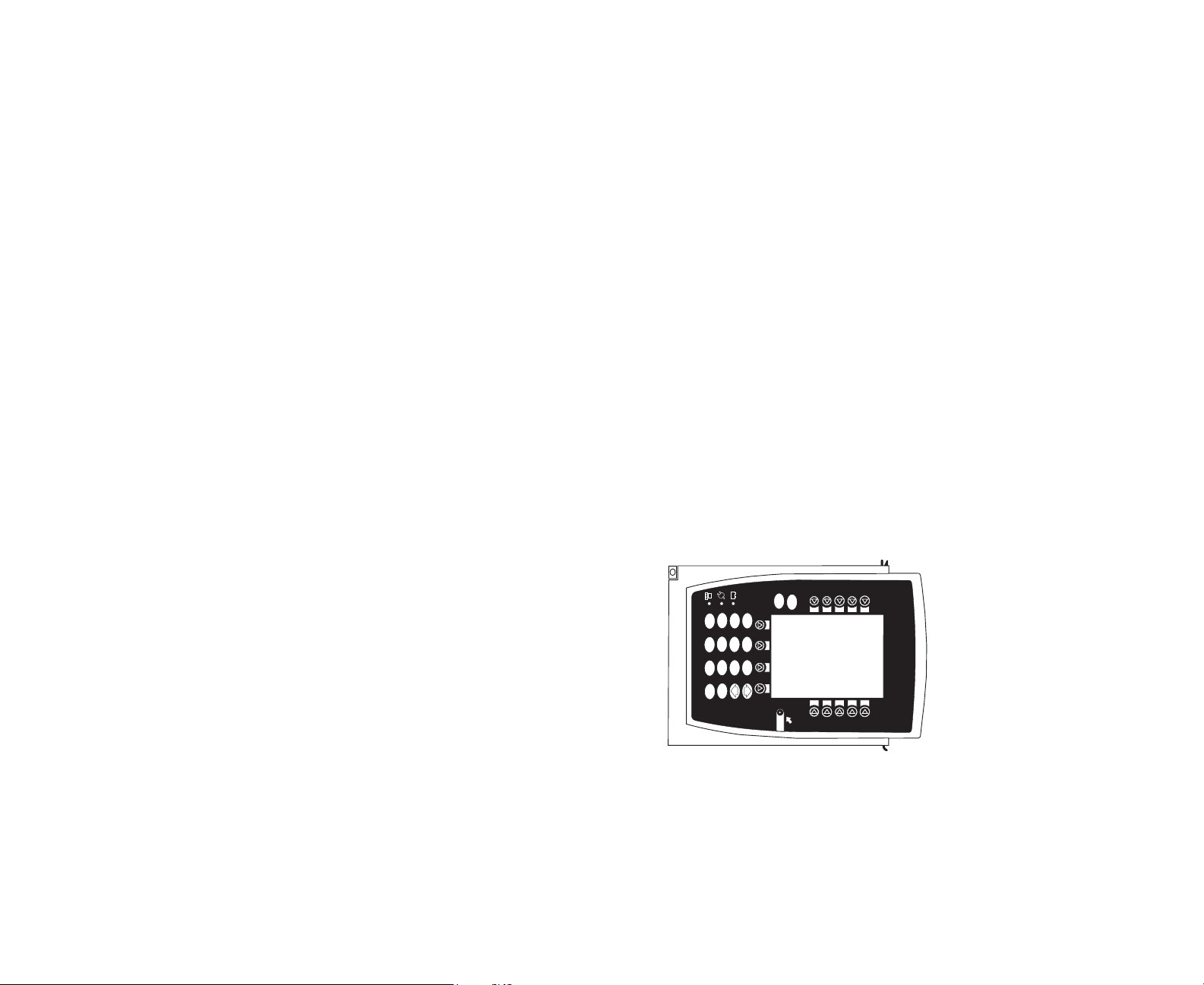

DIRECTIONS FOR USE

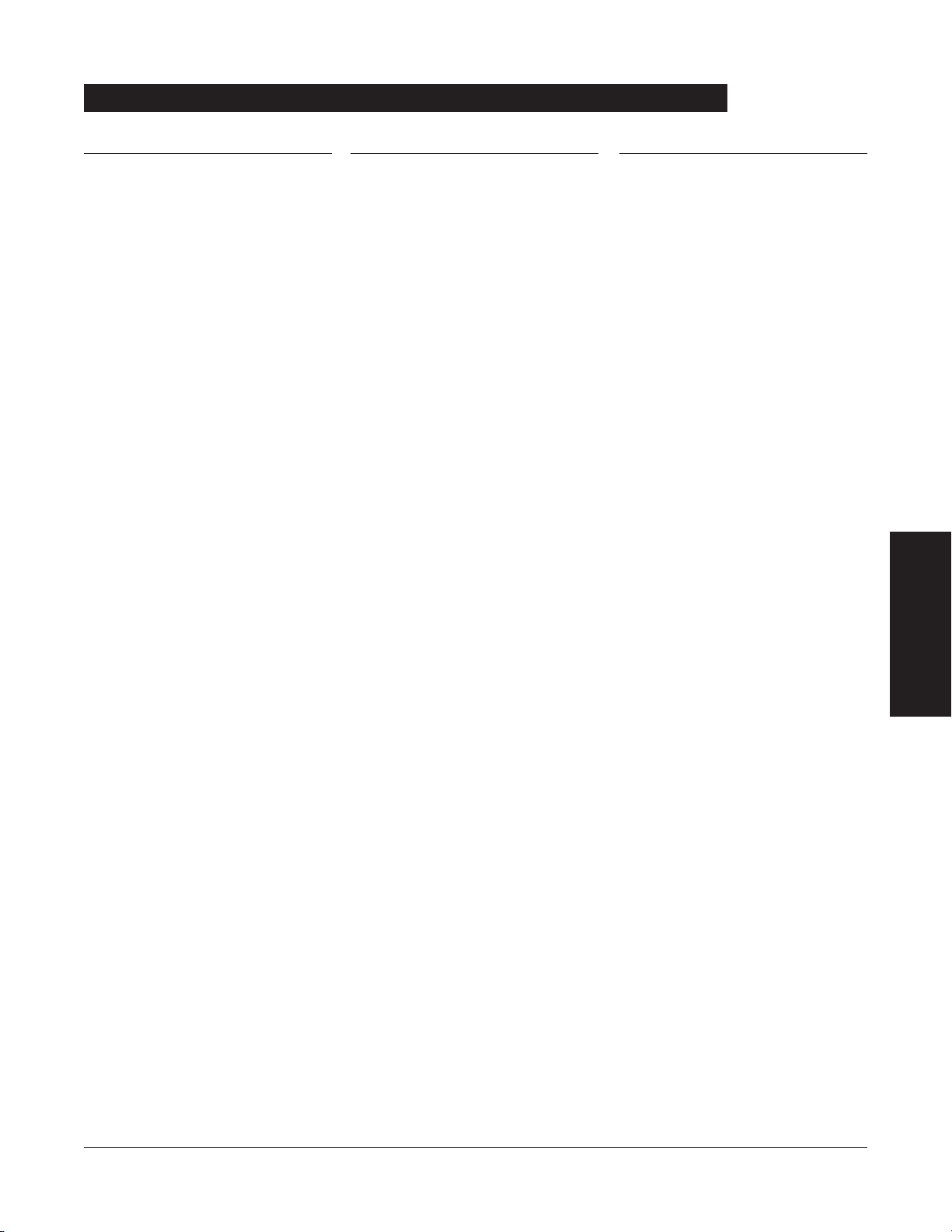

MEDICATION SAFETY SYSTEM

PROGRAMMING MODULE

OPTIONS

SILENCE

CLEAR

1

4

7

5

8

0

2

9

6

.

3

CANCEL

ENTER

SYSTEM

ON

8000 Series

Medley™

8000 SERIES

PROGRAMMING MODULE

TABLE OF CONTENTS

INTRODUCTION

ABOUT THE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

FEATURES AND DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

GETTING STARTED

WARNINGS AND CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CONTROLS AND INDICATORS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Unpacking Programming Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

ATTACHING AND DETACHING CHANNELS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Attaching Channel(s)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Detaching Channel(s)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Adding Channel(s) While System is Powered On

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

DISPLAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Main Display

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Adjusting Display Contrast

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Powering On System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Responding to Maintenance Reminder

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Selecting New Patient and Profile Options

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Entering Patient ID

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Modifying Patient ID

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ADJUSTING AUDIO VOLUME

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SETTING UP TIME OF DAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

REVIEWING SYSTEM CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

REVIEWING SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

REVIEWING SOFTWARE VERSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

VIEWING AND CLEARING GUARDRAILS®EVENT COUNTER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

POWERING OFF

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Powering Off System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Powering Off Channel

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

LOCKING/UNLOCKING TAMPER RESIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

COMPUTER LINK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

ALARMS, ERRORS, MESSAGES

DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

AUDIO CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

ALARMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

ERRORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

MESSAGES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33

MAINTENANCE

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

SYSTEM CONFIGURABLE SETTINGS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

INTRODUCTION GETTING STARTED ALARMS, ERRORS,

MESSAGES

MAINTENANCE

TABLE OF CONTENTS i

ii TABLE OF CONTENTS

MAINTENANCE (Continued)

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

BATTERY CARE AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Battery Type and Charging

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Battery Charge

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Battery Care

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Battery Cautions and Disposal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

INSPECTION REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SERVICE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41

Customer Service

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Technical Support

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41

Product Return

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

GENERAL CONTACT INFORMATION

Customer Advocacy

For clinical and technical questions, feedback, and troubleshooting assistance.

Phone, toll-free, within the United States and Canada: (800) 854-7128, Ext. 7812

E-Mail: CustomerFeedback@alarismed.com

Technical Support

For technical information related to maintenance procedures and service manual support.

For more detailed information, refer to the “Service Information” section of this document.

United States:

Phone:

(858) 458-6003

Toll-free: (800) 854-7128, Ext. 6003

Canada:

Phone, Toll-free:

Eastern: (800) 908-9918

Western: (800) 908-9919

THIS PAGE

INTENTIONALLY

LEFT BLANK

INTRODUCTION

INTRODUCTION 1

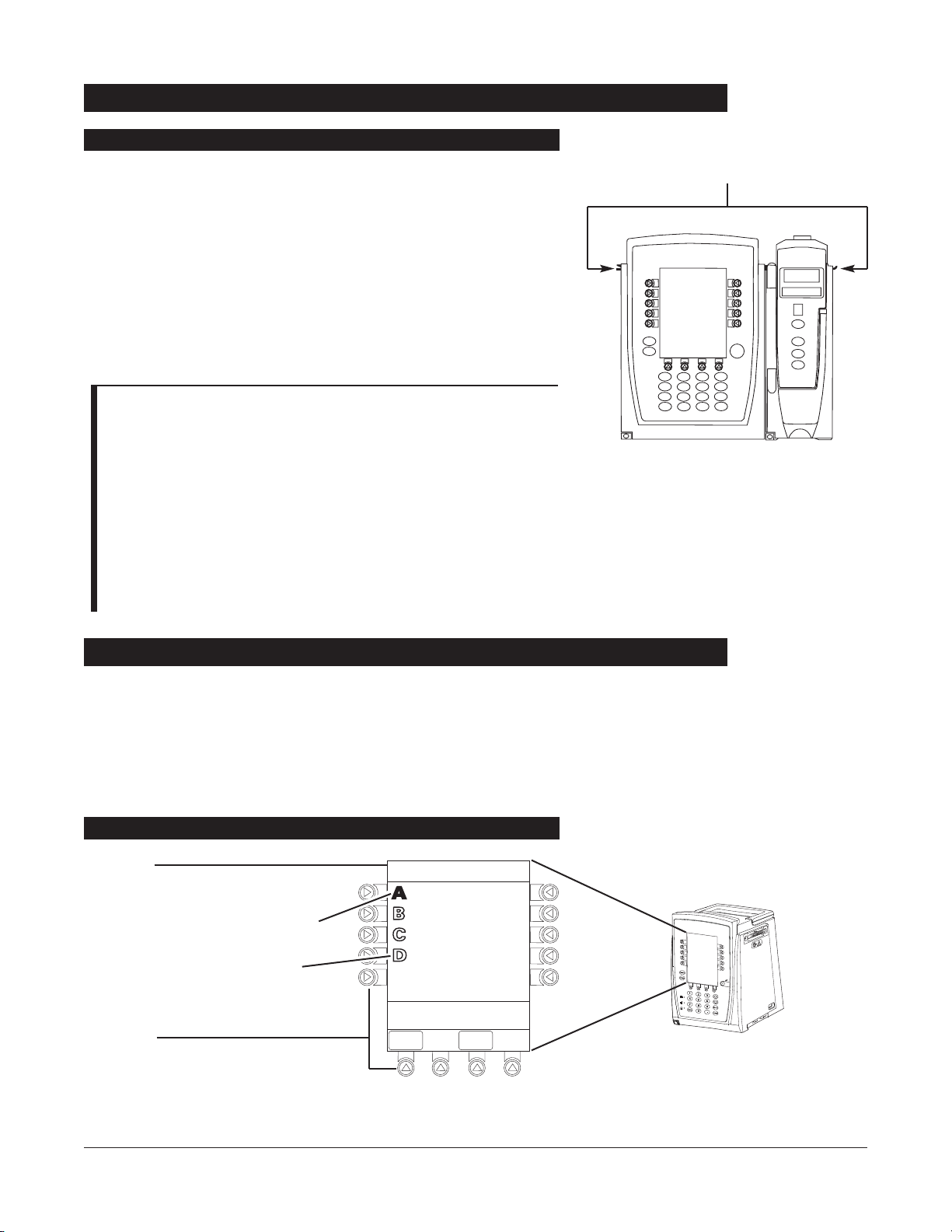

The Medley™ Medication Safety System is a modular infusion

and monitoring system intended for use in today’s growing

professional healthcare environment, for use in adult, pediatric

and neonatal care.

The Medley™ Medication Safety System consists of the

Programming Module (

8000

Series), the Guardrails

®

Safety

Software, and up to four detachable modules (or “channels”)

which provide infusion or monitoring capabilities.

The Medley™ Programming Module is the core of the Medley™

System and provides a common user interface for programming

infusions and monitoring, which helps to reduce complexity at

the point of care.

NOTE: The Medley™ Programming Module name will be changing

in the near future to Medley™ Point-of-Care Unit.

Guardrails®Safety Software for the Medley™ System brings a

new level of medication error prevention to the point of patient

care. The Guardrails

®

Safety Software features medication

dosing guidelines for up to ten patient-specific care areas,

referred to as profiles. Each profile contains a specific drug

library and channel labels, as well as instrument configurations

appropriate for the care area. Optional drug-specific Guardrails

®

Clinical Advisories provide visual messages. Dosing limits for

each drug entry may be either Guardrails

®

Hard Limits that

cannot be overridden during infusion programming or

Guardrails

®

Soft Limits that can be overridden, based on clinical

requirements.

A data set is developed and approved by the facility’s own multidisciplinary team using the Guardrails®Editor, the PC-based

authoring tool. A data set is then electronically transferred to

the Medley™ System by qualified personnel. The approved data

sets are maintained by the Guardrails

®

Editor for future updates

and reference.

Information about Guardrails

®

Alerts that occur during use is

stored within the Medley™ Programming Module, and can be

accessed using the Guardrails

®

Continuous Quality Improvement

(

CQI) Event Tracker and Guardrails

®

CQI

Event Reporter.

This document provides directions for use for the Medley™

Programming Module. Read all instructions before using the

Medley™ System. For additional operating instructions,

indications for use and contraindications, refer to the Directions

for Use for the individual system module(s).

About the System

INTRODUCTION

2 INTRODUCTION

Refer to the “Alarms, Errors, Messages” chapter of this Directions for Use for the definitions of various

alerts. Refer to the Directions for Use that applies to the attached Medley™ Module(s) for features and

definitions specific to that module.

Anesthesia Mode The Anesthesia Mode allows the anesthesiologist to access additional

drugs, in each profile, that are appropriate to anesthesiology. It also

features permanent pause.

Battery Run Time Display The Battery Run Time Display appears on the Main Display prompt bar

when the Programming Module is disconnected from

AC. If enabled,

this feature provides a visual display of the estimated remaining battery

run time under the current operating conditions, when operating on

battery.

Data Set A data set is created using the Guardrails

®

Editor authoring tool and

then electronically transferred to the Medley™ Programming Module.

A data set reflects the facility’s best-practice guidelines for

IV drug

administration and includes: profile drug libraries, clinical advisories,

instrument configurations, and channel label libraries.

Dose Checking The Always Dose Checking option causes a Guardrails

®

Soft Alert to

occur each time a dose limit is exceeded. The drug label in the Channel

Message Display provides an indicator (“

↑↑↑” or “LLL”) that the infusion

is beyond the current Guardrails

®

Soft Limit.

The Smart Dose Checking option causes an initial Guardrails

®

Soft Alert

to occur when a dose limit is exceeded. Subsequent programming

beyond the dose limit will not receive an alert. The drug label in the

Channel Message Display provides an indicator (“

↑↑↑” or “LLL”) if the

infusion is beyond the current Guardrails

®

Soft Limit.

Ease of Use To enhance safety and ease of operation, the Medley™ System provides

a full range of audio and visual alarms, errors, and messages.

Guardrails

®

Safety Software The Guardrails®Safety Software is designed to help prevent

programming errors by:

• Customizing device configurable settings to meet the need of the

selected hospital area/unit (profile).

• Comparing user programming with hospital-defined best-practice

guidelines.

• Providing a Guardrails

®

Prompt if an out-of-limits entry is made.

Features and Definitions

INTRODUCTION 3

Features and Definitions (Continued)

INTRODUCTION

Patient ID Entry An optional alphanumeric

16-character patient identifier can be

entered and displayed.

• When enabled, the

ID entry defaults to the Startup screen.

• When disabled, the

ID entry is only accessible from the System

Options screen.

Pole Clamp The Medley™ Programming Module pole clamp adapts to a wide

variety of surfaces, to provide versatility. The pole clamp features

include:

• Ergonomically designed knob.

• Accommodates diameters from

5

/8to 13/8inches (15.9 to 34.9 mm).

• Vertical or horizontal orientation, allowing it to adapt to both IV

poles and bed rails.

Profile A Profile is a unique set of system configuration settings and best-

practice guidelines for a specific patient population or patient type, and

consists of the following three components:

• Instrument configuration settings.

• A Guardrails

®

Drug Library, which includes drug names, standard

concentrations, dosing units, Guardrails

®

Limits, and optional

associated clinical advisories for both continuous and bolus dose

infusion.

• A Channel Label Library with text (alphanumeric) labels, that allows

identification of channels that are actively infusing nondrug

therapies (for example, saline or

TPN). Channel labels can also be

used to identify the route of delivery (for example, epidural).

Profile settings are established by the facility’s own multi-disciplinary

team prior to system implementation. Profile parameters are used to

create a data set, which is then electronically transferred to the

Programming Module.

System Configuration System Configurations allow system settings to be customized. If the

Profiles feature is enabled, the system settings defined for the selected

profile are automatically activated.

Tamper Resist The Tamper Resist feature provides a quick one-touch lockout of the

front panel keypad.

Alternating Current: Indicates that device should be attached to alternating current source,

50/

60 Hz only.

Attention: Refer to accompanying documentation.

Canadian and

U.S. Certification Mark: Products bearing this mark have been tested and

certified in accordance with applicable

U.S.

and Canadian electrical safety and performance

standards (

CSA C22.2 No.

601.1, UL 2601-1 and IEC 60601–2–24).

Communications Connector: For

RS-232 attachment.

Protection against fluid ingress: Drip Proof

Fuse Replacement: Replace fuse only with same type and rating.

IUI Connector: Inter-Unit Interface connector used to establish power and communications

between the Programming Module and attached modules.

Main Power: Connected to alternating current,

100-240 VAC.

Manufacturing Date: Number adjacent to symbol indicates the month and year of

manufacture.

Potential Equalization Conductor (if so equipped). Note: If the integrity of the

PEC or Hospital

Earth System is in question, operate the instrument using internal battery power.

CAUTION

: Federal (U.S.A.) law restricts this device to sale by or on the order of a physician.

“

SYSTEM ON”

Tamper Resist activate/deactivate switch.

4 INTRODUCTION

Symbols

+

75

IPX1

!

nly

O

MM-YYYY

NOTE: Although the Medley™ Medication Safety System is built

and tested to exacting specifications, it is not intended to replace

the supervision by medical personnel. The user should become

thoroughly familiar with the features and operation of the Medley™

System and exercise vigilance in its utilization.

GETTING STARTED

GETTING STARTED 5

GETTING STARTED

Warnings and Cautions

For WARNINGS and CAUTIONS for detachable module(s), refer to

the individual module’s Directions for Use.

To ensure proper performance of the Medley™ System and to

reduce potential injury, observe the following precautions:

When properly secured/snapped, the bottom latch provides a

very secure connection between modules. If not properly

latched, a module can be dislodged during operation.

WARNING

To ensure proper performance of the Medley™ System and to

reduce potential injury to the operator, observe the following

precautions:

• Always use a grounded, three wire receptacle. Where the

integrity of the protective earth grounding system is in doubt,

operate on internal battery.

• Disconnect from main (

AC) and battery power when

performing maintenance.

User Precautions

A warning is an alert to potential serious outcomes (death,

injury or serious adverse events) to the patient or user.

WARNING

A caution is an alert to take special care for the safe and

effective use of the device.

CAUTION

Do not use the Medley™ System in close proximity of Magnetic

Resonance Imaging (

MRI).

WARNING

O

nly

• The instrument case should only be opened by qualified

service personnel using proper grounding techniques.

Dropping/Jarring

Should an instrument be dropped or severely jarred, it should

be immediately taken out of use and inspected by qualified

service personnel, to ensure its proper function prior to reuse.

Operating Environment

Not for use in the presence of flammable anesthetics.

6 GETTING STARTED

Warnings and Cautions (Continued)

User Precautions (Continued)

Explosion hazard. Do not use in the

presence of flammable anesthetics.

DANGER

Electrical shock hazard. Do not open

case. Refer to qualified service

personnel.

WARNING

GETTING STARTED 7

GETTING STARTED

Use of accessories or cables other

than those specified may result in

degraded electromagnetic

compatibility performance of this

device.

WARNING

Warnings and Cautions (Continued)

User Precautions (Continued)

Radio Frequency Interference

Operating the system near equipment which radiates highenergy radio frequencies (electrosurgical/cauterizing

equipment, portable radios, cellular telephones, etc.) may

cause false alarm conditions. If this happens, reposition the

device away from the source of interference or turn off the

device and manually regulate the flow with the clamp and/or

monitor the vital parameters using an appropriate clinical

alternative.

8 GETTING STARTED

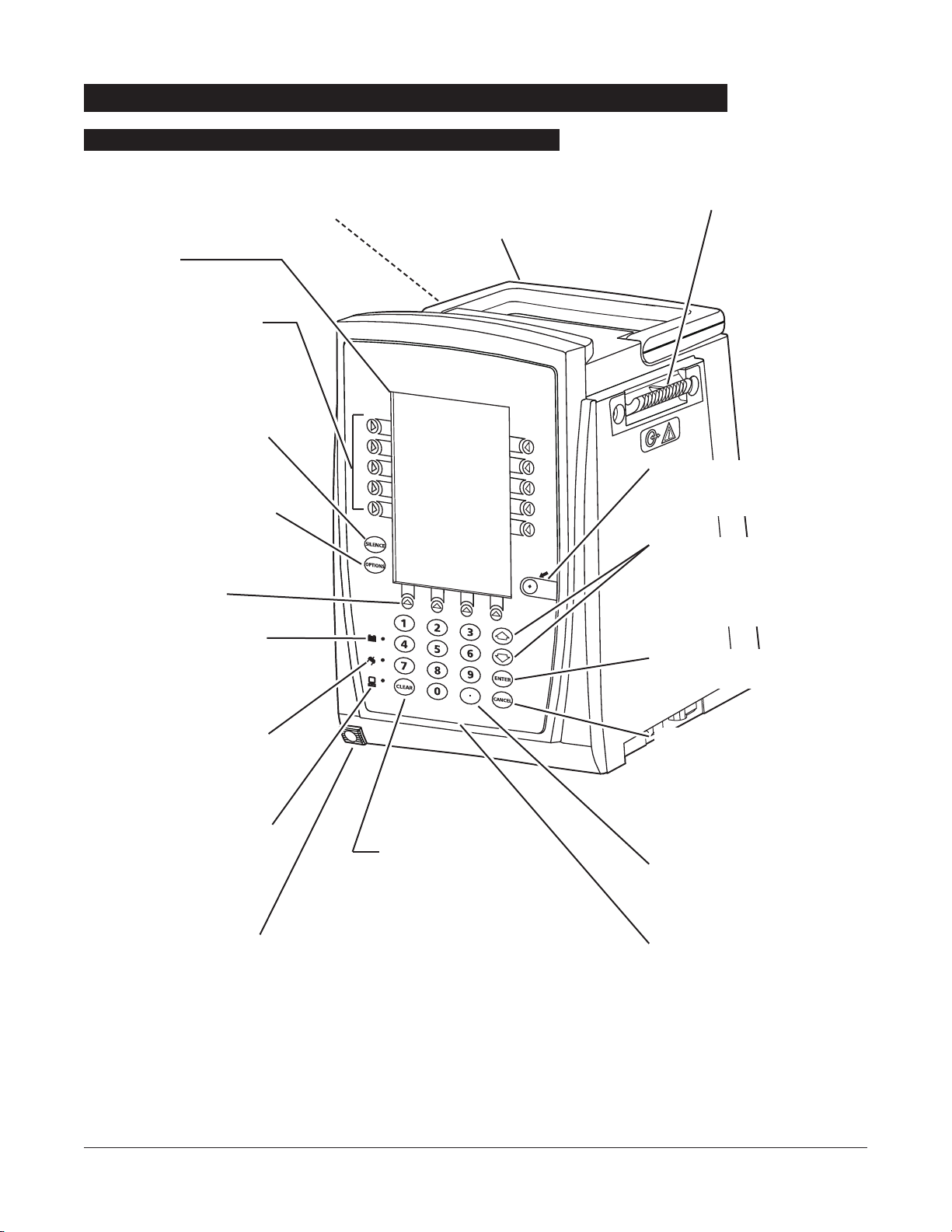

IUI Connector, Left

(not visible)

SYSTEM

ON

Controls and Indicators

Front/Side View

Main Display

Soft Keys -

When pressed,

allows selection of options or

infusion parameters appearing

on Main Display adjacent to soft

key.

Silence Key -

When pressed

during an alarm, silences

audio for two minutes.

Options Key - When pressed,

allows access to available

System or Channel Options.

Soft Keys (see above).

Battery Indicator -

When

illuminated, indicates Medley™

System is operating on battery

power.

Power Indicator - When

illuminated, indicates Medley™

System is connected to an AC

power source.

Computer Monitor Mode

Indicator -

When illuminated,

indicates Medley™ System is

operating in Computer Monitor

mode.

Channel Release Latch -

When pressed, allows channel

to be removed.

Clear Key - When pressed,

clears current selected

parameter setting to “0”.

IUI Connector, Right

Handle

System On Key -

When pressed,

changes Medley™ System from

Standby to Operating mode.

Up/Down Arrows - When

pressed, will increase or decrease

parameter with each key press or

will scroll up and down when

pressed and held.

Enter Key - When pressed,

confirms current parameter entry.

Cancel Key - When pressed,

sequentially backs out of current

setup sequence.

Decimal Key - When pressed,

inserts a decimal point in numeric

data.

Numeric Keypad

GETTING STARTED 9

GETTING STARTED

Controls and Indicators (Continued)

Rear View

IUI Connector, Right IUI Connector, Left

Pole Clamp Knob

Primary Audio Speaker

Connector Plug over RJ45

Communication Data Port

Tamper Resist Switch

AC Power Cord Safety

Retainer

Power Cord Strap

Option Upgrade Panel

(for future use)

Handle

Use this bolt to reorient Pole

Clamp 90° for attachment to

a bed rail instead of a pole.

1. Remove Programming Module from its carton.

2. Check pole clamp for freedom of operation.

3. Check

AC power entry module for contamination.

4. Check for loose parts.

5. Plug module into an

AC outlet for 24 hours prior to use.

Maximum battery capacity, as well as gauge accuracy, is

reached after several charge/discharge/charge cycles. For

best results, fully charge/discharge/charge battery before

placing in use.

6. Perform Periodic Inspections (see “Inspection Requirements”

section in “Maintenance” chapter).

7. Perform check-in procedure [reference Medley™

Maintenance Software User Manual (included with

8970C,

or later) for details].

If the Programming Module is damaged, contact

ALARIS Medical

Systems for authorization to return the equipment for repair.

Instruments are tested and calibrated before they are packaged

for shipment. To ensure proper operation after shipment, it is

recommended that an incoming inspection be performed before

placing the instrument in use.

To enable the Profiles feature, a hospital-defined best-practice

data set must be uploaded to the Programming Module. Prior

to placing the Medley™ System in use, verify whether or not the

Profiles feature has been enabled (reference “Reviewing System

Configuration” section in “Getting Started” chapter).

10 GETTING STARTED

Unpacking Programming Module

Installation

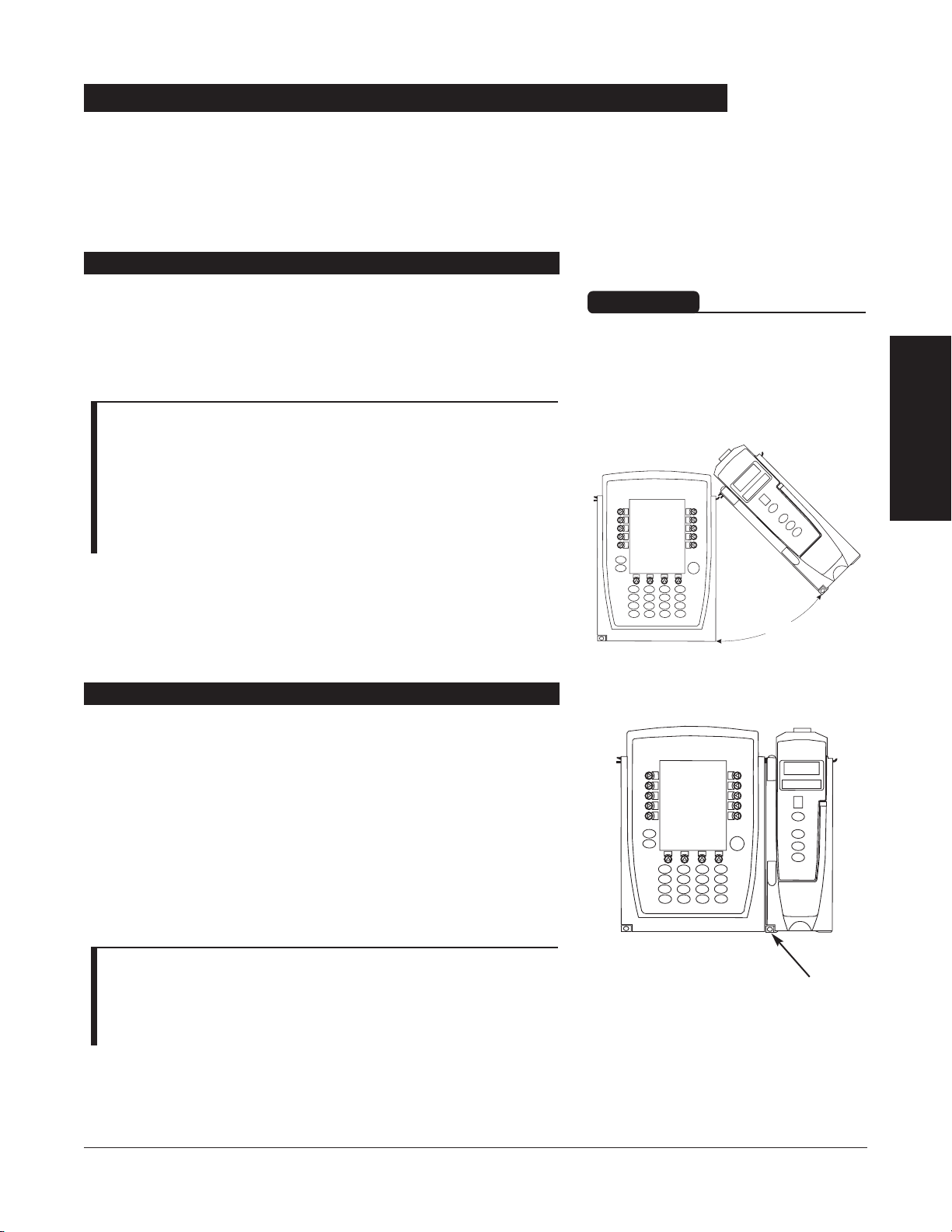

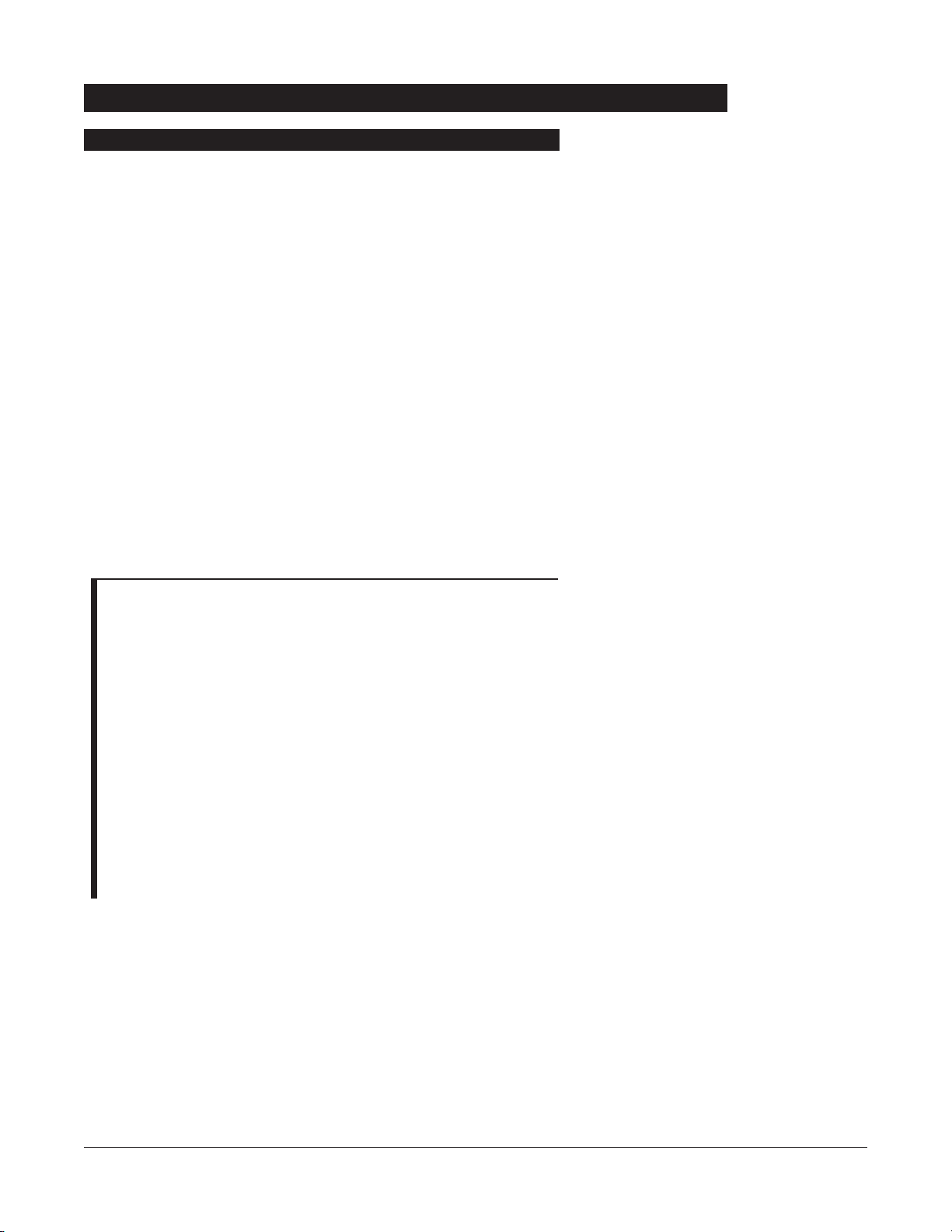

1. Position free channel at a

45°

angle, aligning IUI

Connectors.

2. Rotate free channel down against Programming Module or

attached channel, until bottom latch snaps in place.

NOTES:

• Individual hospitals may choose to permanently attach channels.

To remove permanently attached channels, contact qualified

service personnel.

• Application of adhesive tape or other materials to the sides of

the Programming Module and channels may prevent proper

latching.

Channels can be attached to either side of the Programming

Module or to either side of another channel. The process to

attach or detach is the same for either side, whether

attaching/detaching to/from a Programming Module or another

channel.

GETTING STARTED

11

GETTING STARTED

Attaching and Detaching Channels

Attaching Channel(s)

Detaching Channel(s)

1. Ensure channel(s) is powered off before detaching.

2. Push channel release latch (located directly below IUI

Connectors) and then rotate channel(s) up and away from

Programming Module or attached channel (opposite to

motion shown above) to disengage connectors.

• Medley™ System reidentifies and shows appropriate

channel identification (

A

, B, C or D), from left to right.

• Appropriate channel position(s) (A, B or C) for remaining

channel(s) appear on Main Display.

NOTE: The Medley™ Medication Safety System is designed to

operate a maximum of four channels. Channels added in excess of

four will not be recognized by the system. The channel(s) can be

attached in any position; however, when mounted on an IV pole, it

is recommended that a balanced configuration be maintained.

Release Latch

When properly secured/snapped, the

bottom latch provides a very secure

connection between modules. If not

properly latched, a module can be

dislodged during operation.

WARNING

45°

Add channel as described in “Attaching Channel(s)”.

• System tests channel, causing all

LED segments and Indicator

lights of channel displays to illuminate briefly.

• Appropriate channel identification display (A

, B, C or D)

illuminates. Channels are always labeled left to right, so if a

channel is added to left of other channels, all channels will be

reidentified. Channel reidentification does

NOT interrupt or

affect infusion or monitoring on active channels.

• Channel positions (A

, B, C or D) appear on Main Display.

NOTE: If any of the following conditions are observed, the

affected channel must be removed from use and inspected by

qualified personnel:

• LED segments are not illuminated on channel displays during

power-on test.

• Indicator lights do not illuminate.

• Appropriate channel identification (A, B, C or D) is not

displayed.

If the affected channel operates normally when it is attached via the

alternate IUI connector, it may be used until a replacement channel

can be substituted.

12 GETTING STARTED

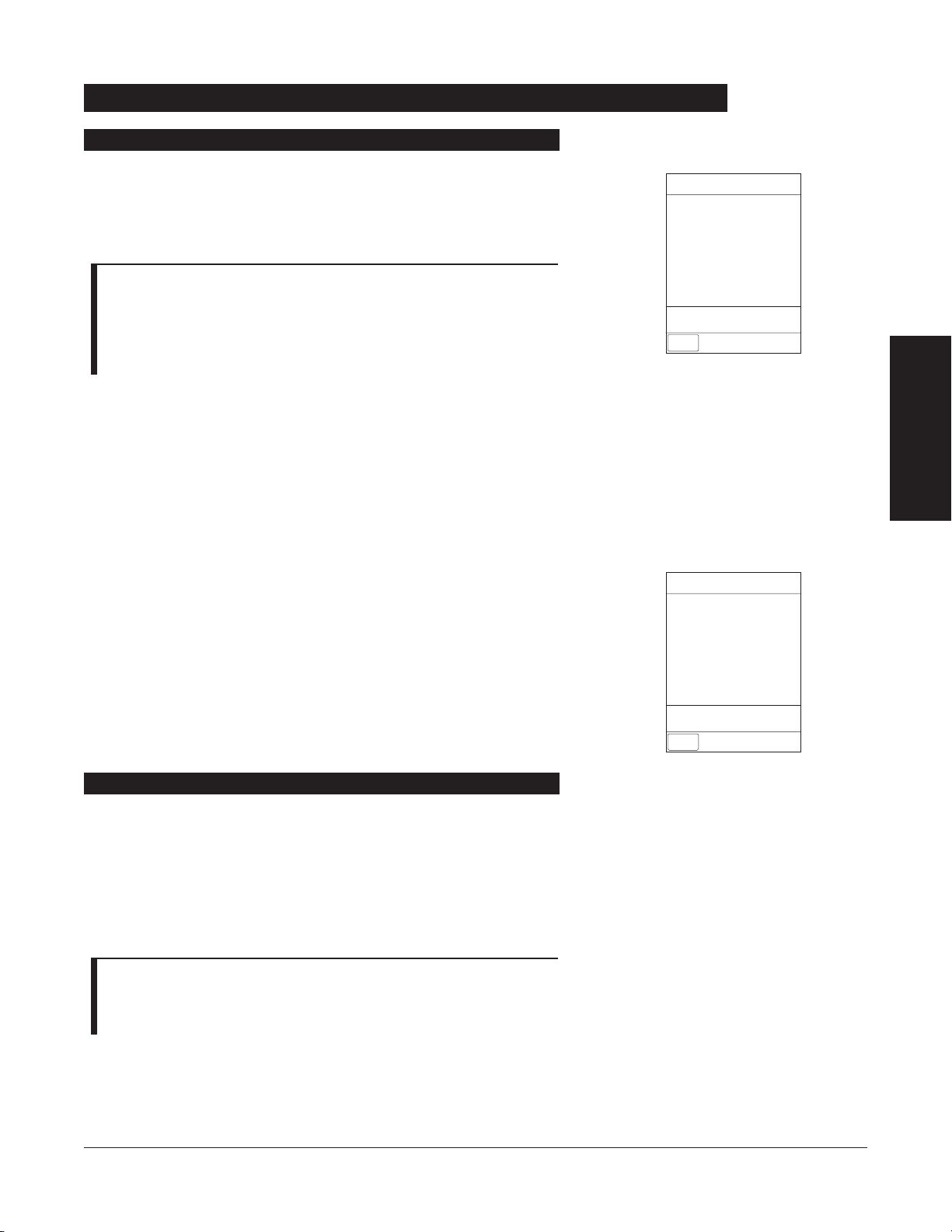

The displays illustrated throughout this document are for

illustration purposes only. The display content will vary,

depending on configuration settings, hospital-defined data set

uploaded using the Guardrails

®

Safety Software, and many other

variables.

Attaching and Detaching Channels (Continued)

Adding Channel(s) While System is Powered On

IUI Connectors

Title Bar

Channel Status

• A solid channel letter display

indicates channel is operating.

• An outlined channel letter

display indicates channel is

attached and ready for use.

Soft Keys

SYSTEM

ON

Displays

Main Display

Midtown Hospital

Adult ICU

VTBI = 250.0 mL

VOLUME

INFUSED

AUDIO

ADJUST

Channel Selected Indicator

“Inactive” Soft Key

Nonhighlighted indicates a

nonselected soft key.

“Active” Soft Key

Highlighted indicates a selected

soft key.

Prompt Bar

Look here for user prompts.

GETTING STARTED

13

GETTING STARTED

Displays (Continued)

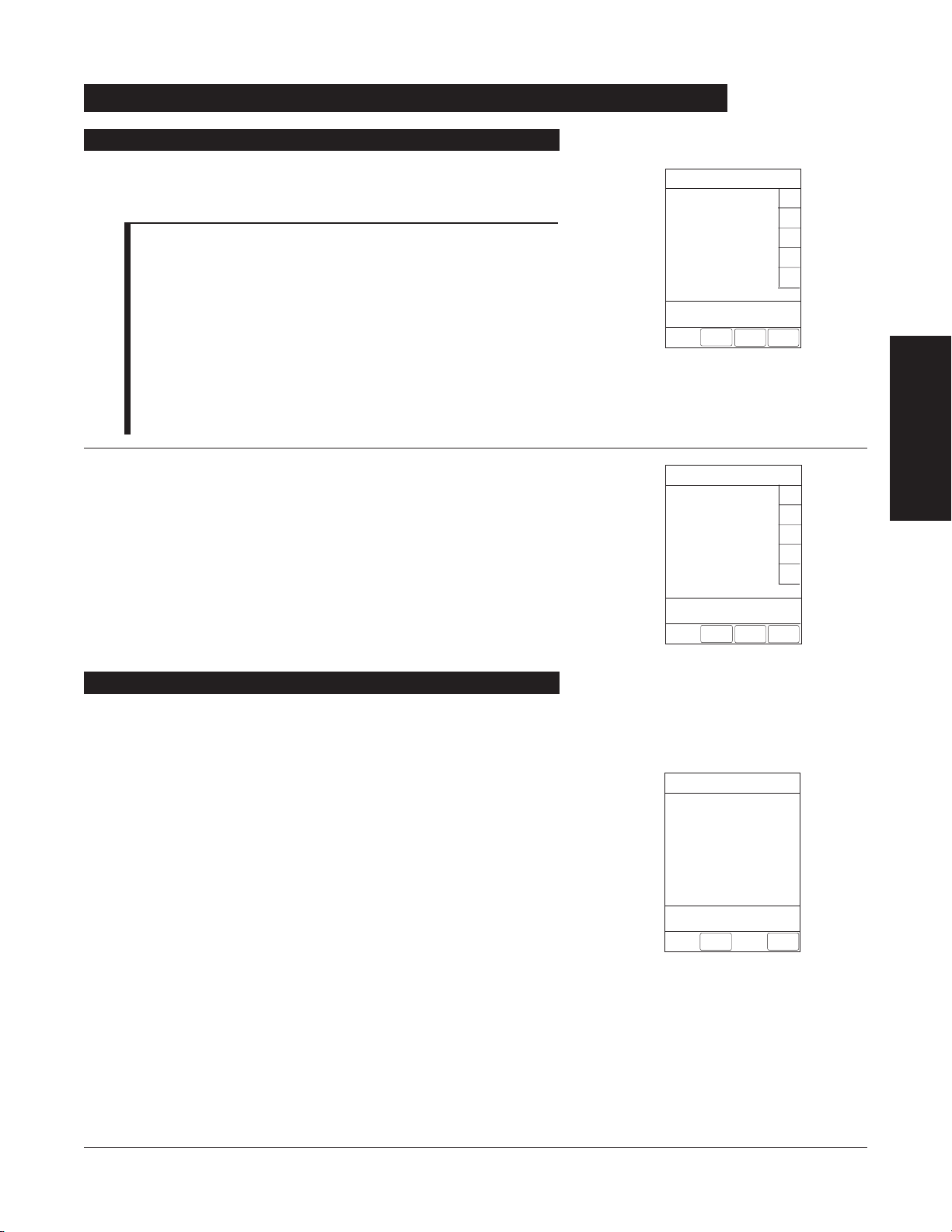

1. Press

OPTIONS

key.

2. Select

DDiissppllaayy CCoonnttrraasstt

soft key.

3. To adjust display for optimum viewing, use

LLiigghhtteerr//DDaarrkkeerr

soft keys.

4. To return to main screen, press

MAIN SSCREEN

soft key.

Adjusting Display Contrast

System Options

>Adjust Display to

Desired Contrast

MAIN

SCREEN

Display Contrast

Lighter

Darker

Medley

™

Medication Safety System

®

>Press START

Infusion Setup

RATE

40

mL/h

_250

mL

PAUSE

SECOND-

ARY

START

VTBI

SYSTEM

ON

Main Display (Continued)

System Options 1 of 3

Display Contrast

Patient ID

Time of Day

Power Down All Channels

Anesthesia Mode

>Select an Option or

EXIT

EXIT

DOWN

PAGE

1. Connect Programming Module to an external

AC power

source.

2. Press

SYSTEM OON

.

3. System self test begins:

• Diagnostics test causes all LED display segments and

Status Indicator lights of attached channel(s) to

illuminate briefly.

• Power Indicator illuminates.

• Appropriate channel identification (

A, B, C or D) displays

on attached channel(s).

• An Audio tone sounds.

• At completion of system-on test,

NNeeww PPaattiieenntt??

screen

appears.

• If

PM Reminder option is enabled and scheduled

preventive maintenance is due,

MAINTENANCE RREMINDER

screen appears.

NOTES:

• Previous infusion parameters are automatically cleared after eight

(

8) hours.

• If any of the following conditions are observed, the Programming

Module or the affected channel must be removed from use and

inspected by qualified personnel:

♦ LED segments are not illuminated during system-on test.

♦ Indicator lights do not illuminate.

♦ Appropriate channel identification (A, B, C or D) is not

displayed.

♦ Audio tone does not sound.

♦ Main Display does not appear backlit, appears irregular, or has

evidence of a row of pixels not functioning properly.

If the affected channel operates normally when it is attached via

an alternate

IUI connector, it may be used until a replacement

channel can be substituted.

14 GETTING STARTED

Start-Up

Powering On System

If the Preventive Maintenance (PM

) Reminder option is enabled

and the Programming Module or an attached module is due for

preventive maintenance, a

MAINTENANCE RREMINDER

message

appears at power up.

NOTES:

• If necessary, the reminder can be temporarily bypassed by

pressing the

CCOONNFFIIRRMM

soft key.

• Notify the appropriate facility personnel when a

MMAAIINNTTEENNAANNCCEE

RREEMMIINNDDEERR

occurs.

1. Remove and, if needed, replace module requiring

maintenance with a new module (reference “Attaching and

Detaching Channels” section).

2. If “system” (Programming Module and attached modules)

was powered off to replace Programming Module, reinitiate

start-up process.

OR

If an “attached module” (such as, a Pump Module) was

powered off and removed,

MAINTENANCE RREMINDER

display

reflects removal of that channel. To continue start–up

process, press

CONFIRM

soft key.

GETTING STARTED

15

GETTING STARTED

Selecting New Patient and Profile Options

Start-Up (Continued)

The option to enter and display a 16-character alphanumeric

patient identifier is always available. The instrument may be

configured to automatically display the

PPaattiieenntt

IIDD

EEnnttrryy

screen

during start up or to provide access only through the

SSyysstteemmss

OOppttiioonnss

menu.

The following procedures assume the Profiles feature is enabled.

NOTE: The display contrast can be adjusted at this time by

pressing the

DISPLAY CCONTRST

soft key and following the directions

on the screen (also see “Displays”, “Adjusting Display Contrast”

section).

Responding to Maintenance Reminder

CONFIRM

B

MAINTENANCE REMINDER

Module(s) due for routine

preventative maintenance:

MAINTENANCE REMINDER

Module(s) due for routine

B

preventative maintenance:

Module A:

CONFIRM

YYYY-MM-DD

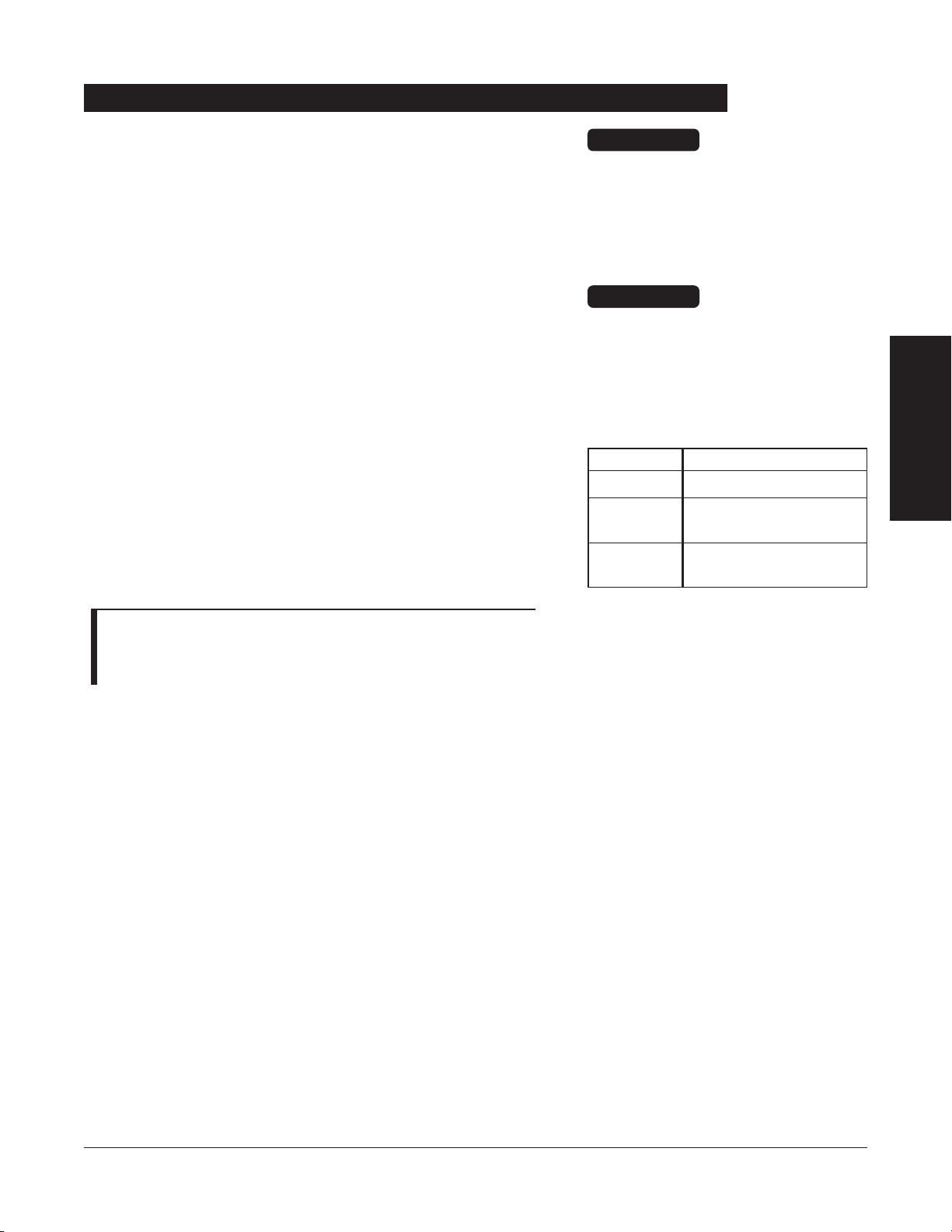

1. Select required

NEW PPATIENT?

option.

To indicate programming is for a new patient and clear all

stored patient parameters from memory, press

YYeess

soft key.

OR

To confirm programming is for same patient and retain all

stored patient parameters, press

NNoo

soft key.

• Last used profile displays.

NOTE: If the Profiles feature is disabled, the main menu

appears.

2. Select correct profile.

To accept current profile, press

YYeess

soft key and proceed to

step

5.

• Main screen appears.

OR

To change profile, press

NNoo

soft key and continue with next

step.

• Profile selection screen appears.

3. To select a profile, press corresponding left soft key.

NOTES:

• To view additional choices, press

PPAAGGEE DDOOWWNN

soft key.

• To view system configuration settings for desired profile,

press

View

soft key for that profile.

4. To confirm profile selection, press

CONFIRM

soft key.

• Main screen appears.

5. To enter Patient

ID, if desired, see “Entering Patient ID”

section.

16 GETTING STARTED

Start-Up (Continued)

Patient ID Entry Feature Disabled

Midtown Hospital

Adult ICU

Yes

No

>Select Yes or No

Adult ICU ?

“Yes” Confirms Same

Profile

Selecting New Patient and Profile Options (Continued)

Midtown Hospital

Profiles

>Select a Profile and

Confirm

CONFIRM

PAGE

DOWN

Neonatal

Peds ICU

Neonatal ICU

Adult General Care

Adult ICU

View

1of2

View

View

View

View

Midtown Hospital

NEW PATIENT ?

“Yes” Clears Previous

Patient Data

>Select Yes or No

DISPLAY

CONTRST

Yes

No

1. Select required

NEW PPATIENT?

option.

• To indicate programming is for a new patient and clear

all stored patient parameters from memory:

a. Press

YYeess

soft key.

♦

PPaattiieenntt IIDD EEnnttrryy

screen appears.

b. If patient identifier is not required, press

CONFIRM

soft key.

OR

Enter patient identifier (reference “Entering Patient

ID

” section).

♦ Last used profile displays.

-- OR --

• To confirm programming is for same patient and retain

all stored patient parameters, press

NNoo

soft key.

♦ Last used profile displays.

NOTE: If the Profiles feature is disabled, the main menu

appears.

2. Select correct profile.

To accept current profile, press

YYeess

soft key.

• Main screen appears.

OR

To change profile, press

NNoo

soft key and continue with next

step.

• Profile selection screen appears.

GETTING STARTED

17

GETTING STARTED

Start-Up (Continued)

Selecting New Patient and Profile Options (Continued)

Midtown Hospital

Adult ICU

Yes

No

>Select Yes or No

Adult ICU ?

“Yes” Confirms Same

Profile

Patient ID Entry Feature Enabled

Midtown Hospital

Yes

No

NEW PATIENT ?

>Select Yes or No

“Yes” Clears Previous

Patient Data

DISPLAY

CONTRST

Patient ID Entry

CONFIRM

A-E

F-J

K-O

P-T

U-Y

PAGE

DOWN

A

B

C

D

E

________________

>Enter Patient ID and Press

CONFIRM

EXIT

3. To select a profile, press corresponding left soft key.

NOTES:

• To view additional choices, press

PPAAGGEE DDOOWWNN

soft key.

• To view system configuration settings for desired profile,

press

View

soft key for that profile.

4. To confirm profile selection, press

CONFIRM

soft key.

• Main screen appears.

18 GETTING STARTED

Start-Up (Continued)

Patient ID Entry Feature Enabled (Continued)

Entering Patient ID

Selecting New Patient and Profile Options (Continued)

When the Patient

ID Entry feature is disabled, the

PPaattiieenntt IDEEnnttrryy

screen can only be accessed through the

SSyysstteemmss OOppttiioonnss

menu.

To enter a patient

ID, begin with step 1 of the following

procedure.

When the Patient

ID Entry feature is enabled, the

PPaattiieenntt IDEEnnttrryy

screen appears after responding

YYeess

to

NNeeww PPaattiieenntt??

prompt.

To enter a patient

ID, begin with step 2 of the following

procedure.

1. To access

PPaattiieenntt

ID

EEnnttrryy

screen:

a. Press

OPTIONS

key.

•

SSyysstteemm OOppttiioonnss

menu appears.

b. Press

PPaattiieenntt

ID

soft key.

•

PPaattiieenntt

ID

EEnnttrryy

screen appears.

System Options 1 of 3

>Select an Option or

EXIT

PAGE

DOWN

EXIT

Display Contrast

Time of Day

Power Down All Channels

Anesthesia Mode

Patient ID

Midtown Hospital

Profiles

Adult ICU

Adult General Care

Neonatal

Peds ICU

Neonatal ICU

>Select a Profile and

Confirm

CONFIRM

1of2

View

View

View

View

View

PAGE

DOWN

2. To enter patient identifier, use numeric data entry keys

and/or alpha speed keys.

NOTES:

• An alphanumeric identifier, of up to

16

characters, can be

entered.

• Press the soft key next to a letter group to list letters in that

group. Press the soft key next to an individual letter to

enter that letter.

• To access the letter “

Z” and special characters (hyphen,

underscore, space), press the

PPAAGGEE DDOOWWNN

soft key.

• To clear an entire entry, press

CCLLEEAARR

key.

• To back up a single character at a time, press

CCAANNCCEELL

key.

3. To verify correct entry, press

CONFIRM

soft key.

• If accessed from

NNeeww PPaattiieenntt??

screen, last used profile

appears.

• If accessed from

SSyysstteemmss OOppttiioonnss

menu, main screen

appears.

• Patient

ID appears on main screen, current profile screen,

and

NNeeww PPaattiieenntt??

screen.

GETTING STARTED

19

GETTING STARTED

Entering Patient ID (Continued)

EXIT

A

B

C

D

PAGE

DOWN

>Enter Patient ID and Press

CONFIRM

E

K-O

F-J

P-T

U-Y

A-E

Patient ID Entry

123456789CD_____

CONFIRM

Start-Up (Continued)

Modifying Patient ID

1. Press

OPTIONS

key.

•

SSyysstteemm OOppttiioonnss

menu appears.

2. Press

PPaattiieenntt

ID

soft key.

•

PPaattiieenntt

ID

EEnnttrryy

screen appears.

System Options 1 of 3

>Select an Option or

EXIT

PAGE

DOWN

EXIT

Display Contrast

Time of Day

Power Down All Channels

Anesthesia Mode

Patient ID

Patient ID Entry

CONFIRM

A-E

F-J

K-O

P-T

U-Y

PAGE

DOWN

A

B

C

D

E

________________

>Enter Patient ID and Press

CONFIRM

EXIT

3. To clear entire entry, press

CLEAR

key.

OR

To back up a single character at a time, press

CANCEL

key.

4. To enter modified patient identifier, use numeric data entry

keys and/or alpha speed keys.

NOTES:

• An alphanumeric identifier, of up to

16 characters, can be

entered.

• Press the soft key next to a letter group to list letters in that

group. Press the soft key next to an individual letter to

enter that letter.

• To access the letter “

Z” and special characters (hyphen,

underscore, space), press the

PPAAGGEE DDOOWWNN

soft key.

5. To verify correct entry, press

CONFIRM

soft key.

• Patient

ID Entry verification screen appears.

6. To accept modified Patient ID, press

YYeess

soft key.

• Main screen appears with new Patient

ID.

OR

To retain original (old) Patient

ID, press

NNoo

soft key.

• Main screen appears with old Patient

ID.

20 GETTING STARTED

Start-Up (Continued)

Modifying Patient ID (Continued)

EXIT

A

B

C

D

PAGE

DOWN

>Enter Patient ID and Press

CONFIRM

E

K-O

F-J

P-T

U-Y

A-E

Patient ID Entry

________________

CONFIRM

EXIT

A

B

C

D

PAGE

DOWN

>Enter Patient ID and Press

CONFIRM

E

K-O

F-J

P-T

U-Y

A-E

Patient ID Entry

234567891EF_____

CONFIRM

>Press Yes or No

Patient ID Entry

Yes

No

Patient ID

123456789CD

will be changed to

234567891EF

Is this correct?

Patient ID Entry

A

B

C

D

E

123456789CD

>Enter Patient ID and Press

CONFIRM

EXIT

CONFIRM

PAGE

DOWN

A-E

F-J

K-O

P-T

U-Y

1. Press

AAuuddiioo AAddjjuusstt

soft key.

2. To change volume to desired level, press either

LLoouuddeerr

or

SSoofftteerr

soft key. To sample alarm loudness level,

TTeesstt

soft

key may be pressed.

3. To return to Programming Module screen, press

MAIN

SCREEN

soft key.

• After

30 seconds without a key press, Main Display

appears.

GETTING STARTED

21

GETTING STARTED

1. Press

OPTIONS

key.

2. Press

TTiimmee ooff DDaayy

soft key.

3. Press

CChhaannggee TTiimmee

soft key.

Setting Up Time of Day

Time of Day

System Options

Current time:

__:__

Change

Time

CONFIRM

Adjusting Audio Volume

Louder

>Change Setting or

Cancel

Audio Volume Adjust

Test

Softer

MAIN

SCREEN

3

VTBI = 250.0 mL

VOLUME

INFUSED

AUDIO

ADJUST

Midtown Hospital

Adult ICU

System Options

Time of Day

Current time:

09:00

CONFIRM

Change

Time

22 GETTING STARTED

4. Enter current Time of Day.

5. Press

CCoonnffiirrmm

soft key.

NOTE: The format is a 24-hour clock (military time).

1. Press

OPTIONS

key.

2. Press

PAGE DDOWN

soft key.

3. Press

SSyysstteemm CCoonnffiigguurraattiioonn

soft key.

4. Select

PPrrooggrraammmmiinngg MMoodduullee

.

5. To review various system configuration settings, press

PAGE

UP

and

PAGE DDOWN

soft keys.

6. To return to main screen, press

CANCEL

key or

EXIT

soft key.

Reviewing System Configuration

Factory Default:

Yes

System Config - Module 1 of 2

Programming Module

Pump Module

SPO2 Module

>Press CANCEL or EXIT

EXIT

Shared Infusion Settings

PAGE

DOWN

Setting Up Time of Day (Continued)

>Press CANCEL or EXIT

PAGE

DOWN

EXIT

System Config - PM 1 of 2

Alarm Audio:

Profile 1

Battery Meter:

Disabled

Clock Setup:

09:00

Dose Checking: ALWAYS

Anesthesia Mode:

Disabled

EXIT

PAGE

UP

System Config - PM 2 of 2

Max Pt. weight:

100 kg

Profiles:

Disabled

Disabled

Enabled

Tamper resist:

PM reminder:

Enabled

Patient ID Entry:

>Press CANCEL or EXIT

System Options

Time of Day

Current time:

14:30

CONFIRM

Change

Time

1. Press

OPTIONS

key.

2. Press

PPaaggee DDoowwnn

soft key.

3. Press

SSeerriiaall NNuummbbeerrss

soft key.

• Serial numbers for Programming Module and all

attached modules display.

NOTE: “nnnn-nnnnnnnn” in the illustrated display

represents a serial number.

4. To return to main screen, press

EXIT

soft key.

GETTING STARTED

23

GETTING STARTED

Reviewing Serial Number

System Options 2 of 3

PAGE

UP

Guardrails Event Counter

System Configuration

>Select an Option or

EXIT

EXIT

Software Versions

Serial Numbers

Battery Runtime

PAGE

DOWN

System Options 1 of 3

>Select an Option or

EXIT

PAGE

DOWN

EXIT

Display Contrast

Time of Day

Power Down All Channels

Anesthesia Mode

Patient ID

PM:

>Press CANCEL or EXIT

1. Press

OPTIONS

key.

2. Press

PAGE DDOWN

soft key.

3. Press

SSooffttwwaarree VVeerrssiioonnss

soft key.

4. To review software version information, press

VViieeww

soft key

next to desired channel.

OR

To return to main screen, press

EXIT

soft key

5. To return to previous screen, press

EXIT

soft key.

NOTE: “nn.nn” in the illustrated display represents a software

version.

24 GETTING STARTED

Reviewing Software Version

Software Rev. Review

APM:

Module A:

Module B:

Module C:

Module D:

View

View

View

View

View

>Select an Option or

EXIT

EXIT

EXIT

>Press CANCEL or EXIT

Software Rev. Review

Module Software: A

Main processor:

nn.nn

nn.nn

nn.nn

Main boot block:

Keyboard:

System Options 1 of 3

>Select an Option or

EXIT

PAGE

DOWN

EXIT

Display Contrast

Time of Day

Power Down All Channels

Anesthesia Mode

Patient ID

System Options 2 of 3

Battery Runtime

System Configuration

Serial Numbers

Software Versions

Guardrails Event Counter

>Select an Option or

EXIT

PAGE

EXIT

UP

PAGE

DOWN

1. Press

OPTIONS

key.

2. Press

PAGE DDOWN

soft key.

3. Press

GGuuaarrddrraaiillss EEvveenntt CCoouunntteerr

soft key.

4. To clear

event counter information, press

CLEAR

key and

then

EXIT

soft key.

OR

To retain

event counter information and return to main

screen, press

EXIT

soft key.

GETTING STARTED

25

GETTING STARTED

1. Press

OPTIONS

key.

2. Press

PPoowweerr DDoowwnn AAllll CChhaannnneellss

soft key.

3. Press

YYeess

soft key.

• During power off sequence, Main Display flashes

POWERING DDOWN

.

Powering Off

Powering Off System

System Options 1 of 3

>Select an Option or

EXIT

PAGE

DOWN

EXIT

Display Contrast

Time of Day

Power Down All Channels

Anesthesia Mode

Patient ID

Viewing and Clearing Guardrails®Event Counter

System Options 2 of 3

PAGE

UP

Guardrails Event Counter

System Configuration

>Select an Option or

EXIT

EXIT

Software Versions

Serial Numbers

Battery Runtime

PAGE

DOWN

System Options

Power Down

All Channels?

>Press Yes or No

Yes

No

Press and hold

CHANNEL OOFF

key until a beep is heard

(approximately

1.5 seconds) and then release to initiate power

down.

NOTE: To interrupt the power down sequence, quickly press any

one of the numeric keys on the Programming Module.

• During power off sequence, Main Display flashes

PPoowweerriinngg

DDoowwnn

.

• Once all attached channels are powered off, Programming

Module automatically powers down.

26 GETTING STARTED

1. Initiate operation of desired channels.

2. Press and hold Tamper Resist Switch, on back of

Programming Module, for three to four seconds. An

advisory tone and a three-second

PANEL LLOCKED

prompt on

Main Display confirm activation. When Tamper Resist is

active, keypad panel is locked; however, clinician may:

• Silence key for audio alarm.

• View volume(s) infused.

• View and test audio alarm setting.

• View selected parameters on SpO

2

Module.

Any other key press will result in a visual

PANEL LLOCKED

prompt and, if

KKeeyy CClliicckk AAuuddiioo

is enabled, an illegal

key–press audio advisory.

3. To unlock keypad panel, press and hold Tamper Resist

Switch for three to four seconds. A three-second

PANEL

UNLOCKED

prompt on Main Display and, if

KKeeyy CClliicckk AAuuddiioo

is enabled, an advisory tone confirms Tamper Resist is off.

Locking/Unlocking Tamper Resist

PANEL UNLOCKED

VTBI = 250.0 mL

VOLUME

INFUSED

AUDIO

ADJUST

Midtown Hospital

Adult ICU

Powering Off Channel

Powering Down

Powering Off (Continued)

Midtown Hospital

Adult ICU

VTBI = 250.0 mL

PANEL LOCKED

VOLUME

INFUSED

AUDIO

ADJUST

GETTING STARTED 27

GETTING STARTED

The optional Computer Link feature allows a hospital computer

to interact with the instrument. The computer cannot start or

stop the instrument, set the rate, or make any change in status.

If the feature is off, the computer cannot communicate with the

instrument.

The Computer Link option is available in the Maintenance Mode.

The computer interface uses a three wire RS-232 signal definition

through an

RJ45 type connector. The table to the right shows

the pin definition. Do not connect anything to the unused

pins.

Qualified service personnel can turn the Computer Link feature

on or off.

NOTE: To assure continued electromagnetic compatibility

performance, the communications cable which attaches to the

instrument should be a category 5 type cable, no longer than

3 meters.

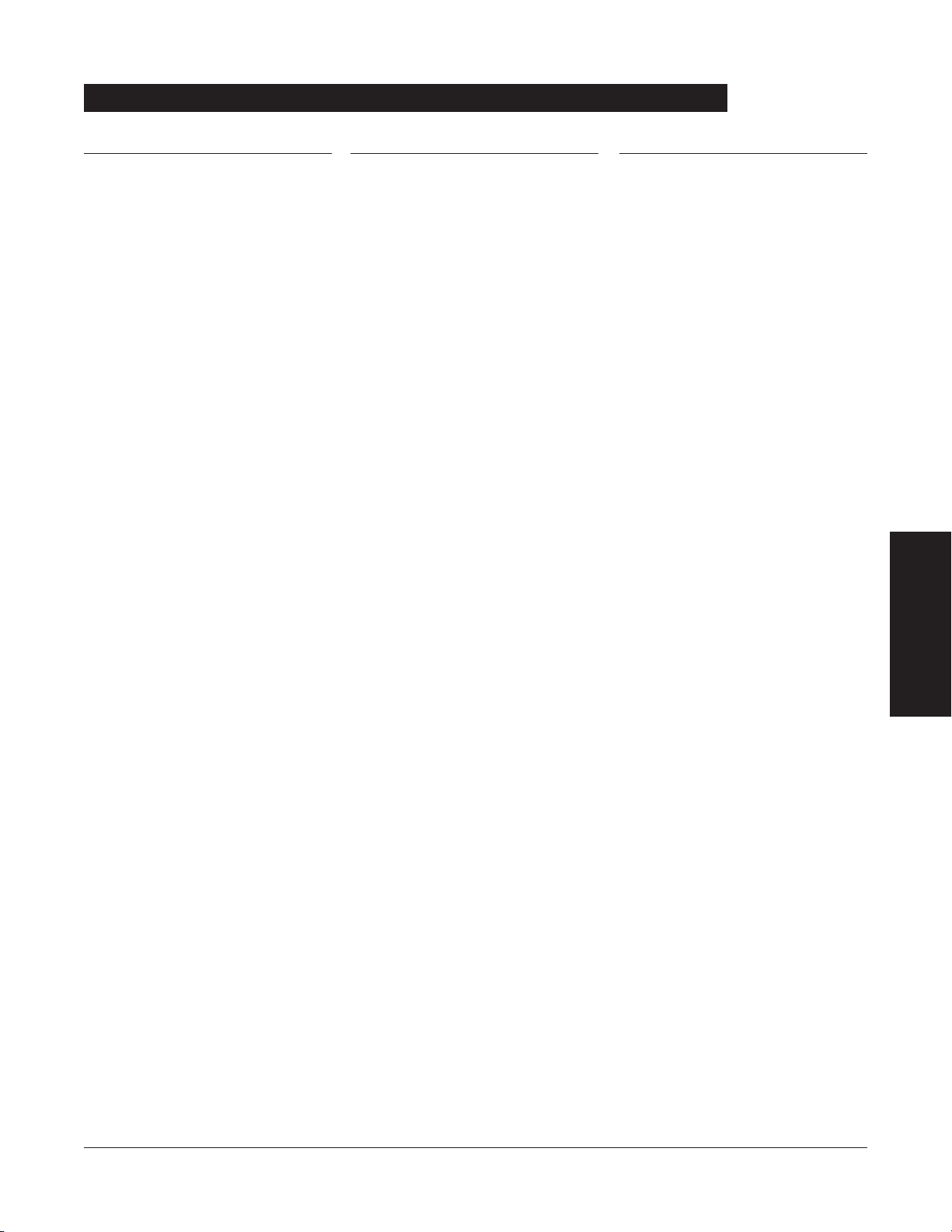

Pin NNumber

4

5

7

Description

Ground

RS-232 TxD (Out of

Programming Module)

RS-232 RxD (Into

Programming Module)

Computer Link

Only systems that have been tested

and certified in compliance to

IEC 601–1/EN 60601–1 standard

should be connected to the Medley™

System Computer/ Connections port.

CAUTION

Use of accessories or cables other

than those specified may result in

degraded electromagnetic

compatibility performance of this

device.

CAUTION

28 GETTING STARTED

THIS PAGE

INTENTIONALLY

LEFT BLANK

Advisory A sequence of audio and/or visual signals indicating the operating status

of the Medley™ Medication Safety System. The audio may be silenced

for approximately two minutes by pressing the

SILENCE

key.

Alarm An audio and visual signal that a potentially unsafe condition is present.

Immediate action is required. The audio may be silenced for

approximately two minutes by pressing the

SILENCE

key.

Error An audio and/or visual signal that a failure has been detected.

Immediate action is required.

Guardrails

®

Alert A visual message to help reduce programming errors by indicating a

Guardrails

®

Limit (“soft” or “hard”) has been exceeded. A response is

required before programming can continue.

Guardrails

®

Clinical Advisory A visual message when a designated drug is selected, to remind clinician

of specific hospital standards of practice when programming an

IV

medication. A specific clinical advisory can be associated with a selected

drug within any of the patient care profiles.

Maintenance Reminder A visual message that, when enabled, appears at module startup when

scheduled preventive maintenance is due/overdue for any part of the

Medley™ System (Programming Module or attached module).

Prompt A visual message, appearing on the bottom line of the Main Display or in

the Channel Message Display. The message may be accompanied by an

audio signal that can be silenced for twelve seconds by pressing the

SILENCE

key.

To enhance safety and ease of operation, the Medley™ System provides a full range of audio and visual

alarms, errors, and messages.

ALARMS, ERRORS, MESSAGES

ALARMS, ERRORS, MESSAGES 29

ALARMS, ERRORS,

MESSAGES

Definitions

Advisory

Alarm

Error (Hardware Detected)

Error (Software Detected)

Illegal Key Press

Key Click

Prompt

SpO

2

Alarm

Switchover

One short beep every two seconds

Choice of three alarm audio profiles,

selectable in System Configuration

Pairs of long beeps

Pairs of long beeps

Two short beeps

One short beep

One short beep every two seconds

Unique alarm pattern.

Six short beeps: secondary switching

to primary. Two short beeps: bolus

switching to continuous.

Variable volume; can be silenced for

two minutes.

Variable volume; can be silenced for

two minutes.

Fixed maximum decibel volume;

cannot be silenced.

Fixed maximum decibel volume; can

be silenced for two minutes.

Variable volume; cannot be silenced.

Fixed minimum volume; can be

silenced and disabled in System

Configuration.

Variable volume; can be silenced.

Different sound than other alarms.

Variable volume; can be silenced and

disabled in System Configuration.

30 ALARMS, ERRORS, MESSAGES

Audio Characteristics

The Programming Module and Main Display provide various types of alert information. The characteristics

of the accompanying audio sounds are as follows:

Type Sound Notes

Battery Discharged

Channel Disconnected

Very Low Battery <5 minutes to

system shutdown

Operation of all channels stopped

due to insufficient battery charge.

Channel(s) disconnected while in

operation or have a communication

problem.

Battery has five minutes or less of

power at current power

consumption rate before operation

stops.

Connect AC power cord to power

source; alarm will be silenced. Press

RESTART key on Pump Module to

continue operation of paused

channels.

To silence alarm and clear message

from screen, press

CONFIRM soft key.

Reattach module, if desired,

ensuring it is securely “clicked” into

place at Channel Release Latch. If

alarm is still present, replace channel

with an operational instrument.

Connect AC power cord to power

source; alarm will be silenced.

ALARMS, ERRORS, MESSAGES 31

ALARMS, ERRORS,

MESSAGES

Alarms

Alarm Meaning Response

Channel Error

Defective Battery

Hardware Detected Error

Missing Battery

Power Supply Error

System Error

Error detected. Operation stops on

affected channel.

Defective battery detected.

Error detected on Programming

Module. Operation stops on all

channels.

Battery detected as not present or

not connected.

Power supply system malfunction

detected.

Error detected on Programming

Module. Operation continues on all

channels.

To silence alarm and continue

operation of unaffected channels,

press

CONFIRM soft key . Replace

channel with an operational

instrument, as required. Service by

qualified personnel is required.

To power down system, press

SYSTEM OFF soft key; or to continue

temporary operation while an

operational Programming Module

can be located, press

SILENCE key.

Service by qualified personnel is

required.

Press

SYSTEM ON key to power down

system. Replace Programming

Module with an operational system.

Service by qualified personnel is

required.

To power down system, press

SYSTEM OFF soft key; or to continue

temporary operation while an

operational Programming Module

can be located, press

SILENCE key.

Service by qualified personnel is

required.

Disconnect AC power immediately.

To power down system, press

SYSTEM OFF soft key; or to continue

operation under battery power while

an operational Programming

Module can be located, press

SILENCE key. Service by qualified

personnel is required.

To power down system, press

SYSTEM OFF soft key; or to continue

temporary operation while an

operational Programming Module

can be located, press

SILENCE key.

Service by qualified personnel is

required.

32 ALARMS, ERRORS, MESSAGES

Errors

Error Meaning Response

Battery Run Time = X.X hours

Low Battery

Panel Locked

Panel Unlocked

Powering Down

Replace Battery

AC power cord is disconnected from

power source. Approximate

remaining battery run time under

current power consumption rate is

displayed.

Low battery threshold sensed;

remaining battery run time is

limited.

Tamper Resist feature is active and

key was pressed.

Tamper Resist feature deactivated.

Last channel powering off. System

shuts off in indicated number of

seconds.

Occurs at System On. Battery has

less than 50% of original capacity.

None. Connect AC power cord to

power source as soon as possible.

Connect AC power cord to power

source; alarm will be silenced.

If appropriate, deactivate Tamper

Resist feature using Tamper Resist

Control on back of Programming

Module.

None.

Press any key, except

SYSTEM ON key,

to cancel power down sequence.

Press either

SYSTEM OFF or CONFIRM

soft key to continue normal

operation with reduced battery

capacity. Service by qualified

personnel is required.

ALARMS, ERRORS, MESSAGES 33

ALARMS, ERRORS,

MESSAGES

Messages

Message Meaning Response

THIS PAGE

INTENTIONALLY

LEFT BLANK

34 ALARMS, ERRORS, MESSAGES

Battery OOperation

: Battery run time is a function of the number of channels attached and channel activity.

With a new, fully charged battery, the system will operate as follows before a "

BATTERY

DISCHARGED

" message occurs:

• 8 hours with 1 Pump Module infusing at 25 mL/h

• 4 hours with 4 Pump Modules infusing at 25 mL/h

• 6 hours with 1 active SpO

2

Module

• 8 hours with 1 Syringe Module infusing at 5 mL/h

• 4 hours with 4 Syringe Modules infusing at 5 mL/h

Communication DData PPort

: RS-232 with a RJ45 connector.

Dimensions

: 6.9"W x 8.8"H x 9"D (including pole clamp)

Electric CClassification

: Class 1, Internally Powered Equipment

NOTE: Refer to module specific Directions for Use for shock protection type and

defibrillation-proof rating information.

Electronic MMemory

: System configuration parameters stored in volatile memory will be retained for at least 6

months by the internal backup lithium battery. Additionally, channel specific parameters

are stored for 8 hours by the Programming Module and then automatically purged by

the system.

Environmental CConditions

: Operating

Storage/Transport

Temperature Range: 41 to 104°F -4 to 140°F

(5 to 40°C) (-20 to 60°C)

Relative Humidity: 20 to 90% 5 to 85%

(Avoid prolonged exposure Noncondensing Noncondensing

to relative humidity >85%)

Atmospheric Pressure: 525 to 4560 mmHg 375 to 760 mmHg

(700 to 6080 hPa) (500 to 1013 hPa)

Equipment OOrientation

: To ensure proper operation, the instrument must remain in an upright position.

Fluid IIngress PProtection

: IPX1, Drip Proof

Leakage CCurrent

: Less than 100 microamps

Power RRequirements

: 100 - 240V ~, 50/60 Hz, 150 VA MAX (See Notes 1 and 2)

Weight

: 7.2 lbs

The Medley™ System Technical Service Manual is available from

ALARIS Medical Systems. It includes

routine service schedules, interconnect diagrams, component parts lists and descriptions, test procedures,

and other technical information, to assist qualified service personnel in repair and maintenance of the

instrument’s repairable components. Maintenance procedures are intended to be performed only by

qualified personnel, using the service manual and Medley™ Maintenance Software.

MAINTENANCE

35

MAINTENANCE

MAINTENANCE

Specifications

NOTES:

1. Power Cords; North America:

To ensure correct polarity and grounding reliability, use power cords that incorporate a NEMA 5-15P (125V) or

NEMA 6-15P (250V) plug only.

2. Power Cords; International:

Use only cords that comply with IEC 60245, or IEC 60227, designation #53 and local electrical codes and/or

regulations.

3. Compliance to Standards:

The Medley™ Medication Safety System has been assessed and complies with the following standards:

UL 2601–1, including A1 and A2; CSA C22.2 No. 601.1, including A1 and A2; IEC/EN 60601–2–24;

IEC/EN 60601–1–2 and AAMI ID26.

36 MAINTENANCE36 MAINTENANCE

Specifications (Continued)

System Configurable Settings

Profile 1, 2 or 3

Enabled - Disabled

Enabled - Disabled

Set date and time

Always, Smart (only with

Profiles feature)

Enabled - Disabled

0.1 - 500 kg

Enabled - Disabled

Enabled - Disabled

Enabled - Disabled

Enabled - Disabled

Feature

Alarm Audio Profile

Anesthesia Mode

Battery Meter Display

Clock Setup (Date and Time)

Dose Checking

Key Click Audio

Max Patient Weight

Patient ID Entry

Preventive Maintenance (PM)

Reminder

Profiles

Tamper Resist

Default Setting Options

Profile 1

Disabled

Disabled

N/A

Always

Enabled

500 kg

Disabled

Enabled

Disabled

Disabled

If the configuration settings need to be changed from the

"Factory Default" settings, refer to the applicable Technical

Service Manual or contact

ALARIS Medical Systems, Technical

Support, for technical, troubleshooting, and preventive

maintenance information.

NOTE: With the Profiles feature enabled, the settings are

configured independently for each profile. A hospital-defined,

best-practice data set must be uploaded to enable the Profiles

feature. Date and Time is a system setting and is the same in all

profiles.

The Medley™ Programming Module is equipped with a 12 volt,

4200

mAh nickel metal hydride battery. The battery is charging

whenever the instrument is plugged into an

AC receptacle. The

life expectancy of the battery is dependent on the amount of

use, the depth of discharge, and the state of the charge that is

maintained. Generally, the battery will have the longest life

(recommended replacement =

2 years) if the instrument is

plugged in and battery use is infrequent. Frequent use of

battery power and insufficient battery charge cycles will

significantly decrease the life of the battery.

The quality of the battery is also a significant factor in

determining battery life and runtime. The battery cannot be

repaired and should not be opened. Replace the battery with

the same type, size and voltage rating. Use of any other brand

may yield poor performance and is not recommended.

Batteries should be charged in a room with a temperature

between

50 - 80.6

°F (

10 - 27°C), to minimize charge time and

maximize battery life.

Plug the Programming Module into an

AC outlet during storage,

to ensure a fully charged battery when needed.

(

AC indicator light) will be on whenever the Programming

Module is plugged in.

MAINTENANCE 37

MAINTENANCE

Battery Care and Maintenance

Battery Type and Charging

Storage

Battery Charge

• The Medley™ Programming Module is shipped with the

battery in a discharged condition.

• Before the Programming Module is released for use, it should

be plugged into a hospital grade

AC outlet and the battery

charged for at least eight hours. This will ensure proper

battery operation when the Medley™ System is first set up for

patient use.

• Whenever possible, leave the power cord connected to an

external

AC power source while operating the instrument.

The battery capacity should be checked at least once every six

months. Refer to the Medley™ System Technical Service Manual

for test and replacement procedures.

If the Programming Module is to be stored at temperatures in

excess of

86°F

(30°C) for one or more months, the battery should

be removed and placed in an environment of

50

– 86°F

(10 – 30

°C).

If the batteries are to be stored for more than one year, they

should be charged at least once per year to prevent leakage and

deterioration in performance due to self-discharge.

When the battery is first being put into use, or has been out of

use for one or more months, it will not have full capacity due to

deactivation of reactants.

Restore such batteries to original performance by repeating one

or two cycles of fully charging and fully discharging.

Some temporary reduction in capacity might become apparent if

the battery is partially discharged repeatedly. Doing one or two

cycles of full discharge and full charge can restore full

performance.

38 MAINTENANCE38 MAINTENANCE

Battery Care and Maintenance (Continued)

Battery Care

Battery Cautions and Disposal

Battery replacement should be performed by qualified service

personnel while the instrument is not in use.

DO NOT open, incinerate or short

circuit. Worn–out batteries must be

disposed of properly, according to

local regulations.

CAUTION

DO NOT spray cleaning fluids directly onto the instrument or

immerse the instrument in fluids.

DO NOT use solutions containing phosphoric acid (Foamy

Q&A*), aromatic solvents (naphtha, paint thinner,

etc.), chlorinated solvents* (Trichloroethane,

MEK,

Toluene, etc.), ammonia, acetone, benzene, xylene or

alcohol, other than as specified below.

DO NOT use hard or pointed objects to clean any part of the

instrument.

Acceptable cleaning solutions are:

Warm water

Mild detergent (

such as, Manu-Klenz)

10% bleach solution (1 part bleach to 9 parts water)

Compublend II

Envirocide

2% Glutaraldehyde in water

Hydrogen Peroxide

3%

70%

Isopropyl Alcohol

2%

Phenols in water (O-Syl 1:128, Pheno-Cen 1:256, Vesphene

)

10%

Providone Iodine (Betadine)

Quaternaries

1:512

WEX-CIDE

NOTE: All recommended solutions must be diluted per the

Manufacturer’s recommendation.

1. Keep instrument upright and do not allow any part of

instrument to become saturated with or submersed in fluid

during cleaning operation.

2. Use a soft cloth dampened with warm water and a mild

nonabrasive cleaning solution to clean all exposed surfaces.

For sanitizing or antibacterial treatment, use 10% bleach

solution and water.

NOTE: A soft-bristled brush may be used to clean hard to

reach and narrow areas.

3. Use a soft cloth dampened with water to rinse off cleaning

solution.

* Excluding 10% bleach solution in water.

MAINTENANCE 39

MAINTENANCE

Cleaning

Turn the instrument off and unplug

the power cord from the

AC power

source before cleaning. Do not spray

fluids directly onto the rear case of

the instrument. Do not steam

autoclave, EtO sterilize, immerse the

instrument or allow fluids to enter

the instrument case. Failure to follow

these instructions may result in an

electrical hazard.

WARNING

The solutions/solvents identified as

NOT

to be used can damage the

surfaces of the instrument.

CAUTION

To ensure the system remains in good operating condition, both

regular and periodic inspections are required.

RReegguullaarr iinnssppeeccttiioonnss

consist of a visual inspection for damage

and cleanliness, and performing the procedure described in the

“Start-Up” section of this Directions for Use before each usage

of the instrument. Regular inspections must be performed by

the hospital/facility and if any damage is found, service is

required.

RREEGGUULLAARR IINNSSPPEECCTTIIOONNSS

PROCEDURE FREQUENCY

INSPECT FOR DAMAGE:

Exterior Surface Each usage

Pole Clamp Each usage

Power Cord Each usage

Keypad Each usage

CLEANING As required

Start-Up Each usage

1. Exterior Surfaces - examine for overall condition and verify:

• No damage, cracks or deformities.

• Case is clean and free from

IV solution residue.

• Labels and markings are legible.

• No tape or other foreign material is on sides of case;

anything of this nature could prevent proper latching of

channels.

•

IUI

Connectors have not been damaged.

2. Pole Clamp

Pole Clamp should be secure and functioning.

3. Power Cord Assembly - examine for:

• Signs of damage, cuts or deformities in cord. If

damaged, replace entire cord.

• Integrity of hospital-grade power plug. Attempt to

wiggle blades, to verify they are secure. If any damage is

suspected, replace entire cord.

4. Keypad

Check membrane switches for damage.

PPeerriiooddiicc iinnssppeeccttiioonnss

of the hardware are required. For detailed

instructions on performing periodic inspections and

maintenance, refer to the Medley™ Medication Safety System

Technical Service Manual and supplemental service bulletins, and

Medley™ Maintenance Software User Manual.

40 MAINTENANCE40 MAINTENANCE

Inspection Requirements

Failure to perform these inspections

may result in improper instrument

operation.

WARNING

Periodic inspections should only be

performed by qualified service

personnel.

CAUTION

Customer Service

Information or assistance may be obtained by calling one of the

following Customer Service numbers:

United States:

Canada:

(800) 482-4822

(800) 387-8309

NOTE: If the instrument shows evidence of damage in transit,

notify the carrier’s agent immediately. Do not return damaged

equipment to the factory before the carrier’s agent has authorized

repairs.

If the instrument fails to respond as described in this document

and the cause cannot be determined, do not use the instrument.

Contact qualified

ALARIS

Medical Systems service personnel.

MAINTENANCE 41

MAINTENANCE

Service Information

Technical support, service information, applications, and

manuals may be obtained by contacting an ALARIS Medical

Systems representative.

United States:

Canada:

Eastern

Western

When submitting any request for service, include:

• Model number

• a description of difficulty experienced

• instrument settings

• administration set/lot number

• solution(s) used

• message displayed at time of difficulty

Instruments returned from the service

depot to your facility may be set to

factory defaults and not have a

hospital-defined data set loaded.

Biomedical personnel in the facility

are responsible for checking-in the

instrument and ensuring the current

hospital-approved data set is loaded.

WARNING

(800) 854-7128, extension 6003

(800) 908-9918