Page 1

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

PR200

Programmable relay

User guide

PR200_2021.01_0309_EN

© All rights reserved

Subject to technical changes and misprints

Page 2

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

1

Contents

Contents ................................................................................................................................................................. 1

Introduction ............................................................................................................................................................ 2

1 Overview ........................................................................................................................................................ 3

1.1 Intended use .............................................................................................................................................. 4

1.2 Ordering key .............................................................................................................................................. 4

2 Specifications ................................................................................................................................................ 5

2.1 Environmental conditions ....................................................................................................................... 7

3 Installation ..................................................................................................................................................... 8

3.1 Mounting .................................................................................................................................................... 8

3.2 Wiring ......................................................................................................................................................... 8

3.2.1 Inputs ................................................................................................................................................ 9

3.2.2 Outputs ........................................................................................................................................... 10

3.2.3 Terminal assignment ..................................................................................................................... 10

3.3 Quick replacement.................................................................................................................................. 11

4 Hardware resources ................................................................................................................................... 12

4.1 Analog inputs AI1…AI4 .......................................................................................................................... 12

4.1.1 Analog mode .................................................................................................................................. 13

4.1.2 Digital mode.................................................................................................................................... 14

4.1.3 Analog input filtering ..................................................................................................................... 14

4.2 Analog outputs AO1, AO2 ..................................................................................................................... 14

4.3 RS485 interface ....................................................................................................................................... 15

4.3.1 Slave mode ..................................................................................................................................... 15

4.3.2 Master mode ................................................................................................................................... 17

4.4 Service modes ........................................................................................................................................ 19

5 Operation ..................................................................................................................................................... 21

5.1 Error mode .............................................................................................................................................. 21

5.2 System menu .......................................................................................................................................... 21

5.2.1 Display navigation ......................................................................................................................... 22

5.2.2 Menu structure ............................................................................................................................... 23

5.3 Display programming ............................................................................................................................. 24

6 Maintenance ................................................................................................................................................ 26

7 Transportation and storage ....................................................................................................................... 27

8 Scope of delivery ........................................................................................................................................ 28

Appendix А. Dimensions .................................................................................................................................. 29

Appendix B. Terminal layouts .......................................................................................................................... 30

Appendix C. Galvanic isolation ........................................................................................................................ 33

Appendix D. Circuit diagrams .......................................................................................................................... 35

Appendix E. Calibration .................................................................................................................................... 36

E.1 General .................................................................................................................................................... 36

E.2 Input ......................................................................................................................................................... 36

E.3 Output 4-20 mA ....................................................................................................................................... 37

E.4 Output 0-10 V .......................................................................................................................................... 37

Appendix F. Battery replacement .................................................................................................................... 39

Appendix G. Interface card installation ........................................................................................................... 41

Page 3

Introduction

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

2

Introduction

This manual describes the functions, configuration, operating instructions, programming and

troubleshooting of the multifunctional programmable relay PR200 (hereinafter referred to as

PR200, device, or relay).

Terms and abbreviations

ALP – programming software akYtec ALP for programming PR series relays, based on

Function Block Diagram (FBD) programming language

ADC – analog-digital converter

DAC – digital-analog converter

Display element – program element used to display information on the device display

Modbus – application layer messaging protocol for client/server communication between

devices connected on different types of buses or networks, originally published by

Modicon (now Schneider Electric), currently supported by an independent organization

Modbus-IDA (www.modbus.org).

Project – user application created in ALP software that also includes the device

configuration

RAM – random access memory, volatile part of the device memory

Retain memory – non-volatile device memory for retain variables

Retain variable – type of variable that keeps its value after device restart (power off/on

cycle)

ROM – read-only memory, non-volatile part of the device memory

Symbols and key words

DANGER

DANGER indicates an imminent dangerous situation that will result in death or serious

injuries if not prevented.

WARNING

WARNING indicates a potentially dangerous situation that could result in death or serious

injuries.

CAUTION

CAUTION indicates a potentially dangerous situation that could result in minor injuries.

NOTICE

NOTICE indicates a potentially dangerous situation that could result in damage to

property.

NOTE

NOTE indicates helpful tips and recommendations, as well as information for efficient and

trouble-free operation.

Page 4

Overview

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

3

1 Overview

The programmable relay PR200 is a small controller. User program is created as a function

plan with the ALP programming software, which is available for download for free. The ALP

project includes the program as well as the device configuration. Dynamically allocated

memory enables to create complicated programs with many functional blocks, display

elements and advanced display management.

The PR200 enables the following basic functions:

output control according to input statuses and program logic

configuration using ALP software or function buttons

comprehensive display programming

2 programmable LEDs

master and / or slave in Modbus network

Real-time clock

expandable with I/O modules

The relay is available in several versions, for DC and AC voltage, equipped with only digital

or a combination of digital and analog inputs and outputs. The analog inputs can be

configured as analog or as digital. The relay can be expanded with additional I/O modules.

Optional are up to two RS485 interfaces for connection to Modbus networks available.

The device is designed in a plastic enclosure for DIN rail mounting. The enclosure has 3-

level stepped form for distributor installation. Plug-in terminal blocks enable quick and easy

replacement of the device.

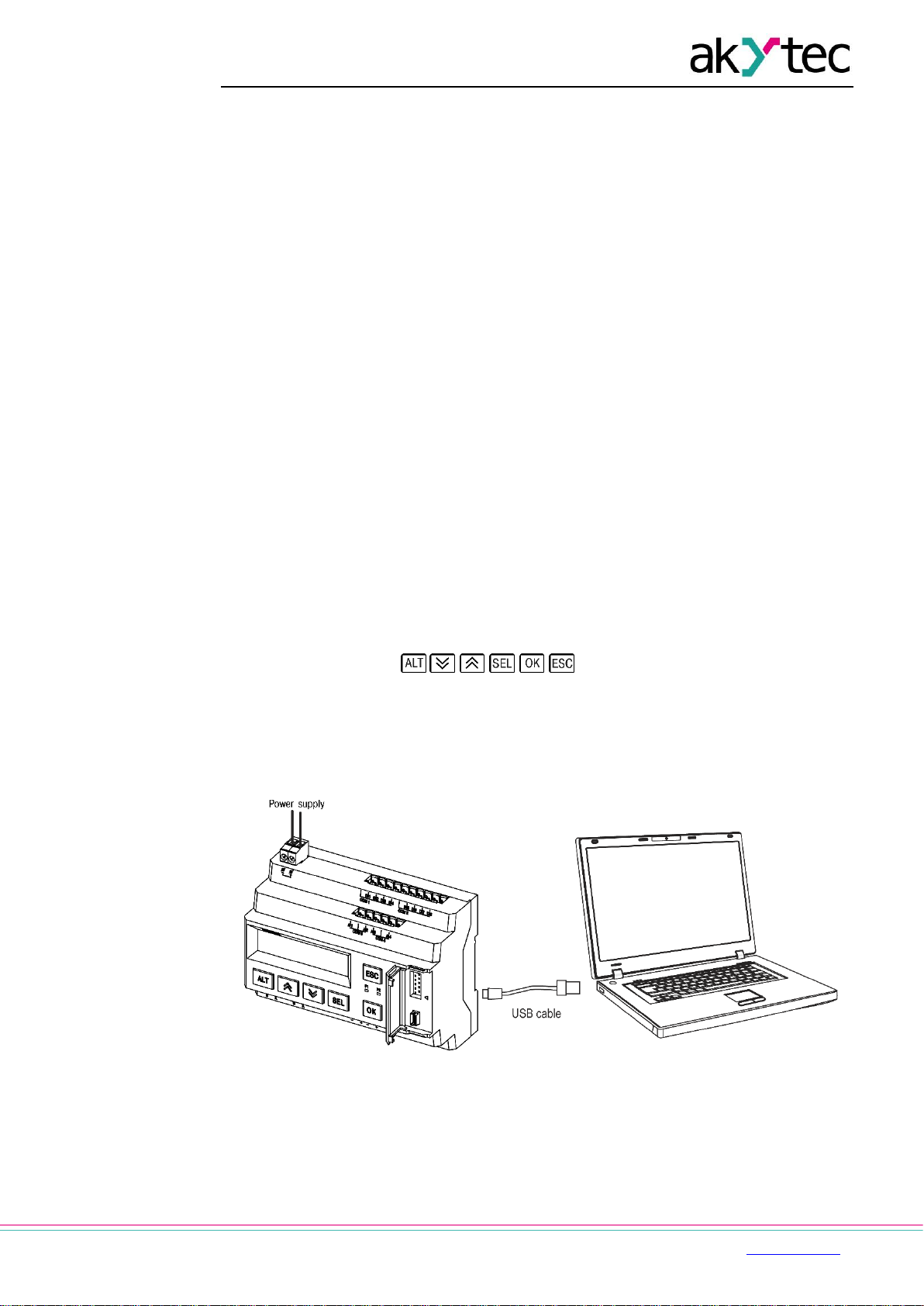

Front view:

two-line 32-character alphanumeric LCD display

two LEDs: F1 (green) and F2 (red), program-controlled

6 function buttons for system menu and display navigation

Under the interface cover (to the right):

EXT: 10 pole connector for extension modules

PRG: mini-USB socket for PC connection. USB A-plug to micro B-plug connection

cable is in the package included.

Fig. 1.1 Connection to PC (open interface cover)

Page 5

Overview

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

4

1.1 Intended use

Programmable relays of PR200 series have been designed and built solely for the intended

use described in this manual, and may only be used accordingly. The technical

specifications contained in this manual must be observed. Only by akYtec GmbH

recommended extension modules may be connected to the relay.

The relay may be operated only in properly installed condition.

Improper use

Any other use is considered improper. Especially to note:

– This device should not be used for medical devices which receive, control or

otherwise affect human life or physical health.

– The device should not be used in an explosive environment.

– The device should not be used in an atmosphere with chemically active substance.

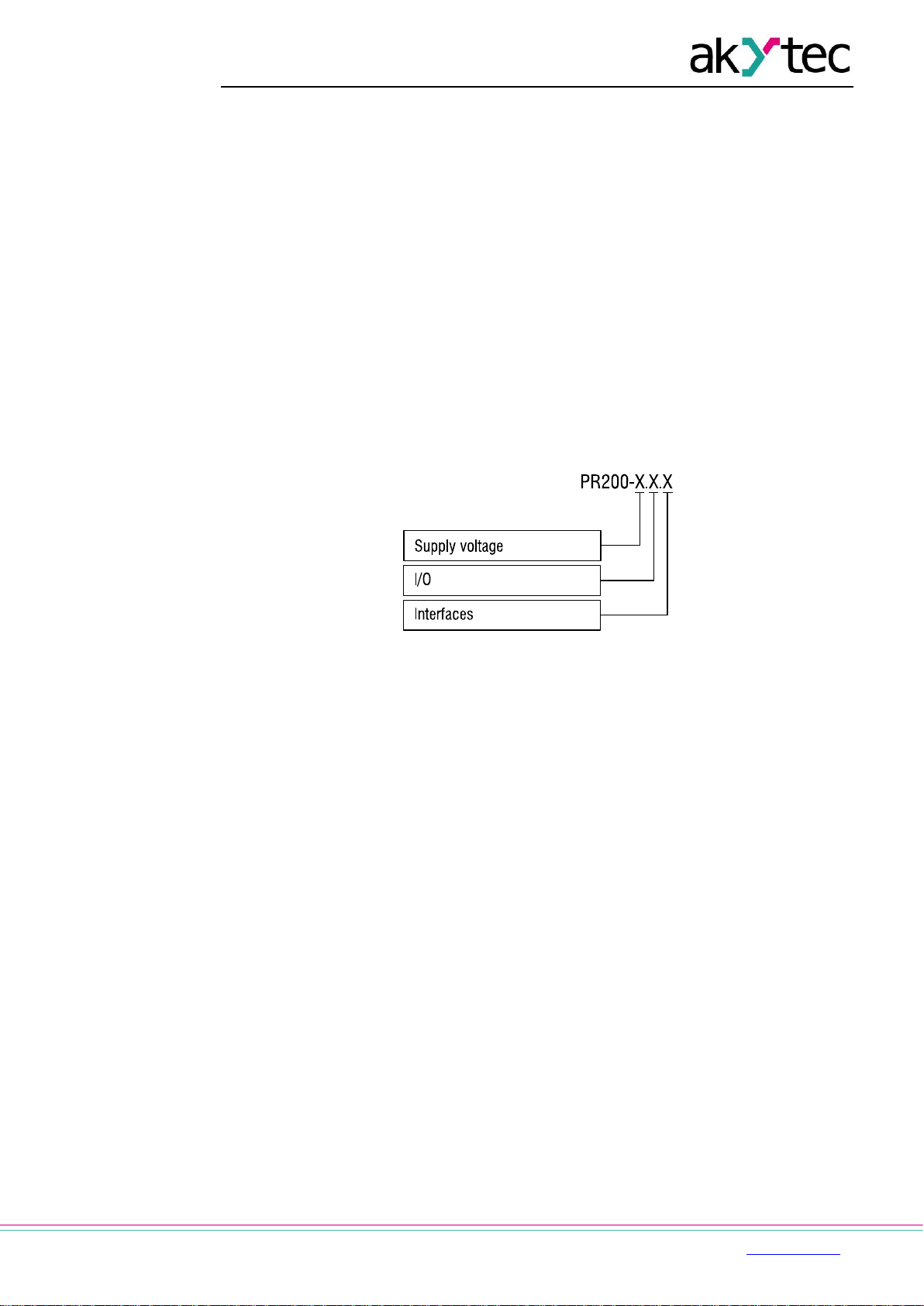

1.2 Ordering key

The relay PR200 can be ordered in various designs depending on the required supply

voltage, number and type of inputs, outputs and interfaces:

Supply voltage

230 - 230 (94…264) V AC

24 - 24 (19…30) V DC

I/O

1 - 8 DI, 6 DO

2 - 8 DI, 4 AI, 8 DO, 2 AO (4-20 mA)

4 - 8 DI, 4 AI, 8 DO, 2 AO (0-10 V)

RS485 interfaces

0 - none *

1 - 1 *

2 - 2

* The models .0 and .1 can be upgraded later by installing up to two interface cards (app. G).

Ordering code for the interface card: PR-IC485

Page 6

Specifications

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

5

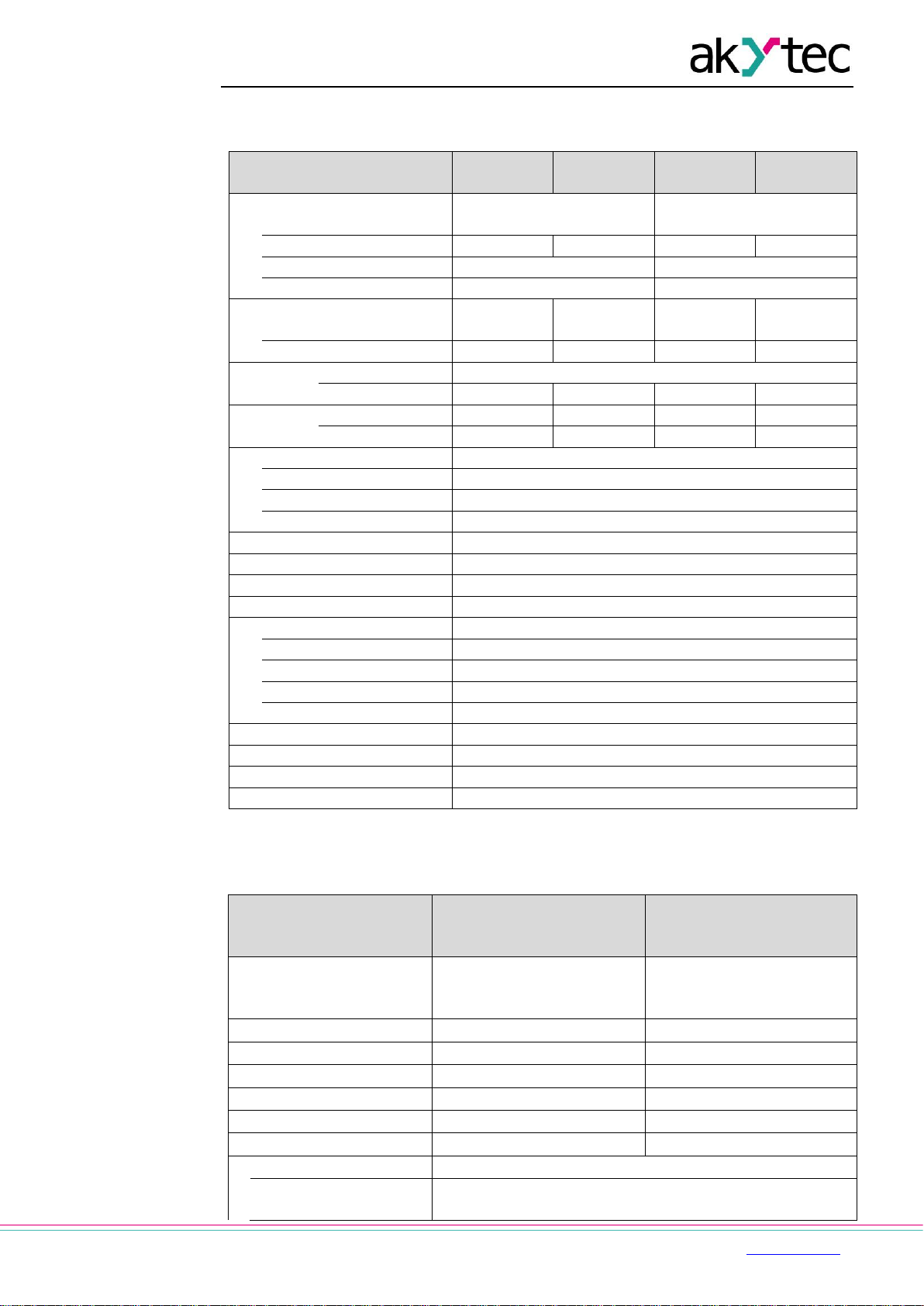

2 Specifications

Table 2.1 General specification

Device

230.1.x

230.2.x

230.4.x

24.1.x

24.2.x

24.4.x

Power supply

230 (94…264) V AC;

50 (47…63) Hz

24 (19…30) V DC

Power consumption, max

10 VA

17 VA

10 W

10 W

Galvanic isolation

2830 V

1780 V

Appliance class

II

III

Integrated voltage source

-

24±3 V DC

100 mA

-

-

Galvanic isolation

-

1780 V - -

Inputs

Digital

8

Analog * - 4 - 4

Outputs

Digital (relay)

6 8 6

8

Analog - 2 - 2

Programming

Software

akYtec ALP

Interface

Mini USB 2.0

Program cycle, min

1 ms

Function buttons

6

LEDs

F1 (green), F2 (red), programmable

LCD display

2x 16 digits, backlight adjustable

Language

English

RS485 interface **

2-pole plug-in terminal block

Protocols

Modbus RTU/ASCII (master/slave)

Baud rate

9.6…115.2 kbit/s

Interface card

PR-IC485 (max. 2)

Galvanic isolation

1500 V

Dimensions

123 x 108 x 58 mm (with terminal blocks)

Mounting

DIN rail (35 mm)

Weight

approx. 350 g

IP code

IP20

* Analog inputs AI1…AI4 can also be configured as digital inputs

** For x.x.1 and x.x.2 models only

Table 2.2 Digital inputs

Device

230.1.x

230.2.x

230.4.x

24.1.x

24.2.x

24.4.x

Input signal

Switch contact

Switch contact

PNP with open collector

Digital signals -3…+30 VDC

Input voltage

230 V AC

24 V DC

Input voltage, max

264 V AC

30 V DC

Logical 1

159…264 V (0.75…1.5 mA)

15…30 V (5 mA)

Logical 0

0…40 V (0…0.5 mA)

-3…+5 V (0…1 mA)

Pulse length, min

50 ms

2 ms

Response time, max

100 ms

30 ms

Galvanic isolation

in groups of 4 (1-4, 5-8)

Test voltage between

input groups

1780 V

Page 7

Specifications

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

6

Device

230.1.x

230.2.x

230.4.x

24.1.x

24.2.x

24.4.x

Test voltage against

other circuits

2830 V

Table 2.3 Analog inputs

Device

x.2.x, x.4.x

Galvanic isolation

none

Analog mode

Input signal

0-10 V, 4-20 mA, 0-4000 ohm

Input voltage *

-36…+36 V

Input resistance (0-10 V)

61 kohm

Input resistance (4-20 mA)

121 ohm

Basic error

±0.5%

Temperature influence

±0.05%/10°C

Resolution

2.7 mV / 6 µA

ADC resolution

12 bit

Sampling time for 4 inputs, max

10 ms

Digital mode

Logic 1 **

0…10 V, adjustable

Logic 0 **

0…10 V, adjustable

Current at input voltage 15…30 V, max

5 mA

* If the voltage at one input is below -0.5 V, the accuracy for all inputs cannot be guaranteed.

** Parameter can be set in ALP Property Box using the option Input mode = digital.

Table 2.4 Digital outputs

Type

relay (NO)

Switching capacity AC

5 A, 250 V (resistive load)

Switching capacity DC

3 A, 30 V

Minimum load current

10 mA (at 5 V DC)

Service life, electrical

3 A, 30 V DC

200,000 switching cycles

5 A, 250 V AC (resistive load)

100,000 switching cycles

Galvanic isolation

in groups of 2 (1-2, 3-4, 5-6, 7-8)

Test voltage between output groups

1780 V

Test voltage against other circuits

2830 V

Table 2.5 Analog outputs

Device

x.2.x

x.4.x

Auxiliary voltage

12…30 V DC

12…30 V DC

Quantity

2

Output signal

4-20 mA

0-10 V

Output load, max

1 kohm

2 kohm

Basic error, max

±0.5%

Temperature influence

±0.05%/10°C

Inductive load, max

50 µH

-

Signal conversion time

100 ms

DAC resolution

10 bit

Galvanic isolation

2830 V, individual

2830 V, in group

Page 8

Specifications

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

7

Table 2.6 Memory

ROM memory

128 kB

RAM memory

32 kB

Retain memory

1016 Byte

Network variable memory *

128 Byte

* The limitation applies only to the slave mode, in which all network variables are

automatically declared as retain.

Table 2.7 Real-time clock

Accuracy

±3 s/day (25°C)

Correction

-2.75…+5.5 min/month

Backup, min

8 years

Backup battery

CR2032

2.1 Environmental conditions

The device is designed for natural convection cooling. It should be taken into account when

choosing the installation site.

The following environment conditions must be observed:

clean, dry and controlled environment, low dust level

closed non-hazardous areas, free of corrosive or flammable gases

Table 2.8

Conditions

Permissible range

Ambient operating temperature

-20…+55°C

Storage temperature

-25…+55°C

Relative humidity

up to 80% (at +25°C, non-condensing)

Altitude

up to 2000 m above sea level

EMC immunity

conforms to IEC 61000-6-2

EMC emission

conforms to IEC 61000-6-4

Page 9

Installation

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

8

3 Installation

The relay is designed for DIN rail mounting. The environmental conditions from the section

2.1 must be observed. For the dimension drawing see Appendix. A

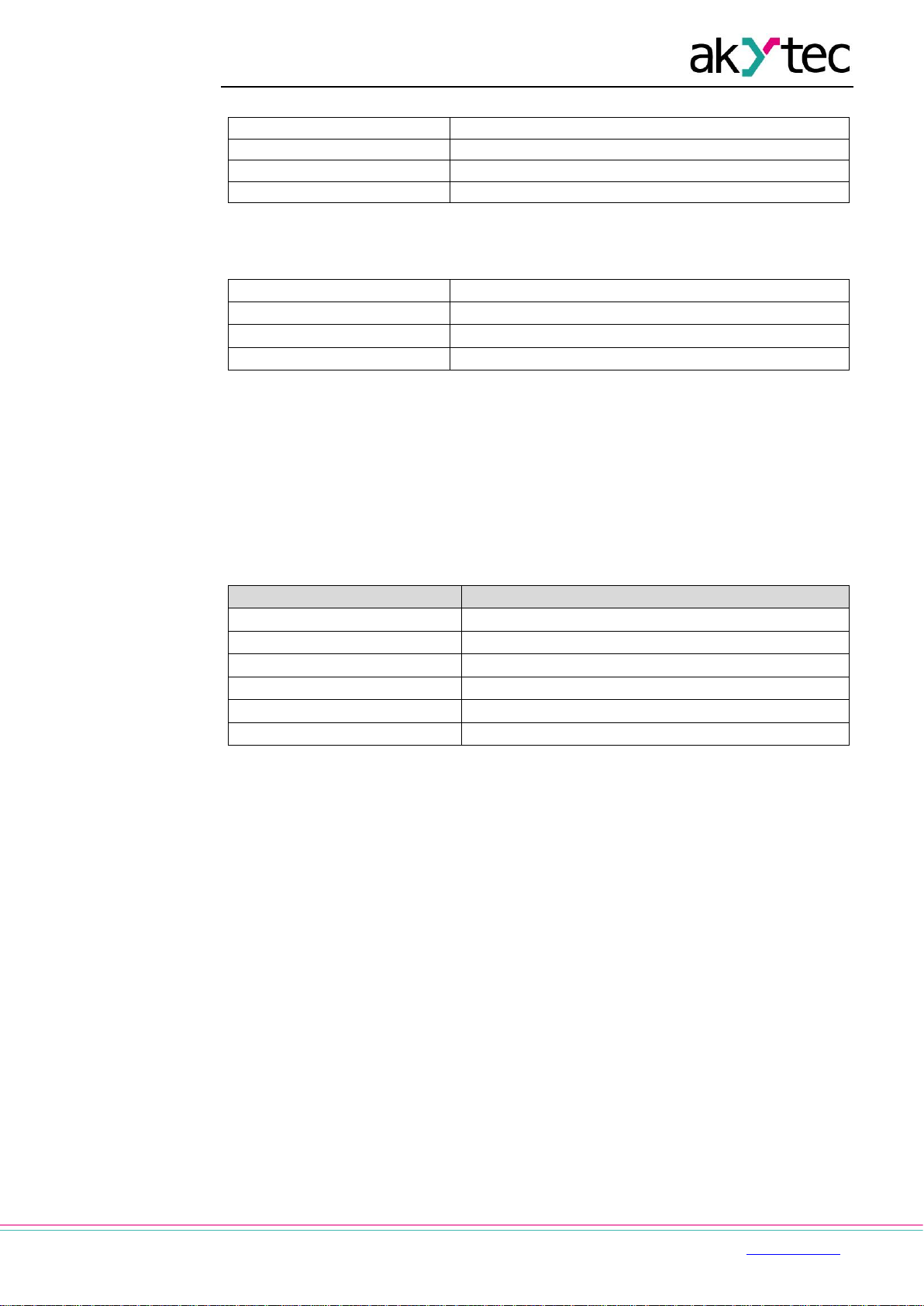

3.1 Mounting

Align the upper slide of the DIN rail

mounting groove with the DIN rail and

push it onto the rail.

Wire external connections in

accordance with sec. 3.2 using plug-in

terminal blocks (included).

Removal:

Take off the terminal blocks without

disconnecting the wires.

Insert a screwdriver into the eyelet of

the slide interlock, push it down and

remove the relay from the rail.

Fig. 3.1

3.2 Wiring

WARNING

Electric shock could kill or seriously injure.

All electrical connections must be performed by a fully qualified electrician.

Ensure that the mains voltage matches the voltage marked on the nameplate.

Ensure that the device is provided with its own power supply line and electric fuse.

Do not feed any external devices from the power contacts of the device.

Remove the terminal blocks only after powering off the device and all connected

equipment.

WARNING

The device must be powered off before connecting to peripheral devices, internal

bus or PC. Switch on the power supply only after the wiring of the device has been

completed.

WARNING

The program runs after transferring it to the relay. It is recommended to transfer the

program before wiring the relay.

Otherwise ensure that all peripheral devices are disconnected from relay outputs

before transferring the program.

NOTICE

Supply voltage for 24 VDC models may not exceed 30 V. Higher voltage can damage

the device.

If the supply voltage is lower than 19 V DC, the device cannot operate properly but

will not be damaged.

NOTICE

Signal cables should be routed separately or screened from the supply cables.

Shielded cable should be used for the signal lines to ensure compliance with the

EMC requirements.

NOTE

Before powering on, make sure that the device was stored at the specified ambient

temperature (-20 ... +55 °C) for at least 30 minutes.

─ For terminal assignment, see Tables 3.1, 3.2

─ For I/O electrical connections, see Fig. 3.2…3.7

─ For terminal blocks layouts, see app. B

Page 10

Installation

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

9

─ Maximum conductor cross-section is 0.75 mm²

3.2.1 Inputs

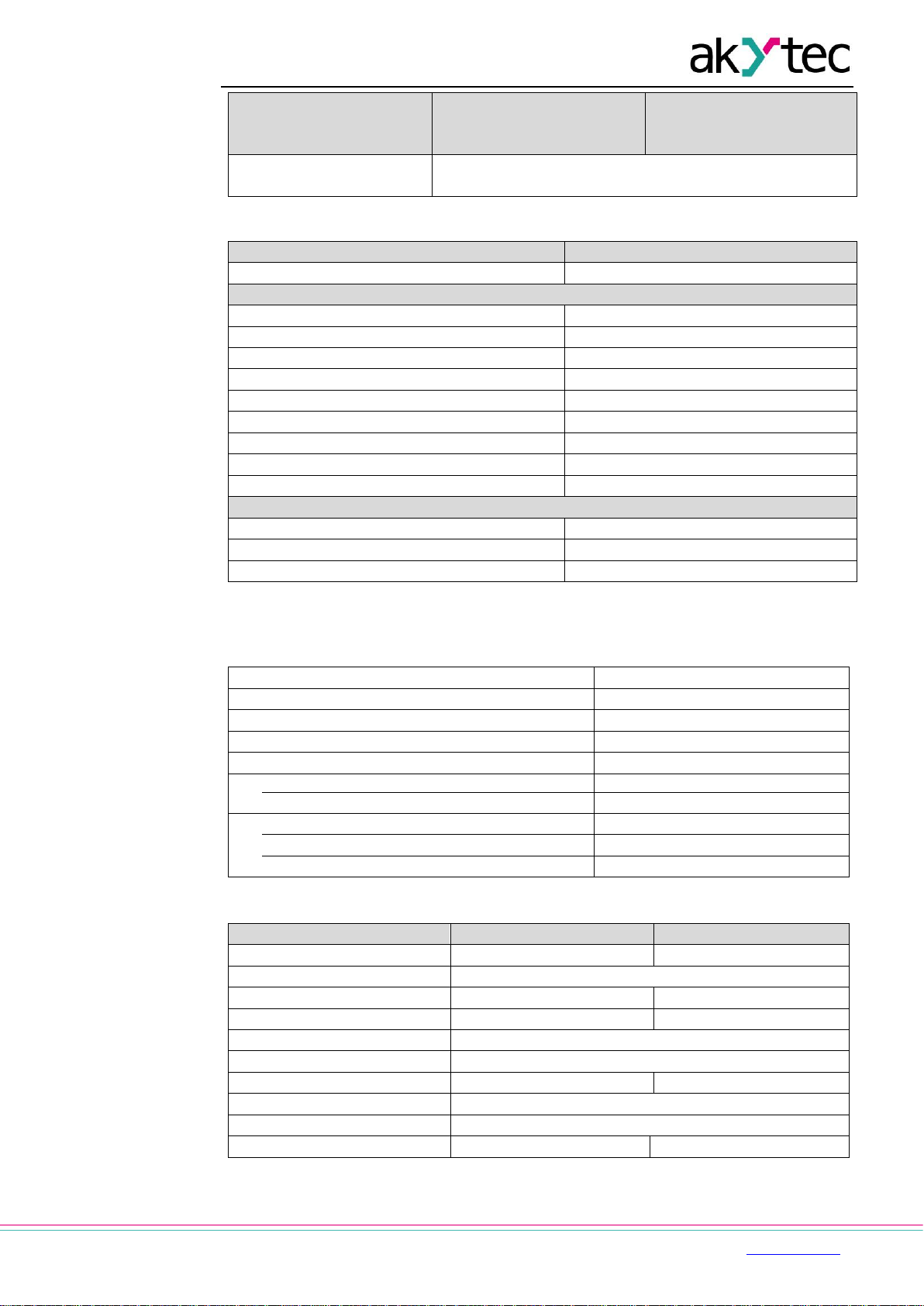

a b

Fig. 3.2 Connection of switch contacts to digital inputs: a) 24.x.x, b) 230.x.x

NOTICE

230.x.x models

The digital inputs are divided into two groups, each of four inputs. All inputs must

be operated on the same phase. Different phases are not allowed.

Fig. 3.3 Connection of 3-wire sensors with PNP transistor outputs to digital inputs (24.x.x

only)

For 24.x.x models, it is permissible to connect sensors with switch contacts and transistor

outputs to digital inputs within the same input group.

If the galvanic isolation between inputs groups is not required, a common power supply,

including the integrated 24 VDC voltage source, can be used for both groups.

a b c

Fig. 3.4 Analog inputs: a) 4-20 mA, b) 0-10 V, c) 0-4000 ohm

Different sensors can be connected within a group. For example, AI1 can be configured as

digital and AI2 as analog 4-20 mA.

Page 11

Installation

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

10

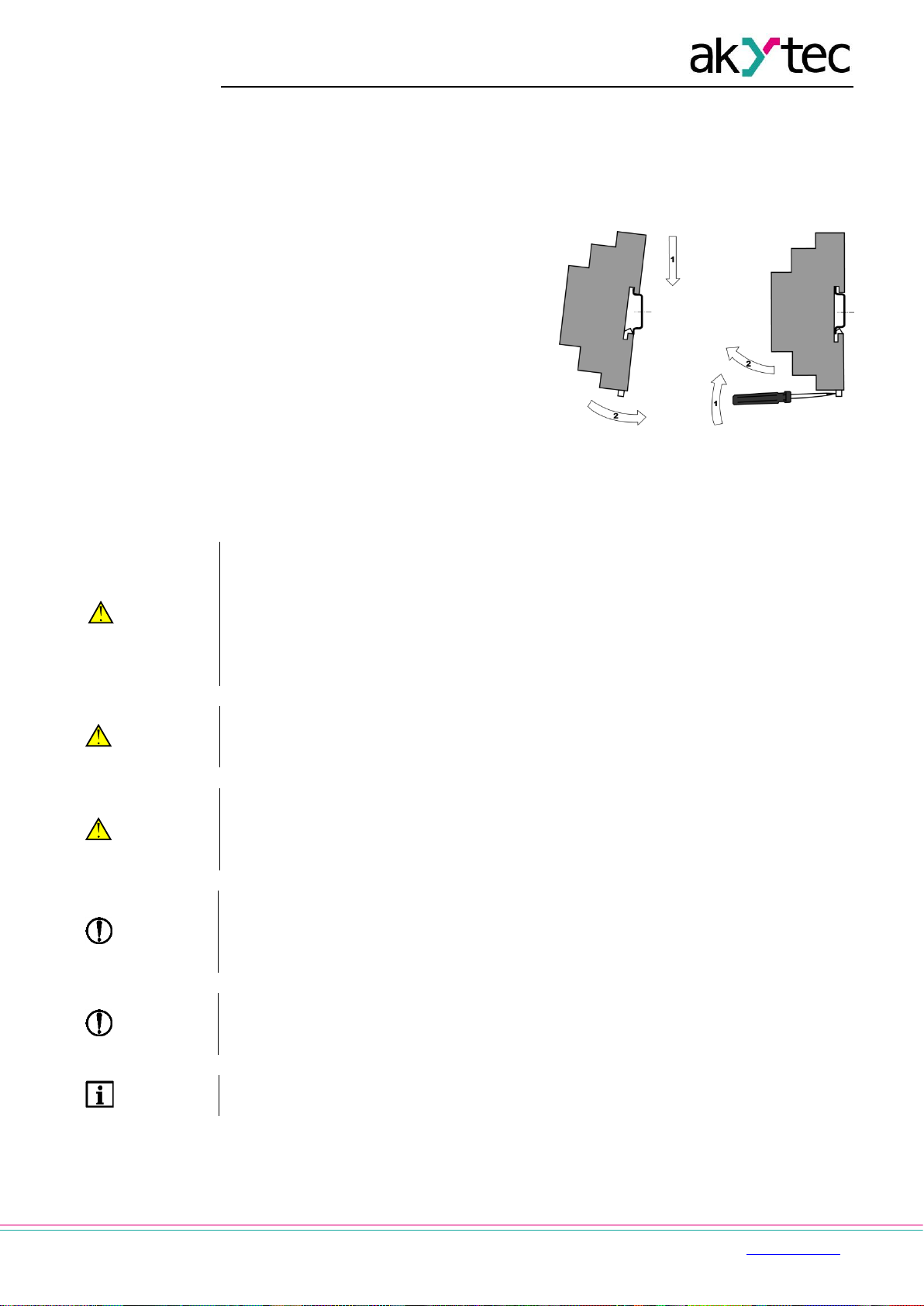

3.2.2 Outputs

Fig. 3.5 Relay outputs

Fig. 3.6 Analog outputs 4-20 mA (x.2.x)

Fig. 3.7 Analog outputs 0-10 V (x.4.x)

NOTICE

The output voltage of an external voltage source may not exceed 30 V. Higher

voltage can damage the device.

For voltage supply of analog outputs 4-20 mA or 0-10 V, the integrated voltage source can

be used.

3.2.3 Terminal assignment

For terminal layouts see App. B.

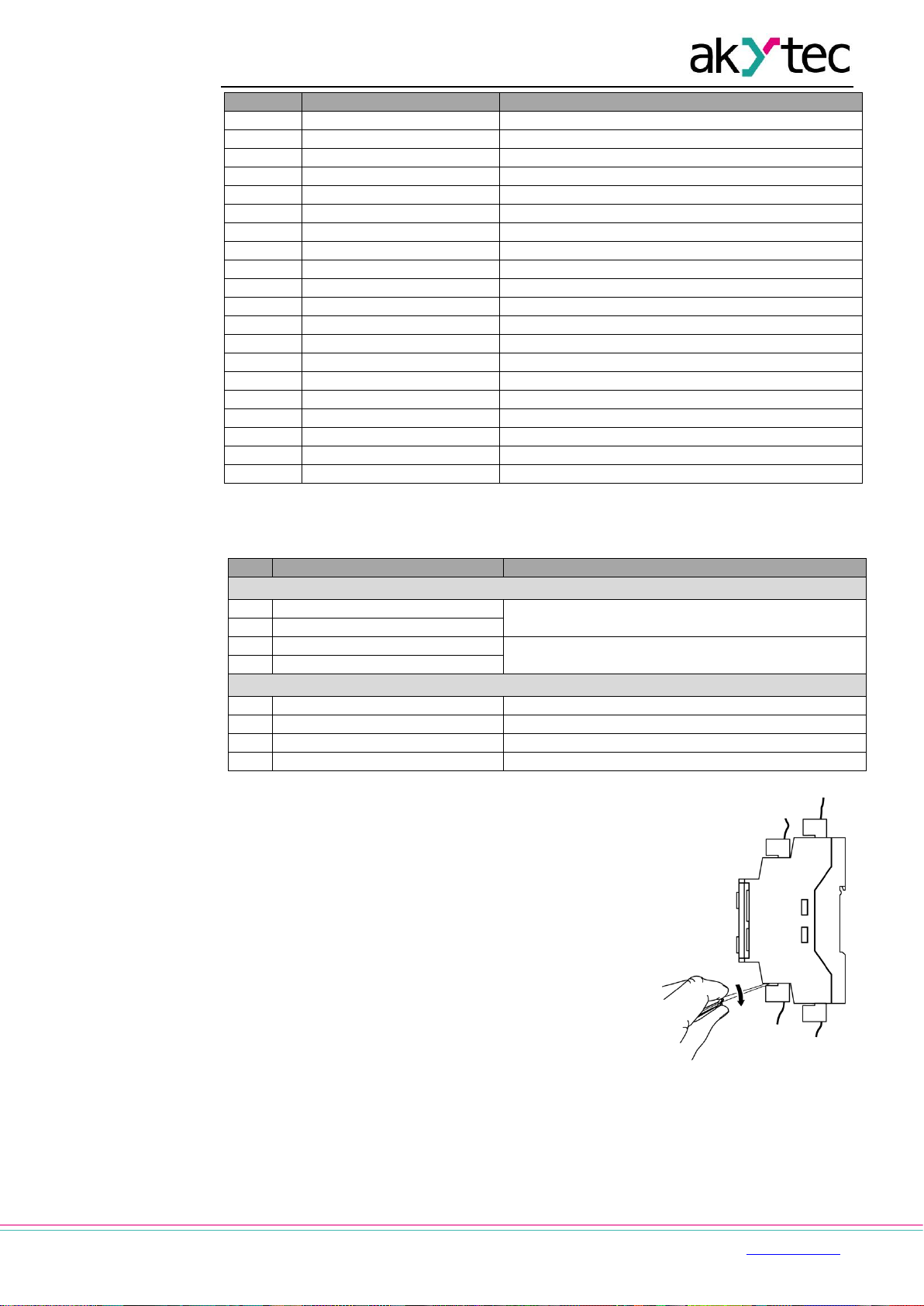

Table 3.1 Terminal assignment

No.

Marking

Description

1

AC230V L / DC24V-

AC / DC power supply *

2

AC230V N / DC24V+

AC / DC power supply *

3

COM1

DI1...DI4 common contact

4

DI1

DI1 digital input

5

DI2

DI2 digital input

6

DI3

DI3 digital input

7

DI4

DI4 digital input

8

COM2

DI5...DI8 common contact

9

DI5

DI5 digital input

10

DI6

DI6 digital input

11

DI7

DI7 digital input

12

DI8

DI8 digital input

13

OUT 24V+

24 VDC integrated voltage source **

14

OUT 24V-

24 VDC integrated voltage source **

15

DO1

DO1 digital output

16

-

DO1...DO2 common contact

17

DO2

DO2 digital output

Page 12

Installation

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

11

No.

Marking

Description

18

DO3

DO3 digital output

19

-

DO3...DO4 common contact

20

DO4

DO4 digital output

21

DO5

DO5 digital output

22

-

DO5...DO6 common contact

23

DO6

DO6 digital output

24

DO7

DO7 digital output

25

-

DO7...DO8 common contact

26

DO8

DO8 digital output

27

AI1

AI1 analog input

28

COM3

AI1...AI2 common contact

29

AI2

AI2 analog input

30

AI3

AI3 analog input

31

COM4

AI3...AI4 common contact

32

AI4

Analog input AI4

33

RS-485 D-

RS485 Interface 1-

34

RS-485 D+

RS485 Interface 1+

35

RS-485 D-

RS485 Interface 2-

36

RS-485 D+

RS485 Interface 2+

37…40

see Table 3.2

* Depending on device model (230.x.x or 24.x.x)

** 230.x.x model only

Table 3.2 Terminals 37-40

No.

Marking

Description

x.2.2

37

АО1-

AO1 analog output (4-20 mA)

38

АО1+

39

АО2-

AO2 analog output (4-20 mA)

40

АО2+

x.4.2

37

V-

-24 VDC external voltage supply

38

V+

+24 VDC external voltage supply

39

АО1

AO1 analog output (0-10 V)

40

АО2

AO2 analog output (0-10 V)

3.3 Quick replacement

PR200 is equipped with plug-in terminal blocks which enable

quick replacement of the device without disconnecting the

existing wiring (Fig. 3.8).

To replace the device:

power off all connected lines including power supply

remove the terminal blocks

replace the device

connect the terminal blocks with existing wiring to the

device

Fig. 3.8 Quick replacement

Page 13

Hardware resources

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

12

4 Hardware resources

To use all hardware resources in a program, the device must be configured. The

configuration is carried out in ALP and is transferred as a part of user project to the device

memory. The configuration parameters are stored in non-volatile memory of the device and

are safe when the device is powered off.

The device can also be configured with the function buttons via the system menu without

being connected to ALP (sect. 5.2). If some parameter has been changed this way, it has to

be taken from the device memory into the ALP project in order to keep the project

syncronized. Use Read button in the corresponding mask in the configuration window.

The following hardware can be configured:

Display

Clock

Interfaces (sect. 4.3)

Extension modules

Inputs (sect. 4.1)

Outputs (sect.4 2)

See ALP Help for detailed information about configuration.

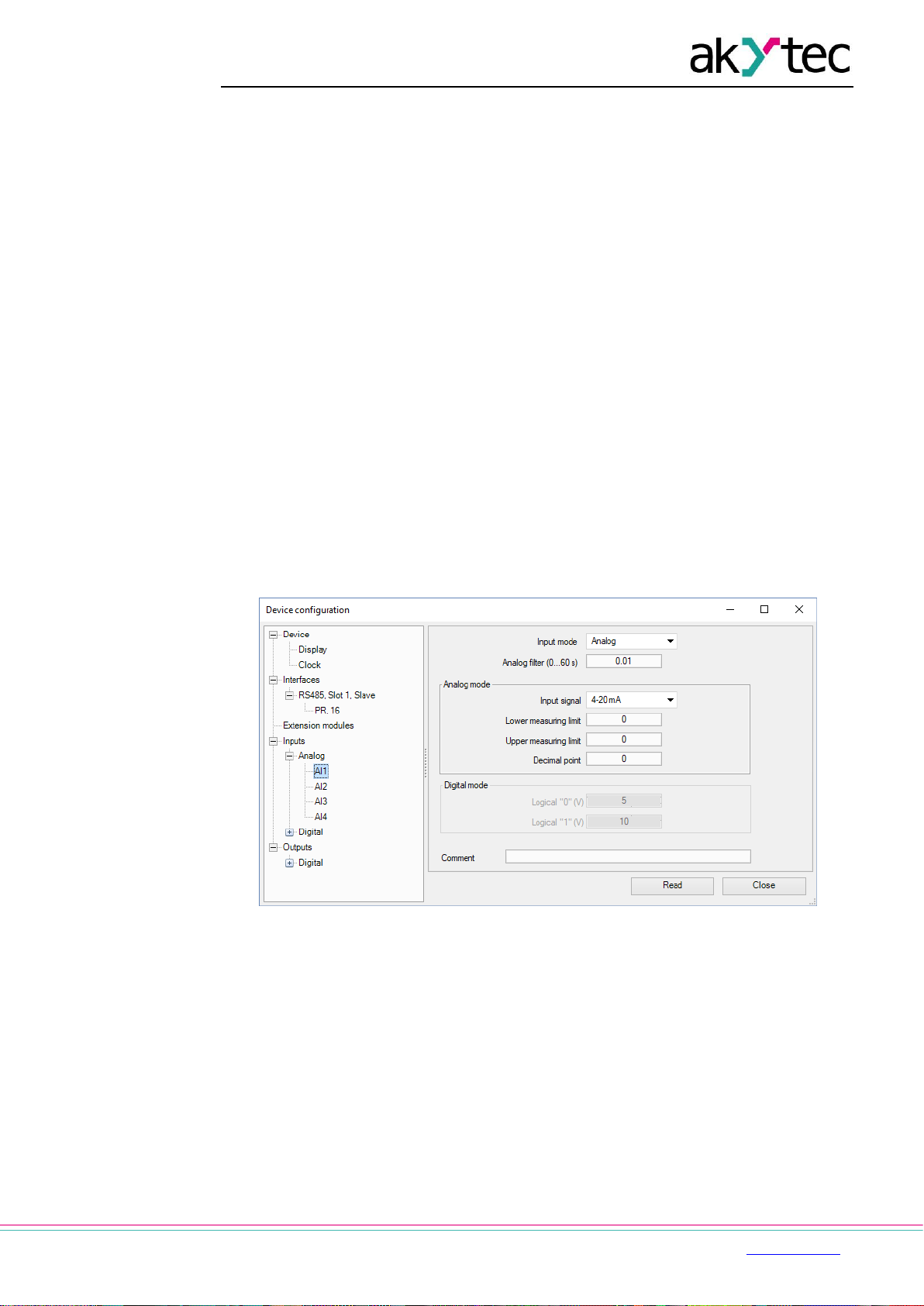

4.1 Analog inputs AI1…AI4

To configure analog inputs use the ALP menu item Device > Configuration. Open the node

Inputs > Analog in the open window Device configuration (Fig. 4.1) and select an analog

input.

Fig. 4.1 Analog input configuration

For quick access select an input in the circuit program and use Property Box (see Fig. 4.2) to

set the parameters. The parameter Input mode has to be set first.

Page 14

Hardware resources

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

13

Fig. 4.2 Property Box for analog input

See ALP Help for detailed information about analog input configuration.

4.1.1 Analog mode

Configurable parameters:

Input mode – select Analog

Filter – filter time constant (0…60 s)

Input signal – 4-20 mA, 0-10 V, 0-4000 ohm

Lower limit – lower measuring limit

Upper limit – upper measuring limit

Decimal places – parameter DP for Modbus request (Table 4.2). The parameter DP

has to be set to determine the accuracy, if the measured value is requested over

Modbus as integer.

If the type of input signal is selected, the input must be configured on the hardware side

using jumpers XP1…XP4 on the middle PCB in accordance with the selection.

The middle PCB is under the top PCB, but the last one does not need to be removed in this

case. The location of the jumpers on the PCB is shown in Fig. 4.3.

Jumper positions corresponding to the input signals are shown in Fig. 4.4.

All analog inputs are configured for 4-20 mA by default.

Fig. 4.3 Input jumpers on the middle PCB

WARNING

The voltage on some components on the circuit board can be dangerous. Direct

contact with the circuit board or penetration of a foreign body in the enclosure must

be avoided.

Page 15

Hardware resources

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

14

NOTICE

If the input signal does not correspond with the hardware configuration, the device

can be damaged. Check the positions of the jumpers XP1…XP4 before wiring.

To configure the input hardware:

– remove the front cover

– set the jumpers on the respective jumper block XP in accordance to the expected

input signal using a thin tool (e.g. tweezers)

– close the front cover.

Fig. 4.4 Input jumper positions

a) 0-10 V, b) 4-20 mA, c) digital mode, d) 0-4000 ohm

The lower and upper measuring limits must be set to scale the input signal.

Scaling is not available if the signal 0-4000 ohm is selected. In that case the measured value

is represented only in REAL32 format. The parameter Decimal places (DP) is not available

for 0-4000 ohm signal as well.

The resistance input is designed for 2 wire sensors only.

The effect of lead resistance can be compensated in the program.

4.1.2 Digital mode

Configurable parameters:

Input mode – select Digital

Filter – filter time constant (0…60 s)

Logical 0 – 0…10 V

Logical 1 – 0…10 V

The input operates as a comparator with parameters Logical 0 and Logical 1 which

determine the hysteresis and can be set in the range of 0…10 V (Fig. 4.5).

Fig. 4.5 Digital mode operation

4.1.3 Analog input filtering

The input filter stabilizes the input reading. The filter setting is a time constant representing

the time interval in which the signal reaches 0.63 of the measured value. It can be set within

the range of 0.01…60 s with the increment of 0.001 second for each input separately.

The greater the time constant, the higher the damping of the interference signal and the

slower the reaction to rapid changes in the input value.

4.2 Analog outputs AO1, AO2

The model x.2.x has two analog outputs 4-20 mA, x.4.x has two analog outputs 0-10 V.

Page 16

Hardware resources

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

15

To control an output, a value of type REAL32 within the range 0…1 has to be assigned to it

in the program.

When the value of 0.5 is applied to the output 4-20 mA, the output current will be 12 mA.

When the value of 0.5 is applied to the output 0-10 V, the output voltage will be 5 V.

See ALP Help for detailed information about analog output configuration.

4.3 RS485 interface

Up to two RS485 interface cards can be installed in the PR200 for communication via

Modbus RTU / ASCII protocol as master or slave.

The interface card is configured as a slave by default. To use the interface as a master, set

the jumpers XP4 and XP5 on the interface card in accordance with the Fig. 4.6:

set the both jumpers to M position

configure the interface using the ALP menu item Device > Configuration

Fig. 4.6 Interface card jumper positions: master (a), slave (b)

See ALP Help for detailed information about RS485 interface configuration. The parameters

can also be changed via system menu (sect. 5.2).

4.3.1 Slave mode

Available network functions:

read digital I/O status

read analog I/O value

read / write network variables

read / write Real-Time Clock data

Corresponding Modbus registers are listed in Tab. 4.1.

Modbus RTU and Modbus ASCII protocols are supported, with automatic protocol detection.

To add an interface, use the context menu of the node Interfaces in the configuration tree

and select Add interface > RS485 (Fig. 4.7). The new interface is a slave by default.

Use the context menu of the new interface to add a master device (Fig 4.8).

Define the name and the Modbus address for the master.

Page 17

Hardware resources

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

16

Fig. 4.7 Slave configuration in Slave mode

Following parameters can be set for Master:

Name – device name in the configuration tree

Address – device address in the Modbus network.

Change register order – reverse the register order according to the method of

storing variables in device memory

Change byte order – reverse the byte order in a register according to the method of

storing variables in device memory

See ALP Help for further details about configuration in the Slave mode.

To create a variable for polling click the icon.

To delete the selected variable click the icon.

Fig. 4.8 Master configuration in Slave mode

Page 18

Hardware resources

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

17

Table 4.1 Modbus registers

Model

Parameter

Data

type

Address (hex)

Modbus

function

Inputs

All

DI1...DI8 input status

BOOL

0x1000 – 0x1007

0x01, 0x02

UINT16

0x0100

0x03, 0x04

x.2.x

x.4.x

AI1 measured value REAL

REAL32

0x0B00, 0х0B01

0x03, 0x04

AI2 measured value REAL

REAL32

0x0B02, 0х0B03

0x03, 0x04

AI3 measured value REAL

REAL32

0x0B04, 0х0B05

0x03, 0x04

AI4 measured value REAL

REAL32

0x0B06, 0х0B07

0x03, 0x04

AI1 measured value UINT *

UINT16

0x0B80

0x03, 0x04

AI2 measured value UINT *

UINT16

0x0B81

0x03, 0x04

AI3 measured value UINT *

UINT16

0x0B82

0x03, 0x04

AI4 measured value UINT *

UINT16

0x0B83

0x03, 0x04

AI1 decimal point (DP) UINT *

UINT16

0x0BC0

0x03, 0x04

AI2 decimal point (DP) UINT *

UINT16

0x0BC1

0x03, 0x04

AI3 decimal point (DP) UINT *

UINT16

0x0BC2

0x03, 0x04

AI4 decimal point (DP) UINT *

UINT16

0x0BC3

0x03, 0x04

AI1 input status (digital mode)

BOOL

0xB800

0x01, 0x02

AI2 input status (digital mode)

BOOL

0xB810

0x01, 0x02

AI3 input status (digital mode)

BOOL

0xB820

0x01, 0x02

AI4 input status (digital mode)

BOOL

0xB830

0x01, 0x02

Outputs

x.1.x

DO1...DO6, F1, F2 output status

BOOL

0x0000 – 0x0007

0x01, 0x02

UINT16

0x0000

0x03, 0x04

x.2.x

x.4.x

DO1...DO8, F1, F2 output status

BOOL

0x0000 – 0x0009

0x01, 0x02

UINT16

0x0000

0x03, 0x04

x.2.x

x.4.x

AO1 output value (0…1)

REAL32

0х0A00, 0х0A01

0x03, 0x04

AO2 output value (0…1)

REAL32

0х0A02, 0х0A03

0x03, 0x04

AO1 output value (0…10000)

UINT16

0x0A80

0x03, 0x04

AO2 output value (0…10000)

UINT16

0x0A81

0x03, 0x04

All

Network variables

BOOL

0x2000 – 0x23F0

0x01, 0x02,

0x05, 0x0F

UINT16

0x0200 – 0x023F

0x03, 0x04,

0x06, 0x10

Real-time clock

All

Seconds

UINT16

0x0400

0x03, 0x04,

0x06, 0x10

Minutes

UINT16

0x0401

0x03, 0x04,

0x06, 0x10

Hours

UINT16

0x0402

0x03, 0x04,

0x06, 0x10

Day

UINT16

0x0403

0x03, 0x04,

0x06, 0x10

Month

UINT16

0x0404

0x03, 0x04,

0x06, 0x10

Year

UINT16

0x0405

0x03, 0x04,

0x06, 0x10

Weekday

UINT16

0x0406

0x03, 0x04

Week of month

UINT16

0x0407

0x03, 0x04

Calendar week

UINT16

0x0408

0x03, 0x04

* AI1 measured value UINT = AI1 measured value REAL * 10 DP (sect. 4.1.1)

For outputs DP = 4 (constant)

4.3.2 Master mode

There can be only one master in Modbus network.

Page 19

Hardware resources

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

18

PR200 as a master can control up to 16 slaves over one RS485 interface. Each slave can

maintain up to 256 variables. To use the same name and the same address for different

slaves is allowed.

To add an interface, use the context menu of the node Interfaces in the configuration tree

and select Add interface > RS485 (Fig. 4.9). Change the mode to Master in the right

window part.

Fig. 4.9 Master configuration in Master mode

Add the required number of slave devices using the context menu of the new interface (Fig

4.10). Define the name and the Modbus address for each slave.

Following parameters can be set for the slave:

Name – device name in the configuration tree

Address – device address in the Modbus network.

Polling cycle – time between requests (0…65535 ms)

Retries – number of request retries if no reply (0…255)

Timeout – maximum time to wait for reply (0…65535 ms)

Status variable – status of slave device (BOOL variable)

Start query – start / stop polling (BOOL variable)

Change register order – reverse the register order according to the method of

storing variables in the device memory

Change byte order – reverse the byte order in a register according to the method of

storing variables in the device memory

See ALP Help for further details about configuration in Master mode.

To create a variable to be requested click th e icon (Fig. 4.10).

To delete the selected variable click the icon.

The reading request is trigged by the Polling cycle by default. Optionally it can be triggered

by changing a variable of type BOOL.

The writing request is triggered by change of parameter value. Optionally it can be triggered

by changing. a variable of type BOOL.

Page 20

Hardware resources

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

19

Fig. 4.10 Slave configuration in Master mode

Note:

If PR200 is a master in the Modbus network, it is necessary to observe the following rules to

speed up the polling of all slaves:

If one or more slaves are disconnected or not accessible, it is recommended to block

the polling of these slaves in the program using the parameter Start query or to

minimize the parameter Timeout for these slaves. Otherwise, the response time is

significantly increased with the number of unavailable slaves and the sum of time-

outs.

When setting the master parameter Interval between requests (Fig. 4.9), the

number of slaves and the total number of requests must be taken into account. If the

total polling takes actually longer than the set value, this parameter will be ignored.

4.4 Service modes

To switch the device to one of the two service modes, use the jumpers XP2 and XP3 on the

top PCB (Fig. 4.11).

WARNING

The voltage on some components on the circuit board can be dangerous. Direct

contact with the circuit board or penetration of a foreign body in the enclosure must

be avoided.

NOTICE

Do not set the jumpers XP2 and XP3 at the same time, otherwise the device can be

damaged.

Page 21

Hardware resources

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

20

Fig. 4.11 Service mode jumpers

RUN-STOP mode

In RUN-STOP mode the execution of the program is interrupted. It can be useful if the

system menu is unavailable, e.g. if the corrupted program leads to device malfunction.

Set XP2 jumper to activate RUN-STOP mode.

In RUN-STOP mode, a new program can be uploaded to the device.

In this mode the device can be used only as a slave and the network variables are disabled.

DOWN mode

DOWN mode is necessary for troubleshooting if a firmware update was unsuccessful (power

outage, communication errors etc.). In this mode the firmware update can be forced. See

ALP Help for further details about firmware update.

Set XP3 jumper to activate DOWN mode.

Page 22

Operation

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

21

5 Operation

Once the program has been transferred to the non-volatile memory, the relay restarts. On

startup, the relay performs a self-test. If it is unsuccessful, the relay will switch to error mode

(sect. 5.1). Otherwise, the program will run (Fig. 5.1)

WARNING

The program is executed after it has been transferred to the relay. It is

recommended to transfer the program before wiring the relay.

Otherwise ensure that all external devices are disconnected from outputs before

transferring the program.

NOTE

Before starting

Before switching on, make sure that the device was stored at the specified ambient

temperature (-20 ... +55 °C) for at least 30 minutes.

Operation of the device is cycle oriented:

1. operational readiness test

2. input process image update

3. program execution for one cycle

4. output process image update

5. back to 1.

Fig. 5.1 Operating sequence

5.1 Error mode

In the error mode, the program is stopped until the error cause is eliminated.

Table 5.1 Error indication

Indication

Cause

Remedy

LOGIC Program

INVALID

Invalid program

Repair the program in ALP

LOGIC Program

MEMORY ERROR

Retain variables cannot be read

LOGIC Program

BLOCKED

RUN-STOP mode is activated,

program stopped (sect. 4.4)

Remove the RUN-STOP jumper

and restart the device

LED F2 lit

Firmware damaged

Update the firmware or contact

the service center

LED F2 blinks

LOGIC Program

STOPPED

Program stopped

Start the program using system

menu and restart the device

5.2 System menu

The system menu allows you to view the most important parameters of the device and

perform a quick configuration without connection to ALP.

The program can be interrupted by using the system menu item Device > Program. Select

Stop program to stop the program execution or Run program to start it. After changing the

setting, the device must be restarted for the change to take effect. When the program is

interrupted, all parameters except the network variables are available via via system menu

and Modbus network in Slave mode.

Page 23

Operation

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

22

Press button for 3 seconds to access the menu.

Press button for 3 seconds to exit the menu.

The menu can be password protected. The password can be set and changed in ALP or

using the system menu. If the password is lost, it can be changed by loading a new project to

the device.

5.2.1 Display navigation

The display can be used in view or edit mode. The edit mode is only for editable display

elements available.

View mode

To move between lines use and buttons.

To enter the selected level, use button, to exit the level, use button.

Edit mode

Use button to enter the edit mode from the current display. The first editable element

starts flashing.

Use and buttons to change the parameter.

To move between characters, use the button combinations:

+ – one character to the left

+ – one character to the right.

To save the new value and exit the edit mode, use .

To reset the parameter to its previous value and exit the edit mode, use button.

To save the new value staying in the edit mode, use button. The next editable parameter

will be displayed selected.

Next time, when the edit mode is activated, the last changed parameter will be displayed.

If a parameter has been changed in the edit mode, it must be transferred to the ALP project

using the Read button in the corresponding dialog window.

Page 24

Operation

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

23

5.2.2 Menu structure

Fig. 5.2 System menu

Inputs

Digital

o I/O state – status of digital inputs displayed as a bitmask: 1/0 (ON/OFF).

The first bit in the mask corresponds to the input DI1.

o Filter – debouncing filter time constant (0…255 ms), displayed in pairs. Use

/ buttons to navigate between pairs.

Analog

o I/O state – status of analog inputs as scaled measured values of REAL32

type, displayed in pairs. Use / buttons to navigate between pairs.

o Sensor – type of the input signal

ALT

OK

OK

OK

OK

OK

OK

ESC

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

Page 25

Operation

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

24

o Filter – analog filter time constant within the range of 0.01…60 s with the

increment of 0.001 s, displayed in pairs. Use / buttons to navigate

between pairs.

o Scale – lower and upper limits for input signal scaling. Use /

buttons to navigate between inputs.

Outputs

Digital

o I/O state – status of digital outputs, including LED indicators F1/F2,

displayed as a bitmask: 1/0 (ON/OFF). The first bit in the mask corresponds

to the output DO1, the last bit in the mask corresponds to the indicator F2.

Analog

o I/O state – status of analog outputs as REAL32 values within the range of

0…1, displayed in pairs. Use / buttons to navigate between pairs.

Interfaces

Interface configuration depends on the interface mode, Master or Slave. Select the interface

to view its parameters (sect. 4.3).

Slave mode

o Settings

Baud rate – Data bits – Parity – Stop bits

o Protocol

Interface mode / Address – master address

Master mode

o Settings

Baud rate – Data bits – Parity – Stop bits

o Protocol

Interface mode / Devices – list of slaves from the project

Address – slave address

Period – Query cycle (ms)

Timeout – Time-out (ms)

Attemts – Retries, max.

Pause – Interval between requests (ms)

Modules

This menu item contains the information about the extension modules connected to the base

device. The item is hidden if there are no modules connected.

Fig. 5.3 Extension module connection

Password

Password can be set or changed (sect. 5.2).

5.3 Display programming

The display can be programmed using one or more display forms. To switch between two

display forms, jump conditions have to be created. Jump condition can be an event of a

Page 26

Operation

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

25

function button or of a variable. For further details about display programming, see ALP

Help.

For display navigation, see section 5.2.1.

When assigning а jump condition to a function button, don't forget that the user function of

the button has a higher priority than its system function, i.e. and buttons cannot be

used to scroll the lines inside a display if they are used as the jump condition for it.

Page 27

Maintenance

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

26

6 Maintenance

The maintenance includes:

– cleaning of the housing and terminal blocks from dust, dirt and debris

– check the device fastening

– checking the wiring (connecting leads, fastenings, mechanical damage)

NOTICE

The device should be cleaned with a damp cloth only. No abrasives or solventcontaining cleaners may be used. During maintenance, observe the safety

instructions in the section "Installation".

Page 28

Transportation and storage

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

27

7 Transportation and storage

Pack the device in such a way as to protect it reliably against impact for storage and

transportation. The original packaging provides optimum protection.

If the device is not taken immediately after delivery into operation, it must be carefully stored

at a protected location. The device should not be stored in an atmosphere with chemically

active substances.

Permitted storage temperature: -25...+55 °C

NOTICE

The device may have been damaged during transportation.

Check the device for transport damage and completeness!

Report the transport damage immediately to the shipper and akYtec GmbH!

Page 29

Scope of delivery

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

28

8 Scope of delivery

PR200 1

Short guide 1

USB cable 1

Terminal blocks (set) 1

Coding elements (set) 1

USB stick with software and documentation 1

NOTE

The manufacturer reserves the right to make changes to the scope of delivery.

Page 30

Appendix А. Dimensions

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

29

Appendix А. Dimensions

Fig. A.1 Dimensions without terminal blocks

Page 31

Appendix B. Terminal layouts

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

30

Appendix B. Terminal layouts

Fig. B.1 PR200-230.1.2

Fig. B.2 PR200-230.2.2

Page 32

Appendix B. Terminal layouts

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

31

Fig. B.3 PR200-230.4.2

Fig. B.4 PR200-24.1.2

Page 33

Appendix B. Terminal layouts

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

32

Fig. B.5 PR200-24.2.2

Fig. B.6 PR200-24.4.2

Page 34

Appendix C. Galvanic isolation

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

33

Appendix C. Galvanic isolation

Fig. C.1 PR200-230.1.x galvanic isolation

Fig. C.2 PR200-230.2.x galvanic isolation

Fig. C.3 PR200-230.4.x galvanic isolation

Fig. C.4 PR200-24.1.x galvanic isolation

Page 35

Appendix C. Galvanic isolation

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

34

Fig. C.5 PR200-24.2.x galvanic isolation

Fig. C.6 PR200-24.4.x galvanic isolation

Page 36

Appendix D. Circuit diagrams

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

35

Appendix D. Circuit diagrams

Fig. D.1 PR200-230.x.x digital input circuit diagram

Fig. D.2 PR200-24.x.x digital input circuit diagram

Fig. D.3 Analog input circuit diagram

Page 37

Appendix E. Calibration

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

36

Appendix E. Calibration

E.1 General

If the accuracy of the input or output of the module is no longer in accordance with the

specification, it can be calibrated.

NOTICE

Ensure a reliable power supply to the device during the calibration. If it fails, the

calibration should be repeated.

– Each analog input and output has its own calibration coefficients for each sensor

type.

– The calibration is performed using a reference signal source connected to the device

input or output.

– The calibration coefficients are calculated based of the ratio between the current

input signal and the reference signal and stored in the non-volatile device memory.

– If the calculated coefficients go beyond the permissible limits, a message about the

error cause will be displayed.

E.2 Input

Input signals: 4-20 mA, 0-10 V, 0-4000 ohm

1. Connect the reference signal source of accuracy class at least

0.05 to the input (Fig. E.1).

2. Connect the basic device to the PC.

3. Switch on the device power supply.

4. Start ALP and select the menu item Device > Calibration to

start the calibration tool.

5. Select the device model in the open dialog window.

6. Select Analog inputs as calibration target (Fig. E.2).

Fig. E.2

7. Select the type of input signal and set the other calibration

parameters (Fig. E.3).

o Set the three points for calibration curve and the filter

time constant.The greater the filter time constant, the

longer the calibration process will take, but the more

precise calibration will be achieved.

o Select the input to calibrate. If you select All, all inputs

will be calibrated sequentially, therefore the

appropriate reference signal has to be applied to all

inputs.

Fig. E.1

Page 38

Appendix E. Calibration

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

37

Fig. E.3

8. Click Next to continue and follow the instructions.

Click the item Reset settings to use the default calibration settings.

E.3 Output 4-20 mA

1. Connect an auxiliary voltage source, a measuring

device of resolution 0.001 V and a reference

resistance box of accuracy class at least 0.05 to the

output (Fig. E.4).

2. Ensure the supply voltage is within the range 15…28

V.

3. Set the reference resistance box to 500 ohm.

4. Connect the device to the PC.

5. Switch on the device power supply.

6. Start ALP and select the menu item Device >

Calibration to start the calibration tool.

7. Select the device model in the open dialog window.

8. Select Analog outputs as calibration target (Fig. E.2).

9. Calculate the output current from the measured output

voltage and the set resistance; enter the result in the

input field (Fig. E.5).

10. Click Next to continue and follow the instructions.

Fig. E.4

Fig. E.5

E.4 Output 0-10 V

1. Connect a reference voltage source and a measuring device of accuracy class at least

0.05 to the output (Fig. E.6).

Page 39

Appendix E. Calibration

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

38

Fig. E.6

2. Connect the device to the PC.

3. Switch on the device power supply.

4. Start ALP and select the menu item Device > Calibration to start the calibration tool.

5. Select the device model in the open dialog window.

6. Select Analog outputs as calibration target (Fig. E.2).

7. Enter the measured output voltage in the input field (Fig. E.5).

8. Click Next to continue and follow the instructions.

Page 40

Appendix F. Battery replacement

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

39

Appendix F. Battery replacement

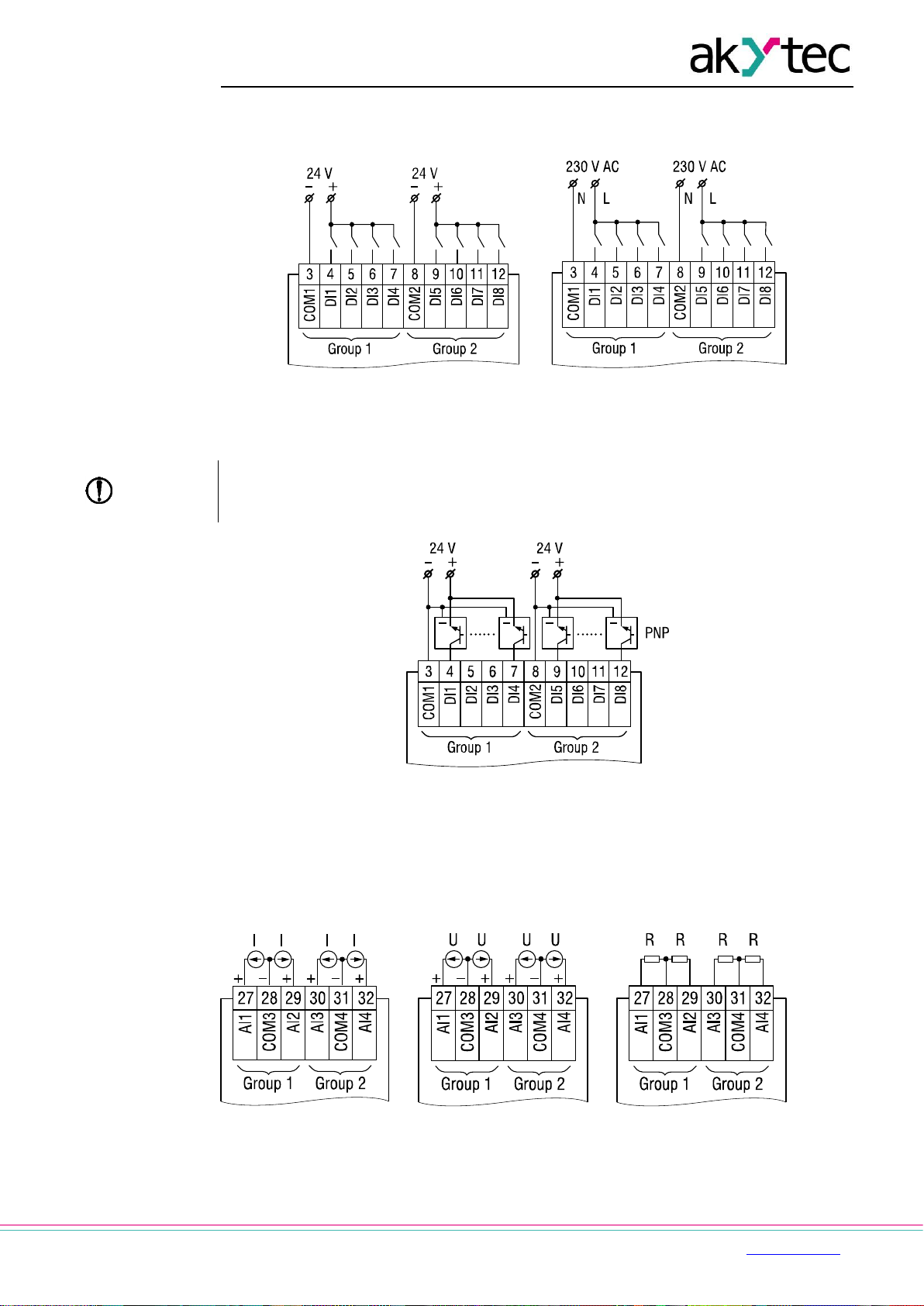

WARNING

Dangerous voltage

The voltage on some components of the circuit board can be dangerous. Direct

contact with the circuit board or penetration of a foreign body in the enclosure must

be avoided.

1. Remove the front cover with the keypad (Fig. F.1)

2. Lever the top PCB from the side of the USB connector with a screwdriver and

carefully release it from the pin connectors of the middle PCB. (Fig. G.2).

3. Turn over the released top PCB, lever the CR2032 battery with the screwdriver and

pull out from the nest (Fig. F.3).

4. Install a new battery

5. Perform the disassemble operations in reverse order to assemble the device.

Fig. F.1 Front cover removing

Fig. F.2 Top PCB removing

Page 41

Appendix F. Battery replacement

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

40

Fig. F.3 Back side view of the top PCB

Page 42

Appendix G. Interface card installation

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

41

Appendix G. Interface card installation

WARNING

Dangerous voltage

The voltage on some components of the circuit board can be dangerous. Direct

contact with the circuit board or penetration of a foreign body in the enclosure must be

avoided.

1. Remove the front cover with the keypad (Fig. G.1).

2. Lever the top PCB from the side of the USB connector with a screwdriver and

carefully release it from the pin connectors of the middle PCB (Fig. F.2, G.1a).

3. Cut an opening in the front cover for the network connection and fix the card on the

mounting pins (Fig. G.1b).

4. Assemble in reverse order.

a b

Fig. G.1

Loading...

Loading...