Page 1

Alignment Procedure

Page 2

Table of Content

Ⅰ. SUMMARIZE ...........................................................................................................................6

Ⅱ. ALIGNMENT CONTENTS: .................................................................................................7

1.

ADJUSTMENT OF B+ VOLTAGE ...................................................................................................7

2.

RF AGC ADJUSTM ENT...............................................................................................................7

3.

SCREEN & FOCUS VOLTAGE ADJUSTME NT.................................................................................9

4.

WHITE BALANCE ADJUSTMENT (NORMAL).............................................................................9

5.

ADJUSTMENT OF SUB-BRIGHTNESS............................................................................................9

6.

PICTURE GEOMETRIC ADJUSTMENT............................................................................................ 9

7.

EHT/HEW RATIO TEST(TEST WITH PC PROGRAM):............................................................10

8.X

RAYS OVER VOLTAGE PROTECTING CIRCUIT TEST :................................................................10

9.

PS LINE POLARTITIES TEST :.....................................................................................................11

10.PS

POWER TEST (RANDOM TEST) :..........................................................................................11

11.

HIGH VOLTAGE AND IB VALUE LIMIT TEST( RANDOM TEST )...................................................12

12.H

EATER VOL TAGE TEST ( RANDOM TEST )...............................................................................12

13.

CCD AND VOL-CHIP FUNCTION TEST ..................................................................................12

14.

INITIALIZATION......................................................................................................................12

15.EEPROM

DATA: ................................................................................................................12

Ⅲ. CDRH DOCUMENT :............................................................................................................21

1.

TESTING FOR EHT AND HEW..................................................................................................21

2.

VALUE OF SAMPLE REGISTER IN X-RAY PROTECTION CIRCUIT................................................21

3.

TEST OF X-RAY PROTECTION CIRCUIT......................................................................................21

Page 3

M123SP Alignment Procedure

Ⅰ. Summarize

M123SP,is NTSC only system model developed for NAFTA market specially. In trial

run, burn the software to TMPA8872PSNG IC by OTP method. After the trial run,

make the mask,please take care in production. To solve the probable problems in

production, for the workers participate in alignment, please be familiar with the Alignment

Procedure, and be master of the features.

There are 2 operation modes:user mode and factory mode. You can use the Remote

control or buttons on the panel to operate in user mode, but only Remote control works in

factory mode.

The way to enter factory mode:Press “D-MODE”button on RC, press“OK”and

“CH+”“ CH-”to select the parameter you want to adjust., Press“VOL+”“ VOL-”

to change the parameters. To quit factory mode,press“D-MODE” button(on the right

of SURR button),the factory data changed will be memorized.

A few special modes:

Aging mode — used before the aging before alignment. The aging could start in

factory mode.

Vertical stop mode—used to confirm the screen voltage. Press “INPUT”button in

factory mode to enter Vertical stop mode. Then press

“INPUT” button again to exit.

White balance alignment mode—used for white balance auto alignment. Press“BUS

OFF” button near the left of MTS button to enter White

balance alignment mode.

Factory mode—. Press “SOUND” button in factory mode to initialize the set. The

screen displays“WAIT”, after the initialization,the screen

displays “OK”,and exit the Factory mode automatically.

Then press “D-MODE”button again,it will not enable you to enter Factory mode if

you want to enter again,you need operate as follows:turn down the volume to 0 press

“Volume down”button on the panel,press“INFO”button on the

RC meantime.

Page 4

Ⅱ. Alignment contents:

t

1. Adjustment of B+ voltage

Receive Philips standard testing pattern to RF input.

If the VR800 exists in the board, adjust it in STANDARD mode until voltage at following

value:

Model B+ (v)

20F512T 21185

20F420T 21K77

J13800/1

20V500T 21228

21A31

13V420T(14001)

20V412T 21266

14F512T PJO559

108±0.5

108±0.5

106±0.5

110±0.5

108±0.5

106±0.5

110±0.5

105±0.5

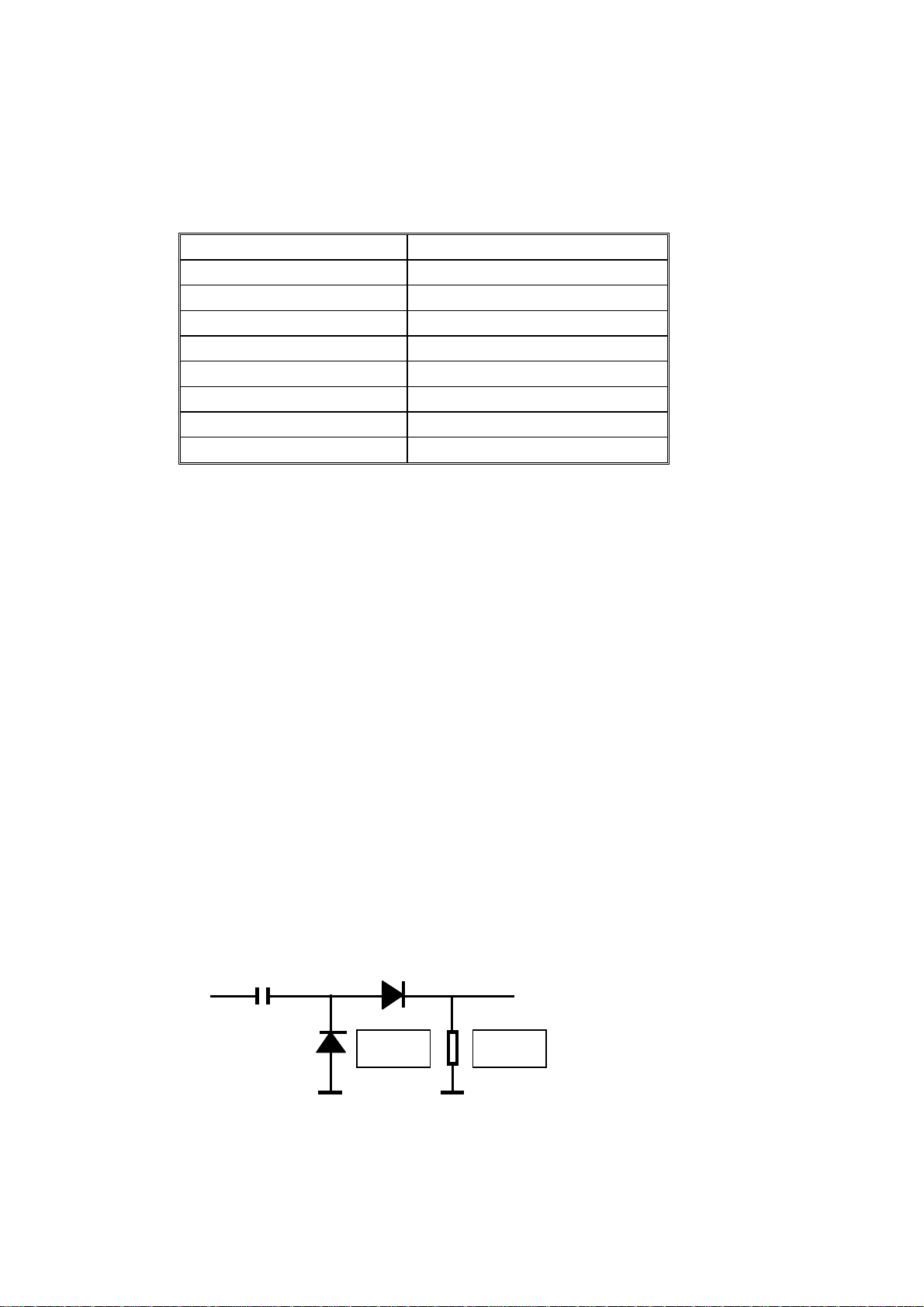

2. RF AGC adjustment

AGC Alignment Procedures:

Apply 8-scale gray signal (80dB), then adjust AGC data in D-mode to get the noise

1)

picture ( snow picture) disappear exactly. Test Pin 1 of TU101 (IF output) and

record the voltage value as V1

P-P.

<Illustrate as Picture A>

2) Apply 8-scale gray signal (80dB), and then adjust AGC data in D-mode until the

synchronization signal distortion appear exactly. Test Pin 1 of TU101 (IF output)

and record the voltage value as V2

3) Calculate the value of V

with the formula: V

P-P

<Illustrate as Picture A>

P-P.

=(V2

P-P

P-P

×V1

P-P)

1/2

Apply 8-scale gray signal (80dB), test Pin 1 of TU101 (IF output), adjust AGC data

until the voltage of Pin 1 of TU101 V

P-P

=(V2

P-P

×V1

P-P)

1/2

。

4) Test three units according to 1),2),3) steps, and record the values of AGC in three

units. Take the average value as benchmark.

Remarks:

Comparing test is necessary due to different probe of Oscilloscope and different Test

Circuit (Picture A).

1) AGC voltage value should be tested afresh, due to the type/supplier of Tuner

input

or Saw filter changed, or other related components changed.

3P f

IN60

outpu

IN60

100K

(Picture A)

Page 5

3. Screen & Focus voltage adjustment

① Apply pattern signal in normal status, enter Factory mode,press“INPUT” button

to stop vertical scan. Note:(the RC/GC/BC is preset to be 40,GD/BD is 40)

Adjust the SCRREEN switch on the flyback transformer to make a horizontal shining ②

line just visible on the screen.

Turn on the vertical output, adjust the “FOCUS” on the flyback transformer to obtain ③

the optimum focus.

4. White balance adjustment (NORMAL)

1) Apply the black and white pattern in normal status;

2) Alignment of normal color temperature

① Change Color Temperature to normal status

② Use a color analyzer to measure the black side of the screen. By changing the value

of RC, GC and BC, set the reading of the color analyzer to THOMSON standard,

x=285+

8, y=294+8.

③ Use a color analyzer to measure the white side of the screen. By changing the value

nd

dark

8,

of GD, BD, set the reading of the color analyzer to THOMSON standard, x=285+

y=294+

8.

④ Separately set the brightness and contrast from min. to max., repeat the step 2 and 3

until the reading of the color analyzer is correct.

Note: Provided the production line is equipped with the self- White balance adjusting

equipment, white balance can be adjusted automatically as following: Press “BUS OFF”

button under factory mode, the TV set will adjust automatically.

THOMSON standard:

Warm X=310+

Cool X=278+

8, Y=314+8

8, Y=282+8

Remark:

1) Provided the production line is equipped with the self- White balance adjusting

equipment, white balance of M123A chassis can be adjusted automatically as following:

Press “I2C BUS” button under factory mode, the TV set will adjust automatically.

2) Free-alignment of warm and cool temperature by presetting the value of RC-W,

GC-W, BC-W, GD-W, BD-W (for warm temperature) / RC-C,GC-C,BC-C,GD-C,BD-C(for

cool temperature ) into memory

5. Adjustment of Sub-brightness

Apply the Grey-scale/Color bar (NTSC signal) to the AV input, in normal status. Enter

factory alignment menu 5, Select BRTC to adjust the sub-brightness, until that the 2

bar of 8 level Grey scale just can be seen.

6. picture geometric adjustment

1. Apply the Philips standard testing pattern in normal status, then enter menu 3,

adjusting the following data to get the min-distortion.

HPOS6(Horizontal Center) PAR A6 (Level) TRAP6 (Trapezia)

HSIZE6(Horizontal Size) CNRT6 (To p) CNRB6 (Bottom)

Page 6

2. Apply the Philips standard testing pattern in normal status, then enter menu 3,

adjusting the following data to get the min-distortion.

HIGH6 (Height) VP60(Vertical Center)

VLIN6(Linearity) VSC6(Vertical-S Correction)

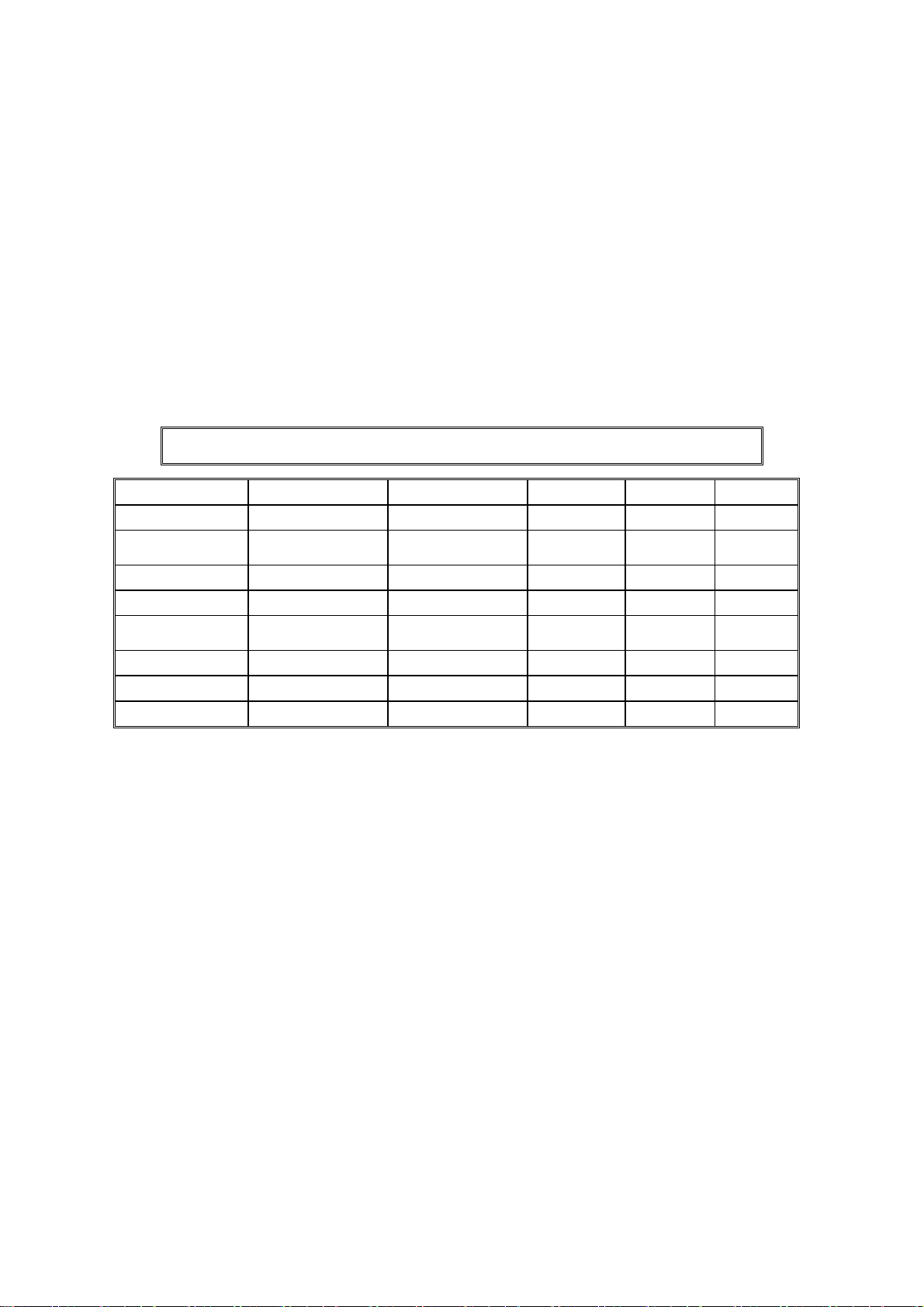

7. EHT/HEW ratio test(test with PC program):

Instruments: EHT test meter,EHT test bar(1000:1),adjustable power supply,virtual

DY( the same L value with CRT in production ).

Test means: Measure the EHT value V when Ib=0,HEW voltage value is V1(DC

voltage at 2 ends of C431).

Check means: apply PC test means,V/V1 should satisfy the requirements below:

EHT/HEW ratio

Model CRT FBT

20F420T(21K77)

J13800/1 44-14OFSN-CH3A 37-FAAT02-BAA1A

20V500T(21228)

21A31

13V420T(14001) 44-14OFSN-CH3A 37-FAAT02-BAA1A

20F512T(21185)

20V412T(21266)

14F512T(PJO559)

44-21RFLW-TS2A 37-FBAT04-CAA1A

44-21OFLN-SG6A 37-FBAT01-CAA6A

44-21RFLW-TS2A 37-FBAT04-CAA1A

44-21RFLW-TS2A 37-FBAT04-CAA1A

44-21OFLN-SG6A 37-FBAT01-CAA6A

44-15RFLP-IR4A 37-FBA003-CAA1A

EHT(0Ua)(KV) HEW(0Ua)(V)

28.5 ±2.5 21.57±1.66 1321±3%

22.5±1.5 20.6±1.66 1092±3%

26.0±2.0 21.00±1.66 1238±3%

28.5 ±2.5 21.57±1.66 1321±3%

22.5±1.5 20.6±1.66 1092±3%

28.5 ±2.5 21.57±1.66 1321±3%

26.0±2.0 21.00±1.66 1238±3%

25.5±1.5 21.70±1.66 1175±3%

RATIO

8.X rays over voltage protecting circuit test :

TV enter working mode,apply more than 26V DC voltage between two ends of C431,

the set should enter protecting mode,or check X rays protecting circuit.

Page 7

9. PS line polartities test :

Connect follow the graphic below:

DC PS

9V

- +

Sound reminder

DX 2.2k

PS socket M

TO F801

Plug the PS line onto the PS socket M, then touch any pin of F801 with the probe, the LED

DX will shine at the moment, with sound reminder, or it is disqualification.

10.PS power test (Random test) :

Instruments: Power meter.

Input signal pattern: Color bar,Sound 1KHZ ,100% modulation.

Input signal intensity: ≥60dBuv (1 Mv rms)

Test points: find the graphic below

Test means: Set the Brightness, CR to the highest, adjust the volume to make

the sound output to be 0.5W. Connect the power meter to test the

power consumption. Transfer the set to be standby, and test the

power consumption at the moment, which should meet the

requirements below:

Model Power Standby power (110V)

20F420T(21K77)

J13800/1

21A31

13V420T(14001)

20V500T(21228)

20F512T(21185)

20V412T(21266)

14F512T(PJO559)

85W ± 10% <3W

65W± 10% <3W

85W ± 10% <3W

65W± 10% <3W

75W ± 10% <3W

85W ± 10% <3W

75W ± 10% <3W

65W± 10% <3W

Page 8

11. High voltage and Ib value limit test( random test )

Instruments: High voltage meter, Ib meter.

Input signal pattern: White vertical

Input signal intensity: 60dBuv (1 Mv rms)

Test means:Connect High voltage meter and Ib meter. Test voltage of different

Ib separately, It should meet the requirements below:

Anode high voltage (Kv)

Model Ib, Ib scope

20F420T(21K77)

J13800/1

20V500T(21228)

21A31

13V420T(14001)

20F512T(21185) ……

20V412T(21266)

14F512T(PJO559)

Ib=50µA

Scope:

50µA&1000µA

….

26.0±2.0

……

…..

26.0±2.0

25.5±2.0

Value Diff.

28.4±2.5 <2

±2.0 <2

22.5

28.4±2.5 <2

±2.0 <2

22.5

28.4±2.5 <2

21”

<2

<2

<2

12.Heater voltage test ( random test )

Instruments :RMS voltage meter

Input signal pattern : Philips test graphic

Input signal intensity :1 mVrms(60dBuV)to 50 mVrms

Connect the RMS voltage meter to the 2 ends of CRT glowers,test the heater voltage of

highest CR and Brightness, It should meet:6.3±0.3Vrms

13. CCD and VOL-CHIP function test

VOL-CHIP and CCD function test,please find the service manual in detail.

14. Initialization

Under the factory mode,press“SOUND”button,the screen displays“WAIT”,

when the screen displays “OK”, the initialization finished. You can enter the next

working procedure.

15.EEPROM DATA:

Note:the items with * are adjustable, other items are not, pls do not adjust them;

Data

Model

20F512T 21185

20F420T 21K77

J13800/1

20V500T(21228)

21A31

13V420T(14001)

FAC 01

RC* GC* BC* GD* BD* HIGH5 VP50 VLIN5 VSC5 VBLK5 VCEN5

40 40 40

40 40 40

40 40 40

40 40 40

40 40 40

40 40 40

FAC 02

40 40 22

40 40 2D

40 40 20

40 40 20

40 40 2D

40 40 20 00 10 13 00 20

06 0A 09 00 17

00 10 16 00 22

00 10 13 00 20

00 10 13 00 20

00 10 16 00 22

Page 9

20V412T(21266)

14F512T(PJO559)

40 40 40

40 40 40

40 40 20

40 40 20

00 10 13 00 20

00 10 13 00 20

Page 10

Data

Model

20F512T 21185

20F420T 21K77

J13800/1

20V500T(21228)

21A31

HIGH6* VP60* VLIN6* VSC6* VBLK6 VCEN6

26 00 10 13 00 25

2E 00 10 17 00 23

21

00 10 13 00 24

26 00 10 13 00 25

2E 00 10 17 00 23

FAC 02

13V420T(14001) 21 00 10 13 00 24

20V412T(21266)

14F512T(PJO559)

26

00 10 13 00 25

26 00 10 13 00 25

FAC 03

Data

Model

20F512T 21185

20F420T 21K77

J13800/1 0F 08 08 08 06 00 02 01

20V500T(21228) 0F 08 08 08 06 00 02 01

21A31

13V420T(14001)

20V412T(21266) 0F 08 08 08 06 00 02 01

14F512T(PJO559) 0F 08 08 08 06 00 02 01

HPOS6 U BLACK V BLACKSTRAP F0SIF FREQ

10 08 08 08 06 00 02 01

0E 08 08 08 06 00 02 01

0E 08 08 08 06 00 02 01

0F 08 08 08 06 00 02 01

STRAP

HL QG

PIF FREQ

NOISE

DET

Data

Model

20F512T 21185

20F420T 21K77

J13800/1 55 0D 25 1B 7F 0E 2C 30

20V500T(21228) 7F 0D 30 1B 7F 0E 2C 30

21A31

13V420T(14001)

20V412T(21266) 7F 0D 30 1B 7F 0E 2C 30

14F512T(PJO559) 50 0D 25 1B 7F 0E 2C 30

CNTX CNTN BRTX BRTN COLX COLN TNTX TNTN

7F 10 20 1B 7F 0E 2C 30

7F 0D 30 1B 7F 0E 2C 30

7F 0D 30 1B 7F 0E 2C 30

55 0D 25 1B 7F 0E 2C 30

FAC 04

Data

Model

20F512T 21185

20F420T 21K77

BRTC* COLC COLP SCOL SCNT CNTC TNTCT TNTCV

48 38 00 07 0F 3A 45 45

3C 38 00 07 0F 3A 58 3D

FAC 05

Page 11

J13800/1 3C 38 00 07 0F 3A 58 3D

20V500T(21228) 3C 38 00 07 0F 3A 58 3D

21A31

13V420T(14001)

20V412T(21266) 3C 38 00 07 0F 3A 58 3D

14F512T(PJO559) 3C 38 00 07 0F 29 58 3D

3C 38 00 07 0F 3A 58 3D

3C 38 00 07 0F 3A 58 3D

Data

Model

20F512T 21185

20F420T 21K77

13800/1

20V500T(21228) 1B 1B 1B 1B 07 1A 1A

21A31

13V420T(14001)

20V412T(21266) 1B 1B 1B 1B 07 1A 1A

14F512T(PJO559) 1B 1B 1B 1B 07 1A 1A

ST3 SV3 SV4 SVD ASSH SHPX SHPN

1B 1B 1B 1B 07 1A 1A

1B 1B 1B 1B 07 1A 1A

1B 1B 1B 1B 07 1A 1A

1B 1B 1B 1B 07 1A 1A

1B 1B 1B 1B 07 1A 1A

FAC 06

Page 12

Data

Model

20F512T 21185

20F420T 21K77

J13800/1 60 00 80 37 C4 C1 09 FF

20V500T(21228) 60 30 80 37 C4 81 09 FF

21A31

13V420T(14001)

20V412T(21266) 60 30 80 37 C4 81 09 FF

14F512T(PJO559) 70 30 80 37 C2 81 09 FF

MOD1 MOD2 MOD3 OPT OPTM1 OPTM2 HDCNT HSTOP

70 30 80 37 C2 81 09 FF

60 30 80 37 C4 C1 09 FF

60 30 80 37 C2 C1 09 FF

60 10 80 37 C4 C1 09 FF

FAC 07

Data

Model

20F512T 21185

‘20F420T 21K77

J13800/1 25 00 21 53 4A 65 1F 16

20V500T(21228) 25 00 21 53 4A 65 1F 16

21A31

13V420T(14001)

20V412T(21266) 25 00 21 53 4A 65 1F 16

14F512T(PJO559) 25 00 21 53 4A 65 1F 16

RF AGC* BRTS OSD OSDF CCD OSD CCD OSDF TXCN RGCN

25 00 21 53 4A 65 1F 16

25 00 21 53 4A 65 1F 16

25 00 21 53 4A 65 1F 16

25 00 21 53 4A 65 1F 16

FAC 08

Data

Model

20F512T 21185

20F420T 21K77

J13800/1 0D 15 27 41 51 5F 6C 6F 32

20V500T(21228) 0D 15 27 41 51 5F 6C 6F 32

21A31

13V420T(14001)

20V412T(21266) 0D 15 27 41 51 5F 6C 6F 32

14F512T(PJO559) 35 48 53 60 66 68 6A 6D 32

V01

35 48 53 60 66 68 6A 6D 32

0D 15 27 41 51 5F 6C 6F 32

V05

35 48 53 60 66 68 6A 6D 32

0D 15 27 41 51 5F 6C 6F 32

V10 V25 V50 V75 V90 V100 VOLMAX

FAC 09

Data

Model

20F512T 21185

20F420T 21K77

CURTCEN VOLX PWTM

A5 7F 08

A5 7F 08

FAC 10

MODE4 MODE5 MODE6 MODE7 MODE8 MODE9

22 0B 1E 47 2D CA

22 0B 1E 47 2D CA

Page 13

J13800/1 A5 7F 08 22 0B 1E 47 2D 02

20V500T(21228) A5 7F 08 22 0B 1E 47 2D CA

21A31

13V420T(14001)

20V412T(21266) A5 7F 08 22 0B 1E 47 2D CA

14F512T(PJO559) A5 7F 08 22 0B 1E 47 2D CA

A5 7F 08

A5 7F 08

22 0B 1E 47 2D CA

22 0B 1E 47 2D C2

Data

Model

20F512T 21185

20F420T 21K77

J13800/1 06 06 02 00 0A 0A 03

20V500T(21228) 06 06 02 00 0A 0A 03

21A31

13V420T(14001)

20V412T(21266) 06 06 02 00 0A 0A 03

14F512T(PJO559) 06 06 02 00 0A 0A 03

CON1 CON2 CON3 STSADJ ALI 1 ALI 2 ALI3

06 06 02 00 0A 0A 03

06 06 02 00 0A 0A 03

06 06 02 00 0A 0A 03

06 06 02 00 0A 0A 03

FAC 11

Page 14

Data

Model

20F512T 21185

20F420T 21K77

J13800/1 10 10 20 64 28 18 22 10

20V500T(21228) 10 10 20 64 28 18 22 10

21A31

13V420T(14001)

20V412T(21266) 10 10 20 64 28 18 22 10

14F512T(PJO559) 10 10 20 64 28 18 22 10

SVM SVM1 OSD2 OSDF2 PYNX PYNN PYXS PYNS

10 10 20 64 28 18 22 10

10 10 20 64 28 18 22 10

10 10 20 64 28 18 22 10

10 10 20 64 28 18 22 10

FAC 12

Data

Model

20F512T 21185

20F420T 21K77

J13800/1 04 03 03 27 14 82 0C

20V500T(21228) 04 03 03 27 14 82 0C

21A31

13V420T(14001)

20V412T(21266) 04 03 03 27 14 82 0C

14F512T(PJO559) 04 03 03 27 14 82 0C

CLTM CLVO CLVS ABL DCBS FLG0 FLG1

04 03 03 27 14 82 0C

04 03 03 27 14 82 0C

04 03 03 27 14 82 0C

04 03 03 27 14 82 0C

FAC 13

Data

Model

20F512T 21185

20F420T 21K77

J13800/1 09 1C 01 08 1A 80 80 00 00 00 00 00

20V500T(21228) 09 1C 01 08 1A 80 80 -- -- -- -- --

21A31 09 1C 01 08 1A 80 80 00 00 00 00 00

13V420T(14001)

20V412T(21266) 09 1C 01 08 1A 80 80 -- -- -- -- -14F512T(PJO559) 09 1C 01 08 1A 80 80 -- -- -- -- --

HAFC AGCC NOIS ONTM NSHP PVLVL PLMT RC-C GC-C BC-C GD-C BD-C

09 1C 01 08 1A 80 80 -- -- -- -- --

09 1C 01 08 1A 80 80 00 00 00 00 00

09 1C 01 08 1A 80 80 00 00 00 00 00

FAC 14

FAC 15

Data

Model

20F512T 21185

20F420T 21K77

J13800/1 00 00 00 00 00 00 00 32 32 5A 32

20V500T(21228) -- -- -- -- -- -- -- 32 32 5A 32

RC-W GC-W BC-W GD-W BD-W YUVGC YUVBC D-COL D-BRI D-CON D-SHP

-- -- -- -- -- -- -- 32 32 5A 32

00 00 00 00 00 00 00 32 32 5A 32

FAC 16

FAC 17

Page 15

21A31 00 00 00 00 00 00 00 32 32 5A 32

13V420T(14001)

20V412T(21266) -- -- -- -- -- -- -- 32 32 5A 32

14F512T(PJO559) -- -- -- -- -- -- -- 32 32 5A 32

00 00 00 00 00 00 00 32 32 5A 32

Data

Model

20F512T 21185

20F420T 21K77

J13800/1 32 32 32 32 32 32 1E 32

20V500T(21228) 32 32 32 32 32 32 1E 32

21A31 32 32 32 32 32 32 1E 32

13V420T(14001)

20V412T(21266) 32 32 32 32 32 32 1E 32

14F512T(PJO559) 32 32 32 32 32 32 1E 32

S-COL S-BRI S-CON S-SHP M-COL M-BRI M-CON M-SHP

32 32 32 32 32 32 1E 32

32 32 32 32 32 32 1E 32

32 32 32 32 32 32 1E 32

FAC 18 FAC 19

Data

Model

20F512T 21185

20F420T 21K77

J13800/1 173 407 01 02 08 06 05 00 00

20V500T(21228) 173 407 01 02 08 06 05 00 00

21A31

13V420T(14001)

20V412T(21266) 173 407 01 02 08 06 05 00 00

14F512T(PJO559) 173 407 01 02 08 06 05 00 00

SEG-POINT1 SEG-POINT2DATA-VLDATA-VHDATA-UF SPE-POS1 SPE-DATA1 SENSI-ONSENSI-OFF

173 407 01 02 08 06 05 00 00

173 407 01 02 08 06 05 00 00

173 407 01 02 08 06 05 00 00

173 407 01 02 08 06 05 00 00

FAC 20

Data

Model

20F512T 21185

20F420T 21K77

J13800/1 2D 4A 38 3E 19 2C

20V500T(21228) 2D 4A 38 3E 19 2C

21A31

13V420T(14001)

20V412T(21266) 2D 4A 38 3E 19 2C

14F512T(PJO559) 2D 4A 38 3E 19 2C

THEATER-BAS

2D 4A 38 3E 19 2C

2D 4A 38 3E 19 2C

2D 4A 38 3E 19 2C

2D 4A 38 3E 19 2C

THEATER-TRE

CONCERT-BASCONCERT-TRE BROCAST-BAS BROCAST-TRE

FAC 21

FAC 22

Page 16

Model

20F512T 21185

20F420T 21K77

J13800/1 03 2A 75 2D 48

20V500T(21228) 03 2A 75 2D 48

21A31

13V420T(14001)

20V412T(21266) 03 2A 75 2D 48

14F512T(PJO559) 03 2A 75 2D 48

VOL_MAI

03 2A 75 2D 48

03 2A 75 2D 48

03 2A 75 2D 48

03 2A 75 2D 48

GATE VOL-OUT AV GAIN OPTM3

Data

Model

20F512T 21185

20F420T 21K77

J13800/1 30 06 00 02 00 00

20V500T(21228) 30 06 00 02 00 00

21A31

13V420T(14001)

20V412T(21266) 30 06 00 02 00 00

14F512T(PJO559) 30 06 00 02 00 00

G2_FLAG00 G2_FLAG01 G2_FLAG02 G2_FLAG03 G2_FLAG04 G2_FLAG05

30 06 00 02 00 00

30 06 00 02 00 00

30 06 00 02 00 00

30 06 00 02 00 00

FAC 25

Page 17

Ⅲ. CDRH Document :

1. Testing for EHT and HEW

Model CRT FBT

20F420T(21K77)

J13800/1 44-14OFSN-CH3A 37-FAAT02-BAA1A

20V500T(21228)

21A31

13V420T(14001)

20F512T(21185)

20V412T(21266) 44-21OFLN-SG6A 37-FBAT01-CAA6A

14F512T(PJO559) 44-15RFLP-IR4A 37-FBA003-CAA1A

44-21RFLW-TS2A 37-FBAT04-CAA1A

44-21OFLN-SG6A 37-FBAT01-CAA6A

44-21RFLW-TS2A 37-FBAT04-CAA1A

44-14OFSN-CH3A 37-FAAT02-BAA1A

44-21RFLW-TS2A 37-FBAT04-CAA1A

2. Value of Sample Register in X-ray protection circuit

Model BOM CRT Designator value

20F420T(21K77)

J13800/1 03-EV13AGP-TU00/1 44-14OFSN-CH3A

20V500T(21228)

21A31

13V420T(14001)

20F512T(21185)

20V412T(21266) 03-D266AGP-TU23W 44-21OFLN-SG6A

14F512T(PJO559) 03-F559AGP-TU23W 44-15RFLP-IR4A

03-DK77AGP-TU23 44-21RFLW-TS2A

03-D228AGP-TU23 44—21OFLN-SG6A

03-DA31AGP-TU26W 44-21RFLW-TS2A

03-E001AGP-TU23W 44-14OFSN-CH3A

03-D185AG-TU60 44-21RFLW-TS2A

EHT(0Ua)

(KV)

28.5 ±2.5 21.57±1.66 1321±3%

22.5±1.5 20.60±1.66 1092±3%

26.0±1.5 21.00±1.66 1238±3%

28.5 ±2.5 21.57±1.66 1321±3%

22.5±1.5 20.60±1.66 1092±3%

28.5 ±2.5 21.57±1.66 1321±3%

26.0±1.5 21.00±1.66 1238±3%

25.5±1.5 21.70±1.66 1175±3%

HEW(0Ua)

(V)

RATIO

R433/R436 470Ω/120Ω

R433/R436 470Ω/100Ω

R433/R436 680Ω/100Ω

R433/R436 470Ω/120Ω

R433/R436 470Ω/100Ω

R433/R436 470Ω/120Ω

R433/R436 680Ω/100Ω

R433/R436 470Ω/82Ω

3. Test of X-ray protection circuit

( X-ray protection circuit will not work with normal voltage, or it does work with over-load voltage)

Model BOM CRT Designator

20F420T(21K77)

J13800/1 03-EV13AGP-TU00/1 44-14OFSN-CH3A

20V500T(21228)

21A31

13V420T(14001)

20F512T(21185)

20V412T(21266) 03-D266AGP-TU23W 44-21OFLN-SG6A

14F512T(PJO559) 03-F559AGP-TU23W 44-15RFLP-IR4A

03-DK77AGP-TU23 44-21RFLW-TS2A

03-D228AGP-TU23 44-21OFLN-SG6A

03-DA31AGP-TU26W 44-21RFLW-TS2A

03-E001AGP-TU23W 44-14OFSN-CH3A

03-D185AG-TU60 44-21RFLW-TS2A

C431

C431

C431

C431

C431

C431

C431

C431

Normal

Voltage

21±1.0

20.6±1.0

±1.0

21

21±1.0

20.6±1.0

21±1.0

±1.0

21

±1.0

21.7

over-load

voltage

>26V

>26V

>26V

>26V

>26V

>26V

>26V

>26V

Loading...

Loading...