Page 1

XR-MD811

EZ

SERVICE MANUAL

MD / CD

STEREO SYSTEM

SYSTEM

XR-MD811

• This Service Manual is the “Revision” and replaces “Simple Manual”

XR-MD811(EZ), (S/M Code No. 09-008-438-0T1).

• If requiring information about the MD mechanism, see Service Manual of

AZG-H, (S/M Code No. 09-005-346-5N2).

STEREO

RECEIVER

RX-LMD811

STEREO MD RECORD/

COMPACT DISC PLAYER

FM-LMD811

BASIC CD MECHANISM : DA23L

BASIC MD MECHANISM : AZG-H YA

SPEAKER

SX-LM810

REMOTE

CONTROLLER

RC-AAT21

S/M Code No. 09-00C-438-0R1

REVISION

DAT A

Page 2

TABLE OF CONTENTS

SPECIFICATIONS .................................................................................................................................................3

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING ........................................................4

DISASSEMBLY INSTRUCTIONS....................................................................................................................5 ~ 6

MODEL NO. RX-LMD811

ELECTRICAL MAIN PARTS LIST ................................................................................................................7 ~ 9

TRANSISTOR ILLUSTRATION ..........................................................................................................................10

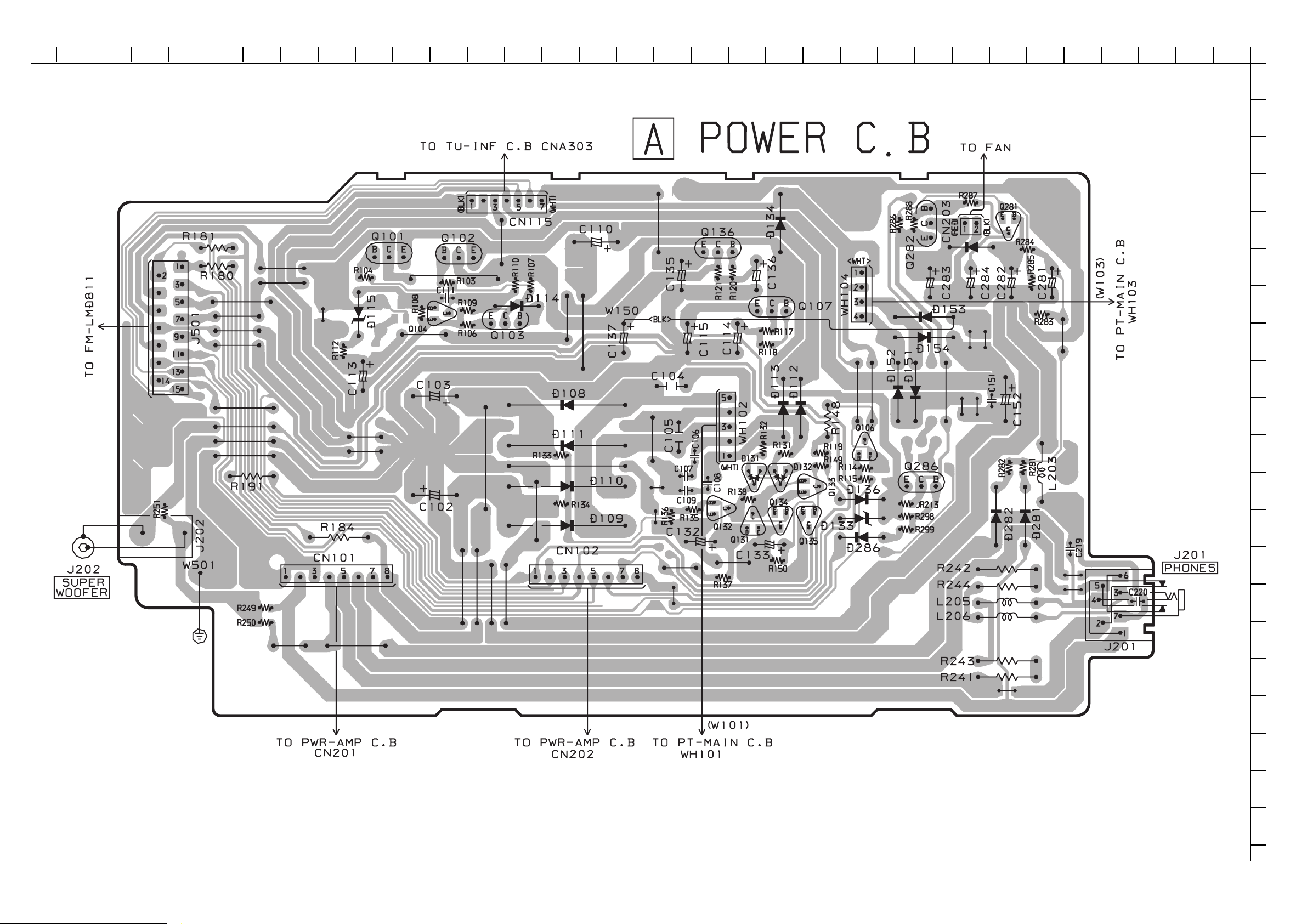

WIRING – 1 (POWER).........................................................................................................................................11

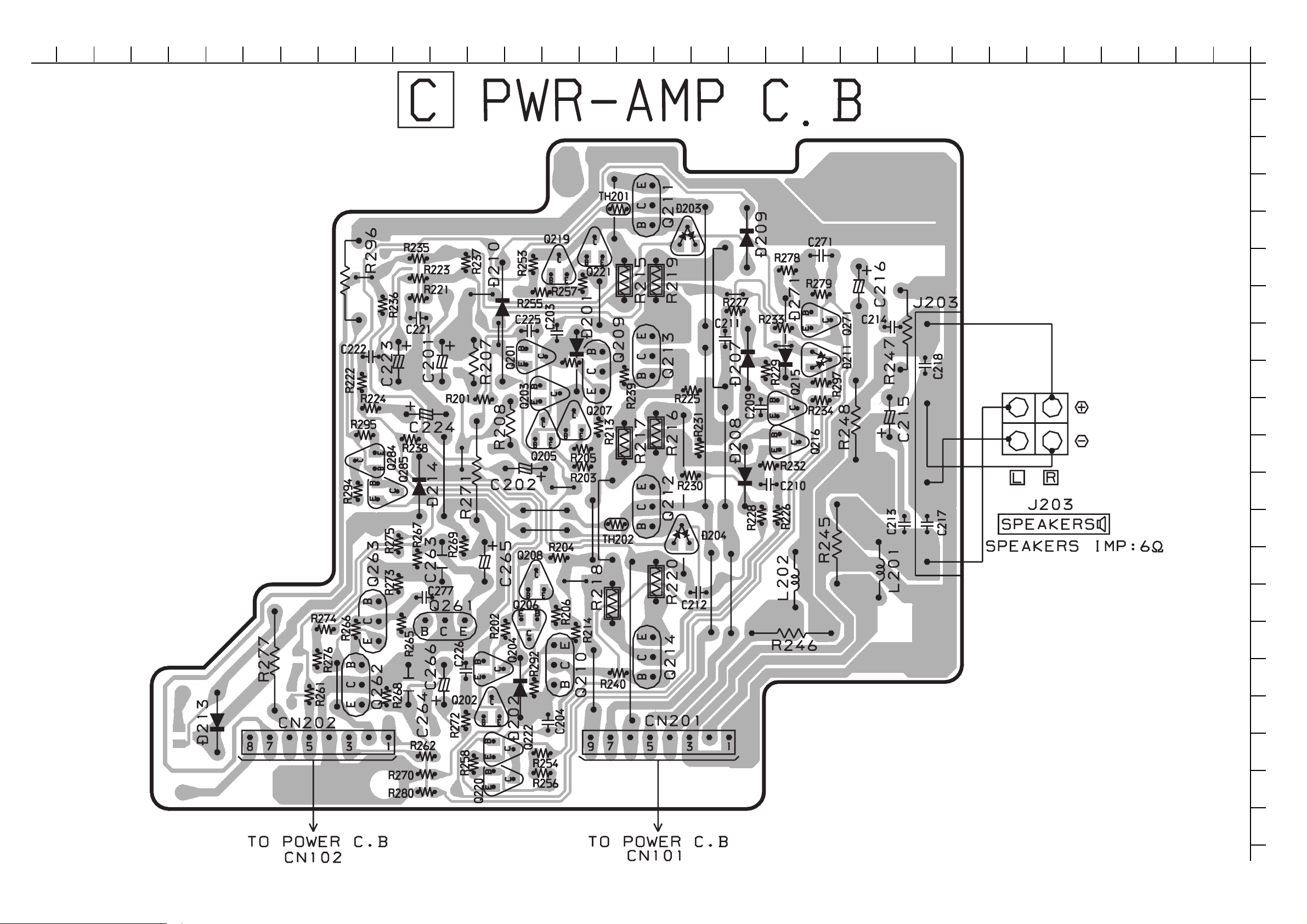

WIRING – 2 (PWR-AMP) .....................................................................................................................................12

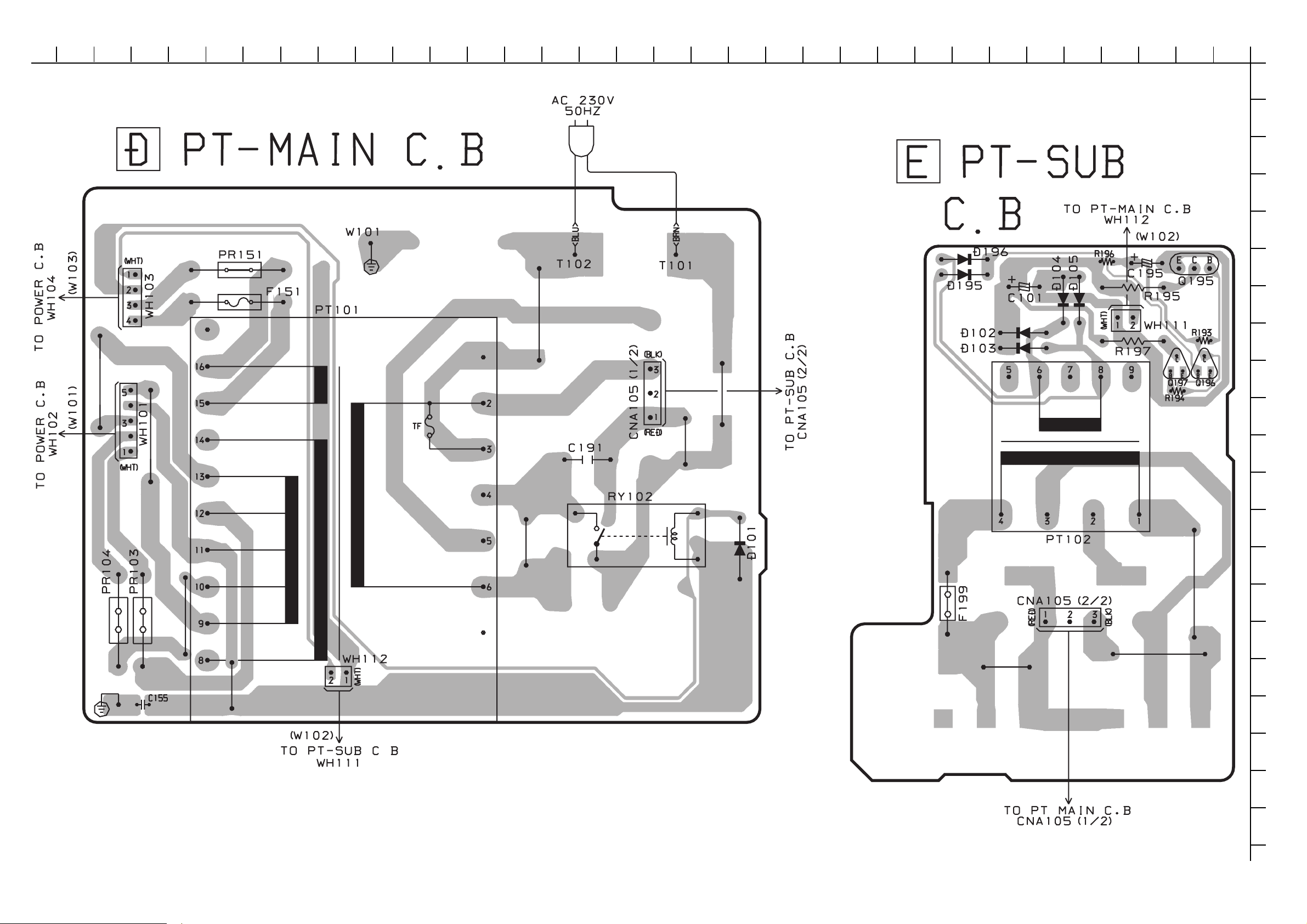

WIRING – 3 (PT-MAIN / PT-SUB) .......................................................................................................................13

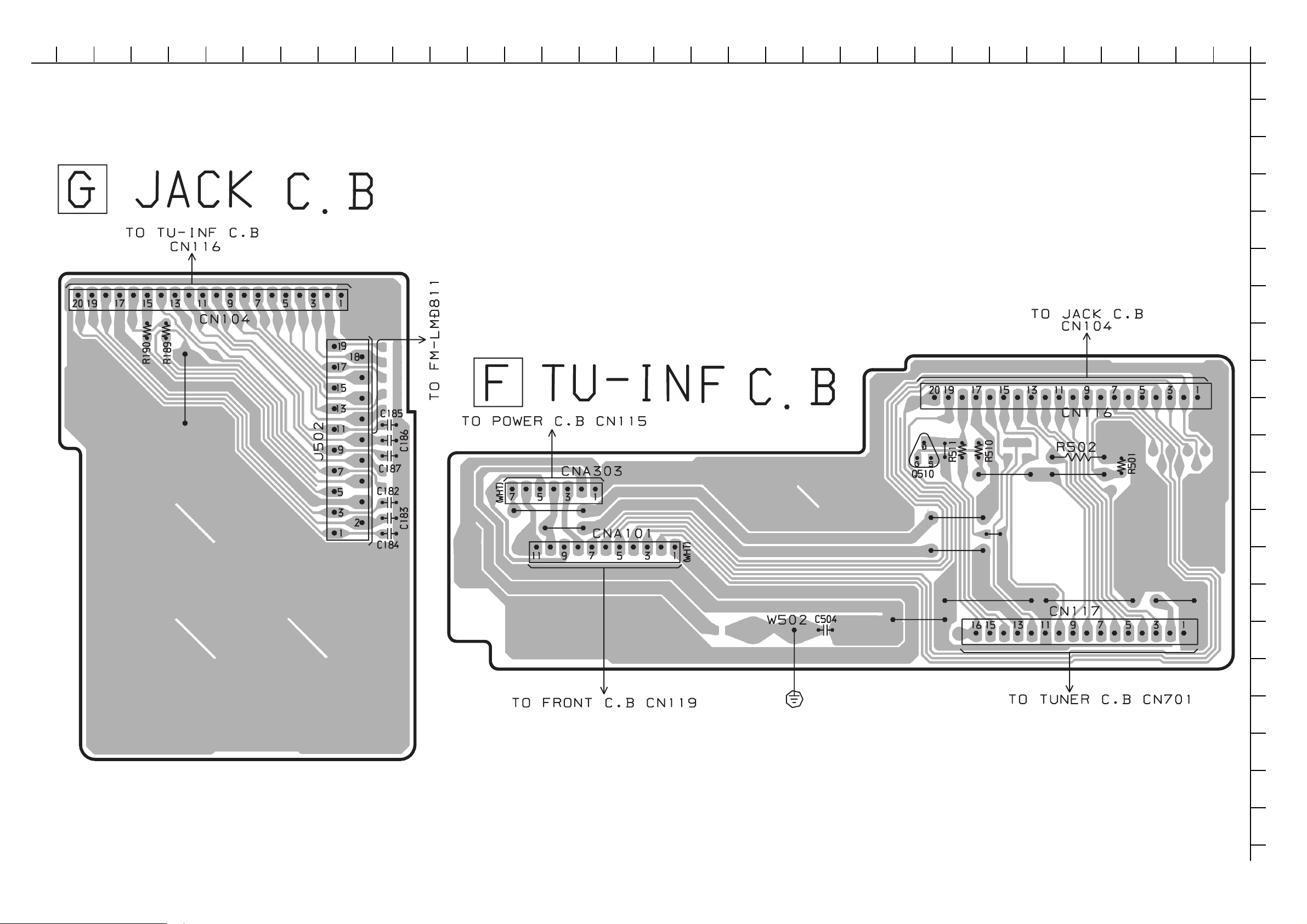

WIRING – 4 (TU-INF / JACK) ..............................................................................................................................14

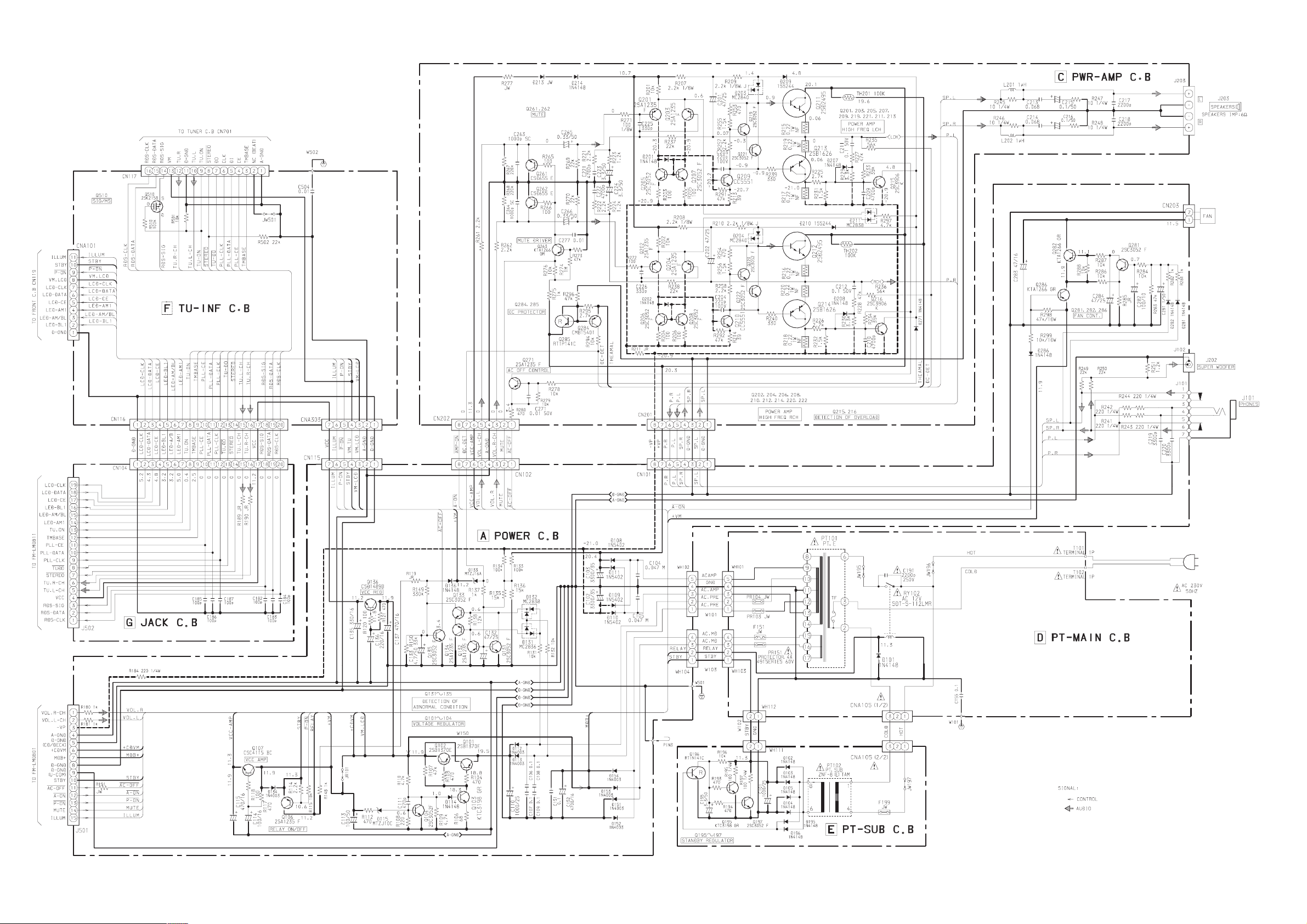

SCHEMATIC DIAGRAM – 1 (POWER / PWR-AMP / PT-MAIN / PT-SUB / TU-INF / JACK).............................15

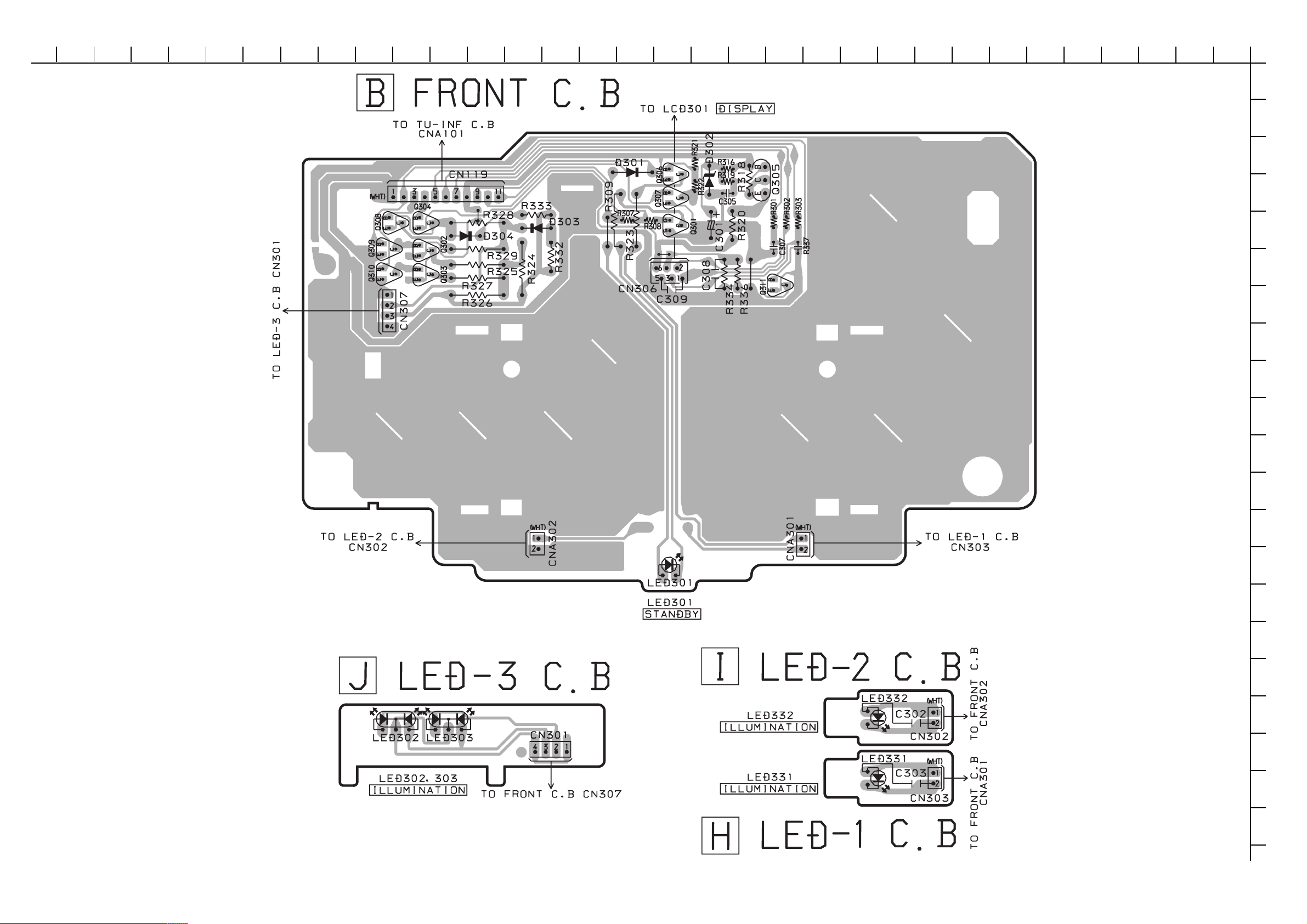

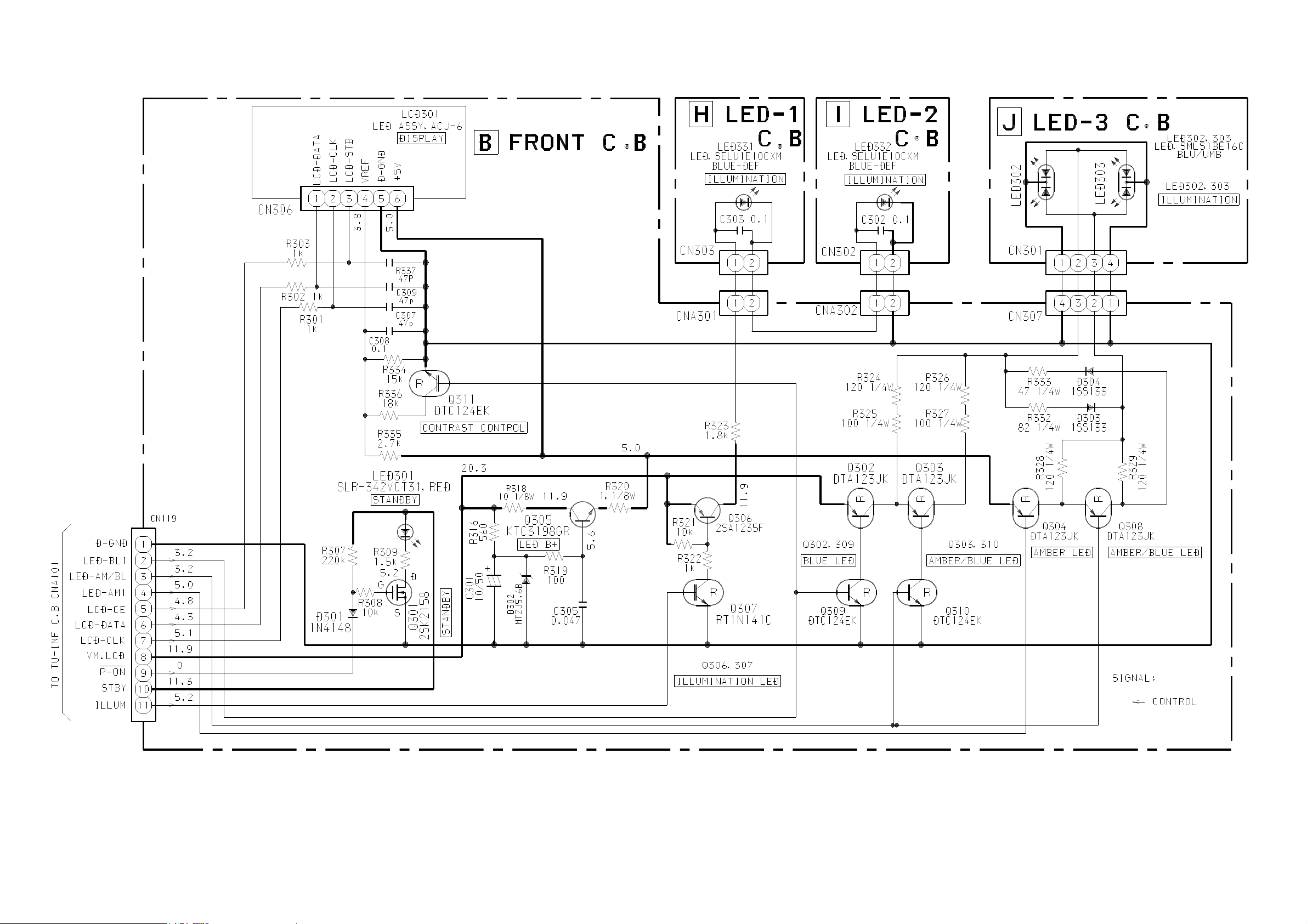

WIRING – 5 (FRONT / LED-1~3).........................................................................................................................16

SCHEMATIC DIAGRAM – 2 (FRONT / LED-1~3) ..............................................................................................17

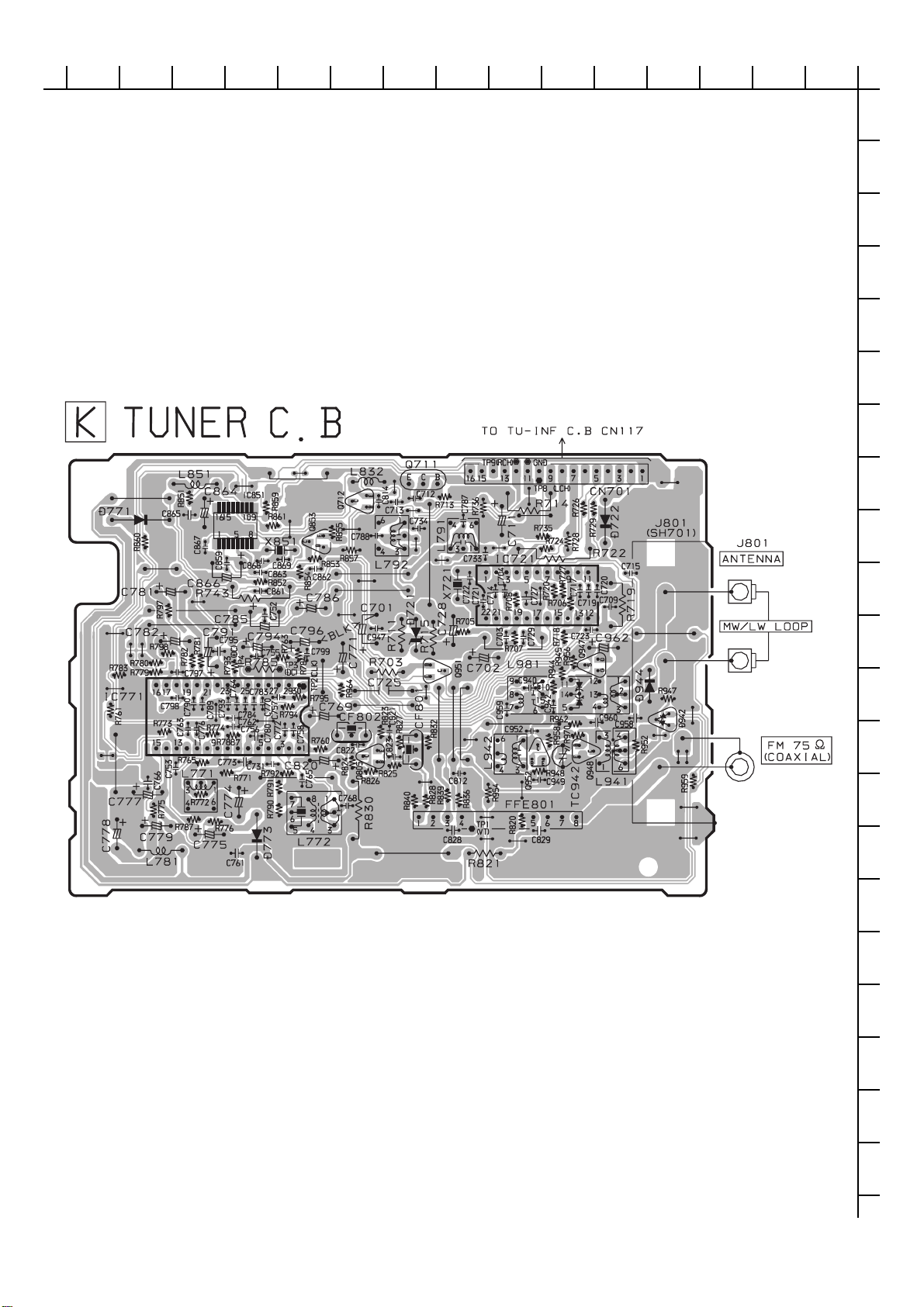

WIRING – 6 (TUNER) ..........................................................................................................................................18

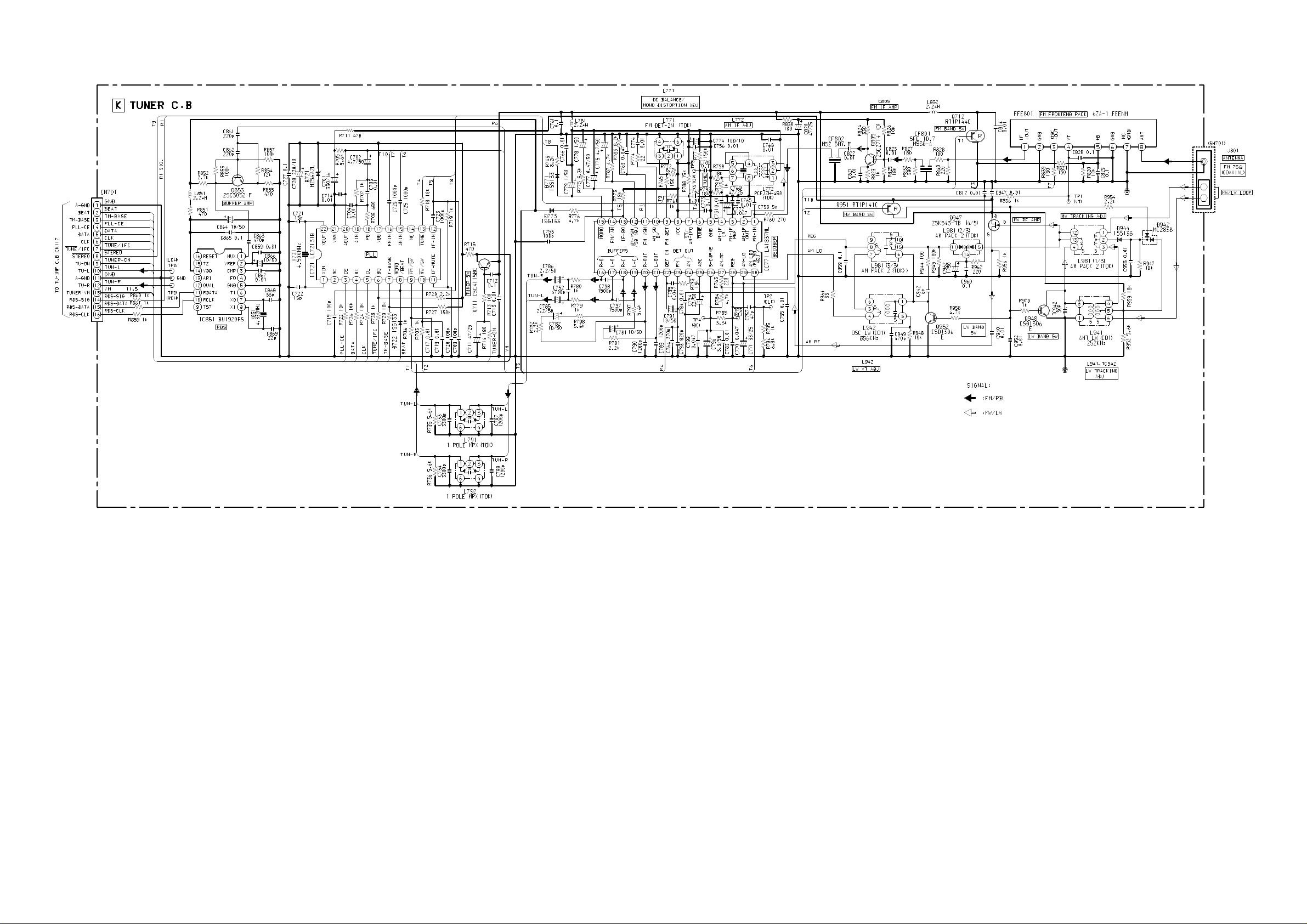

SCHEMATIC DIAGRAM – 3 (TUNER) ...............................................................................................................19

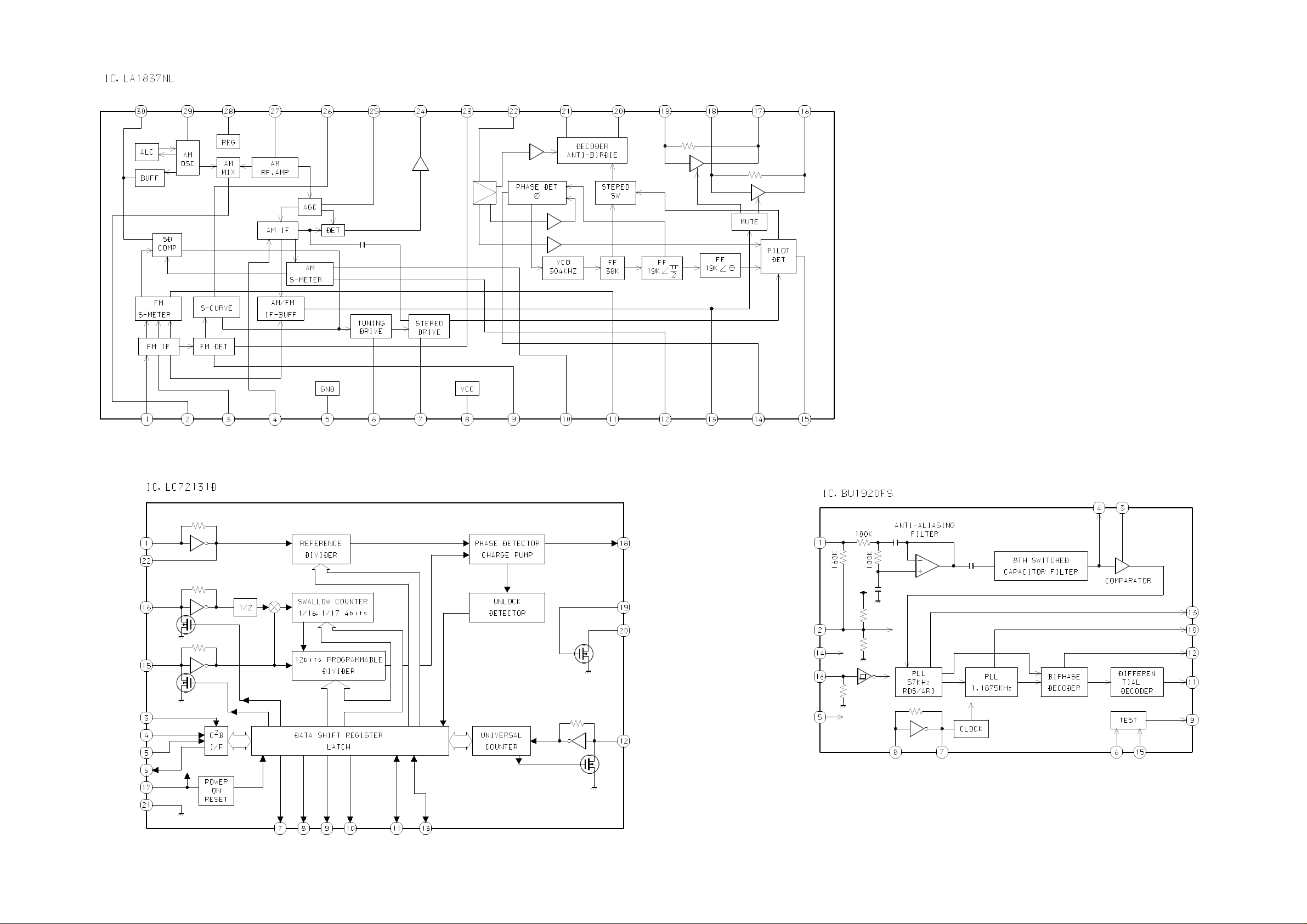

IC BLOCK DIAGRAM.........................................................................................................................................20

LCD DIAGRAM ....................................................................................................................................................21

ADJUSTMENT .....................................................................................................................................................22

MECHANICAL EXPLODED VIEW 1 / 1........................................................................................................... 23

MECHANICAL PARTS LIST 1 / 1 .....................................................................................................................24

MODEL NO. FM-LMD811

ELECTRICAL MAIN PARTS LIST ............................................................................................................25 ~ 27

TRANSISTOR ILLUSTRATION ..........................................................................................................................28

WIRING – 1 (FUNC / KEY / MOTOR / DOOR SW) .............................................................................................29

WIRING – 2 (FRONT / POWER / LED-L / LED-R) ..............................................................................................30

SCHEMATIC DIAGRAM – 1 (FUNC / FRONT / POWER / KEY / MOTOR / DOOR SW / LED-L / LED-R).......31

WIRING – 3 (CD) <1/2> .......................................................................................................................................32

WIRING – 3 (CD) <2/2> .......................................................................................................................................33

SCHEMATIC DIAGRAM – 2 (CD) <1/2> ............................................................................................................34

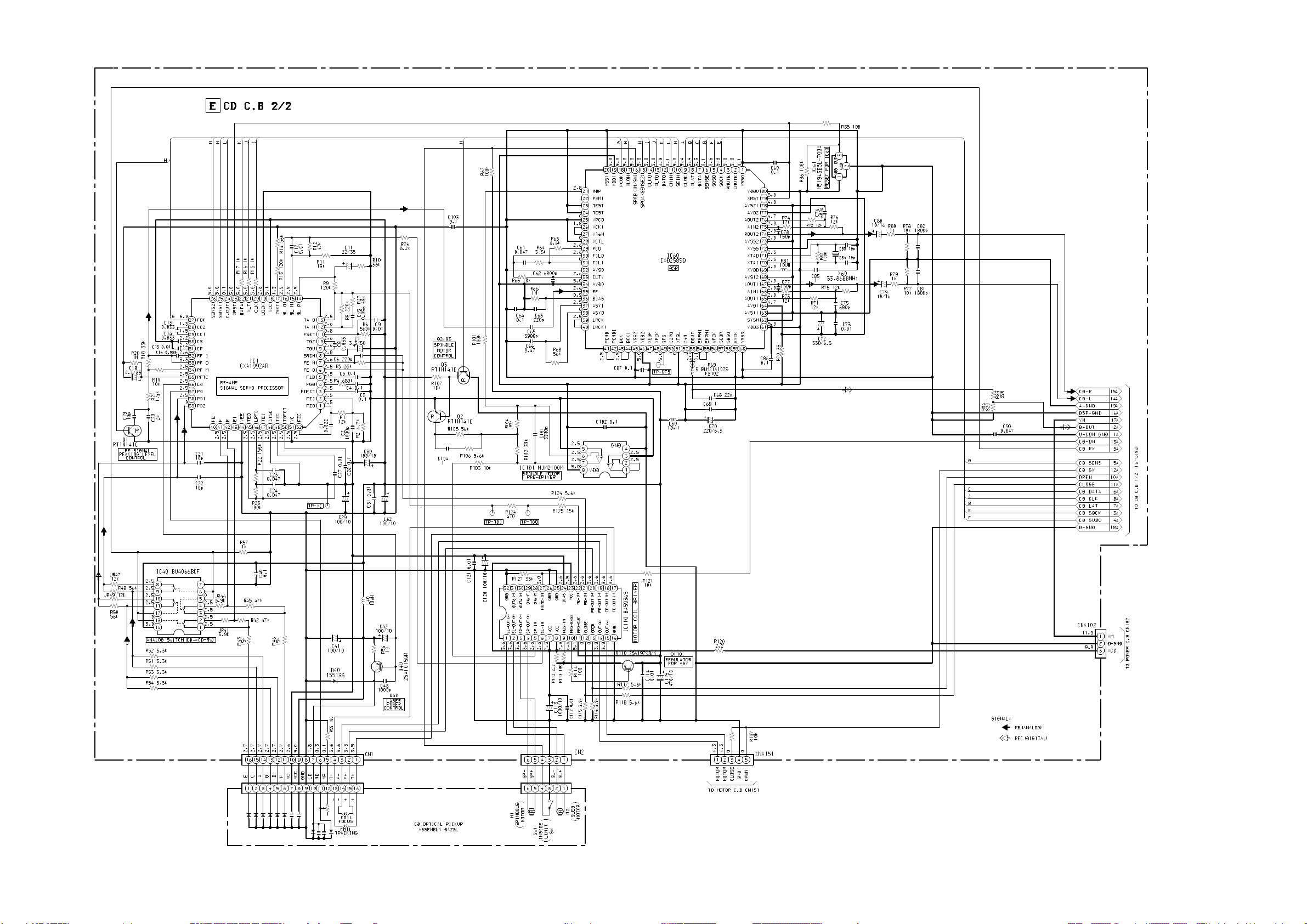

SCHEMATIC DIAGRAM – 3 (CD) <2/2> ............................................................................................................35

IC BLOCK DIAGRAM.........................................................................................................................................36

IC DESCRIPTION .......................................................................................................................................37 ~ 42

ADJUSTMENT <MD> ..................................................................................................................................43 ~ 51

CD TEST MODE ..................................................................................................................................................52

MD TEST MODE..........................................................................................................................................53 ~ 57

MECHANICAL EXPLODED VIEW 1 / 1............................................................................................................58

MECHANICAL PARTS LIST 1 / 1 .....................................................................................................................59

CD MECHANISM EXPLODED VIEW 1 / 1 ......................................................................................................60

CD MECHANISM PARTS LIST 1 / 1 ...............................................................................................................61

GENERAL SPEAKER DISASSEMBLY INSTRUCTIONS (FOR REFERENCE) .............................................62

SPEAKER PARTS LIST.....................................................................................................................................63

ACCESSORIES / PACKAGE LIST .....................................................................................................................63

– 2 –

Page 3

SPECIFICATIONS

STEREO RECEIVER RX-LMD811

<FM tuner section>

Tuning range 87.5 MHz to 108 MHz

Usable sensitivity (IHF) 16.8 dBf

Antenna terminals 75 ohms (unbalanced)

<MW tuner section>

Tuning range 531 kHz to 1602 kHz (9 kHz step)

530 kHz to 1710 kHz (10 kHz step)

Usable sensitivity 350 µV/m

Antenna Loop antenna

<LW tuner section>

Tuning range 144 kHz to 290 kHz

Usable sensitivity 1400 µV/m

Antenna Loop antenna

<Amplifier section>

Power output Rated : 16 W + 16 W (6 ohms,

T.H.D. 1 %, 1 kHz/DIN 45500)

Reference : 20 W + 20 W (6 ohms,

T.H.D. 10 %, 1 kHz/DIN 45324)

DIN MUSIC POWER

35 W + 35 W

Outputs SUPPER WOOFER : 1.0 V

SPEAKERS : accept speakers of

6 ohms or more

PHONES (stereo mini jack) : accepts

headphones of 32 ohms or more

<General>

Power requirements 230 V AC, 50 Hz

Power consumption 60 W

Standby power consumption

16 W (power economizing mode

deactivated)

1.7 W (power economizing mode

activated)

Dimensions of main unit 156 x 114 x 207 mm

(W x H x D)

Weight of main unit 2.8 kg

STEREO MD RECORDER / COMPACT DISC PLAYER

FM-LMD811

<MD recorder section>

Scanning method Non-contact optical scanner

(Semiconductor laser application)

Recording system Magnetic polarity modulation

overwrite system

Rotation speed Approx. 400 to 900 rpm (CLV)

Sampling frequency 44.1 kHz

No. of channels Stereo: 2 channels

Monaural: 1 channel

A-D, D-A converter 1-bit

Frequency 20 to 20000 Hz +0.5 - –1.5 dB

Wow and flatter Unmeasurable

General

Inputs TAPE IN : 500 mV

AUX IN : 500 mV

DIGITAL IN (OPTICAL) :

Outputs LINE OUT : 500 mV

Dimensions of main unit 156 x 114 x 200.7 mm

(W x H x D)

Weight of main unit 1.8 kg

SPEAKER SYSTEM SX-LM810

Cabinet type 2 way, bass reflex (magnetic

shielded type)

Speaker Woofer :

100 mm cone type

Tweeter :

22 mm dome type

Impedance 6 ohms

Output sound pressure level 86 dB/W/m

Dimensions 135 x 223 x 173 mm

(W x H x D)

Weight 1.8 kg

• Design and specifications are subject to change without notice.

• The word "BBE"and the "BBE symbol" are trademarks of BBE

Sound, Inc.

Under license from BBE Sound,Inc.

<Compact disc player section>

Laser Semiconductor laser (λ = 780 nm)

D-A converter 1 bit dual

Signal-to-noise ratio 85 dB (1 kHz, 0 dB)

Harmonic distortion 0.05 % (1 kHz, 0 dB)

Wow and flutter Unmeasurable

– 3 –

Page 4

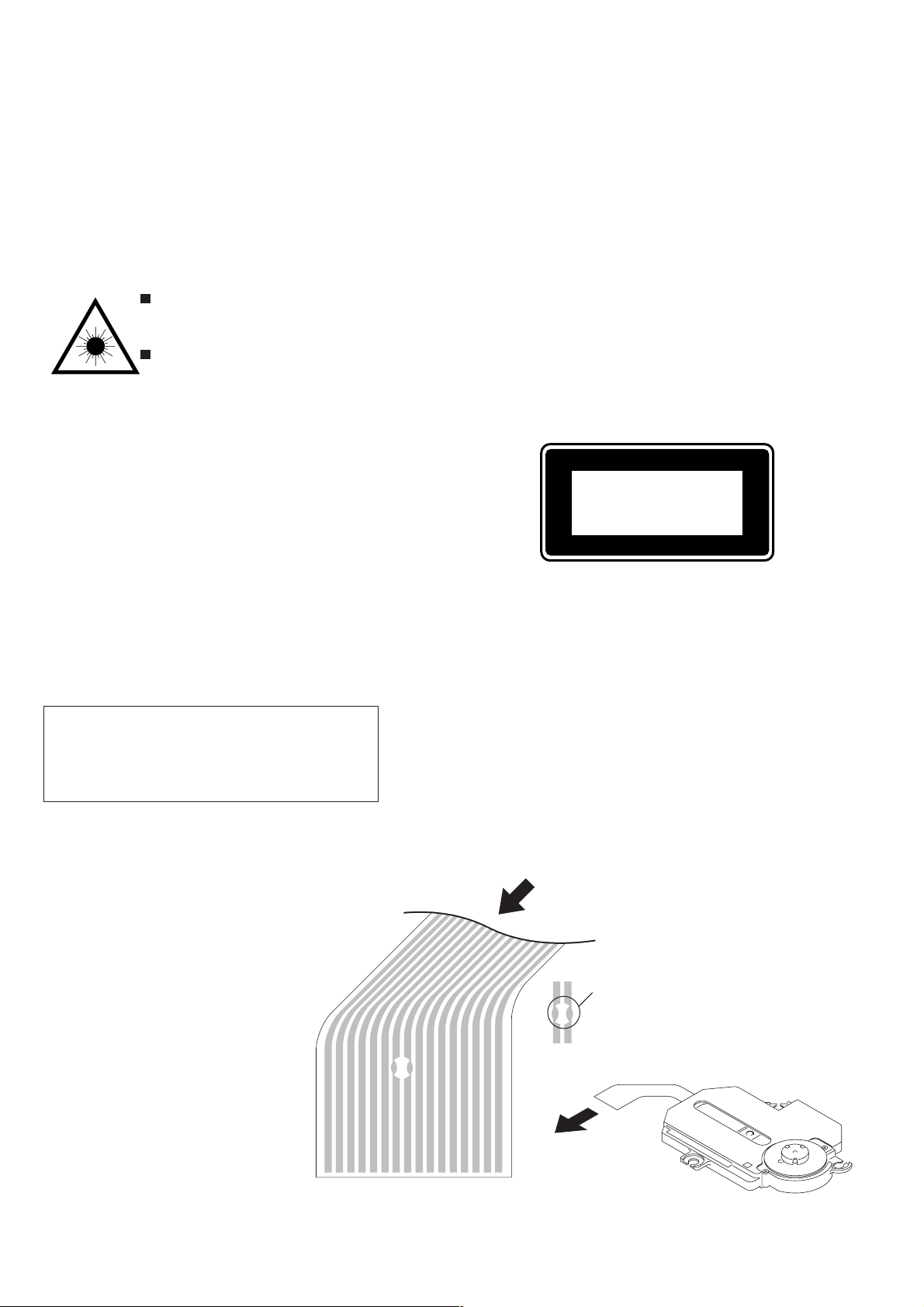

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

PICK UP ASSY

SF-P200L

:SOLDER

116

10 9

This set employs laser. Therefore, be sure to follow carefully the

instructions below when servicing.

WARNING!

WHEN SERVICING, DO NOT APPROACH THE LASER EXIT

WITH THE EYE TOO CLOSELY. IN CASE IT IS NECESSARY TO

CONFIRM LASER BEAM EMISSION. BE SURE TO OBSERVE

FROM A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE OPTICAL

PICK-UP BLOCK.

Caution: Invisible laser radiation when

open and interlocks defeated avoid exposure to beam.

Advarsel:Usynling laserståling ved åbning,

når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

VAROITUS!

Laiteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyt-täjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

VARNING!

Om apparaten används på annat sätt än vad som specificeras i

denna bruksanvising, kan användaren utsättas för osynling

laserstrålning, som överskrider gränsen för laserklass 1.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

ATTENTION

L'utilisation de commandes, réglages ou procédures autres que

ceux spécifiés peut entraîner une dangereuse exposition aux

radiations.

ADVARSEL!

Usynlig laserståling ved åbning, når sikkerhedsafbrydereer ude

af funktion. Undgå udsættelse for stråling.

This Compact Disc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located on the rear

exterior.

CLASS 1

KLASSE 1

LUOKAN 1

KLASS 1

LASER PRODUCT

LASER PRODUKT

LASER LAITE

LASER APPARAT

Precaution to replace Optical block

(SF-P200L)

Body or clothes electrostatic potential could ruin

laser diode in the optical block. Be sure ground

body and workbench, and use care the clothes

do not touch the diode.

1) After the connection, remove solder shown in

the right figure.

– 4 –

Page 5

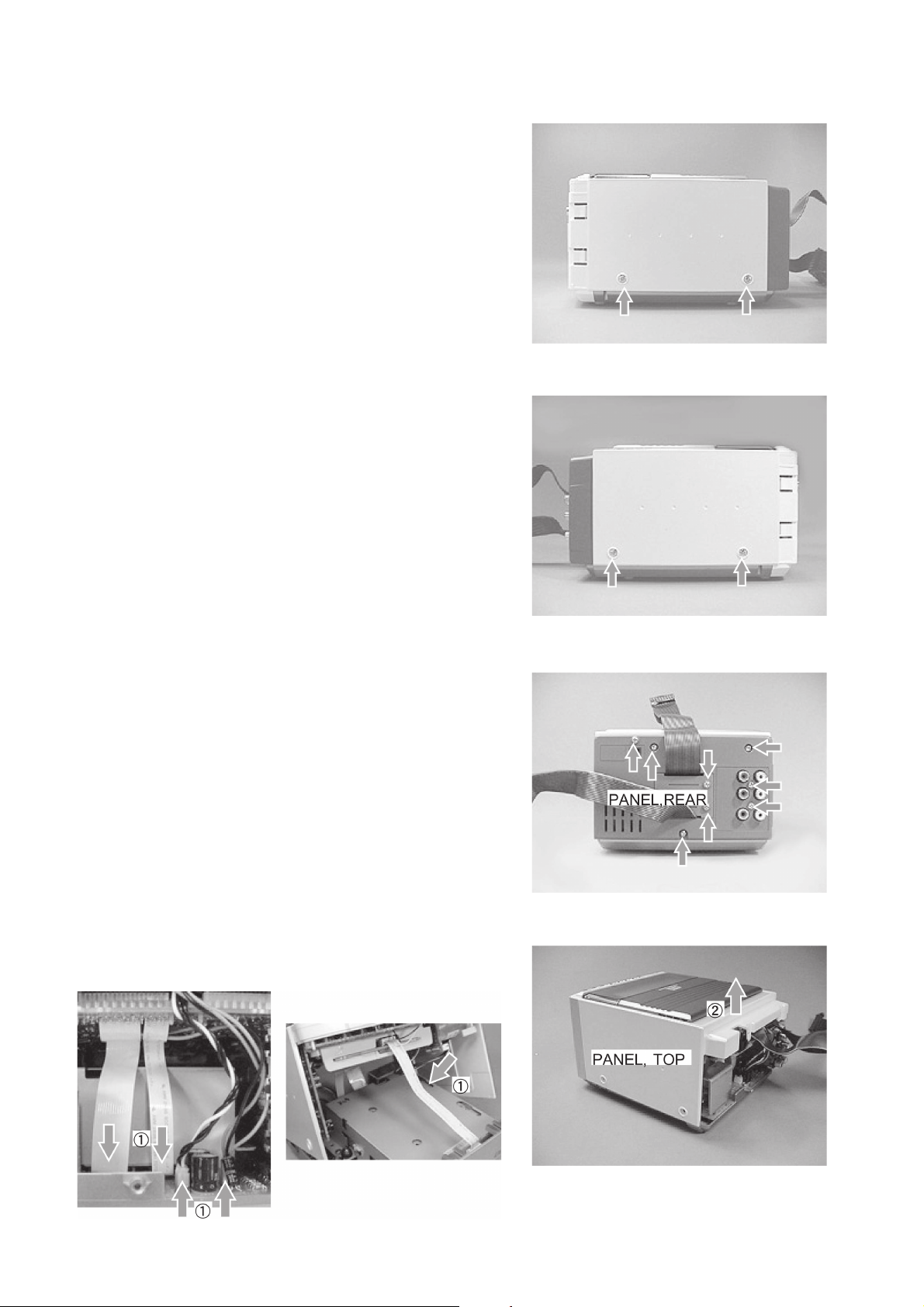

DISASSEMBLY INSTRUCTIONS

FM BLOCK DISASSEMBLY

1. Removing the Ornament Parts

1) Remove the two screws.

2) Remove the two screws.

3) Remove the eight screws and remove PANEL, REAR.

4) Remove the FFC from the connector 1 and remove PANEL,

TOP 2.

– 5 –

Page 6

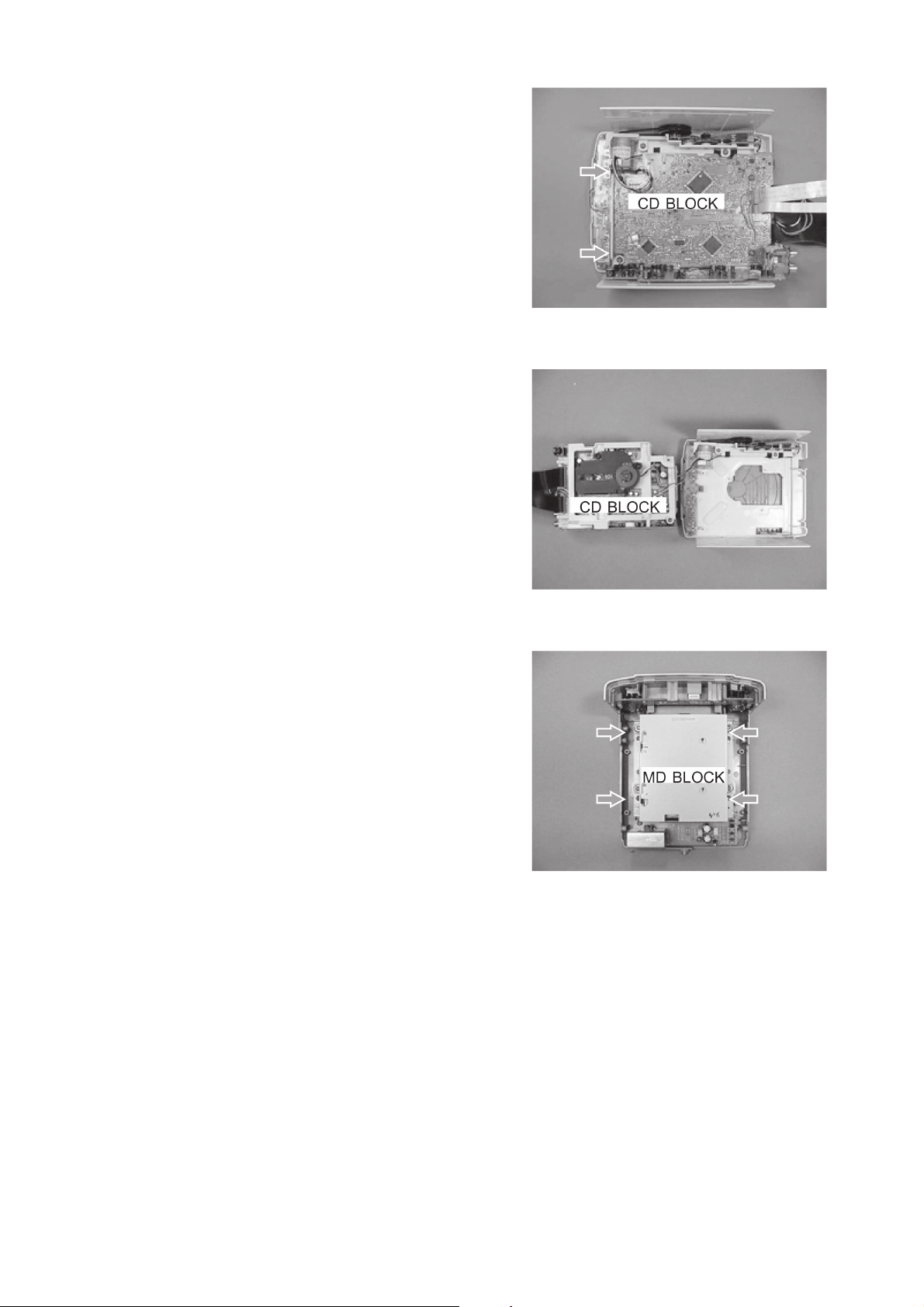

2. Removing the CD Block

1) Remove the two screws and remove the entire CD block.

2) The figure shows the states after the CD block is removed.

3. Removing the MD Block

1) Remove the four screws and remove the MD block.

– 6 –

Page 7

MODEL NO.

RX-LMD811

ELECTRICAL MAIN PARTS LIST

PART NO.

NO.

IC

87-070-127-110 IC,LC72131D

87-A20-913-010 IC,LA1837NL

87-A20-440-040 C-IC,BU1920FS

TRANSISTOR

89-213-702-010 TR,2SB1370E

87-026-610-080 TR,KTC3198GR

87-A30-076-080 C-TR,2SC3052F

87-A30-075-080 C-TR,2SA1235F

87-A30-234-080 TR,CSC4115BC

87-A30-083-080 TR,CSD1489B

87-A30-073-080 C-TR,RT1N 141C

87-A30-190-080 TR,CC5551

87-A30-109-010 TR,2SD 2495

87-A30-108-010 TR,2SB1626

87-A30-119-040 C-TR,2SC3906K R

87-A30-047-080 TR,CSD655E

87-026-609-080 TR,KTA1266GR

87-A30-107-070 C-TR,CMBT5401

87-A30-074-080 C-TR,RT1P 141C

87-A30-087-080 C-FET,2SK2158

87-026-580-080 C-TR,DTA123JK

87-026-236-080 C-TR,DTC124EK

89-505-434-540 C-FET,2SK543-TB(4/5)

89-327-143-080 C-TR,2SC2714(0.1W)

87-A30-072-080 C-TR,RT1P 144C

87-A30-086-070 C-TR,CSD1306E

DIODE

87-070-345-080 DIODE,IN4148

87-070-178-090 DIODE,1N5402-BD54

87-070-274-080 DIODE,1N4003 SEM

87-A40-345-080 ZENER,MTZJ10C

87-A40-269-080 C-DIODE,MC2836

87-A40-270-080 C-DIODE,MC2838

87-A40-004-080 ZENER,MTZJ16A

87-A40-313-080 C-DIODE,MC 2840

87-A40-488-080 DIODE,1SS244

87-017-931-080 ZENER,MTZJ5.6B

87-020-465-080 DIODE,1SS133

87-017-149-080 ZENER,HZS6A2L

POWER C.B

C102 87-016-051-090 CAP,E 2200-35 M SMG

C103 87-016-051-090 CAP,E 2200-35 M SMG

C106 87-010-196-080 CHIP CAPACITOR,0.1-25

C107 87-010-196-080 CHIP CAPACITOR,0.1-25

C108 87-010-196-080 CHIP CAPACITOR,0.1-25

C109 87-010-196-080 CHIP CAPACITOR,0.1-25

C110 87-010-388-010 CAP, E 1000-25 SME

C111 87-012-140-080 C-CAP,S 470P-50

C113 87-010-247-080 CAP, ELECT 100-50V

C114 87-010-112-080 CAP, ELECT 100-16V

C115 87-010-235-080 CAP,E 470-16 SME

C132 87-010-260-080 CAP, ELECT 47-25V

C133 87-010-403-080 CAP, ELECT 3.3-50 M 11L SME

C135 87-010-381-080 CAP, ELECT 330-16V

C136 87-010-101-080 CAP, ELECT 220-16

C137 87-010-235-080 CAP,E 470-16 SME

C151 87-010-196-080 C-CAP,S 0.1-25 Z F

C152 87-A11-174-090 CAP,E 4700-16 M SMG

DESCRIPTIONREF. NO. KANRI

PART NO.

NO.

C219 87-010-184-080 CHIP CAPACITOR 3300P-50

C220 87-010-184-080 CHIP CAPACITOR 3300P-50

C281 87-010-401-080 CAP, ELECT 1-50V

C282 87-010-263-080 CAP, ELECT 100-10V

C283 87-010-380-080 CAP, ELECT 47-16V

C284 87-010-260-080 CAP, ELECT 47-25V

CN101 87-A60-813-010 CONN,8P H BLK TAC-L8P

CN102 87-A60-813-010 CONN,8P H BLK TAC-L8P

CN115 87-A60-624-010 CONN,7P V 2MM JMT

CN203 87-A60-109-010 CONN,2P V S2M-2W

J201 87-A60-420-010 JACK,3.5 ST (MSC)

J202 87-099-801-010 JACK,PIN 1P BLK W/O SW

J501 87-009-065-010 CONNECTOR, 15P H FG

WH104 87-A90-507-010 HLDR,WIRE 2.5-4P

FRONT C.B

C301 87-010-405-080 CAP, ELECT 10-50V

C305 87-010-194-080 CAP, CHIP 0.047

C307 87-010-318-080 C-CAP,S 47P-50 CH

C308 87-A11-144-080 CAP,TC U 0.1-50 KB

C309 87-018-115-080 CAP,TC U 47P-50

CN119 87-A60-675-010 CONN,11P H 2MM JMT

CN306 87-A60-899-010 CONN,6P V BLK FMN-BTRK

CN307 87-099-564-010 CONN,4P TUC-P4P-B1

CNA301 88-805-020-790 CONN ASSY,2P 70MM

CNA302 88-805-020-790 CONN ASSY,2P 70MM

LCD301 8A-CJ6-620-010 LCD ASSY,ACJ-6

LED301 87-A40-317-080 LED,SLR-342VCT31 RED

R337 87-010-318-080 C-CAP,S 47P-50 CH

PWR-AMP C.B

C201 87-010-260-080 CAP, ELECT 47-25V

C202 87-010-260-080 CAP, ELECT 47-25V

C203 87-A10-946-080 C-CAP,S 220P-100 J CH

C204 87-A10-946-080 C-CAP,S 220P-100 J CH

C209 87-010-186-080 CAP,CHIP 4700P

C210 87-010-186-080 CAP,CHIP 4700P

C211 87-012-368-080 C-CAP,S 0.1-50 F

C212 87-012-368-080 C-CAP,S 0.1-50 F

C213 87-010-195-080 C-CAP,S 0.068-25 F

C214 87-010-195-080 C-CAP,S 0.068-25 F

C215 87-010-544-080 CAP, ELECT 0.1-50V

C216 87-010-544-080 CAP, ELECT 0.1-50V

C217 87-010-182-080 C-CAP,S 2200P-50 B

C218 87-010-182-080 C-CAP,S 2200P-50 B

C221 87-010-186-080 CAP,CHIP 4700P

C222 87-010-186-080 CAP,CHIP 4700P

C223 87-010-403-080 CAP,E 3.3-50 M 11L

C224 87-010-403-080 CAP,E 3.3-50 M 11L

C225 87-012-157-080 C-CAP,S 330P-50 CH

C226 87-012-157-080 C-CAP,S 330P-50 CH

C265 87-010-546-080 CAP,E 0.33-50 11L

C266 87-010-546-080 CAP,E 0.33-50 11L

C271 87-015-819-080 CAPACITOR,0.01

C277 87-010-197-080 CAP, CHIP 0.01 DM

CN201 87-A60-812-010 CONN,8P V BLK TAC-L8P

CN202 87-A60-812-010 CONN,8P V BLK TAC-L8P

J203 87-YP6-608-010 TERMINAL,SPKR 4P

L201 87-003-383-010 COIL,1UHK

L202 87-003-383-010 COIL,1UHK

R215 87-A00-258-080 RES,M/F 0.22-1W J

R216 87-A00-258-080 RES,M/F 0.22-1W J

R217 87-A00-258-080 RES,M/F 0.22-1W J

DESCRIPTIONREF. NO. KANRI

– 7 –

Page 8

PART NO. DESCRIPTIONREF. NO. KANRI

DESCRIPTIONREF. NO. KANRI

NO.

R218 87-A00-258-080 RES,M/F 0.22-1W J

R219 87-A00-258-080 RES,M/F 0.22-1W J

R220 87-A00-258-080 RES,M/F 0.22-1W J

TH201 87-A91-042-080 C-THMS,100K 55001

TH202 87-A91-042-080 C-THMS,100K 55001

PT-MAIN C.B

C155 87-010-196-080 CHIP CAPACITOR,0.1-25

C191 87-A10-479-080 CAP,CER 2200P-250 M E KH

!

PR151 87-A90-094-080 PROTECTOR,4A 491SERIES 60V

!

PT101 8Z-CL1-623-010 PT,E

!

RY102 87-A90-976-010 RELAY,AC12V SDT-S-112LMR

!

T101 87-A60-317-010 TERMINAL, 1P MSC

!

T102 87-A60-317-010 TERMINAL, 1P MSC

W101 8A-CU2-662-010 F-CABLE,5P 2.5MM 150MM

W102 8Z-CL1-654-010 F-CABLE,2P 2.5 170MM SUBPT

W103 8Z-CL1-655-010 F-CABLE,4P 2.5 100MM PWR

WH101 87-A90-459-010 HLDR,WIRE 2.5-5P

WH103 87-A90-507-010 HLDR,WIRE 2.5-4P

WH112 87-A90-506-010 HLDR,WIRE 2.5-2P

PT-SUB C.B

C101 87-A10-831-080 CAP,E 1000-25 M SMG

C195 87-010-403-080 CAP, ELECT 3.3-50V

!

PT102 8Z-NF8-659-010 PT,SUB ZNF-8(E)TAM

WH111 87-A90-506-010 HLDR,WIRE 2.5-2P

TU-INF C.B

C504 87-010-190-080 CHIP CAPACITOR,0.01-25

CN116 87-099-574-010 CONN,20P TUC-P20P-B1

CN117 87-A60-189-010 CONN,16P V TUC-P16P-B1

CNA101 8A-CU2-660-010 CONN ASSY,11P 2MM

CNA303 8A-CU2-661-010 CONN ASSY,7P 2MM

JACK C.B

C182 87-010-322-080 C-CAP,S 100P-50 CH

C183 87-010-322-080 C-CAP,S 100P-50 CH

C184 87-010-322-080 C-CAP,S 100P-50 CH

C185 87-010-322-080 C-CAP,S 100P-50 CH

C186 87-010-322-080 C-CAP,S 100P-50 CH

C187 87-010-322-080 C-CAP,S 100P-50 CH

CN104 87-099-563-010 CONN,20P TUC-P20X-B1

J502 87-A60-782-010 CONN,19P H FG

LED-1 C.B

C303 87-A11-148-080 CAP,TC U 0.1-50

CN303 87-A60-619-010 CONN,2P V 2MM JMT

LED331 87-A40-678-010 LED,SELU1E10CXM BLUE-DEF

LED-2 C.B

C302 87-A11-148-080 CAP,TC U 0.1-50

CN302 87-A60-619-010 CONN,2P V 2MM JMT

LED332 87-A40-678-010 LED,SELU1E10CXM BLUE-DEF

LED-3 C.B

CN301 87-099-553-010 CONN,4P H TUC-P

LED302 87-A40-821-080 LED,SMLS1BE16C BLU/UMB

LED303 87-A40-821-080 LED,SMLS1BE16C BLU/UMB

TUNER C.B

C701 87-010-381-080 CAP,ELECT 330-16V

C702 87-010-404-080 CAP,ELECT 4.7-50V

C703 87-012-286-080 CAP,U 0.01-25

C704 87-012-286-080 CAP,U 0.01-25

PART NO.

NO.

C709 87-012-195-080 C-CAP,U 100P-50CH

C711 87-010-260-080 CAP,ELECT 47-25V

C712 87-010-831-080 C-CAP,U,0.1-16F

C713 87-012-286-080 CAP,U 0.01-25

C714 87-012-286-080 CAP,U 0.01-25

C715 87-012-195-080 C-CAP,U 100P-50CH

C717 87-012-286-080 CAP,U 0.01-25

C719 87-012-286-080 CAP,U 0.01-25

C720 87-012-195-080 C-CAP,U 100P-50CH

C721 87-012-176-080 CAP,15P

C722 87-012-176-080 CAP,15P

C723 87-012-274-080 CHIP CAP,U 1000P-50B

C727 87-010-196-080 CHIP CAPACITOR,0.1-25

C728 87-010-248-080 CAP,ELECT 220-10V

C729 87-012-274-080 CHIP CAP,U 1000P-50B

C731 87-012-286-080 CAP,U 0.01-25

C733 87-012-280-080 C-CAP,U 3300P-50 KB

C734 87-012-280-080 C-CAP,U 3300P-50 KB

C752 87-012-282-080 C-CAP,U 4700P-50 KB

C753 87-012-195-080 C-CAP,U 100P-50 J CH

C755 87-012-286-080 CAP,U 0.01-25

C756 87-012-286-080 CAP,U 0.01-25

C757 87-012-188-080 C-CAP,U 47P-50 CH

C758 87-012-167-080 C-CAP,U 5P-50 CH

C761 87-010-196-080 C-CAP,S 0.1-25 ZF

C762 87-012-286-080 CAP,U 0.01-25

C763 87-010-829-080 CAP,U 0.047-16

C764 87-012-145-080 C-CAP,S 270P-50 J CH

C765 87-012-286-080 CAP,U 0.01-25

C766 87-010-197-080 C-CAP,S 0.01-25 KB

C768 87-012-286-080 CAP,U 0.01-25

C769 87-010-260-080 CAP,ELECT 47-25V

C770 87-010-829-080 CAP,U 0.047-16

C771 87-010-383-080 CAP,ELECT 33-25V

C772 87-010-829-080 CAP,U 0.047-16

C773 87-010-196-080 CHIP CAPACITOR,0.1-25

C774 87-010-263-080 CAP,ELECT 100-10V

C775 87-010-404-080 CAP,ELECT 4.7-50V

C776 87-012-286-080 CAP,U 0.01-25

C777 87-010-493-080 CAP,E 0.47-50 M 5L SRE

C778 87-010-401-080 CAP,ELECT 1-50V

C779 87-010-401-080 CAP,ELECT 1-50V

C780 87-010-196-080 CHIP CAPACITOR,0.1-25

C781 87-010-405-080 CAP,ELECT 10-50V

C782 87-010-405-080 CAP,ELECT 10-50V

C783 87-012-286-080 CAP,U 0.01-25

C784 87-012-286-080 CAP,U 0.01-25

C785 87-010-402-080 CAP,ELECT 2.2-50V

C786 87-010-402-080 CAP,ELECT 2.2-50V

C787 87-012-275-080 C-CAP,U 1200P-50 B

C788 87-012-275-080 C-CAP,U 1200P-50 B

C789 87-012-275-080 C-CAP,U 1200P-50 B

C790 87-012-275-080 C-CAP,U 1200P-50 B

C791 87-010-405-080 CAP,ELECT 10-50V

C793 87-012-273-080 C-CAP,U 820P-50 B

C794 87-010-406-080 CAP,ELECT 22-50

C795 87-010-596-080 CAP,S 0.047-16

C796 87-010-403-080 CAP,ELECT 3.3-50V

C797 87-012-276-080 C-CAP,U 1500P-50 KB

C798 87-012-276-080 C-CAP,U 1500P-50 KB

C799 87-010-829-080 CAP,U 0.047-16

C812 87-012-286-080 CAP,U 0.01-25

C814 87-012-286-080 CAP,U 0.01-25

C820 87-010-260-080 CAP,ELECT 47-25V

C821 87-012-286-080 CAP,U 0.01-25

C822 87-012-286-080 CAP,U 0.01-25

C823 87-012-286-080 CAP,U 0.01-25

C828 87-010-196-080 CHIP CAPACITOR,0.1-25

C829 87-010-196-080 CHIP CAPACITOR,0.1-25

C859 87-012-286-080 C-CAP,U 0.01-25 KB

– 8 –

Page 9

PART NO. DESCRIPTIONREF. NO. KANRI

NO.

C861 87-012-199-080 C-CAP,U 220P-50 J CH

C862 87-012-199-080 C-CAP,U 220P-50 J CH

C863 87-012-270-080 C-CAP,U 470P-50 KB

C864 87-010-405-080 CAP,E 10-50 M 11L SME

C865 87-010-196-080 C-CAP,S 0.1-25 ZF

C866 87-010-405-080 CAP,E 10-50 M 11L SME

C867 87-012-286-080 C-CAP,U 0.01-25 KB

C868 87-012-184-080 C-CAP,U 33P-50 J CH

C869 87-012-180-080 C-CAP,U 22P-50 J CH

C940 87-012-286-080 C-CAP,U 0.01-25 KB

C942 87-012-168-080 C-CAP,U 6P-50 D CH

C947 87-012-286-080 C-CAP,U 0.01-25 KB

C949 87-A10-039-080 C-CAP,U 470P-50 J CH

C952 87-012-286-080 C-CAP,U 0.01-25 KB

C958 87-010-197-080 C-CAP,S 0.01-25 KB

C959 87-010-831-080 C-CAP,U 0.1-16 ZF

C960 87-010-196-080 CHIP CAPACITOR,0.1-25

C962 87-010-401-080 CAP,E 1-50 M 11L SME

CF801 87-008-423-010 FLTR,CF SFE10.7MS3G-A

CF802 82-785-747-010 CF,MS2 GHY R

DESCRIPTIONREF. NO. KANRI

PART NO.

NO.

CN701 87-A60-650-010 CONN,16P H GRY TUC-P16X-C1

FFE801 A8-6ZA-191-130 6ZA-1 FEENM

J801 87-033-241-010 TERMINAL,ANT 2P AJ-2039

L771 87-A50-266-010 COIL,FM DET-2N(TOK)

L772 87-A91-110-010 FLTR,PCFJZH-450(TOK)

L781 87-005-847-080 COIL,2.2UH CECS

L791 87-A50-027-010 COIL,1 POLE MPX(TOK)

L792 87-A50-027-010 COIL,1 POLE MPX(TOK)

L832 87-005-847-080 COIL,2.2UH K CECS

L851 87-005-847-080 COIL,2.2UH K CECS

L941 87-A50-020-010 COIL,ANT LW(COI)252KHZ

L942 87-A50-019-010 COIL,OSC LW(COI) 856KHZ

L981 8Z-ZA1-665-010 COIL,AM PACK 2(TOK)

TC942 87-011-164-010 TRIMMER,CER 30P 4.5X3.9 VCT31

X721 87-A70-061-010 VIB,XTAL 4.500MHZ CSA-309

X851 87-A70-091-010 VIB,XTAL 4.332MHZ CSA-309

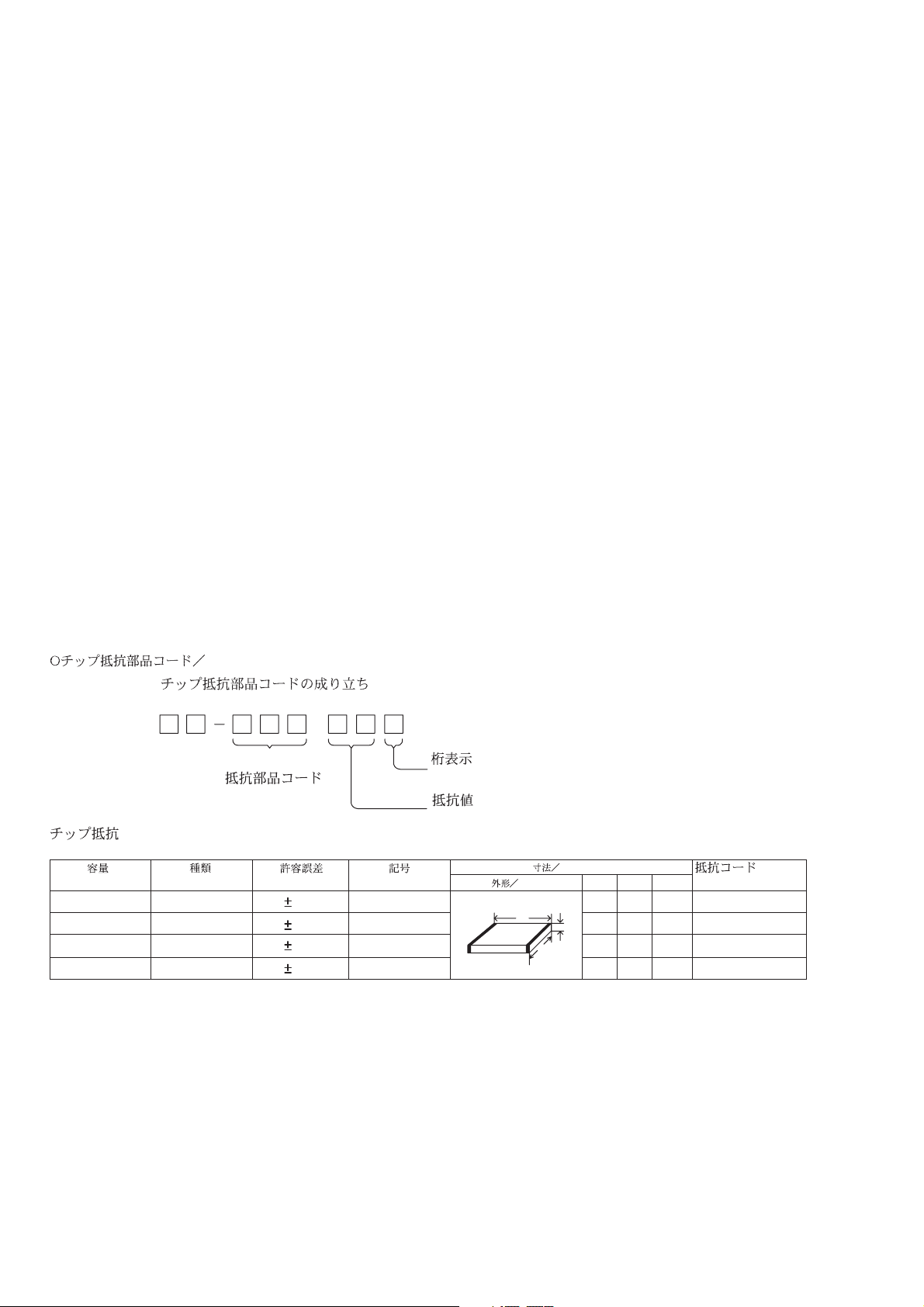

CHIP RESISTOR PART CODE

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

Symbol

CJ

CJ

CJ

Figure

Value of resistor

Form

L

Dimensions (mm)

t

W

0.55

Resistor Code

108

118

128

LW t

1.0 0.5 0.35 104

1.6 0.8 0.45

2 1.25 0.45

3.2

1.6

: A

: A

– 9 –

Page 10

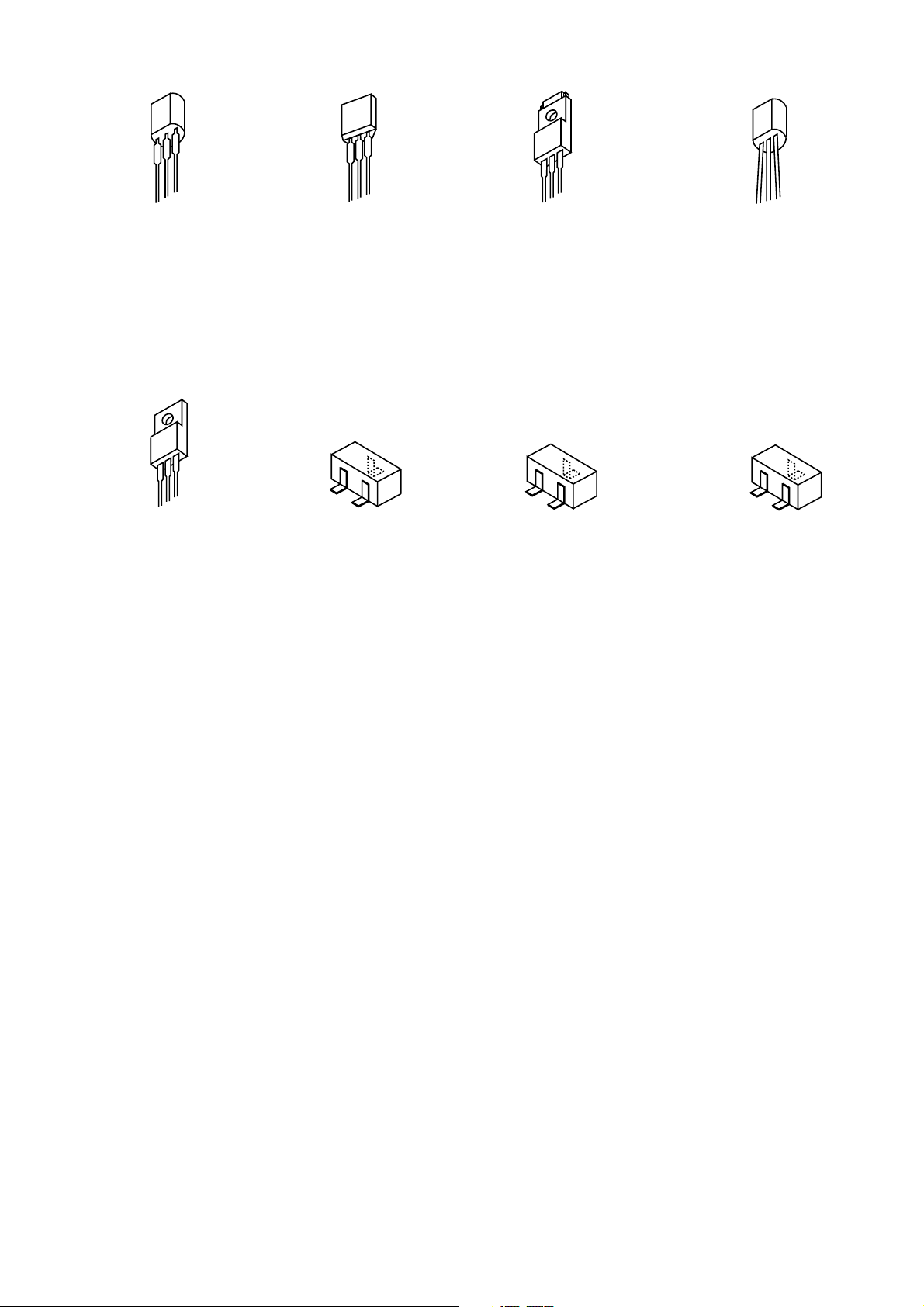

TRANSISTOR ILLUSTRATION

E C B

CSD655

KTA1266

KTC3198

B C E

2SD2495

2SB1626

E C B

CSC4115

G

S

2SK2158

B C E

2SB1370

E C B

CSD1489

CC5551

D

G

D

2SK543

S

B

2SA1235

2SC2714

2SC3052

2SC3906

CMBT5401

C

E

DTA123JK

DTC124EK

RT1N141C

RT1P141C

RT1P144C

CSD1306

– 10 –

Page 11

WIRING 1 (POWER)

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

11

R

S

T

U

Page 12

WIRING – 2 (PWR – AMP)

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

– 12 –

R

S

T

U

Page 13

WIRING – 3 (PT – MAIN / PT – SUB)

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

– 13 –

R

S

T

U

Page 14

WIRING 4 (TU INF / JACK)

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

14

R

S

T

U

Page 15

SCHEMATIC DIAGRAM 1 (POWER / PWR-AMP / PT-MAIN / PT-SUB / TU-INF / JACK)

15

Page 16

WIRING – 5 (FRONT / LED 1 ~ 3)

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

– 16 –

R

S

T

U

Page 17

SCHEMATIC DIAGRAM – 2 (FRONT / LED-1 / LED-2 / LED-3)

– 17 –

Page 18

WIRING – 6 (TUNER)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

– 18 –

R

S

T

U

Page 19

SCHEMATIC DIAGRAM – 3 (TUNER)

– 19 –

Page 20

IC BLOCK DIAGRAM

– 20 –

Page 21

LCD DIAGRAM

LCD ASSY, ACJ-6

– 21 –

Page 22

ADJUSTMENT

TUNER SECTION

1. Clock Frequency Check

Settings : • Test point : TP2 (CLK)

Method : Set to MW 1602kHz and check that the test

point is 2052kHz ± 45Hz.

6. AM IF Adjustment

Settings : • Test point : TP8 (Lch), TP9 (Rch)

• Adjustment location :

L772 ........................... 450kHz

2. MW VT Check

Settings : • Test point : TP1 (VT)

Method : Set to MW 1602kHz and check that the test point is

less than 8.0V. Then set to MW 531kHz and check

that the test point is more than 0.6V.

3. MW Tracking Adjustment

Settings : • Test point : TP8 (Lch), TP9 (Rch)

• Adjustment location : L981 (1/3)

Method : Set to MW 999kHz and adjust L981 (1/3) so

that the test point becomes maximum.

4. LW VT Adjustment

Settings : • Test point : TP1 (VT)

• Adjustment location : L942

Method : Set to LW 144kHz and adjust L942 so that the test

point becomes 1.3V ± 0.05V.

Then set to LW 290kHz and check that the test point is

less than 8.0V.

5. LW Tracking Adjustment

Settings : • Test point : TP8 (Lch), TP9 (Rch)

• Adjustment location :

L941 ........................... 144kHz

TC942 ......................... 290kHz

Method : Set up TC942 to center before adjustment.

The level at 144kHz is adjusted to maximum by L941.

Then the level at 290kHz is adjusted

to maximum by TC942.

7. FM VT Check

Settings : • Test point : TP1 (VT)

Method : Set to FM 108.0MHz and check that the test

point is less than 8.0V. Then set to FM

87.5 MHz and check that the test point is more

than 0.5V.

8. FM Tracking Check

Settings : • Test point : TP8 (Lch), TP9 (Rch)

Method : Set to FM 98.0MHz and check that the test

point is less than 13dBµV.

9. DC Balance / Mono Distortion Adjustment

Settings : • Test point : TP3,TP4 (DC balance)

TP8 (Lch), TP9 (Rch) (Distortion)

• Adjustment location : L771

• Input level : 60dBµV

Method : Set to FM 98.0MHz and adjust L771 so that

the voltage between TP3 and TP4 becomes

0V ± 0.04V.

Next, check that the distortion is less than

1.3%.

– 22 –

Page 23

MECHANICAL EXPLODED VIEW 1 / 1

PWB

PWB

C

1

B

H

2

A

4

3

PWB

B

PWB

C

E

PLATE,SHLD PT

B

CHAS MAIN

(AMP)

A

PT

C

PWB

D

PWB

D

5

HT-SINK,

B

PWB

17

HT-SINK,

ASSY

C

G

PWB

E

SH,SUB PT

21

20

PWB

ZZA-1

PLATE,SUB-PT

C

19

C

12

3

6

11

10

8

F

9

7

15

C

SH,LCD

13

14

PWB

18

TUBU,UL

12-140

16

H

23

22

F

18

C

C

C

– 23 –

Page 24

MECHANICAL PARTS LIST 1 / 1

PART NO.

1 8A-CU2-006-010 PANEL,TOP(AMP)

2 8A-CU2-003-010 CABI,TOP(AMP)

3 8A-CU2-206-010 GUIDE,LED B

4 8A-CU2-205-010 GUIDE,LED A

5 8A-NF7-226-110 HLDR,IC2-T2

6 8A-CU2-001-010 CABI,FR(AMP)

7 8A-CU2-005-010 PANEL,FR(AMP)

8 8A-CU2-009-010 WINDOW,ST-BY

9 8A-CJ6-212-010 HLDR,LCD

10 8A-CU2-008-010 REFLECTOR,FR

11 8A-CU2-202-010 HLDR,ST-BY

12 8A-CU2-007-010 WINDOW,LCD

13 8A-CJ6-021-010 REFLECTOR,LCD

14 8A-CJ6-202-010 GUIDE,LCD

15 8A-CJ6-620-010 LCD ASSY,ACJ-6

16 8Z-NB8-254-010 COVER, PL M3

17 8A-CU2-203-010 HLDR,PT

18 8A-CU2-210-010 FOOT,ACJ-2

!

19 87-A80-092-010 AC CORD ASSY,E BLK SUN FAI

20 87-085-185-010 BUSHING, AC CORD (E)

21 8A-CU2-012-010 CABI,REAR (AMP)-EZ

22 8A-CU2-004-010 CABI,BOTTOM (AMP)

23 8Z-CL1-663-010 FAN,MF40D-12-200MM

A 87-B10-332-010 BVT2+3-6 W/O SLOT CR

B 87-B10-324-010 BVT2+3-8 W/O SLOT CR

C 87-067-703-010 TAPPING SCREW, BVT2+3-10

D 87-067-585-010 TAPPING SCREW, BVTT+4-6

E 87-067-579-010 TAPPING SCREW, BVT2+3-8

F 87-591-095-410 QIT+3-5

G 87-067-758-010 BVT2+3-12 W/O SLOT

H 87-751-096-410 VT2+3-10 W/O SLOT

NO.

DESCRIPTIONREF. NO. KANRI

COLOR NAME TABLE

Basic color symbol Color Basic color symbol Color Basic color symbol Color

B Black C Cream D Orange

G Green H Gray L Blue

LT Transparent Blue N Gold P Pink

R Red S Silver ST Titan Silver

T Brown V Violet W White

WT Transparent White Y Yellow YT Transparent Yellow

LM Metallic Blue LL Light Blue GT Transparent Green

LD Dark Blue DT Transparent Orange GM Metallic Green

YM Metallic Yellow DM Metallic Orange PT Transparent Pink

LA Aqua Blue GL Light Green

– 24 –

Page 25

MODEL NO.

FM-LMD811

ELECTRICAL MAIN PARTS LIST

PART NO.

NO.

IC

87-A20-547-010 C-IC,CXA1992AR

87-017-917-080 IC,BU4066BCF

87-A20-546-010 C-IC,CXD2589Q

87-A20-611-080 IC,M51943BSL-700A

87-001-792-080 IC,NJM2100M

87-A20-445-010 IC,BA5936S

8A-CR2-601-030 C-IC,LC876580W-5S53

87-070-246-010 IC,GP1U271X

87-A21-175-040 C-IC,TC74VHC14FT

87-A20-870-010 IC,GP1F37R

87-A21-111-040 C-IC,M62495FP

87-A21-103-040 C-IC,MM1454XFBE

87-A21-419-040 C-IC,NJM14558MD-TE2

87-A21-022-040 C-IC,BA3880FS

TRANSISTOR

87-A30-073-080 C-TR,RT1N 141C

89-110-155-080 TR,2SA1015GR

87-A30-515-080 TR,2SA1979O/Y

87-A30-047-080 TR,CSD655E

87-026-610-080 TR,KTC3198GR

87-A30-087-080 C-FET,2SK2158

87-A30-071-080 C-TR,RT1N 144C

87-A30-074-080 C-TR,RT1P 141C

89-213-702-010 TR,2SB1370E

87-A30-152-080 TR,2SC5395F

87-A30-466-040 C-TR,DTA144TKA

DIODE

87-020-465-080 DIODE,1SS133

87-070-274-080 DIODE,1N4003 SEM

87-A40-509-080 ZENER,MTZJ6.8C

87-A40-269-080 C-DIODE,MC2836

87-A40-270-080 C-DIODE,MC2838

87-017-083-080 ZENER,HZS4C2

87-A40-299-080 ZENER,DZ5.1M

87-A40-292-080 ZENER,DZ2.7L

FUNC C.B

C501 87-010-180-080 C-CAP 1500P-50

C502 87-010-180-080 C-CAP 1500P-50

C503 87-010-182-080 C-CAP,S 2200P-50 B

C504 87-010-182-080 C-CAP,S 2200P-50 B

C505 87-010-213-080 C-CAP,S 0.015-25 B

C506 87-010-213-080 C-CAP,S 0.015-25 B

C507 87-010-491-040 CAP,E 0.22-50 GAS

C508 87-010-491-040 CAP,E 0.22-50 GAS

C509 87-010-491-040 CAP,E 0.22-50 GAS

C510 87-010-491-040 CAP,E 0.22-50 GAS

C511 87-010-494-040 CAP,E 1-50 GAS

C512 87-010-494-040 CAP,E 1-50 GAS

C513 87-010-154-080 C-CAP,S 10P-50

C514 87-010-553-040 CAP,E 47-16 GAS

C515 87-010-553-040 CAP,E 47-16 GAS

C535 87-016-044-040 CAP,E 100-16 GAS

C536 87-012-142-080 CAP, S 0.33-16

C537 87-010-493-040 CAP,E 0.47-50 GAS

C538 87-010-495-040 CAP,E 2.2-50 GAS

C551 87-010-495-040 CAP,E 2.2-50 GAS

C552 87-010-495-040 CAP,E 2.2-50 GAS

DESCRIPTIONREF. NO. KANRI

PART NO.

NO.

C553 87-010-553-040 CAP,E 47-16 GAS

C554 87-010-498-040 CAP,E 10-16 GAS

C555 87-010-196-080 CHIP CAPACITOR,0.1-25

C556 87-016-044-040 CAP,E 100-16 GAS

C557 87-010-498-040 CAP,E 10-16 GAS

C558 87-010-197-080 CAP, CHIP 0.01 DM

C559 87-010-197-080 CAP, CHIP 0.01 DM

C560 87-010-494-040 CAP,E 1-50 GAS

C561 87-010-494-040 CAP,E 1-50 GAS

C575 87-010-493-040 CAP,E 0.47-50 GAS

C576 87-010-493-040 CAP,E 0.47-50 GAS

C577 87-012-154-080 C-CAP,S 150P-50 CH

C578 87-012-154-080 C-CAP,S 150P-50 CH

C579 87-012-154-080 C-CAP,S 150P-50 CH

C580 87-012-154-080 C-CAP,S 150P-50 CH

C581 87-010-197-080 CAP, CHIP 0.01 DM

C582 87-010-197-080 CAP, CHIP 0.01 DM

C583 87-010-494-040 CAP,E 1-50 GAS

C584 87-010-494-040 CAP,E 1-50 GAS

C585 87-016-044-040 CAP,E 100-16 GAS

C586 87-016-044-040 CAP,E 100-16 GAS

C601 87-010-491-040 CAP,E 0.22-50 GAS

C602 87-010-491-040 CAP,E 0.22-50 GAS

C603 87-010-497-040 CAP,E 4.7-35 GAS

C604 87-010-497-040 CAP,E 4.7-35 GAS

C605 87-010-497-040 CAP,E 4.7-35 GAS

C606 87-010-497-040 CAP,E 4.7-35 GAS

C607 87-010-196-080 CHIP CAPACITOR,0.1-25

C608 87-010-213-080 C-CAP,S 0.015-25 B

C609 87-010-213-080 C-CAP,S 0.015-25 B

C610 87-012-140-080 C-CAP,S 470P-50

C611 87-012-140-080 C-CAP,S 470P-50

C612 87-010-497-040 CAP,E 4.7-35 GAS

C613 87-010-497-040 CAP,E 4.7-35 GAS

C614 87-010-197-080 CAP, CHIP 0.01 DM

C615 87-010-197-080 CAP, CHIP 0.01 DM

C616 87-010-993-080 C-CAP,S 0.056-25 B

C617 87-010-993-080 C-CAP,S 0.056-25 B

C618 87-010-553-040 CAP,E 47-16 GAS

C619 87-010-553-040 CAP,E 47-16 GAS

C646 87-010-196-080 CHIP CAPACITOR,0.1-25

C661 87-010-497-040 CAP,E 4.7-35 GAS

C662 87-010-497-040 CAP,E 4.7-35 GAS

C681 87-010-982-040 CAP,E 33-25 GAS

C682 87-010-982-040 CAP,E 33-25 GAS

CN503 87-099-565-010 CONN,6P TUC-P4P-B1

CN505 87-A60-189-010 CONN,16P V TUC-P16P-B1

J601 87-A60-354-010 JACK,PIN 2P MSP -242V-05

J602 82-MA2-631-010 JACK PIN 4P RVS

JR526 87-005-898-080 C-COIL,S 2.2UH K LK2125

FRONT C.B

C315 87-010-498-040 CAP,E 10-16 GAS

C316 87-018-119-080 CAP, CER 100P-50V

CN303 87-A60-154-010 CONN,6P H FE

CNA307 88-805-020-790 CONN ASSY,2P 70MM

CNA308 88-805-020-790 CONN ASSY,2P 70MM

S312 87-A91-024-180 SW,TACT KSHG611BT

S313 87-A91-024-180 SW,TACT KSHG611BT

S314 87-A91-024-180 SW,TACT KSHG611BT

POWER C.B

C141 87-010-553-040 CAP,E 47-16 GAS

DESCRIPTIONREF. NO. KANRI

– 25 –

Page 26

PART NO. DESCRIPTIONREF. NO. KANRI

NO.

C142 87-A10-207-080 CAP,TCS 0.01-50KBUP050

C143 87-010-382-080 CAP, ELECT 22-25V

C320 87-010-235-080 CAP,E 470-16 SME

C321 87-018-209-080 CAP, CER 0.1-50V

C322 87-010-252-080 CAP, ELECT 1000-6.3V

CN102 87-A60-620-010 CONN,3P V 2MM JMT

CN204 87-A60-620-010 CONN,3P V 2MM JMT

KEY C.B

CN206 87-A60-666-010 CONN,2P H 2MM JMT

S301 87-A91-024-180 SW,TACT KSHG611BT

S302 87-A91-024-180 SW,TACT KSHG611BT

S303 87-A91-024-180 SW,TACT KSHG611BT

S304 87-A91-024-180 SW,TACT KSHG611BT

S305 87-A91-024-180 SW,TACT KSHG611BT

S306 87-A91-024-180 SW,TACT KSHG611BT

S307 87-A91-024-180 SW,TACT KSHG611BT

S308 87-A91-024-180 SW,TACT KSHG611BT

S309 87-A91-024-180 SW,TACT KSHG611BT

S310 87-A91-024-180 SW,TACT KSHG611BT

S311 87-A91-024-180 SW,TACT KSHG611BT

CD C.B

C1 87-010-198-080 CHIP CAPACITOR,0.022-25

C2 87-010-178-080 CHIP CAP 1000P

C3 87-010-196-080 CHIP CAPACITOR,0.1-25

C4 87-010-196-080 CHIP CAPACITOR,0.1-25

C5 87-010-196-080 CHIP CAPACITOR,0.1-25

C6 87-012-156-080 C-CAP,S 220P-50 CH

C7 87-010-496-040 CAP,E 3.3-50 GAS

C8 87-010-369-080 C-CAP,S 0.033-25 K B

C9 87-010-197-080 CAP, CHIP 0.01 DM

C11 87-010-981-040 CAP,E 22-35 5L SRE

C12 87-010-197-080 CAP, CHIP 0.01 DM

C13 87-010-193-080 C-CAP,S 0.033-25

C14 87-010-369-080 C-CAP,S 0.033-25 K B

C15 87-010-197-080 CAP, CHIP 0.01 DM

C16 87-010-369-080 C-CAP,S 0.033-25 K B

C18 87-010-497-040 CAP,E 4.7-35 GAS

C19 87-010-154-080 CAP CHIP 10P

C20 87-010-146-080 CHIP CAP 2PF

C21 87-010-154-080 C-CAP,S 10P-50 CH

C22 87-010-154-080 C-CAP,S 10P-50 CH

C23 87-010-194-080 CAP, CHIP 0.047

C24 87-010-194-080 CAP, CHIP 0.047

C27 87-010-197-080 CAP, CHIP 0.01 DM

C28 87-010-196-080 CHIP CAPACITOR,0.1-25

C29 87-010-264-040 CAP,E 100-10 5L

C30 87-010-264-040 CAP,E 100-10 5L

C31 87-010-197-080 CAP, CHIP 0.01 DM

C32 87-010-264-040 CAP,E 100-10 5L

C40 87-010-196-080 CHIP CAPACITOR,0.1-25

C41 87-010-264-040 CAP,E 100-10 5L

C42 87-010-264-040 CAP,E 100-10 5L

C43 87-010-178-080 CHIP CAP 1000P

C45 87-010-993-080 C-CAP,S 0.056-25 B

C60 87-010-196-080 CHIP CAPACITOR,0.1-25

C61 87-A11-591-080 C-CAP,S 0.047-25 K B

C62 87-010-188-080 CAP,CHIP 6800P

C63 87-012-156-080 C-CAP,S 220P-50 CH

C64 87-010-196-080 CHIP CAPACITOR,0.1-25

C65 87-010-185-080 C-CAP,S 3900P-50 B

C66 87-016-526-080 C-CAP,S 0.47-16

C68 87-010-314-080 C-CAP,S 22P-50V

C69 87-010-805-080 C-CAP,S 1-16

C70 87-A10-505-040 CAP,E 220-6.3 105 SF

C72 87-A10-759-040 CAP,E 330-6.3 SRM

C73 87-010-197-080 CAP, CHIP 0.01 DM

DESCRIPTIONREF. NO. KANRI

PART NO.

NO.

C75 87-010-176-080 C-CAP,S 680P-50 SL

C76 87-010-176-080 C-CAP,S 680P-50 SL

C77 87-012-154-080 C-CAP,S 150P-50 CH

C78 87-012-154-080 C-CAP,S 150P-50 CH

C79 87-010-075-040 CAP,E 10-16 5L

C80 87-010-075-040 CAP,E 10-16 5L

C81 87-010-181-080 CAP,CHIP S 1800P

C82 87-010-181-080 CAP,CHIP S 1800P

C83 87-010-154-080 CAP CHIP 10P

C84 87-010-154-080 CAP CHIP 10P

C85 87-010-805-080 CAP, S 1-16

C86 87-010-196-080 CHIP CAPACITOR,0.1-25

C87 87-010-196-080 CHIP CAPACITOR,0.1-25

C101 87-010-184-080 CHIP CAPACITOR 3300P(K)

C102 87-010-196-080 CHIP CAPACITOR,0.1-25

C103 87-010-196-080 CHIP CAPACITOR,0.1-25

C104 87-016-466-080 C-CAP,S 1-16 K B

C112 87-010-197-080 CAP, CHIP 0.01 DM

C113 87-010-236-080 CAP,E 1000-10 SME

C114 87-010-197-080 CAP, CHIP 0.01 DM

C115 87-010-221-080 CAP, ELECT 470-10V

C120 87-010-264-040 CAP,E 100-10 5L

C121 87-010-197-080 CAP, CHIP 0.01 DM

C201 87-010-560-040 CAP,E 10-50 GAS

C202 87-010-194-080 CAP, CHIP 0.047

C204 87-010-194-080 CAP, CHIP 0.047

C205 87-010-264-040 CAP,E 100-10 5L

C206 87-010-493-040 CAP,E 0.47-50 GAS

C207 87-A10-759-040 CAP,E 330-6.3 SRM

C208 87-010-196-080 CHIP CAPACITOR,0.1-25

C209 87-010-197-080 CAP, CHIP 0.01 DM

C210 87-010-196-080 CHIP CAPACITOR,0.1-25

C221 87-010-314-080 C-CAP,S 22P-50V

C222 87-010-196-080 CHIP CAPACITOR,0.1-25

C223 87-010-316-080 C-CAP,S 33P-50 CH

C224 87-010-178-080 CHIP CAP 1000P

C225 87-010-322-080 C-CAP,S 100P-50 CH

C228 87-010-196-080 CHIP CAPACITOR,0.1-25

C270 87-010-322-080 C-CAP,S 100P-50 CH

C271 87-010-322-080 C-CAP,S 100P-50 CH

C272 87-010-322-080 C-CAP,S 100P-50 CH

C273 87-010-322-080 C-CAP,S 100P-50 CH

C274 87-010-322-080 C-CAP,S 100P-50 CH

C275 87-010-322-080 C-CAP,S 100P-50 CH

C401 87-010-196-080 CHIP CAPACITOR,0.1-25

C402 87-010-178-080 CHIP CAP 1000P

C403 87-010-178-080 CHIP CAP 1000P

C404 87-010-196-080 CHIP CAPACITOR,0.1-25

C405 87-012-140-080 C-CAP,S 470P-50

C406 87-A10-189-040 CAP,E 220-10

C451 87-010-322-080 C-CAP,S 100P-50 CH

C452 87-010-322-080 C-CAP,S 100P-50 CH

C453 87-010-322-080 C-CAP,S 100P-50 CH

C454 87-010-322-080 C-CAP,S 100P-50 CH

C455 87-010-322-080 C-CAP,S 100P-50 CH

C456 87-010-322-080 C-CAP,S 100P-50 CH

CN1 87-A60-429-010 CONN,16P H TOC-A

CN2 87-009-411-010 CONN,6P V B6B-ZR

CN201 87-A90-878-010 HLDR,WIRE 19P 1.5 51016

CN203 87-A60-154-010 CONN,6P H FE

CN205 87-A60-190-010 CONN,16P H TUC-P16X-B1

CN401 87-A60-423-010 CONN,14P V TOC-B

CN402 87-A60-422-010 CONN,8P V TOC-B

CN403 87-099-554-010 CONN,6P H TUC-P6X-B1

CNA102 8A-CR2-668-010 CONN ASSY,3P 2MM

CNA151 88-802-051-290 CONN ASSY,5P W

CNA204 8A-CR2-664-010 CONN ASSY,3P 2MM

CNA206 8A-CR2-663-010 CONN ASSY,2P 2MM

L40 87-003-102-080 COIL, 10UH

L60 87-003-102-080 COIL, 10UH

– 26 –

Page 27

PART NO. DESCRIPTIONREF. NO. KANRI

NO.

L201 87-A50-333-010 COIL,OSC 9.43MHZ

L204 87-A50-190-080 C-COIL,S BLM21A102S

L401 87-A50-189-080 C-COIL,S BLM21B272S

R69 87-A50-190-080 C-COIL,S BLM21A102S

R81 87-005-906-080 C-COIL,S 10.0UH K

R120 87-A91-935-080 PROTECTOR,1A 20P 60V

W201 8A-CR2-661-010 F-CABLE,19P 1.5MM 400MM

W202 8A-CR2-660-010 F-CABLE,15P 1.5MM 400MM

X60 87-A70-005-080 VIB,XTAL 33.8688MHZ HC-49/U03

MOTOR C.B

CN151 87-A60-111-010 CONN,5P V S2M 5W

CNA352 8A-CR2-662-010 CONN ASSY,3P 2MM

M351 87-A91-069-010 MOT,RF-370CA 15370

DOOR SW C.B

CN352 87-099-827-010 CONN,3P V S2M-3W

S351 87-036-109-010 SW, MICRO SPPB61

S352 87-036-109-010 SW, MICRO SPPB61

LED L C.B

CN307 87-A60-109-010 CONN,2P V S2M-2W

LED315 87-A40-678-010 LED,SELU1E10CXM BLUE-DEF

LED R C.B

CN308 87-A60-109-010 CONN,2P V S2M-2W

LED316 87-A40-678-010 LED,SELU1E10CXM BLUE-DEF

DESCRIPTIONREF. NO. KANRI

PART NO.

NO.

CHIP RESISTOR PART CODE

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

Symbol

CJ

CJ

CJ

Figure

Value of resistor

Form

L

Dimensions (mm)

t

W

0.55

Resistor Code

108

118

128

LW t

1.0 0.5 0.35 104

1.6 0.8 0.45

2 1.25 0.45

3.2

1.6

: A

: A

– 27 –

Page 28

TRANSISTOR ILLUSTRATION

E C B

CSD655

KTC3198

G

S

2SK2158

E C B

2SA1015

E C B

2SC5395

B C E

2SB1370

2SA1979

D

B

C

E

DTA144TKA

RT1N141C

RT1P141C

RT1N144C

– 28 –

Page 29

WIRING 1 (FUNC / KEY / MOTOR / DOOR SW)

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

29

R

S

T

U

Page 30

WIRING – 2 (FRONT / POWER / LED – L / LED – R)

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

– 30 –

R

S

T

U

Page 31

SCHEMATIC DIAGRAM – 1 (FUNC / FRONT / POWER / KEY / MOTOR / DOOR SW / LED-L / LED-R)

– 31 –

Page 32

WIRING – 3 (CD) <1 / 2>

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

– 32 –

R

S

T

U

Page 33

WIRING – 3 (CD) <2 / 2>

1 2 3 4 5 6 7 8 9 1011121314151617181920212223242526272829303132

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

– 33 –

Page 34

SCHEMATIC DIAGRAM – 2 (CD) <1/2>

– 34 –

Page 35

SCHEMATIC DIAGRAM – 3 (CD) <2/2>

– 35 –

Page 36

IC BLOCK DIAGRAM

– 36 –

Page 37

IC DESCRIPTION

IC, CXA1992AR

Pin No. Pin Name I/O Description

1

FEO

Output terminal for focus error amplifier. Internally connected to window comparator

O

input for bias condition.

10

11

12

13

14

2

3

4

5

6

7

8

9

FEI

FDFCT

FGD

FLB

FE O

FE M

SRCH

TGU

TG2

FSET

TA M

TA O

SL P

Input terminal for focus error.

I

Capacitor connection terminal for time constant used when there is defect.

I

This pin is connected to GND via capacitor when high frequency gain of the focus

I

servo is attenuated.

This is a pin where the time constant is externally connected to raise the low frequency

I

gain of the focus servo.

Focus drive output.

O

Focus amplifier inverted input pin.

I

This is a pin where the time constant is externally connected to generate the focus

I

search waveform.

This is a pin where the selection time constant is externally connected to set the

I

tracking servo the high frequency gain.

This is a pin where the selection time constant is externally connected to set the

I

tracking high frequency gain.

Pin for setting peak of the phase compensator of the focus tracking.

I

Tracking amplifier inverted input pin.

I

Tracking drive output.

O

Sled amplifier non-inverted input pin.

I

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

SL M

SL O

ISET

VCC

LOCK

CLK

XLT

DATA

XRST

C.OUT

SENS1

SENS2

FOK

CC2

CC1

Sled amplifier inverted input pin.

I

Sled drive output.

O

The current which determines height of the focus search, track jump and sled kick is

I

input with external resistance connected.

Power supply.

I

“L” setting starts sled disorder-prevention circuit.

I

Clock input for serial data transfer from CPU.

I

Latch input from CPU.

I

Serial data input from CPU.

I

Reset system at “L” setting.

I

Signal output for track number counting.

O

FZC, DFCT1, TZC, BALH, TGH, FOH, or ATSC is output depending on the

O

command from CPU.

DFCT2, MIRR, BALL, TGL or FOL is output depending on the command from CPU.

O

Output terminal for focus OK comparator.

O

Input pin where the DEFECT bottom hold output is capacitance coupled.

I

DEFECT bottom-hold output terminal. Internally connected to interruption comparator

O

input.

30

31

CB

CP

Connection terminal for DEFECT bottom-hold capacitor.

I

Connection terminal for MIRR hold-capacitor.

I

Anti-reverse input terminal for MIRR comparator.

– 37 –

Page 38

Pin No. Pin Name I/O Description

32

RF I

I

Input terminal by capacity combination of RF summing amplifier.

33

34

35

36

37

38, 39

40

41, 42

43

44

RF O

RF M

RFTC

LD

PD

PD1, PD2

FE

F, E

EI

VEE

O

O

I/O

—

—

Output terminal of RF summing amplifier. Checkpoint of Eye pattern.

Anti-reverse input terminal for RF summing amplifier.

I

The gain of RF amplifier is decided by the connection resistance between RF M and

RF O terminals.

This is a pin where the selection time constant is externally connected to control the

I

RF level.

APC amplifier output terminal.

I

APC amplifier input terminal.

RFI-V amplifier inverted input pin.

I

These pins are connected to the A+C and B+C pins of the optical pickup, receiving by

currents input.

Bias adjustment pin of the focus error amplifier. (Not used)

F and EIV amplifier inverted input pins.

I

These pins are connected to the F and E of the optical pickup, receiving by current

input.

Gain adjustment pin of the I-V amplifier E. (When not in use of BAL automatic

adjustment). (Not used)

GND connection pin.

45

46

47

48

49

50

51

52

TEO

LPFI

TEI

ATSC

TZC

TDFCT

VC

FZC

O

Output terminal for tacking-error amplifier. Output E-F signal.

I

BAL adjustment comparator input pin. (Input through LPF from TEO)

I

Input terminal for tracking error.

I

Window-comparator input terminal for detecting ATSC.

I

Input terminal for tracking-zero cross comparator.

I

Capacitor connection pin for the time constant used when there is defect.

O

Output terminal for DC voltage reduced to half of VCC+VEE.

I

Input terminal for focus-zero cross comparator.

– 38 –

Page 39

IC, CXD2589Q

Pin No. Pin Name I/O Description

1, 20, 45, 60

VSS

—

GND.

10

11

12

13

14

15

16

17

18

2

3

4

5

6

7

8

9

LMUTE

RMUTE

SQCK

SQSO

SENSE

DATA

XLAT

CLOK

SEIN

CNIN

DATO

XLTO

CLKO

SPOA(SENSE2)

SPOB(IN/SW)

XLON

FOK

Lch-“0” detect flag. (Not used)

O

Rch-“0” detect flag. (Not used)

O

Clock input for SQSO read out.

I

SubQ 80 bit serial output.

O

SENSE signal output to CPU.

O

Serial data input from CPU.

I

Latch input from CPU. Latch serial data at fall down.

I

Clock input to serial data transfer from CPU.

I

SENS input from SSP.

I

Numbers of track jump are counted and input.

I

Serial data output to SSP.

O

Serial-data latch output to SSP. Latch at fall down.

O

Clock output for serial data transfer to SSP.

O

Microcomputer expansion interface. (Input A)

I

Microcomputer expansion interface. (Input B)

I

Microcomputer expansion interface. (Output)

O

Focus OK input terminal. Used for SENS output and servo-auto sequencer.

I

19, 46, 61, 80

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

VDD

MDP

PWMI

TEST

TEST

VPCO

VCKI

V16M

VCTL

PCO

FILO

FILI

AVSO

CLTV

AVDO

RF

BIAS

—

—

—

Power supply. (+5V)

Servo control for spindle motor.

O

External control input for spindle motor. (Not used)

I

TEST terminal. (Connected to GND)

I

TEST terminal. (Connected to GND)

I

Charge pump output for extensive EFM PLL. (Connected to GND)

O

VCO2 oscillator input for extensive EFM PLL.

I

VCO2 oscillator output for extensive EFM PLL.

O

VCO2 control voltage input for extensive EFM PLL. (Connected to GND)

I

Charge pump output for master PLL.

O

Filter (slave = digital PLL) output for master PLL.

O

Filter input for master PLL.

I

Analog GND.

VCO control voltage input for master.

I

Analog power. (+5V)

EFM signal input.

I

Constant current input to asymmetry circuit.

I

37

38

39

40

41

42

43

ASYI

ASYO

LRCK

LRCKI

PCMD

PCMDI

BCK

Comparison voltage input to asymmetry circuit.

I

EFM full-swing output. (L=VSS, H=VDD)

O

D/A interface, LR clock output f=FS.

O

LR clock input.

I

D/A interface, serial data output. (2’s COMP, MSB first)

O

D/A interface, serial data input. (2’s COMP, MSB first)

I

D/A interface bit clock output.

O

– 39 –

Page 40

Pin No. Pin Name I/O Description

44

BCKI

I

D/A interface bit clock input.

47

48

49

50

51

52

53

54

55

56

57

58

59

62

63

XUGF

XPCK

GFS

C2PO

XTSL

C4M

DOUT

EMPH

EMPHI

WFCK

SCOR

SBSO

EXCK

SYSM

AVS11

—

O

XUGF output, MNT1 or RPCK output by switching command. (Not used)

O

XPLCK output, MNT0 output by switching command. (Not used)

O

GFS output, MNT3 or XRAOF output by switching command. (Not used)

O

C2PO output, GTOP output by switching command. (Not used)

X’tal select input terminal, X’tal: 16.9344MHz = “L” 33.8688MHz = “H”.

I

(Connected to GND)

4.2336MHz output, Output 1/4 divided frequency of VCKI at CAV-W mode.

O

(Not used)

O

Digital Out connector output signal.

O

“H” when the playback disc has emphasis. “L” when it does not.

I

De-emphasis ON/OFF, “H” when ON, “L” when OFF.

O

WFCK output. (Not used)

O

H output when the subcode sync S0 or S1 is detected. (Not used)

O

Serial output for SubP-W. (Not used)

I

SBSO read out clock input. (Connected to GND)

I

Mute input terminal, Active the “H” setting. (Connected to GND)

Analogue GND.

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

Note:

• PCMD is the two’s complement output with MSB first.

• GTOP monitors the protection status of the Frame Sync. (H: Sync protection window opened).

• XUGF is the Frame Sync negative pulse which is obtained from the EFM signal. This is the signal before the sync protection.

• XPLCK is the inverted signal of the EFM PLL clock. The PLL works so that the fall-down edge and the changed point of the

EFM signal agree.

• GFS is the signal that goes “H” when the Frame Sync and the internally inserted timing agree.

• RFCK is the signal having 136 micro-seconds (during normal speed) that is generated to have the same accuracy as X’tal.

• C2PO is the signal indicating the error status of the data.

• XRAOF is the signal that is generated when the 16k RAM goes outside the jitter margin ±4F.

AVD1

AOUT1

AIN1

LOUT1

AVS12

XVDD

XTAI

XTAO

XVSS

AVSS2

ROUT2

AIN2

AOUT2

AVD2

AVS21

XRST

—

—

—

—

—

—

—

Analogue power supply. (+5V)

O

Lch/analogue output terminal.

I

Lch/OP AMP input terminal.

O

Lch/LINE output terminal.

Analogue GND.

Power supply for master clock.

Input terminal for crystal oscillator circuit.

I

Input external master clock from this terminal.

Output terminal for crystal oscillator circuit.

O

GND terminal for master clock.

Analogue GND.

Rch/LINE output terminal.

O

Rch/OP AMP input terminal.

I

Rch/analogue output terminal.

O

Analogue power supply. (+5V)

Analogue GND.

Reset system at “L” setting.

I

– 40 –

Page 41

IC, LC876580W-5S53

Pin No. Pin Name I/O Description

1 O-CD-CE O CD IC control chip enable output.

2 I-CD-SENSE I CD IC sense input.

3 O-CD-SQCK O CD IC control data bus clock output.

4 O-AON O AMP ON/OFF control output.

5 O-TUNER-ON O TUNER ON/OFF control output.

6 O-PLL-CLK O PLL IC control clock output.

7 O-PLL-DATA O PLL IC control data output.

8 O-VOL CTL O VOLUME control output.

9 I-CD-SUBQ I CD IC data input.

10 O-CLK SHIFT O MICON clock shift output.

11 I-RESET I Reset input.

12 I-ACOFF:AD I Power failure detection input.

13 I-TU/SIG:AD I TUNER SD detect input.

14 VSS1 – GND.

15 CF1 I

16 CF2 O

17 VDD1 – Power supply input.

18 I-CD SW:AD I CD mechanical switch A/D converter input.

19 I-KEY1:AD I

20 I-KEY0:AD I

21 I-ENCODER:AD I Waveform input for rotary encoder A/D coverter input.

22 O-LED BL1 O Blue LED ON/OFF control output.

23 O-LED BL2 O Blue LED ON/OFF control output.

24 O-LED AM1 O Umber LED ON/OFF control output.

25 O-LED AM2 O Umber LED ON/OFF control output.

26 I-LEVEL:AD I Level meter A/D converter input.

27 I-RDS CLK(TU) I RDS clock input.

28 I-TMBASE I Reference clock input for watch.

29 I-REMOTE I System remote control signal input.

30 ~ 42 NC – Not connected.

43 TP-CLK – Not used.

44 ~45 NC – Not connected.

9.43MHz oscllator circuit.

KEY input. (A/D)

46 VDD3 – Power supply input.

47 I-STEREO I Tuner stereo detect input.

48 I-TUNE I IF count serial data input.

49 I-RDSDATA (TU) I RDS data input.

50 NC – Not used.

51 VP – GND.

52 ~ 55 NC – Not connected.

56 I-CAM I DECK CAM switch input.

57 I-AUTO I DECK AUTO stop signal input.

58 I-SW OPN I DECK open switch input.

– 41 –

Page 42

Pin No. Pin Name I/O Description

59 I-SW CLS I DECK close switch input.

60 ~ 61 NC – Not connected.

62 MD I MD select input.

63 DEMO I DEMO select input.

64 BBE I BBE select input.

65 ECO OFF I ECO select input.

66 AM10K I AM10K select input.

67 FM WIDE&AMST I FM WIDE & AM ST select input.

68 LW I LW select input.

69 SW I SW select input.

70 OIRT I OIRT select input.

71 RDS I RDS select input.

72 VDD4 – Power supply input.

73 O-PLL-CE O PLL IC chip enable output.

74 O-CD-R/W O CD RW mode output.

75 LED ON/OFF O Back light LED ON/OFF control output.

76 TP-CLK O MICON clock test point.

77 Q-SURROUND O Q-SURROUND ON/OFF control output.

78 O-BBE-B O BBE IC control output.

79 O-BBE-A O BBE IC control output.

80 O-L-MUTE O Line out mute ON/OFF control output.

81 O-OPEN O CD tray open data output.

82 O-CLOSE O CD tray close data output.

83 NC – Not connected.

84 O-LCD STB O LCD control data latch strobe output.

85 O-LCD CLK O LCD control clock output.

86 O-LCD DATA O LCD control clock output.

87 O-P.ON O System power supply ON/OFF output.

88 O-CD ON O CD ON/OFF control output.

89 VSS2 – GND.

90 VDD2 – Power supply input.

91 O-CD-DATA O CD IC control data output.

92 O-CD-CLK O CD IC control clock output.

93 O-A MUTE O Audio mute ON/OFF control output.

94 O-MDRST O MD reset output.

95 O-SIN O MD serial data output.

96 O-SOUT I MD serial data input.

97 O-ACLK I MD unit latch clock input.

98 O-ARDY O MD unit latch data ready port control output.

99 O-SREQ O From MD unit serial data transfer request control output.

100 MREO I To MD unit serial data transfer request control input.

– 42 –

Page 43

ADJUSTMENT <MD>

All adjustments and checking of the MD block must be carried out in the test mode.

When the message “NO Adjust” is displayed, all adjustments must be performed.

* With regard to the key operations, see the section headed “Regarding the test mode and key operations for electrical adjustment” for the test

mode at the top of this section on the MD Test Mode in this manual.

Measurement equipment and tools:

Thermometer (centigrade indication), laser power meter (measuring up to 10mW)

Test disc: TGYS-1 (or a software disc), MDW-74 (or equivalent)

Before starting adjustment:

For the adjustment procedure, use a disc that has no scratches or stains. (Note that correct adjustment depends on the condition of the

disc.)

Never perform the MD block electrical adjustment with the MD mechanism turned over or tilted.

Adjustment procedure:

The entire flow chart for the adjustment procedure is shown as follows:

On the mark that is shown in the adjustment procedure

The mark (hand) in the procedure indicates key operations.

Adjustment procedure

START

Start the TEST MODE

1

EEPROM initialization

2

Temperature compensation adjustment

3

4

5

6

Checks after completing the adjustment

7

LASER power check

AUTO SEQUENCE ADJ

Error rate check

END

Be sure to read the paragraph headed “Laser power select key” at the top of the section

*

MD Test Mode in this manual, concerning key operations during the laser power check.

Then operate the keys in accordance with the flow chart.

– 43 –

Page 44

START

Start the TEST MODE

1

While pressing “MD EJECT”

on the main unit, connect the

AC plug to the power outlet

“STOP”

EEPROM initialization

2

“CD OPEN/CLOSE” on the main unit

To be continued

– 44 –

Page 45

Temperature compensation adjustment

3

“DISPLAY” on the remote control unit

“PAUSE”

Adjust temperature compensation

Measure the ambient temperature of the MD

mechanism using the thermometer, compare it with

the display temperature, and adjust the display

temperature to make it equal to the ambient

temperature using “B.SKIP” or “F.SKIP” on the display.

This adjustment is important, to ensure

that the temperature of the circuit boards

is equal to that of the room.

“DISPLAY COLOR” on the remote control unit

“STOP”

To be continued

– 45 –

Page 46

LASER power check

4

Check read power

VOLUME “-” on the main unit

“PAUSE”

Check the preset value for the read power

Ensure that “LSR = 11” is set

Check the light power

Press VOLUME “-” on the main unit twice

“PAUSE”

Check the preset value for the light power

Ensure that “LSR = 9F” is set

“DISPLAY COLOR” on the remote control unit

“DISPLAY COLOR” on the remote control unit

Check the read power.

Measure it using the laser power meter.

Check the laser output: approx. 0.68mW

Check the light power

Be sure to read the paragraph headed “Laser power select key” at the top

*

of the section MD Test Mode in this manual, then operate.

Check the light power.

Measure it using the laser power meter.

Check the laser output: approx. 6.8mW

“STOP”

To be continued

– 46 –

Page 47

AUTO SEQUENCE ADJ

5

Adjust MO DISC

Loading MDW-74

“STOP”

Press “DISPLAY” on the remote control unit twice

“MD MARK” on the remote control unit

“AUTO MARK” lights up

“MD” on the remote control unit

Check the adjustment value of the MO DISC

“PLAY”

Check the adjustment value (IVR, EF balance)

Check the EF balance value:

Within 09 to 15 (hexadecimal)

Check the IVR value:

Within 04 to 0A (hexadecimal)

“DISPLAY” on the remote control unit

Check the adjustment value (Focus/Tracking/Sled gain)

Check the sled gain value:

Within 0C to 30 (hexadecimal)

Check the tracking gain value:

Within 0C to 30 (hexadecimal)

Check the focus gain value:

Within 1A to 50 (hexadecimal)

“DISPLAY COLOR” on the remote control unit

This display means that the

adjustment has failed

“STOP”

“MD EJECT” on the main unit

Eject the disc

To be continued

– 47 –

Page 48

Continuation of

AUTO SEQUENCE ADJ

5

Adjust PIT DISC

Loading TGYS-1

“MD MARK” on the remote control unit

“TIME MARK” lights up

“MD” on the remote control unit

Check the adjustment of PIT DISC

“STOP”

Press “DISPLAY” on the remote control unit twice

Check the adjustment value (IVR, EF balance)

Check the EF balance value:

Within 09 to 15 (hexadecimal)

Check the IVR value:

Within 14 to 19 (hexadecimal)

“DISPLAY” on the remote control unit

Check the adjustment of PIT DISC

This display means that the

adjustment has failed

Check the adjustment value (Focus/Tracking/Sled gain)

Check the sled gain value:

Within 0C to 3F (hexadecimal)

Check the tracking gain value:

Within 0C to 3F (hexadecimal)

Check the focus gain value:

Within 1A to 50 (hexadecimal)

“STOP”

“MD EJECT” on the main unit

Eject the disc

– 48 –

To be continued

Page 49

6

Check the playback error rate

Error rate check

Loading TGYS-1

Check the playback error rate

“MD MARK” on the remote control unit

“TIME MARK” lights up

“B.SKIP F.SKIP”

Move the pickup to the intermediate position

between the innermost and outermost tracks on the disc

“AUX/D-IN” on the remote control unit

0030 or less

“STOP”

“MD EJECT” on the main unit

Eject the disc

To be continued

Address display

“DISPLAY” on the remote control unit

– 49 –

Page 50

Continuation of

6

Checking the record/playback error rate

Loading an MDW-74 disc

“MD MARK” on the remote control unit

Error rate check

Address display

Recording starts automatically from a

position of 600C

A recording time of about 15 to 30

seconds is required

“STOP”

“AUTO MARK” lights up

“B.SKIP F.SKIP”

Move the pickup to the intermediate position

between the innermost and outermost tracks on the disc

“CD” on the remote control unit

“AUX/D-IN” on the remote control unit

“DISPLAY” on the remote

control unit after passing 600C

Check the record/playback error rate

0030 or less

“STOP”

– 50 –

“MD EJECT” on the main unit

Eject the disc

To be continued

Page 51

Checks after completing the adjustment procedure

7

Press “POWER” twice to confirm that

“No Adjust” is not displayed on POWER ON

Remove the 3.3 kΩ resistor connected to the

laser power switch

END

– 51 –

Page 52

CD TEST MODE

1. How to Start the CD Test Mode

While pressing the function CD button, insert the AC plug to the

wall outlet. All the indicators on the display light, which means

that the test mode starts up.

2. How to Exit the CD Test Mode

3. Function Descriptions and Application of the CD Test Mode

No

1

2

3

4

5

Mode

Start mode

Search

mode

Play mode

Traverse

mode

Sled mode

Operation

s

d

a

f

g

FL indication

All indicators light

CD

Normal time

display

Normal time

display

CD TEST

Function

• LD lights

• Continuous focus search *1 *2

• Normal playback

• If TOC cannot be read, focus

search of “2” is continued.

• Tracking servo OFF/ON.

• Each time a is pressed, the

tracking servo repeats turning

OFF/ON.

• Pickup moves to the outermost

track *3

• Pickup moves to the innermost

track (normal operation during

playback)

Disconnect the AC plug.

Checking item

• Checking FL

• Checking microprocessor

• APC circuit

• Laser current

• Focus search waveform

• Focus error waveform

(FOK and FZC are not monitored

in the search mode)

• Focus servo

• Tracking servo

• Sled servo

• Spindle servo

• FOK

• RF waveform

• Tracking servo

• Traverse waveform

• Sled circuit

• Mechanism

*1: The driver IC heats up and the protection circuit starts working when the focus search is continued for 10 minutes or longer. There can be a

case that operations cannot be performed correctly.

In such a case, turn off the main power. After cooling down the machine, restart the machine.

*2: Before performing the visual check of the lens operation, slightly open the CD lid by hand. If you press the OPEN button and open the CD

lid, the search mode exists.

*3: Be careful not to damage the gear because the sled motor rotates while the FF or RWD button is being pressed even if the pick-up is located

in the innermost track or the outermost track.

4. Overview of Operation

Each operation mode can be operated one mode after another using each button in the order starting from the “Start” mode that is shown by the

arrow mark in the illustration.

Start mode

All indicators light

Search mode Traverse mode

Play mode

– 52 –

Page 53

MD TEST MODE

Regarding the test mode and key operations for electrical adjustment:

It is not possible to operate in test mode using the keys only on the main unit alone.

It is mainly the keys on the remote control unit that are used.

Laser power select key:

The following preparatory step is necessary to enable laser power selection in test mode:

Connect the land between R304 (1.2 k ohms) and R305 (10 k ohms) near S304, S305 on the KEY board of the main unit and the land at S311 on

its R311 side with a 3.3 k ohms resistor. (See the following illustration.)

When this preparatory step has been implemented, the laser power can be switched using the VOLUME “-” key on the main unit.

When the test mode is completed, be sure to remove the resistor.

The contents of this test mode manual are as follows:

===========================================================================

1. How to start the MD test mode

2. Checking the MD test mode and checking the audio system output

3. How to cancel the MD test mode

4. How to switch to the servo standby mode

5. Checking the sled move operation

6. Checking the laser power

7. Checking the loading mechanism operation and checking the detection switch

8. Checking the servo operation

8-1. Checking the focus search and spindle kick no. 1

8-2. Checking the focus search and spindle kick no. 2 (checking the “S” curve)

8-3. Checking the focus servo and the sled error (EF balance)

8-4. Checking all servos on

9. Checking the address and error rate

10. How to erase U-TOC (user TOC)

===========================================================================

– 53 –

Page 54

1. How to start the MD test mode

While pressing the “MD EJECT” key, connect the AC plug to the power outlet.

* Notes: 1) Ignore the mechanical abnormality and continue the required MD test mode operations while the test mode is on.

2) Playback and recording operations are not possible while the test mode is in progress.

2. Checking the MD test mode and checking the audio system output

1) When the test mode starts, the following message appears and the test mode becomes operable.

2) Checking the audio system output:

Check that a signal of 1 kHz, -17dB (140mV) is output from the MD mechanism output (D/A OUT) connector.

* Note: No signal is output from the speaker output or headphone output.

3. How to cancel the MD test mode

1) Press the “MD EJECT” key to remove the disc.

2) Disconnect the AC plug from the power outlet.

* If the MD test mode is canceled by any methods other than the procedure described above, the machine may operate abnormally when the

power is turned on again. In this case, disconnect the AC plug.

4. How to switch to the servo standby mode

Once the test mode has been set up, the machine mode is changed to the servo standby mode when the “STOP” key is pressed (“ALL SV OFF”

is displayed). From this mode, the machine can enter the various check modes listed below. When the “STOP” key is pressed, the machine

returns to the “ALL SV OFF” state from the other operating modes.

5. Checking the sled move operation

Both the lens and the pickup move in the direction of the inner circumference or the outer circumference when the “F.SKIP” key is pressed in

the machine’s “ALL SV OFF” state. The pickup moves to the innermost track and the “JAZZ” display lights up when the “INSIDE LIMIT SW”

key is pressed.

The pickup moves in the direction of

the outer circumference.

The pickup moves in the direction of the

inner circumference

(“JAZZ” lights up at the innermost track).

– 54 –

Page 55

6. Checking the laser power

1) The laser power is switched each time the VOLUME “-” key on the main unit is pressed in the “ALL SV OFF” state. The displays are

switched as follows:

“ALL SV OFF”: Laser off

“LASER READ”: Laser read power (approx. 0.68mW)

“LASER 1/2”: Laser 1/2 read power (approx. 0.34mW)

“LASER WRITE”: Laser write power (approx. 6.8mW)

2) After confirming the message, press the “STOP” key or the VOLUME “-” key on the main unit to return to the “ALL SV OFF” display.

* Before starting the above operation, be sure to read the paragraph headed “Laser power select key” at the top of this section on the MD Test

Mode in this manual. Note that the item “Checking the laser power” cannot be operated using the VOLUME “-” key on the remote control

unit.

7. Checking the loading mechanism operation and checking the detection switch

7-1. Checking the loading mechanism operation:

Insert an MO disc in the “ALL SV OFF” state. The OWH can be moved UP/DOWN by pressing the “REC” key and “MD EJECT” key

each time.

“REC”: OWH DOWN (during loading)

“MD EJECT”: Key OWH UP (during loading)/unloading

* Note: Never move down the OWH when a pre-mastered disc such as the test disc (TGYS-1) or the software disc is inserted in the machine.

7-2. Checking the detection switch:

REFLECT SW, REC PROTECT SW, INSIDE LIMIT SW and the disc mode (PIT, MO) selection appear on the display.

“JAZZ” lights up: INSIDE LIMIT SW turns ON.