Akai 1700 Service manual

I

\L

AKAI TAPE

REGI|RDER

oo

AND

to

Molf Et

l7

l7

IASTE OF

CONTENTS

I

spEctFtcAnoNs..

.. ...'.....'......

I

I

HOW TO A.TEASURE DESIGNATED VALUES

OF

SPEC|F|CAT|ONS..,......

..............'

2

I

tocafloN oF coNlRor.s

..... . ..........................,

3

IV

DrsAssEMrLy

oF tApE TRANSPoRT uNtTs

AND AMPL|F|ERS.........

...... ... ...

,l

v

TRANSPORI

MECHAN|SL

.......... .....

6

IJ

ADJUSTMENT

OF

TAPE TRANSPORT

UNIT

................."..

9

II

ADJUSTMENT

oF

al4pr|FrER

... .................... .............'10

rlf

r,{A|NTENANCE

pRocEDURES .. ............. .............It

X(

Lrsl

or

REPLACEI

ENT

pARTs....................................12

X

ExpLoDED vtEw

oF coMpoNENt

p^RTs............ ......,.1,4

xI

TROU3LESHOOTTNG

CHART

................,..............,.21

n

scHEfiATtC DTAGRAM

.,.....,............, ..'.................25

xI

CoNNECTING DfAGRAl.r

...................-..--.-.-.-......-.26

SPECIFICATIONS

MODEL

NUMBER

wtrGHT

(NET

IN CARTON)

DIMENSIONS

POWER RE-

qUIREMENTS

POWER CON.

SUMPTION

RECORDINC

Akai Modcl 1700, portablc 4-track

st.rco tape rccorder.

33 lbs

(15

kg) without acccssorics.

t3-t6'

lH)

x 13-%'

(w)

x 9'

(Dl

case

A. C. 100, ll0, 120,200,220 or 240 volts

interchang€abl€. 50 60cycles.

80VA.

Inline 4 t.ack st€reo and 4-tfack mon-

Inlin€ 4.tiack stefeo, monaural play-

Thrce speeds

cml and l-%"

(a.is

cmJ per second.

(15"

p€r

s€cond

with an optional accessory

capstan and pinch whe€I.)

SYSTEM:

PLAYBACK

SYSTEM:

TAPE SPEED

:

.I'APE

SPEED

DEVIATION

:

WOW AND

FLUTTER

:

TIME

FRDqUENCY

RDSPONStr

DISTORT'ION

SIGNAL-TO-

NOISE RATIO

CROSS TALK

CHANNEL

SEPARATION

Less

than

+

3

pef cent at all

tape

Less than 0.2

%

at 7-t6 ips. R.M.S.

Less than 0.3

%

at 3-7a ips. R.M.S.

Less than 0.45

%

at l-16 ips. R.M.S.

FAST FORWARD

AND

REWIND

150 seconds fof 1,200 ft. tapc at 50

cy-

cles

and 120

s€conds at 60 cyclcs.

40 to 18,000cps. at 7-%;ps;

.L 3 db.80

to

12,000 cps. at 7-l,

ipsj

+

3

db. 80

to 10,000cps.

at 3-3la;ps;

+

4 db. 80 at 4,000cps.

at l-7s ips.

Within 4%at l,000cps,oVU

ltotal

40 db below rccorded lev€lsignal

at all

Within 55db

between each trach.

Better than

80 db at l,000cps

+3

VU.

POWJ]R

INPU'I'

LDVELS:

POWDR

OUTPUT:

Microphone

ir)put lcvcl

-55

db

(VR.

max.jat

l,000cps.

Phono

and radio

input levcl

40 db

(VR.

max.)at l,000cps.

Pre-Amplifier

output, 0.7V at

1,000

cps, impedanc€

more than

l00K

ohms.

Main output,34dbm.

up

(in

600ohmt.

More than

50MEC ohns.

More

than

ore m;nute at A.C.

1,000V.

With headphor€

during reco.ding.

Condenser

start;ng

induction two-

l/l00HP.

Power

factor,70

pe.

cent.

2,900

to I,450

r.p.m. at 50

cps,

3,480 to 1,740

r.p.m.

at 60 cps.

lnline +tf ack

stereo/monau.al

record-

play h€ad

;

Impedance..

.3,500

ohms

+

l0

%

zt

I,000

cps.

4-track

erase head

;

Imp€danc€.

. .4,000 ohms

+15% at 90

Round

dynamic micropho.e

Impedance...50,000ohms

S€Dsit;vity...

55 db.

f.€quency

R€rpoDse...70

ro 15,000

Two 5'x7'

dynahic

speakers.

Imp€dance...8

ohms

Allowable IDput...6

warts

Frequency

R€sponse...8o

ro

12,000

cps,

:!

l0db.

I2AT7

x2, 6BM8x2.

l50Dx2

Up to 7'

r€el

INSULATION

RESISTANCE

INSULATION

YI[,LD

STRENGTH

MONITORINC

SYSTEM

MOTOR

HEADS

MICROPHONE

USED :

SPEAKOR

INCLUDED:

TUBES USED

:

SILICON

DIODE

USED:

REELS

USED :

RECORDING

LEVEL

INDICATOR

: Horizontal,

A-model

VU m€te..

1I

IIOW

TO

NIICNSURE

DESIGNATED

VALUES

OF

SPECIFICATIONS

TAI'I] SPDtrD

DEVIATION

:

\{OW

AND

FLUTTER

:

Reco.d

the l,000cps.

sine

curve

of

the tap€

speed

at rating

sp€eds

with

a standa.d

sound

recorder

(AMPEX

351A,

for instance)

which

is little

af-

fccted

by lhe

tape sPecd

deviation

tlrroughout

the

whole

i€ngth

of the

tape.

Put

th;s standard

taPe

on

th€

tapc recorder

unde.

test

for playing

back, and

nreasure

its

outPut

bY a

couDte.,

then

codvert

thc value

into

rating

power

frequeDcy

to cvaluate

the tape speed dcviatior.

Fo.

a rough

measurement,

the

taPe

spe€d deviation

can also

be measured

with a testing

tape for

speed by

astop

Playback

thc 3,000cps

sianda.d

tape

that guarante€s

wo\d and flutter

with-

h 0.07

p€r cent,

aid read

the effect;ve

valuc

otr wow

mere.

Since

the sedsibility

of

wow and flut-

tcr frequency

bclow

2cps

and above

5 cps. d.ops,

the frequency

over 5cps.

is put

to 3db/OCT

circuit,

and

th€

frequency

bclow 2.ps.

is put

to 6db/

OCT circuit

for adjustment

This ad-

justed

value is

called

auditory com-

Connccr

to

thc input

tcdninal of

the

rcco.dcr,

.ccord a sine

curve swecp

f.equency

at 100 cps

-10

db.

from

Audio

frequency Oscillator.

Adjusl toDe

volume

to

flat,

playback

the tape

by .onnectidg

VTVM

tosp€-

aL€r out

put then read

the frequency

response

to adjusl a

maximum

devia'

}.RLqUI]NCY

RESPONSE:

(OVI]RALL

I'REqUENCY

RESPONSE)

TOTAL HARMONIC

DISTORTION

FACTOR:

Provide

the input

terminal

ol the

,ecord.r

with 1.000.ps.

':nF ,

urvF

signals and

.ecord

these signals on

a

recording

tape at

the zero level

on the

recorder's

VU mete.

Then

playback

the siSnals

under the

no.mal recording

condit;on

to meas-

u.c the distortion

factor

by an oscil

lator.

Remove

the recording

tapc

from

the recorder,

then read the

noisc

lcvelon

the oscjllator

to

8ct

the requ;r-

€d dhtortion

factor

by the following

formula:

d0:d-dl d2

d0..required

d...overall

distortion

factor

dl...noise

l€vel

d2...disto.tion

factor of

the oscilla-

to.

uscd

SICNAL

TO

NOISE: Playback

the sine curve,

250 cPS.

tape

rccorded on a

standard recorder

on

th€ reco.der

to measur€

the voltag€

Removc

the taPe, then measure

the

noisc level under

the same condition

Calculate

the ratio between

the two

in d€cibel.

OUTPUT:

I'layback

on the recorder

thc 1,000 cps.

sine

curvc tape

which

was

record€d

at

the zero VU

level on a standard

recorder.

T€rDinatc the

test recorder

with

€ight

ohms.

Square

the voltag€

rcading, then di

vide the figure

by eight ohms

to get

thc r.m.s.

Powcr

output.

CROSS

TALK:

Record 1,000 cps.

signal at

+3VU

on

the

third tack, then playback

this

signal

through a

l,000cps. Band

Pass

Filter.

Compare

the output

of tracks

I

and

3

in decibels.

2-

f

I

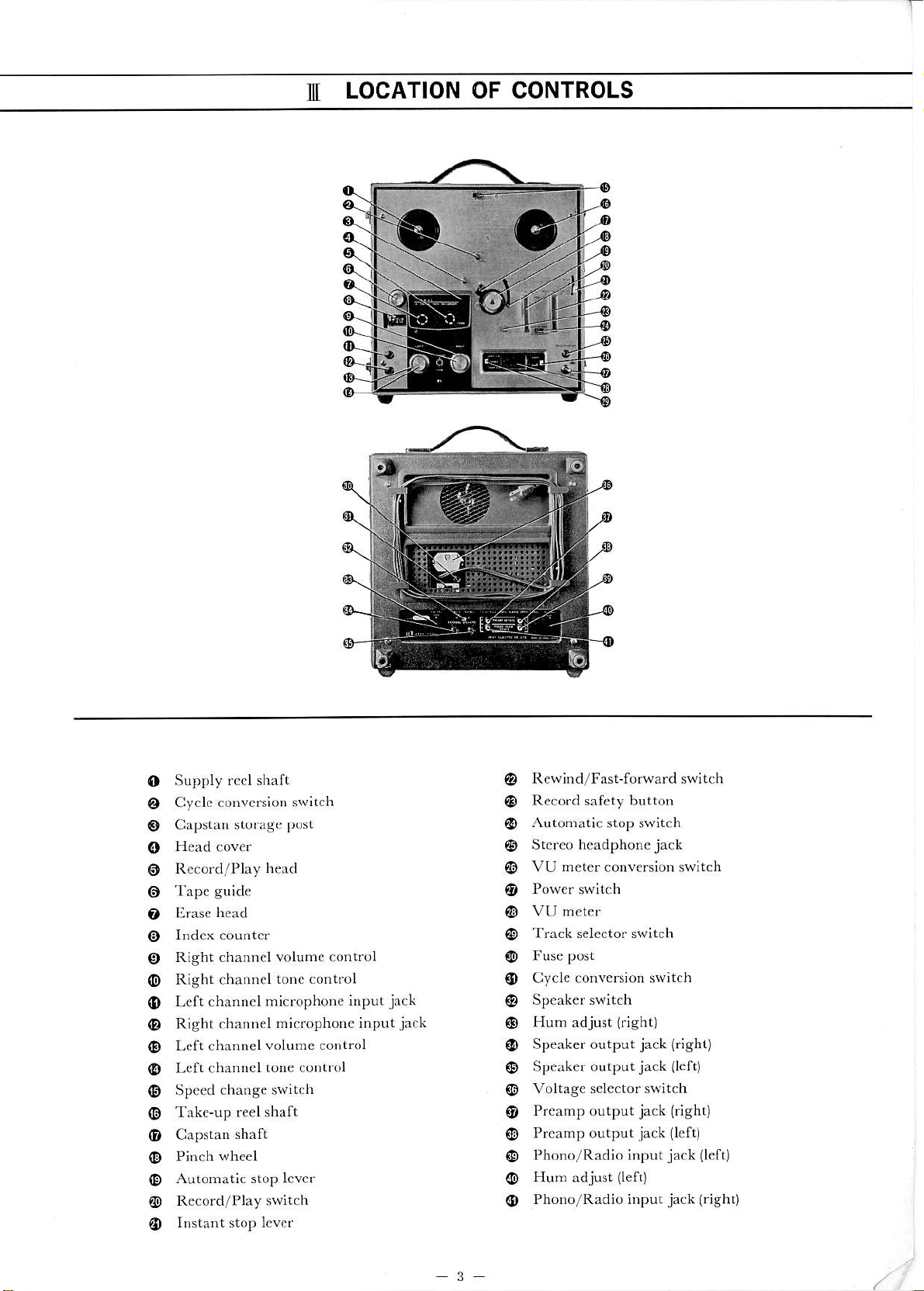

LOCATION OF CONTROLS

@

@

@

(D

(D

o

@

@

o

o

o

0

@

@

o

o

@

o

@

o

@

@

@

(D

(D

@

@

Supply

rccl shaft

Cyclc

convcrsion switch

Capstan storage

post

Tape

guide

trras€

head

Right channel volumc control

Right channel

tonc control

Left channcl

microphone

input

jack

Right channel

microphone input

jack

Left channel

volumc cont.ol

Left channel

tone control

Speed

change switch

Take-up reel shaft

Capstan

shaft

Pinch

wheel

Automatic stop lever

Record/Play switch

Rewind/FasFforward switch

Record safety button

Automatic

stop switch

Stereo headphonejack

VU

h€ter

conv€rsion switch

Track s€lector switch

Cycle conversion sw;tch

Hum adjust

(right)

Speaker output

jack (righr)

Speaker output

jack

llert)

Voltage

sele.tor switch

Preamp output

jack (right)

Preamp output

jack

{left)

Phono/Radio input

jack (l€ft

Hun

adjust

(left)

Phono/Radio input

jack

(rish0

3

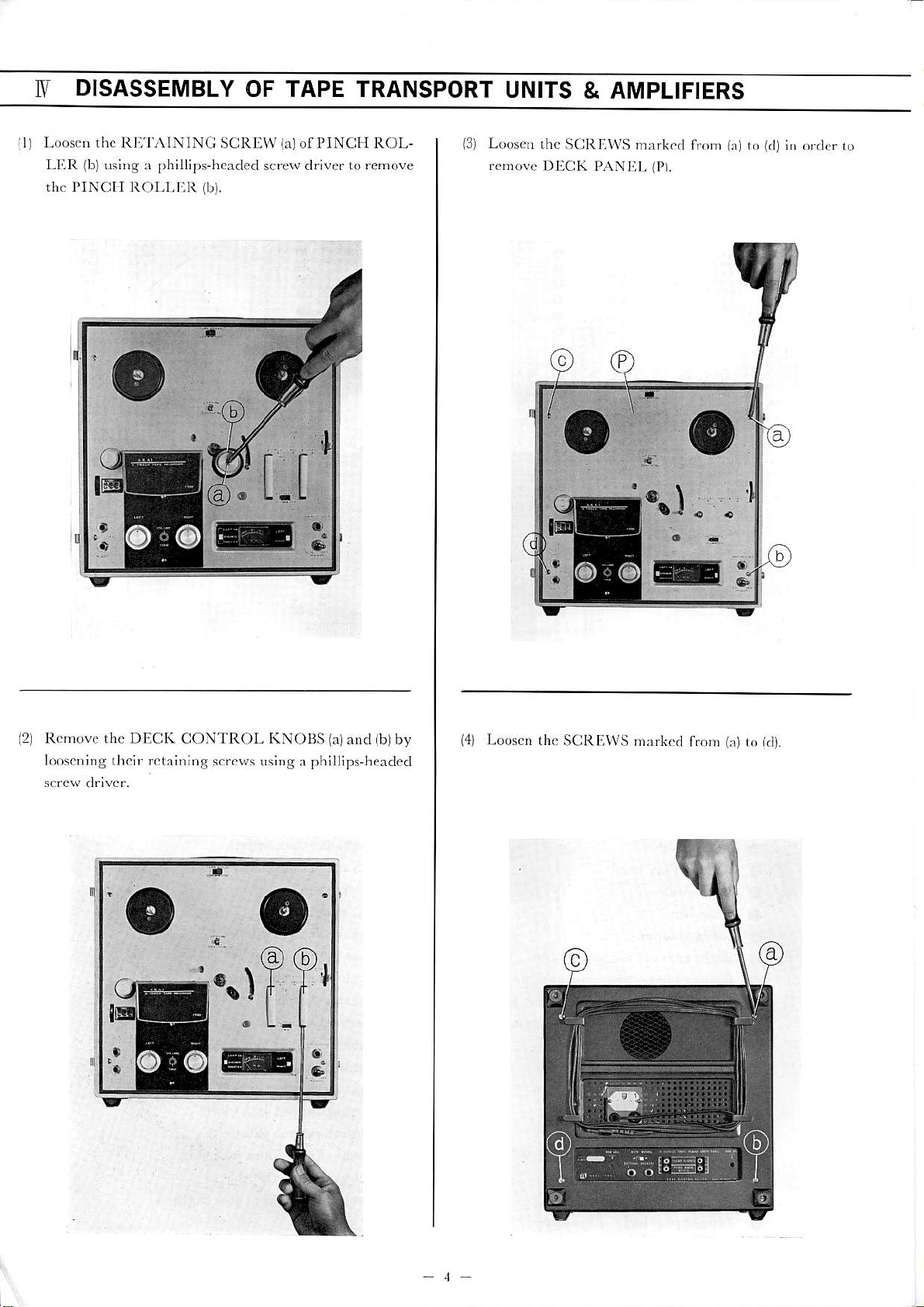

I\I

DISASSEMBLY

OF TAPE TRANSPORT

UNITS

& AMPLIFIERS

ll l-oo!',, rh. lt l:.1.\ I\ lN(;

SUIlll\f

irlof

I'INCIt R()L-

LI{l , ,lt-'.. ,\vl,v ," !i

ih. l'IN(ill lt()l.l.l lt

llil.

13)

L,{iJ.!

thc S(lltli\\'S

nrxrl.(l 1,,,))

r.ri r(j

t{ll

i,r

('(1,.r

ro

r.!!^! l)1'lCK

l).\\l.ll.

tl)1.

12

l.(.,,,,tr | tlx. I)llUK

C( )\ l R( )I- ti\( )lls

ialrnd iblby

io,!c,,i,ig d,cif ritx;fing

s.raL. u';i)g

r

I)liillips

h.adcd

o

99

r.t

I

('11

l.oosci

(h(i

S(iltl:,\\'S,,)rrk.d

f,or)

i.t

r,)

ktr.

I

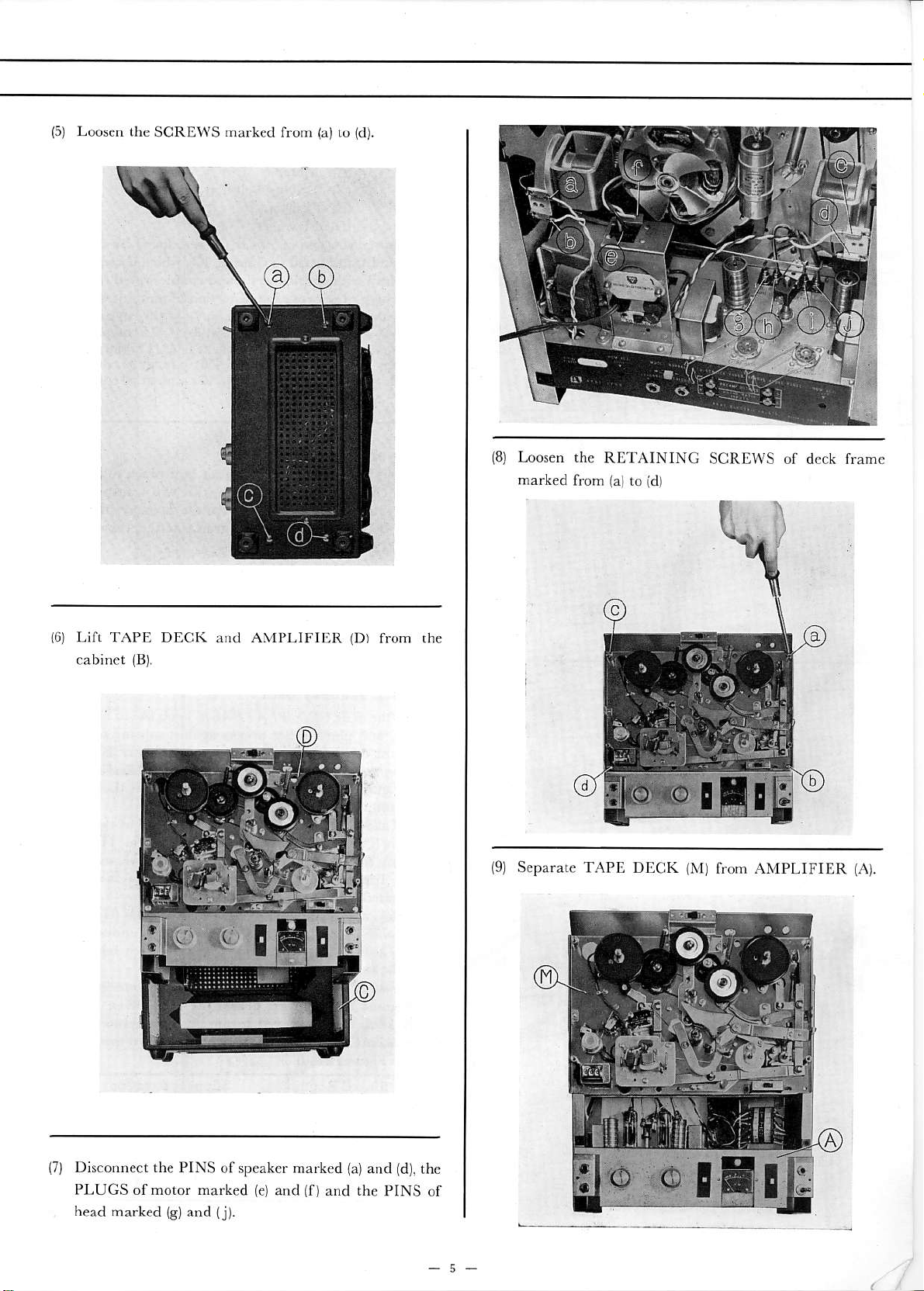

(5)

Loosen

the

SCREWS

narked

from

{a)

to

(d).

Lifl TAPE DECK and

cabinet

(B).

AMI'LIFI liR

(Dr

tr"m

,he

(7)

Disconnect the PINS

of speako marked

{a)

and

(d),

the

PLUGS or motor marked

(€)

and

(f)

and the

PINS of

head

marked

{B)and {j).

(8)

Loosen the

RETAINING

SCRDWS of dcck frame

mark€d

from

(al

to

id)

(9)

SEPA'AIC

TAPE DtrCK

(M)

frOM AMPLIFIER

(A).

Y

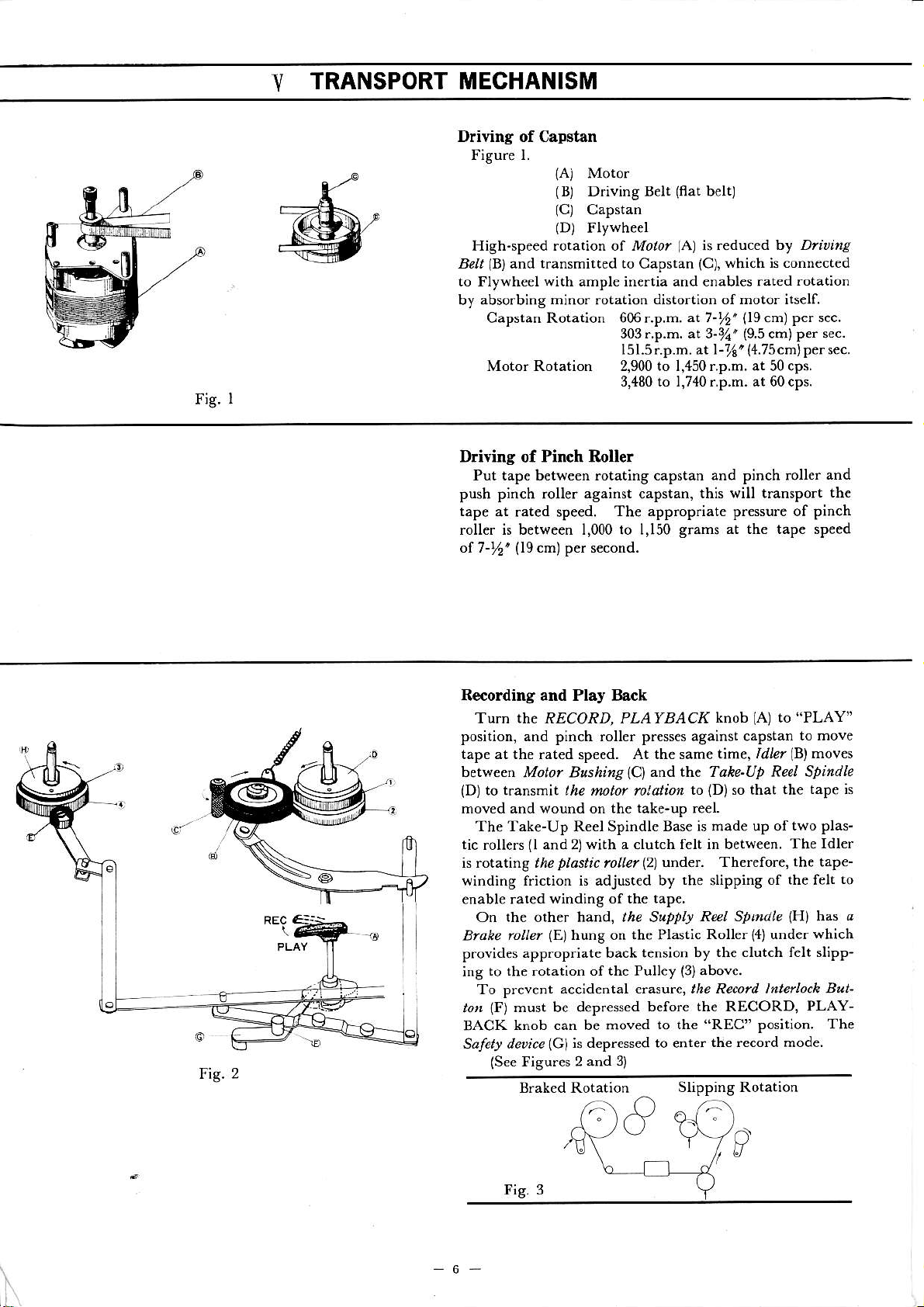

TRANSPORT MECHANISM

Driving of Capstan

Fjgure l.

{Aj

Motor

(B)

Driving Belt

(flat

belt)

(C)

Capstan

(D)

FlYwheel

High-speed rotation of Mot /

(A)

is reduced by D/trire'

Br,

(B)

and transmitted to Capstan

(C),

which is connected

to Flywheel with ample inertia and €nables rated

rotaiion

by absorbing

mino.

rotation

distortion ofDotor itself.

Capstan Rotation 606 r.p.m.

at 7-%'(l9cn)pe. sec.

303r.p.m. at 3-%'(9.5 cm)

per sec.

l5l.5r.p.m, at l

-16'

(4.7s

cmlper sec.

Motor Rotation 2,900 to 1,450 r.p.m. at 50 cps.

3,480 to 1,74{r.p.m. at 60cps.

Fig.

I

Driving of Pinch Roller

Put tape between rotating capstan and pinch roller

and

push pinch

rouer

against

capstan,

this will transport

thc

tape

at rat€d spe€d.

Th€ appropriate pressure of

pinch

roller is between I,000 to I,150

grams at the tape sp€ed

of 7-%'

(19cm)

per s€cond.

R€coding and Play Back

TuJ[ rhe RECORD, PLA rB,4Cf

knob

(A)

to

"PLAY"

position, and pinch roller presses against capstan

to move

tape at the rated

sp€ed.

At the same time,

Idlel

(B)

moves

between

Motor &tshitag

ICI

znd t}:'e Tahe-Ut Reel Spindle

lD)

b rr^ns'lr.it the motol /rldtro,

to

{D)

so that th€

tape is

moved and wound on the take-up re€I.

The Tak€-Up Reel Spindle Base is made up of

two plas-

tic

rollers

(l

and 2l

with a clutch felt in betw€€n.

The ldler

is rot^titg the

plastic

mUel

(2)

under. Therefore, the tape-

winding friction is adjust€d by

the

slipping

of the felt

to

enabl€ rated

winding of the tap€.

on the other ha d, the S*pfb

Reel Sbtndle

IHI

h^s a

Blake

lo e/

lEl

hwg on the Plastic

Roll€r

{4)

under

which

provides

app.opriate back tension by

the .lutch fet slipp-

ing

to the rotation ofthe Pull€y

(3)above.

To prevent

accidental er^sure, the Record lnterloch

But-

to,

(F)

mut be depressed

before the RECORD,

PLAY-

BACK

knob can be moved

to the

"REC"

position.

The

Safet! dnice

lclls

depressed to ente.

the record mode

(See

Fisures 2 and

3)

ffi

\

Slipping Rotation

Fig. 2

-6-

f

FAST-FORWARD MECIIANISM

TurD

lie aASZ FWD-REWIND *no,

(A)

to

"FAST

FWD" position, and

ll's ca-

(B)

undcr lhc knob pushes

up

the Lerer

(C).

The l.tler

(D)

moves

into

the

spacc

bctween

the Plast c Rouer

lF)

above the Take-Up Reel

Spindle and

the uppe. part of th. rotating motor drive bushing to

transm;t the motor rotat;on to the takc-up reel spindle. At

the same tihe,

Brale RoUerc

lH)

and

(I)

cone otr the reel

sp;ndle to free

lr, Srrrl! Reel Sti dlelcl,rheteby allowiDT

fast

windnrg

ofthe tapc onto thc iakc-up rcel.

(Sec

ligures 4 and

5)

FreeRolarion Fl;gh-SpeedRotation

Fig. 5

Fig.4

o

REWIND

MECHANISM

"f

utn the FAST FWD-REtl/N,

izo,

(A)ro

"REWIND"

position, and

the cam

lB)

u^det $e k\ob ptshes

the Leuer

lC)

up. The

ldlerlDl

noves

into thc space

betwecn the

up-

per part of

the

rcIating Motar

dtue bushing

lE)

and

the

Interned ate Pulle,lF) to hansmit

the high-speed

rotation

of themotor through the interm€diate

pulley to

tr? Srrrll

Reet

Spindte

lC).

At the

sahe time, Brale

Roll€ls

(H)

and

(I)

come ofl

the

re€l spindle b tree the

take-at leel spindte

lJl,

ther€by rewinding the tape

into rhe supply reel

ar a fast

(See

F;surcs

6 and 7)

High'Speed Rotation

Fig. 7

'J

YO

o

(a)

sToP

o o

(b) FAST-FORWARD

o

(.)

REWIND

o o

Id) RECORDING

o o

STOP

CONTROL

Push ihc

stop lever to

"STOP"

positlon,

Bruke Ro els

{A)

and

1B)

depres reel spindles to stop .otation

of the reel

sp;ndles.

As thc brake rubb€r depfesses the

plastic rolleG under

the .eel spindles, no triction works

on the tape its€lf.

Supply R*l

Spindle

R*ind

ldle$heel

Take-up Reel Spindle

NOTES :

x

-marks

indicates

"open"

and

O-ma.ks

"engaged"

fig. 8

7

('

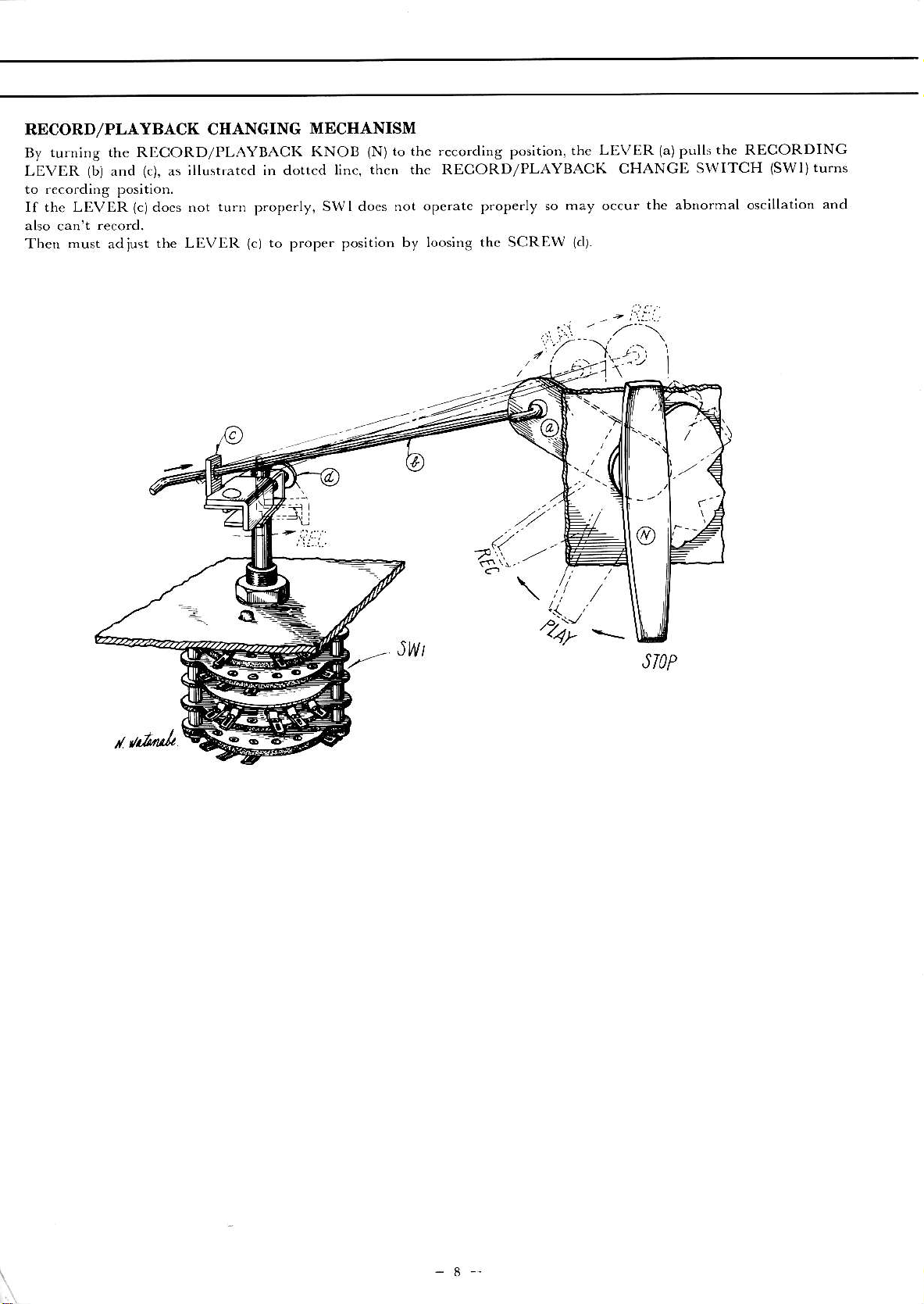

RDCORD/PLAYBACK CIIANGING

MECHANISM

By

turning the RLCORD/PLAYBACK

KNOB

(N)to

the

recording position, thr

LEVIiR

1a)pulls

the RECORDING

LEVER

(bi

and

(c),

as

;llushated in dotted l;nc,

then the RECORD/PLAYBACK

CHANGD SWITCH

(SWl)turns

to .ecording position.

If the LIVER

(c)do.s

not turn

Then

must

adjust

the LI.VIR

propc.ly.

SWI docs not operatc

prope.ly so may occu.

the abnormal oscillation

and

(cl

to proper position

by loos;ng thc SCREW

lcll.

.

r il.',

-

,z--\

Itz__\,/..r',

'l-a1'1';':

,

.'/...

(//

,,-^:,..

,/

\l/

/

..)._u.

.

,4)"

_

JWt

r

U

ADJUSTMENT

OF TAPE

TRANSPORT

UNIT

1. ADJUSTMENT OF

PINCII

WIIEEL

It is imporlant that the piich

wheel shaft i5

kept nr

complcte alignmentwith

the capstan shaft.

A properpinch

wheel

pressur€

is bctween

1.000 and I,150 grahs

whcn the

unit is ope.ated

at the tapc spccd of7-t6

ips. Any devia'

tion

from this specificalion

will result in wow and

flutter.

Check

I'in.h

wheel pre"su,. bv r

.1-.ring

'cale

at.d.

if

r,ecesar

y.

ad

ju"r

rhe pin, h

whpFl

load 5t.inB.

2, ADJUSTMENT OF

TAKE.UP IDLER WHEEL

The

take-up ;dlm wheel

must

be

kcpt in complete align-

ment ltith thc takc-up reel shaft.

Whcn the unit

is set in

fast forward condition,

thc idler

whe€l will contact to the

upper knu.led

wheel

of

the takc-up reel shaft

assembly.

and it

will

contact

to thc lower kn urled

whccl du.ing record

or

play modc. Adjust idlerwhccl

load spr;ngsoihatlhc

idler

wheel pressurc is kept between 50

and 80 grams.

The

;dler

qh..l

rapidlv

wear.

:f Ihf pre*u,.

b

Px,.ssi\c.

The slippage occurs

if thc prcssu.e

is smallef thaD the

3. ADJUSTMENT

OF

REWIND IDLER

WSEEL

The .c\rind

idler

whccl

must be kcpt in complete

align-

mcnt with thc rewi.d

reel

shaft. The amount

of

pressurc

to the k,,urlcd

motor bushing should be maintained

about

50 gfams during rewidd ope.ation. Adjust both thc idler

load spriog aDd

rewind roller.

4. ADJUSTMENT

OF

INTERMEDIATE WHEDL

Thc

intcrnediatc

wheel

is located between the

rewind

idler

whccl

and thc rubbe. ring vhich is uscd on the uppe.

part

of

the supply

reel shaft assembly. When

the unit is

sct in rewind mode, it will

contact

to thcsc parts sihul-

taneously deliverins torque of

motor. An

adequate

pres-

su.cis50grams. Adjust thc load sp.;ngofthc inrermed;ate

wheel if the

pressure is not sufrc;ent.

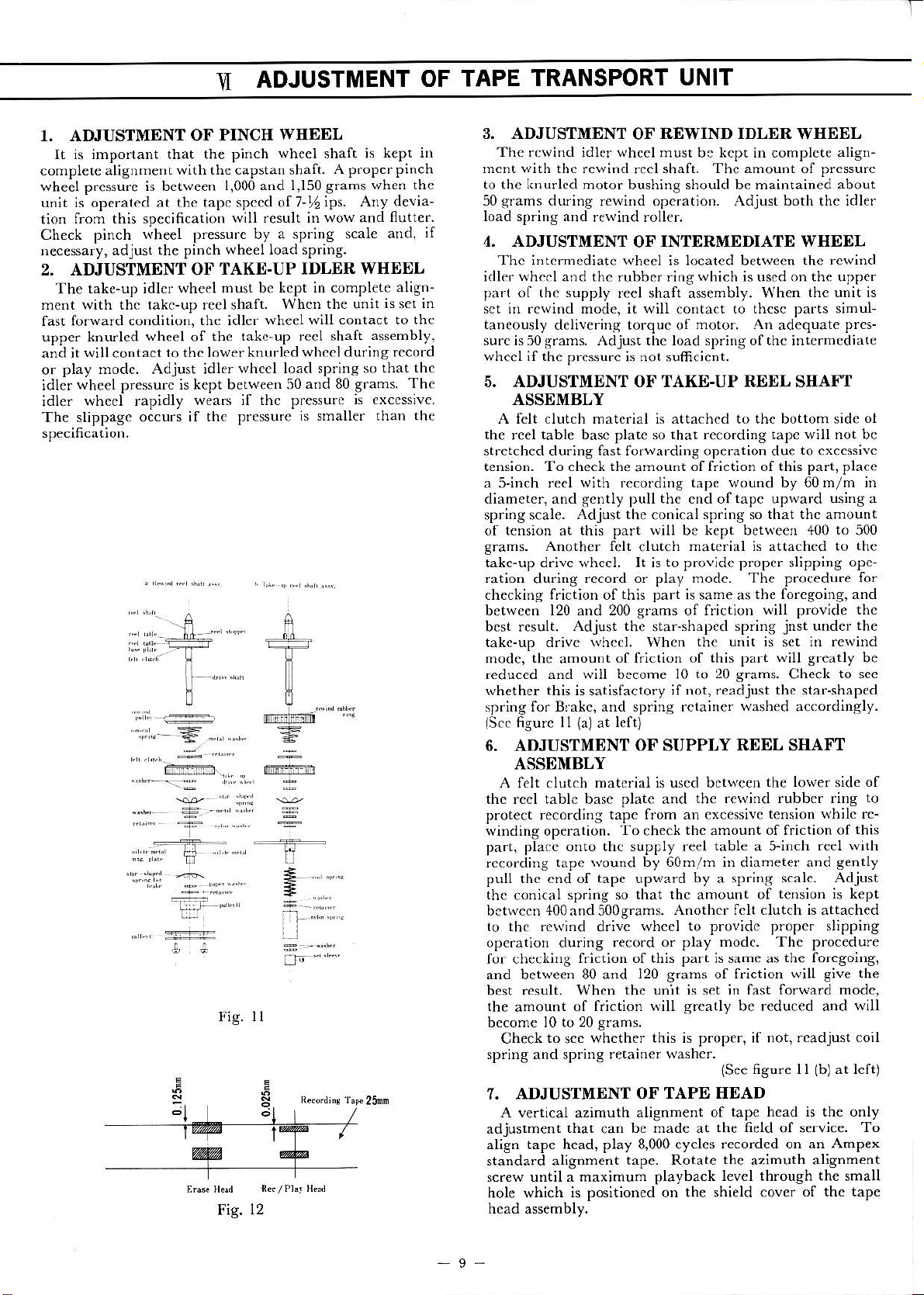

5. ADJUSTMENT OF TAKE-UP REEL SIIAI'T

ASSEMBLY

A felt clutch mat.rial is attachcd to the bottom sid€

ol

the

reel

table

basc plat€ so

that reco.ding tapc w;ll not bc

stretched during lhst forwafding operation due

to

excesivc

tension. To check the

amoudt

of friction of this part, plac€

a S'inch reel

with

fecordins

tape wound by 60m/m in

diameter, and gently pull the cnd of tapc upwarcl

using a

spring scale.

Adjust the

conical

sp.ing so that thc amount

of tension at this part will bc kept between

400 to

500

grams. Anoth€r felt

clutch

matoial ;s

attached

to

the

takc-up drive wheel. It is to pfovide proper slipping

opc-

ration

du.ing

record or play modc. The procedu.e

for

checkins friction of

this part

; same as

the foregoing, and

between 120 and 200 grams of frictioD

will provide the

best result.

Adjust the

star-shapcd

spring

jnst

under

the

takc-up dr;ve

whcel.

lvhen

the unit is

set

in rewind

mode,

the

amou.t

of f.iction of this part

will greatly

be

reduced and \viil become I0

to 20 grams.

Check

to scc

rvhether this is satisfactory ;f iot,

readjust the star-shaped

spring

fo. Bfakc, and spring rctainef

washed

accordingly.

lscc

fisure

ll

(al

at

lefo

6. ADJUSTMENT

OF SUPPLY REEL SIIAFT

ASSDMBLY

A felt clutch

matoial is uscd between

the love.

side

of

thc reel table base plate and

the .ewind rubbcr ring

to

protect reco.ding

tape from an excesive

tension \th;le re-

winding operation.

To

check

thc

amount

offriction of

this

pa.t, place onto thc supply reel

table

a 5-inch

rcel with

rcco.ding

tape wound by 60m/m in diameter and

gently

pulL thc cnd of tape upward by a spring

scale. Adjust

thc

conical sp.ing so

that thc amount of

tens;on ;s kept

bctwecn 400and500grams.

Anothc. fclt clutch is attached

to thc re\v;nd

drive

wheel to provide

proper

sl;pping

ope.atioD cluring

reco.d or play mod.. The procedure

for checkn)g

friction of this part is same as

the

foregoing,

and betwe€n 80 and

120

s.ams

of friction will give

the

best

result. Whcn

the

unit

js

set

;n fasi forward modc,

the

amount

of f.;ction will greatly be reduced and

will

become l0 to 20

grans.

Check

to

sce

whether this is proper, if not,

rcadjust coil

spring and spring r€tainer

washc..

{See

figure I I

(b)

at left)

7. ADJUSTMENT

OF TAPE HEAD

A

vertical azimuth

alignment of

tape head is the only

adjustment

that

can

be made at

the field

of service.

To

align tape head, play 8,000 cycles

recordcd on an AmP€x

standard alignment

tape. Rotate

th€

azimuth al;gnment

sc.ew

until a maximum

playback level through the small

hole which

is positioned on the shield cover

of the tape

head assembly.

-9-

..t,

;

Fig.

ll

R(/.Ly Hli

Fig.

12

:ir".

=..".".,..

Loading...

Loading...