Instruction Manual

Alfa Laval GJ 8

Covering:

Standard Machines

First published: 2015-08

ESE032025-EN1 2015-08

Original manual

Table of Contents

The information herein is correct at the time of issue but may be subject to change without prior notice

1. EC Declaration of Conformity ...... ..... ..... ...... ..... ...... ..... ...... ..... ...... ..... ..... ...................................... …… 1

2. Safety .. ..... ...... ..... ...... ..... ...... ...... ..... ..... ...... ..... ...... ..... ...... ..... ...... ..... ..... ...................................... …… 2

2.1. Important information . ..... ...... ...... ..... ..... ...... ..... ...... ..... ...... ..... ...... ..... ..... ...................................... …… 2

2.2. Warning signs ... ...... ..... ...... ...... ..... ..... ...... ..................................... ..... ..... ................................ …. 2

2.3. Safety precautions .... ..... ...... ...... ..... ..... ...... ..... ...... ..... ...... ..... ...... ..... ..... ...................................... …… 3

3. Introduction ..... ..... ...... ...... ..... ..... ...... ..... ...... ..... ...... ..... ...... ..... ..... ...................................... …… 4

3.1. Description . ...... ..... ...... ..... ..... ...... ..... ...... ..... ...... ..... ...... ..... ..... ...................................... …… 4

3.2. Intended Use . ...... ..... ...... ..... ..... ...... ..... ...... ..... ...... ..... ...... ..... ..... ...................................... …… 4

3.3. Patents and trademarks . ...... ..... ...... ..... ..... ...... ..... ...... ..... ...... ..... ...... ..... ..... ...................................... …… 4

3.4. Marking . ...... ..... ...... ..... ..... ...... ..... ...... ..... ...... ..... ...... ..... ..... ...................................... …… 4

4. Installation . ...... ..... ...... ..... ...... ...... ..... ..... ...... ..... ...... ..... ...... ..... ...... ..... ..... ...................................... …… 5

4.1. Unpacking/delivery ... ..... ...... .......... ..... ...... ..... ...... ..... ...... ..... ...... ..... ..... ...................................... …… 5

4.2. Installation .. ..... ...... .......... ...... ..... ...... ..... ...... ..... ...... ..... ..... ...................................... …… 6

4.3. Recycling Information ..... ...... ..... ..... ...... ..... ........... ...... ........... ..... ..... ...................................... …… …...…. 8

5. Operation . . ...... ..... ...... ..... ..... ...... ..... ........... ...... ..... ..... ...................................... …………..... 9

5.1. Operation/Control ..... ..... ...... ...... ..... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 9

5.2. Trouble Shooting ..... ............ ..... ...... ..... ...... ..... ..... ….. ….. …. ...................................... …………….. 10

5.3. Cleaning Solution Leakage ..... ..... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 12

5.4. Poor Cleaning Performance .... ..... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 13

5.5. Recommended Cleaning . . ...... ..... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 14

6. Maintenance . ...... ..... ...... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 15

6.1. General Maintenance.... ..... ...... ..... ..... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 15

6.2. General dismantling set up ..... ..... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 16

6.3. General dismantling . . ..... ...... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 17

6.4. Inspection and Service of Components . ...... .......... ...... ..... ..... ...................................... …………….. 18

6.5. Reassembly ..... ...... ..... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 21

7. Technical Data .. ..... ...... ..... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 23

7.1. Technical Data .. ...... ..... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 23

7.2. Performance Data .... ..... ...... ..... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 24

7.3. Dimensions . .......... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 25

7.4. Trax Simulation Tool .. ..... ...... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 26

8. Parts List and Service Kits ... ...... ..... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 27

8.1. GJ8 View ..... ..... ...... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 27

8.2. Assembly Drawings - 1 & 2 ..... ..... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 28

8.3. Assembly Drawings - 3, 4, 5, 6, 7 & 8 . ..... ..... ............ .......... ...... ..... ..... ...................................... …………….. 29

8.4. Assembly Drawings - 9, 10, 11, 12, 13, 14, 15, 16 & 17............. ...... ..... ..... ...................................... …………….. 31

8.5. Assembly Drawings – 18, 19, 20, 21, 22, 23, 24 & 25..... ..... ...... ..... ..... ...................................... …………….. 33

8.6. Assembly Drawings – 26, 27, 28 & 29 ..... ............................. ...................................... …………….. 35

8.7. Assembly Drawings – 30, 31, 32, 33 & 34... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 37

8.8. Parts List .... ..... ...... ..... ...... ..... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 40

8.9. Minor Service Kit ...... ..... ...... ..... ..... ..... ............ ..... ...... ..... ...... ..... ..... ...................................... …………….. 43

8.10. Major Service Kit ...... ..... ...... ................. ..... ...... ..... ...... ..... ..... ...................................... …………….. 45

9. Appendix A ………............................................................................................................................................. …… 47

Alfa Laval Tank Equipment Inc.

Company name

604 Jeffers Circle – Exton, PA – 19341, United States

Address

+1 610 408 9940

Phone no.

Tank Cleaning Machine

Alfa Laval GJ 8

Denomination

Type

Executive VP Operations

Andrew Delaney

Title Name

Signature

2015-05-18

Exton, United States

Date Place

EC Declaration of Conformity

The designated company

hereby declare that

From serial numbers from E-0001 to E-XXXX

is in conformity with the following regulations and directives with amendments:

- The Machinery Directive 2006/42/EC

DS/EN ISO 12100:2011

- The Pressure Directive 97/23/EC

According to its own volume and the rated pressure range the product is regarded an Article 3, paragraph 3 Equipment

The person authorised to compile the technical file is the signer of this document.

1

2. Safety

Unsafe practices and other important information are emphasized in this manual. Warnings are emphasized by means of

special signs.

Always read the manual before using the tank cleaning machine!

2.1 Important information

WARNING

Indicates that special procedures must be followed to avoid serious personal injury.

CAUTION

Indicates that special procedures must be followed to avoid damage to the tank cleaning machine.

NOTE

Indicates important information to simplify or clarify procedures.

2.2 Warning signs

General warning:

Dangerous electrical voltage:

Caustic agents:

2

2. Safety

All warnings in the manual are summarized on this page.

Pay special attention to the instructions below so that severe personal injury and/or damage to the tank cleaning machine

are avoided.

2.3 Safety precautions

Installation:

Always read the technical data thoroughly. (See chapter 7 Technical Data)

Any tank-cleaning machine can develop a static electricity charge while in operation.

If the tank being cleaned contains a combustible liquid or vapor having a risk of ignition or explosion, it is imperative to

have the Alfa Laval Gamajet properly grounded using the provided location on the unit.

Operation:

Always read the technical data thoroughly. (See chapter 7 Technical Data)

Necessary precautions must be taken if leakage occurs as this can lead to hazardous situations.

Always handle lye and acid with great care.

When an Alfa Laval Gamajet is operating, there should be covers over every tank opening.

These covers should be sealed well enough to withstand the full force of the jet striking the cover plate.

If the cleaning solution were hot, corrosive, or toxic, a leak would present a serious hazard to any personnel

in the immediate vicinity or to any exposed electrical equipment.

Warning: Any tank-cleaning machine can develop a static electricity charge while in operation. If the tank being

cleaned contains a combustible liquid or vapor having a risk of ignition or explosion, it is imperative to have the

Alfa Laval Gamajet properly grounded using the provided location on the unit.

Maintenance:

Always read the technical data thoroughly. (See chapter 7 Technical Data).

Never service the tank cleaning machine when it is hot.

Always use Alfa Laval genuine spare parts.

Transportation of the tank cleaning machine:

Always drain the tank cleaning machine head and accessories of any liquid

Always use original packaging or similar during transportation.

3

3. Introduction

3.1 Description

The Alfa Laval GJ 8 is a fluid-driven (turbine-driven) 360° rotary nozzle machine designed for cleaning the interior surfaces of

a variety of medium to large tanks and vessels. It is powered entirely by the cleaning solution; it requires no electricity,

compressed air or lubricant for operation. The Alfa Laval GJ 8 is designed primarily for portable service; however, the unit

may also be permanently installed in a vessel. If the Alfa Laval GJ 8 is permanently mounted inside a tank, we strongly

recommend inspecting the unit every few hundred hours of operation. (See Chapter 6 - Preventative Maintenance for more

information.)

WARNING: Under no conditions, whatsoever, should the Alfa Laval GJ 8 ever be immersed in anything, unless you

have prior approval from Alfa Laval Tank Equipment, Inc. Failure to comply with this restriction will void the

warranty!

In order to handle the broadest possible range of applications, the stainless steel Alfa Laval GJ 8 is available with dual or triple

nozzles, and an extensive selection of nozzle sizes, stators (non-rotating turbine), and O-ring materials. The nozzles are

available in six interchangeable sizes - 1/4", 9/32", 5/16", 3/8" and 7/16" /(6.3 mm, 7.1mm, 8mm, 9.5mm and 11.1 mm). The

Alfa Laval Gamajet wash cycle time can be adjusted for special applications by changing the stator, and nozzle size.

Interchangeable stators and nozzle sizes are available for either low or high pressures and/or flow rates. A complete

description of the technical specifications and materials of construction of the Alfa Laval GJ 8 is contained in section 8 Parts list

and Service kits.

3.2 Intended Use

It is to be verified by the end-user:

- that the tank cleaning machine is in conformity with respect to tank, vessel or container size in which it will be used.

- that the construction materials (both metallic and non-metallic) are compatible with product, flushing media, cleaning media,

temperatures and pressure under the intended use.

3.3 Patents and trademarks

This Instruction Manual is published by Alfa Laval Tank Equipment without any warranty. Improvements and changes to this

Instruction Manual may at any time be made by Alfa Laval Tank Equipment without prior notice. Such changes will, however,

be incorporated in new editions of this Instruction Manual.

© Alfa Laval Tank Equipment. All rights reserved.

The Alfa Laval logotype is a trademark or a registered trademark of Alfa Laval Corporate AB. "Gamajet" is a trademark or

registered trademark of Alfa Laval Tank Equipment. The Alfa Laval GJ 8 product has patent in the US (US 6.123.271 & US

6.561.199). Other products or company names mentioned herein may be the trademarks of their respective owners. Any rights

not expressly granted herein are reserved.

3.4 Marking

Alfa Laval tank cleaning machines are all marked to allow recognition of machine type, machine name, Serial number and

manufacturing address. The marking is placed on the body of the tank cleaning machine.

Alfa Laval Tank Equipment – Exton, PA

Patent #: 6,123,271 & 6,561,199

4

4. Installation

Read the instructions carefully and pay special attention to the warnings! Always check the tank cleaning machine before

operation.

4.1

Step 1

CAUTION

Alfa Laval cannot be held responsible for incorrect unpacking.

Step 2

Remove any packing material

Step 3

Inspect the tank cleaning machine for visible transport damage. Inspection!

U

npacking/

delivery

Check the delivery for:

1. Complete Cleaning Machine

2. Delivery note

5

4. Installation

Read the instructions carefully and pay special attention to the warnings! Always check the tank cleaning machine before

operation.

4.2 Installation

Step 1

Always read the technical data thoroughly.

(See chapter 7 Technical Data)

Step 2

Assembly

Every Alfa Laval Gamajet is operationally tested before shipment and is ready to run after unpacking. No assembly is

required prior to use. The Alfa Laval Gamajet has been configured to meet the operating conditions (at the Alfa Laval Tank

Equipment Inc., not at the pump) given to us, e.g. pressure, flow, temperature, cycle time, etc.

Note: Any change to the originally supplied operating conditions will affect the performance of the Alfa Laval Gamajet

accordingly.

Step 3

Inlet Connections

The Alfa Laval GJ 8 is supplied with a combination 1-½” NPT female/2" quick disconnect male inlet connection or 1-½” BSP /2"

quick disconnect male inlet connection. It is recommended that when using the NPT/BSP connection the mating male thread be

wrapped with PTFE pipe joint tape prior to mounting. This will minimize any chance of leakage and will make subsequent

removal much easier.

Step 4

Mounting

Before mounting the Alfa Laval GJ 8, make sure the supply line has been adequately flushed. It should be mounted on a rigid

1-½” pipe using an adjustable or pipe wrench. In most applications, the Alfa Laval GJ 8 will be mounted in the upright position

(inlet connection pointing up); however, the Alfa Laval Gamajet will function at any orientation. We do not recommend attaching

the machine to a hose while in the inverted or horizontal orientation. This form of mounting is not rigid and, thus, will not

maintain the Alfa Laval Gamajet’s position should the unit become unbalanced due to clogging of the nozzles. In addition, we

do not recommend using a Triple Nozzle or directional version machine with a flexible supply line. The dynamic imbalance of

the Triple Nozzle will affect the Alfa Laval Gamajet’s performance accordingly.

Warning: When attaching the Alfa Laval GJ 8 onto the supply pipe, ALWAYS use the wrench on the Collar at the

top/inlet of the unit. Never use a wrench on Stem or Tee Housing to tighten the unit onto the pipe. Doing so risks

internally damaging the machine.

6

4. Installation

Read the instructions carefully and pay special attention to the warnings! Always check the tank cleaning machine before

operation.

Step 5

Location inside Tank

Generally, a single Alfa Laval Gamajet should be positioned in the approximate center of the vessel in order to equalize the

cleaning radius in all directions. Some vessels may have specific cleaning problems such as coils or heavy deposits such as

the liquid level line (bathtub ring). In these situations the Alfa Laval Gamajet should be located closer to the difficult area for the

best cleaning results.

Tanks with internal mechanisms or structures such as an agitator shaft, impellers or baffles will require careful positioning to

minimize the “shadow effect” on areas which do not receive direct jet impact. Sometimes, more than one machine, or, more

than one placement of a single machine, may be necessary to completely avoid shadow problems.

Step 6

Entry Openings

When using the Alfa Laval GJ 8, the vessels being cleaned must provide entry openings large enough to avoid interference

during insertion and removal. The minimum opening size required for Alfa Laval GJ 8 is 228.6 mm / 9.0 inches in diameter.

Step 7

Vessel Drainage

If it is necessary to clean the floor of a vessel, remember that standing liquid will diminish the effectiveness of the jet by

covering any soils underneath. Wherever possible, the tank floor should be pitched toward the drain and the drainage opening

should be large enough to eliminate or reduce any liquid buildup or puddling. If gravity alone is insufficient, a scavenger or

stripper pump should be connected to the drain to suck out the excess wash fluid. In extreme cases, it may be necessary to

use smaller nozzles on the Alfa Laval Gamajet, or even to operate it intermittently to allow time for draining.

Step 8

Filters and Strainers

All tank cleaning systems should be equipped with a filter or strainer that will trap solids 15 mm/1/16" (175 micron, 80 mesh) or

larger, as these will not pass through the Alfa Laval Gamajet. These large particles will not harm the machine, but they can

become caught in one of the internal passages of the machine and cause it to stop turning or reduce its cleaning effectiveness

due to a loss of flow. It will then be necessary to disassemble the Alfa Laval Gamajet and remove the blockage.

In recirculating (closed-loop) cleaning or any other application where the cleaning solution may carry abrasive solids in

suspension, adequate filtration is a must. These particles can be extremely destructive to the Alfa Laval Gamajet, pumps,

valves, and other system components. Filters, properly installed and maintained, will more than pay for themselves with lower

overall operating costs in these applications. Furthermore, to ensure that clogged filters or strainers are cleaned, we

recommend using automatic self-cleaning models.

7

4. Installation

Read the instructions carefully and pay special attention to the warnings! Always check the tank cleaning machine before

operation.

Step 9

Capacity Of Supply Pump

The Alfa Laval GJ 8 can be used with either a centrifugal or positive displacement (constant volume), PD, style pump. In

most cases, if the machine is to be used with a centrifugal pump, it should be configured so that the pump will operate close

to its best efficiency point. The end user must, therefore, take all of the plumbing, elevation, and 8 pressure/flow rate

requirements into account.

If a PD style pump (i.e. piston pump, plunger pump, or mechanical diaphragm pump, etc.) will supply the wash fluid to the

Alfa Laval GJ 8 a different set of rules apply. PD pumps are fixed volume pumps whose flow rate is dependent upon the

speed of the pump; the pumps also have a pressure rating which is the maximum operating pressure. Note: Do not

confuse the maximum operating pressure of a PD pump with the actual operating pressure. The actual operating

pressure is dictated by the fixed flow rate of the pump, the Alfa Laval GJ 8 and the plumbing system. If a PD pump is

used, the Alfa Laval GJ 8 should be sized to, first, match the flow capability of the pump and, second, not exceed the pump's

maximum operating pressure (taking the pressure rating of the plumbing system into account, also).

WARNING: For high-pressure applications (over 250 psig/17 bar), the pressure of the system must "ramp up" to its

operating pressure. If the system experiences a pressure spike or pressure increases at a rate of more than 250

psig per second, the machine may be damaged and parts will wear out prematurely. Damage resulting from this

phenomenon is not covered by the warranty.

4.3 Recycling Information

• Unpacking

- Packing material consists of wood, plastics, cardboard boxes and in some cases metal straps.

- Wood and cardboard boxes can be reused, recycled or used for energy recovery.

- Plastics should be recycled or burnt at a licensed waste incineration plant.

- Metal straps should be sent for material recycling.

• Maintenance

- All metal parts should be sent for material recycling.

• Scrapping

- At end of use, the equipment must be recycled according to relevant, local regulations. Beside the equipment itself, any

hazardous residues from the process liquid must be considered and dealt with in a proper manner. When in doubt, or in the

absence of local regulations, please contact your local Alfa Laval sales company.

8

5. Operation

Read the instruction carefully and pay special attention to the warnings!

5.1 Operation/Control

Step 1

Always read the technical data thoroughly. See chapter 7 Technical Data

CAUTION

Alfa Laval cannot be held responsible for incorrect operation/control.

Step 2

Never touch the tank cleaning machine or the pipelines when pumping hot liquids.

Step 3

Initial Startup

Every Alfa Laval GJ 8 that ships is accompanied by a Birth Certificate. This document indicates how the Alfa Laval GJ 8

performed in our testing tank before it shipped based on the operating conditions supplied to Alfa Laval Tank Equipment Inc.

To ensure the longest possible life of the Alfa Laval GJ 8, please verify the operating conditions and, most importantly, the

machine’s cycle time. The cycle time can be measured by, first, picking a fixed point inside of a vessel as a reference and,

second, timing how long it takes the same nozzle to pass back over that point in the vessel. (This, naturally, will not be the

exact same spot because the spray pattern is indexing.) The measured time in seconds directly corresponds to the machines

full cycle time in minutes. In other words, a single 10-second rotation translates to a 10 minute full cycle time.

9

5. Operation

Yes

No

Does Rotor (pos.

10) turn freely by

- Damaged planetary gearhead (pos. 13) - Section 6.4 Inspection and Service of

- Loose Stem Cap Washer (pos. 42) - Section 6.4 Inspection and Service of

No

Yes

Do Nozzle (pos.

5) and Tee

Housing (pos.

4) both index

when Rotor

(pos. 10) is

Yes

No

Does only Tee

- Worn Tee/ Nozzle housing bevel gear (pos. 17, 18) - Section 6.4 Inspection and

- Cracked/Loose input pinion (pos. 39) - Section 6.4 Inspection and Service of

Components

Pay attention to possible faults

Read the instructions carefully

5.2 Trouble Shooting

hand?

turned?

Housing

(pos. 4) index?

- Cracked Input Pinion (pos. 39) - Section 6.4 Inspection and Service of Components

Components

Components

- Bent stem Collar (pos. 2) - Section 6.4 Inspection and Service of Components

- Cracked/Loose Input Pinions (pos. 39) - Section 6.4 Inspection and Service of

Components

- Worn gear bushing (pos. 32) - Section 6.4 Inspection and Service of

Components

- Worn Tee/ Nozzle housing bearing and cup (pos. 29, 31) - Section 6.4

Inspection and Service of Components

- Loose nozzle housing cup (pos. 30) - Section 6.4 Inspection and Service of

Components

Service of Components

- Using Clutch Drive Machine, if nozzle housing does not operate during normal

operation- Section 6.4 Inspection and Service of Components

Components

- Very loose gear set screw (pos. 40) - Section 6.4 Inspection and Service of

10

5. Operation

Pay attention to possible faults

Read the instructions carefully

Step 1

INSUFFICIENT FLOW

The Alfa Laval Gamajet was configured to meet certain operating conditions supplied to us, such as flow rate (m3/Hr/ GPM),

pressure (Bar/ PSI), temperature, chemical content of the wash fluid, cycle time, etc. If the Nozzle size is too small and/or the

opening at the bottom of the Stator is too large, the Tee Housing will not turn.

Look for restrictions in the fluid supply such as a clogged filter, kinked hose, or deposits in the piping.

Step 2

TIGHT CLEARANCES

A newly overhauled Alfa Laval GJ 8 may fail to operate when first returned to service. If the machine seems otherwise fine, try

running it with at least one Nozzle Tip removed. The reduction in pressure and additional flow will invariably be enough to

overcome the extra resistance of new Bearings and Seals. A few minutes of operation should loosen the clearances enough for

the machine to run normally with the Nozzles remounted.

Step 3

DEBRIS INSIDE

Loosen the Collar Set Screw (45) and remove the Collar (8), then lift out the Stator (9). Look for and remove any debris caught

in the passageways of Stator and Rotor (10). Remove any material wound around the Rotor Shaft (21). In addition check for

any debris caught in the outlet holes of the Stem (3), the vent holes of the (26), the nose of the Tee Housing (4), the Nozzle

Housing (5), and the Nozzles (7).

11

5. Operation

Pay attention to possible faults

Read the instructions carefully

5.3 Cleaning Solution Leakage

- Worn Bearings & Seals

Water exiting from the CIP holes in the Tee Housing will cause a slight spray to exit around the Tee and Nozzle Housing.

However, excessive leakage from the Tee Housing or Nozzle Housing usually indicates worn Housing Bearings (29), and Seals

(31). Inspect them for wear (sealing lips are worn to a smooth surface) or damaged lips or loss of spring tension (indicated by

excessive dry deposits of dirty or abrasive cleaning solution on the spring), and replace as required.

- Worn Bearing Cups

Inspect the Bearing Cups (30) for excessive wear (grooved or scored), particularly near the inside flange where they contact the

(31) Seals. Replace any that show distinct grooves.

- Worn Static Seal Contact Surfaces

Inspect the Bearing and Seal contact surfaces of the Stem (3) and the nose of the Tee Housing (4). If these are worn or

grooved, new Bearings and Seals will be ineffective. Replace the damaged parts as required.

- Leak On Either Side of Bearing Housing

Verify that the Stem Cap SHCS (41) are tight. If tight, inspect the Stem Collar (2), Rotor Shaft Upper Bearing Housing (26), and

Stem (3) for nicks or burrs. File, if necessary.

- Worn Stem Collar O-Rings

Severe leakage between the Inlet Collar (1) and Stem Collar (2) may indicate worn or damaged Stem Collar O-rings (56) and

(57). Remove the Stem Collar as described in Section 2, and inspect the O-rings for signs of damage or wear.

12

5. Operation

Pay attention to possible faults

Read the instructions carefully

5.4 Poor Cleaning Performance

- Inadequate Flow and Pressure

Check the pressure at the Alfa Laval Gamajet inlet under actual operating conditions. The supply piping and hoses must be

large enough to handle the flow rate required for the nozzle size being used to ensure adequate pressure.

Insufficient pressure may also result from line losses when the machine is far from the pump, so the line size must be increased

accordingly for long runs. Although the Alfa Laval Gamajet will rotate at low flow rates, effective cleaning may require

considerably more flow. Proper mechanical operation (the unit turns) is NOT the same thing as effective cleaning (the soils

have been removed)!

- Chemical Concentration and Temperature

Verify that the cleaning solution is the correct compound and in the concentration needed for the deposit being cleaned. If

heating is necessary, also check that the solution is at the proper temperature.

- Plugged Nozzles

Unscrew the Nozzles (7) and inspect for any debris.

- Slow or no Rotation of the Housings

This will result in partial or erratic washing coverage. Refer to previous sections for more information.

- Alfa Laval Gamajet Configuration

Determine if the deposit being cleaned requires greater jet impact or longer jet dwell time (slower rotation) for more thorough

scrubbing. Confirm that the Alfa Laval Gamajet nozzle size, turbine, and gearing are correct for the specific application. Contact

Alfa Laval Tank Equipment for assistance, if needed.

- Inadequate Drainage

Ensure that the vessel drains the effluent or used wash fluid as fast as it’s being sprayed in through the Alfa Laval Gamajet.

The floor of the vessel should be sloped or pitched toward the drain and the drainage opening should be large enough to

gravity-drain the effluent from the vessel. If you still have puddling (build-up of the wash fluid so it covers the floor and shields

the residues underneath), use some form of pump to suck out the effluent.

13

5. Operation

The Tank Cleaning machine is designed for cleaning in place (CIP). CIP = Cleaning In Place. Study the instructions carefully

and pay special attention to the warnings! NaOH = Caustic Soda, HNO3 = Nitric acid.

5.5 Recommended Cleaning

Step 1

Always handle lye and acid with great care.

always use rubber gloves! Always use protective goggles!

Step 2

Never touch the pump or the pipelines when sterilizing.

Step 3

Always rinse well with clean water after using a cleaning agent.

NOTE

Cleaning agents must be stored/disposed of in accordance with

current regulations/directives.

Caustic danger!

Danger of burns!

Always rinse!

Clean Water Cleaning agent

14

6. Maintenance

Maintain the Tank Cleaning Machine with care. Read the instructions carefully and pay special attention to the warnings!

Always keep Minor spare parts kit in stock.

6.1 General Maintenance

Step 1

Always read the technical data thoroughly. (see chapter 7 technical Data)

Step 2

Recommended spare parts:

Order service kits from the service kits list

(See 8.9 Minor Service Kit & 8.10 Major Service Kit)

Ordering spare parts:

Contact your local Alfa Laval Sales Company.

15

6. Maintenance

Maintain the Tank Cleaning Machine with care. Read the instructions carefully and pay special attention to the warnings!

Always keep Minor spare parts kit in stock.

6.2 General dismantling set up

Step 1

NOTE

A rigorously implemented preventative maintenance program will significantly reduce repair costs over the life of the Alfa Laval

Gamajet. The foundation of such a program is regularly scheduled inspections to discover and replace worn or damaged parts

before they can cause the failure of other, more costly, components. The inspection intervals required will depend on the

severity of the application, but a complete internal inspection at 100 hours of operation is recommended initially.

Step 2

STORAGE

The Alfa Laval Gamajet should be washed out with clean water after each use to remove any foreign material or soft

substances left in the machine that may harden during storage and cause the Alfa Laval Gamajet to seize or lock up. A clean

water rinse through the Alfa Laval Gamajet will also wash out any residues of chemical cleaners or recirculated wash water that

could adversely affect the seals and O-rings during prolonged contact in storage. The best position to store the Alfa Laval

Gamajet is to stand it up with the inlet connection facing down.

Step 3

EXTERNAL INSPECTION INTERVALS

Before every shift, the Stator (9) and the Nozzles (7) should be inspected for debris. Examine the Stator by loosening the Collar

Set Screw (45) and removing the main section of the machine from the Collar (8). Note: One does not have to remove the Inlet

Collar (8) from the supply pipe when performing this check; simply, loosen the set screw (45) and unthread the body from the

(8). Look into each Nozzle for signs of debris or build-up. Also, the vent holes on either side of the (26) should be checked for

blockage. Use a fine wire or compressed air to clear them, if necessary.

Step 4

INTERNAL INSPECTION INTERVALS

An interval of 100 hours is recommended initially. If all of the components are found to be in acceptable condition after the first

100 hours, the Alfa Laval Gamajet may then be inspected and routine preventive maintenance should be performed every 300

to 500 hours of operation, depending on the severity of use.

Step 5

TIPS

All the Bearings, Bushings, Seals and O-rings are wear parts. Ideally, they should all be replaced, as a group, every 300 to 500

hours of operation, depending on the severity of use. If just one Bearing or Seal is worn or damaged, replace both it and its

mate, not just the worn or damaged part.

16

6. Maintenance

Read the instructions carefully. The items refer to the parts list and service kits section.

6.3 General dismantling

Step 1

Inlet Collar

Loosen the Collar Set Screw (45) with the 1/8" Hex Key.

Unthread the Collar (8) and remove the Stator (9).

Tip: If (8) does not unthread easily, remove (45) and spray a generous amount of liquid lubricant into the threaded hole. Turn

(8) back and forth to slowly unthread. Forcing the (8) off of the unit without the use of a lubricant may gall the threads on the (8)

and/or (2).

Step 2

Base Assembly

Remove the Socket Head Cap Screws (SHCS) (43) with a 1/4” Hex Key, the Lockwashers (44), and Base (14) from the Tee

Housing (4).

Remove the Nut (52) with an 11/32” socket and Lockwasher (51) from the Output Shaft (12).

Using slotted screwdriver, remove the Idlers Shafts (15), Idler Gear Assemblies (16), and the Output Pinion (11).

Step 3

Stem Collar

Unscrew the SHCS (42) with 5/32” Hex Key, and remove them along with the Lockwashers (41).

Pull the Stem Collar (2) from the Rotor Shaft Upper Bearing Housing (26).

Step 4

Gear Train Assembly

Remove the Gear Train Assembly from the body by tapping on the Ouput Shaft (12) at the Base end of the machine with the

handle of a screw driver.

Step 5

Nozzle Housing

Remove the Nameplate Screws (46) and Lockwashers (47) with a 5/16" socket.

Pull the Nozzle Housing (5) off the nose of the Tee Housing (4).

Remove the inner Housing Seal (31) and Bearing (29). Tip: Use a screwdriver on both sides of the flange of (29) to aid in

removal.

Step 6

Tee Housing

Using a 1/8” slotted screwdriver, remove the Ring Gear Retaining Ring (20), and Pullout the Ring Gear (19).

Unscrew the SHCS (41) using a 5/32" Hex Key, and remove the Lockwashers (42) and Idler Shaft Base (28).

Tip: if the (28) is difficult to remove, screw the SHCS (43) (removed in Step 2.2.2) back into (28) and use them for leverage. Or,

using two slotted screwdrivers, pry between the Tee Housing (4) and Stem (3).

Pull the (4) from the (3).

Remove the lower Tee Housing (31).

Pry/Pull the lower Tee Housing Bearing (29) and Tee Housing Bevel Gear (17) from (3).

17

6. Maintenance

Read the instructions carefully. The items refer to the parts list and service kits section.

6.4 Inspection and Service of Components

Drawing 1

Stator

Inspect all the openings through the Stator (9) to be sure that they are clear and free of debris.

Drawing 4, 5

Base Assembly

Inspect the Output Pinion (11) and Idler Gears (16) for worn, damaged, or sharp/pointed teeth.

Check for signs of scoring and wear on the Idler Shafts (15).

Examine the Idler Gear Bushings (32) on the Idler Gears and the Idler Shaft Bushing (33) on the Base for signs of wear. The

inside diameter of the (32) should not exceed 6.6 mm/ 0.260". This can be measured with a plug gauge or a letter size G drill

bit. The inside diameter of the (33) should not exceed 6.5 mm/ 0.255”. If Bushings need to be replaced remove them with a

small slotted screwdriver or razor blade, then tap replacements into place. Make sure the underside of the bearing’s flan ge is

flush with the metal.

Drawing 8

Stem Collar

Inspect the Small and Large Stem Collar O-rings, (56) and (57), for deterioration (hardening or deformation) or damage and

replace if necessary.

Drawing 20-32

Planetary Gear Train Assembly

General Disassembly and Inspection

Turn to (drawing 20): Unscrew the Nut (52) with an 11/32” socket and remove it with the Lockwasher (51) from the Rotor Shaft

(21). Remove the Rotor (10) from (21). Use a slotted screwdriver for assistance. Check that the Carbide Bushing pressed into

(10) protrudes slightly.

Turn to (drawing 22):Remove the Rotor Shaft Upper Bearing Housing (26) by pulling and twisting it. Take out the Rotor Shaft

Static Seal (22) from the inside of (26). Inspect the interior of (22) for loss of spring tension (indicated by excessive dry deposits

of dirty or abrasive cleaning solution on the spring), replace as required. Check the drain holes on either side of (26) for

blockage.

Turn to (drawing 23): Also, check that the Carbide Bushing (34) pressed into the top of (26) protrudes slightly.

Remove the Gearbox Static Seal (24) from the top of the Gearbox (1), use a 1/8" slotted screwdriver if necessary. Inspect the

interior of (24) for loss of spring tension (indicated by excessive dry deposits of dirty or abrasive cleaning solution on the

spring), replace as required.

Turn to (drawing 24): Pull and twist the Output Shaft Bearing Housing (27) from (1).

Turn to (drawing 26): Remove the Output Shaft (12) from the Gearhead by first, unscrewing the Output Shaft Jam Set Screw

(63) and then the Output Shaft Set Screw (62) using a 3/32" Hex Key. Inspect the Output Shaft (12) for signs of scoring and

wear.

Go back to (drawing 24): Remove the other (24) from the opposite end of (1), use a 1/8" slotted screwdriver if necessary.

Inspect the interior of (24) for loss of spring tension (indicated by excessive dry deposits of dirty or abrasive cleaning solution on

the spring), replace as required.

18

6. Maintenance

Read the instructions carefully. The items refer to the parts list and service kits section.

Drawing 27- 30

Gearhead & Rotor Shaft Assembly

Turn to (drawing 27): Unscrew the Gearhead Short Screws (48) from the Gearhead (13) using a 3/16" slotted screwdriver.

Remove (13) from the Gearbox (1) by pushing on its output shaft. It is not uncommon to find a slight amount of condensation

on (13).

Inspect the (13) by rotating the Rotor Shaft (21) by hand. If the (21) does not turn smoothly in both directions or feels stuck,

return the entire unit to Alfa Laval Tank Equipments, Inc. for service.

Otherwise, using a #1 Phillips screwdriver, loosen, but do not remove the Gearbox Long Screws (49). Do not disturb position of

the Gearhead Flange (53) at this time.

While holding (53) and (13) together, remove the Rotor Shaft Lower Bearing Housing (25) and (21) from (13).

WARNING: Proceed in a cautious manner when performing any work to the Planetary Gearhead due to the complexity

and size of the internal parts.

If the grease inside the (13) is completely or partially filled with liquid (cleaning fluid, water, etc.) or if the inside of the Gearhead

is dry, the grease inside the (13) may have dissolved. If this is the case, please refer to the steps below for adding grease to

the (13). If the (13) rotates freely and is adequately greased, no further inspection is required.

Turn to (drawing 30): In order to grease the gears of the (13) adequately, the Planetary Ring Gear must be removed. To do

this, hold the top tier of Planetary Gears in place with downward pressure and then pull away the Planetary Ring Gear. The

internal components (three individual tiers of planetary gears) of the (13) must remain together as a single unit. Any debris can

then be loosened and removed using an aerosol degreaser and air to dry. Once dry, the Planetary Gears can be lightly handpacked with grease. Alfa Laval Tank Equipment recommends using a Chevron FM NLGI 2 grease for food grade applications

and a Fuch’s ST-80 grease for aggressive chemical environments. Please consult your lubricant specialist for compatibility.

The Planetary Ring Gear can then be reinstalled by aligning the Planetary Gears with the Planetary Ring Gear on tier at a time.

Turn to (drawing 31): Inspect the Input Pinion (39) for hairline cracks on the end face or for worn, damaged, or sharp/pointed

teeth. The assembly of (39), the Rotor Shaft Carbide Thrust Washer (36) and (21) should be tight (circular scoring on the top

of the Rotor (10) and underside of Stator (9) is an indication of (39) slippage). Press (39) back onto (21) if it has slipped, or

replace if cracked.

Check for signs of scoring and wear on (21).

Check the (36) for cracks or chips, and, replace if necessary.

Turn to (drawing 29): Also, check the (60) (inside the (25)) for wear by placing the (21) back through it. There will be drag if the

(60) is still good. If it needs to be replaced, pry out the old (60), and replace it with a new one. Be sure that the seal is as

square as possible to the (25) when installing it. Apply even pressure with the use a flat-faced pin.

Inspect the Rotor Shaft Lower Bearing Housing O-ring (55) and Rotor Shaft O-ring (50) for deterioration (hardening or

deformation) or damage, replace if necessary.

Drawing 25

Output Shaft Bearing Housing

Using a 1/8" slotted screwdriver, remove the Output Shaft Seal Retaining Ring (38).

Using the same screwdriver, carefully pry the Output Shaft Upper Seal (23) out of the Output Shaft Bearing Housing (27).

Check the (23) for wear by placing back onto the Output Shaft (12) and twisting. There will be a little drag if (23) is still good.

Drawing 12- 15

Nozzle Housing

Turn to (drawing 15): Unscrew the Nozzles (7) with an open-end wrench and inspect for debris inside the (7) and Stream

Straightener (54). The inside diameter of (7) must be smooth, round, and free of damage (especially any nicks) for maximum

jet impact. Replace worn or oversized nozzles if the original flow rate is required.

Inspect the Nozzle O-rings (55) for deterioration (hardening or deformation) or damage, replace if necessary.

Turn to (drawing 13): Inspect Nozzle Housing Bevel Gear (18) for wear such as sharp/pointed or broken teeth. Also, check that

(18) does not spin relative to the Nozzle Housing (5). If the teeth are damaged or (18) can be rotated, loosen both of the Bevel

Gear Set Screws (40), and remove (18) from (5). When reinstalling the (18), ensure that the (40) are aligned with the dimples

on the (5) by removing one of the (40) and visually aligning the threaded hole in the gear with the dimple. Also, the Drive Pin

(59) should line up with the slot in the back of the (18).

19

6. Maintenance

Read the instructions carefully. The items refer to the parts list and service kits section.

Turn to (drawing 12): Inspect the Housing Bearings and Seals (29) and (31), replace any that are broken, cracked, or deeply

scored. Clean any deposits from the exterior of both pieces and check (29) fit in the Nozzle Housing Bearing Cups (30). While

they should turn freely, to avoid shortening the life of the Bevel Gears the (29) should be replaced if the thickness of the flange

is less than 0.115". The outside of the seal section of (31) should still have a bead, replace if glazed across the majority of the

seal face. Inspect the interior of (31) for loss of spring tension (indicated by excessive dry deposits of dirty or abrasive cleaning

solution on the spring), replace as required.

Turn to (drawing 14): Clean any deposits from (30) and examine for excessive wear. Light scoring is acceptable, but the Cups

should be replaced if they are grooved in the seal contact area. A good maintenance program will require replacing many

seals, therefore, it may be worthwhile to make or obtain press tools for pressing (30) out of (5). The press tools are available

from Alfa Laval Tank Equipment Inc. Before installing new (30), clean the housing bores and remove any burrs resulting from

(30) removal. Press them in so that their flanges are flush against (5).

Drawing 6, 14, 18

Tee Housing

Turn to (drawing 18): Inspect the Tee Housing (4) for damage to the keyway that engages the Ring Gear (19). If the Ring Gear

was difficult to remove, check to see if (4) is out-of-round (as the result of an external blow, such as dropping) where the Gear

seats.

Check the water outlets on the nose and the CIP holes of (4); they should be free of debris.

Inspect the Tee Housing Bevel Gear (17) for worn, damaged or sharp/pointed teeth.

Turn to (drawing 6): Inspect (19) for worn, damaged or sharp/pointed teeth, and for damage to the key that engages the slot in

(4).

Inspect the Tee Housing Bearings and Seals (29) and (31), replace any that are broken, cracked, or deeply scored. Clean any

deposits from the exterior of both pieces and check the fit of (29) in the Tee Housing Bearing Cups (30). While they should turn

freely, to avoid shortening the life of the Bevel Gears (29) should be replaced if the thickness of the flange is less than 0.115".

The outside of the seal section of (31) should still have a bead, replace if glazed across the majority of the seal face. Inspect

the interior of (31) for loss of spring tension (indicated by excessive dry deposits of dirty or abrasive cleaning solution on the

spring), replace as required.

Turn to (drawing 14): Clean any deposits from (30) and examine for excessive wear. Light scoring is acceptable, but the Cups

should be replaced if they are grooved in the seal contact area. A good maintenance program will require replacing many (30),

therefore, it may be worthwhile to make or obtain press tools for pressing (30) out of (4). The press tools are available from Alfa

Laval Tank Equipment Inc. Before installing new (30), clean the housing bores and remove any burrs resulting from (30)

removal. Lubricate the outside of the new (30) and press them in so that their flanges are flush against (4).

Drawing 33

Stem

Inspect the water outlets of the Stem (3); they should be free of debris.

Check the Clutch O-ring, (61), for deterioration (hardening or deformation) or damage and replace if necessary.

If the machine is pin drive, the Drive Pin, (59), should be securely in the (3).

20

6. Maintenance

Read the instructions carefully. The items refer to the parts list and service kits section.

6.5 Reassembly

General Notes

All parts must be cleaned thoroughly before reassembling. Any deposits remaining on the parts can cause difficult disassembly

the next time the Alfa Laval Gamajet needs servicing.

Apply a dab of a Teflon-based anti-seize compound, except when otherwise noted, to all threads when reassembling; this will

prevent galling of threads and ease any future disassembly.

Whenever lubrication of O-rings is required for assembly, lithium-based soap grease (Calypsol SF 3-097) is acceptable, for

Viton, Zalak, and Kalrez O-rings. Silicon based grease MUST be used for EP O-rings. In either case food grade grease

may be used.

Refer to previous illustrations or the exploded views in section 8 for clarification during reassembly.

Drawing 18, 19

Stem

Turn to (drawing 18): Place (17) back onto the Stem (3). If the machine is pin drive, the slot in the (17) should line up with the

Drive Pin (59) in the (3). Slide the first Tee Housing Bearing (29), flange down, onto (3).

Turn to (drawing 19): Align the Bearing Locating Pin (58) with the hole in underside of (29). Ensure that the flange of (29) is

flush with (17). Slide the first Tee Housing Seal (31), spring up, onto (3). Ensure that this tight against (29).

Drawing 16, 17, 18, 19

Tee Assembly

Turn to (drawing 18): Push the Tee Housing (4) over the Stem (3) until it is fully seated.

Place the second Tee Housing Seal (31), spring side down, over (3).

Tip: First, Place the second Tee Housing Bearing (29) into (28), aligning its hole with the Bearing Locating Pin (58). Now, invert

the (4)/ (3) assembly and place it over (29)/ (28) assembly. This technique ensures correct alignment of (29) and (58). Turn to

(drawing 17): Apply pressure to (28) to drive it, (29), and (31) into (4).

Align the through holes of (28) with the threaded holes in the top of the (3). Screw the four SHCS (41) with their Lockwashers

(42) into place using a 5/32" Hex Key, tightening them in a star pattern.

Turn to (drawing 19): Insert the Ring Gear (19) into (4), being sure to align the key and keyway of the two components.

Reinstall the Ring Gear Retaining Ring (20).

Drawing 10, 11, 12, 13

Nozzle Housing

Turn to (drawing 12): Place the first Housing Bearing (29) onto the nose of the Tee Housing (4). Ensure that the Bearing

Locating Pin (58) and hole in back of (29) are aligned.

Place the first Housing Seal (31), spring side out, onto the nose of the (4).

Turn to (drawing 13): Using an open-end wrench, screw the Nozzles (7) into the Nozzle Housing (5).

Push (5) assembly onto the nose of (4). Ensure that the Bevel Gears mesh properly.

Place the second Housing Seal (31), spring side in, over the nose of (4).

Turn to (drawing 13): Place the second (29) into the Name Plate (6), aligning (58) with the hole in back of (29).

Turn to (drawing 10): Push the two parts ((29) and (6)) over the nose of (4), driving (31) into (5). Align the through hole of (6)

with the threaded holes of (4).

With their Lockwashers (47), thread the Name Plate Screws (46) into the nose of (4). Tighten with a 5/16" socket.

21

6. Maintenance

Read the instructions carefully. The items refer to the parts list and service kits section.

Drawing 20- 31

Gear Train

Turn to (drawing 30): Place the Rotor Shaft (21) assembly partially into the Rotor Shaft Lower Bearing Housing (25). Insert

them into the Planetary Gearhead (13), ensuring that the Input Pinion (39) has properly meshed with the gears inside of (13).

Turn to (drawing 28): Align the threaded holes of (25) with the four Long Screws (49). Tighten in a star pattern with a #1 Phillips

Screwdriver.

Slide the Rotor Shaft O-ring (50) over (21) until it touches (25).

Put the Rotor Shaft Static Seal (22), spring side out, onto (25).

Turn to (drawing 27): Insert the (13) assembly back into the Gearbox (1), aligning the threaded holes in Gearhead Flange (53)

with the through holes in (1).

Using a 3/16" slotted screwdriver, thread the Short Screws (48) into (53). Tighten in a star pattern.

Turn to (drawing 25): Insert the Output Shaft Upper Seal (23), spring side out, into the Output Shaft Bearing Housing (27).

Install the Output Shaft Seal Retaining Ring (38).

Turn to (drawing 26): Reattach the Output Shaft (12) to (13) by aligning the dimple on the flat of (13) with the setscrew hole.

Install the (62) first (do not use anti-seize) using a 3/32" Hex Key and then the (63).

Turn to (drawing 24): Place both of the Gearbox Static Seals (24), spring side out, into either end of the (1). Push the (27)

assembly over (12) and into (1).

Turn to (drawing 22, 23): Push the Rotor Shaft Upper Bearing Housing (26) over (21) and into (1). Be sure to align the Drive

Pin (59), which is pressed into the (26), with the keyway in the (1).

Turn to (drawing 20): Put the Rotor (10), carbide bearing down, onto (21). Place the Lockwasher (51) and Nut (52) onto (21).

Hold (10) stationary while tightening (52) with an 11/32" socket.

Turn to (drawing 9): Insert this assembly into the Stem (3), aligning the through holes of (26) with the threaded holes in (3).

Drawing 7, 8

Stem Collar

Place the Stem Collar (2) on Rotor Shaft Upper Bearing Housing (26), making sure the screw holes are aligned.

Using a 5/32” Hex Key, screw the SHCS (42) with their Lockwashers (41) through (2) and (26) and into the Stem (3). Tighten in

a star pattern.

Drawing 2, 3, 4

Base assembly

Turn to (drawing 3): Place the Output Pinion (11), round opening down, onto the Output Shaft (12).

Thread the Idler Shafts (15) into their respective holes in the Idler Shaft Base (28).

Install the Idler Gears (16), Idler Gear Bushing (32) down, onto (15).

Tip: Twisting the Tee Housing (4) slightly will help (15) drop into place.

Tighten the Nut (52) and the Lockwasher (51) onto (12) with an 11/32" socket.

Turn to (drawing 2): Put the Base (14) back into (4).

Using a 1/4” Hex Key, screw the SHCS (43) and Lockwashers (44) into (28).

Drawing 1

Stator and inlet collar

Using one of the Hex Keys, rotate the Rotor (10). It should spin fairly easily and its veins must not strike the walls of the Stem

Collar (2). Continue turning the Rotor. The Nozzle and Tee Housing will slowly rotate if everything has been assembled

correctly. Insert the Stator (9) into (2). Lubricate the Small and Large Collar O-rings, (56) and (57).

Apply a generous amount of an anti-seize compound (ensuring that it is compatible with the O-ring material used in the 8) to

the threads of the Inlet Collar (8). Screw on the (8) (hand-tight only), and tighten the Collar Set Screw (45) with a 1/8" Hex Key.

22

7. Technical Data

It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the

technical data.

7.1 Technical Data

The Alfa Laval GJ 8 Tank Cleaning Machine is a highly efficient machine at a range of pressures and flows. The instruction

manual is part of the delivery. Read the instructions carefully.

TECHNICAL DATA

Lubricant . . . . . . . . . . . . . . . . . . . Food grade

Max. throw length . . . . . . . . . . . . . 14 - 26 m (45-85 ft.)

Pressure

Working pressure . . . . . . . . . . . . . . 3 - 28+ bar (40 - 400+ PSI)

Recommended pressure . . . . . . . . . 4 - 20 bar (50 - 300 PSI)

Cleaning Pattern

The above drawings show the cleaning pattern achieved on a cylindrical horizontal vessel. The difference between the first

cycle and the full pattern represents the number of additional cycles available to increase the density of the cleaning.

Certificate

2.1 material certificate

PHYSICAL DATA

Materials

1.4404 (316L), PPS, PTFE, FKM (EPDM and FFKM available).

Temperature

Max. working temperature . . . . . . . . 95°C (203°F)

Max. ambient temperature . . . . . . . . 140°C (284°F)

Weight . . . . . . . . . . . . . . . . . . . . . 6.5 kg (14.5 lbs.)

Connections

Standard thread . . . . . . . . . . . . . . . 1½” Rp (BSP) or NPT, female

Available option . . . . . . . . . . . . . . . 2” Rp (BSP) or NPT, female

Options

Electronic rotation sensor to verify 3D coverage.

Caution

Do not use for gas evacuation or air dispersion.

23

7. Technical Data

Inlet Pressure

- - - Wetting, --- Impact cleaning

Inlet Pressure

Cleaning Time

Flow Rate

It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the

technical data.

7.2 Performance Data

Flow Rate Impact Throw Length

24

7. Technical Data

A B C D E F G H I

mm

281

202

215

51

118

216

248

121

165

in

11.06

7.95

8.46

2.01

4.64

8.50

9.76

4.76

6.50

A B C D E F G

mm

281

217

126

51

211

350

248

in

11.05

8.54

5

2.02

8.30

13.78

9.76

It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the

technical data.

7.3 Dimensions

Dimensions Dimensions 180˚ directional version

Dimensions

Dimensions 180˚ directional version

25

7. Technical Data

D12.2m (480”), H19.6m (770”),

2xØ7.94mm (2xØ5/16”) Time = 3.1 min.

D12.2m (480”), H19.6m (770”), 2xØ7.94mm

(2xØ5/16”) Time = 3.1 min.

It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the

technical data.

7.4 Trax Simulation Tool

Standard Design

The choice of nozzle diameters can optimize jet impact length and flow rate at the desired pressure. As standard

documentation, the Alfa Laval GJ 8 can be supplied with a “Declaration of Conformity” for material specifications.

TRAX simulation tool

TRAX is an unique software that simulates how the Alfa Laval GJ 8 performs in a specific tank or vessel. The simulation gives

information on wetting intensity, pattern mesh width and cleaning jet velocity. This information is used to determine the best

location of the tank cleaning device and the correct combination of flow, time, and pressure to implement.

A TRAX demo containing different cleaning simulations covering a variety of applications can be used as a reference and

documentation for tank cleaning applications. The TRAX demo is free and available upon request.

Wetting Intensity

26

8. Parts List and Service Kits

GJ0900

The drawing shows Alfa Laval GJ 8 Tank Cleaning Machine

8.1 GJ8 View

27

8. Parts List and Service Kits

B

A

GJ0902

A

Drawing 1 - Completed Assembly

A: Drawing 2

B: Never hold or turn on tee housing cap during removal of (8)

Drawing 2 – Base Assembly

A : Drawing12

The drawing shows Alfa Laval GJ 8 Tank Cleaning Machine

8.2 Assembly Drawings - 1 & 2

28

8. Parts List and Service Kits

A

Drawing 5 – Idler Gear

A: Press fit

The drawing shows Alfa Laval GJ 8 Tank Cleaning Machine

8.3 Assembly Drawings – 3, 4, 5, 6, 7 & 8

Drawing 3 – Output Pinion Assembly Drawing 4 – Idler Shaft Assembly

29

8. Parts List and Service Kits

A

Drawing 7 – Stem Collar Screws & washer

Drawing 6 – Ring Gear

A: Align the flats and press flush

Drawing 8 – Stem Collar Assembly

The drawing shows Alfa Laval GJ 8 Tank Cleaning Machine

30

8. Parts List and Service Kits

Drawing 9 – Gear train Assembly

A : Drawing 20

Drawing 12 – Nozzle Housing Assembly

A : Drawing 16

A

Drawing 11 – Nose Plate

A : Press fit

Drawing 10 – Nozzle Housing Assembly

A

A

*For Directional Machine, refer to Appendix A

The drawing shows Alfa Laval GJ 8 Tank Cleaning Machine

8.4 Assembly Drawings – 9, 10, 11, 12, 13, 14, 15, 16 & 17

31

8. Parts List and Service Kits

Drawing 13 – Tee Housing Bevel Gear

A : Press fit

Drawing 14 – Nozzle Housing

Drawing 15 – Nozzle

A : Press flush with the bottom edge

A

Drawing 17 – Idler Shaft Base

Drawing 16 – Housing Assembly

*For Directional Machine, refer to Appendix A

The drawing shows Alfa Laval GJ 8 Tank Cleaning Machine

32

8. Parts List and Service Kits

Drawing 18 – The Housing Assembly

A : Drawing 33

Drawing 20 – Geartrain

A : Drawing 22

Drawing 19 – Tee Housing Bevel Gear

A : Press fit

Drawing 21 – Rotor

*For Directional Machine, refer to Appendix A

The drawing shows Alfa Laval GJ 8 Tank Cleaning Machine

8.5 Assembly Drawings – 18, 19, 20, 21, 22, 23, 24 & 25

33

8. Parts List and Service Kits

Drawing 22 – Geartrain Housing

A : Drawing 26

Drawing 23 – Input Shaft Bearing Housing

A : Press fit

Drawing 25 – Output Shaft Bearing Housing

A : Press fit

Drawing 24 – Geartrain Assembly

A

A

The drawing shows Alfa Laval GJ 8 Tank Cleaning Machine

34

8. Parts List and Service Kits

Drawing 26 – Geartrain Assembly

A : Drawing 28

Drawing 27 – Planetary Gearbox Assembly

The drawing shows Alfa Laval GJ 8 Tank Cleaning Machine

8.6 Assembly Drawings – 26, 27, 28 & 29

35

8. Parts List and Service Kits

Drawing 28 – Install Geartrain & Cap

A : Drawing 32

Drawing 29 – Input Geartrain Housing Assembly

The drawing shows Alfa Laval GJ 8 Tank Cleaning Machine

36

8. Parts List and Service Kits

Drawing 31 – Input Shaft assembly

Drawing 30 –Geartrain Assembly

A : Drawing 29

B : Drawing 32

The drawing shows Alfa Laval GJ 8 Tank Cleaning Machine

8.7 Assembly Drawings – 30, 31, 32, 33 & 34

37

8. Parts List and Service Kits

Pos.

Description

Qty.

1

18 TEETH PLANET GEAR BOTTOM BASE

1

2

10 TEETH PLANET GEAR

6

3

17 TEETH PLANET GEAR BASE

1

4

17 TEETH PLANET GEAR BASE

1

5

17 TEETH PLANET GEAR

3 6 PLANET GEAR WASHER

9

7

PLANETARY GEARHEAD WASHER

1

Drawing 32 –Gearhead Assembly

The drawing shows Alfa Laval GJ 8 Tank Cleaning Machine

38

8. Parts List and Service Kits

Drawing 33 –Stem Assembly

Drawing 34 –Tee Housing Assembly

*For Directional Machine, refer to Appendix A

The drawing shows Alfa Laval GJ 8 Tank Cleaning Machine

39

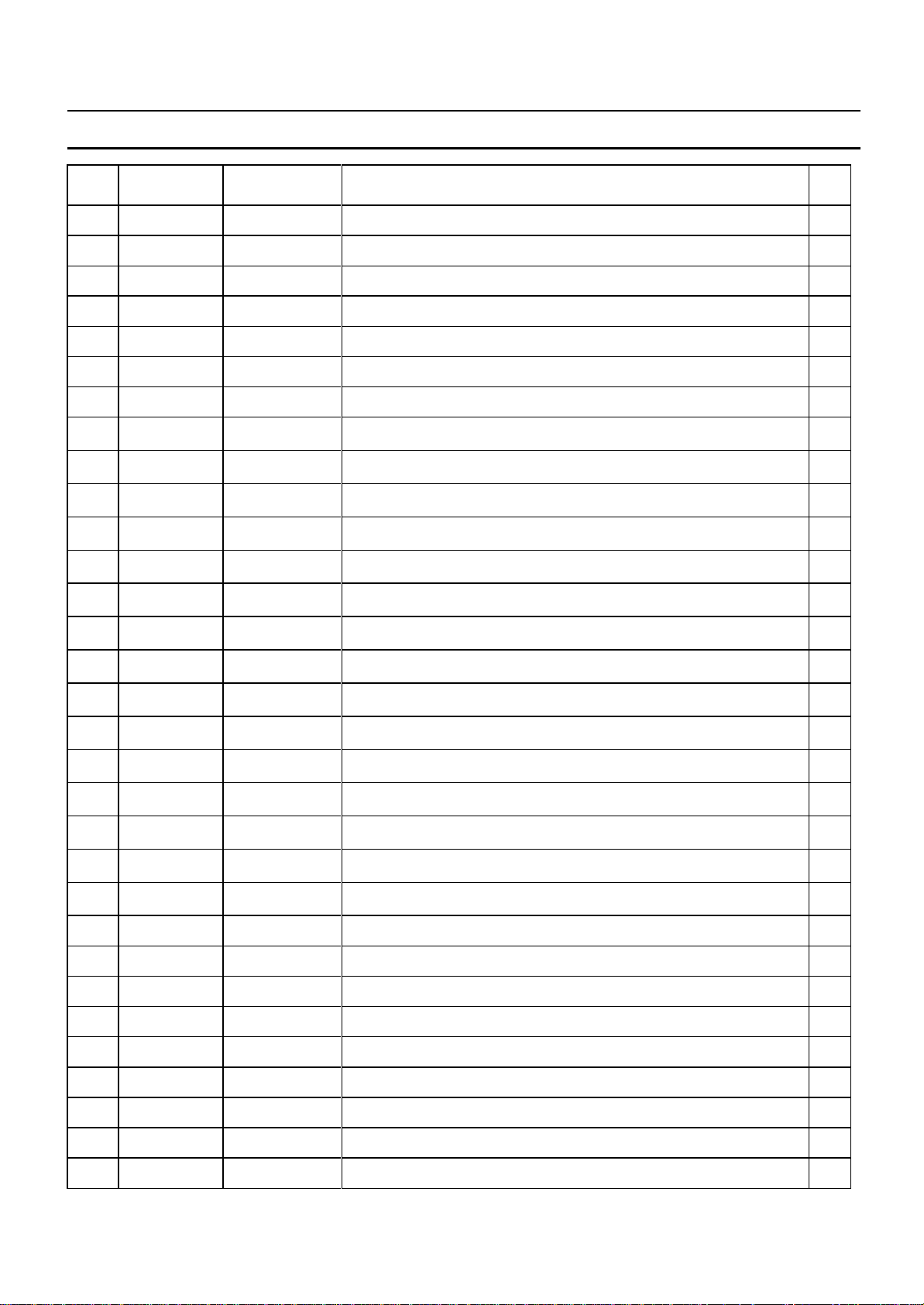

8. Parts List and Service Kits

Pos.

AL No.

Gamajet No.

Description

No.

1

9614602801

E-801

GEARBOX

1 2 9614602901

E-802

STEM COLLAR

1

3

9614603002

E-803-HV

STEM 1 4

9614603101

E-804-HV

TEE HOUSING

1

5.1

9614603201

E-805-ASD-HV

DUAL NOZZLE HOUSING ASSEM. (805-HV-DN, 2 x 832-HV)

1

5.2

9614603301

E-805-AST-HV

TRIPLE NOZZLE HOUSING ASSEM. (805-HV-TN, 2 x 832-HV)

1 6 9614604001

E-806-HV

NAMEPLATE

1

7.1

9614604201

E807ASEHV1/4

NOZZLE ASSEMBLY, EPDM ® , 1/4 BORE SIZE

2 OR

3

7.2

9614604202

E807ASEHV3/8

NOZZLE ASSEMBLY, EPDM ® , 3/8 BORE SIZE

2 OR

3

7.3

9614604203

E807ASEHV5/16

NOZZLE ASSEMBLY, EPDM ® , 5/16 BORE SIZE

2 OR

3

7.4

9614604204

E807ASEHV7/16

NOZZLE ASSEMBLY, EPDM ® , 7/16 BORE SIZE

2 OR

3

7.5

9614604205

E807ASEHV9/32

NOZZLE ASSEMBLY, EPDM ® , 9/32 BORE SIZE

2 OR

3

7.6

9614604206

E807ASVHV1/4

NOZZLE ASSEMBLY, VITON ® , 1/4 BORE SIZE

2 OR

3

7.7

9614604207

E807ASVHV3/8

NOZZLE ASSEMBLY, VITON ® , 3/8 BORE SIZE

2 OR

3

7.8

9614604208

E807ASVHV5/16

NOZZLE ASSEMBLY, VITON ® , 5/16 BORE SIZE

2 OR

3

7.9

9614604209

E807ASVHV7/16

NOZZLE ASSEMBLY, VITON ® , 7/16 BORE SIZE

2 OR

3

7.10

9614604210

E807ASVHV9/32

NOZZLE ASSEMBLY, VITON ® , 9/32 BORE SIZE

2 OR

3

7.11

9614604212

E807ASKHV1/4

NOZZLE ASSEMBLY, KALREZ ® , 1/4 BORE SIZE

2 OR

3

7.12

9614604213

E807ASKHV3/8

NOZZLE ASSEMBLY, KALREZ ® , 3/8 BORE SIZE

2 OR

3

7.13

9614604214

E807ASKHV5/16

NOZZLE ASSEMBLY, KALREZ ® , 5/16 BORE SIZE

2 OR

3

7.14

9614604215

E807ASKHV7/16

NOZZLE ASSEMBLY, KALREZ ® , 7/16 BORE SIZE

2 OR

3

7.15

9614604216

E807ASKHV9/32

NOZZLE ASSEMBLY, KALREZ ® , 9/32 BORE SIZE

2 OR

3

8

9614604901

E-808

COLLAR

1

9.1

9614605001

E-809-LM

STATOR – LM

1

9.2

9614605002

E-809-LRG

STATOR – LRG

1

9.3

9614605003

E-809-LV

STATOR – LV

1

9.4

9614605004

E-809-SMALL

STATOR - SMALL

1

10

9614605101

E-810

ROTOR

1

11

9614605301

E-811

OUTPUT PINION

1

12

9614605401

E-812

OUTPUT SHAFT

1

13

9614605601

E-813

GEARHEAD w/ SS FLANGE ASSEM. (8-513-236,E-858,2x8-513-B)

1

8.8 Parts

List

40

8. Parts List and Service Kits

14

9614605801

E-814

BASE 1 15

9614606101

E-815

IDLER SHAFT

2

16

9614606201

E-816

IDLER GEAR

2

17

9614606401

E-817

TEE HOUSING BEVEL GEAR

1

18

9614606801

E-818-HV

NOZZLE HOUSING BEVEL GEAR

1

19

9614607101

E-820

RING GEAR

1

20

9614607201

E-821

RING GEAR RETAINING RING

1

21

9614607401

E-822-A

ROTOR SHAFT ASSEMBLY (822, 8-512, 841)

1

22

9614607501

E-823

ROTOR SHAFT STATIC SEAL

1

23

9614607601

E-824

OUTPUT SHAFT UPPER SEAL

1

24

9614607701

E-826

GEARBOX STATIC SEAL

2

25

9614607801

E-827

ROTOR SHAFT LOWER BEARING HOUSING

1

26

9614608001

E-828

ROTOR SHAFT UPPER BEARING HOUSING

1

27

9614608201

E-829

OUTPUT SHAFT BEARING HOUSING

1

28

9614608401

E-830-HV

IDLER SHAFT BASE

1

29

9614608601

E-831

TEE/NOZZLE HOUSING BEARING

4

30

9614608701

E-832

TEE/NOZZLE HOUSING CUP

4

31

9614608801

E-835

TEE/NOZZLE HOUSING SEAL

4

32

9614608901

E-837

IDLER GEAR BUSHING

2

33

9614609001

E-838

IDLER SHAFT BUSHING

2

34

9614609101

E-839

CARBIDE BUSHING

3

35

9614609201

E-840

OUTPUT SHAFT UPPER CARBIDE BUSHING

1

36

9614609301

E-841

ROTOR SHAFT CARBIDE THRUST WASHER

1

37

9614609401

E-842

OUTPUT SHAFT LOWER CARBIDE BEARING

1

38

9614609501

E-843

OUTPUT SHAFT UPPER SEAL SNAP RING

1

39

9614674601

8-512

INPUT PINION

1

40

9614609601

E-845

BEVEL GEAR SET SCREW

2

41

9614609701

E-846

STEM-IDLER SHAFT BASE / STEM CAP SCREWS

8

42

9614609801

E-847

STEM-IDLER SHAFT BASE / STEM CAP WASHER

8

43

9614609901

E-848

BASE SCREW

2

44

9614610001

E-849

BASE LOCKWASHER

2

45

9614610101

E-850

COLLAR SET SCREW

1

46

9614610201

E-851

NAMEPLATE SCREW

2

47

9614610301

E-852

NAMEPLATE LOCKWASHER

2

48

9614610401

E-853

GEARHEAD SHORT SCREW

4

49

9614610501

E-854

GEARHEAD LONG SCREW

4

41

8. Parts List and Service Kits

50.1

9614677901

8-541-V

ROTOR SHAFT O-RING, VITON®

1

50.2

9614677902

8-541-EP

ROTOR SHAFT O-RING, EP

1

50.3

9614677903

8-541-K

ROTOR SHAFT O-RING, KALREZ®

1

51

9614678201

8-544

ROTOR / OUTPUT PINION LOCKWASHER

2

52

9614678301

8-545

ROTOR / OUTPUT PINION NUT

2

53

E-858

PLANETARY GEARHEAD STAINLESS FLANGE

1

54

9614610701

E-860-HV

STREAM STRAIGHTENER

2 OR

3

55.1

9614677701

8-539-V

NOZZLE O-RING AND ROTOR SHAFT LOWER BEARING HOUSING ORING, VITON®

3 OR

4

55.2

9614677702

8-539-E

NOZZLE O-RING AND ROTOR SHAFT LOWER BEARING HOUSING ORING, EP

3 OR

4

55.3

9614677703

8-539-K

NOZZLE O-RING AND ROTOR SHAFT LOWER BEARING HOUSING ORING, KALREZ®

3 OR

4

56.1

9614610801

E-862-V

COLLAR STEM SMALL O-RING, VITON®

1

56.2

9614610802

E-862-E

COLLAR STEM SMALL O-RING, EP

1

56.3

9614610803

E-862-K

COLLAR STEM SMALL O-RING, KALREZ®

1

57.1

9614610901

E-863-V

COLLAR STEM LARGE O-RING, VTION®

1

57.2

9614610902

E-863-E

COLLAR STEM LARGE O-RING, EP

1

57.3

9614610903

E-863-K

COLLAR STEM LARGE O-RING, KALREZ®

1

58

9614611001

E-864

BEARING LOCATING PIN

4

59

9614611101

E-866

DRIVE PIN (TWO IF CLUTCH DRIVE)

2 OR

3

60

9614611201

E-867

ROTOR SHAFT SEAL

1

61

9614611401

E-870

CLUTCH O-RING

1

62

9614611501

E-871

OUTPUT SHAFT SET SCREW

1

63

9614611601

E-872

OUTPUT SHAFT JAM SET SCREW

1

64

9614603003

E-803-HV-D

DIRECTIONAL STEM

1

65

9614603103

E-804-D

DIRECTIONAL TEE HOUSING

1

66

9614603601

E-805-DIR-2N

DIRECTIONAL NOZZLE HOUSING

1

67

9614606701

E-818-D

DIRECTIONALNOZZLE HOUSING BEVEL GEAR

1

68

9614608403

E-830-D

DIRECTIONAL IDLER SHIFT BASE

1

69

9614607001

E-819-D

DIRECTIONAL GEAR RETAINING RING

1

42

8. Parts List and Service Kits

Article no: 9614612001 EHV8EPDMKIT ALFA LAVAL GJ 8 KIT - EPDM

Pos. no.

Part No.

Gamajet Part No.

Description

No.

22

9614607501

E823

GJ VIII RS STATIC SEAL

1

pcs.

23

9614607601

E824

GJ VIII OS UPPER SEAL

1

pcs.

24

9614607701

E826

GJ VIII GEARBOX STATIC SEAL

2

pcs.

29

9614608601

E831

GJ VIII TEE HOUSING BEARING

4

pcs.

31

9614608801

E835

GJ VIII TEE HOUSING SEAL

4

pcs.

32

9614608901

E837

GJ VIII IDLER GEAR BUSHING

2

pcs.

33

9614609001

E838

GJ VIII IDLER SHAFT BUSHING

2

pcs.

56

9614610802

E862E

GJ VIII COLLAR STEM SM O-RING

1

pcs.

57

9614610902

E863E

GJ VIII COLLAR STEM LG O-RING

1

pcs.

55

9614677702

8539EP

GJ V GB NS/VIII RSLBH O-RING

4

pcs.

60

9614611201

E867

GJ VIII GEARHEAD SEAL

1

pcs.

61

9614611402

E870E

GJ VIII HV-8 CLUTCH O-RING

1

pcs.

39

9614674601

8512

GJ V/VIII INPUT PINION

1

pcs.

Article no: 9614612301 EHV8KALREZKIT ALFA LAVAL GJ 8 KIT - KALREZ

Pos. no.

Part No.

Gamajet Part No.

Description

No.

22

9614607501

E823

GJ VIII RS STATIC SEAL

1

pcs.

23

9614607601

E824

GJ VIII OS UPPER SEAL

1

pcs.

24

9614607701

E826

GJ VIII GEARBOX STATIC SEAL

2

pcs.

29

9614608601

E831

GJ VIII TEE HOUSING BEARING

4

pcs.

31

9614608801

E835

GJ VIII TEE HOUSING SEAL

4

pcs.

32

9614608901

E837

GJ VIII IDLER GEAR BUSHING

2

pcs.

33

9614609001

E838

GJ VIII IDLER SHAFT BUSHING

2

pcs.

56

9614610803

E862K

GJ VIII COLLAR STEM SM O-RING

1

pcs.

57

9614610903

E863K

GJ VIII COLLAR STEM LG O-RING

1

pcs.

55

9614677703

8539K

GJ V GB NS/VIII RSLBH O-RING

4

pcs.

60

9614611201

E867

GJ VIII GEARHEAD SEAL

1

pcs.

61

9614611403

E870K

GJ VIII HV-8 CLUTCH O-RING

1

pcs.

39

9614674601

8512

GJ V/VIII INPUT PINION

1

pcs.

Article no: 9614612701 EHV8VITONKIT ALFA LAVAL GJ 8 KIT - VITON

Pos. no.

Part No.

Gamajet Part No.

Description

No.

22

9614607501

E823

GJ VIII RS STATIC SEAL

1

pcs.

23

9614607601

E824

GJ VIII OS UPPER SEAL

1

pcs.

24

9614607701

E826

GJ VIII GEARBOX STATIC SEAL

2

pcs.

29

9614608601

E831

GJ VIII TEE HOUSING BEARING

4

pcs.

31

9614608801

E835

GJ VIII TEE HOUSING SEAL

4

pcs.

32

9614608901

E837

GJ VIII IDLER GEAR BUSHING

2

pcs.

33

9614609001

E838

GJ VIII IDLER SHAFT BUSHING

2

pcs.

56

9614610801

E862

GJ VIII COLLAR STEM SM O-RING

1

pcs.

57

9614610901

E863

GJ VIII COLLAR STEM LG O-RING

1

pcs.

55

9614677701

8539

GJ V GB NS/VIII RSLBH O-RING

4

pcs.

60

9614611201

E867

GJ VIII GEARHEAD SEAL

1

pcs.

61

9614611401

E870

GJ VIII HV-8 CLUTCH O-RING

1

pcs.

39

9614674601

8512

GJ V/VIII INPUT PINION

1

pcs.

8.9 Minor Service Kit

43

8. Parts List and Service Kits

Article no: 9614612501 EHV8TEFLONKIT ALFA LAVAL GJ 8 KIT - TEFLON

Pos. no.

Part No.

Gamajet Part No.

Description

No.

22

9614607501

E823

GJ VIII RS STATIC SEAL

1

pcs.

23

9614607601

E824

GJ VIII OS UPPER SEAL

1

pcs.

24

9614607701

E826

GJ VIII GEARBOX STATIC SEAL

2

pcs.

29

9614608601

E831

GJ VIII TEE HOUSING BEARING

4

pcs.

31

9614608801

E835

GJ VIII TEE HOUSING SEAL

4

pcs.

32

9614608901

E837

GJ VIII IDLER GEAR BUSHING

2

pcs.

33

9614609001

E838

GJ VIII IDLER SHAFT BUSHING

2

pcs.

56

9614610804

E862T

GJ VIII COLLAR STEM SM O-RING

1

pcs.

57

9614610904

E863T

GJ VIII COLLAR STEM LG O-RING

1

pcs.

55

9614661501

391130

639-T HOUSING O-RING PTFE

4

pcs.

60

9614611201

E867

GJ VIII GEARHEAD SEAL

1

pcs.

61

9614611404

E870T

GJ VIII HV-8 CLUTCH O-RING

1

pcs.

39

9614674601

8512

GJ V/VIII INPUT PINION

1

pcs.

44

8. Parts List and Service Kits

Article no: 9614612801 EHV8MAJVITONKIT ALFA LAVAL GJ 8 MAJOR – KIT -VITON

Pos. no.

Part No.

Gamajet Part No.

Description

No.

22

9614607501

E823

GJ VIII RS STATIC SEAL

1

pcs.

23

9614607601

E824

GJ VIII OS UPPER SEAL

1

pcs.

24

9614607701

E826