Piston Diaphragm

Dosing Pump

KM 254

Operation Manual

15.720039-V1.0

Please read the Operating and Servicing Manual completely and retain for future reference!

KM 254 en

Imprint

Piston Diaphragm Dosing Pump KM 254

Operation Manual

Version 1.0

Issued by

ALLDOS Eichler GmbH

Reetzstraße 85 • 76327 Pfinztal (Söllingen)

Postfach 1160 • 76317 Pfinztal

Germany

Tel. ++49 (0) 72 40 61-0 / Fax. ++49 (0) 72 40 61-177

Mail: alldos.de@alldos.com

Internet: www.alldos.com

© 2005 by ALLDOS Eichler GmbH

Subject to change.

2 15.720039-V1.0

KM 254 en

Content

Imprint............................................................................................. 2

1 General ........................................................................................... 6

1.1 Introduction ......................................................................................6

1.2 Information About the Product .........................................................6

1.2.1 Pump Types ..................................................................................6

1.2.2 Pump Performance ........................................................................6

1.2.3 Accuracy ........................................................................................7

1.2.4 Admission Pressure and Counterpressure / Suction Height .........7

1.2.5 Sound Pressure Level ...................................................................8

1.2.6 Degree of Protection .....................................................................8

1.2.7 Mains Voltage ................................................................................8

1.2.8 Ambient and Operating Conditions ................................................8

1.2.9 Dosing Medium ..............................................................................9

1.3 Application of the Device .................................................................9

1.3.1 Appropriate, Acceptable and Correct Usage .................................9

1.4 Warranty ........................................................................................10

2 Safety ........................................................................................... 11

2.1 Identification of Safety Instructions in the Operation Manual ........11

2.2 Qualification and Training of Personnel .........................................11

2.3 Risks When Safety Instructions Are Not Observed .......................11

2.4 Safety-Conscious Working ............................................................11

2.5 Safety Instructions for the Operator / User ....................................12

2.6 Safety Instructions for Maintenance, Inspection and Installation

Work ..............................................................................................12

2.7 Unauthorised Modification and Manufacture of Spare Parts .........12

2.8 Improper Operating Methods .........................................................12

2.9 Safety of the System in the Event of a Failure in the Dosing

System ...........................................................................................13

3 Transport and Intermediate Storage ............................................. 14

3.1 Transport .......................................................................................14

3.1.1 Delivery .......................................................................................14

3.1.2 Return ..........................................................................................14

3.2 Unpacking ......................................................................................14

3.3 Intermediate Storage .....................................................................14

4 Product Description and Accessories ........................................... 15

4.1 General Description .......................................................................15

4.1.1 Combined overpressure and degassing valve ............................16

4.1.2 Diaphragm protection system AMS .............................................16

4.1.3 Double diaphragm system / Diaphragm breakage signal

(optional) .....................................................................................16

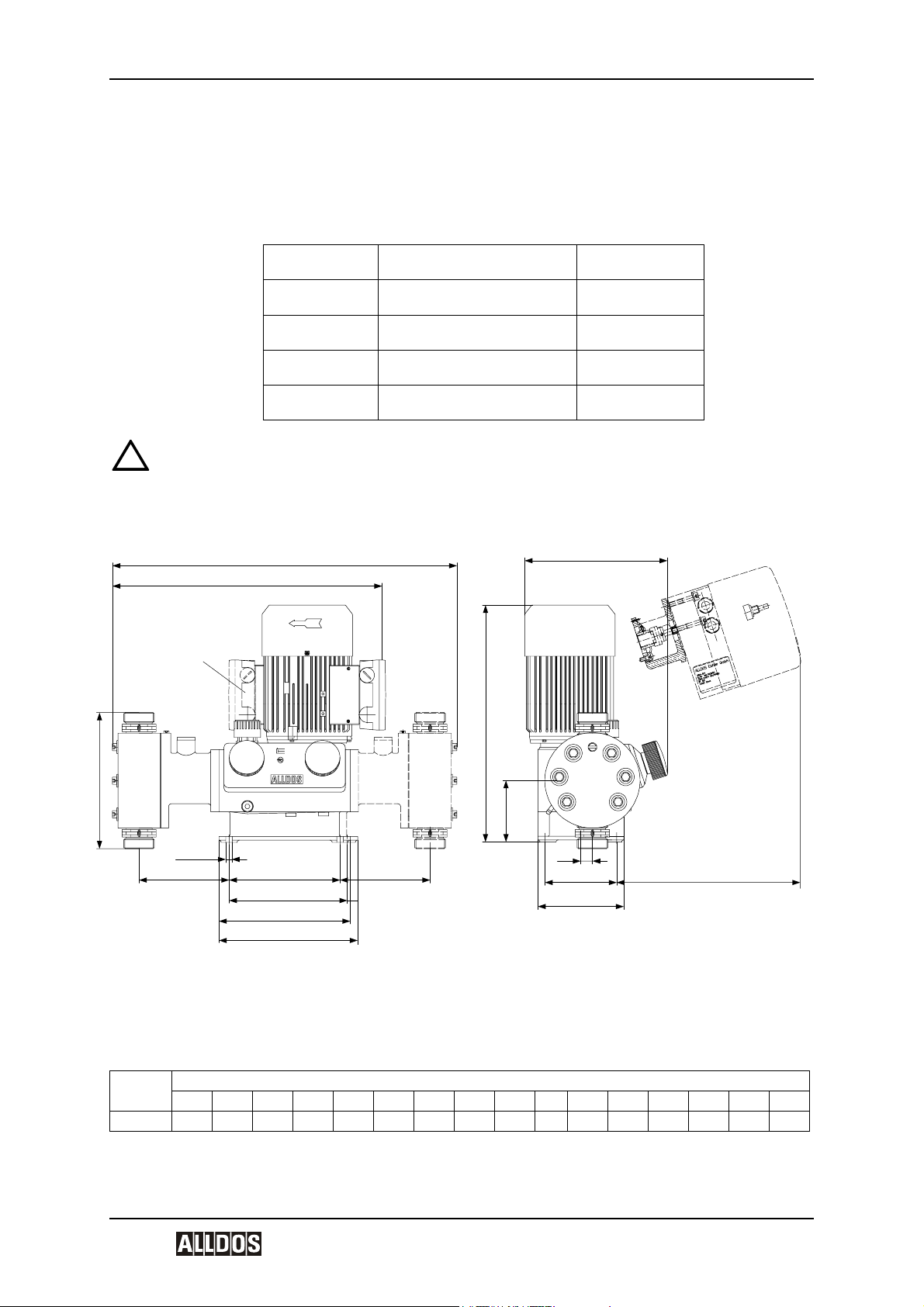

4.2 Dimensional Drawing ....................................................................17

4.3 Weight ...........................................................................................18

4.4 Stroke volume ................................................................................18

V1.0 III

KM 254 en

4.5 Versions ......................................................................................... 18

4.5.1 Dosing heads: Materials and Additional Features ....................... 18

4.5.2 Valves: Materials and Additional Features ..................................18

4.6 Materials ........................................................................................19

4.7 Data of contact manometer for MBS (optional) .............................19

4.8 Installation Location .......................................................................19

4.8.1 Space Required for Operation and Maintenance ........................19

4.8.2 Permissible Ambient Influences ..................................................19

4.8.3 Underground ...............................................................................20

5 Installation .................................................................................... 21

5.1 Mounting ........................................................................................21

5.2 General Information on Installation ................................................21

5.2.1 Approximate values when using pulsation dampers ...................21

5.2.2 Installation Examples and Tips ....................................................22

5.3 Tube/Pipe Lines .............................................................................25

5.3.1 General ........................................................................................25

5.3.2 Connecting the Suction and Pressure Lines ...............................25

5.3.3 Connecting a liquid-heated dosing head (optional) .....................25

6 Electrical Connections .................................................................. 27

6.1 Electrical servomotor (optional) .....................................................27

6.2 Electronic stroke preset counter (optional) ....................................27

6.3 Electrically heated dosing head (optional) .....................................27

6.4 Diaphragm control (optional) .........................................................27

6.5 Connecting the Power Supply Cable .............................................28

7 Start-up/Shutdown ........................................................................ 29

7.1 Safety Information .........................................................................29

7.2 Initial Start-Up/Subsequent Start-Up .............................................29

7.2.1 Checks Before Start-Up ...............................................................29

7.2.2 Oil filling .......................................................................................29

7.2.3 Filling the dosing head for the initial start-up for systems

without dosing medium flooded suction .......................................29

7.2.4 Start-Up/Subsequent Start-Up .....................................................30

7.2.5 After start-up ................................................................................30

7.3 Setting the pressure relief valve ....................................................31

7.4 Zero Point Adjustments .................................................................31

7.4.1 Adjusting the zero point for system pressures up to 100 bar ......31

7.4.2 Adjusting the Zero Point ..............................................................32

7.5 Operating the pump .......................................................................32

7.6 Shutdown ....................................................................................... 33

7.6.1 Switching Off/Uninstalling ............................................................33

7.6.2 Cleaning ......................................................................................33

7.6.3 Storage ........................................................................................33

7.6.4 Disposal .......................................................................................33

IV 15.720039-V1.0

KM 254 en

8 Operating the Pump ..................................................................... 34

8.1 Switching On/Off ............................................................................34

8.1.1 Switching On the Pump ...............................................................34

8.1.2 Switching Off the Pump ...............................................................34

8.2 Setting the dosing capacity ............................................................34

8.2.1 Setting the dosing flow and locking the stroke adjustment

button ..........................................................................................34

8.3 Electrical servomotor (optional) .....................................................34

8.4 Electronic stroke preset counter (optional) ....................................34

8.5 Electrically heated dosing head (optional) .....................................34

9 Maintenance ................................................................................. 36

9.1 General Notes ...............................................................................36

9.2 Diaphragm breakage control for diaphragm breakage signal ........36

9.3 Intervals for cleaning and maintenance .........................................36

9.4 Checking the oil level .....................................................................37

9.5 Cleaning the suction and pressure valves .....................................37

9.6 Changing the diaphragm and gear oil for dosing head with single

diaphragm (no MBS) .....................................................................39

9.6.1 Drain gear oil ...............................................................................39

9.6.2 Removing the dosing head ..........................................................39

9.6.3 Replacing a single diaphragm (no MBS) ..................................... 39

9.6.4 Fitting the dosing head ................................................................40

9.6.5 Filling gear oil ..............................................................................40

9.6.6 Checking the oil level. ..................................................................40

9.7 Replacing the diaphragm for dosing head with double diaphragm 41

9.7.1 Removing the dosing head ..........................................................41

9.7.2 Replace the double diaphragm. ...................................................41

9.7.3 Fitting the dosing head ................................................................42

9.7.4 Filling the double diaphragm with separating agent ....................42

9.7.5 Filling gear oil ..............................................................................43

9.7.6 Checking the oil level. ..................................................................43

9.7.7 Cleaning the ball check valve ......................................................43

10 Possible Errors ............................................................................. 45

11 Spare Parts ................................................................................... 47

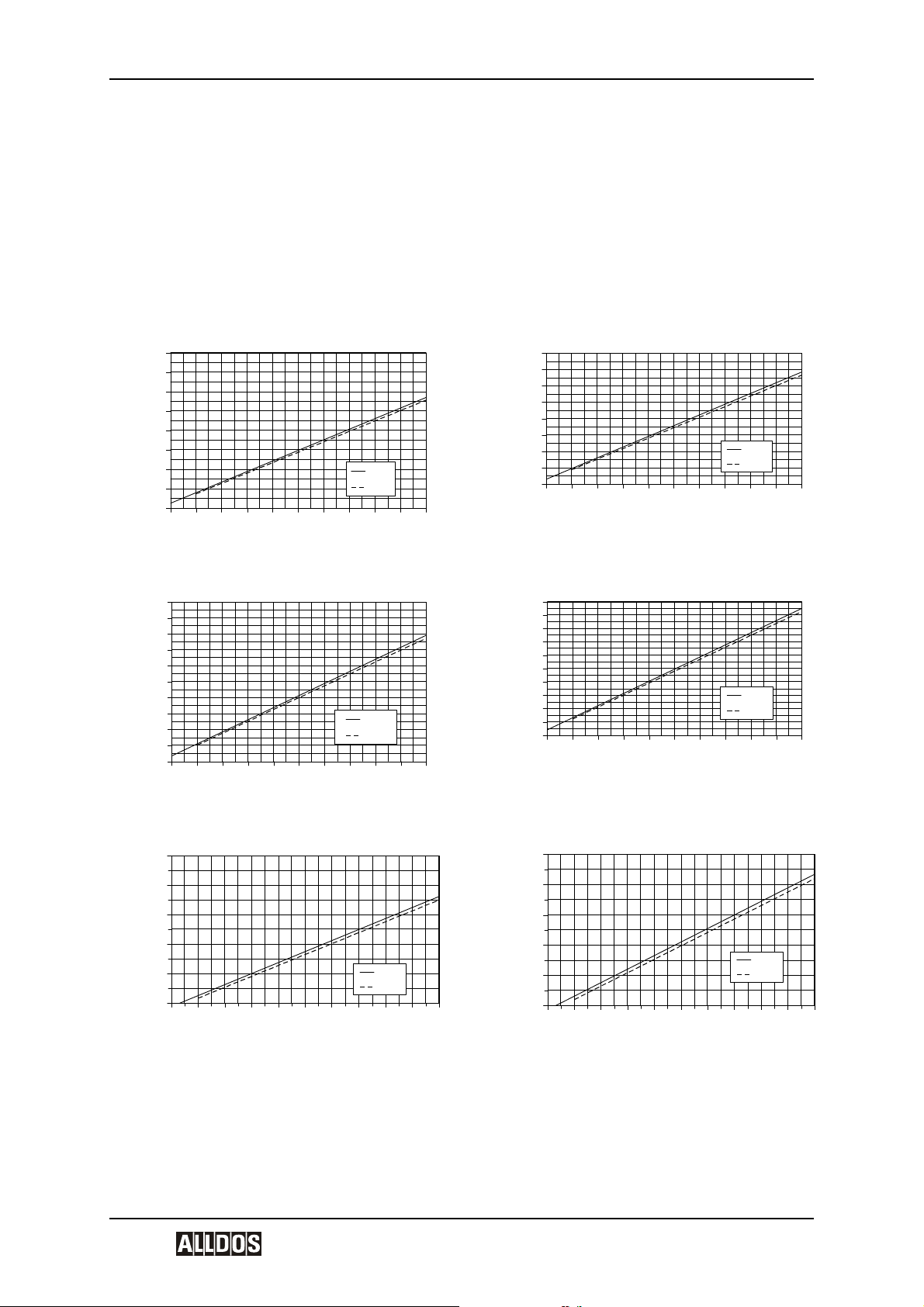

12 Dosing Curves .............................................................................. 49

EC Declaration of Conformity (Translation).................................. 52

V1.0 V

1 General

1.1 Introduction

This operation manual contains all the information required for starting up and handling

the described KM 254 pump.

If you require further information or if any problems arise, which are not discussed in

detail in this operation manual, contact ALLDOS directly for the information needed.

ALLDOS Eichler GmbH

Reetzstr. 85

D-76327 Pfinztal (Söllingen), Germany

The ALLDOS service centre can be reached via our fax service or hotline:

Fax: ++49 (0) 61-211 - Reference "Quality Service"

Hotline: ++49 (0) 61-230

1.2 Information About the Product

1.2.1 Pump Types

The KM 254 piston diaphragm dosing pump is available for a variety of power ranges in

various sizes:

Pump types and designation see type plate

The following is indicated on the type plate of the pump:

• The pump type

specifies the stroke volume, connection size, performance data (see below).

• The serial number of the pump

which is used to store and access the pump configuration at ALLDOS.

• The most important characteristics of the pump configuration

e.g. for dosing head and valve materials, they are described in the "Product Descrip-

tion and Accessories" section.

• Maximum flow rate, maximum counterpressure

• Mains frequency

KM 254 en

The following is indicated on the type plate of the pump drive:

• required energy

• mains frequency

• power consumption

• degree of protection

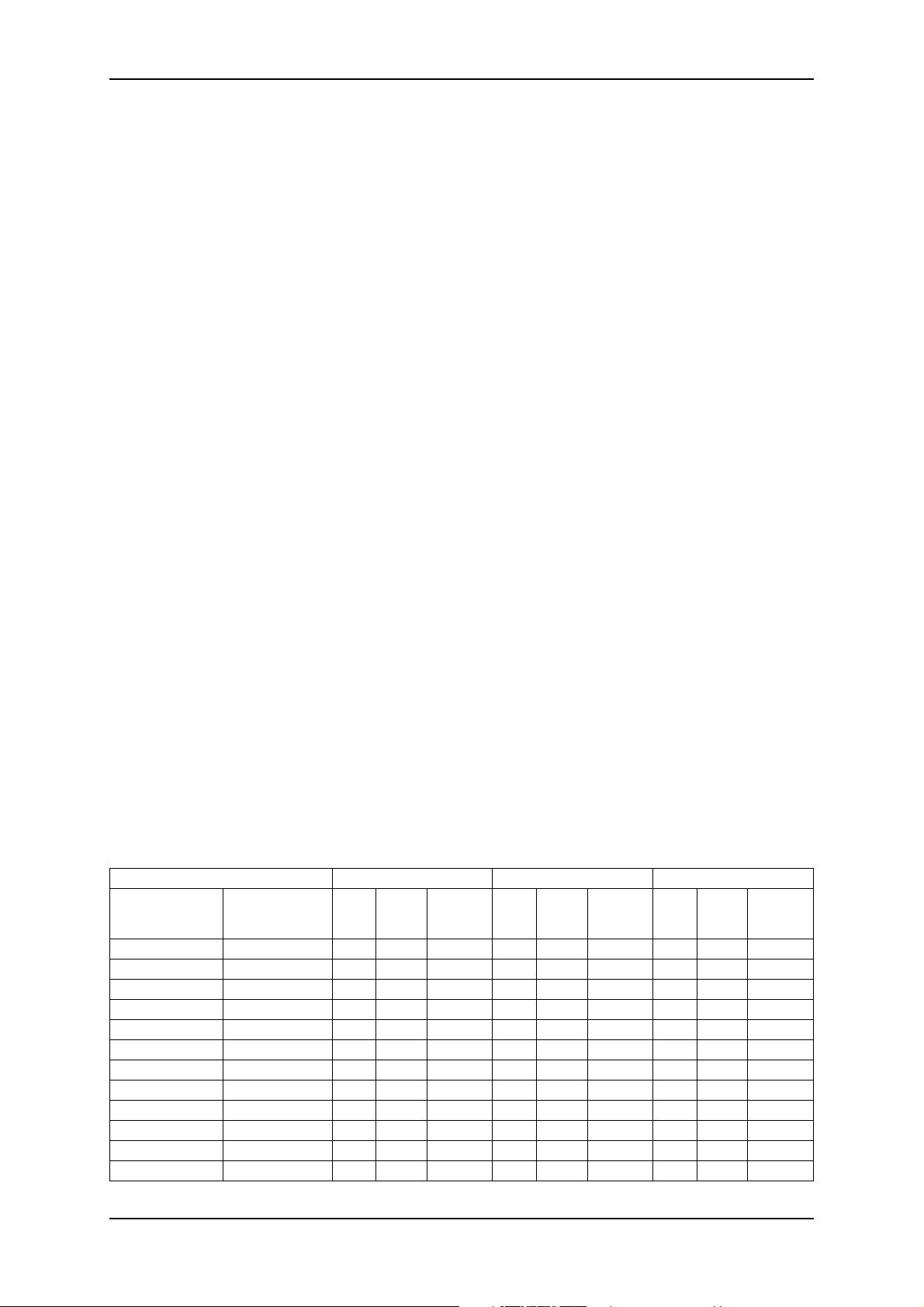

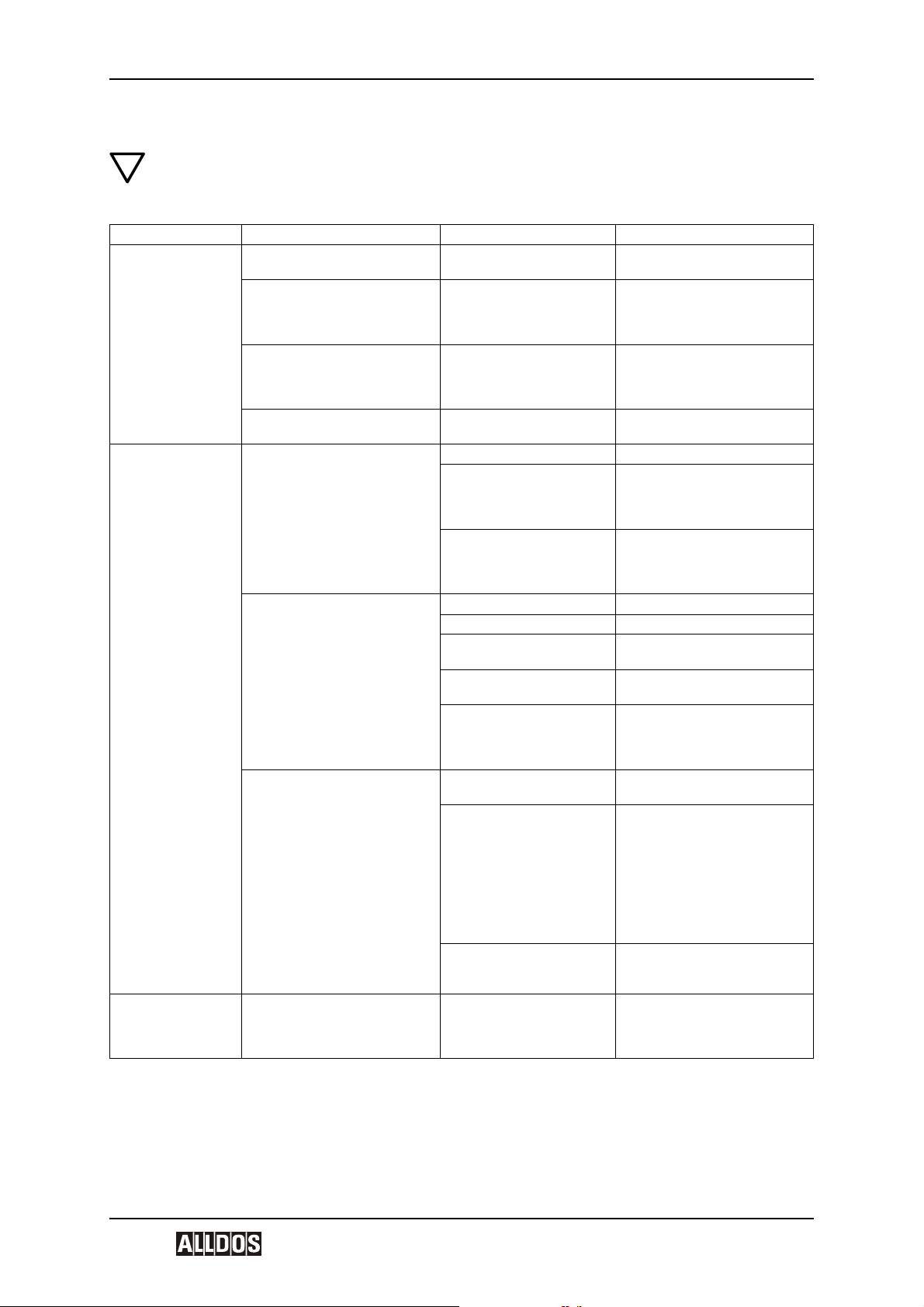

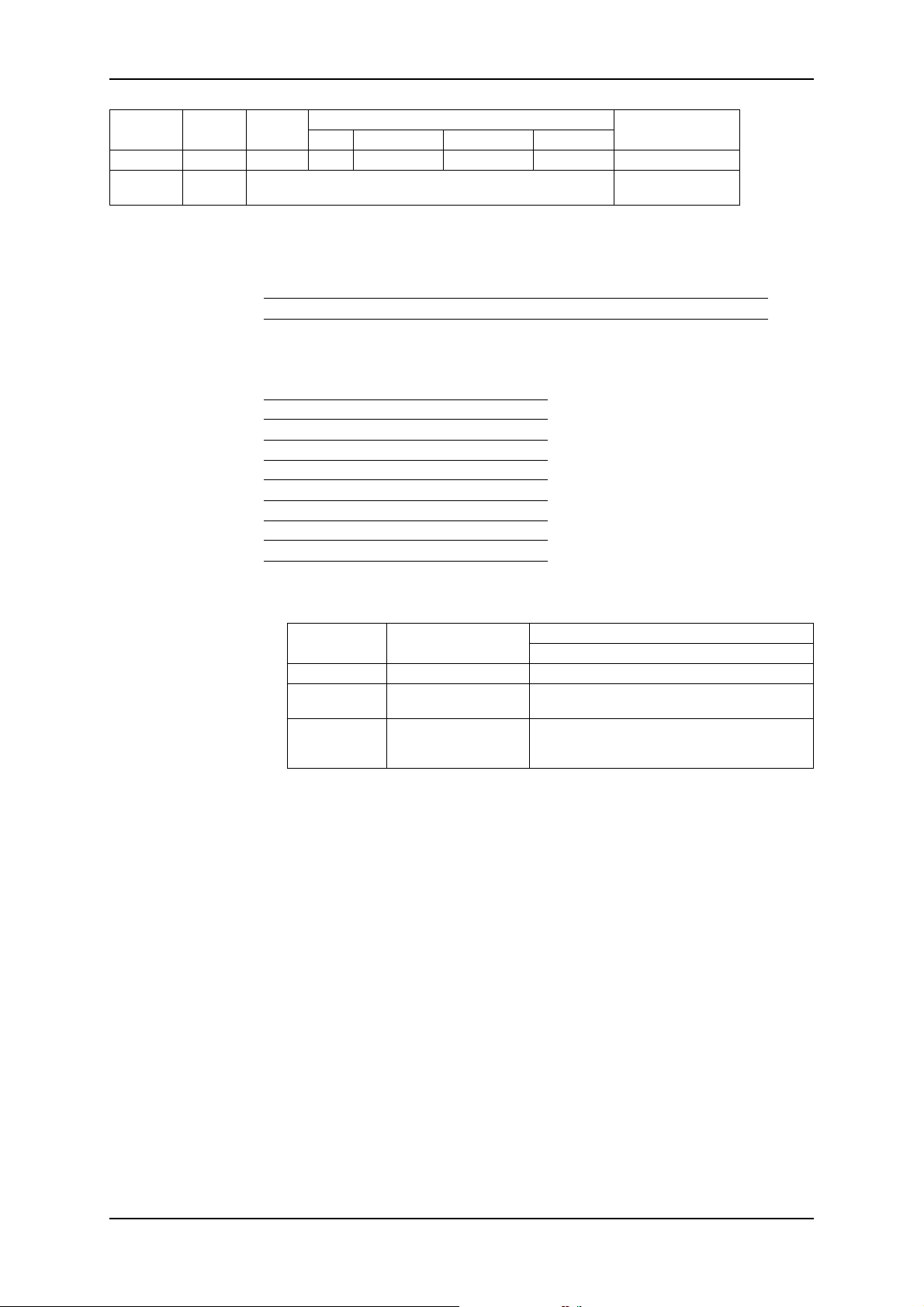

1.2.2 Pump Performance

Performance data at maximum pump counterpressure

Type 50 Hz 60 Hz 100 Hz

Q*

p max

[l/h]

Singlepump Doublepump

254-50 254-50/2 50 10 26 60 10 31 101 10 52

254-102 254-102/2 102 10 54 122 10 65 203 10 108

254-143 254-143/2 143 10 75 172 10 90 286 10 150

254-175 254-175/2 175 10 92 210 10 110 — — —

254-213 254-213/2 213 10 112 255 10 134 — — —

254-291 254-291/2 291 10 153 — — — — — —

254-46 254-46/2 46 16 26 55 16 31 92 16 52

254-97 254-97/2 97 16 54 116 16 65 193 16 108

254-136 254-136/2 136 16 75 163 16 90 271 16 150

254-166 254-166/2 166 16 92 200 16 110 — — —

254-202 254-202/2 202 16 112 242 16 134 — — —

254-276 254-276/2 276 16 153 — — — — — —

[bar]

stroke

value

[n/min]

Q*

[l/h]

p max

[bar]

stroke

value

[n/min]

Q*

[l/h]

p max

[bar]

stroke

value

[n/min]

6 15.720039-V1.0

KM 254 en General

* l/hr per dosing head; double the capacity for double pumps.

Note

The pump can be operated in the range between 10% and 100% of the maximum

dosing capacity.

1.2.3 Accuracy

Note

Dosing flow

smaller ± 1 %

fluctuation

Linearity

deviation

±1 % of the full-scale value (for water with a fully deaerated

dosing head)

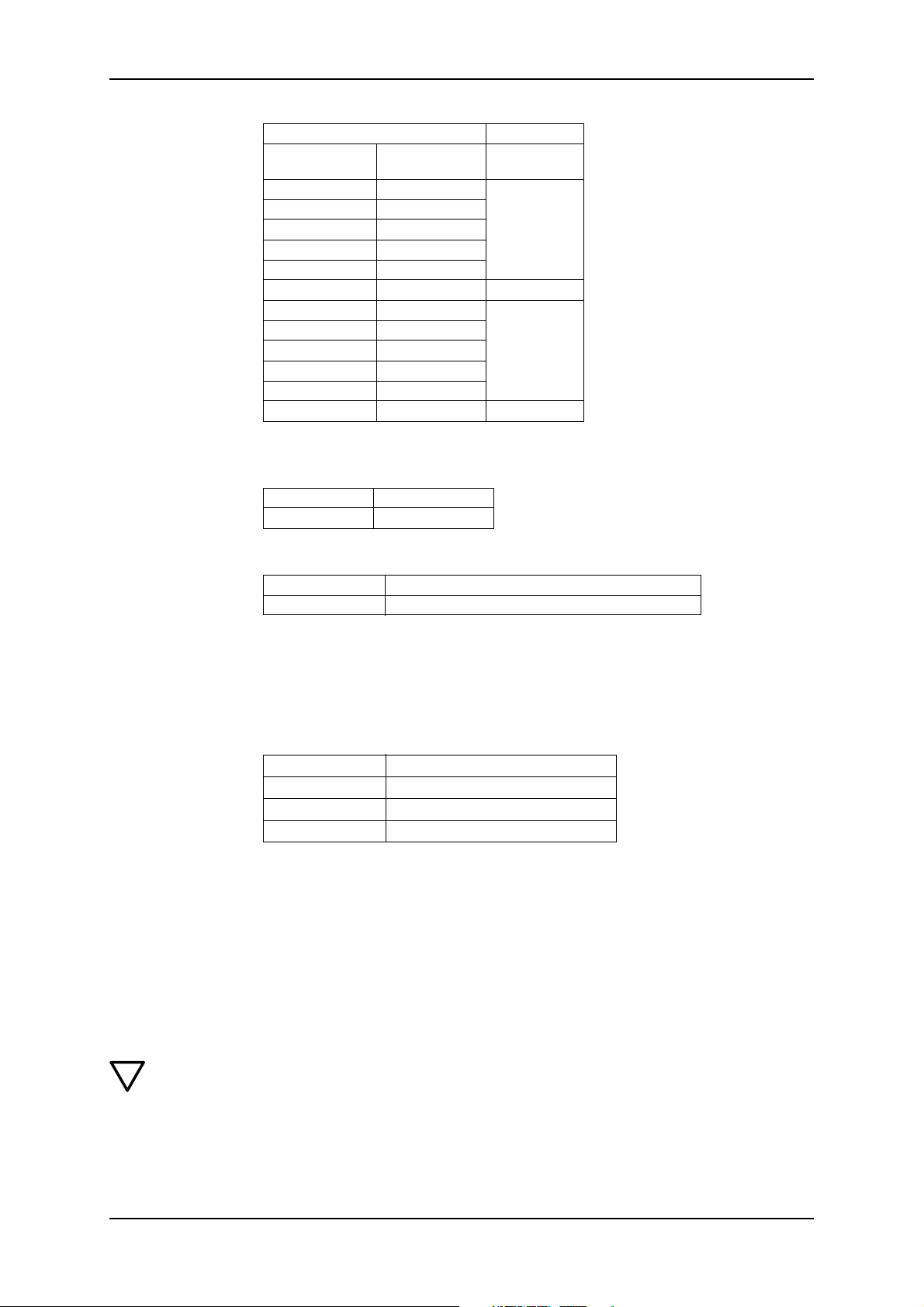

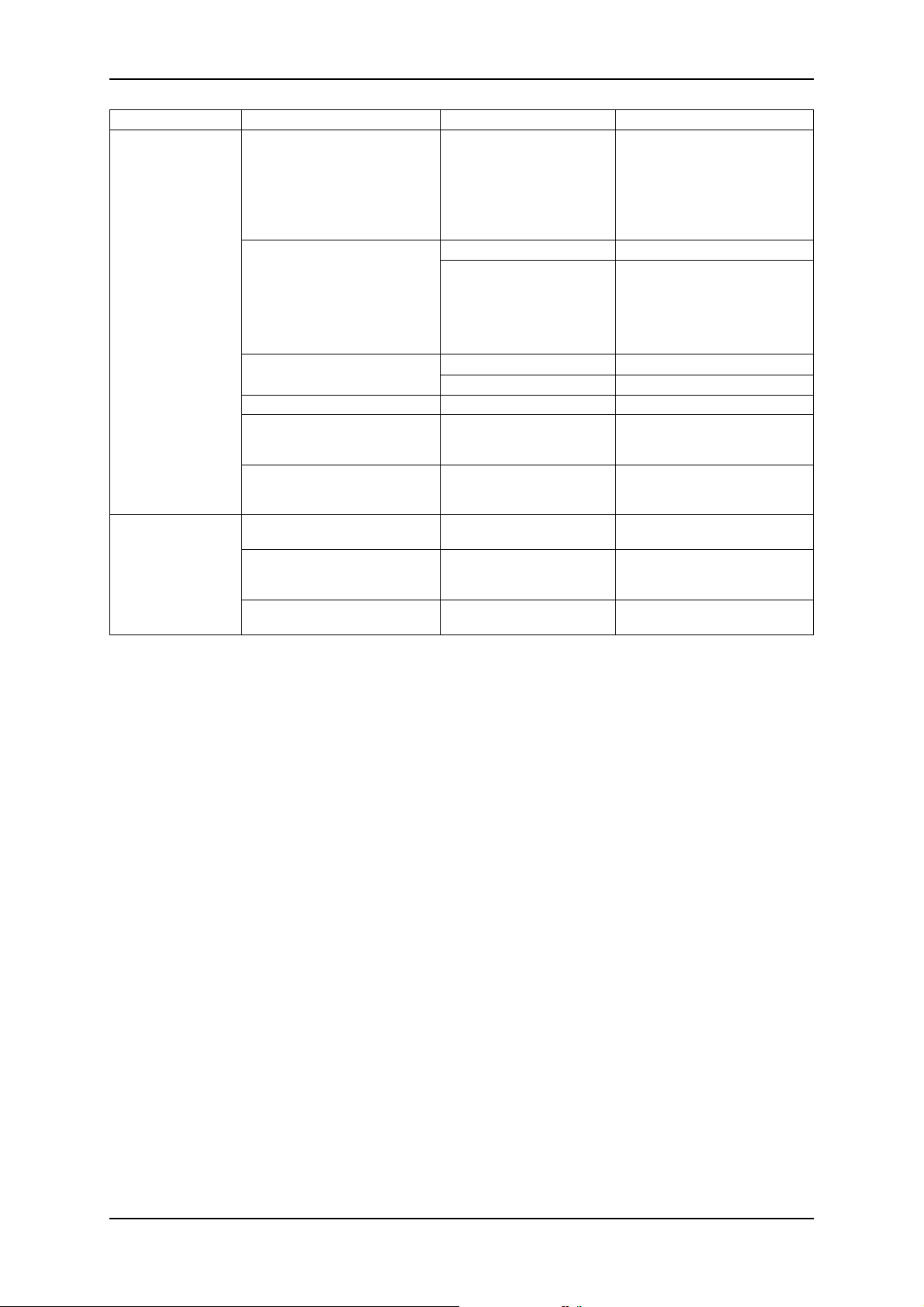

1.2.4 Admission Pressure and Counterpressure / Suction Height

Maximum admission pressure at the suction side [bar]

Typ e [bar]

KM 254 5

Minimum counterpressure at the pressure valve of the pump [bar]

Typ e [bar]

KM 254 2

A positive pressure difference of 2 bar min. is required between the suction valve

and the pressure valve in order for the dosing pump to operate correctly. If the total

counterpressure (at the dosing point) and geodetic height difference between the

suction valve and the dosing point is less than 2 bar (20 m WS), a pressure

retention valve must be installed directly in front of the dosing point.

Maximum counterpressure* [bar]

Typ e

Singlepump Doublepump

254-50 254-50/2

254-102 254-102/2

254-143 254-143/2

254-175 254-175/2

254-213 254-213/2

254-291 254-291/2

254-46 254-46/2

254-97 254-97/2

254-136 254-136/2

254-166 254-166/2

254-202 254-202/2

254-276 254-276/2

*Observe the maximum permissible temperatures

p max

[bar]

10

16

V1.0 7

Maximum suction height * [m] for media with a viscosity similar to water

Typ e

Singlepump Doublepump

254-50 254-50/2

254-102 254-102/2

254-143 254-143/2

254-175 254-175/2

254-213 254-213/2

254-291 254-291/2 flooded suction

254-46 254-46/2

254-97 254-97/2

254-136 254-136/2

254-166 254-166/2

254-202 254-202/2

254-276 254-276/2 flooded suction

*applies to a filled dosing head

Maximum suction height [m] for media with maximum permissible viscosity

Typ e [m]

KM 254 flooded suction

Suction height

max. [m WS]

1

1

KM 254 en

1.2.5 Sound Pressure Level

Type

KM 254 65 ± 5 dB (A), testing according to DIN 45635-01-KL3

1.2.6 Degree of Protection

Depending on the motor variant that is selected, see type plate of the motor.

The specified degree of protection can only be ensured, if the mains cable is connected

with the same degree of protection.

1.2.7 Mains Voltage

Power supply for AC voltage

Nominal voltage Deviation from the nominal value

230 / 400 V ± 10 %

240 / 415 V ± 10 %

115 V ± 10 %

max. permissible mains impedance

(0.084 + j 0.084) Ohm (testing according to DIN EN 61000-3-11)

these details refer to 50 Hz

1.2.8 Ambient and Operating Conditions

Permissible ambient

temperature

Permissible

storage temperature

Permissible humidity relative humidity: 70% at 40 °C, 90% at 35 °C

0 °C to + 40 °C (for an installation height up to 1000 m over NN)

- 20 °C to + 70 °C

Caution

Risk of malfunction or damage to the device!

The installation site must be under cover!

Pumps with electronics are only suitable for indoor use!

Do not install outdoors!

8 15.720039-V1.0

KM 254 en General

1.2.9 Dosing Medium

Note

In the event of questions regarding the material resistance and suitability of the KM

254 for specific dosing media, please contact the manufacturer.

The dosing medium must fulfil the following characteristics for standard version

pumps:

•Liquid

• Non-abrasive *

• non-combustible **

* The dosing of abrasive media is possible with certain versions, on request,

** the dosing of combustible media is possible with certain versions of explosion protected pumps, in

according with ATEX.

Maximum permissible viscosity at operating temperature*

up to stroke

Typ e

KM 254 300 100 5

* The specified values are approximate values and refer to

the standard version of pumps.

Dosing Medium:

Newtonian liquid

non-degassing

without suspended matter

density similar to water

Please note the increasing viscosity at lower temperatures!

value 63 [n / min]

Viscosity (max.) * mPas

stroke value 64 - 120

[n / min]

from stroke

value 121 [n /

min]

Caution

Caution

Permissible media temperature

Dosing head

material

PVC 0 °C 40 °C 20 °C

1.4571 * -10 °C 100 °C 100 °C

2.4610 * -10 °C 100 °C 100 °C

PP 0 °C 40 °C 20 °C

PVDF -10 °C

* At 70°C maximum counterpressure of 3 ba

* For SIP/CIP applications, 145 °C is permissible for a short period of time (approx. 15 min) at < 2

bar.

Min. media

temperature

Max. media temperature < 10 bar

60 °C

70° C at 9 bar

Max. media temperature < 16 bar

20 °C

Risk of malfunction or damage to the device!

The dosing medium must be in liquid phase!

Observe the freezing and boiling point of the dosing medium!

Risk of malfunction or damage to the device!

The resistance of the parts that come into contact with the media depends on the

media, media temperature and operating pressure. Ensure the parts that come into

contact with the media are chemically resistant to the dosing medium in operating

conditions!

Observe the manufacturer's safety instructions when handling chemicals!

Observe limitations of dosing media depending on type of pump!

1.3 Application of the Device

1.3.1 Appropriate, Acceptable and Correct Usage

The KM 254 pump, described here is suitable for dosing liquid media strictly in accordance with the instructions in this manual.

V1.0 9

Note

!

Warning

!

Warning

1.4 Warranty

KM 254 en

Pumps in explosion protected version are identified accordingly on the pump type

plate and motor type plate, and an EC Declaration of conformity is provided in

accordance with guidelines 94/9/EC, which replaces the EC Declaration of conformity which is printed in this instruction manual.

To operate a pump which has been identified as an explosion protected pump for

the dosing of combustible liquids or for operation in potentially explosive operating sites in accordance with guideline 94/9/EC, refer to the enclosed instruction

manual “Operating an explosion protected pump” in addition to this operation

manual.

Other applications or the operation of pumps in ambient and operating conditions,

which are not approved, are considered improper and are not permitted. ALLDOS

Eichler GmbH accepts no liability for any damage resulting from incorrect use.

Warranty in accordance with our general terms of sales and delivery shall only be valid if:

• The KM 254 pump is used in accordance with the information within this operation

manual

• The KM 254 pump is not opened or incorrectly handled

• Repairs are only carried out by authorised and qualified personnel

• Only original spare parts are used for repairs

10 15.720039-V1.0

KM 254 en Safety

2 Safety

This operation manual contains general instructions that must be observed during installation, operation and maintenance of the pump. This operation manual must therefore be

read by the installation engineer and the relevant qualified personnel/operators prior to

installation and start-up, and must be available at the installation location of the pump at

all times.

It is not only the general safety instructions described in this "Safety" section that must be

observed, but all special safety instructions that are provided in the other sections.

2.1 Identification of Safety Instructions in the Operation Manual

Safety instructions or other advice included in this operation manual, which, if not followed

could result in personal injury or damage to the pump and its functions, are identified with

the following symbols:

!

Warning

Risk of accidents and injury!

Warning

Risk accidents and injury caused by electrical voltage!

Caution

Risk of malfunction or damage to the device!

Note

There is an exceptional feature.

Information provided directly on the pump, e.g.

• Labelling of fluid connections

• Arrow indicating the direction of rotation

must be observed and must be legible at all times.

2.2 Qualification and Training of Personnel

Operating, maintenance, inspection and installation personnel must have the relevant

qualifications. The responsibility and supervision of personnel must be strictly controlled

by the operator. Personnel must be trained and instructed if they do not have the required

level of knowledge. If necessary, this can be done by the manufacturer/supplier at the

request of the operator of the pump. It is the responsibility of the operator to make sure

that the contents of the operation manual are understood by the personnel.

2.3 Risks When Safety Instructions Are Not Observed

If safety instructions are not observed, this may have dangerous consequences for

humans, the environment and the pump. If safety instructions are not observed, this may

lead to the loss of any claims for damages.

If individual safety instructions are not observed, this may cause the following damage, for

example:

• Failure of important functions of the pump/system

• Failure of specified methods for maintenance

• Harm to humans from exposure to electrical, mechanical and chemical influences

• Damage to the environment from leakage of harmful substances

2.4 Safety-Conscious Working

The safety instructions described in this operation manual, applicable national regulations

for accident prevention and any internal working, operating and safety regulations of the

operator must be observed.

V1.0 11

KM 254 en

2.5 Safety Instructions for the Operator / User

Hazardous hot or cold parts on the pump must be protected to prevent accidental contact.

Leakages of dangerous substances (e.g. hot, toxic) must be disposed of in a way that is

not harmful to humans or the environment. Legal regulations must be observed.

Damage caused by electrical energy must be prevented (for more details see, e.g. the

regulations of the VDE and the local power supply company).

2.6 Safety Instructions for Maintenance, Inspection and Installation Work

The operator is responsible for ensuring that all maintenance, inspection and installation

work is carried out by authorised and qualified personnel, who have been adequately trained by reading the operation manual.

All work on the pump should only be carried out when it is stopped. The procedure described in the operation manual for stopping the pump must be observed.

Pumps or pump units which produce media that are harmful to health must be decontaminated.

All safety and protective equipment must be immediately restarted or put into operation

once work is complete.

Observe the points described in the initial start-up section prior to subsequent start-up.

Warning

Electrical connections should only be connected by qualified personnel!

The pump housing must only be opened by personnel authorised by ALLDOS!

Observe the manufacturer's safety instructions when handling chemicals.

When working on the dosing head, connections or lines:

Wear the necessary protective clothing (goggles, gloves)!

Before removing the dosing head, valves and media lines, empty any remaining

medium in the dosing head into a driptray by carefully unscrewing the suction

valve.

!

Warning

Install pump so that it is easily accessible for operation and maintenance purposes.

Observe the resistance of the parts that come into contact with the media depends

on the media, media temperature and operating pressure! Observe the restrictions

of the dosing media depending on the pump type.

Only use the specified line types!

Do not open pump, electronics and sensors!

Repairs must only be carried out by authorised and qualified personnel!

Observe flow direction (arrow) of valves!

Do not operate pump next to closed slides. Risk of damage!

2.7 Unauthorised Modification and Manufacture of Spare Parts

Modification or changes to the pump are only permitted following agreement with the

manufacturer. Original spare parts and accessories authorised by the manufacturer are

safe to use. Using other parts can result in liability for any resulting consequences.

2.8 Improper Operating Methods

The operational safety of the supplied pump is only ensured if it is used in accordance

with the "General" section of the operation manual. The specified limit values should on

no account be exceeded.

Note

Pumps in explosion protected version are identified accordingly on the pump type

plate and motor type plate, and an EC Declaration of conformity is provided in

accordance with guidelines 94/9/EC, which replaces the EC Declaration of

conformity which is printed in this instruction manual.

12 15.720039-V1.0

KM 254 en Safety

!

Warning

To operate a pump which has been identified as an explosion protected pump for

the dosing of combustible liquids or for operation in potentially explosive operating sites in accordance with guideline 94/9/EC, refer to the enclosed instruction

manual “Operating an explosion protected pump” in addition to this operation

manual.

If the assumption is made that a safe operation is no longer possible, switch off the

pump and protect it against unintentional operation.

This action should be taken

• if the pump has been damaged,

• if the pump no longer seems to be operational,

• if the pump has been stored for an extended period of time in poor conditions.

2.9 Safety of the System in the Event of a Failure in the Dosing System

KM 254 dosing pumps are designed according to the latest discoveries and are carefully

manufactured and tested. However, a failure may occur in the dosing system. Systems in

which dosing pumps are installed must be designed in such a way that the safety of the

entire system is still ensured following a failure of the dosing pump. The relevant monitoring and control functions are designed for this.

V1.0 13

3 Transport and Intermediate Storage

3.1 Transport

Caution

Risk of malfunction or damage to the pump! Do not throw or drop the pump.

3.1.1 Delivery

The piston diaphragm dosing pump KM 254 is supplied in different packaging depending

on the overall delivery. For transport and intermediate storage, use the correct packaging

to protect the pump against damage.

3.1.2 Return

Clean the pump thoroughly

• before it is returned or stored. It is essential that there are no traces of toxic or

hazardous media remaining on the pump,

• Drain oil from the drive mechanism,

• package pump correctly.

Caution

Risk of malfunction or damage to the pump! ALLDOS accepts no liability for

damage caused by incorrect transportation, missing or unsuitable packaging of the

pump, residual media or leaking oil!

KM 254 en

3.2 Unpacking

Retain the packaging for future storage or return, or dispose of the packaging in accordance with local regulations.

3.3 Intermediate Storage

storage temperature

Permissible

Permissible

humidity

-20°C to +70°C

max. 70 % rel. at 40 °C

max. 90 % rel. at 35 °C

14 15.720039-V1.0

KM 254 en Product Description and Accessories

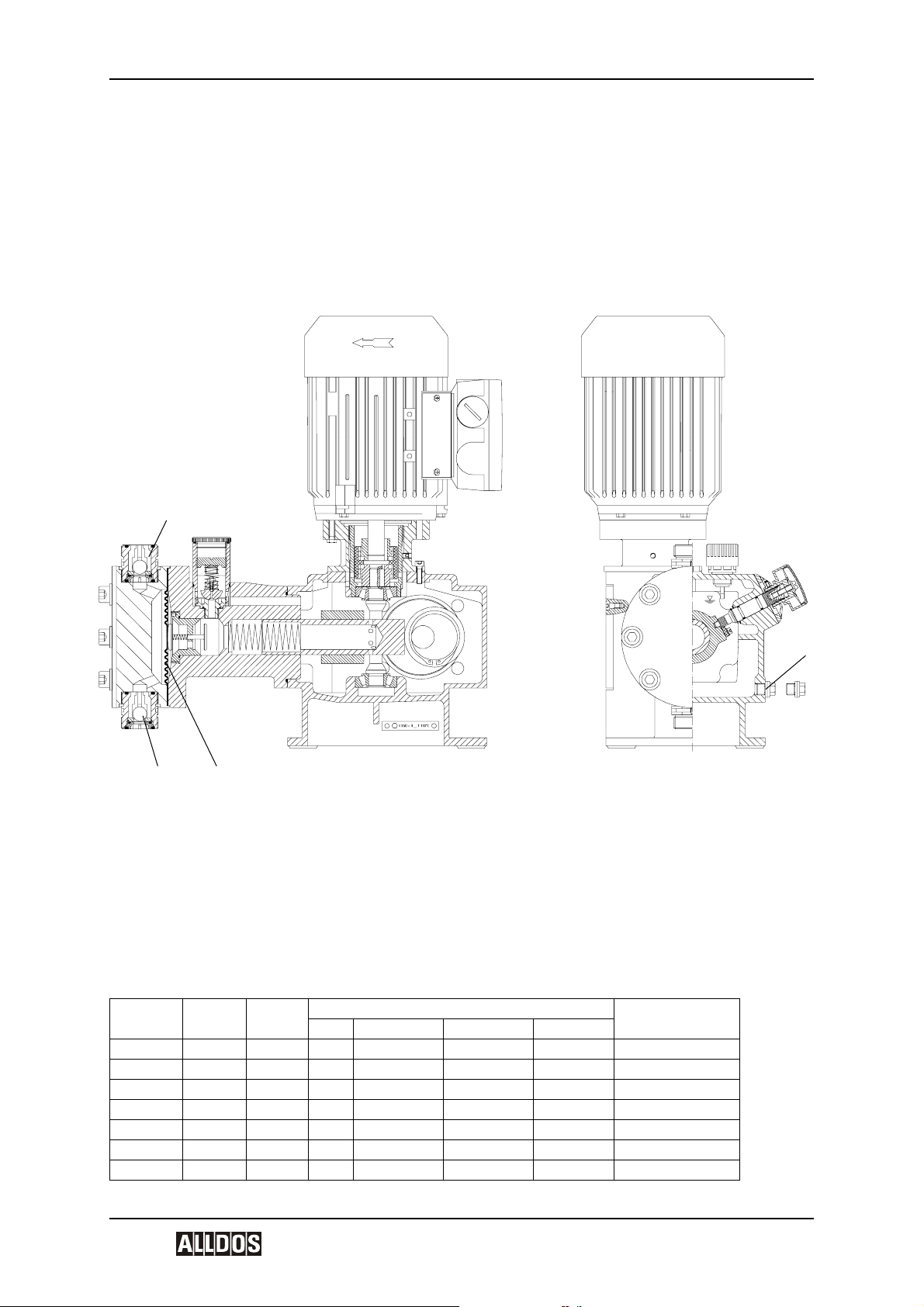

4 Product Description and Accessories

4.1 General Description

The KM 254 are oscillatory positive-displacement pumps with hydraulic diaphragm control. The operation procedure of the dosing pump is shown in the sectional drawing.

The rotational movement of the drive motor (1p) is converted via the worm gearing (2p)

and eccentric (3p) into the oscillatory suction and stroke movement of the piston (6p). The

piston has a hollow bore and a row of radial control holes, which provide a hydraulic connection between the drive area and the piston stroke area. The sliding plug (5p) envelops

the holes during the stroke and seals the stroke area from the drive area.

The hydraulic excursion of the solid teflon diaphragm (Q) displaces an equivalent volume

of dosing medium from the dosing head (2) into the dosing line. With the suction stroke,

the piston creates a low pressure, which propagates in the dosing head, the ball valve

(3b) on the dosing side closes and the dosing medium flows through the suction valve

(3a) into the dosing head.

The stroke volume size is solely determined by the position of the sliding plug. The active

stroke length and corresponding average dosing flow can therefore be changed continuously and linearly from 10-100 % using the stroke adjustment button and Nonius (L).

M3b

3a 9p 3p2p5p6p2Q 4p

1p

F

L

χ

ε

V1.0 15

1p Motor

2p Worm gearing

3p Eccentric

4p Recuperating spring (not with drive size 3)

5p Sliding plug

6p Piston

M combined overpressure and degassing valve

9p Diaphragm protection valve (AMS)

Q Dosing diaphragm

2 Dosing head

3a Suction valve

3b Pressure valve

L Stroke adjustment button

F Aeration screw with oil-level gauge

4.1.1 Combined overpressure and degassing valve

The combined overpressure and degassing valve (M) opens if there is an excessively

high build-up of pressure in the dosing system and provokes the constant degassing of

the hydraulic medium.

4.1.2 Diaphragm protection system AMS

The diaphragm protection system AMS (9p) has a keypad, which is connected to the

dosing diaphragm. The dosing diaphragm oscillates freely in the dosing head and cannot

be overstretched due to a fault in the dosing system, since the diaphragm protection valve

closes if a fault like this occurs.

KM 254 en

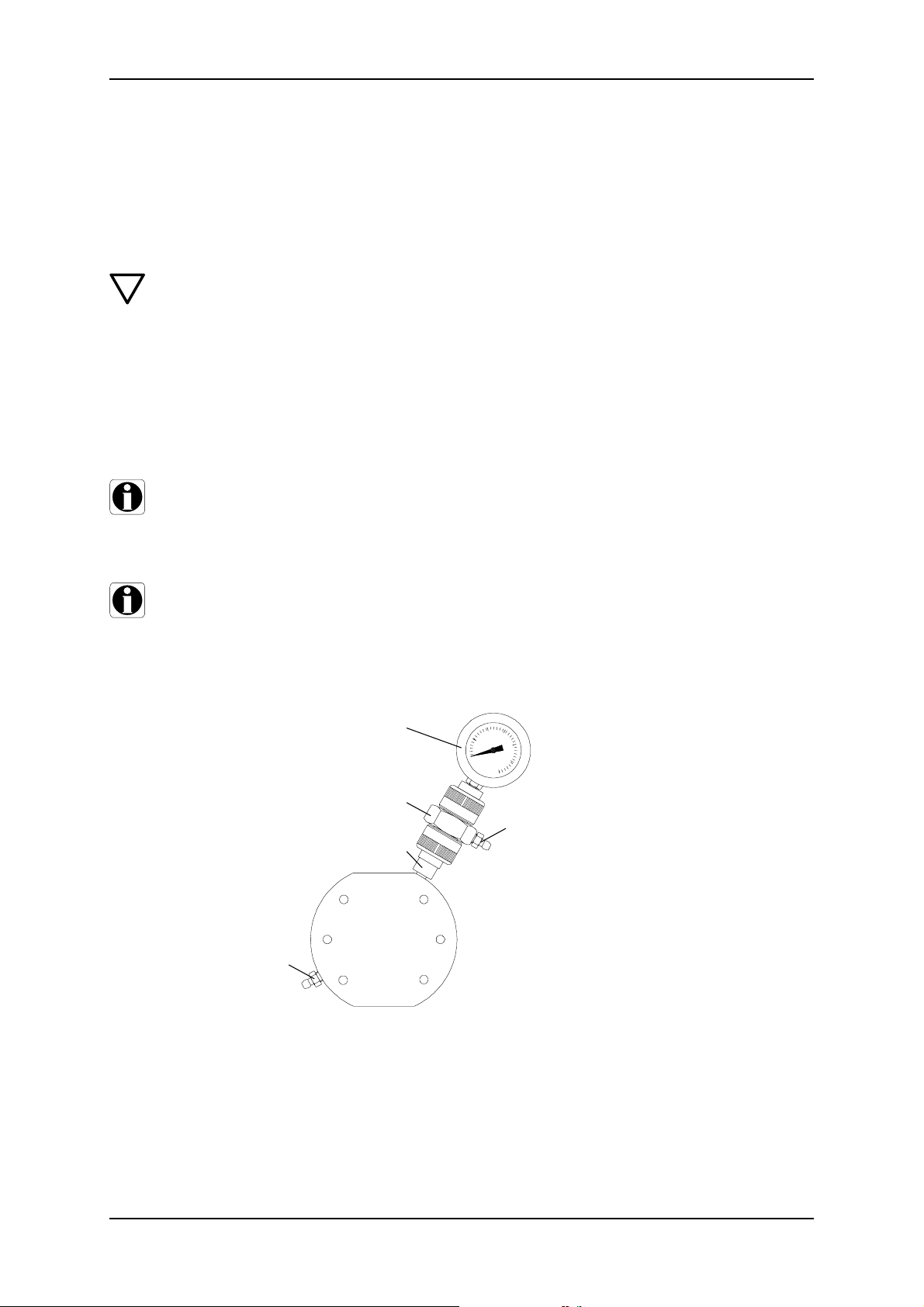

4.1.3 Double diaphragm system / Diaphragm breakage signal (optional)

General

The piston diaphragm and high-tech dosing pumps with drift-free diaphragm breakage

signal are equipped with:

• Dosing head with PTFE double diaphragm system and

• ball check valve with built-in contact manometer

Double diaphragm system

Dosing pumps with a double diaphragm system with no diaphragm breakage signal have

no manometer. In this case the ball check valve is fitted with a locking unit, order No. 541-

013. The valve however can be retrofitted with a contact manometer.

Ball check

In order for the diaphragm breakage signal to work and to protect the diaphragms, the

gap must be fully deaerated. Dosing heads with a double diaphragm are equipped with a

ball check valve (T), to prevent air from flowing back during the filling and deaeration process (2u).

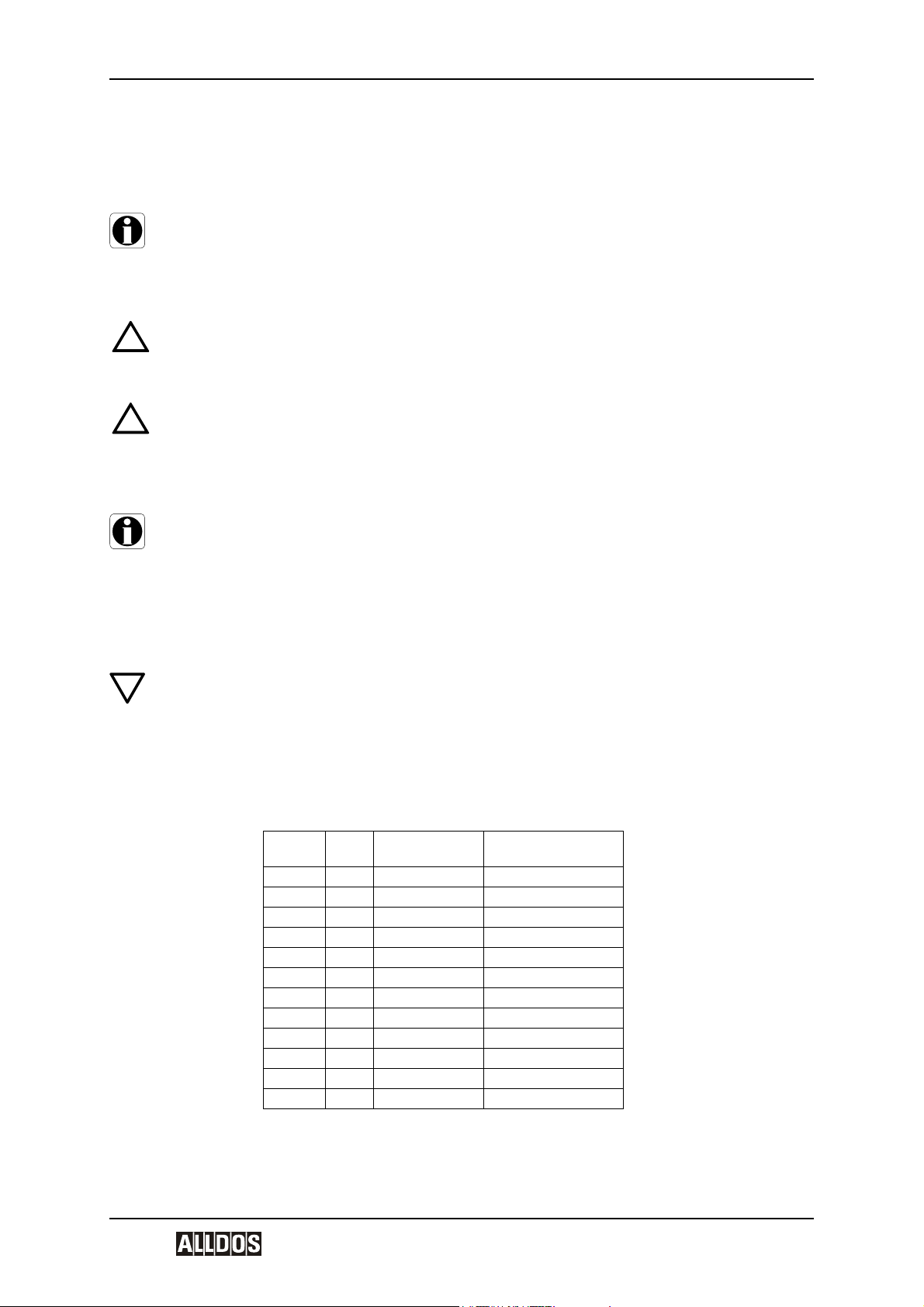

S Contact manometer

T Ball check

2)

6s

U Connection piece

3u

2) For dosing heads with a

double diaphragm with no contact manometer (no diaphragm

breakage signal), a locking unit

2u

(order number 541-013) is fitted

instead of the contact manometer.

3u

S

5s

4u

U

5u

T

Functioning of the diaphragm breakage signal

The check valve and intermediate gap of the diaphragms are filled with a separating

agent (paraffin oil) at the factory and are set in such a way during start-up on the test

stand, that there is always a hydraulically separated equilibrium between the valve and

16 15.720039-V1.0

KM 254 en Product Description and Accessories

diaphragm gap (the manometer indicates “0” when the pump is running and when it is

stopped).

If one of these diaphragms breaks, the dosing or hydraulic medium penetrates into the

intermediate gap and, when the ball is removed, into the valve. The system pressure is

therefore impinged on the valve and the contact manometer is activated. Depending on

the design of the system, the electrically isolated reed contact can trigger an alarm device

or the pump can be switched off.

The contact is triggered at the preset pressure as is shown in the table below:

Part number of

manometer Description/Use Set pressure

!

Warning

541-011

541-011.1

541-012

541-012.1

for pumps up to10 bar

manometer 0 - 10 bar

for pumps up to10 bar

flameproof manometer 0 - 10 bar

for pumps 16 to 100 bar

manometer 0 - 100 bar

for pumps 16 to 100 bar

flameproof manometer 0 - 100 bar

1,5 bar

1,5 bar

10 bar

10 bar

The contact manometer (Ex) in explosion protected version with post switch

should be used if the pump is fitted with a flameproof motor.

4.2 Dimensional Drawing

h

a

Z1

b

e

g

∅ 9mm

k

Dimensions

Type

KM 254 436 492 156 252 207 185 260 126 718 10 185 235 413 180 225 300

Dimensions in mm

abcdef fxghjkl l’nmmx

f

fx

m

mx

Z1 for double pump, motor turned by 180°

fx, mx for double pumps

l for electrical stroke adjustment

l’ or pneumatic stroke adjustment

k

d

j

c

n

l / l'

V1.0 17

4.3 Weight

KM 254 en

Type Dosing Head Material

KM 254

4.4 Stroke volume

Type

KM 254 31,6 30 —

4.5 Versions

4.5.1 Dosing heads: Materials and Additional Features

For all dosing heads:

• Diaphragm material: PTFE

• with no manual deaeration

Index No.

D000 PVC — —

D001 V4A — —

D002 PP — —

D003 PVDF — —

D004 Hastelloy C — —

D050 V4A — liquid heating

D060 PVC

D061 V4A —

D062 PP —

D063 PVDF —

D064 Hastelloy C —

D360 PVC

D361 V4A —

D362 PP —

D363 PVDF —

D364 Hastelloy C —

Weight [kg]

Single / Double pump

PVC, PP, PVDF 27 32

1.4571, 2.4610 32 42

Stroke volume [cm

10bar 16 bar 25 bar

Dosing

Head

MBS Heating flange

with double diaphragm

system for diaphragm

breakage signal

with double diaphragm

system for diaphragm

breakage signal

Contact manometer

in flameproof version

3

]

—

—

4.5.2 Valves: Materials and Additional Features

For KM 254, pn 10 bar:

• Nominal width DN 20

• Screwed connection 1 1/4“

Index No. Valve Body Gasket Valve Ball Seat Description

R000 PVC Viton Glass PTFE

R001 V4A Viton Stainless steel Stainless steel

R002 PP Viton Glass PTFE

R003 PVDF Viton PTFE PTFE

R006 PTFE PTFE Ceramics PTFE

R009 PVDF PTFE PTFE PTFE

R014 PVC EPDM PTFE PTFE

R020 PVC Viton Glass PTFE spring-loaded

R021 V4A Viton Stainless steel Stainless steel spring-loaded

R022 PP Viton Glass PTFE spring-loaded

R024 PVC EPDM Stainless steel Stainless steel spring-loaded

18 15.720039-V1.0

KM 254 en Product Description and Accessories

Index No. Valve Body Gasket Valve Ball Seat Description

R028 PVDF Viton PTFE PTFE spring-loaded

R029 PVDF PTFE PTFE PTFE spring-loaded

R033 V4A Viton Hastelloy 2.4607 spring-loaded

R046 PVC EPDM Stainless steel Stainless steel

R301 V4A Viton Stainless steel Stainless steel for abrasive media

R401 V4A Viton Stainless steel Stainless steel up to 16 bar

R401 V4A Viton Hastelloy C Hastelloy C up to 16 bar

!

Warning

Risk of malfunction or damage to the device!

The resistance of the parts that come into contact with the media depends on the

media, media temperature and operating pressure. Ensure the parts that come into

contact with the media are chemically resistant to the dosing medium in operating

conditions!

Observe the manufacturer's safety instructions when handling chemicals!

Note

Further information on resistance with regard to the medium, medium temperature

and operating pressure is available on request.

4.6 Materials

Pump Housing Material

Pump

Pump housing Al 226

4.7 Data of contact manometer for MBS (optional)

The contact manometer have a reed switch with electrically isolated contact output, maximum switching power 10 W for DC current or 10 VA for AC current. The maximum switching voltage is 100 V, maximum switching current 0.5 A.

The switching function is set up as an NC contact, i.e. if the diaphragm breaks, the current

circuit is interrupted.

The manometer has a 2 m long cable.

4.8 Installation Location

4.8.1 Space Required for Operation and Maintenance

The pump must be placed where it is freely accessible for operation and maintenance work.

Maintenance work must be carried out regularly on the dosing head and the valves.

• Provide sufficient space for removing the dosing head and the valves.

4.8.2 Permissible Ambient Influences

Permissible

0 °C to + 40 °C (for an installation height up to 1000 m over NN

ambient

temperature

Permissible

relative humidity: 70% at 40 °C, 90% at 35 °C

humidity

Caution

Risk of malfunction or damage to the device!

Pumps with electronics are only suitable for indoor use!

Do not install outdoors!

V1.0 19

4.8.3 Underground

The pump must be mounted on a flat surface.

KM 254 en

20 15.720039-V1.0

KM 254 en Installation

5 Installation

5.1 Mounting

Mount the pump on a console or pump foundation using 4 screws.

Note

Make sure that the flow runs in the opposite direction to gravity.

5.2 General Information on Installation

!

Warning

Observe the specifications for the installation location and range of application

described in the “General” section.

!

Warning

Errors, incorrect operation or faults on the pump or system can lead, for example,

to excessive or insufficient dosing, or the permissible pressure may be exceeded.

Possible errors, faults or damage which may result from this must be evaluated by

the operator and appropriate precautions must be taken to avoid them!

Note

Caution

A positive pressure difference of 2 bar min. is required between the suction valve

and the pressure valve in order for the dosing pump to operate correctly. If the total

counterpressure (at the dosing point) and geodetic height difference between the

suction valve and the dosing point is less than 2 bar (20 m WS), a pressure

retention valve must be installed directly in front of the dosing point.

5.2.1 Approximate values when using pulsation dampers

Risk of damage to the system! We always recommend using pulsation dampers for

large high-speed pumps!

Since the pulsation is influenced by many factors, a system-specific calculation is

essential, e.g. on request with our calculation program.

The following table indicates the approximate values, and for which suction line length

suction pulsation dampers are required. The values relate to 50 Hz operation where water

or similar liquids are used as the dosing medium.

Type

Stroke

254-50 26 DN 20 8

254-102 54 DN 20 8

254-143 75 DN 20 5

254-175 92 DN 20 3

254-213 112 DN 20 1,5

254-291 153 DN 20 1

254-46 26 DN 20 8

254-97 54 DN 20 8

254-136 75 DN 20 5

254-166 92 DN 20 3

254-202 112 DN 20 1,5

254-276 153 DN 20 1

value

Nominal width of

suction line

Maximum suction line

length [m]

V1.0 21

5.2.2 Installation Examples and Tips

Picture of optimal installation

KM 254 en

8i

1i

1i Dosing tank

2i Electric agitator

3i Extraction device

4i Suction pulsation damper

5i Dosing pump

6i Overflow valve

7i Pressure retention valve

8i Pulsation damper

9i Measuring glass

10i Injection unit

2i

7i

max. 1m

6i

4i

3i

9i

10i

5i

13i

6i

p

10i

Tank installation:

• For non-degassing media with viscosity similar to

water, the pump can be mounted onto the tank

(observe the admissible suction height).

Preferable for flooded suction.

For dosing media which tend to sedimentation:

• Install a suction line with filter (13i) in a way ensuring

that the suction valve remains several centimetres a

bove the botton of the tank.

22 15.720039-V1.0

KM 254 en Installation

7i

p≥ 2 bar

Pressure retention valve

With open outflow of the dosing medium or low counterpressure:

A positive pressure difference of at least 2 bar has to exist between the counterpressure at the injection point and the pressure of the dosing medium at the suction valve of the dosing

pump.

If this cannot be guaranteed:

• Install a pressure retention valve (7i) directly in front of the

outlet or the injection unit.

p

1

p2 - p

1

1 bar

_

>

Pressure retention valve

To avoid the siphon effect:

p

2

• Install a pressure retention

valve in the dosing line and, if

14i

p

6i

Overflow valve

To protect the dosing pump and the pressure line

10i

against:

necessary, a solenoid valve

(14i) in the suction line.

• Install an overflow valve (6i) in the pressure line.

11i

p

6i

For volatile media:

• flooded suction

10i

• Install a filter in the suction line to prevent the valves

being contaminated.

To install the suction line:

• Keep the suction line as short as possible, avoid a tangled suction line

• If necessary, use swept bends

instead of elbows.

• Always lay the suction line rising to

the suction valve of the dosing pump.

• Avoid loops which cause air bubbles.

For easy deaeration of the dosing head:

12i

Install a ball valve (11i) with bypass line (back to the dosing tank)

immediately behind the pressure valve.

In case of long pressure lines:

• Install a check-back valve (12i) into the dosing line.

V1.0 23

KM 254 en

For suction-side installation

4i

8i

• Depending on the pump type and line length, it

may be necessary to use a suction pulsation

damper (4i).

Observe the “Approximate values when using

pulsation dampers” auf Seite 21 and if necessary

request a system-specific calculation from our

calculation program.

For pressure-side installation

• Depending on the pump type and line length, it may be

necessary to use a pulsation damper (4i) on the

pressure side.

For rigid pipework and line length > 2m, for flexible

pipework and line length > 3m, depending on the

pump type and size, use pulsation dampers (8) to protect the system.

Caution

Risk of damage to the system! We always recommend using pulsation dampers for

large high-speed pumps!

Since the pulsation is influenced by many factors, a system-specific calculation is

essential, e.g. on request with our calculation program.

24 15.720039-V1.0

KM 254 en Installation

5.3 Tube/Pipe Lines

5.3.1 General

!

Warning

The resistance of the parts that come into contact with the media depends on the

media, media temperature and operating pressure. Ensure the parts that come into

contact with the media are chemically resistant to the dosing medium in operating

conditions!

Only use the specified line types! All lines must be free from strain! If necessary,

use swept bends instead of elbows, avoid loops and buckles in the tubes! Ensure

the suction line is as short as possible to avoid cavitation!

To protect the system against excessive build-up of pressure:

Install an overflow valve in the pressure line.

Flow must run in the opposite direction to gravity!

!

Warning

Observe the manufacturer's safety instructions when handling chemicals!

5.3.2 Connecting the Suction and Pressure Lines

• Connect the suction line to the suction valve.

• Connect the pressure line to the pressure valve.

Note

Install suction line in the tank so that the foot valve remains approximately 5 to 10

cm above the bottom of the tank.

When connecting hose lines

• Push the hose firmly onto the connection nipple

and depending on the connection, secure using a

connection counterpart or hose support clip.

• Fit gasket.

• Screw onto the valve using the union nut.

When connecting pipe lines to DN 20

• Depending on the pipe material and connection,

glue it (PVC), weld it (PP, PVDF or stainless

steel) or press it in (stainless steel).

• Fit gasket.

• Screw onto the valve using the union nut.

5.3.3 Connecting a liquid-heated dosing head (optional)

As an option, liquid-heated dosing heads are available in stainless steel version.

V1.0 25

2f

2f1

Ø10

40

2f Dosing head, liquid heated

2f1 Hose nipple, DN10 connection

Demands placed on heating liquid:

• The heating liquid must not attack stainless steel.

• maximum permissible pressure: p

• maximum permissible temperature: T

max

= 3 bar

= 100 °C

max

KM 254 en

26 15.720039-V1.0

KM 254 en Electrical Connections

6 Electrical Connections

Warning

Electrical connections should only be connected by qualified personnel!

Before connecting the power supply cable and the relay contacts: Disconnect the

mains voltage!

Observe the local safety regulations!

The pump housing must only be opened by personnel authorised by ALLDOS!

Protect the cable connections and plugs against corrosion and humidity.

Only remove the protective caps from the sockets that are being used.

6.1 Electrical servomotor (optional)

To connect the servomotor to the mains supply, please refer to the instructions for the

servomotor.

6.2 Electronic stroke preset counter (optional)

To connect the stroke preset counter to the mains supply, please refer to the instructions

for the stroke preset counter.

6.3 Electrically heated dosing head (optional)

2e

2e Dosing head, electrically heated

2e1

2e2

2e3

To connect the temperature controller to the mains supply, please refer to the instructions

for the electric temperature controller.

6.4 Diaphragm control (optional)

2e1 Sensor

2e2 Heating

2e3 Power supply

!

Warning

Pumps in explosion protected version with diaphragm breakage signal are fitted

with a contact manometer in explosion protected version. It must be grounded.

Connecting the earthing cable (4u) see diagram.

V1.0 27

S Contact manometer

5s Union nut

6s Contact output

T Ball check

U Connection piece

2u Deaeration screw

3u O-rings

4u Connection for earthing cable

5u Union nut

*2) or locking unit

5s

4u

5u

S

6s

3u

2)

U

2u

3u

T

6.5 Connecting the Power Supply Cable

Warning

Disconnect the mains voltage before connecting the power supply cable!

Before connecting the power supply cable, check that the mains voltage specified

on the type plate corresponds to the local conditions!

Do not make any changes to the mains cable or plug!

KM 254 en

!

!

Caution

The pump can be automatically started by connecting the mains voltage!

Warning

The assignment between the plug-and-socket connection and the pump must be

labelled clearly (e.g. by labelling the socket outlet).

• Do not switch on the mains voltage until you are ready to start the pump.

Warning

A clearly labelled all-pole isolating switch with a contact opening width of at least 3

mm should be installed between the pump and the mains.

Connect the motor to the mains in accordance with local electrical installation regulations

as is shown on the terminal connection plan (on the lid of the connection box).

Warning

The specified degree of protection can only be ensured, if the mains cable is connected to the same degree of protection.

Caution

Observe direction of rotation!

To protect the motor, install a motor protecting switch or motor contactor, and set

the bimetal relay to the nominal current of the motor for the present voltage and frequency.

This is also necessary for versions with Etron Profi Electronics!

28 15.720039-V1.0

KM 254 en Start-up/Shutdown

7 Start-up/Shutdown

7.1 Safety Information

!

Warning

When dosing dangerous media, observe the corresponding safety precautions!

When working on the dosing head, connections or lines:

wear the necessary protective clothing (goggles, gloves)!

Before removing the dosing head, valves and media lines, empty any remaining

medium in the dosing head into a driptray by carefully unscrewing the suction

valve.

Do not open the pump!

Repairs must only be carried out by authorised specialists!

Caution

Observe flow direction (arrow) of valves!

Tighten plastic valves by hand only. Risk of damage!

7.2 Initial Start-Up/Subsequent Start-Up

7.2.1 Checks Before Start-Up

• Check all electrical connections are correct.

• Check that the mains voltage specified on the type plate corresponds to the local conditions!

• Check all connections are secure and tighten, if necessary.

• Check fixing screws on the dosing head are tightened with the specified torque and

tighten, if necessary.

!

Tighten the dosing head screws crosswise using a torque wrench:

Torque:

50 - 54 Nm for KM 254

7.2.2 Oil filling

Note

The pump is checked at the factory, and the oil is drained for shipping purposes.

Before start-up, add the special oil which is provided.

The piston flange is filled with oil for easy start-up. The stroke adjustment button

must only be adjusted if the gear oil has been added, otherwise the oil will leak

from the piston flange.

1. Unscrew and remove the aeration screw and oil-level gauge (F).

2. Slowly add the hydraulic oil that is provided through the opening of the filling screw

(F), until the oil reaches the mark on the oil-level gauge.

3. Set the stroke adjustment button (L) to “0”.

7.2.3 Filling the dosing head for the initial start-up for systems without dosing medium flooded suction

Warning

When dosing dangerous media, observe the corresponding safety precautions!

When working on the dosing head, connections or lines:

wear the necessary protective clothing (goggles, gloves)!

As assisting suction for systems without dosing medium flooded suction, you can fill the

dosing head with dosing medium before the initial start-up:

1. Unscrew the pressure valve (3b).

2. Add the dosing medium to the dosing head (2).

3. Screw the pressure valve (3b) back in.

V1.0 29

Caution

KM 254 en

Observe arrow for the pressure valve (for flow direction)!

7.2.4 Start-Up/Subsequent Start-Up

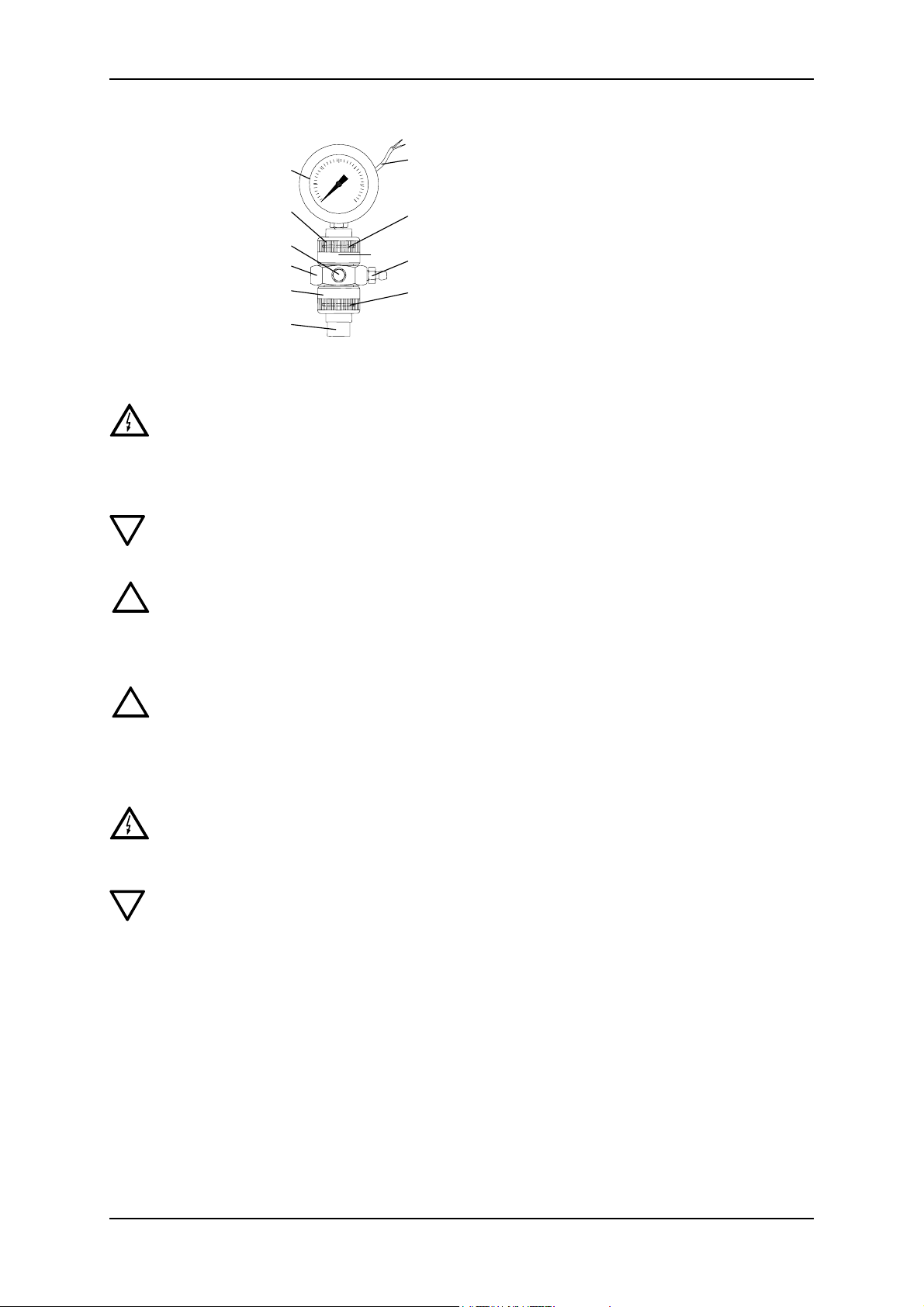

M M

F

3b

1l

L

1q

2

1. Connect the electrical power supply.

2. Depending on the installation, start the pump where possible without counterpressure.

See installation example for easy deaeration of the dosing head in the section on ’Installation’.

3. Set the stroke adjustment button (L) to 0 %.

4. Run the pump for approx. 5 minutes.

5. Checking the oil level.

5.1 Set the stroke adjustment button (L) to 40 %.

5.2 Run the pump for approx. 10 minutes with a stroke adjustment of 40%.

5.3 Switch off pump, check the oil level and add oil if necessary.

5.4 Fit the oil filling screw (F) and the oil-level gauge back on.

– The pump is now ready to operate.

1q Dosing head screws

2 Dosing head

3b Pressure valve

F Oil filling screw

L Stroke adjustment button

1l Cover for stroke adjustment

button

M Pressure relief valve

Note

Caution

Caution

The rod length of the oil level gauge is

for KM 254 35 mm; immersion depth to marking approx. 5 mm.

Check the oil level at least every 2 weeks and add oil if necessary.

Only use original ALLDOS gear oil!

Pump Type Order No. Description

KM 254 single 555-302 3,5 l DHG 68

KM 254 double 555-303 4,5 l DHG 68

7.2.5 After start-up

Following initial start-up and after each time the diaphragm is changed, tighten the

fixing screws on the dosing head:

After approximately 6 - 10 working hours or two days, tighten the dosing head

screws crosswise using a torque wrench.

Torque:

50 - 54 Nm for KM 254

30 15.720039-V1.0

KM 254 en Start-up/Shutdown

7.3 Setting the pressure relief valve

If the written agreement does not specify a system-specific opening pressure, then the

pressure relief valve is set to a slightly greater opening pressure than the bleed pressure

for the pump. It can however be set by the customer to a smaller opening pressure.

Opening pressure of the pressure relief valve

Bleed pressure of

the pump [bar]

10 13

16 18

Setting the opening pressure

Opening pressure of the

pressure relief valve [bar]

To do so, a manometer must be installed in the

pressure line and behind the manometer, a shutoff valve.

To set the pressure relief valve, use a screwdriver.

Set the pressure relief valve as follows:

Caution

Risk of damage to the pump or system! The pressure relief valve looses its

function through blocking, and can produce pressures of several hundred bar in

the pump or system. Do not block the pressure relief valve during adjustments!

5. Close the cover of the pressure relief valve again.

6. Open the shut-off valve after the manometer.

7.4 Zero Point Adjustments

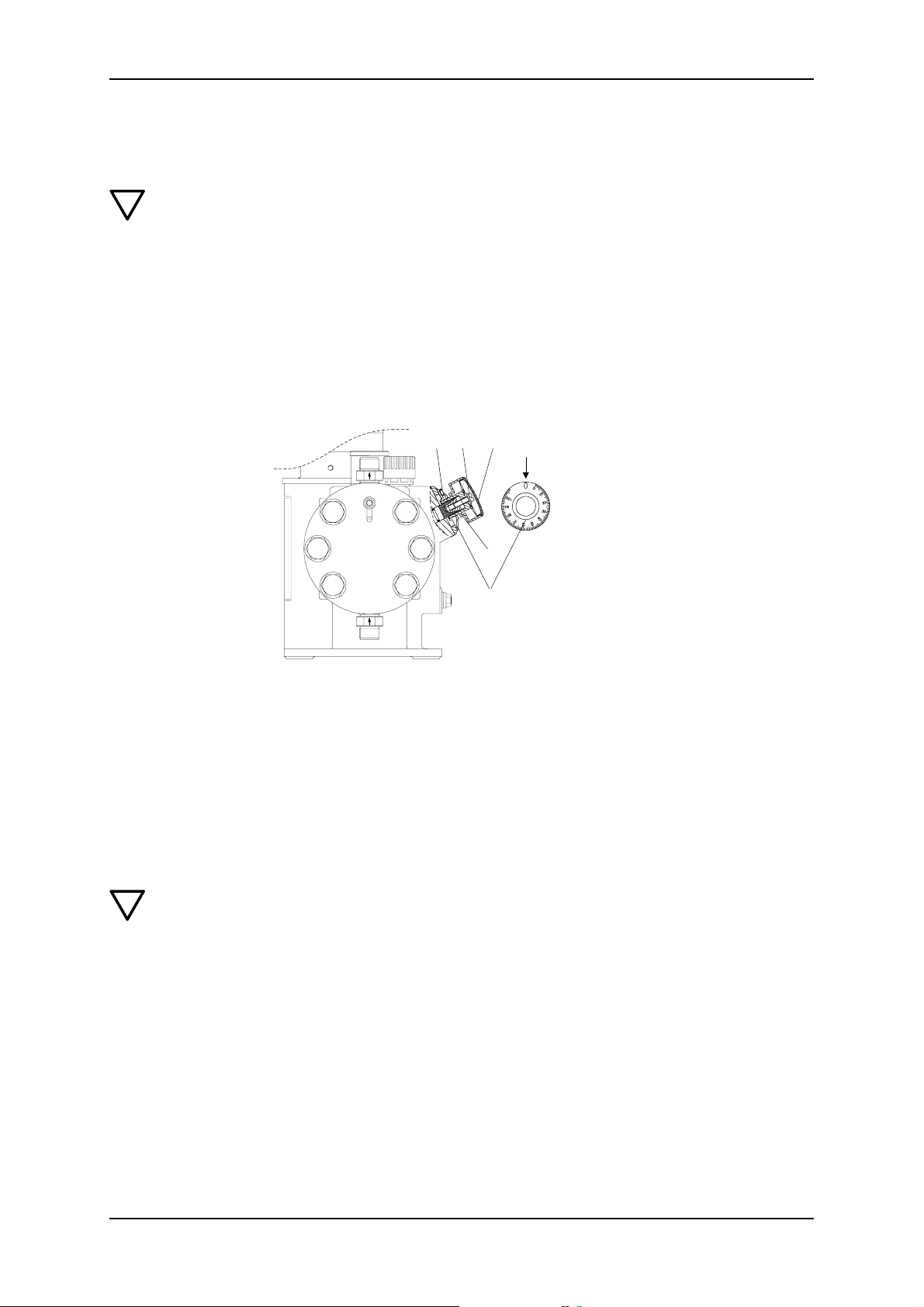

7.4.1 Adjusting the zero point for system pressures up to 100 bar

1m

2m

1. Close the shut-off valve after the manometer.

2. Remove the cover (1m) of the pressure relief

valve.

3. Start up pump.

4. Using the screwdriver, slowly turn the adjusting

screw (2m) of the pressure relief valve anticlockwise, until the desired opening pressure is obtained.

The zero point of the dosing pump is factory-set to a slightly smaller counterpressure than

the bleed pressure of the pump. If the operating counterpressure deviates considerably

V1.0 31

from this value, adjusting the zero point will ensure that the values are more precise.

Counterpressure for zero point setting of the pump at the factory

Bleed pressure of

the pump [bar]

10 3

16 3

7.4.2 Adjusting the Zero Point

KM 254 en

Counterpressure for zero point setting

of the pump at the factory [bar]

!

Warning

3l 2l 1l

L

4l

3l

L Stroke adjustment button

1l Cover

2l Locking screw

3l Screw

4l Scale ring

When dosing dangerous media, observe the corresponding safety precautions!

When working on the dosing head, connections or lines:

wear the necessary protective clothing (goggles, gloves! Always adjust the value

with the pressure line connected and with operating counterpressure.

1. Fit a measuring device on the suction side, e.g. place the suction line in a graduated

measuring beaker.

2. Set dosing flow to 15%.

3. Remove cover (1l) from stroke adjustment button (L).

4. Use a screwdriver to loosen the locking screw (21) by approximately 2 rotations.

5. Switch on the pump.

6. Turn the stroke adjustment button slowly towards the zero point, until the dosing (the

liquid level falls) stops in the measuring device.

7. Switch off the pump.

8. Set the scale ring (4l) to zero

8.1 Loosen the screw (3l) in the scale ring (4l) slightly using an Allan wrench M3,

8.2 Turn the scale ring (4l) until both “0” are the same on the scale and scale ring.

8.3 Tighten screw (3l).

9. Depending on the application, tighten the locking screw (21) so that the stroke adjustment button can still be turned/cannot be turned any more.

10. Replace cover (1l).

7.5 Operating the pump

Note

When operating the pump, refer to the section “Operating the pump”, “Operating

the pump electronics “ (only for Etron Profi Electronics), as well as “Maintenance”

and if necessary for troubleshooting, the section “Possible faults”.

32 15.720039-V1.0

KM 254 en Start-up/Shutdown

7.6 Shutdown

!

Warning

When working on the dosing head, connections or lines:

Risk of injuries! Wear the necessary protective clothing (goggles, gloves)!

Do not allow any chemicals to leak from the pump. Collect and dispose of all chemicals correctly!

Note

If possible, rinse the dosing head before shutting down the pump, e.g.

by supplying it with water.

7.6.1 Switching Off/Uninstalling

• Switch off the pump and disconnect it from the mains.

• Depressurise the system.

• Take suitable steps to ensure that the returning dosing medium is safely collected.

• Carefully remove all lines.

• Uninstall the pump.

7.6.2 Cleaning

• Rinse all parts that have come into contact with the medium very carefully:

• Lines

• Valves

• Dosing Head

• Diaphragm

• Remove any trace of chemicals from the pump housing.

7.6.3 Storage

When you store the pump:

After cleaning (see above)

• Carefully dry all parts and reinstall the dosing head and valves

or

• Change the valves and diaphragm.

See “Maintenance” section.

7.6.4 Disposal

When you dispose of the pump:

After cleaning (see above)

• Dispose of the pump in accordance with the relevant regulations.

V1.0 33

8 Operating the Pump

8.1 Switching On/Off

Caution

Before switching on the pump, check that it is installed correctly. See the “Installation” and “Start-Up” sections.

8.1.1 Switching On the Pump

• Switch on the mains voltage

8.1.2 Switching Off the Pump

• Switch off the mains voltage.

8.2 Setting the dosing capacity

KM 254 en

3l 2l 1l

L

4l

3l

L Stroke adjustment button

1l Cover

2l Locking screw

3l Screw

4l Scale ring

8.2.1 Setting the dosing flow and locking the stroke adjustment button

1. Remove cover (1l) from stroke adjustment button (L).

2. Use a screwdriver to loosen the locking screw (21) by approximately 2 rotations.

3. Increase/reduce the dosing flow while the pump is running.

3.1 Slowly turn the stroke adjustment button to the left / right to set the desired

dosing volume.

4. Depending on the application, tighten the locking screw (21) so that the stroke adjustment button can still be turned/cannot be turned any more.

5. Replace cover (1l).

Caution

Pump cannot be operated if the stroke adjustment button is fully open! Depending

on the pump adjustment, this value may already be < 100 % on the scale display

for system pressures of > 100 bar.

Open the stroke adjustment button completely and then close by approx. 10% in

order to set the dosing flow to 100 %.

8.3 Electrical servomotor (optional)

To operate the servomotor, please refer to the instructions for the servomotor.

8.4 Electronic stroke preset counter (optional)

To operate the stroke preset counter, please refer to the instructions for the stroke preset

counter.

8.5 Electrically heated dosing head (optional)

To operate the temperature controller, please refer to the instructions for the temperature

34 15.720039-V1.0

KM 254 en Operating the Pump

controller.

V1.0 35

9 Maintenance

9.1 General Notes

!

Warning

When dosing dangerous media, observe the corresponding safety precautions!

When working on the dosing head, connections or lines: Wear the necessary protective clothing (goggles, gloves)!

Do not open the pump!

Repairs must only be carried out by authorised and qualified personnel!

Switch off the pump and disconnect it from the mains before carrying out maintenance work and repairs!

Before removing the dosing head, valves and media lines, empty any remaining

medium in the dosing head into a driptray by carefully unscrewing the suction

valve.

Caution

Observe flow direction (arrow) of valves!

Tighten plastic valves by hand only. Risk of damage!

KM 254 en

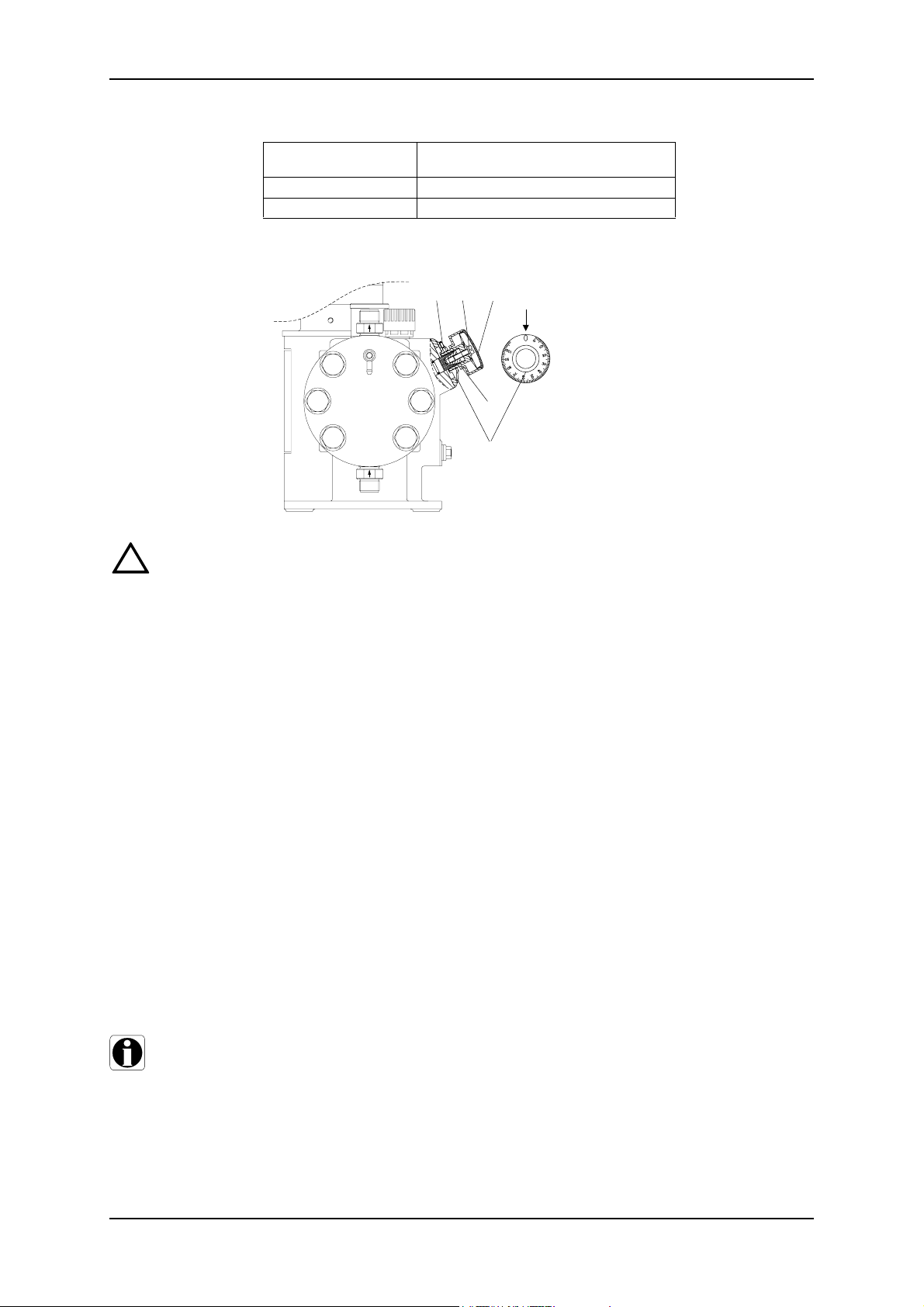

9.2 Diaphragm breakage control for diaphragm breakage signal

If a diaphragm breakage signal (MBS) occurs, you should first of all check whether an

error has been displayed, as different external factors such as for instance, the heating of

hydraulic or dosing medium can cause the cracked medium to be displaced into the valve,

thereby causing an error to occur. Checks after an MBS:

1. Briefly open the MBS deaeration screw (2u) and then close it again.

2. Switch on the pump

3. If an MBS reoccurs after a short period of time, then a diaphragm has broken.

Caution

After a diaphragm breakage, replace the diaphragms and clean the check-back

valve, see section on “Replacing the diaphragm for dosing head with double diaphragm”.

S

U

2u

T

S Contact manometer

T Ball check

U Connection piece

1u Filling screw

2u Deaeration screw

1u

9.3 Intervals for cleaning and maintenance

Check the oil level and add oil if necessary.

• Check the oil level every 2 weeks and add oil if necessary.

36 15.720039-V1.0

KM 254 en Maintenance

Clean the valves.

• At least every 12 months or after 4000 operating hours, or

• if the pump isn’t performing, or

• in the event of an error.

Clean the valves and replace if necessary (for stainless steel valves: inner parts of valve)

Change diaphragms and gear oil.

• At least every 12 months or after 8000 operating hours, change the dosing medium

and gear oil,

• in dusty installation site, change gear oil every 3000 operating hours.

Clean ball check of the double diaphragm

• after a diaphragm breakage, remove the ball check immediately and clean it.

Note

Only clean the ball check after a diaphragm breakage!

9.4 Checking the oil level

Caution

Check the oil level at least every 2 weeks and add oil if necessary.

Note

The rod length of the oil level gauge is

for KM 254 35 mm; immersion depth to marking approx. 5 mm.

9.5 Cleaning the suction and pressure valves

!

Warning

When working on the dosing head, connections or lines: Wear the necessary protective clothing (goggles, gloves)!

Before removing the dosing head, valves and media lines, empty any remaining

medium in the dosing head into a driptray by carefully unscrewing the suction

valve.

Nominal width DN 20

• Screwed connection 1 1/4“

• Stainless steel/plastic

• optional spring-loaded

Clean suction and pressure valves as follows:

1. Unscrew valves.

2. Unscrew screw parts and valve set using round pliers.

3. Dismantle inner part (seat, O-ring, balls, ball cages, if necessary spring).

4. Clean all parts, replace any faulty parts.

5. Reassemble valve.

6. Replace O-rings with new ones and screw valve back in.

V1.0 37

KM 254 en

Caution

2)1)

DN 20 valve

optional spring-loaded

1)

stainless steel/

2)

plastic,

The O-rings must be correctly placed in the specified groove.

Observe flow direction (arrow)!

Tighten plastic valves by hand only. Risk of damage!

38 15.720039-V1.0

KM 254 en Maintenance

9.6 Changing the diaphragm and gear oil for dosing head with single diaphragm (no MBS)

!

Warning

When working on the dosing head, connections or lines:

Wear the necessary protective clothing (goggles, gloves)!

The dosing diaphragm should be replaced with each gear oil change.

Before removing the dosing head, valves and media lines, empty any remaining

medium in the dosing head into a driptray by carefully unscrewing the suction

valve.

Caution

Only use original ALLDOS gear oil!

ALLDOS gear oil

Pump Type Order No. Description

KM 254 single 555-302 3,5 l DHG 68

KM 254 double 555-303 4,5 l DHG 68

Note

Collect gear oil in a container and dispose of correctly.

Caution

9.6.1 Drain gear oil

1. Unscrew the stroke adjustment screw (B) and collect gear oil in a container.

2. Screw the lock screw (B) and the new gasket (1b) back in and tighten well.

Risk of leaking and damage caused by oil loss! For each oil change, a new flat gasket (1b) must be used!

F

B Lock screw

1b Gasket

F Oil filling screw

L Stroke adjustment button

L

1b

B

9.6.2 Removing the dosing head

1. Close dosing lines on suction and pressure side and loosen suction and pressure

valve connections.

2. Loosen the 6 dosing head screws (1q with 2q) and remove the dosing head (2).

9.6.3 Replacing a single diaphragm (no MBS)

• Remove the diaphragm, fit new diaphragm (Q) on suction side (see diagram below).

V1.0 39

2q

1q

2

9.6.4 Fitting the dosing head

• Fit the dosing head and tighten the dosing head screws (1q with 2q) crosswise using a

torque wrench.

KM 254 en

1q Dosing head screw

2q Intermediate disk

2 Dosing head

Q Diaphragm

Q

Note

Caution

Caution

Refer to the “Start-up” section for subsequent start-up!

9.6.5 Filling gear oil

Risk of leaking and damage caused by oil loss! For each oil change, a new flat gasket (1b) must be used!

Check that the lock screw (B) is tightened.

1. Unscrew and remove the aeration screw and oil-level gauge (F).

2. Set the stroke adjustment button (L) to “0”.

3. Slowly add the hydraulic oil through the aeration screw opening (F), until the oil reaches the mark on the oil-level gauge.

4. Wait 30 minutes.

5. Run the pump for approx. 5 minutes with a stroke adjustment of 0%.

6. Run the pump for approx. 10 minutes with a stroke adjustment of 40%.

9.6.6 Checking the oil level.

1. Switch off pump, check the oil level and add oil if necessary.

2. Fit the aeration screw and oil-level gauge (F) back on.

Following initial start-up and after each time the diaphragm is changed, tighten the

fixing screws on the dosing head:

After approximately 6 - 10 working hours or two days, tighten the dosing head

screws crosswise using a torque wrench.

Torque:

50 - 54 Nm for KM 254

40 15.720039-V1.0

KM 254 en Maintenance

2

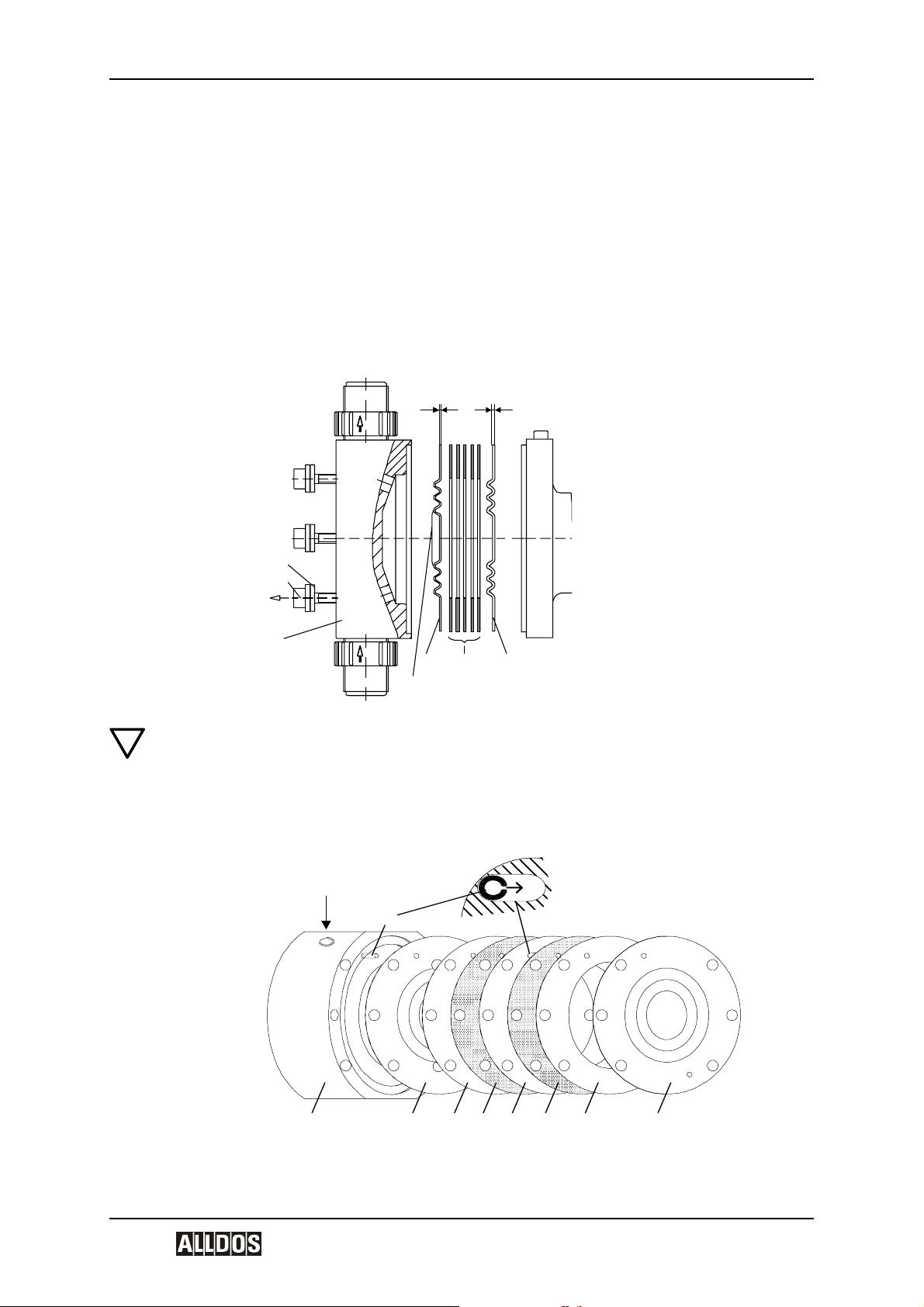

9.7 Replacing the diaphragm for dosing head with double diaphragm

9.7.1 Removing the dosing head

1. Close dosing lines on suction and pressure side and loosen suction and pressure

valve connections.

2. Loosen the 6 dosing head screws (1q with 2q) and remove the dosing head (2).

9.7.2 Replace the double diaphragm.

1. Clean the intermediate disk (3q), sealing rings (4q) and covering rings (5q) - replace

with new ones after a diaphragm has broken.

2. Remove both clamping sleeves (6q) slightly using pliers - replace with new ones after

a diaphragm has broken.

3. Measure the outer wall thickness of both new diaphragms (Q1 and Q2):

s

1 (Q1)

< s

2 (Q2)

.

s1 < s

2

1q Dosing head screw

2q Intermediate disk

2 Dosing head

Q see diagram below

Caution

q

1q

1) The shape of the diaphragm

2

varies depending

on the type of pump.

3q - 5q Q2Q1

1)

Observe correct installation of diaphragms Q1 and Q2 (see diagram)!

Fit the thinner diaphragm (Q1) on eth dosing side and the thicker diaphragm (Q2)

on the oil side/pump side!

4. Fit both new diaphragms (Q1 and Q2) and the parts (3q - 5q) in the correct order, as is

shown in the diagrams (the clamping sleeves (6q) are used for centring purposes).

S

6q

3q

2 5q4q3q4q5q Q2Q1

V1.0 41

Caution

Note

KM 254 en

S Contact manometer (installation position)

Q1 Diaphragm on dosing head side

Q2 Diaphragm on oil side/pump side

3q Intermediate disk

4q Sealing rings

5q Covering rings

6q Clamping sleeves

The paraffin oil between the diaphragms (Q) is connected via the clamping sleeves

(6q) to the contact manometer (S) in order to fill and activate the diaphragm breakage signal. It is able to pass between the diaphragms through the slits in the clamping sleeves and the slits in the intermediate disk.

The clamping sleeves (6q) must therefore be installed in such a way that the slits in

the clamping sleeve face the slits in the intermediate disk (3q) (see above).

9.7.3 Fitting the dosing head

• Fit the dosing head and tighten the dosing head screws crosswise using a torque

wrench.

Refer to the “Start-up” section for subsequent start-up.

Note

9.7.4 Filling the double diaphragm with separating agent

After a diaphragm has broken, the ball check must be cleaned before forng filled

with separating agent. Only clean the ball check after a diaphragm breakage!

After the diaphragm has been replaced for a pump with a double diaphragm, refill the

separating agent between the diaphragm:

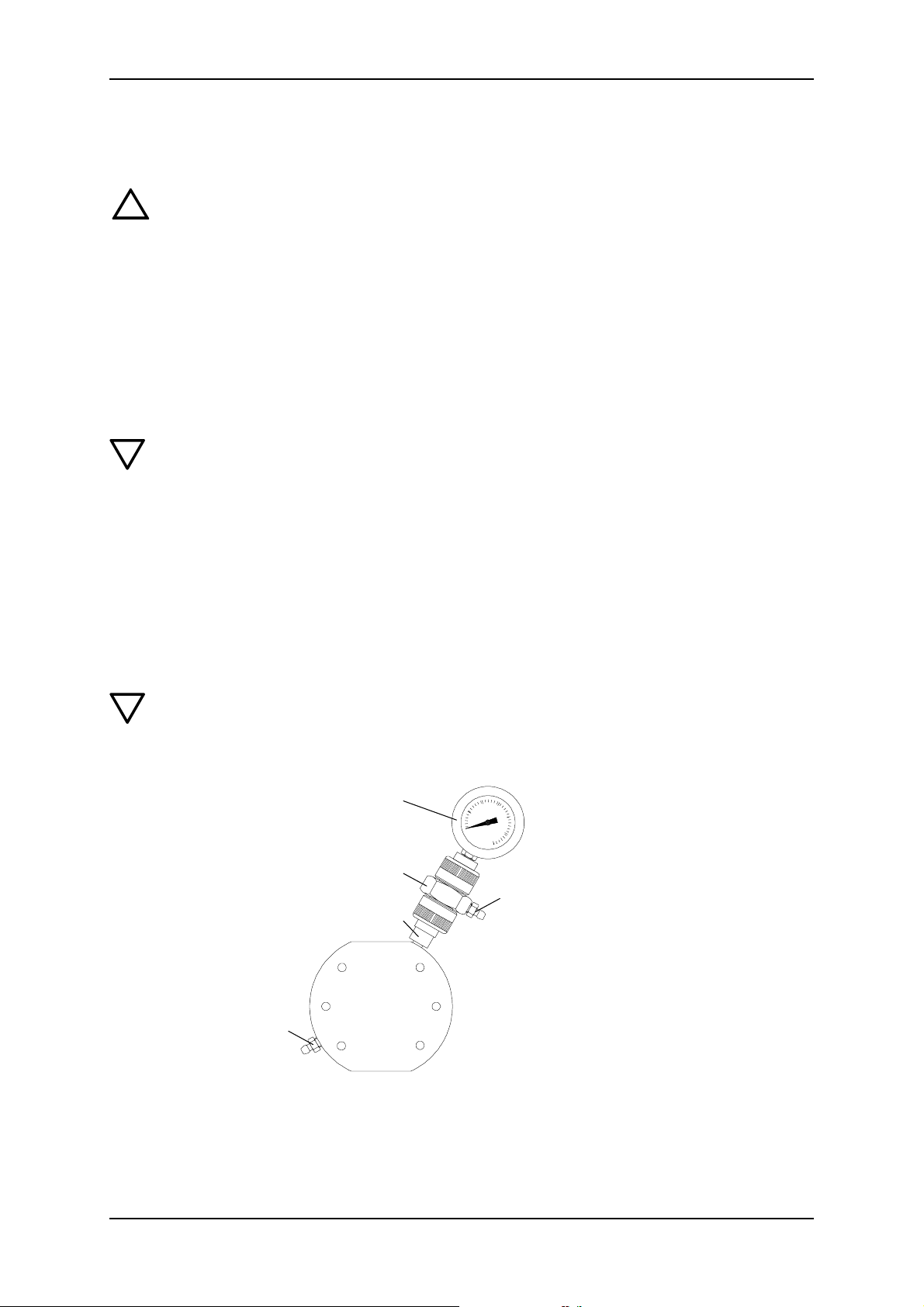

S

U

2u

T

1u

S Contact manometer

T Ball check

U Connection piece

1u Filling screw

2u Deaeration screw

1. Set the stroke adjustment button of the pump to 0 %.

2. Open the filling screw (1u) and deaeration screw (2u) by one rotation.

3. Connect the filling hose to the nipple of the filling screw (1u) and, using the dosing

syringe inject the correct amount of paraffin oil that is specified in the table below.

4. Close filling screw (1u), but leave the deaeration screw (2u) open.

5. Start up the pump with a system counterpressure and 40 % stroke adjustment.

42 15.720039-V1.0

KM 254 en Maintenance

6. Only close the deaeration screw (2u) when the separating agent stops flowing. (after

approx. 5 - 10 min)

Note

Once filled with separating agent and after a few operating hours, especially if the

pressure of the manometer is increasing, deaerate again.

Filling quantity of paraffin oil for dosing pumps with a double diaphragm (per dosing head)

Pump Type Filling quantity in ml

KM 254 6

Ordering data for double diaphragm filling components

Order No. Description

555-410 Filling components, set with paraffin oil, throw-away syringe and hose parts

9.7.5 Filling gear oil

Caution

Risk of leaking and damage caused by oil loss! For each oil change, a new flat gasket (1b) must be used!

Check that the lock screw (B) is tightened.

1. Unscrew and remove the aeration screw and oil-level gauge (F).

2. Set the stroke adjustment button (L) to “0”.

3. Slowly add the hydraulic oil through the aeration screw opening (F), until the oil reaches the mark on the oil-level gauge.

4. Wait 30 minutes.

5. Run the pump for approx. 5 minutes with a stroke adjustment of 0%.

6. Run the pump for approx. 10 minutes with a stroke adjustment of 40%.

Caution

Note

9.7.6 Checking the oil level.

7. Switch off pump, check the oil level and add oil if necessary.

8. Fit the aeration screw and oil-level gauge (F) back on.

Following initial start-up and after each time the diaphragm is changed, tighten the

fixing screws on the dosing head:

After approximately 6 - 10 working hours or two days, tighten the dosing head

screws crosswise using a torque wrench.

Torque:

50 - 54 Nm for KM 254

9.7.7 Cleaning the ball check valve

Only clean the ball check after a diaphragm breakage!

V1.0 43

KM 254 en

S Contact manometer

5s Union nut

2)

6s

6s Contact output

T Ball check

3u

U Connection piece

2u Deaeration screw

2u

3u O-rings

4u Connection for earthing cable

3u

5u Union nut

*2) or locking unit

S

5s

4u

U

5u

T

Removing the ball check and contact manometer

1. For pumps and manometers in flameproof version, unscrew the earthing (4u).

2. Hold the connection piece (U) using a screwdriver and unscrew the union nut (3u).

3. Unscrew the ball check (T) from the dosing head.

Clean the ball check

t7

t1 O-ring

t6

t5

t4

t3

t1

t2 Ball check body

t3 Ball

t4 Spring sheath

t5 Pressure spring

t6 Screw part

t7 O-ring

t2

t1

1. Unscrew screw part (t6) using round pliers.

2. Clean all parts, replace any faulty parts.

3. Reassemble ball check.

4. Refit ball check (T).

5. Screw contact manometer (S) and connection piece (U) back on.