Page 1

EN

ITP11_2016.05_0109_NEW _EN

ITP11

Digital process display 4-20 mA

User guide

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 2

1

Contents

1

Safety guidelines ............................................................................................................................................ 2

2 Intended use ................................................................................................................................................... 3

3 Specifications ................................................................................................................................................. 4

4 Functional description ................................................................................................................................... 5

5 Installation and operation .............................................................................................................................. 6

5.1 Installation ................................................................................................................................................ 6

5.2 Operating mode ....................................................................................................................................... 6

5.3 Programming mode ................................................................................................................................. 8

6 Maintenance .................................................................................................................................................. 11

7 Transportation and storage ......................................................................................................................... 12

8 Scope of delivery .......................................................................................................................................... 13

Appendix A Dimensions ................................................................................................................................... 14

Appendix B Electrical connection ................................................................................................................... 15

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover· Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 3

2

Safety guidelines

1 Safety guidelines

Please read through the user guide carefully before commissioning the device. Damages that arise from

non-observance of the guidelines in the user guide shall be devoid of any liability.

– The device may only be used in the manner described in this user guide.

– No technical modifications may be made to the device.

– The device may not be used if the environmental conditions (temperature, humidity etc.) are not within

the limits indicated in the specification.

– The device may not be used in explosive areas and there may be no chemically active substances in the

air.

– The device should only be cleaned with a damp cloth. No abrasives or solvent-based cleaners should be

used.

Non-observance of the safety guidelines may result in damage to the device and injury to users.

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover· Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 4

3

Intended use

2 Intended use

The ITP11 is a universally applicable, digital display unit. It is designed to be connected to any transmitter

with a 4-20 mA output. The device requires no auxiliary power and is supplied directly from the measured

current.

The field of application of the device includes the control and monitoring of industrial processes. The display

can be used in automated systems as a primary or secondary display.

The device may only be operated

– properly installed and

– in accordance with the specification.

Improper use

– The ITP11 may not be used for medical devices that sustain, monitor or otherwise affect human life or

health.

– The device may not be used in potentially explosive environment.

– The device may not be used in an atmosphere with chemically active substances.

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover· Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 5

4

Supply current

from current loop

Input signal

4-20 mA (2-wire)

Inputs

1

Measuring range

3.8…22.5 mA

Normal operation

3.2…25 mA

Voltage drop, max.

10 V

Accuracy

0.2% + 1 digit

Display

LED, 7-segment display

Character height

14 mm

Display colour

red or green

Number of digits in display

4

Sampling rate (without damping)

1 reading / s

IP Code

front IP65, rear IP20

Dimensions

48 x 26 x 65 mm

Weight

approx. 30 g

Protection class

III

Ambient temperature

-30…+70 °C

Storage temperature

-40…+80 °C

Humidity

up to 80% (non-condensing)

ITP11-X

- - Display color red

G - Display color green

Specifications

3 Specifications

ITP11 can be ordered in different versions. They differ in the display color.

Ordering key:

Table 1

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover· Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 6

5

Functional description

4 Functional description

A 4-digit, 7-segment LED display with 14 mm character height is located on the front of the device for displaying the measured values, error messages, functions and values during programming. The programming

buttons are positioned on the cylindrical surface of the device.

The button is used to set the programming mode and to apply the changes. The parameters can be se-

lected and changed using buttons and . Pressing and holding the buttons increases the speed of parameter changing in three steps.

The operating modes are described in Section 5.

The device has the following functions:

- Display process values, received from process control devices with 4-20 mA output (current loop).

- The measured values are displayed on the 4-digit LED display with a maximum range of -999…+9999 in

accordance with the set limit values and the decimal point position.

- When exceeding the measuring limit, the device displays an error message.

- Switching between linear and square root function (for special transmitters)

- Filter for damping the signal fluctuations with an adjustable time constant

- Password protection against unauthorised access

Fig. 1 Block diagram

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover· Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 7

6

Panel

Gasket

Nut

Body

Installation and operation

5 Installation and operation

5.1 Installation

The device is designed for switch panel mounting in a borehole of Ø22.5 mm (see Appendix A for dimensional drawings).

Carefully position the supplied gasket on the display rear surface. Insert the cylindrical part of the device into

the borehole and tighten the nut from the rear side of the switch panel. Connect the device to the signal cable in accordance with Appendix B.

The device factory settings can be changed before assembly if necessary. For this purpose the display must

be connected to a standard signal 4-20 mA.

Fig. 2 Mounting

5.2 Operating mode

The operating mode is automatically switched on if the standard signal 4-20 mA is connected to the terminals.

The input signal is digitalised, the square root calculated (if the function is enabled) and the signal accordingly to the set parameters calibrated and displayed. The scale factor is calculated based on the parameter

di.Lo “lower limit” (according to input signal 4 mA) and di.Hi “upper limit” (according to input signal 20 mA).

If the input signal is lower than 3.8 mA, the error message Lo is displayed.

If the input signal is higher than 22.5 mA, the error message Hi is displayed.

Square root function

This function is intended for transmitters with square characteristic curve. To enable the function, the parameter Sqrt must be set to ON.

Damping function

Undesirable signal fluctuations can be suppressed through the adjustable filter constant.

The most important feature of the exponential filters is

3 and Table 2).

If the constant increases, the display reacts to changes of the input signal more slowly and the susceptibility

to interference is lower.

τd – the filter time constant (parameter td) (see Fig.

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover· Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 8

7

t

i

( signal jump

d

= 0 s )

= 1 s )

d

I

I

0,63 I

0

t, s

( damped signal

I

II

III

= 3 s )

d

( damped signal

Installation and operation

Fig. 3

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover· Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 9

8

Parameter

Comments

Valid values

on 1)

oFF

– -– -– -–.

-– -– -–.-–

-– -–.-– -–

-–.-– -– -–

di.Lo

Lower limit (with 4 mA)

-999…4.00…9999 2)

di.Hi

Upper limit (with 20 mA)

-999…20.00…9999 3)

td

Filter time constant in seconds

0…1…10

on

oFF

Installation and operation

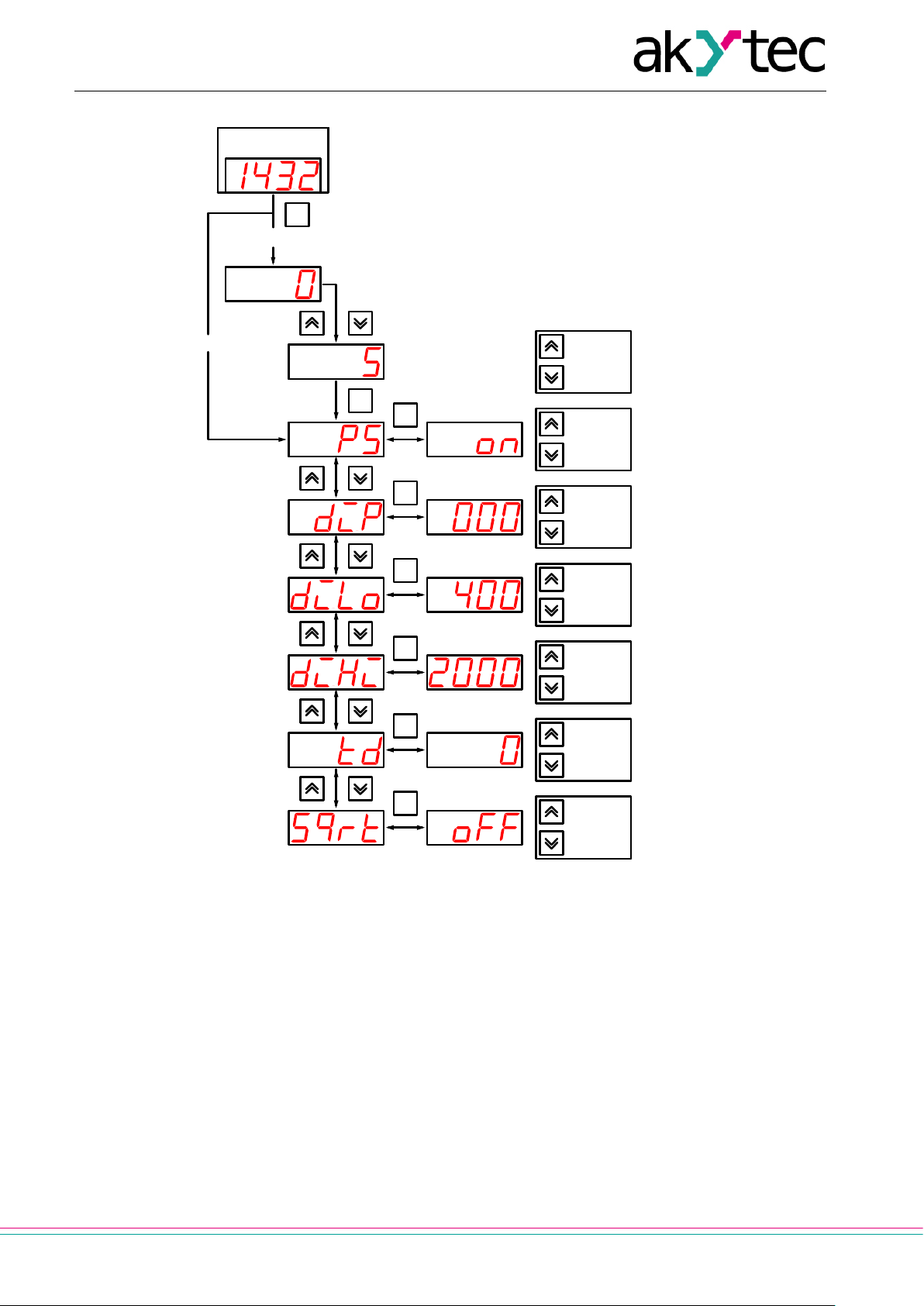

5.3 Programming mode

In programming mode the necessary parameters can be changed (see Table 2).

To return to the operating mode, the button must be pressed for longer than 5 s. If no button is pressed

within 20 s, the device reverts to operating mode automatically.

The flowchart is presented in Fig. 4.

Table 2

PS

di.P

Sqrt

Password protection

Decimal point position

(from the right)

Square root function on/off

Comments:

1. Factory settings are highlighted.

2. With particular setting parameters the device cannot display the necessary minus sign due to the re-

striction to four segments. The parameters are configured as follows:

di.Lo: -999 è 4 mA

di.Hi: 9999 è 20 mA

With an input measured current of 3.8 mA the correct display should be “-1068”. Due to the restriction to

four segments, the minus sign is removed and the display is “1068”.

3. With particular setting parameters the device cannot actually display the necessary 5 figures due to the

restriction to four segments. The parameters are configured as follows:

di.Lo: -999 è 4 mA

di.Hi: 9999 è 20 mA

With an input measured current of 20.8 mA the correct display should be “10548”. Due to the restriction to

four segments, the first character is removed and the display is “0548”.

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover· Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 10

9

PROG

PROG

PROG

PROG

RUN

Decimal point

position

Lower limit

(-999...9999)

(-999...9999)

Upper limit

Damping time

(0...10 s)

PROG

PROG

function

Square root

PROG

Password

on/off

parameter

Change

PROG

Password

PS = oFF

PS = on

parameter

Change

parameter

Change

parameter

Change

parameter

Change

parameter

Change

parameter

Change

on/off

Installation and operation

Fig. 4

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover· Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 11

10

Display

Possible cause of error

Remedy

Lo

Hi

Installation and operation

To enter the programming mode use the button .

To scroll the parameters use the buttons and , to change the parameter use the button .

When the device is switched on for the first time or the password protection is activated, 0 is displayed.

Use the buttons and to enter the correct password (factory setting – 5), then press the button to

confirm.

If an incorrect password is entered, the device reverts to operating mode.

If the password protection is disabled (the parameter PS is oFF), the password is not requested.

If the button is pressed while the parameter PS is being displayed, the following characters appear on the

display: I- - - - . This means that the upper end of the menu has been reached.

If the button is pressed while the parameter Sqrt is being displayed, the following characters appear on

the display: - - - -I. This means that the lower end of the menu has been reached.

Briefly push the button (< 1 s) to change the selected parameter. The display indicates the actual param-

eter value. The factory settings are shown in Fig. 4 and Table 2. The value can be changed using buttons

and . After confirming by pressing the button, you return to the parameter list.

Potential errors and troubleshooting measures are listed in Table 3.

Table 3 Error display

None

Input current lower than 3.8 mA Check input signal

Input current higher than 22.5 mA Check input signal

No input signal Check input signal

Reverse polarity on input Check polarity

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover· Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 12

11

Maintenance

6 Maintenance

The maintenance includes:

– cleaning the housing and the terminals from dust, dirt and debris

– checking the fastening of the device

– checking the wiring (connecting leads, fastenings, mechanical damage)

The device should be cleaned with a damp cloth only. No abrasives or solvent-containing cleaners may be

used.

The safety guidelines in Section 1 must be observed when carrying out maintenance.

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover· Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 13

12

►

The device may have been damaged during transportation.

Report the transport damage immediately to the shipper and akYtec GmbH!

Transportation and storage

7 Transportation and storage

Pack the device in such a way as to protect it reliably against impact for storage and transportation. The

original packaging provides optimum protection.

If the device is not taken immediately after delivery into operation, it must be carefully stored at a protected

location. The device should not be stored in an atmosphere with chemically active substances.

Permitted storage temperature: -40…+80 °C

NOTICE

Check the device for transport damage and completeness!

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover· Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 14

13

Scope of delivery

8 Scope of delivery

– Digital process display ITP11 1

– Gasket 1

– Mounting nut 1

– User guide 1

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover· Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 15

14

PROG

26

48

10

65

Appendix A Dimensions

Appendix A Dimensions

Fig. A.1

To prevent the device spinning, the borehole in the front panel must correspond to the dimensions in Fig.

A.2.

Fig. A.2.

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover· Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Page 16

15

1

2

3

4

4-20 mA

+

ITP11

-

1

2

3

4

MEASURING

4-20 mА

+

+

ITP11

-

-

DEVICE

Appendix B Electrical connection

Appendix B Electrical connection

Fig. B.1

Fig. B.2.

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover· Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Loading...

Loading...