Page 1

mod

VCO User Guide

Vintage discrete transistor core VCO

Thank you for purchasing the AJH Synth MiniMod VCO module, which like all AJH Synth Modules,

has been designed and handbuilt in the UK from the very highest quality components. We hope

that it will help and inspire you towards creating some great music and soundscapes!

The discrete all transistor core of this Voltage Controlled Oscillator is an exact emulation of the

original, and now very rare, R A Moog Model D Oscillator from 45 years ago. It features a fully

matched PNP transistor expo. converter and P-FET transistor buer amplier section but with the

advantage of much improved temperature stability and modern construction using reliable

precision SMT components along with Eurorack modular synthesiser expandibility.

It features front panel switchable octave selection and four independent waveform outputs

including the famous “Sharktooth” waveform, Sawtooth wave, Square wave and Triangle wave

and when used as part of a full MiniMod system can provide a very accurate emulation of the

Model D systhesiser and it’s highly acclaimed “fat vintage” analogue sound.

The Square wave output has fully adjustable Pulse Width Modulation, with manual and CV control

rather than the more restricting selection of square wave or two static xed pulse widths of the

original design.

Also included are Exponential and Linear modulation inputs and two dierent types of oscillator

sync which help to make this a very versatile Eurorack VCO in its own right.

Module width is 14 HP of EuroRack space and it is compatible with standard Euro Rack cases. The

height of the panel is 128.5mm, and depth is 38mm. There are four mounting holes at the corners

of the module and we provide 4 of M3 rack xing screws, along with a Eurorack compatible

power cable. Current consumption is 55mA from the +12V supply rail and 40mA from the -12V

supply rail.

All AJHSynth modules are covered by a one year guarantee against manufacturing defects.

Notes:

As with all vintage analogue oscillators, after powering up it is best to be allowed to “warm up” for 15

minutes or so before use. Tuning immediately after power up is not advised as it takes time for the

internal circuitry to get up to temperature and stabilise. After the warm up period it will maintain pitch

well - much better than the original on which it is based!

It is very important that the power supply ribbon cable is connected correctly, see the “adjustment and

calibration” section for an illustration of the correct orientation.

www.ajhsynth.com

Page 2

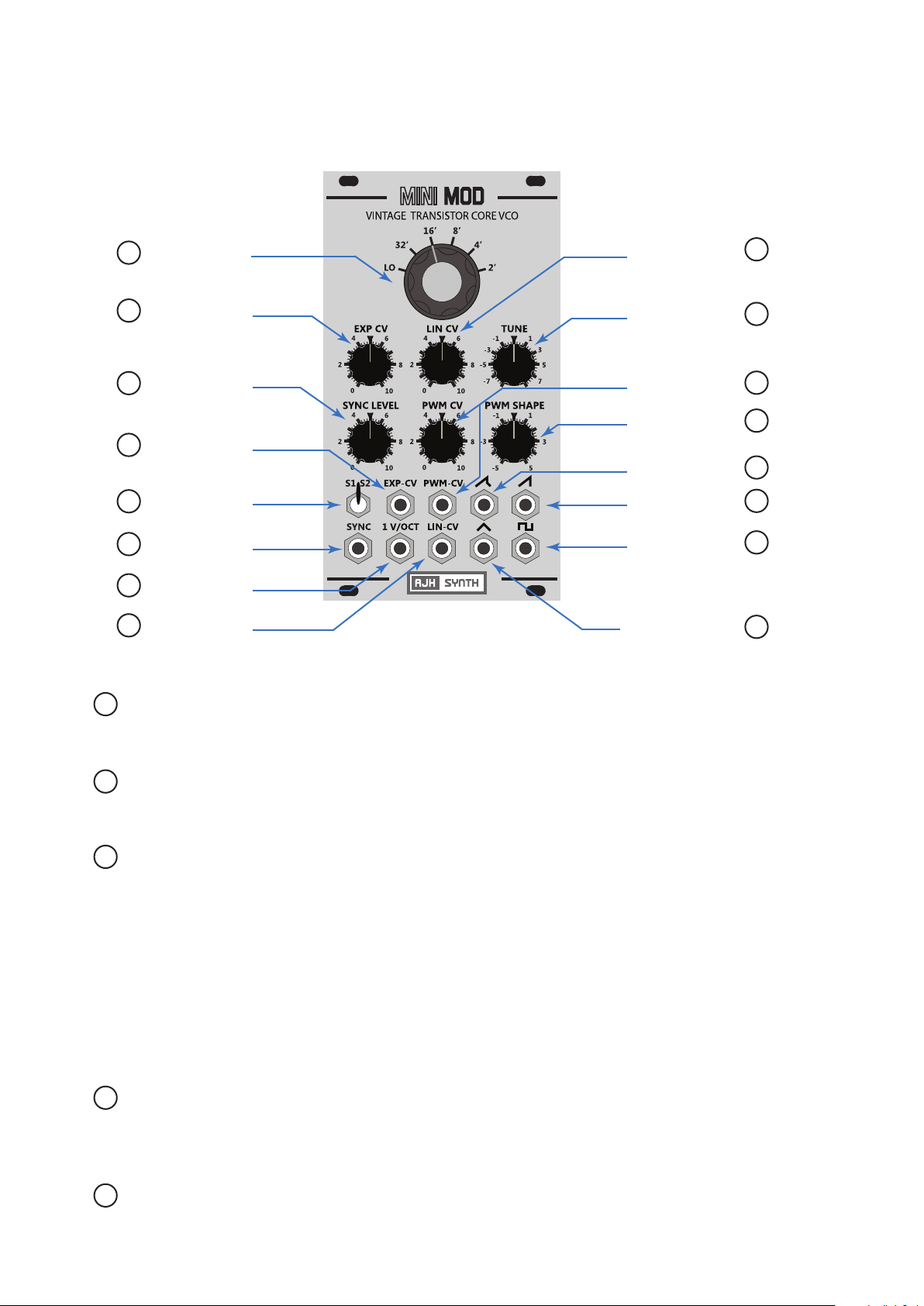

Controls, Inputs and Outputs

1 Octave Switch

5 Exp. CV Level

9 Sync Threshold

4 Exp. CV Input

10 Sync Type

8 Sync Input

3 1 V / Oct. Input

6 Linear Input

Linear CV Level 7

Tune Control 2

PWM Control 16

PWM Shape 15

Shark Output 13

Saw Output 11

Square Output 14

Triangle Output 12

1 Octave Switch :

2 Tune Control :

3 1 V/Oct. Input :

4 Exp CV Input :

Use the Octave switch to quickly select preset octaves, the Lo setting reduces the oscillator frequency into the Low Frequency Oscillator range so that it can be used as a modulation source.

The tune control varies the oscillator pitch by around +/- 8 notes. Larger variations in

pitch can be obtained by applying a positive or negative control voltage to the 1 Volt per

Octave input (3)

This is the 1 Volt per Octave control voltage input. Applying a positive voltage to this

input raises oscillator pitch at the rate of exactly one octave for each volt applied, and a

negative voltage will reduce the pitch by exactly one octave per volt. The acceptable

input range is +/- 7 Volts. A limitation of the vintage oscillator core design means that

tracking may not follow the 1V/Oct law above 10KHz

Distribution Buss 1V/Octave CV signal:

The Eurorack power distribution buss can transmit a 1V/Octave voltage from a Mini/CV

converter or similar source. The MiniMod VCO accepts this signal by default as it is “normalled”

through the 1V/Oct socket, however plugging a jack into the 1V/Oct socket unswitches /

defeats this control voltage and allows the VCO to run free.

This is the Exponential Control Voltage input. Acceptable input voltage range is +/- 5V.

When a voltage is applied to this input it varies the oscillator pitch in a similar fashion to

the 1 V/Oct input, however the amount of control voltage applied to the oscillator core

can be regulated using the Exponential CV Level control (5).

5 Exp. CV Level :

This control adjusts the amount of voltage from the Exp. CV input that is passed to the

oscillator core, its range is 0 to 120%.

Page 3

6 Linear Input :

This is the Linear Control Voltage Input. Acceptable input voltage range is +/- 5V. This is a

more subtle modulation eect which varies the oscillator pitch by up to +/- 7 notes

depending upon the setting of the Linear CV Level Control (7)

7 Linear CV Level :

8 Sync Input :

9 Sync Threshold :

10 Sync Type :

Controls the amount of Linear Modulation applied to the oscillator core from the Linear

CV Input (6)

A rising pulse waveform of +/- 5V (e.g. the Saw waveform from another MiniMod VCO)

can be applied to this input to prematurely reset (synchronise) the oscillator waveform for

interesting sonic results. The sync eect is very level sensitive and is set using the Sync

Threshold control (9).

If it is desired to use a falling ramp waveform from a dierent oscillator for sync it will

need to be fed through an invertor to convert it to the rising ramp waveform required for

eective triggering.

The Sync eect is very level sensitive and the waveform level from the Sync Input (8))

presented to the oscillator core can be set using this control. Start with the control fully

counter clockwise and gradually increase it until the desired eect is obtained. The

frequency relationship between this oscillator and the synchronising oscillator plays a

large part in the resulting sounds created. Experiment!

This switches between two dierent sync types. With the switch “down” regular sync is

eective, which can be used to create ripping “laser harp” type sounds. With the switch

“up” a ramp rather than short pulse is applied to the oscillator core reset transistor and

some interesting harmonic and stepped frequency eects can be created. Dierent Sync

threshold levels are required for the “up” and “down” Sync switch positions.

11 Saw Output :

12 Triangle Output :

13 Shark Output :

14 Square Output :

15 PWM Shape :

16 PWM Control :

Rising ramp waveform output. It has a level of +/-5 volts centred around 0v. The output

impedance is 1Kohm.

Triangle wave output. It has a level of +/-5 volts centred around 0v. The output impedance

is 1Kohm.

The famous “Sharktooth” waveform from the early Model D synthesiser. It has an output

level of +/-5 volts centred around 0v. The output impedance is 1Kohm.

Square wave output. It has a level of +/-5 volts centred around 0v. The duty cycle

(amount of time the waveform is “high” against “low”) can be varied with the Manual

PWM control (15) or under voltage control (16). The output impedance is 1Kohm.

Adjusts the duty cycle of the square wave between approximately 10% and 90%. When

set to the half way (12 o’clock) position the duty cycle is 50%, which creates a regular

square wave.

A control voltage can be applied to the PWM CV Input to vary the PWM duty cycle. The

control voltage range should be between +/- 5volts and the intensity can be controlled

between 0% to 100% with the PWM CV rotary control knob. A low frequency triangle

wave to the PWM CV Input will give the classic sweeping PWM eect. The PWM Shape

Control is still eective when using PWM CV and it changes the oset level.

Page 4

Adjustment and Calibration

Note:

This information is given for completeness, the MiniMod VCO is calibrated after manufacture

and under normal circumstances should not require any user adjustment.

C Octave Adjust HFT Adjust D

A Tune Adjust

A Tune Adjust :

Scale Adjust B

Shape Adjust E

Power Cable

Red Stripe aligns with -12V as shown

Sets the default frequency for the VCO. This is a multi-turn trimmer that should be

adjusted with a ne jeweller’s screwdriver. Turn counter clockwise to increase VCO pitch

and clockwise to reduce the pitch. Adjusting this trimmer will not aect the scaling.

B Scale Adjust :

C Octave Adjust :

D HFT Adjust :

E Shape Adjust :

Sets the volts per octave scaling for the VCO. We do not recommend adjusting this

trimmer unless you have access to a very accurtate voltmeter and frequency counter or

chromatic tuner so that you can observe the eects of adjustment. Rotating counter

clockwise widens the scale and turning clockwise reduces the scale, only minute (less

than 1/4 turn) adjustments should be tried unless the scaling is badly out of adjustment.

Sets the volts per octave scaling for the Octave Selector Switch. The scaling and

frequency should be correctly adjusted before attempting to adjust the Octave scaling.

Set the Octave Switch to 8’ and note the VCO frequency, then set the switch to 2’ and turn

the Octave Adjust until pitch is exactly 2 octaves higher than 8’ setting. Rotating counter

clockwise increases the span and turning clockwise reduces the span.

FOR MANUFACTURER ADJUSTMENT ONLY. Specialist test equipment is needed to

calibrate this trimmer correctly.

FOR MANUFACTURER ADJUSTMENT ONLY. This sets the current level through the

P-FET transistor buer and incorrect adjustment can halt the Oscillator completely, so

NO ATTEMPT should be made to adjust this trimmer.

If you need any help using this module or have any technical questions please feel free to

contact us at support@ajhsynth.com

Copyright © AJHSynth 2014

Loading...

Loading...