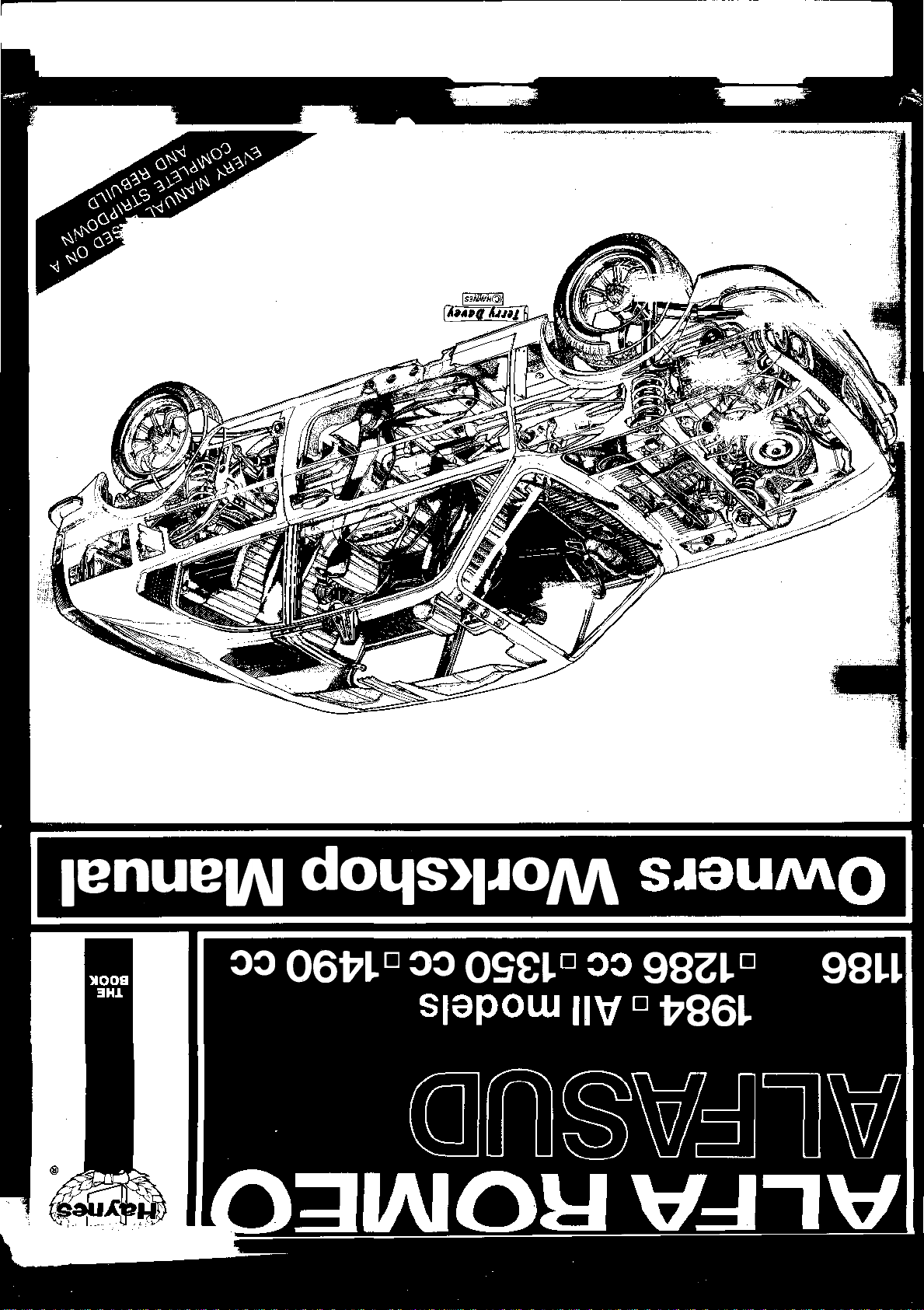

Page 1

|enue|/\|

oo

doqs>|4O/\/\

06W-D oo

09€I-

9831.°

oo

98U

^861-

01 fe£6l

Page 2

Alfasud

by J H Haynes

Member of the Guild of Motoring Writers

and Tim Parker

Models covered

Alfa Romeo Alfasud Saloon, Hatchback and Sprint Coupe models

(including Veloce)

1186

cc,

1286

cc,

1350

cc and

1490

cc

ISBN 0 85696 974 5

© Haynes Publishing Group 1977, 1984

All rights reserved. No part of this book may be reproduced or transmitted in

any form or by any means, electronic or mechanical, including photocopying,

recording or by any information storage or retrieval system, without permission

in writing from the copyright holder.

Printed in England

HAYNES PUBLISHING GROUP

SPARKFORD YEOVIL

SOMERSET BA22 7JJ ENGLAND

HAYNES PUBLICATIONS INC

861 LAWRENCE

NEWBURYPARK

CALIFORNIA

(292-

12K2)

DRIVE

91320 USA

Page 3

Acknowledgements

Thanks are due to Alfa Romeo (GB) Limited for the provision of

technical information and for the use of certain illustrations. The

Champion Sparking Plug Company supplied the illustrations showing

the various spark plug conditions, and Sykes-Pickavant Ltd provided

some of the workshop tools.

About this manual

Its

aim

The aim of this manual is to help you get the best value from your

vehicle. It can do so in several ways. It can help you decide what work

must be done (even should you choose to get it done by a garage),

provide information on routine maintenance and servicing, and give a

logical course of action and diagnosis when random faults occur.

However, it is hoped that you will use the manual by tackling the work

yourself. On simpler jobs it may even be quicker than booking the car

into a garage and going there twice, to leave and collect it. Perhaps

most important, a lot of money can be saved by avoiding the costs a

garage must charge to cover its labour and overheads.

The manual has drawings and descriptions to show the function of

the various components so that their layout can be

the tasks are described and photographed in a step-by-step sequence

so that even a novice can do the work.

Its

arrangement

The manual is divided into twelve Chapters, each covering a logical

sub-division of the vehicle. The Chapters are each divided into Sections,

numbered with single figures, eg 5; and the Sections into paragraphs

(or

sub-sections)

they are in, eg

with decimal numbers following on from the Section

5.1,

5.2, 5.3 etc.

understood.

Then

Special thanks are due to Ron Petheram of Alfacenta, Turgis Green,

near Basingstoke, for much useful information required when updating

the manual. Willshires of Salisbury provided a late model car for

workshop photographic purposes.

It is freely illustrated, especially in those parts where there is a

detailed sequence of operations to be carried out. There are two forms

of illustration: figures and photographs. The

sequence with decimal numbers, according to their position in the

Chapter — eg Fig. 6.4 is the fourth drawing/illustration in Chapter 6.

Photographs carry the same number (either individually or in related

groups) as the Section or sub-section to which they relate.

There is an alphabetical index at the back of the manual as well as

a contents list at the front. Each Chapter is also preceded by its own

individual contents list.

References

a person in the driver's seat facing forwards.

Unless otherwise stated, nuts and bolts are removed by turning

anti-clockwise, and tightened by turning clockwise.

Vehicle manufacturers continually make changes to specifications

and recommendations, and these, when

our manuals at the earliest opportunity.

Whilst every care is taken to ensure that the information in this

manual is correct, no liability can be accepted by the authors or

publishers for loss, damage or injury caused by any errors in, or

omissions

to the

'left'

from,

the information given.

or

'right'

of the

notified,

figures

are numbered in

vehicle

are in the

are incorporated into

sense

of

Introduction to the Alfasud

Introduced in Italy in mid-1972, and in the UK in 1974, the Alfasud

was designed to provide a small car in the Alfa Romeo range. A factory

specifically for the production of the model was built near Naples in

Southern Italy (hence the -sud). Mechanical design of the car was by

Rudolf

Hruschka,

by Giugiaro of Italdesign. The result was a distinctively Italian-looking

car, driven at the front wheels by a water-cooled flat four engine. The

car's handling proved to be superb, setting new standards for vehicles

in its class, and its combination of performance with reasonable price

won it many friends.

Mechanical changes to the Alfasud have been few, consisting mostly

of increasing engine capacity and (on Veloce models) the fitting of

formerly of

Porsche,

while the body was designed

twin carburettors. Body styles available in the UK have been two-door

and four-door saloons and hatchbacks, and the distinctive Coupe style

of the Sprint. An Estate model, available in the rest of Europe, was

regrettably never imported to the

With

productio'n

the initial design may be judged by the continuation of the major

mechanical components in other Alfa Romeo models. The

mechanic may curse some of the more idiosyncratic features of the

original design, but there is no doubt that the Alfasud provides high

performance motoring on a moderate budget, and for this reason alone

it will surely be around for a long time.

of the Alfasud set to finish in

UK.

1984,

the success of

DIY

Page 4

Contents

Page

Acknowledgements

About this manual

Introduction to the Alfasud

Buying spare parts and vehicle identification numbers

Tools and working facilities

Routine maintenance

Safety first!

General data

Jacking and towing

Recommended lubricants and fluids

Chapter 1 Engine

Chapter 2 Cooling and heating systems

Chapter 3

Carburation;

fuel and exhaust systems

2

2

2

5

6

8

10

11

11

12

13

39

45

Chapter 4 Ignition system

Chapter 5 Clutch

Chapter 6 Gearbox and final drive

Chapter 7 Driveshafts, hubs, wheels and tyres

Chapter 8 Braking system

Chapter 9 Electrical system

Chapter

10

Suspension and steering

Chapter

1 1

Bodywork and

Chapter

12

Supplement: Revisions and information on later models

Fault diagnosis

General repair procedures

Conversion factors

Index

fittings

54

61

66

80

83

92

110

120

130

164

167

168

169

Page 5

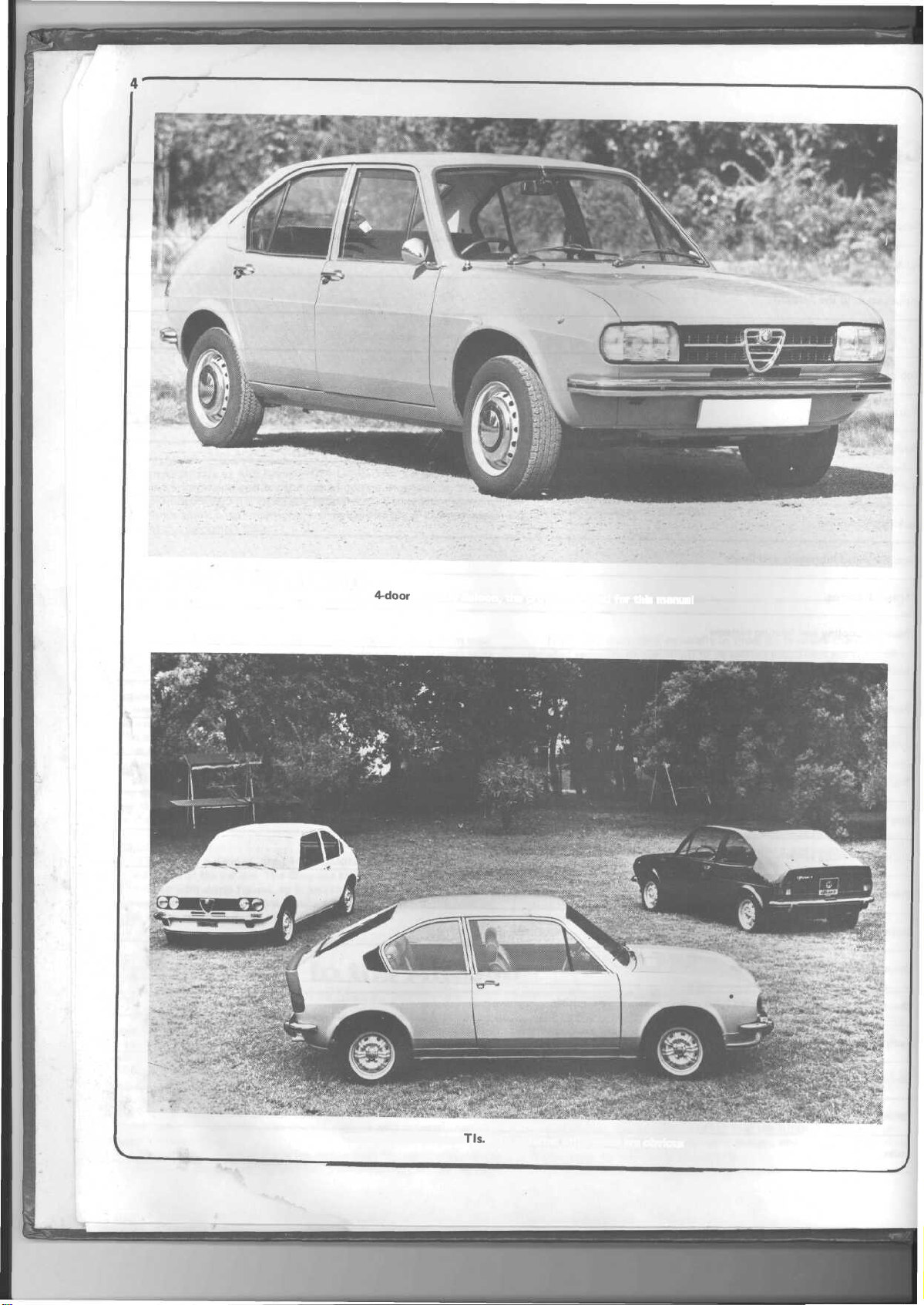

1973

4-door

Alfasud Saloon, the project car used for this manual

1975 group of Alfasud

TIs.

The external differences are obvious

Page 6

Buying spare parts

and vehicle identification numbers

Buying spare parts

Spare parts are available from many sources, for example: Alfa

Romeo garages, other garages and accessory shops, and motor factors.

Our advice regarding spare part sources is as follows:

Officially appointed Alfa Romeo garages - This is the best source of

parts which are peculiar to your vehicle and are otherwise not generally

available (eg complete cylinder heads, internal gearbox components,

badges, interior trim etc). It is also the only place at which you should

buy parts if your car is still under warranty - non - Alfa Romeo

components may invalidate the warranty. To be sure of obtaining the

correct parts it will always be necessary to give the storeman your car's

engine and chassis number, and if possible, to take the

for positive identification. Remember that many parts are available on

a factory exchange scheme - any parts returned should always be clean!

It obviously makes good sense to go straight to the specialists on your

car for this type of part for they are best equipped to supply you.

Other garages and accessory shops - These are often very good places

to buy materials and components needed for the maintenance of your

car (eg oil filters, spark plugs, bulbs, fan belts, oils and greases, touch-up

paint,

filler paste etc). They also sell general accessories, usually have

convenient opening hours, charge lower prices and can often be found

not far from home.

Motor factors - Good factors will stock all of the more important

components which wear out relatively quickly (eg clutch components,

pistons, valves, exhaust system, brake cylinders/pipes/hoses/seals/shoes

and pads

components on a part exchange basis - this can save a considerable

etc).

Motor factors will often provide new or reconditioned

'old'

part along

amount of money.

Gaskets - special note

With gasket sets - for both engine and gearbox - do not be alarmed

if there seem to be many items included in the set you buy, which do

not fit your vehicle. To save a lot of variety of kits they include in one

enough to cover a variety of types over a period of time so you are

certain to have some left over. However, it is a good idea to check the

set before leaving the parts store. Some of the ones you may need

could

be

omitted.

applies to some of the smaller ones.

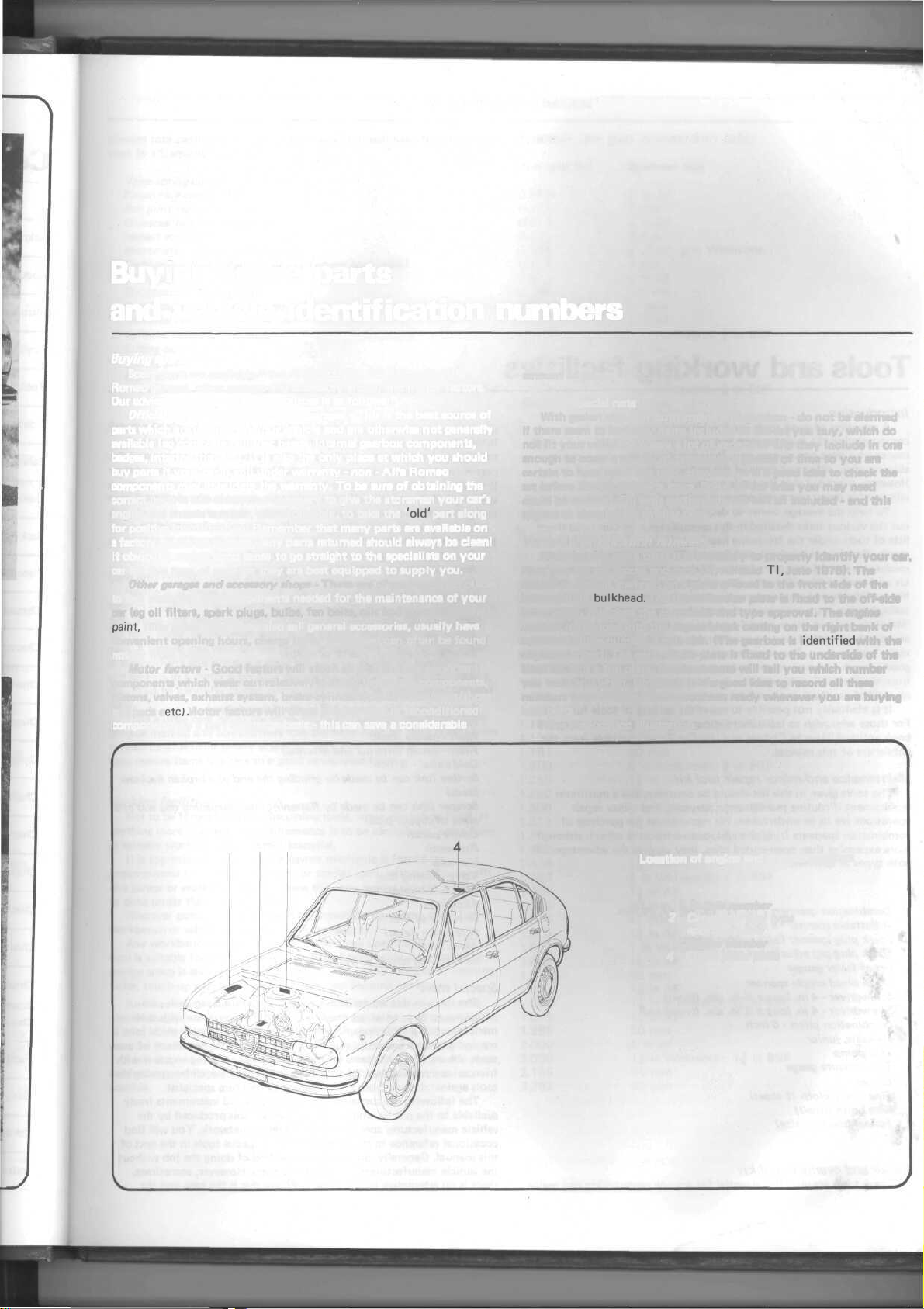

Vehicle identification numbers

When buying spare parts it is necessary to properly identify your car.

First give the car model and date (ie; Alfasud

chassis

number

intermediate

inner wing - this gives the car model and type approval. The engine

number is stamped into the engine block casting on the right bank of

cylinders at the number 3 cylinder. (The gearbox is

engine number). The paint finish plate is fixed to the underside of the

boot lid. It is a foil plate. Commonsense will tell you which number

you want and when. However, it is a good idea to record all these

numbers from your car and have them ready whenever you are buying

new parts.

Note the location illustration.

is

bulkhead.

Oil

seals

particularly

stamped

on a

The Identification plate is fixed to the off-side

are not all

plate affixed

included

Tl,

June 1975). The

to the

front

identified

- and

side

this

of the

with the

2 3 1

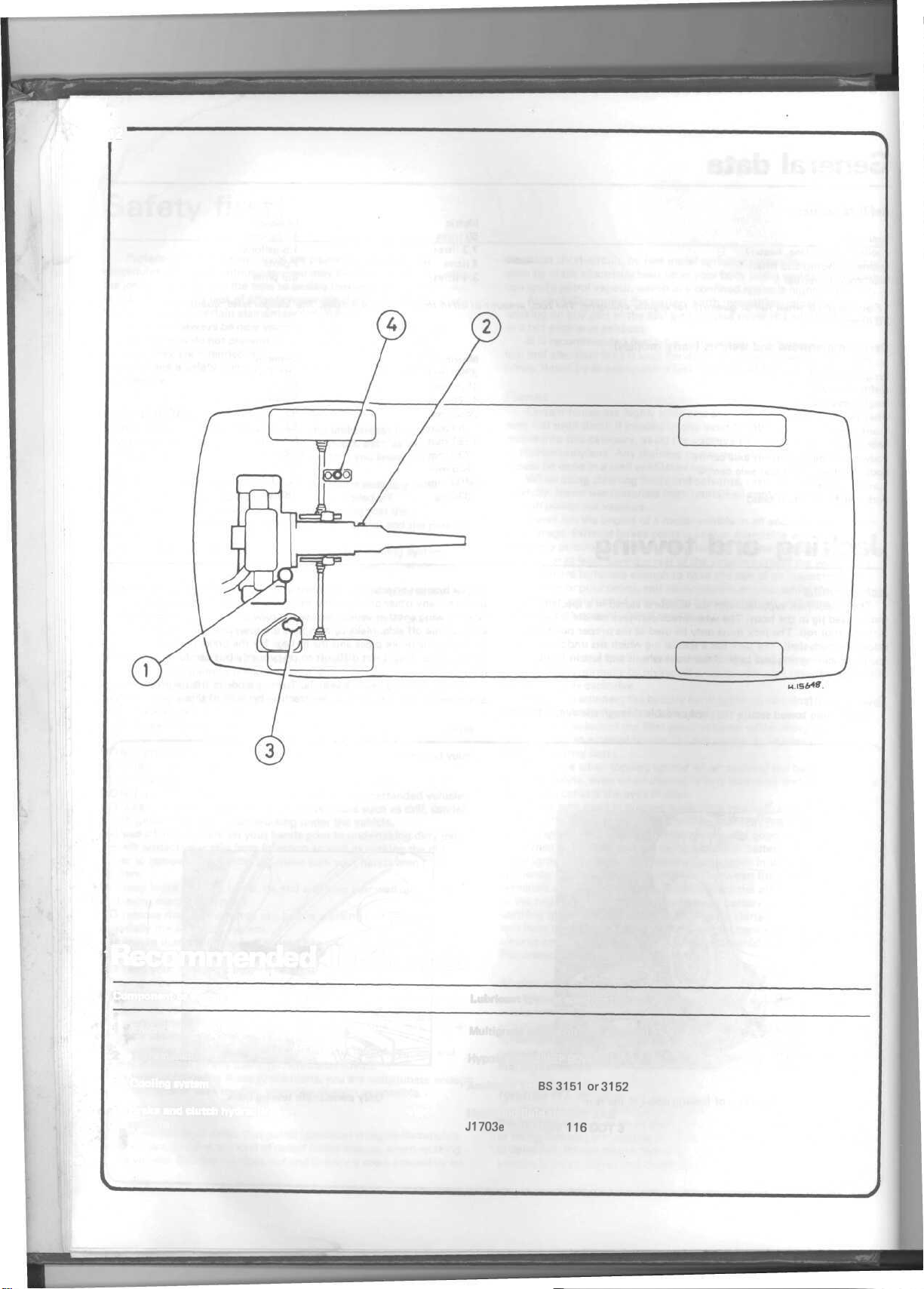

Location of engine and chassis numbers

1 Chassis number

2 Car model and type

approval plate

3 Engine number

4 Finish paint plate

Page 7

Tools and

working

facilities

Introduction

A selection of good tools is a fundamental requirement for anyone

contemplating the maintenance and repair of a motor vehicle. For the

owner

who

does

not

possess

any,

their

able

expense,

However, provided that the tools purchased are of good quality, they

will

last

To help the average owner to decide which tools are needed to carry

out the various tasks detailed in this manual, we have compiled three

lists of tools under the following headings: Maintenance and minor

repair, Repair and overhaul, and Special. The newcomer to practical

mechanics should start off with the

kit and confine himself to the simpler jobs around the vehicle. Then, as

his confidence and experience grows, he can undertake more difficult

tasks, buying extra tools as, and when, they are needed. In this way, a

'Maintenance

and

overhaul'

major

good enough for most repair and overhaul procedures and will add tools

from the

amount of use these tools will be put to.

It is obviously not possible to cover the subject of tools fully here.

For those who wish to

book entitled

publishers of this manual.

offsetting some of the savings made by

for

many

years

and

prove

and minor

tool kit over a considerable period of time without any

cash

outlays.

'Special'

'How

repair'

The

experienced do-it-yourselfer

category when he feels the expense is justified by the

learn

to Choose and Use Car Tools' available from the

more about tools and their use there is a

purchase

an

extremely

'Maintenance

tool kit can be built-up into a

will

prove a consider-

doing-it-yourself.

worthwhile

and minor

will

have a tool

investment.

repair'

tool

'Repair

kit

Maintenance and minor repair tool kit

The tools given in this list should be considered as a minimum

requirement if routine

operations are to be undertaken. We recommend the purchase of

combination spanners (ring one end,

more expensive than open-ended ones, they do give the advantages of

both types of spanner.

Combination spanners - 10,

Adjustable

Spark plug spanner (with rubber insert)

Spark

plug

Set of feeler gauges

Brake bleed nipple spanner

Screwdriver - 4 in. long x % in.

Screwdriver - 4 in. long x % in. dia. (crosshead)

Combination pliers - 6 inch

Hacksaw,

Tyre pump

Tyre pressure gauge

Oil can

Fine emery cloth

Wire brush (small)

Funnel (medium size)

maintenance,

spanner - 9 inch

gap adjustment tool

junior

(1

sheet)

servicing and minor repair

open-ended

11,

13, 14,

dia.

(plain)

the other); although

17,30mm

Repair and overhaul tool kit

These tools are virtually essential for anyone undertaking any major

repairs to a motor vehicle, and are additional to those given in the Basic

list. Include in this list is a comprehensive set of sockets. Although

these are expensive they will be found invaluable as they are so

particularly if various drives are included in the set. We recommend the

1

/2 square-drive type, as this can be used with most proprietary torque

wrenches. If you cannot afford a socket set, even bought piecemeal, then

inexpensive tubular box spanners are a useful alternative.

The tools in this list will occasionally need to supplemented by

tools from the Special list.

Sockets (or box spanners) to cover range 6 to 27 mm

Reversible ratchet drive (for use with sockets)

Extension

Universal joint (for use with sockets)

Torque wrench (for use with sockets)

Mole wrench - 8 inch

Ball pein hammer

Soft-faced

ScrewdriverScrewdriverScrewdriverScrewdriverPliers

Pliers - needle nosed

Pliers - circlip

Cold

Scriber

blade)

Scraper (this can be made by flattening and sharpening one end of a

piece of copper pipe)

Centre punch

Pin punch

Hacksaw

Valve grinding tool

Steel

Allen keys

Selection of files

Wire brush (large)

Axle stands

Jack (strong scissor or hydraulic type)

piece,

10

inch (for use with sockets)

hammer, plastic or rubber

6 in.

long x 5/16

2in.

longx

V/ain.

longx % in. dia. (crosshead)

3in.

- electricians side cutters

chisel-

(this can be made by grinding the end of a broken hacksaw

rule/straight

longx

(internal

% inch

edge

in. dia. (plain)

5/16in.

square (plain)

1/8in.

dia. (electricians)

and external)

versatile-

Special tools

The tools in this list are those which are not used regularly, are

expensive to buy, or which need to be used in accordance with their

manufacturers instructions. Unless relatively difficult mechanical jobs

are

undertaken

tools. Where this is the case, you could consider clubbing together with

friends (or a motorists club) to make a joint purchase, or borrowing the

tools against deposit from a local garage or tool hire specialist.

The following list contains only those tools and instruments freely

available to the public, and not those special tools produced by the

vehicle manufacturer specifically for its dealer network. You will find

occasional reference to these manufacturers special tools in the text of

this manual. Generally, an alternative method of doing the job without

the vehicle manufacturers special tool is given. However,

there is no alternative to using them. Where this is the case and the

frequently,

it

will

not be

economic

to buy

many

of

sometimes,

these

Page 8

Tools and working facilities

relevant tool cannot be bought or borrowed you will have to entrust the

work to a franchised garage.

Valve spring compressor

Piston ring compressor

Ball joint separator

Universal hub/bearing puller

Impact

screwdriver

Micrometer and/or vernier gauge

Carburettor flow balancing device (where applicable)

Dial gauge

Stroboscopic

timing

light

Dwell angle meter/tachometer

Universal electrical

multi-meter

Cylinder compression gauge

Lifting tackle

Trolley jack

Light with extension lead

Buying tools

For practically all tools, a tool factor is the best source since he will

have a very comprehensive

range

compared

with

the

average

garage

or

accessory shop. Having said that, accessory shops often offer excellent

quality tools at discount prices, so it pays to shop around.

Remember, you don't have to buy the most expensive items on the

shelf, but it is always advisable to steer clear of the very cheap tools.

There are plenty of good tools around, at reasonable prices, so ask the

proprietor or manager of the shop for advice before making a purchase.

Care

and

maintenance

of

tools

Having purchased a reasonable tool kit, it is necessary to keep the

tools in a clean and serviceable

dirt,

grease

and

metal particles using a clean,

condition,

After use, always wipe off any

dry

cloth,

before

putting

the tools away. Never leave them lying around after they have been

used. A simple

tool

rack

on the

garage

or

workshop

wall,

for

items

such

as screwdrivers and pliers is a good idea. Store all normal spanners

and sockets in a metal box. Any measuring instruments, gauges,

meters,

etc., must be carefully stored where they cannot be damaged or become

rusty.

Take a little

care when

the

tools

are

used. Hammer heads

inevitably

become marked and screwdrivers lose the keen edge on their blades from

time-to-time. A little timely attention with emery cloth or a file will

soon restore items like this to a good serviceable finish.

Working facilities

Not to be forgotten when discussing tools, is the workshop itself. If

anything more than routine maintenance is to be carried out, some form

of suitable working area becomes essential.

It is appreciated that many an owner mechanic is forced by

circumstances to remove the engine or similar

of a garage or workshop. Having done this, any repairs should always

be done under the cover of a roof.

Wherever possible, any dismantling should be done on a clean flat

workbench or table at a suitable working height.

Any workbench needs a vice: one with a jaw opening of 4 in. (100

mm) is suitable for most jobs. As mentioned previously, some clean dry

storage space is also required for tools, as well as the lubricants, cleaning

fluids, touch-up paints and so on which soon become necessary.

Another item which may be required, and which has a much more

general

usage,

is an

electric

drill

with a chuck capacity

(8 mm). This, together with a good range of twist drills, is virtually

essential

for

fitting

accessories

such

as

wing

Last, but not least, always keep a supply of old newspapers and clean,

lint-free rags available, and try to keep any working area as clean as

possible.

item,

mirrors

without the benefit

of at

least 5/16

and

reversing

lights.

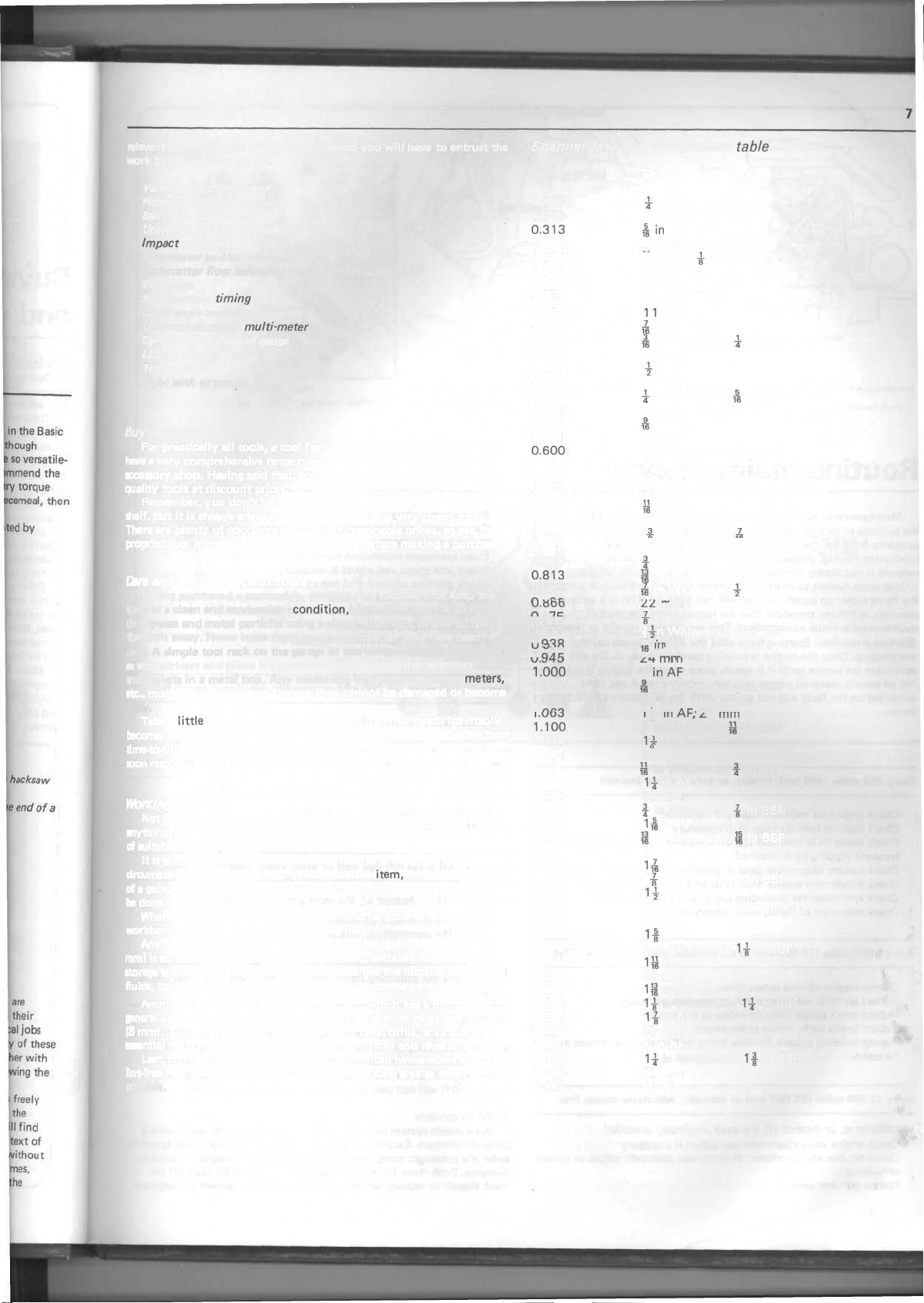

Spanner jaw gap comparison

in.

Jaw gap

0.250

0.276

0.313

0.315

0.344

0.354

0.375

0.394

0.433

0.438

0.445

0.472

0.500

0.512

0.525

0.551

0.563

0.591

0.600

0.625

0.630

0.669

0.686

0.709

0.710

0.748

0.750

0.813

0.820

r\ o c

U.oDD

r\ o ~7

0.875

0.920

o

\J • C7

0

vj.

1

1.010

1.024

1

1.100

1.125

1.181

1.200

1.250

1.260

1.300

1.313

1.390

1.417

1.438

1.480

1.500

1.575

1.614

1.625

1.670

1.688

1.811

1.813

1.860

1.875

1.969

2.000

2.050

2.165

2.362

CHR

945

^M-U

.000

Ofi3

1

,\J\J\J

O O

(in)

Spanner size

|

7 mm

*in

8 mm

32 in AF; £ in Whitworth

9 mm

f in AF

&

^

|

-£

fl

& in Whitworth; f in BSF

ID ' 8

|

ll

i

i

j§

c

c

£

O O

ZZ

|-

|

15

16

O A

^.H-

1

&

26 mm

1— in

| in Whitworth;

1-

30 mm

je

32 mm

-fj§

36 mm

|

40 mm; jf in Whitworth

41 mm

46 mm

50 mm

2 in AF

55 mm

60 mm

table

in

AF

AF

10 mm

1 1

mm

in AF

in Whitworth; £ in BSF

12 mm

in

AF

13 mm

in Whitworth; £ in BSF

14 mm

in AF

1 5 mm

in

AF

16 mm

1 7 mm

in

AF

18 mm

in Whitworth; £ in BSF

8 ' 10

19 mm

in

AF

in AF

in Whitworth; ± in BSF

«-

mm

in AF

in Whitworth; £ in BSF

|n AC

in

Mr

ryi

m

111

1

II

j

p

n

M

in Whitworth; f in BSF

AF'

1

1g

in Whitworth; f in BSF

H

in Whitworth;

1£

in Whitworth;

1£

1I

1|

1 in Whitworth;

1jj

1Ji

1£

1|

H

97 mm

111

r\\ r £. / llllil

j£

in BSF

in AF

in

AF

|-

in BSF

in AF

|f

in BSF

in AF

in Whitworth; 1 in BSF

in AF

in AF

1£

in BSF

in AF

in AF

in Whitworth;

1£

in BSF

in AF

in Whitworth;

1f

in BSF

Page 9

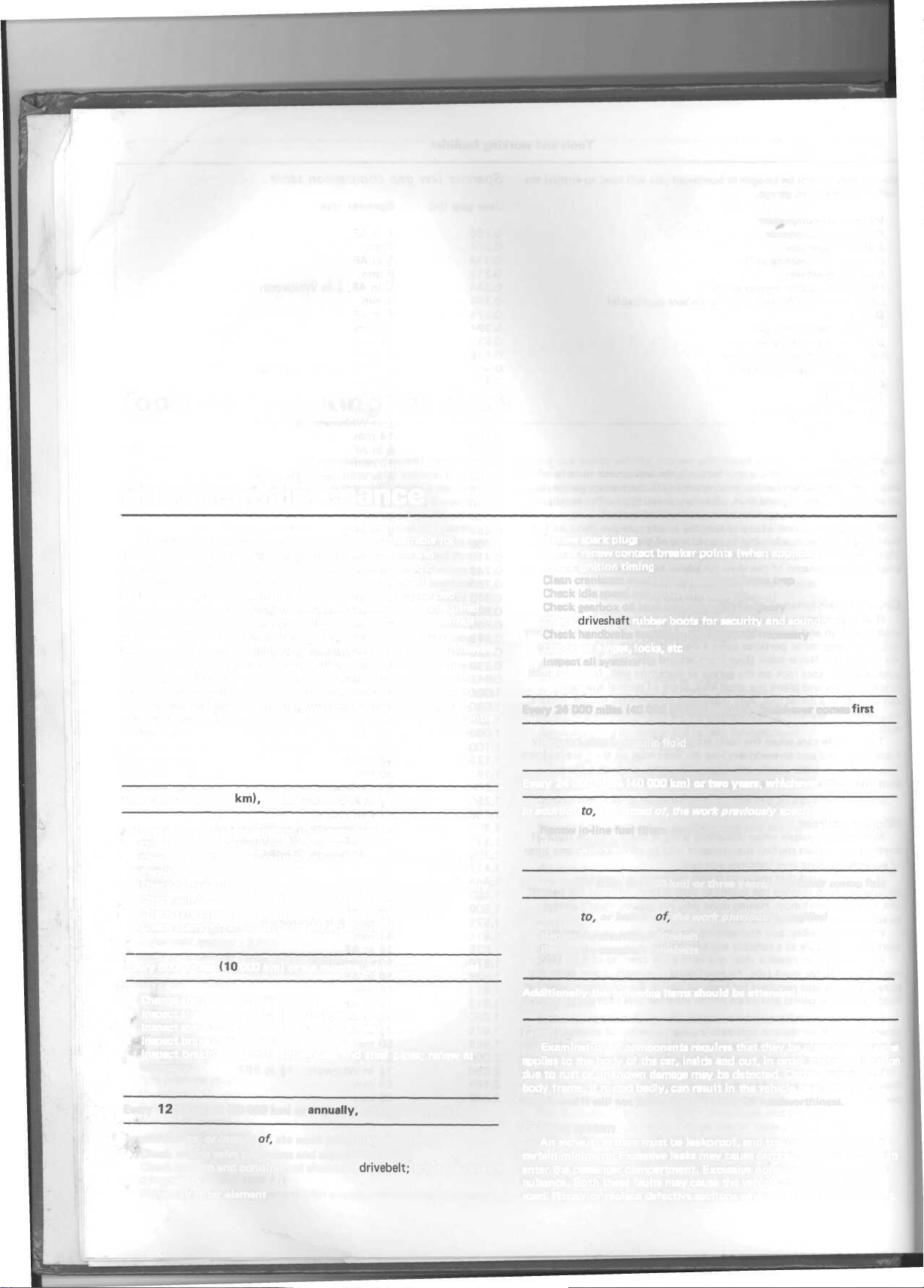

Routine maintenance

Maintenance is essential for ensuring safety and desirable for

the purpose of getting the best in terms of performance and

economy from the car. Over the years the need for periodic

lubrication - oiling, greasing and so on - has been drastically

reduced if not totally eliminated. This has unfortunately tended

to lead some owners to think that because no such action is required

the

items either

delusion. It follows therefore that the largest initial element of

maintenance is visual examination. This may lead to repairs or renewals.

Starting procedure: Starting from cold the Alfasud needs careful

warming up. Once the engine is running carefully coax it. Do not

accelerate the engine until it is warm, since when the engine is cold

the oil cannot reach all points requiring lubrication. A red light

exhibited on the facia will not go out until the oil becomes sufficiently

warm.

Every 250 miles (400

Check engine oil level and top up if necessary

Check coolant level and top up if necessary

Check brake

frequent topping up is required

Check battery electrolyte level (if possible) and top up if necessary

Check windscreen washer

Check tyre pressures (including spare) and tread condition

Check operation of lights, horn, wipers etc

Every 6000 miles

Change engine oil and renew filter

Inspect air filter element; clean or renew as necessary

Inspect spark plugs; clean or renew as necessary

Inspect brake pads; renew as necessary

Inspect braking system flexible hoses and steel pipes; renew as

necessary

Every

12

In addition to, or instead

Check engine valve clearances and adjust if necessary

Check tension and condition of alternator

as necessary

Renew air filter element

no

longer exist

km),

fluid

level

(10

000 miles (20 000 km) or

or

weekly, or before a long journey

and top up if

fluid

000 km) or six months, whichever comes first

of,

the work previously specified

will

last

necessary. Check

level

and top up if

annually,

for

ever.

This

is a

for

necessary

whichever comes first

drivebelt;

adjust or renew

serious

leaks

if

Renew spark plugs

Gap or renew contact breaker points (when applicable)

Check ignition timing

Clean crankcase ventilation hoses and flame trap

Check idle speed and adjust if necessary

Check gearbox oil level and top up if necessary

Check

driveshaft

Check handbrake operation and adjust as necessary

Lubricate hinges, locks, etc

Inspect all systems for leaks, damage, etc

Every 24 000 miles (40 000 km) or annually, whichever comes

Renew brake hydraulic fluid

Every 24 000 miles (40 000 km) or two years, whichever comes first

In addition

Every 36 000 miles (60 000 km) or three years, whichever comes first

In addition

Additionally the following items should be attended to as time can be

spared:

to,

Renew in-line fuel filters (when fitted)

Renew gearbox oil

to,

Renew the alternator drivebelt

Renew the camshaft drivebelts

rubber boots for security and soundness

or instead of, the work previously specified

or instead

of,

the work previously specified

first

Cleaning

Examination

applies to the body of the car, inside and out, in order that deterioration

due to rust or unknown damage may be detected. Certain parts of the

body frame, if rusted badly, can result in the vehicle being declared

unsafe

and it

of

components requires

will

not

pass

the

annual test

that

they

for

roadworthiness.

be

cleaned.

The

same

Exhaust system

An exhaust system must be leakproof, and the noise level below a

certain minimum. Excessive leaks may cause carbon monoxide fumes to

enter the passenger compartment. Excessive noise constitutes a public

nuisance. Both these faults may cause the vehicle to be kept off the

road. Repair or replace defective sections when symptoms are apparent.

Page 10

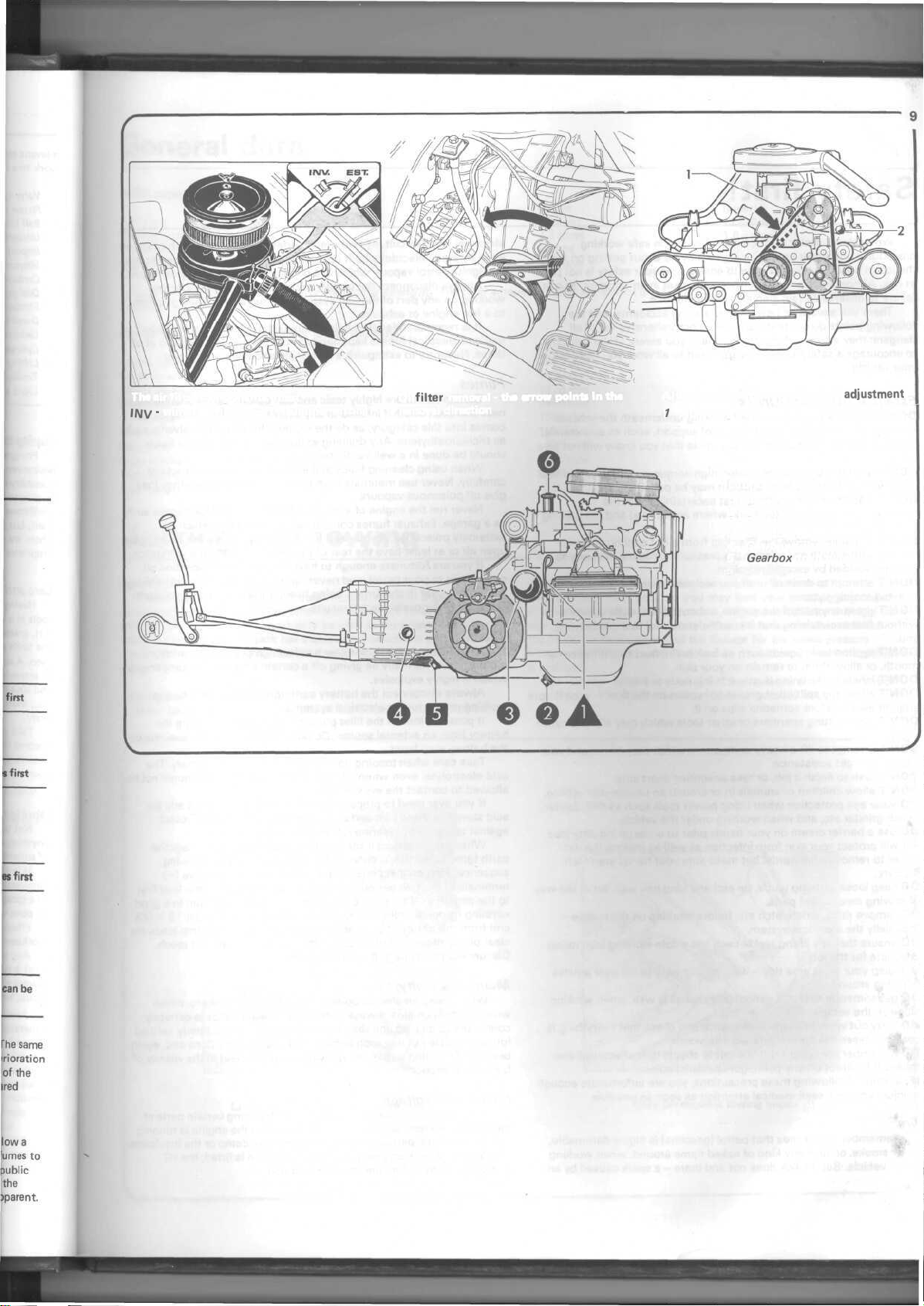

The air filter components. Inset

IIVV ' winter setting, EST - summer setting

Oil

filter

removal - the arrow points in the Alternator/water pump drive belt

removal direction

1

Adjusting bolt 2 Pivot bolt

Lubrication schedule

1 Dipstick

2 Sump drain plug

3 Oil filter

4 Gearbox filler plug

5

Gearbox

6 Oil filler

adjustment

drain plug

Page 11

Safety

first!

Professional motor mechanics are trained in safe working

procedures. However enthusiastic you may be about getting on with

the job in hand, do take the time to ensure that your safety is not put

at risk. A moment's lack of attention can result in an accident, as can

failure to observe certain elementary precautions.

There will always be new ways of having

following points do not pretend to be a comprehensive list of all

dangers; they are intended rather to make you aware of the risks and

to encourage a safety-conscious approach to all work you carry out on

your vehicle.

accidents,

and the

Essential DOs and DON'Ts

DON'T rely on a single jack when working underneath the vehicle.

Always use reliable additional means of

securely placed under a part of the vehicle that you know will not give

way.

DON'T attempt to loosen or tighten high-torque nuts (e.g. wheel hub

nuts) while the vehicle is on a jack; it may be pulled off.

DON'T start the engine without first ascertaining that the

transmission is in neutral (or

brake applied.

DON'T suddenly remove the filler cap from a hot cooling system cover it with a cloth and release the pressure gradually first, or you

may get scalded by escaping coolant.

DON'T attempt to drain oil until you are sure it has cooled sufficiently

to avoid scalding you.

DON'T grasp any part of the engine, exhaust or catalytic converter

without first ascertaining that it is sufficiently cool to avoid burning

you.

DON'T syphon toxic liquids such as fuel, brake fluid or antifreeze by

mouth, or allow them to remain on your skin.

DON'T inhale brake lining dust - it is injurious to health.

DON'T allow any spilt oil or grease to remain on the floor - wipe it up

straight away, before someone slips on it.

DON'T use ill-fitting spanners or other tools which may slip and cause

injury.

DON'T attempt to lift a heavy component which may be beyond your

capability - get assistance.

DON'T rush to finish a job, or take unverified short cuts.

DON'T allow children or animals in or around an unattended vehicle.

DO wear eye protection when using power tools such as drill, sander,

bench grinder etc, and when working under the vehicle.

DO use a barrier cream on your hands prior to undertaking dirty jobs

- it will protect your skin from infection as well as making the dirt

easier to remove afterwards; but make sure your hands aren't left

slippery.

DO keep loose clothing (cuffs, tie etc) and long hair well out of the way

of moving mechanical parts.

DO remove rings, wristwatch etc, before working on the vehicle -

especially the electrical system.

DO ensure that any lifting tackle used has a safe working load rating

adequate for the job.

DO keep your work area tidy - it is only too easy to fall over articles

left lying around.

DO get someone to check periodically that all is well, when working

alone on the vehicle.

DO carry out work in a logical sequence and check that everything is

correctly assembled and tightened afterwards.

DO remember that your vehicle's safety affects that of yourself and

others. If in doubt on any point, get specialist advice.

IF, in spite of following these precautions, you are unfortunate enough

to injure yourself, seek medical attention as soon as possible.

'Park'

support,

where applicable) and the parking

such as axle stands,

Fire

Remember at all times that petrol (gasoline) is highly flammable.

Never smoke, or have any kind of naked flame around, when working

on the vehicle. But the risk does not end there - a spark caused by an

electrical short-circuit, by two metal surfaces contacting each other, or

even by static electricity built up in your body under certain conditions,

can ignite petrol

Always disconnect the battery earth (ground) terminal before

working on any part of the fuel system, and never risk spilling fuel on

to a hot engine or exhaust.

It is recommended that a fire extinguisher of a type suitable for

fuel and electrical fires is kept handy in the garage or workplace at all

times. Never try to extinguish a fuel or electrical fire with water.

vapour,

which in a confined space is highly explosive.

Fumes

Certain fumes are highly toxic and can quickly cause unconscious-

ness and even death if inhaled to any extent. Petrol (gasoline) vapour

comes into this category, as do the vapours from certain solvents such

as

trichloroethylene.

should be done in a well ventilated area.

When using cleaning fluids and solvents, read the instructions

carefully. Never use materials from unmarked containers - they may

give off poisonous vapours.

Never run the engine of a motor vehicle in an enclosed space such

as a garage. Exhaust fumes contain carbon monoxide which is

extremely poisonous; if you need to run the engine, always do so in the

open air or at least have the rear of the vehicle outside the workplace.

If you are fortunate enough to have the use of an inspection pit,

never drain or pour petrol, and never run the engine, while the vehicle

is standing over it; the fumes, being heavier than air, will concentrate

in the pit with possibly lethal results.

Any draining or pouring of such volatile fluids

The battery

Never cause a spark, or allow a naked light, near the vehicle's

battery. It will normally be giving off a certain amount of hydrogen gas,

which is highly explosive.

Always disconnect the battery earth (ground) terminal before

working on the fuel or electrical systems.

If possible, loosen the filler plugs or cover when charging the

battery from an external source. Do not charge at an excessive rate or

the battery may burst.

Take care when topping up and when carrying the battery. The

acid electrolyte, even when diluted, is very corrosive and should not be

allowed to contact the eyes or skin.

If you ever need to prepare electrolyte yourself, always add the

acid slowly to the water, and never the other way round. Protect

against splashes by wearing rubber gloves and goggles.

When jump starting a car using a booster battery, for negative

earth (ground) vehicles, connect the jump leads in the following

sequence: First connect one jump lead between the positive (+)

terminals of the two batteries. Then connect the other jump lead first

to the negative (-) terminal of the booster battery, and then to a good

earthing (ground) point on the vehicle to be started, at least 1 8 in (45

cm) from the battery if possible. Ensure that hands and jump leads are

clear of any moving parts, and that the two vehicles do not touch.

Disconnect the leads in the reverse order.

Mains electricity

When using an electric power tool, inspection light etc, which

works from the mains, always ensure that the appliance is correctly

connected to its plug and that, where necessary, it is properly earthed

(grounded). Do not use such appliances in damp conditions and, again,

beware of creating a spark or applying excessive heat in the vicinity of

fuel or fuel vapour.

Ignition HT voltage

A severe electric shock can result from touching certain parts of

the ignition system, such as the HT leads, when the engine is running

or being cranked, particularly if components are damp or the insulation

is defective. Where an electronic ignition system is fitted, the HT

voltage is much higher and could prove fatal.

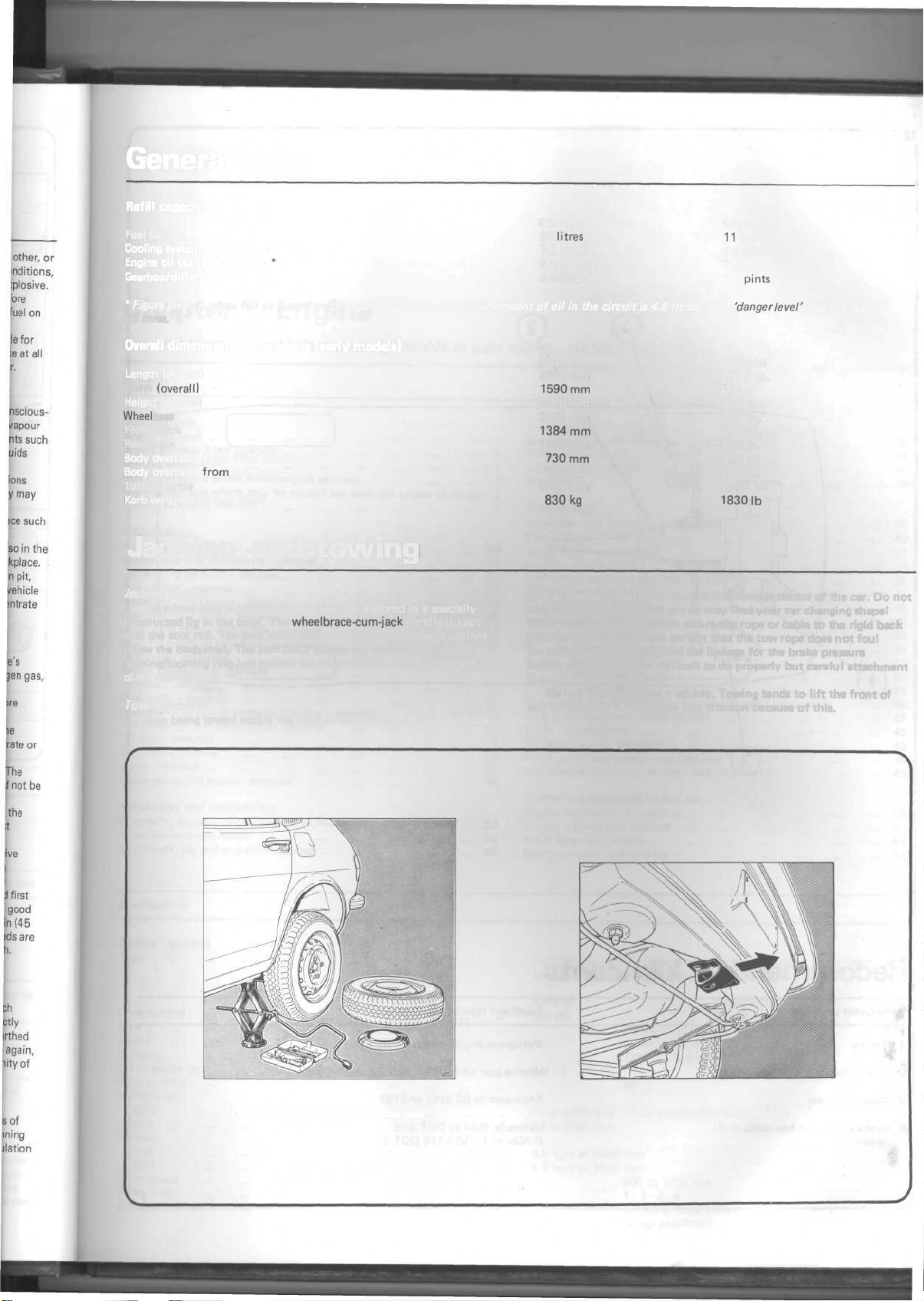

Page 12

General data

Refill capacities

Fuel tank

Cooling system (inc. heater)

Engine oil (sump and filter)

Gearbox/differential

Metric

50

litres

7.3 litres

4 litres

3.4 litres

Imperial

11

gallons

1.6 gallons

7 pints

5.9 pints

* Figure given is when full or quantity for regular changing. The total amount of oil in the circuit is 4.6 litres. The

2.8 litres.

Overall dimensions and weights (early models)

Length (overall)

Width

(overall)

Height (overall)

Wheel

base

Front track

Rear track

Body overhang from front axle centre

Body overhang

Turning circle

Kerb weight (full fuel tank)

from

rear axle centre

Metric

3890

mm

1590mm

1370

mm

2455 mm

1384mm

1351

mm

730mm

705 mm

9400

mm

830kg

Jacking and towing

Jacking points

The scissor-jack supplied with the vehicle is stored in a specially

constructed jig in the boot. The

with the tool roll. The jack must only be used at the proper positions

below the bodyshell. The jack has a special lug which sits under an

opening/locating ring just behind the front wheels and just in front

of the rear wheels

wheelbrace-cum-jack

handle is kept

Towing points

When being towed secure the rope or cable through the eye of the

special bracket attached to the front underside centre of the car. Do not

tow from any other point or you may find your car changing shape!

When towing another vehicle secure the rope or cable to the rigid back

axle, on the off side. Make certain that the tow rope does not foul

the hydraulic brake pipes and the linkage for the brake pressure

limiter valve. This is not difficult to do properly but careful attachment

is necessary.

Do not tow too

any vehicle - the Alfasud can lose traction because of this.

heavy a vehicle.

'danger

Imperial

151.7

62 in.

53.4

in.

95.7

in.

53.9

in.

52.6

in.

28.4

in

27.4

in.

366.6 in.

1830

Ib

Towing

in.

tends

level'

quantity is

to

lift

the

front

of

Location of jacking point at the rear

Only permissible towing hook

Page 13

12

Recommended lubricants

Component or system

1 Engine

2 Transmission

3 Cooling system

4 Brake and clutch hydraulic

systems

Lubricant type or specification

ft/lultigrade engine oil SAE 10W/50

Hypoid gear oil EP 80W/90

Antifreeze to

Hydraulic fluid to DOT SAE

J1703e

BS3151

or FMV55

116

or

3152

DOT 3

Page 14

Chapter 1 Engine

For

modifications,

Contents

and information applicable to later models, see Supplement at end of Manual

Descriptions

Engine removal 5

Engine removal from gearbox ... ... ... ... ... ... 6

General description ... ... ... ... ... ... ... 1

Major operations which entail engine removal 3

Major operations which may be carried out with the engine in the car 2

Method of engine removal ... ... ... ... ... ... 4

Dismantling

Alternator - removal ... ... ... ... ... ... ... 10

Big-end bearings and piston - removal 21

Camshaft drive belts - removal ... ... ... ... ... ... 14

Carburettor - removal ... ... ... ... ... ... ...

Crankcase front cover - removal 20

Crankcase rear cover -

Crankshaft

Cylinder heads and

Distributor-removal

Engine dismantling - general ... ... ... ... ... ... 7

Flywheel - removal 22

Fuel pump - removal ... ... ... ... ... ... ... 13

Inlet manifold and thermostat housing - removal ... ... ... 12

Main bearings and crankshaft - removal ... ... ... ... 24

Oil

Oil pump - removal ... ... ... ... ... ... ... 19

Sump - removal ... ... ... ... ... ... ... ... 18

Water pump and pulley - removal 16

pulley

filter-removal

removal...

and

drives-removal

camshafts-removal

8

9

... ... ... ... ... 23

17

... ... ... ... 15

11

Inspection and renovation

Camshafts, tappets, camshaft pulleys and belts

Crankcase/cylinder

Crankshaft, big-end and main bearings

block

32

26

28

Cylinder compression test

Cylinder heads and valves, plus decarbonisation

Flywheel (and starter ring gear)

Liners, pistons, piston rings and connecting rods

Oil pump ...

Reassembly

Alternator and drivebelt - replacement and tension ...

Camshaft belts and valve timing

Carburettor - replacement

Crankcase preparation ...

Crankshaft and main bearings - reassembly ...

Cylinder heads and camshafts - reassembly and replacement

Distributor - replacement

Engine -

reassembly

Flywheel Front crankcase cover - replacement ...

Fuel pump - replacement

Inlet

Oil pump Pistons and connecting rods - reassembly and replacement

Rear crankcase

Sump - replacement

Tappet clearance adjustment ...

Water pump and pulley - replacement

Ancillary sender units, oil filter and other parts

replacement...

manifold - replacement ...

replacement...

general

cover-replacement

Engine replacement in the car

Engine attachment to gearbox ...

Engine replacement into car

Fault diagnosis - engine

Starting engine and running in ...

25

31

29

27

30

48

42

51

34

35

41

46

33

38

39

47

50

44

36

37

45

43

40

49

52

53

55

54

Specifications

Engine - general

Type

Code number

Bore

Stroke

Capacity ...

Compression ratio

Octane rating

Horsepower:

SAE

DIN

Torque:

SAE

DIN

Idling speed

Firing order

Oil capacity (both)

Horizontally opposed, flat

camshaft on each cylinder bank

Alfasud

301.00

8.8:

1

4-cylinder,

80mm (3.15 in)

59mm (2.32 in)

1186cc(72.4cu in)

99

73 at 6000

63 at 6000 rpm

9.8 kgm at 3500 rpm

8.5 kgm at 3500 rpm

rpm

800 to

1000

1-3-2-4

4 litres (7 Imp. pints)

(sump and filter)

water cooled, single overhead

Alfasud

Tl

301.04

9.0:1

68 at 6000 rpm

rpm

Page 15

14

Chapter

1/Engine

Essential differences between the Alfasud and Alfasud

1 Camshafts and valve timing

2 Cylinder heads

3 Valves

4 Carburettor

Lubrication system

Type ... ... ... ... ... ... ... ... ... ... Wet

Filter Full flow - replaceable cartridge

Capacity:

With filter change ... ... ... ... ... ... ... ... 4 litres (7 Imp. pints)

Without filter change 3.6 litres (6.3 Imp. pints)

Oil

required

Oil pump ... ... ... ... ... ... ... ... ... ... Twin gear

Oil pump gear/body end-clearance Nil

Oil

pump

Oil pressure relief valve

Crankshaft and main bearings

No. of bearings, and type

Journal diameters 59.944 - 59.975 mm

Undersize main bearing shells 0.25, 0.50, 0.75, 1 mm

Bearing clearance

Crankshaft endfloat

Journals, maximum ovality ... ... ... ... ... ... ... 0.02 mm

Crankcase

Main bearing bore diameter 63.663 - 63.673 mm

Thickness of seating for thrust washers (side-to-side) 23.68 - 23.73 mm

Maximum allowable misalignment of bearing ... ... ... ... 0.02 mm

Camshafts and

Camshafts drive ... ... ... ... ... ... ... ... ... 2 gear driven toothed belts, external

Bearings ... ... ... ... ... ... ... ... ... ... Direct in carrier

Journal diameters:

Bearing housing diameter:

Endfloat

Width of camshaft register housing 5.45 - 5.5 mm

Thickness of rear cover gasket

Width of camshaft register ... ... ... ... ... ... ... 5.5 - 5.55 mm

Diameter of tappet bucket housing 36 - 36.025 mm

Diameter of tappet 35.973 - 35.989 mm

Maximum total misalignment of camshaft bearings ... ... ... ... 0.02 mm

Truth of machined faces 0.03 mm

Connecting rods and bearings

Type

Big-end bearings ... ... ... ... ... ... ... ... ... Thin wall shell

Small-end bush ... ... ... ... ... ... ... ... ... Steel bush, lead bronze coated

Big-end journal diameter 49.987 - 50 mm

Big-end diameter 53.696 - 53.708 mm

Undersize big-end bearing shells 0.25, 0.50, 0.75, 1 mm

Clearance of big-end bearing to journal 0.026 - 0.063 mm

Gudgeon (wrist) pin/bush interference ... 0.024 - 0.039 mm

Crankpin, maximum ovality ... ... ... ... ... ... ... 0.02 mm

Cylinders

Type ... ... ... ... ... ... ... ... ... ... Machine into cylinder block with liners

Oversize (liner diameter) ... ... ... ... ... ... ...

Maximum divergence from measurement ... ... ... ... ...

Cylinder heads

Type Aluminium alloy, one per pair of cylinders, cross flow. Alfasud and

Pistons and rings

Type ... Light alloy. Alfasud and Alfasud

Cylinder clearance limit 0.03 - 0.05 mm

Height of piston ring grooves:

to

fill

from lower

gear/backlash...

0.028 - 0.063 mm

limits

bearings

Front 34.94 - 34.956 mm

Centre 46.445 - 46.456 mm

Rear 46.94 - 46.956 mm

Front

35.015-35.040

Centre 46.515 - 46.54 mm

Rear 47.015 - 47.040 mm

0.1-0.3

Forged steel

Top compression 1.525 -

Lower compression 1.775 - 1.795 mm

Oil control ...

4.015

to

upper marks

... ... ... ... " ... ... ... Nil

set

at 4.5 kg/sq cm

-3,

0.05 - 0.24 mm

0.21-0.33

on the

Tl

engines:

dipstick

... ... 1.2

0.2,0.4,0.6mm

0.010mm

Alfasud Tl use different heads

sump,

pressure and splash

thin wall shell

mm

mm

1.545

mm

- 4.035 mm

mm

litres

(2.1 Imp. pints)

Tl

use the same pistons

Page 16

Chapter

Piston ring thickness:

Top compression ... ... ... ... ... ... ... ...

(

Lower compression ... ... ... ... ... ... ... 1.728 -

Oil control 3.978 - 3.990 mm

Piston oversizes

Gudgeon wrist pin ... ... ... ... ... ... ... ... Steel tube

Clearance of gudgeon pin to piston 0.007 0.016mm

Top compression ring gap ... ... ... ... ... ... ... 0.30 - 0.45 mm

Lower compression ring gap ... ... ... ... ... ... ...

Oil control ring gap ... ... ... ... ... ... ... ... 0.25 - 0.40 mm

Gudgeon pin diameter 20.006 Tappet cam followers

Type

..

Diameter of tappet bucket 35.973 - 35.989 mm

Valves,

Inlet:

Valve head diameter 38 - 38.2 mm

Stem diameter

Seat width

Seat angle 90° - 90°

Guide bore diameter 8.013 - 8.031 mm

Exhaust:

Valve head diameter 33 - 33.2 mm

Stem diameter

Seat width

Seat angle 90° - 90°

Guide bore diameter 8.030 - 8.048 mm

Maximum rock in guide (both) ... ... ... ... ... ... 0.9 mm

Valve springs:

Height of

External spring: spring length and load with valve closed ... ... 33.75 mm/22.95 - 24.35 Kg

Internal spring: spring length and load with valve closed

Valve (tappet) clearance (oil removed from camshaft chest) (cold)

Inlet

Exhaust

Valve timing Alfasud Alfasud

Inlet

Inlet

Exhaust opens bbdc 54° 45°

Exhaust closes atdc 6° 7°

0.2,0.4,0.6mm

... ... ... ... ... ... ... ... ... Bucket type, encasing valve

valve seats

0.35-0.40

opens

closes

and

timing

7.895-8

1.07-1.37

7.985-8

1.26-1.56

free

spring ... ... ... ... ... ... ... 46 mm

31.75

0.45-0.50

btdc 6° 12°

abdc 54° 48°

1/Engine

1.478 - 1.490

1.740

0.30 - 0.45 mm

mm/11.35

mm

mm

21.00

mm

mm

mm

30'(included

mm

mm

30'(included

mm

mm (0.018/0.020 in)

angle of seat faces)

angle of seat faces)

- 12.15 Kg

(0.014/0.016

spring,

bearing directly onto camshafts

in)

Tl

15

and

Torque wrench settings

Main

bearing cap

Side brace bolts*

Connecting rod bolts

Flywheel bolts* 9.6-10.7

Crankshaft nut

Drive pulley to camshaft* 6.4-7.1 46.2-51.3

Cylinder head bolts*

Camshaft housing/cylinder head bolts 1.9-2.4

Oil pump set screws:

Large 1.9-2.4

Small

Fuel

pump

Inlet manifold 1.9-2.4

Timing belt tensioner nut:

Cold engine

Hot engine 3.0-3.6

*OHed

threads

1 General description

The Alfasud engine is not particularly conventional. As a flat four,

single overhead

present time. The specifications explain the basic workings of the

engine adequately, this paragraph will explain its significance to the

home mechanic. Do not be put off the Alfasud engine by its

description, nor by what it looks like sitting in the car. It is a relatively

simple unit to remove and equally so to dismantle. No special tools

are strictly necessary but it is a must to use a wide selection of good

bolts*

6.7-7.4

4.1-5.0

4.4-4.9

12.0-14.7

8.3-8.9

0.8-1.0

nuts 1.9-2.4

3.8-4.7

camshaft,

water cooled engine it is unique at the

'paper'

kg f m Ib

48.5-53.5

29.5-36.0

31.8-35.4

69.4-77.3

86.7-106.4

60.0-64.3

13.7-17.3

13.7-17.3

5.7-7.2

13.7-17.3

13.7-17.3

27.4-33.8

21.6-25.9

quality tools. Many spanner (metric) sizes are used; it would be unwise

to tackle the job without a full metric socket set, open and ring spanner

set, screw drivers,

able as the majority of the engine components are assembled at the

factory with gasket cement and thread locking fluid. Have engine and

grease cleaner available, too, as a clean engine is much easier to work on

in this case, than a dirty one. Lots of lint free rag and wooden blocks

to support the components will help. Follow the instructions very

carefully, one sequence out could cost extra time and money. At

times

it is

when this is so.

necessary

hammers,

to

have

punches etc. Have some easing fluid avail-

someone

f ft

else

help you;

you

will

be

told

Page 17

16

7 Cylinder block

2 Main bearing cross-bolts

3 Main

bearing

cap

4 Front engine

5

Front

6 Oil seal

7 Gasket

8 Pressure sensor

cover

bolts

mounting

13

Fig. 1.1. Basic, static engine components

9 Rocker cover

10

End cover

11

Gasket

12 Cam

13 Oil seal

14 Gasket

15 Head gasket

housing

Page 18

17-

16 Sump gasket

17 Sump

17

16

18

Crankcase rear cover

19 Oil seal

20 Oil

filler

21 Dipstick

22 Dipstick stop

23 V ring

24 Oil filter

Page 19

18

Chapter

1/Engine

2 Major operations which may be carried out with the engine in the

car

Little major work can be carried out upon the engine with it still

in the car. As it is relatively easy to take the engine and gearbox out

of the car you may

be easily carried out with the engine in the car. Here is a list of those

tasks which can be carried out with some indication as to whether or

not it would be better to remove the engine:

Replacement of timing toothed belts (easy)

Replacement of inlet

alternator and alternator drive belt, radiator and spark plugs (easy)

Water pump (possible but very difficult due to interference fit of

pump)

Sump (easy)

Big-end bearings (difficult and from below)

Oil pump (easy)

Cylinder heads (see Chapter 12)

find

that nothing more than routine servicing can

manifold,

carburettor,

distributor,

exhaust,

3 Major operations which entail engine removal

It is necessary to remove the engine and gearbox from

carry out the replacement of the following components:

1 Clutch and gearbox

Crankshaft, flywheel, main bearings, pistons and connecting rods

4 Method of engine removal

The engine and gearbox must be removed together complete and

must always be done from below. This may mean either lowering the

engine/gearbox from a hoist under the

bodyshell to sufficient height, or to wheel the engine and gearbox from

under

the car on a

Whatever happens ideal conditions are necessary: flat floor, elbow

hoist and tall stacks.

trolley

jack

and

bodyshell,

physically

having jacked up the

lift

the

ths

bodyshell

car to

over

room,

it.

5.8a The radiator top support

5.10

Disconnect the starter motor cables

5.8b Removing the radiator

5.15

Removing the air cleaner cover

5.9 Accelerator return spring

5.17

Disconnecting the choke cable

5.22 Front brake pipe union

5.23 Moving the clutch slave cylinder out of the

way

Page 20

plete and

hell over it.

elbow room,

5.28 The reversing light switch

5.29 Exhaust pipe connection

5.30 Camshaft cover and bracket

5.31 Rubber

*

I

5.34 Remove the Allen screws

shafts crossmember

O-rings

support exhaust system 5.32 Exhaust

from

the drive- 5.36 Front engine mounting is secured to

pipe-to-cylinder

head connections 5.33 Disc dust cover seen from below

5.37a

Crossmember-to-bodyshell

bolts

attachment

5.37b Anti-roll bar mountings need not be 5.37c Crossmember and anti-roll bar can be

disturbed removed complete

5.38 Gearbox tail mounting

Page 21

20

Chapter

1/Engine

5.39 Engine centre mounting

5.40 Handbrake cable is visible to the rear of

the engine mounting

5.41

b Raise the bodyshell to clear the engine

5 Engine removal

1 Place the car in a convenient spot where it is possible to gain access

underneath it for its full length and where it is possible to leave it

jacked up and supported on stands. A hoist can be used or instead a

trolley

jack

to

lift

the

bodyshell

or

lower

the

engine,

and

room

to use

them.

2 Run the engine until it is at its normal working temperature.

Switch off and chock the rear wheels on both sides of the car. Open

the bonnet and disconnect the battery earth lead. Drain the engine

oil.

3 Remove the front grille. It is fixed by one screw on each side and

four on the bottom edge. Pull off the central badge (it is a push-on fit)

and remove the last screw which is mounted behind it.

4 The four bonnet hinge bolts are now exposed. Have someone hold

the bonnet and remove the four bolts. Squeeze the bonnet support,

unclip it and remove the bonnet to a safe place.

5 It is not

necessary

but it

will

give greater

working

space

if you now

drain the cooling system and then remove the radiator. Jack up the

front of the car and support it. Obtain two receptacles which will

hold about a gallon each and place them under the coolant drain

plugs, one under the centre of each cylinder block. Undo the plugs

and allow the radiator and the cylinder blocks to drain, once you

have removed the expansion chamber filler cap. Remove the

receptacles and lower the car.

6 Remove the bottom and top hoses to the radiator by pinching

the two hose clips on each hose, one at each end, and carefully

levering

off the tight hoses. Remove the expansion chamber hose

at the radiator by unscrewing the hose clip and slipping it off.

7 Pull off the electrical connections to the thermostatically

controlled fan switch and one of these to the fan. The other wire

to the fan is an earth wire and should be disconnected at earth

which is one of the headlamp support studs.

8 Undo the one radiator support which is in the centre of its top

chamber. This is a one stud with a nut fixing, on rubber. Undo the

nut and carefully pull the radiator back at the top towards the

bulkhead, and lift out.

5.41

a Lower the engine to the ground

9 Disconnect the accelerator control linkage from the lever on the

carburettor. You will need to unhook the return spring and a special

connecting ring, a sort of circlip.

10 Disconnect the engine and transmission earth cable which is

connected to an end cover nut adjacent to the starter motor. Discon-

nect the two starter motor cables. Pull off the water temperature

warning light wire from the sender unit on the right hand bank of

cylinders. All these wires are in the same harness. Tie them all back

out of the

11

way.

Pull off the terminals from the alternator and then release the

cables from the retaining clip on the engine lifting hook which is on

the outer end of the inlet manifold fixing. Tie back.

12 Pull off the high tension and low tension cables from the

distributor and tie back.

13 Pull off the cable from the sender unit for the engine oil pressure

warning light.

14 Pull off the

carburettor

air cleaner warm air intake pipe from its

lower fixing and unclip the hose clip at its top end on the air cleaner.

Remove.

15 Unscrew the wing nut on the top of the air cleaner, remove cover

and the element inside. Now remove the air cleaner body and gasket

from the carburettor. This is fixed by two nuts and studs on the

Alfasud and four on the Alfasud

Tl.

Pull off the breather pipes which

come with it.

16 Release the support bracket for the accelerator cable from the

top of the carburettor which is now exposed. It fits over the top of

the inlet.

17 Disconnect the flexible cable and the outer cable of the choke at

the clamp and screw. Two small spanners will be necessary here.

18 For ease of movement remove the plug caps and leads together

with the distributor cap. Then remove the rotor arm.

19 Pull off the brake servo pipe to the inlet manifold and tie back, on

those models so

fitted.

20 Unclip the hose clips and remove as many of the heater hoses as

possible. Remove them from the front side of the inner bulkhead only;

do not remove them at the heater itself. A screwdriver, carefully used

to lever off the hoses, always helps. Some of them are clipped to the

engine oil filler pipe, disconnect here too. Do not forget the pipe to the

expansion chamber also.

21 Disconnect the petrol feed pipe to the fuel pump and tie back.

22 Remove the cap to the brake fluid master cylinder reservoir and

place a piece of thin polythene over the opening and replace the cap.

This prevents brake fluid leakage for the next operation. Disconnect

the front brake flexible pipes from the rigid pipes which come direct

from the master cylinder at the special unions, one on each side of

the inner bulkhead, on the front side. Two spanners will be necessary.

Seal off the pipes with suitable plugs.

23 To remove the clutch slave cylinder from the engine block locate

it close to the engine oil filler pipe. On the far side there is a large

circlip which holds the body of the slave cylinder in place. Release

this circlip and the slave cylinder will come back through its fixing

and can be placed out of harm's way on the other side of the inner

bulkhead. There is no need to disconnect the piping.

Page 22

Chapter 1/Engine

21

24

Inside

the car

pull

off the

at the foot of the gearlever and the rubber gaiter below that. They

are nothing more than simply clipped in.

25

Inside

the car

handbrake.

the pivot pin so that the lever is loose. Now remove the

handbrake

the cable inner about to enable the ferrule to release itself from the

cable

and be

pushed through the lever at an angle.

26 Everything that needs to be done from above the engine has been

completed.

the

place

the front of the car. Remove the

27 Drain the gearbox oil. Replace the plug when the oil has drained.

28

From

switch

cable

drive

cable

retaining spring.

29 Go to the left-hand rear road wheel and just in front of it spray

the

exhaust

a

releasing

breaking

30 Now go to the

engine.

There

exhaust

and to the end of the

air

cleaner

intake.

31 Go

back

clamp

completely.

and

try to

have

to

split

back

the

sets

of

rubber

and rear silencer.

32 Undo and remove the eight nuts which support the four pipes of

the exhaust manifolds at the cylinder heads. Then remove the two

rubber

'0'

part

of the

Obviously

the front or the back as it is released.

33 Now remove the two front disc dust covers. These are individually

fixed

with four

bracket

on the

on the top top side of the cover located into the side of the gearbox.

34 With the appropriate alien key undo and release the alien screws

which

bolts

Allen

screws

be

necessary

releasing

expensive

shafts

and tie

the inner bulkhead.

35

From

hoist.

There

Use

these

the gearbox. For the moment support the engine on the two eyes.

Another

method

with

the

not so

good

36 The front crossmember should come out with the anti-roll bar

attached.

arm/crossmember

to the inner side of the

remove

the two

to

the crossmember. These are located just in front of the anti-roll

bar, in the centre.

37 At each end of the front crossmember are two bolts which locate

it to the

engine

support (front)

anti-roll bar still fixed, should come away. The engine and gearbox

should be supported, of course, by the sling or trolley jack together

with the rear centre mounting and the rear gearbox mounting.

38 Remove the two support bolts for the rear gearbox mounting

located

at the end of the

39 From above with the tail shaft of the gearbox supported by another

pull

Undo

the nut on the

cable

ferrule

pushed

through.

Now

jack

that

you can let it

below

the

gearbox

by

pulling

from

the

side

connection (the exhaust

agent.

The

will

be

helped

front

is a tin

warm

air

intake.

to the

exhaust system,

Tap the

make

the

joint

them.

tail pipe

agent.

to

above

lifting

Undo

bodyshell.

Use a

off the

'O'

ring

ring exhaust system

total system.

it

will

help

bolts.

underside

the two

front

will

be

tight

to use a

Watch

replace. Never

them back, preferably upwards

support

are two

plus a third

lifting

is to

head

protected

but it

will

the

bolt

to the transverse suspension arm at the strut, close

bolts

With these four removed the

gearlever

off the

handbrake lever gaiter

which

locates

It

up the car as

rest

at the

it

off.

Then

of the

joint

is

bound

if you use

of the car to the right-hand exhaust below the

moulding

camshaft cover.

Remove

connection

move

large screwdriver

front

exhaust

supports

The

system should

to

have another person

Two

appear

of the

drive

as

they

piece

of

tubing

the

rubber bellows

'bodge'

the

engine

eyes,

point

when

support

the

work

if no

which

front

hub. Do this on each side. Slacken and

from

below

and

both

tail

shaft.

knob.

Then

handbrake lever

the

has a

step

high

as you can at the

whilst

the

front

wheels.

rear,

disconnect

disconnect

gearbox

by

splits

to be

releasing

which

is

the two

split

with a copper-headed hammer

in

some

part

of the

and

supports

from

below

gearbox sump

shafts

to the

are

'Loctited'

on the

the

proper

and

gearbox

one on

each

it

becomes

engine

with a piece

hoist

is

locates

the

that

fix the

trailing

suspension

pivot

cable

to the

on it and

engine

is

the

speedometer

unclipping

here

into

rusted together

fluid

now.

bolted

to a

This

bolts

and

and

release

way. Eventually

or

punch

system.

Undo

remove

at the

other

now

drop

under

and

bolt

and the

disc/hub

into

Allen

key

as you do

tool.

with

string

with a sling

end of the

visible

from

below

of

wood.

available.

rear

end of the

front

front

pull

out the

and

release

pin,

remove

circlip

lever. Juggle

this

has to be

front

out.

Support

the

reverse

the

special

two

parts)

and its

bracket

is the

on the

carburettor

release

the

exhaust

you

will

to try to tap

the two

the

tail

pipe

end of the

away.

the car to

into a special

other

two are

flanges. These

position.

plus some

this

for

they

Release

the

or

wire

and a

inlet

through

engine

links

the top of

with a trolley

This

method

suspension

mounting

crossmember,

with

'bag'

the

on the

in

light

with

the

front

hold

It may

are

half

to

manifold.

jack

is

the

person under the car (no strength is needed, just a steadying hand)

slacken and remove the centre engine mounting bolt located under

the centre of the inner bulkhead. The engine and gearbox are now

loose.

40 If you are using a hoist allow the engine/gearbox to be lowered

to the ground. Now disconnect the handbrake cable from both the

front brake calipers. A pair of grips and a stout screwdriver are

necessary to do this with some force. The return spring on the cable

is very stiff. Once done, tie the handbrake cable back. Now relocate

the hoist so that it is mounted at three points, the third being through

the support on the gearbox from whence the handbrake cable came.

Raise

the

engine

and

gearbox

unit

just

off the

ground

and

pull

forward

and out

from

under

the

car.

At

some

point

necessary

have

to

is a

minimum

total

unit.

from

you

to

pull

the studs around

have to remove the hoist to clear the front of the car. Take the

engine and gearbox to the point where you intend to work. Three

strong

men

could

lift

the

total

unit

41 If you are using a trolley jack, lower the engine and gearbox unit

and remove the handbrake cable as described in the previous paragraph.

At the jack's lowest point pull the whole unit forward until you are

ready

to

clear

the

over

the

engine

and two

will

persons.

6 Engine removal from gearbox

1 Place the engine and gearbox (preferably) on a strong working

surface

still

the pair on the ground.

2 Remove the nuts, bolts and washers which support the starter

motor to the bell housing. Remove the starter motor.

3 Remove from the underside of both units the flywheel protection

cover. This is retained by a number of bolts and washers to the rear

engine cover and by one at the bottom to the gearbox casing.

4 Remove all the remaining nuts and washers

the

bell

housing.

the gearbox from the engine. Take care with the gearbox shaft which

locates through the centre of the clutch. Do not allow any pressure on

it - pull off straight.

have

with

underside

and

gearbox.

to

the

Both

lift

sling

engine

the

just

complete.

of the

car.

One

person

bodyshell.

supporting

and

gearbox

It

is

will

This

the

may now be

will

lift

the

number

If not

split

it

again

the car

engine

place

by

lifting

of

Dismantling

7 Engine dismantling - general

1

Owners

strong work bench and many tools and pieces of equipment, which

make their life much easier when going through the process of dis-

mantling

the

which,

to the job in the long run. It is essential to have sufficient space in

which to work. Dismantling and reassembly is not going to be completed all in one go and it is therefore absolutely essential that you

have sufficient area to leave things as they are when necessary. A

strong work bench is also necessary together with a good engineer's

vice. If you have no alternative other than to work at ground level,

make

wooden or wood composition material on which to work. If dirt and

grit are allowed to get into any of the component parts all work which

you carry out may be completely wasted. Before actually placing the

engine wherever it is that you may be carrying out the dismantling,

make sure that the exterior is now completely and thoroughly

cleaned.

2 Once dismantling begins it is advisable to clean the parts as they

are removed. A small bath of paraffin is about the best thing to use

for this, but do not let parts which have

immersed in paraffin otherwise there may be a residue which could

cause harmful effects later on. If paraffin does get into oilways every

effort should be made to blow it out. For this it may be

carry

hose. Short oilways such as there are in the crankshaft can be cleared

who

have

dismantled

an engine. For those who are doing a dismantling job for

first

time,

there are a few

if not

sure

the

particular

acquired,

that

the

will

floor

part

only

is at

to a

engines

'musts'

cause

least level

garage

fitted

will

know

the

in the way of preparation

frustration

and

oilways

and

covered

with a suitable

in them become

with a high pressure

need

long

delays

necessary

for a

to

air

Page 23

22

Chapter 1 /Engine

easily with pipe cleaners.

3 Always obtain a complete set of gaskets when the engine is being

dismantled - no gaskets on an engine are re-usable and any attempt

to do so is quite unjustified in view of the relatively small cost involved.

Before throwing any gaskets away, however, make sure that you have

the replacement to hand.

obtained it may be necessary to make one, and the pattern of the old

one is useful in such cases.

4 Generally speaking, it is best to start dismantling the engine from

the top downwards.

times so that it does not topple over whilst you are undoing the very

tight nuts and bolts which will be encountered. Always replace nuts

and bolts into their locations once the particular part has been removed,

if possible. Otherwise keep them in convenient tins or pots in their

groups, so that when the time comes to reassemble there is the

minimum of confusion.

8 Distributor - removal

1 The distributor cap, plug leads and caps should have been removed

already. So should the rotor arm. Pull off the vacuum advance pipe at

the carburettor and leave it attached to the distributor.

2 There is no need to record the position in which the

fixed to enable quick and accurate ignition timing upon replacement

as static timing marks are provided on a dowelled flywheel and there

is a cut on the rim of the distributor body where the caps fit to align

the rotor arm. Also there are adequate instructions for ignition timing

in Chapter 4. The distributor is therefore quickly removed.

3 Slacken the nut fixing the distributor to the adjusting plate on the

rear crankcase cover. Remove the nut and pull the distributor away.

If,

for example, a particular gasket cannot be

In

any case, make sure it is firmly supported at all

distributor

is

9 Oil filter - removal

1 Withdraw the dipstick.

2

Hold

a rag

under

the oil

seal

to

catch

the oil

which

will

flow

filter

off the

gasket.

out

body

fuel

when you release the oil filter. Now use a strap or chain wrench around

the oil filter body and release, unscrew and discard it. An alternate

method if a proper wrench is not available is to unscrew the

using a hammer and screwdriver to drive it in an anticlockwise direction.

3 Always use a new filter on a rebuilt engine.

10 Alternator - removal

1 First slacken the bolts which adjust the alternator drive belt using