Page 1

S

S

S

e

e

e

C

C

C

r

v

r

v

r

v

o

o

o

i

i

i

l

l

l

c

c

c

o

o

o

e

e

e

u

u

u

M

M

r

T

r

r

M

T

T

a

a

a

V

V

V

n

u

n

n

u

u

a

a

a

l

l

l

Page 2

2

M

H

U

U

U

o

o

H

H

O

O

O

M

M

W

1

2

2

2

i

s

s

a

h

C

C

C

h

h

a

a

s

s

s

s

i

i

s

s

s

1

1

:

:

W

W

:

o

d

d

d

P

P

P

C

C

C

e

e

e

3

3

3

-

-

-

l

:

l

l

/

/

/

T

T

T

:

:

B

B

B

N

N

N

D

D

D

A

A

A

9

9

9

3

3

3

8

8

8

1

1

1

Model No: 21WHP3-Bn

Version 1.0

Page 3

3

CONTENTS

SAFETY NOTICE.......................................................................................................................................4

GENERAL DESCRIPTION........................................................................................................................6

TECHNICAL SPECIFICATION................................................................................................................7

GENERAL SPECIFICATION....................................................................................................................8

SAFETY CAUTIONS FOR PRODUCTS..................................................................................................9

ADJUSTMENT MODE ............................................................................................................................10

CHASSIS BLOCK DIAGRAM ................................................................................................................15

FAULT FINDING TREES........................................................................................................................16

IC BLOCK DIAGRAM.............................................................................................................................23

MAIN CHIP INSTRUCTION...................................................................................................................24

FACTORY MENU

EXPLODED VIEW AND PART NAME.................................................................................................48

BOM LIST .................................................................................................................................................49

CIRCUIT DIAGRAM ...............................................................................................................................58

Model No: 21WHP3-Bn

Version 1.0

....................................................................................................................................45

Page 4

4

SAFETY NOTICE

WARNING: BEFORE EXAMINING AND

SERVICING THIS CHASSIS, READ

CAREFULLY THE FOLLOWING

SAFETY INSTRUCTIONS.

X-RAY RADIATION PRECAUTION

1. The primary source of X-RADIATION in television receiver is the picture tube. The picture

tube is specially constructed to limit X-RADIATION emissions. For continued X-RADIATION

protection, the replacement tube must be the same type as the original including suffix letter.

Excessive high voltage may produce potentially hazardous X-RADIATION. To avoid such

hazards, the high voltage must be maintained within specified limit. Refer to this service manual,

high voltage adjustment for specific high voltage limit. If high voltage exceeds specified limits,

take necessary corrective action. Carefully follow the instructions for +B1 volt power supply

adjustment, and high voltage check to maintain the high voltage within the specified limits.

2. The EHT must be checked every time the receiver is serviced to ensure that the CRT does not

emit X-ray radiation as result of excessive EHT voltage. The nominal EHT for this receiver is

22KV at zero beam current (minimum brightness) operating at AC 220V. The maximum EHT

voltage permissible in any operating circumstances must not exceed 25KV. When checking the

EHT, use the High Voltage Check procedure in this manual using an accurate EHT voltmeter.

3. The only source of X-RAY radiation in this receiver is the CRT. To prevent X-ray radiation,

you should use the same type of CRT when replacing it.

4. Some components used in this receiver have safety-related characteristics preventing the CRT

from emitting X-ray radiation. For continued safety, replacement component should only be made

after referring the Product Safety notice below.

SAFETY PRECAUTION

1. The high voltage in the TV reaches to 22KV when the TV is in operation. Be more careful

during opening the back cover.

a. The high voltage existing in the TV is very dangerous. Refer servicing to qualified

personnel only.

b. Before removing the high voltage cap. Discharge the anode of the CRT and the

chassis in case of electric shock.

c. Wear a pair of goggles when handling the CRT to avoid broken pieces damaging

your eyes.

d. Do not hold the CRT neck in case of causing damage to the CRT.

2. When the power cord needs replacing, use the same one as that provided by AKIRA factory.

3. Voltage exists between the hot and cold ground when TV is in operation. Install a separation

transformer during repairing or connecting to any tester for the sake of safety. The power of

the separation transformer should be beyond rated overall power.

Model No: 21WHP3-Bn

Version 1.0

Page 5

5

4. When replacing a burnout fuse, use the one with the same specifications as the original.

5. When replacing old wire, wind new one round the shaft to weld. When replacing components

with safety in performance, use the same type as that specified by AKIRA and install it in the

former way.

6. Never place wire near high-temperature or high-voltage components.

7. An isolation transformer should be connected in the power line between the receiver and the

AC line when a service is performed on the primary of the converter transformer of the set.

8. Comply with all caution and safety-related notes provided on the cabinet back, inside the

cabinet, on the chassis or the picture tube.

9. When replacing a chassis in the cabinet, always be certain that all the protective devices are

installed properly, such as, control knobs, adjustment covers or shields, barriers, isolation

resistor-capacitor networks etc.. Before returning any television to the customer, the service

technician must be sure that it is completely safe to operate without danger of electrical shock.

PRODUCT SAFETY NOTICE

Product safety should be considered when a component replacement is made in any area of a receiver.

Components indicated by mark in the parts list and the schematic diagram designate components in

which safety can be of special significance. It is particularly recommended that only parts designated

on the parts list in this manual be used for component replacement designated by mark. No deviations

from resistance wattage or voltage ratings may be made for replacement items designated by mark.

Model No: 21WHP3-Bn

Version 1.0

Page 6

6

GENERAL DESCRIPTION

AKPH02 chassis series are applied in A14P01/A21P01 respectively which uses

mainly Philips’ advanced UOC-ultimate chip TDA935X/6X/8X and I2C-bus

controlled IC. With combination of microcontroller and small signal processor, the

TDA935X/6X/8X series feature high-integration, high-performance-to-price ratio and

high-reliability and advanced functions with fewer external components, which

provide much convenience for manufacturing and technical service.

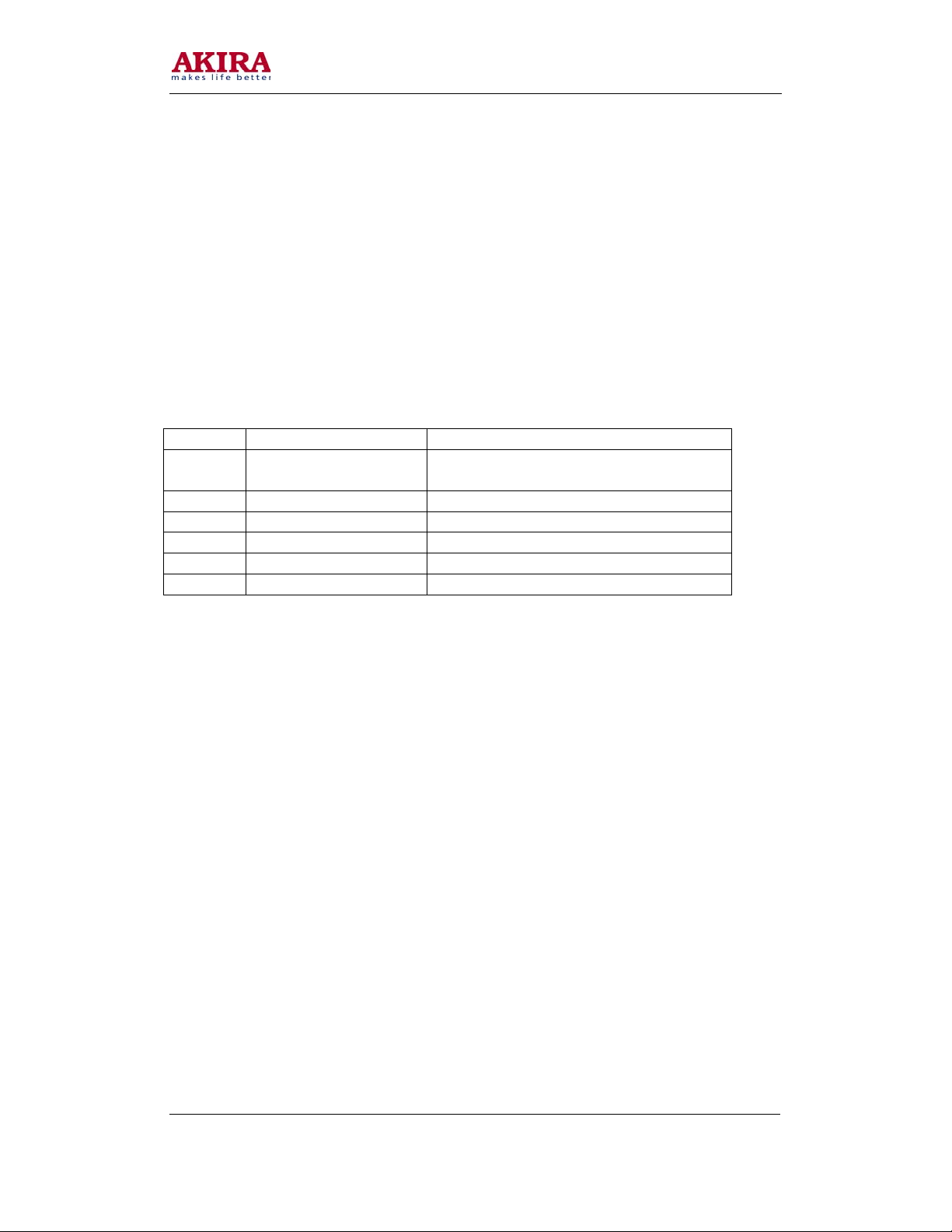

Table 1 provides A14P01/A21P01 mainly ICs and functions.

THE SURVEY

Table 1, the main IC and functions

Position Type Function Description

N301 TDA9361/TDA9381 Microcontroller and small signal

processor(UOC)

N702 ST24C08-W EEPROM

N701 AN7522N Sound power amplifier

N401 LA78040 Vertical scan output stage circuit

N801 LC4052B/CD4052BE AV1/AV2 Switch

N121 LC4052B/CD4052BE AV1/AV2 Switch

SIGNAL PROCESS

The TV signal enters into tuner (A201) from cable or antenna. Pin 10 and pin 11 of N301 are combined

to select the band. Pin 4 of N301 outputs PWM tuning signal. The 38.9MHz IF signal is coupled to

V308 (pre-amplify) and then to SAWF (Z301). After processed in the SAWF, the 38.9MHz signal gets

to pin 23 and pin 24 of OM8370. The IF circuit in OM8370 includes such unit as the AGC amplifying

circuit, 38.9MHz oscillator, PLL video demodulator, video amplifier, IF identify circuit and AFT

circuit. The demodulated signal (CVBS) comes from the pin 38 of OM8370, the sound signal comes

from the pin 44.

The internal CVBS signal needs norm identification then outputs from pin 38 of OM8370, via the trap

circuit (composed of the V351, Z351, Z354, V352 and so on) feeds back to the pin 40 of OM8370. The

RGB signal comes from pin51, Pin52, Pin53 of OM8370, and outputs to the CRT board. The internal

sound signal comes from pin 44 of OM8370 and then input to pin 1 and pin 12 of HEF4052BP. The

sound signals from RF and AV are selected in it. The selected signal is output from Pin 3 and pin13,

then input AN7522N (sound amplifier) or output from AV terminals.

Model No: 21WHP3-Bn

Version 1.0

Page 7

7

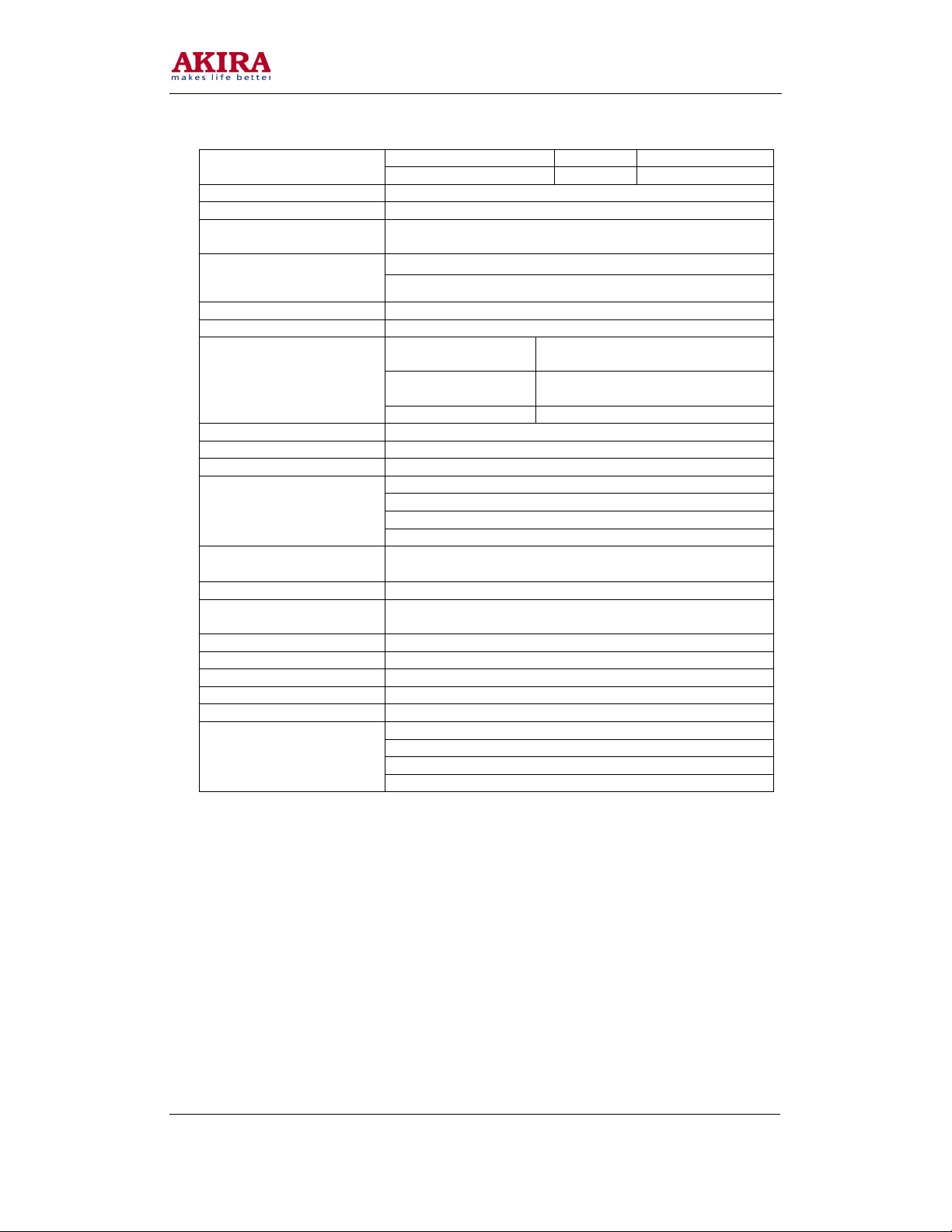

TECHNICAL SPECIFICATION

Test Item Conditional TD171

AC Operating

Range

Total Power

Consumption

EHT

Anode Current Brightness &contrast Maximum I

Heater Voltage TV operate normally V

B+ Normal operating VB+ = 112Vdc

Sound power

output

RF&AV signal input with sound loud speaker

(volume maximum) & Picture set in Dynamic

mode

Philips or Mono-scope pattern signal with howling

sound Contrast & Brightness set in Maximum,

sound increase maximum

Standby Mode 14 Watts

Brightness & contrast set in Maximum Min: 26.2KVdc

Typical Design value Average: 26.5KVdc

Brightness &contrast Minimum Max: 27.8KVdc

RF signal input broadcasting at

217.25MHz/BG/DK(1KHz)

Volume is maximum

140Vac ~ 240Vac

90Watts

≤ 1.2mA

ABL

= 6.2Vac

Heater

V = 6.3Vrms

P = 5Watts X 2

Model No: 21WHP3-Bn

Version 1.0

Page 8

8

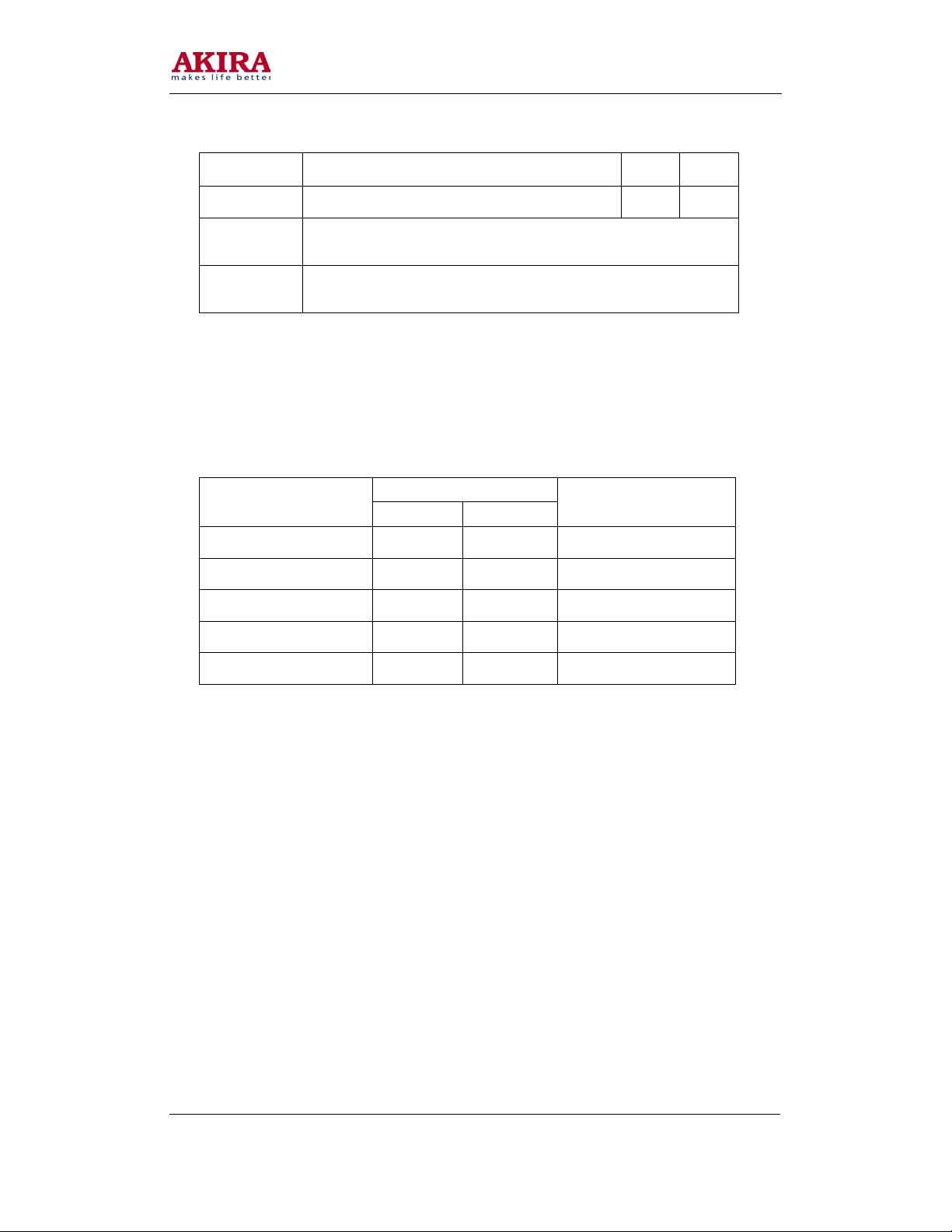

GENERAL SPECIFICATION

Power consumption

Receive system DK/BG/I

Color system PAL/ SECAM/ NTSC

Vision intermediate

frequency

Inter-carrier frequency

Chroma if frequency PAL 34.47/ 35.32MHz

Antenna type DIN TYPE 75 Ohm

Channel receiving

Tuning system VS tuning

AV IN/ OUT 2 AV STEREO IN + 1 AV STEREO OUT

Component IN 1 YUV-Component IN

AV IN/ OUT specification

OSD language

Audio output power > 8W (1KHz, 0.5V INPUT, 10% THD

Safety authentication

standard

LED indicator Power ON

Hand set type HS08

Hans set power supply Pin AAx2

Color picture tube 14” 21” 90 degree tube

Remote control distance 5m

External input/output

2

I

C Bus Control

Auto Search

Off/On Timer

Teletext

14” 70W MAX

21” 90W MAX

38.9MHz

5.5 MHz(B/G)

6.5MHz(D/K)

VHF Low channel

(VL)

VHF high channel

(VH)

UHF channel (U) =471.25 to 863.25 MHz

VIDEO IN ----1.0 0.2V

AUDIO IN ----0-2V (RMS)

VIDEO OUT ----1.0 0.2V

AUDIO OUT ---- 0-2V (RMS)

English, Russian, Turkish, French, Spanish, Vietnamese,

Indonesian, Arabian, Persian

CB

Video/Audio (L/R) 2set input

YUV input

S-Video input

Video/ Audio (L/R) 1 set output

=48.25 to 147.25 MHz

=154.25 to 463.25 MHz

75 Ohm

p-p

p-p

75 Ohm

Model No: 21WHP3-Bn

Version 1.0

Page 9

9

SAFETY CAUTIONS FOR PRODUCTS

Many electric and mechanical components in AKPH01 chassis have special safety performances,

which are always neglected. Even if replacing them with some components with the same voltage and

power, you can not get effective protection to X-ray. In the circuit diagram, these special electric

components are indicated by the special mark ! and on the shadow. When replacing any of them, use

the one with the same specifications as the original’s. Otherwise, it may cause X-ray radiation and

damage to overall safety.

CIRCUIT ADJUSTMENTS

GENERAL INFORMATIONS

All adjustment are thoroughly checked and corrected when the receiver leaves the

factory. Therefore the receiver should operate normally and produce proper color and

B/W pictures upon installation. However, several minor adjustments may be required

depending on the particular location in which the receiver is operated.

This receiver is shipped completely in carton. Carefully draw out the receiver from

the carton and remove all packing materials. Power cord into a convenient 220 volts

50 Hz AC two pin power outlet. Turn the receiver ON. Check and adjust all the

customer controls such as BRIGHTNESS, CONTRAST and COLOUR Controls to

obtain natural color or B/W picture.

AUTOMATIC DEGAUSSING

A degaussing coil is mounted around the picture tube so that external degaussing after

moving the receiver is normally unnecessary, providing the receiver is properly

degaussed upon installation. The degaussing coil operates for about 1 second after the

power to the receiver is switched ON. If the set is moved or faced in a different

direction, the power switch must be switched off at least 30 minutes in order that the

automatic degaussing circuit operates properly. Should the chassis or parts of the

cabinet become magnetized to cause poor color purity, use an external-degaussing

coil. Slowly move the degaussing coil around the faceplate of the picture tube, the

side and front of the receiver and slowly withdraw the coil to a distance of about 2m

before disconnecting it from AC source. If color shading still persists, perform the

COLOUR PURITY ADJUSTMENT and CONVERGENCE ADJUSTMENTS

procedures.

Model No: 21WHP3-Bn

Version 1.0

Page 10

10

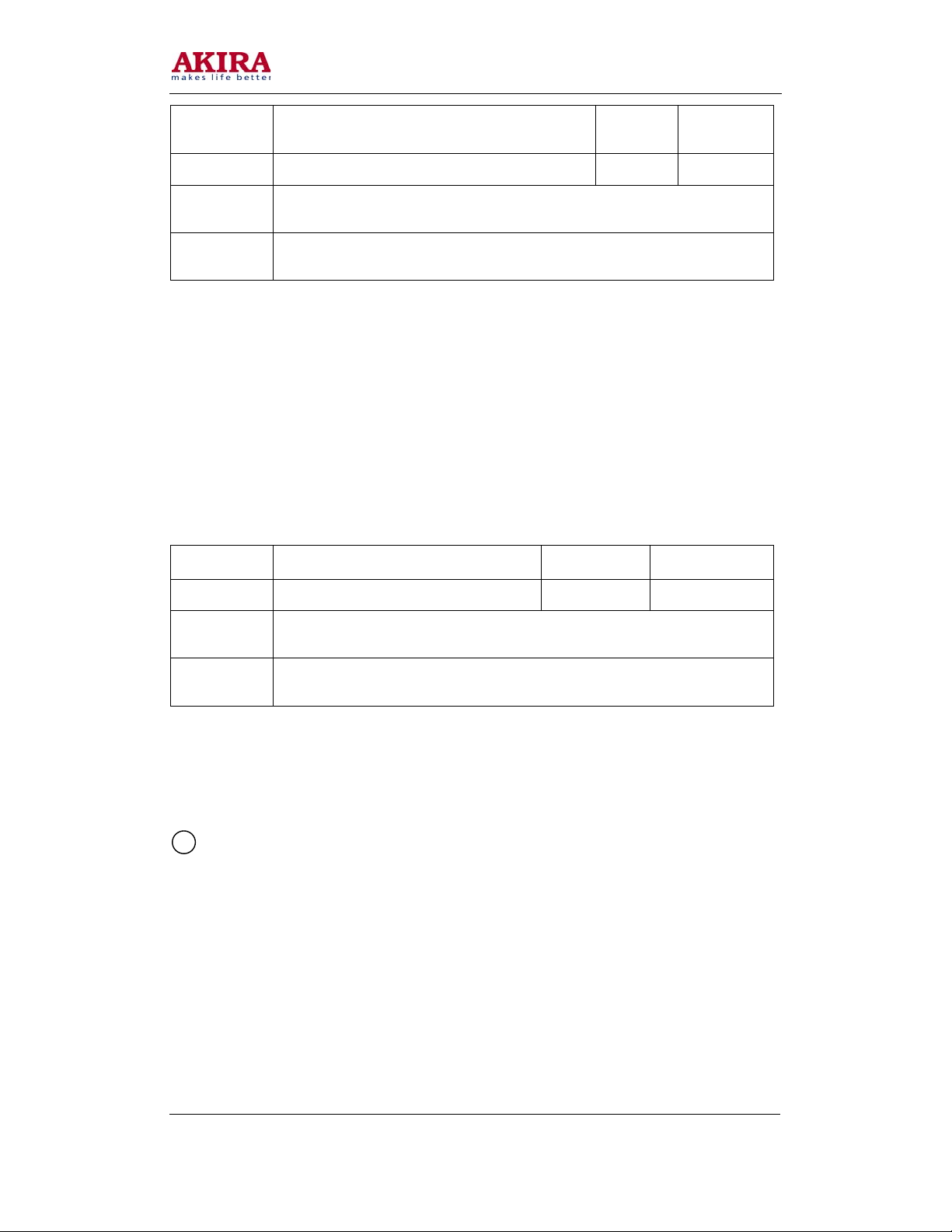

ADJUSTMENT MODE

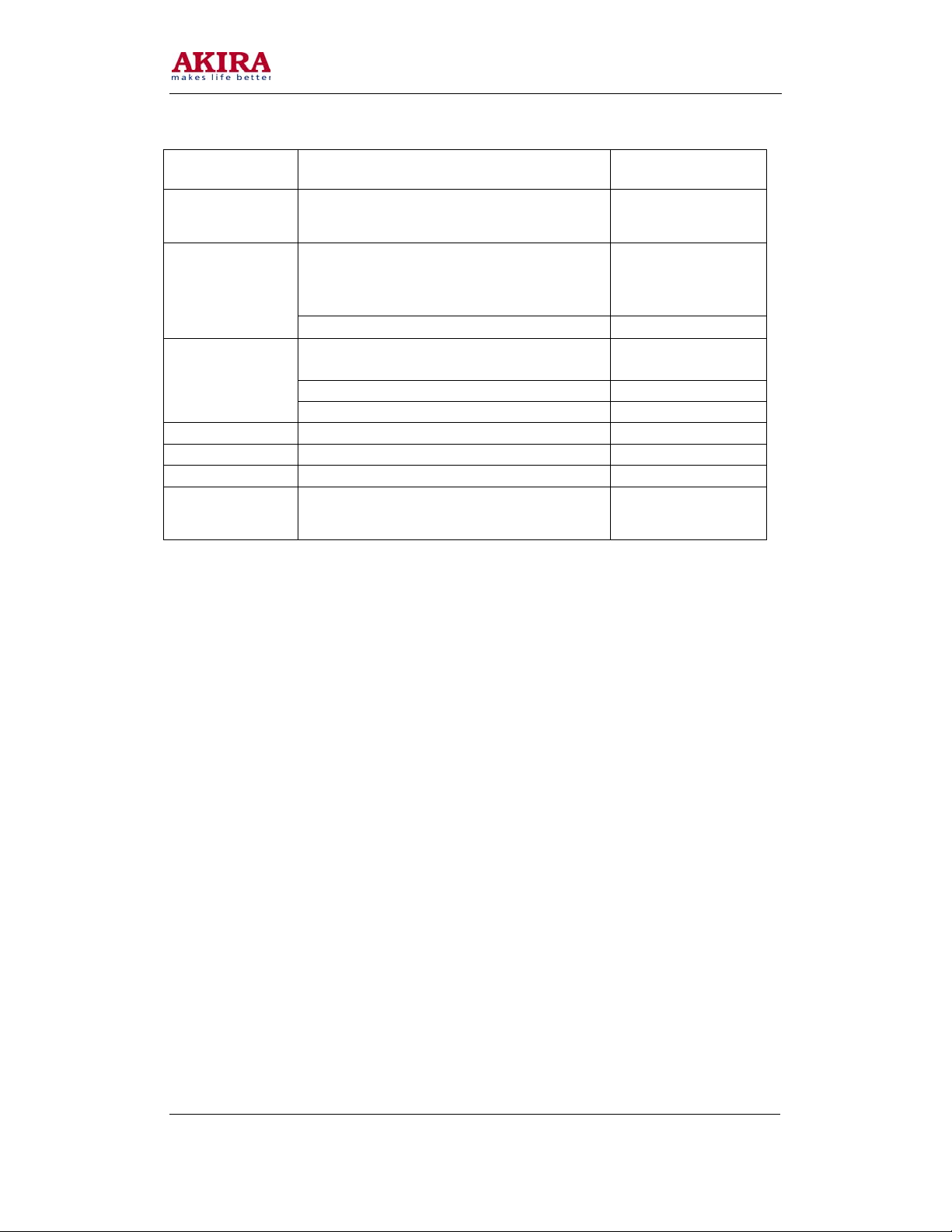

Item B+ adjustment, TV signal receiving

AKPH01 chassis

Measuring

Equipment

Preparation

Before Adj.

TV SG (Signal Generator)

Digital multi-meter

The set is turned on

Connect the TV SG to RF input terminal of the set.

Adjustment procedure

1, Turn VR501 potentiometer to adjust B+ to specified voltage.

2, Check voltages for video out, vertical out, circuit work and audio

power out as follow

+B 110 110

Video Out 188 188

Vertical Out 26 26

Voltage (volt)

14 inch 21 inch

Tolerance

±2V

±5V

±1V

Circuit Work 13 13

Audio Power Out 12 12

3, TV signal receiving

1. Press MENU key, to select POS.MEMORY item.

Press V+ or V- key, to select SEARCH or AUTOMEMORY

item, press P+ key to start searching.

2. Press P+ or P- key to inspect the set if there is channel skipped,

if so, searching again by SEARCH as above described.

Model No: 21WHP3-Bn

Version 1.0

±1V

±1V

Page 11

11

Item

AKPH01 chassis

Measuring

Equipment

Preparation

before Adj.

Inspection procedure

1, Input the TV signal which system is designated in technical specification

2, Switch TV system to the set by pressing SYS key on user remote controller

according to the TV system in SG. The picture and sound must be normal.

3, Press TV/AV key, to select AV input. The picture and sound must be normal

4, AV output inspection. Load a 75Ω resistor to VIDEO output terminal,1Vp-p

video output signal that is from TV signal should be observed on the

oscilloscope. Load a 10K resistor to AUDIO output terminal, 0.7Vp-p audio

output signal that is from TV should be observed on the oscilloscope.

TV system adapting & AV in/output

inspection

SG (with NTSC3.58). User remote controller

Dual trace oscilloscope

Input TV and AV signal

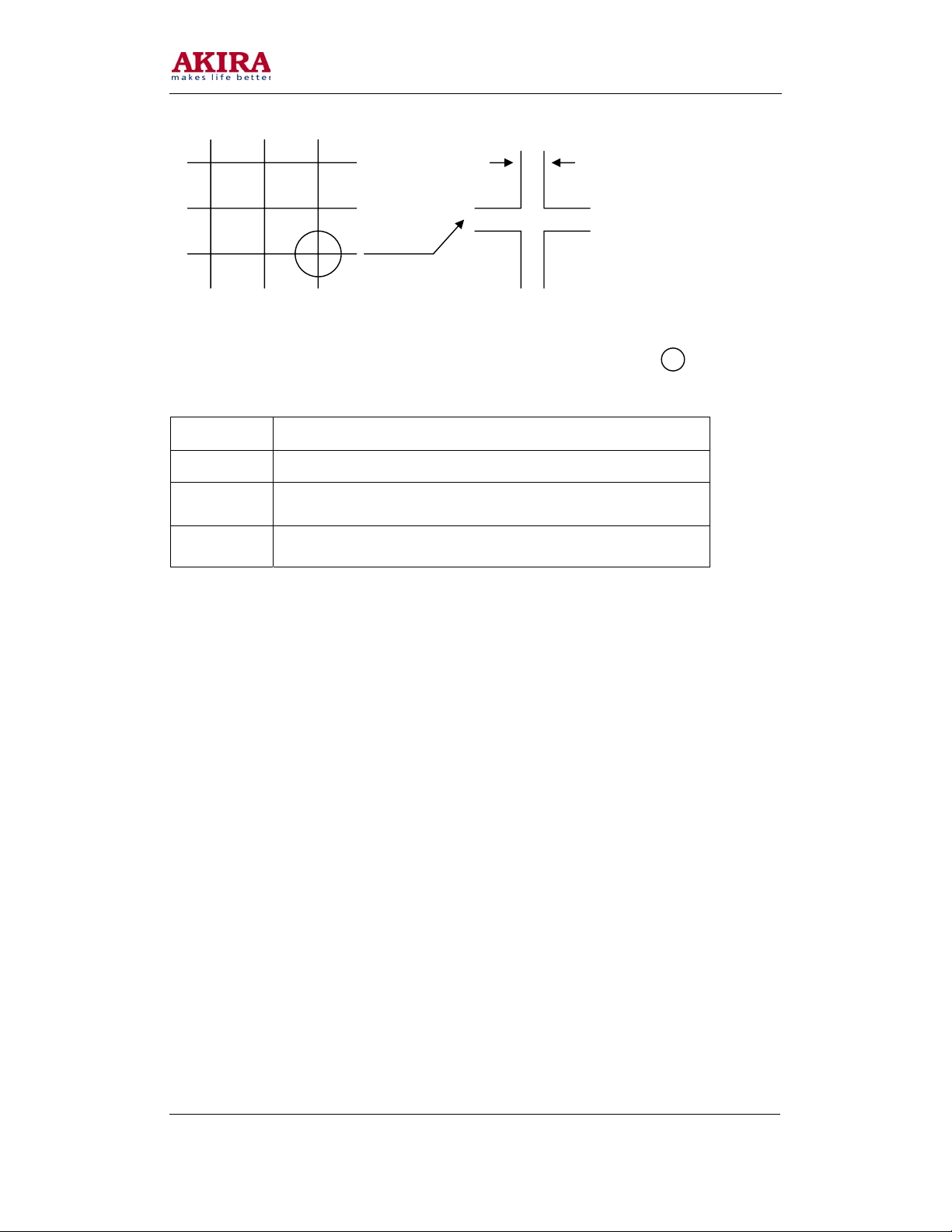

Item Focus adjustment

AKPH01 chassis

Measuring

Equipment

Preparation

before Adj.

SG

Brightness, contrast and color should be set in standard

Adjustment procedure

1, Receive the cross-hatch pattern signal

2, Turn the focus adjusting VR watching the screen and adjust the vertical line of

mark to make the most thin. Then the focus adj. VR is set as close low voltage

side as possible.

Stop the focus adj. VR at the point that focus is a bit worse at once, turn back to the

left and then turn back to the right a little again.

Model No: 21WHP3-Bn

Version 1.0

Page 12

12

Magnified drawing of part

Item White balance adjustment

AKPH01 chassis

To be fine

H. line

V. line

Measuring

Equipment

Preparation

before Adj.

MENU9 CRT cut-off and white balance and sub-brightness adjustment.

Receive gray and white 2 steps signal.

CRT cut off adjustment.

a)

1. push [P+][P-] key to select “SC”, push [V+][V-] key then automatically vertical

scan will be stopped.

2. adjust SCREEN control on Flyback transformer to get the darkest single

horizontal line (red,

purple or more white

3. push [V+][V-] key again, vertical scan work repeat.

white balance adjustment.

b)

a) select RD/BD menu.

b) adjustment RD/BD to get color temperature as x=282, y=292.

sub-brightness adjustment (use stair case signal)

c)

1.

adjust SB to get the darkest step being out off.

Model No: 21WHP3-Bn

Version 1.0

SG and white balance meter

service remote controller

Warm up the set for more than 30 min.

Brightness, contrast and color should be set in standard

green, or blue, sometimes shows more yellow, more

).

select SB MENU.

Page 13

13

Item RF. AGC adjustment

AKPH01 chassis

Measuring

Equipment

Preparation

before Adj.

Adjustment procedure

1, Receive the color bar signal that is 87.5% modulation and 60dBu level

2, Press AGC-TOP on service remote controller to select AGC-TOP adjustment,

press + or – key to adjust the voltage of AGC-TOP to 6.2±0.05V that is read on

the digital multi meter.

Item

AKPH01 chassis

Measuring

Equipment

Preparation

before Adj.

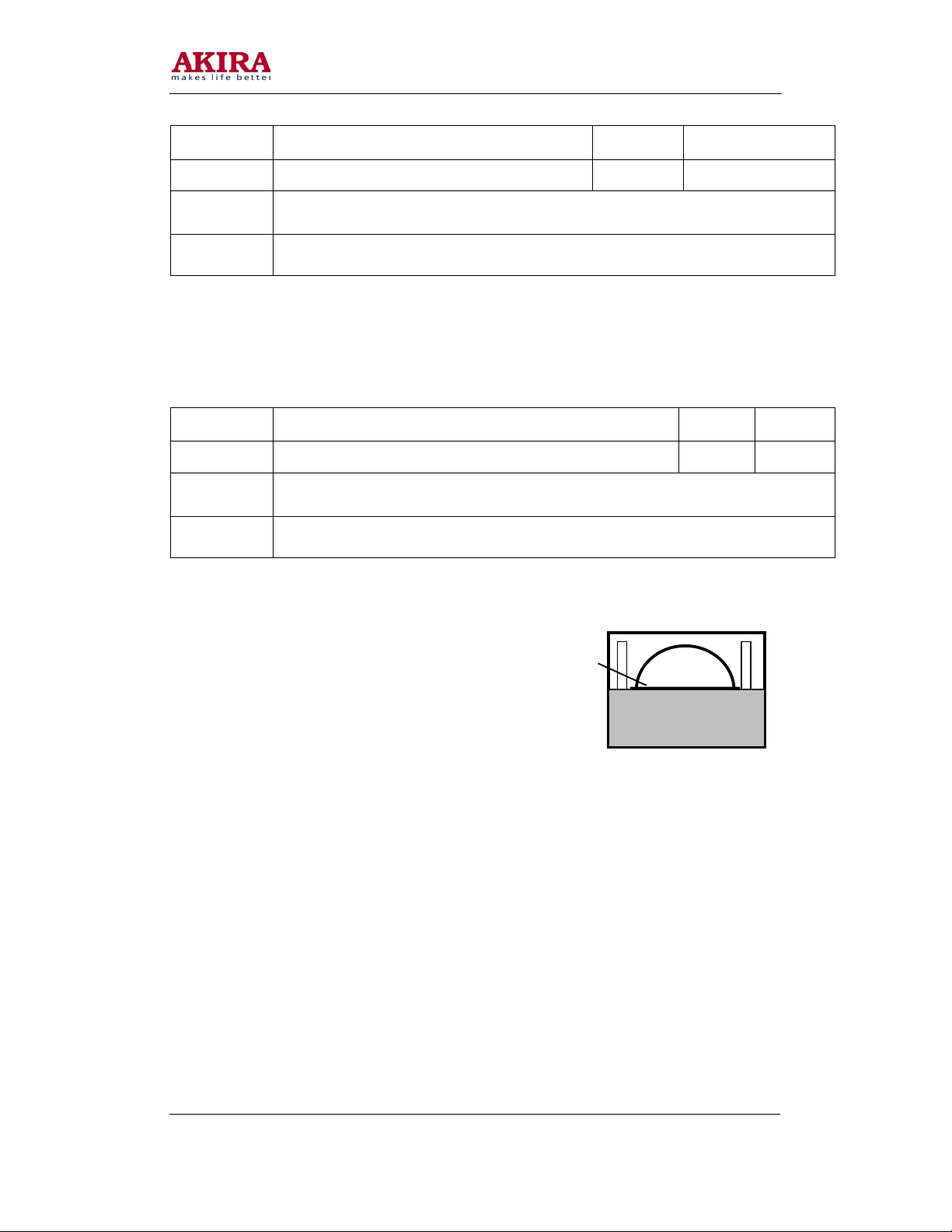

MENU8 Geometrical adjustment

Receive standard Crosshatch pattern

signal for PAL system .

Adjust VSLOPE value, to the horizontal

a)

line just appear from

half bottom shadow.

Adjust VSHIFT value, the center

b)

horizontal line correspond to

CRT vertical center.

Adjust Vamp value, to get 90% of vertical picture contents would be displayed

c)

on CRT.

Adjust HSHIFT value, to get the picture horizontal center correspond to CRT

d)

horizontal center.

Receive standard Crosshatch pattern signal for NTSC system, and again adjust.

e)

SG and digital multi meter

service remote controller

Connect a digital multi meter to AGC point on the chassis

Vertical height, linearity and Hor. position adjustment

SG

service remote controllers

Brightness, contrast and color should be set in standard

.

Horizontal line

Shadow

Model No: 21WHP3-Bn

Version 1.0

Page 14

14

Item OSD position adjustment

AKPH01 chassis

Measuring

Equipment

Preparation

before Adj.

Adjustment procedure

1, Press 5 key on service remote controller to set the set into design mode adjustment

2, Press ↑ or ↓ key to select OSD VPOS item, press → or ← key to adjust the OSD to

the center position on the screen or press OSD HPOS on service remote controller

and press + or – key to adjust the OSD position.

3, Press M key again to quit design mode adjustment.

service remote controller

Brightness, contrast and color should be set in standard

Item The functions of the set inspection

AKPH01 chassis

Measuring

Equipment

Preparation

Before Adj.

Inspection procedure

1, Receive the Philips pattern signal

2, Press PIC key on user remote controller to call the menu as adjusting picture

quality. Adjust color, brightness, contrast, sharpness and tint (in NTSC)

respectively and all adjustment should be right

3, Press V+ key to increase the sound volume, no distortion heard at maximum

level, press V- key to decrease the sound volume, no sound heard at

minimum level

4, Press POWER key to switch the set into standby status, at mean time the

manufactory adjustment mode is cancelled

5, Press POWER key again, the set should work in normal receiving mode

6, Press (mute), QV (display), PP and TIMER key respectively,

the relevant function should be normal

SG

User remote controller

The set is turned on

Model No: 21WHP3-Bn

Version 1.0

Page 15

15

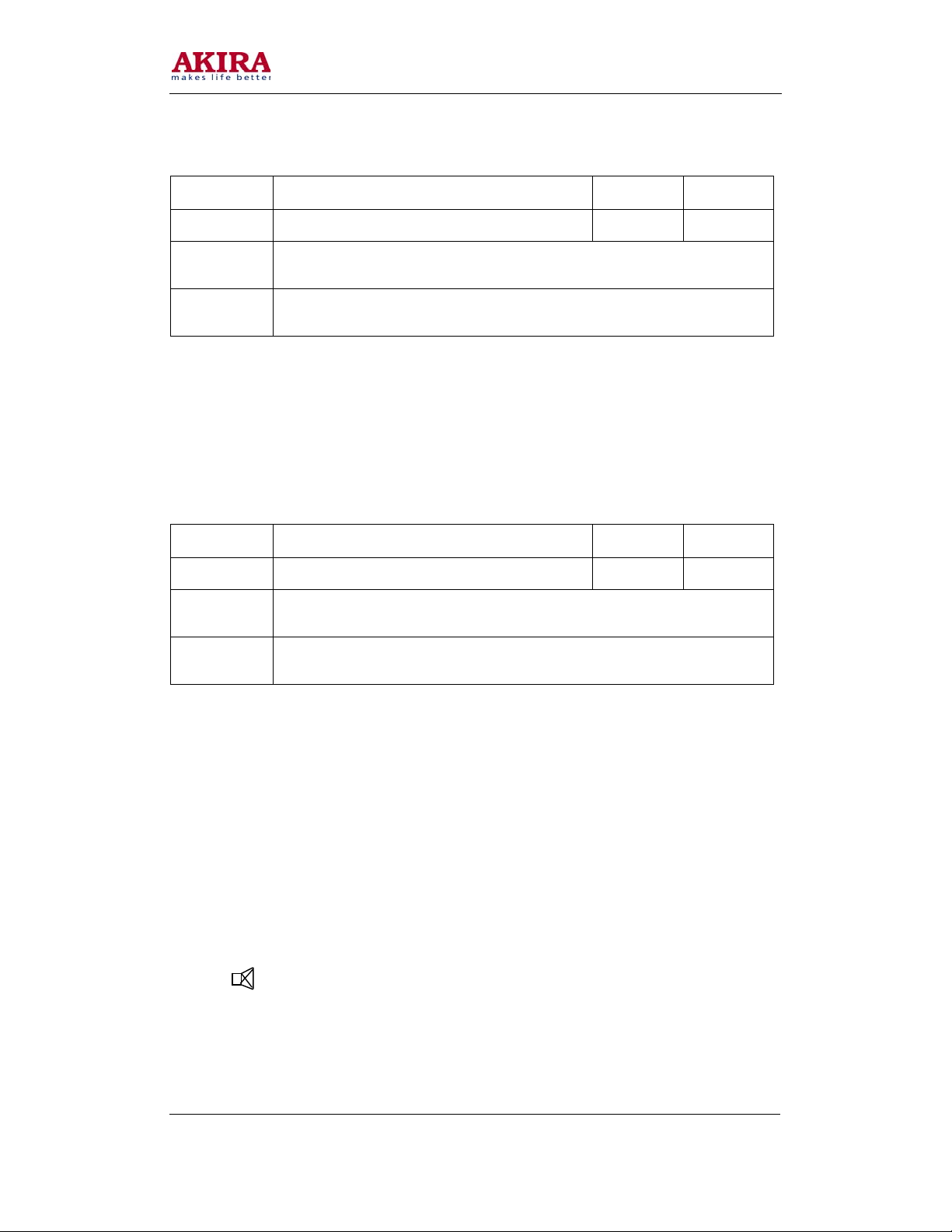

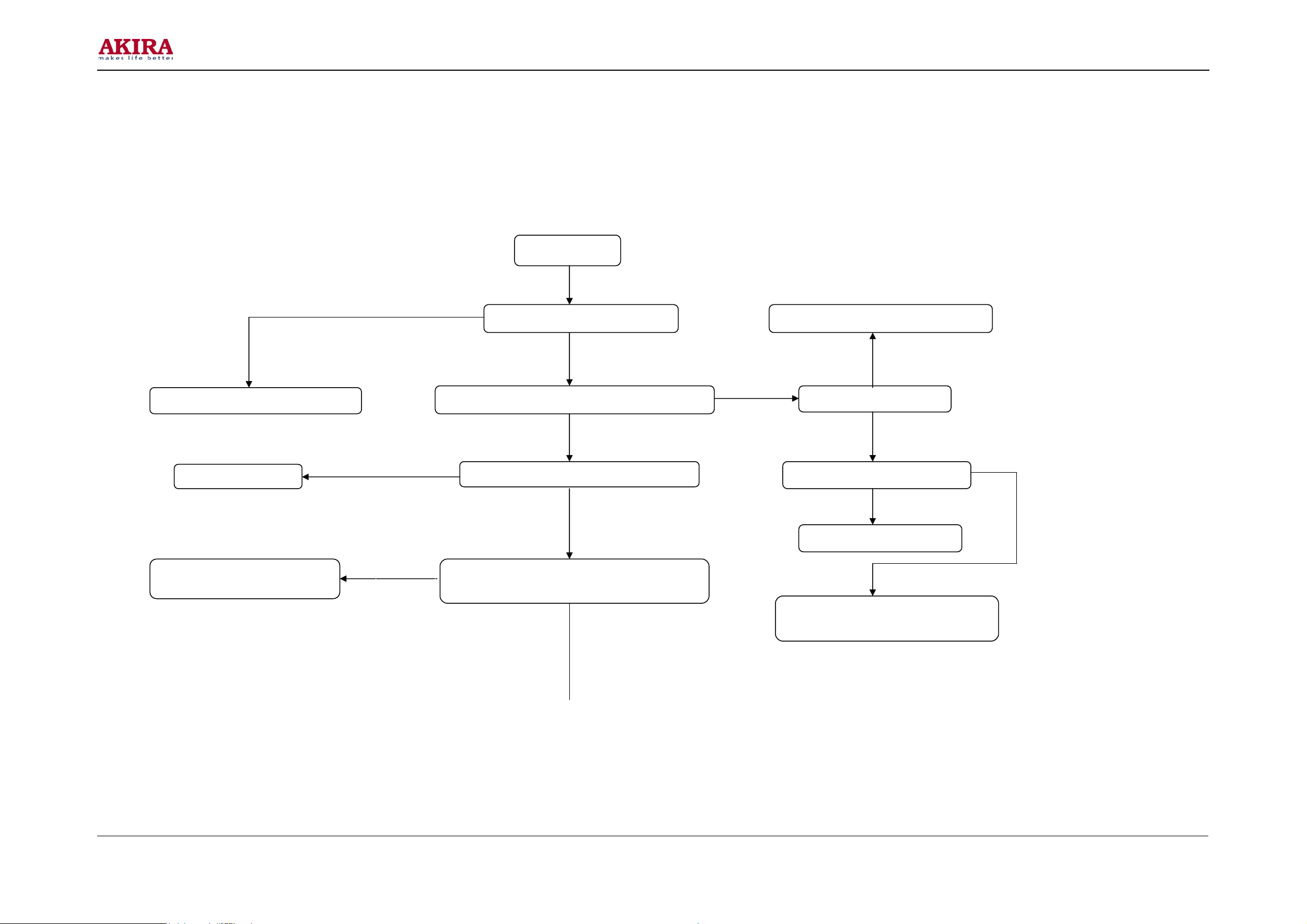

CHASSIS BLOCK DIAGRAM

Video-out

Audio-out L

Audio-out R

Video-in1

Audio-in1L

Audio-in1R

Y

Cr

Cb

S-video

HF TUNER

A101

BAND1

BAND2

KEY BOARD

AC150-260V

50/60Hz

V-in2 A-in2LA-in2R

14

15

N801CD4052

11

11

15

IF PRE-AMP

V308

REMOTE

RECEIVER

U701

AV SWITH

14

AV SWITH

N161CD4052

12

13

9

10

2 3 4 5

13

10

1

SAWF

Z301

MEMORY

N702

ST24C08

Resistance

disturbance

C501L502

rectification

VD503-VD506

TV AUDIO OUT

9

Bridge

SIF TRAPS

Z351,Z352,Z354

V352

6

AUDIO AMPLIFIER

12

10

SP161

8Ω5W

R

(N101) AN7522N

SP162

L

8Ω5W

63

62

44

47

46

48

43

V351

42

38 7

PHILIPS UOC

TDA9351/61/81

40

53

52

51

21

8

9

VIDEO

AMPLIFIER

V912V913

V922V923

V932V933

FIELD OUTPUT

4

2

CRT

POWER AMP

23

24

11

10

6

64

2

3

SCL

6

SDA

5

22

33

N401LA78040

HORIZONTAL

DRIVE

V450

T450

HORIZONTAL

OUTPUT

V451

HEAT

FOCUS

EHT

SCREEN

FBT(T402)

BSC25

-15V

Filter C507

+300V

POWER SUPPLY

CIRCUIT

V1512V553V1511T

501N504

16V

13V

15V

24V

110V

200V

+15V

Model No: 21WHP3-Bn

Version 1.0

Page 16

16

N

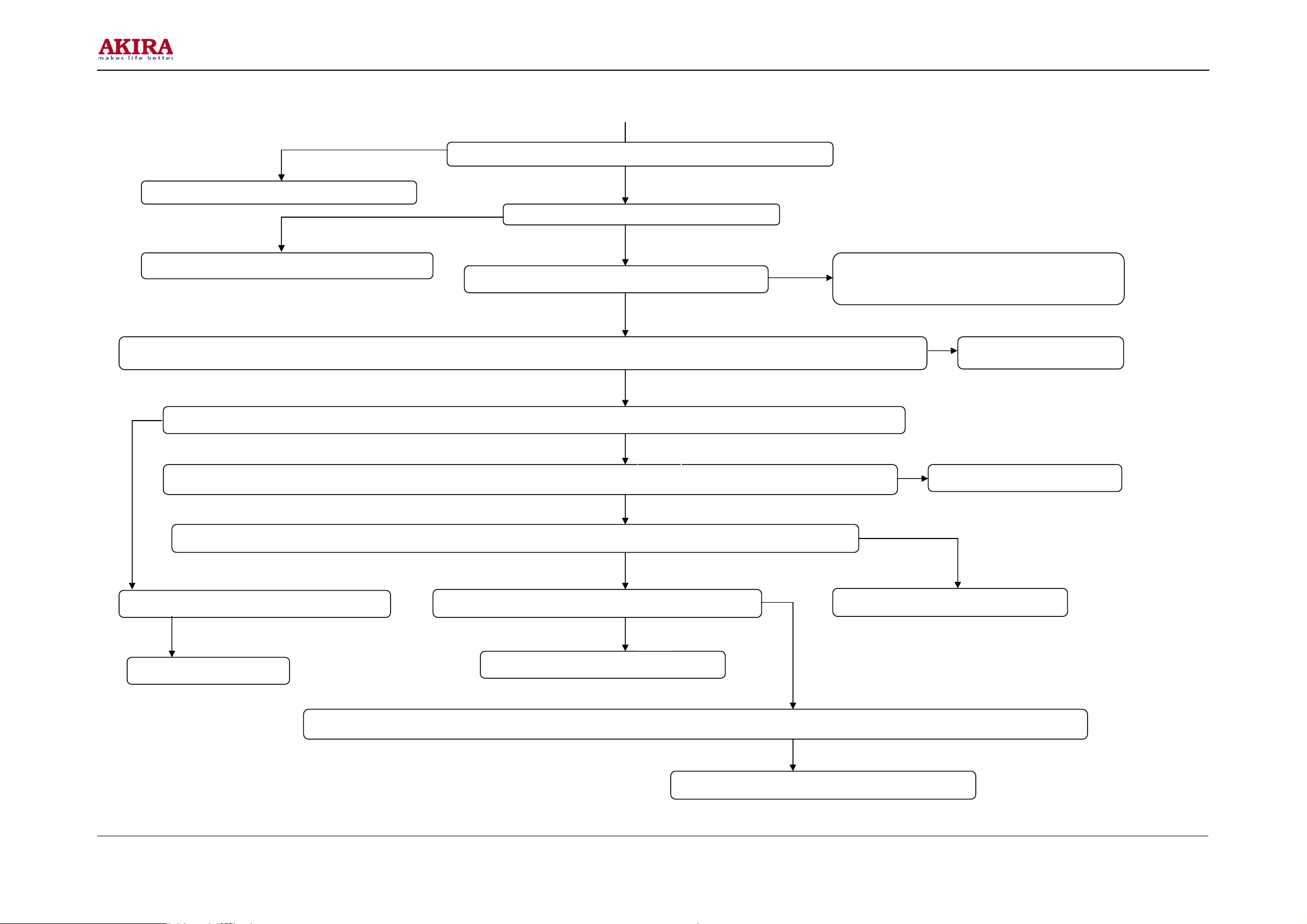

FAULT FINDING TREES

A Three-None(no raster, no picture, no sound)

This failure is mainly caused by big-power circuit such as power supply, horizontal scanning, vertical scanning.

The detail checking and repairing steps are as follow.

Voltage of C507

NO

Check if V1513 collect-emitter

Was broken down

0V

Check XR502,F501,power

Swich, AC cord and plug

YES

Check V1513,V1512,F501,XR502,VD503

300V

Test voltage of V1513 base

0.6V

Check T501,VD1517,

C1515,C1517,V451,

Check if it get right

When cut off V504

VD522-VD529

C455,C456,T451

C467

Test the voltage of

N301 pin1

CPU has sent the

Power-off signal

Check the voltage

of V1513 collector

0V

YES

4.5-5.5V

300V

1V

0V

0V

Check T501

Check V1513

0V

Check if V504

is broken down

Test the voltage of C528B

50V

Cut off R458

NO

V

V

e

r

e

r

e

r

,

,

,

variation

v

o

l

v

o

l

v

o

2

4

V

2

4

V

2

4

V

t

a

g

e

t

a

g

e

l

t

a

g

e

,

a

n

d

,

a

n

,

a

n

T

T

T

e

s

t

o

t

h

e

s

t

o

t

h

e

s

t

o

t

h

1

8

8

V

1

8

8

1

8

a

a

8

s

s

a

s

LOW

VD525,VD1561,VR501,V542,

VD1517,V504,V1511

Check VD522,C528B

115V

Recover R458, unplug

XS403 for a While,then

test the voltage of C528B

No variation

Check V451,T451,T450,

Deflection coil

Check L452,VD436,C461

Deflection coil

s

d

115V

s

u

s

u

d

Normal

c

h

c

h

u

c

h

1

2

V

1

2

V

1

2

V

Check V451 pin C voltage

Check T451,V451,R458

130V

115V

N301 pin39voltage

8V

N301 pin33 voltage

2V

V450 pin C voltage

24V

Check R452,V450

Others

115V

Check R539,V1553,VD1561

504,V1511,V1512,R556

Others

Check N301,N401

0V

Check VD543,C525,

]R454,C453,T450,

C455,V451

0V

Check T451

Model No: 21WHP3-Bn

Version 1.0

Page 17

17

B Two-None (no picture, no sound)

The failure shows that the set does not display the picture but it has noise wave or blue background or OSD on the screen. This means that the circuits of power supply, horizontal scanning, vertical scanning

and video amplification are normal and they are not considered in the repairing. The failures are mainly in the small signal processing circuits.

Before checking these circuits, a kind of practical test method is introduced. It is called “Signal-input way ”. The detail is described as follow: We can use the resistance function of an analog multimeter,

connect the red pole (negative in ohm scope) on the circuit board ground, then touch softly the test point with another pole (black pole) in ohm scope meanwhile observe the reactivity on the output device.

Note : In the TV test, we mainly observe the noise wave on the CRT and listen to the noise voice liking as “Ka…..Ka” from the loudspeakers.

1. No picture

Check RF signal input and adaptor

Check N703, A101

Check R301,R302,

N301,A101

NO

Check if A101 has input signal

Check the “ VT ” voltage when auto searching

0V

Check the “ +5V ” voltage on A101

0V

The voltage between VL and BH vary from 0V to

5V or not when auto searching

No picture

YES

YES

Out of the “ 0-33V ” range

In the “ 0-33V ” range

5V

Check R703,N703,C703A

33V

The voltage on the C703

33V

No variation

Check the voltage on the C705

0-33V

Check R707, C707, A101

Check ,V701,N301, R701, R701A

,R704,R705,C701,C705,C706

Model No: 21WHP3-Bn

Version 1.0

Page 18

18

Check R317, R318, R316,C307,A101,N301

Check,L331, C333, L752,C753A, L751, C751

Observe if there is snow-noise-wave disturbance on the CRT via using “Signal-input way ” by touching pin 23 and pin 24 of N301

YES

Observe if there is snow-noise-wave disturbance on the CRT via using “ Signal-input way ” by touching pin 38 of N301

Observe if there is snow-noise-wave disturbance on the CRT via using “Signal-input way ”by touching pin 17 of N301

Observe if snow-noise-wave disturbance on the CRT via using “ signal-input way ”by touching pin 40 of N301

Check if voltage on pin 31 of N301 is 1.7V

≥2V

Check C323,A101,N301

2V

Exam the voltage of “ AGC ” on A101 without antenna

3.8V

0V

Test the voltage on pin 14, 54, 56of N301

8V

Test the voltage on pin 51, 52, 53, 50 of N301

5V

NO

NO

NO

NO

Test if there is the sync signal on the pin 39 of N301

NO

Check C361,C362,L361,N301

Observe if these is snow-noise-wave disturbance on the CRT via using “ Signal-input way ” by touching pin 51,52,53 of N301

Check R381,R382,R383,V912,V922,V932,N301

0V

YES

Check N503, N301,C532, R565,C524,

,VD561,V542

YES

Check N505, N301

YES

Check R331,C336,C337

YES

Check V351,V352,L351,Z351,C364

NO

Model No: 21WHP3-Bn

Version 1.0

Page 19

19

5. No sound

In this kind of failure, first of all we should observe if there is the picture on the CRT. It proves the small signal circuit to work correctly with the picture on the CRT and we only check the sound signal

processing and sound amplification circuit. The repairing method(B1) may be referred without picture. The detail checking and repairing steps are as follow.

Note:

Before repairing, assure that the volume is on and the state of set is in “TV” .

Check R733, C732, N301

Check R157,C157,N161

Check R153,C153,R154,C154,N121

Check C157,C153, N101

Model No: 21WHP3-Bn

Version 1.0

YES

YES

Hear if there is the voice liking “Ka…Ka ” in the loudspeaker via using “ Signal-input way ” by touching pin 7 of N301

NO

YES

Hear if there is the voice liking “Ka…Ka ” in the loudspeaker via using “ Signal-input way ” by touching pin 44 of N301

NO

YES

YES

Hear if there is the voice liking “Ka…Ka ” in the loudspeaker via using “ Signal-input way ” by touching pin 3 of N121

NO

Hear if there is the voice liking “Ka…Ka ” in the loudspeaker via using “ Signal-input way ” by touching pin 13 of N121

NO

Hear if there is the voice liking “Ka…Ka ” in the loudspeaker via using “ Signal-input way ” by touching pin 6,8of N161

NO

5V

The voltage on pin 1 of N701

Check VD521,R165,C522,T501,N161

Hear if there is the voice liking “Ka…Ka ” in the loudspeaker via using “ Signal-input way ” by touching pin 2,10 of N701

Check SP161, SP162, N161

12.5V

NO

Check C367,R369,V395,N301

Check 8V-power supply

YES

8V

The voltage on pin 16 of N121

8V

The voltage on pin 9,10of N121

8V

Check R126,N505, N121

Page 20

20

C Only horizontal line in the middle of the screen:

If vertical deflection circuit does not work, this kind of failure will happen. In deflection yoke, there only has horizontal sweeping , the electron beam in the CRT only moves in the horizontal orientation

, so form this failure. (While checking horizontal and vertical deflection circuit’ s failure , we have better to use an oscilloscope).

Model No: 21WHP3-Bn

Version 1.0

Check C401,C402,R401,R402,N301

Check R405, C408, N401, N301

Abnormal

Abnormal

The waveform on the pin 21,22 of N301

Normal

The voltage on pin 2 of N401

24V

Measuring the waveform on pin 1 of N401

Normal

Measuring the waveform on pin 5 of N401

Normal

Measuring the waveform on the deflection yoke

Abnormal

Check R407,C408,R406,XS403, deflection yoke

0V

Check VD470, R470,VD401,N401

The deflection yoke on the CRT

Abnormal

Check N402

Page 21

21

D Only vertical line in the middle of the screen

This is a dangerous failure. It probable causes flashover and smoking inside the set. Don’ t let your TV work for a long time as this failure appears. Because the electron beam can not move in the horizontal

orientation, the failure should be in the horizontal deflection circuit. We mainly check the open-circuit fault in horizontal deflection circuit.

The detail checking and repairing steps are as follow:

Check if there is bad solder between XS403, and the main board

Check L452, VD436, C467,C455,especial in inductive components and connector

YES

The horizontal yoke is opened or not

Whether “ XS403” is opened

Vertical line

YES

Repair CRT

NO

NO

Model No: 21WHP3-Bn

Version 1.0

Page 22

22

E UOC does not work

In television, remote-control system is similar with the computer system. In theory , it can work if it holds two conditions as follow:

1. The power supply: In general, it is 5V, the error is not above 10% and the disturbance pulse is as small as possible.

2. The clock pulse: In TDA93XX circuit, the clock pulse is generated by pin58 / pin59 of N301 and 12M crystal oscillator.

Television’ s remote-control system also needs reset circuit that can preset the values in internal register. The circuit around pin57

of N204 is called auto-reset circuit. If UOC detects errors in resetting, it will come to the state of program protected.

The detail checking and repairing steps are as follow:

NO

Observe if there is sine wave on the pin 58 or pin 59

of N301 with an oscilloscope

3.3V

The voltage on the pin 56 of N301

N301 does not work

3.3V

Check the voltage on the positive pole of C548

=3.3V

Check X761, N301

Check N301

3.3V

Check the voltage on the pin 54 of N301

Check L752,L753

YES

3.3V

Check the voltage on the emitter of VD564

3.3V

3.3V

Check VD522, T501

Check alternant voltage on secondary coil of N505,

YES

Check T501, VD522,R565

Check the voltage on the positive pole of VD522

3V

=14V

F No OSD (On Screen Display)

This failure is usually cause by the circuit of character generated and located. Most of reasons are that the horizontal and vertical flyback pulse signals do not come to UOC.

We can judge this failure by measuring the wave of the character in an oscilloscope.

The detail checking and repairing steps are as follow:

Model No: 21WHP3-Bn

Version 1.0

Check the wave on the pin 7 of FBT

NO

Check FBT T451

No OSD

YES

Check C482, R485, VD483, R487, N301

NO

Check R561,VD564

Check R565,R546,N505

Page 23

23

IC BLOCK DIAGRAM

Fig 1: UOC-TDA9381 Illustration

Model No: 21WHP3-Bn

Version 1.0

Page 24

24

MAIN CHIP INSTRUCTION

Pin 1 Standby control, “1” is on, “0” is off.

Pin 2 SCL

Pin 3 SDA

Pin 4 Tuning PWM output

Pin 5 Auto AV control SW, connected with the SCART 8th pin. Input. The rising edge

or the falling edge operates.

Pin 6 Key board input.

Pin 7 Volume

Pin 8 Mute control, “1” is mute, “0” is off.

Pin 9, Pin 12,

Pin 18, Pin 30,

Pin 35, Pin 41,

Pin 55

Pin 10 BAND 1 control output.

Pin 11 BAND 2

Pin 13 SECAM PLL, connected with a capacitance (no use in this type).

Pin 14 +8V power source supply

Pin 15 Using a capacitor of 220n in series to GND. This pin decouples the internal

Pin 16 Phase-2 control loop, this pin requires a capacitor at 2.2nF © in series to GND.

Pin 17 Phase-1 control loop filter connected to pin 17 is suitable for various signal

Pin 18 GND

Pin 19 Bandgap decoupling, the bandgap circuit provides a very stable and temperature

Pin 20 East-west pillow signal output.

Pin 21, Pin 22 Vertical drive output.

Pin 23, Pin 24 IF input.

Pin 25 Reference current/ This pin requires a resistor to ground. The optimal reference

Pin 26 Vertical sawtooth. This pin requires a capacitor to ground of 100nF.

Pin 27 AGC output. This output is used to control (reduce) the tuner gain for strong RF

Pin 28 Audio de-emphasis.

Pin 29 Sound decoupling. This pin requires a capacitor connected to ground. The pin

Pin 30 GND

Pin 31 Sound loop filter.

Pin 32 AVL filter

Pin 33 Horizontal drive signal output, needs a resistor in series to +8V.

Pin 34 Sandcastle output /flyback input.

Pin 35 External audio input, this pin should be grounded in this chassis.

Model No: 21WHP3-Bn

Version 1.0

GND

digital supply voltage of the video process and minimizes the disturbance to the

sensitive analogue parts.

conditions like strong /weak and VCR signal. This is achieved by switching of

the loop filter time constant by changing the Phase-1 output current.

independent reference voltage. This reference voltage (4.0V) ensures optimal

performance of the analogue video processor part of the OM8370 and is used in

almost all functional circuit blocks.

current is 100mA which is determined by this resistor. The 100mA reference

current should not be changed because the geometry processor is optimized for

this current. Furthermore the output current of vertical drive and EW are

proportional to this current.

signals.

acts as a low pass filter needed for the DC feedback loop.

Page 25

25

Pin 36 EHT tracking /over voltage protection. If something is wrong, the anode high

voltage rise the heater voltage will rise too. When the rising voltage arrive some

limit, the V406 works, the voltage of pin 36 will exceed 3.9V. The OM8370 will

stop working.

Pin 37 PLL loop filter.

Pin 38 CVBS output. Monitor or RF videos can be selected.

Pin 39 +8V supply source

Pin 40 CVBS input

Pin 42 Y signal input

Pin 43 C signal input

Pin 44 Main audio output. This pin is connected to the TDA9859.

Pin 45 RGB signal input blanking.

Pin 46, Pin 47,

Pin 48

Pin 49 ABL. It means been current limiter input. R410 is the control resistor.

Pin 50 Black current input from the CRT board.

Pin 51, Pin 52,

Pin 53

Pin 54 +3.3V

Pin 55 GND

Pin 56 +3.3V

Pin 57, Pin 58,

Pin 59

Pin 60 Reset. NC in this chassis

Pin 61 +3.3V

Pin 62 NC

Pin 63 This pin is connected to the HEF4094. Functions expending.

Pin 64 IR signal input.

Model No: 21WHP3-Bn

Version 1.0

RGB signal input.

RGB drive signal output to the CRT board.

12MHz crystal

Page 26

26

Fig 2: HEF4052BP Illustration

Model No: 21WHP3-Bn

Version 1.0

Page 27

27

FUNCTION TABLE OF N4052

Input

Ē

L L L Y0A – ZA; Y0B – ZB

L L H Y1A – ZA; Y1B – ZB

L H L Y2A – ZA; Y

L H H Y3A – ZA; Y3B – ZB

H X X NONE

Notes:

H = HIGH state (the more positive voltage)

L = LOW state (the less positive voltage)

X = state is immaterial

A

1

A0

Channel On

2B

– ZB

Model No: 21WHP3-Bn

Version 1.0

Page 28

28

IC N402 <VERTICAL OUTPUT> LA78040 (or STV9302)

Model No: 21WHP3-Bn

Version 1.0

Page 29

29

Model No: 21WHP3-Bn

Version 1.0

Page 30

30

Model No: 21WHP3-Bn

Version 1.0

Page 31

31

Model No: 21WHP3-Bn

Version 1.0

Page 32

32

Model No: 21WHP3-Bn

Version 1.0

Page 33

33

Model No: 21WHP3-Bn

Version 1.0

Page 34

34

Model No: 21WHP3-Bn

Version 1.0

Page 35

35

Model No: 21WHP3-Bn

Version 1.0

Page 36

36

Model No: 21WHP3-Bn

Version 1.0

Page 37

37

Model No: 21WHP3-Bn

Version 1.0

Page 38

38

Model No: 21WHP3-Bn

Version 1.0

Page 39

39

Model No: 21WHP3-Bn

Version 1.0

Page 40

40

1 Inverting input

2 Vcc

3 Pump up out

4 GND

5 VER output

6 Output stage Vcc

7 Non inv. Put

Model No: 21WHP3-Bn

Version 1.0

Page 41

41

Fig 4 AN7522N Illustration

Model No: 21WHP3-Bn

Version 1.0

Page 42

42

Model No: 21WHP3-Bn

Version 1.0

Page 43

43

Model No: 21WHP3-Bn

Version 1.0

Page 44

44

Fig 5: KA5Q0765RT Illustration

Model No: 21WHP3-Bn

Version 1.0

Page 45

45

FACTORY MENU

Main power +B setting

Receive standard color pattern RF signal. Set picture to “Standard Mode”. Adjust VR501, to get +B

(VD542 -) voltage =110V.

I2C bus control adjustment method

How to enter and exit factory mode (with customer’s remote controller)

6. Press [menu] key → display picture menu

7. Press digital key “8” “5” “0” “0” → display “M”

8. Push [standby] key two time to exit factory mode and return to normal.

How to select menus in factory mode

In factory mode (“M” mode) there are ten menus totally. From Menu 0 to Menu 9 can be

selected directly.

For example, to select Menu 7, you should press the numeric key 7.

The BUS DATA for TDA9381

MI Items Variable Preset

M0 AVL ON/OFF ON

FSL ON/OFF ON

FMWS ON/OFF OFF

FFI ON/OFF OFF

OSO ON/OFF ON

FCO ON/OFF OFF

WOOFER ON/OFF OFF

DUAL OUT 0~1 0

Volume mode 0~1 1

M1 BAND 0~2 2

AV CFG* 0~8 3

NTSC MX USA

VIDEO OUT CVBS

PIN5 NTSC

PRO 0~3 0

M2 VISION IF 38.9M

DK ON/OFF OFF

BG ON/OFF ON

I ON/OFF OFF

M ON/OFF OFF

SIF PREFER BG

AUTO SOUND ON/OFF ON

M3 START ON 0~2 0

ENGLISH ON/OFF ON

ARABIC ON/OFF OFF

PERSIAN ON/OFF OFF

TURKISH ON/OFF OFF

FRANCE ON/OFF OFF

RUSSIA ON/OFF OFF

Model No: 21WHP3-Bn

Version 1.0

Page 46

46

MI Items Variable Preset

M4 SUBCON 0~63 63

SUBCOL 0~63 63

SUBSHP 0~63 63

SUBTINT 0~15 15

YDLY PAL 0~15 12

YDLY NTSC 0~15 12

YDLY SEC 0~15 12

YDLY AV 0~15 12

UOC VOL ON/OFF Off

CATHODE 0~15 15

SC BRI 0~63 10

M5 OSD VPOS 0~63 53

OSD HPOS 0~59 15

WIDE 0~63 15

ZOOM 0~63 59

NENU TITLE 0~6 3

E2PROM ADRESS 0~33

E2PROM VALUE 0~95

E2PROM WRITE

M6 SHIPMODE

SEARCH SPEED 0~3 0

M7 AGC-TOP 0~63 25

AGC-SPEED 0~3 2

M8 FREQUENCY 50HZ 60HZ

VSLOPE 0~63 30 30

VSHIFT 0~63 42 42

VAMP 0~63 37 37

VSCOR 0~63 19 19

HSHIFT 0~63 39 39

M9 BT 0~63 48

CT 0~63 48

SC OFF

RB 0~63 32

GB 0~63 32

RD 0~63 32

GD 0~63 32

BD 0~63 32

SB 0~63 40

NOTE:

The data provided in the form provides to consult only!

Model No: 21WHP3-Bn

Version 1.0

Page 47

47

Directions for use

1. M1/AV CFG

Mode Function select

0 TV→AV

1 TV→AV1→AV2

2 TV→AV1→AV2→S-VIDEO

3 TV→AV1→AV2→S-VIDEO→YUV

4 TV→AV→S-VIDEO

5 TV→AV→S-VIDEO→YUV

6 TV→AV→YUV

7 TV-EURO

8 TV-AV-EURO

2. method of LOGO input:

3) when E2PROM ADRESS = 0, to adjust E2PROM VALUE may be changed

horizontal position of LOGO.

It’s range is from 10 to 20.

4) when E2PROM ADRESS =1, to adjust E2PROM VALUE may be changed

vertical position of LOGO.

It’s range is from 1 to 30.

5) when E2PROM ADRESS =2, to adjust E2PROM VALUE may be changed

color of LOGO.

It’s range is from 0 to 7.

VALUE 0 1 2 3 4 5 6 7

COLOR RED BLUE GREEN CYAN ORANGE PINK YELLOW WHITE

6) when E2PROM ADRESS =3, to adjust E2PROM VALUE may be changed

size of LOGO.

It’s range is from 0 to 3.

7) when E2PROM ADRESS =4~33, to adjust E2PROM VALUE may be changed

character of LOGO.

It’s range is from 0 to 95.

Model No: 21WHP3-Bn

Version 1.0

Page 48

48

EXPLODED VIEW WITH PART NAME

Model No: 21WHP3-Bn

Version 1.0

Page 49

49

BOM LIST

Ref. No Part No. Name Specification

R411 RJB393F-NAAF Resistor metal Rj13-1/6W-39KΩ-F

R312 D10B683J-T Carbon resistor RT13-1/6W-10Ω-J

R871 D10B4R7J-T Carbon resistor RT13-1/6W-10Ω-J

R914 D10B4R7J-T Carbon resistor RT13-1/6W-22Ω-J

R924 D10B330J-T Carbon resistor RT13-1/6W-22Ω-J

R934 D10B101J-T Carbon resistor RT13-1/6W-22Ω-J

R398 D10B101J-T Carbon resistor RT13-1/6W-33Ω-J

R806 D10B101J-T Carbon resistor RT13-1/6W-33Ω-J

R368 D10B101J-T Carbon resistor RT13-1/6W-47Ω-J

R708 D10B101J-T Carbon resistor RT13-1/6W-47Ω-J

R911 D10B101J-T Carbon resistor RT13-1/6W-47Ω-J

R921 D10B101J-T Carbon resistor RT13-1/6W-47Ω-J

R931 D10B101J-T Carbon resistor RT13-1/6W-47Ω-J

R354 D10B101J-T Carbon resistor RT13-1/6W-56Ω-J

R355 D10B101J-T Carbon resistor RT13-1/6W-56Ω-J

R304 D10B101J-T Carbon resistor RT13-1/6W-68Ω-J

R801 D10B101J-T Carbon resistor RT13-1/6W-75Ω-J

R313 D10B101J-T Carbon resistor RT13-1/6W-82Ω-J

R301 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R302 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R363 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R365 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R366 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R381 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R382 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R383 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R401 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R402 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R452 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R723 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R724 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R743 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R815 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R824 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R861 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R862 D10B101J-T Carbon resistor RT13-1/6W-100Ω±5%

R815A D10B151J-T Carbon resistor RT13-1/6W-150Ω±5%

R848 D10B151J-T Carbon resistor RT13-1/6W-150Ω±5%

R852 D10B151J-T Carbon resistor RT13-1/6W-150Ω±5%

R353 D10B151J-T Carbon resistor RT13-1/6W-180Ω±5%

R311 D10B151J-T Carbon resistor RT13-1/6W-220Ω±5%

R917 D10B221J-T Carbon resistor RT13-1/6W-220Ω±5%

R927 D10B221J-T Carbon resistor RT13-1/6W-220Ω±5%

R937 D10B221J-T Carbon resistor RT13-1/6W-220Ω±5%

R913 D10B301J-T Carbon resistor RT13-1/6W-300Ω±5%

R923 D10B301J-T Carbon resistor RT13-1/6W-300Ω±5%

R933 D10B301J-T Carbon resistor RT13-1/6W-300Ω±5%

R805 D10B331J-T Carbon resistor RT13-1/6W-330Ω±5%

R916 D10B331J-T Carbon resistor RT13-1/6W-330Ω±5%

R926 D10B331J-T Carbon resistor RT13-1/6W-330Ω±5%

R936 D10B331J-T Carbon resistor RT13-1/6W-330Ω±5%

R322 D10B391J-T Carbon resistor RT13-1/6W-390Ω±5%

R308 D10B471J-T Carbon resistor RT13-1/6W-470Ω±5%

Model No: 21WHP3-Bn

Version 1.0

Page 50

50

Ref. No Part No. Name Specification

R1517 D10B471J-T Carbon resistor RT13-1/6W-470Ω±5%

R316 D10B681J-T Carbon resistor RT13-1/6W-680Ω±5%

R482 D10B681J-T Carbon resistor RT13-1/6W-680Ω±5%

R128 D10B102J-T Carbon resistor RT13-1/6W-1KΩ±5%

R129 D10B102J-T Carbon resistor RT13-1/6W-1KΩ±5%

R369 D10B102J-T Carbon resistor RT13-1/6W-1KΩ±5%

R460 D10B102J-T Carbon resistor RT13-1/6W-1KΩ±5%

R464 D10B102J-T Carbon resistor RT13-1/6W-1KΩ±5%

R481 D10B102J-T Carbon resistor RT13-1/6W-1KΩ±5%

R734 D10B102J-T Carbon resistor RT13-1/6W-1KΩ±5%

R802 D10B102J-T Carbon resistor RT13-1/6W-1KΩ±5%

R803 D10B102J-T Carbon resistor RT13-1/6W-1KΩ±5%

R816 D10B102J-T Carbon resistor RT13-1/6W-1KΩ±5%

R818 D10B102J-T Carbon resistor RT13-1/6W-1KΩ±5%

R825 D10B102J-T Carbon resistor RT13-1/6W-1KΩ±5%

R827 D10B102J-T Carbon resistor RT13-1/6W-1KΩ±5%

R305 D10B122J-T Carbon resistor RT13-1/6W-1.2KΩ±5%

R560 D10B122J-T Carbon resistor RT13-1/6W-1.2KΩ±5%

R397 D10B152J-T Carbon resistor RT13-1/6W-1.5KΩ±5%

R732 D10B152J-T Carbon resistor RT13-1/6W-1.5KΩ±5%

R430 D10B182J-T Carbon resistor RT13-1/6W-1.8KΩ±5%

R405 D10B182J-T Carbon resistor RT13-1/6W-1.8KΩ±5%

R1523 D10B182J-T Carbon resistor RT13-1/6W-1.8KΩ±5%

R351 D10B222J-T Carbon resistor RT13-1/6W-2.2KΩ±5%

R371 D10B222J-T Carbon resistor RT13-1/6W-2.2KΩ±5%

R451 D10B222J-T Carbon resistor RT13-1/6W-2.2KΩ±5%

R463 D10B222J-T Carbon resistor RT13-1/6W-2.2KΩ±5%

R701A D10B222J-T Carbon resistor RT13-1/6W-2.2KΩ±5%

R321 D10B272J-T Carbon resistor RT13-1/6W-2.7KΩ±5%

R702 D10B332J-T Carbon resistor RT13-1/6W-3.3KΩ±5%

R721 D10B332J-T Carbon resistor RT13-1/6W-3.3KΩ±5%

R722 D10B332J-T Carbon resistor RT13-1/6W-3.3KΩ±5%

R728 D10B332J-T Carbon resistor RT13-1/6W-3.3KΩ±5%

R735 D10B332J-T Carbon resistor RT13-1/6W-3.3KΩ±5%

R736 D10B332J-T Carbon resistor RT13-1/6W-3.3KΩ±5%

R737 D10B332J-T Carbon resistor RT13-1/6W-3.3KΩ±5%

R741 D10B332J-T Carbon resistor RT13-1/6W-3.3KΩ±5%

R742 D10B332J-T Carbon resistor RT13-1/6W-3.3KΩ±5%

R455 D10B392J-T Carbon resistor RT13-1/6W-3.9KΩ±5%

R462 D10B392J-T Carbon resistor RT13-1/6W-3.9KΩ±5%

R131 D10B472J-T Carbon resistor RT13-1/6W-4.7KΩ±5%

R133 D10B472J-T Carbon resistor RT13-1/6W-4.7KΩ±5%

R154 D10B472J-T Carbon resistor RT13-1/6W-4.7KΩ±5%

R158 D10B472J-T Carbon resistor RT13-1/6W-4.7KΩ±5%

R306 D10B472J-T Carbon resistor RT13-1/6W-4.7KΩ±5%

R733 D10B472J-T Carbon resistor RT13-1/6W-4.7KΩ±5%

R370 D10B562J-T Carbon resistor RT13-1/6W-5.6KΩ±5%

R540 D10B562J-T Carbon resistor RT13-1/6W-5.6KΩ±5%

R701 D10B562J-T Carbon resistor RT13-1/6W-5.6KΩ±5%

R1511 D10B562J-T Carbon resistor RT13-1/6W-5.6KΩ±5%

R153A D10B822J-T Carbon resistor RT13-1/6W-8.2KΩ±5%

R157A D10B822J-T Carbon resistor RT13-1/6W-8.2KΩ±5%

R126 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R127 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

Model No: 21WHP3-Bn

Version 1.0

Page 51

51

Ref. No Part No. Name Specification

R163 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R380 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R395 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R396 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R434 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R461 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R548 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R551 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R704 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R705 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R706 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R707 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R709 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R816A D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R818A D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R825A D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R827A D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R851A D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R852A D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R912 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R922 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R932 D10B103J-T Carbon resistor RT13-1/6W-10KΩ±5%

R331 D10B153J-T Carbon resistor RT13-1/6W-15KΩ±5%

R162 D10B223J-T Carbon resistor RT13-1/6W-22KΩ±5%

R384 D10B223J-T Carbon resistor RT13-1/6W-22KΩ±5%

R804 D10B223J-T Carbon resistor RT13-1/6W-22KΩ±5%

R1515 D10B223J-T Carbon resistor RT13-1/6W-22KΩ±5%

R1556 D10B223J-T Carbon resistor RT13-1/6W-22KΩ±5%

R484 D10B223J-T Carbon resistor RT13-1/6W-27KΩ±5%

R487 D10B223J-T Carbon resistor RT13-1/6W-27KΩ±5%

R171 D10B333J-T Carbon resistor RT13-1/6W-33KΩ±5%

R175 D10B333J-T Carbon resistor RT13-1/6W-33KΩ±5%

R317 D10B333J-T Carbon resistor RT13-1/6W-33KΩ±5%

R385 D10B333J-T Carbon resistor RT13-1/6W-33KΩ±5%

R172 D10B473J-T Carbon resistor RT13-1/6W-47KΩ±5%

R732A D10B473J-T Carbon resistor RT13-1/6W-47KΩ±5%

R745 D10B473J-T Carbon resistor RT13-1/6W-47KΩ±5%

R173 D10B683J-T Carbon resistor RT13-1/6W-68KΩ±5%

R483 D10B104J-T Carbon resistor RT13-1/6W-100KΩ±5%

R802A D10B104J-T Carbon resistor RT13-1/6W-100KΩ±5%

R803A D10B104J-T Carbon resistor RT13-1/6W-100KΩ±5%

R807 D10B104J-T Carbon resistor RT13-1/6W-100KΩ±5%

R318 D10B154J-T Carbon resistor RT13-1/6W-150KΩ±5%

R174 D10B274J-T Carbon resistor RT13-1/6W-270KΩ±5%

R465 D10B564J-T Carbon resistor RT13-1/6W-560KΩ±5%

R404 D10C1R0J-T Carbon resistor RT14-1/4W-1Ω±5%

R468 D10C2R7J-T Carbon resistor RT14-1/4W-2.7Ω±5%

R513 D10C220J-T Carbon resistor RT14-1/4W-22Ω±5%

R561 D10C270J-T Carbon resistor RT14-1/4W-27Ω±5%

R486 D10C101J-T Carbon resistor RT14-1/4W-100Ω±5%

R161 D10C222J-T Carbon resistor RT14-1/4W-2.2KΩ±5%

R1526 D10C222J-T Carbon resistor RT14-1/4W-2.2KΩ±5%

R485 D10C103J-T Carbon resistor RT14-1/4W-10KΩ±5%

R1522 D10C153J-T Carbon resistor RT14-1/4W-15KΩ±5%

Model No: 21WHP3-Bn

Version 1.0

Page 52

52

Ref. No Part No. Name Specification

R539 D10C513J-T Carbon resistor RT14-1/4W-51KΩ±5%

R539A D10C513J-T Carbon resistor RT14-1/4W-51KΩ±5%

R1554 D10C154J-T Carbon resistor RT14-1/4W-150KΩ±5%

R942 D10C334J-T Carbon resistor RT14-1/4W-330KΩ±5%

R407 D10D271J-T Carbon resistor RT15-1/2W-270Ω±5%

R453 D10D102J-T Carbon resistor RT15-1/2W-1KΩ±5%

R1555 D10D473J-T Carbon resistor RT15-1/2W-47KΩ±5%

R507 D10D124J-T Carbon resistor RT15-1/2W-120KΩ±5%

R1520 D10D124J-T Carbon resistor RT15-1/2W-120KΩ±5%

R406 S10E1R2J-C Metal oxide resistor RY16/RY21-1W-1.2Ω±5%

R300A S10E220J-C Metal oxide resistor RY17/RY21-1W-22Ω±5%

Ref. No Part No. Name Specification

R466 S10E102J-C Metal oxide resistor RY16/RY21-1W-1KΩ±5%

R941 S10F5R6J-C Metal oxide resistor RY17/RY21-2W-5.6Ω±5%

R530 S10F560J-C Metal oxide resistor RY17/RY21-2W-56Ω±5%

R454 S10E271J-C Metal oxide resistor RY17/RY21-2W-270Ω±5%

R546 S10F271J-C Metal oxide resistor RY17/RY21-2W-270Ω±5%

R467 S10F103J-C Metal oxide resistor RY17/RY21-2W-10KΩ±5%

R703 S10F103J-C Metal oxide resistor RY17/RY21-2W-10KΩ±5%

R915 S10F123J-C Metal oxide resistor RY17/RY21-2W-12KΩ±5%

R925 S10F123J-C Metal oxide resistor RY17/RY21-2W-12KΩ±5%

R935 S10F123J-C Metal oxide resistor RY17/RY21-2W-12KΩ±5%

R556 S10F223J-C Metal oxide resistor RY17/RY21-2W-22KΩ±5%

R519! Glass-Glazed Fixed RES RI40-1/2W-24MΩ±5%

R918 Glass-Glazed Fixed RES RI40-1/2W-1.5KΩ±5%

R928 Glass-Glazed Fixed RES RI40-1/2W-1.5KΩ±5%

R938 Glass-Glazed Fixed RES RI40-1/2W-1.5KΩ±5%

R555 ! F10DR27J-C Fuse resistor RF10-1/2W-0.27Ω±5%

R565 ! F10DR27J-C Fuse resistor RF10-1/2W-0.27Ω±5%

R566 ! F10DR27J-C Fuse resistor RF10-1/2W-0.27Ω±5%

R165 ! F10DR47J-C Fuse resistor RF10-1/2W-0.47Ω±5%

R470 ! F10DR47J-C Fuse resistor RF10-1/2W-0.47Ω±5%

R472 ! F10DR47J-C Fuse resistor RF10-1/2W-0.47Ω±5%

R480 ! F10F3R9J-C Fuse resistor RF10-2W-3.9Ω±5%

R458 W11H3R9K Wire-wound resistor RXG6-5W-3.9Ω-J

R502 ! W10J1R8K Wire-wound resistor RXG6-6W-1.8Ω-J

R1524 W11H270K Wire-wound resistor RX27-5W-27Ω-K

R504 W11H680K Wire-wound resistor RX27-5W-68Ω-K

PS501 P10X180J-C Thermittor PTC-180HM

VR501 V11D202B Potentiometer WI06-2AA2KΩ

C761 C2CF330J-T Ceramic capacitor CC1-06A-CH-50/63V-33pF-J

C762 C2CF330J-T Ceramic capacitor CC1-06A-CH-50/63V-33pF-J

C701 C2CF121J-T Ceramic capacitor CC1-06A-CH-50/63V-120pF-J

C701A C2CF121J-T Ceramic capacitor CC1-06A-CH-50/63V-120pF-J

C911 C2BF331K-T Ceramic capacitor CC1-06A-RH-50/63V-330pF-J

C921 C2BF331K-T Ceramic capacitor CC1-06A-RH-50/63V-330pF-J

C931 C2BF331K-T Ceramic capacitor CC1-06A-RH-50/63V-330pF-J

C803 C2BF471K-T Ceramic capacitor CC1-06A-RH-50/63V-470pF-J

C805 C2BF471K-T Ceramic capacitor CC1-06A-RH-50/63V-470pF-J

C812 C2BF471K-T Ceramic capacitor CC1-06A-RH-50/63V-470pF-J

C814 C2BF471K-T Ceramic capacitor CC1-06A-RH-50/63V-470pF-J

C824 C2BF471K-T Ceramic capacitor CC1-06A-RH-50/63V-470pF-J

C826 C2BF471K-T Ceramic capacitor CC1-06A-RH-50/63V-470pF-J

Model No: 21WHP3-Bn

Version 1.0

Page 53

53

Ref. No Part No. Name Specification

C732 C2BF471K-T Ceramic capacitor CC1-06A-RH-50/63V-470pF-J

C381 C2BF561K-T Ceramic capacitor CC1-06A-RH-50/63V-560pF-J

C323 C2BF821K-T Ceramic capacitor CC1-06A-RH-50/63V-820pF-J

C308 C2BF102K-T Ceramic capacitor CC1-06A-RH-50/63V-1000pF-J

C311 C2BF102K-T Ceramic capacitor CT1-06A-2B4-50/63V-1000pF-K

C340 C2BF102K-T Ceramic capacitor CT1-06A-2B4-50/63V-1000pF-K

C401 C2BF102K-T Ceramic capacitor CT1-06A-2B4-50/63V-1000pF-K

C402 C2BF102K-T Ceramic capacitor CT1-06A-2B4-50/63V-1000pF-K

C481 C2BF102K-T Ceramic capacitor CT1-06A-2B4-50/63V-1000pF-K

C721 C2BF102K-T Ceramic capacitor CT1-06A-2B4-50/63V-1000pF-K

C861 C2BF102K-T Ceramic capacitor CT1-06A-2B4-50/63V-1000pF-K

C335 C2BF222K-T Ceramic capacitor CT1-06A-2B4-50/63V-2200pF-K

C324 C2BF472K-T Ceramic capacitor CT1-06A-2B4-50/63V-4700pF-K

C336 C2BF472K-T Ceramic capacitor CT1-06A-2B4-50/63V-4700pF-K

C162 C2FF103Z-T Ceramic capacitor CT1-08A-2F4-50/63V-0.01uF-Z

C302 C2FF103Z-T Ceramic capacitor CT1-08A-2F4-50/63V-0.01uF-Z

C309 C2FF103Z-T Ceramic capacitor CT1-08A-2F4-50/63V-0.01uF-Z

C312 C2FF103Z-T Ceramic capacitor CT1-08A-2F4-50/63V-0.01uF-Z

C313 C2FF103Z-T Ceramic capacitor CT1-08A-2F4-50/63V-0.01uF-Z

C332 C2FF103Z-T Ceramic capacitor CT1-08A-2F4-50/63V-0.01uF-Z

C362 C2FF103Z-T Ceramic capacitor CT1-08A-2F4-50/63V-0.01uF-Z

C472 C2FF103Z-T Ceramic capacitor CT1-08A-2F4-50/63V-0.01uF-Z

C475 C2FF103Z-T Ceramic capacitor CT1-08A-2F4-50/63V-0.01uF-Z

C535 C2FF103Z-T Ceramic capacitor CT1-08A-2F4-50/63V-0.01uF-Z

C703A C2FF103Z-T Ceramic capacitor CT1-08A-2F4-50/63V-0.01uF-Z

C723 C2FF103Z-T Ceramic capacitor CT1-08A-2F4-50/63V-0.01uF-Z

C744 C2FF103Z-T Ceramic capacitor CT1-08A-2F4-50/63V-0.01uF-Z

C752 C2FF103Z-T Ceramic capacitor CT1-08A-2F4-50/63V-0.01uF-Z

C756 C2FF103Z-T Ceramic capacitor CT1-08A-2F4-50/63V-0.01uF-Z

C482 C2BP101K-T Ceramic capacitor CT1-08C-2B4-500V-100PF-Z

C405 C2BP221K-T Ceramic capacitor CT1-08C-2B4-500V-220F-Z

C452 C2BP102K-T Ceramic capacitor CT1-08C-2B4-500V-1000pF-K

C451 C2BP392K-T Ceramic capacitor CT1-08C-2B4-500V-3900pF-K

C503 C2BW102K-O Ceramic capacitor CT81-08C-2R-1KV-1000pF-K

C504 C2BW102K-O Ceramic capacitor CT81-08C-2R-1KV-1000pF-K

C505 C2BW102K-O Ceramic capacitor CT81-08C-2R-1KV-1000pF-K

C506 C2BW102K-O Ceramic capacitor CT81-08C-2R-1KV-1000pF-K

C529 C2BW471K-O Ceramic capacitor CT81-08C-2R-1KV-470pF-K

C543 C2RX471K-O Ceramic capacitor CT81-08C-2R-2KV-470pF-K

C509 C2RX681K-O Ceramic capacitor CT81-08C-2R-2KV-680pF-K

C527

C456 C2EX102Z-O Ceramic capacitor CT81-08C-2R-2KV-1000pF-K

C943

C515A ! C2EM102M-O Ceramic capacitor CTJ1-AC250V-470PF-±20%

C598! C2EM102M-O Ceramic capacitor CTJ1-AC250V-470PF-±20%

C515 ! C2EM102M-O Ceramic capacitor CTJ1-AC250V-1000PF-±20%

C548 E10C101M-T Electrolytic Capacitor CD110-10V-100uF –M

C163A E20C100M-T Electrolytic Capacitor CD110-16V-10uF –M

C172 E20C100M-T Electrolytic Capacitor CD110-16V-10uF -M

C301 E20C100M-T Electrolytic Capacitor CD110-16V-10uF –M

C307 E20C100M-T Electrolytic Capacitor CD110-16V-10uF –M

C322 E20C100M-T Electrolytic Capacitor CD110-16V-10uF –M

C2RX681K-O

C2EX102Z-O

Model No: 21WHP3-Bn

Version 1.0

Ceramic capacitor

Ceramic capacitor

CT81-08C-2R-2KV-680pF-K

CT81-08C-2R-2KV-1000pF-K

Page 54

54

Ref. No Part No. Name Specification

C363 E20C100M-T Electrolytic Capacitor CD110-16V-10uF –M

C364 E20C100M-T Electrolytic Capacitor CD110-16V-10uF –M

C367 E20C100M-T Electrolytic Capacitor CD110-16V-10uF -M

C751 E20C100M-T Electrolytic Capacitor CD110-16V-10uF –M

C807 E20C100M-T Electrolytic Capacitor CD110-16V-10uF –M

C841 E20C100M-T Electrolytic Capacitor CD110-16V-10uF –M

C871 E20C100M-T Electrolytic Capacitor CD110-16V-10uF -M

C745 E20C220M-T Electrolytic Capacitor CD110-16V-22uF -M

C116 E20C470M-T Electrolytic Capacitor CD110-16V-47uF –M

C171 E20C470M-T Electrolytic Capacitor CD110-16V-47uF –M

C333 E20C470M-T Electrolytic Capacitor CD110-16V-47uF –M

C352 E20C470M-T Electrolytic Capacitor CD110-16V-47uF –M

C561 E20C470M-T Electrolytic Capacitor CD110-16V-47uF –M

C723A E20C470M-T Electrolytic Capacitor CD110-16V-47uF –M

C811 E20C470M-T Electrolytic Capacitor CD110-16V-47uF –M

C823 E20C470M-T Electrolytic Capacitor CD110-16V-47uF –M

C361 E20C101M-T Electrolytic Capacitor CD110-16V-100uF –M

C743 E20C101M-T Electrolytic Capacitor CD110-16V-100uF –M

C525 E20C471M-T Electrolytic Capacitor CD110-16V-470uF –M

C532 E20C471M-T Electrolytic Capacitor CD110-16V-470uF –M

C801 E20C471M-T Electrolytic Capacitor CD110-16V-470uF –M

C406 E20D101M-T Electrolytic Capacitor CD110-25V-100uF -M

C471 E20D101M-T Electrolytic Capacitor CD110-25V-100uF -M

C471A E20D101M-T Electrolytic Capacitor CD110-25V-100uF -M

C474 E20D101M-T Electrolytic Capacitor CD110-25V-100uF -M

C474A E20D101M-T Electrolytic Capacitor CD110-25V-100uF -M

C161 E20D471M Electrolytic Capacitor CD110-25V-470uF -M

C522 E20D102M Electrolytic Capacitor CD110-25V-1000uF –M

C524 E20D222M Electrolytic Capacitor CD110-25V-2200uF –M

C453 E20E470M-T Electrolytic Capacitor CD110-35V-47uF -M

C530 E20E331M-T Electrolytic Capacitor CD110-35V-330uF -M

C121 E20FR47M-T Electrolytic Capacitor CD110-50V-0.47uF –M

C123 E20FR47M-T Electrolytic Capacitor CD110-50V-0.47uF –M

C372 E20FR47M-T Electrolytic Capacitor CD110-50V-0.47uF –M

C374 E20FR47M-T Electrolytic Capacitor CD110-50V-0.47uF -M

C153 E20F1R0M-T Electrolytic Capacitor CD110-50V-1uF –M

C157 E20F1R0M-T Electrolytic Capacitor CD110-50V-1uF –M

C163 E20F1R0M-T Electrolytic Capacitor CD110-50V-1uF –M

C337 E20F1R0M-T Electrolytic Capacitor CD110-50V-1uF –M

C804 E20F1R0M-T Electrolytic Capacitor CD110-50V-1uF –M

C806 E20F1R0M-T Electrolytic Capacitor CD110-50V-1uF -M

C813 E20F1R0M-T Electrolytic Capacitor CD110-50V-1uF –M

C815 E20F1R0M-T Electrolytic Capacitor CD110-50V-1uF –M

C825 E20F1R0M-T Electrolytic Capacitor CD110-50V-1uF –M

C837 E20F1R0M-T Electrolytic Capacitor CD110-50V-1uF -M

C339 E20F2R2M-T Electrolytic Capacitor CD110-50V-2.2uF –M

C755 E20F2R2M-T Electrolytic Capacitor CD110-50V-2.2uF –M

C303 E20F4R7M-T Electrolytic Capacitor CD110-50V-4.7uF –M

C304 E20F4R7M-T Electrolytic Capacitor CD110-50V-4.7uF –M

C325 E20F4R7M-T Electrolytic Capacitor CD110-50V-4.7uF –M

C464 E20F4R7M-T Electrolytic Capacitor CD110-50V-4.7uF -M

C703 E20F220M-T Electrolytic Capacitor CD110-50V-22uF -M

C462 E20F470M-T Electrolytic Capacitor CD110-50V-47uF -M

Model No: 21WHP3-Bn

Version 1.0

Page 55

55

Ref. No Part No. Name Specification

C466 E21H4R7M-T Electrolytic Capacitor CD110-160V-4.7uF -M

C528B E20H101M Electrolytic Capacitor CD110-160V-100uF-M

C477 E21K100M-T Electrolytic Capacitor CD110-250V-10uF -M

C941 E21K100M-T Electrolytic Capacitor CD110-250V-10uF -M

C458 E20H100M Electrolytic Capacitor CD110-160V-10uF -M

C507 E20M101M Electrolytic Capacitor CD293-400V-100uF-±10%

C326 F20F104J-T Mylar capacitor CL11-50V/63V-0.1uF-K

C338 F20F104J-T Mylar capacitor CL11-50V/63V-0.1uF-K

C365 F20F104J-T Mylar capacitor CL11-50V/63V-0.1uF-K

C411

C331 F20F224J-T Mylar capacitor CL11-50V/63V-0.22uF-K

C334 F20F224J-T Mylar capacitor CL11-50V/63V-0.22uF-K

C404 F20F224J-T Mylar capacitor CL11-50V/63V-0.22uF-K

C461 F20F474J-T Mylar capacitor CL21-50V/63V-0.47uF-K

C321 F20G332J-T Mylar capacitor CL11-100V-3300PF-K

C154 F20G562J-T Mylar capacitor CL11-100V-5600PF-K

C158 F20G562J-T Mylar capacitor CL11-100V-5600PF-K

C1515 F22G123J-T Mylar capacitor CL21X-100V-0.012uF-K

C1517 F20G223K-T Mylar capacitor CL11-100V-0.022uF-K

C403 F20G333K-T Mylar capacitor CL11-100V-0.033uF-K

C408 F20G333K-T Mylar capacitor CL11-100V-0.033uF-K

C1513 F20G473K-T Mylar capacitor CL11-100V-0.047uF-K

C427 F20G473K-T Mylar capacitor CL11-100V-0.047uF-K

C1514 F20G104K-T Mylar capacitor CL11-100V-0.1uF-K

C460 F20G104K-T Mylar capacitor CL11-100V-0.1uF-K

C705 F20G104K-T Mylar capacitor CL11-100V-0.1uF-K

C706 F20G104K-T Mylar capacitor CL11-100V-0.1uF-K

C707 F20G104K-T Mylar capacitor CL11-100V-0.1uF-K

C467 F20J394J Polypropylene capacitor CBB21-200V-0.3*9uF±5%

C415 ! F20Z822J Polypropylene capacitor CBB81-1.6KV-8200PF-J

C501 ! F20R224M Polypropylene capacitor CBB62-250VAC-0.22uF

L414 LXXX0001 H-linear LH01

L351 L2X239K-T Inductor LGA0204-3.9uH-K

L302 L3X210K-T Inductor LGA0204-1uH-K

L331 L3X2100K-T Inductor LGA0307-10uH-K

L361 L3X2100K-T Inductor LGA0307-10uH-K

L751 L3X2100K-T Inductor LGA0307-10uH-K

Ref. No Part No. Name Specification

L752 L3X2100K-T Inductor LGA0307-10uH-K

L753 L3X2100K-T Inductor LGA0307-10uH-K

L401 L3X2220K-T Inductor LGA0307-22uH-K

L911 L3X2820K-T Inductor LGA0307-82uH-K

L912 L3X2820K-T Inductor LGA0307-82uH-K

L913 L3X2820K-T Inductor LGA0307-82uH-K

L501 ! LMXX0002 Degaussing coil

N504 ! RX0001XX Photo electricity coupler PC817B/C

VD1001 DL0008XX LED RED 5mm

VD171 DR0001XX-T Diode IS1555/IN4148A

VD461 DR0001XX-T Diode IS1555/IN4148A

VD462 DR0001XX-T Diode IS1555/IN4148A

VD482 DR0001XX-T Diode IS1555/IN4148A

VD561 DR0001XX-T Diode IS1555/IN4148A

VD734 DR0001XX-T Diode IS1555/IN4148A

F20F104J-T

Model No: 21WHP3-Bn

Version 1.0

Mylar capacitor

CL11-50V/63V-0.1uF-K

Page 56

56

Ref. No Part No. Name Specification

VD911 DR0001XX-T Diode IS1555/IN4148A

VD921 DR0001XX-T Diode IS1555/IN4148A

VD931 DR0001XX-T Diode IS1555/IN4148A

VD1514 DR0001XX-T Diode IS1555/IN4148A

VD1516 DR0001XX-T Diode IS1555/IN4148A

VD1518 DR0001XX-T Diode IS1555/IN4148A

VD912 DR0002XX-T Diode BAV21

VD922 DR0002XX-T Diode BAV21

VD932 DR0002XX-T Diode BAV21

VD401 DR0003XX-T Diode FR105

VD470 DR0003XX-T Diode FR105

VD471 DR0003XX-T Diode FR105

VD525 DR0003XX-T Diode FR105

VD1517 DR0003XX-T Diode FR105

VD503 DR0015XX-T Diode TVR4N/TRM11C

VD504 DR0015XX-T Diode TVR4N/TRM11C

VD505 DR0015XX-T Diode TVR4N/TRM11C

VD506 DR0015XX-T Diode TVR4N/TRM11C

VD436 DR0017XX Diode RGP10J

VD472 DR0017XX Diode RGP10J

VD524 DR0017XX Diode RGP10J

VD521 DR0018XX Diode RGP15D

VD543 DR0018XX Diode RGP15D

VD300A DZ0001XX-T Diode RD5.1EB3/HZ5C1

VD481 DZ0002XX-T Diode HZ22-2

VD564 DZ0006XX-T Diode RD3.3L/HZ3C3

VD1561 DZ0006XX-T Diode RD6.4L/HZ6C2

VD381 DZ0011XX-T Diode RD7.1EB2/HZ7C1

VD382 DZ0011XX-T Diode RD7.1EB2/HZ7C1

VD383 DZ0011XX-T Diode RD7.1EB2/HZ7C1

VD1519 DZ0011XX-T Diode RD7.1EB2/HZ7C1

Ref. No Part No. Name Specification

VD460 DZ0010XX-T Diode HZ9A3

VD483 DZ0010XX-T Diode HZ9A3

VD822 DZ0010XX-T Diode HZ9A3

VD861A DZ0010XX-T Diode HZ9A3

VD941 DZ0010XX-T Diode HZ9A3

N703 IXXX0080 IC upc574J/CW574

N161 IXXX0180 IC AN7522N

N505 IXXX0118 IC TA78M05 5V

N121 IXXX0120 IC LC4052B/CD4052B

N801 IXXX0120 IC LC4052B/CD4052B

N301 IC TDA9381

N401 IXXX0142 IC LA78040

N702 IXXX0173 IC BR ST24C08-W

N503 IXXX0118 IC TA78M08 8V

V1511 RXA1015X-T Audion 2SA1015Y/2SA608/2SA733Q

V171 RXA1015X-T Audion 2SA1015Y/2SA608/2SA733Q

V542 RXB892XX-T Audion 2SB892/2SB985T

V308 RXC1674X-T Audion 2SC1674

V911 RXC2482X Audion 2SC2482

V921 RXC2482X Audion 2SC2482

V931 RXC2482X Audion 2SC2482

Model No: 21WHP3-Bn

Version 1.0

Page 57

57

Ref. No Part No. Name Specification

V913 RXC421X Audion BF421/BF423

V923 RXC421X Audion BF421/BF423

V933 RXC421X Audion BF421/BF423

V912 RXC422X Audion BF422/BF420

V922 RXC422X Audion BF422/BF420

V932 RXC422X Audion BF422/BF420

V450 RXC2383X-T Audion 2SC2383-O

V1512 RXC3807X Audion 2SC3807/2SC5070

V1513 RXC5287X Audion 2SD1710/2SC4584/C5586

V121 RXC945XX-T Audion 2SC945/2SC1815/2SC536E

V122 RXC945XX-T Audion 2SC945/2SC1815/2SC536E

V173 RXC945XX-T Audion 2SC945/2SC1815/2SC536E

V351 RXC945XX-T Audion 2SC945/2SC1815/2SC536E

V352 RXC945XX-T Audion 2SC945/2SC1815/2SC536E

V354 RXC945XX-T Audion 2SC945/2SC1815/2SC536E

V395 RXC945XX-T Audion 2SC945/2SC1815/2SC536E

V504 RXC945XX-T Audion 2SC945/2SC1815/2SC536E

V801 RXC945XX-T Audion 2SC945/2SC1815/2SC536E

V1553 RXC945XX-T Audion 2SC945/2SC1815/2SC536E

V451 RXD2140X Audion TT2190LS

V701 RXC2369XX-T Audion PH2369

Z352 FC0007XX Ceramic trap filter XT6.0M

Z354 FC0008XX Ceramic trap filter XT5.5M

Z351 FC0006XX Ceramic trap filter XT6.5M

Z301 SAWF K2966 38.9M

F501 ! FXXX0020 FUSE 3.15A 250V

A1001 RXXX0016 Remote receiver HS0038

A101 BXATB066 Tuner ET-5G1E-EV100

SW1001 KXXX0101 Touch switch PUSH SW.(L:5mm)

SW1002 KXXX0101 Touch switch PUSH SW.(L:5mm)

SW1003 KXXX0101 Touch switch PUSH SW.(L:5mm)

SW1004 KXXX0101 Touch switch PUSH SW.(L:5mm)

SW1005 KXXX0101 Touch switch PUSH SW.(L:5mm)

SW1006 KXXX0101 Touch switch PUSH SW.(L:5mm)

Z761 XC0004XX-A XTLO 12.0MHz(18P)

Model No: 21WHP3-Bn

Version 1.0

Page 58

CIRCUIT DIAGRAM

58

Model No:21WHP3_BN

Version 1.0

Page 59

Loading...

Loading...