Page 1

EN

SMI2_2016.05_0113_EN

SMI2

RS485 Display

User guide

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 2

1

Contents

1

Safety guidelines ............................................................................................................................................ 2

2 Intended use ................................................................................................................................................... 3

3 Specification ................................................................................................................................................... 4

4 Functional description ................................................................................................................................... 5

5 Installation and commissioning .................................................................................................................... 6

5.1 Installation ................................................................................................................................................ 6

5.2 Programming ........................................................................................................................................... 6

5.3 Configuration ........................................................................................................................................... 6

5.4 Configuration check ................................................................................................................................. 7

5.5 “Factory settings” mode ........................................................................................................................... 7

6 Operation ......................................................................................................................................................... 8

6.1 Slave mode .............................................................................................................................................. 8

6.2 Master mode ............................................................................................................................................ 8

6.3 Operating parameters .............................................................................................................................. 8

6.4 Alarm logic ............................................................................................................................................... 8

6.5 Error display ............................................................................................................................................. 9

7 Maintenance .................................................................................................................................................. 10

8 Transportation and storage ......................................................................................................................... 11

9 Scope of delivery .......................................................................................................................................... 12

Appendix A Dimensions ................................................................................................................................... 13

Appendix B Electrical connection ................................................................................................................... 14

Appendix C Communication protocol ............................................................................................................. 15

Appendix D Functions and data transfer ........................................................................................................ 16

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 3

2

Safety guidelines

1 Safety guidelines

Please read through the user guide carefully before commissioning the device. Damages that arise from

non-observance of the guidelines in the user guide shall be devoid of any liability.

– The device may only be used in the manner described in this user guide.

– No technical modifications may be made to the device.

– The device may not be used if the environmental conditions (temperature, humidity etc.) are not within

the limits indicated in the specification.

– The device may not be used in explosive areas and there may be no chemically active substances in the

atmosphere.

– The device should only be cleaned with a damp cloth. No abrasives or solvent-based cleaners should be

used.

Non-observance of the safety guidelines may result in damage to the device and injury to users

.

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 4

3

Intended use

2 Intended use

The device is intended for use in a RS485 network and supports the protocols Modbus RTU, Modbus ASCII

and akYtec. It can operate either as a slave or a master.

The field of application of the device includes the control and monitoring of industrial processes. The device

can be used in automated systems as a primary or secondary display.

The device may only be operated

– properly installed and

– in accordance with the specification.

Improper use

– The SMI2 may not be used for medical devices that sustain, monitor or otherwise affect human life

or health.

– The device may not be used in potentially explosive environment.

– The device may not be used in an atmosphere with chemically active agents.

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 5

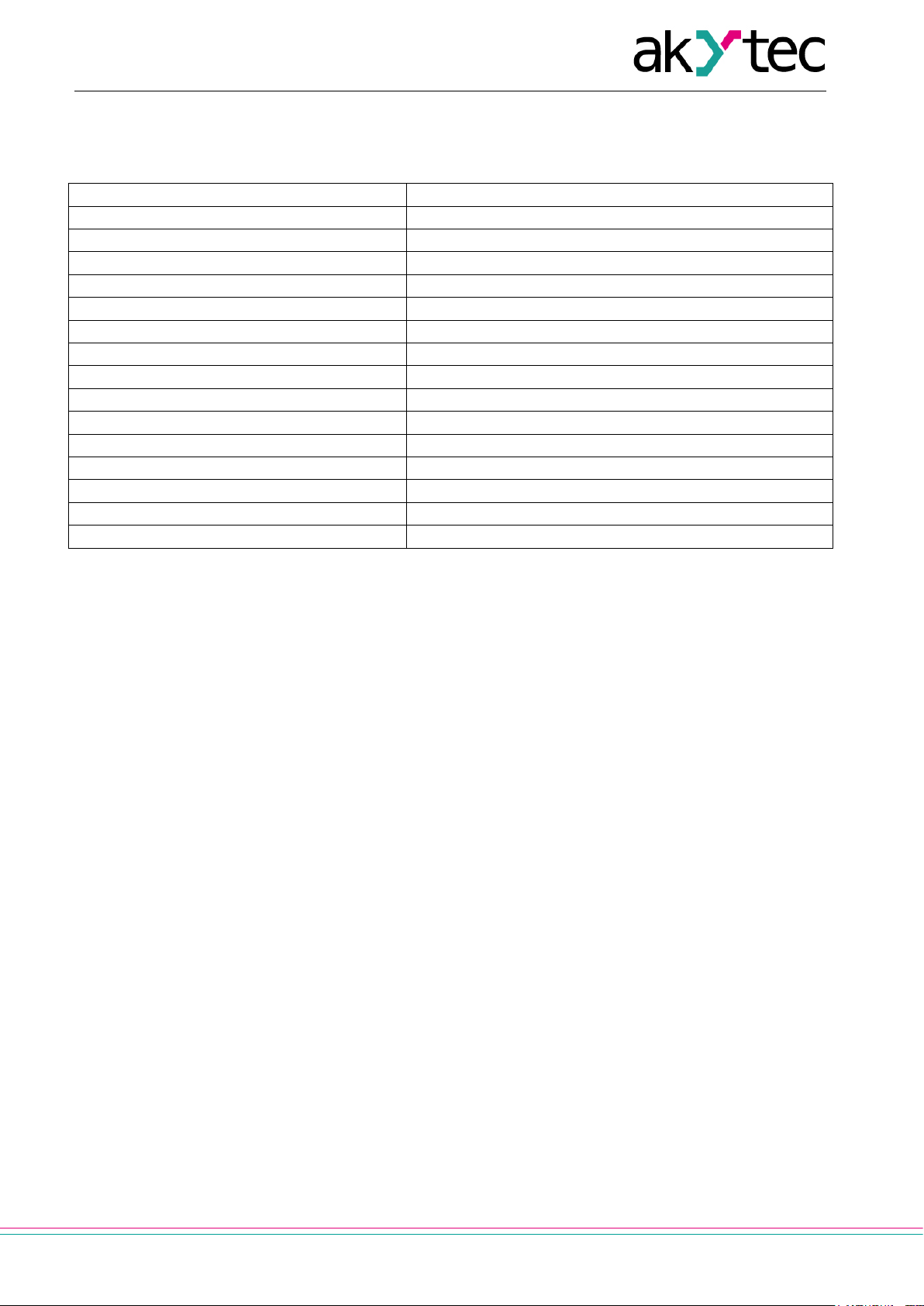

4

Power supply

12 / 24 (10.5…30) V DC

Power consumption, max.

1.5 W

Protocol

Modbus RTU/ASCII, akYtec

Interface

RS485 (2-wire bus)

Baud rate

2.4…115.2 kBit/s

Display

LED, 7-segment display, 4-digit

Character height

14 mm

Display colour

red

IP Code

front IP65, rear IP20

Dimensions

48 x 26 x 65 mm

Weight

approx. 30 g

Protection class

III

Ambient temperature

-25…+55 °C

Storage temperature

-40…+70 °C

Humidity

up to 80% (non-condensing)

Galvanic isolation

yes

Specification

3 Specification

Table 3.1 Specification

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 6

5

PS

Display

SMI2

Converter

TTL

↔RS485

Micro-

8 8 8 8

RESET

RS485

controller

10.5...30 V DC

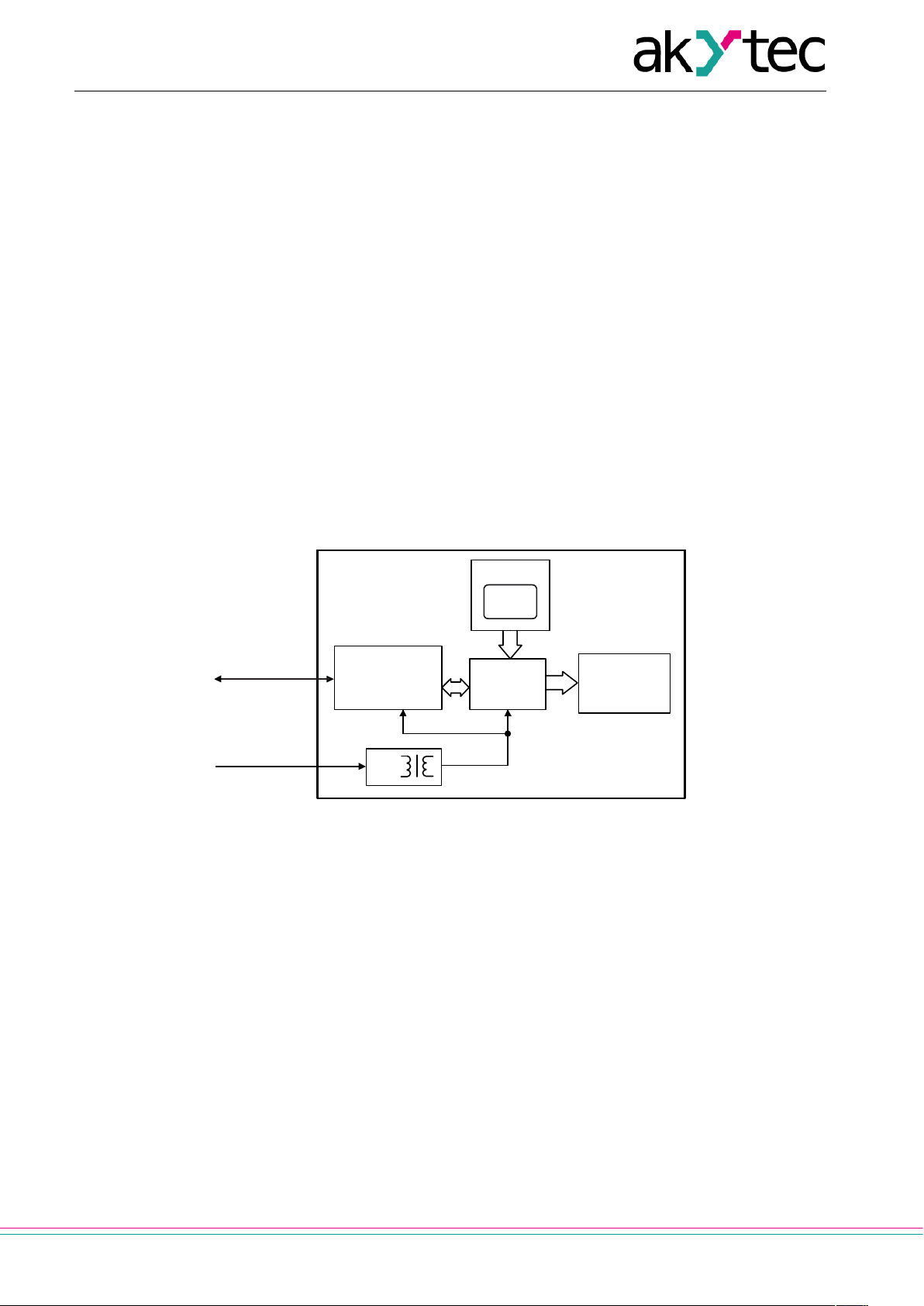

Functional description

4 Functional description

A 4-digit, 7-segment LED display (red) with 14 mm character height displays data received from the RS485

network, error messages and/or configuration parameters of the device.

The secondary voltage source with galvanic isolation guarantees a stable power supply to the device and

offers protection against polarity reversal.

The RESET button is positioned on the cylindrical surface of the device. The button enables to retrieve the

configuration parameters and to restore factory settings, if necessary.

The device has the following functions:

– receiving data from a master device in the slave mode

– querying data from a slave device in the master mode

– processing received data according to the set parameters

– displaying transmitted value

– displaying transmitted value of a type Int or Word with the set number of decimal points

– optional flashing function

– displaying errors if the data transfer is faulty or the received value cannot be displayed (see 6.5)

– displaying configuration parameters of the device

– modifying configuration parameters according to data received from the master

PS – Power supply

Fig. 1 Block diagram

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 7

6

Switch panel

Gasket

Nut

Enclosure

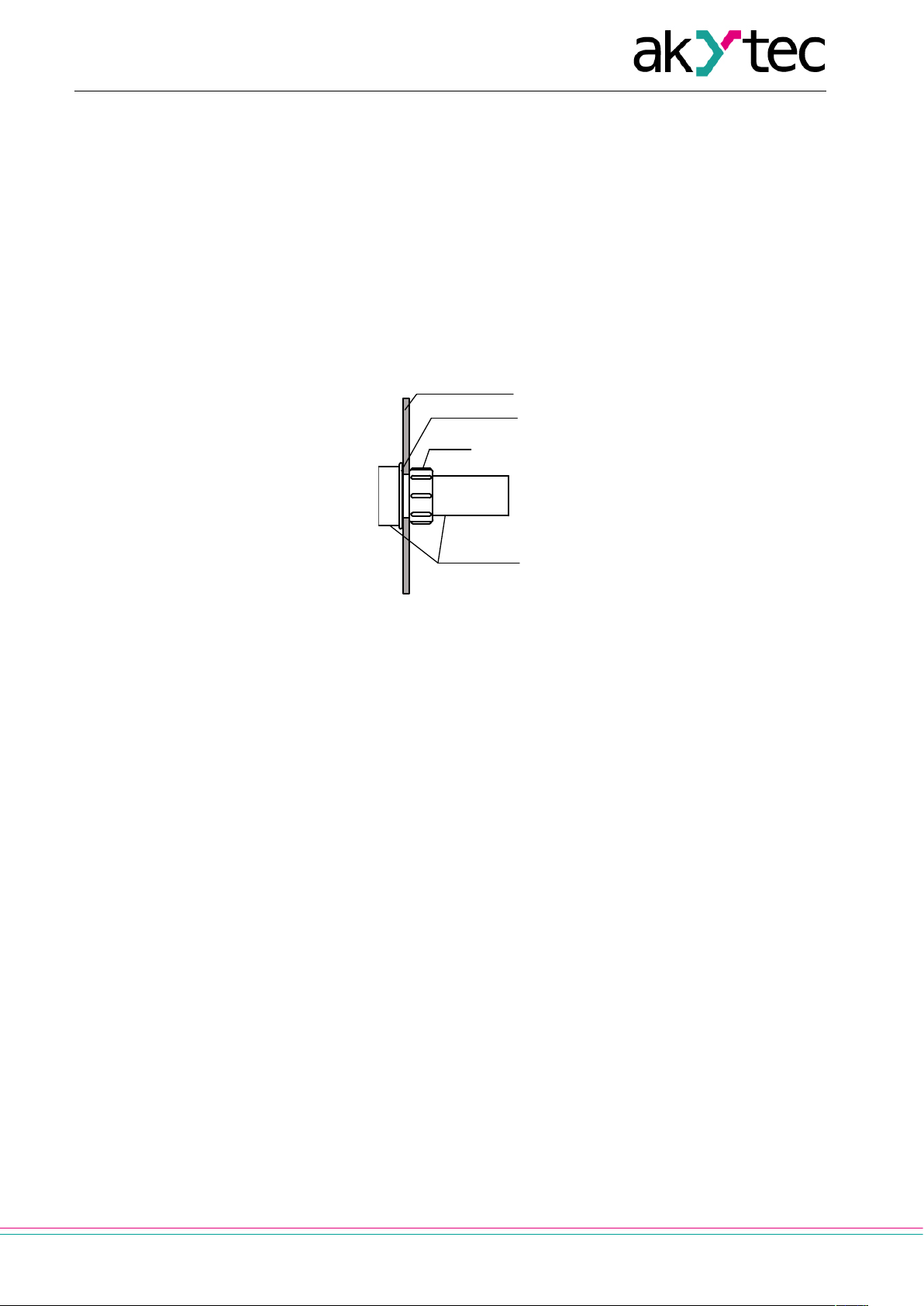

Installation and commissioning

5 Installation and commissioning

5.1 Installation

The SMI2 is designed for switch panel mounting in a borehole of Ø22.5 mm (see Appendix A for dimensions).

Carefully position the supplied gasket on the display rear surface. Insert the cylindrical part of the device into

the borehole and tighten the nut from the rear side of the switch panel. Connect the device to the auxiliary

voltage and signal cables in accordance with Appendix B.

The factory settings can be changed before assembly if necessary (see Appendix D.3). For this purpose the

device must be connected to the RS485 interface of the programming device (PC) and to the auxiliary power

supply. For further details see 5.3.

Fig. 2 Mounting

5.2 Programming

The display may only be programmed in the RS485 network with the communications protocol Modbus

RTU/ASCII or akYtec in the slave mode. The protocol type is specified in the parameter Protocol type (t.Pro)

(see Table D3).

The configuration software „Konfigurator SMI2“ allows to configure the device via the akYtec protocol. The

CD with the configuration software is supplied with the device. Further steps are given in 5.3.

The parameters are divided into two main groups: the configuration parameters and transmitted data.

The configuration parameters are device information, network parameters and operating parameters. The

latter determine how the device processes the received information.

The configuration parameters are constants and are saved in the permanent memory (Table D3).

The transmitted data are variable data exchanged between the master and slave. These are not saved (Table D4).

Each parameter has a name consisting of Latin letters (up to four), which can be separated by points.

5.3 Configuration

Required steps for configuration:

– Connect a USB/RS485 or RS232/RS485 converter (not supplied) to the PC

– Connect the display to the 24 V DC power supply and to the RS485 terminals of the converter according

– Switch on auxiliary voltage

– Install and start SMI2 configuration software

– In the menu select “Device -> Port configuration…“ and set the parameters to the device factory settings

to Fig. B1

(see 5.5)

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 8

7

►

Installation and commissioning

– Check connection with the device (menu “Device -> Check connection”)

– A new device can be configured immediately.

As soon as the parameter Protocol type (t.Pro) is changed and saved, the communication with the device is

interrupted. To enable the SMI2 configuration software to communicate with the device again, the “Factory

settings” mode must be temporarily activated.

5.4 Configuration check

After the RESET button is pressed for a short time, the display extinguishes for 3 seconds, and all current

parameters of the device are then displayed.

The parameters are presented in the following way:

– Parameter name (2 seconds),

– Parameter value (2 seconds),

– Pause (1 second),

– Next parameter.

The display order corresponds to the register number from the Table D3, column 2.

The RESET button must be pressed for a short time again to terminate the display of parameters.

5.5 “Factory settings” mode

In this mode the device works within the factory settings, whereby the parameters configured by the user are

saved and not overwritten. This function can be useful if the device must be configured and its network

parameters are unknown.

To activate this mode, press the RESET button for more than 2 s. The flashing word Fact is displayed and

the device accepts the factory settings (see Appendix D.1).

To disable the mode, the RESET button must be pressed again for more than 2 s or the command APLY

must be sent by the master. The flashing word Fact then fades out and the device resumes the user parameters. The factory settings are effective as long as Fact is displayed.

If the network parameters are queried in this mode, the values of the saved

user network parameters are returned, not the factory setting.

NOTICE

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 9

8

►

Parameter dP

Display

Factor

0

----

1 1

----.

1

2

---.-

10-1

3

--.--

10-2

4

- .---

10-3

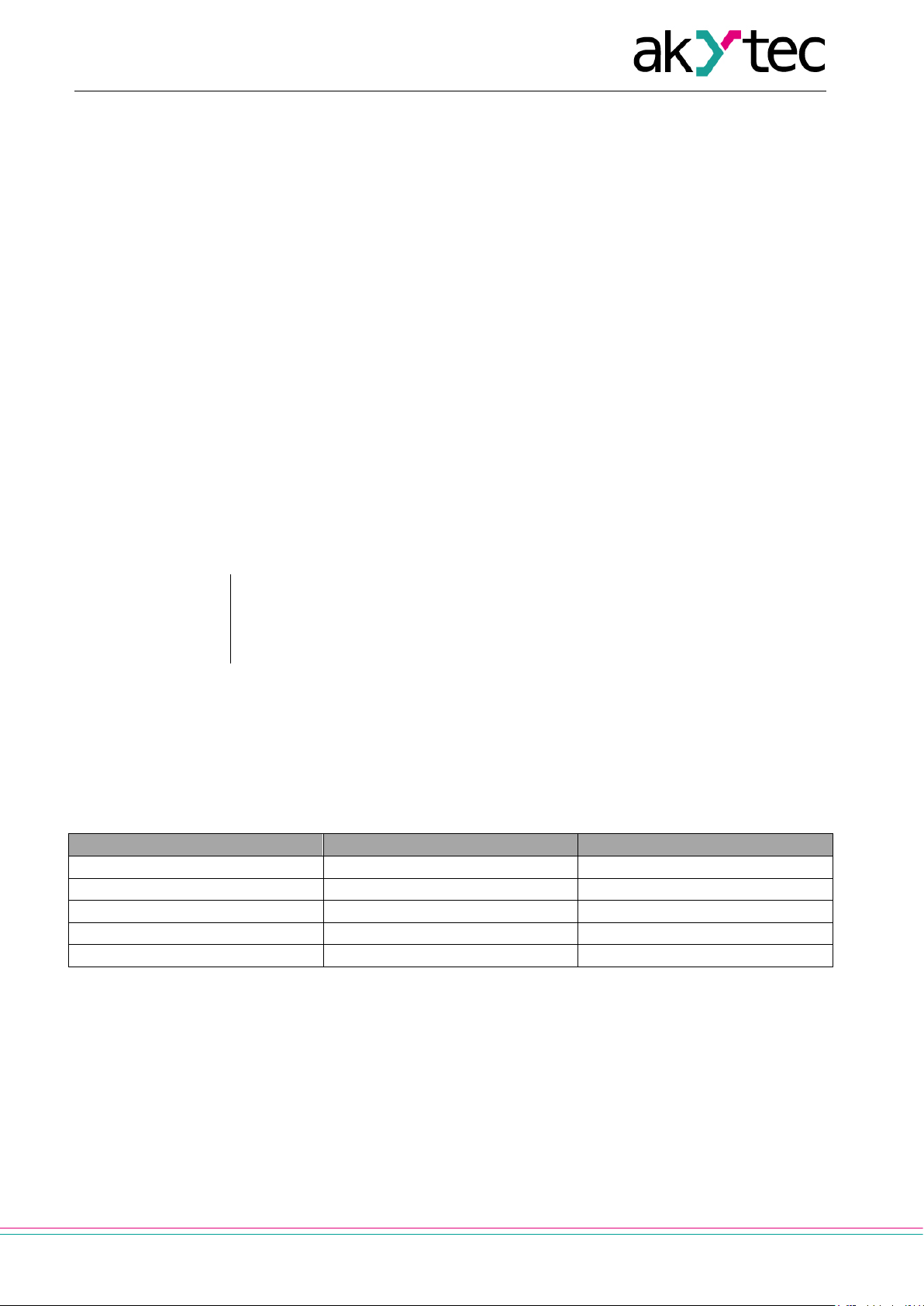

Operation

6 Operation

The operating mode is automatically enabled as soon as the device is supplied with power.

The device supports master and slave modes. The mode can be set in the parameter dEv.r (see Table D3).

The factory setting is 0 (slave).

6.1 Slave mode

In the slave mode the SMI2 receives the data from the master and processes it in accordance with the operating parameters. The results are shown on the display.

6.2 Master mode

To enable the master mode, the parameter dEv.r must be set to 1. To do this the “Factory settings” mode

must be temporarily activated (see 5.5).

In the master mode the SMI2 sends requests to the slave device in the set cycle (parameter SLA.P). The

following parameters must be configured:

– SLA.A - Address of the slave in the network

– SLA.r - Register number for the request

– SLA.P - Query cycle with increment of 100 ms, standard value – 10 (= 1 s)

– SLA.F - Modbus reading function (0x0003 or 0x0004)

The transmitted values are displayed in the same way in both modes in accordance with the set operating

parameters.

The master mode supports only the protocol Modbus RTU/ASCII

NOTICE

6.3 Operating parameters

The complete parameter list is provided in the Table D3.

The data type (Int, Word, Float, String, Image) for the data transmission is set in the parameter dAtA.

For data types Int and Word the transmitted values are displayed with the set decimal point position (parameter dP).

Table 6.1 Decimal point position

The transmitted value is displayed with or without flashing, depending on whether the value lies within or

outside the alarm limits, and the set alarm logic. The flashing interval is set in the parameter PF.

The device cannot be programmed in the master mode. To do this the “Factory

settings” mode must be temporarily activated (see 5.5).

6.4 Alarm logic

Any exceedance of the alarm limits is displayed by flashing LEDs in accordance with the alarm logic.

∩-Logic (parameter AL.t = 1) − the display flashes if the current value lies within the interval

(Т – Δ) < t < (T + Δ),

whereby T − is the setpoint of the monitored process value (parameter C.SP) and Δ − is the hysteresis (parameter HYST).

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 10

9

Display

Cause

|- - |

There is no data packet within the defined time (parameter t.out).

dt.LL

Transmitted value is too small, e.g. the number is smaller than -999

dt.hh

Transmitted value is too high, e.g. the number is larger than 9999

►

Operation

U-Logic (parameter AL.t = 2) − the display flashes if the current value lies outside the interval

(Т – Δ) < t < (T + Δ).

If the parameter AL.t = 0, the function is deactivated.

For the String (dAtA = 3) and Image (dAtA = 4) data types alarm logic is not implemented.

6.5 Error display

Table 6.2 Error display

NOTICE

When using string type data, non-representable symbols are displayed as spaces.

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 11

10

Maintenance

7 Maintenance

The maintenance includes:

– cleaning the housing and the terminals from dust, dirt and debris

– checking the fastening of the device

– checking the wiring (connecting leads, fastenings, mechanical damage)

The device should be cleaned with a damp cloth only. No abrasives or solvent-containing cleaners may be

used.

The safety guidelines in Section 1 must be observed when carrying out maintenance.

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 12

11

►

The device may have been damaged during transportation.

Report the transport damage immediately to the shipper and akYtec GmbH!

Transportation and storage

8 Transportation and storage

Pack the device in such a way as to protect it reliably against impact for storage and transportation. The

original packaging provides optimum protection.

If the device is not taken immediately after delivery into operation, it must be carefully stored at a protected

location. The device should not be stored in an atmosphere with chemically active substances.

Permitted storage temperature: -40…+70 °C

NOTICE

Check the device for transport damage and completeness!

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 13

12

Scope of delivery

9 Scope of delivery

– SMI2 1

– Gasket 1

– Mounting nut 1

– User guide 1

– CD with configuration software 1

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 14

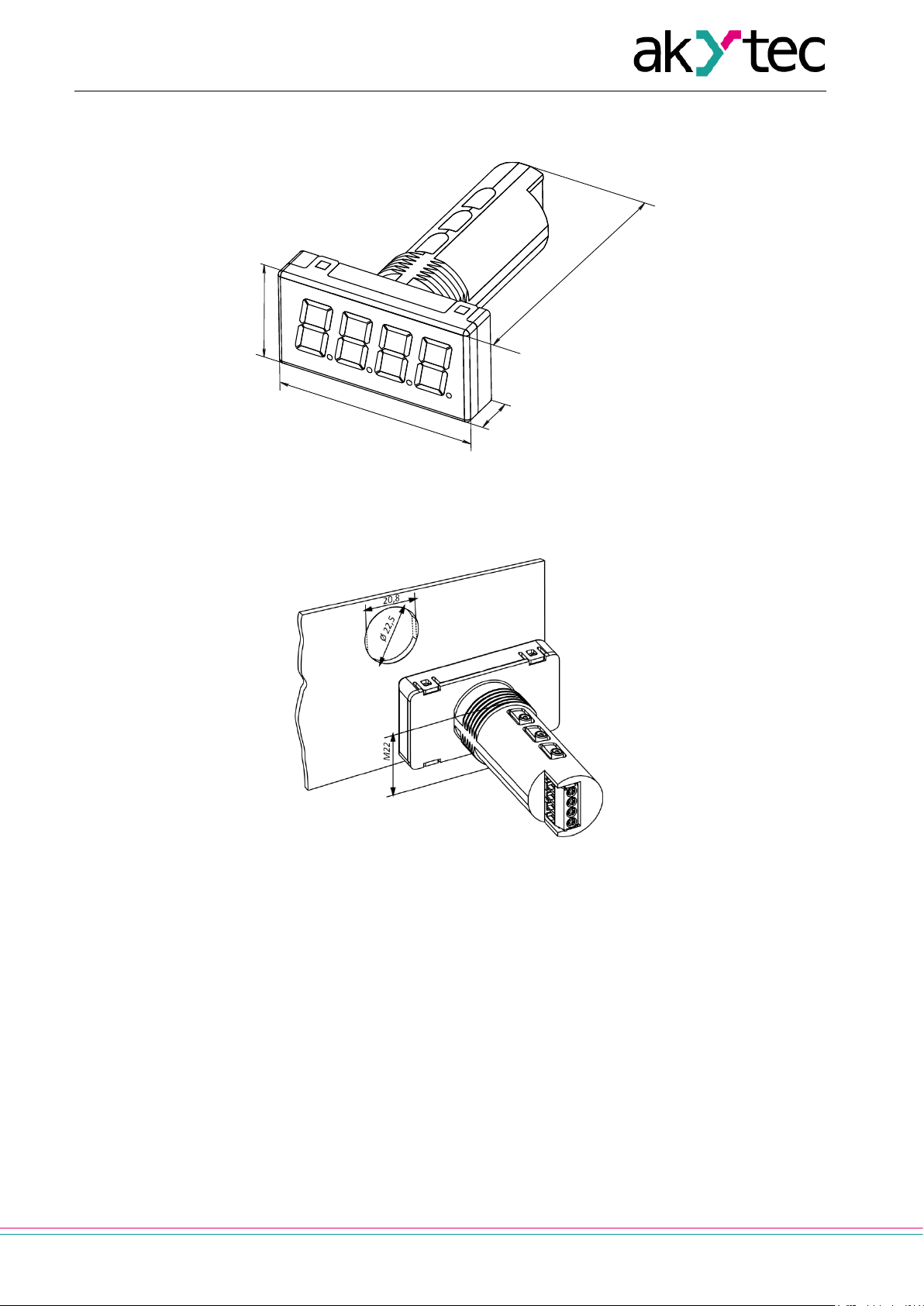

13

RESET

26

48

10

65

Appendix A Dimensions

Appendix A Dimensions

Fig. A1

To prevent the device spinning, the borehole in the front panel must correspond to the dimensions in Fig. A2.

Fig. A2

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 15

14

1

2

3

4

24 V DC

+

B/-

А/+

-

RS485

SMI2

Appendix B Electrical connection

Appendix B Electrical connection

Fig. B1

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 16

15

Appendix C Communication protocol

Appendix C Communication protocol

The device supports the following protocols: Modbus RTU, Modbus ASCII and akYtec. The protocol akYtec

is an internal protocol and is used by the configuration software.

C.1 Addressing

The device receives an individual address so that it can be addressed selectively.

The broadcast address is a reserved address that can be used to address all devices.

The individual addresses are from 1 to 247; the address 0 is reserved as a broadcast address.

If the device has the address 0, it is addressed with every address, but does not send a response.

The device address is set in the parameter Addr. The factory setting is 16.

C.2 Master

Every participant may send messages. However, these are normally initiated by the master and answered by

an addressed slave.

A PLC or a PC with an RS232/485 converter and/or USB/RS485 converter can serve as a master in the

RS485 network.

There may only be one master in a RS485 network.

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 17

16

Address

Function code

Checksum

12

17

ZZ

Address

Function code

Data length (byte)

Data

Checksum

12

17

14

SMI2 VX.YY

ZZ

Appendix D Functions and data transfer

Appendix D Functions and data transfer

The following functions are supported in the Modbus protocol:

– 03, 04 (read registers) – read one or more registers;

– 06 (write single register) – write one register;

– 16 (write multiple registers) – write block of registers;

– 17 (report server ID) – read the device name and the firmware version.

Example. Function 17 (Report Server ID)

This function is used to read the device name and the firmware version. The example with the device address 12 is shown in Tables D1 and D2

Table D1 Format of the request (Master -> Slave)

Table D2 Format of the response (Slave -> Master)

Comments

The values X and YY are set by the manufacturer.

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 18

17

Register

no. (dec)

Device information

Device name

0-1

SMI2

Char[8]

read only

Firmware version

2-3

X.YY

Char[4]

read only

Network parameters

Baud rate

4

0 – 2.4 kBd

byte

read/write

Data bits

Len

5

7 8 byte

read/write

Parity

6

0 - none

byte

read/write

Stop bits

Sbit

7

1 – one

byte

read/write

Response delay

rS.dL

8

0…45…255 ms

byte

read/write

Time-out

t.out

9

0…600 s

UInt16

read/write

Device address

Addr

10

Modbus: 1…16…247

UInt16

read/write

Protocol

11

0 – Modbus ASCII

2 – akYtec

byte

read/write

Address bits

A.Len

12

8 – 8 bit

byte

read/write

Last error code

13

0…255

always 0

byte

read only

see Table D5

Broadband offset

Ad.Ad

16

0…1000…65535

UInt16

(2 bytes)

read/write

Master/Slave mode

dEv.r

40

0 – Slave

byte

read/write

Slave address *)

SLA.A

41

1…16…247

UInt16

read/write

Start address *)

SLA.r

42

0…65535

UInt16

read/write

Query cycle*)

SLA.P

43

0…10…255

byte

read/write

Appendix D Functions and data transfer

D.1 Parameters

Comment: Default values are printed in bold.

Table D3 Configuration parameters

dEv

vEr

bPS

PrtY

Parameter

Values Data type Comment

1 – 4.8 kBd

2 – 9.6 kBd

3 – 14.4 kBd

4 – 19.2 kBd

5 – 28.8 kBd

6 – 38.4 kBd

7 – 57.6 kBd

8 – 115.2 kBd

1 - even

2 - odd

(8 bytes)

(8 bytes)

not displayed

t.Pro

(only akYtec protocol)

n.Err

2 – two

(2 bytes)

akYtec: 0…16…2047

(2 bytes)

1 – Modbus RTU

11 – 11 bit

At switch on -

not displayed

1 – Master

(2 bytes)

(2 bytes)

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

x100 ms

Page 19

18

Modbus function *)

SLA.F

44

3 – 0x0003

4 – 0x0004

byte

read/write

Operating parameters

Data type

17

0 – Int

byte

read/write

Decimal point position

18

0 (- - - -)

4 (-.- - -)

byte

read/write

Flash interval

PF

19

200 … 9999 ms

UInt16

(2 bytes)

read/write

Alarm logic

20

0 – off

2 – U-Logic

byte

read/write

Setpoint

C.SP

21-22

-999 … 0.0 … +9999

Single

(8 bytes)

read/write

Hysteresis (Δ)

HYST

23-24

0 … 10.0 … 9999

Single

(8 bytes)

read/write

Register

Status byte

14

0 … 255

byte

Read only

Data type Int value

val.I

25

-32768 … 0 … 32767

Int16

read/write

Data type Word value

val.W

26

0 … 65535

UInt16

read/write

Data type Float value

27-28

0.0

Single

read/write

Data type String value

29-32

see **)

Char [8]

read/write

Data type Image value

33-34

see **)

Char [4]

read/write

Display mode for data type

35

0 – flashing off

byte

read/write

Actual state of the display

O.Str

36-37

see ***)

Char [4]

read only

Standard display mode

O.mod

38

0×00 – flashing off

byte

read only

Command

15

0x81

byte

Save changed parame-

Appendix D Functions and data transfer

dAtA

1 – Word

2 – Float

3 – String[8]

4 – Image

dP

1 (- - - -.)

2 (- - -.-)

3 (- -.- -)

AL.t

1 – ∩-Logic

Table D4 Transmitted data

Comment: not displayed during the Configuration check (see 5.4).

Parameter

Stat

val.F

val.S

val.P

String and Image

ind.M

segments

no. (dec)

Values Data type Comment

default – (- - - -)

default – ( )

1 – flashing on

0×ВB – flashing on

(2 bytes)

(2 bytes)

(8 bytes)

(8 bytes)

(4 bytes)

(4 bytes)

Bit 0 – EEPROM error

Bit 1 – Parameter error

Aply

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

default – 0

ters

Page 20

19

0

Error-free frame transmission

1

Illegal function

2

Set decimal point position larger than 4

3

Write access to read-only memory

33

Framing error

39

Incorrect checksum

40

Descriptor not found

49

Actual memory area smaller than indicated

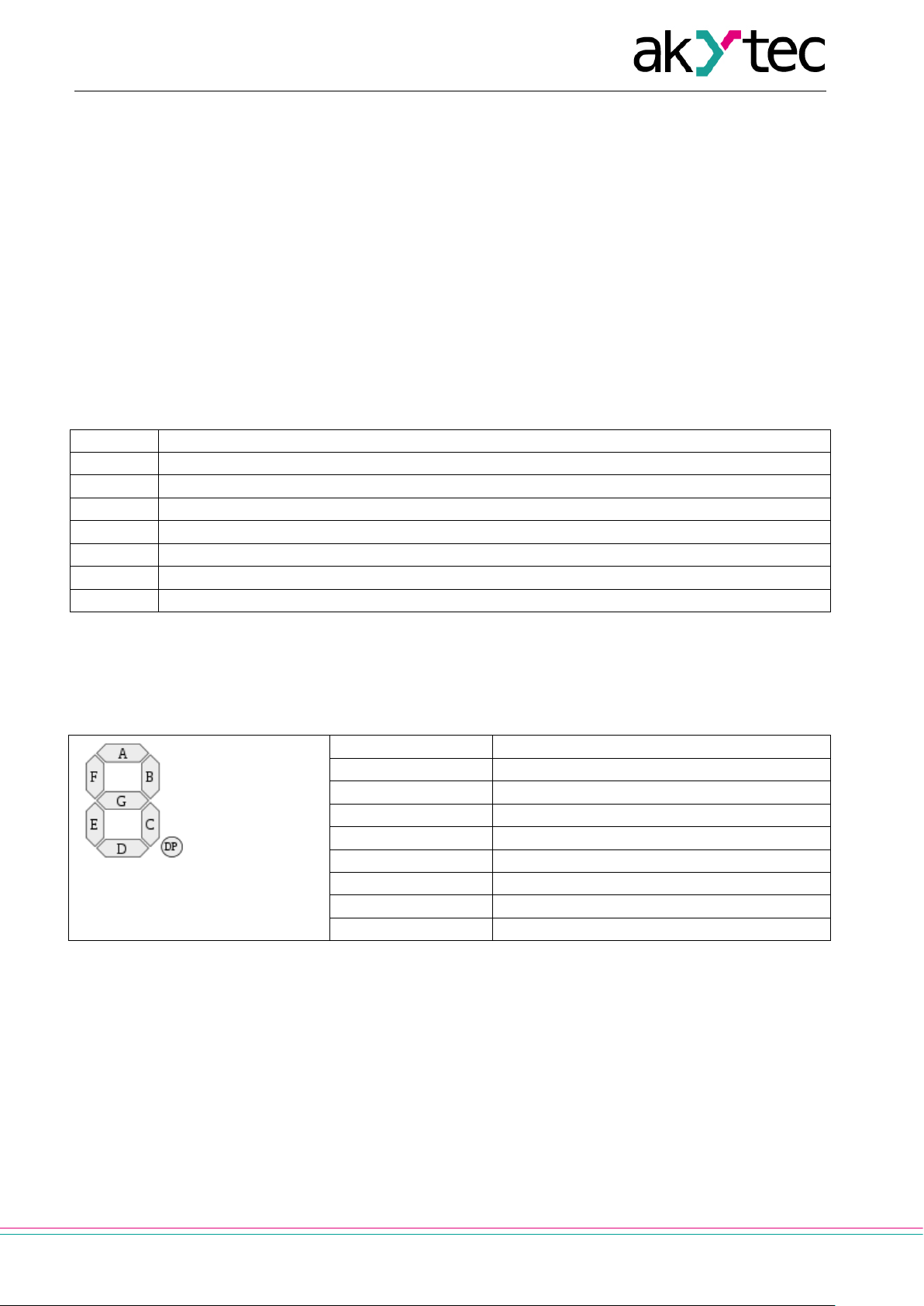

Segment

Bit

A 7 B

6

D 4 E 3 F 2 G 1 DP

0

Appendix D Functions and data transfer

Comments

*) Available only in master mode

**) The display supports the following characters:

Figures 0 … 9;

Upper and lower case letters of the Latin alphabet;

Symbols " ", "_", "–", "."

Examples: 1) char[8] = "A.B.C.D"; 2) char[8] = "ABCD"; 3) char[8] = "ABCD."

***) 4 bytes data shows the status of each display segment. The first byte is reserved for the first digit

from the right. The allocation of bits for the individual segments is described in Table D6.

D.2 Error codes

Table D5

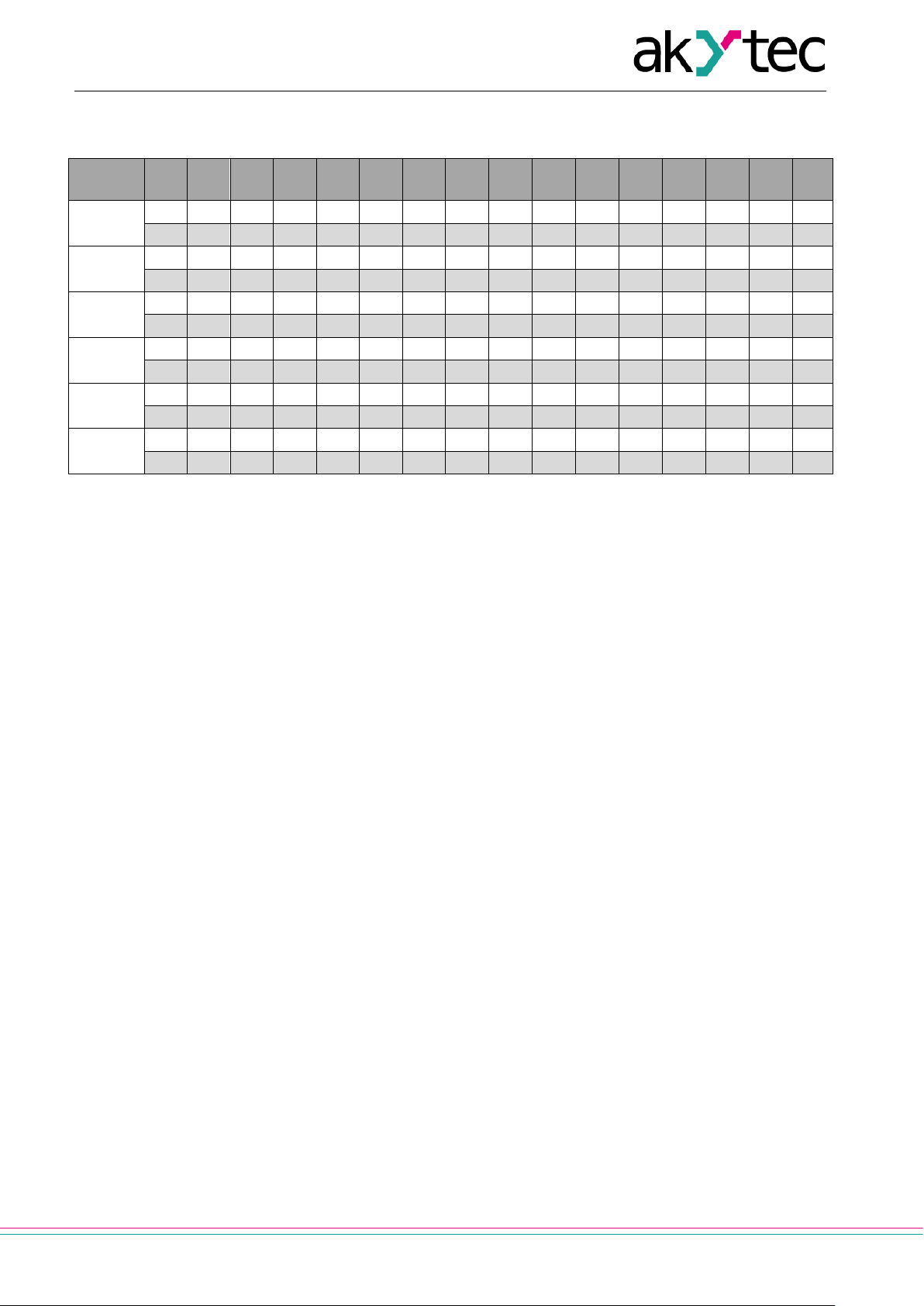

D.3 Segment addressing

Table D6

C 5

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 21

20

ASCII-

– .

– .

0 1 2 3 4 5 6 7 8 9

0 1 2 3 4 5 6 7 8

9

A B C D E F G H I J K L M N

O

A b C d E F G H i J K L M N

O

P Q R S T U V W X Y Z

_

P Q R S t U V W X Y Z

_

a b c d e f g h i j k l m n

o

a b c d E F G h i J K L M n

o

p q r s t u v w x y z

P Q r S t U V W X Y Z

Device address:

0x64 (100)

Function code:

0x10 (16)

Starting address:

0x1D (29)

Number of registers:

0x02 (2)

Data length (byte):

0x04 (4)

Data:

0x57(W) 0x4F(O) 0x52(R) 0x44(D)

CRC:

0xC0 0x07

Device address:

0x64 (100)

Function code:

0x10 (16)

Starting address:

0x1D (29)

Number of registers:

0x04 (4)

Data length (byte):

0x08 (8)

Data:

0x57(W) 0x2E(.) 0x4F(O) 0x2E(.) 0x52(R) 0x2E(.) 0x44(D) 0x2E(.)

CRC:

0x90 0x31

Appendix D Functions and data transfer

D.4 Symbol presentation

Table D7 ASCII code and the symbol presentation

Code

.0 .1 .2 .3 .4 .5 .6 .7 .8 .9 .A .B .C .D .E .F

2.

3.

4.

5.

6.

7.

D.5 Examples

Example 1

The device with the address 100 should display the text WORD.

Request:

64 10 00 1D 00 02 04 57 4F 52 44 C0 07

Example 2

The device with the address 100 should display the text W.O.R.D..

Request:

64 10 00 1D 00 04 08 57 2E 4F 2E 52 2E 44 2E 90 31

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Loading...

Loading...