IMPORTANT NOTE TO THE INSTALLER

Read these instructions before commencing installation.

Unvented cylinders are a controlled service as defined in the

latest edition of the building regulations and should only be

fitted by a competent person.

The relevant regulations are : England and Wales – Building Regulation G3 ,

Scotland – Technical Standard P3 , N Ireland – Building Re gulation P5

After installation the Benchmark log book must be

completed and left, with these instructions, with

the householder for future reference.

INSTALLATION INSTRUCTIONS FOR ALBION

ULTRASTEEL UNVENTED CYLINDERS. DIRECT,

INDIRECT, AND SOLAR MODELS.

Issue 1 June 2008

INTRODUCTION

The Ultrasteel Unvented cylinder is made from Duplex Stainless Steel for excellent corrosion

resistance. Ultrasteel has a strong rust-proofed steel case and is highly insulated with

environmentally friendly foam.

It is available in 6 capacities from 120 – 300 litres and in Direct, and Indirect versions.

Solar models are also available in 4 capacities from 180 - 300 litres, in Direct or Indirect

versions.

Ultrasteel is supplied complete with all the necessary safety and control devices needed

to connect to the cold water mains. All are pre-adjusted. High quality controls have

been selected to combine high flowrate performance with minimum pressure drop to

make Ultrasteel perform well in all areas, even those with poor water pressure. Ultrasteel is

WRAS approved to show compliance with Building Regulations G3+L

STORAGE PRIOR TO INSTALLATION

Ultrasteel should be stored in its original packaging in an upright position in an area free from excessive damp.

UNPACKING THE UNIT

ULTRASTEEL COMES COMPLETE WITH ALL

THE FITTINGS YOU NEED TO COMPLETE

THE INSTALLATION:

Expa nsion Ves sel

120 & 150 ltr units - 12 ltr ves sel

180, 210 & 250 ltr units - 19 ltr ves sel

300 ltr u nit - 24 ltr ves sel

Expa nsion Ves sel Hos e Wall Mounting Ki t for

Dual Th ermos tat High Flow Rate

Expa nsion Ves sel

Inlet Co ntrol Se t

15/22mm Tundish

Temperatu re and Pre ssure

Relief Va lve

Two Port Valve

Direc t Models (Electric )

• Inlet control set.

• Temp & Pressure relief valve.

• 15mm / 22mm Tundish.

• Expansion vessel.

• Wall mounting bracket.

• Expansion vessel hose.

• 2 x 3 kW Immersion heaters.

• Installation & Maintenance Instructions.

• Benchmark Logbook.

Direc t Solar Models (Elect ric )

• Inlet control set.

• Temp & Pressure relief valve.

• 15mm / 22m Tundish.

• Expansion vessel.

• Wall mounting bracket.

• Expansion vessel hose.

• 2 x Immersion heaters.

• 1 x Two port valve.

• 1 x Single High limit stat.

• Installation & Maintenance Instructions.

• Benchmark Logbook.

• 2 x Sensor pocket retaining bungs.

Indir ect Models

(Ga s, Oil or Electric bo ilers)

• Inlet control set.

• Temp & Pressure relief valve.

• 15mm / 22mm Tundish.

• Expansion vessel.

• Wall mounting bracket.

• Expansion vessel hose.

• 1 x 3kW Immersion Heater ( 2 x 3kW

250 & 300 litre units).

• Two port zone valve.

• Dual Thermostat.

• Installation & Maintenance Instructions.

• Benchmark Logbook.

Indir ect Solar Models

(Alternative Energy Source)

• Inlet Control set.

• Temp & Pressure relief valve.

• 15mm / 22mm Tundish.

• Expansion vessel.

• Wall mounting bracket.

• Expansion vessel hose.

• Immersion Heater.

• 2 x Two port valves.

• 1 x Dual Thermostat.

• 1 x Single Control stat.

• 1 x Single High limit stat.

• Installation & Maintenance Instructions.

• Benchmark Logbook.

• 2 x Sensor pocket retaining bungs.

Incol oy long li fe 240V x

3kW Imm ersio n Heater

Instal lation &

Mainte nance

Instru ctions

Bench mark

Logboo k

2

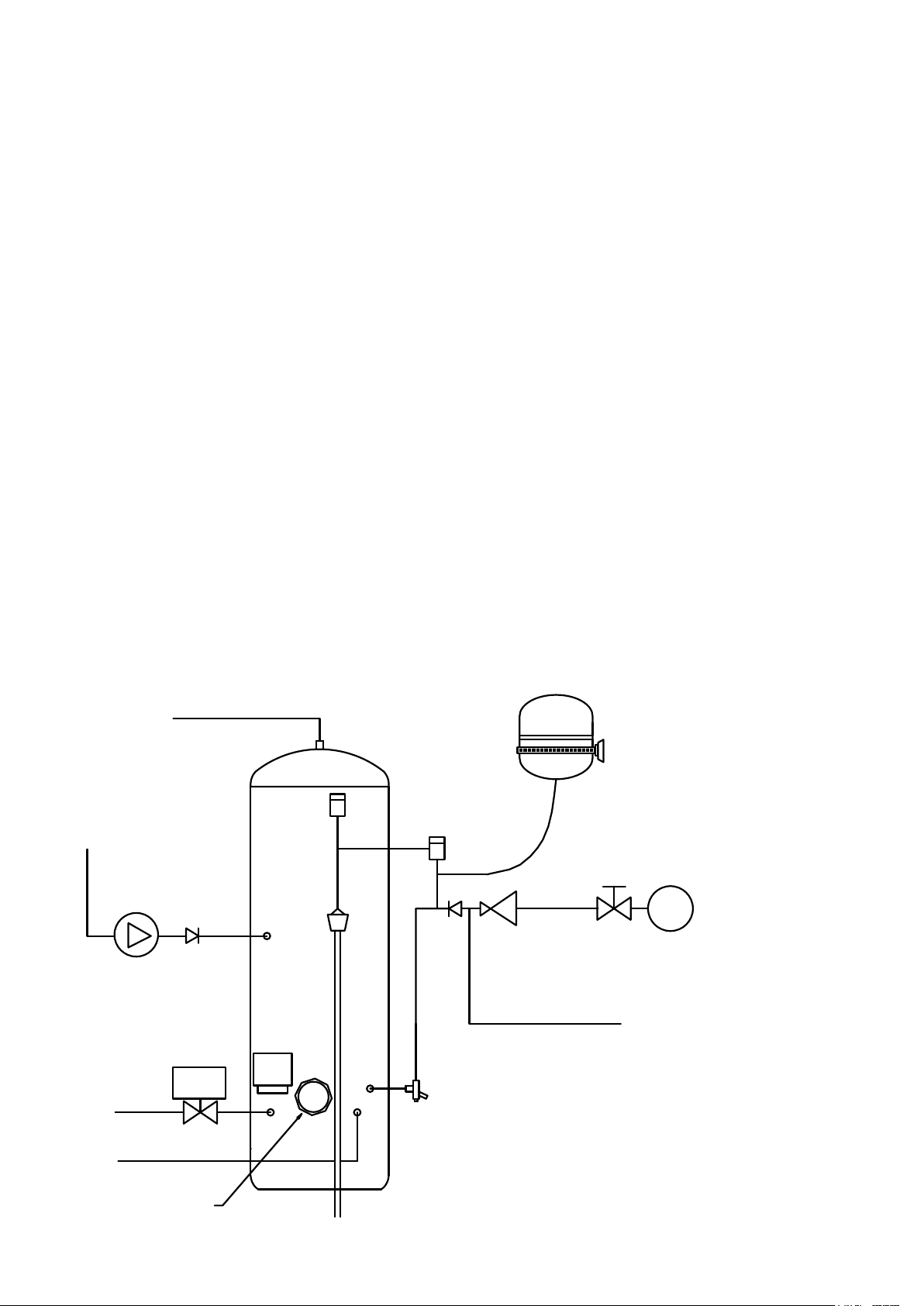

WATER SUPPLY

IMMERSION

HEATER

COLD

MAIN

ISOLATING

VALVE

PRESSURE

REDUCING

VALVE

EXPANSION

VESSEL

WITH WALL

BRACKET

FLEXIBLE

HOSE

NON

RETURN

VALVE

EXPANSION

RELIEF

VALVE

TUNDISH

TEMPERATURE

& PRESSURE

RELIEF VALVE

BALANCED

COLD

CONNECTION

COLD

INLET VIA

DRAIN

NON

RETURN

VALVE

BRONZE

PUMP

SECONDARY RETURN CIRCUIT

( 210, 250 & 300 L SIZES )

INDIRECT UNITS ONLY

DUAL

STAT

2 PORT

VALVE

BOILER

FLOW

BOILER

RETURN

HOT OUTLET

Ultrasteel operates at 3 bar (controlled by the inlet control set) and is capable of delivering over 50 litres per minute. The high

quality inlet control set has been designed to make the most of the flow rates available however the performance of any Unvented

system is only as good as the mains water supply. The maximum possible water demand should be assessed taking into

consideration that both hot and cold services are supplied simultaneously from the mains.

The water supply should be checked to ensure it can meet these requirements. If necessary consult the local water company

regarding the likely pressure and flow rate availability.

If measuring the water pressure note that a high static (no flow) mains pressure is no guarantee of good flow availability. In a

domestic installation 1.5 bar and 25 l/m should be regarded as the minimum. The maximum mains pressure the inlet control set

can cope with is 16 bar.

Consideration should be given to upgrading existing ½” (15mm) cold mains pipework to a larger size if the recommended

minimum pressure/flowrate is not being achieved.

SITING THE UNIT

Ultrasteel can supply outlets above it or at some distance from it. Site the unit to minimise “dead leg” distances especially to the

point of most frequent use.

Outlets above the Ultrasteel will reduce the outlet pressure available by 0.1 bar for every 1m of height difference The unit should

be protected from frost. Particular care is needed if siting in a garage or outbuilding. All exposed pipework should be insulated

Ultrasteel must be installed VERTICALLY on a flat base capable of supporting the weight of the cylinder when full (see technical

specification section for weights). The minimum recommended cupboard size is 650mm square.

Access for maintenance of the valves should be considered. The immersion heaters are 375mm long and care should be taken

that they can be withdrawn for servicing if required. The discharge pipework from the safety valves should fall continuously and

terminate safely.

SCHEMATIC DIAGRAM

Notes :

The Pressure reducing valve, Non return valve and

Expansion relief valve are combined together in the

inlet control set. On 120 – 180 litre sizes there is no

dedicated secondary return boss and the secondary

return circuit should be tee’d into the cold feed pipe

just above the drain elbow

3

GENERAL INSTALLATION

COLD MAINS PIPEWORK

Run the cold main through the building to the place where the Ultrasteel is to be

installed. Take care not to run the cold pipe near hot water or heating pipe work

so that the heat pick up is minimized. Identify the cold water supply pipe and fit an

isolating valve (not supplied) A 22mm BS1010 stopcock can typically be used but a

22mm quarter turn full bore valve would be better as it does not restrict the flow as

much. Do not use “screwdriver slot” or similar valves. Make the connection to the

cold feed of the cylinder and incorporate a drain valve. Position the inlet control just

ABOVE the Temperature & Pressure Relief Valve (TPRV) mounted on the side of the

cylinder. This ensures that the cylinder does not have to be drained down in order

to service the inlet control set. Ensure that the arrow points in the direction of the

water flow.

Select a suitable position for the expansion vessel. Mount it to the wall using the bracket provided. Use the hose to connect to the

inlet control group.

BALANCED COLD CONNECTION

If there are to be showers, bidets or monobloc taps in the installation then a

balanced cold supply is necessary. There is a 22mm balanced connection on the

inlet control set. An alternative method where a two part inlet control set is supplied

is to split the inlet control set into its two main assemblies. Site the pressure

reducing valve immediately after the incoming cold mains stopcock (typically under

the kitchen sink.) All outlets in the house will be at 3 bar and thus automatically

balanced. The expansion relief valve section must still be mounted just above the

TPRV on the cylinder. A ¾”F-22mm compression adaptor will be needed (not supplied).

Cold Main s In

Turn to test

(At Rear)

Expans ion Vessel

Connect ion

(Remove 3 /4” Plug)

(expans ion vessel not to sca le)

HOT WATER PIPEWORK

Run the first part of the hot water distribution pipework in 22mm. This can be

reduced to 15mm and 10mm as appropriate for the type of tap etc. Your aim should

be to reduce the volume of the hot draw off pipework to a practical minimum so that

the time taken for the hot water is as quick as possible. Do not use monobloc mixer

tap or showers if the balanced cold connection is not provided. Outlets of this type

can back pressurize the unit and result in discharge. Select a suitable position for

Pressure G auge Port

Balance d Cold

Connect ion

the expansion vessel. Mount it to the wall using the bracket provided and connect to

the inlet control set with the flexible hose provided. Ensure that the top of the vessel is accessible for servicing.

Outlet to Cyc linder

Expans ion

Relief to

Tundish

PRIMARY COIL CONNECTIONS

Connect the primary connections ( Indirect only ) using the compression connections provided. The primary circuit must be

positively pumped. Gravity circulation is not suitable. Either primary connection may be used as the primary flow. Reheat times

are identical either way. The primary circuit can be open vented or sealed with up to a maximum pressure of 3.5 bar. If you seal

the primary circuit an additional expansion vessel and safety valve is required. The boiler may be Gas, Electric, or Oil but must

be under effective thermostatic control. Uncontrolled heat sources such as some AGA’s, back boilers, solid fuel stoves, etc are

NOT SUITABLE. Please contact our technical department for guidance. Connect the two port zone valve ( indirect only ) into the

primary flow pipework. The direction of flow arrow should be towards the primary flow connection. On twin coil solar cylinders we

have provided an extra thermostat boss should you wish to use it. Again a two port zone valve should be fitted (supplied).

For Solar products refer to pages 10-13.

SECONDARY CIRCULATION

Ultrasteel can be used with secondary circulation. An appropriate WRAS approved bronze circulator should be used in

conjunction with a non return valve to prevent backflow. On large secondary circulation systems it may be necessary to

incorporate an extra expansion vessel into the circuit to accommodate the increased system water volume. Secondary

circulation should be avoided on Direct electrically heated units being used on of f peak electricity tariffs.

A secondary return boss is fitted as standard on 210, 250 & 300L. On smaller sizes tee into the cold feed pipe above the drain.

IMMERSION HEATERS

Only immersion heaters with a thermal cutout may be used. To help ensure this the immersion heaters have a special 1¾“

thread. They are rated at 3 kW at 240 V and are of a low noise Incoloy construction. They have both a thermostat and a high limit

cutout. Please order the correct replacement via ourselves, fitting non-approved immersions may affect your guarantee. When

fitting, ensure the ‘O’ ring is positioned correctly on the head of the immersion heater and lubricate before fitting. Fit it by hand

until almost home then tighten gently as the ‘O’ rings will seal easily. The electrical supply to each immersion heaters must be

fused at 13A via a double pole isolating switch to BS 3456. The cable must be 2.5mm2 heat resistant (85°C HOFR) sheathed

flex complying to BS 6141:1981 Table 8. Do not operate the immersion heater/s until the unit is full of water. Do not operate the

immersion heater/s if any sterilisation liquid is in the cylinder as this will cause premature failure. Fit the immersion thermostat

4

(indirect only) into the thermostat pocket. Complete the wiring – use the appropriate wiring diagrams on page 6.

DISCHARGE ARRANGEMENT

Fig 3: Diagram of a typical discharge

pipe arrangement (extract from Building

Regulation G3 )

Note: The discharge will consist of

scalding water and steam. Asphalt,

roofing felt and non-metallic rainwater

goods may be damaged by such

discharges.

Note: It is not acceptable to

discharge straight into a soil pipe.

Position the inlet control group so that the discharge from both the two safety valves can be joined together via a 15mm end feed

Tee. (Fig.3) Connect the Tundish and route the discharge pipe. The discharge pipework must be routed in accordance with Part

G3 of schedule 1 of the Building Regulations. The information that follows is not exhaustive and if you are in doubt you should

seek advice. The two safety valves will only discharge water under fault conditions. When operating normally water will not be

discharged. The tundish should be vertical, located in the same space as the unvented hot water storage system and be fitted

as close as possible and within 500mm of the safety device e.g. the temperature relief valve. The discharge pipe (D2) from the

tundish should terminate in a safe place where there is no risk to persons in the vicinity of the discharge, be of metal and:

A) Be at least one pipe size larger than the nominal outlet size of the safety device unless its total equivalent hydraulic

resistance exceeds that of a straight pipe 9m long i.e. discharge pipes between 9m and 18m equivalent resistance length

should be at least two sizes larger than the the nominal outlet size of the safety device, between 18 and 27m at least 3 sizes

larger, and so on. Bends must be taken into account in calculating the flow resistance. Refer to diagram 1, Table 1 and the

worked example. An alternative approach for sizing discharge pipes would be to follow BS6700 Specification for design

installation, testing and maintenance of services supplying water for domestic use within buildings and their curtilages.

B) Have a vertical section of pipe at least 300mm long, below the tundish before any elbows or bends in the pipework.

C) Be installed with a continuous fall.

WORKE D EX AMPL E

D) It is preferable for the discharge to be visible at both the tundish and the

final point of discharge but where this is not possible or practically difficult

there should be clear visibility at one or other of these locations. Examples of

acceptable discharge arrangements are:

1. Ideally below the fixed grating and above the water seal in a trapped gulley.

2. Downward discharges at a low level; i.e. up to 100mm above external surfaces such as car

parks, hard standings, grassed areas etc. are acceptable providing that where children play

or other wise come into contact with discharges, a wire cage or similar guard is positioned to

prevent contact whilst maintaining visibility.

3. Discharges at a high level; e.g. in to metal hopper and metal down pipe with the end of the

discharge pipe clearly visible (tundish visible or not) or onto a roof capable of withstanding high

temperature discharges of water and 3m from any plastic guttering systems that would collect

such discharges (tundish available ).

4. Where a single pipe serves a number of discharges, such as in blocks of flats, the number

served should be limited to not more than 6 systems so that any installation c an be traced

reasonably easily. The single common discharge pipe should be at least one pipe size larger

than the largest individual discharge pipe to be connected. If unvented hot water storage

systems are installed where discharges from safety devices may not be apparent i.e. in

dwellings occupied by blind, infirm or disabled people, consideration should be given to the

installation of an electronically operated device to warn when discharge takes place.

The example be low is for G1/2 te mpera ture rel ief valv e with

a disch arge pipe (D2 ) having 4 N o. elbows and len gth of 7m

from the t undis h to the point of discharge.

From Tabl e 1:

Maxi mum res istan ce allowed for a str aight l ength of 2 2mm

coppe r disch arge pi pe (D2 ) from a G1/2 tem perature reli ef

valve is : 9.0m Subt ract the resist ance for 4 No. 22mm

elbows a t 0.8m each = 3.2m Ther efore the maxi mum

permi tted le ngth equates to : 5.8m 5.8m is l ess tha n the

actual l ength o f 7m therefore calcu late the next largest si ze.

Maxi mum res istan ce allowed for a str aight l ength of 28 mm

pipe ( D2) fro m a G1/2 temper ature re lief val ve equates to:

14m As the actua l length is 7m, a 28mm (D2) copper pip e will

be satis factor y.

Table1

Sizing of coppe r disch arge pi pe ‘D2’ for a te mpera ture

relief v alve with a G1/2 outlet size (a s suppl ied) .

Size of

disch arge

pipewo rk

22mm Up to 9m 0.8m

28mm Up to 18m 1m

35mm Up to 27m 1.4m

Maxi mum

lengt h of

straig ht pipe

(no be nds or

elbows )

Deduc t the figu re below

from the m aximum

lengt h for each bend or

elbow in t he disc harge

pipe

5

WIRING DIAGRAM TWO 2 PORT ZONE VALVE (S-PLAN)

VARIANT DUAL THERMOSTAT WIRING

WIRING DIAGRAM 3 PORT MID POSITION VALVE (Y-PLAN) + 2 PORT VALVE

VARIANT DUAL THERMOSTAT WIRING

6

COMMISSIONING

FILLING

Check the pressure in the expansion vessel is 3 bar (45PSI), i.e. the same as the setting of the pressure reducing valve. The valve

is of the car tyre (Schrader) type. Check all the connections for tightness including any factory made connections such as the

immersion heater and the temperature and pressure relief valve. Before filling open the hot tap furthest away from the Ultrasteel

to let air out. Open the cold main isolation valve and allow the unit to fill. When water flows from the tap allow it to run for a short

while to flush through any dirt, swarf or flux residue. Close the tap and open every other hot tap in turn to purge all remaining air.

DIRECT UNITS

After filling with water and after sterilisation liquid has been purged, switch on the power to the immersion heaters and allow the

unit to start to heat. The immersion heater is supplied preset at 55°C. Turning fully to + sets to approx 65°C

INDIRECT UNITS

Consult the boiler manufacturers commissioning instructions and fill the primary circuit. Ensure the lever on the two port valve is

set to the filling position. When full move the lever back. Switch the programmer to Domestic Hot water (DHW) and allow the unit

to start to heat. Adjust the dial of the dual thermostat to between 55°C and 65°C as required.

STORAGE TEMPERATURE

The recommended storage temperature for both direct and indirect cylinders is 60-65°C. In hard water areas consideration should

be given to reducing this to 50-55°C. In many healthcare applications the guidance on Legionella control and safe water delivery

temperatures will require storing the water at 60-65°C, distributing at 50- 55°C and using thermostatic mixing valves to control the

final temperature.

For details consult the NHS Estates Guidance on safe hot water temperatures.

SAFETY VALVE CHECKS

During heat-up there should have been no sign of water coming from either the expansion relief valve or the temperature /

pressure relief valve. Now hold both of these safety valves fully open allowing as much water as possible to flow through the

tundish. Check that your discharge pipework is free from debris and is carrying the water away to waste efficiently Release the

valves and check that they reseat properly.

SERVICING

GENERAL

Servicing should only be carried out by competent installers and any spare parts used must be purchased from Albion. NEVER

bypass any safety devices or operate the unit without them being fully operational.

DRAINING

Isolate from the electrical supply to prevent the immersion heaters burning out. Isolate the unit from the cold mains. Attach a hose

to the draining tap ensuring it reaches to a level below the unit (This will ensure an efficient syphon is set up and the maximum

amount of water is drained from the unit). Open the hot tap closest to the unit and open the draining tap WARNING: WATER

DRAINED OFF MAY BE VERY HOT!

ANNUAL MAINTENANCE

Ultrasteel requires an annual service in order to ensure safe working and optimum performance. It is essential that the following

checks are performed by a competent installer on an annual basis. Commonly this is done at the same time as the annual boiler

service.

1) Twist the cap of the expansion relief valve on the inlet control set and allow water to flow for 5 seconds. Release and make

sure it resets correctly. Repeat with the pressure / temperature relief valve. In both cases check that the discharge pipework is

carrying the water away adequately. If not check for blockages etc. and clear. WARNING: THE WATER DISCHARGED MAY BE

VERY HOT!

2) Check that any immersion heaters fitted are working correctly and that they are controlling the water at a temperature

between 55°C and 65°C.

3) Check the pressure in the expansion vessel is charged to 3 bar. Turn off the water supply to the unit and open a hot tap

first. The air valve on expansion vessel is a Schrader (car tyre ) type. Air or CO2 may be used to charge the expansion vessel.

4) Unscrew the head on the inlet control set and clean the mesh filter within.

5) The benchmark log book supplied with this unit should be updated at each service.

YOUR GUARANTEE MAY BE VOID WITHOUT PROOF OF ANNUAL SERVICING

SPARE PARTS

We carry the full range of spares listed below in stock. If you order before noon we will dispatch the same day for delivery the next

to most locations. Tel: 01924 376026.

TS201 - Inlet control set (pressure reducing valve, strainer and

expansion relief valve )

TS202 - Temperature & pressure relief valve

TS3 - Tundish

TS4 - Expansion relief valve (car tridge only)

TS105 - 2 port valve

TS207 - Dual thermostat

TS9 - Immersion heater ( same on all models )

TS212 - 12 litre Expansion Vessel ( 120 & 150 ltr sizes )

TS219 - 19 Litre Expansion vessel ( 180 , 210 & 250 ltr sizes)

TS224 - 24 litre expansion vessel ( 300 ltr size )

TS216 - Wall mounting bracket

TS214 - Expansion vessel hose ( ¾” M x ¾” F )

TS27 - Single control stat

TS28 - Single high limit stat

- Sensor pocket retaining plugs

7

FAULT FINDING

8

ABCDEF

22mm HOT

DRAWOFF

“

“

F PTRV BOSS

F STAT BOSS

SECOND

IMMERSION HEATER

(not always fitted. See table)

22mm SECONDARY

RETURN (not always fitted.

See table)

22mm COLD FEED WITH

DIP PIPE TO DEFLECTOR

IN BOTTOM OF CYLINDER

1

2

1

2

160mm

195mm

FDF

22mm HOT

DRAWOFF

“

F PTRV BOSS

22mm SECONDARY

RETURN (not always fitted.

See table)

22mm COLD FEED WITH

DIP PIPE TO DEFLECTOR

IN BOTTOM OF CYLINDER

1

2

TECHNICAL SPECIFICATIONS

Ultrasteel

Direct

PRODUCT

CODE

CAPACITY

(Litres)

HEIGHT DIAMETER D F WEIGHT

(Kg - EMPTY)

AUD 120 120 906 550 N/F 510 30 150

AUD 150 150 1093 550 N/F 610 35 185

AUD 180 180 1281 550 N/F 710 40 220

AUD 210 210 1469 550 1000 810 45 255

AUD 250 250 1719 550 1250 950 50 300

AUD 300 300 2032 550 1500 1100 55 355

All dim ensio ns are in m m and are of t he case d unit. N /F = not fi tted

Ultrasteel

Indirect

WEIGHT

(Kg-FULL)

PRODUCT

CODE

AUI 120 120 906 550 290 330 390 345 N/F N/F 35 155

AUI 150 150 1093 550 330 370 465 385 N/F N/F 40 190

AUI 180 180 1281 550 330 370 465 385 N/F N/F 45 225

AUI 210 210 1469 550 365 405 465 465 N/F 1150 50 260

AUI 250 250 1719 550 365 405 465 560 950 1400 55 305

AUI 300 300 2032 550 365 405 465 660 1100 1600 60 360

All dim ensio ns are in m m and are of t he case d unit. N /F = not fi tted

CAPACITY

(Litres)

HEIGHT DIAMETER A B C D E F WEIGHT

(Kg - EMPTY)

WEIGHT

(Kg-FULL)

9

ULTRASTEEL SOLAR UNVENTED

DIRECT SINGLE COIL CYLINDER

Detail for the installation of a Solar Unvented cylinder in an electric home.

General

When installing this product it is essential the overall installation meets all current legislation including, in particular, the high limit

isolation requirements of Building Regulation G3. This document is designed to assist in achieving that aim.

Water

The potable water connection and tundish discharge connection are to be connected in exactly the manner described in Pages 1

to 7 of this manual.

Immersion Heaters

The standard issue immersion heaters are designed for domestic usage where the lower heater is connected to a low rate off

peak tariff and the upper heater used for occasional top up purposes. Heaters of this nature are not designed to be permanently

live. For usage outside of domestic parameters Titanium immersion elements are recommended.

Solar Connections

The flow and return from the solar heat source are to be connected to the indirect coil. Either primary coil connection (A) may be

utilised as the flow or return. The solar sensor, supplied as part of the solar controls, inserts into Pocket B and is held in-situ with

the black sensor pocket retaining bung provided. It is necessary to mount the solar pump in the return pipework with the Danfoss

HP22 two port valve (supplied with the cylinder) installed between the cylinder and the pump. This valve is of the powered open,

sprung closed design and is wired through the Danfoss ITL100 high limit stat which inserts into Pocket F. Two wiring options for

high limit isolation are provided in fig 1 and fig 2. The superior option is fig 2 which disconnects the pump movement as well as

providing valve closure. (see pages 11 & 12)

ULTRASTEEL SOLAR UNVENTED

INDIRECT TWIN COIL CYLINDER

Indirect, twin coil, units can be installed in two separate formats:

a) In a solar powered system with a fossil fuel boiler.

b) In a system with two independent fossil fuel boilers.

With either format it is essential the overall installation meets all current legislation including, in particular, the high limit isolation

requirements of Building Regulation G3. This document is designed to assist in achieving this aim.

UPPER COIL

The upper coil is connected to the fossil fuel boiler as per the instructions for the Ulrasteel Unvented Indirect single coil model with

the Danfoss ITD100 control and high limit thermostat inserted into pocket D (lower diagram page 12). The wiring requirements are

as depicted on page 11.

LOWER COIL: SOLAR INSTALLATION

In a solar powered system the lower coil is connected to the solar heat source. Either primary coil connection may be utilised

as the flow or return. The solar cylinder sensor, supplied as part of the solar controls, inserts into pocket B (fig. page 12). It is

necessary to mount the solar pump in the return pipework with the Danfoss HP22 two port valve (supplied with the cylinder)

installed between the cylinder and the pump. This valve is of the powered open, sprung closed design and is wired through the

Danfoss ITL100 high limit stat which inserts into pocket F (lower diagram page 12). Two wiring options for high limit isolation are

provided in fig. 1 and fig. 2 page 11. The Danfoss ITC100 control thermostat is not required in a solar installation.

10

LOWER COIL: TWO BOILER INSTALLATION

Where the lower coil is to be used with a fossil fuel boiler, the pipework requirements are as per that of a Ulrasteel Indirect single

coil cylinder described earlier in this book. Electrically the ITC100 inserts into Pocket B (fig. Page 12) to control the boiler input and

the Danfoss ITL100 limit stat into Pocket F (lower diagram page 12). The Danfoss HP22 two port valve may be installed into either

the flow or return pipework. Wiring of the ITC100 and ITL100 are as per the wiring detail using the ITD100 on page 6.

WIRING DIAGRAM:

SOLAR HIGH LIMIT CONTROL

11

TECHNICAL SPECIFICATIONS

AB GCDEF

22mm HOT DRAWOFF

SECONDARY RETURN

(not always fitted)

22mm COLD FEED

WITH DIP PIPE

TO DEFLECTOR

IN BOTTOM

OF CYLINDER

25.0015.0

0

45.0

0

45.0

0

35.0

0

“

F PTRV BOSS

1

2

“

F PTRV BOSS

1

2

AB HGCDEF

22mm HOT DRAWOFF

SECONDARY RETURN

(not always fitted)

22mm COLD FEED

WITH DIP PIPE

TO DEFLECTOR

IN BOTTOM

OF CYLINDER

25.0015.0

0

45.0

0

45.0

0

35.0

0

“

F PTRV BOSS

1

2

“

F PTRV BOSS

1

2

Ultrasteel

Solar

Direct

PRODUCT

CODE

CAPACITY

(Litres)

HEIGHT DIAMETER A B C D E F G WEIGHT

(Kg - EMPTY)

AUSD 180 180 1281 550 290 345 445 710 N/F 1080 390 45 225

AUSD 210 210 1469 550 365 420 500 810 1150 1268 465 50 260

AUSD 250 250 1719 550 365 420 575 950 1400 1518 465 55 305

AUSD 300 300 2032 550 365 420 670 1100 1600 1831 465 60 360

All dim ensio ns are in m m and are of t he case d unit. N /F = not fi tted

Ultrasteel

Solar

Indirect

WEIGHT

(Kg-FULL)

CODE

AUSI 180 180 1281 550 290 345 674 729 N/F 1080 390 725 50 230

AUSI 210 210 1469 550 365 420 779 834 1150 1268 465 830 55 265

AUSI 250 250 1719 550 365 420 854 909 1400 1518 465 905 60 310

AUSI 300 300 2032 550 365 420 979 1034 1600 1832 465 1030 65 365

PRODUCT

All dim ensio ns are in m m and are of t he case d unit. N /F = not fi tted

12

CAPACITY

(Litres)

HEIGHT DIAMETER A B C D E F G H WEIGHT

(Kg - EMPTY)

WEIGHT

(Kg-FULL)

ALBION ULTRASTEEL

SOLAR UNVENTED CYLINDERS

Al bi on Ul tr astee l Solar c ylind ers h ave be en de sig ned spe cif ica lly

with Solar ap plications i n mi nd. Featu ring a purpose d esign ed

sola r coi l wh ich all ows maximu m heat transfe r of sol ar en ergy

into th e stored water, t he c yli nders a re s uit able fo r us e with

a w ide ran ge of sol ar s ystems now avai lable i n th e UK a nd are

an effi cie nt a nd envi ro nme ntall y fri end ly way of prov iding

dome stic hot water. U ltras te el So lar cyl inder s als o of fer the

bene fit of ma ins pre ssure hot water – power f ul shower s and fas t

fi ll ing bat hs .

Ultr aste el So lar C ylind ers a re d esi gne d to acc ept hea t in put f ro m a re newab le/sus taina ble ( ie: Sola r) h eat sou rce.

Where th is inpu t doe s not fully m eet the desire d te mpera tu re a g uar anteed qu antit y of water c an be h eate d to a n ac cep table

temperature by the hous eho lde rs tradit ional h eat sou rc e of g as, oil or el ect ricit y.

Th e Do mes tic Heati ng Comp lia nce Gui de docu men t L1A and L1B provid es exce ll ent adv ice i n sizin g bo th c ylind er de signa te d solar

area s and hea t exch ang ers to t he s urface a rea of the sola r col lectors. Us ing thi s guide A lbion a re able to of fer siz ing adv ice for

specificatio n.

Ultr aste el So lar cyl ind ers are avail abl e in a r ange of sizes f rom

180 to 300 litres a nd in Dir ect or Indi rec t ve rsions. Ultras te el

Sola r cylin der s are man ufactur ed from h igh grade D upl ex

stai nle ss ste el an d come wi th a 25 year f ully transfe ra ble

Guar antee o n th e in ner c ontai ner.

Water Capacities

Model Designated solar area Fossil fuel area Total Capacity

180 55 125 180

210 65 145 210

250 75 175 250

300 100 200 300

Lower (Solar) Coil Specification

Model Surface Area (m2) Fluid Content (litres)

180 0.670 3.687

210 0.878 4.826

250 0.878 4.826

300 0.878 4.826

NB: The total detail of compliance guide document

should be consulted prior to specifying product or

commencing design.

Maximum Nett Surface Area of Collector panel (m2)

As detailed in domestic compliance guide.

Model Solar Pump speed

< 0.5LPM > 0.5LPM

180 3.35 6.70

210 4.39 8.78

250 4.39 8.78

300 4.39 8.78

In addition our insulation process offers benefits to the

‘green’ specifier.

Ozone Depletion Potential (ODP) ZERO

Global Warming Potential (GWP) ONE

13

NOTES

14

GUARANTEE

The Ultrasteel’s stainless steel vessel carries

a 25 year guarantee against faulty materials or

manufacture provided that:

It has been correctly installed as per this

•

document and all the relevant standards,

regulations and codes of practice in force

at the time.

It has not been modified in any way, other

•

than by Albion.

It has not been misused, tampered with or

•

subjected to neglect.

It has only been used for the storage of

•

potable water.

It has not been subjected to frost damage.

•

The unit has been serviced annually.

•

The benchmark log book has been filled in

•

after each annual service.

The guarantee period starts from the date of

•

purchase and no registration is required.

The extended guarantee is not transferable,

•

and rests with the original householder.

The system is fed from a public water

•

supply.

EXCLUSIONS –THE GUARANTEE DOES NOT

COVER

The effects of scale build up.

Any labour charges associated with replacing the unit or its

parts. Any consequential losses caused by the failure or

malfunction of the unit.

GUIDANCE IN THE EVENT OF A PROBLEM

If you have a problem in the first year contact the plumber who

fitted the unit. Thereafter contact the plumber who carries out

the annual servicing for you. If your Ultrasteel develops a leak

we will supply you with a new one. We ask for an nominal upfront payment to prevent fraud. We will require the original

unit to be returned to us for inspection along with a copy of

your benchmark log book. If it is confirmed that it has failed

within the terms of the warranty your upfront payment will be

refunded.

If a component part fails within the two year guarantee period

we will send you a new one without any upfront charge. Credit

card details may be taken to prevent fraud. We ask you to

post the faulty part back to us within one month by recorded

delivery.

If you do not return the part we will charge you for it and for the

postage and packing. If your part fails after two years service,

we will ask for upfront payment.

Please note that invoices for servicing may be

requested to prove that the unit has been

serviced annually.

All the components fitted to / or supplied with

the Ultrasteel carry a 2 year guarantee.

USER INSTRUCTIONS

Your stainless system is automatic in normal use and requires only annual servicing. You should employ an competent installer to

perform the annual servicing. Normally this is timed to coincide with the annual boiler service.

IF WATER IS FLOWING FROM THE SAFETY VALVES THROUGH THE TUNDISH THIS INDICATES

A FAULT CONDITION AND ACTION IS NEEDED.

If this water is hot turn the boiler and / or the immersion heater off. Do not turn off the water until the discharge runs cool. The

discharge may also stop.

CALL A COMPETENT PLUMBER OUT TO SERVICE THE UNIT.

Tell them you have a fault on an unvented cylinder. We stock all the spare parts they may need.

15

Albion Water Heaters Ltd, Station Road, Caythorpe, Nr. Grantham, Lincolnshire NG32 3EW

T: 01400 272726 F: 01400 273508 www.albionwaterheaters.com

kingspanhws.com

Specification summary...

Materials

Inner shell - Duplex Stainless Steel

Coil - 22mm Diameter Stainless Steel

Bosses - Stainless Steel

Every Ultrasteel cylinder is water tested to a pressure of 15 bar.

Insulation

Fire retardant polyurethane foam, nominal thickness 50mm.

The foam is CFC-Free and HCFC-Free.

The foam has an Ozone Depletion Potential of ZERO and a Global Warming

Potential of One.

Casework

Zintec corrosion proofed steels throughout

Durable.

Anode

None fitted/none required

Expansion Vessel

12 Litre size with 120 and 150 Litre models

18 Litre size with 180, 210 and 250 Litre models

25 Litre size with 300 Litre model

Control Settings

Pressure Reducing Valve - 3 Bar

Expansion Relief Valve - 6 Bar

Pressure and Temperature Relief Valve - 7 Bar/90°C

High Limit Thermostat in Dual Thermostat - 85°C

High Limit Thermostat in Immersion Heater - 85°C

Immersion Heater

1

3

/4” BSP Parallel Threaded Head

Long Life Incoloy Sheathed Low Noise Element 14” Long

Long Life Incoloy Sheathed Thermostat Pocket 11” Long

Brazed Construction

11” Combined Thermostat and Safety Cut-Out

Element Rating 3Kw at 240V A/C

Approvals

WRAS Approved to the Water Regulations

WRC-NSF Approved to Building Regulations G3 & L

CE Compliant and fitted with a BEAB Approved

Immersion Heater

Guarantee Terms

The Stainless Ultrasteel’s stainless steel vessel carries a 25 year guarantee against faulty

materials or manufacture provided that:

It has been correctly installed as per the Installation Instructions and all the relevant

standards, regulations and codes of practice in force at the time.

It has not been modified in any way, other than by Albion.

It has not been misused, tampered with or subjected to neglect.

The system is fed from the public mains water supply.

It has only been used for the storage of potable water.

It has not been subjected to frost damage.

The unit has been serviced annually.

The benchmark log book has been filled in after each annual service.

The guarantee period starts from the date of purchase and no registration is required.

Please note that invoices for servicing may be requested to prove that the unit

has been serviced annually.

All the components fitted to/or supplied with the Stainless HE carry a

2 year guarantee.

Exclusions –The Guarantee does not cover

The effects of scale build up.

Any labour charges associated with replacing the unit or its parts.

Any consequential losses caused by the failure or malfunction of the unit.

Kingspan Hot Waters Systems have a policy of continuous product development

and may introduce product modifications from time to time. As a consequence

details given in this brochure are subject to alteration without notice.

Albion is a market leader in the manufacture

and supply of quality hot water systems.

Albion Water Heaters Ltd, part of Kingspan group, is a major

manufacturer of domestic hot water storage systems in the UK

and offers the trade products backed by the service and technical

development skills that only a company of its size can.

All sites are licensed to British standards quality assurance BS EN

ISO 9001 : 2000 and Albion is a BSi registered firm. This means

that all manufacturing plants are monitored by an independent

inspectorate and that the quality systems employed by Albion meet

the stringent requirements set down.

Specifiers, stockists and users can depend on Albion for

consistent quality and supply. Albion continues to develop

energy saving and innovative hot water products for domestic

and commercial applications.

ALBION IS A MARKET LEADER IN THE

MANUFACTURE AND SUPPLY OF QUALITY HOT

WATER SYSTEMS.

Specification summary...

Material s

OHSAS 18 001

Inner shell - Duplex Stainless Steel

Coil - 22mm Diameter Stainless Steel

Bosses - Stainless Steel

Every Ultrasteel cylinder is water tested to a pressure of 15 bar.

Insulation

Fire retardant polyurethane foam, nominal thick ness 50mm.

The foam is CFC-Free and HCFC-Free.

The foam has an Ozone Depletion Potential of ZERO and a Global Warming

Potential of O ne.

Casework

Zintec corrosion proofed steels throughout

Durable, metallic finish outer casing.

Anod e

None fitted/none required

Expansion Vessel

12 Litre size with 120 and 150 Litre models

19 Litre size with 180, 210 and 250 Litre models

24 Litre size with 300 Litre model

Control Setti ngs

Pressure Reducing Valve - 3 Bar

Expansion Relief Valve - 6 Bar

Pressure and Temperature Relief Valve - 7 Bar/90°C

High Limit Thermostat in Dual T hermostat - 85°C

High Limit Thermostat in Immersion Heater - 85°C

Immersion Heater

13/4” BSP Parallel Threaded Head

Long Life Incoloy Sheathed Low Noise Eleme nt 14” Long

Long Life Incoloy Sheathed Thermostat Pocket 11” Long

Brazed Construction

Combined Thermostat and Safety Cut-Out

Element Rating 3Kw at 240V A/C

Approvals

WRAS Approved to the Water Regulations

WRC-NSF Approved to Building Regulations G3 & L

CE Compliant and fitted with a BEA B Approved

Immersion Heater

Kingspan Hot Waters Systems have a policy of continuous product development

and may introduce produ ct modificatio ns from time to time. As a consequenc e

details given in this bro chure are subject to alteration without notice.

Albion Water Heaters Ltd, part of Kingspan group, is a major

manufacturer of domestic hot water storage systems in the UK

and offers the trade products backed by the service and technical

development skills that only a company of its size can.

All sites are licensed to British standards quality assurance BS EN

ISO 9001 : 2000 and Albion is a BSi registered firm. This means

that all manufacturing plants are monitored by an independent

inspectorate and the quality systems employed by Albion meet

the stringent requirements set down.

Specifiers, stockists and users can depend on Albion for

consistent quality and supply. Albion continues to develop

energy saving and innovative hot water products for domestic

and commercial applications.

Issue 01

June 2008

www.

Loading...

Loading...