Page 1

MANUFACTURING

NUMBERS:

9210719

9210721

9210728

VERTICAL CONTACT

P/N 1010930 Rev. C 09/13

TOASTER

With Mechanical Driven Butter Wheel

Models VCT-1000

Owner’s Manual

Page 2

VERTICAL CONTACT TOASTER

TABLE OF CONTENTS

Owner Information .....................................................2

General ......................................................................2

Warranty Information .................................................2

Service/Technical Assistance ....................................3

Important Safety Information ....................................4

Specifications .............................................................5

Electrical Ratings .......................................................5

Electrical Cord & Plug Configurations .......................5

Dimensions ................................................................5

Model Designation .....................................................5

Installation ...................................................................6

Unpacking ..................................................................6

Equipment Setup .......................................................6

Assembling the Unit ..................................................6

OWNER INFORMATION

General

The Vertical Contact Toaster, is designed for contact

toasting of buns. The toaster design allows the operator to place buns on both sides of the heated Platen

at the same time. Buns are placed into the top of the

toaster and uniform, golden brown, warm buns are then

retrieved from the bottom of the toaster in

approximately 15 seconds (VCT-1000) or 45 seconds

(VCT-50).

This manual provides the safety, installation, and operating procedures for the Vertical Contact Toaster. We

recommend that all information contained in this

manual be read prior to installing and operating the

unit.

Your Vertical Contact Toaster is manufactured from the

finest materials available and assembled to Roundup’s

strict quality standards. This unit has been tested at

the factory to ensure dependable trouble-free

operation.

Operation .....................................................................8

Operating Instructions ...............................................8

Safety Features .........................................................8

Maintenance ................................................................9

Daily ...........................................................................9

Replacing the Black and Silver Release Sheet .........9

Checking the Conveyor Belt Chains .......................10

Replacing the Spring Tensioners .............................11

Troubleshooting .......................................................12

Wiring Diagram .........................................................14

Replacement Parts ...................................................15

Limited Warranty ......................................Back Cover

Warranty Information

Please read the full text of the Limited Warranty in this

manual.

If the unit arrives damaged, contact the carrier immediately and file a damage claim with them. Save all

packing materials when filing a claim. Freight damage

claims are the responsibility of the purchaser and are

NOT covered under warranty.

The warranty does NOT extend to:

• Damages caused in shipment or damage as

result of improper use.

• Installation of electrical service.

• Normal maintenance as outlined in this manual.

• Malfunction resulting from improper maintenance.

• Damage caused by abuse or careless handling.

• Damage from moisture into electrical

components.

• Damage from tampering with, removal of, or

changing any preset control or safety device.

IMPORTANT! Keep these instructions for future reference. If the unit changes

ownership, be sure this manual accompanies the equipment.

2

P/N 1010930 Rev. C 09/13

Page 3

VERTICAL CONTACT TOASTER

OWNER INFORMATION (continued)

Service/Technical Assistance

If you experience any problems with the installation

or operation of your unit, contact your local Roundup

Authorized Service Agency.

Fill in the information below and have it handy when

calling your Authorized Service Agency for assistance.

The serial number is on the specification plate located

on the rear of the unit.

Purchased From:

Date of Purchase:

Model No.:

Serial No.:

Mfg. No.:

Refer to the service agency directory included with your

unit.

Authorized Service Agency

Name:

Phone No.:

Address:

Use only genuine Roundup replacement parts in this

unit. Use of replacement parts other than those supplied by the manufacturer will void the warranty. Your

Authorized Service Agency has been factory trained

and has a complete supply of parts for this toaster.

You may also contact the factory at 1-877-392-7854

if you have trouble locating your nearest Authorized

Service Agency.

IMPORTANT

A.J. Antunes & Co. reserves the right to change specifications and product design

without notice. Such revisions do NOT entitle the buyer to corresponding changes,

improvements, additions, or replacements for previously purchased equipment.

P/N 1010930 Rev. C 09/13

3

Page 4

VERTICAL CONTACT TOASTER

IMPORTANT SAFETY INFORMATION (continued)

In addition to the warnings and cautions in this manual,

use the following guidelines for safe operation of the

unit.

• Read all instructions before using equipment.

• For your safety, the equipment is furnished with

a properly grounded cord connector. Do NOT

attempt to defeat the grounded connector.

• Install or locate the equipment only for its intended use as described in this manual. Do NOT use

corrosive chemicals in this equipment.

• Do NOT operate this equipment if it has a damaged cord or plug, if it is not working properly, or

if it has been damaged or dropped.

• This equipment should be serviced by qualified

personnel only. Contact the nearest Roundup

Authorized Service Agency for adjustment or

repair.

• Do NOT block or cover any openings on the unit.

• Do NOT immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do NOT allow cord to hang over edge of table or

counter.

The following warnings and cautions appear throughout

this manual and should be carefully observed.

• Turn the power off, unplug the power cord, and

allow unit to cool down before performing any

service or maintenance.

• The procedures in this chapter may include

the use of chemical products. These chemical

products will be highlighted with bold face letters followed by the abbreviated HCS (Hazard

Communication Standard). See Hazard

Communication Standard manual for the appropriated Material Safety Data Sheets (MSDS).

• The toaster should be grounded according to

local electrical codes to prevent the possibility of

electrical shock. It requires a grounded receptacle with separate electrical lines, protected by

fuses or circuit breaker of the proper rating.

• Bread may burn. Therefore toasters must not be

used near or below curtains or other combustible

walls and materials. Failure to maintain safe

operating distances may cause discoloration or

combustion.

• Failure to use Release Sheets may result in

damage to the equipment and loss of warranty

coverage.

• All electrical connections must be in accordance

with local electrical codes and any other applicable codes.

• WARNING ELECTRICAL SHOCK HAZARD.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR

DEATH.

- Electrical ground is required on this appliance.

- Do NOT modify the power supply cord plug.

If it does not fit the outlet, have a proper outlet

installed by a qualified electrician.

- Do NOT use an extension cord with this

appliance.

- Check with a qualified electrician if you are

unsure if the appliance is properly grounded.

- If the power cord is damaged, it must be

replaced with a power cord available from

the manufacturer or an Authorized Service

Agency.

4

P/N 1010930 Rev. C 09/13

Page 5

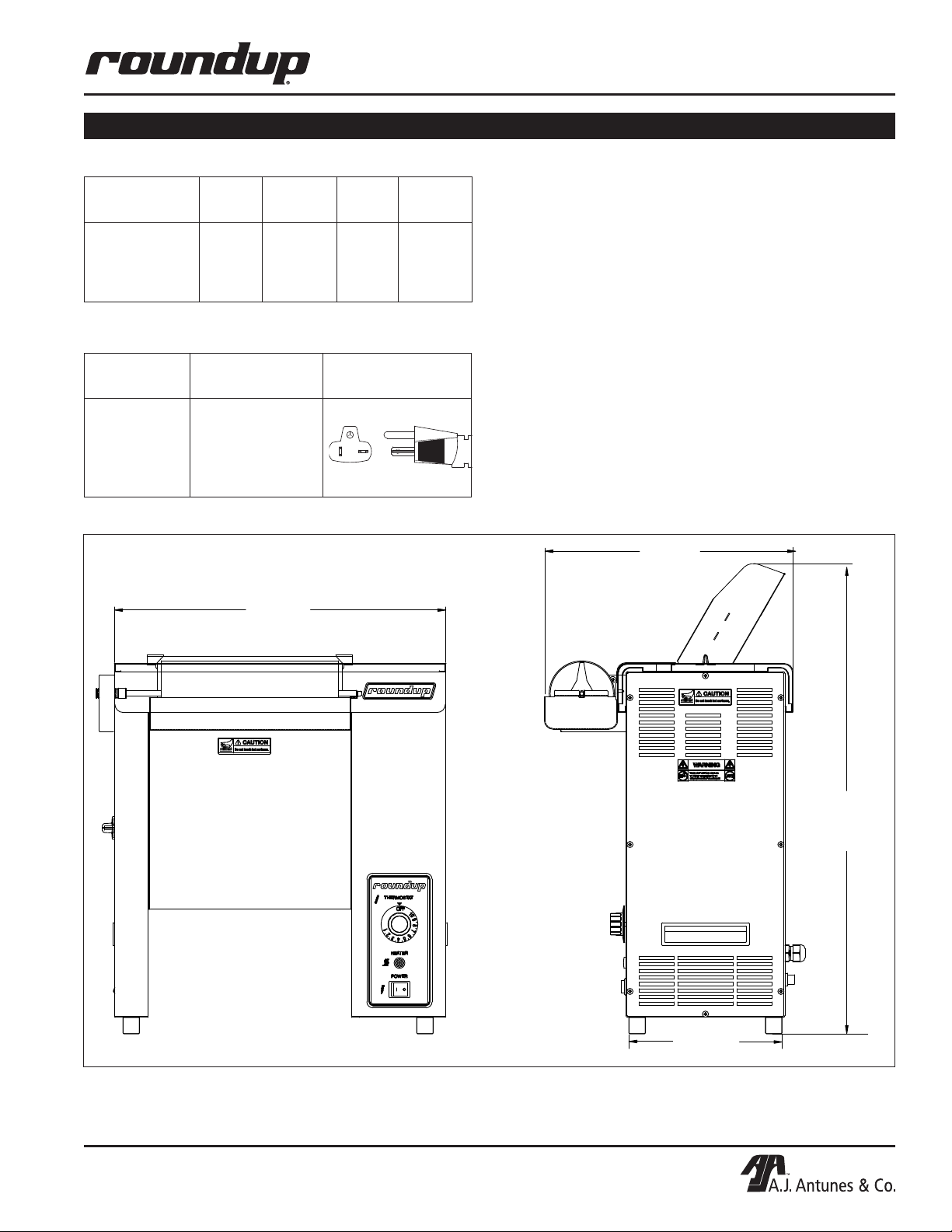

Electrical Ratings

VERTICAL CONTACT TOASTER

SPECIFICATIONS

Model &

Mfg. No.

Volts Watts Amp. Hertz

VCT-1000

9210719

9210721

208–

240

2600–

3455

12.5–

14.4

9210728

Electrical Cord & Plug Configurations

Model &

Mfg. No.

VCT-100 0

9210719

9210721

9210728

Description Configuration

NEMA 6-20P 20

Amp, 250 VAC

Non–Locking

(Assembly Only)

Dimensions

20-5/16"

(515.87 mm)

60

15-1/4”

(387.35 mm)

P/N 1010930 Rev. C 09/13

29-3/16”

(741.36 mm)

9-3/4”

(247.65 mm)

5

Page 6

VERTICAL CONTACT TOASTER

INSTALLATION

Unpacking

1. Remove unit and all packing materials from

shipping carton.

2. Open the large box. It should contain:

• Bun Chute (Figure 1)

• Butter Wheel and Pan (Figure 1)

• Two Release Sheets (Figure 1)

• Owner’s Manual

• Authorized Service Agency Directory

3. Remove all packing materials and protective

coverings from the unit and parts.

NOTE: If any parts are missing or damaged, con-

tact A.J. Antunes & Co. IMMEDIATELY at

630-784-1000.

Equipment Setup

When placing the toaster into service, pay attention to

the following guidelines.

• Make sure power to the unit is off and the toaster

is at room temperature.

• Do NOT block or cover any openings on the unit.

• Do NOT immerse cord or plug in water.

• Keep cord away from heated surfaces.

Assembling the Unit

NOTE: The factory has a pre-installed a Release

Sheet over the Platen (Figure 1). Verify that it is

properly in place before proceeding.

1. Remove the Bun Chute from the box and install

(Figure 1).

2. Remove the Butter Wheel and Pan from box.

3. Install the Pan over the front edge of the Heat

Shield and place the Butter Roller in Pan and

engage into gear case (Figure 1).

NOTE: Make sure the Heat Shield is activating the

Conveyor Interlock Safety Switch (Figure 1). The

conveyors will not rotate unless the Heat Shield

is in place and activating the Conveyor Safety

Interlock Switch.

CAUTION

Failure to use Release Sheets may result in damage

to the unit and loss of warranty coverage.

NOTE: Check the Release Sheet to make sure it

is not caught in the conveyor. Additional Release

Sheets can be purchased through your Authorized

Service Agency under P/N 7000249 (3-Pack) or

7000250 (10-Pack).

• Do NOT allow cord to hang over edge of table or

counter.

• Connect the unit to the power supply. Refer to

the specification plate for the proper voltage.

6

P/N 1010930 Rev. C 09/13

Page 7

Butter

Wheel

VERTICAL CONTACT TOASTER

INSTALLATION (continued)

Bun

Feeder

(optional)

(optional)

Butter

Wheel Pan

Bun Chute

Assembly

connected over

the bottom rear

support rod

Heat Shield

Yellow

Support

Rod

Front

Conveyor

Belt Chain

Spring Tensioner

Assembly

Platen

Release

Sheet

Retainer

Clips

Release

Sheet

Yellow Support

Rod

Rear

Conveyor

Belt Chain

Conveyor

Safety

Interlock

Switch

Rear Conveyor

Cover Assembly

Front Conveyor

Cover Assembly

P/N 1010930 Rev. C 09/13

Bun Chute

Figure 1. VCT-1000 With Mechanical Driven Butter Wheel

7

Page 8

VERTICAL CONTACT TOASTER

1

2

4

5

1 = 1/2"(12.7mm)

2 = 5/8"(15.9mm)

3 = 11/16"(17.5mm)

6 = 7/8"(22.2mm)

THICKNESS

THICKNESS

1

2

3

4

6

6

5

4 = 3/4"(19.1mm)

5 = 13/16"(20.6mm)

3

1

2

3

4

5

1 = 1/2"(12.7mm)

2 = 5/8"(15.9mm)

4 = 3/4"(19.1mm)

5 =13/16"(20.6mm)

6 = 7/8"(22.2mm)

THICKNESS

THICKNESS

1

2

3

4

5

6

6

3 =11/16"(17.5mm)

OPERATION

Operating Instructions

IMPORTANT

Verify that the Release Sheet is installed completely

over the Platen (Figure 1) before proceeding. Failure

to use Release Sheet may cause permanent damage

to the Platen surface that is not covered by warranty.

1. Set the Bun Thickness Compression Knobs

(Figure 3) to the desired settings.

2. Turn the power on.

3. Turn the Temperature Control to 10. Allow the

unit to warm up for 30 minutes before proceeding.

4. Slide buns across the rotating Butter Wheel with

the cut face down and drop buns into toaster

(Figure 2). Cut sides of heel and crown must face

each other.

NOTE: After initial run of 4-6 buns, adjust controls

according to the desired finished product.

5. Toasted product will drop into the Bun Landing

Area (Figure 2).

6. Test at least 4 buns before putting toaster into service. Turn Temperature Control to lower setting

for lighter toasting or to higher setting for darker

toasting.

Bun Thickness

Adjustment Controls

(See Figure 3)

Bun Landing

Area

Figure 2. Toaster Controls

Power

Switch

Hi-Limit Reset

Reset

Button

Protective

Cap

Temperature Control

7. Turn the power off when finished toasting and

follow the daily cleaning procedures.

Safety Features

HI-LIMIT RESET BUTTON

A Hi-Limit Control turns off electrical power to the heater if the Platen overheats. To reset this control, allow

10-15 minutes for the unit to cool down, Remove the

Protective Cap, and press the Reset Button located at

the rear of the unit (Figure 2).

If the unit requires continuous resetting, contact your

Authorized Service Agency.

CONVEYOR INTERLOCK SAFETY SWITCH

A Conveyor Interlock Safety Switch is located on top of

the unit under the Heat Shield (Figure 1). The Conveyor

Belt Chains will not rotate unless the Heat Shield is

seated properly in place and activating the Conveyor

Interlock Safety Switch.

Figure 3. Bun Thickness Compression Knobs

8

P/N 1010930 Rev. C 09/13

Page 9

VERTICAL CONTACT TOASTER

MAINTENANCE

CAUTION

Turn the power off, unplug the power cord, and allow

the unit to cool down 30 minutes before performing

any service or maintenance.

CAUTION

To prevent damage to the unit, do NOT use abrasive

cleaners on the Release Sheet.

CAUTION

Failure to use Release Sheets may result in damage

to the unit and loss of warranty coverage.

Daily

NOTE: Pre-buttering/pre-oiling buns before feeding

them into the toaster leads to butter/oil accumulation on the Release Sheet. This is normal, however

excessive buildup can lead to buns sticking and

burning. It is recommended that the Release Sheet

be replaced or cleaned once for every 6 hours of

operation. Dirty Release Sheets can be soaked in

hot, soapy water for later cleaning. Continue to

rotate Release Sheets, alternating between sides to

maximize usage.

Tools Required:

• Heat-Resistant Gloves

• Clean Towels

• Multipurpose Detergent Solution

• Sanitizer Solution

1. Turn the power off, unplug the power cord, and

clean the Release Sheet and Belt Wraps while

they are warm.

2. Put on heat-resistant gloves and remove the

Butter Wheel, Pan, and Heat Shield (Figure 1).

3. Wash the Butter Wheel, Pan, and Heat Shield in

a sink and wipe them with a damp sanitized towel

and allow them to air dry.

4. Remove the Release Sheet and place it on a

clean, flat dry surface.

5. Wipe the silver side of the Release Sheet with

a clean towel dampened with Multipurpose

Detergent Solution immediately followed by a

second clean towel dampened with sanitizer and

allow it to air dry before continuing.

6. Once the silver side is dry, repeat Step 5 on the

black side of the Release Sheet.

7. Wipe down the outside of the toaster with a

clean, damp, sanitized towel.

8. Install the Release Sheet by draping it over both

sides of the Platen with the crease centered on

the Platen.

NOTE: To prolong the life of the Release Sheet,

rotate it from the black side to the silver side on a

daily or weekly basis.

9. Install the Bun Chute so the hooks are installed

over the lower rear yellow Support Rod.

10. Install the Heat Shield with the Release Sheet

retainer clips securely over the Release Sheet

and Platen.

11. Reinstall the Butter Wheel and Pan, and plug in

the unit.

NOTE: Make sure the Heat Shield is activating the

Conveyor Safety Interlock Switch. The conveyors

will not rotate unless the Heat Shield is in place

and the Conveyor Safety Interlock Switch is

activated.

NOTE: Check the Release Sheet to make sure it is

not caught in the Conveyor. Additional Release

Sheets can be purchased through your Authorized

Service Agency under P/N 7000249 (3-Pack) or

7000250 (10-Pack).

Replacing the Black and Silver Release

Sheet (Every 4–6 weeks)

NOTE: Depending on toaster usage and on how

well it is cleaned daily, the black and silver Release

Sheet should last between 30–45 days.

1. Remove and discard the Release Sheet.

2. Lay a new Release Sheet on a clean, dry surface

and fold it in half lengthwise and gently crease it

at the fold using only your fingers (Figure 4).

3. Install the Release Sheet just as you would after

daily cleaning.

Fold over so

ends meet.

Figure 4. Folding the Release Sheet

Press lightly with

finger to form crease.

P/N 1010930 Rev. C 09/13

9

Page 10

VERTICAL CONTACT TOASTER

MAINTENANCE (continued)

Checking the Conveyor Belt Chains

(Every 3–6 Months)

NOTE: The Bun Thickness Compression Knobs

(Figure 3) must be set to “6 & 6” prior to measuring or removing or reinstalling the Conveyor Belt

Chains.

MEASURING CONVEYOR BELT CHAINS

1. Turn the unit off, unplug the power cord, and

allow the unit to cool.

2. Remove the Butter Wheel, Pan, and Heat

Shield (Figure 1) and set the Bun Thickness

Compression Knobs to 6 & 6.

3. Open both Conveyor Covers.

4. Facing the toaster, locate the approximate centerpoint of the Conveyor Chain.

5. Pull the Conveyor Chain away from the edge of

the toaster (Figure 5).

6. Stand a U.S. Dime on end between the frame

and the chain (Figure 5).

7. If the gap is significantly wider than the coin,

REMOVE links as described below.

8. Disconnect the Conveyor Belt Chain by squeezing any two links together and unhooking both

ends one link (Figure 6). Needle-nose pliers may

be used.

NOTE: There are two small 1/2” links on each side

of the Conveyor Belt Chain. The rest are large 3/4”

links.

9. Remove one 1/2” link from the belt.

10. Reassemble the Conveyor Belt Chain onto the

sprockets as described in Replacing Conveyor

Belt Chains.

11. Measure the gap again to ensure it is not too

tight.

12. Check the opposite side of the toaster using the

same steps.

NOTE: If the Conveyor Belt Chain is too tight to be

reassembled, remove an additional small 1/2” link

and install a large 3/4” link in its place. This will

shorten the Conveyor Belt Chain by 1/4” overall.

Figure 5. Measuring the Conveyor Belt Links

Rotation

Upper Support Rod

Large Link

P/N 0800121

Small Link

P/N 0800204

Figure 6. Conveyor Belt Links

10

P/N 1010930 Rev. C 09/13

Page 11

VERTICAL CONTACT TOASTER

MAINTENANCE (continued)

REPLACING CONVEYOR BELT CHAINS

1. Turn the power off, unplug the power cord, and

allow the unit to cool before proceeding.

2. Remove the Butter Wheel, Pan, and Heat Shield

and set the Compression Control Knobs to 6 & 6.

3. Open both Conveyor Covers.

4. Disconnect the Conveyor Belt Chain by squeezing

any two links together and unhooking both ends

of one link (Figure 6).

5. Place the replacement Conveyor Belt Chain on

the top sprockets with hook ends down.

NOTE: The ends of the hooks must point down

(Figure 6).

6. Wrap the Conveyor Belt Chain around the top

and lower sprockets and connect by hooking both

ends together.

NOTE: Make sure the Conveyor Belt Chain is

installed under the Upper Support Rod and over the

Lower Support Rod.

Replacing the Spring Tensioners

1. Remove the Acorn Nuts (Figure 7).

2. Remove the old Spring Tensioner Assembly.

3. Replace Tensioner Assembly and reassemble

unit.

Acorn Nuts

Tape

Figure 7. Replacing Spring Tensioner Assy.

Weld

Screws

Spring

Tensioner

Assy.

P/N 1010930 Rev. C 09/13

11

Page 12

VERTICAL CONTACT TOASTER

TROUBLESHOOTING

WARNING

To avoid possible personal injury and/or damage to the unit, inspection, test, and repair of electrical equipment

should be performed by qualified service personnel. The unit should be unplugged when servicing, except when

electrical tests are required. Use extreme care during electrical circuit tests. Live circuits will be exposed.

Problem Possible Cause Corrective Action

No heat and conveyor

belts do not move.

No heat but Conveyor

Belt Chains rotate.

Platen is hot but

Conveyor Belt Chains do

not rotate.

Conveyor Belt Chains

hesitate to rotate and/or

skip on sprockets.

Toaster is installed incorrectly. Perform the installation and operating proce-

dures found in the Installation and Operation

sections of this manual.

Inoperable power cord or Power

Switch.

Hi-Limit Control is tripped. Reset the Hi-Limit Control.

Wiring problem. Contact your maintenance person or Authorized

Wiring problem. Contact your maintenance person or Authorized

Inoperative Platen.

Inoperable Thermostat

Heat Shield not installed. Install Heat Shield.

Conveyor Safety Interlock Switch not

activated by the Heat Shield.

Spring Tensioner Assembly is

damaged or missing.

Conveyor Belt Chain links too loose. Adjust Conveyor Belt Chain length as described

Inoperable Drive Motor. Contact your maintenance person or Authorized

Loose Drive Motor Sprocket

Setscrew.

Drive Motor Chain has fallen off

sprocket(s).

Inoperable Safety Interlock Switch.

Conveyor Belt Chains installed

incorrectly.

Conveyor Belt Chains too loose. Adjust Conveyor Belt Chain length as described

Spring Tensioner Assembly is

damaged or missing.

Check receptacle for correct voltage (see the

Specifications section of this manual).

If necessary, contact your maintenance person

or Authorized Service Agency for service.

Service Agency for service.

Service Agency for service.

Re-install the Heat Shield correctly so that the

Heat Shield applies appropriate pressure on the

Conveyor Safety Interlock Switch.

Replace Spring Tensioner if damaged or

missing.

in the Maintenance section of this manual.

Service Agency.

Install Conveyor Belt Chains as described in the

Maintenance section of this manual. Be sure that

the ends of the hooks are facing down.

in the Maintenance section of this manual.

Replace Spring Tensioner Assembly if damaged

or missing.

12

P/N 1010930 Rev. C 09/13

Page 13

Problem Possible Cause Corrective Action

Product is over toasted

or Platen heat is too

high or drop time is too

slow.

Product is under toasted or Platen heat is too

low or drop time is too

fast.

Product is getting

stuck or Conveyor Belt

Chains stop when

product is toasting.

VERTICAL CONTACT TOASTER

TROUBLESHOOTING (continued)

Temperature set too high. Set Temperature Control to a lower setting.

Bun Thickness Compression

Knobs set improperly.

Buns sticking on Release Sheet. Clean or replace Release Sheet as described in the

Conveyor Cover Assembly not

installed properly.

Loose sprocket setscrews. Check drive chain for kinks, broken or bent links,

Conveyor Belt Chain too loose. Adjust Conveyor Belt Chain length as described in the

Spring Tensioner Assembly is

damaged or missing.

Bun Thickness Compression

Knobs set improperly.

Wiring problem. Contact your maintenance person or Authorized

Inoperable Thermostat.

Conveyor Drive Motor inoperable or incorrect conveyor motor

or sprocket installed.

Bun Thickness Compression

Knobs Set improperly.

Release Sheet not cleaned

properly or is missing.

Conveyor Drive motor inoperative or incorrect voltage motor

installed in toaster.

Conveyor Drive Chain loose,

worn, or broken. Loose motor

drive sprocket.

Conveyor Belt Chain too loose. Adjust Conveyor Belt Chain length as described in the

Spring Tensioner Assembly is

damaged or missing.

Measure bun thickness and set Bun Thickness

Compression Knobs accordingly.

Maintenance section of this manual.

Re-install Conveyor Cover Assembly.

or other damage. Check motor sprocket and drive

sprockets; tighten setscrew on flat of shaft if required.

Check for damaged/worn sprocket and replace as

required.

Maintenance section of this manual.

Replace Spring Tensioner Assembly if damaged or

missing.

Measure bun thickness and set Bun Thickness

Compression Knobs correctly.

Service Agency for service.

Measure bun thickness and set Bun Thickness

Compression Knobs accordingly.

Clean or replace Release Sheet as described in the

Maintenance section of this manual.

Contact your maintenance person or Authorized

Service Agency for service.

Check drive chain for kinks, broken or bent links,

or other damage. Check motor sprocket and drive

sprockets, tighten setscrew on flat of shaft if required.

Check for damaged/worn sprockets and replace as

required.

Maintenance section of this manual.

Replace Spring Tensioner Assembly if damaged or

missing.

P/N 1010930 Rev. C 09/13

13

Page 14

VERTICAL CONTACT TOASTER

POWER

BLK

WIRING DIAGRAM

Pictorial Wiring Diagram

VCT-50 & VCT-1000

CORD

NOTE: ALL WIRES TO BE 14 GA. AWM-105°C

UNLESS OTHERWISE SPECIFIED.

* 16 GA. TFE-200°C

GRN

BLK/BRN

WHT/BLU

GRN-YEL

TERMINAL

BLOCK

= 18 GA. AWM-105°C

# 16 GA. AWM-105°C

% 14 GA. TFE-200°C

21

54

GND

WHT

= WHT

HI-LIMIT

THERMOSTAT

INDICATOR

*WHT

%WHT

M

MOTOR 50 Hz

WHT

GRN

POWER

SWITCH

LIGHT

=BLK

BLK

THERMOSTAT

% BLK

% BLK

% BLK

INTERLOCK

SWITCH

PLATEN HEATER

60 Hz

50 Hz

14

P/N 1010930 Rev. C 09/13

Page 15

VERTICAL CONTACT TOASTER

REPLACEMENT PARTS

Parts Identification

Interlock

Switch

Idler Sprocket

Front Drive

Sprocket

Temperature

Control

Thermostat

Power Switch

Drive Chain

Rear Drive

Sprocket

Fan Blade

Hi-Limit Control

Drive Motor Assy.

P/N 1010930 Rev. C 09/13

15

Page 16

VERTICAL CONTACT TOASTER

3

3

8

64

52

38

29

61

76

83

55

93

86

82

10

63

60

98

48

106

105

34

33

66

35

107

110

53

32

123

122

119120

118

117

111

116

115

114

116

112

REPLACEMENT PARTS (continued)

16

P/N 1010930 Rev. C 09/13

Page 17

VERTICAL CONTACT TOASTER

21

70

87

17

19

70

20

90

89

91

72

12

12

62

17

70

72

18

19

17

23

17

70

16

80

75

70

56

74

42

67

67

70

42

67

67

53

23

67

46

22

58

84

43

11

24

32

39

109

108

83

54

REPLACEMENT PARTS (continued)

P/N 1010930 Rev. C 09/13

17

Page 18

VERTICAL CONTACT TOASTER

REPLACEMENT PARTS (continued)

2

79

34

78

88

70

16

31

37

65

1

30, 94

5

67

5

5

5

4

40

4

31, 95

41

9

7

65

6

51

6

7

65

62

1

95

44

67

6

41

9

65

6

7

67

94

85

96

83

85

76

40

30

76

45

18

P/N 1010930 Rev. C 09/13

Page 19

VERTICAL CONTACT TOASTER

REPLACEMENT PARTS (continued)

Item Part No. Description Qty.

1 0011266 Conveyor Belt Chain 2

(Incl. Items Below)

0800204 1/2” Pitch Link, Small 2

0800121 3/4” Pitch Link, Large 38

2 2150117 Idler Shaft 1

3 0011609 Conveyor Cover Assy. 2

4 0010475 Tensioner Assy. (Incl. #40, 76, 85) 4

5 7000644 Rod, Conveyor Cover with Screw 4

6 7000207 Sprocket w/ Setscrew 8

7 7000199 Spacer Kit (Pack of 2) 2

8 0011444 Control Housing Cover Assy. 1

9 2150118 Drive Shaft 3

10 2100212 Handle 2

11 4030355 Thermostat 1

12 7000296 Ball Bearing - Steel (Pack of 2) 1

16 7000167 Bearing & Retainer Kit 6

7000224 Bearing & Retainer Kit (Incl. 6 of #16) 1

17 2150181 Drive Sprocket 2

2150109 Drive Sprocket (Mfg. No. 9210728) 2

18 2150187 Drive Chain 1

19 0011299 Idler Sprocket & Bearing 1

20 0011300 Bracket, Idler Sprocket Assy. 1

(Incl. #19, 87, 89, 90, 91)

21 0503589 Bracket, Motor Mounting 1

22 7000240 Drive Motor Kit 230V, 9 RPM 1

0012112 Gear Motor Assy 230V/3RPM 1

(Mfg. No. 9210728)

23 2150173 Sprocket w/Setscrew, Motor 1

24 4010137 Power Switch, On/Off 1

25 2150109 Drive Sprocket, Rear 1

30 0503496 Tensioner Bracket, Right 2

31 0503497 Tensioner Bracket, Left 2

32 1000899 Label, Housing 1

33 1001047 Label, Dial Compression 1

34 2100253 Knob, Control 2

35 0011552 End Housing Cover Assy. 1

37 0021170 Weldment, End Housing 1

38 7000249 Release Sheet (Pack of 3) 39 0021194 Control Housing 1

40 7000121 Slide Rail Kit (Includes 2 2

Slide Rails for tensioners)

41 0021207 Conveyor Cam 2

42 7000176 Thermocouple Retainer Kit 2

43 4030332 High Limit Control 1

44 0011573 Idler Shaft Assy. (Top, Front) 1

45 0503455 Tension Spring, Inner 4

46 0503590 Slide Plate, Motor Mounting 1

48 0503677 Bun Chute 1

51 7000200 Platen 1

52 2100252 Tape 2

53 7000400 Interlock Switch 1

54 0503608 Cover Plate 2

55 303P127* Hinge Pin, Belt Wrap 2

56 4060355 Terminal Block 1

58 4000170 Fan Blade, Motor 1

60 040K251 Strain Relief Kit (Incl. #63) 1

61 05P2199* Spacer 4

62 0500464 Retainer, Bearing 2

63 040P138* Locknut, 1/2” 1

64 0011528 Heat Shield Assy. 1

65 325P163* Setscrew, 1/4-28 x 5/16” 8

66 100P864* Label, Caution Hot 1

67 310P109* Screw, Hex, #10-32 x 3/8” 2

68 304P105* Nut, #4-40, “KEPS” 4

Item Part No. Description Qty.

69 406P107* Cable Tie 1

70 308P143* Nut, #8-32, “KEPS” 6

71 310P103* Screw, Hex, #10-32 x 1/4” 4

72 310P157* Washer, #10 6

73 308P101* Nut, #8-32 3

74 306P101* Nut, Hex, #6-32 2

75 306P123* Screw, #6-32 x 7/8” 2

76 308P145* Nut, Hex Acorn, #8-32 14

77 100P900* Label, Service 1

78 325P104* Washer, 1/4” 4

79 325P109* Screw, 1/4-20 x 1/2” 4

80 308P124* Screw, 1-Way, #8-32 x 1/2” 1

82 310P136* Screw, #10-32 x 1-1/4” 4

83 308P133* Screw, #8-32 x 1/4” 1

84 308P157* Screw, Tap, #8-32 x 3/8” 20

85 308P181* Screw, Flat Hd., #8-32 x 3/8” 4

86 218P145* Cover, Leg, Bumper 4

87 331P103* Shoulder Bolt, 5/16-18 x 1” 1

88 306P105* Screw, #6-32 x 1/2” 8

89 331P106* Lockwasher, 5/16” 1

90 212P118* Flat Washer, 5/16” 1

91 331P101* Nut, Hex, 5/16-18 1

92 300P102* Nut, Tinnerman 2

93 210K230 Bumper, Recess Leg, 1” (Qty. of 4) 1

94 0503495 Retainer, Tensioner Bracket, RH 1

95 0503507 Retainer, Tensioner Bracket, LH 1

96 2100259 Slide Rail 4

98 0700452 Power Cord 6-20P 250V 1

99 306P104* Screw, #6-32 x 1/4” 6

104 4060374 Ground Lug 1

105 0021320 Butter Wheel Roller 1

106 0503987 Butter Pan 1

107 7000292 Bun Feeder Assembly 1

108 2100133 Knob, Thermostat 1

109 4060323 Indicator Light, Amber 120V 1

4060229 Indicator Light, Amber 250 V 1

110 0011374 Spring Tensioner Assembly 2

111 308P157 Screw, #8-32 x 3/8” 7

112 2150204 Bearing, Shaft, 1/2” 4

114 2150212 Sprocket, 12 Tooth 1

115 2150207 Sprocket, 28 Tooth 1

116 2120149 Spacer, Nylon 2

117 0503891 Housing 1

118 0400295 Plug, Pry Out 1

119 0011553 Shaft Assembly 1

120 2150205 Chain Drive 1

122 7000692 Shaft Coupling Kit (Incl. Items Below) 1

2150201 Shaft, Drive 1

2150202 Coupler 1

123 0021507 Bun Feeder (Mfg. No. 9210719 1

& 9210728 only)

0011549 Bun Feeder (Mfg. No. 9210721 only) 1

124 2140152 Lubricant (not shown) 1

* Sold only as packages of 10.

P/N 1010930 Rev. C 09/13

19

Page 20

LIMITED WARRANTY

Equipment manufactured by Roundup Food Equipment Division of A.J. Antunes & Co. has been constructed of

the finest materials available and manufactured to high quality standards. These units are warranted to be free

from electrical and mechanical defects for a period of one (1) year from date of purchase under normal use and

service, and when installed in accordance with manufacturer’s recommendations. To insure continued operation of the units, follow the maintenance procedures outlined in the Owner’s Manual. During the first 12 months,

electro-mechanical parts, non-overtime labor, and travel expenses up to 2 hours (100 miles/160 km), round trip

from the nearest Authorized Service Center are covered.

1. This warranty does not cover cost of installation, defects caused by improper storage or handling prior to placing of the Equipment. This warranty does not cover overtime charges or work done by unauthorized service

agencies or personnel. This warranty does not cover normal maintenance, calibration, or regular adjustments

as specified in operating and maintenance instructions of this manual, and/or labor involved in moving adjacent

objects to gain access to the equipment. This warranty does not cover consumable/wear items. This warranty

does not cover damage to the Load Cell or Load Cell Assembly due to abuse, misuse, dropping of unit/shock

loads or exceeding maximum weight capacity (4 lbs). This warranty does not cover water contamination problems such as foreign material in water lines or inside solenoid valves. It does not cover water pressure problems

or failures resulting from improper/incorrect voltage supply. This warranty does not cover Travel Time & Mileage

in excess of 2 hours (100 miles/160 km) round trip from the nearest authorized service agency.

2. Roundup reserves the right to make changes in design or add any improvements on any product. The right

is always reserved to modify equipment because of factors beyond our control and government regulations.

Changes to update equipment do not constitute a warranty charge.

3.

If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful inspection

should be made of the shipment as soon as it arrives and visible damage should be noted upon the carrier’s receipt.

Damage should be reported to the carrier. This damage is not covered under this warranty.

4. Warranty charges do not include freight or foreign, excise, municipal or other sales or use taxes. All such freight

and taxes are the responsibility of the purchaser.

5. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, EACH OF WHICH IS HEREBY EXPRESSLY DISCLAIMED. THE REMEDIES DESCRIBED ABOVE

ARE EXCLUSIVE AND IN NO EVENT SHALL ROUNDUP BE LIABLE FOR SPECIAL CONSEQUENTIAL OR

INCIDENTAL DAMAGES FOR THE BREACH OR DELAY IN PERFORMANCE OF THIS WARRANTY.

Loading...

Loading...