Page 1

AlfaSpid Rotator and Controller

Instruction Manual

Copyright AlfaRadio Ltd 2002-2006 2006-01-09

www.alfaradio.ca

780.466.5779

Page 2

AlfaSpid Rotator www.alfaradio.ca Page 2

Table of Contents

Introduction......................................................................................... 3

Shipping Contents..............................................................................3

Technical Data ................................................................................... 3

Control Panel...................................................................................... 4

Rear Panel ......................................................................................... 5

Installation..........................................................................................6

Wiring Connections.........................................................................6

Bench Testing.................................................................................7

Resetting the Controller......................................................................8

Controller Operation...........................................................................9

Function Mode................................................................................9

Normal Operations Mode.............................................................. 10

Half Auto Mode.............................................................................10

Auto Mode .................................................................................... 10

Preset Mode ................................................................................. 10

Setup Mode .................................................................................. 11

Programable High Limit ................................................................11

Programmable Low Limit.............................................................. 12

Programmable Reset Value..........................................................12

Preset 1 - 6 ...................................................................................12

Mouse Controller..............................................................................14

Trouble shouting and testing……………………………………………15

Using the AlfaSpid Rotator with LONG Cable Distances .................17

Warranty ………………………………………………………………….19

Notes................................................................................................ 20

This manual is for use with units sold by AlfaRadio Ltd. of

Edmonton, Alberta, Canada. Units sold by others may have

different firmware and may operate from different voltages.

Page 2 of 21 Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8 780 466 5779

Page 3

Page 3 of 21 www.alfaradio.ca AlfaSpid Rotator

Introduction

The AlfaSpid rotator is an extra heavy-duty rotator designed to run

large communication antennas and comes complete with an

electronic control unit. The rotator is designed to be mounted pipe to

pipe or on an optional adaptor plate for conventional in tower

mounting. It can also be mounted outside of the tower on the mast,

or used in a side mount configuration.

Shipping Contents

Rotator................................................................................................ 1

Controller............................................................................................ 1

........................................................................................................... 1

GMA Fuses ........................................................................................ 2

Optional

Custom Mouse ...................................................................................1

Technical Data

Input Voltage (Typical)...............................................12 – 24 Volts DC

Input Current (Nominal Draw).............................................3 – 4 Amps

Motor......................................................................... 12 – 24 Volts DC

Fuse ...............................................................................8.0 Amp GMA

Rotation Speed......................................120 sec (12 V) / 60 sec (24 V)

Turning Torque (in-lbs).................................1400 (12 V) / 1740 (24 V)

Braking Torque (in-lbs)........................................................... > 14,000

Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8

Page 4

AlfaSpid Rotator www.alfaradio.ca Page 4

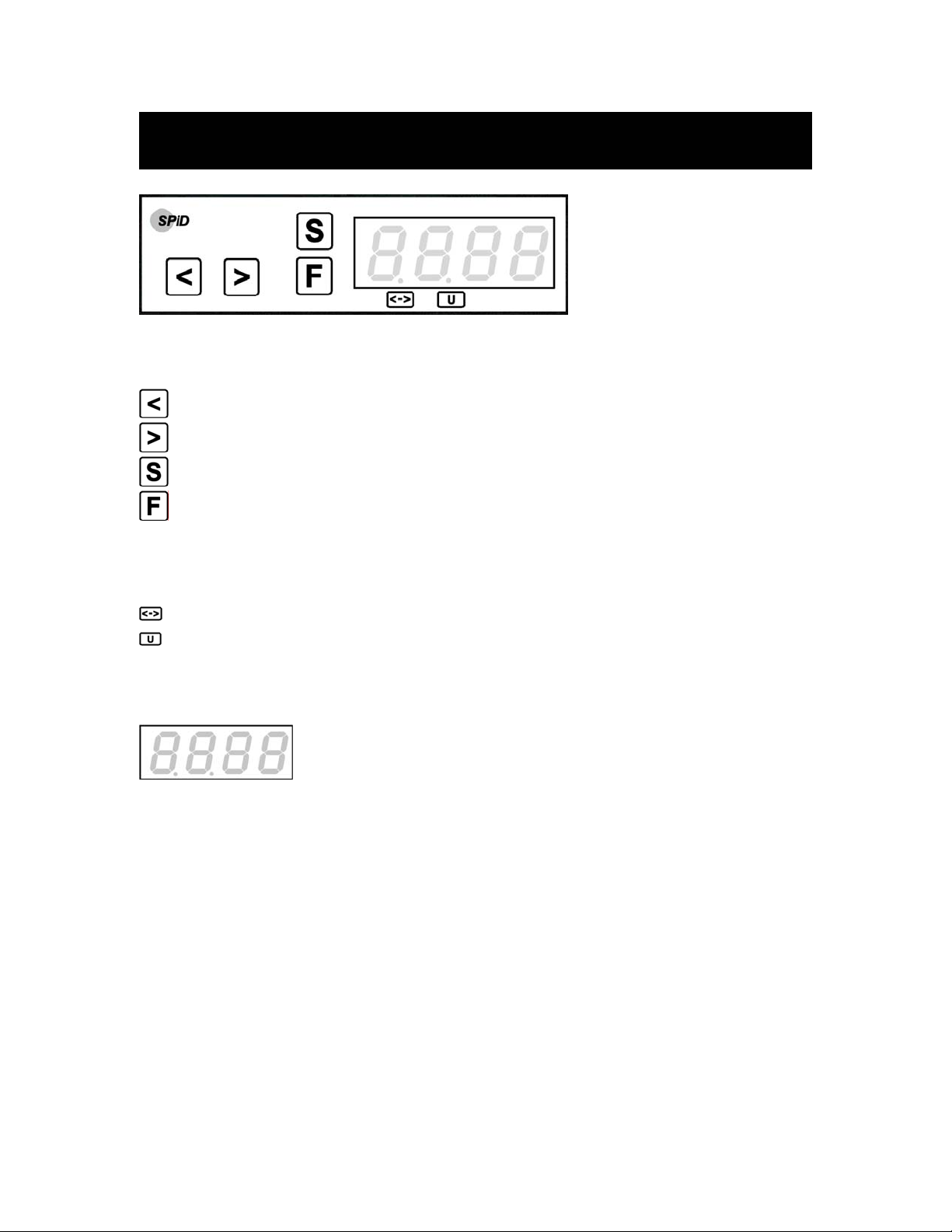

Front Panel Front Panel Front Panel Control Panel

Buttons

-Left (Decrease)

-Right (Increase)

-Setup

-Function

Indicators

-Overlap

-Not currently used

7 segment 4-digit display

- Multifunction display

Page 4 of 21 Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8 780 466 5779

Page 5

Page 5 of 21 www.alfaradio.ca AlfaSpid Rotator

Rear Panel

-Fuse Holder

- Power Cord

- Power Switch

- Terminal Strip

-DB-9 connector (male)

-DB-9 connector (female)

Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8

Page 6

AlfaSpid Rotator www.alfaradio.ca Page 6

Installation

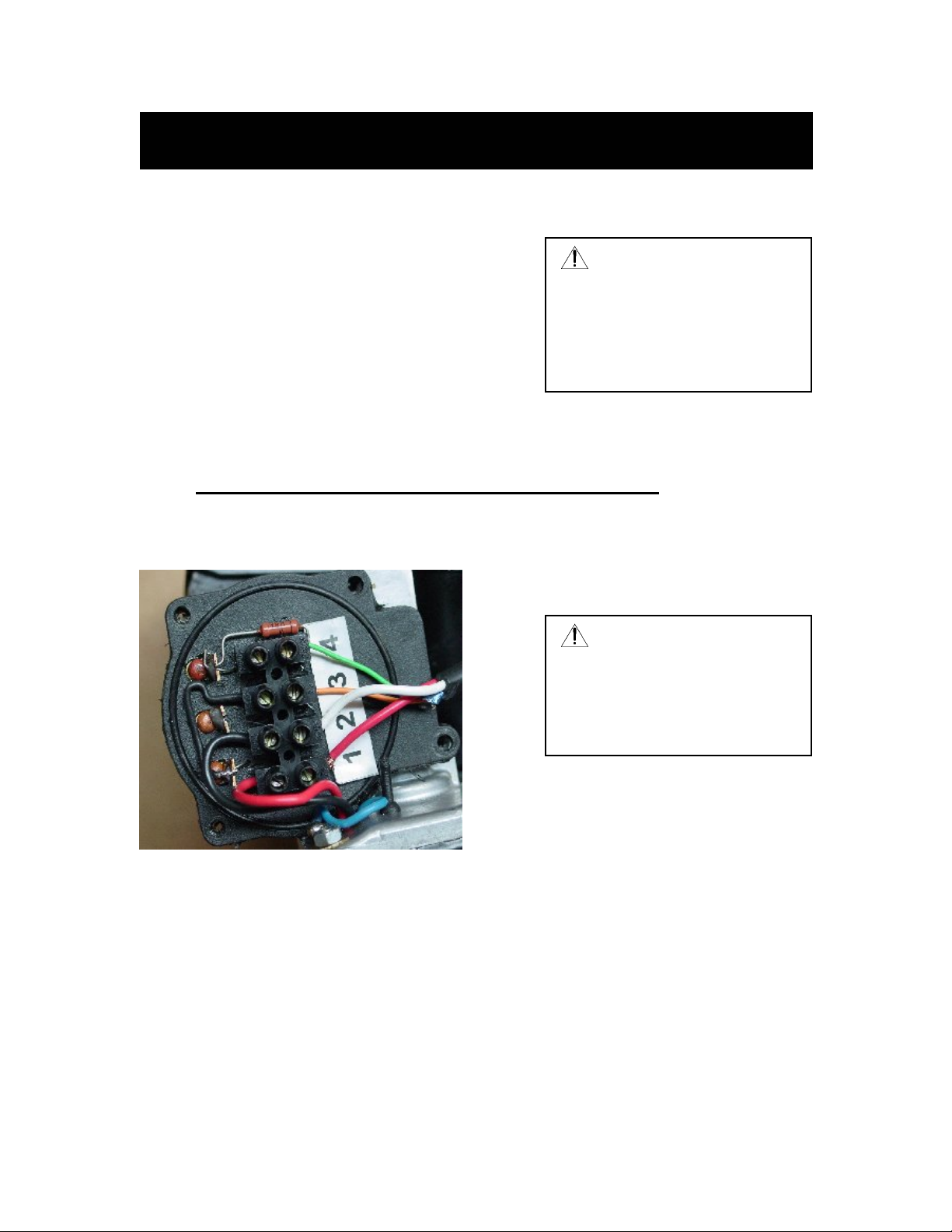

Wiring Connections

The rotator unit must be wired to the

control unit with 4-wire cable. The

gauge of the 4-wire cable to connect the

control unit to the rotator depends upon

the distance between rotator and

controller. The wire for the impulse

sensing may be quite thin - #22 or similar, even for relatively long

distances.

Length Gauge Motor

10 m (32') #18 (1.19 mm)

30 m (100') #16 (1.42 mm)

60 m (200') #14 (1.75 mm)

TIP:

Before final installation of

equipment, it is strongly

suggested you check out all

functions and connections on

a workbench.

CAUTION!:

Do not accidentally switch

the motor wires with the

impulse wires. Damage to

the control unit may occur!

Remove cover from the motor body as shown and make connections

as follows:

1 Motor Drive to 1 on controller terminal

2 Motor Drive to 2 on controller terminal

3 Impulse Sense to 3 on controller terminal

4 Impulse Sense to 4 on controller terminal

Page 6 of 21 Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8 780 466 5779

Page 7

Page 7 of 21 www.alfaradio.ca AlfaSpid Rotator

Bench Testing of Control Box

The control box is normally expected to be operated from a 12 Volt

DC supply; however it may be operated from other unregulated DC or

AC sources as well. DC or AC voltage levels between 10 and 26

Volts capable of at least 5 Amps are acceptable, typically 12 or 14

Volts.

The polarity of the power to the control box input leads is not critical

for D.C. operation; a diode rectifier on the input will provide the proper

polarity to the electronics and provide reverse polarity protection as

well as A.C. operation.

TIP: Because of several steering diodes in the motor path, the

voltage delivered to the motor (neglecting wire loss) will be about 1.4

volts less than the power supply voltage. For longer runs and/or

thin wiring a higher voltage (up to approx 24V) to the control unit is

beneficial. A simple way to estimate if the voltage to the motor is

adequate is by timing the rotation. Under no or a very small load, the

360 degree rotation time with 12V DC at the motor is about 120

second (2 minutes). With 24 V DC is about 60 second (1 minute). A

DC Ammeter in the motor lead is also useful, it should indicate

between 1 and 3 amps with a small load. On windy days or heavy

load, the current may fluctuate up to 3 to 5 amps.

It is highly recommended to ground the Control Box.

Notes – testing and troubleshooting

Pressing

should make the rotator move clockwise. Pressing

should make the rotator move counter-clockwise. If rotation is

reversed, switch lines 1 and 2 on the back of the controller.

Impulse sense lines (3 & 4) have no polarity concerns.

Part of the protection circuitry involves removing motor power if

the controller receives no sense indication. If the motor turns for

a few seconds and then you hear the relay in the control box drop

out, the motor has either stalled or there is a problem in the impulse

sense wiring.

Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8

Page 8

AlfaSpid Rotator www.alfaradio.ca Page 8

Resetting the Controller

Since there are no mechanical limits in the rotator, it may be installed

with the antenna pointing in any direction. There is no reason to

locate “TRUE NORTH” until you are ready to calibrate the control

box. Use the controller to position the antenna to physically point

north, then reset the controller as follows:

Turn the unit OFF. Then while holding the

control unit back on. This will now show

controller is now set for North.

Display adjustment:

button depressed turn

on the display. The

Press the

button to cycle thru to the normal (i.e. blank) setting until

you see the display after P5 X, (X is the mode for computer interface)

It will be blinking. The display shows the normal degree reading i.e.

30 degrees, with the left or right arrows the display reading can be

changed with out turning the rotator in this mode, this feature can be

used if, for any reason, the direction of the antenna becomes

incorrect. This may be caused by antenna to mast slippage or

incorrect initial alignment. The Rotator to mast will not slip unless

there is improper installation. See Heading Adjust (numbers blinking)

else where in this document.

IMPORTANT:

The AlfaSpid rotator is now set at the counter-clockwise end of its

normal rotation range. Normal rotation range is in a clockwise

direction for 360 degrees.

From the reset position, you can rotate counter-clockwise an

additional 180 degrees in over-travel, as well 360 degrees clockwise,

plus an additional 180 degrees into clockwise over-travel.

Counter-clockwise over-travel is indicated by a steady dot above the

over-travel icon.

Rotation past 359 degrees into the clockwise

over-travel is indicated by a blinking dot above the over-travel icon.

Page 8 of 21 Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8 780 466 5779

Page 9

Page 9 of 21 www.alfaradio.ca AlfaSpid Rotator

Controller Operation

Technical Note:

You will need to leave sufficient coax length to accommodate the

additional 180 degrees of over-travel on each end of normal rotation.

Failure to do so can cause damage to your coax and/or antennas.

The AlfaSpid controller has multiple modes of operation. You will

need to become familiar with these modes to be able to make full use

of your rotator.

Function Mode

The

character on the display indicates the function mode you are

currently in.

button steps through the function menus. The leftmost

- Normal Operations Mode

- Half Auto Mode

- Auto Mode

- Preset Mode

displays to the left will be

replaced by your actual

beam heading

The 0 in the

Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8

Page 10

AlfaSpid Rotator www.alfaradio.ca Page 10

- Normal Operations Mode

In Normal Operations Mode, the

as long as the buttons are pressed. Pressing

and buttons cause rotation

while in normal

operations mode will take you to setup mode.

- Half Auto Mode

In Half Auto Mode, the

and buttons can be used to pre-select

the desired beam heading. The heading displayed on the

controller will rapidly change in the direction of desired rotation.

Once the desired beam heading is shown on the display, release

the key. Approximately ½ of a second after no key presses have

been detected, the display will revert back to the actual beam

heading, and rotation towards the desired heading will take place.

Pressing any key while in transit to the desired heading will cancel

the action.

- Auto Mode

In Auto Mode, the controller will respond to commands from

control software running on an attached computer. The

and

buttons can still be used as a manual override.

- Preset Mode (requires optional mouse)

In Preset Mode, the

and buttons cause rotation as long as

the buttons are pressed. With the optional mouse attached, the

six preset buttons can be used to select a desired beam heading.

Preset beam heading values are set in Setup Mode

Page 10 of 21 Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8 780 466 5779

Page 11

Page 11 of 21 www.alfaradio.ca AlfaSpid Rotator

Setup Mode

The

button steps through the setup menu. The display cycles

through each of the setup menu items.

- Programmable High Limit Default flashing “DOT” 180

- Programmable Low Limit Default not flashing “DOT” 180

- Programmable Reset Value 0 or 180

- Preset 1

- Preset 2

- Preset 3

- Preset 4

- Preset 5

- Preset 6

- Program Simulation

- Heading Adjust (numbers blinking)

- Programmable High Limit

The Programmable High Limit is a user adjustable clockwise travel

limit value. By reducing this value, the maximum clockwise

rotation travel can be restricted. Use the

and buttons adjust

the value.

These limits can be used when side mounting the rotor to keep the

antenna from colliding with the tower.

Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8

Page 12

AlfaSpid Rotator www.alfaradio.ca Page 12

- Programmable Low Limit

The Programmable Low Limit is a user adjustable counterclockwise travel limit value. By increasing this value, the minimum

counter-clockwise rotation travel can be restricted. Use the

and

buttons adjust the value.

- Programmable Reset Value

The Programmable Reset Value can be set to either 0 degrees, or

180 degrees. This is the beam heading set when a power on

reset event is triggered. If you wish to reset your rotator to south,

set this value to 180.

- Preset 1

.

- Preset 6

These 6 presets are user adjustable values that map to the 6

preset buttons on the optional mouse controller. You can set each

preset to a commonly used beam heading, allowing rapid single

button heading selections.

Page 12 of 21 Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8 780 466 5779

Page 13

Page 13 of 21 www.alfaradio.ca AlfaSpid Rotator

- Program Simulation

Program Simulation allows the user to set the serial

communication protocol used by the rotator. When set to emulate

another brand of rotator, the AlfaSpid will respond to commands,

and send responses back to the computer as if it were the rotator

brand selected. If your favourite software supports a rotator,

chances are, the AlfaSpid will be able to interface to your software.

There are 4 modes available:

- Spid ( AlfaSpid )

- Orion

- Hygain

- Yaesu

- Heading Adjust (numbers blinking)

This setting can be used to make minor heading adjustments

without causing the rotator to turn. If you notice that the heading

displayed on the controller to a known signal source is out by a few

degrees, you can change the heading displayed on the LED readout

to match the known heading, rather than having to turn back to North

and reset the controller.

Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8

Page 14

AlfaSpid Rotator www.alfaradio.ca Page 14

Mouse Controller (Optional)

The optional mouse controller allows easy desktop access to the

most commonly used front panel controls. These buttons are

functionally equivalent to the corresponding front panel controls.

- Left (Decrease)

- Right (Increase)

- Stop ( also the wheel between

highly modified computer mouse.

You can not use a regular mouse

with the AlfaSpid rotator nor vice-

The mouse controller is a

left and right buttons )

In addition to the above controls, you will find 6 programmable preset

buttons on the mouse. Programmable preset buttons are only

available via the optional mouse controller. Preset headings are

programmed via the Setup Mode

The mouse ball serves no function; the mouse simply provides an

ergonomically pleasing case in which to mount the controls.

Page 14 of 21 Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8 780 466 5779

Page 15

Page 15 of 21 www.alfaradio.ca AlfaSpid Rotator

Alfa Radio Ltd. Trouble shouting tips

Before contacting AlfaRadio Ltd. Please make the following tests:.

The following are some trouble shouting tips, if for some reason your

AlfaSpid will not operate correctly.

It is important to confirm correct operation before installing on the

tower. This will rule out any damage that may have been caused by

the shipping company.

Check the Limits - PH and PL settings and rule out overlap.

Simple resistance tests can reveal incorrect or shorted wiring.

Pins 1 and 2 are the motor winding and will have a low resistance.

Typical 2-3 ohms.

Pins 3 and 4 are the sense lines and typically will have either an open

circuit or have about 1200 ohms depending on the status of the reed

switch in the rotator and the length and gauge of used wire.

There should be no conductivity between 1 and 3 or 1 and 4, or

between 2 and 3 or 2 and 4

All lines should have no conductivity to ground.

Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8

Page 16

AlfaSpid Rotator www.alfaradio.ca Page 16

Be careful not to over wind your coax with the next test, as there

will be no protection from over turning.

Find a small 12 volts supply which will deliver 3 to 4 amps. ( a small

12 Volt battery will work just fine )

To confirm that the motor runs you may connect 12 volts D.C. to the

lines that go to the motor, pins 1 and 2, it should turn. Reversing the

12 Volts D.C. should cause the motor to turn in the reverse direction.

Be careful not to over wind your coax with the next test, as there

will be no protection from over turning.

To confirm that the sense circuit in the rotator is working, connect an

ohm meter to the senses lines pins 3 and 4, apply 12 volts to the

motor lines pins 1 and 2; you should see the ohm meter reading

alternate between open circuit and about 1200 ohms.

Pin on Rotator not controller Typical Reading Your reading

Depends on the length of

Pins 1 to 2 About 2 to 4 Ohms __________

Pins 3 to 4 Open or 1200 Ohms __________

Pins 1 to 3 Open __________

Pins 2 to 3 Open __________

Pins 2 to 4 Open __________

__________

Pin 1 to Ground Open __________

Pin 2 to Ground Open __________

Pin 3 to Ground Open __________

Pin 4 to Ground Open __________

__________

Voltage on controller

Pins 1 to 2 About 12 volts with motor running

Pins 3 to 4 About 8.5 volts or 2.5 volts *

wire to rotator

Depends on the status of

the read switch

Depends on the supply

voltage (14 volt applied)

Depends on the status of

the read switch

and the Supply voltage ( 12

volts )

Page 16 of 21 Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8 780 466 5779

Page 17

Page 17 of 21 www.alfaradio.ca AlfaSpid Rotator

Using the AlfaSpid Rotator with LONG Cable Distances

By VE6JY

Since the motor uses relatively low voltage DC, a combination of long

cable runs and/or thinner than required cable may reduce the voltage at the

motor to an unacceptably low value. It may turn in warm weather or light winds

but the power will not be available to rotate under more severe conditions.

While it is easy to say just use a heavier cable, this may be costly,

impractical or both. I have one tower that is over 1700 feet (approx 500 meters

away) and running large cable out there would be very expensive.

My solution is to use this rotator controller's output voltage to control

another set of relays that will feed a higher voltage DC to the motor. In the

above-mentioned example, I find a voltage between 60 to 80 volts gave suitable

performance. This is a pretty extreme case but it illustrates the versatility of this

design. The external DC supply voltage needed will vary depending on the DC

voltage rating of your motor, the cable size and length of the run. Typically 36 to

50 volts at 3-5 amps should be quite adequate. These DC motors are quite

tolerant on their voltage ratings.

Relay Board Schematic

Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8

Page 18

AlfaSpid Rotator www.alfaradio.ca Page 18

Relays chosen should be suitable for the proper coil voltage as well as

appropriate current carrying capability. A relay capable of 5 to 10 amps DC is

adequate. The diode in series with Relay K1 is any general purpose 1 amp style

such as the 1N400x series. If the motor rotates incorrectly, simply reverse the

leads to the motor or from the External DC Supply.

The controller also has the capability to, with a small modification, allow

you to input your external DC voltage into the unit and use the internal relays to

control the rotator as usual.

This information is presented as a guide to help the user realize a solution

to the long cable run situation.

If you do not feel comfortable wiring basic circuitry to do this, please

contact Alfa Radio Ltd. (www.alfaradio.ca) for a pre-wired solution.

Prepared for Alfa Radio Ltd by VE6JY Don Moman Dec 6/2001

Page 18 of 21 Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8 780 466 5779

Page 19

Page 19 of 21 www.alfaradio.ca AlfaSpid Rotator

12 MONTH LIMITED WARRANTY

AlfaSpid Rotator and controller

Alfa Radio Ltd. Warrants to the user, who originally purchased the product, that

the product will be free from defects in material and workmanship for the following

periods after such date of purchase: Material, 12 months : Workmanship, 12 months.

Alfa Radio Ltd. will, at its option, repair or replace free of charge such defective

products subject to the following conditions:

1. Delivery of the product prepaid to Alfa Radio Ltd. or its authorized dealer.

2. Determination by the Alfa Radio Ltd. that a defect exists and is covered by

the limited warranty. Defects due to alteration, repair by an unauthorized

person, misuse, accidental damage, lightning strikes, use of the equipment for

purpose other than those for which it was designed, and the like, are NOT

COVERED by this limited warranty. Repairs therefore will be subject to

normal service charges.

3. Repairs and replacement parts are covered under this limited warranty only

for the remaining term of the original limited warranty.

4. Under no circumstances is Alfa Radio Ltd. liable for consequential damages

to person(s) or property by the use of this product.

5. Alfa Radio Ltd. reserves the right to make changes or improvements in design

or manufacture without incurring any obligations to install such changes upon

any of the product previously manufactured.

All claims of defect or shortage should be sent prepaid to:

Alfa Radio Ltd.

11211 - 154 Street

Edmonton, Alberta

T5M 1X8

CANADA

and must be accompanied by the letter describing the problem in detail along with a

copy of your proof-of-purchase.

WE SERVICE WHAT WE SELL

Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8

Page 20

AlfaSpid Rotator www.alfaradio.ca Page 20

NOTES:

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

Page 20 of 21 Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8 780 466 5779

Page 21

Page 21 of 21 www.alfaradio.ca AlfaSpid Rotator

Typical travel of the AlfaSpid Rotator

Alfa Radio Ltd. 11211 - 154 St. Edmonton, Alberta, Canada T5M 1X8

Loading...

Loading...