Page 1

KAWA

ELECTRONIC

RESEARCIT

& DEYELOPMENT

CENTRE

Reference

Revision

Date

Page

In

House

Customer

BOM

Description

Prepared

No

No.

Model

Model

By:

No.

No.

&e

Service

: SM:0

: 2006

:P1of67

: PDP501D

: PDP5073TM

:

:

Service

PDPSOIDMIA1LS

May

25

PDPSOIDMIA1LS

Manual

for

-A01

PDP5073TM

Manual

-

001

LG

X3

Checked

Approved

Received

DOC

Rev

NO.

0

By:

By:

By:

Electronic

Mechanical

Engineering

MK

Department

Initial

Release

Engineer

Engineer

Manager

The

Latest

Revision

Detaits

DATE

2006-Mav-25

Page 2

SERVICE MANUAL

Model:

PDP5073TM

Safety Precaution.........................................................................1~2

Technical Specifications..............................................................3~9

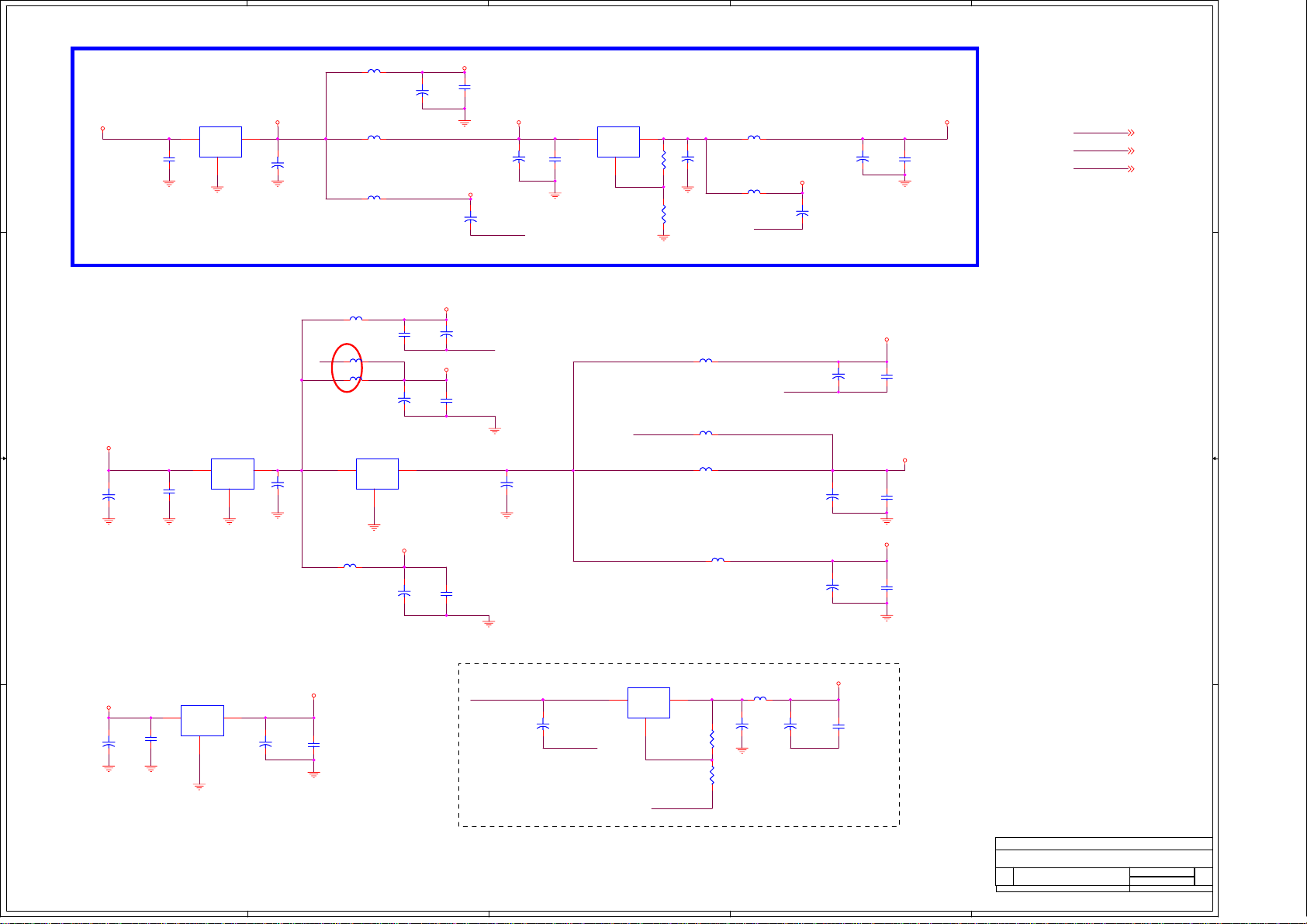

Circuit Diagram..........................................................................10~30

Basic Operations & Circuit Description.....................................31~36

Main IC Information.......................................................................37

Panel Information....................................................................38~55

Spare Part List.........................................................................56~59

Exploded View............................................................................60

If you forget your V-Chip Password...............................................61

Software Upgrade...................................................................62~65

This manual is the latest at the time of printing, and does not

include the modification which may be made after the printing,

by the constant improvement of product.

Page 3

Safety Precaution

1/65

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

The lightning flash with arrowhead symbol,

within an equilateral triangle, is intended to

alert the user to the presence of uninsulated

“dangerous voltage” within the product’s enclo

sure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

CAUTION: TO REDUCE THE RISK OF

ELECTRIC SHOCK, DO NOT REMOVE COVER

(OR BACK). NO USER-SERVICEABLE PARTS

INSIDE. REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL ONLY.

PRECAUTIONS DURING

SERVICING

1. In addition to safety, other parts and

assemblies are specified for conformance with

such regulations as those applying to spurious

radiation. These must also be replaced only

with specified replacements.

Examples: RF converters, tuner units, antenna

selection switches, RF cables, noise-blocking

capacitors, noise-blocking filters, etc.

2. Use specified internal Wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

3. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulating Tape

2) PVC tubing

3) Spacers (insulating barriers)

4) Insulating sheets for transistors

5) Plastic screws for fixing micro switches

4. When replacing AC primary side components

(transformers, power cords, noise blocking

capacitors, etc.), wrap ends of wires securely

about the terminals before soldering.

5. Make sure that wires do not contact heat

generating parts (heat sinks, oxide metal film

resistors, fusible resistors, etc.)

6. Check if replaced wires do not contact sharply

edged or pointed parts.

7. Make sure that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

The exclamation point within an equilateral

triangle is intended to alert the user to the

presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the appliance.

MAKE YOUR CONTRIBUTION

TO PROTECT THE

ENVIRONMENT

Used batteries with the ISO symbol

for recycling as well as small accumulators

(rechargeable batteries), mini-batteries (cells) and

starter batteries should not be thrown into the

garbage can.

Please leave them at an appropriate depot.

WARNING:

Before servicing this TV receiver, read the

SAFETY INSTRUCTION and PRODUCT

SAFETY NOTICE.

SAFETY INSTRUCTION

The service should not be attempted by anyone

unfamiliar with the necessary instructions on this

apparatus. The following are the necessary

instructions to be observed before servicing.

1. An isolation transformer should be connected in

the power line between the receiver and the

AC line when a service is performed on the

primary of the converter transformer of the set.

2. Comply with all caution and safety related

provided on the back of the cabinet, inside the

cabinet, on the chassis or picture tube.

3. To avoid a shock hazard, always discharge the

picture tube's anode to the chassis ground

before removing the anode cap.

4. Completely discharge the high potential voltage

of the picture tube before handling. The picture

tube is a vacuum and if broken, the glass will

explode.

Page 4

5. When replacing a MAIN PCB in the cabinet,

2/65

always be certain that all protective are

installed properly such as control knobs,

adjustment covers or shields, barriers, isolation

resistor networks etc.

6. When servicing is required, observe the original

lead dressing. Extra precaution should be given

to assure correct lead dressing in the high

voltage area.

7. Keep wires away from high voltage or high

tempera ture components.

8. Before returning the set to the customer,

always perform an AC leakage current check

on the exposed metallic parts of the cabinet,

such as antennas, terminals, screwheads,metal

overlay, control shafts, etc., to be sure the set

is safe to operate without danger of electrical

shock. Plug the AC line cord directly to the

AC outlet (do not use a line isolation

transformer during this check). Use an AC

voltmeter having 5K ohms volt sensitivity or

more in the following manner.

Connect a 1.5K ohm 10 watt resistor paralleled

by a 0.15µF AC type capacitor, between a

good earth ground (water pipe, conductor etc.,)

and the exposed metallic parts, one at a time.

Measure the AC voltage across the combination

of the 1.5K ohm resistor and 0.15 uF

capacitor. Reverse the AC plug at the AC

outlet and repeat the AC voltage measurements

for each exposed metallic part.

The measured voltage must not exceed 0.3V

RMS.

This corresponds to 0.5mA AC. Any value

exceeding this limit constitutes a potential

shock hazard and must be corrected

immediately.

The resistance measurement should be done

between accessible exposed metal parts and

power cord plug prongs with the power switch

"ON". The resistance should be more than

6M ohms.

AC VOLTMETER

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this

apparatus have special safety-related

characteristics.

These characteristics are offer passed

unnoticed by visual spection and the protection

afforded by them cannot necessarily be obtained

by using replacement components rates for a

higher voltage, wattage, etc.

The replacement parts which have these

special safety characteristics are identified by

marks on the schematic diagram and on the parts

list.

Before replacing any of these components,

read the parts list in this manual carefully. The

use of substitute replacement parts which do not

have the same safety characteristics as specified

in the parts list may create shock, fire, or other

hazards.

9. Must be sure that the ground wire of the AC

inlet is connected with the ground of the

apparatus properly.

Good earth ground

such as the water

pipe, conductor,

etc.

AC Leakage Current Check

Place this probe

on each exposed

metallic part

Page 5

Technical Specifications PDP5073TM

3/65

1. Standard Test Conditions

All tests shall be performed under the following conditions, unless otherwise specified.

1.1 Ambient light : 150ux (When measuring IB, the ambient luminance

≦0.1Cd/m2)

1.2 Viewing distance : 50cm in front of PDP

1.3 Warm up time : 30 minutes

1.4 PDP Panel facing : no restricted

1.5 Measuring Equipment : Minolta CA 100 photometer

1.6 Magnetic field : no restricted

1.7 Control settings : Brightness, Contrast, Tint, Color set at Center(50)

1.8 Power input : 120Vac, 60Hz

1.9 Ambient temperature : 20°C ± 5°C (68°F ± 9°F)

1.10 Display mode : Resolution 1366 (H) x 768 (V) Pixels

1.11 Other conditions :

1.11.1 With image sticking protection of PDP module, the luminance will descend

by time on a same still screen and rapidly go down in 5 minutes. When

measuring the color tracking and luminance of a same still screen, be sure

to accomplish the measurement in one minute to ensure its accuracy.

1.11.2 Due to the structure of PDP, the extra-high-bright same screen should not

hold over 5 minutes for fear of branding on the panel.

Page 6

Technical Specifications PDP5073TM

4/65

ELECTRICAL CHARACTERISTICS

2. Power Input

2.1 Voltage : 120VAC

2.2 Input Current : 4.0A

2.3 Maximum Inrush Current : <30 A (FOR AC 120V ONLY)

Test condition : Measured when switched off for at least 20 mins

2.4 Frequency : 60Hz(±3Hz)

2.5 Power Consumption : 480W Typical

Test condition : full white display with maximum brightness and

contrast

2.6 Power Factor : Meets IEC1000-3-2

2.7 Withstanding voltage : 1.5kVac or 2.2kVdc for 1 sec

3. Display

3.1 Screen Size : 50” Plasma display

3.2 Aspect Ratio : 16:9

3.3 Pixel Resolution : 1366 x 768

3.4 Peak Brightness : 1000 cd/m² (Panel module without filter)

3.5 Contrast Ratio (Dark room) : 10000:1 (Panel module without filter)

3.6 Viewing Angle : Over 160°

3.7 OSD language : English, Spaish, French

4. Signal

4.1 AV & Graphic input

4.1.1 Composite signal : AV

4.1.2 Y,C Signal : S-Video

4.1.3 Component signal : YPbPr HDTV compatible

4.1.4 Graphic Input : D-Sub 15 pin detachable cable

4.1.5 HDMI : HDMI

4.1.6 PnP compatibility : DDC 1.0

4.1.7 I/P frequency : f

recommended)

: 31.5kHz to 60kHz/fV: 56.25Hz to 75Hz (640x480

H

Page 7

Technical Specifications PDP5073TM

5/65

4.2 Audio input

Audio Input(L/Rx5) : 1 for DVI / D-Sub

2 for YPbPr

1 for S-Video

1 for AV

4.3 Audio output

Audio Output (L/Rx1) : Monitor out(L/R)

SPDIF : Coaxial x 1 (only for HDMI)

5. Environment

5.1 Operating environment

5.1.1 Temperature : 5º to 33°C

5.1.2 Relative humidity: 20% to 85%(non-condensing)

5.2 Storage and Transport

5.2.1 Temperature : -20°C to 60°C (-4º to 140°F)

5.2.2 Relative humidity: 5% to 95%

6. Panel Characteristics

6.1 Type : LG X3

6.2 Size : 50”, 1190mm(W)x700mm(H)x58mm(D)±1mm

6.3 Aspect ratio : 16:9

6.4 Viewing angle : Over 160°

6.5 Resolution : 1366 x 768

6.6 Weight : Approx 21.4kg +/- 0.5kg (1EA)

6.7 Color : 1073.7 million colors by combination of 10 bits R,G,B

digital

6.8 Contrast : Max 10000:1 (In dark room 1% White Window pattern

at center)

6.9 Peak brightness : Typical 1000cd/㎡ (1% White Window pattern at center)

6.10 Color Coordinate Uniformity : Contrast; Brightness and Color control

at normal setting

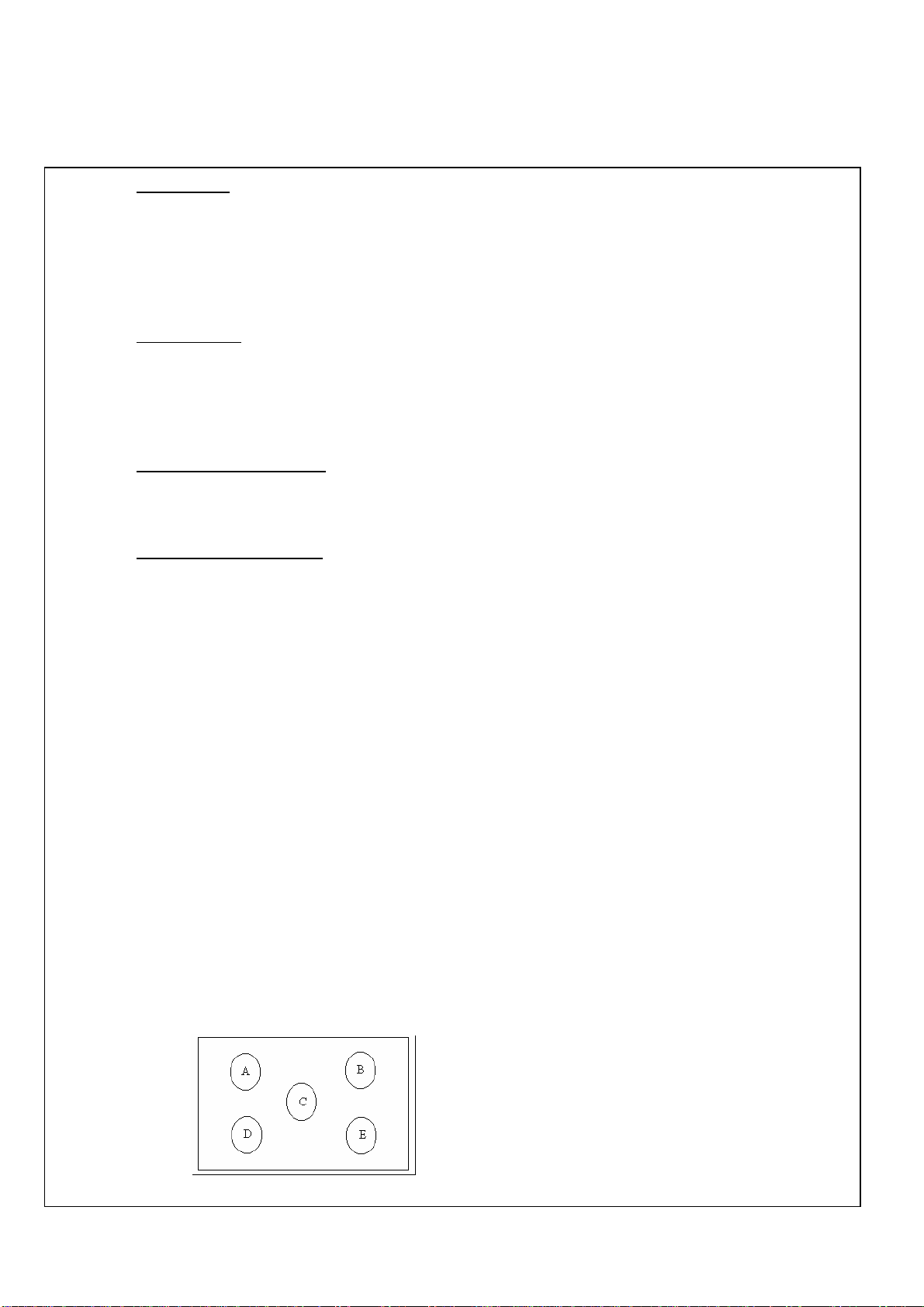

Test Pattern : Full white pattern

Average of point A,B,C,D and E +/- 0.01

Page 8

Technical Specifications PDP5073TM

6/65

6.11 Color temperature : Contrast and Brightness at Normal;

Color temperature set at Middle

x=0.285±0.02

y=0.293±0.02

6.12 Cell Defect Specifications

Subject to Panel supplier specification as appends.

7. Front Panel Control Button

7.1 SEL. Up / Down Button : Select the up or down item in OSD menu.

VOL. Left / Right Button : Press the key to increase the volume left or right.

When selecting the adjusting item on OSD menu

increase or decrease the data-bar.

MENU Button : Press the key to display or exit the menu.

SOURCE Button : Press the key to select the input signals source.

7.2 STANDBY Button : Switch on main power, or switch off to enter power

Saving modes.

7.3 Main Power Switch : Turn on or off the unit.

8. OSD Function

Full on screen display

9. Agency Approvals

Safety UL60950

Emissions FCC class B

10. Reliability

10.1 MTBF: 20,000 hours (Use moving picture signal at 25°C ambient)

11. Accessories: User Manual x 1, Remote Control x 1, Stand x 1, Power Cord x 1, Battery x2.

Page 9

Technical Specifications PDP5073TM

7/65

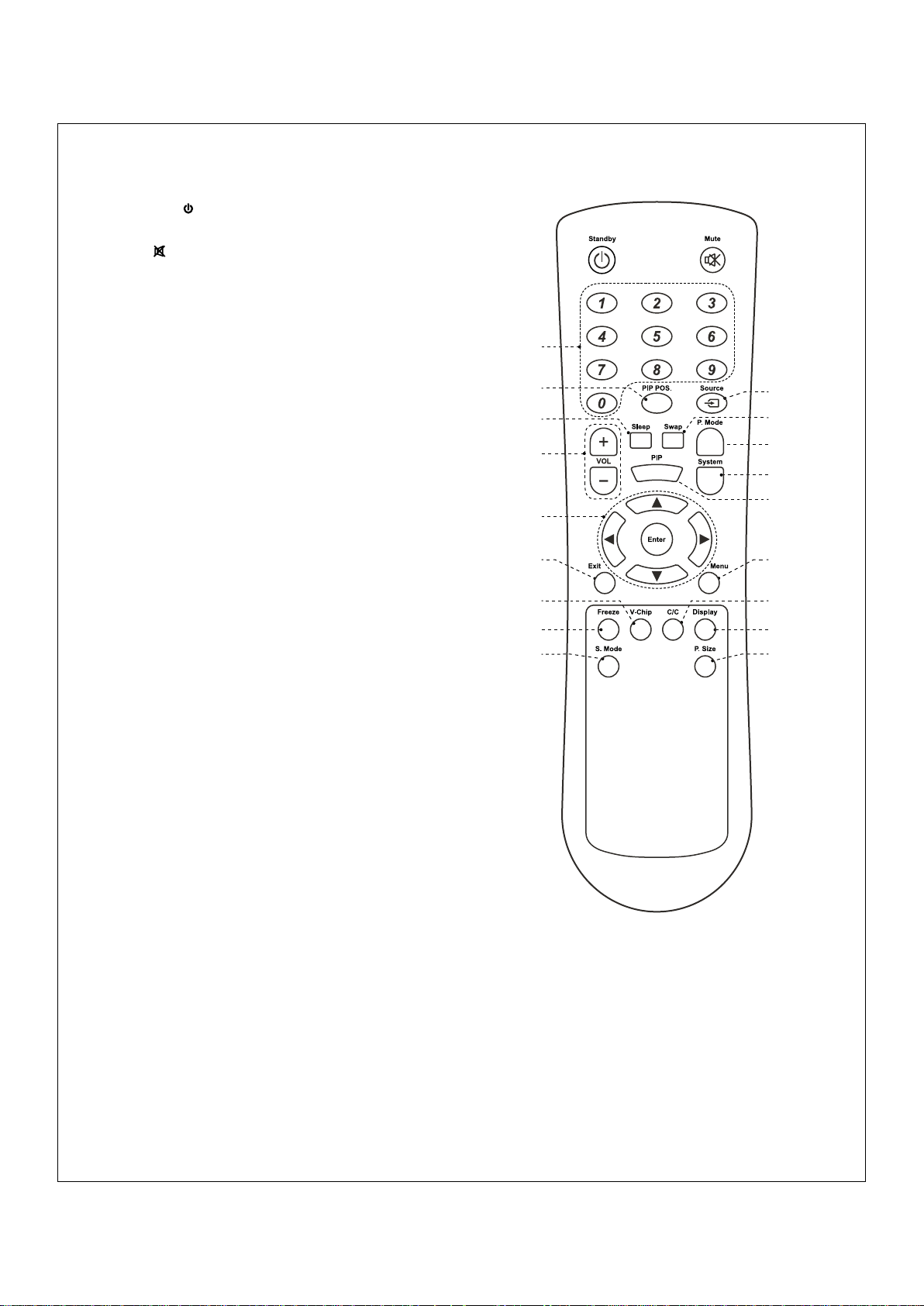

12. Remote Control

Standby( ): Press this button to turn off to

standby and turn on from standby.

Mute( ): Press this button to quiet the sound

system. Press again to reactivate the

sound system.

Number buttons: Use these buttons to enter

the password.

PIP POS. : Press the button to select different

Image Position in PIP Mode.

Source: Press this button and use ▲ / ▼

button to select the signal sources. AV, S-Video,

YPbPr 1, YPbPr 2, VGA or HDMI.

Sleep: Press this button to

time, such as “15 Min, 30 Min, 60 Min, 90 Min,

120 Min or off”.

Swap: Press this button to switch the Main

window or Sub window pictures in PIP and

Split Screen

VOL +/- : Press these buttons to

decrease the volume

P. Mode : Press the button to select different

picture effect, such as “Normal, Vivid, Hi-Bright,

User or Cinema”.

System: Press this button to select the color

system, such as “AUTO or NTSC 3.58”.

PIP: Press this button to enter PIP function.

Enter : Press to enter or confirm.

◄ / ► : They are used as ◄ / ► buttons in

the OSD Menu screen.

/ ▼ : They are used as ▲ / ▼ buttons in

▲

the OSD Menu screen.

Exit: Press this button to exit the OSD Menu.

Menu: Press this button to pop up the OSD

Menu and press it again to exit the OSD Menu.

V-Chip: Press this button to enter the V-Chip

Function. (Only for AV or S-Video)

Freeze: Press this button to hold on the screen. Press again to normal.

C/C: Press this button to enter the Closed Caption Function. (Only for AV or S-Video)

Display: Press the button to display the source information.

S. Mode: Press the button to select different sound effect, such as “Normal, News,

Cinema, Concert or User”.

P. Size: Press this button, the picture will change according

(inactive for VGA)

.

.

select

the sleep

increase or

to

Full, 4:3 or Panoramic.

Page 10

Technical Specifications PDP5073TM

8/65

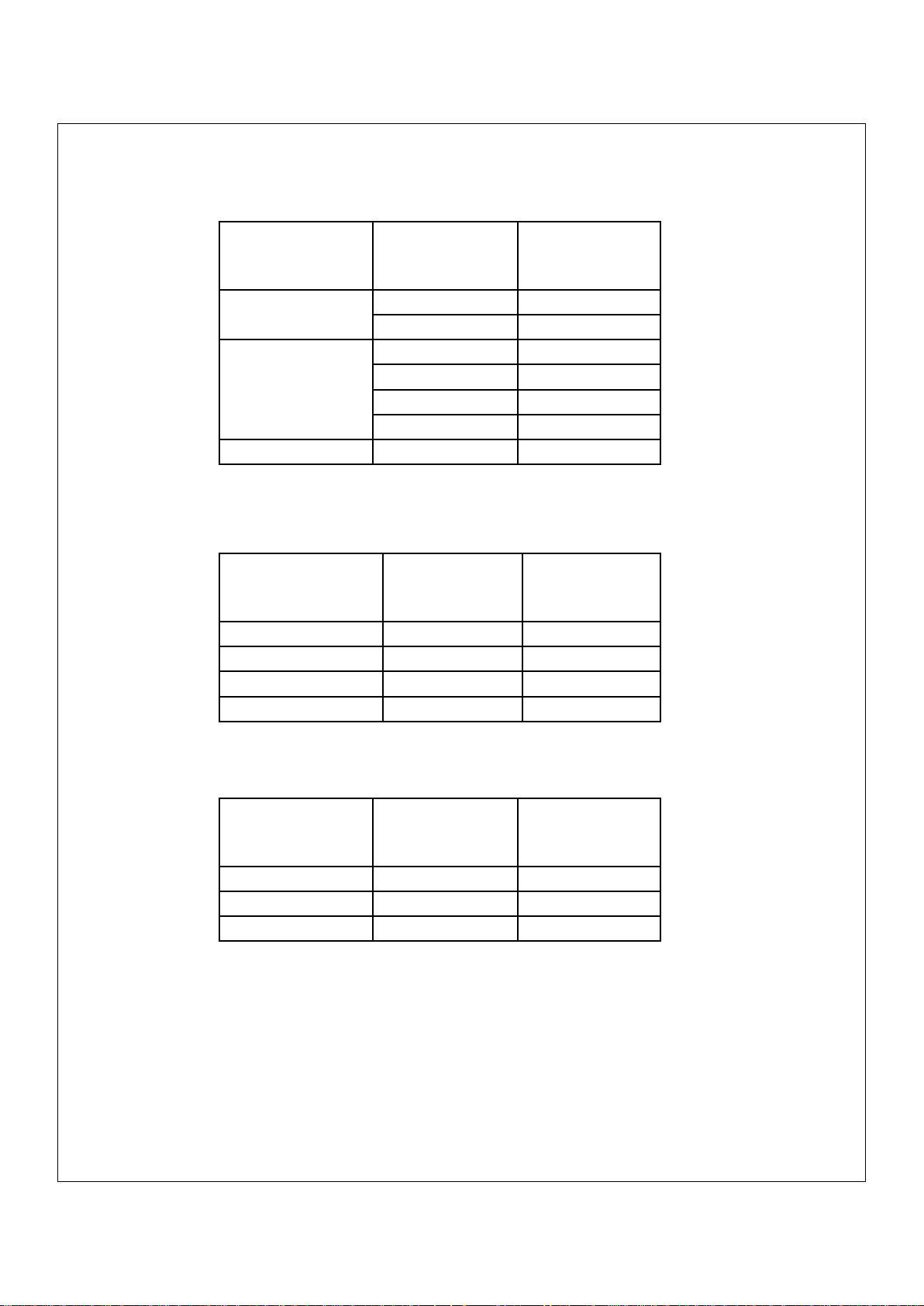

13. Support the Signal Mode

VGA Mode

A.

B. YPbPr Mode

Horizontal

Resolution

640 x 480

800 x 600

1024 x 768 48.40 60.00

Resolution

480i 15.734 59.94

480p(720x480) 31.468 59.94

720p(1280x720) 45.00 60.00

1080i(1920x1080) 33.75 60.00

Frequency

(KHz)

31.50 60.00

37.86 72.81

35.16 56.25

37.90 60.32

46.90 75.00

48.08 72.19

Horizontal

Frequency

(KHz)

Vertical

Frequency

(Hz)

Vertical

Frequency

(Hz)

C. HDMI Mode

Horizontal

Resolution

480p 31.468 59.94

720p 45.00 60.00

1080i 33.75 60.00

- When the signal received by the Display exceeds the allowed range, a warning message

shall appear on the screen.

- You can confirm the input signal format from the on-screen.

Frequency

(KHz)

Vertical

Frequency

(Hz)

Page 11

Technical Specifications PDP5073TM

9/65

PHYSICAL CHARACTERISTICS

14. Power Cord

Length : 1.8m nominal

Type : optional

15. Cabinet

15.1 Color : “Black” colour as defined by colour plaque reference number

15.2 Weight

Net weight : 54.5 kg(with stand, speaker and handles)

Gross weight : 61.0 kg

15.3 Dimensions(w/o stand)

Width : 1227.8 mm

Height : 871 mm

Depth : 286 mm

Page 12

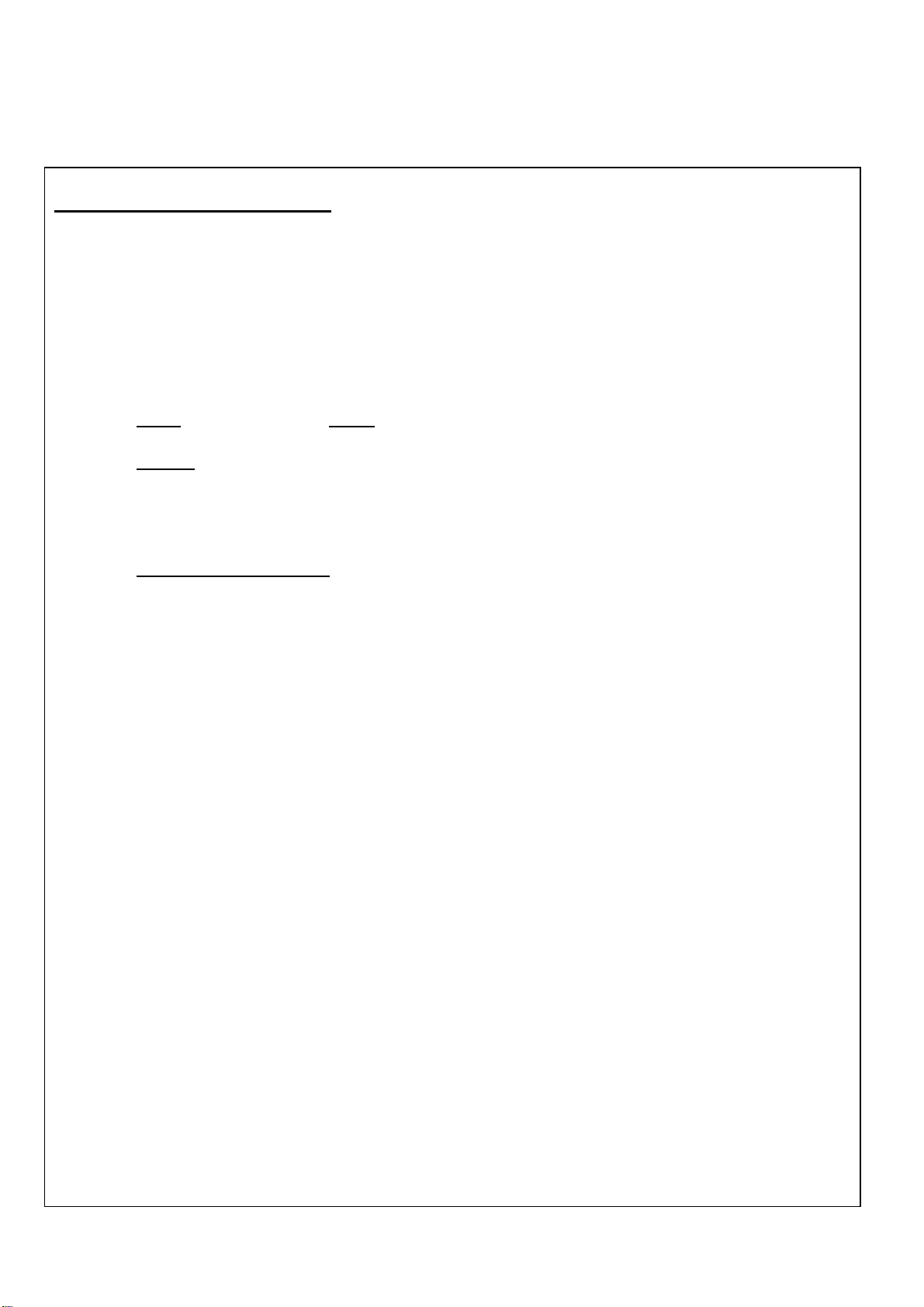

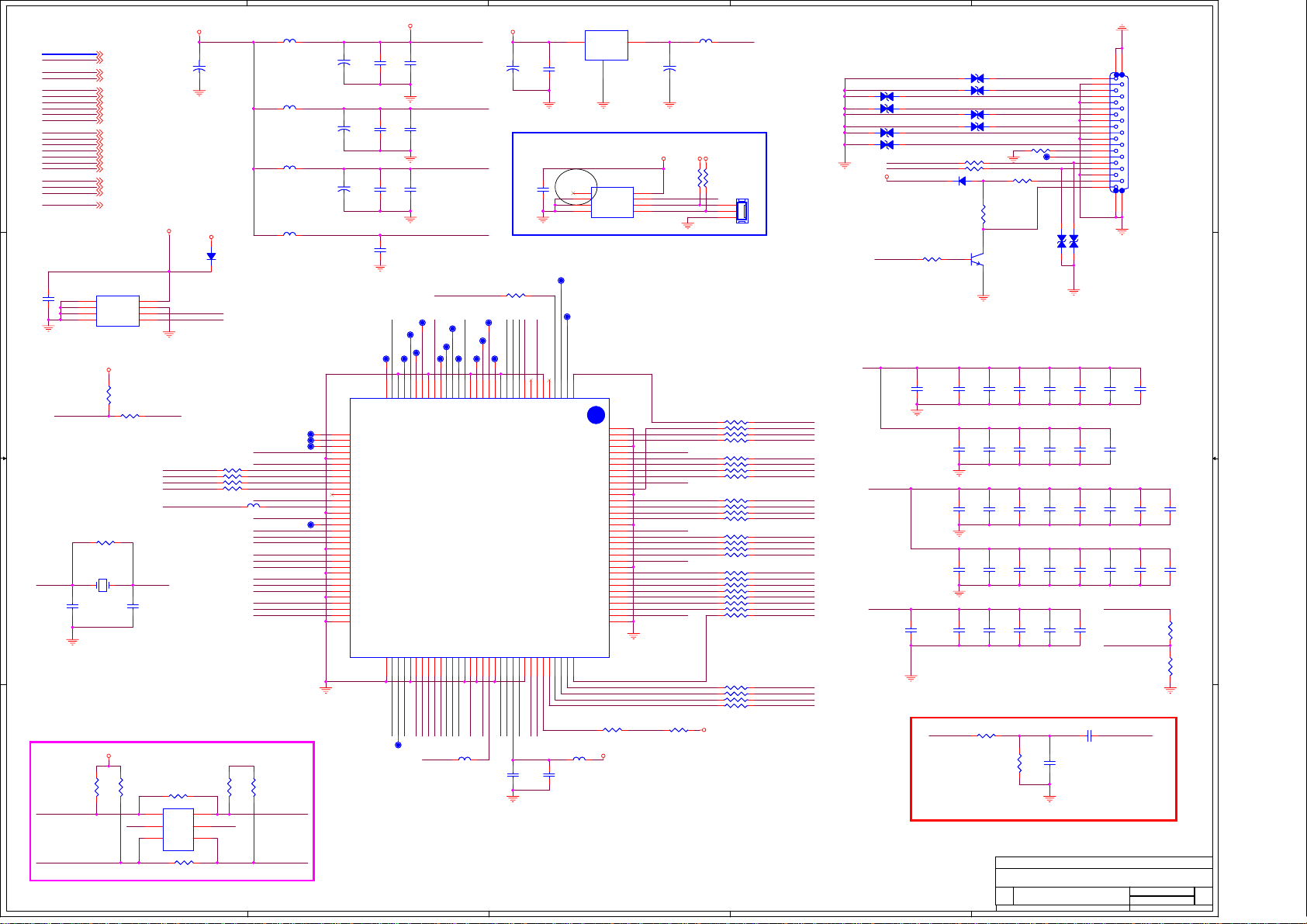

A

10/65

4 4

UART0

(Communication with MT5351)

Video[0...23]

data audio signal

From MT5351

J24

TMDS0~3

5V

HDMIPLUG_PWR

HDMI_I2C

EEPROM

24C02

(U51)

HDMI

Connector

P1

3 3

control signal

MT8293

HDMI Receiver

(U25)

UPA672T

(U34)

Level Shift

B

74LVC244A

U30-U33

(BUFFER)

Video/audio signal

control signal

I2C(MT8202I2C)

MT8253

I2C

3.3V

HDCP_I2C

EEPROM

24C04

(U50)

3.3v

2.5v

MT8202

U12

1.8v

C

TO PDPLVDS Data

PDP

Connector

PDP

Control Signal

D

E

3.3V

MT8202 Download

VGA

MAX3232

(U54)

Level shift

VGA Signal Input

VGA_I2C

EEPROM

5V

24C02

(U53)

2 2

CVBS3(CVBS0 is from tuner)

UART

(TXD/RXD)

Data[0..31]

Address[0..11]

Flash

16Mb

(U17)

DDR

128Mb

(U18)

DDR

128Mb

(U19)

3.3V

1.25V

LP2996

(U20)

2.5V

YPbPr×2

S_VIDEO

S_Video Audio

AV1 Audio

1 1

A

HEF4052

(U52)

B

AV Audio inAV2 Audio

YPbPr1 Audio in

YPbPr2 Audio in

VGA Audio in

Din

WM8776

(U41)

NJM4558

OPA

(U60)

CLK

Dout

I2C(MT8202I2C)

EEPROM

24C16

(U2)

Audio Bypass

NJM4558

OPA

(U46)

Video Bypass

AUDIO Bypass

5V

R2S15103

(U57)

TO

Speaker

KAWA Confidential

KAWA Confidential

KAWA Confidential

MT8202 Block

MT8202 Block

MT8202 Block

E

Rev

Rev

Rev

Drawn:

<Designer>

Drawn:

<Designer>

Drawn:

<Designer>

<Checker>

<Checker>

<Checker>

Checked:

Checked:

Checked:

of

of

of

22Friday, March 17, 2006

22Friday, March 17, 2006

22Friday, March 17, 2006

ZhongShan KAWA Electronic Inc.

ZhongShan KAWA Electronic Inc.

ZhongShan KAWA Electronic Inc.

Title

Title

Title

Document Number

Document Number

Document Number

Size

Size

Size

AKAI_MT8202_MT5351_V1.0

AKAI_MT8202_MT5351_V1.0

AKAI_MT8202_MT5351_V1.0

D

D

D

Date: Sheet

Date: Sheet

C

D

Date: Sheet

1

1

1

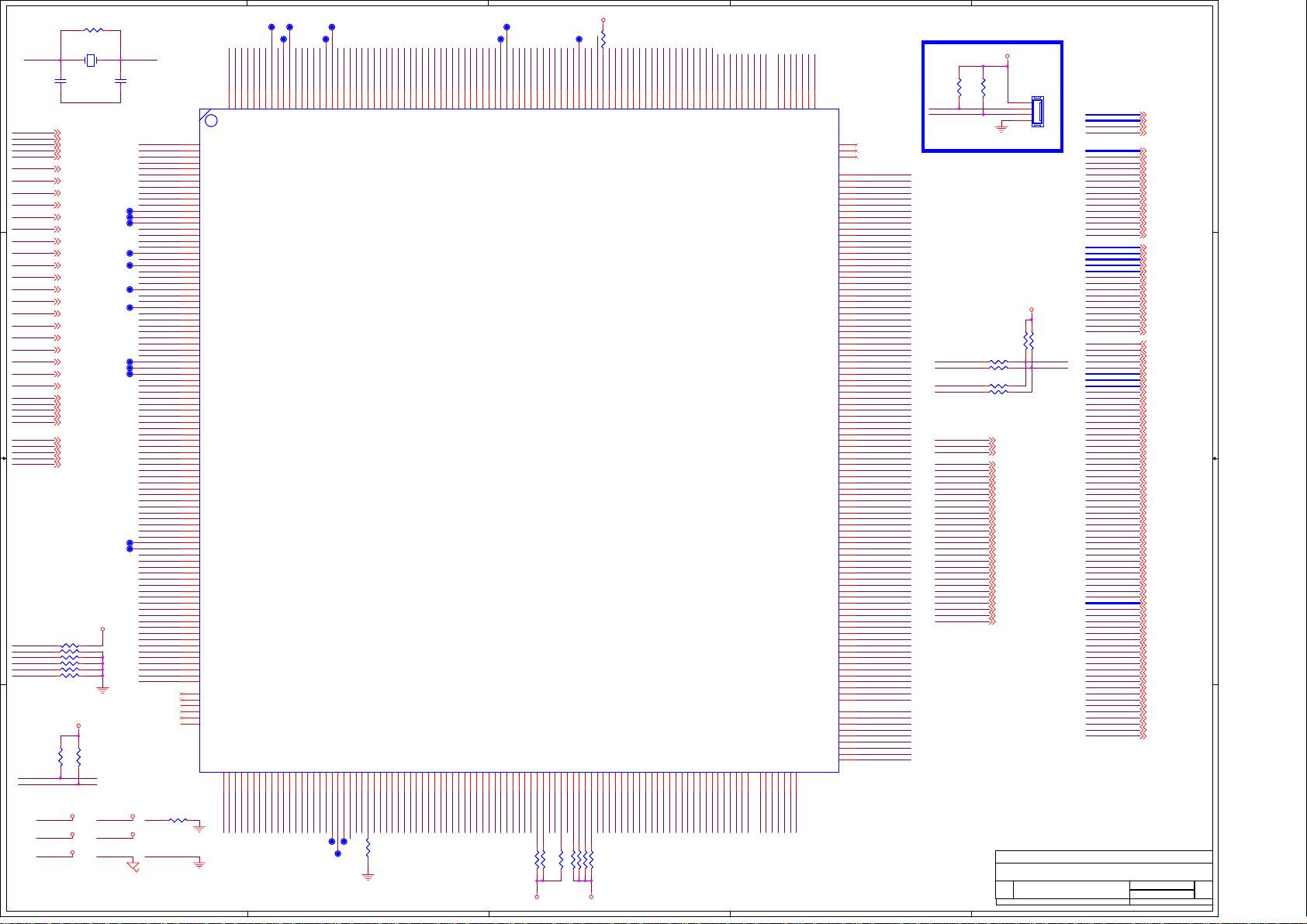

Page 13

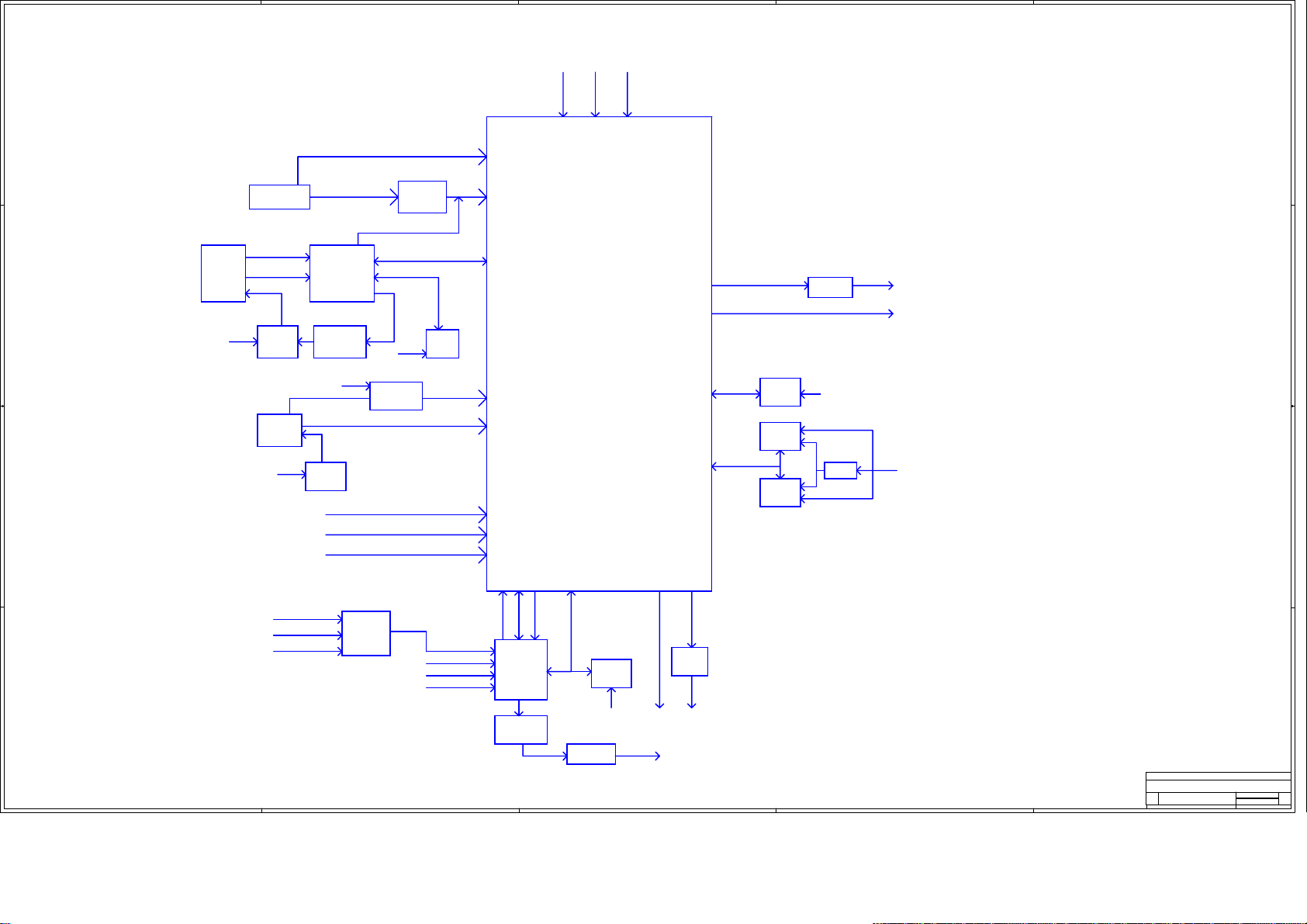

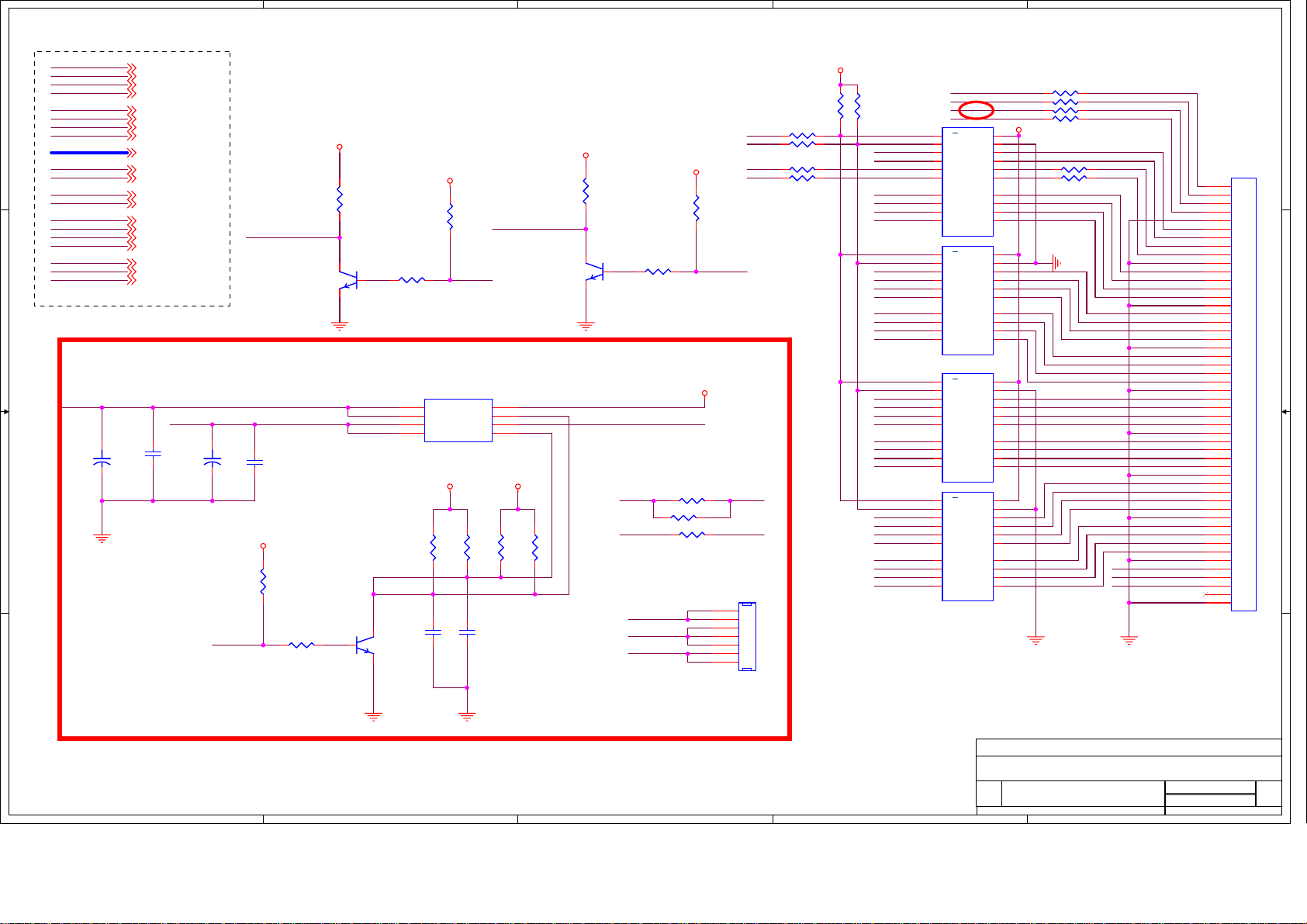

Circuit Diagram

11/65

- Main (Video) board

- Keypad board

- Remote control receiver board

- External L/R Speakers board

- Remote control board

Page 14

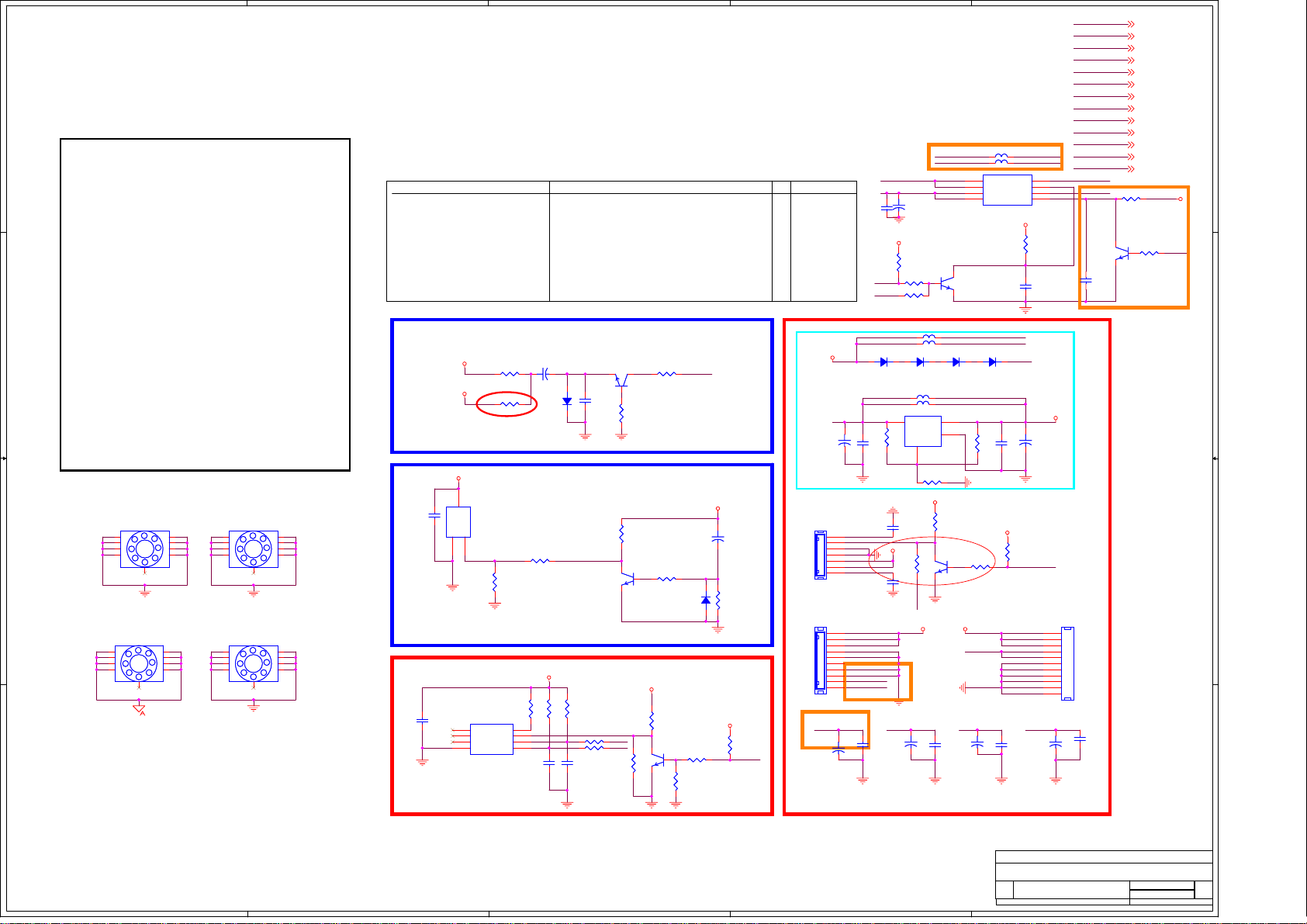

5

12/65

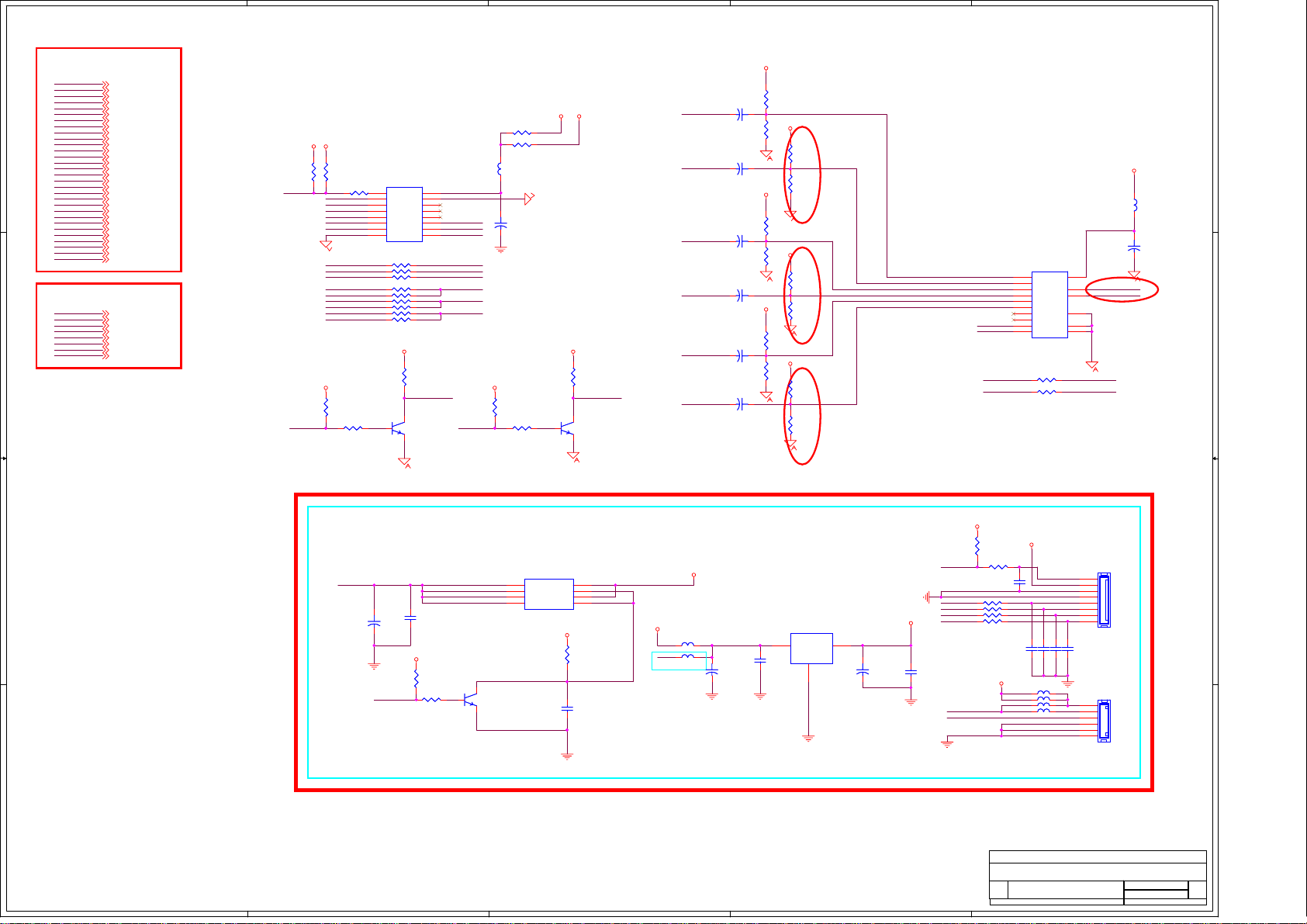

MT8202E (PBGA388) LCDTV BOARD 4 LAYERS FOR AKAI

D D

1. INDEX / POWER / RESET / EEPROM

2. LDO

3. MT8202E PBGA388

4. MT8202 DECOUPLING

5. DDR MEMORY & FLASH

6. MT5351 INTERFACE

7. HDMI MT8293

8. DAUGHTER BOARD IN

9. WM8776 & VIDEO BYPASS

4

Rev DateP#History

AKAI_MT8202_27US_LVDS_V0.0

AKAI_MT8202_27US_HDMI_LVDS_V0.0

3

New

ADD HDMI / VIDEO /AUDIO CONNECTOR INPUT IN

2005/11/22

2

9VV 9V

9VV

VCC +5V/+6V

9V

+

+

CE12

CE12

100uF/10v

GPIO14

GPIO19

SB33B

R776

R776

10k

10k

100uF/10v

C22UF25V/D5H11

C22UF25V/D5H11

HI = > POWER ON

LO = > POWER OFF

R7770/NC R7770/NC

1

R7780 R7780

CB20

CB20

0.1uF

0.1uF

Q44

Q44

2N3904

2N3904

SOT23/SMD/NC

SOT23/SMD/NC

3 2

FB42 FB/NCFB42 FB/NC

FB43 FB/NCFB43 FB/NC

U62

U62

8

D1

7

D1

6

D2

5

D2

IRF7316

IRF7316

SOIC8/SMD

SOIC8/SMD

5VSB

S1

G1

S2

G2

1

2

3

4

R775

R775

22k

22k

C681

C681

1uF/NC

1uF/NC

1

LVDSVDD

SCL

SDA

URST#

8202UP3_1

GPIO2

GPIO4

GPIO14

GPIO19

9V

12V

RELAY_ON

9V

VS_ON

9VV

C4

1uFC41uF

LVDSGND 2,3,4

SCL 9,14

SDA 9,14

URST# 3

8202UP3_1 3

GPIO2 3,12

GPIO4 3

GPIO14 3,13

GPIO19 3,13

9V 7,9,14

12V 12,13

RELAY_ON 12

VS_ON 12

Q45

Q45

2N3904

2N3904

1

R57 1KR57 1K

3 2

5VSB

R77922K R77922K

GPIO2

10. AUDIO / VIDEO IN CIRCUIT

12V

12V

D26

D26

9VV

1N4001/SMD

1N4001/SMD

VCC

+

+

R37NCR37

NC

8202UP3_1 HIGH :POWER OFF

8202UP3_1 LOW :POWER ON

CB6

CB6

0.1uF/NC

0.1uF/NC

CE6

CE6

100uF/16v.NC

100uF/16v.NC

SB33B

R635

R635

10k/NC

10k/NC

R340

R340

8202UP3_1

4.7k

4.7k

J6

CE145

CE145

470uF/16v

470uF/16v

1

2

3

4

5

6

7

8

9

10

11

+

+

J6

11x1

11x1

DIP11/P2.54

DIP11/P2.54

+5V/+6V

LVDSVDD

+

+

CB3

CB3

0.1uF

0.1uF

0.1uF

0.1uF

CB207

CB207

D23

D23

1N4001/SMD

1N4001/SMD

FB39 FB/NCFB39 FB/NC

=

=

FB40 FB/NCFB40 FB/NC

U61 KA278RA05/NC TO-220F-4LU61 KA278RA05/NC TO-220F-4L

IN1OUT

CB4

CB4

R52NCR52

0.1uF/NC

0.1uF/NC

NC

C153

C153

5VSB

R236

R236

0/NC

0/NC

C154

C154

+12V

9VV

9VV

VCC

CE144

CE144

220uF/16v

220uF/16v

FB2 FB/NCFB2 FB/NC

FB3 FB/NCFB3 FB/NC

D24

D24

1N4001/SMD

1N4001/SMD

GND

VDIS

4

R22 NCR22 NC

5VSB

R339

R339

10k

10k

SOT23/SMD

SOT23/SMD

3 2

ADD1

+12V

+

+

CB15

CB15

0.1uF

0.1uF

D25

D25

2

3

Q21

Q21

1

2N3904

2N3904

+5V/+6V

12V +12V

CE2

CE2

100uF/16v

100uF/16v

C C

11 . VGA & PC AUDIO IN

12. LVDS OUT

SB33A

13. BACK LIGHT / KEYPAD

14. TUNER IN

5VSB

15. AV IN

16. AUDIO IN

17.AUDIO Amplifier

POWER DOWN RESET# CIRCUIT

CE110

R337 10R337 10

R225

R225

10/NC

10/NC

CE110

47uF/16v

47uF/16v

+

+

1N4148D21N4148

D2

CB188

CB188

0.1uF

0.1uF

2N3904

2N3904

3 2

+12V

URST#

0

R3380R338

Q20

Q20

1

R744

R744

470

470

1N4001/SMD

1N4001/SMD

DIODE SMD/NC

DIODE SMD/NC

+5V/+6V VCC

+

+

CE3

CE3

100uF/16v/NC

100uF/16v/NC

SB33B

POWER ON RESET# CIRCUIT

CB5

CB5

0.1uF

0.1uF

3

U1

U1

LM809

LM809

VCC

SOT-23/SMD/NC

SOT-23/SMD/NC

GND1RESET

2

U2

U2

1

NC

2

NC

3

NC

GND4SDA

EEPROM 24C16

EEPROM 24C16

SOP8/SMD

SOP8/SMD

SYSTEM EEPROM

R11

R11

100k/NC

100k/NC

VCC

WP

SCL

R324

R324

10K

10K

R9

1k/NCR91k/NC

URST#

Q19

Q19

3 2

2N3904

2N3904

SOT23/SMD

SOT23/SMD

R10

R10

1

4.7K

4.7K

1N4148/SMD

1N4148/SMD

5VSB

5VSB

R637

R637

R638

R638

R6390R639

10K

10K

10K

10K

0

8

7

6

5

C175

C175

20pF

20pF

R674 100R674 100

R675 100R675 100

C176

C176

20pF

20pF

SYSROMWP

SCL

SDA

R13

R13

20K

20K

Q4

Q4

2N3904

2N3904

R676 10K/NCR676 10K/NC

SOT23/SMD

SOT23/SMD

3 2

CB2

CB2

0.1uF/NC

HOLE/GNDH2HOLE/GND

H2

1

1

HOLE/GNDH4HOLE/GND

1

1

2

2

3

3

4

4

5

5

2

2

3

3

4

4

5

5

9

9

8

8

7

7

6

6

B B

H4

9

9

8

8

7

7

6

6

A A

HOLE/GNDH1HOLE/GND

H1

9

9

8

8

7

7

6

6

9

9

8

8

7

7

6

6

2

2

3

3

4

4

5

5

1

1

HOLE/GNDH3HOLE/GND

H3

2

2

3

3

4

4

5

5

1

1

0.1uF/NC

D1

D1

R14 10KR14 10K

1

R15

R15

10K/NC

10K/NC

SB33B

+

+

CE4

CE4

10uF/25v

10uF/25v

R8

47kR847k

SB33B

H : WP DISABLE

L : WP ENABLE

R645

R645

10K

10K

GPIO4

1000pF/NC

1000pF/NC

VS_ON

7

SYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWRSYS_PWR

6

5

4

3

2

RELAY_ON

1

1000pF/NC

1000pF/NC

J23

J23

DIP7/W/H/P2.54

DIP7/W/H/P2.54

J7

J7

1

2

3

4

5

6

7

R. ANGLE

R. ANGLE

8

9

10

DIP10/W/H/P2.54

DIP10/W/H/P2.54

9VV

CB1

CE1

CE1

220uF/16v

220uF/16v

CB1

+

+

0.1uF

0.1uF

FROM POWER BOARD

KAWA Confidential

KAWA Confidential

KAWA Confidential

ZhongShan KAWA Electronic Inc.

ZhongShan KAWA Electronic Inc.

ZhongShan KAWA Electronic Inc.

Title

Title

Title

INDEX / POWER / RESET / EEPROM

INDEX / POWER / RESET / EEPROM

INDEX / POWER / RESET / EEPROM

Document Number

Document Number

Document Number

Size

Size

Size

AKAI_MT8202_27US_LVDS_V0.0

AKAI_MT8202_27US_LVDS_V0.0

AKAI_MT8202_27US_LVDS_V0.0

C

C

C

Date: Sheet

Date: Sheet

5

4

3

2

Date: Sheet

Rev

Rev

<Designer>

<Designer>

<Designer>

<Checker>

<Checker>

<Checker>

117Monday, April 03, 2006

117Monday, April 03, 2006

117Monday, April 03, 2006

Rev

1

1

1

of

of

of

Drawn:

Drawn:

Drawn:

Checked:

Checked:

Checked:

1

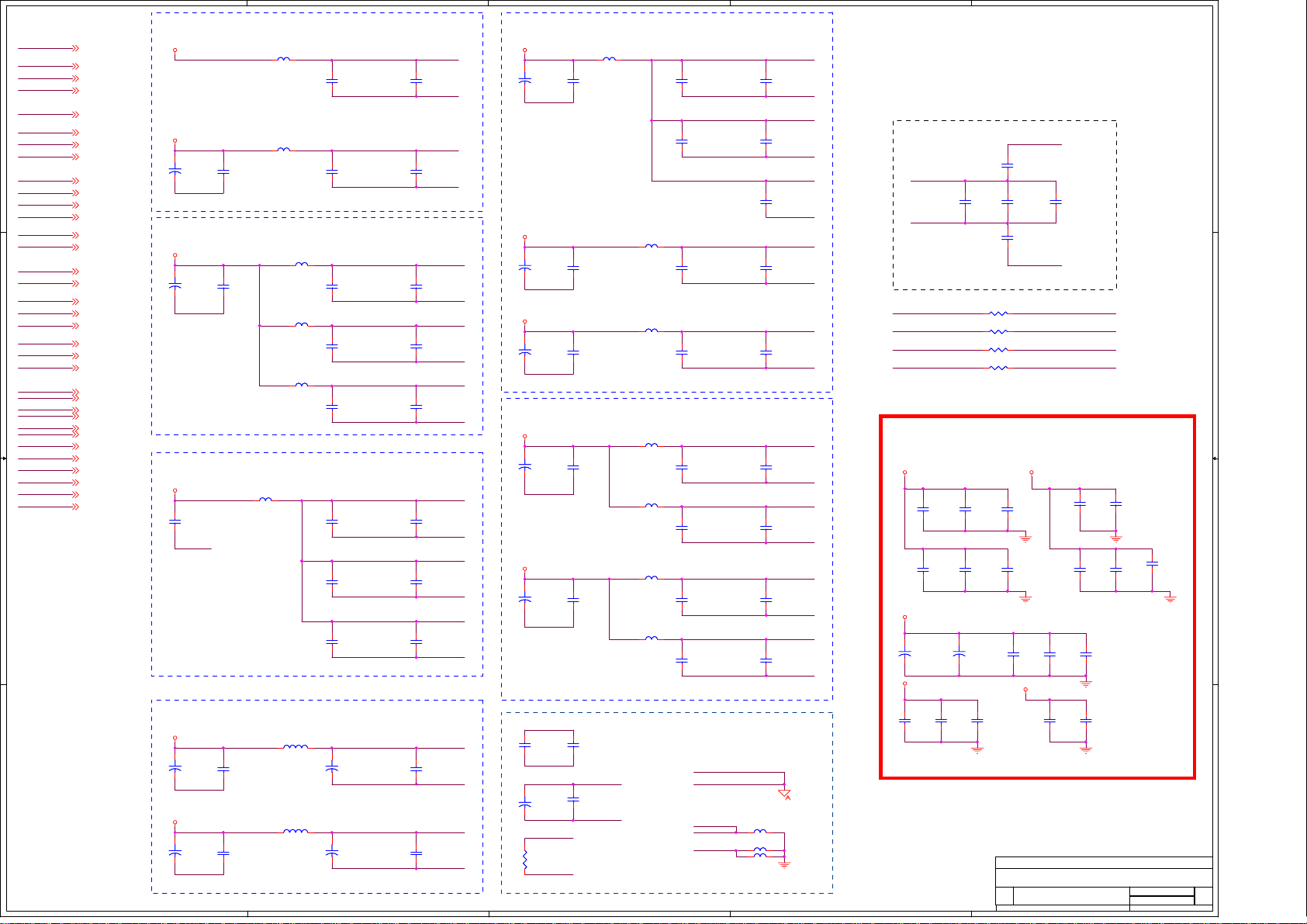

Page 15

5

13/65

4

3

2

1

ASB33A

+

+

CE7

CE7

100uF/16v

100uF/16v

SB33B

CB8

CB8

0.1uF

0.1uF

ASB33A

+

+

CE8

CE8

100uF/16v

100uF/16v

CE10

CE10

100uF/16v

100uF/16v

LVDS_GND

CB10

CB10

0.1uF

0.1uF

SB18ASB33A

LVDS_GND

VFE_GND

VFE_GND1

LVDS_GND 3,4,12

VFE_GND 3,4,8,11

VFE_GND1 3,4,8,11

U4

U4

AZ1117/adj

AZ1117/adj

3

+

+

CB9

CB9

0.1uF

0.1uF

2

OUT

IN

ADJ/GND

1

SOT223/SMD

SOT223/SMD

R773

R773

110 1%

110 1%

R774

R774

62 1%

62 1%

+

+

CE79

CE79

100uF/16v

100uF/16v

L5 FBL5 FB

L8 FBL8 FB

ASB18A

LVDS_GND

ASB18A

+

+

CE11

CE11

100uF/16v

100uF/16v

+

+

SB18ASB18SB33A

CE9

CE9

100uF/16v

100uF/16v

L4 FBL4 FB

Power ON alive source

AZ1117-3.3V

AZ1117-3.3V

U3

CB7

CB7

0.1uF

0.1uF

U3

3

IN

1

D D

5VSB

OUT

ADJ/GND

SOT223/SMD

SOT223/SMD

SB33

2

+

+

CE78

CE78

100uF/16v

100uF/16v

L6 FBL6 FB

L7 FBL7 FB

1.25x(1+62/110)=1.95V

OUT

ADJ/GND

ADCV33A

CB202

CB202

0.1uF

0.1uF

+

+

AZ1117-1.8V

AZ1117-1.8V

SOT223/SMD

SOT223/SMD

2

+

CE14

+

CE14

100uF/16v

100uF/16v

DV33A

CB17

CB17

0.1uF

0.1uF

VFE_GND1

+

+

CE82

CE82

100uF/16v

100uF/16v

SB18

L47 FBL47 FB

L43 FB/1206L43 FB/1206

L49 FB/NCL49 FB/NC

ADCV18A

VFE_GND

+

+

+

+

CE17

CE17

220uF/16v

220uF/16v

ADCV18A

CE13

CE13

100uF/16v

100uF/16v

DV18A

CB189

CB189

0.1uF

0.1uF

DV18A

CB18

CB18

0.1uF

0.1uF

L46 FBL46 FB

C C

AZ1117-3.3V

CB206

CB206

0.1uF

0.1uF

AZ1117-3.3V

3

IN

U7

U7

OUT

ADJ/GND

1

SOT223/SMD

SOT223/SMD

2

+

CE81

+

CE81

100uF/16v

100uF/16v

VCC

+

+

CE103

CE103

470uF/16v

470uF/16v

SB33

change 2/16

L10 FBL10 FB

L48 FBL48 FB

3

IN

CE15

CE15

220uF/16v

220uF/16v

U8

U8

1

AV33A

CE18

CE18

220uF/16v

220uF/16v

4

AV33A

+

+

CB21

CB21

0.1uF

0.1uF

AV33A

+

+

CE108

CE108

220uF/16v

220uF/16v

LVDS_GND

U37

U37

3

IN

ADJ/GND

1

SOT223/SMD

SOT223/SMD

3

L42FBL42

B B

AZ1117-3.3V

AZ1117-3.3V

SOT223/SMD

SOT223/SMD

U11

CB23

CB23

0.1uF

0.1uF

U11

3

2

OUT

IN

ADJ/GND

1

+

+

CE21

CE21

220uF/16v

220uF/16v

VCC

+

+

CE104

CE104

470uF/16v

470uF/16v

A A

5

DV33B

CB24

CB24

0.1uF

0.1uF

FB

AZ1117/adj

AZ1117/adj

OUT

LVDS_GND

L50 FBL50 FB

DACVDD

+

CE109

+

CE109

220uF/16v

220uF/16v

LVDS_GND

DACVDD

R325

R325

300 1%

300 1%

R326

R326

180 1%

180 1%

+

+

L51 FBL51 FB

CE80

CE80

100uF/16v

100uF/16v

2

1.25x(1+180/300)=1.99V

AV18A

+

+

LVDS_GND

CE20

CE20

220uF/16v

220uF/16v

CB187

CB187

0.1uF

0.1uF

2

AV18A

CB22

CB22

0.1uF

0.1uF

KAWA Confidential

KAWA Confidential

KAWA Confidential

ZhongShan KAWA Electronic Inc.

ZhongShan KAWA Electronic Inc.

ZhongShan KAWA Electronic Inc.

Title

Title

Title

LDO

LDO

LDO

Document Number

Document Number

Document Number

Size

Size

Size

AKAI_MT8202_27US_LVDS_V0.0

AKAI_MT8202_27US_LVDS_V0.0

AKAI_MT8202_27US_LVDS_V0.0

C

C

C

Date: Sheet of

Date: Sheet

Date: Sheet

Drawn:

<Designer>

Drawn:

<Designer>

Drawn:

<Designer>

Checked:

Checked:

Checked:

<Checker>

<Checker>

<Checker>

217Thursday, March 30, 2006

217Thursday, March 30, 2006

217Thursday, March 30, 2006

of

of

1

Rev

Rev

Rev

1

1

1

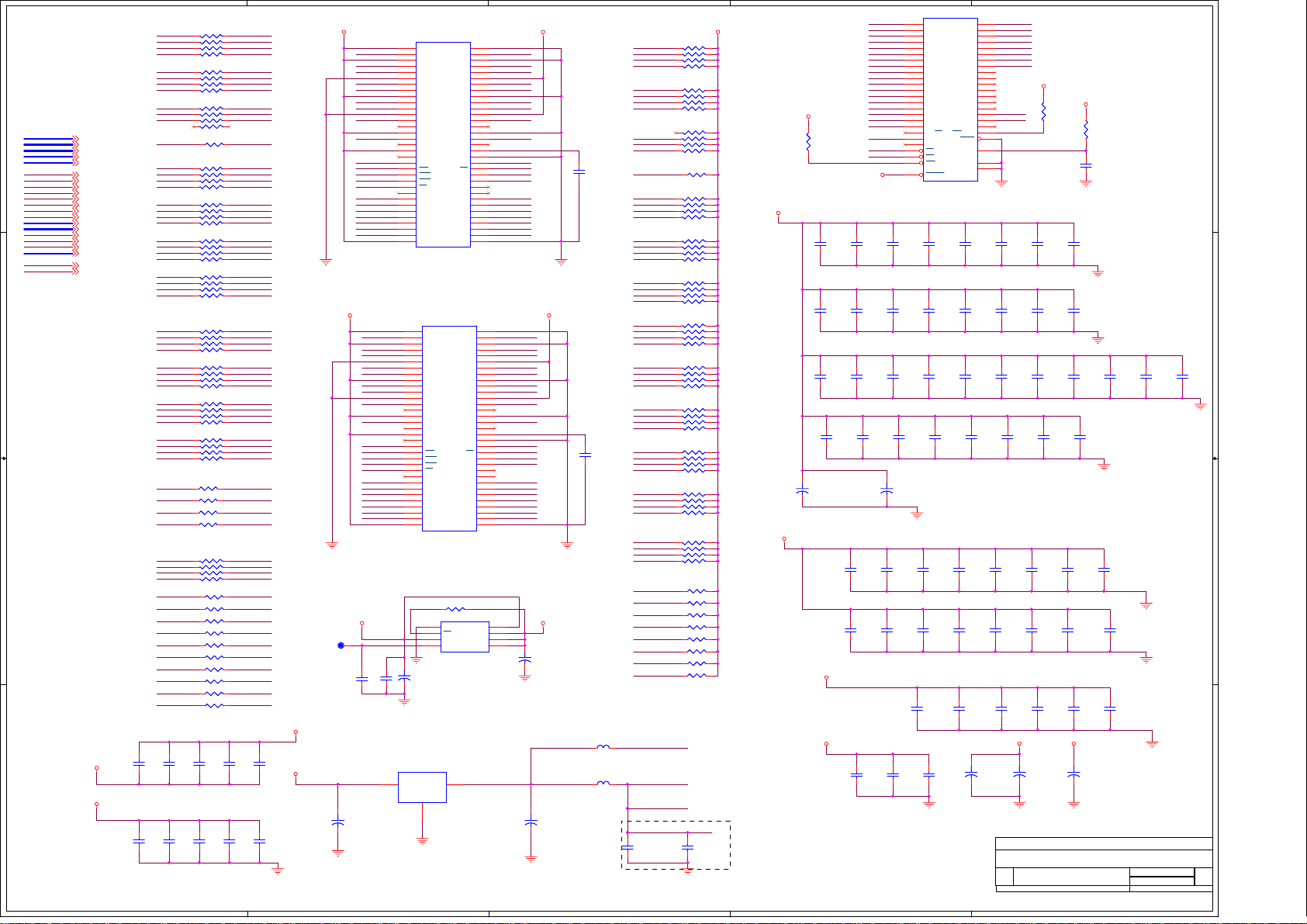

Page 16

5

14/65

AUDIO_GND

TESTP3

C23

D23

TP3

TN3

HIGHA1F3DVSS18

HIGHA2

F2

F_A9

F_A20

AL

ADACVSS

IOA20

F_A21

TP3TP3

TP2TP2

TP4TP4

MPX1

MPX2

ACENT

AADCVSS

AADCVDD

TESTP2

AR

TESTN2

ADACVDD

C24

B24

ADACVDD

ACENT/AOSDAT2

IOA18

G3

M12

F_A18

F_A8

AVDD_VAD0

C26

C25

E24

B25

D24

B26

F23

AF

SIF

TP2

TN2

AADCVSS

AADCVDD

IOA6H2IOA5H3DVDD33AH4IOA4

HIGHA0G2IOA7

H1

G1

IOA7

IOA3

IOA6

IOA5

IOA4

SB33A

TP50TP50

AVICM

A26

A24

A25

AVICM

AL/AOSDAT0

AR/AOSDAT1

IOA19

IOA21

IOWR#

J2

F1

G4

IOWR#

F_A19

GND

R34 820kR34 820k

Y1

SB33B

TP80TP80

TP12TP12

TP13TP13

TP45TP45

TP46TP46

TP47TP47

TP31TP31

TP8TP8

TP9TP9

TP10TP10

TP48TP48

TP49TP49

DV18A

DV33A

VFE_GND

DV18A

DV33A

5

XTALO

C2

27pFC227pF

PLLVDD1

LVDS_GND

PLLVDD2

LVDS_GND

PLLVDD3

XTALVDD

XTALO

XTALI

LVDS_GND

LVDS_GND

ADC_IN4

ADC_IN3

ADC_IN2

ADC_IN1

ADC_IN0

ADCVDD

PWM2VREF

SVM

B

LVDS_GND

G

DACVDDA

LVDS_GND

DACVDDB

R

LVDS_GND

DACFS

DACVREF

DACVDDC

TESTP4

TESTN4

VPLLVDD1

LVDS_GND

VPLLVDD2

LVDDA

AP7

AN7

CLK2+

CLK2LVDS_GND

AP6

AN6

AP5

AN5

LVDDB

AP4

AN4

AP3

AN3

LVDS_GND

CLK1+

CLK1AP2

AN2

LVDDC

AP1

AN1

AP0

AN0

LVDS_GND

SB18A

GPIO19

SB33A

8202UP3_5

8202UP3_1

8202UP3_0

VSYNC

HSYNC

DE

VCLK

F_A17

IOA0

F_D7

GND

F_D6

F_D5

F_D4

GND

F_D3

F_D2

F_D1

F_D0

F_OE#

IOCE#

IOA1

SB18A

F_A16

F_A15

F_A14

F_A13

ICE

GND

U12

U12

R351 1kR351 1k

C22

B22

C21

A23

B21

A22

A20

A21

A19

D21

D20

C20

B20

C19

B19

D18

C18

B18

A18

D19

A17

C16

C17

D16

B17

D17

A16

B16

C15

A15

B15

D15

D14

A13

D13

C12

D12

C11

D11

C14

C10

D10

C13

A12

B12

B14

A11

B11

A10

B10

B13

A14

L12

L11

AA3

C9

D9

C8

D8

A9

B9

A8

B8

K4

D7

D5

C7

B7

A7

B6

A6

C6

D6

C3

C2

C4

B1

B2

A2

B3

A3

B4

A4

B5

A5

C1

K3

D2

D1

E4

E3

A1

C5

J3

J4

N2

PLLVDD1

PLLVSS2

PLLVDD2

PLLVSS3

PLLVDD3

XTALVDD

XTALO

XTALI

XTALVSS

ADCVSS

ADIN4/GPIO

ADIN3/GPIO

ADIN2/GPIO

ADIN1/GPIO

ADIN0/GPIO

ADCVDD

PWM2VREF

SVM

B

DACVSSA

G

DACVDDA

DACVSSB

DACVDDB

R

DACVSSC

FS

VREF

DACVDDC

TP4

TN4

VPLLVDD1

VPLLVSS

VPLLVDD2

LVDDA

A7P

A7N

CK2P

CK2N

LVSSA

A6P

A6N

A5P

A5N

LVDDB

A4P

A4N

A3P

A3N

LVSSB

CK1P

CK1N

A2P

A2N

LVDDC

A1P

A1N

A0P

A0N

LVSSC

DVDD18A

GPIO

DVDD33A

UP3_5

UP3_1

UP3_0

VSYNCO

HSYNCO

GPIO

GPIO

A17

IOA0

AD7

DVSS18

AD6

AD5

AD4

DVSS33

AD3

AD2

AD1

AD0

IOOE#

IOCS#

IOA1

DVDD18A

A16

HIGHA7

HIGHA6

HIGHA5

NC BALL

NC BALL

NC BALL

NC BALL

NC BALL

NC BALL

HIGHA4

E2

F_A12

LVDS_GND

B23

E1

F_A11

TESTN3

D22

PLLVSS1

HIGHA3

F4

F_A10

XTALI

D D

AUDIO_GND

AADCVSS

LVDS_GND

VFE_GND

VFE_GND1

AVDD_VAD1

AVDD_VFE1

PLLVDD1

PLLVDD2

PLLVDD3

XTALVDD

VPLLVDD1

DACVDDA

DACVDDB

DACVDDC

AVDD_VFE0

AVDD_VAD0

AADCVDD

ADACVDD

ADCVDD

VPLLVDD2

C C

LVDDA

LVDDB

LVDDC

TESTP2

TESTP3

TESTN3

TESTP4

TESTN4

AVICM

PWM2VREF

DACFS

REFP

REFN

B B

DE

DE

SVM

CVBS3

AOSDATA0

AOSDATA3

27MHzY127MHz

C1

22pFC122pF

LVDS_GND

AUDIO_GND 4,10

AADCVSS 4,10

LVDS_GND 2,4,12

VFE_GND 2,4,8,11

VFE_GND1 2,4,8,11

AVDD_VAD1 4

AVDD_VFE1 4

PLLVDD1 4

PLLVDD2 4

PLLVDD3 4

XTALVDD 4

VPLLVDD1 4

DACVDDA 4

DACVDDB 4

DACVDDC 4

AVDD_VFE0 4

AVDD_VAD0 4

AADCVDD 4

ADACVDD 4

ADCVDD 4

VPLLVDD2 4

LVDDA 4

LVDDB 4

LVDDC 4

TESTP2 9

TESTP3 4

TESTN3 4

TESTP4 4

TESTN4 4

AVICM 4

PWM2VREF 4

DACFS 4

REFP 4

REFN 4

R673 10K/NCR673 10K/NC

R364 10K/NCR364 10K/NC

R341 10KR341 10K

R342 10KR342 10K

R434 10KR434 10K

R441 10KR441 10K

SB33B

R39

R39

R40

R40

10k

10k

10k

10k

RXD1

TXD1

A A

SB33A

SB33B

SB18A

SB33A

SB33B

SB18A

TP5TP5TP23TP23

REFP

CVBS0

CVBS2

CVBS3

REFN

CVBS1

VFE_GND1

G24

F24

D25

D26

E26

E25

G23

REFP

REFN

CVBS1

CVBS0

CVBS2

AVSS_VAD0

AVDD_VAD0

WR#

RD#

IOA3D3INT0L1PRST#L2UP3_4L3IR

IOALE

IOA2

J1

K1

K2

D4

ALE

IOA2

INT0#

URD#

URST#

UWR#

8202UP3_4

TP51TP51

TP52TP52

4

SY0

VFE_GND1

AVDD_VFE0

H23

J23

CVBS3

AVSS_VFE0

AVDD_VFE0

ICE

L4

M2

ICE

IR

DV18A

R745NCR745

NC

4

TP7TP7

TP6TP6

PB1-

PR0+

Y1-

SOY1

PR1-

SY1

SC1

PR1+

SC0

PB1+

AVDD_VAD1

L26

G26

F26

J26

G25

F25

K26

J25

K25

L23

SY1

SY0

SC1

SC0

PB1P

PB1N

PR1P

PR1N

AVDD_VAD1

MT8202

MT8202

SOCKET

SOCKET

DVDD18U4RXDM3TXDM4AOMCLK

AOBCKN1LINN4DVSS18

AOSDATA0/GPIOP1AOSDATA1/GPIOP2AOSDATA2/GPIOP3AOSDATA3/GPIOP4DVSS33

AOLRCK

N3

M1

M11

RXD

TXD

AOLRCK

AOBCLK

AOSDATA0

ADIN

GND

AOMCLK

AOSDATA1

Y0+

PR0-

PB0-

Y0-

PB0+

Y1+

L25

Y1N

AOSDATA2

SOY0

VFE_GND

TESTN1

TESTP1

RED+

RED-

AVDD_VFE1

P26

M26

P24

L24

Y1P

SOY1

PR0N

N12

AOSDATA3

GND

M25

GPIO0

R24

P25

N26

P23

N25

PB0N

PR0P

GPIO0/AOSDATA4R1GPIO3R4GPIO1/AOSDATA5R2FCICLK/GPIOT1GPIO4T4GPIO5/TXDU1GPIO6/RXDU2DVDD18U3GPIO7V1GPIO9V3GPIO8V2GPIO10V4GPIO13W3GPIO14W4GPIO15Y1GPIO16

GPIO1

GPIO2

Y0P

Y0N

PB0P

GPIO2R3FCICMD/GPIO

FCLK

FCMD

GPIO3

R26

R25

R23

M24

RN

TP1

TN1

SOY0

AVSS_VAD1

AVDD_VFE1

FCIDAT/GPIO

T2

T3

TXD1

GPIO4

GPIO7

FDAT

RXD1

DV18A

GREEN-

T26

RP

GN

GPIO8

GREEN+

T25

GP

GPIO9

R35310K R35310K

SB33B

VFE_GND

BLUE-

BLUE+

VGASOG

U25

N24

T24

U26

BP

BN

SOG

GPIO11W1GPIO17

GPIO12

W2

GPIO12

GPIO10

GPIO11

GPIO13

R22010K R22010K

TP43TP43

VGAHSYNC#

VGAVSYNC#

SCART_FB

V26

V25

U24

VSYNC

HSYNC

AVSS_VFE1

FAST_BLANK

Y2

GPIO15

GPIO14

GPIO16

R22110K R22110K

R8710K R8710K

R8610K R8610K

SDA0

SCL0

V23

U23

SCL0

Y3

Y4

GPIO17

GPIO18

R8810K R8810K

SB33B

SB33B

CCIR_V7

V24

SDA0

CCIR_V7/GPIO

SDA

GPIO18

AA1

IOSDA

R8910K R8910K

3

R32310K R32310K

2

1

SB33B

GND

GND

CCIR_V3

CCIR_V1

SDA1

HDMISD3

CCIR_V0

Y26

CCIR_V1/GPIO

DQ3

AC1

A_DQ4

CCIR_V0/GPIO

DQ4

CCIR_VCLK

W23

CCIR_VCLK/GPIO

DQ5

AC2

A_DQ5

T16

DVSS33

DQ6

AC3

A_DQ6

SCL1

AB24

N11

GND

AB23

SCL1

DVSS25

AC4

A_DQ7

AA24

SDA1

HDMISD3/GPIO

DQ7

DQS0

AD1

A_DQS0

HDMISD1

HDMISD2

AA26

AA23

HDMISD2/GPIO

DQM0

AD5

AD2

DV25A

A_DQM0

CCIR_V6

CCIR_V2

CCIR_V5

CCIR_V4

Y25

Y24

Y23

W26

W25

W24

R16

DVSS18

CCIR_V2/GPIO

CCIR_V3/GPIO

CCIR_V4/GPIO

CCIR_V5/GPIO

CCIR_V6/GPIO

SCL

DQ2

DQ1

DQ0

DVDD33

DVDD25

AA2

AB3

AB2

AB1

AA4

AB4

AC5

IOSCL

DV25A

A_DQ3

A_DQ0

A_DQ2

DV33A

A_DQ1

3

HDMISD0

AA25

HDMISD0/GPIO

HDMISD1/GPIO

DVDD25

DQS1

AE1

A_DQS1

HDMILRCK

AC24

HDMILRCK/GPIO

DQ8

AF1

A_DQ8

DV18A

DV33A

HDMIBCLK

HDMIMCLK

VI23

VI19

VI22

VI20

VI21

AE26

AD25

AD26

AC25

AC26

AB25

AC20

AC23

AB26

VI20

VI21

VI22

VI23

DVDD33

DVDD18

HDMIBCLK/GPIO

HDMIMCLK/GPIO

DQ12

DVSS18

DQ11

DQ10

RVREF

DVSS18

DQ9

DVSS25

P12

P11

AF3

AF2

R12

AE3

AE2

AD3

GND

A_DQ10

A_DQ11

GND

VREF

GND

A_DQ9

A_DQ12

VI18

VI19

GND

VI17

AF26

AE25

VI18

DGND/BALL

L13

L14

GND

VI17

DGND/BALL

L15

GND

AADCVSS

E23

AADCVSS

DGND/BALL

DGND/BALL

L16

GND

VFE_GND1

VFE_GND1

VFE_GND

VFE_GND1

VFE_GND1

M23

H24

H25

H26

K23

VFE_GND

VFE_GND1

VFE_GND1

VFE_GND1

VFE_GND1

VCLK_DVI

HSYNC_DVI

VSYNC_DVI

CEN_DVI/GPIO

DE_SOG/GPIO

OUT_27MHZ/GPIO

GPIO/PWM1

GPIO/PWM0

DVDD25OPT

DVDD25OPT

DVDD25OPT

DVDD25_CLK

DGND/BALL

DGND/BALL

DGND/BALL

DGND/BALL

DGND/BALL

DGND/BALL

DGND/BALL

DGND/BALL

DGND/BALL

DGND/BALL

DGND/BALL

DGND/BALL

M15

M13

M14

GND

GND

GND

VFE_GND

N23

VFE_GND

NC BALL

NC BALL

NC BALL

VI16

VI15

VI14

VI13

VI12

VI11

DVSS18

VI10

DVSS33I

DVDD18

DE_DVI

DVDD33I

DQ31

DQ30

DQ29

DQ28

DQ27

DVSS25

DQ26

DQ25

DQ24

DQS3

DQM1

DVSS18

DQS2

DQ23

DQ22

DVSS25

DQ21

DQ20

DVDD18

DQ19

DQ18

DQ17

DQ16

RA4

RA5

DVSS25

RA6

RA7

RA8

DVSS18

RA9

RA11

CKE

RCLK

RCLKB

DVSS25

RA3

RA2

RA1

RA0

RA10

DVDD25

BA1

DVDD18

BA0

RCS#

RAS#

DVSS25

CAS#

RWE#

DQ15

DQ14

DQ13

DVDD25

R36

R36

R35

R35

10k

10k

10k

10k

RXD

TXD

GND

GND

GND

GND

GND

RS-232

IOSDA

R47 0R47 0

IOSCL

R48 0R48 0

8202UP3_5

R49 0/NCR49 0/NC

8202UP3_4

R50 0/NCR50 0/NC

8202UP3_4 FOR S/W SCL

8202UP3_5 FOR S/W SDA

CVBS0

CVBS1

CVBS2

SY0

SC0

SY1

SC1

RED+

REDGREEN+

GREENBLUE+

BLUEVGASOG

VGAHSYNC#

VGAVSYNC#

Y0+

Y0PB0+

PB0PR0+

PR0SOY0

Y1+

Y1PB1+

PB1PR1+

PR1SOY1

J24

K24

T23

VI16

AF25

VI15

AD24

VI14

AE24

VI13

AF24

VI12

AD23

VI11

AE23

T15

AF23

R15

AD22

VI9

AE22

VI8

AF22

VI7

AC21

VI6

AD21

VI5

AE21

VI4

AE19

AF21

VI3

AD20

VI2

AC22

AE20

VI1

AF20

VI0

AC19

AD19

AF19

AF18

AE18

AD18

AC18

AD17

AC17

AE17

AF17

AC16

AC15

AD16

AE16

T14

AF16

AE15

AD14

AF15

AD15

AE14

R14

AF14

AF13

AE13

T13

AD13

AC13

AC9

AF12

AC14

AE12

AD12

AC12

AF11

AE11

R13

AD11

AC11

AF10

T12

AE10

AD10

AC10

AC7

AE9

AF9

T11

AD9

AF8

AE8

AD8

AF7

AD6

AE7

AC8

AD7

AF6

AE6

R11

AF5

AE5

AF4

AE4

AD4

AC6

P16

P15

P14

P13

N16

N15

N14

N13

M16

BGA388/SMD

BGA388/SMD

MT8202

MT8202

2

GND

VI10

GND

VI9

VI8

VI7

VI6

VI5

VI4

HDMIODCK

VI3

VI2

DV18A

VI1

VI0

HDMIDE

HDMIHSYNC

HDMIVSYNC

HDMICEN

DE_SOG

27MHZ

PWM1

PWM0

DV33A

A_DQ31

A_DQ30

A_DQ29

SDV25A

A_DQ28

A_DQ27

A_DQ26

A_DQ25

A_DQ24

A_DQS3

SDV25A

A_DQM1

A_DQS2

A_DQ23

A_DQ22

A_DQ21

A_DQ20

DV18A

A_DQ19

SDV25A

A_DQ18

A_DQ17

A_DQ16

A_RA4

A_RA5

A_RA6

A_RA7

A_RA8

A_RA9

A_RA11

A_CKE

DV25A

A_CLK

A_CLK#

GND

A_RA3

A_RA2

A_RA1

A_RA0

A_RA10

DV25A

A_BA1

DV18A

A_BA0

A_CS#

A_RAS#

GND

A_CAS#

A_WE#

A_DQ15

A_DQ14

A_DQ13

DV25A

GND

GND

GND

GND

GND

GND

GND

GND

GND

J4

J4

1

2

3

4

4x1 W/HOUSING

4x1 W/HOUSING

DIP4/W/H/P2.0

DIP4/W/H/P2.0

SB33B

R101

R101

R103

R103

4.7K

4.7K

4.7K

4.7K

SDA_8202

SCL_8202

CVBS0 10

CVBS1 10

CVBS2 10

SY0 10

SC0 10

SY1 10

SC1 10

RED+ 11

RED- 11

GREEN+ 11

GREEN- 11

BLUE+ 11

BLUE- 11

VGASOG 11

VGAHSYNC# 11

VGAVSYNC# 11

Y0+ 10

Y0- 10

PB0+ 10

PB0- 10

PR0+ 10

PR0- 10

SOY0 10

Y1+ 10

Y1- 10

PB1+ 10

PB1- 10

PR1+ 10

PR1- 10

SOY1 10

ZhongShan KAWA Electronic Inc.

ZhongShan KAWA Electronic Inc.

ZhongShan KAWA Electronic Inc.

Title

Title

Title

MT8202E PBGA388

MT8202E PBGA388

MT8202E PBGA388

Document Number

Document Number

Document Number

Size

Size

Size

AKAI_MT8202_27US_LVDS_V0.0

AKAI_MT8202_27US_LVDS_V0.0

AKAI_MT8202_27US_LVDS_V0.0

C

C

C

Date: Sheet

Date: Sheet

Date: Sheet

AP[0..7]

AN[0..6]

CLK1+

CLK1-

VI[0..23]

HDMIMCLK

HDMIBCLK

HDMILRCK

HDMISD0

HDMISD1

HDMISD2

HDMISD3

HDMIODCK

HDMIDE

HDMIHSYNC

HDMIVSYNC

HDMICEN

DE_SOG

27MHZ

A_DQS[0..3]

A_RA[0..11]

A_BA[0..1]

A_DQM[0..1]

A_DQ[0..31]

A_CLK

A_CLK#

A_CKE

A_CS#

A_RAS#

A_CAS#

A_WE#

VREF

DV25A

SDV25A

IR

F_A21

IOCE#

F_OE#

IOWR#

F_A[8..20]

F_D[0..7]

IOA[0..7]

URST#

INT0#

SDA_8202

SCL_8202

SCL1

SDA1

ADC_IN0

8202UP3_0

8202UP3_1

PWM0

PWM1

GPIO0

GPIO1

GPIO2

GPIO3

GPIO4

GPIO7

GPIO8

GPIO9

GPIO10

GPIO11

GPIO12

GPIO13

GPIO14

GPIO15

GPIO16

GPIO17

GPIO18

GPIO19

VCLK

CCIR_VCLK

CCIR_V7

CCIR_V6

CCIR_V5

CCIR_V4

CCIR_V[0..3]

SCL0

SDA0

ADC_IN4

TXD1

RXD1

TXD

RXD

AOMCLK

AOBCLK

AOLRCK

ADIN

AOSDATA1

AOSDATA2

AL

AR

MPX1

MPX2

FCLK

FCMD

FDAT

SCL_8202

SDA_8202

1

AP[0..7] 12

AN[0..6] 12

CLK1+ 12

CLK1- 12

A_DQS[0..3] 5

A_RA[0..11] 5

A_BA[0..1] 5

A_DQM[0..1] 5

A_DQ[0..31] 5

A_CLK 5

A_CLK# 5

A_CKE 5

A_CS# 5

A_RAS# 5

A_CAS# 5

A_WE# 5

VREF 5

TXD1 7

RXD1 7

TXD 7,11

RXD 7,11

AOMCLK 9,16

AOBCLK 9,16

AOLRCK 9,16

AOSDATA1 9

KAWA Confidential

KAWA Confidential

KAWA Confidential

Drawn:

Drawn:

Drawn:

Checked:

Checked:

Checked:

VI[0..23] 6,7

HDMIMCLK 6,7

HDMIBCLK 6,7

HDMILRCK 6,7

HDMISD0 6,7

HDMISD1 6

HDMISD2 6

HDMISD3 6

HDMIODCK 6,7

HDMIDE 6,7

HDMIHSYNC 6,7

HDMIVSYNC 6,7

HDMICEN 6

DE_SOG 6

27MHZ 6

DV25A 5

SDV25A 5

IR 13,15

F_A21 13

IOCE# 5

F_OE# 5

IOWR# 5

F_A[8..20] 5

F_D[0..7] 5

IOA[0..7] 5

URST# 1

INT0# 6

SDA_8202 6,9,12

SCL_8202 6,9,12

SCL1 7

SDA1 7

ADC_IN0 8

8202UP3_0 13

8202UP3_1 1

PWM0 13

PWM1 13

GPIO0 12

GPIO1 15

GPIO2 1,12

GPIO3 7

GPIO4 1

GPIO7 9

GPIO8 17

GPIO9 17

GPIO10 13

GPIO11 8

GPIO12 13

GPIO13 13

GPIO14 1,13

GPIO15 8

GPIO16 8

GPIO17 8

GPIO18 8

GPIO19 1,13

VCLK 13

CCIR_VCLK 12

CCIR_V7 8

CCIR_V6 7

CCIR_V5 8

CCIR_V4 12

CCIR_V[0..3] 6,8,13

SCL0 7

SDA0 7

ADC_IN4 14

ADIN 9

AOSDATA2 16

AL 9

AR 9

MPX1 10

MPX2 10

FCLK 12

FCMD 12

FDAT 12

SCL_8202 6,9,12

SDA_8202 6,9,12

<Designer>

<Designer>

<Designer>

<Checker>

<Checker>

<Checker>

317Thursday, March 30, 2006

317Thursday, March 30, 2006

317Thursday, March 30, 2006

of

of

of

Rev

Rev

Rev

1

1

1

Page 17

5

15/65

STANDBY ANALOG POWER

XTALVDD

ADCVDD

AVICM

PWM2VREF

DACFS

D D

LVDDA

LVDDB

LVDDC

AVDD_VFE0

AVDD_VAD0

AADCVDD

ADACVDD

VPLLVDD1

VPLLVDD2

AVDD_VAD1

AVDD_VFE1

PLLVDD1

PLLVDD2

PLLVDD3

DACVDDA

C C

DACVDDB

DACVDDC

TESTP3

TESTN3

TESTP4

TESTN4

REFP

REFN

AADCVSS

AUDIO_GND

LVDS_GND

VFE_GND

AADCVSS

VFE_GND1

B B

XTALVDD 3

ADCVDD 3

AVICM 3

PWM2VREF 3

DACFS 3

LVDDA 3

LVDDB 3

LVDDC 3

AVDD_VFE0 3

AVDD_VAD0 3

AADCVDD 3

ADACVDD 3

VPLLVDD1 3

VPLLVDD2 3

AVDD_VAD1 3

AVDD_VFE1 3

PLLVDD1 3

PLLVDD2 3

PLLVDD3 3

DACVDDA 3

DACVDDB 3

DACVDDC 3

TESTP3 3

TESTN3 3

TESTP4 3

TESTN4 3

REFP 3

REFN 3

AADCVSS 3,10

AUDIO_GND 3,10

LVDS_GND 2,3,12

VFE_GND 2,3,8,11

AADCVSS 3,10

VFE_GND1 2,3,8,11

ASB18A

ASB33A

+

+

CE26

CE26

10uF/10V

10uF/10V

LVDS_GND

L12 FBL12 FB

L13 FBL13 FB

C10

C10

1uF

1uF

NORMAL VIDEO DAC POWER

DACVDD

+

+

CE28

CE28

10uF/10V

10uF/10V

LVDS_GND

FB5 FB

FB5 FB

BEAD/SMD/0603

BEAD/SMD/0603

C14

C14

1uF

1uF

FB6 FB

FB6 FB

BEAD/SMD/0603

BEAD/SMD/0603

FB8 FB

FB8 FB

BEAD/SMD/0603

BEAD/SMD/0603

NORMAL VIDEO DAC POWER

AV33A

C20

C20

1uF

1uF

LVDS_GND

FB10 FB

FB10 FB

BEAD/SMD/0603

BEAD/SMD/0603

NORMAL AUDIO ADC / DAC POWER

ADCV33A

+

+

CE33

CE33

10uF/10V

10uF/10V

A A

AADCVSS

ADCV33A

+

CE35

+

CE35

10uF/10V

10uF/10V

AUDIO_GND

5

C27

C27

1uF

1uF

C28

C28

1uF

1uF

L14 150uH

L14 150uH

L/IND/DIP/P10.0

L/IND/DIP/P10.0

L15 150uH

L/IND/DIP/P10.0

L/IND/DIP/P10.0

+

+

+

+

C5

4.7uFC54.7uF

C11

C11

4.7uF

4.7uF

C15

C15

4.7uF

4.7uF

C16

C16

4.7uF

4.7uF

C18

C18

4.7uF

4.7uF

C21

C21

4.7uF

4.7uF

C23

C23

4.7uF

4.7uF

C25

C25

4.7uF

4.7uF

CE34

CE34

470uF/16V

470uF/16V

CE36

CE36

470uF/16V

470uF/16V

4

3

2

1

NORMAL ANALOG POWER

XTALVDD

CB26

CB26

0.1uF

0.1uF

LVDS_GND

ADCVDD

CB29

CB29

0.1uF

0.1uF

LVDS_GND

DACVDDA

CB33

CB33

0.1uF

0.1uF

LVDS_GND

DACVDDB

CB34

CB34

0.1uF

0.1uF

LVDS_GND

DACVDDC

CB37

CB37

0.1uF

0.1uF

LVDS_GND

LVDDA

CB40

CB40

0.1uF

0.1uF

LVDS_GND

LVDDB

CB42

CB42

0.1uF

0.1uF

LVDS_GND

LVDDC

CB45

CB45

0.1uF

0.1uF

LVDS_GND

AADCVDD

CB47

CB47

0.1uF

0.1uF

AADCVSS

ADACVDD

CB48

CB48

0.1uF

0.1uF

AUDIO_GND

4

ASB18A

FB1 FBFB1 FB

+

+

CE24

CE24

10uF/10V

10uF/10V

LVDS_GND

AV18A

+

+

CE27

CE27

10uF/10V

10uF/10V

LVDS_GND

AV33A

+

+

CE29

CE29

10uF/10V

10uF/10V

LVDS_GND

C6

1uFC61uF

CB31

CB31

1uF

1uF

CB35

CB35

1uF

1uF

FB4 FBFB4 FB

FB7 FBFB7 FB

NORMAL VIDEO ADC POWER

ADCV33A

+

+

CE30

CE30

10uF/10V

10uF/10V

VFE_GND1

ADCV18A

+

+

CE32

CE32

10uF/10V

10uF/10V

VFE_GND

AVICM

CB25

CB25

0.1uF

0.1uF

AUDIO_GND

+

+

CE25

CE25

47uF/16V

47uF/16V

DACFS

R42

R42

820

820

LVDS_GND

CB38

CB38

1uF

1uF

CB43

CB43

1uF

1uF

C3

C3

10uF/10v

10uF/10v

C0805/SMD

C0805/SMD

PWM2VREF

C8

C8

0.1uF

0.1uF

C0603/SMD

C0603/SMD

LVDS_GND

FB9 FBFB9 FB

FB11 FBFB11 FB

FB13 FBFB13 FB

FB15 FBFB15 FB

3

C7

4.7uFC74.7uF

C9

4.7uFC94.7uF

C13

C13

4.7uF

4.7uF

C17

C17

4.7uF

4.7uF

C19

C19

4.7uF

4.7uF

C22

C22

4.7uF

4.7uF

C24

C24

4.7uF

4.7uF

C26

C26

4.7uF

4.7uF

AADCVSS

AUDIO_GND

VFE_GND

VFE_GND1

LVDS_GND

L9 FBL9 FBL15 150uH

L2 FBL2 FB

L3 FBL3 FB

PLLVDD1

CB27

CB27

0.1uF

0.1uF

LVDS_GND

PLLVDD2

CB28

CB28

0.1uF

0.1uF

LVDS_GND

PLLVDD3

CB30

CB30

0.1uF

0.1uF

LVDS_GND

VPLLVDD1

CB32

CB32

0.1uF

0.1uF

LVDS_GND

VPLLVDD2

CB36

CB36

0.1uF

0.1uF

LVDS_GND

AVDD_VFE0

CB39

CB39

0.1uF

0.1uF

VFE_GND1

AVDD_VAD0

CB41

CB41

0.1uF

0.1uF

VFE_GND1

AVDD_VFE1

CB44

CB44

0.1uF

0.1uF

VFE_GND

AVDD_VAD1

CB46

CB46

0.1uF

0.1uF

VFE_GND

VFE_GND1

C51

C51

10uF/10v

10uF/10v

C0805/SMD

REFP

REFN

TESTP3

TESTN3

TESTN4

C0805/SMD

C49

C49

10uF/10v

10uF/10v

C0805/SMD

C0805/SMD

R43 49.9 1%R43 49.9 1%

R44 49.9 1%R44 49.9 1%

R45 49.9 1%R45 49.9 1%

R46 49.9 1%R46 49.9 1%

C173

C173

0.1uF

0.1uF

C50

C50

10uF/10v

10uF/10v

C0805/SMD

C0805/SMD

VFE_GND1

C174

C174

0.01uF

0.01uF

PLLVDD1

PLLVDD1

VPLLVDD1TESTP4

VPLLVDD1

MT8202 DIGITAL POWER & DECOUPLING

DV18A

CB52

CB52

CB53

CB53

0.1uF

0.1uF

0.1uF

0.1uF

C32

C32

C33

C33

3300pF

3300pF

3300pF

3300pF

5VSB

+

+

DV33A

2

CE37

CE37

220uF/16v

220uF/16v

CB59

CB59

0.1uF

0.1uF

CB60

CB60

0.1uF

0.1uF

+

+

CE38

CE38

220uF/16v

220uF/16v

SB33A

CB49

CB49

CB50

CB50

0.1uF

0.1uF

0.1uF

CB55

CB55

0.1uF

0.1uF

0.1uF

C29

C29

0.01uF

0.01uF

C30

C30

3300pF

3300pF

CB54

CB54

0.1uF

0.1uF

C34

C34

3300pF

3300pF

PUT ON NEARLY BGA

CB57

CB57

CB58

SB18A

0.1uF

0.1uF

C31

C31

3300pF

3300pF

CB58

0.1uF

0.1uF

CB51

CB51

0.1uF

0.1uF

KAWA Confidential

KAWA Confidential

KAWA Confidential

Drawn:

Drawn:

Drawn:

Checked:

Checked:

Checked:

1

<Designer>

<Designer>

<Designer>

<Checker>

<Checker>

<Checker>

417Thursday, March 30, 2006

417Thursday, March 30, 2006

417Thursday, March 30, 2006

of

of

of

CB56

CB56

0.1uF

0.1uF

SB18A

CB61

CB61

0.1uF

0.1uF

ZhongShan KAWA Electronic Inc.

ZhongShan KAWA Electronic Inc.

ZhongShan KAWA Electronic Inc.

Title

Title

Title

MT8202 DECOUPLING

MT8202 DECOUPLING

MT8202 DECOUPLING

Document Number

Document Number

Document Number

Size

Size

Size

AKAI_MT8202_27US_LVDS_V0.0

AKAI_MT8202_27US_LVDS_V0.0

AKAI_MT8202_27US_LVDS_V0.0

C

C

C

Date: Sheet

Date: Sheet

Date: Sheet

Rev

Rev

Rev

1

1

1

Page 18

5

16/65

RN2

RN2

A_RA3

7 8

A_RA2

5 6

A_RA1

3 4

A_RA0

1 2

RN4

RN4

A_RA6

7 8

A_RA7

5 6

A_RA4

3 4

A_RA5

1 2

RN6

RN6

A_RA8

7 8

A_RA9

5 6

A_RA11

D D

A_DQS[0..3]

A_DQS[0..3] 3

A_RA[0..11]

A_RA[0..11] 3

A_BA[0..1]

A_BA[0..1] 3

A_DQM[0..1]

A_DQM[0..1] 3

A_DQ[0..31]

IOA[0..7]

F_D[0..7]

F_A[8..20]

A_DQ[0..31] 3

A_CLK 3

A_CLK# 3

A_CKE 3

A_CS# 3

A_RAS# 3

A_CAS# 3

A_WE# 3

VREF 3

IOA[0..7] 3

F_D[0..7] 3

IOCE# 3

F_OE# 3

IOWR# 3

F_A[8..20] 3

DV25A 3

SDV25A 3

VREF

VREF

VREF

VREF

CB120

CB120

0.1uF

0.1uF

VREF DECOUPLING

CB125

CB125

0.1uF

0.1uF

5

A_CLK

A_CLK#

A_CKE

A_CS#

A_RAS#

A_CAS#

A_WE#

VREF

IOCE#

F_OE#

IOWR#

DV25A

SDV25A

C C

B B

A A

3 4

1 2

A_RA10

R64 22R64 22

RN8

RN8

A_DQ0

7 8

A_DQ1

5 6

A_DQ2

3 4

A_DQ3

1 2

RN10

RN10

A_DQ4

7 8

A_DQ5

5 6

A_DQ6

3 4

A_DQ7

1 2

RN11

RN11

A_DQ8

7 8

A_DQ9

5 6

A_DQ10

3 4

A_DQ11

1 2

RN13

RN13

A_DQ12

7 8

A_DQ13

5 6

A_DQ14

3 4

A_DQ15

1 2

RN16

RN16

A_DQ16

7 8

A_DQ17

5 6

A_DQ18

3 4

A_DQ19

1 2

RN17

RN17

A_DQ20

7 8

A_DQ21

5 6

A_DQ22

3 4

A_DQ23

1 2

RN19

RN19

A_DQ24

7 8

A_DQ25

5 6

A_DQ26

3 4

A_DQ27

1 2

RN21

RN21

A_DQ28

7 8

A_DQ29

5 6

A_DQ30

3 4

A_DQ31

1 2

A_DQS0

R66 47R66 47

A_DQS1 D_DQS1

R67 47R67 47

A_DQS2

R68 47R68 47

A_DQS3

R69 47R69 47

A_CAS#

7 8

A_WE#

5 6

A_CS# D_CS#

3 4

A_RAS#

1 2

A_BA1

R71 22R71 22

A_BA0

R73 22R73 22

A_DQM0

R76 22R76 22

A_DQM1

R78 22R78 22

A_CKE

R80 22R80 22

A_CLK

R82 22R82 22

A_CLK# D_CLK#

R84 22R84 22

D_CLK

R327 100/NCR327 100/NC

D_CLK

R328 100/NCR328 100/NC

D_CLK

R329 100/NCR329 100/NC

CB121

CB121

0.1uF

0.1uF

CB126

CB126

0.1uF

0.1uF

RN25

RN25

22x4

22x4

22x4

22x4

22x4

22x4

47x4

47x4

47x4

47x4

47x4

47x4

47x4

47x4

47x4

47x4

47x4

47x4

47x4

47x4

47x4

47x4

22x4

22x4

CB122

CB122

0.1uF

0.1uF

CB127

CB127

0.1uF

0.1uF

SDV25

CB123

CB123

0.1uF

0.1uF

CB128

CB128

0.1uF

0.1uF

D_RA3

D_RA2

D_RA1

D_RA0

D_RA6

D_RA7

D_RA4

D_RA5

D_RA8

D_RA9

D_RA11

D_RA10

D_DQ0

D_DQ1

D_DQ2

D_DQ3

D_DQ4

D_DQ5

D_DQ6

D_DQ7

D_DQ8

D_DQ9

D_DQ10

D_DQ11

D_DQ12

D_DQ13

D_DQ14

D_DQ15

D_DQ16

D_DQ17

D_DQ18

D_DQ19

D_DQ20

D_DQ21

D_DQ22

D_DQ23

D_DQ24

D_DQ25

D_DQ26

D_DQ27

D_DQ28

D_DQ29

D_DQ30

D_DQ31

D_DQS0

D_DQS2

D_DQS3

D_CAS#

D_WE#

D_RAS#

D_BA1

D_BA0

D_DQM0

D_DQM1

D_CKE

D_CLK

D_CLK#

D_CLK#

D_CLK#

CB124

CB124

0.1uF

0.1uF

CB129

CB129

0.1uF

0.1uF

DV25B

VCC

4

DV25B DV25B

D_DQ0

D_DQ1

D_DQ2

D_DQ3

D_DQ4

D_DQ5

D_DQ6

D_DQ7

D_DQS0

D_DQM0

D_WE#

D_CAS#

D_RAS#

D_CS#

D_BA0

D_BA1

D_RA10

D_RA0

D_RA1

D_RA2 D_RA5

D_RA3

DV25B

D1V25

TP40TP40

CB110

CB110

CB111

CB111

0.1uF

0.1uF

0.1uF

0.1uF

+

CE44

+

CE44

220uF/16v

220uF/16v

4

U18

U18

1

VDD

2

DQ0

3

VDDQ

4

DQ1

5

DQ2

6

VSSQ

7

DQ3

8

DQ4

9

VDDQ

10

DQ5

11

DQ6

12

VSSQ

13

DQ7

14

NC

15

VDDQ

16

LDQS

17

NC

18

VDD

19

DNU

20

LDM

21

WE

22

CAS

23

RAS

24

CS

25

NC

26

BA0

27

BA1

28

A10/AP

29

A0

30

A1

31

8M x 16

8M x 16

A2

32

A3

33

VDD

HY5DU281622ET-5 8Mx16 TSOP(II)-66/SMD

HY5DU281622ET-5 8Mx16 TSOP(II)-66/SMD

U19

U19

1

D_DQ16

D_DQ17

D_DQ18 D_DQ29

D_DQ19

D_DQ20

D_DQ21

D_DQ22

D_DQ23

D_DQS2

D_DQM1

D_WE#

D_CAS#

D_RAS#

D_CS#

D_BA0

D_BA1

D_RA10

D_RA0

D_RA1

D_RA2

D_RA3

VDD

2

DQ0

3

VDDQ

4

DQ1

5

DQ2

6

VSSQ

7

DQ3

8

DQ4

9

VDDQ

10

DQ5

11

DQ6

12

VSSQ

13

DQ7

14

NC

15

VDDQ

16

LDQS

17

NC

18

VDD

19

DNU

20

LDM

21

WE

22

CAS

23

RAS

24

CS

25

NC

26

BA0

27

BA1

28

A10/AP

29

A0

30

A1

31

A2

32

A3

33

VDD

HY5DU281622ET-5 8Mx16 TSOP(II)-66/SMD

HY5DU281622ET-5 8Mx16 TSOP(II)-66/SMD

D1V25

VREF

+

+

LT1084-2.5 TO-252-3

LT1084-2.5 TO-252-3

U21

3

IN

CE42

CE42

220uF/16v

220uF/16v

TO-252-3/SMDU21

TO-252-3/SMD

IC LP2996 DDR Termination SOP8

IC LP2996 DDR Termination SOP8

ADJ/GND

1

DQ15

VSSQ

DQ14

DQ13

VDDQ

DQ12

DQ11

VSSQ

DQ10

VDDQ

VSSQ

UDQS

VREF

UDM

DDR

DDR

8M x 16

8M x 16

DDR

DDR

R74 4.7kR74 4.7k

U20

U20

1

GND

2

SD

3

VSENSE

VREF4VDDQ

2

OUT

VSS

DQ9

DQ8

VSS

CKE

A12

A11

VSS

VSSQ

VDDQ

VSSQ

VDDQ

VSSQ

UDQS

VREF

NC

NC

CK

CK

NC

A9

A8

A7

A6

A5

A4

DQ15

DQ14

DQ13

DQ12

DQ11

DQ10

UDM

66

D_DQ15

65

64

D_DQ14

63

D_DQ13

62

61

D_DQ12

60

D_DQ11

59

58

D_DQ10

57

D_DQ9

56

55

D_DQ8

54

53

52

D_DQS1

51

50

49

48

D_DQM0

47

D_CLK#

46

D_CLK

45

D_CKE

44

43

42

D_RA11

41

D_RA9

40

D_RA8

39

D_RA7

38

D_RA6

37

36

D_RA4

35

34

66

VSS

D_DQ31

65

64

D_DQ30

63

62

61

D_DQ28

60

D_DQ27

59

58

D_DQ26

57

D_DQ25

56

DQ9

55

D_DQ24

54

DQ8

53

NC

52

D_DQS3

51

50

NC

49

48

VSS

D_DQM1

47

D_CLK#

46

CK

D_CLK

45

CK

D_CKE

44

CKE

43

NC

42

A12

D_RA11

41

A11

D_RA9

40

A9

D_RA8

39

A8

D_RA7

38

A7

D_RA6

37

A6

D_RA5

36

A5

D_RA4

35

A4

34

VSS

8

VTT

7

PVIN

6

AVIN

5

VREF

VREF

+

+

DV25B

DV25B

CE41

CE41

47uF/16v

47uF/16v

+

CE46

+

CE46

220uF/16v

220uF/16v

3

CB64

CB64

0.1uF

0.1uF

CB93

CB93

0.1uF

0.1uF

L16 FBL16 FB

L17 FBL17 FB

3

D_RA3

D_RA2

D_RA1

D_RA0

D_RA5

D_RA4

D_RA7

D_RA6

D_RA8

D_RA9

D_RA11

D_BA1

D_DQ0

D_DQ1

D_DQ2

D_DQ3

D_DQ4

D_DQ5

D_DQ6

D_DQ7

D_DQ8

D_DQ9

D_DQ10

D_DQ11

RN15

RN15

D_DQ12

D_DQ13

D_DQ14

D_DQ15

RN18

RN18

D_DQ16

D_DQ17

D_DQ18

D_DQ19

RN20

RN20

D_DQ20

D_DQ21

D_DQ22

D_DQ23

RN22

RN22

D_DQ27

D_DQ26

D_DQ25

D_DQ24

RN23

RN23

D_DQ31

D_DQ30

D_DQ29

D_DQ28

D_CS#

D_RAS#

D_BA0

D_RA10

D_DQS2

D_DQS3

D_CAS#

D_WE#

D_DQM1

D_DQS1

D_DQS0

D_DQM0

SDV25A

DV25B

DV25A

CLOSE TO 8202 PIN

DV25A

C56

C56

10uF/10v

10uF/10v

C0805/SMD

C0805/SMD

RN3

RN3

7 8

5 6

3 4

1 2

75x4

75x4

RN5

RN5

75x4

75x4

RN7

RN7

75x4

75x4

R65 75R65 75

RN9

RN9

7 8

5 6

3 4

1 2

75x4

75x4

RN12

RN12

7 8

5 6

3 4

1 2

75x4

75x4

RN14

RN14

7 8

5 6

3 4

1 2

75x4

75x4

7 8

5 6

3 4

1 2

75x4

75x4

75x4

75x4

75x4

75x4

1 2

3 4

5 6

7 8

75x4

75x4

1 2

3 4

5 6

7 8

75x4

75x4

RN24

RN24

7 8

5 6

3 4

1 2

75x4

75x4

R70 75R70 75

R72 75R72 75

R75 75R75 75

R77 75R77 75

R79 75R79 75

R81 75R81 75

R83 75R83 75

R85 75R85 75

CB130

CB130

0.1uF

0.1uF

D1V25

78

56

34

12

12

34

56

78

12

34

56

78

12

34

56

78

D1V25

SB33B

2

R63

R63

10k

10k

IOWR#

SB33B

U17

U17

IOA1

25

A0

IOA2

24

A1

IOA3

23

A2

IOA4

22

A3

IOA5

21

A4

IOA6

20

A5

IOA7 F_D6

19

A6

F_A8

18

A7

F_A9

8

A8

F_A10

7

A9

F_A11

6

A10

F_A12

5

A11

F_A13

4

A12

F_A14

3

A13

F_A15

2

A14

F_A16

1

A15

F_A17

48

A16

F_A18

17

A17

15

RY/BY

F_A20

9

A19

10

A20

IOCE#

26

CE

F_OE#

28

OE

11

WE

12

RESET

TSOP 48 PIN

D1V25

CB68

CB94

CB94

0.1uF

0.1uF

CB102

CB102

0.1uF

0.1uF

CB112

CB112

0.1uF

0.1uF

CB67

CB67

0.1uF

0.1uF

CB75

CB75

0.1uF

0.1uF

CB83

CB83

0.1uF

0.1uF

C41

C41

3300pF

3300pF

+

+

CB68

0.1uF

0.1uF

CB76

CB76

0.1uF

0.1uF

CB84

CB84

0.1uF

0.1uF

CE40

CE40

220uF/16v

220uF/16v

CB95

CB95

0.1uF

0.1uF

CB103

CB103

0.1uF

0.1uF

CB113

CB113

0.1uF

0.1uF

C42

C42

3300pF

3300pF

DV25A

C54

C54

3300pF

3300pF

CB66

CB66

0.1uF