Page 1

A

A

A

S

S

S

i

i

i

e

e

e

r

r

r

r

r

r

C

C

C

v

v

v

i

i

i

o

o

o

c

c

c

n

n

n

e

e

e

d

d

d

M

M

M

i

i

i

t

t

t

a

a

a

i

i

i

o

o

o

n

n

n

n

n

n

u

u

u

e

e

e

a

a

a

r

r

r

l

l

l

Page 2

2

M

M

M

o

o

o

d

d

d

e

e

e

l

l

l

G

G

G

r

r

r

o

o

o

u

u

u

p

p

p

:

:

:

A

A

A

C

C

C

-

-

-

S

S

S

7

7

7

Model :

AC-S7CK

AC-S7HK

Model No: AC-S7CK_S7HK

Version 1.0

Page 3

3

Content

Feature …………………………………..……………………………………………….. 4

Specifications ……………………………………………………………………………. 5

Operating range …………………………………………………………………………. 5

Remote control …………………………………………………………………………...7

Refrigeration cycle ………………………………………………………………………. 10

Operation details ………………………………………………………………………… 12

Installation ……………………………………………………………………………….. 22

2-way, 3-way valve ……………………………………………………………………… 33

Trouble shooting ………………………………………………………………………… 41

Exploded drawing …………………………………………………………………… …. 49

Part list …………………………………………………………………………………… 52

Model No: AC -S7CK_S7HK

Version 1.0

Page 4

4

Automatically switches the appliance ON at preset time intervals, ensuring a comfortable

when

t to cool the room as soon as

CHAPTER 1: FEATURES

MODE

COOLING Cools, dehumidifies and filters the room air. Maintains desired room temperature.

HEATING Heats and filters the room air. Maintains desired room temperature.

DESCRIPTION

SMART

DRY

FAN ONLY Re-circulates and filters the room air. Maintains constant air movement in the room.

SLEEP

AUTO FAN

FAN SPEED

HIGH

MEDIUM

LOW

Operates the appliance at COOLING, HEATING or DRY mode, maintaining desired

temperature dependent upon the room temperature.

Dehumidifies and softly cools the room air. This mode is advisable to be used when the

room temperature is rather cool but the humidity is rather high.

The SLEEP mode will be canceled after being set for 8 hours. The set temperature will

be increased 0.5o per hour during the first two hours in COOLING or DRY and

decreased 1 o per hour in the first three hours in HEATING.

The appliance automatically selects the indoor fan speed in accordance to the room

temperature. At the start, the appliance operates at high fan speed. As the room

temperature gets closer to the set temperature, the fan switches to a lower speed for

quieter operation.

1. The appliance can set at different indoor fan motor speed by pressing the FAN

SPEED button on the remote controller.

2. When this symbol is being displayed on the LCD of the remote controller, the signal is

transmitting from the remote controller to the air conditioner.

TEMP. SET

UP

DOWN

TIMER

Auto -restart

SUPER

Press DOWN button once, the set temperature is decreased by 1 o .

Press UP button once, the set temperature is increased by 1 o .

environment before you return home, or switches OFF the appliance automatically

you sleep without wasting electricity.

When the power supply restores after its failure, the machine will start to work

automatically with the previous setting parameters.

Strong cooling when you just come into your room and wan

possible.

Model No: AC -S7CK_S7HK

Version 1.0

Page 5

5

CHAPTER 2: SPECIFICATIONS

(SEE APPENDIX A)

CHAPTER 3: OPERATING RANGE

1. TEMPERATURE RANGE FOR T1 CLIMATE AIR CONDITIONER

l The preset temperature of the appliance ranges from 18oC to 32oC.

l The ambient temperature of the cooling only air conditioner ranges from 18oC to

43oC.

l The ambient temperature of the heat pump ranges from –7oC to 43oC.

l The rated cooling operation test condition is as following.

Indoor DB/WB temperature: 27oC /19oC

outdoor DB/WB temperature: 35oC /24oC

l The rated heating operation test condition is as following.

l indoor DB/WB temperature: 20oC /Max.15oC

l outdoor DB/WB temperature: 7

2. TEMPERATURE RANGE FOR T3 CLIMATE AIR CONDITIONER

l The preset temperature of the appliance ranges from 18oC to 32oC .

l The ambient temperature of the cooling only air conditioner ranges from 21oC to

52oC.

l The rated cooling operation test condition is as following.

Indoor DB/WB temperature: 27oC /19oC

o

C /6oC

outdoor DB/WB temperature: 35oC /24oC

Model No: AC -S7CK_S7HK

Version 1.0

Page 6

6

AC -S7CK_S7HK

3. REFRIGERANT PIPING

l The maximum length of the connecting refrigerant piping between indoor unit

and outdoor unit is 15m and the maximum elevation difference between indoor

and outdoor units are 5m.

l If the refrigerant piping is longer than 7m,additional refrigerant charge 20g/m for

below 1/2 inch gas pipe and 30g/m for below 5/8 or 3/4 inch gas pipe is advis-

able.

Indoor unit

e

b

d

l

u

o

h

s

n

o

i

t

a

v

e

l

e

m

5

n

a

h

t

s

s

e

l

Pipe length is

15 meters Max

Indoor unit

Outdoor unit

l Outside diameter of the refrigerant piping is as following.

Models

OD of liquid pipe

(small pipe)

Outdoor unit

e

b

d

l

u

o

h

m

s

5

n

n

o

a

i

h

t

t

a

v

s

e

s

l

e

e

l

Curled tube for

returning water

OD of gas pipe

(large pipe)

7K, 9K (COOLING ONLY & HEAT PUMP 6mm or 1/4 inch 10mm or 3/8 inch

12K, 18K,24K ( COOLING ONLY &

6mm or 1/4 inch 12mm or 1/2 inch

HEAT PUMP)

Model No:

Version 1.0

Page 7

7

CHAPTER 4: REMOTE CONTROLLER

The remote controller transmits signals to the system.

4

9

5

3

6

2

7

8

1

1. ON/OFF BUTTON

l The appliance will be started when it is energized or will be stopped when it is in

operation, if you press this button.

2. MODE BUTTON

l Used to select the type of operation mode.

COOLING mode

Model No: AC -S7CK_S7HK

Version 1.0

Page 8

8

DRY mode

FAN ONLY mode

HEATING mode

3. FAN SPEED BUTTON

l Used to select the indoor fan motor speed.

Automatic fan speed

High fan speed

Medium fan speed

Low fan speed

4.TEMPERATURE SETTING BUTTON

l Used to adjust the preset room temperature.

l Used to adjust time in TIMER mode.

5. SWING BUTTON

l Press to adjust airflow direction.

6. SMART BUTTON

l Used to enter fuzzy logic operation directly, regardless of the unit is on or off.

7. TIMER SET/CANCEL BUTTON

l Used to set or cancel the timer operation.

8. SLEEP BUTTON

l Used to set or cancel SLEEP mode operation during COOLING, HEATING, DRY

or SMART mode operation.

9. SUPER BUTTON

l Used to start or stop the fast cooling.

(Fast cooling operates at high fan speed with 18 oC setting temperature

automatically)

The indication symbols on LCD:

Model No: AC -S7CK_S7HK

Version 1.0

Page 9

9

Indication symbols on LCD:

Medium fan speed

Signal transmit.

Super indicator

Smart indicator

Sleep indicator

Cooling indicator

Dry indicator

Fan only indicator

Heating indicator

Auto fan speed

High fan speed

Low fan speed

Model No: AC -S7CK_S7HK

Version 1.0

Page 10

10

2-way valve

CHAPTER 5: REFRIGERATION CYCLE

1. Cooling only appliance

Indoor unit

ЦЖАдПµН³Н¼

evaporator

Outdoor unit

accumulator

compressor

gas side

liquid side

3-way valve

capillary

condenser

Model No: AC -S7CK_S7HK

Version 1.0

Page 11

11

2. Heat pump

¼¼Êõ²ÎÊý:

Outdoor unit

compressor

defrost

Flow of refrigerant

heating cooling

accumulator

reverse valve

gas side

Indoor unit

3-way valve

evaporator

liquid side

2-way valve

check valve

capillary

condenser

Model No: AC -S7CK_S7HK

Version 1.0

Page 12

12

AC -S7CK_S7HK

CHAPTER 6: OPERATION DETAILS

1. SAFETY CONTROL

l 3 minutes delay for compressor

The compressor is ceased for 3 minutes to balance the pressure in the refrigeration

cycle in order to protect the compressor.

l 59 seconds delay for reversing valve

The 4-way reversing valve delay for 59 seconds to prevent the refrigerant abnormal

noise when the HEATING operation is OFF or switched to other operation modes.

l Over-current control

The compressor will be switched OFF when it is over-current for 5 seconds, and

when the current is normal and the compressor has been stopped for 3 minutes , the

compressor will be turned ON.

l Freeze preventive control

When the indoor pipe temperature falls below –1oC during COOLING or DRY

operation for 3 minutes, the compressor and outdoor fan motor turn OFF with buzzer

3 beeps . When the indoor pipe temperature recovers to 5oC and the compressor has

been stopped for 3 minutes, the compressor and outdoor fan motor will be turned

ON.

l Overheating protection system

When overloading occurs during the heating operation, this system controls the

outdoor fan motor and compressor according to the indoor pipe temperature to

prevent the overloading of the compressor and restrain the rise in high pressure.

When the indoor pipe temperature exceeds 53oC, the outdoor fan motor will be

turned OFF, and when the indoor pipe temperature falls below 49oC, the outdoor fan

motor recovers to ON. When the indoor pipe temperature exceeds 63oC, the

appliance will be turned OFF with 4 beeps of buzzer and cannot recover

automatically.

Model No:

Version 1.0

Page 13

13

2. AIR FLOW DIRECTION CONTROL

l This function is to swing the louver up and down automatically and to set it at a

desired position.

l The procedure is as following.

F Press the ON/OFF button to operate the appliance. The louver will swing

automatically to the default position.

F Press the SWING button to swing the louver up and down automatically.

F Repress the SWING button to stop the louver at a desired position.

l The louver is controlled by a step motor. The different default position of different

modes is as following:

F The louver can swing from 0° to 110°.

F The louver closes at 0°.

F The louver swings from 25° to 65° with an automatic setting point of 45° during

COOLING operation.

F The louver swings from 10° to 30° with an automatic setting point of 30° during

DRY operation.

F The louver swings from 45° to 98° with an automatic setting point of 85° during

HEATING operation.

F The louver swings from 45° to 98° with an automatic setting point of 85° during

FAN only operation.

3. COOLING MODE OPERATION

l When the COOLING mode operation is selected without setting temperature, the

appliance will set the preset temperature at 26 oC automatically with the AUTO

FAN speed.

l When selecting the COOLING mode operation, the appliance will operate ac-

cording to the setting by the remote controller and the operation diagram is as

following:

Model No: AC -S7CK_S7HK

Version 1.0

Page 14

14

ROOM TEMP.

SET TEMP.+1¡æ

(COMP.ON)

SET TEMP.-1¡æ

(COMP. OFF)

More than

3 mins

More than

3 mins

Indoor fan motor

speed

set

speed

set set

low

speed

set

speed

low

speed

set

speed

Compressor

ON OFF ON OFF ON

Outdoor fan motor

ON OFF ON OFF ON

4. DRY MODE OPERATION

l The appliance starts as COOLING operation. If 3 minutes elapses after starting,

the appliance will sense the intake air temperature and minus 1.5oC as the

setting temperature.

l During DRY operation, the compressor ON when temperature is the setting

temperature plus 1oC. The compressor OFF when temperature is the setting

temperature minus 1oC. The setting temperature can only be adjusted by 2oC

up and down.

l When the appliance operates at DRY mode, the indoor motor speed is LOW.

5. HEATING MODE OPERATION (ONLY AVAILABLE FOR HEAT PUMP)

l The appliance will operate at the setting by the remote controller and the opera-

Model No: AC -S7CK_S7HK

Version 1.0

Page 15

*

*

o

o

tion diagram is shown as following.

SET TEMP.+4.5¡æ

Set Temp +1

(Comp Off)

(COMP. OFF)

SET TEMP.+2.5¡æ

Set Temp -1

(COMP. ON)

(Comp On)

ROOM TEMP.

1o

15

More than

3 mins

B

A

30 secs

A

B

30 secs

Indoor fan motor speed

Compressor ON OFF ON OFF

Outdoor fan motor ON OFF ON OFF

* The indoor fan motor is controlled by Cold Air Preventive System.

set

UL OFF

speed

*

set

UL

speed

*

OFF

l The indoor fan motor is controlled by Cold Air Preventive System.

6. COLD AIR PREVENTIVE SYSTEM (ONLY AVAILABLE FOR HEAT PUMP)

l This system is intended to prevent cold air from being discharged during

HEATING operation.

l The indoor fan motor speed will be controlled as following. (for7K, 9K, 12K, 18K

and 22K heat pump)

Model No: AC -S7CK_S7HK

Version 1.0

Page 16

16

l The indoor fan motor speed will be controlled as following. (for 24K heat pump)

7. SMART MODE OPERATION

l When SMART air conditioning is selected, the operation mode and preset

temperature are set automatically according to the room temperature at starting

operation.

l The operation procedure of cooling only is as following.

Intake air temperature at

operation start

Preset temperature

Operation mode COOLING DRY

*The initial mode will be continued and independent upon the room temperature

changing.

l The operation procedure of heat pump is as following.

Model No: AC -S7CK_S7HK

Version 1.0

Over 26oC Below 26oC

26oC

Intake air temperature minus

1.5oC

Page 17

17

Intake air temperature at

Over 26oC 21oC ~ 26oC Below 21oC

operation start

Preset temperature

26oC

Intake air temperature at

22oC

operation start

Operation mode COOLING DRY HEATING

The initial mode will be continued and independent upon the room temperature

changing.

l If initial mode is selected, that mode is continued, independent upon the

temperature changing.

l The indoor fan motor speed is automatically determined by Auto Fan Speed. If

you are not satisfied with the auto fan speed, you can adjust the fan speed by

pressing the FAN BUTTON.

8. AUTO FAN SPEED

l When the Auto Fan Speed is selected in COOLING or HEATING operation, the

indoor fan motor speed is automatically controlled by the intake air temperature

and the preset temperature.

l The operation procedure of COOLING is as following.

Intake air temp.

Set temp.+3¡æ

Set temp.+1¡æ

Set temp.+1¡æ

Intake air temp.

Indoor fan

motor speed

Low

Indoor pipe temperature risesIndoor pipe temperature rises Indoor pipe temperature falls

Medium

High

Set temp.+2¡æ

Set temp.

Indoor fan

motor speed

High

Medium

Low

Model No: AC -S7CK_S7HK

Version 1.0

Page 18

18

l The operation procedure of HEATING is as following.

Intake air temp.

Set temp.

Set temp.-2¡æ

Intake air temp.

Indoor fan

motor speed

High

Medium Low

Indoor pipe temperature risesIndoor pipe temperature rises Indoor pipe temperature falls

Low

Set temp.-1¡æ

Set temp.-3¡æ

Indoor fan

motor speed

9. INDOOR FAN SPEED CONTROL

l Auto Fan Speed control

When set to Auto Fan Speed, the indoor fan motor speed is controlled by the

difference between the intake air temperature and the preset temperature. The more

the difference, the higher the indoor fan motor speed. Auto Fan Speed is only

HighMedium

available for COOLING and HEATING modes.

l Manual fan speed control

Basic fan motor speed adjustment (3 setting, LOW, MEDIUM and HIGH) can be

conducted by using the Fan Speed Selection button on the remote controller.

l The indoor fan speed in different modes is shown as following.

Fan Speed High(H) Medium(M) Low(L) Stop

COOLING Manual OK OK OK N/A

Automatic OK OK OK N/A

HEATING Manual OK OK OK N/A

Automatic OK OK OK N/A

Cold Air Preventive OK OK OK OK

DRY N/A N/A OK N/A

FAN ONLY OK OK OK N/A

Model No: AC -S7CK_S7HK

Version 1.0

Page 19

19

10. EMERGENT START

l If you lose the remote controller or it is out of work, you can also operate the

appliance by pressing the EMERGENT BUTTON on the indoor unit for an

emergent start.

l The operation mode is SMART if an emergent start is presented when the

appliance is connected to the power at first time. If the appliance is in stand by,

the operation mode will restore the last time setting when you press the

EMERGENT BUTTON.

11. AUTORESTART FUNCTION

When the unit is connected to power, pressing the EMERGENT BOTTON for over

5 seconds;

if the unit without auto restart function, it will be of the function of auto restart

after the buzzer 1 beeps;

if the unit with auto restart function, it will discharge the auto restart function

after the buzzer 1 beeps.

12. DEFROST

l The defrost timer (integrating the operation time of compressor)counts time by

microprocessor during HEATING operation.

l 50 minutes later after starting HEATING operation or after defrost, when the

outdoor pipe temperature falls to –8oC , the defrosting is started. When the

outdoor pipe temperature exceeds 8oC or the defrosting time reaches 10

minutes, the defrosting is ended.

l During the defrosting operation, the red LED indicator on the indoor unit of the

appliance flickers.

l In the defrost operation, firstly the compressor and the outdoor fan motor are

turned OFF. 59 seconds later the reversing valve is turned OFF. 60 seconds

later the compressor is turned ON.

l The maximum defrost time is 10 minutes.

l In the end of defrosting, the compressor is turned OFF, 59 seconds later the

reversing valve is turned ON. 60 seconds later the compressor and outdoor fan

motor are turned ON and starting HEATING operation.

l During the defrost operation, the indoor fan motor is controlled by Cold Air

Model No: AC -S7CK_S7HK

Version 1.0

Page 20

20

Preventive System.

l The HEATING and defrosting operation is alternated as following.

Switch ON

Heating

Min 50 mins

l The defrosting procedure is shown as following.

Heating

Min 50 mins

Defrosting

Max 10 mins

Heating

Min 50 mins

Model No: AC -S7CK_S7HK

Version 1.0

Page 21

21

AC -S7CK_S7HK

13. TIMER MODE OPERATION

l The setting time ranges from 0.5 hour to 24 hours.

l OFF-TIMER can be set when the appliance is in operation, and it will be

switched OFF when the preset time is achieved.

l ON-TIMER can be set when the appliance is in suspension, and it will be

switched ON when the preset time is achieved.

l Pressing TIMER button once, the last setting time display on the LCD of remote

controller. You can adjust the setting time by pressing the TEMPERATURE

SETTING BUTTON. Pressing the TIMER button again, the timer mode is se-

lected and the yellow LED indicator on the indoor unit lights up.

l The TIMER mode can be cancelled by pressing the TIMER button again on the

remote controller.

14. SLEEP MODE OPERATION

l The SLEEP mode can only be set during COOLING,DRY,SMART or HEATING

operation.

l An energy conservation operation will be achieved if selecting SLEEP mode

combined with OFF-TIMER. The operation will be turned OFF after the preset

time. The maximum preset time of SLEEP mode is 8 hours(default time).

l When selecting the COOLING or DRY operation with SLEEP mode, the

operation diagram is as following. The setting temperature will be raised by

0.5oC per hour in the first two hours after the starting. The operation will stop

after 8 hours.

Max 8 hours

2 hours

1 hour

Set temp.

0.5¡æ

0.5¡æ

SLEEP START

SLEEP STOP

l When selecting HEATING operation with SLEEP mode, the setting temperature

will be decreased by 3oC during successive 3 hours later. The operation will

Model No:

Version 1.0

Page 22

22

stop in 8 hours. The operation diagram is as following.

Max 8 hours

1 hour

2 hours

Sleep start

1¡æ

2¡æ

3¡æ

3 hours

Sleep stop

CHAPTER 7: INSTALLATION

Notice: There is detailed information about installation in the OPERATING AND

INSTALLATION INSTRUCTIONS MANUAL. The same information is not repeated in

this TECHNICIAN SERVICE MANUAL.

1. SELECT THE BEST LOCATION

l Indoor unit

F There should not be any heat source or steam near the unit.

F There should not be any obstacles to prevent the air circulation.

F A place where air circulated in the room will be good.

F A place being drained can be easily obtained.

F A place where noise prevention is taken into consideration.

F Do not install the unit near the door way.

F Ensure the spaces from the wall, ceiling, fence or other obstacles.

l Outdoor unit

F If an awning is built over the unit to prevent direct sunlight or rain exposure, be

careful that heat radiation from the condenser is not restricted.

F There should not be any animals or plants which could be affected by air dis-

charged.

F Ensure the spaces from the wall, ceiling, fence or other obstacles.

F A place where noise does not annoy your neighbors.

Model No: AC -S7CK_S7HK

Version 1.0

Page 23

23

2. DRILL THE PIPING HOLE WITH 70mm DIAMETER HOLE-CORE DRILL

l Line according to the arrows marked on the lower left and right side of the in-

stallation plate.

l The meeting point of the extended line is the center of the hole.

l Drill the piping hole at either the right or the left and the hole should be slightly

slant to the outdoor side.

3. PIPING AND DRAINAGE OF INDOOR UNIT

l Preparation of piping

1) Cut the pipes and the cable

F Use the accessory piping kit or the pipes purchased locally.

F Measure the distance between the indoor and the outdoor units.

F Cut the pipes a little longer than measured distance.

Model No: AC -S7CK_S7HK

Version 1.0

Page 24

24

F Cut the cable a 1.5m longer than the pipe length.

Model No: AC -S7CK_S7HK

Version 1.0

Page 25

25

AC -S7CK_S7HK

2) Remove burrs

F Remove burrs from cut edges of pipes.

F Turn the pipe end down to avoid the metal powder entering the pipe.

F Caution: If the burrs are not removed, they may cause a gas leakage.

Model No:

Version 1.0

Page 26

26

3) Flaring the pipes

F Insert the flare nuts, mounted on the connection ports of both indoor and outdoor

units, onto the copper pipes. Some refrigerant gas may leak, when the flare nuts

are removed from the indoor unit, as some gas is charged to prevent the inside of

the pipe from rusting.

F Fit the copper pipe end into the bar of flare tool about 0~0.5mm higher .

F Flare the pipe ends.

4) Tape the flaring portion to protect it from the dust or damages.

l Indoor unit installation

F Hook the indoor unit onto the upper portion of installation plate.(Engage the two

hooks of the rear top of the indoor unit with the upper edge of the installation

plate.)

F Ensure the hooks are properly seated on the installation plate by moving it in left

and right.

l Connecting the piping to the indoor unit

F Align the center of the piping and sufficiently tighten flare nut with fingers.

F Finally, tighten the flare nut with torque wrench until the wrench clicks.

F Wrench tightening the flare nut torque wrench, ensure the direction for tightening

follows the arrows on the wrench.

Model No: AC -S7CK_S7HK

Version 1.0

Page 27

27

Pipe Size Torque

Liquid Side(φ6 or 1/4 inch) 1.8 kg.m

Liquid Side (φ10 or 3/8 inch) 3.5 kg.m

Liquid Side(φ12 or 1/2 inch) 5.5 kg.m

Gas Side (φ10 or 3/8 inch) 3.5 kg.m

Gas Side(φ12 or 1/2 inch) 5.5 kg.m

Gas Side(φ16 or 5/8 inch) 7.5 kg.m

Gas Side(φ19 or 3/4 inch) 10.0 kg.m

l Wrap the insulation material around the connecting portion.

4. CONNECTING PIPINGS AND THE CABLE TO OUTDOOR UNIT

l Connecting the piping to outdoor unit

F Align the center of the piping and sufficiently tighten the flare nut with fingers.

F Finally, tighten the flare nut with torque wrench until the wrench clicks.

Model No: AC -S7CK_S7HK

Version 1.0

Page 28

28

F When tightening the flare nut with torque wrench, ensure the direction for tight-

ening follows the arrows on the wrench.

Pipe Size Torque

Liquid Side(φ 6 or 1/4 inch) 1.8 kg.m

Liquid Side (φ 10 or 3/8 inch) 3.5 kg.m

Liquid Side(φ 12 or 1/2 inch) 5.5 kg.m

Gas Side (φ 10 or 3/8 inch) 3.5 kg.m

Gas Side(φ 12 or 1/2 inch) 5.5 kg.m

Gas Side(φ 16 or 5/8 inch) 7.5 kg.m

Gas Side(φ 19 or 3/4 inch) 10.0 kg.m

l Connecting the cable to the outdoor unit as shown in OPERATING AND

INSTALLATION INSTRUCTIONS MANUAL.

Model No: AC -S7CK_S7HK

Version 1.0

Page 29

29

5. CHECKING THE DRAINAGE AND CONNECTING THE CABLE TO INDOOR

UNIT

l Checking the drainage

1) Remove the grille from the cabinet

F Set the up-and-down air direction louver to open position(horizontally) by finger

pressure.

F Remove the screw caps and the securing screws.

F To remove the grille, pull the lower left and right side of the grille toward you

(slightly titled) and lift it straight upward(Two tabs on the top inside edge of the

grille are clear of their slots).

2) Check the drainage

F Pour glass of water on the evaporator.

F Ensure if water flows from drainage hose of indoor unit.

l Form the piping

F Wrap the connecting portion of indoor unit with the insulation material and se-

cure it with two plastic bands (for the right piping).

Model No: AC -S7CK_S7HK

Version 1.0

Page 30

30

F If you may connect an additional drainage hose, the end of the drainage-outlet

should keep distance from the ground.(Do not dip it into water, and fix it on the

wall to avoid swinging in the wind.)

l In case of the outdoor unit is installed below position of the indoor unit.

F Tape the piping, drainage hose and connecting cable from down to up.

F Form the piping gathered by taping along the exterior wall and fix it onto the wall

by saddle or equivalent.

Model No: AC-S7CK_S7HK

Version 1.0

Page 31

31

l In case of the outdoor unit is installed upper position of the indoor unit.

F Tape the piping and connecting cable from down to up.

F Form the piping gathered by taping along the exterior wall and the trap is re-

quired to prevent water from entering into the room.

F Fix the piping onto the wall by saddle or equivalent.

l Connecting the cable to the indoor unit as shown in the OPERATING AND

INSTALLATION INSTRUCTIONS MANUAL.

6. AIR PURING OF THE PIPINGS AND INDOOR UNIT

l Air purging preparation

F Remove the caps from the 2-way and 3-way valves.

F Remove the service-port cap from the 3-way valve.

F To open the valve, turn the valve spindle of 2-way valve counter-clockwise ap-

proximate 90°° and hold it there for 5 seconds, then close it.

F Caution: Do not leak the gas in the air during air purging.

Model No: AC-S7CK_S7HK

Version 1.0

Page 32

32

AC -S7CK_S7HK

way valve again, turn the

clockwise

until it stops

Re-tighten the connecting portion with

Leakage

Locate a repair leak

Purge the air, push the pin on the service port of the 3-way valve for three

r

l Leakage checking

F Check a gas-leakage of the connection portion of the piping.

F If there is no leakage found, open 2-way again, turn the valve spindle coun-

ter-clockwise until it stops.

F If there is leakage found, re-tighten the connecting portion with wrench. If the

leakage persists, locate a leakage and repair it until leakage ceases.

Open 2valve spindle counter-

No leakage found

Leakage found

wrench

Leakage ceases

seconds with a hexagonal wrench, wait for one minute. Repeat the operation fo

three times.

l Air purging

F To purge the air, push the pin on the service port of 3-way valve for three sec-

onds with a hexagonal wrench, wait for one minute.

F Repeat the operation three times.

Model No:

Version 1.0

Page 33

33

l Set the both 2-way and 3-way valves to open position with the hexagonal wrench

for the unit operation.

l Checking a gas leakage for the left piping

F connect the manifold gauge to the service port of 3-way valve. Measure the

pressure.

F Keep it for 5~10 minutes. Ensure if the pressure indicated on the gauge is as

same as that of measured at the first time.

l Follow the result of right side piping.

l The additional gas for air purging has been charged in the outdoor unit. However,

if the flare connections have not been done correctly and gas leaks a gas cylinder and the charge set will be needed.

Model No: AC -S7CK_S7HK

Version 1.0

Page 34

34

CHAPTER 8: 2-WAY, 3-WAY VALVE

2-way Valve(Liquid Side) 3-way Valve(Gas Side)

Works Spindle position Spindle position Service port

Shipping

Air purging

(Installation)

Operation

Pumping down

(Transferring)

Evacuation

(Servicing)

Gas charging

(Servicing)

Pressure check

(Servicing)

Gas releasing

(Servicing)

Closed

(with valve cap)

Open

(counter-clockwise)

Open

(with valve cap)

Closed

(clockwise)

Open Open

Open Open

Open Open

Open Open

Closed

(with valve cap)

Closed

(clockwise)

Open

(with valve cap)

Open

(counter-clockwis

e)

Closed

(with cap)

Open

(push-pin)

Closed

(with cap)

Open

(connected manifold

gauge)

Open

(with charging

cylinder)

Open

(with charging

cylinder)

Open

(with charging

cylinder)

Open

(with charging

cylinder)

Model No: AC -S7CK_S7HK

Version 1.0

Page 35

35

1. AIR PURGING (INSTALLATION)

l Required tools: hexagonal wrench, adjustable wrench, torque wrenches, wrench

to hold the joints, and gas leak detector.

l The additional gas for air purging has been charged in the outdoor unit. However,

if the flare connections have not been done correctly and gas leaks, a gas cylinder and the charge set will be needed.

l The air in the indoor unit and in the piping must be purged. If air remains in the

refrigerant pipes, it will affect the compressor, reduce the cooling and heating

capacity, and could lead to a malfunction.

l Be sure to use a torque wrench to tighten the service port cap (after using the

service port), so that it prevents the gas leakage from the refrigeration cycle.

l Caution: Do not leak the gas in the air during air purging.

l Air purging procedure

F Recheck the piping connections.

F Open the valve spindle of the 2-way valve counter-clockwise proximately

90°°,wait 10 seconds, and then set it to closed position. Be sure to use a hex-

agonal wrench to operate the spindle.

Model No: AC -S7CK_S7HK

Version 1.0

Page 36

36

F Check the flare connections for refrigerant gas leakage.

F Purge the air from the system. Set the 2-way valve to the open position and

remove the cap from the 3-way valve’s service port. Using the hexagonal wrench

to press the valve core pin, discharge for three seconds and then wait for one

minute. Repeat this three times.

F Use torque wrench to tighten the service port cap to a torque of 1.8kg.cm.

F Set the 3-way valve to the back seat.

F Mount the valve caps to the 2-way and 3-way valves.

F Check for gas leakage. At this time, especially check for gas leakage from the

2-way and 3-way valve’s caps, and from the service port cap.

l Caution: If gas leakage is discovered, take the following measures.

F If the gas leakage stops when the piping connections are tightened fur-

ther ,continue working.

F If the gas leakage does not stop when the piping connections are tightened,

repair the location of the leakage, discharge all of the gas through the service

port, and then recharge with the specified amount of gas from a gas cylinder.

2. PUMPING DOWN (BEFORE RE-INSTALLATION)

Model No: AC -S7CK_S7HK

Version 1.0

Page 37

37

AC -S7CK_S7HK

l Confirm that both the 2-way and 3-way valves are set to the open position.

F Remove the valve caps and confirm that the valve spindles are in the open

position.

F Be sure to use a hexagonal wrench to operate the valve spindle.

l Operate the unit for 10~15 minutes.

l Stop operation and wait for 3 minutes, then connect the charge set to the service

port of the3-way valve.

F Connect the charge hose with the push pin to the service port.

l Air purging of the charge hose

F Open the low-pressure valve on the charge set slightly to purge air from the

charge hose.

l Set the 2-way valve to the closed position.

l Operate the air conditioner at the cooling cycle and stop it when the gauge indi-

cates 1kg/cm2.g.

l Immediately set the 3-way valve to the closed position.

F Do this quickly so that the gauge ends up indicating 3 to 5kg/cm2.g.

l Disconnect the charge set, and amount the 2-way and 3-way valve’s caps and

the service port cap.

F Use torque wrench to tighten the service port cap to a torque of 1.8 kg.m.

F Be sure to check for gas leakage.

3. RE-AIR PURGING FOR RE-INSTALLATION

l Confirm that both the 2-way valve and the 3-way valve are set to the closed

position.

l Connect the charge set and a gas cylinder to the service port of the 3-way valve.

F Leave the valve on the gas cylinder closed.

l Air purging

F Open the valves on the gas cylinder and the charge set. Purge the air by loos-

ening the flare nut on the 2-way valve approximately 45°°for 3 seconds, then

Model No:

Version 1.0

Page 38

38

closing it for 1 minute. Repeat 3 times.

F After purging the air, use a torque wrench to tighten the flare nut on the 2-way

valve.

l Check the flare connections for gas leakage.

l Disconnect the charge set and the gas cylinder, and set the 2-way and 3-way

valves to the open position.

F Be sure to use a hexagonal wrench to operate the valve spindles.

l Mount the valve caps and the service port cap.

F Use torque wrench to tighten the service port cap to a torque of 1.8kg.m.

F Be sure to check for gas leakage.

l Caution: Do not leak the gas in the air during air purging.

4. BALANCE REFRIGERANT OF THE 2-WAY, 3-WAY VALVES (GAS LEAKED)

l Confirm that both the 2-way and 3-way valves are set to the back seat.

l Connect the charge set to the 3-way valve’s service port.

Model No: AC -S7CK_S7HK

Version 1.0

Page 39

39

F Leave the valve on the charge set closed.

F Connect the charge hose with the push pin to the service port.

l Open the valve (Low side)on the charge set and discharged the refrigerant until

the gauge indicates 0kg/cm2.g.

F If there is no air in the refrigerant cycle (the pressure when the air conditioner is

not running is higher than 1 kg/cm2.g),discharge the refrigerant until the gauge

indicates 0.5 to 1 kg/cm2.g.If this is the case, it will not be necessary to apply an

evacuation.

F Discharge the refrigerant gradually. If it is discharged too suddenly, the refrigera-

tion oil will also be discharged.

5. EVACUATION (ALL AMOUNT OF REFRIGERANT LEAKED)

l Connect the vacuum pump to the charge set’s center hose.

l Evacuating for approximately one hour.

F Confirm that the gauge needle has moved toward -76cmHg (vacuum of 4

mmHg or less)

Model No: AC -S7CK_S7HK

Version 1.0

Page 40

40

l Close the valve (Low side) on the charge set, turn off the vacuum pump, and

confirm that the gauge needle does not move (approximately 5 minutes after

turning off the vacuum pump).

l Disconnect the charge hose from the vacuum pump.

F If the vacuum pump oil becomes dirty or depleted, replenish as needed.

6. GAS CHARGING (AFTER EVACUATION)

l Connect the charge hose to the charging cylinder.

F Connect the charge hose which you disconnected from the vacuum pump to the

valve at the bottom of the cylinder.

F If you are using a gas cylinder ,also use a scale and level the cylinder so that the

system can be charged with liquid.

l Purge the air from the charge hose.

F Open the valve at the bottom of the cylinder and press the check valve on the

charge set to purge the air.(Be careful of the liquid refrigerant).The procedure is

the same if using a gas cylinder.

l Open the valve (Low side on the charge set) and charge the system with liquid

Model No: AC -S7CK_S7HK

Version 1.0

Page 41

41

refrigerant.

F If the system can not be charged with the specified amount of refrigerant, it can

be charged with a little at a time (approximately 150g each time) while operating

the air conditioner in the cooling cycle. However, one time is not sufficient, wait

approximately 1 minute and then repeat the procedure (pumping down pin).

F This is different from previous procedures. Because you are charging with liquid

refrigerant from the gas side, absolutely do not attempt to charge with larger

amounts of liquid refrigerant while operating the air conditioner.

l Immediately disconnect the charge hose from the 3-way valve’s service port.

F Stopping partway will allow the gas to be discharged.

F If the system has been charged with liquid refrigerant while operating the air

conditioner before disconnecting the hose.

l Mount the valve caps and service port cap.

F Use torque wrench to tighten the service port cap to a torque of 1.8kg.m.

F Be sure to check for gas leakage.

Model No: AC -S7CK_S7HK

Version 1.0

Page 42

42

AC -S7CK_S7HK

Dusty condenser

Excessive amount of

Inefficient

Clogged strainer or

Gas side

Measure gas side

CHAPTER 9: TROUBLESHOOTING

1. REFRIGERATION CYCLE SYSTEM

l In order to diagnose malfunctions, make sure that there is no electrical problems

before inspecting the refrigeration cycle. Such problems include insufficient

thermal insulation, problem with the power supply, malfunction of a compressor

and indoor or outdoor fan motor.

l The normal indoor outlet air temperature and pressure of the refrigeration cycle

depends upon various conditions. The standard values for them are shown in the

following table.

Normal Pressure and Outlet Air Temperature

Gas Pressure

MPa(kg/cm2.g)

Cooling Mode 0.4~0.6(4~6) 12~16

*Condition: Indoor fan speed: High ; Outdoor DB temperature:35

l Checking procedure

Difference in the intake

And outlet air temperature

Less than 8oC at the cooling operation

Value of electric current

during operation

Normal

Preventing heat

radiation

refrigerant

Insufficient refrigerant

pressure

Outlet Air Temperature

l Measure the air temp.

difference (oC)

l Measure

electric

current

during

operation

l

pressure from the

service port of

the

3-way valve

capillary tube

Model No:

Version 1.0

Page 43

43

Heat radiation deficiency of the

2. RELATION BETWEEN THE CONDITION OF THE AIR CONDITIONER AND

PRESSURE AND ELECTRIC CURRENT IN COOLING OPERATION

l Carry out the measurements of pressure, electric current and temperature fifteen

minutes after an operation is started.

Condition of the air conditioner Lower pressure High pressure

Insufficient refrigerant

(gas leakage)

Clogged capillary tube or

strainer

Short circuit in the indoor unit Decreased Decreased Decreased

Nature of fault Symptom

Inefficient compressing of

a compressor

outdoor unit

Inefficient compression Increased Decreased Decreased

3. DIAGNOSIS METHODS OF A MALFUNCTION OF A COMPRESSOR

Electric current during

operation

Decreased Decreased Decreased

Decreased Decreased Decreased

Increased Increased Increased

F Electric current during operation becomes approximately

20% lower than the normal value.

F The discharge tube of the compressor becomes abnormally

hot (normally 70 to 90)

F The difference between high pressure and low pressure

becomes almost zero.

Locked compressor F Electric current reaches a high level abnormally, and the

value exceeds the limit of an ammeter . In some cases, a

breaker turns OFF.

F The compressor has a humming sound.

Model No: AC -S7CK_S7HK

Version 1.0

Page 44

44

AC -S7CK_S7HK

4. TROUBLE SUSPENSION TABLE

SYMPTON PROBABLE CAUSE CORRECTIVE ACTION

The RUN indicator

(green)does not light up

The indoor fan does not

function correctly

The outdoor fan does not

function correctly

The power source voltage is

lower than 198V

No voltage Repair general wiring

Correct voltage

The remote controller

batteries are used up

No voltage between indoor

fan motor terminals

Indoor fan motor is broken Replace indoor fan motor

No voltage between outdoor

fan motor terminals on the

indoor power P.C.B

No voltage between outdoor

fan motor terminals on the

outdoor unit

Outdoor fan is blocked Remove obstructions

Repair the power supply

Replace control P.C.B or

display P.C.B

Reload new batteries

Replace the control P.C.B

Replace the control P.C.B

Check and repair electrical

wiring between indoor and

outdoor units

The compressor does not

start up

Outdoor fan motor is broken Replace outdoor fan motor

Outdoor fan motor capacitor

is broken

No voltage between

compressor terminals on the

indoor unit

Low voltage between

compressor terminals on the

indoor unit

No voltage between

compressor terminals on the

outdoor unit

The running capacitor is

broken

OLP of compressor trips Wait for one hour or so

Compressor winding shorted

or broken

Replace capacitor

Repair control P.C.B

Repair control P.C.B

Repair electrical wiring

between indoor and outdoor

units

Replace running capacitor

Replace compressor

Model No:

Version 1.0

Page 45

45

AC -S7CK_S7HK

SYMPTON PROBABLE CAUSE CORRECTIVE ACTION

The refrigeration

system does not

function correctly

No cooling or

heating, only

indoor fan

operates

No cooling or

heating, indoor and

outdoor fan

operate

Water accumulates

and overflows from

indoor unit

Check for leakage or restriction

with ammeter, pressure gauge

or surface thermometer

something wrong with power

P.C.B

Outdoor fan motor faulty or other

fault caused compressor OLP

trips

Compressor OLP trips because

of low voltage, high

temperature,R22 leakage, little

outdoor air circulation and etc

Running capacitor faulty Replace running capacitor

Compressor is broken Replace compressor

Drainage hose or port of

drainage pan clogged

Repair refrigeration system and

charge refrigerant if necessary

Replace control P.C.B

Remove obstruction or other fault

Check the problems and try

again one hour later

Remove clogged dirt

Power supply failure Repair power supply

The air conditioner

does not function

at all with remote

controller or AUX

switch button on

the indoor unit

The secondary voltage of

transformer is approximately

17VAC

The secondary voltage of

transformer is not approximately

17VAC

Replace control P.C.B

Replace transformer

5. Checking procedure of control circuit

Note: Do not check indoor and outdoor units at the same time. Be sure to check them

one by one.

Model No:

Version 1.0

Page 46

46

AC -S7CK_S7HK

Is the measured

Use a tester to measure

outdoor unit

between “L” and “N”

The machine does not function

at all with remote controller and

EMERGENCY button on the

indoor unit.

Replace the transformer

with a new one.

Model No:

Version 1.0

Correct

power supply

of terminal board?

None of the three

LEDs is ON

Yes

Measure the secondary

voltage of transformer

Is the connecting

cord correctly

connected?

value approx.

17.0 V AC?

Yes

Replace the control P.C.B.

with a new one.

Is the fuse

down?

Replace the fuse and

varister with new ones

Correct the

connecting

cord correctly

the voltage between “L”

and “N” of terminal

board on the

Check the electric

circuit on the outdoor

unit

Page 47

47

signal of the remote

one.

Table.

Model No: AC -S7CK_S7HK

Version 1.0

The machine does not function

with the remote controller.

Push the ON/OFF button on the

wireless remote controller.

Is transmitting

controller active?

YES

Does beep sound

from the indoor

unit?

NO

Does connector of

display P.C.B.

connect in place?

YES

Using a tester, measure the

voltage of the receiver on

display P.C.B.assembly.

Push the ON/OFF button

on the remote controller.

When the signal is

received, does the

voltage change?

Replace the control P.C.B.

assembly with a new one

NO

Are batteries of

remote controller

proper?

Replace the wireless

remote controller.

YES

Is indicator lamp

of indoor unit

proper?

Is timer lamp

of indoor unit

flashing?

Replace the control

P.C.B.assembly

YES

YES

NO

NO

NO

Replace the batteries

with new ones.

YES

Indoor unit is normal.

Inspect the outdoor

Unit or refer to

trouble

Suspension Table.

Refer to

Trouble

Suspension

NO

Replace the display

P.C.B.

assembly with a new

YES

Page 48

48

The room is not cooled at all or not cooled enough

in cooling operation.

The room is not heated at all or not heated enough

in heating operation.

The compressor does not operate.

Push the buttons EMERGENCY

on the indoor unit.

Refer to Trouble Suspension Table

Measure the resistances of room temperature

and indoor pipe temperature thermisters.

Some of the three indicator LEDs are lit.

Measure the secondary voltage of transformer.

Replace the control P.C.B. with a new one.

Is the measured

value approximately

17.0 V AC?

YES

NO

Replace the transformer

with a new one.

NO

Is the fuse

breakdown?

YES

Replace the fuse and varister

with a new one.

Model No: AC -S7CK_S7HK

Version 1.0

Page 49

49

AC -S7CK_S7HK

CHAPTER 10: EXPLODED DRAWINGS

1. Exploded view of indoor unit for model: AC-S7CK, AC-7SHK

Model No:

Version 1.0

Page 50

50

AC -S7CK_S7HK

2. Exploded view of outdoor unit for model: AC-S7CK

Model No:

Version 1.0

Page 51

51

AC -S7CK_S7HK

3. Exploded view of outdoor unit for model: AC-S7HK

Model No:

Version 1.0

Page 52

52

CHAPTER 11: PART LIST

1. Part List of Indoor Unit for AC-S7CK

No. DESCRIPTION Part No. Q’ty

1 Installation Plate 1101297 1

2 Chassis 1002110 1

3 Indoor Fan 1402283 1

4 Bearing 120268 1

5 Evaporator Assembly 8130118 1

6 Cabinet 2107261 1

7 Air Filter 1306145 2

8 Front Cover 8100636 1

9 Safety Cover 2109232 1

10 Bearing Support 100251 1

11 Left Louver Link 1201291 1

12 Vertical Deflector A 1201288 2

13 Pipe Assembly (AC-S7/10CK) 81303151 1

13a Pipe Assembly (AC-S13CK) 81303174 1

14 Draining Pan 210691 1

15 Motor Fixing Ring 1203179 1

16 Display PCB 8140921 1

17 Power Supply Cord Clamp2

Power Supply Cord Clamp1

18 Terminal Board 3PS 150265 1

19 Terminal Fixer 1109245 1

20 Control PCB (AC-S7/10CK) 8140943 1

20a Control PCB (AC-S13CK) 8140928

21 Indoor Fan Motor 1402153 1

22 Transformer 814051 1

23 Electric Box 1005213 1

24 Power Supply Cord 1501185 1

25 Power Supply Cord Clamp 1203185 1

26 Terminal Board 3PU 150264 1

27 Power Supply PCB (AC-S7/10CK) 8140944 1

27a Power Supply PCB (AC-S13CK) 8140926 1

28 Water Preventive Plate 1203393 1

29 Drain Hose 210995 1

30 Support 1201292 1

31 Upper Louver Link 1201290 2

32 Vertical Deflector B 1201289 10

33 Louver Motor 1402136 1

34 Right Louver Link 1201293 1

35 Horizontal Louver 1201381 1

36 Remote Controller 1401394 1

37 Thermistor 1411366 1

Model No: AC -S7CK_S7HK

Version 1.0

110963

1109147

1

1

Page 53

53

2. Part List of Outdoor Unit for AC-S7CK

No. DESCRIPTION Part No. Q’ty

1 Top Cover 810136 1

2 Condenser 8130226 1

3 Motor Stay Bracket 811022 1

4 Outdoor Fan Motor 1402371 1

5 Outdoor Fan 1402181 1

6 Cabinet 810065 1

7 Fan Guard 821072 1

8 Back Lattice Plate

9 Electrical Assembly 8140117 1

10 Electrical Assembly Plate 821022 1

11 Electrical Assembly Seal 1

12 Power Supply Cord Clamp 1 110963 1

13 Power Supply Cord Clamp 2 1109147 1

14 Terminal Board 2U 150217(A) 2

15 Terminal Board 3PU 150264 1

16 Fan motor Capacitor 141111 1

17 Compressor Capacitor 14111418 1

18 Power Supply Cord 1501545 1

19 Capacitor Fixing Ring 812031 1

20 Bulkhead 811094 1

21 Chassis 810027 1

22 Compressor 1304297 1

23 Right Side Plate 810038 1

24 Valve Fixing Plate 811092 1

25 Terminal Cover 821021 1

26 3 Way Valve Assembly 8130917 1

27 2 Way Valve Assembly 8130916 1

28 Suction Pipe 81303149 1

29 Discharging Pipe 81303150 1

30 Capillary Tube Assembly 81303143 1

Model No: AC -S7CK_S7HK

Version 1.0

Page 54

60

AC -S7CK_S7HK

3. Part List of Indoor Unit for AC-S7HK

No. DESCRIPTION Part No. Q’ty

1 Installation Plate 1101297 1

2 Chassis 1002110 1

3 Indoor Fan 1402283 1

4 Bearing 120268 1

5 Evaporator Assembly 8130118 1

6 Cabinet 2107261 1

7 Air Filter 1306145 2

8 Front Cover 8100636 1

9 Safety Cover 2109232 1

10 Bearing Support 100251 1

11 Left Louver Link 1201291 1

12 Vertical Deflector A 1201288 2

13 Pipe Assembly 81303151 1

13a Pipe Assembly 81303174 1

14 Draining Pan 210691 1

15 Motor Fixing Ring 1203179 1

16 Display PCB 8140921 1

17 Power Supply Cord Clamp2

Power Supply Cord Clamp1

18 Terminal Board 5PU 150262 1

19 Terminal Fixer 1109245 1

20 Control PCB (AC-S7/10HK) 8140943 1

20a Control PCB (AC-S13HK) 8140976

21 Indoor Fan Motor 1402153 1

22 Transformer 814051 1

23 Electric Box 1005213 1

24 Power Supply Cord 1501185 1

25 Power Supply Cord Clamp 1203185 1

26 Terminal Board 3PS 150265 1

27 Power Supply PCB (AC-S7/10HK) 8140942 1

27a Power Supply PCB (AC-S13HK) 8140975 1

28 Water Preventive Plate 1203393 1

29 Drain Hose 210995 1

30 Support 1201292 1

31 Upper Louver Link 1201290 2

32 Vertical Deflector B 1201289 10

33 Louver Motor 1402136 1

34 Right Louver Link 1201293 1

35 Horizontal Louver 1201381 1

36 Remote Controller 1401394 1

37 Thermistor 1411366 1

110963

1109147

1

1

Model No:

Version 1.0

Page 55

55

4. Part List of Outdoor Unit for AC-S7HK

No. DESCRIPTION Part No. Q’ty

1 Top Cover 810136 1

2 Condenser 8130226 1

3 Motor Stay Bracket 811022 1

4 Outdoor Fan Motor 1402371 1

5 Outdoor Fan 1402181 1

6 Cabinet 810065 1

7 Fan Guard 821072 1

8 Back Lattice Plate

9 Electrical Assembly 8140117 1

10 Electrical Assembly Plate 821022 1

11 Electrical Assembly Seal 1

12 Power Supply Cord Clamp 1 110963 1

13 Power Supply Cord Clamp 2 1109147 1

14 Terminal Board 2U 150217(A) 2

15 Terminal Board 3PU 150264 1

16 Fan motor Capacitor 141111 1

17 Compressor Capacitor 14111418 1

18 Power Supply Cord 1501545 1

19 Capacitor Fixing Ring 812031 1

20 Bulkhead 811094 1

21 Chassis 810027 1

22 Compressor 1304297 1

23 Right Side Plate 810038 1

24 Valve Fixing Plate 811092 1

25 Terminal Cover 821021 1

26 3 Way Valve Assembly 8130917 1

27 2 Way Valve Assembly 8130916 1

28 4 Way Valve 141187 1

28a 4 Way Valve Coil 1411458 1

29 Capillary Tube Assembly 81303135 1

Model No: AC -S7CK_S7HK

Version 1.0

Page 56

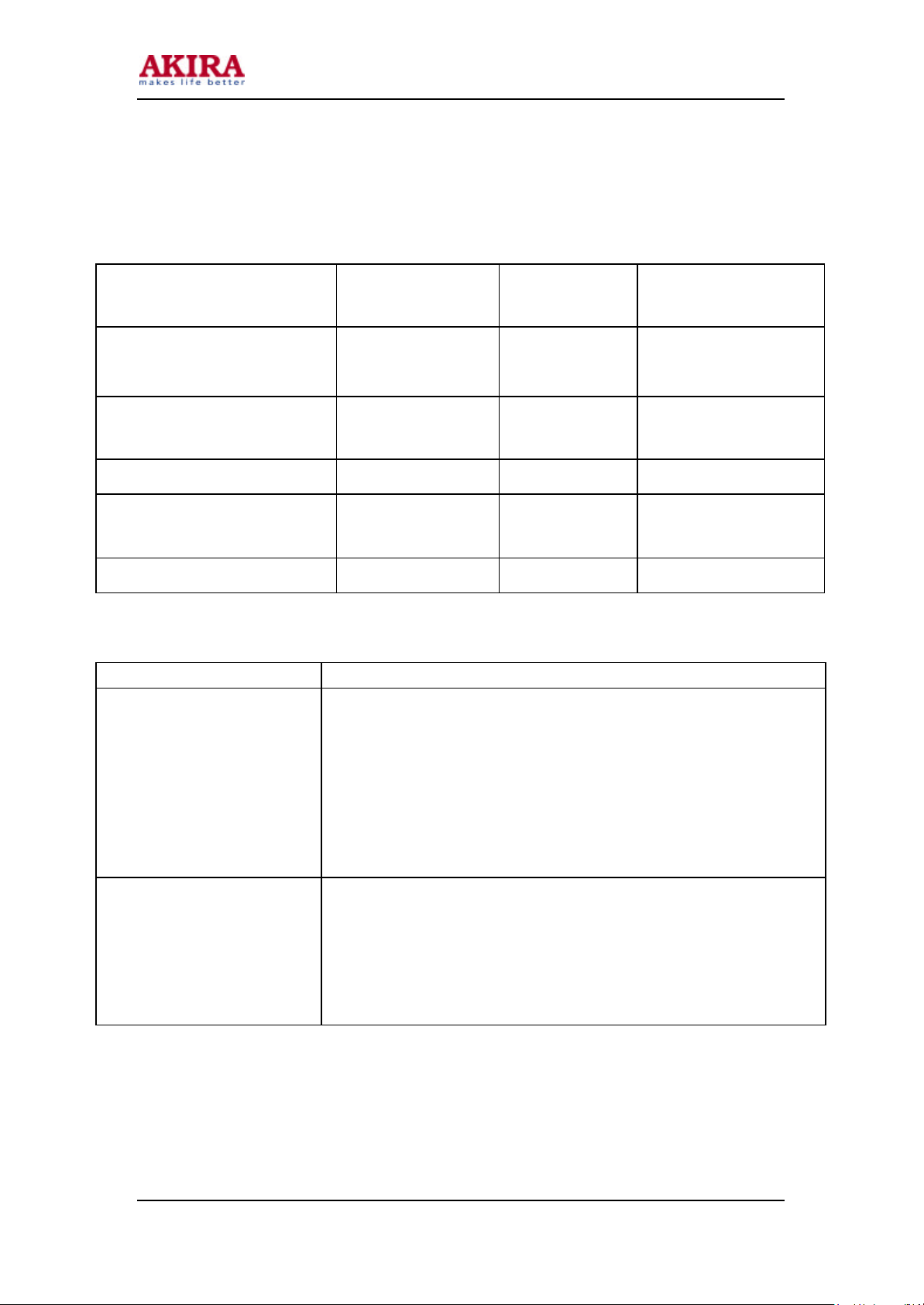

APPENDIX AAPPENDIX A

Description

Akira Model No. AC-S7CK AC-S7HK AC-S10CK AC-S10HK AC-S13CK AC-S13HK AC-S19CK AC-S19HK AC-S24CK AC-S24HK

Type (Cool only / Heat Pump) C C/H C C/H C C/H C C/H C C/H

Cooling Capacity (Btu)

Heating Capacity (Btu)

Power Input (W)

Current (A)

EER (Btu/Hw)

Indoor Noise (H/L)

Circulation Air Flow(m3/h)

Indoor Unit (WxDxH)mm

Indoor Unit Carton (WxDxH)mm

Outdoor Unit (WxDxH)mm

Outdoor Unit Carton (WxDxH)mm

Indoor N/G Wt (kg) 8.0/10 8.0/10 8.0/10 8.0/10 8.0/10 8.0/10 11.0/14 11.0/14 13.2/21 13.2/21

Outdoor N/G Wt (kg) 26.0/31 30.0/35 28.0/33 30.0/35 28.0/33 34.0/39 50.0/58 53.0/61 55.0/63 56.0/64

Compressor Brand Mitsubishi Toshiba LG Toshiba

Gas Pipe Diameter

Liquid Pipe Diameter

Piping (m)

40HQ CTN Loading

7000

N/V

Mitsubishi LG

7000

730

3.4

9.1

420 420 480 750 780

3/8" (or 10mm)

10000 13000 19000

N/V

770x179x240

830x240x310

755x252x530

890x350x580

10000

800 1425 1590 2700

9.0 8.6

35/30Db 38/33Db 43/37Db35/30Db 40

245 sets 152 sets 123 sets

Singapore / AKIRASingapore / AKIRA

N/V

13000

6.23.7

1/2" (or 12mm)

1/4" (or 6mm)1/4" (or 6mm)

55

N/V

897x179x297

1010x300x410

800x268x637

975x400x755

19000

7.5

10 8.89

24000

N/V

12.5

1025x203x3139

1130x300x395

832x380x702

970x765x410

Hitachi

5/8" (or 16mm)

3/8" (or 10mm)

24000

Indoor Unit Picture

Loading...

Loading...