Page 1

®

OKIPAGE 20 & 20DX

User’s Guide

OKIDATA

Page 2

Every effort has been made to ensure that the information in this document

is complete, accurate, and up-to-date. OKIDATA assumes no responsibility

for the results of errors beyond its control. OKIDATA also cannot guarantee

that changes in software and equipment made by other manufacturers and

referred to in this guide will not affect the applicability of the information

in it. Mention of software products manufactured by other companies does

not necessarily constitute endorsement by OKIDATA.

Copyright 1998 by OKIDATA. All rights reserved.

First edition January, 1998.

Written and produced by the OKIDATA Publications Department. Please

address any comments on this publication

• by mail to:

Publications Department

OKIDATA

532 Fellowship Road

Mount Laurel, New Jersey 08054

OKIDATA, OKIPAGE and Oki Smoothing Technology (OST) are registered

trademarks and OKILAN is a trademark of Oki Electric Industry Company,

Ltd. OKIDATA marque déposée de Oki Electric Industry Company, Ltd.;

marca registrada, Oki Electric Industry Company, Ltd.

Hewlett-Packard, HP, LaserJet, and PCL5e are registered trademarks of

Hewlett-Packard Company. PostScript and Adobe are trademarks of Adobe

Systems Inc. which may be registered in certain jurisdictions. IBM is a registered trademark of International Business Machines Corp. Epson is a registered

trademark of Epson America, Inc. Microsoft and Windows are either registered

trademarks or trademarks of Microsoft Corporation in the United States and/or

other countries. Intellifont is a registered trademark of Compugraphic Corporation. Zip Code is a registered trademark of the United States Postal Service.

ENERGY STAR is a registered trademark of the United States Environmental

Protection Agency.

Portions of software © 1994-1995 Adobe Systems Incorporated. All Rights

Reserved.

• or by email to: pubs@okidata.com

We welcome you to visit our web site: http://www.okidata.com

ENERGY STAR

As an ENERGY STAR® Partner, OKIDA TA has

determined that this product meets the

ENERGY STAR guidelines for energy efficiency.

Page 3

Contents

Chapter 1: Setting Up .................................1

Select a Suitable Location .................................1

Unpack...............................................................1

Your printer ...................................................1

The accessories ............................................. 1

Check the contents.............................................1

Getting to Know Your Printer ............................ 2

Front Vie w.................................................2

Rear Vie w..................................................2

Prepare the Image Drum....................................3

Install the Toner .................................................4

Load Paper.........................................................5

Paper Specifications ......................................5

Weight .......................................................5

Usable T ypes.............................................5

Finish ........................................................5

Composition..............................................5

Letterhead Stationary/Preprinted Forms...5

Paper Feed Paths ...........................................5

Load the Paper Tray ......................................6

The Paper Tray Gauge ..............................6

Storing Paper .................................................7

Select a Paper Exit Path ................................7

Top Paper Exit...........................................8

Rear Paper Exit ......................................... 8

Connect to Your Computer ................................ 9

Parallel Connection .......................................9

Attach the Parallel Cable ..........................9

IEEE 1284 Parallel Interface ....................9

Bi-Directional Parallel Mode....................9

Parallel Interface Pin Assignments .........10

Serial Connection: RS232-C .......................11

Attach the Serial Cable ...........................11

RS232-C Serial Interface ........................11

Serial Mode.............................................11

Serial Interface Pin Assignments ............11

Connect to Power.............................................12

Check the Menu: Model 20DX Only ..............12

Print the Demo Page........................................12

Install the Printer Software.............................. 12

Chapter 2: The Control Panel.................. 13

Select the Display Language ...........................13

Control Panel Lights........................................13

Paper Size Indicator.........................................13

Control Panel Button Functions ......................14

Button Function Summary ..........................14

Chapter 3: The Printer Menus................. 15

Selecting Printer Features Using Your

Software.........................................................15

Selecting Printer Features Using Your Pr inter

Driver.............................................................15

Selecting Printer Features Using the Printer

Main Menus...................................................15

Printing the Main Menus ............................15

How to Use the Main Menus ......................15

Quick Access Menus............................... 16

Using the Level-1 Menu .........................16

Level-1 Menu Settings............................17

Level-1 Menu Selections for IBM PPR III

XL & EPSON FX Emulations.............. 20

Using the Level-2 Menu .........................21

Level-2 Menu Settings............................21

The User Maintenance Menu ..........................24

Summary of Maintenance Menu

Categories: ............................................24

Maintenance Menu Settings ...................24

English–i

Page 4

Chapter 4: The Front Feeder................... 27

Using the Front Feeder to Print Multiple Pieces

of Media ........................................................28

The Front Feeder: Printing Individual Pieces

(Manual Feed) ...............................................29

Manual Feed: Standard Paper .....................29

Setting up Manual Feed for Standard

Weight Paper......................................... 29

Manual Feed: Envelopes .............................30

Setting up to Print an Envelope ..............30

Manual Feed: Labels ...................................31

Setting up to Print Labels .......................31

Manual Feed: Transparencies......................32

Setting up to Print a Transparency..........32

Manual Feed: Heavy (Card) Stock..............33

Heavy (Card) Stock Specifications.........33

Setting up to Print Heavy Stock..............33

Using the Automatic Tray Switch Feature ......34

Chapter 5: Duplex Printing..................... 35

Portrait Versus Landscape ...............................35

Duplex Printing: Windows NT 3.51 ................35

Duplex Printing: Windows 3.1x ...................... 35

Duplex Printing: Windows 95 ........................36

Duplex Printing: Windows NT 4.0 ..................36

Chapter 6: Fonts....................................... 37

Available Fonts ................................................37

Printing a Sample of Resident Fonts...........37

Summary of Available Fonts .......................37

Fixed Scalable Fonts............................... 37

Proportional Scalable Fonts....................37

Bitmap Fonts...........................................38

IBM/Epson Emulation Fonts .................. 38

Selecting Fonts ................................................39

Using Bar Code Fonts ..................................... 39

Symbol Sets .....................................................39

Adobe PostScript Fonts Option .......................39

Chapter 7: Accessories............................. 41

Optional Paper Handling Accessories .............41

Multi-Purpose Feeder..................................41

Paper Expansion Tray .................................41

Duplex Feeder .............................................41

Additional Options ..........................................41

Network Card ..............................................41

Adobe PostScript Level 2 SIMM Kit..........42

Flash ROM Memory SIMMs......................42

Expanded Memory SIMMs.........................42

SIMM Configurations .....................................42

Chapter 8: Maintenance.......................... 43

General Consumables Information..................43

The T oner Cartridge: Type 7 .......................43

Toner Cartridge Life ............................... 43

The Image Drum: Type 7 ............................43

Image Drum Life ....................................43

Replacing the Toner Cartridge......................... 44

Replacing the Image Drum Cartridge .............46

Cleaning the LED Array ..................................48

Generating a Drum Cleaning Page ..................48

Chapter 9: Problem Solving.................... 49

Paper Jams .......................................................49

Paper Jam Messages....................................49

Why Paper Jams Occur ...................................50

Clearing Paper Jams ........................................50

Clearing a Paper Input Jam ......................... 50

Clearing a Paper Feed Jam.......................... 51

Clearing a Paper Exit Jam...........................52

Clearing Duplex Feeder Paper Jams................52

Clearing Duplex Feeder Input Jams............ 52

Clearing Duplex Feeder Open Jam .............52

Clearing Duplex Feeder Jam 1 & 2.............53

Clearing Duplex Feeder Jam 3.................... 54

Printer Display Messages ................................54

Print Quality Problems ....................................57

Adjusting Print Quality ...............................60

Software Problems ......................................60

Hardware Problems .........................................62

Appendix A: S ervice & Suppor t ............. 63

How to Get Service..........................................63

Your Dealer .................................................63

Customer Support Center............................ 63

Customer Service Representatives..............63

Faxable Facts...............................................63

Internet ........................................................64

Okidata Service Centers..............................64

Okidata US and Canada Service Center

Locations .............................................. 64

Purchasing Supplies ........................................64

Ways to Purchase ........................................64

Supply Order Numbers ...............................64

Toner Cartridge, “Type 7”.......................64

Image Drum, “Type 7”............................64

Appendix B: Specifications ..................... 65

General Specifications.....................................65

Typefaces .........................................................65

Paper Handling Specifications ........................65

Environmental Specifications..........................65

Electrical Specifications ..................................66

Physical Specifications....................................66

Appendix C: Installing SIMMs ................ 67

SIMM Configurations .....................................67

Installing SIMMs.............................................67

Limited Warranty...................................... 71

On-Site Repair .................................................71

Okidata Service Centers..............................72

Material Safety Data Sheet..................... 7 3

Index........................................................... 75

E–ii Contents

Page 5

Important Safety Instructions

Your OKIDATA printer has been carefully designed to give you years of

safe, reliable performance. As with all electrical equipment, however, there

are a few basic precautions you should take to avoid hurting yourself or

damaging the printer:

• Read the setup and operating instructions in this handbook carefully. Be

sure to save it for future reference.

• Read and follow all warning and instruction labels on the printer itself.

• Unplug the printer before you clean it. Use only a damp cloth; do not

use liquid or aerosol cleaners.

• Place your printer on a firm, solid surface. If you put it on something

unsteady, it may fall and be damaged; if you place it on a soft surface,

such as a rug, sofa, or cushioned surface, the vents may be blocked,

causing the printer to overheat.

• To protect your printer from overheating, make sure all openings on the

printer are not blocked. Don’t put the printer on or near a heat source,

such as a radiator or heat register. If you put it in any kind of enclosure,

make sure it is well ventilated.

• Do not use your printer near water, or spill liquid of any kind into it. Be

certain that your power source matches the rating listed on the back of

the printer. If you’re not sure, check with your dealer or with your local

power company.

• Your printer has a grounded, 3-prong plug as a safety feature, and it will

only fit into a grounded outlet. If you can’t plug it in, chances are you

have an older, non-grounded outlet; contact an electrician to have the

outlet replaced. Do not use an adapter to defeat the grounding.

• The printer must be installed near a power outlet which remains easily

accessible.

• To avoid damaging the power cord, don’t put anything on it or place it

where it will be walked on. If the cord becomes damaged or frayed,

replace it immediately.

• If you’re using an extension cord or power strip with the printer, make

sure that the total of the amperes required by all the equipment on the

extension is less than the extension’s rating. The total ratings of all

equipment plugged into the outlet should not exceed 15 amperes.

• Do not poke anything into the ventilation slots on the printer; you could

get an electrical shock or cause hazardous electrical arcing.

• Aside from the routine maintenance described in this handbook, don’t try

to service the printer yourself; opening the cover may expose you to

shocks or other hazards. Don’t make any adjustments other than those

outlined in the handbook—you may cause damage requiring extensive

repair work. Appendix A, Support, Service, and Warranty Information,

explains how to get your printer serviced by qualified OKIDATA technicians.

• If anything happens that indicates that your printer is not working

properly or has been damaged, unplug it immediately and follow the

procedures in Appendix A for having your printer serviced. These are

some of the things to look for:

- The power cord or plug is frayed or damaged.

- Liquid has been spilled into the printer, or it has been exposed to

water.

- The printer has been dropped, or the cabinet is damaged.

- The printer doesn’t function normally when you’re following the

operating instructions.

English–iii

Page 6

Warranty Enhancement Programs

• Available in the U.S. and Canada only

For more information . . .

OKI Extend™

This program offers you the

opportunity to purchase an

extension of the standard

warranty for your Okidata

printer. You can add 1 or 2 years

to the standard warranty.

OKI On-Site™

If you experience a malfunction

of your Okidata printer and the

problem can not be resolved

over the phone, this program

offers you repair of your printer

right at your place of business,

by our national service provider.

For pricing and more detailed information on these programs:

• call 1-800-OKIDATA (1-800-654-3282)

or

• visit our Web site: http://www.okidata.com

iv–English

Page 7

FCC/IC/CE Statements

Federal Communications Commission

Radio Frequenc y Inter ference Statement

for 120-Volt Models

WARNING: This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and

can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Plug the unit into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/television technician for help.

✔ It is the responsibility of the user to obtain the required shielded cable in

order to ensure compliance of this equipment with FCC regulations.

Changes or modifications not expressly approved by OKIDATA may void

your authority to operate this device.

Industry Canada Radio Inter ference Statement

for 120-Volt Models

This OKIDATA apparatus complies with the Class B limits for radio

interference as specified in the Industry Canada Radio Interference Regulations.

English–v

Page 8

Federal Communications Commission

European Union Council of the

Radio Frequency Interference Statement

for 230/240-Volt Models

WARNING: This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio frequency energy and,

if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

✔ It is the responsibility of the user to obtain the required shielded cable in

order to ensure compliance of this equipment with FCC regulations.

Changes or modifications not expressly approved by OKIDATA may void

your authority to operate this device.

Industry Canada Radio Interference Statement

for 230/240-Volt Models

This OKIDATA apparatus complies with the Class A limits for radio

interference as specified in the Industry Canada Radio Interference Regulations.

European Communities Statements

of Electromagnetic Conformance for

230/240-Volt Models

This product complies with the requirements of the Council Directive 89/

336/EEC on the approximation of the laws of the member states relating to

electromagnetic compatibility.

This product is in conformity with Directive 73/23/EEC on the harmoniza-

tion of the laws of Member States relating to electrical equipment designed

for use within certain voltage limits.

E–vi FCC/IC/CE

Page 9

Chapter 1: Setting Up

This chapter explains how to unpack and install your printer.

Selec t a Suitable Loc ation

Before unpacking your printer, select a suitable location for it which meets

the following criteria:

• A firm, level surface, such as a table or desktop

• Clearance to open the cover, the paper tray, and the rear paper exit

extender

• Air circulation around the printer to prevent overheating (recommended

minimum of 4" in all directions)

• A nearby power source

• Room temperature of 50° to 90°F (10° to 32°C)

• Relative humidity of 20-80%

• No direct sunlight

Unpack

Your printer

1. Unpack the printer and place it on the surface you’ve selected.

2. Remove the printer from the plastic bag.

3. Lift up the corner of the protective film and peel it off the control panel.

The accessories

As you unpack the accessories, please save the packing material in the ev ent

you need to repack the printer for shipping.

Important! Be sure to store the black light-shield bag near the printer to

protect the image drum in case you need to take it out of

the printer for more than a minute or so. This bag is also

used to store the image drum in case you need to ship the

printer.

Check the contents

➊ OKIPAGE 20 Printer

➋ Toner Cartridge with LED lens

cleaners

➌Power Cord

➍ Software Support CD

➎ Software Support

Diskette

➏ Light-shield bag

If you are missing

anything, contact your

dealer.

➋

➊

➌

➏

➍

You will need to purchase:

• Paper (see page 5)

• Interface cable: either bi-directional IEEE-1284 parallel cable (see page

9) or RS232-C serial cable (see page 11)

➎

English–1

Page 10

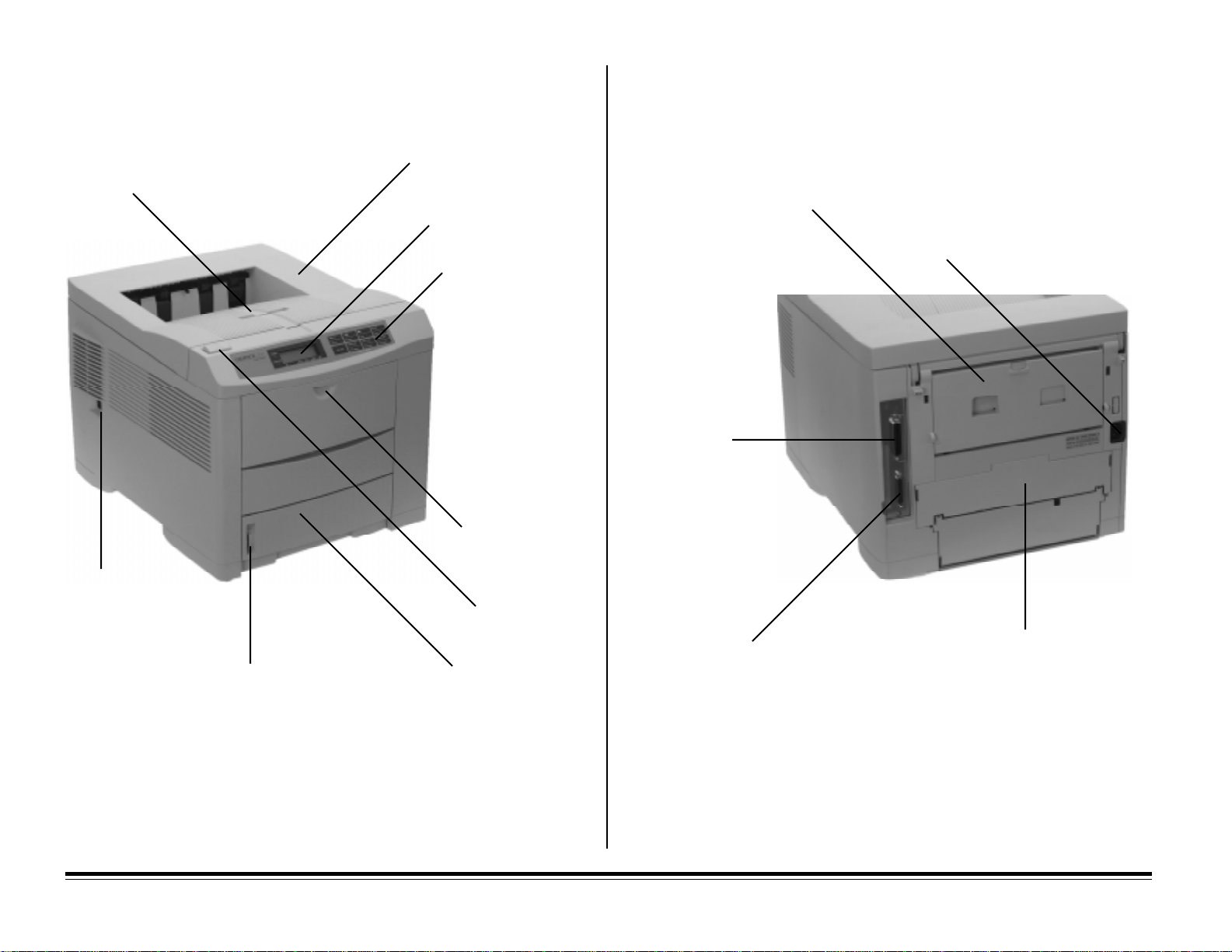

Getting to Know Your Printer

Top Exit Path

Printer Cov er

Display

Control Panel

Rear Paper Exit

Power Cord Socket

IEEE 1284

Parallel Interface

Front Feeder

On/Off Switch

OPEN Button

Paper TrayPaper Gauge

Front View

E–2 Chapter 1: Setting Up

RS232-C Serial Interface

OKIPAGE 20: Removable Plate for

installing optional

Duplex Feeder

OKIPAGE 20DX: Duplex Feeder

Rear View

Page 11

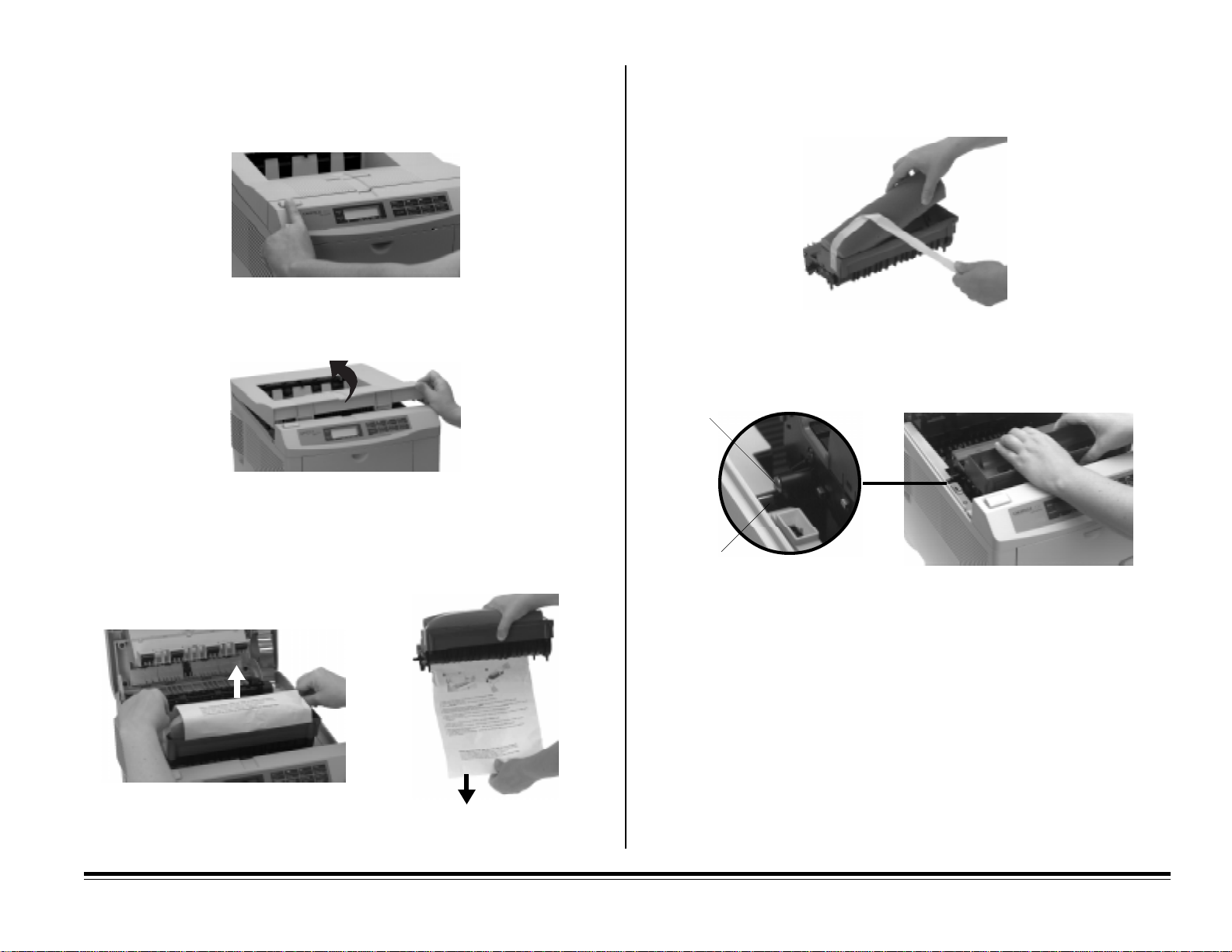

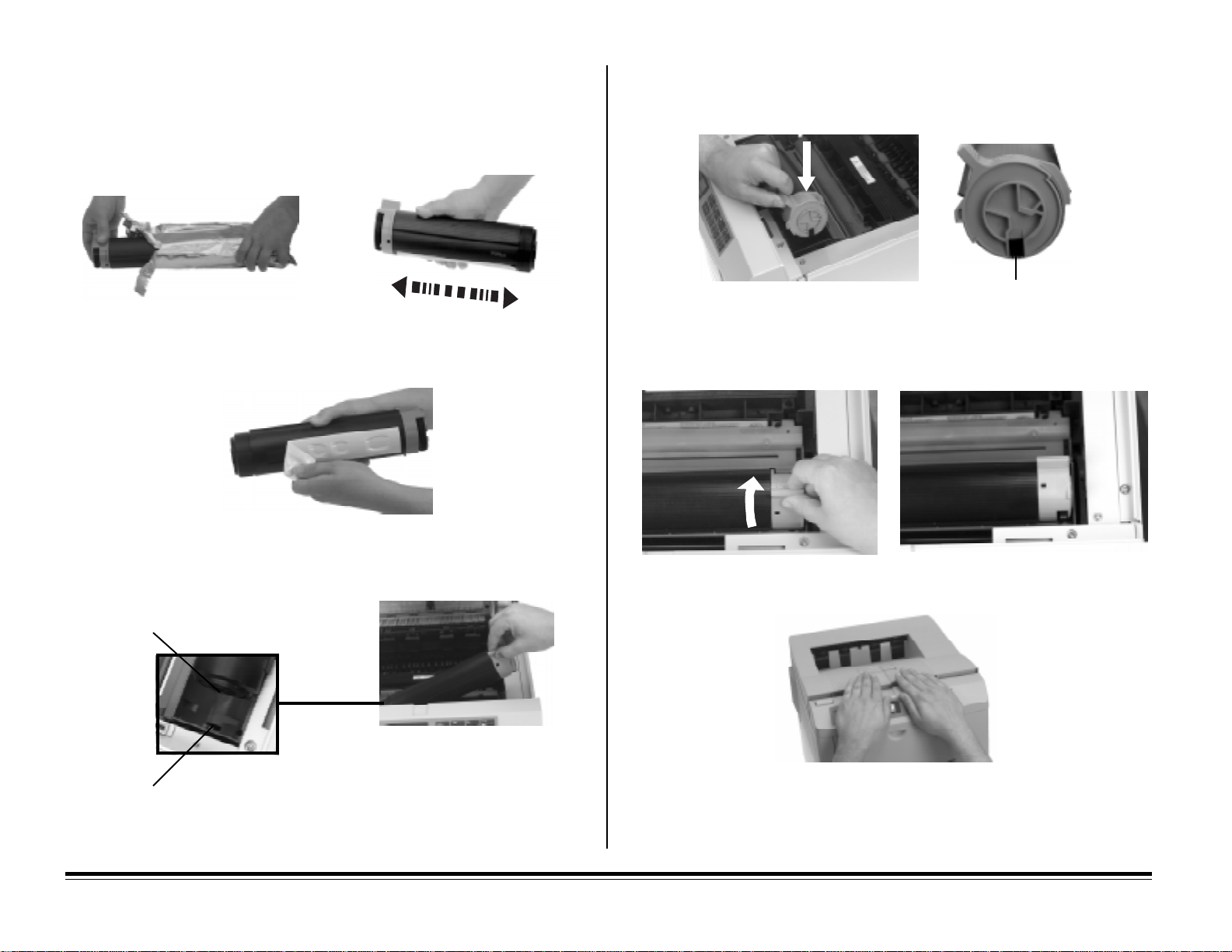

Prepare the Image Drum

1. Press the OPEN button.

2. Lift the cover (the cov er must be lifted completely to remove the image

drum cartridge).

Caution!Be careful not to touch the image drum’s shiny green sur-

face!

4. Remove the tape and shipping insert from the image drum and discard

them.

5. Reinstall the image drum in the printer, placing the alignment pins on

each side of the drum into the slots in the printer.

Pin

3. Lift out the image drum and remove the protective paper.

Slot

Chapter 1: Setting Up E–3

Page 12

Install the Toner

1. Remove the toner cartridge from the foil package and shake it fr om side

to side a few times to distribute the toner ev enly.

4. Lower the right side of the toner cartridge, aligning the slot in the cartridge with the ridge in the image drum.

Slot

2. Carefully peel off the tape from the bottom of the cartridge.

3. Place the left end of the toner cartridge into the toner well, inserting the

recess in the end of the toner cartridge over the tab on the image drum.

Recess

Tab

5. Push the gray lock lever toward the back of the printer until it stops.

6. Close the printer cover.

Note: If you get toner on your clothing, brush it off with a dry cloth. Wash

clothing in cold water; hot water sets toner.

E–4 Chapter 1: Setting Up

Page 13

Load Paper

Paper Specifications

When you buy paper , keep in mind that page pr inters require a smooth

finish paper. For most everyday applications, paper rated for copiers and

laser printers should work well with your printer. Before buying any large

quantity of a particular paper, always test a sample first.

Paper Feed Paths

Paper can be supplied to the printer in four ways:

• From the paper tray which

holds up to 530 sheets of

20-lb. paper

Weight

• Main Tray : 16 - 28 lb.

• Optional Paper Expansion Tray: 16-28 lb.

• Front Feeder: 16 – 36 lb.

• Optional Multipurpose Feeder: 16-24 lb.

• Duplex Feeder (OKIPAGE 20DX): 16-24 lb. (option for OKIPAGE 20)

Usable Types

• Bond

• Smooth, low moisture paper rated for copier and laser printers

• Cover stock; heavy bond (36 lb. max.): Manual feed only

Finish

• Smooth, non-textured

• Copier-type paper or paper with a Sheffield rating of 100 to 250

Composition

• 100% wood pulp or low cotton content

Note: Most papers have some cotton or rag content. Avoid papers with a

high cotton or rag content.

• From the 100-sheet Front

Feeder (see Chapter 4)

• From the optional

100-sheet/50 envelope

multipurpose feeder (see

Chapter 7)

• From the optional paper

expansion tray which holds

up to 530 sheets of 20-lb.

paper (see Chapter 7)

Letterhead Stationery/Preprinted Forms

• Ink must withstand 392°F (200°C) for 0.1 second.

The paper tray will accommodate 16 to 28 lb. paper within the following

size ranges:

• Width: 3.4 to 8.5 inches (86.4 to 216 mm)

• Length: 5.5 to 14 inches (140 to 355.6 mm)

Chapter 1: Setting Up E–5

Page 14

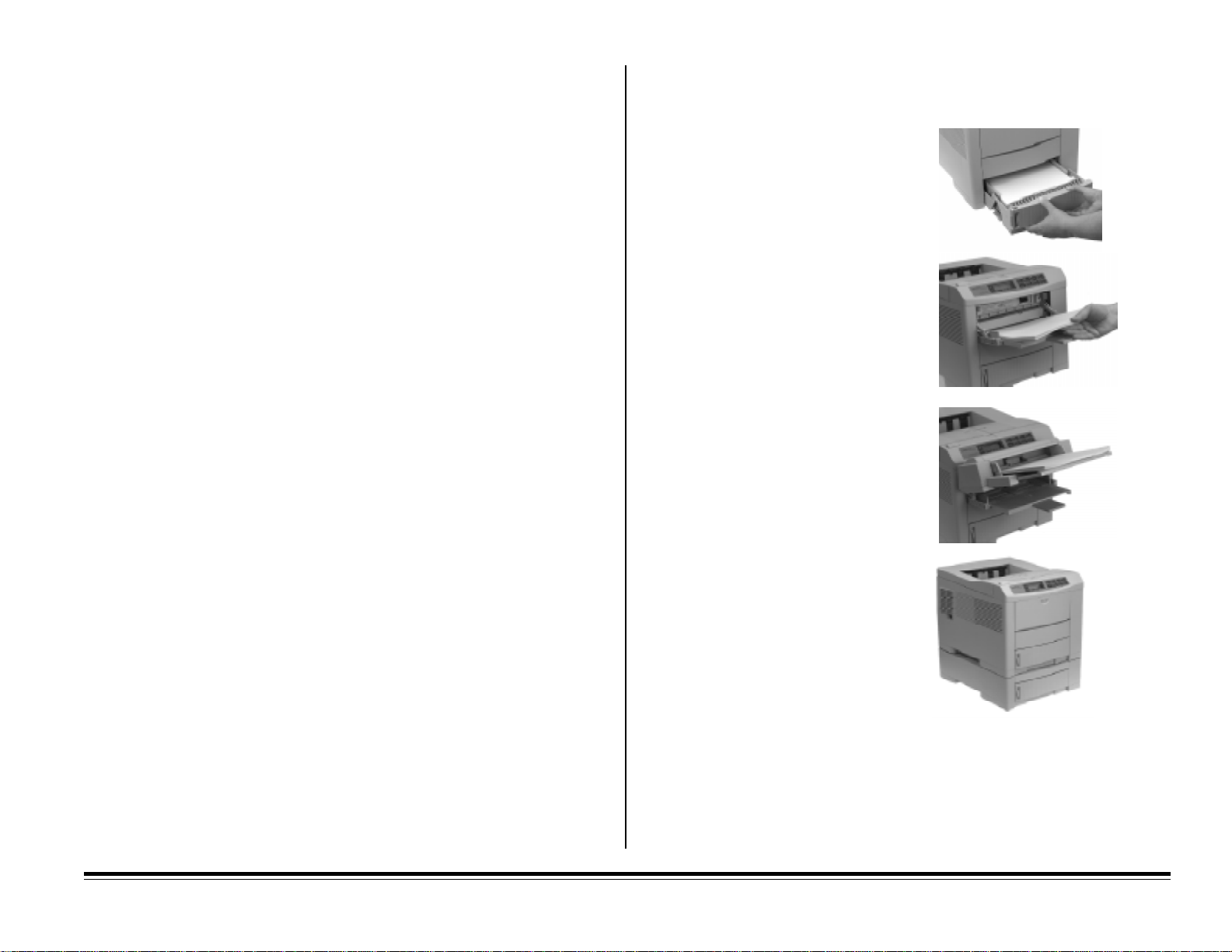

Load the Paper Tray

1. Pull out the paper tray.

2. Adjust the rear and side paper guides before loading paper. This will help

to avoid paper jams.

4. Push the tray into the printer until it locks.

The Paper Tray Gauge

The paper tray gauge indicates the amount of paper left in the tray. This

eliminates having to open the tray to check how much paper remains.

3. Fan a stack of paper (up to 530 sheets of 20 lb. paper) and place it in the

tray under the tabs. Do not fill above the PAPER FULL marks.

E–6 Chapter 1: Setting Up

Page 15

Storing Paper

If paper is stored improperly, print quality could be affected.

Select a Paper Exit Path

The OKIPAGE 20 has two paper paths:

• Store paper in a dark, dry place such as a closet or a cabinet

• Don’t open the package until you are ready to use it

• Always store paper lying flat or it may curl

• Store your paper in a static-free environment

• Ideally, store paper at a constant temperature of 70°F (21.1°C) with less

than 50% humidity .

• Discard the top sheet from each ream of paper before loading it into the

paper tray — it may be contaminated with glue or dust.

• Top Exit: the normal exit used for routine printing

• Rear Exit: used for special types of print media such as envelopes,

labels, transparencies, etc.

Chapter 1: Setting Up E–7

Page 16

Top P aper Exit

The top paper exit is the one normally used for routine printing.

• Printed pages feed face down into the bin on top of the printer

• Bin holds 250 sheets of 20 lb. paper

• Pages stack in the correct order

• When the bin is full, STACKER FULL REMOVE THE PAPER displays

in the control panel window and printing will stop until the paper is

removed

To use the top paper exit:

1. Lift out the paper catcher and pull it toward the front of the printer until it

stops.

Rear Paper Exit

Use rear exit when printing on heavy paper, envelopes, labels, and transparencies.

• Printed pages feed face up into the rear tray

• Tray holds a maximum of 100 sheets of 20 lb. paper or 10 envelopes

• Pages stack in reverse order

• To avoid paper jams, remove paper when rear exit tray is full.

To use rear paper exit:

Caution! Do not extend the rear exit tray while printing: a paper jam may

occur!

1. Pull the tray down.

2. Flip up the extender.

2. Pivot out the extenders.

E–8 Chapter 1: Setting Up

Page 17

Connect to Your Computer

Parallel Connection

Attach the Parallel Cable

We recommend that you use a bi-directional parallel printer cable. For best

results, purchase a cable marked “IEEE 1284-compliant.”

Important! To comply with FCC regulations, the cable must be

shielded and UL and CSA approved.

Note: OKIDATA has tested and approved the following bi-directional cable:

Part Number 70000803. See Appendix A for purchasing information.

To connect the printer to your computer:

1. Turn both your printer and computer OFF.

2. Insert the wide connector on the cable into the parallel port on your

printer. Make sure the connector is fully inserted, then snap both wire

clips into the notches on the cable connector.

IEEE 1284 Parallel Interface

Parallel cable requirements:

• Cable must be shielded with twisted pair conductors, and must be UL

and CSA approved

• Maximum length for bi-directional cable is 6 feet (1.8 meters). For

lengths greater than 6 feet, use a cable marked IEEE 1284-compliant.

• Printer connector is an IEEE 1284-B receptacle (36 pins, 0.085” center

line)

• Port supports bi-directional IEEE 1284 communications (compatibility,

nibble, and ECP modes)

Bi-Directional Parallel Mode

If you are using the Status Monitor software, which provides on-line

feedback of the printer status, BI-DIRECTION must be set to ENABLE

(default) in the Level-2 printer main menu (see Chapter 3).

The recommended cable length for bi-directional communications is 6 ft.

(1.8 meters). The standard parallel cables available at computer stores

should work fine. For extended distances, higher quality IEEE 1284-compliant cables are available.

3. Insert the other end of the cable into the parallel port on your computer

and tighten the screws.

Caution!Be sure not to over tighten the screws — this could damage

the screw posts on your computer!

Chapter 1: Setting Up E–9

Page 18

Parallel Interface Pin Assignments

.oNniPemaNlangiSnoitceriDlangiSelbitapmoCelbbiNPCEsnoitcnuF

1ebortSataDretnirpoTebortSnklCtsoHklCtsoHebortsgnilpmasatadlellaraP

8-2ntiBataDretnirpoT)BSL(nataD)BSL(nataD)BSL(nataDatadtupnilellaraP

98tiBataDretnirpoT)BSM(8ataD)BSM(8ataD)BSM(8ataDatadtupnilellaraP

01egdelwonkcAretnirpmorFkcAnklCrtPklChpireP

11ysuBretnirpmorFysuBysuBrtPkcAhpirePmralagnirudrognissecorptnirpgniruD

21dnErepaPretnirpmorFrorrEPqeRataDkcAesreveRkcAnrepapfodnE

31tceleSretnirpmorFtceleSgalfXgalfX)enil-no(etatstceleS

41deeFotuAretnirpoTdFotuAnysuBtsoHkcAtsoHedomegnahcottseuqeR

51----- )desuton(

61V0- dnGcigoLdnGcigoLdnGcigoLdnuorglangiS

71dnuorGsissahC- dnGsissahCdnGsissahCdnGsissahCdnuorgsissahC

81V5+retnirpmorFhgiHcigoLlarehpirePhgiHcigoLlarehpirePhgiHcigoLlarehpireP.xamAm05

91V0- )ebortSn(dnuorGlangiS)ebortSn(dnuorGlangiS)ebortSn(dnuorGlangiSdnuorglangiS

72ot02V0- )8-1ataD(dnuorGlangiS)8-1ataD()8-1ataD(dnuorglangiS

82V0-

92V0- )tluaFn,ysuB(dnuorGlangiS)tluaFn,ysuB(dnuorGlangiS)tluaFn,ysuB(dnuorGlangiSdnuorglangiS

03V0-

)kcAn,tceleS

,rorrEP(dnuorGlangiS

)kcAn,tceleS

,dFotuAn(dnuorGlangiS

)tinln,nltceleSn

)tinln,nltceleSn

,rorrEP(dnuorGlangiS

)kcAn,tceleS

,dFotuAn(dnuorGlangiS

,rorrEP(dnuorGlangiS

,dFotuAn(dnuorGlangiS

)tinln,nltceleSn

gninoitcnuf

dnuorglangiS

dnuorglangiS

fodnerotupniatadfonoitelpmoC

13EMIRPtupnIretnirpoTtinlntinlnqeResreveRnlangisgnizilaitinI

23tluaFretnirpmorFtluaFnliavAataDnqeRhporePnmralagnirudrotuorepaP

33V0---- dnuorglangiS

43-----53- retnirpmorF--- "1"cigoLtaxiF

63nItceleSretnirpoTnItceleSnevitcA4821evitcA4821edoMegnahcottseuqeR

E–10 Chapter 1: Setting Up

Page 19

Serial Connection: RS232-C

Attach the Serial Cable

To connect the printer to your computer:

1. Turn both your printer and computer OFF.

2. Insert the male connector on the cable into the serial port on your printer.

Make sure the connector is fully inserted, then tighten the screws.

Serial Mode

The serial interface settings on your printer and computer must match. To

change printer settings, enter the Level 2 menu (press ON-LINE to place the

printer off-line, then press MENU 1/Menu 2 for 2 seconds, until PRINT

appears) and select the RS232C SERIAL category. Set FLOW CON-

MODE

, BAUD RATE, DATA BITS, PARITY, and MIN. BUSY to match the settings

TROL

on your computer. Following are the printer default settings for these

parameters:

FLOW CONTROL DTR HI POLARITY

BAUD RATE 9600 BAUD

DATA BITS 8 BITS

PARITY NONE

MIN. BUSY 200 mSECONDS

Serial Interface Pin Assignments

niPlangiSlobmySnoitceriD

1dnuorGemarFGF-

3. Insert the other end of the cable into the serial port on your computer and

tighten the screws.

Caution!Be sure not to over tighten the screws — this could damage

the screw posts!

RS232-C Serial Interface

Serial cable requirements:

• Cable must be shielded with twisted pair conductors, and must be UL

and CSA approved

• Maximum length for serial cable is 6 feet (1.8 meters).

• Printer connector is Type 17LE-13250-27 (D4CC) receptacle (25 pins)

Chapter 1: Setting Up E–11

2ataDdettimsnarTDTretnirpoT

3ataDdevieceRDRretnirpoT

4dneSottseuqeRSTRretnirpmorF

6-5- --

7dnuorGlangiSGS-

71-8---

81).xamam05(V5+-retnirpmorF

91- --

02ydaeRlanimreTataDRTDretnirpmorF

52-12---

Page 20

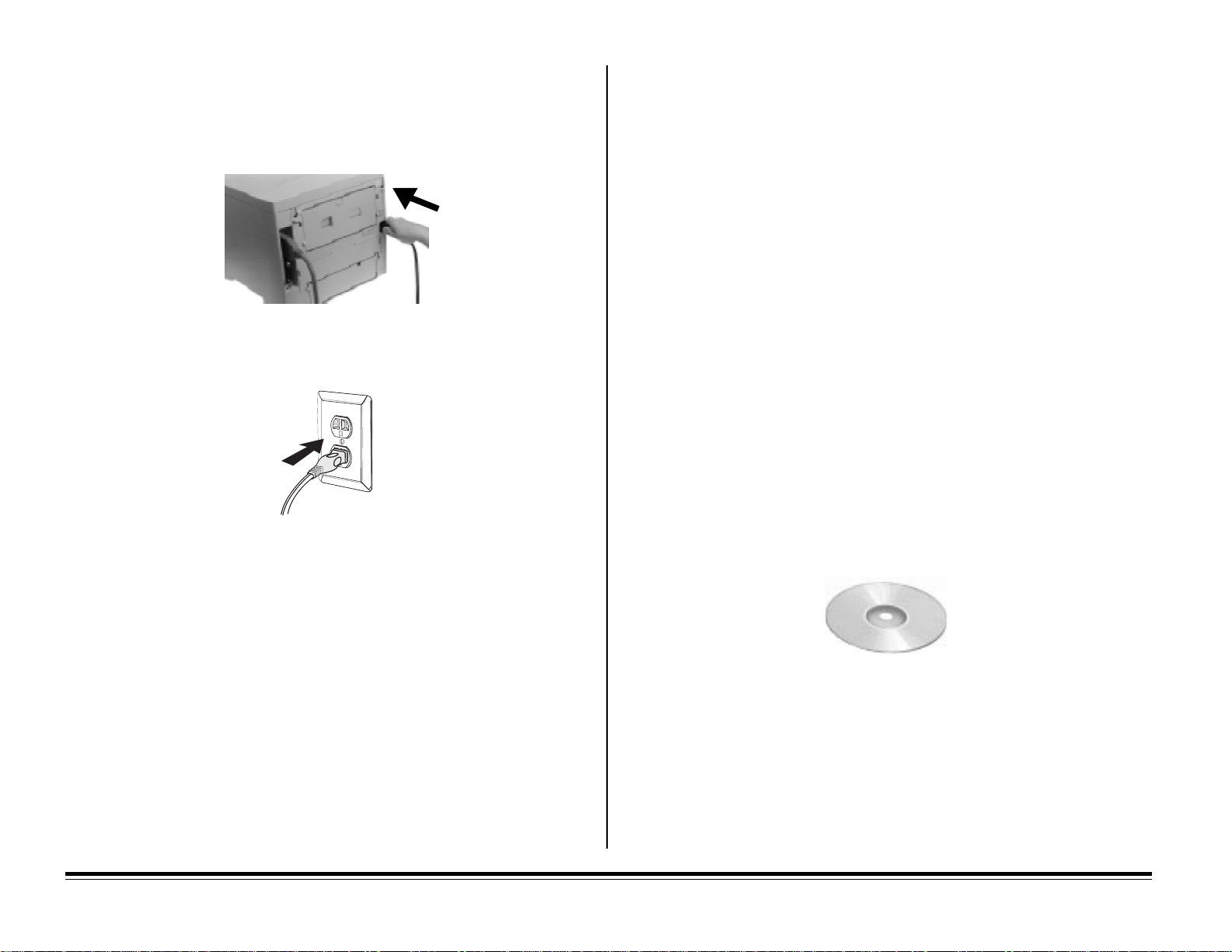

Connect to Power

1. Plug the female end of the power cord supplied with the printer into the

power socket on the back of the printer.

2. Plug the other end of the cable into a suitable grounded power outlet or

power strip.

4. Press MENU1/Menu 2 twice.

DUPLEX PRINTING displays.

5. Make sure the second line of the display reads

ENTER button, then ©/Reset, then ENTER.

ON * displays.

6. Press ON LINE to exit the menu.

ON *. If not, press the

Print the Demo Page

1. Turn the printer ON.

INITIALIZING displays briefly in the control panel window, then ON-LINE

displays.

2. Press ON-LINE to place the printer off-line.

3. Press FORM FEED/Print Demo for 2 seconds (until the display reads

PRINT DEMO PAGE).

®

4. To print the Demo Page for the HP

Power Save. To pr int the Demo Page for the IBM® or Epson® emulation,

press ©/Reset until the emulation you want appears on the second line of

the display , then press ENTER/ Power Save.

The Demo page prints.

PCL6 emulation, press ENTER/

Caution!If you are using a power strip, be sure the total amperage rating

of the strip does not exceed the total amperage of the equipment

plugged into it.

Check the Menu: Model 20DX Only

Install the Printer Software

Check the menu to be sure that the Duplex printing feature is turned on:

1. Turn the printer ON.

INITIALIZING displays briefly in the control panel window, then ON-LINE

displays.

2. Press ON-LINE to place the printer off-line.

3. Press MENU1/Menu 2.

PERSONALITY displays.

E–12 Chapter 1: Setting Up

You are now ready to install the printer software. See the separate booklet

“Software Install Guide” for information on printer drivers and instructions

on loading the printer software.

Page 21

Chapter 2: The Control Panel

Selec t the Display Language

Printer messages can be displayed in the control panel window in a number

of languages. English is the default language. To change the display language:

1. Press ON-LINE to change the printer status to off-line.

2. Press MENU 1/Menu 2 and hold for 2 seconds.

PRINT MODE displays.

3. Press MENU 1/Menu 2 until LANGUAGE displays.

4. Press ENTER/Power Save.

ENGLISH displays.

5. Press ©/Reset until the desired language displays.

6. Press ENTER/Power Save to select the new language as the default

setting.

7. Press ON-LINE to engage the change and place the printer back on-line.

Control Panel Lights

The lights indicate the printer status:

READY Light

READY Light (Amber)

On: Printer is on-line, ready to receive data

Off: Printer is off-line, unable to receive data; initializing;

warming up; error

Blinking: Printer is printing a menu, fonts, or demo page

AT TENTION Light (Red)

On: Warning—toner is low, change drum, near end of fuser life

Off: Normal state

Blinking: Operator assistance required—paper jam, paper out, paper

request, service required

Paper Size Indicator

Paper Size Indicator

[set for LETTER, the default]

ATTENTION Light

The flashing marker in the printer display window indicates the paper size

installed in the paper tray. This feature eliminates having to open the paper

tray to see which paper size is loaded.

English–13

Page 22

Control Panel Button Functions

To access printer functions from the control panel, place the printer off-line

(press the ON-LINE button: OFF-LINE appears on the display).

Press: In Menu Mode advances to the next item. Also used with

§

/Recover to generate a drum cleaning page: see “Generating a

Drum Cleaning Page” in Chapter 8.

Press/hold: Deletes data in buffer and executes internal reset.

Press: In Menu Mode: sets displayed Menu item as the user default.

• To access the top function of each button, press the button briefly.

• To access the bottom function, press and hold the button for 2 to 3

seconds.

Button Function Summary

Press: Enters Level-1 menu. Once in the Lev el-1 menu, press this

button to move to the ne xt menu item, or press and hold to cycle

backwards through all the Level-1 menu categories.

Press/hold: Enters Level-2 menu.

Press: In Menu Mode returns to previous item; press and hold to cycle

backwards through all the items within a category. Also used

with ©/Reset to generate a drum cleaning page: see “Generating

a Drum Cleaning Page” in Chapter 8.

Press/hold: Clears error condition and returns printer on-line.

Press/hold: Enters the Power Save quick menu.

Press: Changes printer status from receive data mode (on-line) to local

function mode (off-line).

Press: Enters the Paper Size Quick Menu.

Press/hold: Prints a listing of the current and default menu settings (HP

PCL 6, IBM Proprinter III XL, or Epson FX).

Press: Enters the Tray Select Quick Menu.

Press/hold: Prints a sample of installed printer fonts (HP PCL 6, IBM

Proprinter III XL, or Epson FX).

Press: Ejects the current page. Any data held in the buffer is printed.

Press/hold: Prints a Demo Page (HP PCL 6, IBM Proprinter III XL, or

E–14 Chapter 2: The Control Panel

Epson FX).

Page 23

Chapter 3: The Printer Menus

Most printer features are selected directly from your software application. If

you want to use the printer’s Menu to select features, see Chapter 3. Re-

member, features selected in your software will override features selected in

the printer’s Menu.

Selec ting Printer Features Using Your Software

Most printer features like font, paper size, and page orientation can be set in

your software program. This is the easiest way to control your printer.

Check your software documentation for information.

Selec ting Printer Features Using Your Printer

Driver

Printer features can also be set using the Status Monitor software included

with your printer. However, these settings will be overridden by any settings

made within your software package.

Selec ting Printer Features Using the Printer

Main Menus

Printing the Main Menus

To print a list of the menu items and settings currently engaged:

1. Place the printer off-line (press ON LINE).

2. Press and hold PAPER SIZE/Print Menu until the display reads PRINT

.

MENU

3. To print the menu for the HP PCL6 emulation, press ENTER/Power

©

Save. To print the menu for the IBM or Epson emulation, press

until the emulation you want appears on the second line of the display,

then press ENTER/Power Save.

4. The menu prints.

The printout shows the factory default settings, the current user settings, and

the amount of memory installed in your printer.

/Reset

How to Use the Main Menus

Main menu features are

• accessed using control panel buttons

• displayed in the control panel window

• organized by Categories → Items → Selections

You can also select printer features in the printer main menus by using the

control panel. However, features set in your software program will override

the same features selected in the printer main menu.

Important! Use the printer main menu only when your software does

not let you select features or when you are setting printer

features that your software does not control.

There are two levels within the main printer menu: Level-1 and Level-2. To

access the menus, place the printer off-line (press ON LINE), then

• to access the Level-1 menu, press MENU 1/Menu 2 (the display will read

PERSONALITY).

• to access the Level-2 menu, press and hold the MENU 1/ Menu 2 button

until the display reads

PRINT MODE).

English–15

Page 24

Quick Access Menus

The PAPER SIZE, TRAY TYPE, and POWER SAVE menu features can be

accessed directly without having to step through the main menu.

To do this:

1. Place the printer off-line (press ON LINE).

2. Press and release PAPER SIZE, or

Press and release TRAY TYPE, or

Press POWER SAVE for two full seconds.

3. Press © repeatedly until you see the selection you want.

4. Press ENTER/Power Save to set the selection as the default.

An asterisk (*) appears to indicate the new default setting.

5. Press ON LINE to exit the menu and place the printer back on-line.

Using the Level-1 Menu

1. Press ON-LINE to place the printer off-line.

2. Press MENU 1/Menu 2 to enter the Level-1 menu.

3. Continue to press MENU 1/Menu 2 repeatedly to advance through the

Level-1 menu categories.

3. Press ENTER/Power Save to select a category.

The current default setting displays.

Note: Some categories include more than one item. In such categories,

after you press ENTER, press MENU 1/Menu 2 to advance to the

next item before proceeding to step 4.

4. Press © repeatedly to display the selections. Stop when you see the

selection you want.

5. Press ENTER/Power Save to set a selection as the default.

An asterisk (*) appears to indicate the new default setting.

6. Repeat steps 3 through 5 until you have made all the menu changes you

wish to make, then press ON LINE to exit the Menu Mode and place the

printer back on-line.

Notes:

• If the MENU 1/Menu 2 button is pressed and held while in Menu Mode,

the printer cycles through the categories in reverse order.

• If you enter the Level-1 menu and make a selection while there is data

present in the buffer, or while a DLL/Macro is present, the RESET TO

©

SAVE message appears on the display. When you press the

button, all data in the buffer and any temporary soft fonts or macros will

be cleared.

/Reset

Example:

If you have one of the optional paper expansion trays installed

and you want to set the printer to automatically switch to

another tray with the same size paper when the first tray runs

out of paper:

1. Press ON LINE.

2. Press MENU 1/Menu 2 to enter the Menu Mode.

3. Press MENU 1/Menu 2 again to move to the

TRAY SELECT category.

4. Press ENTER.

5. Press MENU 1/Menu 2 twice to move to the AUTO TRAY

SWITCH item.

6. Press

7. Press ENTER to engage the ON selection (an asterisk will

appear next to ON).

8. Press ON LINE to exit the Menu Mode.

once to get to the ON selection.

E–16 Chapter 3: The Printer Menus

Page 25

Level-1 Menu Settings

TRAY SELECT

DUPLEX PRINTING (continued)

Summary of Level-1 Categories:

• PERSONALITY

• TRAY SELECT

• DUPLEX PRINTING

• EDIT SIZE

• PAPER SIZE

• MEDIA TYPE

• PAPER SIZE CHECK

• COPIES

• FONTS & SYMBOLS

• PAGE LAYOUT1

• PAGE LAYOUT2

• HOST INTERFACE

Level-1 Menu Categories (e.g., PERSONALITY),

Items (e.g., EMULATION) and Selections (e.g., HP

LaserJet 5

, IBM PPR II XL, Epson FX) are summa-

rized below: default Selections are in italic (e.g.,

AUTO Emulation

PERSONALITY

EMULATION

AUTO Emulation

HP LaserJet 5

IBM PPR III XL

Epson FX

Adobe® PostScript® (appears only if PostScript

selection is installed)

Notes: Auto Emulation automatically

).

switches between HP LaserJet 5, IBM

PPR III XL and Epson FX emulations.

MANUAL FEED

OFF

ON

Notes: Selects Manual Feed mode: paper is

fed from the Manual Feeder regardless

of the PAPER FEED setting. When the

job is ready to print, MANUAL

REQUEST

will appear on the display;

be sure to place paper on Manual

Feeder, then press FORM FEED

button to start printing.

PAPER FEED

TRAY 1

TRAY 2*

TRAY 3*

FRONT TRAY (Manual Feeder)

MULTI FEEDER*

Notes: * Selection only appears if appropriate

optional accessory is installed.

Select paper source.

AUT O TRAY SWITCH

OFF

ON

Notes: ON = When paper tray, printer

automatically switches to the optional

Paper Expansion Tray, if installed, then

to the Manual Feeder, then to the

optional Multi-Purpose feeder, if

installed.

DUPLEX PRINTING (appears in OKIPAGE 20 menu

only if Duplex Feeder is installed.)

DUPLEX

ON

OFF

Notes: Selects duplex printing (for OKIPAGE

20, optional Duplex Feeder must be

installed).

BIND

LONG EDGE

SHORT EDGE

Notes: Select the orientation for duplex

printing so that the front and back of

printing is properly aligned for the

selected orientation of the pages

(Duplex Printing must be set to ON).

Long Edge sets the orientation for

portrait printing. Short Edge sets the

orientation for landscape printing.

EDIT SIZE

CASSETTE SIZE

LETTER

EXECUTIVE

LEGAL 14

LEGAL13

A4 SIZE

A5 SIZE

A6 SIZE

B5 SIZE

COM-9

COM-10

MONARCH

DL ENVELOPE

C5 ENVELOPE

C4 ENVELOPE

Notes: HP PCL6 mode: Sets the paper size

when the software does not. With the

default Cassette Size selected, the

paper size will be whatever is detected

in the paper tray. If manual feed is

being used, the paper size will be the

one selected in the Level-1 menu

(default is letter).

PostScript mode: Ignored.

Chapter 3: The Printer Menus E–17

Page 26

Level-1 Menu Settings (continued)

MEDIA TYPE

MEDIA TYPE (continued)

PAPER SIZE

FRONT/MANUAL

LETTER

EXECUTIVE

LEGAL 14

LEGAL13

A4 SIZE

A5 SIZE

A6 SIZE

B5 SIZE

COM-9

COM-10

MONARCH

DL ENVELOPE

C5 ENVELOPE

C4 ENVELOPE

Notes: Select paper size installed in Manual

Feeder. If paper size installed does not

match setting, printer will display

message requesting the size set in

menu.

MULTI FEEDER (appears if option is installed)

LETTER

EXECUTIVE

LEGAL14

LEGAL13

A4 SIZE

A5 SIZE

A6 SIZE

B5 SIZE

COM-9

COM-10

MONARCH

DL ENVELOPE

C5 ENVELOPE

Notes: Appears only if the optional

Multi-Purpose Feeder is installed.

TRAY 1

LIGHT

MEDIUM LIGHT

MEDIUM

MEDIUM HEAVY

HEAVY

Notes: Improves print quality and toner

fusing.

Light = 16 lb (60 g/m2)

Medium Light = 18 lb (68 g/m2)

Medium = 20 lb (75 g/m2)

Medium Heavy = 24 lb (90 g/m2)

Heavy = 28 lb (105 g/m2)

TRAY 2 (appears if option is installed))

LIGHT

MEDIUM LIGHT

MEDIUM

MEDIUM HEAVY

HEAVY

Notes: Improves print quality and toner

fusing. Only appears in the menu when

the optional Paper Expansion Tray is

installed.

Light to Heavy weight values are same

as specified for Tr ay 1.

TRAY 3 (appears if option is installed))

LIGHT

MEDIUM LIGHT

MEDIUM

MEDIUM HEAVY

HEAVY

Notes: Improves print quality and toner

fusing. Only appears in the menu when

two optional Paper Expansion Trays

are installed.

Light to Heavy weight values are same

as specified for Tr ay 1.

FRONT/MANUAL

LIGHT

MEDIUM LIGHT

MEDIUM*

MEDIUM HEAVY

HEAVY

TRANSPARENCY

Notes: Specify print media weight/type to

improve print quality and toner fusing.

Light to Heavy weight values are same

as specified for Tr ay 1.

MULTI FEEDER (appears if option is installed))

LIGHT

MEDIUM LIGHT

MEDIUM*

MEDIUM HEAVY

HEAVY

TRANSPARENCY

Notes: Specify print media weight/type to

improve print quality and toner fusing.

Light to Heavy weight values are same

as specified for Tr ay 1.

PAPER SIZE CHECK

ENABLE

DISABLE

Notes: ENABLE = printer only accepts paper

size selected in software which

matches size of paper actually loaded

in tray.

DISABLE = printer will accept any

paper size selected in software.

COPIES

1

to 999

Notes: Select number of copies to print for

each document.

E–18 Chapter 3: The Printer Menus

Page 27

FONTS & SYMBOLS

FONTS & SYMBOLS (continued)

PAGE LAYOUT1

FONT SOURCE

RESIDENT

SIMM

DOWNLOAD

Notes: Select font source.

SIMM appears only if optional Flash

ROM SIMM is installed.

DOWNLOAD appears if a soft font is

loaded.

FONT NO.

I000

to I0xx

C000

S001

Notes: xx = font ID number (see font print

sample).

Prefix indicates font source:

I = internal (resident) — I000 =

Courier;

C = Card Font (appears only if

optional Flash ROM SIMM is installed)

S = downloaded soft font (appears only

if soft font is loaded)

FONT HEIGHT

10.00 CPI

Range: 0.44 to 99.99 CPI

Notes: Appears if scalable, fixed Courier or

Letter Gothic font is selected.

CPI = characters per inch, settable in

0.01-cpi (press ©/Reset) or 0.1-cpi

(press/hold ©/Reset) increments.

FONT HEIGHT

12.00 POINT

4.00 to 999.75 points

Notes: Appears if font selected is propor-

tional/scalable (e.g., CG Times, CG

Omega, Univers, etc.).

Sets character height in points in

0.25-point (press ©/Reset) or 1-point

(press/hold ©/Reset) increments.

72 points = 1 inch

SYMBOL SET (HP PCL6 emulation)

PC-8,

ROMAN-8, ISO L1, PC-8 Dan/Nor,

PC-850, Legal, ISO-2 IRV, ISO-4 UK, ISO-6

ASC, ISO-10 S/F, ISO-11 SWE, ISO-14, JASC,

ISO-15 Ita, ISO-16 Por, ISO-17 Spa, ISO-21

Ger, ISO-25 Fre, ISO-57 Chi, ISO-60 Nor,

ISO-61 Nor, ISP-69 Fre, ISO-84 Por, ISO-85

Spa, German, Spanish, ISO Dutch, Roman Ext,

ISO Swedish1, ISO Swedish2, ISO Swedish3,

IBM-437, IBM-850, IBM-860, IBM-863,

IBM-865, PC Set1, PC Ext US, PC Ext D/N, PC

Set2 US, PC Set2 D/N, UN Math, UN Int’l, UN

US, PS Math, PS Text, Math-8, Pi Font, MS

Publish, Win 3.0, DeskTop, Win 3.1 L1, MC

Text, PC-852, Win 3.1 L5, Win 3.1 L2, CWI

Hung, PC-857 TK, ISO L2, ISO L5, PC-8 TK,

Kamenicky, Hebrew NC, Hebrew OC, Plska

Mazvia, ISO L6, Win 3.1 Cyr, PC-866, Win 3.1

Grk, PC-869, PC-855, Greek-437, Greek-437

Cy, Greek-928, Win 3.1 Heb, Serbo Croat2,

Ukrainian, Bulgarian PC-1004, WIN BALTIC,

PC-775, Serbo Croat1, HP ZIP, USPSZIP,

USPSFIM, USPSSTP, Wingdings, Symbol,

OCR-A, OCR-B

A4 PRINT WIDTH

78 COLUMN

80 COLUMN

Notes: HP Mode only. When using A4 size

paper, select 78 columns or condense

to 80 columns so characters will fit on

a line.

WHITE PAGE SKIP

OFF

ON

Notes: HP Mode only. ON = printer will

ignore FF code when buffer is empty.

(Cancels printing a blank page at the

end of a print job.)

CR FUNCTION

CR

CR + LF

Notes: HP Mode only. CR + LF = add LF

command to each CR command.

LF FUNCTION

LF

LF + CR

Notes: HP Mode only. LF+CR= add CR

command to each LF command.

PAGE LAYOUT2

ORIENTATION

PORTRAIT

LANDSCAPE

Notes: Sets printing oriented with the width of

the page (Portrait) or with the length of

the page (landscape).

LINES PER PAGE

60 LINES

5 TO 128 LINES

Notes: Select lines per page in 1 line incre-

ments.

Chapter 3: The Printer Menus E–19

Page 28

Level-1 Menu Settings (continued)

FONTS & SYMBOLS (continued)

PAGE LAYOUT1

HOST INTERFACE

PARALLEL

ENABLE

DISABLE

Notes: Enables parallel interface.

RS232C

ENABLE

DISABLE

Notes: Enables serial interface.

OKI HSP

ENABLE

DISABLE

Notes: Enables network interface.

Level-1 Menu Selections for IBM PPR III XL &

EPSON FX Emulations

Default settings below are in italic.

FONTS & SYMBOLS

CHARACTER PITCH

10 CPI

12 CPI

17 CPI

20 CPI

PROPORTIONAL

Notes: Specifies character pitch.

FONT CONDENSE

12 CPI to 20 CPI

12 CPI to 12 CPI

Notes: IBM emulation only.

CHARACTER SET

SET 2

SET 1

Notes: Choose Character Set: Standard IBM

Set 1 or Line Graphics IBM Set II

SYMBOL SET

IBM 437

PC Set1, PC Ext US, PC Ext D/N, PC Set2 US,

PC Set2 D/N, Roman-8, ISO L1, PC-8,

PC-Dan/Nor, PC-850, Legal, ISO-2 IRV, ISO-4

UK, ISO-6 ASC, ISO-10 S/F, ISO-11 Swe,

ISO-14 JASC, ISO-15 Ita, ISO-16 Por, ISO-17

Spa, ISO-21 Ger, ISO-25 Fre, ISO-57 Chi,

ISO-60 Nor, ISO-61 Nor, ISO-69 Fre, ISO-84

Por, ISO-86 Spa, Ger man, Spanish, ISO Dutch,

Roman Ext, ISO Swedish1, ISO Swedish2, ISO

Swedish3, UN Math, UN Int’l, UN US, PS Math,

PS Text, Math-8, Pi Font, MS Publish, Win 3.0,

DeskTop, Win 3.1 L1, MC Text, PC-852, Win 3.1

L5, Win 3.1 L2, CWI Hung, PC-857 TK, ISO L2,

ISO L5, PC-8 TK, Kamenicky, Hebrew NC,

Hebrew OC, Plska Mazvia, ISO L6, Win 3.1

Heb, Win 3.1 Cyr, PC-866, Win 3.1 Grk,

PC-869, PC-855, Greek-437, Greek-437 Cy,

Greek-928, Serbo Croat2, Ukranian, Bulgarian,

PC-1004, Win Baltic, PC-775, Serbo Croat1

, IBM 850, IBM 860, IBM 863, IBM 865,

Notes: Selects special character set to be used.

LETTER O STYLE

DISABLE

ENABLE

Notes: Specifies the style of the letter O.

ZERO CHARACTER

NORMAL

SLASHED

Notes: Sets whether or not the number 0 will

have a slash through it to differentiate

it from the capital letter O.

LINE PITCH

6 LPI

8 LPI

Notes: Sets the number of lines per inch.

WHITE PAGE SKIP

OFF

ON

Notes: Sets whether blank pages are “printed.”

CR FUNCTION

CR

CR+LF

Notes: Sets what happens when CR command

is received. CR + LF produces a line

feed after the carriage return.

LF FUNCTION

LF

LF+CR

Notes: IBM emulation only.

Sets what happens when a LF command is received. LF+CR produces a

carriage return in addition to the line

feed.

LINE LENGTH

80 COLUMN

136 COLUMN

Notes: Specifies the number of characters in

one line.

FORM LENGTH

11 INCH (LETTER)

11.7 INCH (A4)

Notes: Specifies length of paper.

E–20 Chapter 3: The Printer Menus

Page 29

PAGE LAYOUT1 (continued)

Using the Level-2 Menu

Level-2 Menu Settings

TOF POSITION

0.0 INCH

Range 0.0 to 1.0 INCH

Notes: Sets Top of Form in 0.1-inch incre-

ments. This determines the print start

position relative to the top of the paper.

LEFT MARGIN

0.0 INCH

Range 0.0 to 1.0 INCH

Notes: Shifts the left margin further to the

right.

The Level-2 menu includes selections that are

rarely changed once they are set. To access the

Level-2 menu:

1. Press ON-LINE to place the printer off-line.

2. Press and hold MENU 1/Menu 2 until you see

PRINT MODE on the display. Once you are in

the menu, press MENU 1/Menu 2 repeatedly

to advance through the Menu categories.

3. Press ENTER to select a category.

The current default setting displays.

©

4. Press

/Reset repeatedly until you see the

selection you want.

5. Press ENTER to set a selection as the default.

An asterisk (*) will appear to indicate the new

default setting.

Note: Some categories include a number of

items. In such categories, after you press

ENTER in step 3, press MENU 1/Menu 2

to advance to the next selection before

proceeding to step 4.

Summary of Level-2 Categories:

• PRINT MODE

• MEMORY USAGE

• AUTO OPERATION

• DARKNESS CONTROL

• POWER SAVING

• LOW TONER

• TONER SAVING

• CLEARABLE WARNINGS

• ERROR REPORT

• PARALLEL I/F

• RS232C SERIAL

• LANGUAGE

Level-1 Menu Categories (e.g., PRINT MODE),

Items (e.g., RESOLUTION) and Selections (e.g.,

600x1200 DPI, 300 DPI) are summarized below:

default selections are in italic (e.g.,

PRINT MODE

RESOLUTION

600 DPI

600x1200 DPI

300 DPI

Notes: Select print density in dots per inch.

When a print job is sent at a resolution

which is different from this menu

setting, it will automatically be

converted and printed at the value

selected in the print job.

MEMORY USAGE

FONT PROTECTION

AUTO

OFF

400 KB

Notes: HP PCL 6 mode: Sets the font cache

size. If you change settings, the printer

memory will be reconfigured and all

downloaded fonts and PCL macros

will be lost.

PostScript mode: Fixed at automatic:

other settings not implemented at this

time.

MEMORY FREE AREA

####KB/ReadOnly

Notes: Displays memory area available for

downloading fonts (cannot be changed

through the menu).

600 DPI

).

Chapter 3: The Printer Menus E–21

Page 30

Level-2 Menu Settings (continued)

AUTO OPERATION (continued)

LOW T ONER

AUTO OPERATION

AUTO CONTINUE

OFF

ON

Notes: HP PCL 6 mode: controls what

happens when a memory overflow/

print overrun situation occurs. OFF =

printer will remain off-line until you

press the /Recover button. ON =

printer will return to the on-line state

automatically 15 seconds after it goes

off-line.

PostScript mode: this setting is

ignored. When a memory overflow/

print overrun situation occurs, the

ATTENTION light will come on until

the print process is completed. It will

then automatically go out and the

printer will return to the on-line state.

WAIT TIMEOUT

OFF

Range 5 to 300 SEC

Notes: Sets the length of time the printer waits

for additional data to be received.

HP PCL 6 mode: If the amount of time

selected passes before the printer

receives additional data, the printer

will print any data it has in the buffer

and reset.

PostScript mode: If the amount of time

selected passes before the printer

receives additional data, the printer

will cancel the print job immediately

and reset without any further printing.

MANUAL TIMEOUT

60 SECONDS

30 SECONDS

OFF

Notes: PostScript mode only. Sets the amount

of time the printer will wait for paper

to be loaded in the Manual Feeder

before cancelling the print job.

DARKNESS CONTROL

DARKNESS

0

+1

+2

–2

–1

Notes: Set print density (darkness). Negative

values lighten print; positive values

darken print.

POWER SAVING

0 SEC

8 MIN

DISABLE

Notes: 0 SEC = Reduces power consumption.

Immediately after printer stops

receiving data, fuser heating element

shuts off; 30 seconds later fan shuts

off. When printer receives data, fuser

warms up before printing begins.

8 MIN. = Reduces power consumption.

8 minutes after printer stops receiving

data, fuser heating element shuts off;

30 seconds later fan shuts off. When

printer receives data, fuser warms up

before printing begins.

DISABLE = Fuser and fan are always

on, printer is ready to print at all times.

ON

OFF

Notes: ON = When low toner is detected,

TONER LOW displays, indicating that

toner cartridge should be replaced

soon: at this point 100 more sheets will

print before the TONER EMPTY

message displays.

OFF = When low toner is detected,

TONER EMPTY displays, indicating

that the toner cartridge needs replacement. You must replace the toner

cartridge immediately, or open and

close the cover to remove the message,

which will then reappear after every 20

pages are printed.

TONER SAVING

DISABLE

MEDIUM

LIGHT

Notes: Select medium or light to reduce the

amount of toner used. This will result

in lighter printing to conserve toner

and is recommended only for proofs

and draft print jobs.

E–22 Chapter 3: The Printer Menus

Page 31

CLEARABLE WRNINGS

PARALLEL I/F

RS232C SERIAL (continued)

ON

JOB

Notes: Sets the disposition of error messages

which can be cleared by pressing the

©

/Reset button.

HP PCL 6 mode: ON = Message

displays until you press ©/Reset to

clear the display. OFF = Message will

automatically clear when next print job

is received, whether or not you have

pressed the ©/Reset button.

PostScript mode: Invalid. Error

message will automatically be cleared

from display as soon as the print job

ends.

ERROR REPORT

OFF

ON

Notes: HP PCL 6 mode: Invalid.

PostScript mode: Change to ON if you

wish to set the printer to print the error

contents and the operand stack

condition during a PostScript error.

PARALLEL SPEED

HIGH

MEDIUM

Notes: HIGH = Data transfer speed maxi-

mized. MEDIUM = Select if data

transmission problems occur, or with

earlier computers.

BI-DIRECTION

ENABLE

DISABLE

Notes: ENABLE = Select Bi-directional

parallel communication (Compatible,

Nibble, ECP).

DISABLE = Bi-directional communications are NOT supported.

I-PRIME

OFF

ON

Notes: Applicable only for IBM and Epson

emulations. Sets whether or not the

I-Prime signal is ignored (OFF =

ignored).

RS232C SERIAL

FLOW CONTROL

DTR HI POLARITY

DTR LO POLARITY

XON/XOFF

ROBUST XON

Note: Sets the type of serial communication

protocol used.

BAUD RATE

300 BAUD

600 BAUD

1200 BAUD

2400 BAUD

4800 BAUD

9600 BAUD

19200 BAUD

Note: Sets the communication speed in bits

per second.

DATA BITS

8 BITS

7 BITS

Note: Sets the number of data bits used in

serial interface communication.

PARITY

NONE

EVEN

ODD

Note: Sets the serial interface parity.

MIN. BUSY

200 mSECONDS

2 SECOND

Note: Sets the length of the busy signal.

LANGUAGE

LANGUAGE

ENGLISH

DEUTSCH

FRANCAIS

ITALIANO

CASTELLANO

SVENSKA

NORSK

DANSK

NEDERLANDS

TÜRKÇE

PORTUGUES

POLSKI

Note: Sets the display language

Chapter 3: The Printer Menus E–23

Page 32

The User Maintenance Menu

The User Maintenance Menu includes printer

maintenance and operating functions. Functions

are described below.

To enter the Maintenance Menu:

1. Turn off the printer.

2. Press and hold MENU 1/Menu 2 while

turning the printer on, until

displays.

3. Press MENU 1/Menu 2 repeatedly to advance

to the category you want.

4. Press ENTER to engage a category function,

or press © to see other selections, then press

ENTER to engage the selection you want.

5. Press ON-LINE (except for HEX DUMP) to

invoke the function.

Summary of Maintenance Menu Categories:

• MENU RESET

• HEX DUMP

• DRUM CNT RESET

• REC BUF

• OP MENU

• X ADJUST

• Y ADJUST

• DUP ADJUST

• 2ND TRAY

• 3RD TRAY

• FRONT

• PLACE PG

• SETTING

• CLN CYCL

USER MNT

Maintenance Menu Settings

MENU RESET

Note: Resets the Level-1 menu to factory

defaults.

HEX DUMP

Notes: Prints a hex dump of received data for

diagnostics. If less than a page of data

is received, you must press the FORM

FEED/Print Demo button to print the

page.

To exit hex dump mode, turn off the

printer.

DRUM CNT RESET

Note: Use this to reset the drum counter after

replacing, and only after replacing, the

image drum cartridge.

RECEIVE BUFFER

AUTO

8KB

20KB

50KB

100KB

1MB

Notes: Sets the size of the receive buffer. If

you set a large value, the printing

speed will be faster, but memory

overflows will occur more frequently.

When this value is changed, all

downloaded fonts, macros, and I/O

data are lost.

OP MENU

ENABLE

DISABLE

Notes: DISABLE = Disables all control panel

buttons except ON-LINE. Use this

feature to prevent changing menu

items you have personally selected.

ENABLE = All control panel buttons

are active.

X ADJUST

0mm (

Range +2.00 to –2.00 mm, in 0.25 mm

intervals)

Notes: Adjust horizontal print position in 0.25

mm increments. Plus (+) indicates

right movement, minus (–) indicates

left movement.

Y ADJUST

0mm (

Range +2.00 to –2.00 mm, in 0.25 mm

intervals)

Notes: Adjust vertical print position in 0.25

mm increments. Plus (+) indicates

downward movement, minus (–)

indicates upward movement.

In PostScript mode, any negative

values selected will be ignored.

E–24 Chapter 3: The Printer Menus

Page 33

DUP ADJ

0mm (

Range +2.00 to –2.00 mm, in 0.25 mm

intervals)

Notes: For the OKIPAGE 20, this setting only

applies when the optional Duplex

Feeder is installed.

Adjust vertical print position in 0.25

mm increments. Plus (+) indicates

downward movement, minus (–)

indicates upward movement.

In PostScript mode, any negative

values selected will be ignored.

2ND TRA Y

5 (

Range 1 to 16)

Notes: Applies only when the optional Paper

Expansion Tray is installed. Sets the

priority of the optional tray in the HP

PCL 6 emulation.

3RD TRA Y

9 (

Range 1 to 16)

Notes: Applies only when two optional Paper

Expansion Trays are installed. Sets the

priority of the second optional tray in

the HP PCL 6 emulation.

FRONT

PLACE PG

CENTER

LEFT

Notes: Sets placement of printed image on the

page.

SETTING

0 (

Range –1 to +1 in increments of 1)

Notes: Adjust to improve print quality:

–2 Rough/thick papers and/or low

temperature/humidity

–1

0 Normal media/environmental

conditions

+1

+2 Rough papers and/or high tem-

perature/humidity

CLN CYCL

NORMAL

MIDDLE

HIGH

Notes: Sets the frequency of the page cleaning

sequence:

NORMAL = every 20 pages

MIDDLE = every 10 pages

HIGH = every 3 pages.

4 (

Range 1 to 16)

Notes: Sets the priority of the Manual Feeder

in the in the HP PCL 6 emulation.

Chapter 3: The Printer Menus E–25

Page 34

Page 35

Chapter 4: The Front Feeder

Use the Front Feeder to print on special

media without having to change the paper

you have loaded in the tray(s). You can

print up to 100 pieces of media or you can

use the Front Feeder as a manual feed unit

to print individual pieces of media

“on-the-fly.”

For media other than standard paper, you

must use the rear paper exit. This eliminates curling, and for labels, it

eliminates peeling.

You can use the Front Feeder to print on the following media:

• Standard weight paper that is different from the paper loaded in the

paper tray: e.g., letterhead, different size

– Up to 100 sheets

– 16 to 28-lb.

– Letter, 13" & 14" Legal, Executive, A4, A5, B5, C5

(minimum 3.4" x 2.8"; maximum 8.5" x 14")

– Use either top or rear paper exit path

• Envelopes

– Up to 10 envelopes

– 16 to 28-lb.

– Com 10, Com 9, Monarch, DL, C4, C5

– Use envelopes that have seams that run down the sides and squared-off

flaps: envelopes with v-type flap are not recommended.

– Use envelopes with a smooth, even surface that are designed for laser

printers: no metal clasps, snaps, windows, or self-adhesive flaps

– Use rear paper exit only

• Labels

Important! Carrier sheet and label adhesive must withstand the

fusing process heat of 392° F (200°C) for 1 second. Label

adhesive must not be exposed; if it is, it will cause

jamming in the printer.

– Up to 100 sheets

– Letter or A4

– Use label sheets designed for laser printers

– Labels must cover the entire carrier sheet.

– Use rear paper exit only

• Transparencies (up to 100 sheets)

Important! Transparencies must withstand the fusing process heat of

392° F (200°C) for 1 second without wrinkling or

gumming up.

– Letter or A4

– Use transparencies designed for laser printers

– Use rear paper exit only

• Heavy weight paper such as index or card stock

– Up to 100 sheets

– Up to 36-lb.

– Letter, 13" & 14" Le gal, Executive, A4, A5, B5, C5 (minimum 3.4” x

2.8”; maximum 14”)

– Use rear paper exit only

English–27

Page 36

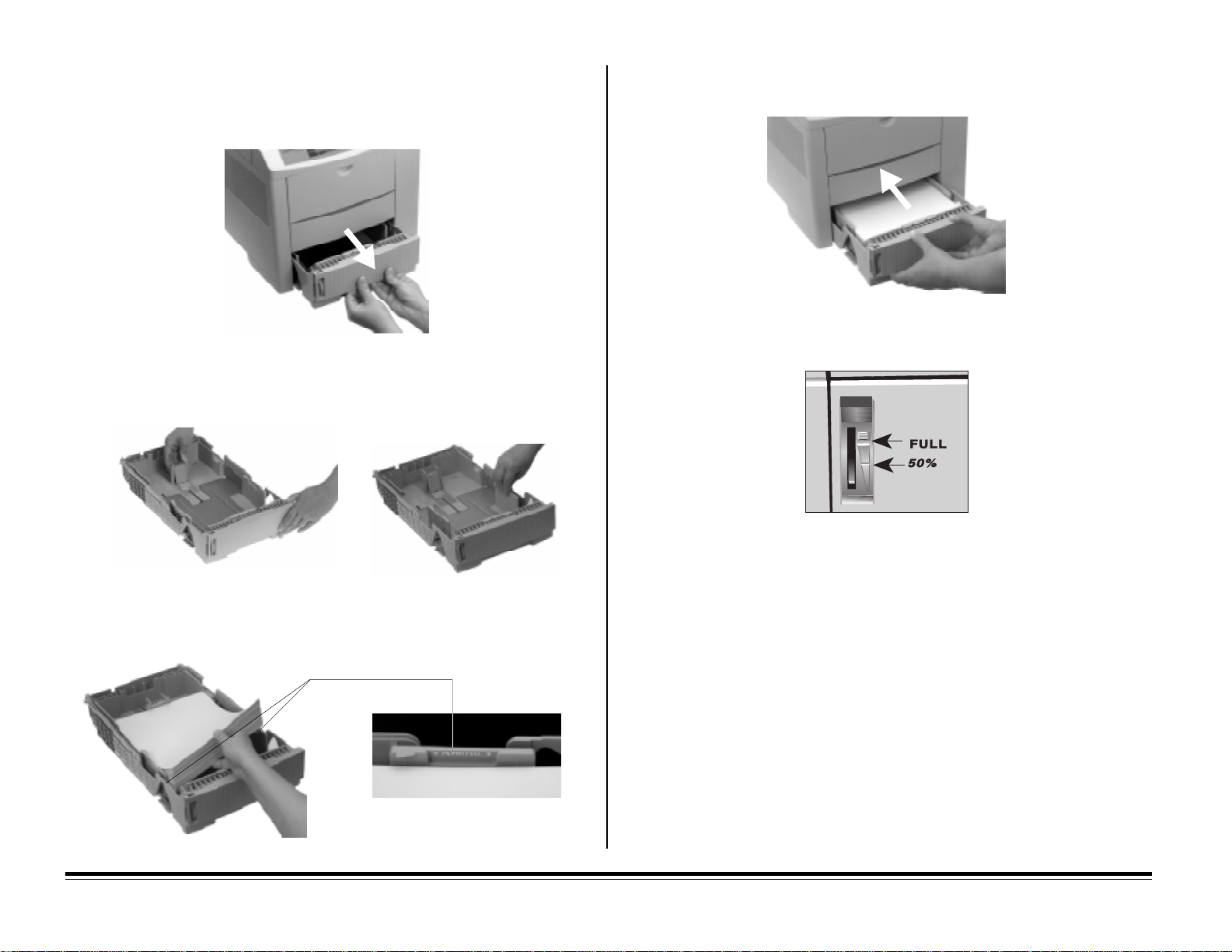

Using the Front Feeder to Print Multiple Pieces

of Media

To set up the printer for multiple-piece print jobs using the Front Feeder:

1. In your software program:

a. Enter the printer setup menu.

b. Select Front Feeder.

c. Select the media type, size and orientation.

2. Lower the printer’s Front Feeder.

3. Flip out the tray, then pivot out the extender.

e. Press MENU 1/Menu 2 (display reads

f. Press

g. Press ON LINE to return the printer to on-line status.

Note: When you are done printing using the Front Feeder, reenter the

5. Open the rear paper exit path (not required for standard weight paper).

6. Adjust the Front Feeder paper width guides for the media you will be

using and load the print media.

©

/Reset until the display reads FRONT TRA Y, then press ENTER

to engage the setting (an Asterisk will appear next to FRONT TRA Y).

Level-1 menu and change the PAPER FEED setting back to its

former setting (normally TRAY 1).

PAPER FEED).

4. Enter the Level-1 menu and make changes:

a. Press the ON LINE button (printer goes off line).

b. Press MENU 1/Menu 2 until TRAY SELECT displays.

c. Press ENTER.

d. Make sure that MANUAL FEED is set to OFF (the factory default),

then press ENTER.

Note: Insert letterhead paper face-up, with the top edge of the paper

7. Send the print job.

Note: The software application will override the printer menu settings.

E–28 Chapter 4: The Front Feeder

nosed into the printer.

Page 37

The Front Feeder: Printing Individual Pieces

(Manual Feed)

You can open up the Front Feeder and use it as a manual feeder to print an

individual piece of standard paper, an envelope, or specialty print media,

without having to change any of the menu settings.

Manual Feed: Standard P aper

Setting up Manual Feed for Standard Weight Paper

1. In your software program:

a. Enter the printer setup menu.

b. Select Manual Feed.

c. Select the paper size and orientation.

2. Lower the printer’s Manual Feeder.

4. Adjust the paper width guides.

5. Load a sheet of paper.

3. Flip out the tray, then pivot out the extender.

Note: Insert letterhead paper face-up, top edge of paper in first.

6. Send the print command from your software.

7. When prompted to, press the FORM FEED button on the printer control

panel.

The page prints.

Chapter 4: The Front Feeder E–29

Page 38

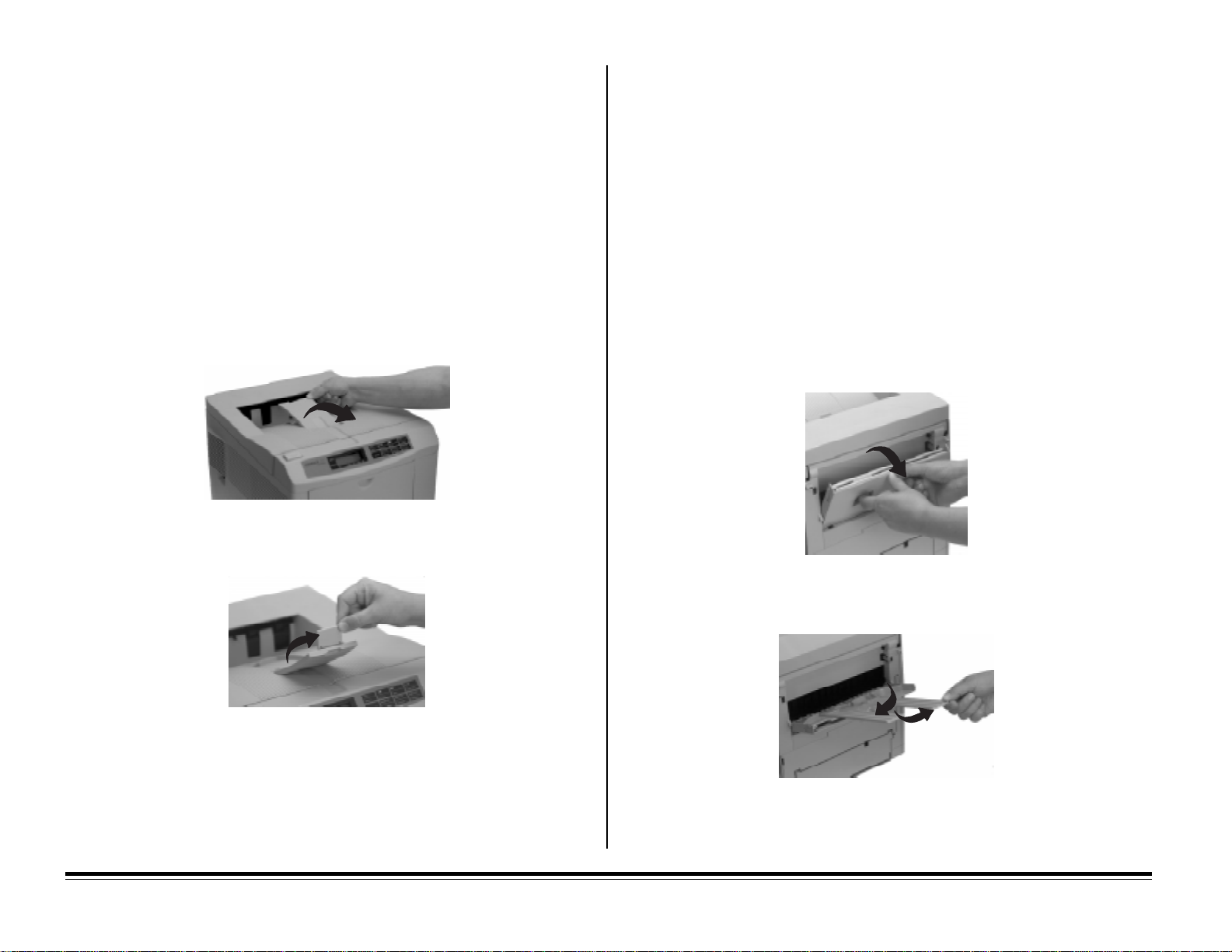

Manual Feed: Envelopes

Important!

• Use rear paper exit to avoid curling

• Do not use v-flap type envelopes (see page 27)

Setting up to Print an Envelope

1. In your software program:

a. Enter the printer setup menu.

b. Select Manual Feed.

c. Select the envelope size.

d. Select landscape orientation.

2. Lower the rear paper exit tray and pull out the rear exit extender.

4. Flip out the manual feed tray, then pivot out the extender.

5. Adjust the paper width guides.

3. Lower the Front Feeder.

6. Insert the envelope with return address on lower left side and flap underneath.

Return Address

7. Send the print command from your software.

8. When prompted to, press the FORM FEED button on the printer control

panel.

The printed envelope will exit at the rear.

E–30 Chapter 4: The Front Feeder

Page 39

Manual Feed: Labels

Important! Sheet and label adhesive must withstand the fusing process

heat of 392°F (200°C) for 1 second.

Label adhesive must not be exposed; if it is, it will cause

jamming in the printer.

• Labels must cover the entire carrier sheet.

• Use rear paper exit to avoid peeling.

Setting up to Print Labels

1. In your software program:

a. Enter the printer setup menu.

b. Select Manual Feed.

c. Select the label sheet size.

2. Lower the rear paper exit tray and pull out the rear exit extender.

4. Flip out the tray, then pivot out the extender.

5. Adjust the paper width guides.

6. Insert the label sheet face up.

3. Lower the Front Feeder.

7. Send the print command from your software.

8. When prompted to, press the FORM FEED button on the printer control

panel.

The printed label sheet will exit at the rear.

Chapter 4: The Front Feeder E–31

Page 40

Manual Feed: Transparencies

Important! Transparency must withstand the fusing process heat of

392°F (200°C) for 1 second without wrinkling or gumming

up.

• Use transparencies designed for laser printers.

• Use rear paper exit to avoid curling.

Setting up to Print a Transparency

1. In your software program:

a. Enter the printer setup menu.

b. Select Manual Feed.

c. Select the transparency size.

2. Lower the rear paper exit tray and pull out the rear exit extender.