Page 1

DRIVING INSTRUCTION

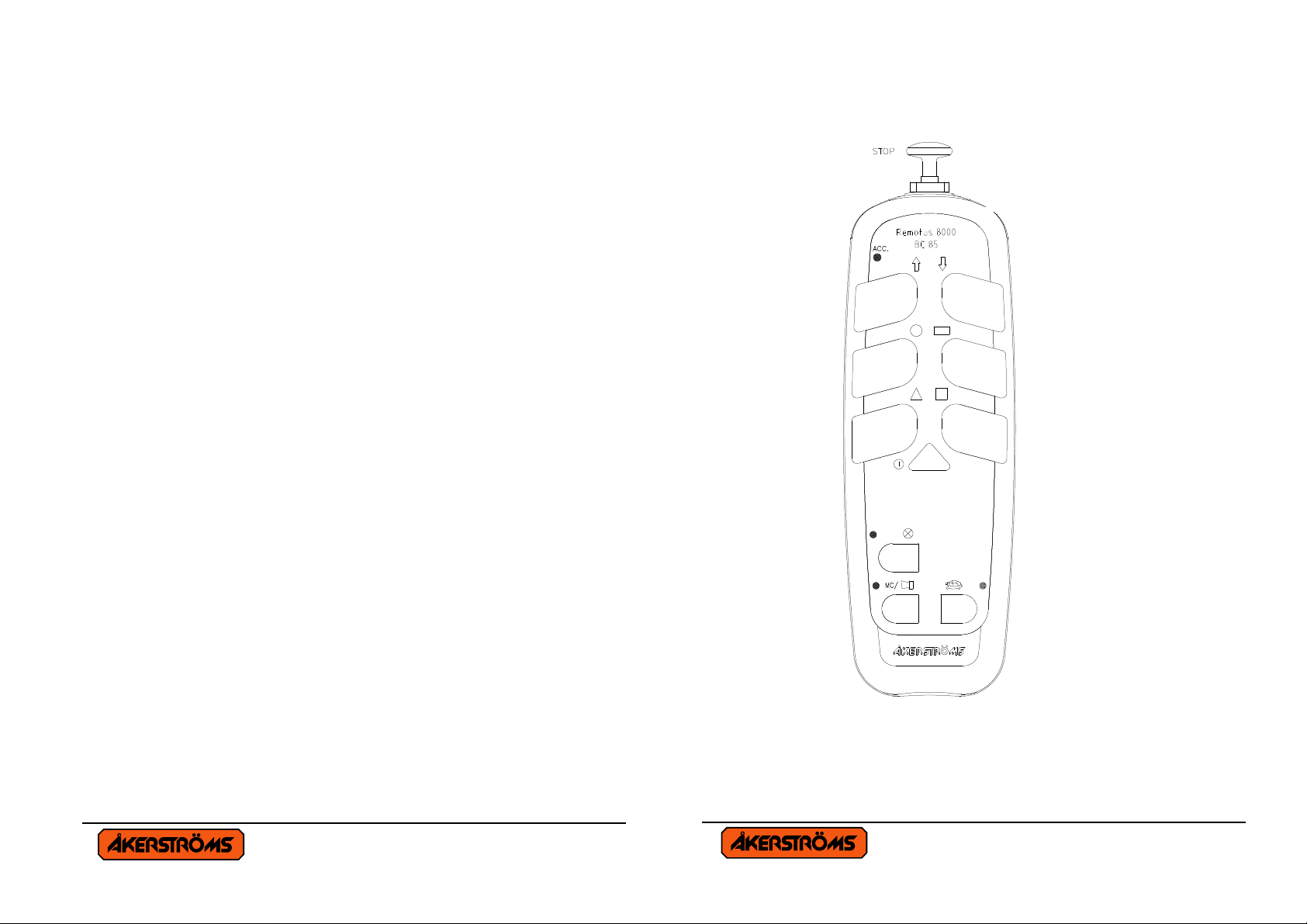

REMOTUS BC8518

928754-000 USA

MANUAL BC8518 No. 928754-000 USA

Version: A0 Approved by: HH

Page 1 (12)

Variant 1.

MANUAL BC8518 No. 928754-000 USA

Version: A0 Approved by: HH

Page 2 (12)

Page 2

Variant 2.

MANUAL BC8518 No. 928754-000 USA

Version: A0 Approved by: HH

Page 3 (12)

TRANSMITTER ON

Pull out the stop button and the transmitter is switched on. The

operation indicator lamp (ACC.) starts blinking and the transmitter

is on.

ELECTRONIC LOCK

If the operating indication LED is red, the electronic lock is

activated. Contact the works manager or see the Installations

manual.

MAIN CONTACTOR ON

Then the transmitter is on, press the signal button and this actuates

the Main Contactor in the receiver, and it is ready for operation.

NORMAL RUN

The transmitter is designed with two pushbuttons for HOIST

Up / Down, two for BRIDGE Forward / Backward and two for

TROLLEY Left / Right. Each button is divided into 2 steps

(a perceptible resistance) which facilitates the running at a certain

speed. The first speed is obtained when the pushbutton is half

compressed and the second speed is obtained when the pushbutton is

totally compressed.

All the motions can be run simultaneously and the motions stop

when the pushbutton is released, otherwise make an EMERGENCY

STOP.

MANUAL BC8518 No. 928754-000 USA

Version: A0 Approved by: HH

Page 4 (12)

Page 3

MICRO RUN

X X

Push in the button for MICRO and the diode lamp for micro lights.

The micro-run movements are only at lowest speed in micro-run

mode irrespective of the compression of the pushbuttons. The

buttons are looped so that only one movement can be operated at a

time. The other functions are working as in ordinary runs.

FLOODLIGHT ⊗

The lights can be operated at any time after switching the Main

contactor ON, Light OFF must be set before Main Contactor OFF.

Otherwise the function remains. A diodlamp indicate that the light is

on.

One extra function and Choice 1 and 2, works only on variant 2.

(See page 3)

EXTRA

Function is obtained immediately when the switch is actuated in

position .

CHOICE 1, 2 or 1+2

Push the button for 1 and/or 2, and the diode lamps indicate the

selection.

MANUAL BC8518 No. 928754-000 USA

Version: A0 Approved by: HH

Page 5 (12)

SIGNAL

A signal can be emitted at any time during the run and is obtained as

long as the push button switch is depressed.

EMERGENCY STOP

Depress the STOP button for Emergency STOP.

TRANSMITTER OFF

MAIN CONTACTOR OFF

Depress the triangular button for about 2 seconds, until the

indication for operation goes out, which switches off the transmitter.

At the same time the Main Contactor in the receiver is deactivated.

AUTOMATIC SWITCH OFF

FUNCTION

The indicator lamp for operation goes out and the Main Contactor is

de-energized. For renewed activation of the Main contactor restart is

required, press the stop button, pull it out again and press the signal

button. Accumulator voltage below 5,7V also causes automatic

switch-off.

MANUAL BC8518 No. 928754-000 USA

Version: A0 Approved by: HH

Page 6 (12)

Page 4

TRANSMITTER LED INDICATIONS

If the transmitter under start up or under operating detect a fault in

any self-tests it will indicate with a continuously red light. After that

the transmitter closes down. If it indicates continuously yellow light

when you start up the transmitter, at least one of the pushbuttons is

activated.

INDICATIONS EXPLANATIONS

Green flashing Operating

Yellow flashing Battery voltage low < 6,3 V

Yellow continuously Discharge battery voltage < 5,7 V

Red continuously,

at start

Red continuously,

Electronic lock, see the Installation

manual

Fault, see the Installation manual

at operating

DISCHARGED BATTERY

The transmitter is equipped with an indicator lamp for battery status.

The lamp blinks slowly green when the battery voltage is normal

(7,4V), but starts to blink rapidly yellow, when it falls (6,3V). When

the indicator lamp has started blinking rapidly yellow, the

transmitter can be operated for approx 10 min. before the voltage is

so low (5,7V) that the transmitter switches off automatically. The

indicator lamp showing fixed light indicates this.

MANUAL BC8518 No. 928754-000 USA

Version: A0 Approved by: HH

Page 7 (12)

CHARGING INSTRUCTIONS

• The battery has got power for 12 hours continuous operation.

• Charging time is 2 hours.

230V AC CHARGING DEVICE

• Manufacture ANSMANN

The charging device has a green LED, shows that the charger is

connected to the main, and a red LED who indicates:

Continuously indication Charging

Flashing indication The battery is wrong or not connected

No indication Full charged battery

• Manufacture MASCOT

Do not connect the charger to the mains before it is connected to

the battery. The charging device has a LED who indicates:

Orange indication Quick charge

Yellow indication Maintenance charge

Green indication Full charged battery

DC CHARGING DEVICE

• The charging device has a fixed GREEN indication for quick.

charge. When the battery is charged the indication switches off.

Still a certain maintenance charge is going on.

• NOTE! If the indication not light when the battery is placed in

the charger, the remaining capacity in the battery is to high to

enable quick charge.

• Take the battery out of the charger before the main-connection is

disconnected.

MANUAL BC8518 No. 928754-000 USA

Version: A0 Approved by: HH

Page 8 (12)

Page 5

• A WELL MAINTAINED BATTERY IS NECESSARY FOR

!

! ! ! ! ! !

! !

FAULTLESS OPERATION

• CHARGE THE BATTERY AS SOON AS THERE IS

POSSIBILITY.

• THE BATTERY MUST NOT BE CHARGED IF THE

TEMPERATURE IS LOWER THAN +10°C OR HIGHER

THAN +35°C.

• Only use by supplier approved charger.

DISCHARGED BATTERY.

A Li-Ion battery is environment conformed, but as usually, all

batteries shall be handed back for recycling. When the battery will be

changed, the used Li-Ion-battery shall be returned to the distributor,

where a new battery is to be bought. Just to make sure that a proper

battery will be required. An alternative is to directly dispose of the

battery for recycling.

Old batteries shall be returned for recycling.

MANUAL BC8518 No. 928754-000 USA

Version: A0 Approved by: HH

Page 9 (12)

INSTRUCTIONS FOR CRANE OPERATORS

These instructions have to be followed. Marked

1. Check that the radiotransmitter operates on the crane,

which you are going to drive (ex. give a signal). Check the

function of the radiotransmitter.

2. Check that no unauthorized person is on or at the crane

when you start to drive it. The blocking device at entry of

the crane should be closed.

3. Check the position of the symbols for driving direction

(crane-trolley travel).

4. At the beginning of each shift the crane operator is to test

brake, limitswitches and emergency stop function as well

as the STOP button on the transmitter.

5. The crane operator is when driving the crane to walk or

stand at a suitable distance from the crane hoist in order to

have adequate overview of the operation.

6. It is prohibited to move the crane load over oneself or

workmates. Signal in order to warn workmates.

7. Avoid driving into end stops since equipment and goods

can be damaged.

8. Check your own free passageway in order to avoid tripping

over material on the ground when you drive the crane Keep

the workplace in good order.

MANUAL BC8518 No. 928754-000 USA

Version: A0 Approved by: HH

Page 10 (12)

Page 6

! !

9. If you loose control of the crane movements, release the

! !

! !

!

pushbuttons in order to stop the crane. If still it does not

stop, actuate the STOP function.

10. Find out where the crane's main power disconnection is in

order to be able to quickly switch off if required.

11. Never hand over the transmitter to anybody who has not

undergone training in radio-control crane operation.

12. After completed operation you should always switch the

transmitter off with STOP. Note! Do never put the

transmitter aside without switching the transmitter off with

STOP.

13. The main contactor of the crane is to be switched off after

end of working hours. The transmitter is then to be kept

inaccessible to unauthorized persons.

14. In case of faults or breakdowns in the radiocontrol

equipment the crane should permit operating from the cab

or with suspended operating gear. In such case first turn the

switch from radio operation to manual operation. Make

certain how this switch-over is to be made before you start

driving any individual crane.

15. Make sure that the receiver cannot be activated when you

service the transmitter.

ALWAYS REPORT DEFECTS AND DEFICIENCIES TO

THE WORK MANAGEMENT.

MANUAL BC8518 No. 928754-000 USA

Version: A0 Approved by: HH

Page 11 (12)

FCC Identifier OG4BC8518

This device complies with Part 15 of the FCC rules. Operation is

subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

Caution: Any changes or modifications not expressly approved by

the party responsible for compliance could void the user´s authority

to operate tne equipment.

MANUAL BC8518 No. 928754-000 USA

Version: A0 Approved by: HH

Page 12 (12)

Loading...

Loading...