Page 1

XR-M88

K(S)

XR-M89

EZ(S)

SERVICE MANUAL

COMPACT DISC STEREO SYSTEM

SYSTEM

XR-M88

XR-M89 RX-LM89 FD-LM89 SX-LM200

This Service Manual is the “Revision Publishing” and replaces “Simple Manual”

(S/M Code No.09-996-333-3T2)

RECEIVER

RX-LM88

.

• BASIC TAPE MECHANISM : TN-708C-128R

• BASIC CD MECHANISM : KSM-620AAA

CD/

CASSETTE

FD-LM88

SPEAKER

SX-LM200

S/M Code No. 09-996-333-3R2

REVISION

DATA

Page 2

TABLE OF CONTENTS

SPECIFICATIONS................................................................................................................................... 3

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING................................................. 4

Precaution to replace Optical block......................................................................................................... 4

MODEL NO. RX-LM88/RX-LM89

ELECTRICAL MAIN PARTS LIST........................................................................................................ 5-7

TRANSISTOR ILLUSTRATION............................................................................................................... 7

FL (13-ST-36GNAK) GRID ASSIGNMENT/ANODE CONNECTION ...................................................... 8

WIRING-1 (POWER AMP)................................................................................................................ 9, 10

SCHEMATIC DIAGRAM-1 (POWER AMP)..................................................................................... 11, 12

WIRING-2 (FRONT)........................................................................................................................ 13, 14

SCHEMATIC DIAGRAM-2 (FRONT)............................................................................................... 15, 16

WIRING-3 (TUNER)........................................................................................................................ 17, 18

SCHEMATIC DIAGRAM-3 (TUNER)............................................................................................... 19, 20

ELECTRICAL ADJUSTMENT/PRACTICAL SERVICE FIGURE .................................................... 21, 22

IC DESCRIPTION........................................................................................................................... 23, 24

IC BLOCK DIAGRAM............................................................................................................................ 25

MECHANICAL EXPLODED VIEW 1/1.................................................................................................. 26

MECHANICAL PARTS LIST 1/1............................................................................................................ 27

MODEL NO. FD-LM88/FD-LM89

DISASSEMBLY INSTRUCTIONS .................................................................................................... 28-32

ELECTRICAL MAIN PARTS LIST.................................................................................................... 33-35

TRANSISTOR ILLUSTRATION............................................................................................................. 36

WIRING-1 (CD) ................................................................................................................................ 37-40

SCHEMATIC DIAGRAM-1 (CD 1/2)................................................................................................ 41, 42

SCHEMATIC DIAGRAM-2 (CD 2/2)................................................................................................ 43, 44

WIRING-2 (TAPE) ........................................................................................................................... 45, 46

WIRING-3 (KEY) ............................................................................................................................. 47, 48

WIRING-4 (FUNC) .......................................................................................................................... 49, 50

SCHEMATIC DIAGRAM-3 (TAPE/FUNC/KEY) ............................................................................... 51, 52

TEST MODE ......................................................................................................................................... 53

ELECTRICAL ADJUSTMENT......................................................................................................... 54, 55

IC DESCRIPTION............................................................................................................................ 56-61

IC BLOCK DIAGRAM............................................................................................................................ 62

MECHANICAL EXPLODED VIEW 1/1.................................................................................................. 63

MECHANICAL PARTS LIST 1/1............................................................................................................ 64

TAPE MECHANISM EXPLODED VIEW 1/1.......................................................................................... 65

TAPE MECHANISM PARTS LIST 1/1 ...................................................................................................66

CD MECHANISM EXPLODED VIEW 1/1 ............................................................................................. 67

CD MECHANISM PARTS LIST 1/1....................................................................................................... 67

MODEL NO. SX-LM200

SPEAKER DISASSEMBLY INSTRUCTIONS ....................................................................................... 68

SPEAKER PARTS LIST 1/1 .................................................................................................................. 69

ACCESSORIES/PACKAGE LIST.......................................................................................................... 69

2

Page 3

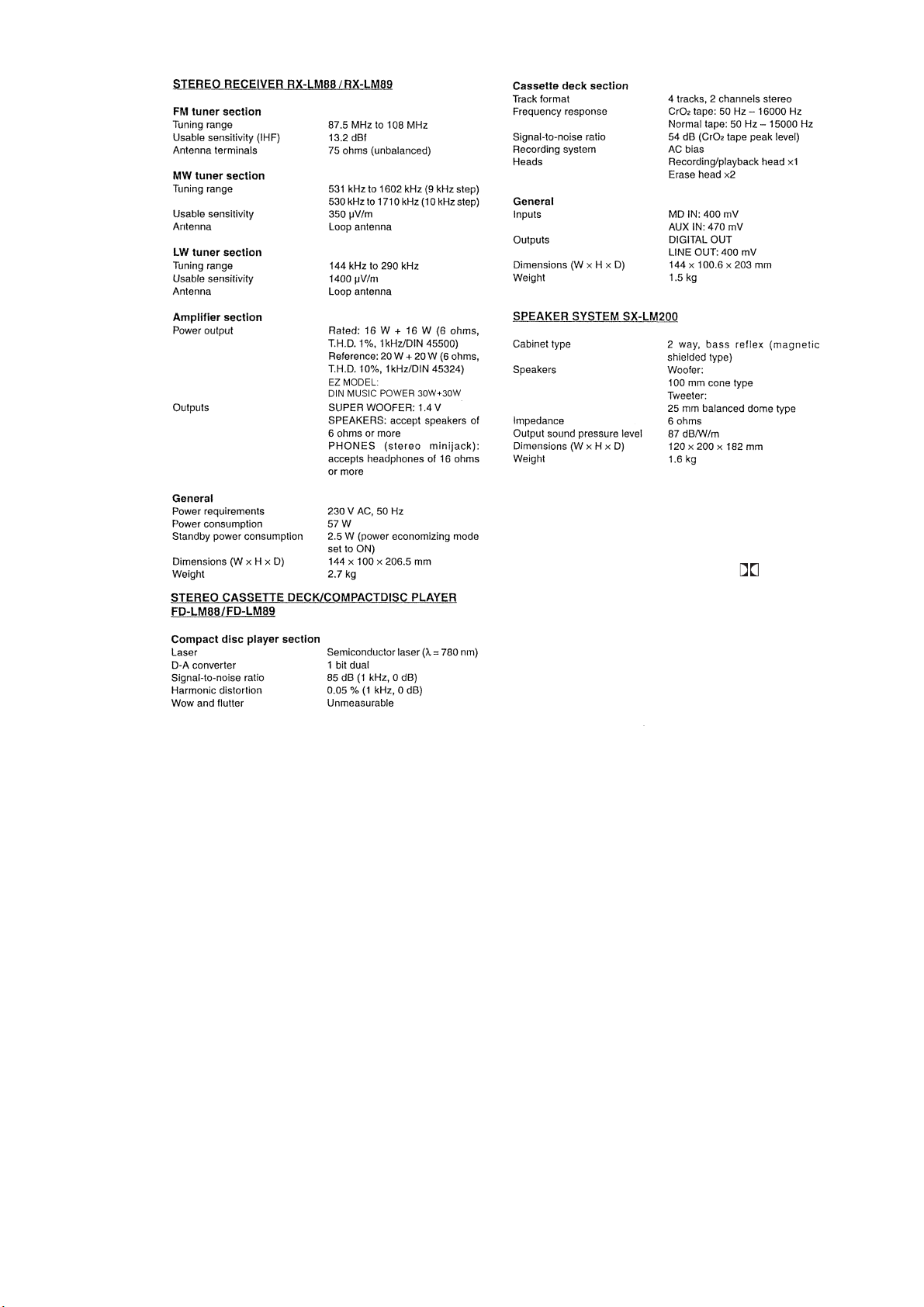

SPECIFICATIONS

Design and specifications are subject to change without

•

notice.

Dolby noise reduction manufactured under license from

•

Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol

of Dolby Laboratories Licensing Corporation.

The word “BBE” and the “BBE symbol” are trademarks

•

of BBE Sound,Inc.

Under license from BBE Sound,Inc.

are trademarks

3

Page 4

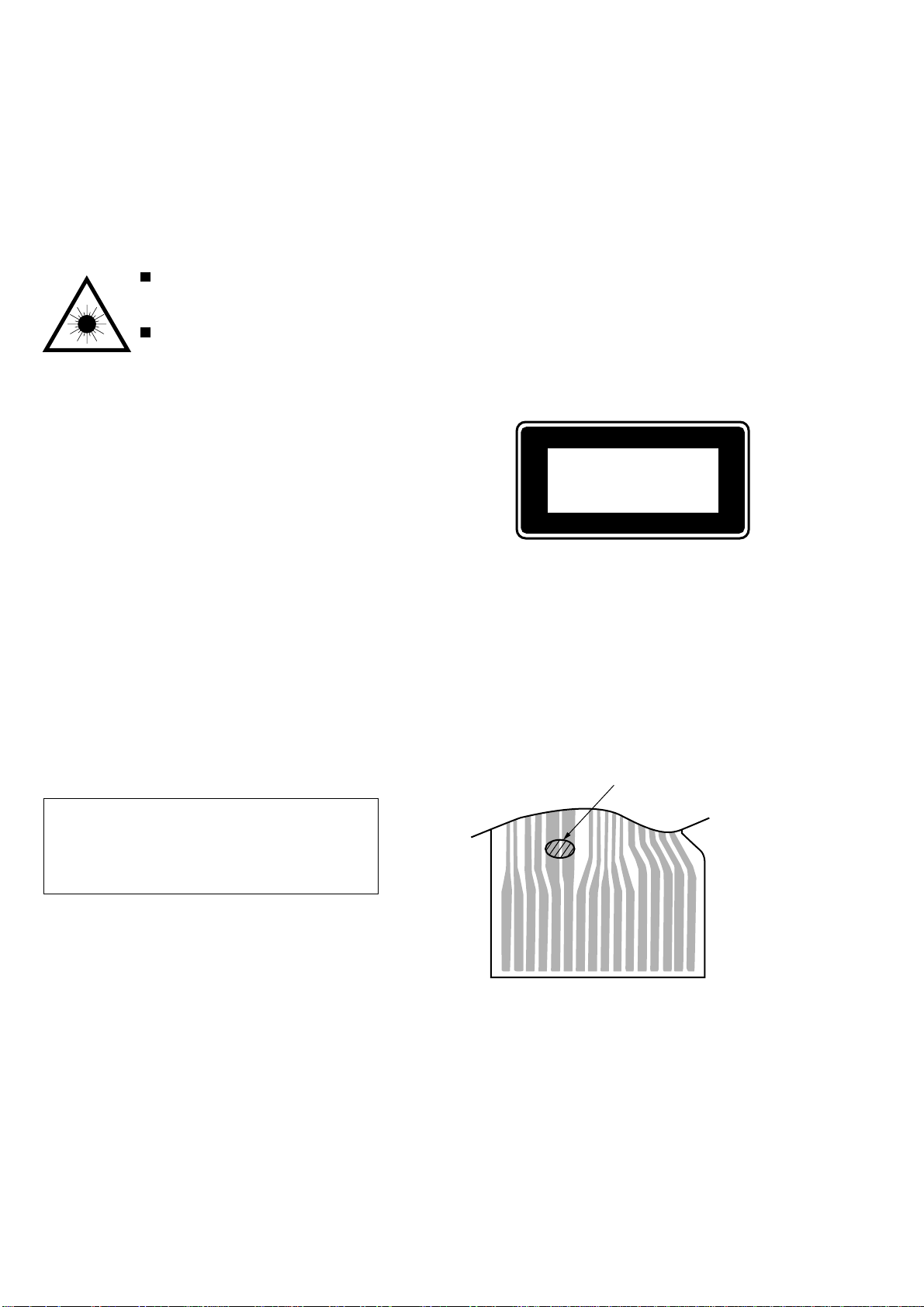

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

This set employs laser. Therefore, be sure to follow carefully the

instructions below when servicing.

WARNING!

WHEN SERVICING, DO NOT APPROACH THE LASER EXIT

WITH THE EYE TOO CLOSELY. IN CASE IT IS NECESSARY TO

CONFIRM LASER BEAM EMISSION. BE SURE TO OBSERVE

FROM A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE OPTICAL

PICK-UP BLOCK.

Caution: Invisible laser radiation when

open and interlocks defeated avoid exposure to beam.

Advarsel:Usynling laserståling ved åbning,

når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

VAROITUS!

Laiteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyt-täjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

VARNING!

Om apparaten används på annat sätt än vad som specificeras i

denna bruksanvising, kan användaren utsättas för osynling

laserstrålning, som överskrider gränsen för laserklass 1.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

ATTENTION

L'utilisation de commandes, réglages ou procédures autres que

ceux spécifiés peut entraîner une dangereuse exposition aux

radiations.

ADVARSEL!

Usynlig laserståling ved åbning, når sikkerhedsafbrydereer ude

af funktion. Undgå udsættelse for stråling.

This Compact Disc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located on the rear

exterior.

CLASS 1

KLASSE 1

LUOKAN 1

KLASS 1

LASER PRODUCT

LASER PRODUKT

LASER LAITE

LASER APPARAT

Precaution to replace Optical block

(KSM-620AAA)

Body or clothes electrostatic potential could ruin

laser diode in the optical block. Be sure ground

body and workbench, and use care the clothes

do not touch the diode.

1) After the connection, remove solder shown in

the right figure.

SOLDER

4

Page 5

MODEL NO. RX-LM88

ELECTRICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

NO.

IC

87-070-127-110 IC,LC72131 D

87-A20-913-010 IC,LA1837NL

8Z-CL1-627-010 IC,LC866532A-5L31RX

TRANSISTOR

89-213-702-010 TR,2SB1370 (1.8W)

87-026-610-080 TR,KTC3198GR

87-A30-076-080 C-TR,2SC3052F

87-A30-075-080 C-TR,2SA1235F

87-A30-234-080 TR,CSC4115BC

87-026-609-080 TR,KTA1266GR

87-A30-073-080 C-TR,RT1N 141C

87-A30-190-080 TR,CC5551

87-A30-307-010 TR,2SD2619

87-A30-306-010 TR,2SB1677

87-A30-119-040 C-TR,2SC3906K R

87-A30-047-080 TR,CSD655E

87-A30-107-070 C-TR,CMBT5401

87-A30-074-080 C-TR,RT1P 141C

87-A30-071-080 C-TR,RT1N 144C

87-A30-087-080 C-FET,2SK2158

87-A30-072-080 C-TR,RT1P 144C

89-327-143-080 TR,2SC2714 (0.1W)

89-505-434-540 C-FET,2SK543(4/5)

87-A30-086-070 C-TR,CSD1306E

DIODE

87-070-345-080 DIODE,IN4148

87-070-178-090 DIODE,1N5402-BD54

87-070-274-080 DIODE,1N4003 SEM

87-A40-345-080 ZENER,MTZJ10C

87-A40-269-080 C-DIODE,MC2836

87-A40-270-080 C-DIODE,MC2838

87-A40-004-080 ZENER,MTZJ16A

87-A40-312-080 ZENER,DZ33M

87-A40-313-080 C-DIODE,MC 2840

87-A40-488-080 DIODE,1SS244

87-A40-509-080 ZENER,MTZJ6.8C

87-017-149-080 ZENER,HZS6A2L

87-020-465-080 DIODE,1SS133 (110MA)

POWER C.B

C101 87-010-387-080 CAP,E 470-25 SME

C102 87-016-051-090 CAP,E 2200-35 SMG

C103 87-016-051-090 CAP,E 2200-35 SMG

C106 87-010-196-080 CHIP CAPACITOR,0.1-25

C107 87-010-196-080 CHIP CAPACITOR,0.1-25

C108 87-010-196-080 CHIP CAPACITOR,0.1-25

C109 87-010-196-080 CHIP CAPACITOR,0.1-25

C110 87-010-928-090 CAP,E 4700-25 SMG

C111 87-012-140-080 CAP 470P

C113 87-010-247-080 CAP, ELECT 100-50V<K>

C113 87-010-384-080 CAP, ELECT 100-25V<EZ>

C114 87-010-060-080 CAP, ELECT 100-16V

C115 87-010-235-080 CAP,E 470-16 SME

C132 87-010-260-080 CAP, ELECT 47-25V

C133 87-010-403-080 CAP, ELECT 3.3-50V

C151 87-010-196-080 CHIP CAPACITOR,0.1-25

C152 87-A11-174-090 CAP,E 4700-16 M SMG

C171 87-010-260-080 CAP, ELECT 47-25V

C172 87-010-513-080 CAP, ELECT 47-35V

C173 87-010-260-080 CAP, ELECT 47-25V

C174 87-010-260-080 CAP, ELECT 47-25V

C175 87-010-247-080 CAP, ELECT 100-50V

C176 87-010-263-080 CAP, ELECT 100-10V

C182 87-010-322-080 C-CAP,S 100P-50 J CH

REF. NO PART NO. KANRI DESCRIPTION

NO.

C183 87-010-322-080 C-CAP,S 100P-50 J CH

C184 87-010-322-080 C-CAP,S 100P-50 J CH

C185 87-010-322-080 C-CAP,S 100P-50 J CH

C186 87-010-322-080 C-CAP,S 100P-50 J CH

C187 87-010-322-080 C-CAP,S 100P-50 J CH

C191 87-A10-479-080 CAP,CER 2200P-250 M E KH

C195 87-010-405-080 CAP, ELECT 10-50V<EZ>

C195 87-010-405-010 CAP, ELECT 10-50V<K>

C281 87-010-401-080 CAP, ELECT 1-50V

C282 87-010-263-080 CAP, ELECT 100-10V

C283 87-010-380-080 CAP, ELECT 47-16V

C284 87-010-405-080 CAP, ELECT 10-50V

CN101 87-A60-813-010 CONN,8P H BLK TAC-L8X

CN102 87-A60-813-010 CONN,8P H BLK TAC-L8X

CN104 87-A60-770-010 CONN,18P B TMC-D(X)

CN203 87-A60-109-010 CONN,2P V S2M-2W

CN301 87-A60-778-010 CONN,18P B TMC-D(P)

CN302 87-A60-058-010 CONN,10P V 9604S-10C

CN305 8Z-CL1-665-010 CONN ASSY,5P FR

J201 87-A60-420-010 JACK,3.5 ST (MSC)

J202 87-099-801-010 JACK,PIN 1P BLK

J501 87-A60-782-010 CONN,19P H FG

W101 8Z-CL1-656-010 F-CABLE,7P 2.5 150MM PWR

W102 8Z-CL1-654-010 F-CABLE,2P 2.5 170MM SUBPT

W103 8Z-CL1-655-010 F-CABLE,4P 2.5 100MM PWR

WH102 87-A90-460-010 HLDR,WIRE 2.5-7P

FRONT C.B

C301 87-012-145-080 CAP, CHIP S 270P CH

C303 87-010-312-080 C-CAP,S 15P-50 CH

C304 87-015-785-080 CHIP CAPACITOR, 0.1FZ-25Z

C305 87-010-196-080 CHIP CAPACITOR,0.1-25

C341 87-010-493-080 CAP,E 0.47-50 GAS

C342 87-A10-189-040 CAP,E 220-10

C343 87-010-196-080 CHIP CAPACITOR,0.1-25

C347 87-010-405-080 CAP, ELECT 10-50V

C351 87-010-194-080 CAP, CHIP 0.047

C352 87-010-194-080 CAP, CHIP 0.047

C358 87-010-263-080 CAP, ELECT 100-10V

C371 87-010-404-080 CAP, ELECT 4.7-50V

C372 87-010-404-080 CAP, ELECT 4.7-50V

C373 87-010-408-080 CAP, ELECT 47-50V

FL301 8Z-CL1-630-010 FL,13-ST-36GNAK

HL301 8Z-CL1-204-010 HLDR,FL

L301 87-A50-052-010 COIL,CLOCK 5.76MHZ T1

LED361 87-A40-568-010 LED,L-13HD RED

POWER AMP C.B

C201 87-010-260-080 CAP, ELECT 47-25V

C202 87-010-260-080 CAP, ELECT 47-25V

C203 87-A10-946-080 C-CAP,S 220P-100 J CH

C204 87-A10-946-080 C-CAP,S 220P-100 J CH

C209 87-010-186-080 CAP,CHIP 4700P

C210 87-010-186-080 CAP,CHIP 4700P

C211 87-012-368-080 C-CAP,S 0.1-50 F

C212 87-012-368-080 C-CAP,S 0.1-50 F

C213 87-010-195-080 C-CAP,S 0.068-25 F

C214 87-010-195-080 C-CAP,S 0.068-25 F

C215 87-010-544-080 CAP, ELECT 0.1-50V

C216 87-010-544-080 CAP, ELECT 0.1-50V

C217 87-010-182-080 C-CAP,S 2200P-50 B

C218 87-010-182-080 C-CAP,S 2200P-50 B

C219 87-010-184-080 C-CAP,S 3300P-50 B<EZ>

C220 87-010-184-080 C-CAP,S 3300P-50 B<EZ>

C221 87-010-186-080 CAP,CHIP 4700P

C222 87-010-186-080 CAP,CHIP 4700P

C223 87-010-403-080 CAP, ELECT 3.3-50V

C224 87-010-403-080 CAP, ELECT 3.3-50V

5

Page 6

REF. NO PART NO. KANRI DESCRIPTION

C225 87-012-157-080 C-CAP,S 330P-50 J CH<EZ>

C226 87-012-157-080 C-CAP,S 330P-50 J CH<EZ>

C265 87-010-546-080 CAP, ELECT 0.33-50V

C266 87-010-546-080 CAP, ELECT 0.33-50V

C271 87-015-819-080 CAPACITOR,0.01

C277 87-010-197-080 CAP, CHIP 0.01 DM

CN201 87-A60-812-010 CONN,8P V BLK TAC-L8P

CN202 87-A60-812-010 CONN,8P V BLK TAC-L8P

J203 87-YP6-608-010 TERMINAL,SPKR 4P

L201 87-003-383-010 COIL,1UH-S

L202 87-003-383-010 COIL,1UH-S

R215 87-A00-258-080 RES,M/F 0.22-1W J

R216 87-A00-258-080 RES,M/F 0.22-1W J

R217 87-A00-258-080 RES,M/F 0.22-1W J

R218 87-A00-258-080 RES,M/F 0.22-1W J

R219 87-A00-258-080 RES,M/F 0.22-1W J

R220 87-A00-258-080 RES,M/F 0.22-1W J

TH201 87-A91-042-080 C-THMS,100K 55001

TH202 87-A91-042-080 C-THMS,100K 55001

MAIN PT C.B

!

PR151 87-A90-094-080 PROTECTOR,4A 491SERIES 60V

!

PT101 8Z-CL1-623-010 PT,E

RY102 87-A90-976-010 RELAY,AC12V SDT-S-112LMR

!

T101 87-A60-317-010 TERMINAL, 1P MSC

!

T102 87-A60-317-010 TERMINAL, 1P MSC

WH101 87-A90-460-010 HLDR,WIRE 2.5-7P

SUB PT C.B

!

PT102 8Z-CL1-673-010 PT,SUB ZCL-1(E)

TU INF C.B

C501 87-010-189-080 C-CAP,S 8200P-50 B<EZ>

C502 87-010-189-080 C-CAP,S 8200P-50 B<EZ>

CN114 87-099-570-010 CONN,13P TUC-P13P-B1<K>

CN115 87-A60-114-010 CONN,4P H S2M-4WR

CN116 87-A60-077-010 CONN,10P H 9604S-10F

CN117 87-A60-189-010 CONN,16P V TUC-P16P-B1<EZ>

TUNER C.B

C701 87-010-381-080 CAP, ELECT 330-16V

C702 87-010-404-080 CAP, ELECT 4.7-50V

C703 87-012-286-080 CAP, U 0.01-25

C704 87-012-286-080 CAP, U 0.01-25

C709 87-012-195-080 C-CAP,U 100P-50CH

C711 87-010-260-080 CAP, ELECT 47-25V

C712 87-010-831-080 C-CAP,U,0.1-16F

C713 87-012-286-080 CAP, U 0.01-25

C714 87-012-286-080 CAP, U 0.01-25

C715 87-012-195-080 C-CAP,U 100P-50CH

C717 87-012-286-080 CAP, U 0.01-25

C719 87-012-286-080 CAP, U 0.01-25

C720 87-012-195-080 C-CAP,U 100P-50CH

C721 87-012-176-080 CAP 15P

C722 87-012-176-080 CAP 15P

C723 87-012-274-080 CHIP CAP,U 1000P-50B

C725 87-018-131-080 CAP, CER 1000P-50V

C727 87-010-196-080 CHIP CAPACITOR,0.1-25

C728 87-010-248-080 CAP, ELECT 220-10V

C729 87-012-274-080 CHIP CAP,U 1000P-50B

C731 87-012-286-080 CAP, U 0.01-25

C733 87-012-280-080 CAP, U 3300P-50

C734 87-012-280-080 CAP, U 3300P-50

C752 87-012-282-080 CAP, U 4700P-50

C753 87-012-195-080 C-CAP,U 100P-50CH

NO.

REF. NO PART NO. KANRI DESCRIPTION

NO.

C755 87-012-286-080 CAP, U 0.01-25

C756 87-012-286-080 CAP, U 0.01-25

C757 87-012-188-080 C-CAP,U 47P-50 CH

C758 87-012-167-080 C-CAP,U 5P-50 CH

C761 87-010-196-080 CHIP CAPACITOR,0.1-25

C762 87-012-286-080 CAP, U 0.01-25

C763 87-010-829-080 CAP, U 0.047-16

C765 87-012-286-080 CAP, U 0.01-25

C766 87-010-197-080 CAP, CHIP 0.01 DM

C768 87-012-286-080 CAP, U 0.01-25

C769 87-010-260-080 CAP, ELECT 47-25V

C770 87-010-829-080 CAP, U 0.047-16

C771 87-010-383-080 CAP, ELECT 33-25V

C772 87-010-829-080 CAP, U 0.047-16

C773 87-010-196-080 CHIP CAPACITOR,0.1-25

C774 87-010-263-080 CAP, ELECT 100-10V

C775 87-010-404-080 CAP, ELECT 4.7-50V

C776 87-012-286-080 CAP, U 0.01-25

C777 87-010-493-080 CAP,E 0.47-50 GAS

C778 87-010-401-080 CAP, ELECT 1-50V

C779 87-010-401-080 CAP, ELECT 1-50V

C780 87-010-196-080 CHIP CAPACITOR,0.1-25

C781 87-010-405-080 CAP, ELECT 10-50V

C782 87-010-405-080 CAP, ELECT 10-50V

C783 87-012-286-080 CAP, U 0.01-25

C784 87-012-286-080 CAP, U 0.01-25

C785 87-010-405-080 CAP, ELECT 10-50V

C786 87-010-405-080 CAP, ELECT 10-50V

C787 87-012-275-080 C-CAP,U 1200P-50 B

C788 87-012-275-080 C-CAP,U 1200P-50 B

C789 87-012-275-080 C-CAP,U 1200P-50 B

C790 87-012-275-080 C-CAP,U 1200P-50 B

C791 87-010-405-080 CAP, ELECT 10-50V

C793 87-012-273-080 C-CAP,U 820P-50 B

C794 87-010-406-080 CAP, ELECT 22-50

C795 87-010-596-080 CAP, S 0.047-16

C796 87-010-403-080 CAP, ELECT 3.3-50V

C797 87-012-276-080 CAP, CHIP SS 1500 PBK

C798 87-012-276-080 CAP, CHIP SS 1500 PBK

C799 87-010-829-080 CAP, U 0.047-16

C812 87-012-286-080 CAP, U 0.01-25

C814 87-012-286-080 CAP, U 0.01-25

C820 87-010-260-080 CAP, ELECT 47-25V

C821 87-012-286-080 CAP, U 0.01-25

C822 87-012-286-080 CAP, U 0.01-25

C823 87-012-286-080 CAP, U 0.01-25

C828 87-010-196-080 CHIP CAPACITOR,0.1-25

C829 87-010-196-080 CHIP CAPACITOR,0.1-25

C859 87-012-286-080 CAP, U 0.01-25<EZ>

C861 87-012-199-080 CAP 220P<EZ>

C862 87-012-199-080 CAP 220P<EZ>

C863 87-012-270-080 CAP, U 470P-50<EZ>

C864 87-010-405-080 CAP, ELECT 10-50V<EZ>

C865 87-010-196-080 CHIP CAPACITOR,0.1-25<EZ>

C866 87-010-405-080 CAP, ELECT 10-50V<EZ>

C867 87-012-286-080 CAP, U 0.01-25<EZ>

C868 87-012-184-080 C-CAP,U 33P-50 CH<EZ>

C869 87-012-180-080 C-CAP,U 22P-50 CH<EZ>

C940 87-012-286-080 CAP, U 0.01-25

C942 87-012-168-080 C-CAP,U 6P-50 CH

C947 87-012-286-080 CAP, U 0.01-25

C949 87-A10-039-080 C-CAP,U 470P-50 J CH

C952 87-012-286-080 CAP, U 0.01-25

C958 87-010-197-080 CAP, CHIP 0.01 DM

C959 87-010-831-080 C-CAP,U,0.1-16F

C960 87-010-196-080 CHIP CAPACITOR,0.1-25

C962 87-010-401-080 CAP, ELECT 1-50V

CF801 87-008-423-010 CERAMIC FILTER, SFE10.7

CF802 82-785-747-010 CF MS2 GHY R

CN701 87-A60-700-010 CONN,13P H GRY TUC-P13X-C1<K>

6

Page 7

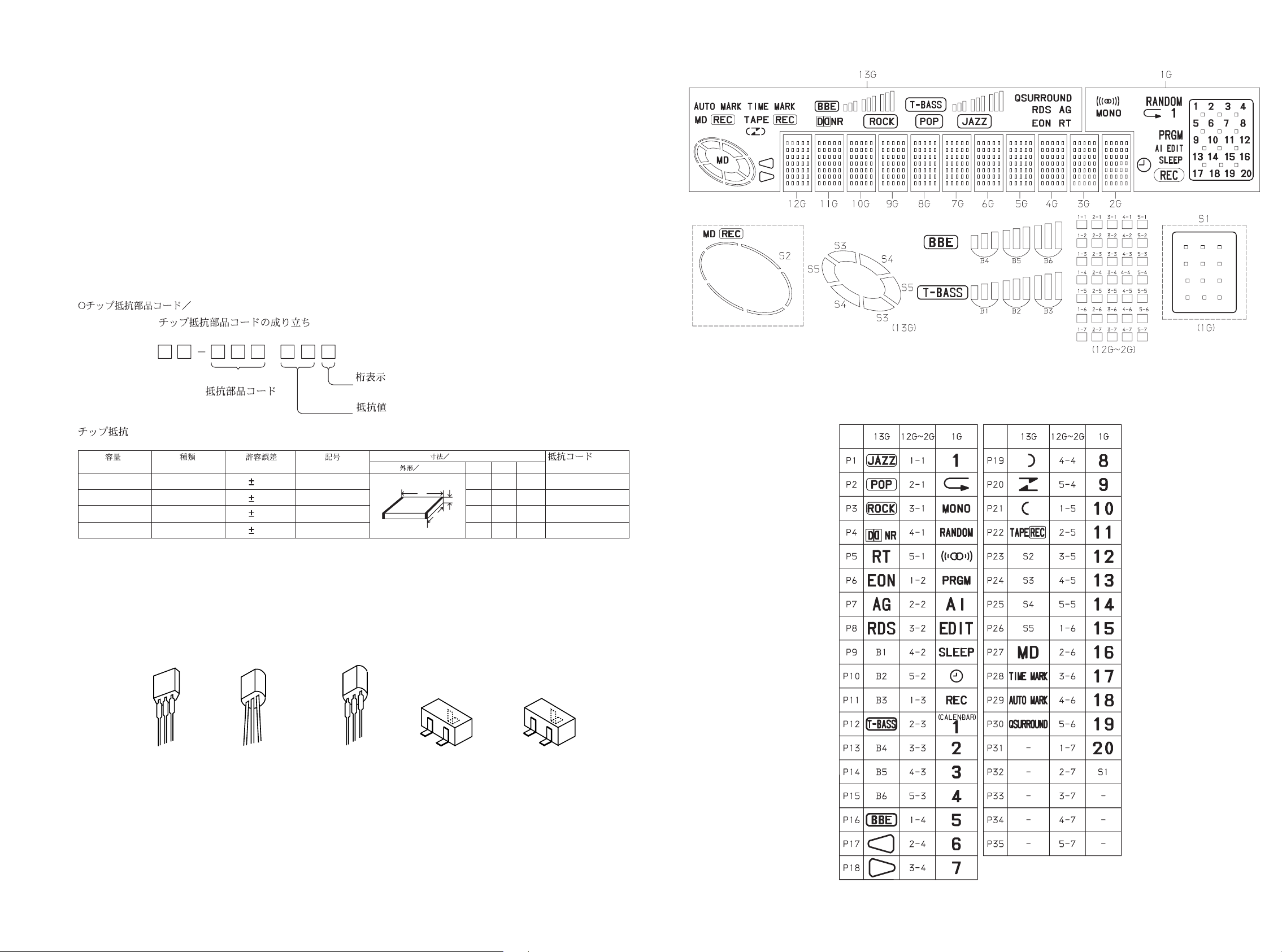

FL (13-ST-36GNAK) GRID ASSIGNMENT/ANODE CONNECTION

GRID ASSIGNMENT

REF. NO PART NO. KANRI DESCRIPTION

NO.

C962 87-010-401-080 CAP, ELECT 1-50V

CF801 87-008-423-010 CERAMIC FILTER, SFE10.7

CF802 82-785-747-010 CF MS2 GHY R

CN701 87-A60-700-010 CONN,13P H GRY TUC-P13X-C1

CN701 87-A60-650-010 CONN,16P H GRY TUC-P16X-C1<EZ>

FFE801 A8-6ZA-191-130 6ZA-1 FEENM

J801 87-033-241-010 TERMINAL,ANT AJ-2039

L771 87-A50-266-010 COIL,FM DET-2N(TOK)

L772 87-A91-110-010 FLTR,PCFJZH-450 (TOK)

L781 87-005-847-080 COIL,2.2UH(CECS)

• Regarding connectors, they are not stocked as they are not the initial order items.

The connectors are available after they are supplied from connector manufacturers upon the order is received.

CHIP RESISTOR PART CODE

REF. NO PART NO. KANRI DESCRIPTION

NO.

L791 87-A50-027-010 COIL,1 POLE MPX(TOK)

L792 87-A50-027-010 COIL,1 POLE MPX(TOK)

L832 87-005-847-080 COIL,2.2UH(CECS)

L851 87-005-847-080 COIL,2.2UH(CECS)<EZ>

L941 87-A50-020-010 COIL,ANT LW(COI)

L942 87-A50-019-010 COIL,OSC LW(COI)

L981 8Z-ZA1-665-010 COIL,AM PACK 2(TOK)

TC942 87-011-164-010 CAPACITOR,TRIMMER 30P

X721 87-A70-061-010 VIB,XTAL 4.500MHZ CSA-309

X851 87-A70-091-010 VIB,XTAL 4.332MHZ CSA-309<EZ>

Chip Resistor Part Coding

88

A

Resistor Code

Figure

Value of resistor

ANODE CONNECTION

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

TRANSISTOR ILLUSTRATION

ECB ECBECB

2SA933 2SA1235

2SA1318

2SC2001

CSD655E

CSD1489B

KTC3198

Symbol

CJ

CJ

CJ

KTA1266

Dimensions (mm)

Form

L

t

W

C

B

E

DTA144TK

DTC114TK

RT1N144C

0.55

Resistor Code

108

118

128

LW t

1.0 0.5 0.35 104

1.6 0.8 0.45

2 1.25 0.45

3.2

1.6

D

G

S

2SK2158

: A

: A

87

Page 8

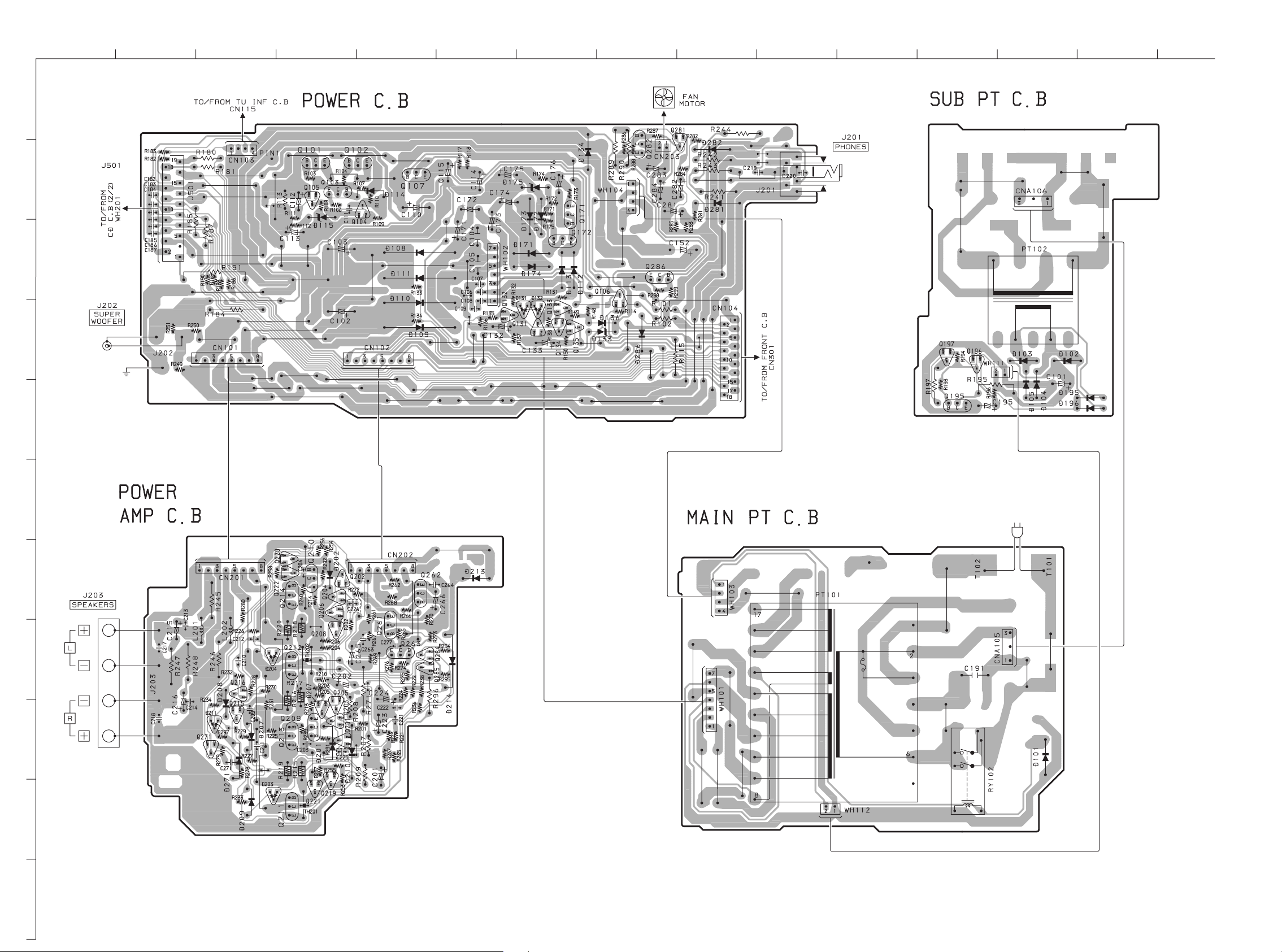

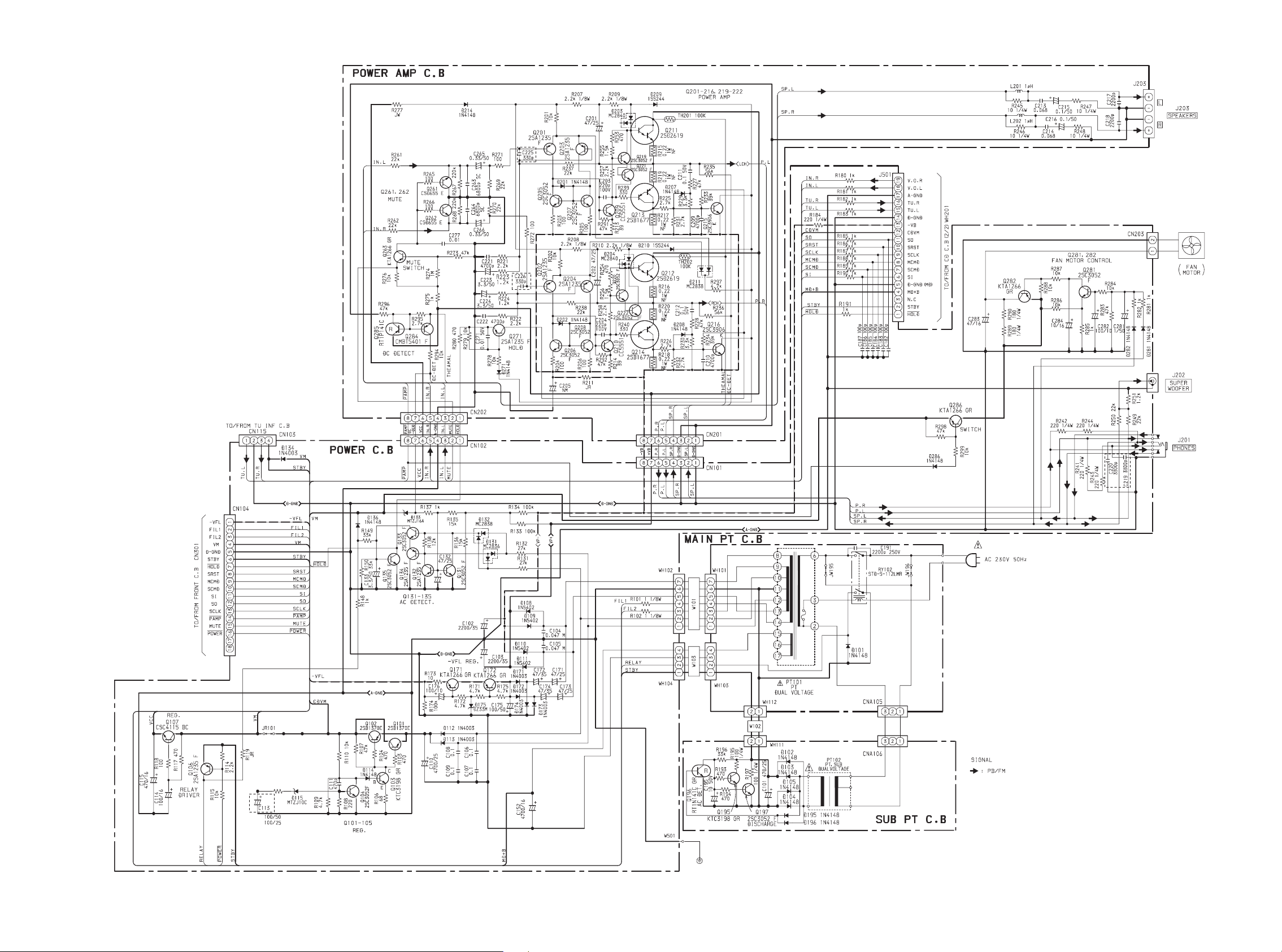

WIRING-1 (POWER AMP)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

AC230V 50Hz

G

EZ

MODEL

H

I

EZ

MODEL

J

K

109

Page 9

SCHEMATIC DIAGRAM-1 (POWER AMP)

EZ MODEL

EZ MODEL

EZ MODEL

K MODEL:

EZ MODEL:

1211

Page 10

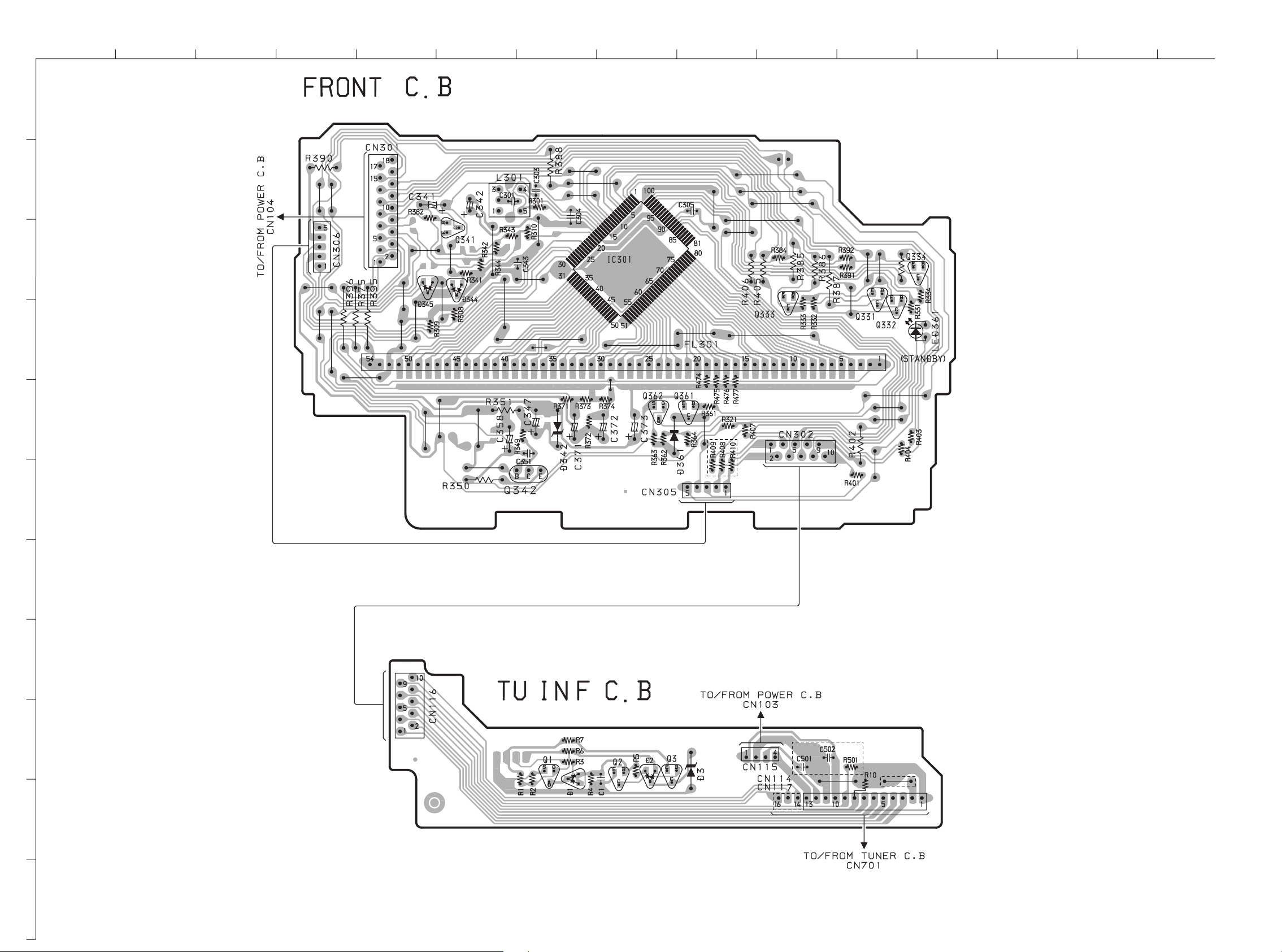

WIRING-2 (FRONT)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

EZ MODEL

F

G

H

I

EZ MODEL

K MODEL:

EZ MODEL:

EZ

MODEL

K MODEL

J

K

1413

Page 11

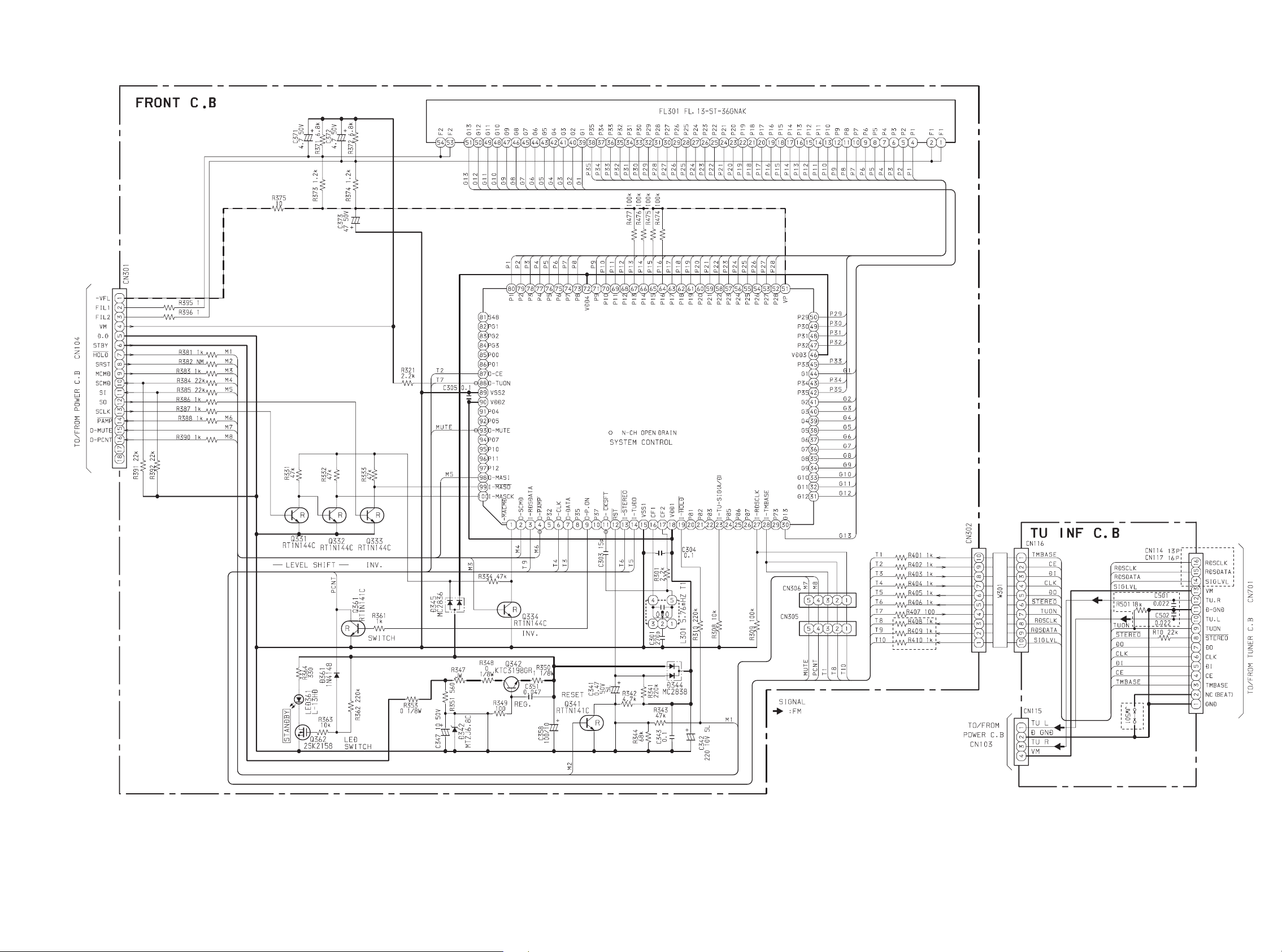

SCHEMATIC DIAGRAM-2 (FRONT)

IC301

LC866532A-5L31RX

EZ MODEL

EZ

MODEL

K MODEL

K:

EZ:

1615

Page 12

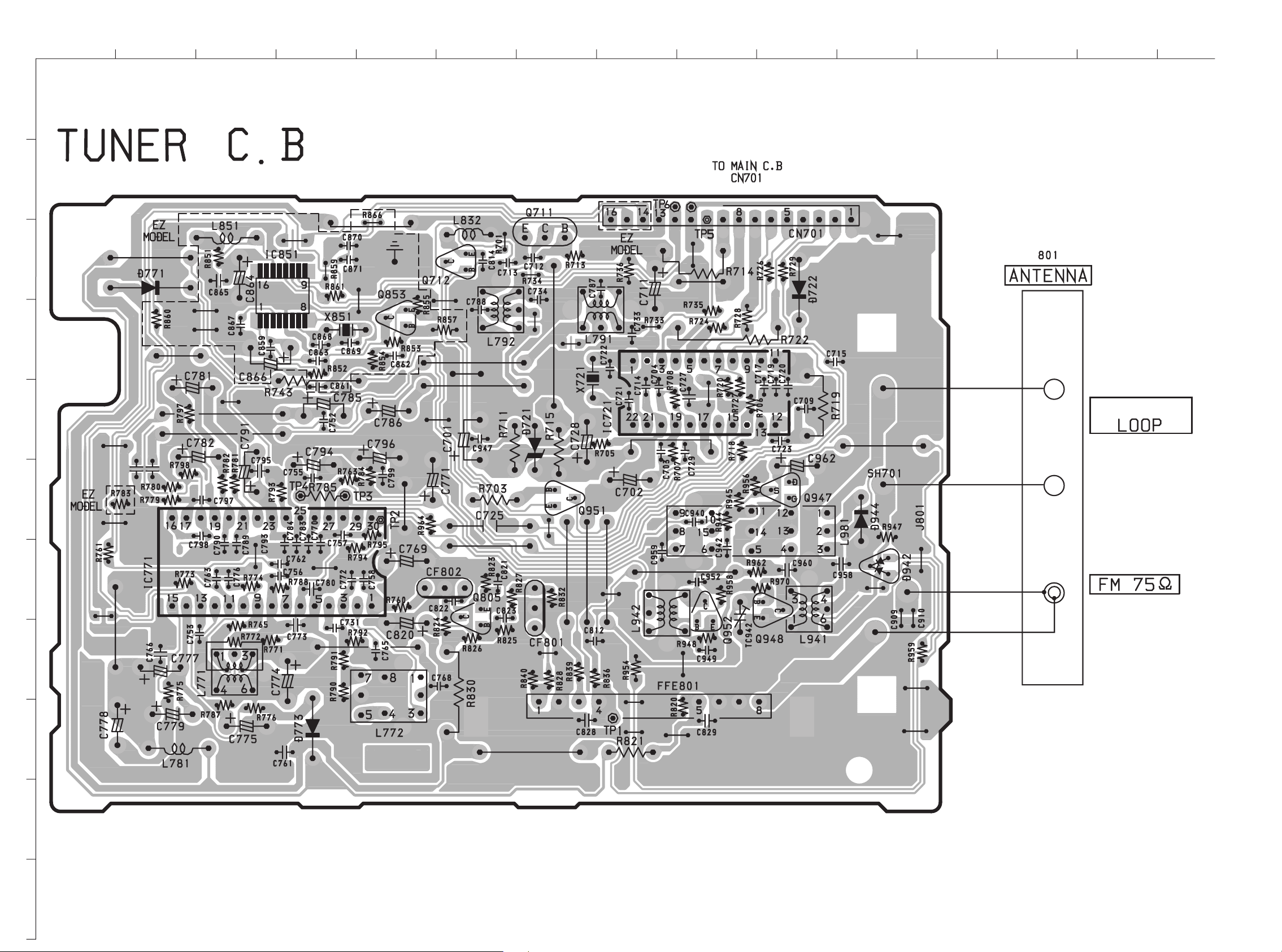

WIRING-3 (TUNER)

1

A

B

234567

8

9

10

11 12 13

14

C

D

E

F

G

J

MW / LW

H

I

J

K

1817

Page 13

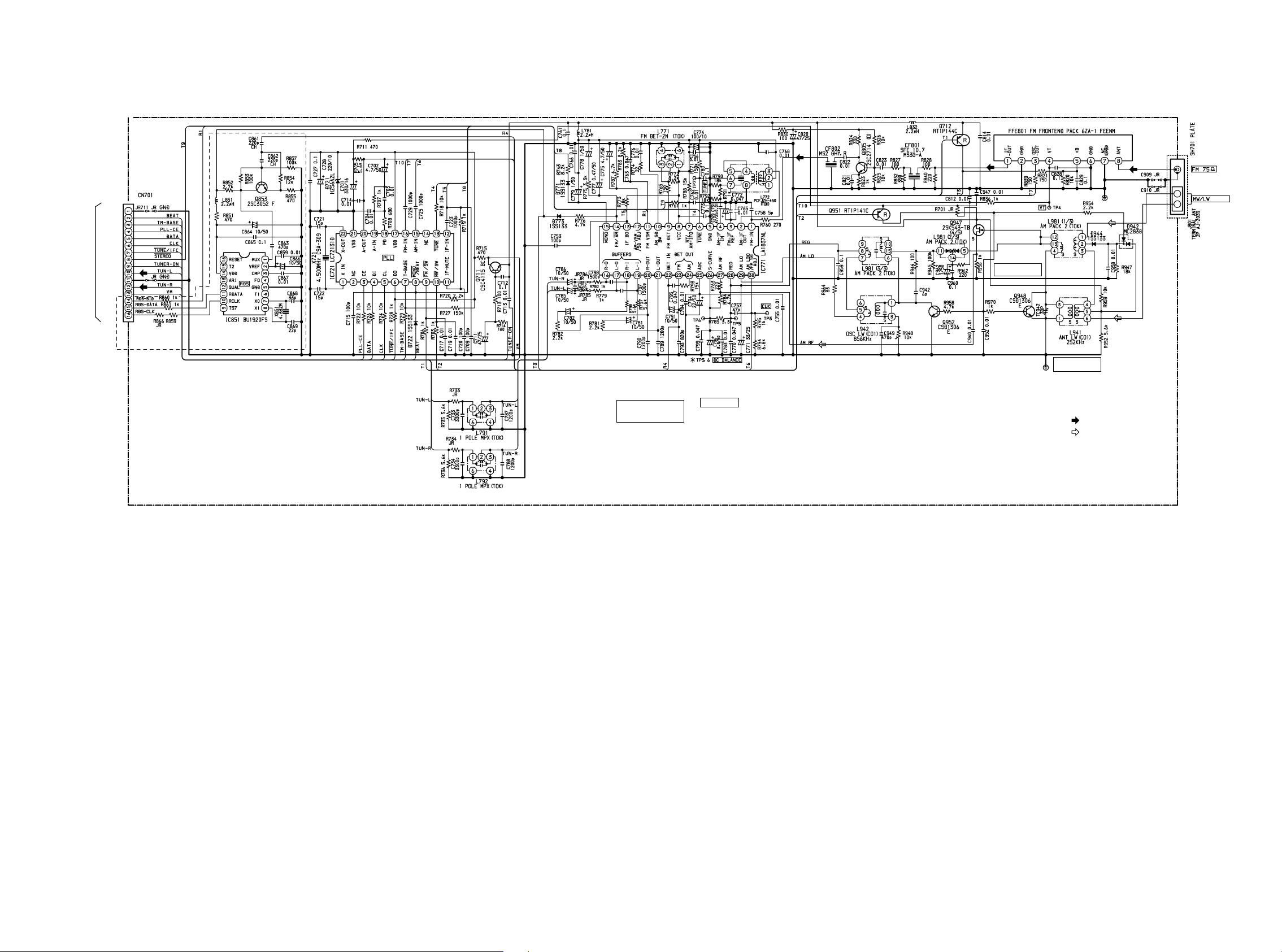

SCHEMATIC DIAGRAM-3 (TUNER)

TO/FROM MAINC.B CN701

BUFFER

AMP

EZ MODEL

TU+B

SW

L771

DC BALLANCE /

MONO DISTORTION

ADJ

L772

MW IF ADJ

BAND SW

BAND

SW

BAND

SW

AMP

MW TRACKING

ADJ

LW TRACKING

ADJ

L941,TC942

SIGNAL

: FM

:MW/LW

LOOP

TUNER C.B

2019

Page 14

ELECTRICAL ADJUSTMENT 2/2

8

L771

TP4

IC771

TP3

R785

30

TP2

3

L772

TP1

4

L942

L981

FFE801

TUNER C.B

L941TC942

7

7

4

< TUNER SECTION >

1. Clock Frequency Check

Settings: • Test point: TP2 (CLK IC770 pin30)

Method: Set to MW 1602kHz and check that the test

point becomes 2052kHz±45Hz (EZ).

2. MW VT Check

Settings: • Test point: TP1 (VT)

Method: Set to MW 1602kHz and check that the test

point is less than 8.0V.

Then set to MW 531kHz and check that the

test point is more than 0.6V.

3. MW IF Adjustment

Settings: • Test point: TP5, TP6

L772 .............................................. 450kHz

4. MW Tracking Adjustment

Settings: • Test point: TP5, TP6

• Adjustment location: L981

Method: Set to MW 999kHz and adjust L981 so that the

test point becomes maximum.

5. FM VT Check

Settings: • Test point: TP1 (VT)

Method: Set to FM 87.5MHz, 108.0MHz and check that

the test point is more than 0.5V (87.5MHz) and

less than 8.0V (108.0MHz).

PRACTICAL SERVICE FIGURE

< TUNER SECTION >

< FM SECTION >

IHF Sensitiviy: Less than 13dB

(THD 3%) (at 108.0/98.0MHz)

Less than 14dB

(at 98.0MHz)

Distortion: Less than 1.2% (98.0MHz)

Stereo separation: More than 12dB (98.0MHz)

Intermediate frequency: 10.7MHz

< MW SECTION >

Sensitivity: Less than 60dB (at 600kHz)

(S/N 20dB) Less than 58dB

(at 1000/1400kHz)

Distortion: Less than 1.5%

(at 1000kHz)

< LW SECTION >

Sensitivity: Less than 70dB (at 144kHz)

Less than 68dB (at 198kHz)

Less than 66dB (at 290kHz)

6

TP6

GND

12 11 10

TP5

6. LW VT Adjustment

Settings: • Test point: TP2 (VT)

• Adjustment location: L942

Method: Set to LW 144kHz and adjust L942 so that the

test point becomes 1.3V±0.05V.

Then set to LW 290kHz and check that the test

point is less than 8.0V.

CN701

7. LW Tracking Adjustment

Settings: • Test point: TP5, TP6

• Adjustment location:

L941 .............................................. 144kHz

TC942 ...........................................290kHz

Method: Set up TC942 to center before adjustment.

The level at 144kHz is adjusted to MAX by

L941. Then the level at 290kHz is adjusted to

MAX by TC942.

8. DC Balance/Mono Distortion Adjustment

Settings: • Test point: TP3, TP4

• Adjustment location: L771

• Input level: 54dB

Method: Set to FM 98.0MHz and adjust L771 so that

the voltage between TP3 and TP4 becomes

0V±0.04V.

Next, check that the distortion is less than

1.3%.

2221

Page 15

IC DESCRIPTION

IC, LC866532A-5L31RX

Pin No. Pin Name I/O Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20-22

23

24-26

________________

I-MACMD

O-SCMD

1-RDSDATA

___________

O-PAMP

P32

O-CLK

O-DATA

P35

O-P.ON

P37

_____________

O-CKSFT

________

RST

________________

I-STEREO

I-TUDO

VSS1

CF1

CF2

VDD1

____________

I-HOLD

P81-P83

I-TU-SIG

P85-P87

I

Command input from master microprocessor.

O

Serial data output to master microprocessor.

I

RDS data input.

O

Power supply control output (power supply ON/OFF of POWER AMP).

—

NC.

O

Connected to TUNER PLL IC LC72131 pin-5 CL.

O

Connected to TUNER PLL IC LC72131 pin-4 DI.

—

NC.

O

Power save mode control output

—

NC.

O

Clock shift output. “L” at clock shift.

I

Microprocessor reset.

I

TUNER, STEREO detection.

I

Connected to TUNER PLL IC LC72131 pin-6 D0.

—

GND.

I

5.76 MHz. Connected to oscillator.

O

—

Microprocessor power supply (µ-com 5V).

I

Hold state detection. (Ignored by slave microprocessor)

—

NC.

I

RDS signal level AD value input (A/D).

—

NC.

27

28

29

30-41

42, 43

44

45

46

47-50

51

52-71

72

73-80

81

82-84

85, 86

87

88

I-RDSCLK

I-TMBASE

P73

G13-G2

P35, P34

G1

P33

VDD3

P32-P29

VP

P28-P9

VDD4

P8-P1

S48

PG1-PG3

P00, P01

O-CE

O-TUON

I

RDS CLK input.

I

Reference clock input for watch. Connected to PLL ICLC72131 pin-7.

—

NC.

O

FL tube grid output. (13G-2G).

O

FL tube anode output. (P35, P34).

O

FL tube grid output. (1G).

O

FL tube anode output. (P33).

—

Microprocessor power supply. (µ-com 5V).

O

FL tube anode output. (P32-P29).

—

Connected to minus power supply -VFL for FL.

O

FL tube anode output. (P28-P9).

—

Microprocessor power supply. (µ-com 5V).

O

FL tube anode output. (P8-P1).

—

—

NC.

—

O

Connected to TUNER PLL IC LC72131pin-3 CE.

O

TUNER power supply. ON/OFF output.

89

VSS2

—

GND.

23

Page 16

Pin No. Pin Name I/O Description

90

91, 92

93

VDD2

P04, P05

O-MUTE

—

—

Microprocessor power supply. (µ-com 5V).

NC.

O

Main mute output.

94

95-97

98

99

100

P07

P10-12

O-MASI

____________

I-MASO

I-MACLK

—

—

NC.

O

Serial data output to master microprocessor.

I

Serial data input from master microprocessor.

I

Transfer clock input from master microprocessor.

24

Page 17

IC BLOCK DIAGRAM

IC, BU1920FS

IC, LA1837

IC, LC72131

25

Page 18

MECHANICAL EXPLODED VIEW 1/1

P.C.B

3

2

F

1

FL

E

F

C

E

HT-SINK,SUB

8

7

20

HT-SINK,MAIN ASSY

A

G

A

5

4

B

13

6

B

B

C

19

14

P.C.B

SHLD-PLATE PT

G

J

P.C.B

G

P.C.B

10

A

11

I

SHLD-PLATE

SUB.PT

18

P.C.B

A

15

B

B

C

B

H

H

16

12

P.C.B

P.C.B

9

CHAS,MAIN

17

26

Page 19

MECHANICAL PARTS LIST 1/1

REF. NO PART NO. KANRI DESCRIPTION

1 8Z-CL1-056-010 WINDOW,DISP EX<88<K>>

1 8Z-CL1-055-010 WINDOW,DISP EZ<89<EZ>>

2 8Z-CLB-013-010 PANEL,RX CS<88<K>>

2 8Z-CLB-015-010 PANEL,RX CS EZ<89<EZ>>

3 8Z-CL1-001-010 CABI,FR RX

4 8Z-CL1-204-010 HLDR,FL

5 88-910-131-110 FF-CABLE,10P 1.25

6 8Z-CL1-003-010 CABI,TOP RX

7 8Z-CL1-655-010 F-CABLE,4P 2.5 100MM PWR

8 8Z-CL1-656-010 F-CABLE,7P 2.5 150MM PWR

9 8Z-CL1-213-010 COVER, PWB AC

10 87-A90-193-010 HLDR,CV100 (B)

11 8Z-CL1-203-010 HLDR,SUB PT

12 8Z-CL1-663-010 FAN,MF40D-12-200MM

13 8Z-CLB-073-010 PANEL,REAR RX CS EZ<89<EZ>>

13 8Z-CLB-071-010 PANEL,REAR RX CS K<88<K>>

14 87-A90-460-010 HLDR,WIRE 2.5-7P

15 87-085-185-010 BUSHING, AC CORD (E)

!

16 87-A80-092-010 AC CORD ASSY,E BLK SUN

!

16 87-A80-007-110 AC CORD ASSY,K BLK<88<K>>

NO.

FAI<89<EZ>>

REF. NO PART NO. KANRI DESCRIPTION

17 81-669-025-010 FOOT, H11

18 8Z-CL1-654-010 F-CABLE,2P 2.5 170MM SUBPT

!

19 8Z-CL1-623-010 PT,E

20 86-NF6-211-010 HLDR,IC T1.6

A 87-067-703-010 TAPPING SCREW, BVT2+3-10

B 87-744-095-410 VT2+3-8 W/O SLOT CR2

C 87-B10-068-010 UTT2+3-6 W/O SLOT CR

D 8Z-CL1-034-010 S-SCREW,ZCL1

E 87-591-094-010 QIT+3-6 GOLD

F 87-067-761-010 TAPPING SCREW, BVT2+3-10

G 87-067-585-010 TAPPING SCREW, BVTT+4-6

H 87-751-095-410 VT2+3-8

I 87-067-584-010 TAPPING SCREW, BVT2+3-6

J 87-067-981-010 BVT2+3-6 BLK

NO.

COLOR NAME TABLE

Basic color symbol Color Basic color symbol Color Basic color symbol Color

B Black C Cream D Orange

G Green H Gray L Blue

LT Transparent Blue N Gold P Pink

R Red S Silver ST Titan Silver

T Brown V Violet W White

WT Transparent White Y Yellow YT Transparent Yellow

LM Metallic Blue LL Light Blue GT Transparent Green

LD Dark Blue DT Transparent Orange

27

Page 20

MODEL NO. FD-LM88

DISASSEMBLY INSTRUCTIONS

1. Remove the two screws.

1

2. Remove the two screws.

28

2

Page 21

3. Remove the eight screws and remove the PANEL, REAR FD.

3

4. While moving up the rear of the PANEL, TOP, remove the PANEL, TOP by pulling it to the front.

29

Page 22

5. Remove the FFC and cord. Be careful that the FFC especially cannot be removed easily.

6. Remove the screws.

6

30

Page 23

7. Remove the two FFCs.

8. Remove the claw and remove the CABI FRFD together with the entire front board.

31

Page 24

9. While moving up the CD board and the function board, remove the CD board and the function board. You can locate the

mechanism deck.

32

Page 25

ELECTRICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

NO.

IC

87-A20-446-010 C-IC,LA9241ML

87-A20-459-010 C-IC,LC78622ED

87-A20-445-010 IC,BA5936

8Z-CLB-621-010 C-IC,LC866560-5M02FD

87-A20-455-010 IC,HA12211

87-001-982-010 IC,TA7291S

87-A21-111-040 C-IC,M62495FP

87-A21-022-040 C-IC,BA3880FS

87-A21-103-040 C-IC,MM1454XFBE

87-017-888-080 IC,NJM4558MD

87-A20-914-010 IC,SPS-442-1-F

TRANSISTOR

87-026-463-080 TR,2SA933S (0.3W)

89-113-184-080 TR,2SA1318T

87-026-297-080 TR,DTA144TK

87-026-239-080 TR,DTC114TK (0.2W)

87-A30-047-080 TR,CSD655E

87-A30-075-080 C-TR,2SA1235F

87-026-610-080 TR,KTC3198GR

87-A30-083-080 TR,CSD1489B

87-A30-071-080 C-TR,RT1N 144C

87-A30-087-080 C-FET,2SK2158

87-A30-076-080 C-TR,2SC3052F

89-320-011-080 TR,2SC2001K

87-026-609-080 TR,KTA1266GR

DIODE

87-020-465-080 DIODE,1SS133 (110MA)

87-A40-270-080 C-DIODE,MC2838

87-A40-509-080 ZENER,MTZJ6.8C

87-070-274-080 DIODE,1N4003 SEM

87-A40-269-080 C-DIODE,MC2836

87-017-931-080 ZENER,MTZJ5.6B

87-A40-292-080 ZENER,DZ2.7L

87-001-731-080 ZENER,HZS6C2L

CD C.B

C1 87-010-496-040 CAP,E 3.3-50 GAS

C2 87-010-197-080 CAP, CHIP 0.01 DM

C3 87-010-264-040 CAP,E 100-10 5L

C4 87-A10-189-040 CAP,E 220-10

C5 87-010-197-080 CAP, CHIP 0.01 DM

C6 87-010-553-040 CAP,E 47-16 GAS

C7 87-012-349-080 C-CAP,S 1000P-50 CH

C8 87-010-198-080 CAP, CHIP 0.022

C9 87-010-264-040 CAP,E 100-10 5L

C10 87-010-264-040 CAP,E 100-10 5L

C12 87-010-494-040 CAP,E 1-50 GAS

C13 87-010-193-080 CHIP CAPACITOR,0.033

C14 87-010-560-040 CAP,E 10-50 GAS

C16 87-010-491-040 CAP,E 0.22-50 GAS

C17 87-012-349-080 C-CAP,S 1000P-50 CH

C18 87-010-213-080 C-CAP,S 0.015-50 B

C20 87-010-193-080 CHIP CAPACITOR,0.033

C22 87-010-184-080 CHIP CAPACITOR 3300P(K)

C23 87-010-992-080 C-CAP,S 0.047-25 B

C25 87-012-349-080 C-CAP,S 1000P-50 CH

C27 87-010-176-080 C-CAP,S 680P-50 SL

C29 87-010-186-080 CAP,CHIP 4700P

C30 87-012-156-080 C-CAP,S 220P-50 CH

C31 87-010-493-040 CAP,E 0.47-50 GAS

C32 87-010-553-040 CAP,E 47-16 GAS

C33 87-010-494-040 CAP,E 1-50 GAS

C34 87-010-184-080 CHIP CAPACITOR 3300P(K)

REF. NO PART NO. KANRI DESCRIPTION

NO.

C35 87-010-197-080 CAP, CHIP 0.01 DM

C36 87-010-553-040 CAP,E 47-16 GAS

C37 87-010-404-040 CAP,E 4.7-50 SME

C38 87-010-196-080 CHIP CAPACITOR,0.1-25

C40 87-010-145-080 C-CAP,S 1P-50 CH

C42 87-010-315-080 C-CAP,S 27P-50 CH

C45 87-010-196-080 CHIP CAPACITOR,0.1-25

C46 87-010-196-080 CHIP CAPACITOR,0.1-25

C47 87-010-196-080 CHIP CAPACITOR,0.1-25

C48 87-010-315-080 C-CAP,S 27P-50 CH

C50 87-012-140-080 CAP 470P

C51 87-012-156-080 C-CAP,S 220P-50 CH

C55 87-010-264-040 CAP,E 100-10 5L

C57 87-010-316-080 C-CAP,S 33P-50 CH

C58 87-010-316-080 C-CAP,S 33P-50 CH

C59 87-010-264-040 CAP,E 100-10 5L

C60 87-010-196-080 CHIP CAPACITOR,0.1-25

C61 87-010-196-080 CHIP CAPACITOR,0.1-25

C62 87-010-370-040 CAP,E 330-6.3 SME

C65 87-010-497-040 CAP,E 4.7-35 GAS

C66 87-010-196-080 CHIP CAPACITOR,0.1-25

C67 87-010-264-040 CAP,E 100-10 5L

C68 87-010-322-080 C-CAP,S 100P-50 CH

C75 87-010-197-080 CAP, CHIP 0.01 DM

C76 87-A10-102-080 CAP,E 1000-10 REA

C79 87-010-264-040 CAP,E 100-10 5L

C80 87-010-197-080 CAP, CHIP 0.01 DM

C81 87-010-560-040 CAP,E 10-50 GAS

C82 87-010-560-040 CAP,E 10-50 GAS

C83 87-012-157-080 C-CAP,S 330P-50 CH

C84 87-012-157-080 C-CAP,S 330P-50 CH

C93 87-010-197-080 CAP, CHIP 0.01 DM

C94 87-010-197-080 CAP, CHIP 0.01 DM

C98 87-012-154-080 C-CAP,S 150P-50 CH

C102 87-010-322-080 C-CAP,S 100P-50 CH

C104 87-010-322-080 C-CAP,S 100P-50 CH

C105 87-010-322-080 C-CAP,S 100P-50 CH

C110 87-010-196-080 CHIP CAPACITOR,0.1-25

C141 87-016-460-080 C-CAP,S 0.22-16 B

C146 87-010-560-040 CAP,E 10-50 GAS

C150 87-010-264-040 CAP,E 100-10 5L

C151 87-010-197-080 CAP, CHIP 0.01 DM

C201 87-012-145-080 CAP, CHIP S 270P CH

C203 87-010-312-080 C-CAP,S 15P-50 CH

C204 87-015-785-080 CHIP CAPACITOR, 0.1FZ-25Z

C205 87-010-196-080 CHIP CAPACITOR,0.1-25

C210 87-012-349-080 C-CAP,S 1000P-50 CH

C217 87-010-498-040 CAP,E 10-16 GAS

C220 87-010-197-080 CAP, CHIP 0.01 DM

C221 87-010-235-080 CAP,E 470-16 SME

C222 87-010-101-080 CAP, ELECT 220-16

C223 87-010-381-080 CAP, ELECT 330-16V

C241 87-010-493-040 CAP,E 0.47-50 GAS

C242 87-A10-759-040 CAP,E 330-6.3 SRM

C243 87-010-196-080 CHIP CAPACITOR,0.1-25

C246 87-010-196-080 CHIP CAPACITOR,0.1-25

C251 87-010-194-080 CAP, CHIP 0.047

C254 87-010-264-040 CAP,E 100-10 5L

C473 87-010-221-080 CAP, ELECT 470-10V

C474 87-010-197-080 CAP, CHIP 0.01 DM

CN1 87-A60-429-010 CONN,16P H TOC-A

CN2 87-009-411-010 CONN,6P ZH V

CN3 87-A60-111-010 CONN,5P V S2M 5W

CN201 87-A60-424-010 CONN,16P V TOC-B

CN202 87-A60-957-010 CONN,9P V TOC-B

CN203 87-A60-826-010 CONN,6P B TMC-D(X)

CN204 87-099-559-010 CONN,13P TUC-P13X-B1

D150 87-A40-558-010 LED,SLZ-8128A-01-A

L1 87-003-102-080 COIL, 10UH

L4 87-003-152-080 COIL, 100UH

33

Page 26

REF. NO PART NO. KANRI DESCRIPTION

NO.

L150 87-003-171-010 COIL, 15UH FL5R100

L201 87-A50-052-010 COIL,CLOCK 5.76MHZ T1

SFR130 87-A90-787-080 SFR,100K H HOKU

W201 8Z-CL1-653-010 F-CABLE,19P 1.5 FG

WH201 87-A90-878-010 HLDR,WIRE 19P 1.5 51016

X1 87-A70-046-010 VIB,XTAL 16.934MHZ

TAPE C.B

C90 87-010-197-080 CAP, CHIP 0.01 DM

C91 87-015-684-040 CAP,E 47-16 7L

C92 87-015-686-040 CAP,E 22-25 M 7L SRA

C303 87-012-157-080 C-CAP,S 330P-50 CH

C304 87-012-157-080 C-CAP,S 330P-50 CH

C307 87-010-196-080 CHIP CAPACITOR,0.1-25

C311 87-010-198-080 CAP, CHIP 0.022

C312 87-010-198-080 CAP, CHIP 0.022

C315 87-010-182-080 C-CAP,S 2200P-50

C316 87-010-182-080 C-CAP,S 2200P-50

C321 87-A10-201-080 C-CAP,S0.33-16 KB

C322 87-A10-201-080 C-CAP,S0.33-16 KB

C325 87-010-807-080 CAP,E 330-6.3 SR

C327 87-015-692-040 CAP,E 0,22-50 KB

C328 87-015-692-040 CAP,E 0,22-50 KB

C332 87-010-196-080 CHIP CAPACITOR,0.1-25

C335 87-015-695-040 E/CAP 1UF 50V TAPG

C336 87-015-695-040 E/CAP 1UF 50V TAPG

C337 87-010-196-080 CHIP CAPACITOR,0.1-25

C351 87-012-140-080 CAP 470P

C352 87-012-140-080 CAP 470P

C354 87-010-175-080 CAP 560P

C355 87-010-176-080 C-CAP,S 680P-50 J

C356 87-015-684-040 CAP,E 47-16 7L

C358 87-010-187-080 C-CAP,S 5600P-50 K B

C359 87-010-197-080 C-CAP,S 0.01-25 K B

C360 87-010-187-080 C-CAP,S 5600P-50 J

C370 87-010-196-080 CHIP CAPACITOR,0.1-25

C379 87-015-697-040 CAP,E 3.3-50 M 7L SRA

C380 87-015-697-040 CAP,E 3.3-50 M 7L SRA

C391 87-012-153-080 C-CAP,S 120P-50 J CH

C392 87-012-153-080 C-CAP,S 120P-50 J CH

C399 87-015-683-040 CAP,E 33-16 M 7L SRA

C401 87-010-197-080 CAP, CHIP 0.01 DM

C402 87-010-060-040 CAP,E 100-16

C403 87-015-684-040 CAP,E 47-16 7L

C404 87-A10-924-040 CAP,E 47-16 BP SME

C441 87-015-677-040 CAP,E 100-6.3 7L

C442 87-018-211-080 CAP, CER 0.01-50

C454 87-010-175-080 CAP 560P

C455 87-010-176-080 C-CAP,S 680P-50 CH

C456 87-015-684-040 CAP,E 47-16 7L

C458 87-010-187-080 C-CAP,S 5600P-50 KB

C459 87-010-197-080 C-CAP,S 0.01-25 KB

C460 87-010-187-080 C-CAP,S 5600P-50 K B

CN301 87-A60-957-010 CONN,9P V TOC-B

CN302 87-A60-057-010 CONN,11P V 9604S-11C

CN401 87-A60-424-010 CONN,16P V TOC-B

CN402 87-A60-957-010 CONN,9P V TOC-B

CN403 87-099-668-010 CONN,9P TUC-P 9P-B1

L301 87-A50-049-010 COIL,TRAP 85K(COI)

L302 87-A50-049-010 COIL,TRAP 85K(COI)

L351 87-A50-500-010 COIL,OSC BIAS 85KHZ

L451 87-A50-500-010 COIL,OSC BIAS 85KHZ

RY301 87-A91-375-010 RELAY,AC DC12V G6S-2

RY302 87-A91-375-010 RELAY,AC DC12V G6S-2

RY303 87-A91-375-010 RELAY,AC DC12V G6S-2

SFR351 87-024-436-080 SFR,47K RH063EC

SFR352 87-024-436-080 SFR,47K RH063EC

SFR451 87-024-436-080 SFR,47K RH063EC

REF. NO PART NO. KANRI DESCRIPTION

NO.

SFR452 87-024-436-080 SFR,47K RH063EC

FUNCTION C.B

C501 87-010-197-080 CAP, CHIP 0.01 DM

C531 87-010-374-040 CAP,E 47-10

C532 87-010-374-040 CAP,E 47-10

C535 87-010-213-080 C-CAP,S 0.015-50 B

C536 87-010-213-080 C-CAP,S 0.015-50 B

C537 87-010-400-040 CAP,E 0.47-50

C538 87-010-400-040 CAP,E 0.47-50

C539 87-010-564-040 CAP,E 0.33-50 M

C540 87-010-564-040 CAP,E 0.33-50 M

C541 87-010-401-040 CAP,E 1-50 SME

C542 87-010-401-040 CAP,E 1-50 SME

C543 87-010-154-080 CAP CHIP 10P

C583 87-010-182-080 C-CAP,S 2200P-50 K B

C584 87-010-182-080 C-CAP,S 2200P-50 K B

C591 87-010-180-080 C-CER 1500P

C592 87-010-180-080 C-CER 1500P

C603 87-010-402-040 CAP,E 2.2-50 SME

C604 87-010-402-040 CAP,E 2.2-50 SME

C605 87-010-408-040 CAP,E 47-50 SME

C607 87-010-405-040 CAP,E 10-50

C608 87-010-405-040 CAP,E 10-50

C609 87-010-196-080 CHIP CAPACITOR,0.1-25

C610 87-010-384-040 CAP,E 100-25 SME

C611 87-010-197-080 CAP, CHIP 0.01 DM

C612 87-010-197-080 CAP, CHIP 0.01 DM

C621 87-010-401-040 CAP,E 1-50 SME

C622 87-010-401-040 CAP,E 1-50 SME

C653 87-010-404-040 CAP,E 4.7-50 SME

C654 87-010-404-040 CAP,E 4.7-50 SME

C655 87-010-404-040 CAP,E 4.7-50 SME

C656 87-010-404-040 CAP,E 4.7-50 SME

C657 87-010-188-080 CAP,CHIP 6800P

C658 87-010-188-080 CAP,CHIP 6800P

C659 87-012-140-080 CAP 470P

C660 87-012-140-080 CAP 470P

C662 87-010-260-040 CAP,E 47-25 SME

C665 87-010-197-080 CAP, CHIP 0.01 DM

C666 87-010-197-080 CAP, CHIP 0.01 DM

C667 87-010-598-080 C-CAP,S 0.068-16VRK

C668 87-010-598-080 C-CAP,S 0.068-16VRK

C669 87-010-260-040 CAP,E 47-25 SME

C670 87-010-196-080 CHIP CAPACITOR,0.1-25

C671 87-010-545-040 CAP,E 0.22-50

C672 87-010-545-040 CAP,E 0.22-50

C677 87-010-404-040 CAP,E 4.7-50 SME

C678 87-010-404-040 CAP,E 4.7-50 SME

C721 87-010-401-040 CAP,E 1-50 SME

C722 87-010-401-040 CAP,E 1-50 SME

C723 87-012-154-080 C-CAP,S 150P-50 CH

C724 87-012-154-080 C-CAP,S 150P-50 CH

C725 87-012-154-080 C-CAP,S 150P-50 CH

C726 87-012-154-080 C-CAP,S 150P-50 CH

C727 87-010-404-040 CAP,E 4.7-50 SME

C728 87-010-404-040 CAP,E 4.7-50 SME

C733 87-010-197-080 CAP, CHIP 0.01 DM

C734 87-010-381-080 CAP, ELECT 330-16V

C735 87-010-197-080 CAP, CHIP 0.01 DM

C851 87-A10-201-080 C-CAP,S0.33-16 KB

C852 87-010-384-040 CAP,E 100-25 SME

C853 87-010-400-040 CAP,E 0.47-50

C854 87-010-402-040 CAP,E 2.2-50 SME

CN503 87-099-670-010 CONN,9P TUC-P9X-B1

CN504 87-099-570-010 CONN,13P TUC-P13P-B1

J501 82-MA2-631-010 JACK PIN 4P RVS

J701 87-A60-354-010 JACK,PIN 2P MSP -242V-05

34

Page 27

IC BLOCK DIAGRAM

IC, BA5936

REF. NO PART NO. KANRI DESCRIPTION

NO.

KEY C.B

S801 87-A91-024-080 SW,TACT KSH0611BT

S802 87-A91-024-080 SW,TACT KSH0611BT

S803 87-A91-024-080 SW,TACT KSH0611BT

S804 87-A91-024-080 SW,TACT KSH0611BT

S805 87-A91-024-080 SW,TACT KSH0611BT

S806 87-A91-024-080 SW,TACT KSH0611BT

S807 87-A91-024-080 SW,TACT KSH0611BT

S808 87-A91-024-080 SW,TACT KSH0611BT

S809 87-A91-024-080 SW,TACT KSH0611BT

S810 87-A91-024-080 SW,TACT KSH0611BT

S811 87-A91-024-080 SW,TACT KSH0611BT

RMC C.B

C841 87-010-405-040 CAP,E 10-50

CN801 87-A60-827-010 CONN,6P B TMC-D(P)

S821 87-A91-024-080 SW,TACT KSH0611BT

REF. NO PART NO. KANRI DESCRIPTION

NO.

MOTOR C.B

CNA101 88-802-051-290 CONN ASSY,5P

CNA103 8Z-CL1-670-010 CONN ASSY,3P H O/C

DOOR SW C.B

S101 87-036-109-010 PUSH SWITCH

S102 87-036-109-010 PUSH SWITCH

• Regarding connectors, they are not stocked as they are not the initial order items.

The connectors are available after they are supplied from connector manufacturers upon the order is received.

CHIP RESISTOR PART CODE

IC, M62495FP

Rog CURRENT

DETECTOR

TERMINAL

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

TRANSISTOR ILLUSTRATION

2SA933

1608

2125

3216

ECB ECBECB

2SA1318

2SC2001

CSD655E

CSD1489B

KTC3198

5%

5%

5%

Symbol

CJ

CJ

CJ

KTA1266

Figure

Value of resistor

Form

L

B

2SA1235

2SC3052

DTA144TK

DTC114TK

RT1N144C

Dimensions (mm)

W

E

LW t

1.0 0.5 0.35 104

t

1.6 0.8 0.45

2 1.25 0.45

1.6

0.55

3.2

C

G

2SK2158

Resistor Code

108

118

128

D

S

: A

: A

IC, BA3880FS

IC, MM1454XFBE

VCC

LIN VREF QF1 QF2 QF3 QF4 QF5

16 15 14 13 12 11 10 9

+

–

QSurround

BIAS

+

–

1 2 3 4 5 6 7 8

RIN PNR B/Q DET QF6 ROUT LOUT GND

–

+

3635

Page 28

WIRING-1 (CD)

CD C.B (COMPONENT SIDE)

14

13 12 11 10 9 8

7

6

5

432

1

A

B

C

D

E

F

G

H

I

J

3837

Page 29

CD C.B (CONDUCTOR SIDE)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

H

EZ MODEL

I

J

4039

Page 30

SCHEMATIC DIAGRAM-1 (CD 1/2)

4241

Page 31

SCHEMATIC DIAGRAM-2 (CD 2/2)

EZ MODEL

IC201

LC866560W-5M02FD

UNIT

4443

Page 32

WIRING-2 (TAPE)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

K

4645

Page 33

WIRING-3 (KEY)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

K

4847

Page 34

WIRING-4 (FUNC)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

TO/FROM

H

I

TAPE C.B

CN302

DECK C.B

1

11

SW2

SW1

J

K

3

1

2

SW4

PH2PH1

SW3

5049

Page 35

SCHEMATIC DIAGRAM-3 (TAPE/FUNC/KEY)

M1

M2

DECK

C.B

SW3

SW2

SW1

PH1

PH2

SW4

5251

Page 36

TEST MODE

ELECTRICAL ADJUSTMENT

1. CD Test Mode

1-1. How to Start Up the CD Test Mode

While pressing the “CD OPEN/CLOSE” button, connect the AC plug to the power outlet.

When the CD test mode is started up, When the CD test mode starts up, all displays turn on.

Note: When the PANEL, TOP has been removed for each CHAS, GEAR, be sure to short pin-4 and pin-5 of the connector CN3 on

the CD board in order to recognize that the CD lid is closed.

1-2. Releasing the CD Test Mode

Remove the shorting between pin-4 and pin-5 of the connector CN3 on the CD board to return to the original setup.

Then press the POWER button or the FUNCTION button, or remove the AC plug from the power outlet to release the CD test

mode.

1-3. Function Description of the Test Mode

MODE

Start mode

Search mode

Play mode

Traverse mode

Sled mode

Note: If the focus search operation is continued for 10 minutes or longer, heating of the driver IC is accumulated to trigger the

protection circuit that will stop operation of the CD system. .Turn off the main power and re-start operation about 10 minutes

later.

Operation

Starting up the

test mode

9

2

;

6

5

Indication on display

CD TEST

CD

Track No. and

playing time are

displayed

Track No. and

playing time flash

CD TEST

Function

Continuous focus searching.

The pickup lens repeats the fullswing up-down motion * Note

Normal playback.

When the TOC reading is not

possible, the same movement as

in the search mode.

Playback PAUSE mode

The pickup moves to the

innermost track

The pickup moves to the

outermost track

Contents

Check APC circuit.

Laser current measurement.

Focus error waveform check.

Focus servo.

Tracking servo.

CLV servo.

Sled servo.

Tracking servo OFF.

Sled servo.

Check operation of the

mechanism.

CD C.B

< CD SECTION >

Note: • Connect a probe (10: 1) of the oscilloscope test point

for adjustment.

• Connect ground (-) terminal of oscilloscope probe to

TP3 (VREF) for all adjustment.

1. Focus Bias Adjustment

Make the focus bias adjustment when replacing and repairing

the optical block.

Oscilloscope

(DC range)

TP1 (RF)

TP2 (VREF)

1) Connect an oscilloscope to test points TP1 (RF) and TP2

(VREF).

2) Turn on the power switch.

3) Insert test disc TCD-782 (YEDS-18) and play back the

second program.

4) Adjust SFR103 so that RF signal of the test point TP1 (RF) is

MAX and CLEARREST.

+

–

TP1

(RF)

1

TP2

(VREF)

IC1

TP3

(TE)

2. Tracking Balance Check

TP3 (TE)

TP2 (VREF)

1) Connect an oscilloscope to test points TP3 (TE) and TP2

(VREF).

2) Start up the CD test mode.

3) Insert the test disc TCD-782 (YEDS-18) and enter the

traverse mode of the CD test mode.

4) Confirm that the traverse waveform on an oscilloscope is

vertically symmetrical as shown in the figure below.

5) After confirming the waveform, release the CD test mode.

VREF

SFR130

CN2

R2

Oscilloscope

(DC range)

+

–

A

B

A=B

VOLT/DIV: 20mV

TIME/DIV: 1mS

EYE PATTERN

must be CLEAR and MAX.

VOLT/DIV: 0.5V

TIME/DIV: 0.5µS

MAX

1.8±0.1 Vp-p

0V

3. Laser Current Check

The current of the laser signal can be checked with the

voltages on both sides of R2 (voltage across 10 ).

The difference for the specified value shown on the label

must be within ± 6.0mA.

Laser current Iop =

5453

KSS-213F

15165

SG442

44.2mA

Voltage across R2

10Ω

Page 37

ELECTRICAL ADJUSTMENT

TAPE C.B

SFR351

SFR352

< DECK SECTION >

1. Record/Playback Frequency Response Characteristics Adjustment

Adjustment conditions

Settings: • Test tape: TTA-602

• Test point: LINE OUT (J701)

• Input signal: 1kHz/10kHz, AUX IN (J501)

• Adjustment locations: FORWARD direction ..... SFR351(Lch), SFR352 (Rch)

• Adjustment locations: REVERSE direction ....... SFR451 (Lch), SFR452 (Rch)

* Adjustment can be performed from the bottom of the cabinet.

Method: 1) Input the 1kHz signal and adjust the input signal level for -20 dB.

2) Set the XR-M88 into the record mode and record the 1kHz and 10kHz signals alternately.

3) Play back the segment that is recorded in step 2) and adjust SFR351 and SFR352 so that both the

1kHz and 10kHz signals have the same level within 0 dB +3/-4dB.

4) Perform the same adjustment by adjusting SFR451 and SFR452 in the REVERSE mode in the

same way.

SFR451

IC301

SFR452

55

Page 38

IC DESCRIPTION

IC, LC866560W-5M02FD

Pin No. Pin Name I/O Description

1

2

O-MACMD

____________

I-SCMD

O

Command output to slave microprocessor.

I

Command input from slave microprocessor.

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20, 21

22

23

O-ARDY

O-SREQ

I-MREQ

O-SURROUND

O-SRST

O-VOLCTL

P36

O-COIN

_____________

O-CKSFT

________

RST

I-DRF

I-SQOUT

VSS1

CF1

CF2

VDD1

____________

I-HOLD

I-KEY1, I-KEY2

AN3

AN4

—

—

Serial data send/receive preparation completion output for MD UNIT control. (TAPE

O

REC MUTE output).

Serial data transfer request for MD UNIT control. (FWD/RWD switching output

O

during TAPE PLAY/REC).

I

Serial data transfer request for MD UNIT control. (REC/PB switching output).

O

QSURROUND ON/OFF output.

O

Reset signal output to slave microprocessor.

O

Connected to VOL/P.EQ IC M62439SP pin-! CONT.

O

NC.

O

Connected to CD DSP LC78622E pin-56 COIN and CD ASP LA9240M pin-52 DAT.

O

Clock shift output. “L” at clock shift.

I

Microprocessor reset.

I

Connected to CD ASP LA9240M pin-54 DRF.

I

Connected to CD DSP LC78622E pin-55 SQOUT.

GND.

I

5.76 MHz. Connected to oscillator.

O

Microprocessor power supply. (µ-com 5V).

I

Hold state detection. (A/D).

I

KEY AD data input.

I

DECA MECA state detection input. (AD).

I

TAPE MUSIC SENSOR input. (A/D).

24

25

26

27

28

29

30-45

46

47-49

50

51

52

53-55

56

57

58

59

I-CDDSW

I-SPE

P87

I-WRQ

P72

I-RMC

T0-T15

VDD3

MODE1-MODE3

T.U.R

VP

I-SUP.R

PC5-PC7

I-AMST

I-AM10K

I-LW

I-SW

—

—

—

I

CD DOOR OPEN/CLOSE state detection input. (AD).

I

Spare level detection. (A/D).

I

NC.

I

Connected to CD DSP LC78622E pin-53 WRQ.

I

NC.

I

Remote control signal input.

NC.

Microprocessor power supply. (µ-com 5V).

I

DECK MECA state detection input.

I

Rotation detection of TAKE UP REEL of DECK MECA.

Connected to negative polarity power supply -VFL for FL.

I

Rotation detection of TAKE UP REEL of DECK MECA.

I

NC.

I

I

INITIAL DIODE MATRIX input.

I

I

56

Page 39

Pin No. Pin Name I/O Description

60

61

62

63

64

65

66-71

72

73

74, 75

76, 77

78

79, 80

81

82

83, 84

85

I-OIRT

I-RDS

_________

I-BBE

_______________

I-DOLBY

_______

I-TAPE/MD

_____________

I-DEMO

PE2-PE7

VDD4

PF0

PF1, PF2

PF3, PF4

_____________________

I-DOOR DET

PF6, PF7

O-CDDOPEN

O-CDDCLOSE

PG2, PG3

O-BBEA

I

I

I

INITIAL DIODE MATRIX input.

I

I

I

NC.

I

Microprocessor power supply. (µ-com 5V).

—

DECK MECA MAIN MOTOR control output.

O

DECK MECA SUB control output.

O

NC.

—

Over-current detection input to the CD DOOR MOTOR.

I

NC.

—

CD DOOR OPEN control output.

O

CD DOOR CLOSE control output.

O

NC.

—

O

BBE LEVEL switching output.

86

O-BBEB

O

87

88

89

90

91

92

93

94

95

96

97

98

99

100

O-CD

_______________

O-MDRST

VSS2

VDD2

O-RWC

____________

O-CQCK

O-L.O.M

P07

O-SIN

I-SOUT

I-ACLK

O-MASO

___________

I-MASI

O-MACLK

Power supply control output of CD block.

O

MD UNIT 7ZG-9A reset signal output.

O

GND.

—

Microprocessor power supply. (µ-com 5V).

—

Connected to CD DSP LC78622E pin-59 RWC and CD ASP LA9240M pin-53 CF.

O

Connected to CD DSP LC78622E pin-57 CQCK and CD ASP LA9240M pin-51 CL.

O

LINE OUT MUTE output.

O

NC.

—

Serial data output for MD UNIT control.

O

Serial data input for MD UNIT control.(FWD REC BIAS control output).

I

Serial clock input for MD UNIT control. (RWD REC BIAS control output).

I

Serial data output to slave microprocessor.

O

Serial data input from slave microprocessor.

I

Transfer clock output to slave microprocessor.

O

____________

57

Page 40

IC, LA9241ML

Pin No. Pin Name I/O Description

1

FIN2

Pin to which external pickup photo diode is connected. RF signal is created by adding

I

with the FIN1 pin signal. FE signal is created by subtracting from the FIN1 pin signal.

10

11

12

13

14

15

16

2

3

4

5

6

7

8

9

FIN1

E

F

TB

TE–

TE

TESI

SCI

TH

TA

TD–

TD

JP

TO

FD

I

Pin to which external pickup photo diode is connected.

Pin to which external pickup photo diode is connected. TE signal is created by

I

subtracting from the F pin signal.

I

Pin to which external pickup photo diode is connected.

I

DC component of the TE signal is input.

I

Pin to which external resistor setting the TE signal gain is connected between the TE pin.

O

TE signal output pin.

TES “Track Error Sense” comparator input pin. TE signal is passed through a band-

I

pass filter then input.

I

Shock detection signal input pin.

I

Tracking gain time constant setting pin.

O

TA amplifier output pin.

Pin to which external tracking phase compensation constants are connected between

I

the TD and VR pins.

I

Tracking phase compensation setting pin.

I

Tracking jump signal (kick pulse) amplitude setting pin.

O

Tracking control signal output pin.

O

Focusing control signal output pin.

17

18

19

20

21

22

23

24

25

26

27

28

29

30, 31

FD–

FA

FA–

FE

FE–

AGND

NC

SP

SPG

SP–

SPD

SLEQ

SLD

SL–, SL+

—

—

Pin to which external focusing phase compensation constants are connected between

I

the FD and FA pins.

Pin to which external focusing phase compensation constants are connected between

I

the FD– and FA– pins.

Pin to which external focusing phase compensation constants are connected between

I

the FA and FE pins.

O

FE signal output pin.

I

Pin to which external FE signal gain setting resistor is connected between the FE pin.

Analog signal GND.

No connection.

O

Single ended output of the CV+ and CV– pin input signal.

I

Pin to which external spindle gain setting resistor in 12 cm mode is connected.

Pin to which external spindle phase compensation constants are connected together

I

with SPD pin.

O

Spindle control signal output pin.

I

Pin to which external sled phase compensation constants are connected.

O

Sled control signal output pin.

I

Sled advance signal input pin from microprocessor.

32, 33

34

35

JP–, JP+

TGL

TOFF

I

Tracking jump signal input pin from DSP.

I

Tracking gain control signal input from DSP. Low gain when TGL = H.

I

Tracking off control signal input pin from DSP. Off when TOFF = H.

58

Page 41

Pin No. Pin Name I/O Description

36

TES

O

Pin from which TES signal is output to DSP.

37

38

39, 40

41

42

43

44

45

46

47

48

49

50

51

52

HFL

SLOF

CV–, CV+

RFSM

RFS–

SLC

SLI

DGND

FSC

TBC

NC

DEF

CLK

CL

DAT

“High Frequency Level” is used to judge whether the main beam position is on top of

O

bit or on top of mirror.

I

Sled servo off control input pin.

I

CLV error signal input pin from DSP.

O

RF output pin.

RF gain setting and EFM signal 3T compensation constant setting pin together with

I

RFSM pin.

“Slice Level Control” is the output pin which controls the RF signal data slice level by

O

DSP.

I

Input pin which control the data slice level by the DSP.

—

Digital system GND.

O

Output pin to which external focus search smoothing capacitor is connected.

I

“Tracking Balance Control” EF balance variable range setting pin.

—

No connection.

O

Disc defect detector output pin.

I

Reference clock input pin. 4.23 MHz of the DSP is input.

I

Microprocessor command clock input pin.

I

Microprocessor command data input pin.

53

54

55

56

57

58

59

60

61

62

63

64

CE

DRF

FSS

VCC2

REFI

VR

LF2

PH1

BH1

LDD

LDS

VCC1

I

Microprocessor command chip enable input pin.

O

“Detect RF” RF level detector output.

I

“Focus Search Select” focus search mode (± search/+ search) select pin.

—

Servo system and digital system Vcc pin.

—

Pin to which external bypass capacitor for reference voltage is connected.

O

Reference voltage output pin.

I

Disc defect detector time constant setting pin.

I

Pin to which external capacitor for RF signal peak holding is connected.

I

Pin to which external capacitor for RF signal bottom holding is connected.

O

APC circuit output pin.

I

APC circuit input pin.

—

RF system Vcc pin.

59

Page 42

IC, LC78622ED

Pin No. Pin Name I/O Description

1

2

3

4

5

DEFI

TAI

PDO

VVSS

ISET

—

I

Defect sense signal (DEF) input pin. (Connect to 0V when not used).

I

O

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

Phase comparator output pin to control external VCO.

GND pin for built-in VCO. Be sure to connect to 0V.

For PLL.

I

Pin to which external resistor adjusting the PD0 output current.

6

7

8

9

10

11

12, 13

14

15

16

17

18

19, 20

21

22

23

24-28

29

VVDD

FR

VSS

EFMO

EFMIN

TEST2

CLV+, CLV–

___

V/P

HFL

TES

TOFF

TGL

JP+, JP–

PCK

FSEQ

VDD

SL+ - PUIN

EMPH

—

—

O

O

O

O

O

O

O

O

—

I/O

O

Power supply pin for built-in VCO.

I

Pin for VCO frequency range adjustment.

Digital system GND. Be sure to connect to 0V.

EFM signal output pin.

For slice level control.

I

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

EFM signal input pin.

Disc motor control output. Three level output is possible using command.

Rough servo or phase control automatic selection monitoring output pin. Rough servo

at H. Phase servo at L.

I

Track detect signal input pin. Schmidt input.

I

Tracking error signal input pin. Schmidt input.

Tracking OFF output pin.

Tracking gain selection output pin. Gain boost at L.

Track jump control signal output pin. Three level output is possible using command.

EFM data playback clock monitoring pin 4.3218 MHz when phase is locked in.

Sync signal detection output pin. H when the sync signal which is detected from EFM

signal and thesync signal which is internally generated agree.

Digital system power supply pin.

The pin is controlled by the serial data

command from microprocessor. When

General purpose input/output pin 1 to 5.

the pin is not used, set the pin to the input

terminal and connect to 0V, or alternately

set the pin to output terminal and leave

the pin open.

De-emphasis monitor output pin. De-emphasis disc is being played back at H.

30

31

32, 33

34

35

36

37

38

39

40

41

42

C2F

DOUT

TEST3, TEST4

N.C.

MUTEL

LVDD

LCHO

LVSS

RVSS

RCHO

RVDD

MUTER

—

—

—

—

—

O

C2 flag output pin.

O

DIGITAL OUT output pin. (EIAJ format).

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

Not used. Set the pin to open.

O

L-channel 1-bit DAC.

O

L-channel mute output pin.

L-channel power supply pin.

L-channel output pin.

L-channel GND. Be sure to connect to 0V.

R-channel GND. Be sure to connect to 0V.

O

R-channel output pin.

R-channel 1-bit DAC.

R-channel power supply pin.

O

R-channel mute output pin.

60

Page 43

Pin No. Pin Name I/O Description

43

44

45

46

47

XVDD

XOUT

XIN

XVSS

SBSY

—

Crystal oscillator power supply pin.

O

Pin to which external 16.9344 MHz crystal oscillator is connected.

I

—

Crystal oscillator GND pin. Be sure to connect to 0V.

O

Subcode block sync signal output pin.

IC BLOCK DIAGRAM

IC, BA5936

Rog CURRENT

DETECTOR

TERMINAL

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

EFLG

PW

SFSY

SBCK

FSX

WRQ

RWC

SQOUT

COIN

___________

CQCK

________

RES

TST11

16M

4.2M

TEST5

______

CS

TEST1

O

C1, C2, single and dual correction monitoring pin.

O

Subcode P, Q, R, S, T, U and W output pin.

O

Subcode frame sync signal output pin. Falls down when subcode enters standby.

Subcode read clock input pin. Schmidt input. (Be sure to connected to 0V when not

I

in use.)

Pin outputting the 7.35 kHz sync signal which is generated by dividing frequency of

O

crystal oscillator.

O

Subcode Q output standby output pin.

I

Read/write control input pin. Schmidt input.

O

Subcode Q output pin.

I

Command input pin from microprocessor.

I

Command input read clock or subcode read input clock from SQOUT pin

I

LC78622 reset input pin. Set this pin to L once when the main power is turned on.

O

Test signal output pin. Use this pin as open (normally L output).

O

16.9344 MHz output pin.

O

4.2336 MHz output pin.

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

Chip select signal input pin with built-in pull-down resistor. Be sure to connect to 0V

I

while it is not controlling.

I

Test signal input pin without built-in pull-down resistor. Be sure to connect to 0V.

IC, M62495FP

IC, BA3880FS

Note: The same potential must be applied to the respective power supply terminals. (VDD, VVDD, LVDD, RVDD, XVDD)

IC, MM1454XFBE

VCC

LIN VREF QF1 QF2 QF3 QF4 QF5

16 15 14 13 12 11 10 9

+

–

QSurround

BIAS

+

–

1 2 3 4 5 6 7 8

RIN PNR B/Q DET QF6 ROUT LOUT GND

–

+

6261

Page 44

MECHANICAL EXPLODED VIEW 1/1

4

G

K

P.C.B

P.C.B

6

7

F

11

D

10

I

5

E

B

8

C

9

15

13

12

C

14

MECHANICAL PARTS LIST 1/1

1

2

3

21

K

25

16

22

23

24

17

26

27

28

29

31

B

30

P.C.B

32

33

P.C.B

20

19

I

J

18

REF. NO PART NO. KANRI DESCRIPTION

NO.

1 8Z-CL1-014-010 PANEL,CD

2 8Z-CL1-012-010 WINDOW,CD

3 8Z-CL1-004-010 CABI,TOP FD

4 8Z-CL1-007-010 BOX,CD

5 8Z-CL1-205-010 HLDR,GEAR

6 87-A91-069-010 MOT,RF-370CA15370

7 8Z-CL1-210-010 PULLEY,MOTOR

8 8Z-CL1-211-010 PULLEY,CD

9 8Z-CL1-212-010 BELT,CD

10 8Z-CL1-209-010 GEAR,B

11 8Z-CL1-208-010 GEAR,A

12 8Z-CL1-011-010 WINDOW,MD

13 8Z-CL1-033-010 PLATE,WINDOW FD

14 8Z-CLB-012-010 PANEL,FD CS

15 8Z-CLB-002-010 PANEL,CS

16 8Z-CLB-004-010 PANEL,FLAP CS

17 8Z-CLB-005-010 SPR-T,FLAP

18 8Z-CLB-001-010 CABI,FR CS

19 8Z-CL1-028-010 CAP, EJECT

20 8Z-CL1-207-010 BTN,EJECT

21 8Z-CLB-014-010 PANEL,CONT CS

22 8Z-CL1-016-010 CAP, POWER

23 8Z-CL1-017-010 CAP, FUNC

24 8Z-CL1-018-010 CAP, REC

25 8Z-CL1-019-010 CAP, PAUSE

26 8Z-CL1-020-010 CAP, STOP

27 8Z-CLB-003-010 CAP, PLAY CS

28 8Z-CL1-022-010 CAP, REW

29 8Z-CL1-023-010 CAP, FF

30 8Z-CL1-024-010 CAP, DOWN

REF. NO PART NO. KANRI DESCRIPTION

NO.

31 8Z-CL1-025-010 CAP, UP

32 8Z-CL1-026-010 CAP, OPEN

33 8Z-CL1-206-010 BTN,CONT

34 88-HV1-207-010 DMPR,MECHA

35 8Z-CL1-653-010 F-CABLE,19P 1.5 FG

36 87-A90-878-010 HLDR,WIRE 19P 1.5 51016

37 8Z-CLB-653-010 FF-CABLE, 16P 1.0 150MM

38 8Z-CLB-651-010 FF-CABLE, 9P 1.0 150MM

39 84-ZG1-245-210 CAP,OPTICAL

40 8Z-CL1-029-010 LID,CORD

41 8Z-CL1-202-010 CHAS,CD

42 8Z-CLB-074-010 PANEL,REAR FD CS EZ<89<EZ>>

42 8Z-CLB-072-010 PANEL,REAR FD CS K<88<K>>

43 8Z-CLB-203-010 W.3.2-120.7

44 8Z-CLB-006-010 RING PWB DECK

A 8Z-CL1-034-010 S-SCREW,ZCL1

B 87-067-703-010 BVT2+3-10 W/O SLOT

C 87-761-096-410 VFT2+3-10 GLD

D 87-B10-162-010 VFT2+2-6

E 87-261-092-410 V+3-4 GLD

F 87-067-579-010 TAPPING SCREW, BVT2+3-8

G 87-B10-269-010 UT2+3-12 W/O CR

H 87-261-101-410 V+3-18

I 87-721-095-410 QT2+3-8 W/O SLOT

J 87-067-761-010 BVT2+3-10 BLK

K 87-744-095-410 UT2+3-8CR

L 87-067-421-010 VTT+2-4

P.C.B

P.C.B

39

42

K

34

A

G

G

40

K

G

SHLD-PLATE,HEAD

COLOR NAME TABLE

Basic color symbol Color Basic color symbol Color Basic color symbol Color

B Black C Cream D Orange

34

KSM-620AAA

L

41

G Green H Gray L Blue

LT Transparent Blue N Gold P Pink

R Red S Silver ST Titan Silver

T Brown V Violet W White

WT Transparent White Y Yellow YT Transparent Yellow

LM Metallic Blue LL Light Blue GT Transparent Green

LD Dark Blue DT Transparent Orange

36

37

35

38

HT-SINK,MD

TN-708C-128R

P.C.B

44

43

F

CHAS,MAIN CS

A

F

P.C.B

H

6463

Page 45

TAPE MECHANISM EXPLODED VIEW 1/1

32

TAPE MECHANISM PARTS LIST 1/1

15

C

20

13

23

24

25

26

CUSHION

RUBBER

31

F

34

35

36

29

30

REF. NO PART NO. KANRI DESCRIPTION

33

C

21

J

7

F

G

1 S1-970-015-070 CHASSIS RIVET ASY

2 S1-970-020-010 MAIN PLATE

3 S1-970-020-020 B GEAR

4 S1-970-020-030 C GEAR

5 S1-970-020-040 D GEAR

6 S1-970-020-120 P GEAR W

7 S1-970-020-060 P G PLATE

8 S1-970-020-070 GUIDE BKT

9 S1-950-100-020 MIDDLE PULLEY

10 S1-970-033-030 HEAD PANEL ASSY

11 S6-201-050-020 RPF AC-5544BM-5949

12 S1-970-043-010 O P PLATE ASSY

13 S1-970-045-040 EJECT LEVER RIVET ASSY

14 S1-970-045-020 S.B PLATE RIVET ASSY

15 S1-970-047-070 O.P PLATE HOLDER

16 S1-970-060-020 FR GEAR

17 S1-970-060-010 FR PLATE

18 S1-970-073-030 PINCH ROLLER ARM(F) ASSY

19 S1-970-073-040 PINCH ROLLER ARM(R)ASSY

20 S1-970-020-130 REC SENSOR F

21 S1-970-020-140 REC SENSOR R

22 S1-970-020-150 CR DETECTIVE PLATE HOLDER

23 S1-970-093-010 SUB MOTOR ASSY

24 S1-970-103-010 MAIN MOTOR ASSY

25 S1-970-100-020 M CONNECTOR ASSY

NO.

REF. NO PART NO. KANRI DESCRIPTION

NO.

26 S1-950-140-030 WIRE CLUMPER

27 S1-970-113-010 FL CAPSTAN ASSY

28 S1-970-110-060 MAIN BELT(G)

29 S1-970-120-010 CASE LIFTER B

30 S1-970-120-160 CASSETTE CASE R

31 S1-970-120-040 P.S ACTUATOR PLATE

32 S1-970-120-050 P.S SPRING

33 S1-970-120-030 PACK SLIDER

34 S1-950-080-220 RELL CAP

35 S1-970-080-120 REEL WING SPRING

36 S1-970-083-020 REEL ASSY(K)

37 S1-970-133-070 REEL PWB ASSY

A 87-267-545-310 CAMERA TAPPING SCREW S 2.0-2.5

B 87-263-033-010 SCREW,2.0-4.0

C 87-351-547-410 S TAPING SCREW(FOR CAMERA)M2-3

D 87-B10-255-010 TAMS SCREW M2-3

E 86-544-439-010 P.WASHER(CUT)0.85-2.8-0.25

F S9-W06-500-400 P.WASHER(CUT)1.55-3.5-0.5

G 87-081-978-010 P.WASHER 2.1-3.5-0.2

H 87-067-529-010 P.WASHER 2.1-3.5-0.35

I S1-821-120-230 PK COLLAR SCREW A

J S9-W06-400-700 HLW WASHER(CUT)2.1-4.0-0.35

D

F

34

35

36

22

J

7

F

1

9

E

8

19

18

B

11

G

37

6

10

3

4

5

A

H

27

12

2

16

14

17

I

28

6665

Page 46

CD MECHANISM EXPLODED VIEW 1/1

MODEL NO. SX-LM200

SPEAKER DISASSEMBLY INSTRUCTIONS

Type.1

Type.4

Insert a flat-bladed screwdriver into the position indicated by the

arrows and remove the panel. Remove the screws of each speaker

unit andthen remove the speaker units.

A

C

TOOLS

1 Plastic head hammer

2 (-) flat head screwdriver

3 Cut chisel

6

7

1

1 2 3

2

5

Type.2

Remove the grill frame and four pieces of rubber caps by pulling

out with a flat-bladed screwdriver. Remove the screws from hold