Alemite 8424 Service Manual

Service Guide

Flow Meter

Description

General

This Electronic digital meter features a turbine

measurement system, designed for precise

measuring of low viscosity fluids. It is divided into

two using macrogroups:

1. With body made of inconductive plastic

material of light color, designed to be used with

water/urea solution.

2. With body made of conductive plastic material

of dark color (assessed resistance: 50 ohm),

designed to be used with DIESEL FUEL,

WATER and windscreen fluids.

The circuit board can be rotated with respect to

its housing, thus allowing easy display reading in

any position. The circuit board housing, easily

accessible, is enclosed by a plastic cover sealed

through a rubber guard acting as a gasket as well.

The whole unit can be easily removed by

unscrewing the 4 screws securing the circuit board

and the cover.(Fig.2)

Turbine Measurement System

8424

Figure 1 Flow Meter Model 8424

Figure 1 Flow Meter Model 8424Figure 1 Flow Meter Model 8424

Display

WARNING

When repositioning the circuit board, make sure

the battery contact cable is not placed above the

circular housing of the bulb.

The turbine is placed inside a hole through the

body of 8424, fitted with threaded inlet and outlet.

The body of 8424 is made of a plastic material that

allows several types of threads with relevant

combinations. 8424 has two rubber guards which

are designed to act as gaskets thus reducing the

number of its components.

The liquids compatible with 8424 must be at low

viscosity, namely: Diesel fuel, Water, Water/urea

solution, Kerosene, Windscreen, Petrol.

671005 and is not to be copied, used, or disclosed to others without express written permission. Revision (1-11)

This document contains confidential information that is the property of Alemite, LLC

Operating Modes

Figure 2 Flow Meter 8424 (Housing Rotated)

Alemite, LLC

167 Roweland Drive, Johnson City, Tennessee 37601

www.alemite.com

Copyright © 2011 by Alemite, LLC

SER 8424

SER 8424 Flow Meter

4

5

6

9

7

1

2

3

8

The user can choose between two different operating

modes:

1. Normal Mode: Mode with display of Partial and Total

dispensed quantities.

2. Flow Rate Mode: Mode with display of Flow Rate , as

well as Partial dispensed quantity.

The meter features a non-volatile memory for storing

the dispensing data, even in the event of a complete power

break for long periods. The measurement electronics and

the LCD display are fitted in the top part of the 8424 which

remains isolated from the fluid-bath measurement chamber

and sealed from the outside by means of a cover.

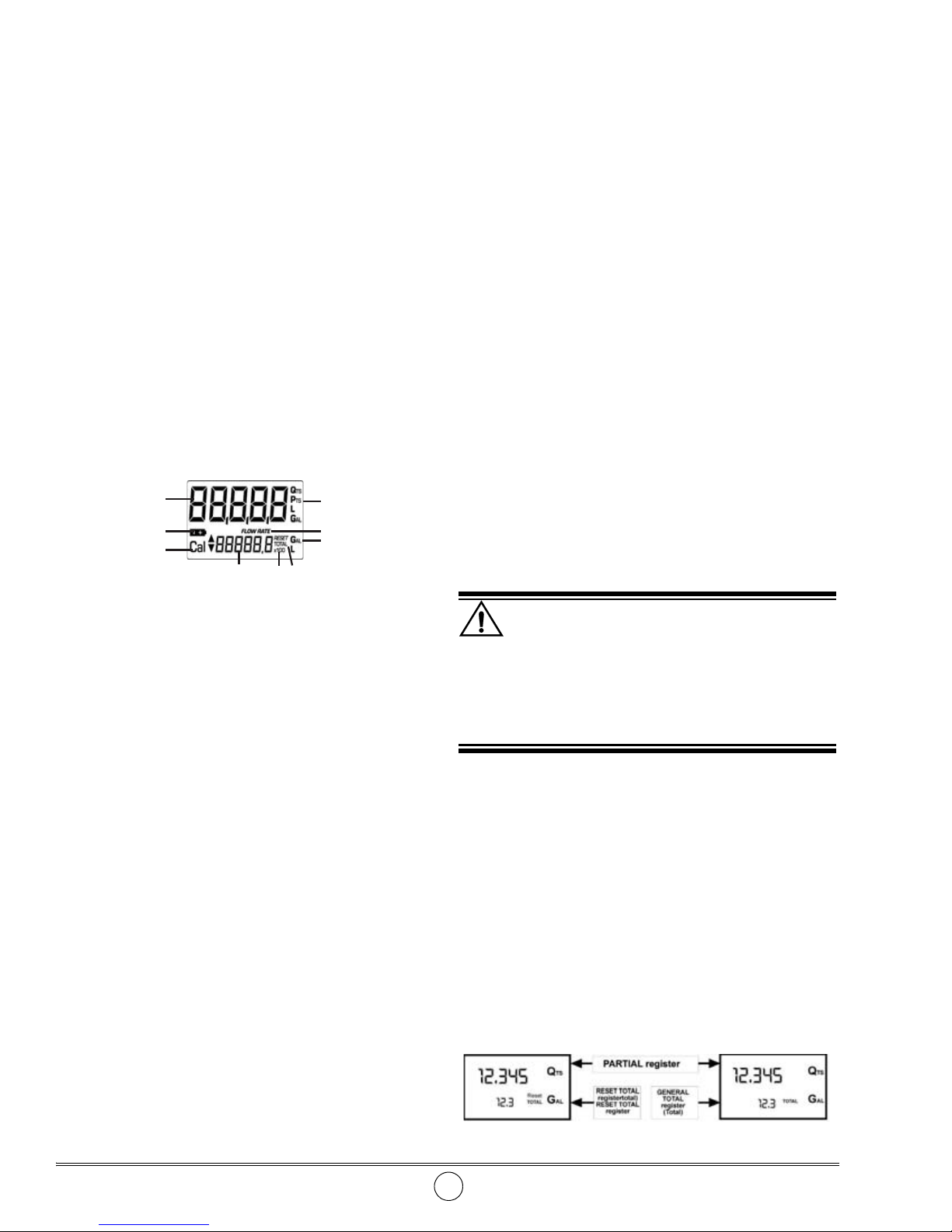

LCD Display

The “LCD” of the METER features two numerical

registers and various indications displayed to the user only

when the applicable function so requires.

1. For the reset key, resetting the partial register and

resettable total (reset total)

2. For the cal key, entering instrument calibration mode.

Used together, the two keys permit entering

configuration mode, useful for changing the units of

measurements and calibration factor.

Battery Housing

The 8424 is powered by two standard type 1.5 V

batteries (size AAA). The battery housing, easily

accessible, is closed by a metal cover sealed through a

rubber guard acting as a gasket. The whole unit can be

easily removed by unscrewing the 4 screws securing the

cover and the guard to the body.

Installation

8424 features a threaded, inline inlet and outlet (1” gas

or NPT male and female). It has been designed to be easily

installed in any position: fixed in-line or mobile on a

dispensing nozzle. In order to improve the life of the

turbine, it is recommended to fit a strainer before the meter

itself.

1. Partial register (5 digits with moving decimal FROM

0.1 to 99999) indicating the volume dispensed since the

reset button was last pressed;

2. Indication of battery charge;

3. Indication of calibration mode;

4. Totals register (6 digits with moving decimal point

FROM 0.1 to 999999), that can indicate two types of

Total: General Total that cannot be reset (TOTAL)

Resettable total (Reset TOTAL)

5. Indication of total multiplication factor (x10/x100)

6. Indication of type of total, (TOTAL/Reset TOTAL);

7. Indication of unit of measurement of Totals:

8. Indication of Flow Rate mode

9. Indication of unit of measurement of Partial:

User Buttons

The 8424 features two buttons (reset and cal) which

individually perform two main functions and, together,

other secondary functions. The main functions performed

are:

WARNING

At the female inlets, tighten the couplings at a

max. torque of 55N/m. At the female inlets, tighten

the couplings at a max. torque of 55N /m.

With The Gas-female Inlets, Do Not Use Conical

Threaded Couplings.

Daily Use

The only operations that need to be done for daily use

are partial and/or resettable total register resetting.

Occasionally the meter may need to be configured or

calibrated. To do so, please refer to the relevant sections.

Below are the two typical normal operation displays.

One display page shows the partial and reset total

registers. The other shows the partial and general total.

Switch over from resettable total to general total display is

automatic and tied to phases and times that are in factory

set and cannot be changed.

Revision (1-11) 2 Alemite, LLC

Flow Meter SER 8424

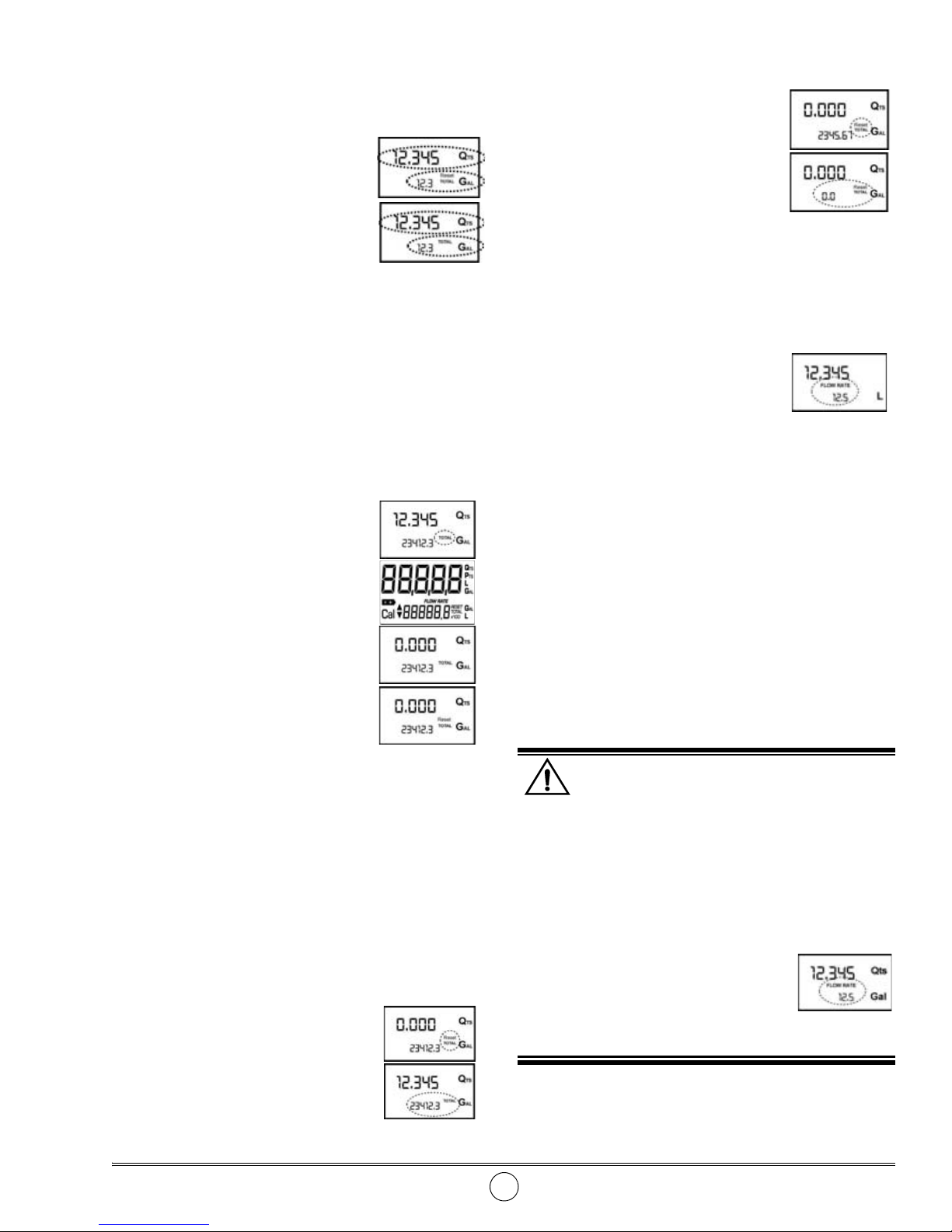

Dispensing in Normal Mode

Normal mode is the standard

dispensing. While the count is

made, the partial and resettable total

are displayed at the same time

(reset total).

Should one of the keys be

accidentally pressed during

dispensing, this will have no effect.

A few seconds after dispensing has ended, on the

lower register, the display switches from resettable

total to general total: the word reset above the word

total disappears, and the reset total is replaced by the

general total. This situation is called standby and

remains stable until the user operates the 8424 again.

Partial Reset

The partial register can be reset by

pressing the reset key when the meter

is in standby, meaning when the

display screen shows the word

“TOTAL”.

After pressing the reset key, during

reset, the display screen first of all

shows all the lit-up digits and then all

the digits that are not lit up.

At the end of the process, a display

page is first of all shown with the reset

partial and the reset total.

3. The meter starts to reset the partial

4. While the display page showing the

reset total is displayed Press the

reset key again for at least 1 second.

5. The display screen again shows all

the segments of the display

followed by all the switched-off segments and finally

shows the display page where the reset Reset Total is

shown.

Dispensing with Flow Rate Mode display

It is possible to dispense fluids,

displaying at the same time:

• The dispensed partial

• The Flow Rate in [Partial Unit/minute]

• As shown on the following display page:

Procedure for entering this mode:

• Wait for the Remote Display to go to Standby,

meaning the display screen shows Total only

• Quickly press the CAL key.

• Start dispensing

The flow rate is updated every 0.7 seconds.

Consequently, the display could be relatively unstable at

lower flow rates. The higher the flow rate, the more stable

the displayed value.

After a few moments, the reset total is replaced by the

non resettable Total.

Resetting the Reset Total

The reset total resetting operation can only be

performed after resetting the partial register. The reset

total can in fact be reset by pressing the reset key at length

while the display screen shows reset total as on the

following display page:

Schematically, the steps to be taken are:

1. W ait for the display to show normal

standby display page (with total

only displayed)

2. Press the reset key quickly

Alemite, LLC 3 Revision (1-11)

WARNING

The flow rate is measured with reference to the

unit of measurement of the Partial. For this reason,

in case the unit of measurement of the Partial

and Total being different, as in the example shown

below, it should be remembered that the indicated

flow rate relates to the unit of measurement of the

partial. In the example shown, the flow rate is

expressed in Qts/min. The word

“Gal” remaining alongside the flow

rate refers to the register of t he

Totals (Reset or NON Reset) which

are again displayed when exiting

from the flow rate reading mode.

To return to “Normal” mode, press the CAL key again.

Loading...

Loading...