AKA Sidewinder User Manual

Technical

Document

Sidewinder Specifications:

Model:

Version:

Gas Source:

Length:

Width:

Weight:

Adjustable Range:

Max Input:

**There are different length endcaps available for the Sidewinder

so the total length can be shortened or lengthened for a more

custom fit to the end user.

Sidewinder

A

Compressed air, Nitrogen or

2

CO

4.875 inches (total length)*

1” dia main body/1.125” dia

swivel sleeve.

0.308 lbs (with QD)

0-700 PSI

800 PSI

Adjusting the Sidewinder Regulator:

To decrease output when looking at the regulator from

the bottom, turn the allen wrench clockwise to decrease

the pressure. To increase output when looking at the

regulator from the bottom, turn the allen wrench counter

clockwise to increase the pressure.

Trouble Shooting:

Disassembly of Sidewinder Regulator:

To properly disassemble the Sidewinder regulator and

not scratch the outside, you will need a few items: Two

pieces of 2x4s about 4 inchs long, a cloth strap wrench,

a bench vise, a good adjustable wrench, and a set of

allen wrenches.

1. Remove all air sources.

2. Clamp the reg. body upper and reg. middle between

the two pieces of wood. The wood will keep the

regulators outside surface from getting scratched up.

3. Using the adjustable wrench on the swivel nut unscrew the swivel assembly from the bottom of the

regulator. Once loose unscrew the two pieces. Be careful

not to lose the reg. washer and the o-ring that are on

the inside this portion of the regulator.

4. Reclamp the regulator between the two pieces of

wood, clamp on the reg. body upper. Using the strap

wrench loosen the reg. body middle from the reg. body

upper. Inspect the o-rings for damage or wear. Replace

if needed.

Remember to shoot the gun several times after any

adjustment to the Sidewinder regulator so you can see

what the velocity settles in at. If the regulator creeps in

pressure range, check to make sure there is not a piece

of debris in between the regulator seat and the regulator

piston. Make sure the vent hole on the side of regulator

body middle is open and clean. If it is plugged the

regulator will not fuction properly.

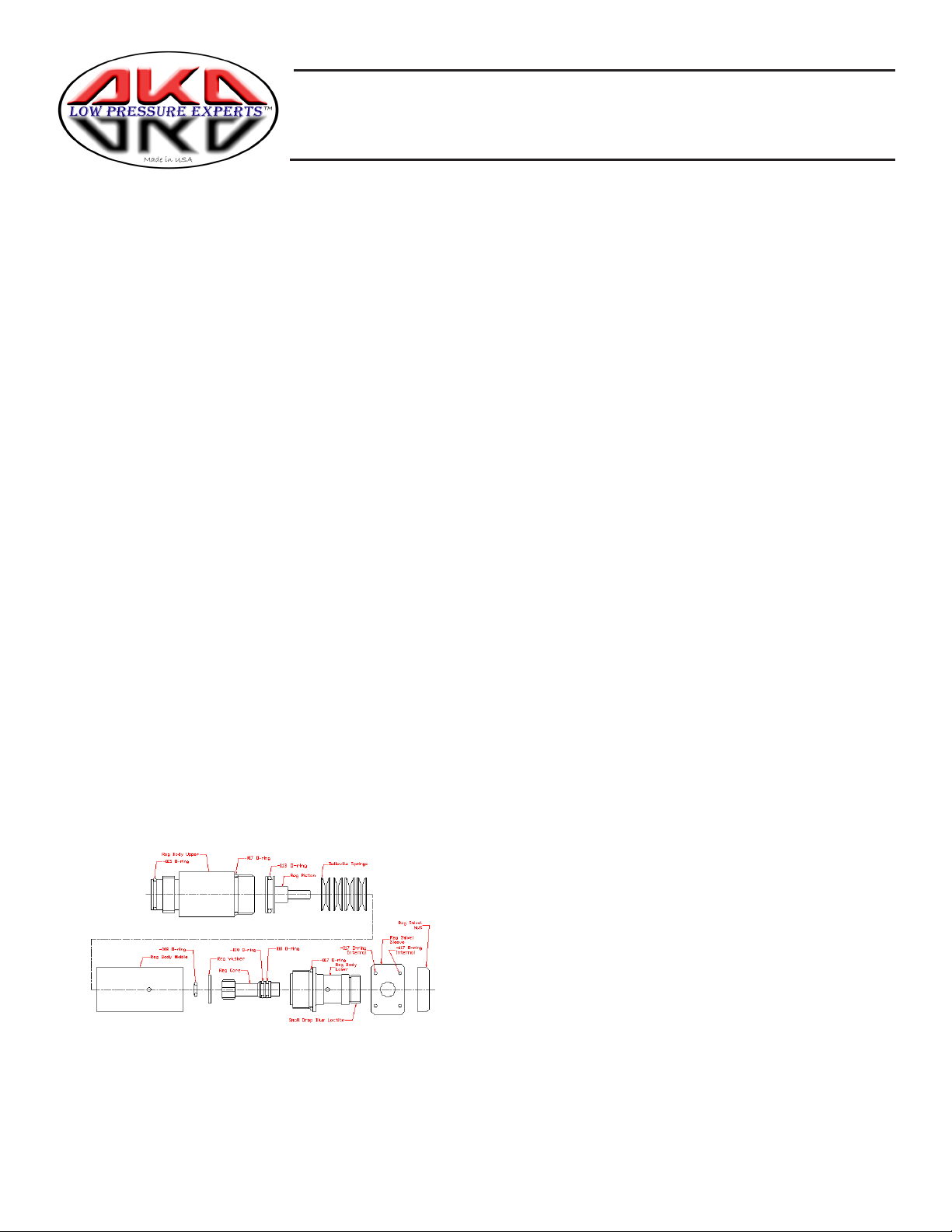

Schematic and Parts Chart:

(1) Regulator body upper

(1) -017 o-ring 1 -015 o-ring

(1) Regulator body middle

(1) -008 o-ring

(1) Regulator piston

(1) -113 o-ring

(8) Belleville springs

(1) Regulator washer

(1) Regulator Sleeve

(2) -017 o-ring

(1) Male Quick Disconnect

(1) Regulator body lower

(1) -017 o-ring

(1) Regulator core

(2) -010 o-ring

(1) 10-32 set screw

5. Once the two halves are separated you can remove

the piston and springs from the regulator body middle.

Be careful not to damage the piston or the o-rings.

Remember in what order the parts came out of the

regulator. Replace o-rings or springs if needed.

6. To disassemble the swivel joint, clamp the threaded

end of the swivel between the two pieces of wood. Use

the adjustable wrench to loosen the swivel nut. The

swivel nut is BLUE LOCTITED in place.

7. Using a gentle twisting action gently pull the swivel

sleeve from the regulator body lower. Inspect the o-rings

for damage or wear. Replace if needed.

8. Use an allen wrench and unscrew the regulator core

from the regulator body lower. The core comes out

through the front of the regulator body lower. Do not try

backing it out. Be careful not to damage any o-rings. If

needed replace the o-rings or if the reg. seat is damaged

replace the whole core assembly.

9. You can now replace the major components to the

regulator if needed. The regulator goes back together

easily. Use the strap wrench to tighten. Do not overtighten, just snug down and use a drop of blue loc-tite

on the threads to keep the regulator bodies tight

together.

Loading...

Loading...