A la Cart 98000-1 Installation Manual

OPERATOR MANUAL/USER GUIDE

IMPORTANT INFORMATION, KEEP FOR OPERATOR

This manual provides information for:

MODEL SYSTEM II

MEAL DELIVERY SYSTEM

· Hot Side, flexible to cold foods

· Cold Side

· Conduction heating with adjustable heat intensities

· Available Capacity: 20 trays

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND

WARNINGS CONTAINED IN THIS MANUAL.

NOTIFY CARRIER OF DAMAGE AT ONCE

It is the responsibility of the consignee to inspect the container upon receipt of

same and to determine the possibility of any damage, including concealed damage. Unified Brands suggests that if you are suspicious of damage to make a

notation on the delivery receipt. It will be the responsibility of the consignee to file

a claim with the carrier. We recommend that you do so at once.

Manufacture Service/Questions 888-994-7636.

Information contained in this document is known to be current and accurate at the time

of printing/creation. Unified Brands recommends referencing our product line websites,

unifiedbrands.net, for the most updated product information and specifications.

PART NUMBER SYSII REV A (08/11)

1055 Mendell Davis Drive

Jackson, MS 39272

888-994-7636, fax 888-864-7636

unifiedbrands.net

Table of Contents

SECTION 1: Product Information

Product Description ...................................................................... page 3

Components & Accessories ....................................................... page 3-5

System II Cart Specication Sheet ............................................ page 6-7

System II Controller/Chiller Specication Sheet ......................... page 8-9

SECTION 2: Overview & Operating Instructions

Menu Planning ............................................................................. page 10

Plating Guidelines ................................................................... page 10-11

Plating Principles & Diagrams ............................................... page 11-16

Tray Presentation/Placement of Dishware ................................... page 17

Tray Presentation Diagrams .................................................... page 18-20

Display Panel Instructions ...................................................... page 21-26

• Overview of Display Panel ...................................................... page 21

• Normal Chiller Operation and Sequence of Events ............. page 22

• Using Manual Retherm & Hold Cycles ................................... page 23

• Using “Options” Menu for Programming, Reading Error Log, & Setting

Password .......................................................................... page 24-26

Instructional Postings ............................................................ page 27-32

• Cart Loader Checklist ............................................................ page 27

• Dock Cart to Chiller ............................................................... page 28

• Undock Cart from Chiller ........................................................ page 29

• Cart Cleaning ......................................................................... page 30

• Dishware Care – China ............................................................ page 31

• Dishware Care – Plastic .......................................................... page 32

Cleaning Agents .......................................................................... page 33

2 OM-SYSTEM II

SECTION 3: Troubleshooting Guide

Faults & Errors ........................................................................ page 34-35

Maintenance Log ........................................................................ page 36

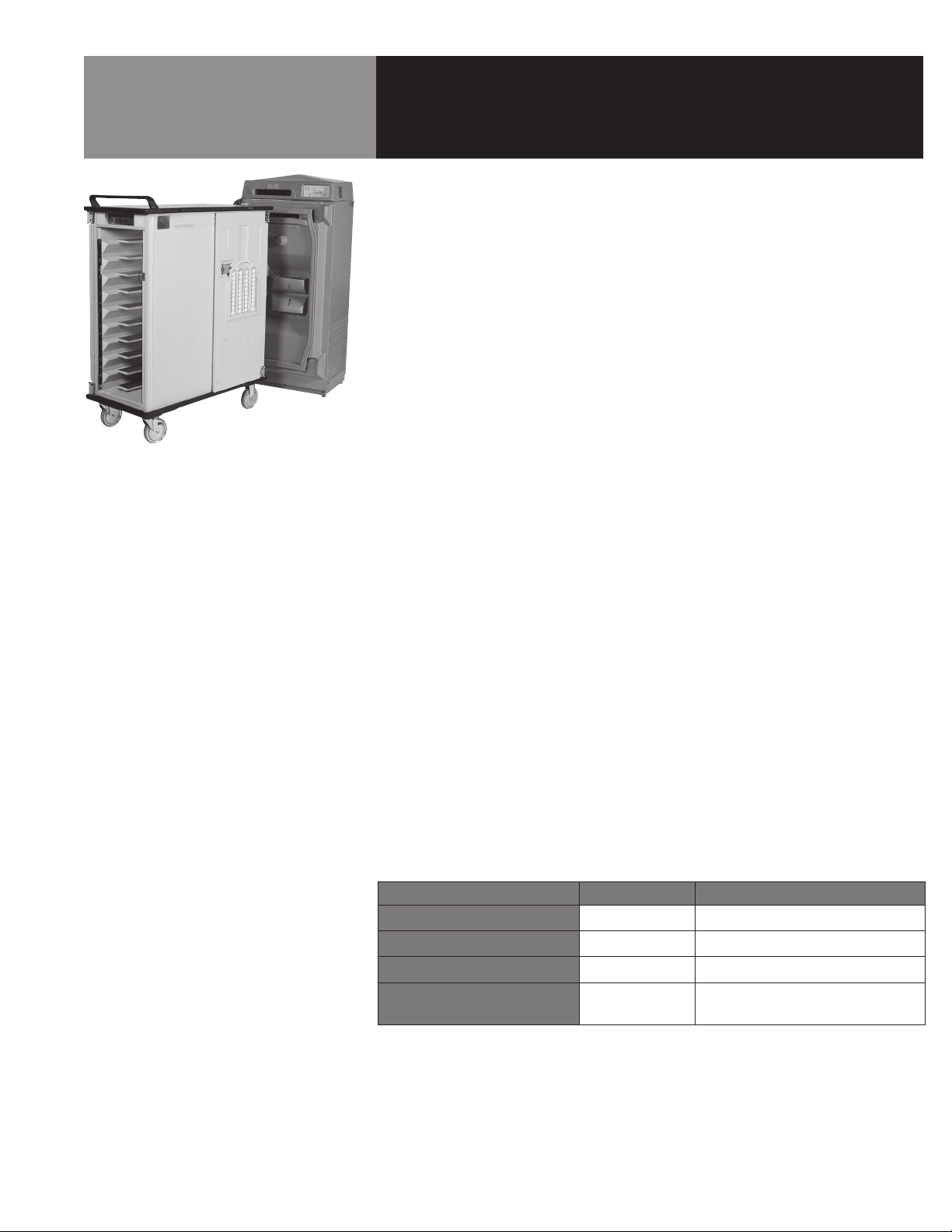

Product Information

PRODUCT DESCRIPTION

System II Retherm Cart PN 98000-1; Controller/Chiller PN 98004-1

• System II uniquely uses a conduction heating method for rethermalizing hot

foods. The intensity of the conduction heating is adjustable, unlike any other

conduction retherm system on the market.

• Food is plated cold and completed trays are placed inside the retherm cart and

docked to a controller/chiller unit to hold foods in a refrigerated state, until an

automatic or manual retherm cycle is started.

• Conduction heaters are used for the entrée, and soup or hot side dish that can

be adjusted for heat intensity, in an approximate 38 minute heating cycle.

• Chilled air circulates throughout the entire cart, and the cart is thermostatically

controlled at 36° - 39° F. during the chill, retherm, and hold modes to keep cold

foods cold.

• The tray is 14” x 18” and is constructed with a ridge near the center that

horizontally divides the hot side from the cold side. The retherm cart holds 20

trays.

• Standard `A la Cart dishware is used on the hot side of the tray; any type or

brand of dishware can be used on the cold side of the tray in addition to or in

place of `A la Cart dishware.

• System II utilizes advanced retherm technology and programming features,

whereby the heater intensity per meal can be customized, a self-diagnostic

check of heaters and refrigeration is conducted with each use, and a security

password can be set, as outlined in the System II Display Panel Instructions

found in Section 2.

• System II is ready to use with the optional `A la Cart Central Management Control

System (CMCS).

COMPONENTS & ACCESSORIES

ITEM PART NO. ITEM DESCRIPTION

System II Cart 98000-1 51.25” H x 21.5” W x 41.375” L

System II Controller/Chiller 98004-1 Holds 20 trays

Menu Minder Card 91144-1 60.7” H x 26” W x 24” D

Central Management Control

System (CMCS)

97603-1

Requires 208 VAC,

3 ph., 5 wire; 30 amp

OM-SYSTEM II 3

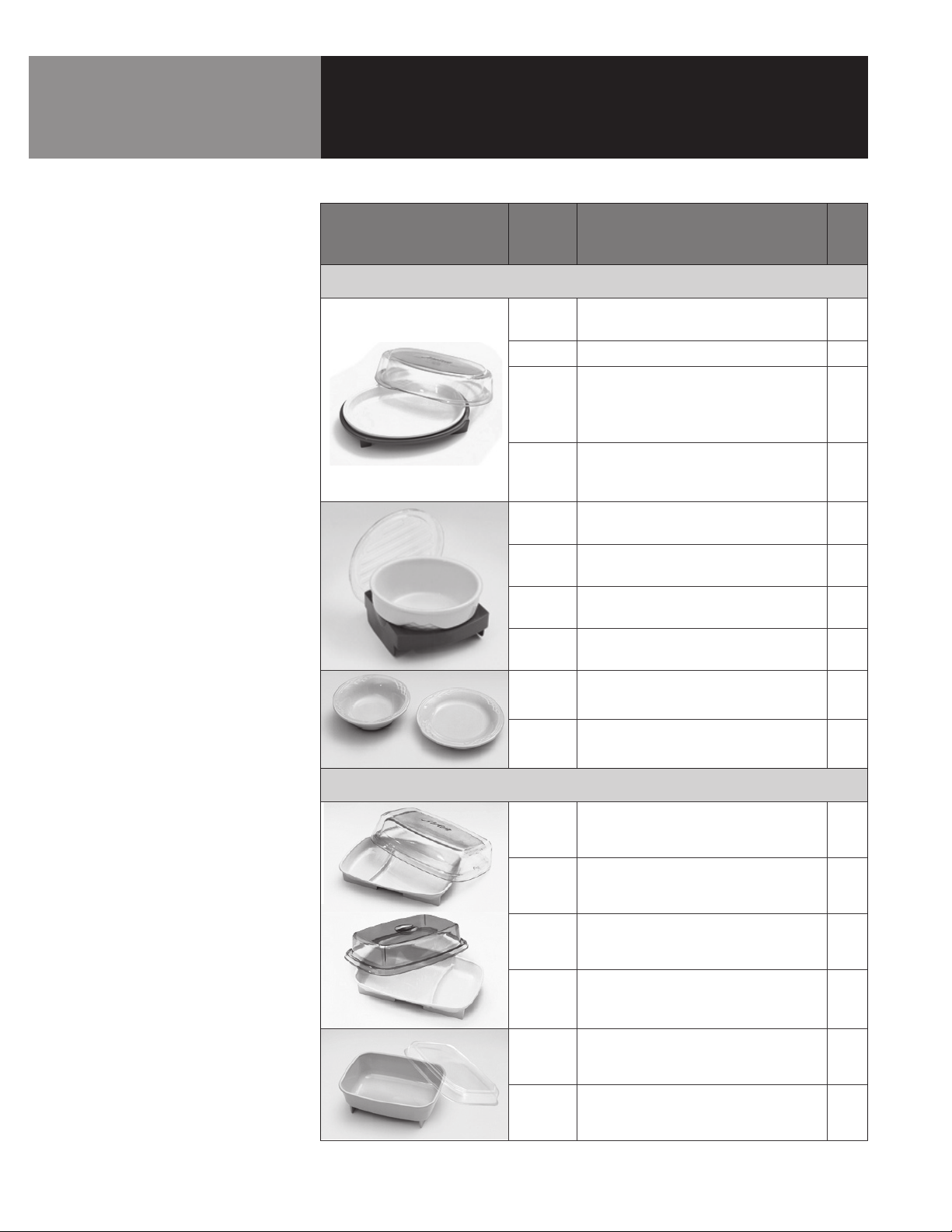

Items can be purchased

separately. All dishware and

trays come with a standard

90-day warranty except

where noted.

Product Information

COMPONENTS & ACCESSORIES Continued

IMAGE PART NO. ITEM DESCRIPTION

CHINA TABLEWARE

NO. PER

CASE

90682-2

90687-2 Entrée Dish Cradle, dark gray plastic 36

90689-2

90658-2

90684-2

90688-2 Soup Bowl Cradle, dark gray plastic 24

90662-3 Soup Bowl Lid, opaque, disposable 1K

90662-4 Soup Bowl Lid, high heat, disposable 2K

90685-2

90686-2

Entrée Plate, oval, 8 3/8“L, 6 1/2”W,

7/8”H

Insulated Entrée Cover, oval, tinted

polysulphone, 9”L x 6 1/2”W x 2”H,

2 1/2” food clearance (polysulphone,

1-year warranty)

Insulated Entrée Cover, oval, clear, 6

1/2”W x 2”H, 2 1/2” food clearance

(polycarbonate, 90-day warranty)

Soup Bowl, 10 oz., 4 11/16“ diameter,

1 7/8“H,1 5/8” inner wall height, white

Bread Plate, 5 1/4” diameter,

13/16”H

Dessert Cup, 4 11/16” diameter,

15/16”H

36

48

48

24

48

48

4 OM-SYSTEM II

PLASTIC TABLEWARE

90682-1

90689-3

90658-3

90658-1

90684-1

90662-1 Soup Bowl Lid, clear, disposable

Entrée Dish, rectangular, divided, 8

1/2“L x6”W, 1 3/8”H

Insulated Entrée Cover, tinted

(polysulphone, 1year warranty)

Insulated Entrée Cover, clear

(polycarbonate, 90-day warranty)

Non-insulated Entrée Cover, tinted, 8

7/8”L x 6 3/8”W x 1 7/8”H,

2 1/2” food clearance

Soup Bowl, 10 oz., 5 ½” L x 4”W x 1

7/8”H, inner wall height 1 3/8”

45

48

48

70

56

500

Items can be purchased

separately. All dishware and

trays come with a standard

90-day warranty except

where noted.

Product Information

COMPONENTS & ACCESSORIES Continued

IMAGE PART NO. ITEM DESCRIPTION

PLASTIC TABLEWARE CONTINUED

NO. PER

CASE

DISPOSABLE DISHWARE

TRAYS

90683-1

90659-1

90811-1

90812-1

90662-4 Soup Bowl Lid, disposable, high heat 2K

90709-5 Grey Tray, 14” x 18” 20

90709-7 Speckled Almond Tray, 14” x 18” 20

Side Dish, 5 ½”H x 4”W x 1 3/8”H,

inner wall height 15/16”

Side Dish Cover, 6 15/16”L x

4 7/16”W x 1 7/8”H, 2 ½” food

clearance

Entrée Dish, 9” oval, white

(requires Entrée Plate Cradle and

Entrée Cover listed under China

Tableware)

Soup Bowl, 10 oz. round, white

(requires Soup Bowl Cradle listed

under China Tableware)

80

56

500

500

TRAY MATS

90664-1 Moon Rise Tray Mat, ts 14” x 18” tray 1K

90666-1 Flower Tray Mat, ts 14” x 18” tray 1K

90667-1

90668-1 Patriotic Tray Mat, ts 14” x 18” tray 1K

90669-1 Fall Tray Mat, ts 14” x 18” tray 1K

90665-2

Southwestern Tray Mat, ts 14” x 18”

tray

Season’s Greetings Tray Mat,

ts 14” x 18” tray

1K

1K

OM-SYSTEM II 5

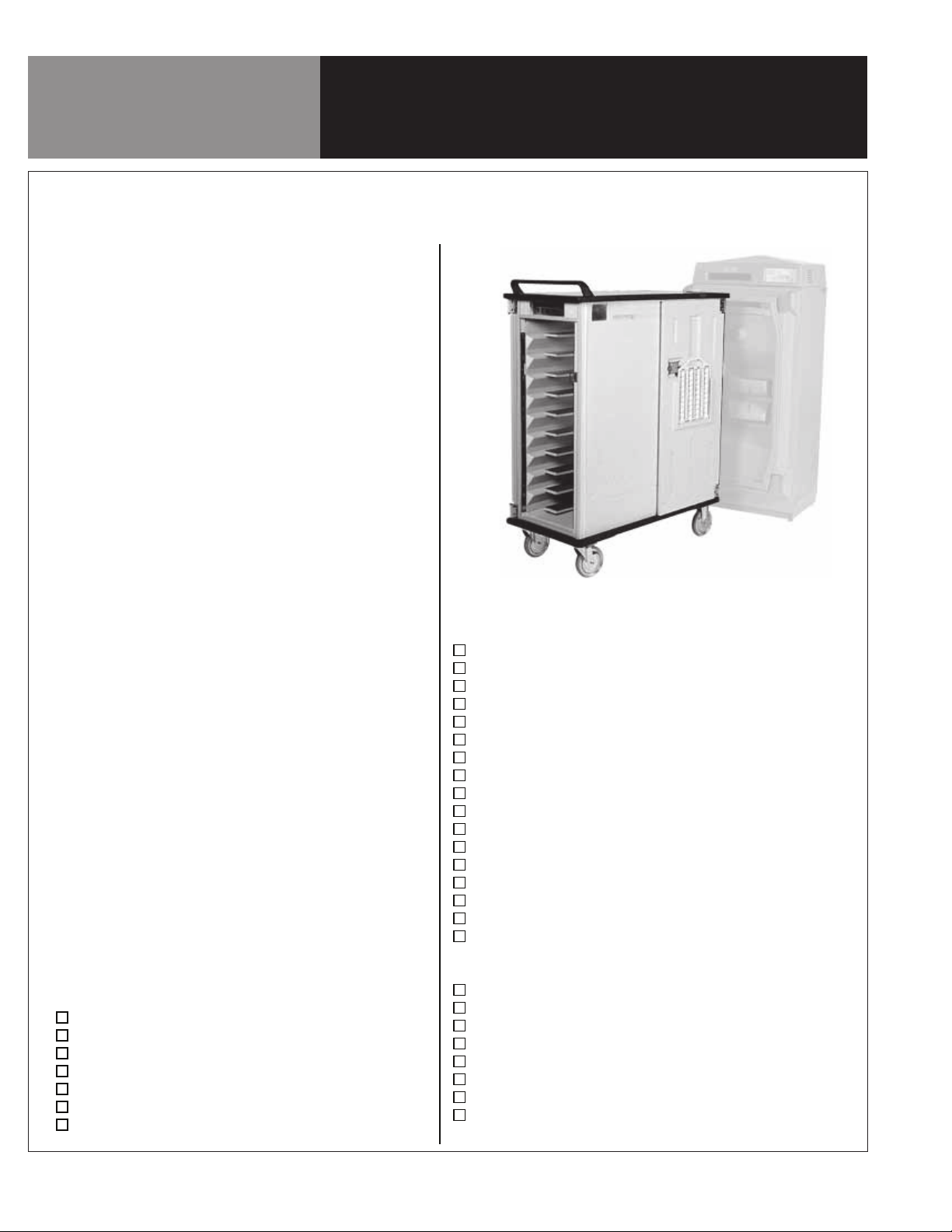

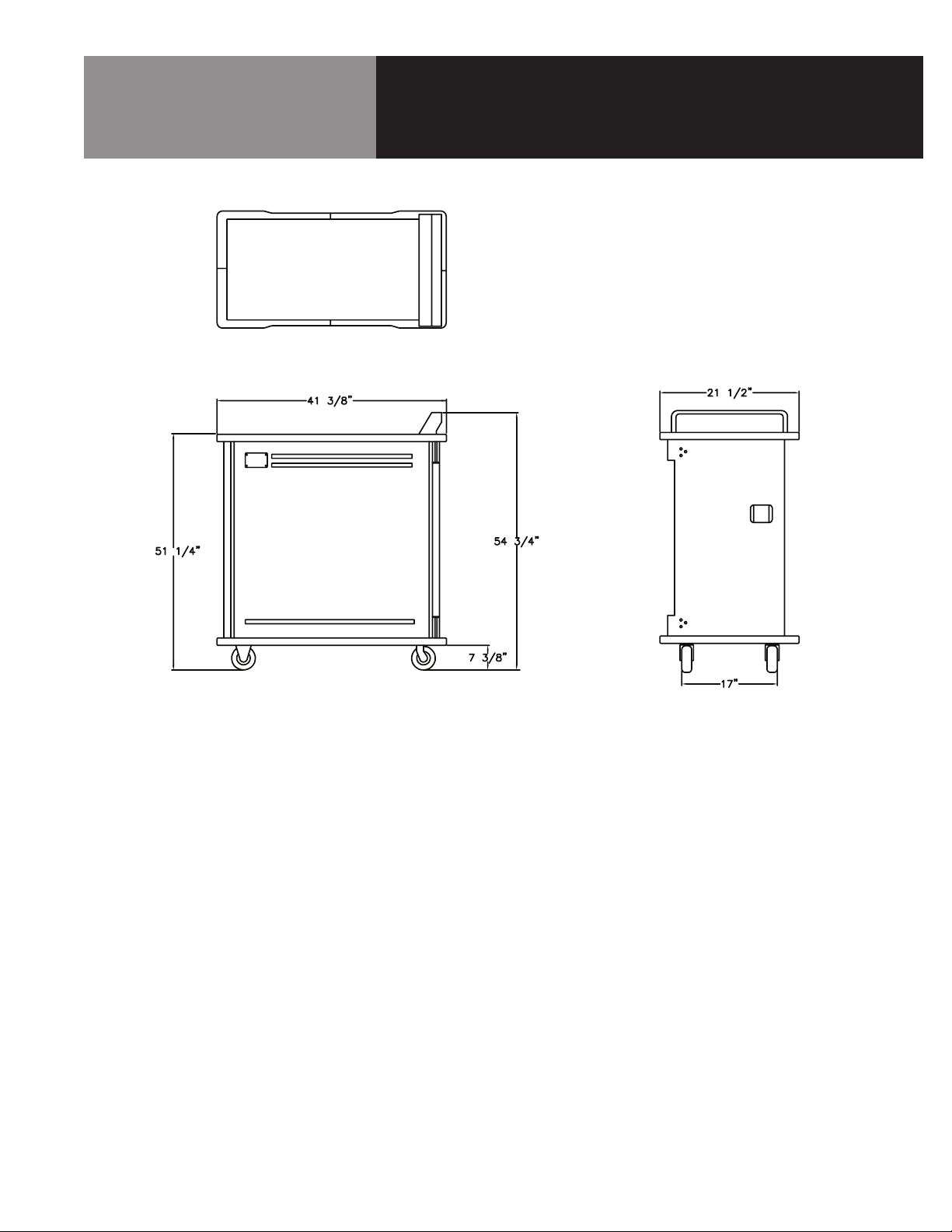

SPECIFICATION SHEET/CART

Product Information

System II Cart

Model Numbers

20-Tray Model 98000-1

Description

The System II Cart is both a meal storage unit (prior to rethermalization)

and a meal delivery and tray retrieval unit. The design offers the

optimum in operational simplicity and reliability.

Specifications

CABINET EXTERIOR: High-impact molded polyethylene and stainless

steel construction.

CABINET BASE/INTERIOR: The cabinet interior and base are formed,

welded and riveted stainless steel.

DOORS: Two stainless steel and molded polyethylene doors; swing

270 degrees; held open via magnets.

MOBILITY: 4 swivel casters; 2 locking and 2 nonlocking.

REFRIGERATION SYSTEM: Cooling provided by a cold air supply from

a companion Controller Chiller Unit. Refrigerant is R404.

HEATING: Individual conduction heaters slide between the tray surface

and the underside of the dishware. Rethermalization controlled by the

processor in the Controller Chiller Unit.

ELECTRICAL: Plugs into Controller Chiller Unit and receives all

commands and heating power from that unit.

Standard Features

• Narrow width for all standard door openings

• Cold rethermalizing environment – trays and covers remain cool

to the touch

• “Gentle” heating during rethermalization – preserves food quality

Dimensions (WxLxH)

• 21.5” x 41.375” x 51.25 ”

• Weight: 231 lbs

Accessories - Dishware

90682-2 Oval China Entrée Dish

90658-2 China Entrée Cover

90687-2 Cradle Oval China Entree

90689-2 China Insulated Entrée Cover

90682-1 Plastic Entrée Dish

90658-3 Plastic Entrée Cover

90689-3 Plastic Insulated Entrée Cover

model 98000-1

Accessories - Dishware Continued

90684-1 Plastic Soup Bowl

90684-2 China Soup Bowl

90688-2 Cradle China Soup Bowl

90685-2 China Dessert Cup

90686-2 China Bread Plate

90662-3 China Soup Bowl Lid

90662-1 Plastic Soup Bowl Lid

90664-1 Moonrise Tray Mat

90665-2 Seasons Greetings Tray Mat

90666-1 Flower Tray Mat

90667-1 Southwestern Tray Mat

90668-1 Patriotic Tray Mat

90669-1 Fall Tray Mat

90709-5 Gray Tray

90709-7 Speckled Almond Tray

90811-1 Disposable Entrée Dish

90812-1 Disposable Soup Bowl

Accessories - Support Equipment

G101099 Enclosed Tray Transport Cart

98003-1 A la Cart Transport Cart

207304 Open Rack for 32 Trays

BR229004 Mobile Basket Rack

DC501-5-480 Side Dish Cart

DC501-7-240 Entree Dish Cart

95008-1 Tray Storage Rack

97603-1 CMCS

6 OM-SYSTEM II

SPECIFICATION SHEET/CART

Model 98000-1

Product Information

OM-SYSTEM II 7

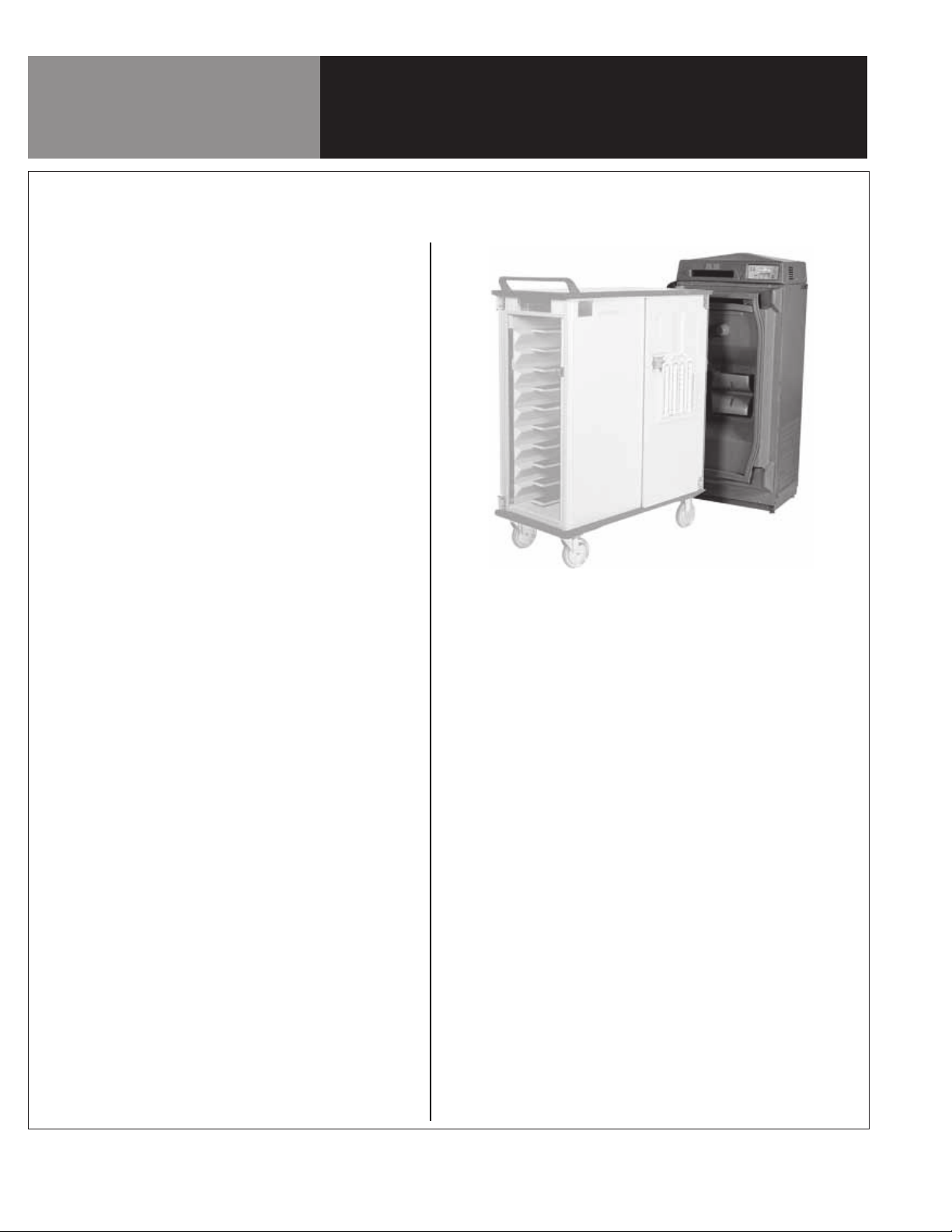

SPECIFICATION SHEET/

control all units – on every floor, in remote buildings – right from a computer

track cart arrival and meal delivery times, as well as faults. CMCS generates

CONTROLLER/CHILLER

Product Information

System II Controller/Chiller

Model Numbers

Model 98004-1

Description

The A la Cart Controller/Chiller is the companion unit to the System

II Cart. It is typically located in the pantry on the patient floor of a

hospital, and in a central kitchen or any other location dedicated for

storage and holding of loaded carts before delivery to the patient floor.

Controller/Chiller units easily accommodate centralized or

decentralized holding and rethermalization plans.

The Controller/Chiller provides a chilling function to the trays during

the initial loading and holding phase and then maintains chilling for

dishes that are served cold, during rethrermalization of dishes that

are served hot. The processor in the Controller/Chiller unit initiates

the rethermalization sequence inside the System II Cart by turning on

electrical power to the conduction heaters.

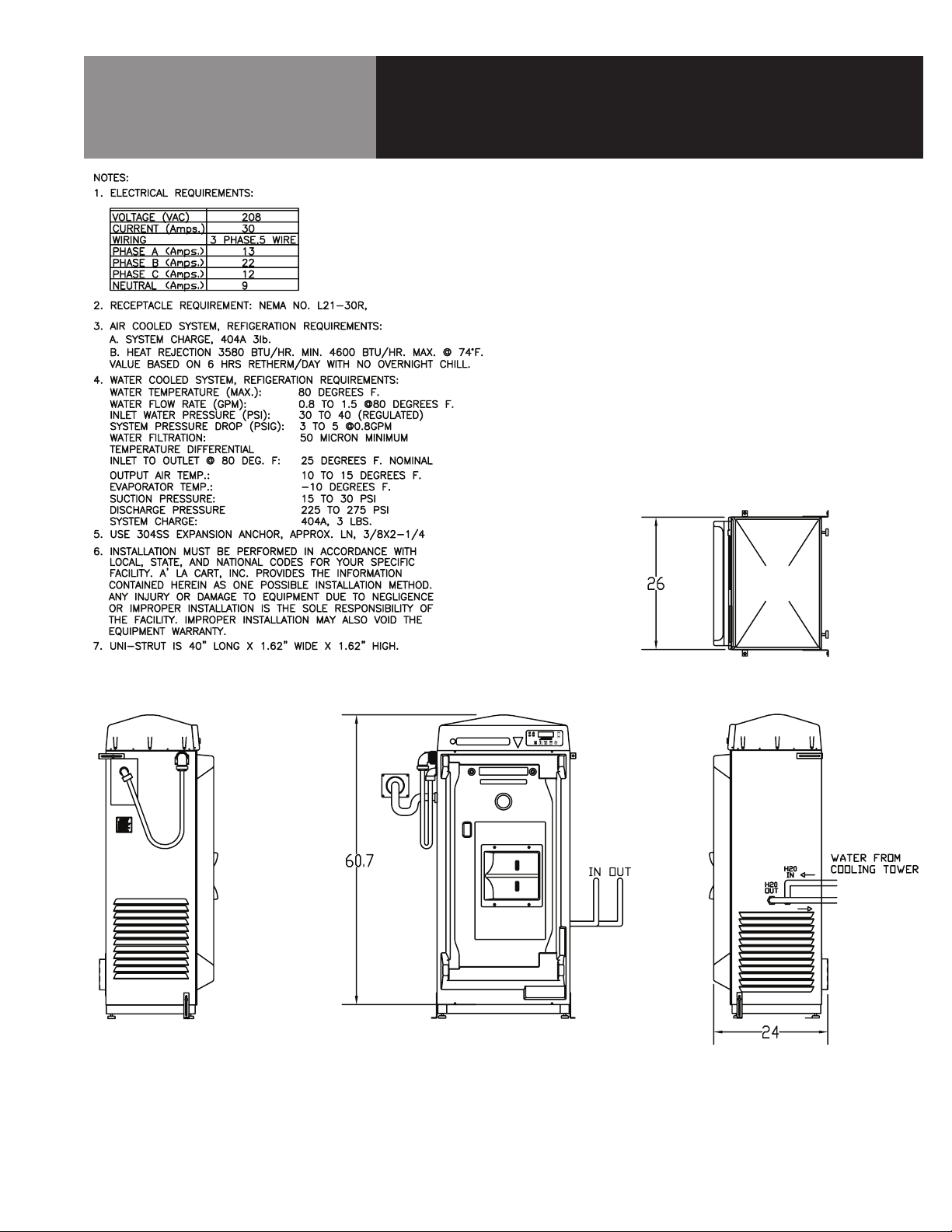

Specifications

CABINET EXTERIOR: Heavy Gauge aluminum with a textured powdercoat. Front fascia and top are formed from a high impact, flame

retardant plastic (UL approved).

REFRIGERATION SYSTEM: 208 Vac, single phase (internally fused)

compressor with R404A refrigerant.

ELECTRICAL REQUIREMENTS: 208 Vac, 30 Amps, 3 phase WYE, 60

Hz, 5-wire grounded, Plug configuration: NEMA L-2130-P

TEMPERATURE STATEMENT: The chiller thermostatically maintains a

System II cart at 38 degrees.

model 98004-1

MANAGEMENT: An A la Cart Central Management Control System (CMCS)

can be added to any System II operation. It can program, monitor and

in an office or central kitchen. On-screen indicators provide real time

information regarding the status of every Controller/Chiller unit, so you can

temperature logs that document food safety compliance and produces

management reports for HACCP control.

Dimensions (WxLxH)

• 24” x 26” x 60.7”

• Weight: 242 lbs

MOBILITY: The Chiller/Controller unit can be easily moved using a

two wheel hand truck. This facilitates installation and allows for easy

chiller relocation during renovation or hospital growth.

CONTROL: programmable electronic controller; self diagnostics for

Chiller and System II cart; unsafe temperature display for HACCP

monitoring.

8 OM-SYSTEM II

SPECIFICATION SHEET/

Model 98004-1

CONTROLLER/CHILLER

Product Information

OM-SYSTEM II 9

Overview & Operating Instructions

MENU PLANNING

With System II any menu format can be utilized, depending on your patients or

clientele, length of stay, budget, and other factors. System II provides maximum

flexibility with the type of food items to include in your menu that will result in

excellent end point quality, due to the ability to customize heat intensity settings for

the entrée and soup/side heaters separately for each mealtime. This allows for having

a combination of different density foods on the same tray that retherm together with

excellent results. You can confidently plan to include a variety of menu items of

various density, thickness, texture, and moistness. All foods are prepared according to

cook/chill standards, methods, and procedures, prior to plating.

PLATING GUIDELINES

Many factors determine how hot foods are plated in System II which, in turn, affects

the end result of rethermalization. These major factors include:

• food density

• thickness

• texture

• input temperatures

• food item’s tolerance to heat

• type of dishware (plastic vs. china)

With System II you have the flexibility of setting the power intensity that is applied

to the heaters during the retherm and hold cycles. This allows you to establish the

appropriate end point temperatures for the rethermed plate quality you desire. It is

done by setting “duty cycle values” for each meal on the entrée and side heaters. The

duty cycle value is equal to the number of seconds per minute that a heater remains

on during the retherm and hold cycles. Refer to the “Display Panel Instructions” in this

manual for instructions on how to set the duty cycles. In general, meals that contain

delicate more “easy-to-heat” items require a lower duty cycle value, such as breakfast

items like scrambled eggs and French Toast. Meals that contain thick meats require a

higher duty cycle value. The table below shows the standard duty cycles.

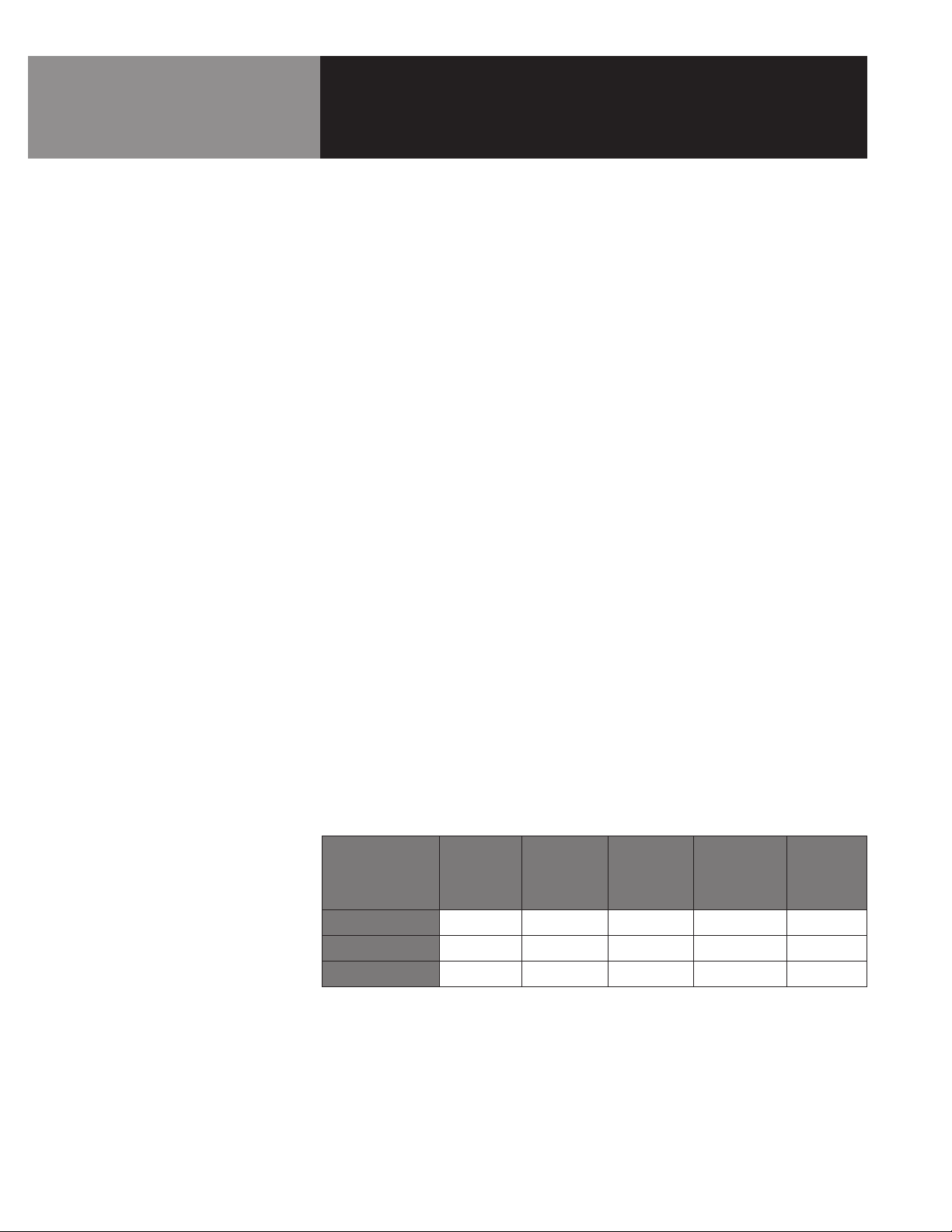

Standard Duty Cycle Values

RETHERM

CYCLE

TOTAL MINS

Factory Setting 38 60 60 60 60

China Dishware 38 45 55 55 55

Plastic Dishware 40 36 45 45 45

BREAKFEAST

ENTRÉE

SEC/MIN

BREAKFAST

SIDE

SEC/MIN

LUNCH/

DINNER

ENTRÉE

SEC/MIN

LUNCH/

DINNER

SIDE

SEC/MIN

10 OM-SYSTEM II

Overview & Operating Instructions

Plating procedures are the most critical for the hot foods, or hot side of the tray, and will

be addressed in this section. For cold foods, placement of items on the tray is important

to ensure that the cold foods are set away from the heat, near the outer most edge of

the cold side of the tray.

China dishware conducts heat differently than plastic dishware. It gets hotter more

quickly and stays hotter for a longer period of time than plastic. China also distributes

heat a little more evenly than plastic, although the center of the dish is always the

hottest spot for both. Plastic dishware takes longer to heat, therefore the retherm time

is generally longer than it is for china. Plating procedures need to be individualized for

each facility based on their menu items, food consistency and the type of dishware used.

To simplify plating techniques all food items can be classified as easy or hard to heat.

“Easy to heat” food items are low to the plate, moist, and have maximum plate contact.

“Hard to heat” food items rest high on the plate, are dry, and very dense. Easy to heat

items are made hard to heat by either placing away from the center of the dish, using a

buffer under the product, placing on plate frozen (breakfast items only) and/or reducing

heat time. Hard to heat items are made easier to heat by either placing in center of the

dish, adding moisture to product, increasing plate surface contact, and/or increasing

heat times. Ideal plating combinations are one hard to heat item with two easy to heat

items. These points are illustrated in the Plating Principles below.

PLATING PRINCIPLES

TYPE OF HEAT: CONDUCTION HEAT

• Heat transfers from heating element -----> to dishware -----> to food

• Center of the plate is the hottest spot; heat transfers out to the edges

EASY TO HEAT

• Fish

• Eggs, Omelets

• Pancakes, French Toast

• Sliced Meats

• Sausage Patty

• Casseroles

• “Low” products

• Breakfast breads

TO MAKE HEATING “HARDER”

• place to side of dish

• use a buffer underneath (fruit slices,

melba toast, etc.)

• place in high heat cup (i.e. eggs)

• plate partially frozen

(breakfast items only)

• reduce heat time

HARD TO HEAT

• Baked Potatoes

• Whole Potatoes

• Bread Dressing

• Thick/dense meats

• Meats with bone

• Sausage links (rounded)

• “High” products (i.e. hot

sandwiches)

• Hard Cooked Eggs (rounded)

TO MAKE HEATING “EASIER”

• place in center of dish

• add moisture

• add sauce

• increase plate surface area

• increase heat time

OM-SYSTEM II 11

Overview & Operating Instructions

It is highly recommended that food product testing be conducted on all menu

items that will be rethermed to determine the proper plating of food items, and verify

that the desired food consistency, quality, flavor and end temperature are met after

rethermalization. When testing product, a complete entrée plate is to be tested.

Ideally 6 to 10 trays of food are tested at a time. The emphasis in food product

testing is evaluating food placement on the plate. A variety of plating options exist

for some menu items, depending on what is desired as the end product. Each facility

must decide on what is most acceptable to them in terms of presentation and food

temperatures.

From the food product testing, plating diagrams can be developed to illustrate proper

plating of menu items for your specific menu. See the sample plating diagrams below:

Breakfast Examples (All Easy to Heat Items)

1. Hard Cooked Eggs: Place in

high heat cup in center of dish.

2. Bacon or Sausage Patty: Place

on side of the plate.

3. Breakfast Breads: Place on a

doily on edge of plate.

Bacon or

Sausage Patty

Eggs

Breakfast

Breads

(Muffins)

1. Scrambled Eggs or Omelete or

Breakfast Burrito: Burrito can

be frozen.

2. Breakfast Potatoes: Place in

center of entree plate.

3. English Muffin or Bagel: Toast

and place toast side down on

plate.

Note: Breakfast burrito to be

wrapped in foil.

1. French Toast or Pancakes:

Place pancakes or french toast

to edge of plate.

2. Breakfast Meats: Place on side

of the plate.

Omelete

Pancakes or

French Toast

Breakfast

Potatoes

Bagel or

English

Muffin

Breakfast

Meats (Bacon,

Sausage Patty)

12 OM-SYSTEM II

Loading...

Loading...