Page 1

Page 3-1

ALIGNMENT PROCEDURES

ALIGNMENT PROCEDURES (Continued)

:37

789

Operating Conditions

Unless otherwise noted, the following conditions must be

observed when aligning the ITC222 chassis:

Chassis must be operated from a 120VAC isolation

transformer, with line voltage set to 120VAC (±2.0V).

Picture controls (black level, contrast, etc.) must be set to

factory presets via the Picture Quality menu.

Procedures must be performed in the sequence given.

A 10X probe must be used for oscilloscope and frequency

measurements.

The audio output leads must not be shorted together or to

ground with the chassis on.

All video signals must have -40 IRE sync tips unless specified

otherwise.

Chassis AC power must be removed for 10 seconds before

disconnecting any cable.

A 3-minute warm-up is required for chassis or module related

alignments. A 15-minute warm-up is required for Kine or

Convergence related alignments.

Required Test Equipment

- Dual-Trace Oscilloscope

- Digital Voltmeter

- Frequency Counter

- Audio Signal Generator

- NTSC Signal Generator (B&K 1249, or equivalent)

- MTS Signal Generator (B&K 2009, or equivalent)

- Sweep/Marker Generator (or Standard Signal

Generator)

- YPrPb Signal Generator (DVD player w/YPrPb)

- DC Power Supply (5.0V/0.25A) for TAG001

- Chipper Check® software

- Chipper Check® interface box and computer

- Personal Computer (IBM Compatible w/ CD ROM and

Sound Card)

NOTE: For optimum performance it is critical that this in-

strument be properly aligned. For Auto Convergence

to work correctly it is HIGHLY RECOM-

MENDED that the geometry alignments are first

verified

Small Signal Board (SSB) Replacement

All alignment data is stored in EEPROMs located on the

Small Signal Board (SSB). If the SSB needs to be replaced,

it is HIGHLY RECOMMENDED the EEPROM data be

downloaded by using Chipper Check. Once the SSB has

been replaced, upload the alignment data back into the

instrument. Then verify that the instrument is properly

aligned.

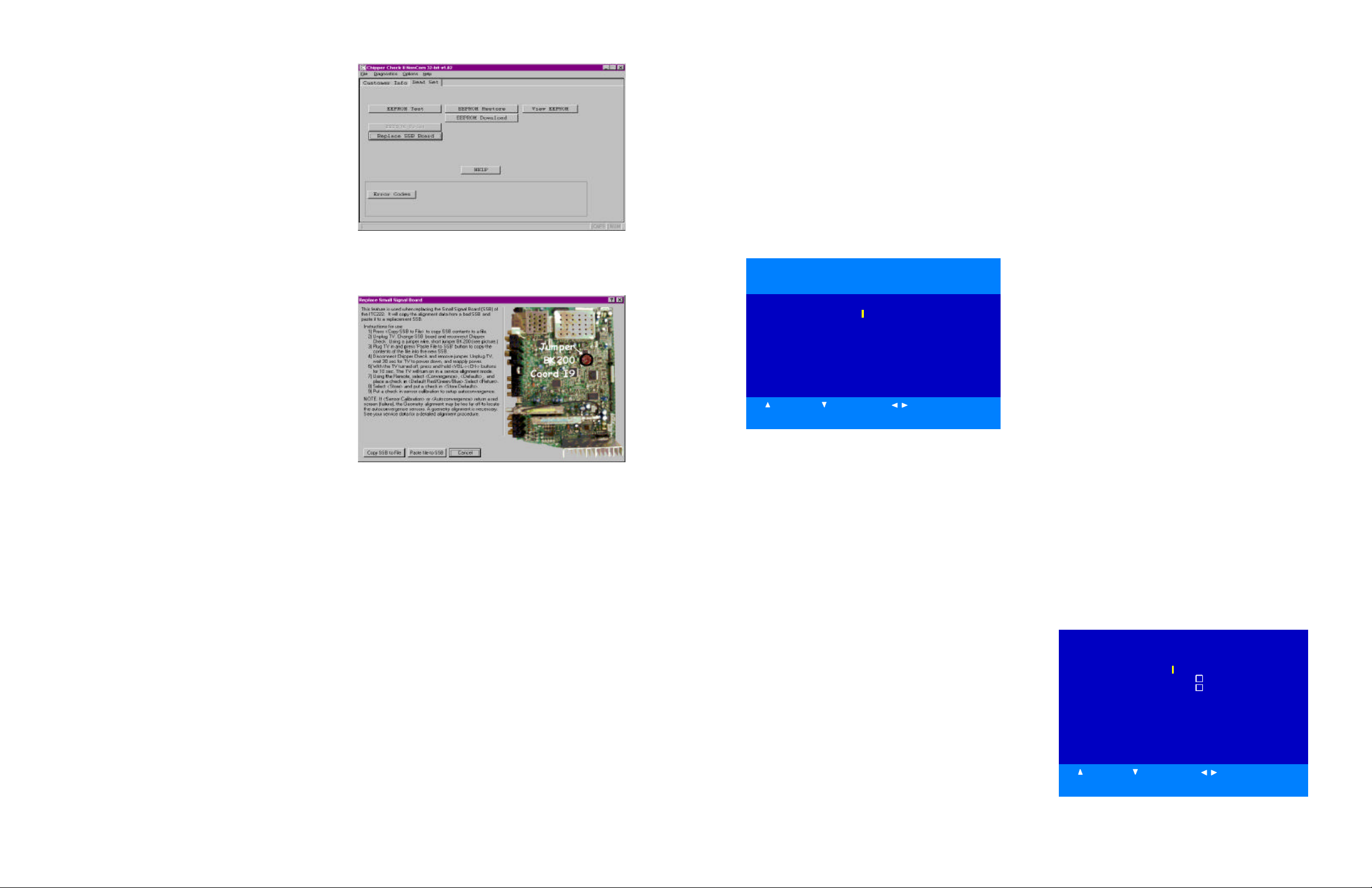

1. Open Chipper Check. Select “Dead Set” “ITC222”.

Follow the On Screen Instructions to establish a connection. Fill in the Customer Information on the “Customer

Info” tab and change to the EEPROM tab.

The following menu should appear.

2. Press the “Replace SSB Board” The following screen

appears

3. Chose “Replace SSB Board Procedure”. Follow the instructions on this screen to copy the alignment data from

the defective SSB to the new SSB.

NOTE: It may be necessary to perform the geometry align-

ment to get the auto convergence to work correctly.

Please refer to the section on Geometry Alignments

CRT Replacement (PTV Models)

If only 1 or 2 CRT’s are replaced use a convergence pattern

to align the new CRT. Align the new CRT to the pattern

generated by the existing CRT by adjusting the Yoke and

Centering Rings. Then run Auto Convergence. If all 3 CRT’s

are replaced, it will be necessary to first center the Green

CRT using a pattern with a center dot. Then align Red and

Blue following the Geometry Alignment procedures.

Service Mode

Most of the alignments for this chassis are software-driven.

Those alignments must be accessed and modified

through the front panel service mode.

Entering the TV Service Mode Using the Front Panel

Controls

1.

Press and release the

POWER button to turn the

instrument off.

2. Wait 10 seconds before trying to enter the Field Service

Mode.

3. Press and hold the VOLUME DOWN and CHANNEL

DOWN buttons for at least 8 seconds.

4. The instrument will switch on and come up with the field

service main menu on the screen. LED will illuminate

before the picture comes up.

The instrument should display the following menu:

Soft-Ver. ITC222_V100-0 000046

DVD Soft-Ver. 3.12

Config. W - - V - - -P - Serial-No. AMN456

QUIT

TUBE

CHASSIS SETUP

FEATURE SETUP

GEOMETRY

VIDEO

EVENT HISTORY

SOUND

MISCELLANEOUS

CONVERGENCE

DVD

UP DOWN

SELECT

Main Menu

The

CH /\ and CH \/ buttons on the front panel are used

to navigate up or down in the menu.

The VOL + and VOL - buttons on the FPA are used to

select a menu item or decrease or increase a value in a

selection list.

The remote control can also be used to navigate the field

NOTE: Before the Field Service Mode is exited; you must

service mode.

check STORE or all changes to alignments will be

• Clear button: When this button is pressed the Field

lost.

Service Mode disappears and the every-day TV

functions are available.

• Menu button: To re-enter the Field Service Mode,

make a long press on the Menu button. The service

technician re-enters in the same menu point where

he left the Field Service Mode.

• ∧: This button is used to navigate up in the menu.

• ∨: This button is used to navigate down in the menu.

• <: This button is used to select a menu item, to

decrease a value or to select the previous value in a

selection list.

• >: This button is used to select a menu item, to

increase a value or to select the next value in a

selection list.

• OK: This button is used to select or deselect a

menu item.

Main Menu

Soft-Ver: Displays the current software version.

Runtime Counter: Displays the total runtime in

hours and mintues.

DVD Soft-Ver: For DVD models only, displays the

current software version.

Config: Displays the configuration code of the

instrument. Each character represents a paraticular

hardware feature or option.

Serial-No.: Displays the serial number of the

instrument.

Common features found in the submenus

Return: The submenu is closed and the main Field

Service Mode menu appears.

Defaults: The default values for the current menu

are copied from ROM to RAM.

Note: If Default is checked a complete realignment of

that particular menu is required.

Store: All current values from a menu group are

stored into memory.

Restore: The last stored settings for the menu

displayed are copied from NVM to RAM.

Tube Type Menu

1. Select the correct tube type from a pulled down

list on the right hand side of the menu. (This

will activate new tube type values along with

default video and geometry parameters)

2. Check STORE to save new parameters in

memory.

TUBE

Return

Tube Type RP 16x9

Store

Restore

UP DOWN SELECT

Tube Submenu

Page 3-2

Page 2

Page 3-4

Page 3-3

ALIGNMENT PROCEDURES (Continued)

Chassis Setup

ALIGNMENT PROCEDURES (Continued)

Subwoofer: Allows the instrument to be configured for

a subwoofer

Pict. Rotation: Specifies whether the picture rotation

option is available or not. (DV Models Only)

Autoconvergence: Specifies whether the

autoconvergence option is available or not. (PTV Models

Only)

DVI: Specifies whether the DVI option is available or

not.

Toplight: Specifies whether the toplight option is

available or not.

CHASSIS SETUP

Return

Subwoofer

Pict. Rotation

Autoconvergen ce

DVI

Toplight

Defaults

UP DOWN SELECT

Chassis Setup Submenu

Feature Setup

Curtains Effect: Determines if the curtains feature is

available to the user.

Opt. Still Pict. : Determines if the Optimised Still Picture

feature is available to the user.

Auto Film Mode: Determines if the Automatic Film

Mode Detection feature is available to the user.

Burn-In Prot. : Determines if the Burn-In Protection

feature is available to the user.

FEATURE SETUP

Return

Curtains Effect

Opt. Still Pict.

Auto Film Mode

Demo Mode

Burn-In Prot.

Welcome/Contact

Program Info

Defaults

UP DOWN SELECT

Feature Setup Submenu

Geometry Alignment

Entering the Geometry menu the display mode must be

set to Standard Scanning Mode (480i/480p and 1080i).

All 480i/480p alignments should be completed using the

RF input. Use either component input or DVI-input for

1080i adjustments.

Geometry Submenu

Alignment Procedure (Direct View Models Only)

NOTE: Unless otherwise noted all Geometry adjustments

must performed in both 480i/p and 1080i modes.

1. Place the instrument in the Field Service Mode.

2. Enter the Tube submenu. Verify the correct tube type

is selected.

3. Enter the Geometry submenu.

4. Adjust H-Amplitude (Horizontal Amplitude) for slight

underscan.

5. Enter the Video submenu. Selct the G2 alignment.

Adjust the Screen control on the flyback until the just

becomes visible.

Geometry Submenu

6. Adjust PL557 on the Dynamic Focus Board to center the

raster between the tube border.

7. Realign G2 for 150V on the highest cathode.

8. Tune the instrument to receive a crosshatch pattern.

9. Return to the Geometry submenu.

10. Adjust V-Slope (Vertical Slope) until the middle line of

the test pattern is just visible. (Not used in 1080i)

11. Using a Monoscope pattern, adjust V-Amplitude (Vertical Amplitude) until the first and last horizontal line of

the test pattern is just hidden by the tube.

NOTE: Instruments with 16/9 CRT’s must have this

alignment performed with the format set to 16/9.

12. Adjust V-Position (Vertical Position) until the picture is

centered vertically. It may be necessary to recheck the VAmplitude (Step 11) adjustment.

13. Adjust V-Linearity (Vertical Linearity) for equal height

of the squares in the crosshatch pattern.

NOTE: Instruments with 16/9 CRT’s must have this

alignment performed with the format set to 16/9.

14. Adjust H-Position (Horizontal Position) until the test pattern is horizontally centered.

15. Using a Monoscope pattern adjust H-Amplitude (Horizontal Amplitude) until the first and last horizontal line of

the test pattern is just hidden by the tube. It may be necessary to recheck the H-Position (Step 14) adjustment.

16. Using a Crosshatch pattern adjust EW-Amplitude (East

West Amplitude) until the vertical lines in the middle of

the CRT are straight.

17. Adjust EW-Upper Corner (East West Corner) until the

vertical lines are straight at the top of the screen.

18. Adjust EW-Lower Corner (East West Corner) until are

straight at the bottom of the screen.

19. Adjust EW-Symmetry (East West Symmetry or H-Bow)

until the left and right border of the screen are the same.

NOTE: It may be necessary to repeat Steps 14- 19 after this

adjustment for optimum performance.

20. Adjust H-Parallel (Horizontal Parallelogram) the offset

between the top and bottom of the picture.

21. Adjust EW-Trapezium (East West Trapezium) for best

compromise between Left and right vertical lines.

22. Adjust Breathing (EHT Compensation) until horizontal

amplitude will change with different beam current at the

same ratio as vertical amplitude.

23. H-Max and H-M set the range limitations of the H-Amplitude adjustment. This adjustment should only be used

in cases where CRT is replaced and it does not appear in

the CRT list. To access this adjustment, the Development Support must be checked in the Miscellanous Setup

menu.

24. To check the box to set the shutdown threshold for the

XRP circuitry, hold down the “OK” button for

approxomately 5 seconds. During this automatic process

the screen will blank, then reappear once it is finished.

25. Before exiting the Geometry menu, check Store to save

changes to memory.

26. After the Geometry Alignments, check the Earth-Field

Compensation (EFC) adjustment (DV Models Only). Enter the Advanced Picture Setting Menu. Using a crosshatch pattern, adjust the EFC for minimum picture rotation at the top and bottom.

Alignment Procedure (Projection Models Only)

NOTE: Unless otherwise noted all Geometry adjustments

must performed in both 480i/p and 1080i modes.

1. Place the instrument in the Field Service Mode.

NOTE: It is recommended the Geometry alignments be

performed using the Green CRT only.

2. Enter the Tube submenu. Verify the correct tube type is

selected.

3. Tune the instrument to receive a crosshatch pattern.

4. Return to the Geometry submenu.

5. Adjust V-Slope (Vertical Slope) until the middle line of

the test pattern is just visible. (Not used in 1080i)

6. Exit the Geometry submenu and turn the instrument OFF.

Disconnect the Convergence Yoke connectors BW001

and BW002 (Located in lower right corner of the Convergence Amplifier PCB). Turn the instrument ON and

tune to receive a center line pattern. Adjust horizontal

and vertical center lines according to the chart below

with the static convergence magnets. When completed

turn the instrument OFF and reconnect the convergence

yoke connectors.

Page 3

Kine

Socket

Phosphor

ALIGNMENT PROCEDURES (Continued)

ALIGNMENT PROCEDURES (Continued)

Page 3-5

Page 3-6

Screen Size

40" 2.4 cm (0.94 in) 2.4 cm (0.94 in)

52" 3.1 cm (1.22 in) 3.1 cm (1.22 in)

56" 3.3 cm (1.29 in) 3.3 cm (1.29 in)

61" 3.5 cm (1.37 in) 3.5 cm (1.37 in)

Red Center Line

Set Left of Center

Blue Center Line

Set Right of Center

7. Place in the Field Service Mode. Enter the Geometry

submenu. Using a Monoscope pattern, adjust V-Amplitude (Vertical Amplitude) until the first and last horizontal line of the test pattern is just hidden by the tube.

8. Adjust V-Position (Vertical Position) until the picture is

centered vertically.

9. Adjust V-Linearity (Vertical Linearity) for equal height

of the squares in the crosshatch pattern.

10. Adjust H-Position (Horizontal Position) until the test pattern is horizontally centered.

11. Using a Monoscope pattern adjust H-Amplitude (Horizontal Amplitude) until the first and last horizontal line

of the test pattern is just hidden by the tube.

12. Using a Crosshatch pattern adjust EW-Amplitude (East

West Amplitude) until the vertical lines in the middle of

the CRT are straight.

13. Adjust EW-Trapezium (East West Trapezium) for best

compromise between Left and right vertical lines.

14. Adjust EW-Symmetry (East West Symmetry or H-Bow)

until the left and right border of the screen are the same.

NOTE: It may be necessary to repeat Steps 10- 14 after this

adjustment for optimum performance.

15. Adjust Breathing (EHT Compensation) until horizontal

amplitude will change with different beam current at the

same ratio as vertical amplitude.

16. H-Max and H-M set the range limitations of the H-Amplitude adjustment. This adjustment should only be used

in cases where CRT is replaced and it does not appear in

the CRT list. To access this adjustment, the Development Support must be checked in the Miscellanous Setup

menu.

17. Check the box to set the shutdown threshold for the XRP

circuitry by holding down the “OK” button for 5 sec.

During this automatic process the screen will blank, then

reappear once it is finished.

18. Before exiting the Geometry menu, check Store to save

changes to memory.

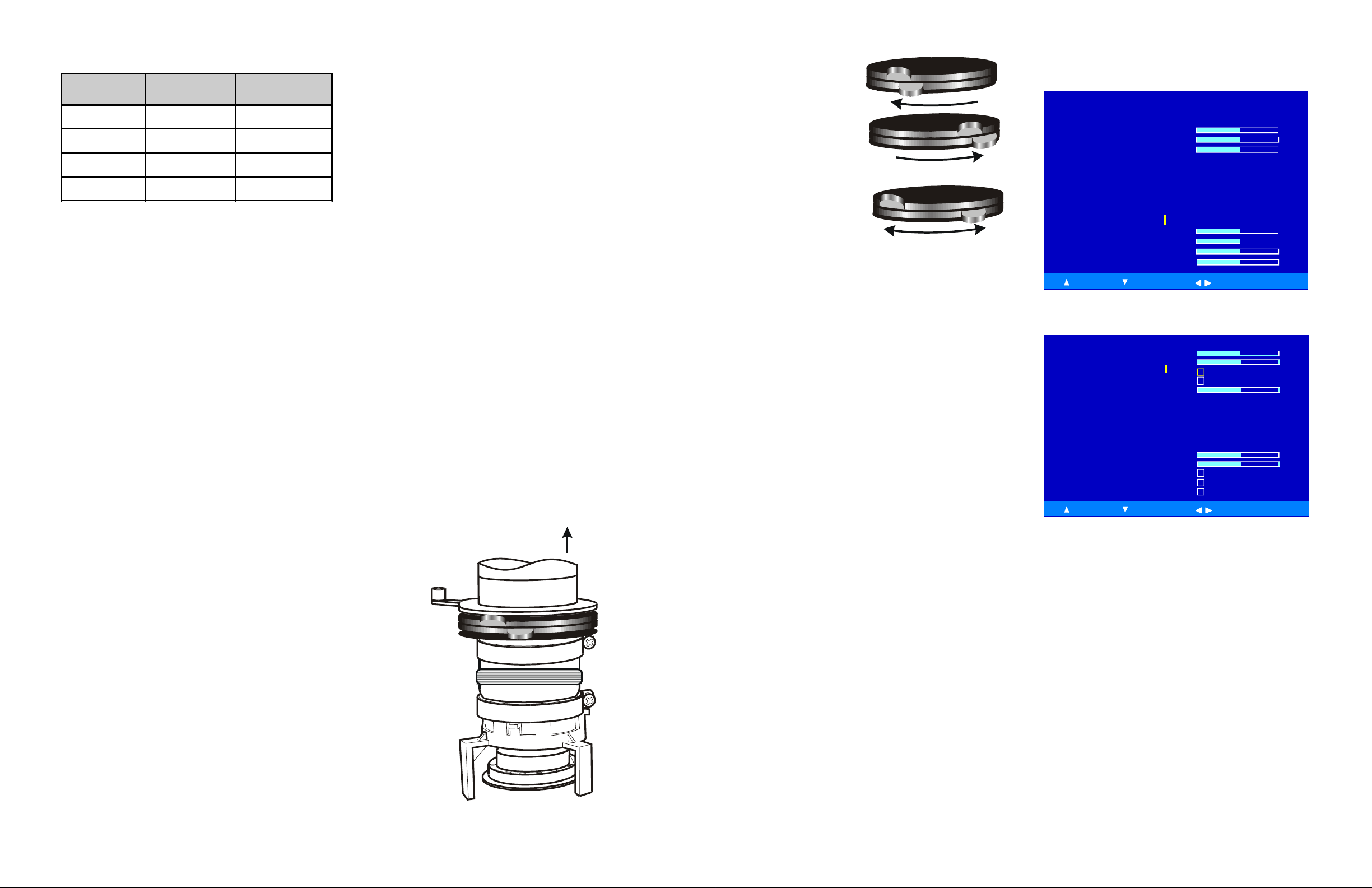

Yoke Centering Ring Adjustment

If Chipper Check is not available it is possible to replace a

single CRT and realign geometry by using the centering rings

on the CRT.

Using the convergence pattern available when in service

menu the pattern from the replacement CRT may be adjusted

to align with either of the two remaining CRT's using the centering rings shown in Figure 1.

First make certain the replacement CRT and yoke are assembled and placed back in the mounting as close as possible

to the original CRT and yoke. At this point having the convergence pattern on screen will assist in the mechanical mounting.

Using the centering rings and observing the convergence

pattern, rotate and move the pattern until the replacement color

overlays as close as possible to the two colors not replaced.

Moving the ring tabs together around the neck of the CRT

draws the raster in small circles. Spreading the tabs apart

moves the raster in more linear angles. The closer the tabs

are together, the less affect on the CRT beam they have.

When the raster is as close as possible fix the magnets with

paint or nail polish to prevent further movement.

After fixing the magnets, if gross geometry errors are apparent, geometry alignment is indicated. If the raster is close,

use the "Auto-convergence" feature provided in the consumer

menu to re-align convergence. This should correct most minor geometry problems. Follow auto-convergence with the

consumer red and blue centering adjustments, then evaluate

the raster again.

In most cases convergence will now be acceptable. If only

slight convergence errors are noted the technician should enter the manual digital convergence menu and begin "touchup" of the screen.

If gross geometry errors are still apparent re-evaluate

whether the errors are noticable on the replacement CRT or

whether they are global, affecting all three CRT's. If the errors affect all three CRT's a full geometry alignment is indicated. If the errors only affect one CRT, particulary the replacement, return to the mechanical placement and centering

ring adjustments and begin those procedures again.

Screen

Centering

SVM Yoke

Figure 1 - Centering Rings

Rotate Tabs Together

Spread Tabs Apart

Figure 2 - Centering Ring Tab Movement

Focus Adjustments

Before attempting the Focus Adjustments, allow the

instrument to warm up for a minimum of 15 minutes.

Dynamic Focus CRT (DV Models Only)

1. Tune the instrument to receive a crosshatch pattern.

2. Turn the F1 (Static) control on the focus block fully clockwise

3. Adjust the F1 control while observing the vertical lines

along the left side of the screen for best possible focus.

4. Turn the F2 (Dynamic) control on the focus block fully

clockwise.

5. Adjust the F2 control while observing the horzontal lines.

Adjust for best possible focus.

6. Repeat step 3 and 5 for best possible overall focus.

Single Focus CRT (DV Models Only)

1. Tune the instrument to receive a crosshatch pattern.

2. Turn PL501 (Located on the Dynamic Focus PCB) to the

full counter clockwise position.

3. Adjust F2 on the focus block for best possible focus of the

horizontal lines.

4. Adjust PL501 for best possible focus of the vertical lines.

5. Repeat steps 3 and 4 for best possible overall focus.

Focus Adjustment (PTV Models)

1. Tune instrument to receive a crosshatch pattern.

2. Preset Contrast to maximun.

3. Adjust each CRT separately. Cover the two CRT’s not being adjusted and adjust for best overall focus.

5. Adjust the Green Electrical Focus control, located behind

the speaker grill for best overall focus.

6. Repeat procedure for the Red and Blue CRT’s.

Video Alignments

VIDEO PA L RF - BG

Return

Peak White

Whitepoint R

Whitepoint G

Whitepoint B

G2 Alignment

Scaling Colour

Scaling Brightness

Cut off R

Cut off G

UP D OWN SELECT/CHANGE

VIDEO PAL RF - BG

Scaling Contrast

Scaling Tint

Contrast max

Drive Loop Disable

Text Contrast

Full White 4/3

Drive Level

Defaults

Store

Restore

UP DOWN SELECT/CHANGE

D4

80

F0

40

- 22

78

+90

D4

80

-18

- 22

78

Video Alignment Submenu

Before attempting the Video Alignments, allow the

instrument to warm up for a minimum of 15 minutes.

1. Tune the instrument to receive a crosshatch

pattern.

5. Place the instrument in the Field Service Mode.

6. Enter the Video submenu.

7. Select G2 adjustment.

8. Adjust Screen control until retrace lines become

visible, then adjust to make retrace lines invisible.

9. Press any key to exit the G2 alignment mode.

10. Select a pluge test pattern. Pattern should have a

0% background with a -2% and +2% bar.

11. Adjust Scaling Black Level to make the -2% bar

invisible, keeping the +2% bar visible.

Page 4

Page 3-7

ALIGNMENT PROCEDURES (Continued)

ALIGNMENT PROCEDURES (Continued)

12. Select a 75% color bar test pattern.

13. Connect a scope to the Blue Cathode of the CRT

board.

14. Adjust the Scaling Color to the levels shown

below.

For these adjustments this bar and the next brighter

bar will be used. On most patterns the remainder of

the bars will progressively become brighter.

2. Adjust Black Cutoff R or Black Cutoff G until any

tinting disappears from the black bar. When properly

adjusted the adjacent bar should be a very low level

gray with no color tinting.

3. Now observe the brighter portions of the bars.

Adjust Whitpoint R, G, or B to remove any signs of

tint in the higher brightness bars. Observe the bars

for signs of CRT overdrive. Some compromise may

be required, but the higher IRE bars should be as

free from color tinting as possible.

Note: There are separate color temperature alignments for

RF (NTSC), Comp 1H, Comp 2H, DVI and

AUX_RGB (If unit has DVD option installed).

2. Adjust for peak white.

3. Contrast Max and Scaling Contrast are preset

according to the CRT type selected and do not need

to be adjusted.

Event

If a run-time event occurs, its error code will be stored in

the NVM. The stored event codes can be read in one of two

methods. The first is with the event menu. The last five

event codes will be displayed, along with a time stamp

from the run time counter. The time stamp will display the

last occurrence of a particular event. The time stamp is

displayed as “Run Hours”. An event counter counts how

many times that event has occurred. The counter will not

count beyond 255. The most recent event code is displayed

on top. To clear the event codes from memory, select the

Clear Event Codes box. A long press will clear all stored

codes.

Note: This alignment must be performed in each of the

following modes, Tuner, Comp 1H, Comp 2H, DVI

and AUX_RGB (if DVD option is installed).

16. The Drive Level Alignment is preset according to

the CRT type selected and does not need to be

adjusted.

17. Before exiting the Video Alignment Submenu, check

Store to save all alignments.

Color Temperature (Overview)

Color Temperature for the ITC222 is similar to past chassis.

Some form of staircase pattern similar to the figure below is

required. Proper identification of the “0” (if available) and

“7.5” or “setup” bars on screen and the waveform produced

on the cathodes of the CRT will be needed. Consult the

specifications manual for the pattern generator used to

confirm the location of these bars.

The oscilloscope waveform shows the relationship between

the bars and the video signal at the cathodes of the CRT.

This waveform is present on all three cathodes. With the

oscilloscope adjusted to provide a full peak to peak readout

of the waveform at the horizontal rate, the 7.5 IRE setup

bar will the critical area. Be certain this bar can be identi

fied using the equipment available. If a 7.5 IRE bar is not

available, 10 IRE may be used.

It should be noted that bar patterns differ. Some vary from

10 to 100 IRE in various steps and in different directions,

but most should have an identifiable 7.5 to 10 IRE bar.

The purpose of the color temperature setup is to assure

uniform gray level from black to the brightest scenes. If a

uniform gray screen is displayed, no matter the brightness

level, no tinting in either red, green or blue direction should

be apparent. This is known as “color tracking”. Once the

proper color temperature is set, AKB will maintain the

cutoff of the CRT to assure proper low light performance.

Black Cutoff R/G, Whitepoint R/G/B Setup

(Recommended Method)

1. Apply a gray test pattern giving a 12 IRE flat

window. Connect Colorimeter near the center of

the screen.

2. Adjust Black Offset R and Black Offset G to

obtain the following color coordinates.

Direct View Projection TV

X 0.282 0.283

Y 0.298 0.296

3. Apply a gray test pattern giving a 50 IRE flat

window.

4. Adjust Whitepoint R, G, and B for the following

color coordinates.

Direct View Projection TV

X 0.282 0.278

Y 0.298 0.291

Note: This alignment must be done in the following

modes, RF (NTSC), Comp 1H, Comp 2H, DVI

and AUX_RGB (If unit has DVD option

installed).

Black Cutoff R/G, Whitepoint R/G/B Setup

(Alternative Method)

1. Apply a vertical gray bar staircase pattern (at least

8 bars from “7.5” to “>75” IRE). Identify the 7.5

IRE bar location. It is the “black” or “cutoff” bar.

Peak White Alignment

1. Apply a white centered pattern of 100 IRE 2% of

the picture surface on a dark background.

2. Adjust for peak white at center of the screen.

3. Check Scaling Black Level, Whitepoint, Black

Offset and Peak White adjustments. It may be

necessary to adjust these alignments several times

for optimum performance.

Note: This alignment must be done in the following

modes, RF (NTSC), Comp 1H, Comp 2H, DVI and

AUX_RGB (If unit has DVD option installed).

Full White 3/4 Alignment

1. Insert a full white pattern of 100 IRE through RF.

(Instrument will automatically set to ¾ mode).

2. Adjust for full white across the screen.

Text Contrast, Contrast Max, Scaling Contrast

Alignments

1. Insert a white centered pattern of 100 IRE, 2% of

the picture surface with a black background.

Only the last error code stored in the NVM can be

read with this method. The LED will blink two separate digits.

Example, if the error code of 23 is the last error code stored

EVENT HISTORY

Return

Clear Event Codes

Code Co unt Time Stamp

11 00 1 00 0135:30

24 01 2 00 0090:10

78 00 3 00 0043:54

51 00 1 00 0001:20

00 00 0 00 0000:00

Test: Brightness Sensor: 2 Colour: R

Direction: Right Value: 125 Scan mode: 2H

UP DOWN SELECT/CHANGE

Event Submenu

in the NVM, the LED will have 2 short flashes, followed by

a short pause. Then will flash 3 times, followed by a long

pause. This will be repeated 4 times.

First allow the instrument to sit unplugged for 60 seconds.

At plug in the LED will first blink twice to indicate

microprocessor has reset. When an attempt is made to power

up, the instrument will attempt 3 times to start. The LED

will display a series of flashes followed by the error codes.

The LED will flash the error code 4 times.

Sound Setup

Effect Strength (MED): Modifies the bass effect

strength for the user setting MEDIUM.

Effect Stength (HIGH) : Modifies the bass effect

strength for the user setting HIGH.

Page 3-8

Page 5

Page 3-9

ALIGNMENT PROCEDURES (Continued)

ALIGNMENT PROCEDURES (Continued)

R e s t or e

10 80

Low Pass Frequency: Modifies the low pass cut-off

frequency.

High Pass Frequency : Modifies the high pass cut-off

frequency.

Sub-woofer Corner Frequency : Modifies the subwoofer corner cut-off frequency.

SOUND

Return

Effect Strength (MED) 80

Effect Strength (HIGH) 9A

Low Pass Frequency 80

High Pass Frequency 56

Sub-woofer Corner Frequency 80

Defaults

Store

Restore

UP DOWN SELECT/CHANGE

Sound Setup Submenu

Miscellaneous

Clear Programs:

Select with a 2 second press to clear

all programs stored in memory and set Picture

Preference, User Picture and Audio settings to factory

values. Returns the instrument to “Out of Factory Mode”.

Default Presets : Sets the default value for all factory

sound and picture presets.

Bus Quiet: In this mode the NVM can be read, modified

or reprogrammed. Enter this function with with a 2

second press. This mode is cancelled with a press of

Clear, Left, Right, Up, Down or On-Off keys.

Development Support : Enables or Disables access to

development support functions in the field service

menus.

Restore Factory Settings : Restores the correct “Out

of Box” condition.

Switch 2nd Tuner to Main : Causes the current signal

on the 2nd tuenr to be switched to the main screen and

the monitor output jacks. Any channel change will

override this feature and return tuning to normal.

MISCELLANOUS

Return

Clear Progs

Default Presets

Bus Quiet

Development Support

Restore Factory Settings

FFI Bit

Switch 2nd tuner to main

UP DOWN SELECT

Miscellaneous Setup Menu

Convergence (PTV Models Only)

Overview

The ITC222 employs a ditigal convergence circuit that makes

it possible to electronically align up to 208 separate points

on the screen. 3 levels of convergence adjustment is provided.

Level 1: Provides 9 adjustment points

Level 2: Provides 25 adjustment points

Level 3: Provides 195 adjustment points

CONVERGE NC E AL I G NM E N T

Ret u r n

Le vel

1 (3 x 3 )

Le vel

2 (5 x 5 )

L e v e l

3 ( 1 5 x

1 3 )

S e n s or c a l i br a t i o n

A u t o c o n v er ge nc e

Def a ul t s

St or e

U P

D O W N

S E L E C T / C H A N G E

Convergence Submenu

It is recommended to adjust Levels 1 and 2 only if repairs

have been made to the Convergence Signal circuitry or after

CRT replacement. Before performing the Convergence

Alignment procedure it is HIGHLY RECOMMENDED the

Geometry Alignment of the instrument is checked.

Note: Alignments must be performed in order. If Level 3

is adjusted, prior to Levels 1 or 2, all Level 3

7. Select “Return” to exit the Convergence Alignment

Menu.

alignments will be lost.

Note: This procedure must be performed in both the 480P

and 540P (1080I) modes. The initial service menu

In Level 1 and 2, Press OK to select the color to be

aligned. The position of the adjustment point can adjusted

screen will indicate which mode the instrument is

in.

using the navigation keys (up, down, left and right) on the

remote. Press the 2 key of the remote to move to the next

adjustment point. Press the EXIT/CLEAR key to exit

when completed.

DVD (DVD Models Only)

1. Place the instrument in the Field Service Mode.

2. Enter the DVD submenu.

3. Activate DVD Factory Mode by selecting the box. Press

Level 3 alignment works simular to Levels 1 and 2. The

only difference, to move to the next adjustment point press 2

(up), 8 (down), 6 (right) and 4 (left) on the remote unit.

when completed with convergence, press STORE to save all

changes.

Sensor Calibration is used to calculate a reference border

for the autoconvergence photo sensors. Check the box to

begin the process. Autoconvergence starts the

autoconvergence process.

Defaults enters a default submenu. Checking the box loads a

and hold the OK button for at least 2 seconds. The screen

will then show the menu shown below. This process may

take several seconds.

1. Place the instrument in the Field Service Mode.

2. Enter the DVD submenu.

DVD

Return

Activate DVD Factory Mode

A 2 second press on the OK key will cause the

TV to put the internal DVD into factory mode.

This may take a few seconds. When completed

the DVD field service commands will be available.

set of default values from the convergence backup NVM to

the Convergence IC RAM. The box will remain checked until

the value is changed or store or restore is pressed in the

convergence submenu.

UP DOWN SELECT

Note: Before the Convergence Alignement menu is exited,

you must check Store or all settings will be lost.

DVD Submenu

Manual Convergence Procedure

1. Turn instrument “On”. Allow to warm up for 20

munitues. Turn instrument “Off”. Enter the Service

Menu holding the “Channel Down” and “Volume

3. Activate DVD Factory Mode by selecting the box. Press

and hold the OK button on the remote for at least 2 seconds. The menu will then change to the menu shown below. This process may take several seconds.

Down” on the FPA for 8 seconds. Enter the

“Convergence Menu”.

2. Perform “Level 3” (and/or Level 1, Level 2) manual

convergence as describe above. When completed,

press “Clear”, then select “Return” to go back to

the main Convergence Alignment Menu.

3. Check “Store” in the main Convergence Menu. A

check mark will appear in the box.

4. Select “Defaults” to enter the Default Menu.

DVD

Return

Activate DVD Factory Mode

Restore Factory Settings

OSD to Video Ratio Normal...

Test Pattern 1 - 5 2...

Start SW update

5. Select “Store Defaults”. Press and hold OK on the

Remote for 2.5 seconds. Then select “Return” to

go back to the main Convergence Alignment Menu.

6. Perform “Sensor Calibration”. Select it and press

UP DOWN SELECT

“OK”.

Note: If the Sensor Calibration is successful, the software

will answer by flashing a GREEN SCREEN . If the

GREEN SCREEN does not appear, turn the

instrument off and begain the convergence

procedure again.

DVD Submenu (with Factory Mode Activated)

Restore Factory Settings: This will re-initialise

the DVD’s NVM content using the system NVM.

OSD to Video Ratio: Aligns the ratio between the

Page 3-10

Page 6

ALIGNMENT PROCEDURES (Continued)

Page 3-11

ALIGNMENT PROCEDURES (Continued)

Page 3-12

DVD Video Signal and the DVD OSD Video Signal.

This is internally adjusted by the DVD and cannot be

modified.

Test Pattern 1 - 5: Provides 5 test patterns for alignment.

1. Scaling Color 75/White, 75% Color Bars

2. Cutoff Alignment, 140mVp/p

3. Drive Alignment, 455mVp/p

4. Peak White Alignment, 700mVp/p

5. Color Temperature and Peak White

Event

Code

Event Circuit Condition

11 I2C_1 Low SDA Line Data Line of I2C Bus_1 Held Low

12 I2C_1 Low SCL Line Clock Line of I2C Bus_1 Held Low

13/95 I2C_2 Low SDA Line Data Line of I2C Bus_2 Held Low

14/95 I2C_2 Low SCL Line Clock Line of I2C Bus_2 Held Low

15 I2C_3 Low SDA Line Data Line of I2C Bus_3 Held Low

16 I2C_3 Low SCL Line Clock Line of I2C Bus_4 Held Low

140/170/700/359/455mVp/p

Start Software Update: Allows the DVD software to be

update. The update is sent as a CDROM

1. Selecting this function will automantically

open the DVD and switch the instrument

to the DVD mode.

2. Place the CDROM in the instrument.

Follow the instructions provided on the

screen. Durning the update process the

display will read “Updating DVD Soft

ware”.

3. After the software update is complete, the

DVD player will reboot. This may take

several seconds to complete. Once it is

complete, the instrument will exit the

DVD Factory Mode. The display will

return to the DVD submenu.

17 I2C_4 Low SDA Line Data Line of I2C Bus_4 Held Low

18 I2C_4 Low SCL Line Clock Line of I2C Bus_4 Held Low

19 Chassis Detection HW No Valid Chassis Detected

21/22/23/24 Free Event Code

25 No ACKN Main Tuner Tuner Main Tuner Does Not Answer

26 No ACKN PIP Tuner Tuner PIP Tuner Does Not Answer

27 No ACKN IX300 Video Video Switch Does Not Answer

28 No ACKN IV300 PSI PSI IC Does Not Answer

29 PDD Bit Is Set PSI IV300 Power Down Detection

31 No ACKN IV400 Deflection IC Does Not Answer

32 POR Bit Is Set Deflection IV400 Power Down Detection

33 Safety_INT Is Active Deflection Safety Circuit Is Active

34 NHF Bit Is Set Deflection Horizontal Flyback Problem

35 NRF Bit Is Set Deflection Oscillator Is Not Locked

36 BCF Bit Is Set Deflection Tube Is Still Not Warm After Warmup Time

37 NDF Bit Is Set Deflection Vertical Problem

38

39 SL Bit Is Set Deflection Phase 1 Not Locked

41 No ACKN IA001 Audio IA001 Does Not Answer

42 RESET Bit is Set Audio The RESET Bit of IA001 Is Active

43 Not Used

44 No ACKN IA900 Audio IC Does Not Answer

45 Wrong MSP Audio Wrong MSP Is Fitted

46/47 Reserved/Not Used

48 No ACKN Main IF IF IF IC (Main Tuner) Does Not Answer

49 No ACKN PIP IF IF IF IC (PIP Tuner) Does Not Answer

XRP Bit Is Set Durning

Normal Operation

Deflection X-Ray Protection

Page 7

Event

ALIGNMENT PROCEDURES (Continued) ALIGNMENT PROCEDURES (Continued)

Page 3-13

Page 3-14

Code

51 No ACKN IV100 Upconverter IC Does Not Answer

52 POR Bit Is Set Upconverter Power Down Detection (IV100)

53 Not Used

54 No ACKN IR005 NVM IC Does Not Answer

55 No ACKN IR006 Port Expander IC Does Not Answer

56 FLS Bit Is Set Flash Info Of The HOP Occurred

57 TECI Message Failed Software Can Not Perform A System Command

58 Event Code Validation Code Validation Failed

59 Wrong GenCAM Version Used GenCAM cut 2.1 Must Be Used

61 5V Good HW Switched 5V Not Available

62 5V and 8V Good HW Switched 5V & 8V Not Available

63 Power_Fail HW Unexpected Level On Power_Fail Line Found (Mains To Low)

64 XRP Alignment HW XRP Adjustment Detected Overvoltage

Event Circuit Condition

Event

Code

92 General I2C Problem SW General Problem Of One Of The I2C Cells

93 Install Problem Of I2C Bus 1 & 2 SW Problem To Install I2C Bus Driver

94 Install Problem Of I2C Bus 3 & 4 SW Problem To Install I2C Bus Driver

95

96 Install Problem Of ADC Driver SW Problem To Install ADC Driver

97 Install Problem Of AV-Link Driver SW Problem To Install AV-Link Driver

98 Install Problem Of SDRAM Timing SW Problem To Install The SDRAM Timing

99 Watchdog SW Watchdog Was Active

Install Problem Of Port Driver Or

Event Circuit Condition

Bus Driver

SW Problem To Install The Port Driver Or I2C Bus Driver

65 XRP NVM Verify HW Write To XRP NVM Area Failed

66 XRP NVM Not Recoverable HW XRP NVM Contents Are Corrutped And Can Not Be Recovered

67 Reserved

68 5V Failed During Operation HW Switched 5V Not Available During Operation

69 H & V Sync Not Valid HW H & V Sync (For OSD) Not Present

71 No ACKN IC040 Video Frame Comb Filter IC Does Not acknowledge

72 No ACKN IX400 Video 2H Video Switch Does Not Acknowledge

73/74/75/76/77 Reserved

78 No ACKN DVD Unit DVD DVD Does Not Answer

79 DVD Ready Bit DVD DVD Ready Bit Is Set

81 No ACKN Convergence IC IK201 PTV Models Convergence IC Does Not Answer

82 No ACKN M24C32 (RP-NVM) PTV Models NVM IC Does Not Answer

83 Wrong Convergence Test Pattern PTV Models Convergence Test Pattern Is Wrong

84 Before Is Was An RP PTV Models Tube Type Is RP, But Convergence Was Not Detected

85 Convergence NVM 1 Problem PTV Models Convergence 1 NVM Data Is Wrong

86 Convergence NVM 2 Problem PTV Models Convergence 2 NVM Data Is Wrong

87 IK201 Loop Blocked PTV Models IK201 Electrical Loop Blocked

88 POR Bit Is Set PTV Models The POR Set Of IK201 Is Set

89 Convergence Power Supply Off PTV Models Convergence Power Suopply Is Not Valid

91 Watchdog Disabled SW Watchdog Function Is Disabled

Loading...

Loading...