All American 225 Operator's Manual

OPERATOR’S MANUAL

MODEL 225

CAN SEALER

web page: www.allamerican-chefsdesign.com

WISCONSIN ALUMINUM FOUNDRY CO.

1931 SOUTH 14TH STREET

MANITOWOC, WI 54220 USA

920-682-8627 FAX: 920-682-4090

email: customerrelations@wafco.com

Table of Contents

Page 3 - Introduction & Getting Started

Page 4 - Parts Diagram

Page 5 - Maintenance

Page 6 - Adjustments & Seam Gauge

Page 7 - Trouble Shooting

Page 8 - Parts Picture List

Page 9 - Parts List

Page 10 - Warranty Information

Page 11 - Packing List

2

INTRODUCTION

This can sealer was thoroughly inspected and tested at the factory before shipment. Immediately

upon receipt, carefully check the can sealer for damage before using it. Do not operate the can sealer

if it is damaged; call 920-682-8627 for further instruction.

The 225 comes with either the CY-28 No. 2 Chuck or the CY-27 No. 3 chuck and the CY-3 Base Plate.

These are designed and set up to seal a No. 2 or No. 3 can. A sample can was used to set up the

machine and was locked in place during shipping to help protect the machine. Prior to removing the

container, lower and raise the base plate by turning the Can Lifter Handle as far as possible to the left

and then back to the right a few times. Pay attention to the amount of pressure you have to apply to

the Lifter Handle when locking the can into place. It is good to develop a feel for the amount of base

plate pressure required to properly seal a can. Cans with a bigger or smaller diameter will require a

different size Chuck and Base Plate. Height adjustment with spacers is necessary before attempting

to seal other size cans.

GETTING STARTED

1. The sealer can be firmly attached to a table or bar using the four bolt holes (cast into sealer

base) to bolt down the sealer. If that isn’t possible, you can use a C-clamp to attach the sealer

to a bench top.

2. For operation, the seaming lever rivets (CY-22R) should be in the number 2 or the size you are

sealing hole of the cam roller lever (CY-22).

3. Lower the Base Plate (CY-3) by turning the Can Lifter Handle (CY-10) as far as possible to the

left.

4. Place lid on filled can and set can on Base Plate (CY-3).

5. Raise can until it is clamped firmly between the Base Plate and Chuck by turning Can Lifter

Handle (CY-10) as far as possible to the right until handle locks itself against the Frame (CY-1).

The can is now ready to be sealed.

6. Turn the Hand Crank (CY-11) until the first operation roller touches the can. Continue to turn

until the first operation roller pulls away from the can. This hooks the lid to the can. Keep

turning the Hand Crank until the second operation roller touches the can; continue to turn

until the second operation roller pulls away from the can. This finishes the seal. (You will turn

the hand crank a total of 18 times).

7. When both arms are away from the can, pull can lifter handle toward you and remove can.

8. Wipe down the machine frequently to prevent buildup of foreign material.

3

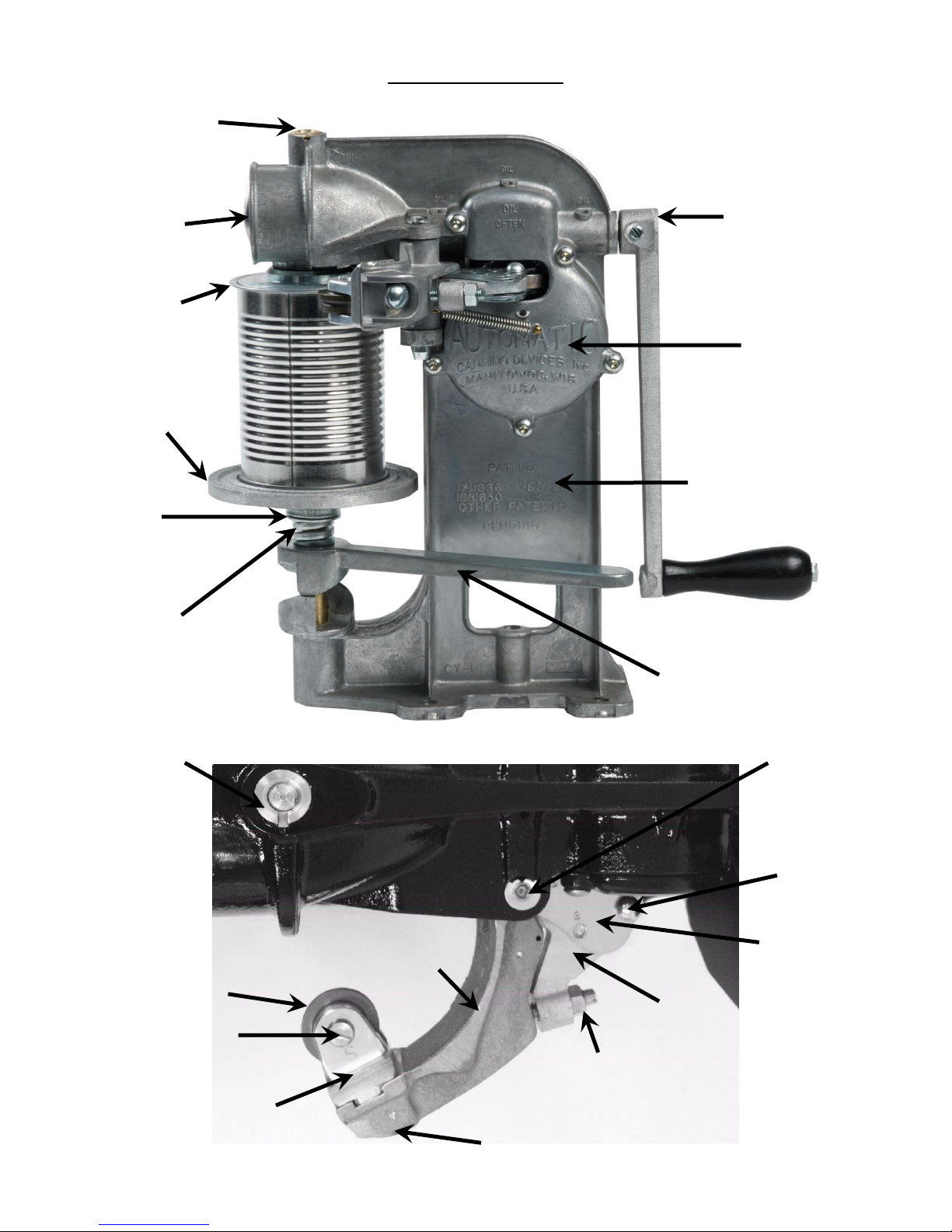

Roller Bearing Lever

CY-9F & CY-9S

Seaming Roller Pin

CY-18F & CY-18S

Seaming Lever

CY-8F& CY-8S

Adjusting Lever

CY-24FS

Cam Roller Lever

CY-22

Operation Roller

CY-14 & CY-15

Lock Screw for Roller Bearing

CY-9LS

Adjusting Screw CY-24AS

and Lock Nut CY-24LN

Crank

Cam Worm Wheel

CY-2

Frame for 225

CY-1

Can Lifter Handle

CY-10

Chuck Holder

CY-19

Front Gear

CY-65

Base Plate

CY-32

Compression

CY-34

Chuck Holder

CY-19

Rivet for Cam Roller

CY-22R

Seaming Lever Pin

CY-17

Base Plate

CY-3

CY-28

PARTS DIAGRAM

Bushing

Complete

Cover

CY-11

No. 2 Chuck

Shaft

Spring

Cover

Bushing

4

Loading...

Loading...