Page 1

XR-MD100

K(S)

XR-MD101

EZ(S)

SERVICE MANUAL

BASIC TAPE MECHANISM : 2ZM-1 YR9

MD / CD STEREO SYSTEM

This Service Manual is the "Revision Publishing" and replaces "Simple Manual"

(S/M Code No. 09-993-315-0T1).

BASIC CD MECHANISM: 3ZG-3 E3N

BASIC MD MECHANISM: 7ZG-9 YB

S/M Code No. 09-993-315-0R3

REVISION

DATA

Page 2

TABLE OF CONTENTS

SPECIFICATIONS .................................................................................................................................. 3

ACCESSORIES/PACKAGE LIST ........................................................................................................... 3

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING/

Precaution to replace Optical block......................................................................................................... 4

DISASSEMBLY INSTRUCTIONS........................................................................................................ 5-8

ELECTRICAL MAIN PARTS LIST ..................................................................................................... 9-14

TRANSISTOR ILLUSTRATION ............................................................................................................ 14

BLOCK DIAGRAM-1 (MAIN)........................................................................................................... 15, 16

BLOCK DIAGRAM-2 (MD) .............................................................................................................. 17, 18

WIRING-1 (MAIN) ........................................................................................................................... 19, 20

SCHEMATIC DIAGRAM-1 (MAIN).................................................................................................. 21, 22

WIRING-2 (FRONT)........................................................................................................................ 23, 24

SCHEMATIC DIAGRAM-2 (FRONT) .............................................................................................. 25, 26

WIRING-3 (CD) ............................................................................................................................... 27, 28

SCHEMATIC DIAGRAM-3 (CD) ..................................................................................................... 29, 30

WIRING-4 (MD)............................................................................................................................... 31, 32

SCHEMATIC DIAGRAM-4 (MD) ..................................................................................................... 33, 34

WIRING-5 (TUNER)........................................................................................................................ 35, 36

SCHEMATIC DIAGRAM-5 (TUNER) .............................................................................................. 37, 38

WIRING-6 (AC/PT)................................................................................................................................ 39

WIRING-7 (MECHA/LOAD) .................................................................................................................. 40

FL GRID ASSIGNMENT/ANODE CONNECTION ................................................................................ 41

ELECTRICAL ADJUSTMENT/PRACTICAL SERVICE FIGURE ..................................................... 42-45

IC DESCRIPTION............................................................................................................................ 46-57

IC BLOCK DIAGRAM....................................................................................................................... 58-60

MECHANICAL EXPLODED VIEW 1/1............................................................................................ 61, 62

MECHANICAL PARTS LIST 1/1 ........................................................................................................... 63

TAPE MECHANISM PARTS LIST 1/1 .................................................................................................. 64

TAPE MECHANISM EXPLODED VIEW 1/1 ................................................................................... 65, 66

CD MECHANISM EXPLODED VIEW 1/2 ............................................................................................. 67

CD MECHANISM PARTS LIST 1/2 ...................................................................................................... 68

CD MECHANISM EXPLODED VIEW 2/2 ............................................................................................. 69

CD MECHANISM PARTS LIST 2/2 ...................................................................................................... 69

MD MECHANISM EXPLODED VIEW 1/3............................................................................................. 70

MD MECHANISM PARTS LIST 1/3...................................................................................................... 70

MD MECHANISM EXPLODED VIEW 2/3............................................................................................. 71

MD MECHANISM PARTS LIST 2/3...................................................................................................... 72

MD MECHANISM EXPLODED VIEW 3/3............................................................................................. 73

MD MECHANISM PARTS LIST 3/3...................................................................................................... 74

SPEAKER DISASSEMBLY INSTRUCTIONS....................................................................................... 75

SPEAKER PARTS LIST 1/1.................................................................................................................. 76

SPRING APPLICATION POSITION .....................................................................................................77

2

Page 3

SPECIFICATIONS

MAIN UNIT XR-MD100

FM tuner section

Tuning range 87.5 MHz to 108 MHz

Usable sensitivity (IHF) 13.2 dBf

Antenna terminals 75 ohms (unbalanced)

MW tuner section

Tuning range 531 kHz to1602 kHz (9 kHz step)

530 kHz to 1710 kHz (10 kHz

step)

Usable sensitivity 350 µV/m

Antenna Loop antenna

LW tuner section

Tuning range 144 kHz to 290 kHz

Usable sensitivity 1400 µV/m

Antenna Loop antenna

Amplifier section

Power output Rated: 25 W+25 W (6 ohms,

T.H.D. 1%,1 kHz/DIN 45500)

Reference: 30+30 W (6 ohms,

T.H.D. 10%,1 kHz/DIN 45324)

DIN MUSIC POWER

(EZ MODEL)

66.9 W+66.9 W

Inputs VIDEO/AUX: 400 mV

DIGITAL IN

sampling frequency: 48 kHz/32

kHz

Optical input level: more than

-21 dBm

Outputs SUPER WOOFER: 1.4 V

SPEAKERS: accept speakers of

6 ohms or more

PHONES (stereo minijack):

accepts headphones of 16 ohms

or more

Cassette deck section

Track format 4 tracks, 2 channels stereo

Frequency response CrO2 tape: 50 Hz–16000 Hz

Normal tape: 50 Hz–15000 Hz

Signal-to-noise ratio 60 dB (Dolby B NR ON, CrO2

tape peak level)

Recording system AC bias

Heads Deck: Recording/playback/erase

head * 1

Compact disc player section

Laser Semiconductor laser ( =780 nm)

D-A converter 1 bit dual

Signal-to-noise ratio 90 dB (1 kHz, 0 dB)

Harmonic distortion 0.05% (1 kHz,0 dB)

Wow and flutter Unmeasurable

MD recorder section

Scanning method Non-contact optical scanner

(Semiconductor laser application)

Recording system Magnetic polarity modulation

overwrite system

Rotation speed Approx.400-900 rpm (CLV)

Sampling frequency 44.1 kHz

No. of channels Stereo: 2 channels

Monaural: 1 channel

A-D, D-A converter 1-bit

Frequency 20–20000 Hz+0.2– -1.5 dB

Wow and flutter Unmeasurable

SPEAKER SYSTEM SX-M100

Cabinet type 2 way, bass reflex (magnetic

shielded type)

Speakers Woofer: 130 mm cone type

Tweeter: 60 mm cone type

Impedance 6 ohms

Output sound pressure level 87 dB/W/m

Dimensions (W * H * D) 175 * 275 * 227 mm

Weight 3.0 kg

General

Power requirements 230 V AC, 50 Hz

Power consumption 80 W

Standby power consumption 1.4 W (power-economizing mode

set to ON)

Dimensions (W * H * D) 175 * 275 * 333 mm

Weight 6.0 kg

Design and specifications are subject to change without

•

notice.

Dolby noise reduction manufactured under license from

•

Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol

of Dolby Laboratories Licensing Corporation.

The word “BBE” and the “BBE symbol” are trademarks

•

of BBE Sound,Inc.

Under license from BBE Sound,Inc.

are trademarks

ACCESSORIES/PACKAGE LIST

REF. NO PART NO. KANRI DESCRIPTION

NO.

1 87-A90-118-010 ANT,WIRE FM (Z)

2 87-A90-030-010 ANT,LOOP AM-NC C

3 8Z-CL4-906-010 IB,EZ(9L)S<EZ>

3 8Z-CL4-905-010 IB,K(E)S<K>

4 8Z-CK4-952-010 RC UNIT,RC-ZAT04

3

Page 4

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

This set employs laser. Therefore, be sure to follow carefully the

instructions below when servicing.

WARNING!

WHEN SERVICING, DO NOT APPROACH THE LASER EXIT

WITH THE EYE TOO CLOSELY. IN CASE IT IS NECESSARY TO

CONFIRM LASER BEAM EMISSION. BE SURE TO OBSERVE

FROM A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE OPTICAL

PICK-UP BLOCK.

Caution: Invisible laser radiation when

open and interlocks defeated avoid exposure to beam.

Advarsel:Usynling laserståling ved åbning,

når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

VAROITUS!

Laiteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyt-täjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

VARNING!

Om apparaten används på annat sätt än vad som specificeras i

denna bruksanvising, kan användaren utsättas för osynling

laserstrålning, som överskrider gränsen för laserklass 1.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

ATTENTION

L'utilisation de commandes, réglages ou procédures autres que

ceux spécifiés peut entraîner une dangereuse exposition aux

radiations.

ADVARSEL!

Usynlig laserståling ved åbning, når sikkerhedsafbrydereer ude

af funktion. Undgå udsættelse for stråling.

This Compact Disc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located on the rear

exterior.

CLASS 1

KLASSE 1

LUOKAN 1

KLASS 1

LASER PRODUCT

LASER PRODUKT

LASER LAITE

LASER APPARAT

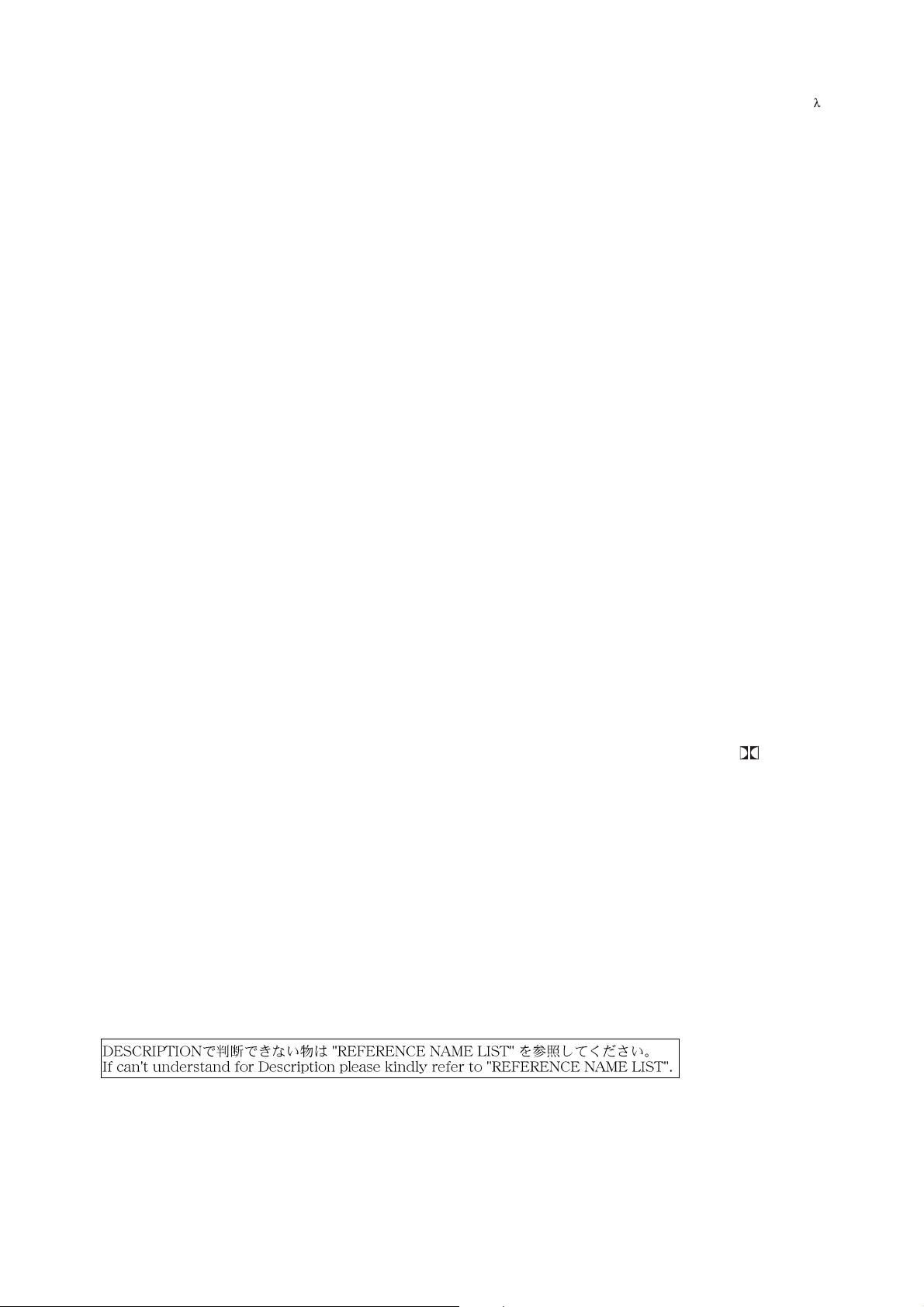

Precaution to replace Optical block

(KSS-213F)

Body or clothes electrostatic potential could ruin

laser diode in the optical block. Be sure ground

body and workbench, and use care the clothes

do not touch the diode.

1) After the connection, remove solder shown in

the right figure.

Precaution to replace Optical block

(KMS-260A)

Body or clothes electrostatic potential could ruin

laser diode in the optical block. Be sure ground

body and workbench, and use care the clothes

do not touch the diode.

1) After the connection, remove solder

shown in the right figure.

1 VEE

¡ TRK –

4

Page 5

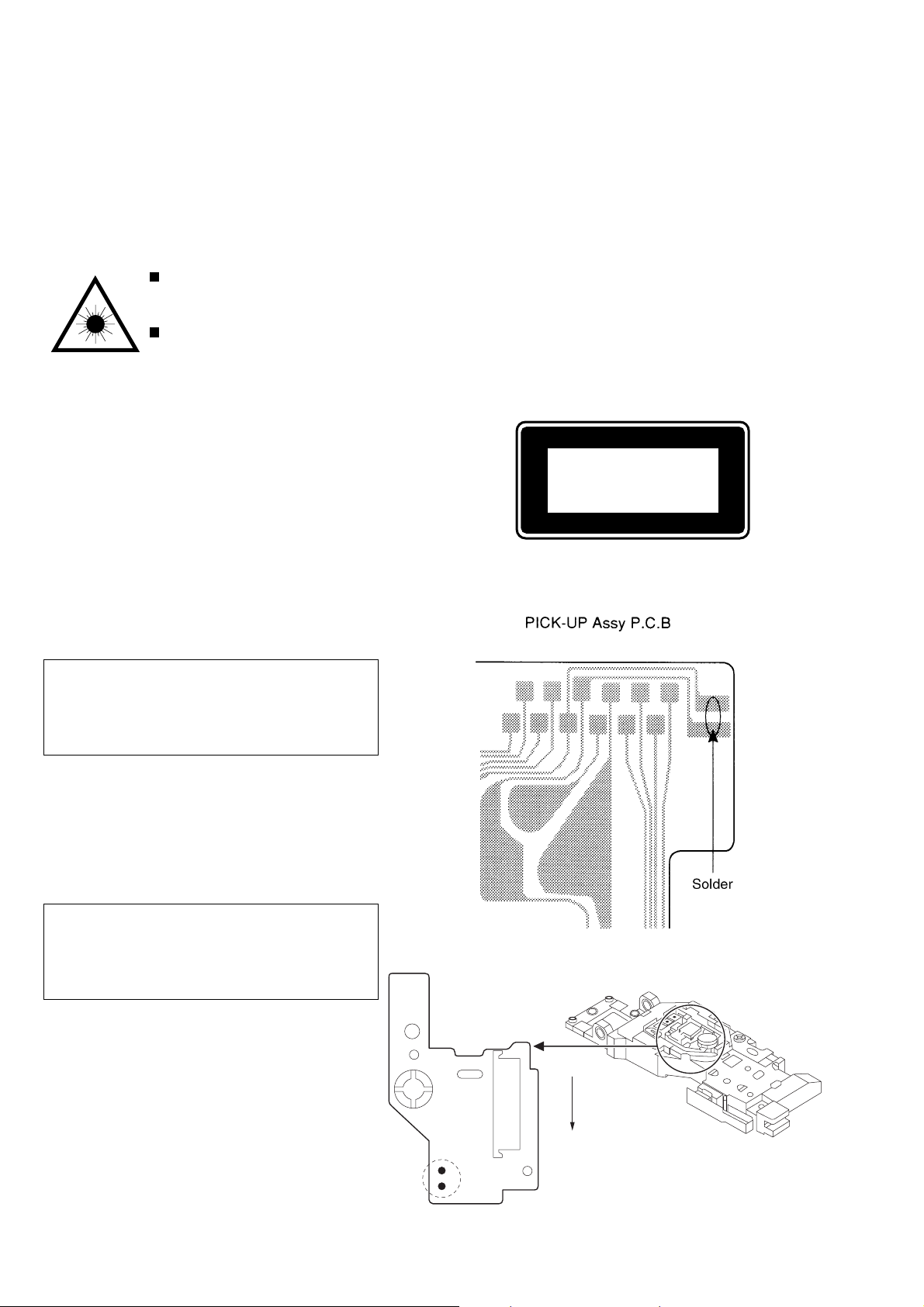

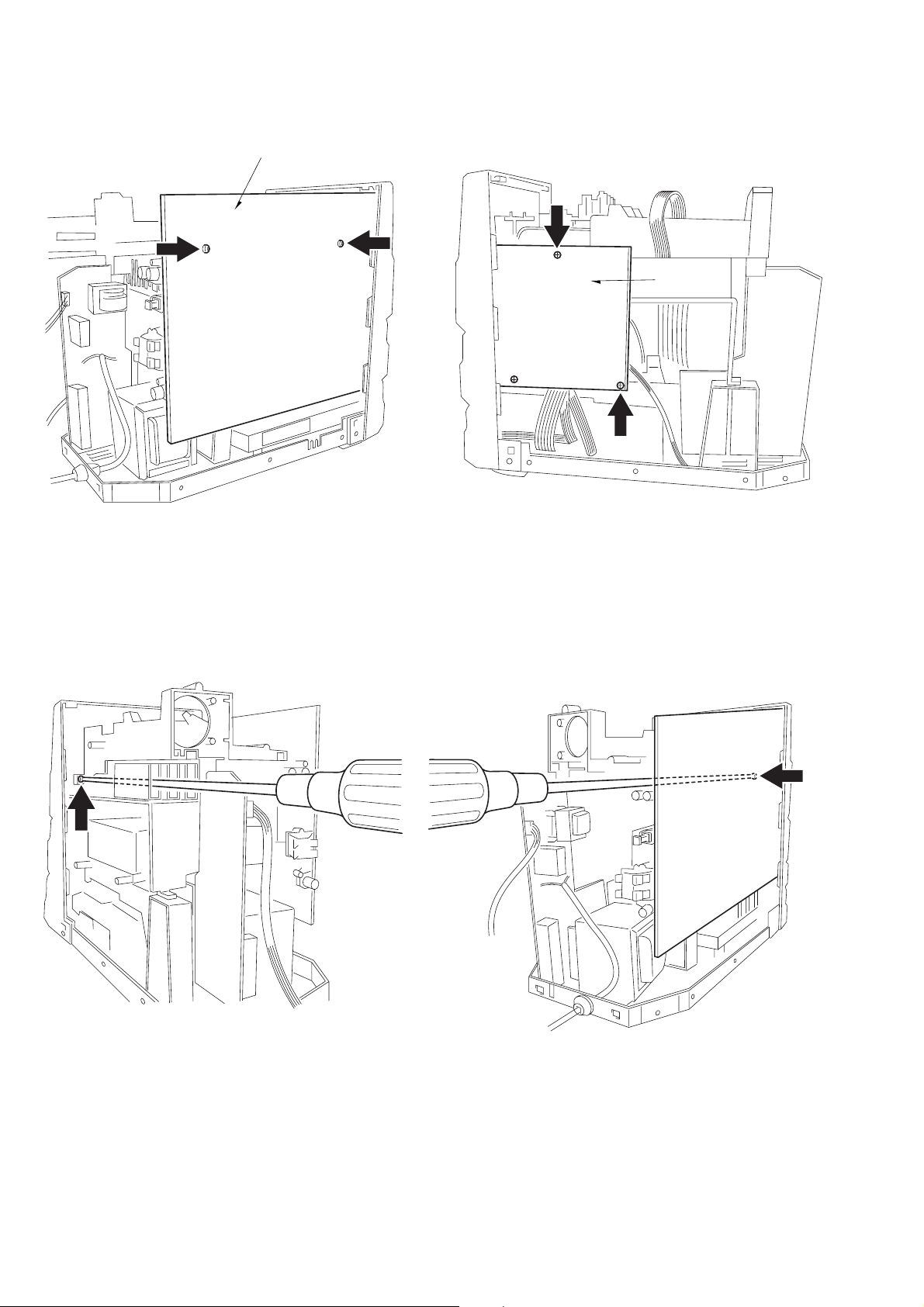

DISASSEMBLY INSTRUCTIONS

Disassembly Procedure

1. Open the cabinet

1) Remove the screws (1BVT2+3-10*1, 2UTT2+3-6*3 w/o SLOT B), and remove the PANEL SIDE L.

2) Remove the screws (3BVT2+3-10*1, 4UTT2+3-6*3 w/o SLOT B), and remove the PANEL SIDE R.

3) Remove the screw (5BVT2+3-10*3) from the rear side, open the deck lid, remove the screw (6BVT2+3-16*2), and remove

the TOP PANEL.

5

6

REAR PANEL

3

1

PANEL

SIDE L

2

4) Remove the screw (BVT2+3-10*11) from the rear side, and remove the REAR PANEL.

PANEL SIDE R

4

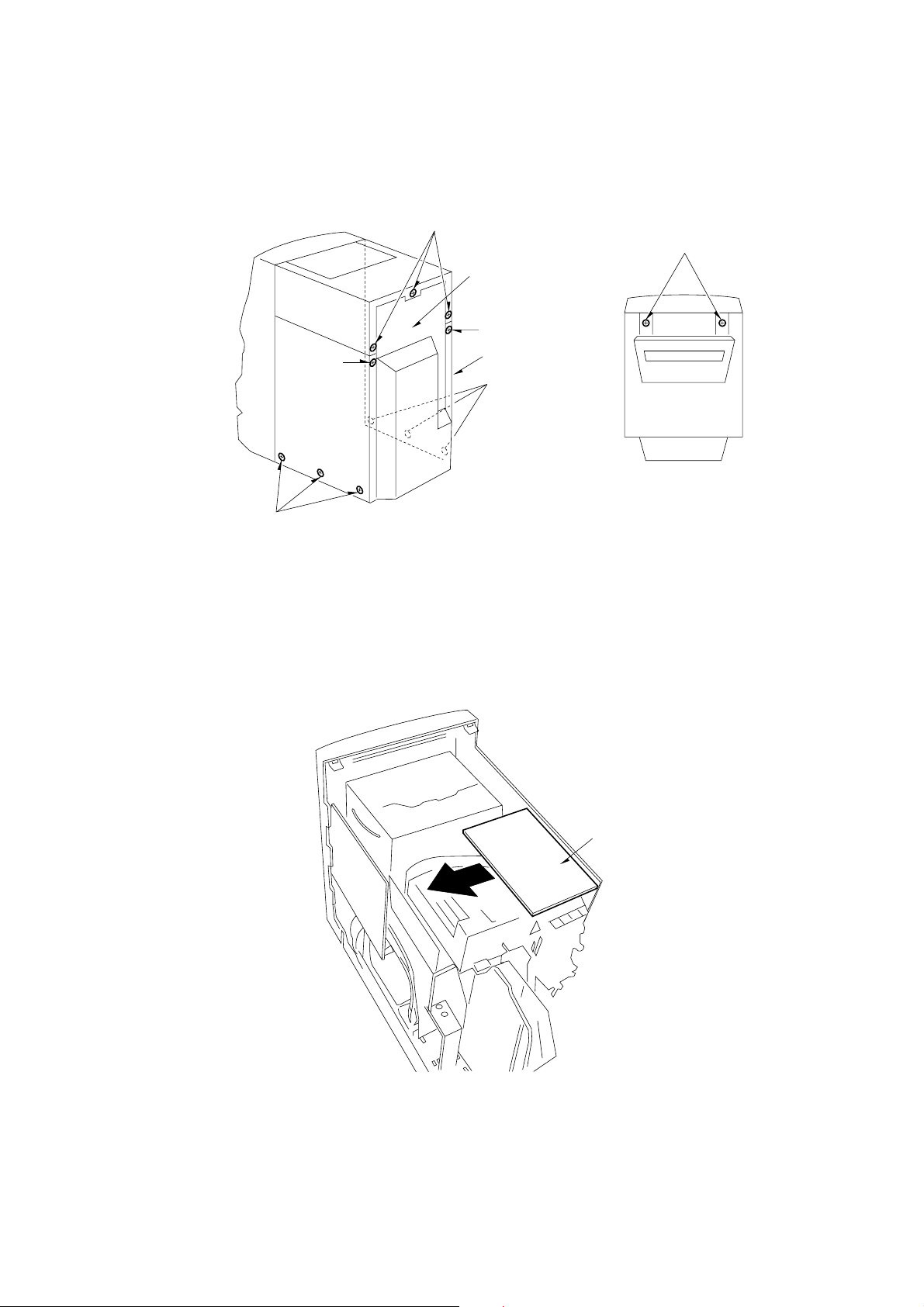

2. Removing the deck mechanism.

1) Remove the TUNER C.B in the direction of the arrow.

TOP PANEL

TUNER C.B

5

Page 6

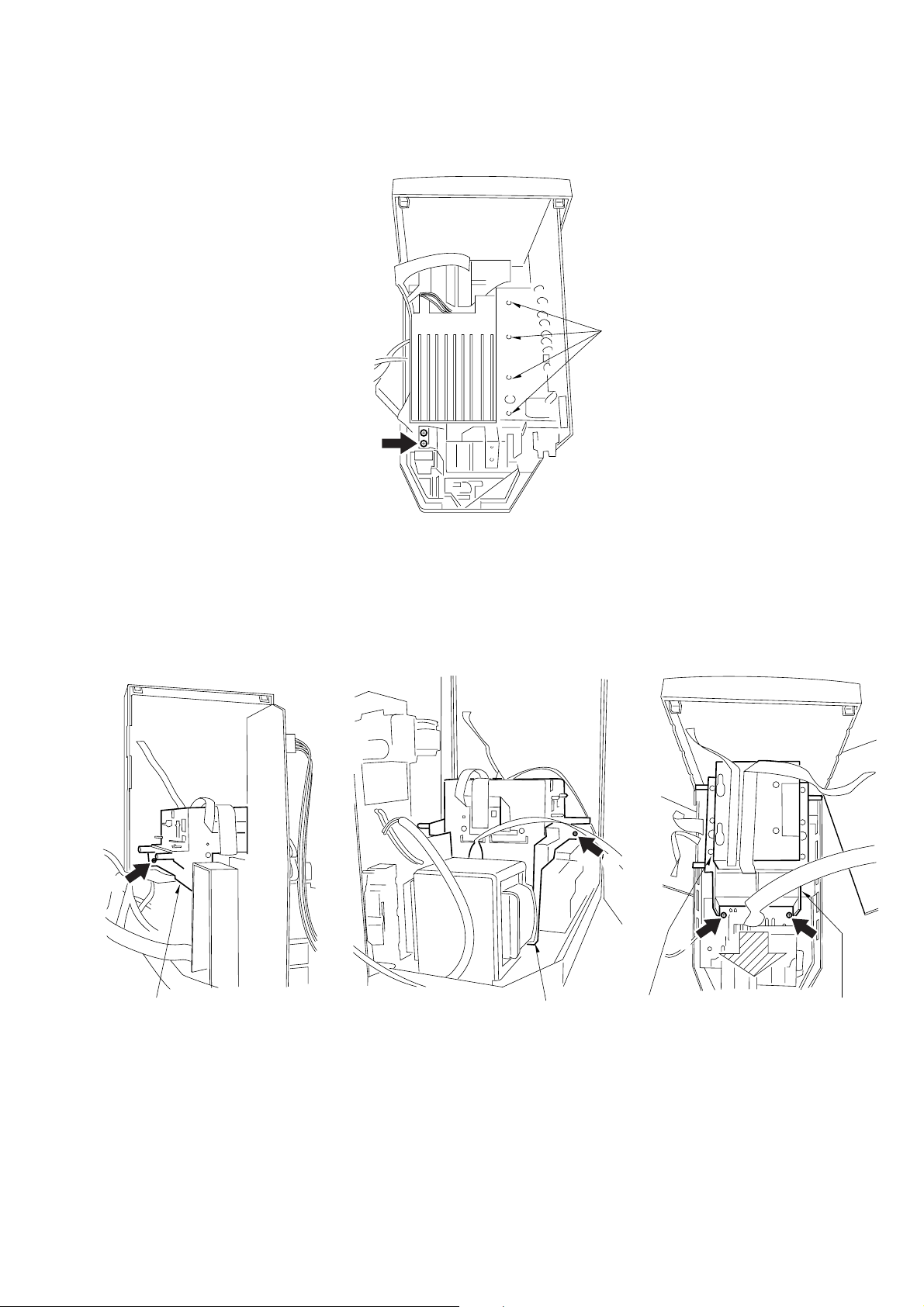

2) Remove the screw (7BVT2+3-10*2) on the top of the MAIN C.B, and remove the screw (8BVT2+3-10*3) from the CD C.B.

MAIN C.B

8

7

3) Remove the CD C.B, remove the screw (9UTT2+3-6*1), insert a screwdriver tip through the clearance between the parts and

the chassis, and remove the screw (0UTT2+3-6*1).

7

CD C.B

8

9

AC

C.B

4) Remove the cord, and remove the deck mechanism together with the chassis.

0

MAIN C.B

6

Page 7

3. Removing the MD mechanism.

1) Remove the screw (!BVTT+4-6*4) securing the transformer, and move the transformer to the rear.

2) Remove the screw (@BVT2+3-10*1) that fixes the heat side to the holder, and remove the MAIN C.B.

!

@

3) Remove the screw (#BVT2+3-10*4), and remove the MD mechanism together with the chassis.

#

#

AC

C.B

MD chassis

MD chassis

MD mechanism

# #

MD chassis

Upper side

7

Page 8

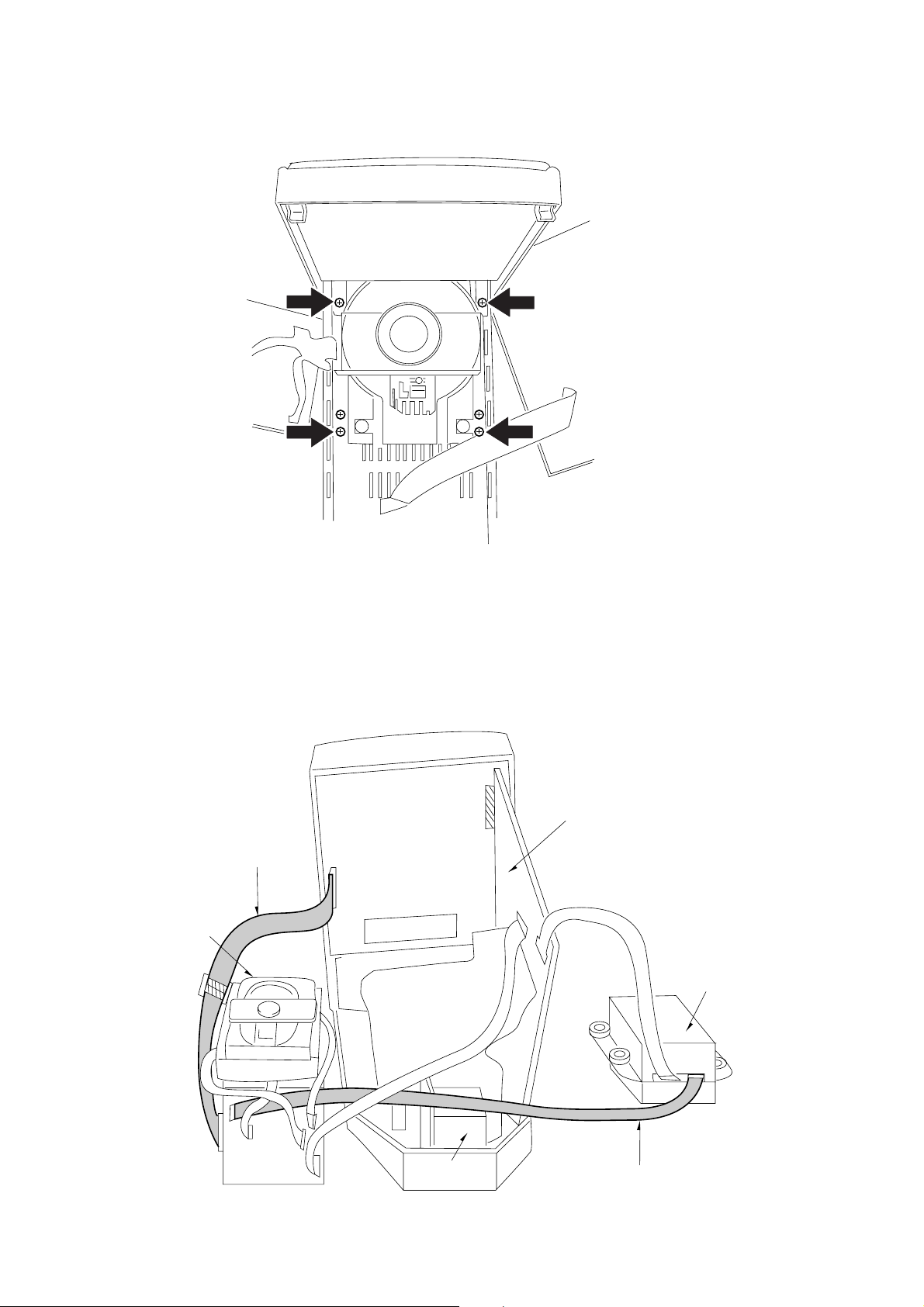

4. Removing the CD mechanism.

1) Remove the screw ($BVT2+3-6*4), open the tray, remove the CD panel, and remove the CD mechanism.

$

$

Upper side

SERVICE JIG AND TOOLS

After opening the board, use the following jig and tools as shown in the figure.

JIG. EX TENSION (TANAKA) ...................SV-J00-019-010

FFC, 8P-1.0 ...................................................SV-J00-043-010

$

$

Extension FFC

(JIG, EXTENSION (TANAKA))

CD mechanism

Component side of CD C.B

FRONT C.B

Heat sink

Transformer

Rear side of the unit

MAIN C.B

MD mechanism

Extension FFC (FFC, 8P-1.0)

8

Page 9

ELECTRICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

NO.

IC

87-A20-446-010 C-IC,LA9241ML

87-A20-459-010 C-IC,LC78622ED

87-A20-445-010 IC,BA5936

87-070-289-040 IC,BU 2092F

8Z-CL4-620-010 IC,LC87F65C8A

87-A20-914-010 IC,SPS-442-1-F

87-A20-455-010 IC,HA12211

87-A20-355-010 IC,CXA1553P

87-A21-111-040 C-IC,M62495FP

87-A21-103-040 C-IC,MM1454XFBE

87-017-915-080 IC,BU4094BCF

87-A21-022-040 C-IC,BA3880FS

87-A20-870-010 IC,GP1F37R

87-A21-175-040 C-IC,TC74VHC14FT

87-070-127-110 IC,LC72131 D

87-A20-913-010 IC,LA1837NL

87-A20-440-040 C-IC,BU1920FS

87-A20-707-010 C-IC,CXA2523AR

87-A20-708-010 C-IC,CXD2652AR

87-A20-709-040 C-IC,BD7910FV

87-ZG9-607-010 C-IC,CXP81952M-523R

87-ZG9-606-040 C-IC,MN41V4400SJ-08

87-A20-755-080 C-IC,AK93C45AF

87-A20-710-040 C-IC,S-8110AMP

87-A20-711-040 C-IC,BA5970FP

87-A20-712-040 C-IC,BA6417F

87-A21-110-040 C-IC,AK4519VF

87-017-853-040 IC,NJM2100V

87-A20-797-040 C-IC,NJU7221U30

87-A20-798-040 C-IC,NJU7221U35

87-A20-714-040 C-IC,NJM2370U33

TRANSISTOR

87-026-463-080 TR,2SA933S (0.3W)

87-026-239-080 TR,DTC114TK (0.2W)

87-A30-076-080 C-TR,2SC3052F

87-A30-075-080 C-TR,2SA1235F

87-A30-268-040 C-TR,2SA1514K(S)

87-A30-074-080 C-TR,RT1P 141C

89-113-187-880 TRNSISTOR,2SA1318 (0.5W)

87-A30-047-080 TR,CSD655E

89-213-702-010 TR,2SB1370 (1.8W)

87-026-245-080 TR,DTC114ES

87-A30-198-080 TR,KTC3199GR

87-026-610-080 TR,KTC3198GR

87-A30-196-080 TR,2SC4115SRS

87-A30-072-080 C-TR,RT1P 144C

87-A30-073-080 C-TR,RT1N 141C

87-A30-087-080 C-FET,2SK2158

87-026-609-080 TR,KTA1266GR

87-A30-190-080 TR,CC5551

87-A30-215-010 TR,2SD2025

87-A30-214-010 TR,2SB1344

87-A30-106-070 C-TR,CMBT5551

87-A30-105-080 C-TR,RT1P 441C

87-A30-159-080 C-TR,KTA1298Y

87-A30-084-080 TR,CSB1058B

89-327-143-080 TR,2SC2714 (0.1W)

87-026-297-080 TR,DTA144TK

87-A30-071-080 C-TR,RT1N 144C

87-A30-234-080 TR,CSC4115BC

87-A30-072-080 C-TR,RT1P 144

89-327-143-080 TR,2SC2714 (0.1W)

87-A30-076-080 C-TR,2SC3052F<K>

87-A30-074-080 C-TR,RT1P 141C

87-A30-086-070 C-TR,CSD1306E

89-505-434-540 C-FET,2SK543(4/5)

REF. NO PART NO. KANRI DESCRIPTION

NO.

87-026-423-080 C-TR RN2305

89-115-884-080 CHIP -TRANSISTER 2SA1588Y

89-341-164-080 CHIP-TRANSISTOR,2SC4116 Y

87-026-412-080 C-TR RN1305

DIODE

87-A40-291-080 DIODE,1N4148 (CPT)

87-A40-270-080 C-DIODE,MC2838

87-A40-269-080 C-DIODE,MC2836

87-A40-004-080 ZENER,MTZJ16A

87-070-178-090 DIODE,1N5402-BD54

87-070-274-080 DIODE,1N4003 SEM

87-A40-345-080 ZENER,MTZJ10C

87-017-083-080 ZENER,HZS4C2

87-A40-312-080 ZENER,DZ33M

87-A40-488-080 DIODE,1SS244

87-A40-509-080 ZENER,MTZJ6.8C

87-A40-293-080 ZENER,DZ2.7M

87-001-731-080 ZENER,HZS6C2L

87-A40-299-080 ZENER,DZ5.1M

87-017-149-080 ZENER,HZS6A2L

87-020-465-080 DIODE,1SS133 (110MA)

87-A40-270-080 C-DIODE,MC2838

87-001-166-080 DIODE,1SS301

87-A40-412-040 C-DIODE,SB05-05CP

MAIN C.B

C61 87-010-260-080 CAP, ELECT 47-25V

C62 87-010-403-080 CAP, ELECT 3.3-50V

C63 87-010-197-080 CAP, CHIP 0.01 DM

C102 87-016-051-090 CAP,E 2200-35 SMG

C103 87-A10-479-080 CAP,CER 2200P-250 M E KH

C106 87-010-196-080 CHIP CAPACITOR,0.1-25

C107 87-010-196-080 CHIP CAPACITOR,0.1-25

C108 87-010-196-080 CHIP CAPACITOR,0.1-25

C109 87-010-196-080 CHIP CAPACITOR,0.1-25

C110 87-010-928-090 CAP,E 4700-25 SMG

C111 87-012-140-080 CAP 470P

C112 87-010-112-080 CAP, ELECT 100-16V

C113 87-010-247-080 CAP, ELECT 100-50V

C114 87-010-112-080 CAP, ELECT 100-16V

C115 87-010-235-080 CAP,E 470-16 SME

C151 87-010-196-080 CHIP CAPACITOR,0.1-25

C152 87-A11-233-090 CAP,E 4700-16 105 KMG

C153 87-010-196-080 CHIP CAPACITOR,0.1-25

C154 87-A10-105-080 CAP,E 1000-6.3 REA

C171 87-010-260-080 CAP, ELECT 47-25V

C172 87-010-260-080 CAP, ELECT 47-25V

C173 87-010-260-080 CAP, ELECT 47-25V

C174 87-010-260-080 CAP, ELECT 47-25V

C175 87-010-247-080 CAP, ELECT 100-50V

C176 87-010-247-080 CAP, ELECT 100-50V

C201 87-010-260-080 CAP, ELECT 47-25V

C202 87-010-260-080 CAP, ELECT 47-25V

C203 87-A10-946-080 C-CAP,S 220P-100 J CH

C204 87-A10-946-080 C-CAP,S 220P-100 J CH

C209 87-010-186-080 CAP,CHIP 4700P

C210 87-010-186-080 CAP,CHIP 4700P

C211 87-012-368-080 C-CAP,S 0.1-50 F

C212 87-012-368-080 C-CAP,S 0.1-50 F

C213 87-010-195-080 C-CAP,S 0.068-25 F

C214 87-015-837-080 C-CAP,0.068 F

C215 87-010-544-080 CAP, ELECT 0.1-50V

C216 87-010-544-080 CAP, ELECT 0.1-50V

C217 87-010-182-080 C-CAP,S 2200P-50 B

C218 87-010-182-080 C-CAP,S 2200P-50 B

C221 87-010-186-080 CAP,CHIP 4700P

C222 87-010-186-080 CAP,CHIP 4700P

9

Page 10

REF. NO PART NO. KANRI DESCRIPTION

C223 87-010-403-080 CAP, ELECT 3.3-50V

C224 87-010-403-080 CAP, ELECT 3.3-50V

C265 87-010-546-080 CAP, ELECT 0.33-50V

C266 87-010-546-080 CAP, ELECT 0.33-50V

C267 87-010-380-080 CAP, ELECT 47-16V

C267 87-010-380-080 CAP, ELECT 47-16V

C277 87-010-197-080 CAP, CHIP 0.01 DM

C303 87-012-157-080 C-CAP,S 330P-50 CH

C304 87-012-157-080 C-CAP,S 330P-50 CH

C307 87-010-196-080 CHIP CAPACITOR,0.1-25

C311 87-010-198-080 CAP, CHIP 0.022

C312 87-010-198-080 CAP, CHIP 0.022

C315 87-010-181-080 CAP,CHIP S 1800P

C316 87-010-181-080 CAP,CHIP S 1800P

C317 87-012-142-080 CAP, S 0.33-16

C318 87-012-142-080 CAP, S 0.33-16

C319 87-012-141-080 CHIP-CAPACITOR,0.22-16F

C320 87-012-141-080 CHIP-CAPACITOR,0.22-16F

C321 87-012-141-080 CHIP-CAPACITOR,0.22-16F

C322 87-012-141-080 CHIP-CAPACITOR,0.22-16F

C324 87-010-260-080 CAP, ELECT 47-25V

C325 87-010-370-080 CAP,E 330-6.3 SME

C327 87-010-404-080 CAP, ELECT 4.7-50V

C328 87-010-404-080 CAP, ELECT 4.7-50V

C332 87-010-196-080 CHIP CAPACITOR,0.1-25

C335 87-010-401-080 CAP, ELECT 1-50V

C336 87-010-401-080 CAP, ELECT 1-50V

C337 87-010-196-080 CHIP CAPACITOR,0.1-25

C339 87-010-196-080 CHIP CAPACITOR,0.1-25

C340 87-010-196-080 CHIP CAPACITOR,0.1-25

C351 87-012-140-080 CAP 470P

C352 87-012-140-080 CAP 470P

C354 87-010-175-080 CAP 560P

C355 87-010-178-080 CHIP CAP 1000P

C356 87-010-260-080 CAP, ELECT 47-25V

C357 87-010-197-080 CAP, CHIP 0.01 DM

C358 87-010-183-080 C-CAP,S 2700P-50 B

C359 87-010-183-080 C-CAP,S 2700P-50 B

C360 87-010-183-080 C-CAP,S 2700P-50 B

C370 87-010-196-080 CHIP CAPACITOR,0.1-25

C371 87-010-179-080 CAP,CHIP S B1200P

C372 87-010-179-080 CAP,CHIP S B1200P

C373 87-010-179-080 CAP,CHIP S B1200P

C374 87-010-179-080 CAP,CHIP S B1200P

C375 87-010-545-080 CAP, ELECT 0.22-50V

C376 87-010-545-080 CAP, ELECT 0.22-50V

C378 87-018-209-080 CAP, CER 0.1-50V

C381 87-010-197-080 CAP, CHIP 0.01 DM

C382 87-010-318-080 C-CAP,S 47P-50 CH

C383 87-010-197-080 CAP, CHIP 0.01 DM

C384 87-010-402-080 CAP, ELECT 2.2-50V

C385 87-010-184-080 CHIP CAPACITOR 3300P(K)

C386 87-010-196-080 CHIP CAPACITOR,0.1-25

C388 87-010-154-080 CAP CHIP 10P

C399 87-010-265-080 CAP, ELECT 33-16V

C501 87-010-154-080 CAP CHIP 10P

C502 87-010-374-080 CAP, ELECT 47-10V

C503 87-010-374-080 CAP, ELECT 47-10V

C505 87-010-187-080 CAP CHIP S5600P

C506 87-010-187-080 CAP CHIP S5600P

C509 87-010-182-080 C-CAP,S 2200P-50 B

C510 87-010-182-080 C-CAP,S 2200P-50 B

C511 87-010-213-080 C-CAP,S 0.015-50 B

C512 87-010-213-080 C-CAP,S 0.015-50 B

C513 87-010-400-080 CAP, ELECT 0.47-50V

C514 87-010-400-080 CAP, ELECT 0.47-50V

C515 87-010-400-080 CAP, ELECT 0.47-50V

C516 87-010-400-080 CAP, ELECT 0.47-50V

C517 87-010-401-080 CAP, ELECT 1-50V

C518 87-010-401-080 CAP, ELECT 1-50V

C551 87-010-402-080 CAP, ELECT 2.2-50V

C552 87-010-402-080 CAP, ELECT 2.2-50V

C561 87-010-407-080 CAP, ELECT 33-50V

C562 87-010-407-080 CAP, ELECT 33-50V

C581 87-010-404-080 CAP, ELECT 4.7-50V

NO.

REF. NO PART NO. KANRI DESCRIPTION

C582 87-010-404-080 CAP, ELECT 4.7-50V

C603 87-010-402-080 CAP, ELECT 2.2-50V

C604 87-010-402-080 CAP, ELECT 2.2-50V

C605 87-010-408-080 CAP, ELECT 47-50V

C607 87-010-405-080 CAP, ELECT 10-50V

C608 87-010-405-080 CAP, ELECT 10-50V

C609 87-010-196-080 CHIP CAPACITOR,0.1-25

C610 87-010-384-080 CAP, ELECT 100-25V

C611 87-010-197-080 CAP, CHIP 0.01 DM

C612 87-010-197-080 CAP, CHIP 0.01 DM

C620 87-010-380-080 CAP, ELECT 47-16V

C621 87-010-196-080 CHIP CAPACITOR,0.1-25

C622 87-010-322-080 C-CAP,S 100P-50 CH

C631 87-010-400-080 CAP, ELECT 0.47-50V

C653 87-010-404-080 CAP, ELECT 4.7-50V

C654 87-010-404-080 CAP, ELECT 4.7-50V

C655 87-010-404-080 CAP, ELECT 4.7-50V

C656 87-010-404-080 CAP, ELECT 4.7-50V

C657 87-010-188-080 CAP,CHIP 6800P

C658 87-010-188-080 CAP,CHIP 6800P

C659 87-012-140-080 CAP 470P

C660 87-012-140-080 CAP 470P

C662 87-010-408-080 CAP, ELECT 47-50V

C663 87-010-178-080 CHIP CAP 1000P

C664 87-010-178-080 CHIP CAP 1000P

C665 87-010-197-080 CAP, CHIP 0.01 DM

C666 87-010-197-080 CAP, CHIP 0.01 DM

C667 87-010-195-080 C-CAP,S 0.068-25 F

C668 87-010-195-080 C-CAP,S 0.068-25 F

C669 87-010-408-080 CAP, ELECT 47-50V

C670 87-010-196-080 CHIP CAPACITOR,0.1-25

C671 87-010-404-080 CAP, ELECT 4.7-50V

C672 87-010-404-080 CAP, ELECT 4.7-50V

C675 87-010-401-080 CAP, ELECT 1-50V

C676 87-010-401-080 CAP, ELECT 1-50V

C901 87-010-196-080 CHIP CAPACITOR,0.1-25

C902 87-010-178-080 CHIP CAP 1000P

C903 87-010-178-080 CHIP CAP 1000P

C904 87-010-196-080 CHIP CAPACITOR,0.1-25

C905 87-012-140-080 CAP 470P

C906 87-010-196-080 CHIP CAPACITOR,0.1-25

C951 87-010-401-080 CAP, ELECT 1-50V

C952 87-010-263-080 CAP, ELECT 100-10V

C953 87-010-380-080 CAP, ELECT 47-16V

C960 87-010-405-080 CAP, ELECT 10-50V

CN101 87-A60-111-010 CONN,5P V S2M 5W

CN501 87-099-719-010 CONN,30P TYK-B(X)

CN502 87-A60-423-010 CONN,14P V TOC-B

CN503 87-A60-133-010 CONN,8P V FE

CN702 87-A60-189-010 CONN,16P V TUC-P16P-B1

CN901 8Z-CL4-656-010 CONN ASSY,2P V DTL SHLD

J201 87-A60-420-010 JACK,3.5 ST (MSC)

J202 87-099-801-010 JACK,PIN 1P BLK

J203 87-A60-659-010 TERMINAL,SPKR 4P HSP-134V-05Z

L201 87-003-383-010 COIL,1UH-S

L202 87-003-383-010 COIL,1UH-S

L301 87-A50-049-010 COIL,TRAP 85K(COI)

L302 87-A50-049-010 COIL,TRAP 85K(COI)

L351 87-007-342-010 COIL,OSC 85K BIAS

PN301 87-A60-112-010 CONN,7P V S2M-7W

!

PR103 87-026-681-080 PROTECTOR,5A 60V 491

!

PR104 87-026-681-080 PROTECTOR,5A 60V 491

!

PR151 87-A90-094-080 PROTECTOR,4A 491SERIES 60V

!

PR152 87-A90-094-080 PROTECTOR,4A 491SERIES 60V

R215 87-A00-258-080 RES,M/F 0.22-1W J

R216 87-A00-258-080 RES,M/F 0.22-1W J

R217 87-A00-258-080 RES,M/F 0.22-1W J

R218 87-A00-258-080 RES,M/F 0.22-1W J

R219 87-A00-258-080 RES,M/F 0.22-1W J

R220 87-A00-258-080 RES,M/F 0.22-1W J

R908 87-008-372-080 FILTER, EMI BL OIRNI

SFR303 87-A90-557-080 SFR,33K H HOKU

SFR304 87-A90-557-080 SFR,33K H HOKU

SFR305 87-024-436-080 SFR,47K RH063EC

SFR306 87-024-436-080 SFR,47K RH063EC

NO.

10

Page 11

REF. NO PART NO. KANRI DESCRIPTION

NO.

SFR351 87-024-436-080 SFR,47K RH063EC

SFR352 87-024-436-080 SFR,47K RH063EC

TH51 87-A91-042-080 C-THMS,100K 55001

TH52 87-A91-042-080 C-THMS,100K 55001

W101 8Z-CL4-658-010 F-CABLE,10P 2.5 300MM

CD C.B

C1 87-010-403-080 CAP, ELECT 3.3-50V

C2 87-010-197-080 CAP, CHIP 0.01 DM

C3 87-010-263-080 CAP, ELECT 100-10V

C4 87-010-248-080 CAP, ELECT 220-10V

C5 87-010-197-080 CAP, CHIP 0.01 DM

C6 87-010-374-080 CAP, ELECT 47-10V

C7 87-012-349-080 C-CAP,S 1000P-50 CH

C8 87-010-198-080 CAP, CHIP 0.022

C9 87-010-248-080 CAP, ELECT 220-10V

C10 87-010-263-080 CAP, ELECT 100-10V

C12 87-010-401-080 CAP, ELECT 1-50V

C13 87-010-193-080 CHIP CAPACITOR,0.033

C14 87-010-405-080 CAP, ELECT 10-50V

C17 87-012-157-080 C-CAP,S 330P-50 CH

C18 87-010-213-080 C-CAP,S 0.015-50 B

C20 87-010-193-080 CHIP CAPACITOR,0.033

C22 87-010-183-080 C-CAP,S 2700P-50 B

C23 87-010-956-080 CHIP-CAP,S 0.068-25B

C25 87-010-994-080 C-CAP,S 680P-50 CH

C29 87-010-186-080 CAP,CHIP 4700P

C30 87-012-156-080 C-CAP,S 220P-50 CH

C31 87-010-400-080 CAP, ELECT 0.47-50V

C32 87-010-374-080 CAP, ELECT 47-10V

C33 87-010-401-080 CAP, ELECT 1-50V

C34 87-010-184-080 CHIP CAPACITOR 3300P(K)

C35 87-010-197-080 CAP, CHIP 0.01 DM

C36 87-010-374-080 CAP, ELECT 47-10V

C37 87-010-404-080 CAP, ELECT 4.7-50V

C38 87-010-196-080 CHIP CAPACITOR,0.1-25

C40 87-010-145-080 C-CAP,S 1P-50 CH

C42 87-010-312-080 C-CAP,S 15P-50 CH

C45 87-010-196-080 CHIP CAPACITOR,0.1-25

C46 87-010-196-080 CHIP CAPACITOR,0.1-25

C47 87-010-196-080 CHIP CAPACITOR,0.1-25

C48 87-010-315-080 C-CAP,S 27P-50 CH

C50 87-012-140-080 CAP 470P

C51 87-012-156-080 C-CAP,S 220P-50 CH

C52 87-012-140-080 CAP 470P

C53 87-010-322-080 C-CAP,S 100P-50 CH

C54 87-012-153-080 C-CAP,S 120P-50 CH

C55 87-010-263-080 CAP, ELECT 100-10V

C57 87-010-316-080 C-CAP,S 33P-50 CH

C58 87-010-316-080 C-CAP,S 33P-50 CH

C59 87-010-263-080 CAP, ELECT 100-10V

C60 87-010-196-080 CHIP CAPACITOR,0.1-25

C61 87-010-196-080 CHIP CAPACITOR,0.1-25

C62 87-A10-373-080 CAP,E 220-6.3 M SSL

C65 87-010-404-080 CAP, ELECT 4.7-50V

C66 87-010-196-080 CHIP CAPACITOR,0.1-25

C67 87-010-263-080 CAP, ELECT 100-10V

C69 87-012-154-080 C-CAP,S 150P-50 CH

C75 87-010-197-080 CAP, CHIP 0.01 DM

C76 87-A10-102-080 CAP,E 1000-10 REA

C77 87-010-197-080 CAP, CHIP 0.01 DM

C78 87-010-221-080 CAP, ELECT 470-10V

C79 87-010-263-080 CAP, ELECT 100-10V

C80 87-010-197-080 CAP, CHIP 0.01 DM

C81 87-010-405-080 CAP, ELECT 10-50V

C82 87-010-405-080 CAP, ELECT 10-50V

C83 87-010-181-080 CAP,CHIP S 1800P

C84 87-010-181-080 CAP,CHIP S 1800P

C90 87-010-196-080 CHIP CAPACITOR,0.1-25

C91 87-010-408-080 CAP, ELECT 47-50V

C92 87-010-382-080 CAP, ELECT 22-25V

C93 87-010-197-080 CAP, CHIP 0.01 DM

C94 87-010-197-080 CAP, CHIP 0.01 DM

C95 87-010-197-080 CAP, CHIP 0.01 DM

REF. NO PART NO. KANRI DESCRIPTION

NO.

C101 87-010-322-080 C-CAP,S 100P-50 CH

C102 87-010-322-080 C-CAP,S 100P-50 CH

C103 87-010-322-080 C-CAP,S 100P-50 CH

C104 87-010-322-080 C-CAP,S 100P-50 CH

C105 87-010-322-080 C-CAP,S 100P-50 CH

C110 87-010-196-080 CHIP CAPACITOR,0.1-25

CN1 87-A60-424-010 CONN,16P V TOC-B

CN2 87-A60-131-010 CONN,6P V FE

CN3 87-A60-130-010 CONN,5P V FE

CN4 87-099-719-010 CONN,30P TYK-B(X)

CN5 87-A60-133-010 CONN,8P V FE

CN6 87-A60-422-010 CONN,8P V TOC-B

CNA1 87-A60-109-010 CONN,2P V S2M-2W

L1 87-003-102-080 COIL, 10UH

L4 87-003-152-080 COIL, 100UH

L5 87-003-152-080 COIL, 100UH

SFR130 87-024-437-080 SFR100K,RH063EC

X1 87-A70-046-010 VIB,XTAL 16.934MHZ

FRONT C.B

C131 87-010-402-040 CAP,E 2.2-50 SME

C132 87-010-400-040 CAP,E 0.47-50

C151 87-010-196-080 CHIP CAPACITOR,0.1-25

C152 87-010-322-080 C-CAP,S 100P-50 CH

C201 87-012-145-080 CAP, CHIP S 270P CH

C203 87-018-149-080 CAP,TC-U 15P-50 CH

C204 87-015-785-080 CHIP CAPACITOR, 0.1FZ-25Z

C205 87-010-196-080 CHIP CAPACITOR,0.1-25

C206 87-018-209-080 CAP, CER 0.1-50V

C207 87-018-209-080 CAP, CER 0.1-50V

C231 87-010-405-040 CAP,E 10-50

C232 87-010-178-080 CHIP CAP 1000P

C241 87-010-400-040 CAP,E 0.47-50

C242 87-A10-189-040 CAP,E 220-10

C243 87-010-196-080 CHIP CAPACITOR,0.1-25

C245 87-010-378-040 CAP,E 10-16

C246 87-010-196-080 CHIP CAPACITOR,0.1-25

C247 87-010-194-080 CAP, CHIP 0.047

C249 87-018-208-080 CAP 0.047-50F

C250 87-010-198-080 CAP, CHIP 0.022

C251 87-010-263-040 CAP,E 100-10

C351 87-010-197-080 CAP, CHIP 0.01 DM

C352 87-010-197-080 CAP, CHIP 0.01 DM

C353 87-010-197-080 CAP, CHIP 0.01 DM

C354 87-010-197-080 CAP, CHIP 0.01 DM

C371 87-010-421-040 CAP,E 4.7-50 5L

C372 87-010-421-040 CAP,E 4.7-50 5L

C373 87-010-408-040 CAP,E 47-50 SME

C501 87-010-196-080 CHIP CAPACITOR,0.1-25

CN101 87-099-720-010 CONN,30P TYK-B(P)

CN102 87-099-720-010 CONN,30P TYK-B(P)

CNA401 88-802-092-420 CONN ASSY,9P

D153 87-A40-568-010 LED,L-13HD RED

D154 87-001-161-080 LED SEL2410E

D155 87-001-161-080 LED SEL2410E

D156 87-001-161-080 LED SEL2410E

D157 87-001-161-080 LED SEL2410E

D158 87-001-161-080 LED SEL2410E

D161 87-A40-276-080 LED,SML1816W UMB/GRN

D163 87-A40-276-080 LED,SML1816W UMB/GRN

D165 87-A40-276-080 LED,SML1816W UMB/GRN

D167 87-A40-276-080 LED,SML1816W UMB/GRN

D169 87-A40-276-080 LED,SML1816W UMB/GRN

FL301 8Z-CL4-621-010 FL,13-ST-36GNK

L201 87-A50-052-010 COIL,CLOCK 5.76MHZ T1

S301 87-A90-696-080 SW,TACT TS2103-03-430

S302 87-A90-696-080 SW,TACT TS2103-03-430

S303 87-A90-696-080 SW,TACT TS2103-03-430

S304 87-A90-696-080 SW,TACT TS2103-03-430

S305 87-A90-696-080 SW,TACT TS2103-03-430

S306 87-A90-696-080 SW,TACT TS2103-03-430

S307 87-A90-696-080 SW,TACT TS2103-03-430

S308 87-A90-696-080 SW,TACT TS2103-03-430

S309 87-A90-696-080 SW,TACT TS2103-03-430

11

Page 12

REF. NO PART NO. KANRI DESCRIPTION

NO.

S310 87-A90-696-080 SW,TACT TS2103-03-430

S311 87-A90-696-080 SW,TACT TS2103-03-430

S312 87-A90-696-080 SW,TACT TS2103-03-430

S321 87-A90-696-080 SW,TACT TS2103-03-430

S322 87-A90-696-080 SW,TACT TS2103-03-430

S323 87-A90-696-080 SW,TACT TS2103-03-430

S324 87-A90-696-080 SW,TACT TS2103-03-430

S325 87-A90-696-080 SW,TACT TS2103-03-430

S326 87-A90-696-080 SW,TACT TS2103-03-430

S327 87-A90-696-080 SW,TACT TS2103-03-430

S328 87-A90-696-080 SW,TACT TS2103-03-430

S329 87-A90-696-080 SW,TACT TS2103-03-430

S330 87-A90-696-080 SW,TACT TS2103-03-430

S331 87-A90-696-080 SW,TACT TS2103-03-430

S351 87-A90-085-010 SW,RTRY EC16B 24204

S352 87-A90-535-010 SW,RTRY EC16B24304

LED C.B

D181 87-001-161-080 LED SEL2410E

D182 87-002-738-080 LED,SEL2210R TP6

D183 87-001-161-080 LED SEL2410E

TUNER C.B

C701 87-010-381-080 CAP, ELECT 330-16V

C702 87-010-404-080 CAP, ELECT 4.7-50V

C703 87-012-286-080 CAP, U 0.01-25

C704 87-012-286-080 CAP, U 0.01-25

C709 87-012-195-080 C-CAP,U 100P-50CH

C711 87-010-260-080 CAP, ELECT 47-25V

C712 87-010-831-080 C-CAP,U,0.1-16F

C713 87-012-286-080 CAP, U 0.01-25

C714 87-012-286-080 CAP, U 0.01-25

C715 87-012-195-080 C-CAP,U 100P-50CH

C717 87-012-286-080 CAP, U 0.01-25

C719 87-012-286-080 CAP, U 0.01-25

C720 87-012-195-080 C-CAP,U 100P-50CH

C721 87-012-176-080 CAP 15P

C722 87-012-176-080 CAP 15P

C723 87-012-274-080 CHIP CAP,U 1000P-50B

C725 87-018-131-080 CAP, CER 1000P-50V

C727 87-010-196-080 CHIP CAPACITOR,0.1-25

C728 87-010-248-080 CAP, ELECT 220-10V

C729 87-012-274-080 CHIP CAP,U 1000P-50B

C731 87-012-286-080 CAP, U 0.01-25

C733 87-012-280-080 CAP, U 3300P-50

C734 87-012-280-080 CAP, U 3300P-50

C752 87-012-282-080 CAP, U 4700P-50

C753 87-012-195-080 C-CAP,U 100P-50CH

C755 87-012-286-080 CAP, U 0.01-25

C756 87-012-286-080 CAP, U 0.01-25

C757 87-012-188-080 C-CAP,U 47P-50 CH

C758 87-012-167-080 C-CAP,U 5P-50 CH

C761 87-010-196-080 CHIP CAPACITOR,0.1-25

C762 87-012-286-080 CAP, U 0.01-25

C763 87-010-829-080 CAP, U 0.047-16

C765 87-012-286-080 CAP, U 0.01-25

C766 87-010-197-080 CAP, CHIP 0.01 DM

C769 87-010-260-080 CAP, ELECT 47-25V

C770 87-010-829-080 CAP, U 0.047-16

C771 87-010-383-080 CAP, ELECT 33-25V

C772 87-010-829-080 CAP, U 0.047-16

C773 87-010-196-080 CHIP CAPACITOR,0.1-25

C774 87-010-263-080 CAP, ELECT 100-10V

C775 87-010-404-080 CAP, ELECT 4.7-50V

C776 87-012-286-080 CAP, U 0.01-25

C777 87-010-493-080 CAP,E 0.47-50 GAS

C778 87-010-401-080 CAP, ELECT 1-50V

C779 87-010-401-080 CAP, ELECT 1-50V

C780 87-010-196-080 CHIP CAPACITOR,0.1-25

C781 87-010-405-080 CAP, ELECT 10-50V

C782 87-010-405-080 CAP, ELECT 10-50V

C783 87-012-286-080 CAP, U 0.01-25

C784 87-012-286-080 CAP, U 0.01-25

REF. NO PART NO. KANRI DESCRIPTION

C785 87-010-405-080 CAP, ELECT 10-50V

C786 87-010-405-080 CAP, ELECT 10-50V

C787 87-012-275-080 C-CAP,U 1200P-50 B

C788 87-012-275-080 C-CAP,U 1200P-50 B

C789 87-012-275-080 C-CAP,U 1200P-50 B

C790 87-012-275-080 C-CAP,U 1200P-50 B

C791 87-010-405-080 CAP, ELECT 10-50V

C793 87-012-273-080 C-CAP,U 820P-50 B

C794 87-010-406-080 CAP, ELECT 22-50

C795 87-010-596-080 CAP, S 0.047-16

C796 87-010-403-080 CAP, ELECT 3.3-50V

C797 87-012-276-080 CAP, CHIP SS 1500 PBK

C798 87-012-276-080 CAP, CHIP SS 1500 PBK

C799 87-010-829-080 CAP, U 0.047-16

C814 87-012-286-080 CAP, U 0.01-25

C820 87-010-260-080 CAP, ELECT 47-25V

C821 87-012-286-080 CAP, U 0.01-25

C822 87-012-286-080 CAP, U 0.01-25

C823 87-012-286-080 CAP, U 0.01-25

C859 87-012-286-080 CAP, U 0.01-25<K>

C861 87-012-199-080 CAP 220P<K>

C862 87-012-199-080 CAP 220P<K>

C863 87-012-270-080 CAP, U 470P-50<K>

C864 87-010-405-080 CAP, ELECT 10-50V<K>

C865 87-010-196-080 CHIP CAPACITOR,0.1-25<K>

C866 87-010-405-080 CAP, ELECT 10-50V<K>

C867 87-012-286-080 CAP, U 0.01-25<K>

C868 87-012-184-080 C-CAP,U 33P-50 CH<K>

C869 87-012-180-080 C-CAP,U 22P-50 CH<K>

C940 87-012-286-080 CAP, U 0.01-25

C942 87-012-168-080 C-CAP,U 6P-50 CH

C947 87-012-286-080 CAP, U 0.01-25

C949 87-A10-039-080 C-CAP,U 470P-50 J CH

C952 87-012-286-080 CAP, U 0.01-25

C958 87-010-197-080 CAP, CHIP 0.01 DM

C959 87-010-831-080 C-CAP,U,0.1-16F

C962 87-010-401-080 CAP, ELECT 1-50V

CF801 87-008-423-010 CERAMIC FILTER, SFE10.7

CF802 82-785-747-010 CF MS2 GHY R

CN701 87-A60-700-010 CONN,13P H GRY TUC-P13X-C1<E>

CN701 87-A60-650-010 CONN,16P H GRY TUC-P16X-C1<K>

FFE801 A8-6ZA-191-130 6ZA-1 FEENM

J801 87-033-241-010 TERMINAL,ANT AJ-2039

L771 87-A50-266-010 COIL,FM DET-2N(TOK)

L772 87-A91-110-010 FLTR,PCFJZH-450 (TOK)

L781 87-005-847-080 COIL,2.2UH(CECS)

L791 87-A50-027-010 COIL,1 POLE MPX(TOK)

L792 87-A50-027-010 COIL,1 POLE MPX(TOK)

L832 87-005-847-080 COIL,2.2UH(CECS)

L851 87-005-847-080 COIL,2.2UH(CECS)<K>

L941 87-A50-020-010 COIL,ANT LW(COI)

L942 87-A50-019-010 COIL,OSC LW(COI)

L981 8Z-ZA1-665-010 COIL,AM PACK 2(TOK)

TC942 87-011-164-010 CAPACITOR,TRIMMER 30P

X721 87-A70-061-010 VIB,XTAL 4.500MHZ CSA-309

X851 87-A70-091-010 VIB,XTAL 4.332MHZ CSA-309<K>

MD C.B

C100 87-016-296-080 C-CAP,TN 22-4SV(A)

C101 87-016-296-080 C-CAP,TN 22-4SV(A)

C102 87-012-286-080 CAP, U 0.01-25

C103 87-010-787-080 CAP, U 0.022-25

C104 87-010-662-080 C-CAP,E 22-6.3

C105 87-010-831-080 C-CAP,U,0.1-16F

C106 87-016-462-080 C-CAP,S 1-16 F

C107 87-012-195-080 C-CAP,U 100P-50CH

C108 87-012-274-080 CHIP CAP,U 1000P-50B

C109 87-016-436-080 C-CAP,TN 47-4(B2)

C111 87-016-296-080 C-CAP,TN 22-4SV(A)

C112 87-012-286-080 CAP, U 0.01-25

C113 87-012-284-080 CAP, U 6800P-50

C114 87-010-828-080 CHIP CAPACITOR,U 0.033-25F

C115 87-A10-369-080 C-CAP,S 0.47-16 K B

NO.

12

Page 13

REF. NO PART NO. KANRI DESCRIPTION

C116 87-012-282-080 CAP, U 4700P-50

C117 87-016-462-080 C-CAP,S 1-16 F

C118 87-012-282-080 CAP, U 4700P-50

C119 87-016-491-080 C-CAP,S 0.22-16 FZ

C120 87-010-787-080 CAP, U 0.022-25

C121 87-012-286-080 CAP, U 0.01-25

C122 87-010-829-080 CAP, U 0.047-16

C123 87-012-286-080 CAP, U 0.01-25

C124 87-010-662-080 C-CAP,E 22-6.3

C125 87-010-662-080 C-CAP,E 22-6.3

C126 87-010-831-080 C-CAP,U,0.1-16F

C201 87-010-831-080 C-CAP,U,0.1-16F

C202 87-010-831-080 C-CAP,U,0.1-16F

C203 87-010-785-080 C-CAP,U0.015-25BK

C204 87-016-461-080 C-CAP,S 0.47-16F

C205 87-010-831-080 C-CAP,U,0.1-16F

C206 87-012-270-080 CAP, U 470P-50

C207 87-016-461-080 C-CAP,S 0.47-16F

C208 87-012-286-080 CAP, U 0.01-25

C209 87-010-831-080 C-CAP,U,0.1-16F

C210 87-012-172-080 CAPACITOR CHIP U 10P CH

C211 87-012-172-080 CAPACITOR CHIP U 10P CH

C212 87-012-195-080 C-CAP,U 100P-50CH

C213 87-010-662-080 C-CAP,E 22-6.3

C214 87-012-274-080 CHIP CAP,U 1000P-50B

C217 87-012-188-080 C-CAP,U 47P-50 CH

C218 87-012-172-080 CAPACITOR CHIP U 10P CH

C219 87-016-296-080 C-CAP,TN 22-4SV(A)

C220 87-010-662-080 C-CAP,E 22-6.3

C221 87-010-831-080 C-CAP,U,0.1-16F

C222 87-016-444-080 C-CAP,TN 47-10 F95E

C223 87-010-831-080 C-CAP,U,0.1-16F

C224 87-A10-685-080 C-CAP,S 470P-100 J CH

C225 87-010-831-080 C-CAP,U,0.1-16F

C226 87-010-831-080 C-CAP,U,0.1-16F

C227 87-012-274-080 CHIP CAP,U 1000P-50B

C228 87-012-274-080 CHIP CAP,U 1000P-50B

C229 87-012-274-080 CHIP CAP,U 1000P-50B

C232 87-012-274-080 CHIP CAP,U 1000P-50B

C233 87-012-274-080 CHIP CAP,U 1000P-50B

C236 87-010-831-080 C-CAP,U,0.1-16F

C300 87-010-831-080 C-CAP,U,0.1-16F

C301 87-010-831-080 C-CAP,U,0.1-16F

C302 87-010-831-080 C-CAP,U,0.1-16F

C305 87-016-462-080 C-CAP,S 1-16 F

C307 87-010-831-080 C-CAP,U,0.1-16F

C308 87-010-831-080 C-CAP,U,0.1-16F

C311 87-010-662-080 C-CAP,E 22-6.3

C312 87-012-195-080 C-CAP,U 100P-50CH

C321 87-012-274-080 CHIP CAP,U 1000P-50B

C322 87-012-274-080 CHIP CAP,U 1000P-50B

C323 87-012-274-080 CHIP CAP,U 1000P-50B

C324 87-012-274-080 CHIP CAP,U 1000P-50B

C325 87-012-274-080 CHIP CAP,U 1000P-50B

C400 87-010-831-080 C-CAP,U,0.1-16F

C401 87-010-831-080 C-CAP,U,0.1-16F

C402 87-010-831-080 C-CAP,U,0.1-16F

C403 87-010-831-080 C-CAP,U,0.1-16F

C404 87-010-831-080 C-CAP,U,0.1-16F

C405 87-010-661-080 C-CAP,E 10-16

C406 87-010-779-080 C-CAP,E 100-6.3

C407 87-012-197-080 C-CAP,U 150P-50 CH

C408 87-012-197-080 C-CAP,U 150P-50 CH

C411 87-012-271-080 CAP, U 560P-50

C412 87-012-271-080 CAP, U 560P-50

C413 87-012-197-080 C-CAP,U 150P-50 CH

C414 87-012-197-080 C-CAP,U 150P-50 CH

C417 87-012-268-080 C-CAP,U 330P-50 B

C418 87-012-268-080 C-CAP,U 330P-50 B

C423 87-012-286-080 CAP, U 0.01-25

C424 87-012-286-080 CAP, U 0.01-25

C429 87-012-286-080 CAP, U 0.01-25

C430 87-012-286-080 CAP, U 0.01-25

C431 87-010-779-080 C-CAP,E 100-6.3

C434 87-010-831-080 C-CAP,U,0.1-16F

NO.

REF. NO PART NO. KANRI DESCRIPTION

C501 87-010-831-080 C-CAP,U,0.1-16F

C502 87-010-831-080 C-CAP,U,0.1-16F

C503 87-010-662-080 C-CAP,E 22-6.3

C504 87-010-831-080 C-CAP,U,0.1-16F

C505 87-010-662-080 C-CAP,E 22-6.3

C506 87-010-831-080 C-CAP,U,0.1-16F

C506 87-010-831-080 C-CAP,U,0.1-16F

C507 87-010-661-080 C-CAP,E 10-16

C508 87-010-831-080 C-CAP,U,0.1-16F

C509 87-010-662-080 C-CAP,E 22-6.3

C510 87-010-831-080 C-CAP,U,0.1-16F

C510 87-010-831-080 C-CAP,U,0.1-16F

C511 87-010-661-080 C-CAP,E 10-16

C513 87-010-661-080 C-CAP,E 10-16

C514 87-010-661-080 C-CAP,E 10-16

C515 87-012-337-080 C-CAP,U 56P-50 CH

C516 87-012-337-080 C-CAP,U 56P-50 CH

C517 87-012-278-080 C-CAP,U 2200P-50 B

C518 87-012-278-080 C-CAP,U 2200P-50 B

C519 87-010-831-080 C-CAP,U,0.1-16F

C520 87-010-661-080 C-CAP,E 10-16

C521 87-010-831-080 C-CAP,U,0.1-16F

C522 87-010-661-080 C-CAP,E 10-16

C523 87-010-662-080 C-CAP,E 22-6.3

C524 87-010-662-080 C-CAP,E 22-6.3

C525 87-012-274-080 CHIP CAP,U 1000P-50B

C526 87-012-274-080 CHIP CAP,U 1000P-50B

C527 87-010-661-080 C-CAP,E 10-16

C528 87-010-661-080 C-CAP,E 10-16

C530 87-010-831-080 C-CAP,U,0.1-16F

C531 87-010-831-080 C-CAP,U,0.1-16F

C600 87-010-662-080 C-CAP,E 22-6.3

C601 87-010-779-080 C-CAP,E 100-6.3

C602 87-010-779-080 C-CAP,E 100-6.3

C603 87-010-662-080 C-CAP,E 22-6.3

C604 87-010-779-080 C-CAP,E 100-6.3

C605 87-012-286-080 CAP, U 0.01-25

C607 87-010-831-080 C-CAP,U,0.1-16F

C607 87-010-831-080 C-CAP,U,0.1-16F

C608 87-010-831-080 C-CAP,U,0.1-16F

CN400 87-A60-027-080 C-CONN,8P H WHT

CN401 87-A60-062-010 CONN,05P V 9604S-05C

FB501 87-A90-828-080 C-F-BEAD, BK1608LM182

L100 87-A50-117-080 C-COIL,10UHLQH3C

L101 87-A50-012-080 C-COIL,100UH LQH3C

L102 87-A50-117-080 C-COIL,10UHLQH3C

L103 87-A50-117-080 C-COIL,10UHLQH3C

L201 87-A50-117-080 C-COIL,10UHLQH3C

L202 87-A50-117-080 C-COIL,10UHLQH3C

L203 87-A50-116-080 C-COIL,4.7UHLQH3C

L301 87-A50-117-080 C-COIL,10UHLQH3C

L501 87-A50-116-080 C-COIL,4.7UHLQH3C

L502 87-A50-116-080 C-COIL,4.7UHLQH3C

L503 87-A50-116-080 C-COIL,4.7UHLQH3C

L504 87-005-774-080 C-COIL,4BLH

L505 87-005-774-080 C-COIL,4BLH

L611 87-A50-163-080 C-COIL,ZBFS5101-PT

L612 87-005-512-080 C-COIL,BLM21A05

L613 87-005-512-080 C-COIL,BLM21A05

L614 87-A50-163-080 C-COIL,ZBFS5101-PT

L615 87-A90-034-080 C-FLTR,EMI BLM41P750

L616 87-A50-163-080 C-COIL,ZBFS5101-PT

R423 87-025-564-080 C-RES,U M/F 47K D

R424 87-025-564-080 C-RES,U M/F 47K D

R425 87-022-583-080 C-RES,U M/F 12K D

R426 87-022-583-080 C-RES,U M/F 12K D

X200 87-A70-105-080 C-VIB,XTAL 22.5792MHZ SMD-49

X301 87-A70-100-080 C-VIB,CER 12.0MHZ PBRC-BR-A

LOAD C.B

M450 87-A90-672-010 MOT,M25E-4

SW451 87-A90-673-010 SW,MICRO ESE11SH1C

SW452 87-A90-117-010 SW,PUSH 1-1-1 MPU103

NO.

REF. NO PART NO. KANRI DESCRIPTION

NO.

MECHA C.B

SW400 87-A90-611-010 SW,PUSH 3-2-2 MPU20300MLB0

SW401 87-A90-612-010 SW,PUSH 2-1-1 MPU10371MLB1

DECK C.B

SFR1 87-024-581-010 SFR,3.3K DIA 6H KOA

SOL2 82-ZM1-618-310 SOL ASSY,27

SW2 87-036-110-010 SW,PUSH SPPB 62

SW3 87-036-110-010 SW,PUSH SPPB 62

SW4 87-036-110-010 SW,PUSH SPPB 62

SW5 87-036-110-010 SW,PUSH SPPB 62

SW6 87-A90-248-010 SW,MICRO ESE11SH

RELAY C.B

CON301 88-CE2-655-010 CONN ASSY,7P V RPH

DRIVE C.B

M20 87-045-358-019 MOT,RF-310TA 43

M21 87-045-356-019 MOT,RF-310TA 30

SW1 87-A90-042-019 SW,LEAF MSW 17310 MVPO

REF. NO PART NO. KANRI DESCRIPTION

CD MOTOR C.B

M1 87-045-305-019 MOTOR, RF-500TB

SW1 87-036-110-019 SW,PUSH SPPB 62

SW2 87-036-110-019 SW,PUSH SPPB 62

AC C.B

C101 87-010-387-080 CAP,E 470-25 SME

C103 87-016-051-090 CAP,E 2200-35 SMG

C105 87-010-403-080 CAP, ELECT 3.3-50V

CN102 87-A60-109-010 CONN,2P V S2M-2W

!

RY101 87-A90-976-010 RELAY,AC12V SDT-S-112LMR

T101 87-A60-317-010 TERMINAL, 1P MSC

T102 87-A60-317-010 TERMINAL, 1P MSC

PT C.B

!

PT102 8Z-NF8-662-010 PT,SUB ZNF-8(E)

NO.

• Regarding connectors, they are not stocked as they are not the initial order items.

The connectors are available after they are supplied from connector manufacturers upon the order is received.

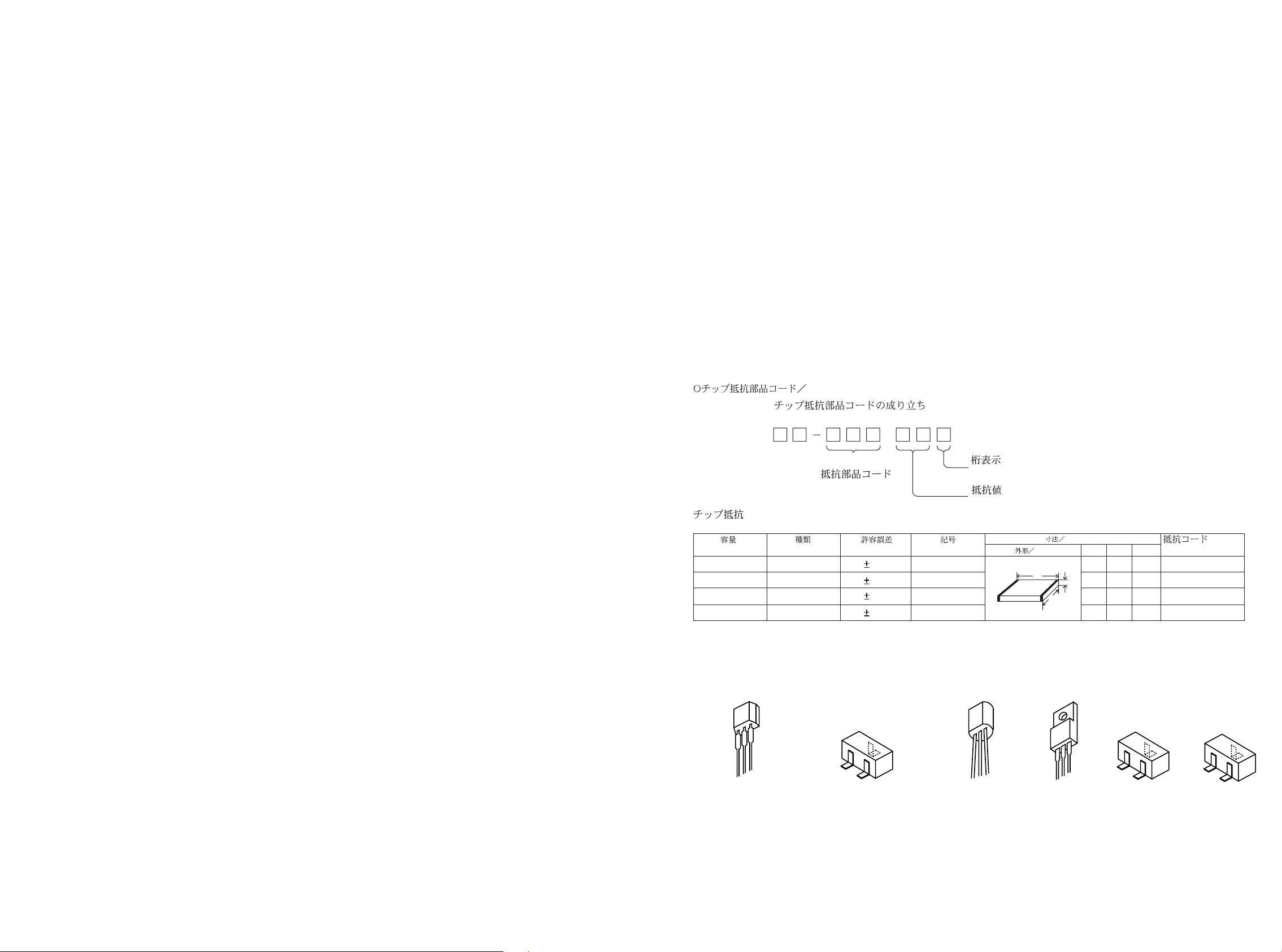

CHIP RESISTOR PART CODE

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

TRANSISTOR ILLUSTRATION

C

B

E C B

2SA933

DTC114ES

2SA1235

2SA1514

2SC2714

2SC3052

CMBT5551

DTA144TK

E

DTC114TK

KTA1298Y

RT1P141C

RT1P144C

RT1P441C

Symbol

Figure

Value of resistor

CJ

CJ

CJ

E C B

2SA1318

CC5551

CSD655E

CSB1058B

KTA1266GR

KTC3198GR

Dimensions (mm)

Form

L

W

1.0 0.5 0.35 104

t

1.6 0.8 0.45

3.2

BCE

2SB1344

2SB1370

2SC4115

2SD2025

KTC3199GR

LW t

2 1.25 0.45

0.55

1.6

D

G

2SJ461-T1

S

Resistor Code

108

118

128

G

S

2SK2158

: A

: A

D

1413

Page 14

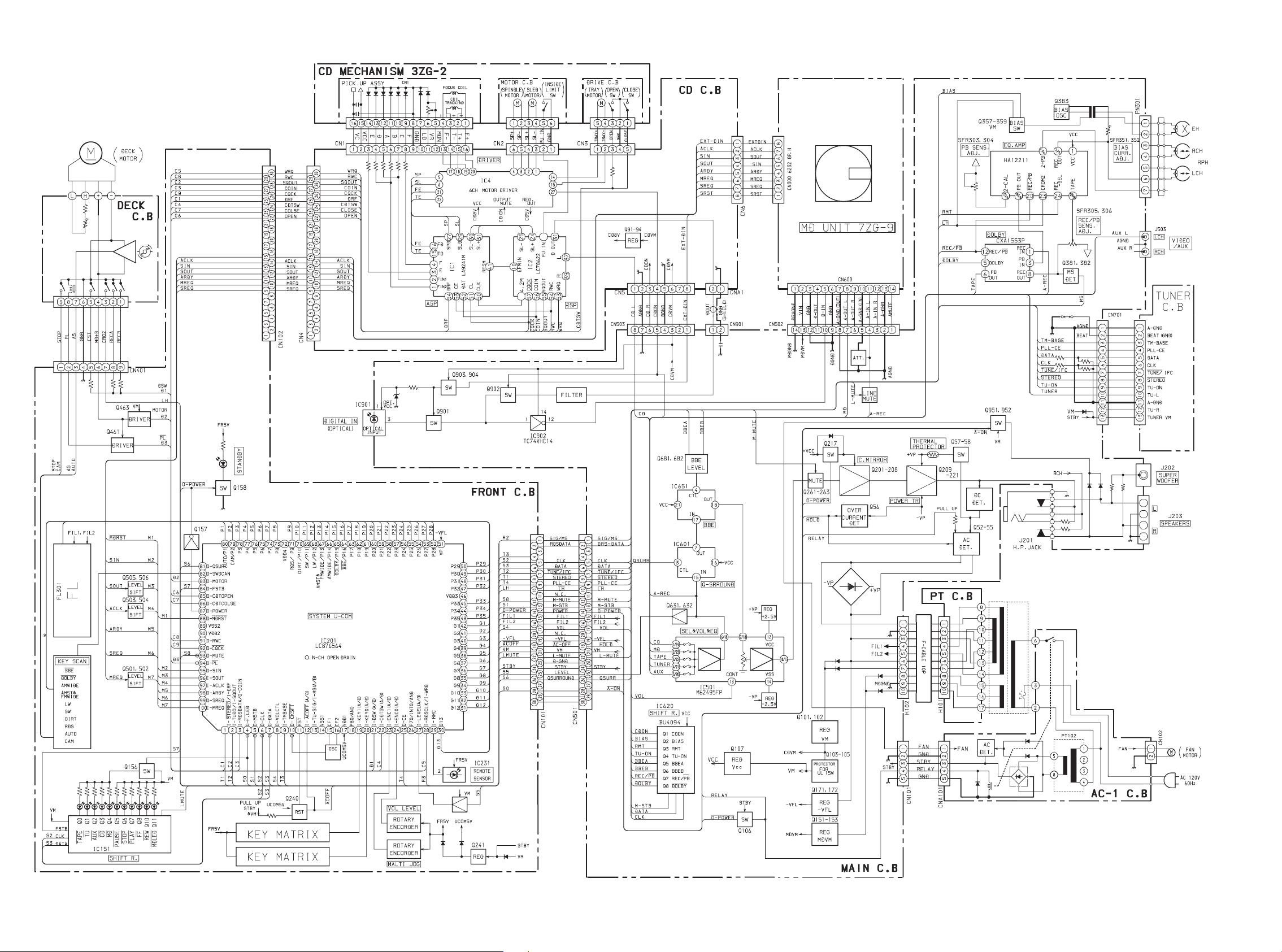

BLOCK DIAGRAM-1 (MAIN)

IC 1

SFR1

DN6851

27

61

1615

Page 15

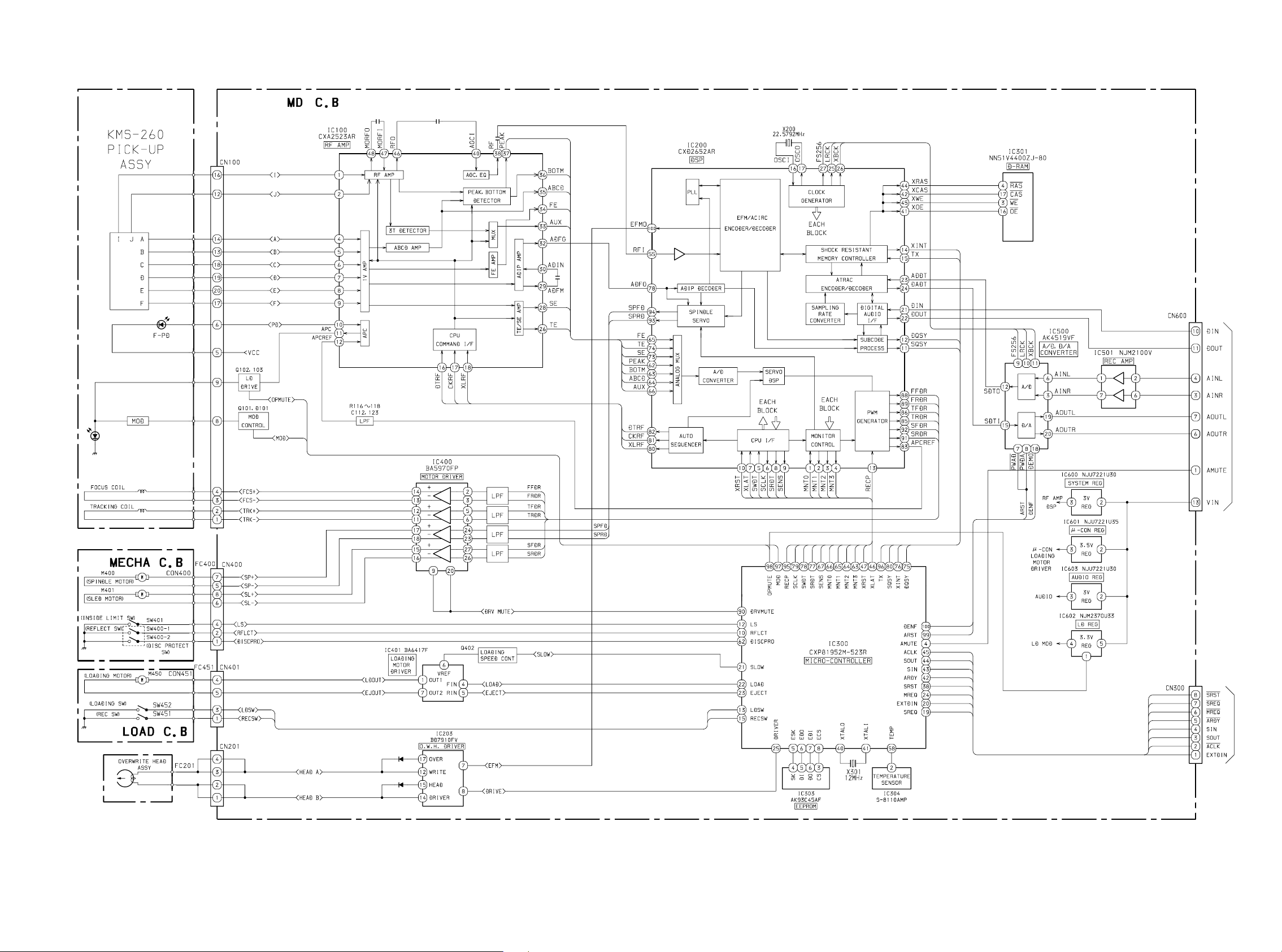

BLOCK DIAGRAM-2 (MD)

TO MAIN C.B CN502TO CD C.B CN6

1817

Page 16

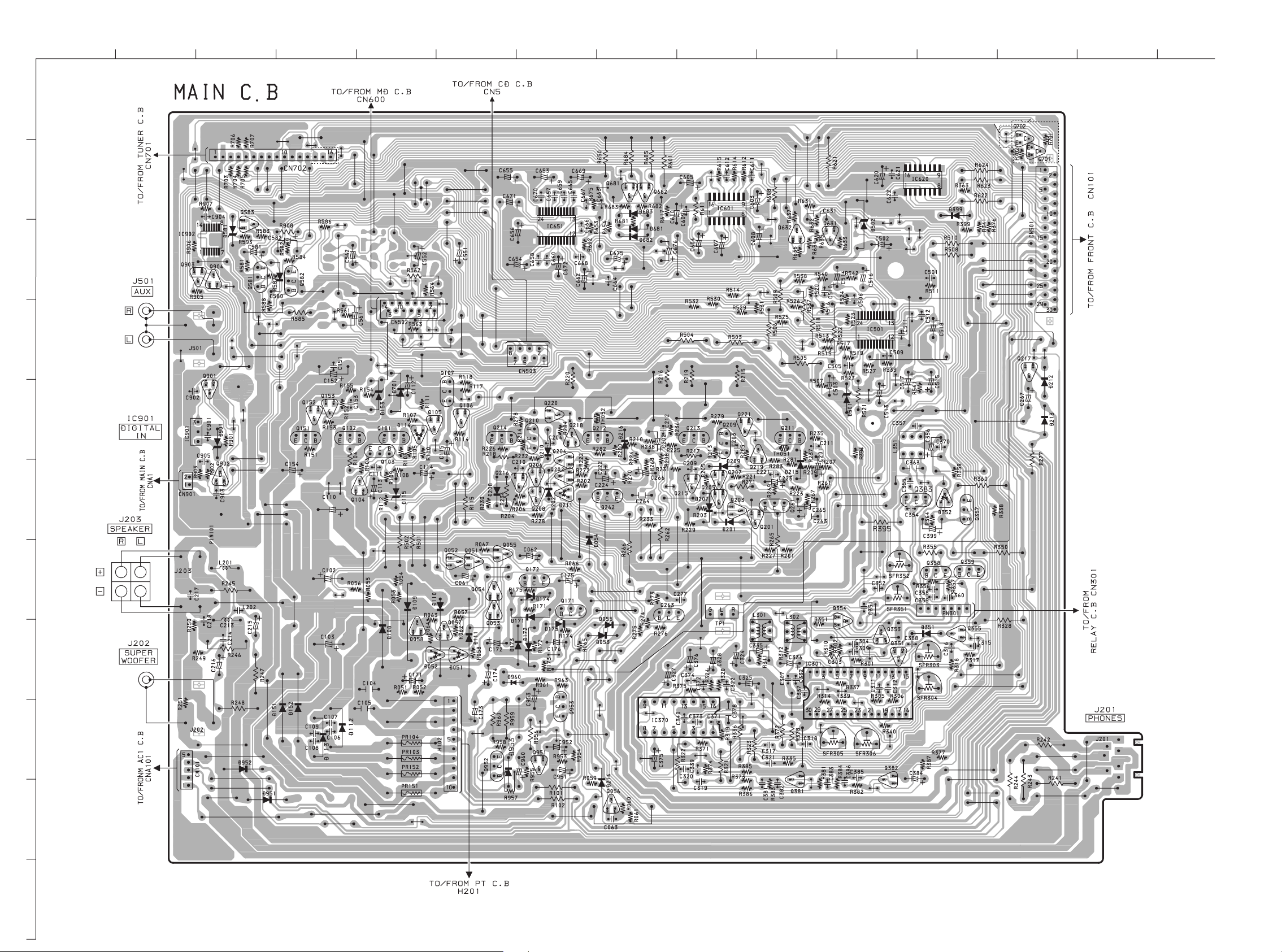

WIRING-1 (MAIN)

1

A

B

C

D

234567

EZ MODEL

1413

8

9

10

11 12 13

K MODEL

EZ MODEL

14

E

F

G

H

I

J

K

2019

Page 17

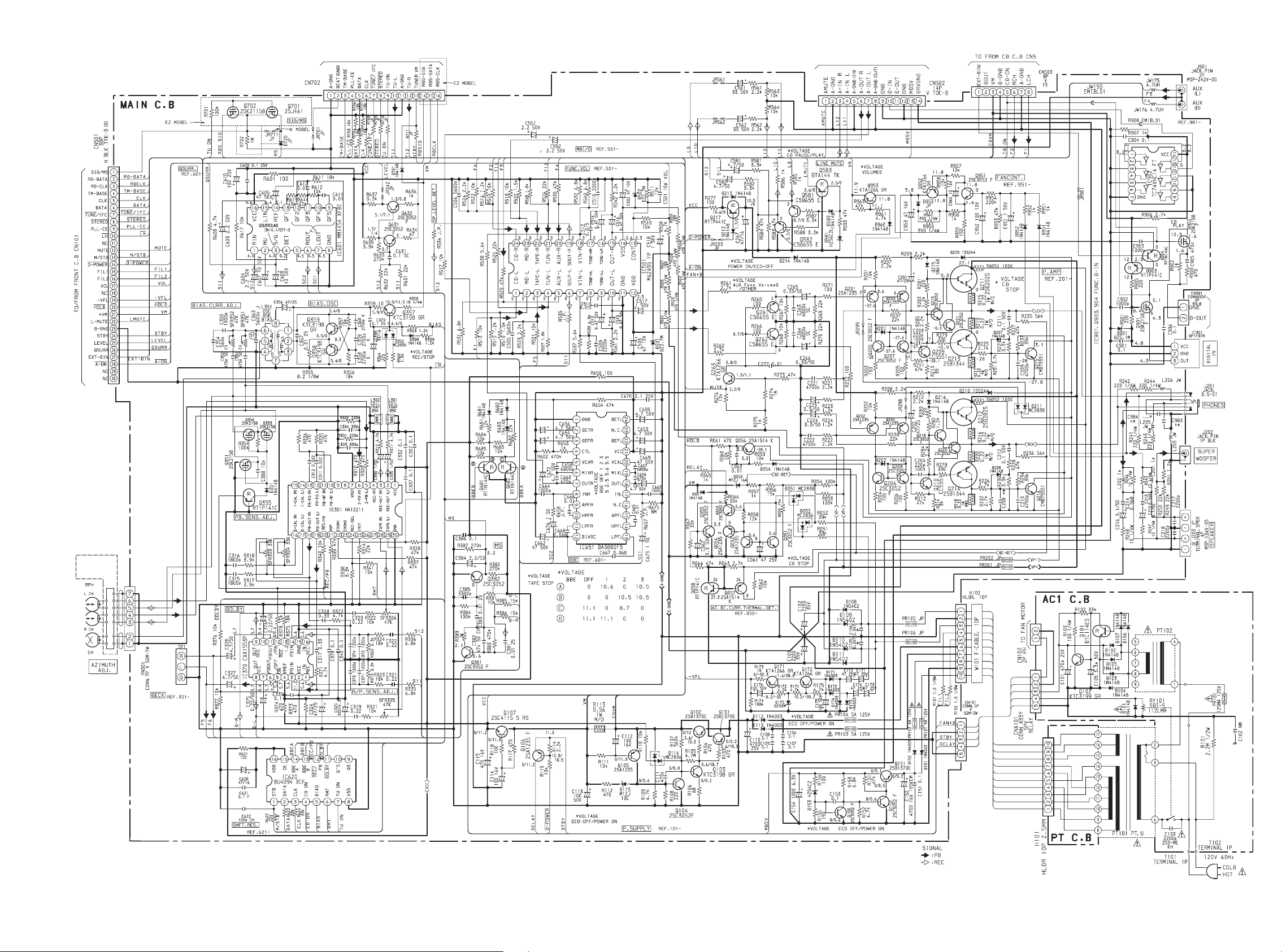

SCHEMATIC DIAGRAM-1 (MAIN)

TO FROM TUNER C.B CN701

TO/FROM MD C.B CN600

RD-DATA

CNA1

CD C.B

TO/FROM

RELAY

C.B

2221

Page 18

WIRING-2 (FRONT)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

K

2423

Page 19

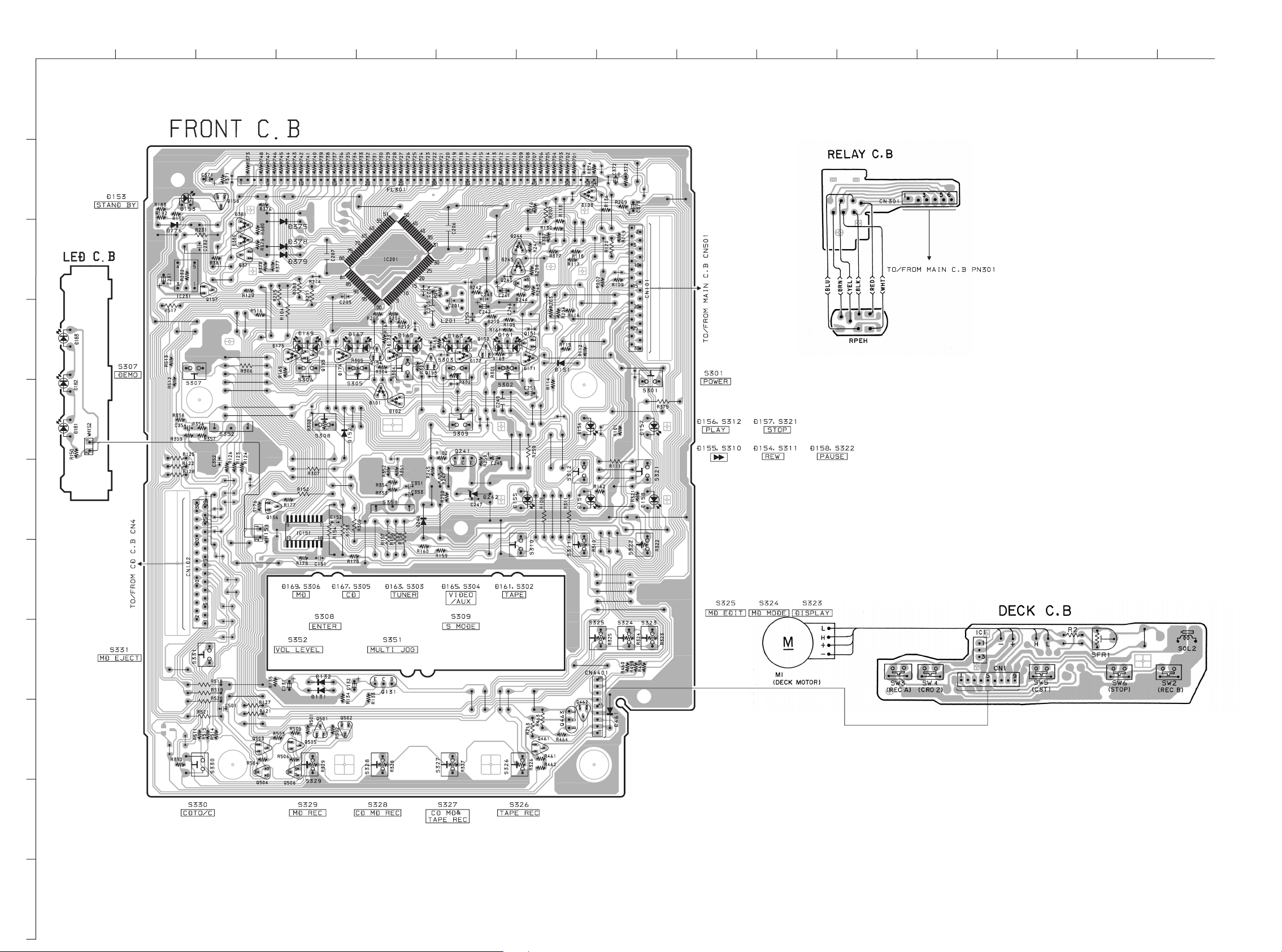

SCHEMATIC DIAGRAM-2 (FRONT)

2625

Page 20

WIRING-3 (CD)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

H

KSS-213F

I

CD PICK UP ASSY

J

K

2827

Page 21

SCHEMATIC DIAGRAM-3 (CD)

KSS-213F

3029

Page 22

WIRING-4 (MD)

7

654321

(COMPONENT SIDE)

A

A

B

B

C

C

D

D

1

2

3

456

(CONDUCTOR SIDE)

7

E

E

F

F

G

G

H

H

I

I

TO/FROM MAIN C.B

CN502

TO/FROM CD C.B

CN6

J

J

3231

Page 23

SCHEMATIC DIAGRAM-4 (MD)

TO/FROM CD C.B CN6TO/FROM MAIN C.B CN502

3433

Page 24

WIRING-5 (TUNER)

1

A

B

C

D

234567

8

9

10

11 12 13

14

J

MW / LW

E

F

G

H

I

J

K

3635

Page 25

SCHEMATIC DIAGRAM-5 (TUNER)

TO/FROM MAINC.B CN701

BUFFER

AMP

EZ MODEL

TU+B

SW

L771

DC BALLANCE /

MONO DISTORTION

ADJ

L772

MW IF ADJ

BAND SW

BAND

SW

BAND

SW

AMP

MW TRACKING

ADJ

LW TRACKING

ADJ

L941,TC942

SIGNAL

: FM

:MW/LW

LOOP

TUNER C.B

3837

Page 26

WIRING-6 (AC/PT)

1

234567

WIRING-7 (MECHA/LOAD)

1

234567

A

B

C

D

E

A

B

C

D

E

F

G

H

I

J

F

G

H

I

J

K

K

4039

Page 27

FL (13-ST-36GNK) GRID ASSIGNMENT/ANODE CONNECTION

41

Page 28

ELECTRICAL ADJUSTMENT 1/2

SFR1

1

R.P.E HEAD

DECK C.B

MAIN C.B

22

C352

TP-1

G L R

SFR305 SFR306

SFR352

TP2

SFR351

IC301

L351

6

4

SFR303

3

SFR304

42

5

Page 29

< DECK SECTION >

1. Tape Speed Adjustment

Settings: • Test tape: TTA-100

• Test point: TP1

• Adjustment location: SFR1

Method: Playback the test tape by DECK2 and adjust

SFR1 so that the frequency counter reads

3000Hz±5Hz. Check that the counter reading

in the REV mode is within the range of ±45Hz

of that in the FWD mode.

2. Azimuth Adjustment

Settings: • Test tape: TTA-300

• Test point: TP1

• Adjustment location: Head azimuth

adjustment screw

Method: Playback the 10kHz signal of the test tape and

adjust the adjustment screw so that the output

becomes the -5dB point below the maximum

reading. The adjustment must ends with the

clockwise rotation of the adjustment screw.

Perform this adjustment in both FWD and

REV directions. Fix the adjustment screw with

adhesive agent upon completion of adjustment.

3. PB Sensitivity Adjustment

Settings: • Test tape: TTA-200

• Test point: TP1

• Adjustment location:

SFR303 (Lch)

SFR304 (Rch)

Method: Play back the test tape and adjust SFRs so that

the output level of the TP1 becomes

245mV±5mV.

4. REC/PB Frequency Response Adjustment

Settings: • Test tape: TTA-602

• Test point: TP1

• Input signal: 315Hz/10kHz (LINE IN)

• Adjustment location: SFR351 (Lch)

SFR352 (Rch)

Method: Establish the record mode. Input the 315Hz

and the 10kHz signals from LINE IN with the

input level so that TP1 has the signal level of

12mV. Record the 1kHz and the 10kHz

signals, then play them back. Adjust SFR so

that the output difference between the 315Hz

and the 10kHz signals becomes 0dB±0.5dB.

5. REC/PB Sensitivity Adjustment

Settings: • Test tape: TTA-602

• Test point: TP1

• Input signal: 1kHz /10kHz (LINE IN)

• Adjustment location: SFR305 (Lch)

SFR306 (Rch)

Method: Establish the record mode. Input the 1kHz

signal from LINE IN with the input level so

that TP1 has the signal level of 12mV. Record

the 1kHz signal, then play it back. Adjust

SFR so that the output level becomes

12mV±0.5dB.

6. Bias OSC Frequency Adjustment

Settings: • Test tape: TTA-601

• Test point: TP2

• Adjustment location: L351

Method: Set to the REC mode. Adjust L351 so that the

frequency at TP2 is 85.0kHz±1kHz.

PRACTICAL SERVICE FIGURE

< DECK SECTION >

Tape speed: 3000Hz±5.0%

Wow & flutter: Less than 0.21%

(W.R.M.S)

Distortion (REC/PB): Less than 2%

(NORM, CrO2)

Noise level (PB): Less than 50mV

(DOLBY NR OFF, NORM)

Less than 35mV

(DOLBY NR ON, CrO

Test tape: NORMAL TTA-100

TTA-300

TTA-601

TTA-602

2 TTA-200

CrO

2)

43

Page 30

ELECTRICAL ADJUSTMENT 2/2

TP4

8

L771

R785

IC771

TP3

3

L772

TP1

4

FFE801

L942

TUNER C.B

L941TC942

7

30

7

TP2

L981

4

6

TP6

GND

12 11 10

TP5

CN701

44

Page 31

< TUNER SECTION >

1. Clock Frequency Check

Settings: • Test point: TP2 (CLK IC770 pin30)

Method: Set to MW 1602kHz and check that the test

point becomes 2052kHz±45Hz (EZ).

2. MW VT Check

Settings: • Test point: TP1 (VT)

Method: Set to MW 1602kHz and check that the test

point is less than 8.0V.

Then set to MW 531kHz and check that the

test point is more than 0.6V.

3. MW IF Adjustment

Settings: • Test point: TP5, TP6

L772 .............................................. 450kHz

PRACTICAL SERVICE FIGURE

< TUNER SECTION >

< FM SECTION >

IHF Sensitiviy: Less than 13dB

(THD 3%) (at 108.0/98.0MHz)

Less than 14dB

(at 98.0MHz)

Distortion: Less than 1.2% (98.0MHz)

Stereo separation: More than 12dB (98.0MHz)

Intermediate frequency: 10.7MHz

< MW SECTION >

Sensitivity: Less than 60dB (at 600kHz)

(S/N 20dB) Less than 58dB

(at 1000/1400kHz)

Distortion: Less than 1.5%

(at 1000kHz)

4. MW Tracking Adjustment

Settings: • Test point: TP5, TP6

• Adjustment location: L981

Method: Set to MW 999kHz and adjust L981 so that the

test point becomes maximum.

5. FM VT Check

Settings: • Test point: TP1 (VT)

Method: Set to FM 87.5MHz, 108.0MHz and check that

the test point is more than 0.5V (87.5MHz) and

less than 8.0V (108.0MHz).

6. LW VT Adjustment

Settings: • Test point: TP2 (VT)

• Adjustment location: L942

Method: Set to LW 144kHz and adjust L942 so that the

test point becomes 1.3V±0.05V.

Then set to LW 290kHz and check that the test

point is less than 8.0V.

7. LW Tracking Adjustment

Settings: • Test point: TP5, TP6

• Adjustment location:

L941 .............................................. 144kHz

TC942 ........................................... 290kHz

Method: Set up TC942 to center before adjustment.

The level at 144kHz is adjusted to MAX by

L941. Then the level at 290kHz is adjusted to

MAX by TC942.

< LW SECTION >

Sensitivity: Less than 70dB (at 144kHz)

Less than 68dB (at 198kHz)

Less than 66dB (at 290kHz)

8. DC Balance/Mono Distortion Adjustment

Settings: • Test point: TP3, TP4

• Adjustment location: L771

• Input level: 54dB

Method: Set to FM 98.0MHz and adjust L771 so that

the voltage between TP3 and TP4 becomes

0V±0.04V.

Next, check that the distortion is less than

1.3%.

45

Page 32

IC DESCRIPTION

IC, LA9241ML

Pin No. Pin Name I/O Description

1

2

FIN2

FIN1

Pin to which external pickup photo diode is connected. RF signal is created by adding

I

with the FIN1 pin signal. FE signal is created by subtracting from the FIN1 pin signal.

I

Pin to which external pickup photo diode is connected.

10

11

12

13

14

15

16

17

3

4

5

6

7

8

9

E

F

TB

TE–

TE

TESI

SCI

TH

TA

TD–

TD

JP

TO

FD

FD–

Pin to which external pickup photo diode is connected. TE signal is created by

I

subtracting from the F pin signal.

I

Pin to which external pickup photo diode is connected.

I

DC component of the TE signal is input.

I

Pin to which external resistor setting the TE signal gain is connected between the TE pin.

O

TE signal output pin.

TES “Track Error Sense” comparator input pin. TE signal is passed through a band-

I

pass filter then input.

I

Shock detection signal input pin.

I

Tracking gain time constant setting pin.

O

TA amplifier output pin.

Pin to which external tracking phase compensation constants are connected between

I

the TD and VR pins.

I

Tracking phase compensation setting pin.

I

Tracking jump signal (kick pulse) amplitude setting pin.

O

Tracking control signal output pin.

O

Focusing control signal output pin.

Pin to which external focusing phase compensation constants are connected between

I

the FD and FA pins.

18

19

20

21

22

23

24

25

26

27

28

29

30, 31

32, 33

34

FA

FA–

FE

FE–

AGND

NC

SP

SPG

SP–

SPD

SLEQ

SLD

SL–, SL+

JP–, JP+

TGL

—

—

Pin to which external focusing phase compensation constants are connected between

I

the FD– and FA– pins.

Pin to which external focusing phase compensation constants are connected between

I

the FA and FE pins.

O

FE signal output pin.

I

Pin to which external FE signal gain setting resistor is connected between the FE pin.

Analog signal GND.

No connection.

O

Single ended output of the CV+ and CV– pin input signal.

I

Pin to which external spindle gain setting resistor in 12 cm mode is connected.

Pin to which external spindle phase compensation constants are connected together

I

with SPD pin.

O

Spindle control signal output pin.

I

Pin to which external sled phase compensation constants are connected.

O

Sled control signal output pin.

I

Sled advance signal input pin from microprocessor.

I

Tracking jump signal input pin from DSP.

I

Tracking gain control signal input from DSP. Low gain when TGL = H.

35

TOFF

I

Tracking off control signal input pin from DSP. Off when TOFF = H.

46

Page 33

Pin No. Pin Name I/O Description

36

TES

O

Pin from which TES signal is output to DSP.

37

38

39, 40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

HFL

SLOF

CV–, CV+

RFSM

RFS–

SLC

SLI

DGND

FSC

TBC

NC

DEF

CLK

CL

DAT

CE

DRF

FSS

—

—

“High Frequency Level” is used to judge whether the main beam position is on top of

O

bit or on top of mirror.

I

Sled servo off control input pin.

I

CLV error signal input pin from DSP.

O

RF output pin.

RF gain setting and EFM signal 3T compensation constant setting pin together with

I

RFSM pin.

“Slice Level Control” is the output pin which controls the RF signal data slice level by

O

DSP.

I

Input pin which control the data slice level by the DSP.

Digital system GND.

O

Output pin to which external focus search smoothing capacitor is connected.

I

“Tracking Balance Control” EF balance variable range setting pin.

No connection.

O

Disc defect detector output pin.

I

Reference clock input pin. 4.23 MHz of the DSP is input.

I

Microprocessor command clock input pin.

I

Microprocessor command data input pin.

I

Microprocessor command chip enable input pin.

O

“Detect RF” RF level detector output.

I

“Focus Search Select” focus search mode (± search/+ search) select pin.

56

57

58

59

60

61

62

63

64

VCC2

REFI

VR

LF2

PH1

BH1

LDD

LDS

VCC1

—

—

—

Servo system and digital system Vcc pin.

Pin to which external bypass capacitor for reference voltage is connected.

O

Reference voltage output pin.

I

Disc defect detector time constant setting pin.

I

Pin to which external capacitor for RF signal peak holding is connected.

I

Pin to which external capacitor for RF signal bottom holding is connected.

O

APC circuit output pin.

I

APC circuit input pin.

RF system Vcc pin.

47

Page 34

IC, LC78622ED

Pin No. Pin Name I/O Description

1

2

3

4

5

DEFI

TAI

PDO

VVSS

ISET

—

I

Defect sense signal (DEF) input pin. (Connect to 0V when not used).

I

O

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

Phase comparator output pin to control external VCO.

GND pin for built-in VCO. Be sure to connect to 0V.

For PLL.

I

Pin to which external resistor adjusting the PD0 output current.

6

7

8

9

10

11

12, 13

14

15

16

17

18

19, 20

21

22

23

24-28

29

VVDD

FR

VSS

EFMO

EFMIN

TEST2

CLV+, CLV–

___

V/P

HFL

TES

TOFF

TGL

JP+, JP–

PCK

FSEQ

VDD

SL+ - PUIN

EMPH

—

—

O

O

O

O

O

O

O

O

—

I/O

O

Power supply pin for built-in VCO.

I

Pin for VCO frequency range adjustment.

Digital system GND. Be sure to connect to 0V.

EFM signal output pin.

For slice level control.

I

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

EFM signal input pin.

Disc motor control output. Three level output is possible using command.

Rough servo or phase control automatic selection monitoring output pin. Rough servo

at H. Phase servo at L.

I

Track detect signal input pin. Schmidt input.

I

Tracking error signal input pin. Schmidt input.

Tracking OFF output pin.

Tracking gain selection output pin. Gain boost at L.

Track jump control signal output pin. Three level output is possible using command.

EFM data playback clock monitoring pin 4.3218 MHz when phase is locked in.

Sync signal detection output pin. H when the sync signal which is detected from EFM

signal and thesync signal which is internally generated agree.

Digital system power supply pin.

The pin is controlled by the serial data

command from microprocessor. When

General purpose input/output pin 1 to 5.

the pin is not used, set the pin to the input

terminal and connect to 0V, or alternately

set the pin to output terminal and leave

the pin open.

De-emphasis monitor output pin. De-emphasis disc is being played back at H.

30

31

32, 33

34

35

36

37

38

39

40

41

42

C2F

DOUT

TEST3, TEST4

N.C.

MUTEL

LVDD

LCHO

LVSS

RVSS

RCHO

RVDD

MUTER

—

—

—

—

—

O

C2 flag output pin.

O

DIGITAL OUT output pin. (EIAJ format).

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

Not used. Set the pin to open.

O

L-channel 1-bit DAC.

O

L-channel mute output pin.

L-channel power supply pin.

L-channel output pin.

L-channel GND. Be sure to connect to 0V.

R-channel GND. Be sure to connect to 0V.

O

R-channel output pin.

R-channel 1-bit DAC.

R-channel power supply pin.

O

R-channel mute output pin.

48

Page 35

Pin No. Pin Name I/O Description

43

44

45

46

47

XVDD

XOUT

XIN

XVSS

SBSY

—

—

Crystal oscillator power supply pin.

O

Pin to which external 16.9344 MHz crystal oscillator is connected.

I

Crystal oscillator GND pin. Be sure to connect to 0V.

O

Subcode block sync signal output pin.

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

EFLG

PW

SFSY

SBCK

FSX

WRQ

RWC

SQOUT

COIN

___________

CQCK

________

RES

TST11

16M

4.2M

TEST5

______

CS

TEST1

O

C1, C2, single and dual correction monitoring pin.

O

Subcode P, Q, R, S, T, U and W output pin.

O

Subcode frame sync signal output pin. Falls down when subcode enters standby.

Subcode read clock input pin. Schmidt input. (Be sure to connected to 0V when not in

I

use.)

Pin outputting the 7.35 kHz sync signal which is generated by dividing frequency of

O

crystal oscillator.

O

Subcode Q output standby output pin.

I

Read/write control input pin. Schmidt input.

O

Subcode Q output pin.

I

Command input pin from microprocessor.

I

Command input read clock or subcode read input clock from SQOUT pin

I

LC78622 reset input pin. Set this pin to L once when the main power is turned on.

O

Test signal output pin. Use this pin as open (normally L output).

O

16.9344 MHz output pin.

O

4.2336 MHz output pin.

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

Chip select signal input pin with built-in pull-down resistor. Be sure to connect to 0V

I

while it is not controlling.

I

Test signal input pin without built-in pull-down resistor. Be sure to connect to 0V.

Note: The same potential must be applied to the respective power supply terminals. (VDD, VVDD, LVDD, RVDD, XVDD)

49

Page 36

IC, LC87F65C8A

Pin No. Pin Name I/O Description

1

_______________

I-STEREO/DRF

I

Connected to stereo detection and tuner CD ASP LA9240ML pin-54 DRF.

Connected to tuner PLL IC LC72131 pin-6 DO and connected to CD DSP

2

I-TUDO/I-SQOUT

I

LC78622ED pin-55 DAT.

3

I-RDSDATA/O-COIN

Connected to RDS data input CD DSP LC78622ED pin-56 COIN and CD ASP

I

LA9240ML pin-52 DAT.

4

5

6

___________

O-F.LED

O-M.STB

O-CLK

O

Function LED control output.

O

Connected to main shift resistor 4094 pin-1 STB.

Connected to front shift resistor BU2092 pin-3 CLK, main shift resistor 4094 pin-3

O

CLK, and tuner PLL IC LC72131 pin-5 CL.

7

O-DATA

Connected to front shift resistor BU2092 pin-2 DATA, main shift resistor 4094 pin-

O

2 DATA, and tuner PLL IC LC72131 pin-4 DI.

8

9

10

11

12

13

O-VOLCTL

I-TMBASE

_____________

O-CKSFT

RESET

I-ACOFF

I-TU-SIG/I-MS

O

O

I/O

Connected to VOL/P.EQ IC M62439SP pin-! CONT.

I

Reference clock input for clock PLL IC LC72131 pin-7.

Clock shift output is shifted: “L”

Microprocessor reset.

I

Hold status detection.

I

RDS signal level AD value input, and CD ASP LA9240ML pin-52 DAT.

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30-42

43-45

46

VSS

CF1

CF2

VDD1

N.C

I-KEY1

I-KEY0

I-DSW

I-CDTSW

I-ENC1

I-ENC0

O-CE

N.C.

I-LEVEL

I-RD-CLK/I-WQR

I-RMT

T0-T12

S13-S15

VDD3

—

—

—

—

—

—

—

GND.

Connected to 5.76 MHz oscillator

Connected to 5.76 MHz oscillator.

Microprocessor power supply. (µ-com 5 V)

Not connected.

I

Key AD value input.

I

Key AD value input.

I

Deck MECA status detection input. (AD)

I

CD tray OPEN/CLOSE status detection input. (AD)

I

AD value input from multiple jog rotary encoder outputs A and B.

I

Electronic VOL’s AD value input from rotary encoder outputs A and B.

O

Connected to tuner PLL IC LC72131 pin-3 CE.

Not connected.

I

Level meter input.

I

Connected to RDS CLK input and CD DSP LC78622ED pin-53 WRQ.

I

Remote control input.

O

FL tube grid output. (13G-1G)

O

FL tube anode output. (P35-P33)

Microprocessor power supply. (µ-com 5 V)

47-50

51

52-63

64

65

S16-S19

VP

S20-S31

________

S32/BBE

______________

S33/DOLBY

—

O

FL tube anode output. (P32-P29)

Connected to minus power supply for FL, -VFL.

O

FL tube anode output. (P28-P17)

O

FL tube anode output (P16), and INT.DIODE MATRIX input.

O

FL tube anode output (P15), and INT.DIODE MATRIX input.

50

Page 37

Pin No. Pin Name I/O Description

66

67

68

S34/AM10k

S35/FMWIDE&AMST

S36/LW

FL tube anode output (P14), and INT.DIODE MATRIX input.

O

FL tube anode output (P13), and INT.DIODE MATRIX input.

O

FL tube anode output (P12), and INT.DIODE MATRIX input.

O

69

70

71

72

73-78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

S37/SW

S38/OIRT

S39/RDS

VDD4

S40-S45

S46/CAM

S47/AUTO

O-QSURR

O-SWSCAN

O-MOTOR

O-FSTB

O-CDOPEN

O-CDCLOSE

O-P.ON

______________

O-MDRST

VSS2

VDD2

O-RWC

___________

O-CQCK

—

—

—

FL tube anode output (P11), and INT.DIODE MATRIX input.

O

FL tube anode output (P10), and INT.DIODE MATRIX input.

O

FL tube anode output (P9), and INT.DIODE MATRIX input.

O

Microprocessor power supply. (µ-com 5 V)

FL tube anode output. (P8-P3)/SHOP

O

(P2)/deck mechanism status detection input. (CAM)

O

(P1)/deck mechanism status detection input. (AUTO)

O

Q-surround IC control output.

O

Key scan detection timing switch.

O

Deck mechanism motor control output.

O

Connected to front shift resistor IC BU2092 pin-5.

O

CD tray open control output.

O

CD tray close control output.

O

Power supply ON/OFF control.

O

MD unit 7ZG-9A reset signal output.

O

GND.

Microprocessor power supply. (µ-com 5 V)

Connected to CD DSP LC78622ED pin-54 RWC and CD ASP LA9240ML pin-53 CE.

O

___________

Connected to CD DSP LC78622ED pin-57 CQCK and CD ASP LA9240ML pin-51

O

CL.

93

94

95

96

97

98

99

100

O-MUTE

_____

O-PL

O-SIN

I-SOUL

I-ACLK

O-ARDY

O-SREQ

O-MREQ

Main mute output.

O

Deck mechanism plunger solenoid control output.

O

MD unit control serial data output.

O

MD unit control serial data input.

I

MD unit control serial data input.

I

MD unit control serial data send/receive ready output.

O

MD unit control serial data transfer request .

O

MD unit control serial data transfer request.

O

51

Page 38

IC, CXD2652AR

Pin No. Pin Name I/O Description

1

2

3

MNT0

MNT1

MNT2

Monitor output terminal.

O

Monitor output terminal.

O

Monitor output terminal.

O

10

11

12

13

14

15

16

17

18

19

20

21

22

4

5

6

7

8

9

MNT3

SWDT

SCLK

XLAT

SRDT

SENS

XRST

SQSY

DQSY

RECP

XINT

TX

OSCI

OSCO

XTSL

NC

DVSS

DIN

DOUT

—

—

Monitor output terminal.

O

Microprocessor serial interface data input.

I

Microprocessor serial interface shift clock input.

I

Microprocessor serial interface latch input. Latched at falling down edge.

I

Microprocessor serial interface data output.

O

The terminal which outputs internal status in accordance with the address of the

O

microprocessor serial interface.

Reset input. L: reset.

I

Disc sub code Q sync/ADIP sync output.

O

Subcode Q sync output of U-bit CD or MD format when the DIGITAL IN source is

O

CD or MD.

Laser power selection input. H: Recording power, L: Playback power.

I

Interrupt request output terminal. L is output when interrupt status is generated.

O

Record data output enable signal input terminal. H: enable.

I

Crystal oscillator circuit input terminal.

I

Crystal oscillator circuit output terminal. (Inverted output of OSCI).

O

OSCI terminal input frequency selection. H: 512 Fs (22.5792 MHz), L: 1024 Fs

I

(45.1584 MHz).

Not connected.

Digital GND.

Digital audio interface signal input.

I

Digital audio interface signal output.

O

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

ADDT

DADT

LRCK

XBCK

FS256

DVDD

A03

A02

A01

A00

A10

A04

A05

A06

A07

—

Analog recording signal input terminal. (External A/D converter output is connected to

I

this terminal).

RECORD monitor output/decode audio data output.

O

LRCK (44.1 kHz) output terminal to external audio block.

O

Bit clock output (2.8224 kHz) output terminal to external audio block.

O

256 Fs output. (11.2896 MHz).

O

Digital power supply.

Address output to external DRAM.

O

Address output to external DRAM.

O

Address output to external DRAM.

O

Address output to external DRAM.

O

Address output to external DRAM. (Not used).

O

Address output to external DRAM.

O

Address output to external DRAM.

O

Address output to external DRAM.

O

Address output to external DRAM.

O

52

Page 39

Pin No. Pin Name I/O Description

38

39

40

A08

A11

DVSS

—

O

Address output to external DRAM.

O

Address output to external DRAM. (Not used).

Digital GND.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

XOE

XCAS

A09

XRAS

XWE

D1

D0

D2

D3

MVCI

ASYO

ASYI

AVDD

BIAS

RFI

AVss

PDO

O

O

O

O

O

I/O

I/O

I/O

I/O

O

—

—

O