September 2004

T H E R M A L S T O R E U N I T S

F O R U S E R G U I D E S E E

P A G E S 1 2 T O 1 4

INSTALLATION GUIDE

®

MAINSFLOW

CASED CONTRACTOR

THERMAL STORE UNITS

PLEASE LEAVE IN POCKET

PROVIDED ON THE UNIT

FOR USER GUIDE SEE

PAGES 12 TO14

C

O

O

M

T

D

E

N

G

I

S

E

D

THERMAL STORE

SPECIFICATION

P

L

Y

W

I

T

H

IMPORTANT

Please ensure that all installations meet current by-laws

and comply to best industry practice.

Follow component manufacturer's guidelines. This booklet

is published as a guide only, Albion cannot accept

responsibility for errors or ommissions.

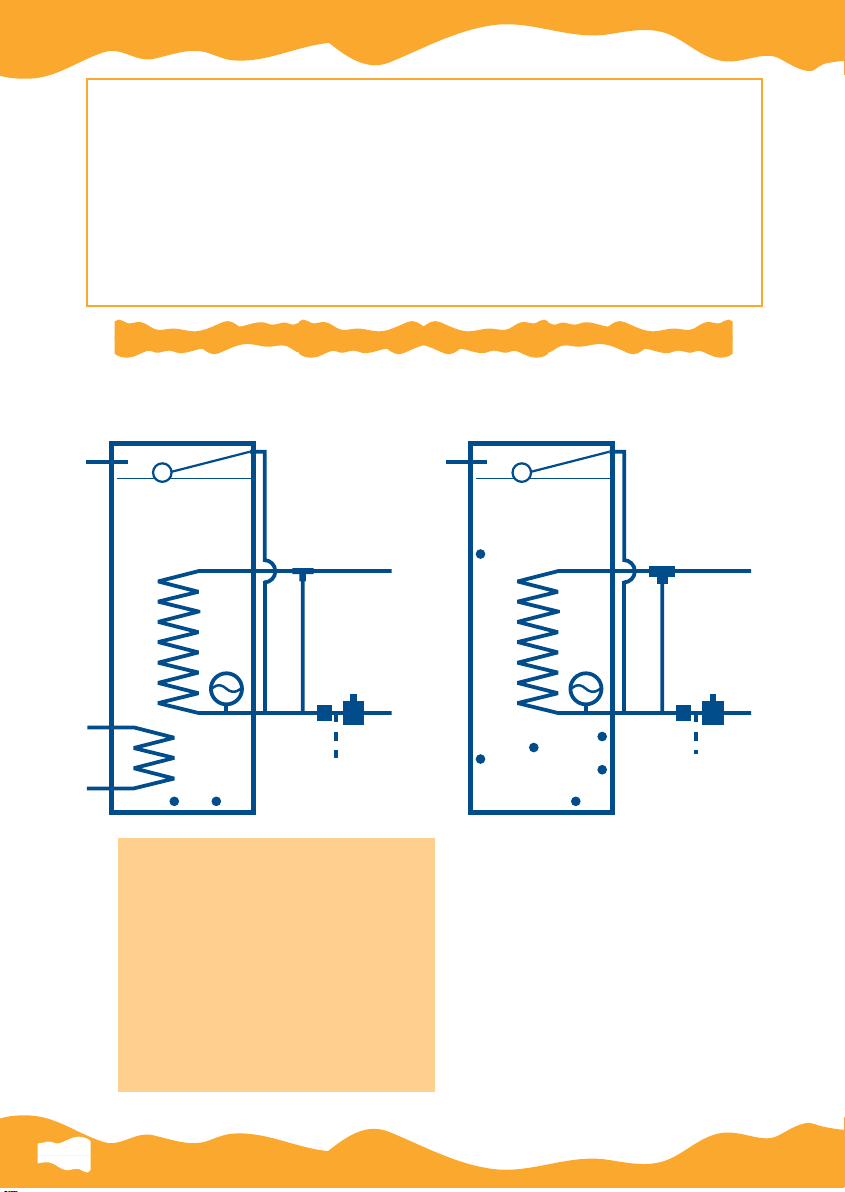

MAINSFLOW CASED CONTRACTOR UNIT

INDIRECT DIRECT

A

C

B

D

DOMESTIC

HOT OUT

E

DOMESTIC

JH

A Warning pipe (Installer to fit)

B Ball float (Supplied)

C Primary Coil/ Boiler Tappings

D Blending valve

E Expansion vessel

F Service valve

G 3.0 bar pressure reducing valve

H Drain Point

J Thermostat connection

K Radiator circuit tappings

COLD OUT

F

G

COLD

MAINS

A

C

C

B

D

DOMESTIC

HOT OUT

E

G

F

K

J

K

H

DOMESTIC

COLD OUT

COLD

MAINS

1

INTRODUCTION

The Albion Mainsflow operates on the Thermal Store principle

eliminating the need for cold water storage in the loft and

producing mains pressure hot water to all taps and shower

facilities at high flow rates in accordance with BS6700.

The Mainsflow Thermal Store principle reverses the traditional

operation of the cylinder in the heating system. The store of water

is heated from the boiler, DIRECTLY to the store or INDIRECTLY

via a second coil. The secondary (domestic) water is provided

through a multi-tube heat exchanger, fed from the main.

Mainsflow DIRECT (single coil) must be fitted in open vented mode,

preferably in twin pump configuration (See page 2, diagram 1).

Mainsflow INDIRECT (twin coil) units can be used with sealed

system boilers i.e. a fully sealed heating system, or with more

traditional open vented systems, where flexible siting is required

- the store being static. The Indirect is usually fitted into a Y

plan system. (See page 2, diagram 2).

Mainsflow Indirect can also be used in central boiler schemes

linking several cylinders to a single boiler or buffer store.

Mainsflow Indirect Cased Contractors are corrosion proofed

and guaranteed for five years. The corrosion proofer is supplied

inside the unit as a soluble crystal. It will not degrade and will

dilute in hot water.

For Direct Units or if you re-commission after use, please add

new inhibitor eg. Fernox MBI or MB2 or Sentinel X100. Follow

manufacturers' instructions to maintain guarantees.

2

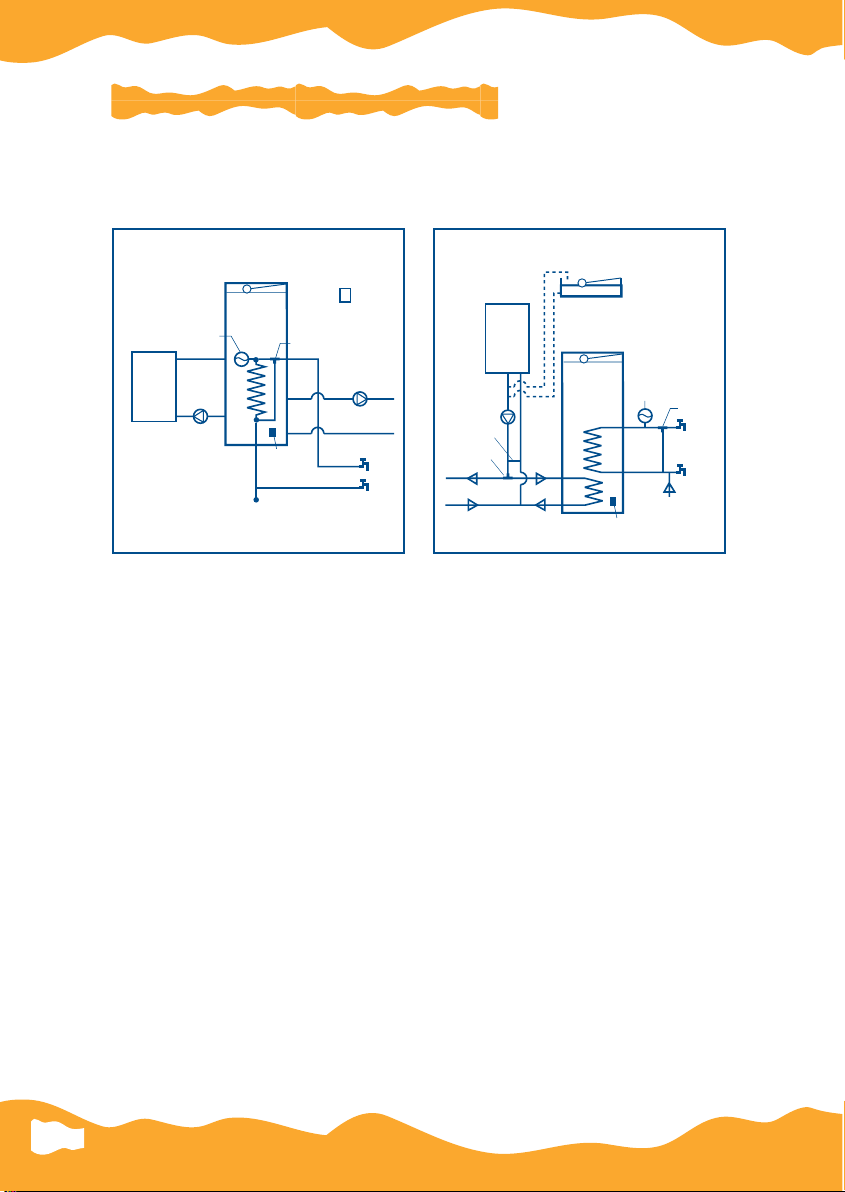

TYPICAL SCHEMATIC LAYOUTS

The Mainsflow units have been engineered to ensure maximum

efficiency from fully pumped systems.

They are not for use in systems with gravity flow and return pipes.

In addition each system is insulated with Albion's unique 100%

CFC free foam and cased in a smart white appliance finish.

DIRECT MAINSFLOW

TWIN PUMP

INDIRECT MAINSFLOW

'Y' PLAN/SEALED SYSTEM

COLD MAINS

PUMP

1

PUMP 2

SPACE

HEATING

HOT

ROOM

THERMOSTAT

COLD

BOILER

STORE

THERMOSTAT

PROBE TYPE

BLENDING

VALVE

EXPANSION

VESSEL

HOT

COLD

BY-PASS

SPACE HEATING

BOILER

*FEED/EXPANSION - OPEN VENTED ONLY

STATIC

STORE

POTABLE

WATER

COLD MAINS

GAS OR OIL

BOILER,

SEALED OR

*OPEN VENTED

PRIMARY

WATER

DIVERTER

VALVE

STORE

THERMOSTAT

PROBE TYPE

BLENDING

VALVE

EXPANSION

VESSEL

Diagram 1

Diagram 2

3

COLD SUPPLY

Mainsflow units are designed to provide hot water directly from the rising

main. Output performance is directly related to the adequacy of the

incoming mains supply. When choosing Mainsflow, installers and

specifiers must take into account flow rates and pressure. The units are

designed to deliver hot water at given flow rates and it is therefore

important to ensure that the mains supply into the property is adequate, ie

a minimum of 2 bar pressure at 20 litres per minute for single bathroom

applications and appropriately for larger installations.

The supplied pressure reducing valve must be fitted. It is recommended

that some cold outlets are connected direct to the mains (kitchen, utility

and outside taps) prior to the pressure reducing valve. The pressure

reducing valve needs to be as far upstream from the cylinder as possible.

The Mainsflow multi-tube heat exchangers are such that scale deposition

will be minimised. However, in areas where concentration of CaCO

3

is

greater than 200mg/l it is recommended that suitable in line scale

eliminators are fitted. If fitted, a by-pass pipe must be installed so that the

system can build up a natural patina for protection prior to using a

proprietary scale eliminator. Consult the manufacturers' guidelines.

INSTALLATION

Albion Mainsflow units should be sited to enable access and removal of all

plumbing connections and components including the unit and overflow

pipes. The units should be positioned on a flat base capable of supporting

them when full up to 300kg (250 litre model).

Where Mainsflow Direct model is used care must be taken to ensure that the

unit is sited to ensure sufficient head for trouble free operation of the system.

They must be sited with the water level at least 500mm above the top of the

highest radiator or highest point in the primary circuit*. Care must always

be taken to allow a clearance of 200mm between the top of all

combination units and the ceiling to allow access to the ball valve for

servicing and adjustment.

The Mainsflow Indirect can be sited anywhere within the property as the

store is static, taking care to discharge pipes effectively.

* Check boiler minimum head requirements.

4

PIPE SIZING

To enable effective distribution of the available supply it is

important in any mains pressure system that pipe sizing is in

accordance with BS6700. As an indication the following pipe

connections are necessary.

Mains supply to the dwelling 22mm (25mm MDPE).

Mains cold supply to the Mainsflow should be run in 22mm

copper.

The hot water draw-off should be 22mm to the bath tap

branch.

The tee-offs to the basins/sinks should be in 10mm, whilst

the tee-offs to the showers should be 15mm.

Primary flow and return pipework should be a minimum of

22mm and sized to 28mm or 35mm according to the boiler

manufacturers' instructions. By-pass pipework must be strictly

in accordance with boiler manufacturers' requirements.

Cold feed to heat exchanger 22mm.

Expansion tank discharge pipework 22mm copper or

22mm plastic solvent weld.

1.)

2.)

MAINSFLOW SIZING

A GUIDE TO SIZING YOUR MAINSFLOW CASED CONTRACTOR

MODEL

MFT140 CON

Specify DIRECT

or INDIRECT

MFT170 CON

Specify DIRECT

or INDIRECT

MFT200 CON

Specify DIRECT

or INDIRECT

MFT250 CON

Specify DIRECT

or INDIRECT

APPLICATION

(TO BS6700)

Single bath and

en-suite shower

2/3 bed property

Two baths

2/3 bed property

Three bath

4 bed property

Three baths and two

en-suite showers

5 bed property

CYLINDER

SIZE

1280 x 560

1500 x 560

1700 x 560

2200 x 560

BOILER

(x 1000 BTU)

40

60

80

100

SIZING

(kW)

12 kW

18 kW

24 kW

30 kW

WEIGHT

(EMPTY)

35kg

37kg

39kg

41kg

WEIGHT

(FULL)

175kg

217kg

249kg

291kg

5

In line with good practice, servicing valves should be fitted to

the system to facilitate maintenance and balancing of the

system. Also all factory made joints should be checked after

installation in case they have loosened during transit. Albion

will not accept responsibility for damage caused where

connections are not checked when commissioning.

Hot and cold taps and mixing valves used in conjunction with

the Mainsflow must be suitable for operating at 10 bar.

Aerated taps are recommended to prevent splashing.

Note: If a water meter is fitted it must be sized appropriately to

prevent flow and pressure restriction. It must be located at least

6 metres upstream from the cylinder. The same distance

applies to non return valves.

6

SERVICING

Units must be serviced annually and the log book at the back of this

guide must be updated. Failure to do this will invalidate the warranty

INSTALLATION CHECKLIST & PROBLEM SOLVING

Store Temperature

Direct units must be maintained at a minimum of 75

o

C. Always

use immersion cylinder thermostats. Indirect (i.e. two coil units)

must be maintained at a minimum of 70

o

C.

Incoming Mains

Minimum 22mm bore, preferred pressures over 2.0 bar. It is

essential to install the 3 bar pressure reducing valve supplied,

to control excess pressure (see page 4).

Hardness

Scale will be a problem where CaCO

3

exceeds 200mg/l. It is

recommended that incoming water is treated appropriately

(see page 4).

Boiler Pump Overrun (Direct models)

See Albion wiring and schematic diagrams (see pages 9 and 10).

System Layout

See Albion diagrams. The water level of the unit must be at the

highest point of the system (see page 4).

Potable Water Controls

These must be fitted to ensure that performance is safe and

complies with by-laws (see page 1 and 3).

Commissioning

Always flush thoroughly on both primary and secondary

circuits. There is no need to flush static stores (indirect models).

Adjust the blending valve if necessary for domestic hot water

preferred temperature.

Inhibitor

Already present in Indirect models, however, add after recommissioning if the unit has been in use. Do not allow any

dilution by draining down after inhibitor is added. Where drain

down occurs new inhibitor must be introduced (see page 2).

7

PROBLEM SOLVING

Poor Flow

140 Litre units are capable of delivering up to 25 litres per

minute 170,210,250 models deliver up to 30 litres per minute.

Check this initially at one outlet (bath). If the flow rate is less

than this, check incoming water pressure flow rates, check all

service valves are open and check blending valves/filters.

Poor hot water temperature

Check that the flow rate is within design parameters. If not,

reduce using flow restrictors.

Check the blending valve is not blocked and is fully open.

Check the store temperature is 75

o

C for Direct unit (70oC for indirect units).

A thorough check of all electrical components to ensure that

they are set and programmed correctly is essential.

Always ensure correct boiler size for the type of system and

dwelling. Smaller boilers will reduce performance, some

modulating boilers will extend recovery times.

Running overflow/warning pipe

Intermittent Adjust the float valve to ensure water level is at

water line point.

Continuous 1) Possible ball valve malfunction - check ball

valve closes fully. If not - replace.

2) Ball valve closes fully. If overflow still runs Check for fractured potable heat exchanger.

Close incoming mains. If overflow stops fault

may be with potable heat exchanger Replace Unit.

THE ALBION HOT-LINE IS MANNED DURING OFFICE

HOURS ON 0121 585 5151.

8

WIRING DIAGRAM

NL1234 C1E 124

L

NE2

3

2

23

LNE

23

EN

L

32

12345678910

FP715

PROGRAMMER

ITC

IMMERSION STAT

RMT 230

ROOM STAT

HEATING PUMP

EN

L

32

BOILER PUMP

BOILER

IMPORTANT – CONNECT NEUTRALS & EARTHS AS NUMERICALLY INDICATED

DIRECT TWIN PUMP FOR BASIC BOILERS AND BOILERS

WITH TIMED PUMP OVERRUN (See Inset)

MAINS

BOILER WITH TIMED PUMP OVERRUN

BOILER

L

N

E

SWITCHED LIVE

PUMP LIVE

JUNCTION BOX

1

2

3

5

9

REMOVE LINK 5 - 9

N.B. FOR THERMAL PUMP OVERRUN

USE MFK 2.

MAINSFLOW DIRECT INTERGRATED THERMAL STORE

9

HEATING SYSTEM

NL1234 CE1124

L

NE2

3

2

23

P

S/L

E

21

EN

L

32EN

L

32

12345678910

HEATING PUMPBOILER PUMP

NL

GBRBLO

3

12

FP715

PROGRAMMER

ITC

IMMERSION STAT

RMT 230

ROOM STAT

HP22 OR 28

ZONE VALVE

BOILER WITH

PUMP OVERRUN

GAS/OIL BOILER WITH REQUIREMENT FOR THERMAL PUMP OVERRUN

DHW

BY PASS

PIPE

GAS/OIL

BOILER

ZONE

VALVE

BOILER

PUMP

P1

HEATING

PUMP

P2

HEATING BY PASS

(IF REQ'D)

HEATING FLOW HEATING RETURN

WIRING DIAGRAM

MAINS

FUSE

3 AMP

IMPORTANT

– CONNECT NEUTRALS & EARTHS AS NUMERICALLY

INDICATED

DIRECT TWIN PUMP THERMAL OVERRUN

MAINSFLOW DIRECT INTERGRATED THERMAL STORE

10

WIRING DIAGRAM

LN431

LNE

L

N

E

EN

L

32

12345678910

HOT WATER ONLY, SINGLE PUMP OPTION

WITHOUT PUMP OVER RUN

C2E1

BL

BR

GO

Br

BI

O

G

2

1

2

PUMP TO 10 ON

BOILER WITH OVER RUN

23

FP715

PROGRAMMER

ITC

IMMERSION STAT

142

RMT 230

ROOM STAT

HP22 OR 28

ZONE VALVE

IMPORTANT –

CONNECT NEUTRALS & EARTHS AS NUMERICALLY INDICATED

2

3

23

MAINS

FUSE

3 AMP

P/L

S/L

E

21

NL

3

CONNECT 10 & 9 FOR BOILERS

WITH PUMP OVER RUN

910

WITH PUMP OVER RUN

MAINSFLOW INDIRECT HOT WATER ONLY STORE

11

For servicing of ball valve and float, checking water levels, inhibitor

concentration or warning pipe connection

Access to the inside of the cased Mainsflow is via the top of the unit. The

cased lid is a friction fit and lifts off. This lid is insulated. Removal of the

lid exposes a standard aluminium combination tank top. This again is a

friction fit and will pull off. REMOVE CAREFULLY.

The stored water will be HOT (80ºc). There is no cold tank. Water droplets

of condensation may have formed on the underside of the combination

tank top, for safety reasons you may prefer to carry out this procedure

when tank is cold.

On completion of remedial work or service maintenance ensure the cold

water level does not exceed the height of the swage line.

Refit the aluminum top ensuring the overhanging edge is a tight fit to the

copper tank.

Refit the case lid ensuring insulation is securely in place.

ACCESS TO THE STORE

APPROVED MAINSFLOW SPARES

Thermostatic Blending Valve

Pressure Reducing Valve

Single Non Adjustable Thermostat

Expansion Vessel / Stock Arrestor

TBV1

PRV 3.0 bar

NAT 1

SA1

DESCRIPTION CODE

12

A USERS GUIDE TO THERMAL STORE

This leaflet describes thermal store hot water and central heating system installed in

these premises in simple terms.

Advice is given on the use of and adjustment of the various controls to get the best out

of the system.

Albion Mainsflow Systems offer the householder efficiency and high performance. All

services are linked to the mains cold water service. This eliminates bulk cold water

storage in the loft and generally improves hot water delivery at taps and shower outlets.

Please ensure that you follow the start up procedure at all times when the system has

been switched off or when an apparent fault occurs. This should be done before calling

out a plumber or service engineer.

THE SYSTEM

The system is designated a ‘thermal store’. The water in this system is controlled

by an immersion cylinder thermostat installed in the store. For the production of

hot water and central heating it is recommended that the store has to be on a 24

hour programme. However, the unit can be timed if pump or boiler noise is a

problem to come on in the morning and go off in the evening. This should be a

continuous period.

HOT WATER

When hot water is required, water from the cold mains is passed through a high

efficiency coil located in the store. The water in the store is at radiator temperature, too

hot to pass straight to the taps, so a blending valve is fitted to introduce cold water.

The resultant temperature at the taps being approximately 55

o

C

To fill a normal bath to an average depth takes approximately 4 minutes, hot water is

available during boiler operation.

CENTRAL HEATING

When central heating is required from a Direct Integrated System the room thermostat

switches on the heating pump. When rooms have reached the full design temperature

the thermostat will turn off the heating pump. The boiler pump will continue until the

store temperature is replenished. With a Indirect Hot Water Store the heating flow to

the radiators is provided directly from the boiler again controlled by a room thermostat.

TO START

If the system is new and the boiler has not been ‘on’ then it is necessary to pre-heat

the store (cylinder). This is done by turning the boiler ‘on’. The thermostat on the boiler

must be set at maximum at all time for the system to function correctly. Instruction for

lighting the boiler will be found behind the boiler panel. Set the heating clock to ‘off’

and leave for approximately 1

1

/4 hours, after this time set the clock to operate ‘on’

and ‘off’ to your requirements.

If the boiler is turned off for any reason, say holidays etc., and the store cools off, then

the above must be carried out before satisfactory operation will be achieved. It may be

necessary to operate the reset button on the programmer to reset unit.

USER GUIDE

13

OPERATION

To ensure high efficiency and rapid response to heating demands and to give 24 hour

hot water the highly insulated store is maintained at full temperature at all times,

consequently the boiler and store pump will operate at times when the central heating

clock is ‘off’. This is a normal function of the system and is one of the reasons that it is

so efficient.

The unit can be timed if pump or boiler noise is a problem, with one "off" period during

the night to suit demand.

BLENDER

As previously mentioned, this controls the temperature of the hot water at the taps to a

maximum of approximately 55

o

C and is factory set but if required the installer can

adjust this to give small variations in temperature either hotter or cooler.

STORE THERMOSTAT

This is factory set with fine adjustments being made by the installer. No further

adjustment should be made by anyone other than a qualified installer, otherwise

efficiency and performance will be affected.

THE ROOM THERMOSTAT

If the room thermostat is provided, start by setting it at the temperature quoted for the

room in which it is fitted and then adjust it to whatever setting you find most

comfortable. But remember if you overheat your house by 1

o

C, fuel costs will rise by 3

to 5 per cent. So set the thermostat just high enough for you to be comfortable.

Rather than opening windows or turning on extractor fans to control room

temperatures, use the thermostat. Where you need extra ventilation, as in kitchens and

bathrooms, keep it to the minimum necessary. And remember to shut that door! A

room thermostat can do its job much more effectively behind closed doors.

THE PROGRAMMER

The time clock enables your central heating system to be switched on and off automatically

usually twice every 24 hours, at a time selected by you to suit your daily routine.

Where the house is empty during the daytime, a sensible arrangement is for the heating to

come on about an hour before you get up, go off half an hour before you go out, come on

again and hour before you come home and go off again half an hour before you go to bed.

Please refer to the individual programmer instruction applicable to your unit.

Also note that if the appliance has been switched off for some days it maybe

necessary to use the reset button to start the programmer.

14

FROST THERMOSTAT

If the boiler is fitted in a semi-exposed situation, such as a garage or outbuilding, a

frost thermostat may be fitted. This overrides the clock should the temperature

approach freezing. It will be set by the installer and you should not alter the setting.

VENTILATION

Under no circumstances should any ventilation grilles provided for the boiler be

blocked.

AIR RELEASE VALVES

If only the bottom of the radiator gets hot, trapped air is usually the cause and this

can easily be released. Having first turned the time clock ‘off’, open the air release

valve which is at the top of the radiator. Open the valve half a turn only until water

appears, then close it. A piece of cloth is useful to catch the water.

IMPORTANT

Radiators should not be covered by curtains or furniture. Heat trapped behind closed

curtains will mostly be lost through the window. Nor should radiators be boxed in.

They may be painted with any oil-based gloss paint but not with metallic paint which

will reduce their efficiency, or emulsion paint which is water-based and may cause

rusting.

Before calling out plumbers or your normal contact please ensure that

the full start up procedure has been followed.

15

TM

is supported by

WATERHEATER

MANUFACTURERS

ASSOCIATION

Thermal Store

Installation,

Commissioning and

Service Record

Log Book

(To be retained by customer).

INSTALLER DETAILS

APPLIANCE DETAILS

COMMISSIONING RECORDS

SERVICE INTERVAL RECORD

IMPORTANT

FAILURE TO INSTALL & COMMISSION THIS APPLIANCE TO THE

MANUFACTURER’S INSTRUCTIONS MAY INVALIDATE THE WARRANTY

This note does not affect your statutory rights.

INSTALLER & COMMISSIONING ENGINEER DETAILS

CUSTOMER DETAILS

NAME

ADDRESS

TEL No.

INSTALLER DETAILS

NAME

ADDRESS

TEL No.

DATE

REGISTRATION DETAILS

REG No.

ID SERIAL No. etc.

COMMISSIONING ENGINEER

DETAILS

NAME

ADDRESS

SERVICE REQUIREMENTS

1

Check valve operation of pressure

reducing valve should be 3.0 bar static

- only adjust if necessary

2

Check flow rates are satisfactory - clean

filter in pressure reducing valve only if

required. Do not exceed stated flow

rates.

3

Check charge in expansion vessel.

Should be 3.0 bar - inflate as required

after decommissioning the system.

4

Check operation of ball valve float,

adjust or replace as required.

5

Check store inhibitor strength;

If Fernox MBI = 4%

If Sentinal x 100 = 1%

If Albion static store inhibitor = 1%

TEL No.

DATE

REGISTRATION DETAILS

REG No.

ID SERIAL No. etc.

Should further assistance or clarification be required contact Albion Advice

on 0121 585 5151

Failure to carry out annual

service/maintenance requirements and

log proof in service/maintenance

records may invalidate warranty.

APPLIANCE DETAILS

MANUFACTURER MODEL

CAPACITY LITRES SERIAL NO.

GENERAL INSTALLATION

HAS A CHECK BEEN DONE FOR JOINT TIGHTNESS AND LEAKS? YES NO

HAS A CHECK BEEN DONE FOR ELECTRICAL SAFETY? YES NO

SERVICE INTERVAL RECORD

It is recommended that your heating system is serviced regularly and that your service engineer completes the

appropriate Service Interval Record below.

SERVICE PROVIDER

Before completing the appropriate Service Interval Record below, please ensure you have carried out the service

as described in the manufacturer’s instructions and in compliance with all the relevant codes of practice.

SERVICE 1 DATE

ENGINEER NAME

COMPANY NAME

TEL No.

ID SERIAL No.

COMMENTS

SIGNATURE

SERVICE 3 DATE

ENGINEER NAME

COMPANY NAME

TEL No.

ID SERIAL No.

COMMENTS

SIGNATURE

SERVICE 5 DATE

ENGINEER NAME

COMPANY NAME

TEL No.

ID SERIAL No.

COMMENTS

SERVICE 2 DATE

ENGINEER NAME

COMPANY NAME

TEL No.

ID SERIAL No.

COMMENTS

SIGNATURE

SERVICE 4 DATE

ENGINEER NAME

COMPANY NAME

TEL No.

ID SERIAL No.

COMMENTS

SIGNATURE

SERVICE 6 DATE

ENGINEER NAME

COMPANY NAME

TEL No.

ID SERIAL No.

COMMENTS

SIGNATURE

SERVICE 7 DATE

ENGINEER NAME

COMPANY NAME

TEL No.

ID SERIAL No.

COMMENTS

SIGNATURE

WHEN ALL OF THE ABOVE SERVICE HAVE BEEN COMPLETED, PLEASE CONTACT YOUR SERVICE ENGINEER

FOR AN ADDITIONAL SERVICE INTERVAL RECORD SHEET.

SIGNATURE

SERVICE 8 DATE

ENGINEER NAME

COMPANY NAME

TEL No.

ID SERIAL No.

COMMENTS

SIGNATURE

COMMISSIONING PROCEDURE INFORMATION

BOILER PRIMARY SETTINGS

IS THE PRIMARY SEALED OR OPEN VENTED SYSTEM? Sealed Open

IF SEALED THEN WHAT IS THE SYSTEM PRESSURE? Hot Cold BAR

IF SEALED THEN WHAT IS THE CHARGE PRESSURE OF EXPANSION VESSEL? BAR

WHAT IS THE AVAILABLE BOILER FLOW TEMPERATURE?

WHAT IS THE BOILER RETURN TEMPERATURE WHEN CYLINDER/STORE IS SATISFIED?

ALL MAINS PRESSURE SYSTEMS

WHAT IS INCOMING COLD WATER PRESSURE? BAR

HAS A WATER TREATMENT DEVICE BEEN FITTED? YES NO

IF YES TO ABOVE THEN WHAT TYPE?

THERMAL STORE SYSTEMS ONLY

IS THE STORE TREATED WITH INHIBITOR?

(NOTE - FOR INDIRECT THERMAL STORES THE STORE MUST BE TREATED IN ADDITION

TO THE PRIMARY SYSTEM)

IS A 3 BAR PRESSURE REDUCING VALVE FITTED?

IS THE EXPANSION VESSEL FULLY CHARGED AT 3 BAR?

IS THE OVERFLOW/WARNING PIPE INSTALLED IN LINE WITH BEST

PRACTICE?

IS THE BLENDING VALVE SET AT 55

IS THE DHW FLOW CONTROLLED TO THE APPROPRIATE RATE?

IF CYLINDER IS IT VENTED CORRECTLY?

IS THE CYLINDER STAT SET TO 70

o

C TO 75oC?

(INTEGRAL IN CASED CONTRACTOR)

o

C?

CONCENTRATION

YES NO

TYPE

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

o

o

C

C

ALL PRODUCTS

HAS THE SYSTEM BEEN EXPLAINED TO THE HOUSEHOLDER? YES NO

HAS THE SYSTEMS LITERATURE BEEN LEFT WITH THE HOUSEHOLDER? YES NO

ENGINEERS SIGNATURE CUSTOMERS SIGNATURE

Loading...

Loading...