hex stud (2)

Sex bolt

head (2)

#12 S.A.E.

washer (2)

6

Page 7

4 Assemble top rod according to door height.

Maximum approved door height for a 5547 non-re device is 10’.

• All stock size devices are furnished with adjustable top rods to t door heights from 6’8” to 8’.

• Extension rods are available for door heights up to 10’ (non-re devices only).

e. Assemble top rod tube over hex rod. Align hole in tube that corresponds to predrilled height.

f. Assemble rod member on thumbturn or lever devices if required (376L and 376T only). See directions in control box.

g. Install rod connector pins. Do not peen yet.

Rod connector

Top rod furnished with

(4) predrilled holes to

provide additional

adjustment if required.

6'8" 6'10" 7'0" 7'2" Door

pins

TOP ROD

Rod member used with

376L and 376T trim only

8'0" Door hole

on end

Hex rod Rod connector pin

Miscellaneous Door Heights up to 8'0"

a. Measure door opening height (finished floor to rabbet)

b. Subtract measured height from 8'0" to get difference

c. Measure this difference from the 8'0" hole on the hex rod and mark a line.

d. Assemble top rod tube over hex rod. Align hole in tube with the scribed line.

e. Mark location of the hole in the tube on the hex rod.

f. Drill a 3/16" hole thru the hex rod.

g. Align the holes and install the rod connector pins. Do not peen yet.

7'2" Hole Drill 3/16" Hole 8'0" Hole

Difference

Miscellaneous Door Heights up to 10'0"

a. Measure door opening height (finished floor to rabbet)

b. Subtract measured height from 10'0" to get difference

c. Measure this difference from the 10'0" hole on the hex rod and mark a line.

d. Assemble top rod tube over hex rod. Align hole in tube with the scribed line. Cut hex rod if required.

e. Mark location of the hole in the tube on the hex rod.

f. Drill a 3/16" hole thru the hex rod.

g. Align the holes and install the rod connector pins. Do not peen yet.

Top rod tube

Constant Dimension

Door Opening Height

Difference

For non-fire devices, extension rods are

available for door heights up to 10'.

Constant Dimension

Door Opening Height

Difference

8'0"

-

=

10'0"

-

=

Drill 3/16" Hole 10'0" Hole

Difference

7

Page 8

5 Install cylinder release bracket to top rod assembly (if required).

For 5547NL devices only (supplied with trim).

Note that handing stamped on bracket corresponds

with handing of door.

a. Install cylinder release bracket.

b. Secure with top socket retaining screw.

Cylinder release

bracket

Tabs

Top rod

connector

c

a

Top socket

retaining screw

b

d

6 Set latch projection.

a. Prior to installing top rod assembly into door channel, conrm 1/2” latch projection and alignment to rod control assembly as

shown below. Adjust as needed.

b. Peen the rod connector pins securely.

Align to hole for

socket retaining screw

Top rod furnished with (4) predrilled holes to

provide additional adjustment if required.

1/2" latch

projection

a

Rod control

assembly

Rod connector pins

b

Top

of door

7 Install top rod and bolt guide assembly.

a. Slip top rod assembly thru opening in top of door.

b. Insert top rod connector into rod control assembly. Start socket retaining screw (from blind fastener package) into rod control .

c. Cut top bolt guide as hand of door requires.

d. Install top bolt guide assembly.

Top

of door

b

Rod control

assembly

a

Cut off here for RHR door

Top bolt guide

assembly

c

Cut off here for LHR door

d

8

LHR shown

Page 9

8 Assemble bottom rod.

Bottom rod furnished with four pre-drilled holes

a. Assemble bottom rod. Select correct hole for desired length.

b. Peen the rod connector pin securely.

BOTTOM ROD

Rod connector pin

b

a

to provide additional adjustment if required

9 Install bottom rod and bolt guide assembly.

a. Slip bottom rod assembly thru opening in bottom of door.

b. Insert rod connector into rod control assembly. Start socket retaining screw (from blind fastener package) into rod control.

c. Install bottom bolt guide assembly (cut rst if required).

d. Adjust bottom rod connector until bolt has 1/2” extension, then tighten socket set screw. n

Bottom

of door

a

b

Rod control

assembly

For 1-3/4" narrow

c

stile application,

cut at dotted line.

Bottom

bolt guide

assembly

d

¹⁄₂"

1/4" maximum undercut or threshold needed

9

Page 10

10 Adjust top rod.

a. Depress top latch bolt. It should stay retracted. If latch does

not stay retracted, adjust top rod at rod control assembly.

Depress plunger to verify latch release.

Top of

door

b. If using NL trim, adjust cylinder release bracket to contact

trim cylinder cam, if required. Secure with top socket

retaining screw.

c. Test top and bottom bolt extension and retraction by lifting

rod control with screwdriver or equivalent tool. Full latch

bolt extension is 1/2”.

Top of

door

Adjust rod member as needed (376L and 376T trim only).

11 Apply outside trim (if required).

a. See directions in trim carton. Line “X-X” on trim template

corresponds to line “X-X” on device template and is parallel

to edge of door. Locate line “X-X” on outside face of door.

b. Prepare outside face of lock stile and apply trim.I

12 Attach lock stile case to door.

Use short screws from device mounting package 900520.

13 Hang door and install sill strike or threshold, if any.

C

of Bolt

L

1⁷⁄₈"

¹⁄₄"

304L Strike

FLAT SILL

APPLICATION

C

of Bolt

L

10

³⁄₄" Dia.

LATCH TRACK

THRESHOLD APPLICATION

Page 11

14 Install sot strike.

a. For wood frame, locate sot strike position and mortise

frame for strike.

• 472-U strike for 1-3/4” thick door

• 473-U strike for 2-1/4” thick door

C

Latch bolt

L

¹⁄₂"

b. For non-reinforced metal frame, locate sot strike position

and prepare for 471-U strike. Double door application

shown. For single door application use appropriate handing

as shown

Suggested

mortar guard

6" Min.

1" Min.

472-U strike for 1³⁄₄" doors

473-U strike for 2¹⁄₄" doors

1¹⁄₁₆"

2¹⁄₈"

#10 wood screws for

wood frames, 4 holes.

Size of pilot holes

for wood frames depends

on hardness of wood

²⁵⁄₃₂"

1⁹⁄₁₆"

WOOD FRAME PREPARATION

1"

1¹⁄₂"

¹⁵⁄₁₆" ¹⁄₁₆"

⁷⁄₁₆"

³⁄₈"

³⁄₄"

Edge of

stop

⁷⁄₈"

¹⁄₂"

¹⁄₈"

C

L

Latch bolt

¹⁄₁₆" to ³⁄₃₂"

Door opening -

C

L

double door application

Latch bolt

C

L

LHR door

1⁵⁄₁₆"

²¹⁄₃₂"

¹⁵⁄₁₆"

⁷⁄₈"

1³⁄₄"

Double door application

shown. For single door

application, use appropriate

handing as shown.

¹⁷⁄₃₂"

1¹⁄₁₆"

⁹⁄₃₂"

³⁄₁₆" Dia.

C'sink ⁵⁄₁₆" Dia.

x 82° in frame

2 holes each strike

Latch bolt

C

L

RHR door

471-U STRIKE

HOLLOW METAL FRAME PREPARATION

Edge of stop

Strike

C

L

⁹⁄₃₂"

c. For aluminum and reinforced hollow metal frame

preparation, see below.

1⁵⁄₁₆" Min.

⁷⁄₁₆"

⁷⁄₈"

³⁄₄"

Edge of stop

Latch

C

L

bolt

REINFORCED HOLLOW METAL

AND ALUMINUM FRAME PREPARATION

11

Page 12

15 Apply hinge stile case and crossbar tube.

case parallel to

a. Remove lever arm wedge-tite set screws. Make sure

wedges and split rings are installed on lever arms.

a. Dog lever arms in depressed position.

b. Slip crossbar tube on lock stile and hinge stile lever arms.

(See instruction 941009 for cutting crossbar, if necessary.)

c. Be sure crossbar is level and hinge stile case is parallel to

edge of door and approximately on centerline of exposed

stile.

Exposed stile

C

L

Mark door

for location

of sex bolts

Device

C

L

Hinge stile

edge of door

39¹³⁄₁₆"

to finished

floor

d. Using holes in hinge stile case, mark location and prepare

door for sex bolts. Drill 13/32” dia. outside and 3/8” dia.

inside.

e. Seat sexbolts in hinge stile of door with a soft hammer to

prevent marking of door and sexbolts.

f. With crossbar in place, install hinge stile case using 625

sexbolts and C\v” mounting screws from mounting package

900520.

g. Tighten wedge-tite set screws securely with dog key and

screwdriver or equivalent for leverage, and test crossbar for

free action. (See instruction 941009.)

Customer Service

1-877-671-7011 www.allegion.com/us

© Allegion 2019

Printed in U.S.A.

911066-00 Rev. 03/19-c

Loading...

Loading...