Alemite 3679 Service Manual

Service Guide

Electronic Meter

Description

CAUTION

Do not operate this meter with an antifreeze and water mixture.

Meter will not register properly.

Meter model 3679 is designed to measure a variety of fluids that

include motor oils (SAE 5-50), gear oils (SAE 80-240), and automatictransmission fluid.

The meter is totally electronic except for the oval gear metering

mechanism. The electronic register is powered by two 1-1/2 Volt AAA

alkaline batteries.

The meter can be programmed to register in:

• pints, quarts, or gallons, and totalize in gallons

• liters and totalize in liters

NOTE: The meter is factory programmed to register in

quarts and totalize in gallons.

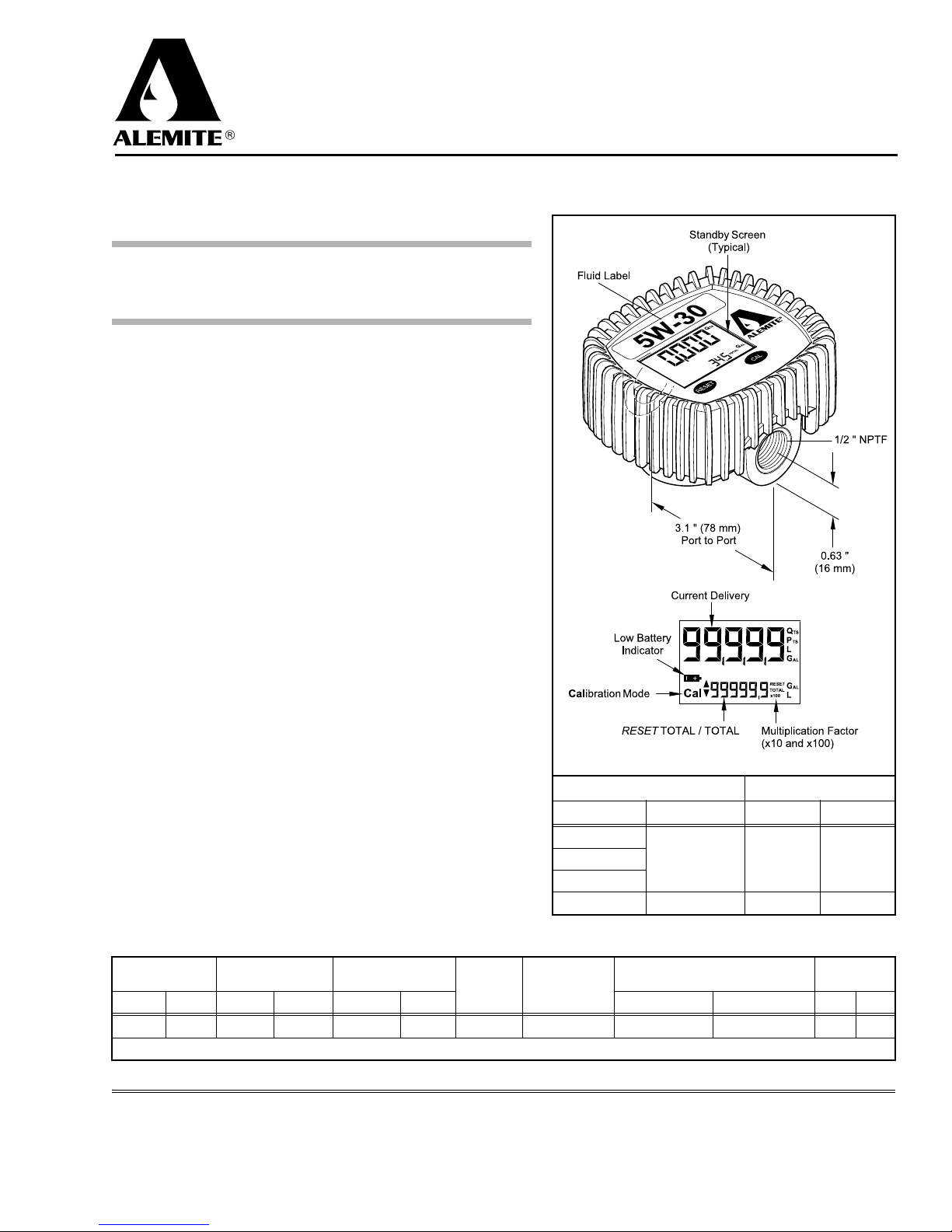

A liquid-crystal display shows the following amounts of fluid

dispensed by volume:

• Current delivery

• RESET TOTAL (momentary)

•TOTAL

All three amounts display with a floating decimal point.

• Current delivery (0.000 to 99999)

• RESET TOTAL and TOTAL (0.0 to 999999)

The meter’s non-volatile memory retains the unit of measure, totals,

and calibration factor during battery replacement.

3679

Operation

To zero the current delivery and RESET TOTAL the meter must be

in Standby. See Figure 1.

Press the Reset button to zero the current delivery.

When the RESET TOTAL is required to be reset:

1. Press the Reset button.

•The RESET TOTAL displays for 5 seconds.

2. Press and hold the Reset button while the RESET TOTAL displays.

•The RESET TOTAL is reset to zero.

The RESET TOTAL and TOTAL update automatically during

fluid delivery.

Max. Operating

Pressure

psi bar ° F ° C ° F ° C in. cm lbs kg

1000 70 -4 to 158 -20 to 70 23 to 122 -5 to 50 ± 1% 1% 3.7 x 4.2 x 2.4 9.4 x 10.7 x 6.1 0.83 0.38

* With SAE 10W Oil at 68° F (20° C)

670890

Storage

Temperature

This document contains confidential information that is the property of Alemite, LLC

and is not to be copied, used, or disclosed to others without express written permission.

Programmable Units of Measure Flow Rate in Units / Min.

Current Totalizer Min. Max.

pint

quart

gallon

liter liter 1 liter 30 liters

Figure 1 Electronic Meter Model 3679

Operating

Temperature

Ta ble 1 Electronic Meter Model 3679 Specifications

167 Roweland Drive, Johnson City, Tennessee 37601

Copyright © 2010 by Alemite, LLC

Accuracy* Repeatability*

Alemite, LLC

www.alemite.com

Dimensions (w/ Guard)

gallon

L x W x H

1/4 gallon 8 gallons

Weight

SER 3679

Revision (5-10)

SER 3679 Electronic Meter

Meter Programming

IMPORTANT: The meter must be in Standby to

begin any programming function. See Figure 1.

Change Unit of Measure

1. Press and hold the Cal and Reset buttons at the same time.

•The Unit screen appears.

2. Repeatedly press the Reset button.

• The screen scrolls through the available units of measure

(see Figure 1).

Once the desired units of measure appear:

3. Press and hold the Cal button.

• The chosen units of measure are stored in memory and

active.

• The meter cycles to Standby.

Calibration Factor Determination

To determine the meter’s calibration factor* in use:

1. Press and hold the Cal button.

• The calibration factor screen appears.

The word Fact (short for factory) indicates the calibration set

at the factory is in use (1.000). User indicates the Factory

calibration factor has been superseded and is in use.

If the meter indicates User but the Factory calibration factor

(1.000) is required:

2. Press the Reset button.

• The screen changes from the User calibration factor to the

Factory calibration factor.

3. Press the Cal button.

• The meter cycles to Standby.

•The Factory calibration factor (1.000) is active.

•The User calibration factor is deleted from memory.

* The calibration factor is a value that the meter uses to

calculate the amount of fluid dispensed.

User Calibration

Variables that cause a meter to require recalibration are:

• fluid viscosity

• fluid flow rate

• back-pressure

Field Calibration

This method of programming the meter requires dispensing a

known quantity of fluid.

1. Press and hold the Cal button.

• The calibration factor screen appears.

2. Press and hold the Reset button.

•The Field screen appears.

3. Dispense any amount of fluid greater than 5 quarts or liters

into an appropriate-sized graduated beaker.

• Dispense the fluid at the normal flow rate.

Should the field value match the dispensed value:

4. Press the Reset button.

• An upward arrow appears.

5. Press and hold the Reset button.

• The meter cycles to Standby.

The calibration factor remains the same.

If the field value does not match the actual amount:

6. Press the Reset button.

• An upward arrow appears.

This arrow enables the user to increase the field value.

7. Press the Reset button again to change the direction of the

arrow.

• A downward arrow appears.

This arrow enables the user to de crease the value .

With the proper arrow chosen:

8. Press the Cal button.

• The value changes one digit.

NOTE: Press and hold the Cal button to change

the value at a faster rate.

Once the required value displays:

9. Press and hold the Reset button.

•The User calibration factor is stored in memory and active.

• The meter cycles to Standby.

Direct Calibration

This method of calibration is useful to correct an inaccuracy

of a known percentage.

For example, if the calibration factor is set at 1.000 and the

meter registers more than the actual amount dispensed by 5%:

• the calibration factor should be decreased to 0.950

(1.000 x 0.95 = 0.950).

Conversely, if the meter registers less that the actual amount

dispensed by 5%:

• the calibration factor should be increased to 1.050

(1.000 x 1.05 = 1.050).

To program a calculated calibration factor into the meter:

1. Press and hold the Cal button.

• The calibration factor screen appears.

2. Press and hold the Reset button.

•The Field screen appears.

3. Press and hold the Reset button once again.

•The Direct screen appears with an upward arrow.

This arrow enables the user to increase the direct value.

4. Repeat steps 7 through 9 above.

Revision (5-10) 2 Alemite, LLC

Electronic Meter SER 3679

Installation

WARNING

Prior to installation, the following safety

precautions must be observed. Personal injury can

occur.

Do not exceed the pressure rating of any component

in the system.

Protect all fluid and air supply lines from puncture

or damage. Check all lines for weak or worn conditions prior to use.

Never point a control valve at any portion of your

body or another person. Accidental discharge of

pressure and/or material can result in personal

injury.

Read each step of the instructions carefully. Make

sure a proper understanding is achieved before proceeding.

CAUTION

Install a 40-micron or finer filter at the inlet side of

this meter. Jammed gears, damage to components,

or inaccurate readings can occur.

Maintenance

WARNING

Release all pressure within the system prior to per-

forming any maintenance procedure.

Repairs should only be performed by a qualified person

using original repair parts.

Read each step of the instructions carefully. Make sure a

proper understanding is achieved before proceeding.

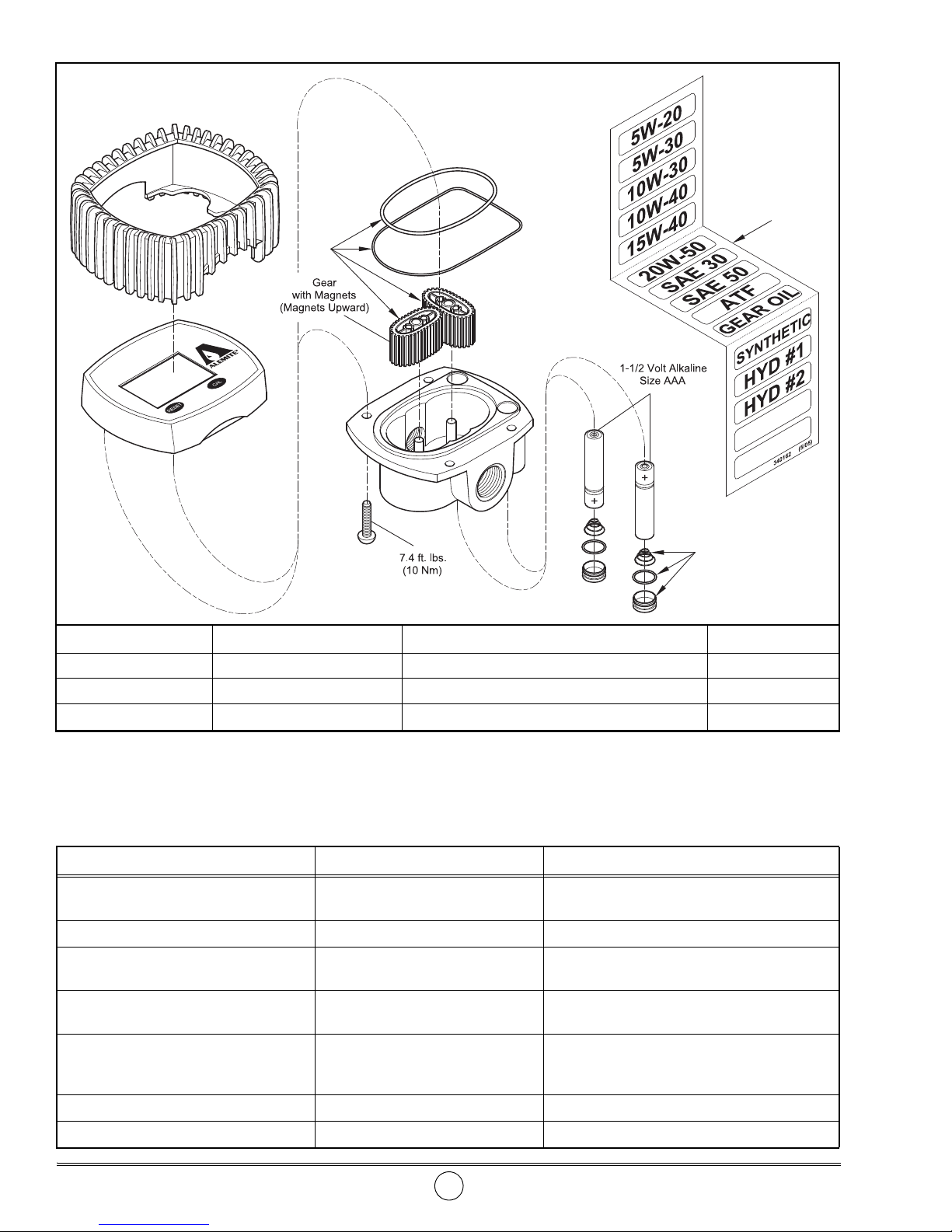

Battery Replacement

NOTE: All meter values remain in memory.

The batteries should be replaced once the battery icon appears on

the display. See Figure 1.

IMPORTANT: The meter will no longer register

should the battery icon begin to flash.

WARNING

Recycle or discard the used batteries properly. Do

not burn or puncture the batteries. Toxic materials may be

emitted which can cause personal injury.

Prior to meter installation, flush all contaminants by

pumping fluid through the system.

Apply thread sealant to all male pipe threads upon

installation.

CAUTION

Avoid touching the flat surfaces of the new batteries. Skin

oils can cause battery deterioration. Clean any suspect battery with alcohol prior to installation.

Install the new Batteries as indicated on the bottom of the meter.

All values remain the same including the Current delivery.

Metering Gear Replacement

IMPORTANT: Install the gear with the magnets (magnets upward) onto the left post of the body as shown

on Figure 2.

Install the additional gear perpendicular to the magnet gear. Rotate the gear assembly to ensure the gears

are properly positioned.

Alemite, LLC 3 Revision (5-10)

Changes Since Last Printing

Kit part number updated

SER 3679 Electronic Meter

1

2

3

Item No. Part No. Description Quantity

1 393772-9 Kit, Oval Gear 1

2 340162

3

393772-12 Kit, Battery Cap 2

Figure 2 Electronic Meter Model 3679 - Exploded View

Troubleshooting Chart

Meter Indications Possible Problems Solution

Battery icon appears solid or flashes on

display or LCD values are faded

Meter does not measure accurately Incorrect calibration factor Recalibrate the meter

Display blank Batterie s installed incorrectly Install the batteries as indicated on the bottom of

Reduced or zero flow 1. Gears jammed

Meter does not count and the flow rate

is normal

Err 1 flashing Damaged register Replace meter

Err 2 displays Temporary lapse in data calculation Wait until the register updates automatically

1. Weak batteries

2. Dirty contacts

2. Clogged system

1. Gears installed incorrectly

2. Register defective

Labels, Fluid 1

1. Replace batteries

2. Clean batteries and terminals

the meter

1. Overhaul metering gear cavity

2. Clean system filter

1. Install the magnet gear (magnets upward) onto

the left post of the body. See Figure 2.

2. Replace meter

Revision (5-10) 4 Alemite, LLC

Loading...

Loading...