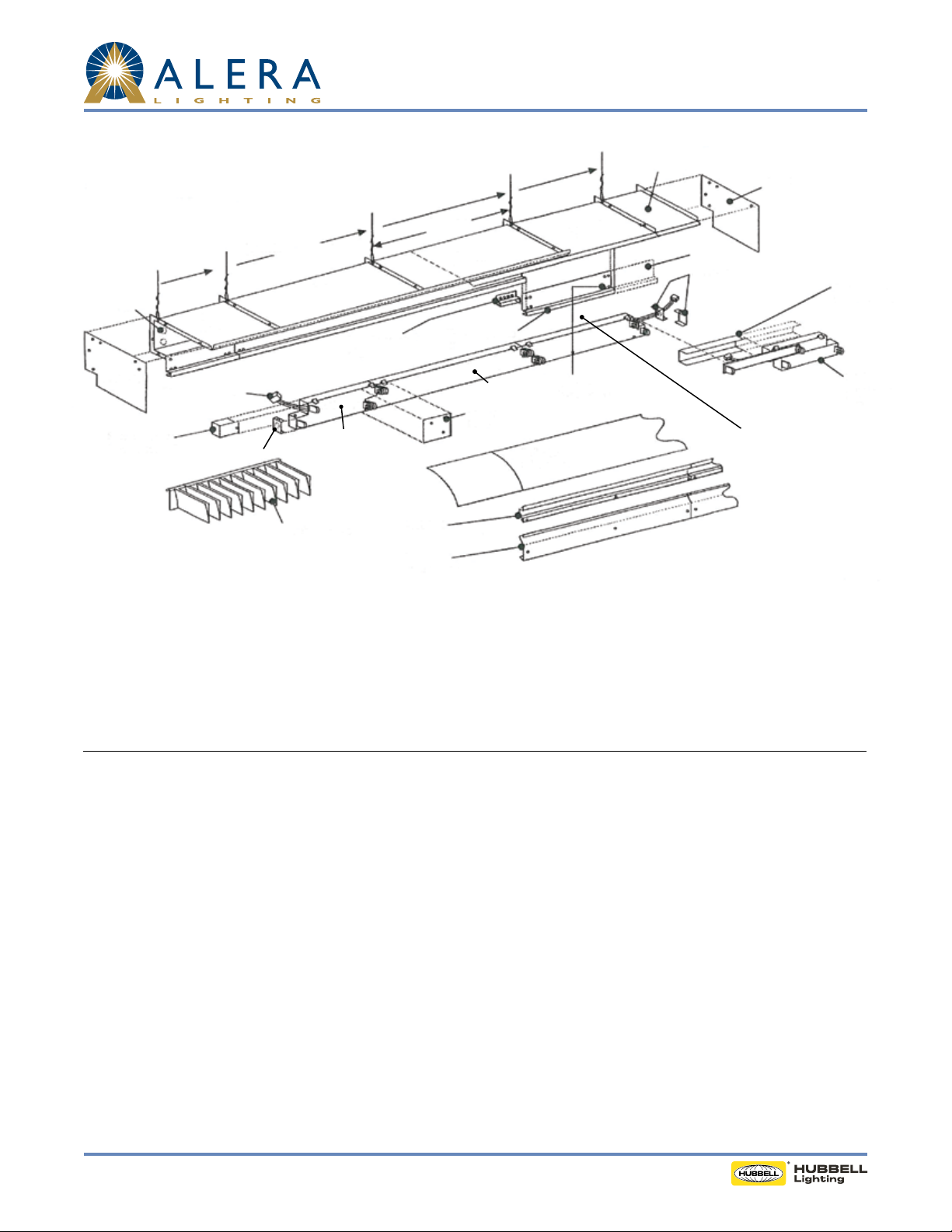

IN STA LL ATI ON DATA

AL 2-LIGHT

Technical Installation Data

Straight Run (View shown from wall side)

Work in this direction

Power Feed

Endplate

Service Cover

Power Access Only

21" Housing

Plug-In Connector

Electrical End

Assembly

33" Housing

AL3-2T8-EPU

3' Electrical Unit

Parabolic Louver

Sample: AL-2T8-P-R-LD-EPU-15.00 consists of:

Trim Connector/

Aligner

Wall Rail

Wall Plate

(where required)

Hanging

Wires

90" Housing

Trim Rail,

cut to length

AL4-2T8-EPU

4' Electrical Unit

Connector Plate

Adjustment Housing

Drill (4) holes

(template provided)

Reector

(where required)

Adjustment

Cut

Electrical End

Assembly

Endplate

AL3-2T8-EPU-ADJ

3' Adjustable Electrical Unit

AL4-2T8-EPU

4' Electrical Unit

Wireway cover

(cut to length)

(3) 92745 Wall Rails

(3) 92746 Wall Plates

(1) 97561-00 90" Housing

(1) 97561-03 33" Housing

(1) 97561-04 21" Housing

(1) 97559-00 ADJ Housing

(2) AL4 2T8 EPU

(1) AL3 2T8 EPU

(1) AL3 2T8 EPU ADJ

(4) 107945-04 Parabolic Louvers

(1) 116612 Electrical End Assembly

(2) 97416-00 End Row End Plates

(4) 114084 Reector

General

1. Fasteners not provided for wall rail or wall plates.

2. All fasteners provided for housing, endplates, connector/aligners and electrical unit connections.

3. Pieces requiring a eld cut: Wall Rail (steel), Wall Plate (steel), Trim Rail (aluminum), Wireway Cover (aluminum) and Diusers (plastic,

steel, or aluminum)

Housing (CAUTION: For hard ceiling applications, see page 4.)

1. Install wall rails (see next page), fasteners not provided.

2. Install wall plates if required. Fasteners not provided.

3. Starting from right end of row (facing wall) install endplate on rst (shortest) housing with screws and nuts provided.

4. Install rst (shortest) housing and work to left installing progressively longer housings.

5. Top lip of housings tip into upper hook form of wall rail. Secure housing rmly in place by attening wall rail bend tab over housing lip.

6. Connect hanging wires loosely.

7. Install each successive housing (shortest to longest) in similar manner, connecting housings with screws and nuts provided and then hang

loosely on hanging wires.

8. Also install trim connector/aligners at each joint as row installation progresses.

9. Install endplate on adjustable housing into last "xed length" housing and hang entire assembly as a unit. Adjustable housing is then pulled

out to required dimension.

10. Square-cut trim rail for adjustable housing to required length; drill four (4) each 7⁄32" holes using template provided and install with sheet

metal screws.

11. Level entire row on hanging wires.

Page 1 /4 Rev. 01/14/ 14 RECESSED / AL 2-LIGHT TID

© 2014 Ale ra Lighting, a division of Hubbell Lighting, Inc. S pecifications su bject to change without notice.

701 Millennium Blvd. Greenville, SC 29607 / Tel 864.678.1000 / Website www.aleralighting.com

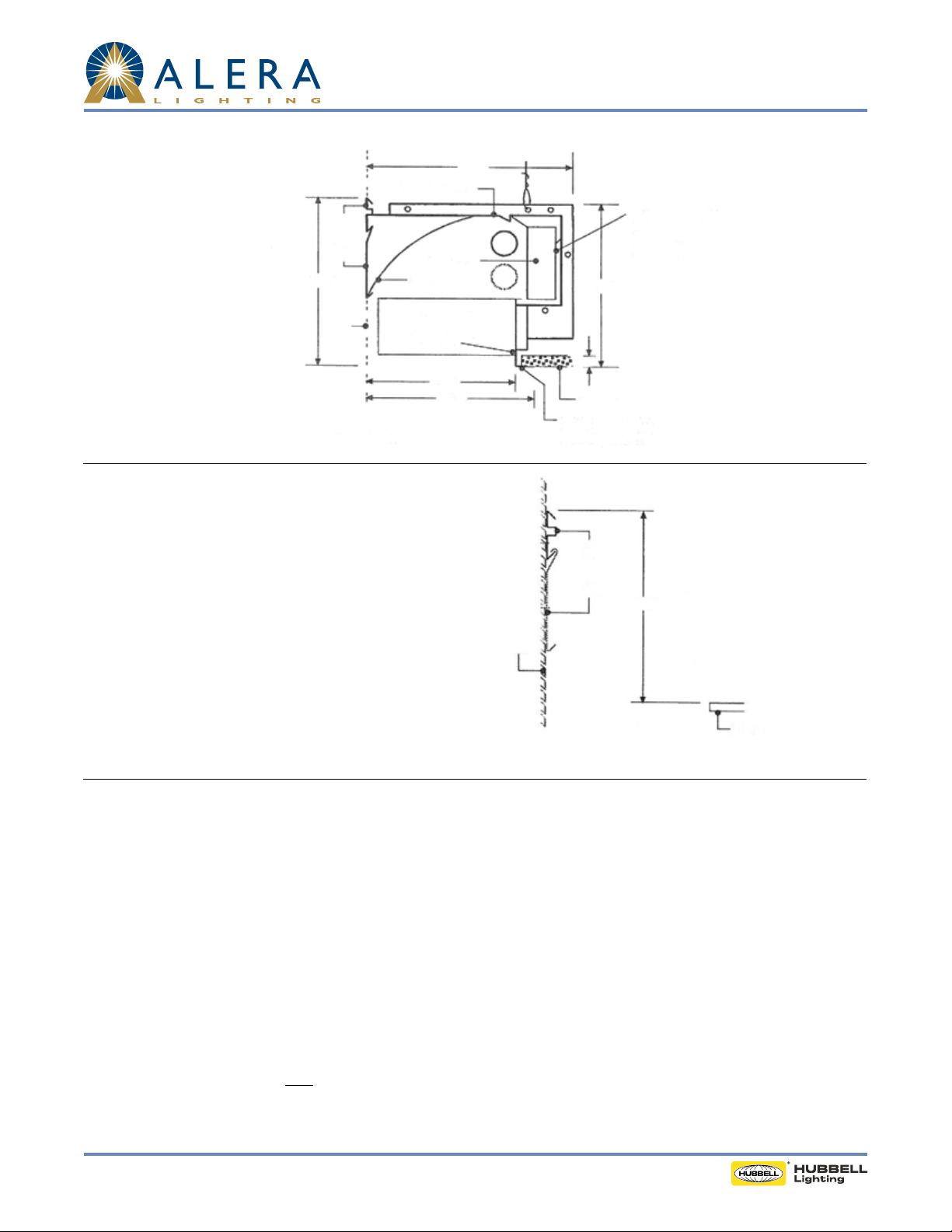

IN STA LL ATI ON DATA

Step One - Install Wall Rail

Wall

Rail

Wall

Plate

10⅜"

Wall

AL-2T8P-R-LD

"AL" Housing (Chassis)

Electrical Unit

Reector

Parabolic Louver

Non-supporting

xture trim

8½"

15

⁄32"

9

AL 2-LIGHT

Technical Installation Data

12"

Access to ceiling for wiring and

J-box inspection must be cut in

housing by installing contractor

10"

1"

Ceiling Tile (by others)

Install drywall into xture

trim and secure other end to

building structure

1. Mount wall rail to wall 10⅜" from nished ceiling

plane to top of wall rail. Fasteners not provided. Wall rail

Wall Rail

furnished in 90" sections.

2. Where applicable, hook wall plate over bottom lip of

wall rail and fasten to wall.

Wall Plate

10⅜"

3. Install AL components per instructions.

4. Important: To save steps and time:

A. Start at the right end of each row facing the wall and

Wall

work left and

B. Install smallest (lower wattage) housings and electrical

units rst and then work up to the largest units.

Ceiling Plate

Electrical

1. Starting from right end of row (facing wall), snap in place electrical unit, starting with the shortest unit and progressing to the longest unit.

2. Each unit has polarized plug-in connector. After wire connections, secure units together with connector plate that slips over lampholders.

Screws are provided.

3. Power feed is at end of row. Clip o plug to make connections. Install service cover and electrical end assembly.

4. Determine length for snap-on wireway cover for adjustable unit. Cut wireway cover, plug in wiring connection and snap adjustable unit

into place.

5. Install clip to hold Adjustable Unit in place.

6. Install lamps.

7. Install lamp shield.

8. Where required, snap in reectors. Reectors overlap at adjustable unit.

Diusers

1. Install plastic shielding bae or parabolic louver. Cut last piece to t. Note: On parabolic louver, it may be necessary to cut the last

two (2) louvers to maintain an even louver spacing appearance.

2. Plastic or bae lays in place: parabolic louver cantilevers o lip trim rail.

3. Important: Cut nal plastic piece after sucient lamp or building warm-up to allow for plastic expansion.

Page 2 /4 Rev. 01/14/14 RECESSED / AL 2-LIGHT TID

© 2014 Ale ra Lighting, a division of Hubbell Lighting, Inc. S pecifications su bject to change without notice.

701 Millennium Blvd. Greenville, SC 29607 / Tel 864.678.1000 / Website www.aleralighting.com

IN STA LL ATI ON DATA

Pattern with Corners (View shown from wall side)

Work in this direction

Adjustable

Housing

Adjustable

Electrical Unit

Inside Corner Reector

Inside Corner Louver

Power Feed

Inside Corner

Housing

Inside Corner Flex

Trim Connector/

Aligner

Access Only

21" Housing

Electrical

Unit

90" Housing

Electrical Unit

Inside Corner ReectorService Cover Power

Adjustable

Housing

Trim Rail, Cut

to length

AL 2-LIGHT

Technical Installation Data

Outside Corner

Housing

Electrical

Adjustable Electrical Unit

Unit

21" Housing

Outside Corner Flex

Outside Corner Reectors (2)

Outside Corner Louver

Note: Wall Rail and Wall Plate not shown (see below)

Special Notes for Patterns with Corners

1. Housings: When installing patterns with corners, install corner housings rst after the installation of all wall rails (and wall plates). Then

proceed with each straight run per above.

2. Electrical: (a) AL row lengths are pre-calculated to provide ample light in corners. Be sure electrical units extend fully into corners before

eld cutting. (b) For corners requiring a continuous circuit around corner, a pre-cut ex conduit connector kit is provided

3. Diusers: Plastic for corners has pre-cut 45 angles. Install angled corner pieces rst and then straight-cut nal remaining piece to t.

Page 3 /4 Rev. 01/14/1 4 RECESSED / AL 2-LIGHT TID

© 2014 Ale ra Lighting, a division of Hubbell Lighting, Inc. S pecifications su bject to change without notice.

701 Millennium Blvd. Greenville, SC 29607 / Tel 864.678.1000 / Website www.aleralighting.com

Wall Rail

12"

"AL" Housing (Chassis)

AL 2-LIGHT

Technical Installation Data

Access to ceiling for

wiring and J-Box

inspection must be cut

in housing by installing

contractor

10 ⅜"

Wall Plate

Reector

Wall Line

Electrical Unit

Parabolic Louver

Non-supporting

xture trim

8 ½"

9 15⁄32"

10"

Ceiling Construction (by others)

Install drywall into xture

trim and secure other end to

building structure

HARD CEILING APPLICATIONS

The AL system is designed primarily for suspended acoustical ceilings. Fixture trim will not support drywall. Additional drywall support must be

provided adjacent to xture by ceiling installer.

The sketch to the right shows a method of installing the AL in a drywall ceiling. Note the ceiling must be installed after the AL housings. Also,

the access holes to the plenum through the xture must be cut by the contractor.

Page 4 /4 Rev. 01/14/ 14 RECESSED / AL 2-LIGHT TID

© 2014 Ale ra Lighting, a division of Hubbell Lighting, Inc. S pecifications su bject to change without notice.

701 Millennium Blvd. Greenville, SC 29607 / Tel 864.678.1000 / Website www.aleralighting.com

Loading...

Loading...