Page 1

XP-V319

ALH1SK

SERVICE MANUAL

COMPACT DISC PLAYER

MODEL CODE : 86HR8-0117(B)

BASIC CD MECHANISM : DA23L

S/M Code No. 09-003-339-8N2

DATA

Page 2

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

This set employs laser. Therefore, be sure to follow carefully the

instructions below when servicing.

WARNING!

WHEN SERVICING, DO NOT APPROACH THE LASER EXIT

WITH THE EYE TOO CLOSELY. IN CASE IT IS NECESSARY TO

CONFIRM LASER BEAM EMISSION. BE SURE TO OBSERVE

FROM A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE OPTICAL

PICK-UP BLOCK.

Caution: Invisible laser radiation when

open and interlocks defeated avoid exposure to beam.

Advarsel:Usynling laserståling ved åbning,

når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

VAROITUS!

Laiteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyt-täjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

VARNING!

Om apparaten används på annat sätt än vad som specificeras i

denna bruksanvising, kan användaren utsättas för osynling

laserstrålning, som överskrider gränsen för laserklass 1.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

ATTENTION

L'utilisation de commandes, réglages ou procédures autres que

ceux spécifiés peut entraîner une dangereuse exposition aux

radiations.

ADVARSEL!

Usynlig laserståling ved åbning, når sikkerhedsafbrydereer ude

af funktion. Undgå udsættelse for stråling.

This Compact Disc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located on the rear

exterior.

CLASS 1

KLASSE 1

LUOKAN 1

KLASS 1

LASER PRODUCT

LASER PRODUKT

LASER LAITE

LASER APPARAT

-2-

Page 3

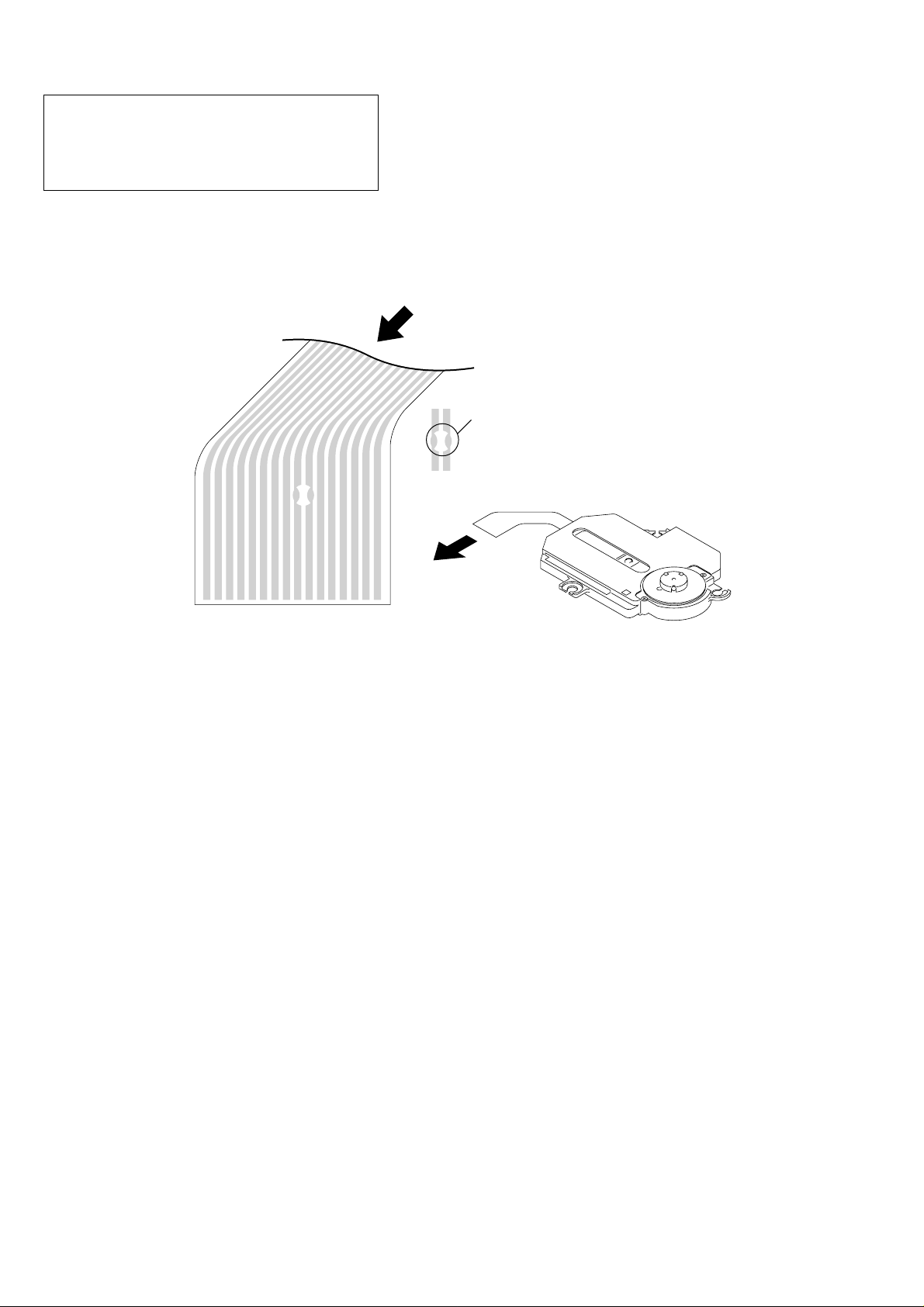

Precaution to replace Optical block

(SF-P200)

Body or clothes electrostatic potential could ruin

laser diode in the optical block. Be sure ground

body and workbench, and use care the clothes

do not touch the diode.

1) After the connection, remove solder shown in

the right figure.

:SOLDER

10 9

PICK UP ASSY

116

SF-P200

-3-

Page 4

SPECIFICATIONS

Design and specifications are subject to change without notice.

•

-4-

Page 5

ELECTRICAL MAIN PARTS LIST-1/2

REF. NO PART NO. KANRI DESCRIPTION

NO.

IC

87-A21-448-040 C-IC,BH6554FV

87-A21-083-040 C-IC,BH6508FS

87-A21-381-040 C-IC,LA9235M

87-A21-591-010 C-IC,LC78641NE-D

87-A21-085-040 C-IC,TA2120FN

8A-HC7-607-010 C-IC,UPD789406AGC-014-8BT

TRANSISTOR

89-211-323-080 C-TR,2SB1132R

87-A30-332-040 C-TR,CPH3106

87-A30-278-040 C-FET,2SK2980

87-A30-287-040 C-TR,DTC114TKA

87-A30-246-040 C-TR,2SA1037AK

86-NFZ-667-040 C-TR,DTC123JKA

89-416-643-080 C-TR,2SD1664R

89-324-123-080 C-TR,2SC2412K S

DIODE

87-A40-592-040 C-ZENER,HZM11NB2

87-A40-590-040 C-DIODE,HRW0202A

87-A40-554-040 C-DIODE,RB491D

87-A40-469-080 C-DIODE,HSM2838CTR

87-A40-836-040 C-ZENER,HZM6.2NB1

MAIN C.B

C101 87-010-553-040 CAP,E 47-16 GAS

C102 87-010-551-040 CAP,E 33-10 GAS

C103 87-A10-505-040 CAP,E 220-6.3 105 SF

C104 87-010-503-040 CAP,E 220-4 GAS

C105 87-010-498-040 CAP,E 10-16 GAS

C106 87-010-502-040 CAP ELECT GAS 100/4

C107 87-010-196-080 CHIP CAPACITOR,0.1-25

C108 87-012-145-080 CAP, CHIP S 270P CH

C109 87-010-198-080 CAP, CHIP 0.022

C110 87-A10-826-080 C-CAP,S 1-10 K B

C111 87-010-196-080 CHIP CAPACITOR,0.1-25

C112 87-010-196-080 CHIP CAPACITOR,0.1-25

C113 87-A10-826-080 C-CAP,S 1-10 K B

C115 87-010-196-080 CHIP CAPACITOR,0.1-25

C116 87-010-196-080 CHIP CAPACITOR,0.1-25

C117 87-010-196-080 CHIP CAPACITOR,0.1-25

C201 87-A10-505-040 CAP,E 220-6.3 105 SF

C202 87-010-175-080 CAP 560P

C204 87-010-213-080 C-CAP,S 0.015-50 B

C205 87-010-213-080 C-CAP,S 0.015-50 B

C206 87-A10-826-080 C-CAP,S 1-10 K B

C207 87-A10-826-080 C-CAP,S 1-10 K B

C208 87-010-177-080 C-CAP,S 820P-50 SL

C209 87-010-213-080 C-CAP,S 0.015-50 B

C210 87-010-213-080 C-CAP,S 0.015-50 B

C212 87-A10-826-080 C-CAP,S 1-10 K B

C301 87-016-557-040 CAP,E 100-6.3 SF

C302 87-010-502-040 CAP ELECT GAS 100/4

C303 87-016-557-040 CAP,E 100-6.3 SF

C304 87-010-502-040 CAP ELECT GAS 100/4

C305 87-010-501-040 E/CAP GAS 47-4

C306 87-010-196-080 CHIP CAPACITOR,0.1-25

C308 87-010-196-080 CHIP CAPACITOR,0.1-25

C309 87-010-178-080 CHIP CAP 1000P

C311 87-010-318-080 C-CAP,S 47P-50 CH

C313 87-A10-826-080 C-CAP,S 1-10 K B

C314 87-A10-201-080 C-CAP,S0.33-16 KB

C351 87-016-557-040 CAP,E 100-6.3 SF

C352 87-010-503-040 CAP,E 220-4 GAS

C353 87-A10-826-080 C-CAP,S 1-10 K B

REF. NO PART NO. KANRI DESCRIPTION

NO.

C354 87-010-196-080 CHIP CAPACITOR,0.1-25

C355 87-010-312-080 C-CAP,S 15P-50 CH

C356 87-010-312-080 C-CAP,S 15P-50 CH

C357 87-010-196-080 CHIP CAPACITOR,0.1-25

C358 87-010-322-080 C-CAP,S 100P-50 CH

C359 87-A10-369-080 C-CAP,S 0.47-16 K B

C360 87-016-669-080 C-CAP,S 0.1-25 K B

C361 87-010-322-080 C-CAP,S 100P-50 CH

C362 87-016-669-080 C-CAP,S 0.1-25 K B

C363 87-010-197-080 CAP, CHIP 0.01 DM

C364 87-016-369-080 C-CAP,S 0.033-25 B K

C365 87-010-322-080 C-CAP,S 100P-50 CH

C367 87-010-175-080 CAP 560P

C368 87-010-196-080 CHIP CAPACITOR,0.1-25

C701 87-010-501-040 E/CAP GAS 47-4

C702 87-010-495-040 CAP,E 2.2-50 GAS

C703 87-010-498-040 CAP,E 10-16 GAS

C704 87-010-503-040 CAP,E 220-4 GAS

C705 87-010-503-040 CAP,E 220-4 GAS

C706 87-010-498-040 CAP,E 10-16 GAS

C707 87-010-501-040 E/CAP GAS 47-4

C708 87-A10-826-080 C-CAP,S 1-10 K B

C709 87-A10-826-080 C-CAP,S 1-10 K B

C710 87-012-155-080 C-CAP 180P-50CH

C711 87-012-155-080 C-CAP 180P-50CH

C712 87-012-141-080 CHIP-CAPACITOR,0.22-16F

C713 87-010-196-080 CHIP CAPACITOR,0.1-25

C714 87-010-196-080 CHIP CAPACITOR,0.1-25

C715 87-010-196-080 CHIP CAPACITOR,0.1-25

C716 87-010-196-080 CHIP CAPACITOR,0.1-25

C717 87-010-196-080 CHIP CAPACITOR,0.1-25

C801 87-010-501-040 E/CAP GAS 47-4

C802 87-010-196-080 CHIP CAPACITOR,0.1-25

C803 87-010-196-080 CHIP CAPACITOR,0.1-25

C804 87-010-178-080 CHIP CAP 1000P

C805 87-010-322-080 C-CAP,S 100P-50 CH

C806 87-010-319-080 C-CAP,S 56P-50 CH

C807 87-010-319-080 C-CAP,S 56P-50 CH

C808 87-010-196-080 CHIP CAPACITOR,0.1-25

CN201 87-A61-104-010 CONN,16P H WHITE 52089-1610

CN202 87-009-411-010 CONN,6P ZH V

FB701 87-A50-623-080 C-COIL,BK2125HS102

FB702 87-A50-623-080 C-COIL,BK2125HS102

FB703 87-A50-623-080 C-COIL,BK2125HS102

FB704 87-A50-623-080 C-COIL,BK2125HS102

J101 87-A61-447-010 JACK,DC DJ26B BLK 6

J701 87-A61-446-010 JACK,3.5 GRN ST W/REM

L101 87-A50-574-010 COIL,100UH #7607

L102 87-A50-573-010 COIL,330UH LHL06NB

L301 87-A50-455-080 C-COIL,47UH-FSLB2520

L302 87-A50-501-080 C-COIL,10UH-FSLB2520

L351 87-A50-501-080 C-COIL,10UH-FSLB2520

L801 87-A50-501-080 C-COIL,10UH-FSLB2520

L802 87-A50-455-080 C-COIL,47UH-FSLB2520

LCD101 8A-HC7-602-010 LCD,AHC-7

R105 87-022-355-080 C-RES,S10K-1/10W F

R107 87-022-358-080 C-RES,S 18K-1/10W F

R307 87-022-202-080 C-RES,S33K 1/10WF

R308 87-022-202-080 C-RES,S33K 1/10WF

R309 87-022-202-080 C-RES,S33K 1/10WF

R310 87-022-202-080 C-RES,S33K 1/10WF

R311 87-022-364-080 C-RES,S 82K-1/10W F

R312 87-022-364-080 C-RES,S 82K-1/10W F

S101 87-A90-095-080 SW,TACT EVQ11G04M

S102 87-A90-095-080 SW,TACT EVQ11G04M

S103 87-A90-095-080 SW,TACT EVQ11G04M

S104 87-A90-095-080 SW,TACT EVQ11G04M

S105 87-A90-095-080 SW,TACT EVQ11G04M

S106 87-A90-095-080 SW,TACT EVQ11G04M

S801 87-A91-622-010 SW,MICRO PV1102

-5-

Page 6

ELECTRICAL MAIN PARTS LIST-2/2

REF. NO PART NO. KANRI DESCRIPTION

NO.

S802 87-A91-742-010 SW,SL 4-1-3 HSW2061-010010

VR701 87-A90-462-010 VR,RTRY 30KCX2 H RK14J12A0

X351 87-A70-202-080 C-VIB,CER 16.93MHZ CSACV-MXJ04

REF. NO PART NO. KANRI DESCRIPTION

NO.

• Regarding connectors, they are not stocked as they are not the initial order items.

The connectors are available after they are supplied from connector manufacturers upon the order is received.

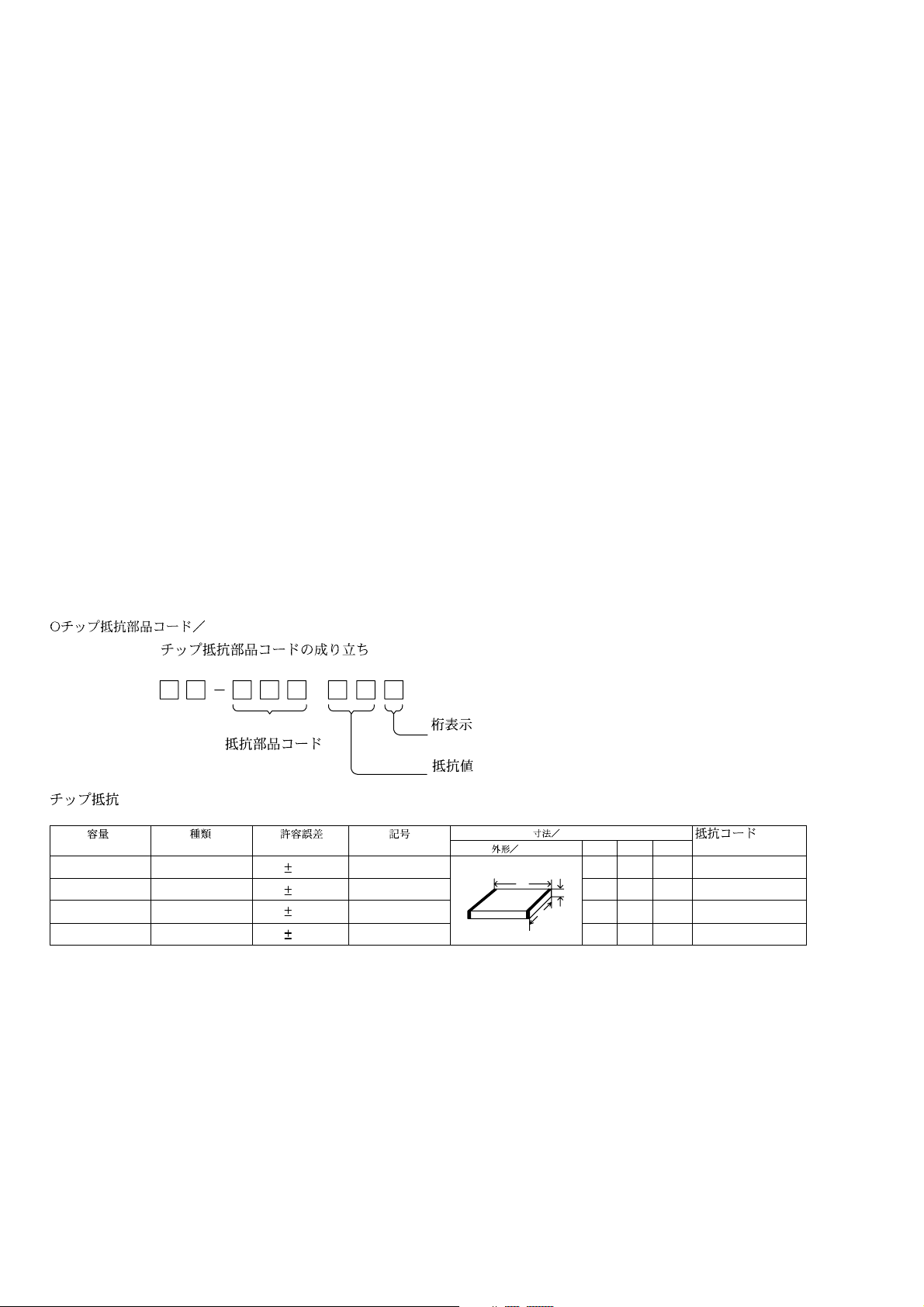

CHIP RESISTOR PART CODE

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

Symbol

Figure

Value of resistor

CJ

CJ

CJ

Form

L

W

Dimensions (mm)

LW t

1.0 0.5 0.35 104

t

1.6 0.8 0.45

2 1.25 0.45

1.6

0.55

3.2

Resistor Code

108

118

128

: A

: A

-6-

Page 7

TRANSISTOR ILLUSTRATION-1/1

C

B

E

2SA1037

2SC2412

CPH3106

DTC114TK

DTC123JK

BCE

2SB1132

2SD1664

D

G

S

2SK2980

-7-

Page 8

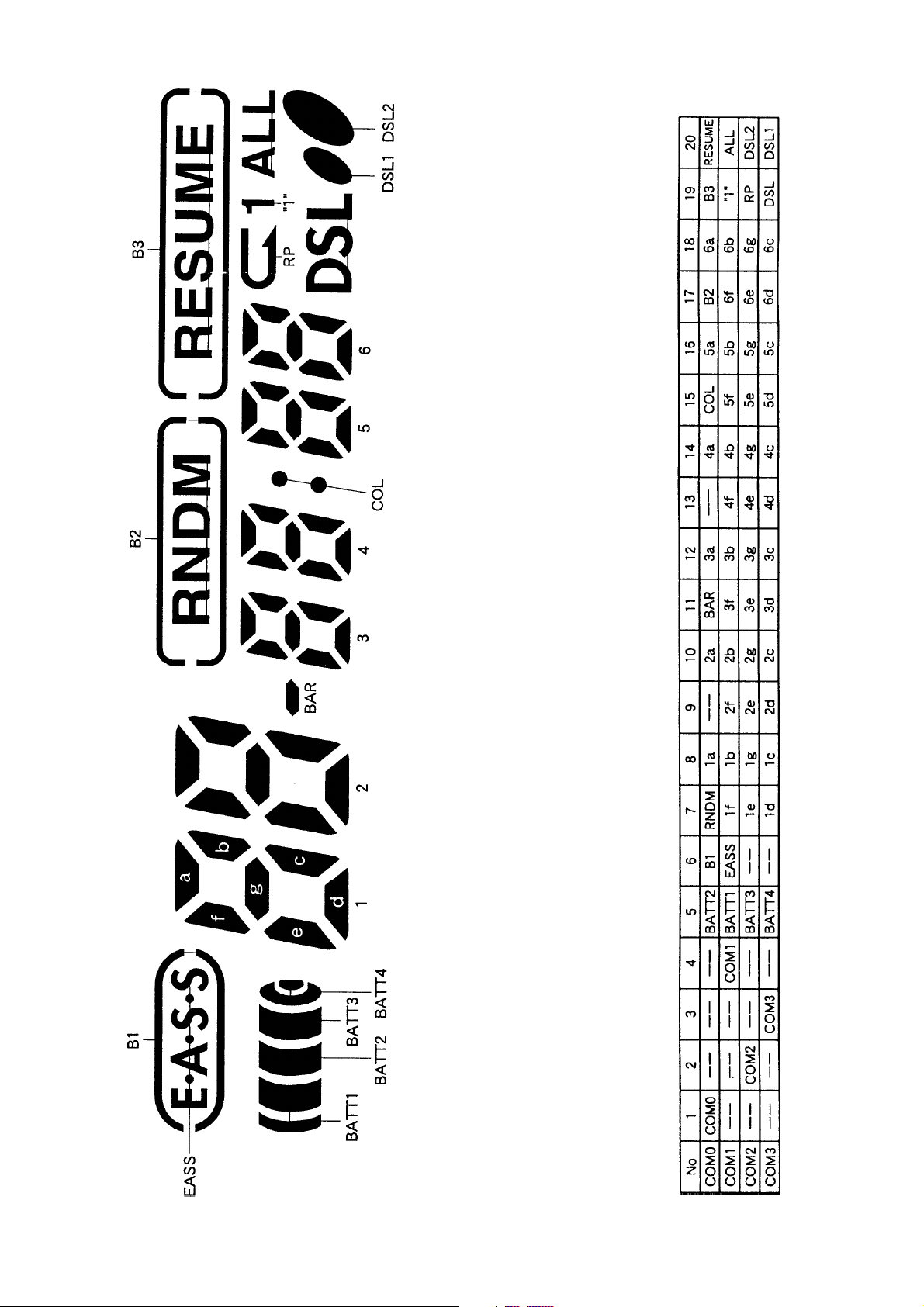

FL (AHC-7) GRID ASSIGNMENT/ANODE CONNECTION-1/1

GRID ASSIGNMENT

ANODE CONNECTION

-8-

Page 9

WIRING-1/1

101112131415161718192021222324

1234567892526272829303132

A

B

C

D

SF-P200

E

F

G

H

I

J

K

L

M

-9-

N

O

P

Q

R

S

T

U

Page 10

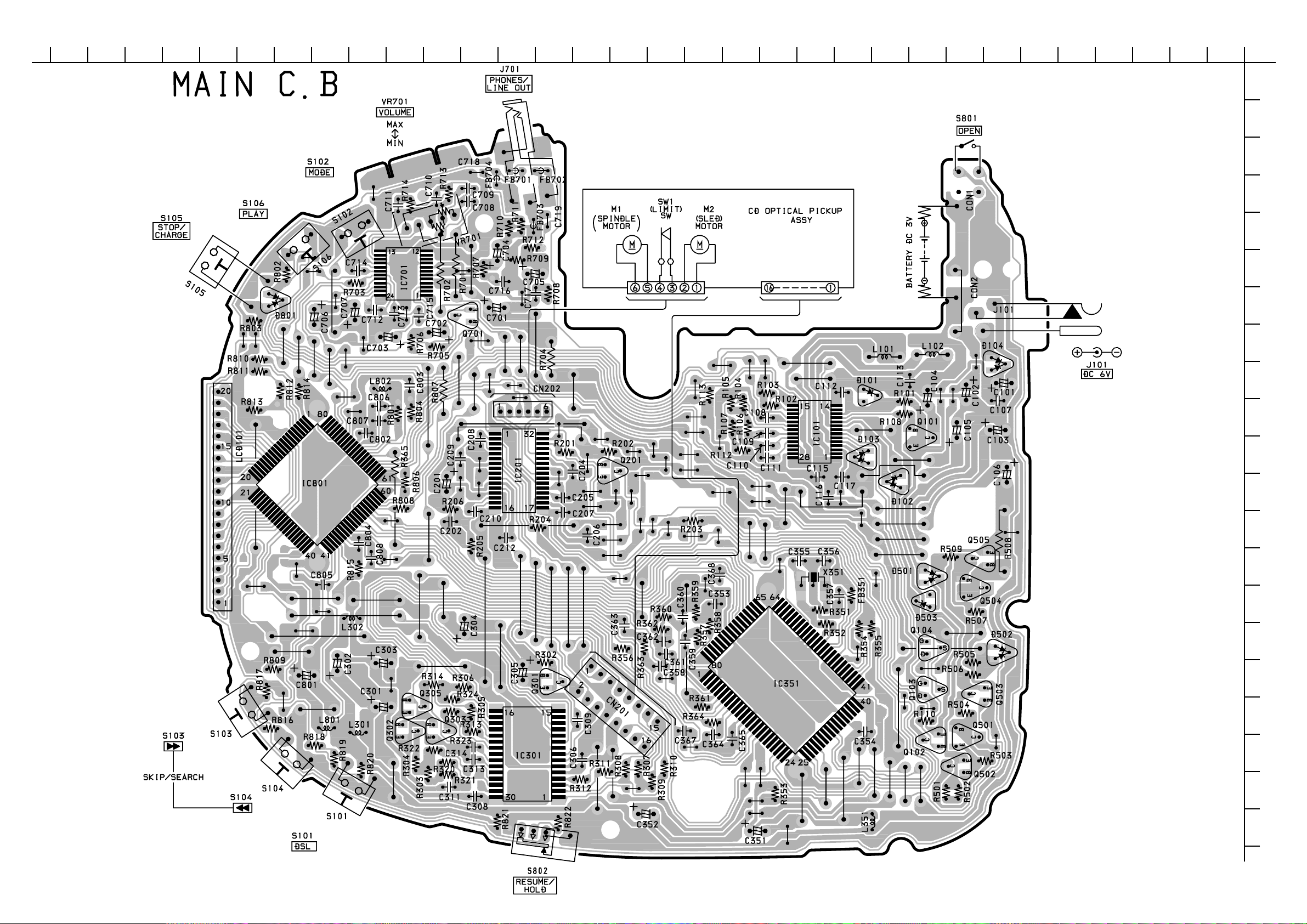

SCHEMATIC DIAGRAM-1/1

Z

-10-

Page 11

TEST MODE-1/3

IC101

IC351

IC701

IC201

IC801

IC301

27

Q305

RF

31

VC

TEST MODE SHORT LAND

-11-

Page 12

TEST MODE-2/3

The servo circuit of this model has been designed to be free of adjustments and controlled within the IC. Therefore, adjustments and disk judgement

are performed automatically every time the TOC is read out. The adjustment status of each servo inside the IC can be monitored in this test mode.

1. Startup procedure

1) Short the test land.

2) Insert the AC plug.

3) Press the STOP button. (The test mode starts.)

Note 1) The test mode is canceled by disconnecting the AC plug.

Note 2) The OPEN/CLOSE switch cannot be operated during the test mode.

2. Checking the RF level

Test point: RF & VC (Vref)

Test disk: TCD-782

Play back the disk and confirm that the RF waveform is in the following state:

0.8Vp-p or more

VOLT/DIV:200mV

TIME/DIV:0.5us

3. Checking each servo

The adjustment values of each servo can be checked by pressing the MODE button repeatedly during playback. The switching

procedure is as follows.

Check mode OFF™Vref offset (RO)™focus offset (FO)™tracking offset (TO)™tracking balance (TB)™tracking gain (TG) ™

focus gain (FG)™focus bias (FB)™check mode OFF

Example: Tracking offset (TO) Adjustment value™F5

RNDM RESUME

1

DSL

Tracking offset

* Adjustment values are indicated in hexadecimal.

When displaying each mode on the LCD and pressing the PLAY button in the STOP status, the center value is displayed on the LCD.

After the disk starts rotating, the adjustment value that was set during automatic adjustment is displayed. The display range of the

center values and adjustment values of each mode are as follows. There are 256 steps for displaying the values of all modes.

Center value

1) Vref offset (RO)

2) Focus offset (FO)

3) Tracking offset (TO)

4) Tracking balance (TB)

5) Tracking gain (TG)

6) Focus gain (FG)

7) Focus bias (FB)

Adjustment value

Center value

00

00

00

80

40

40

00

Display range

80-7F

80-7F

80-7F

00-FF

00-FF

00-FF

80-7F

-12-

Page 13

TEST MODE-3/3

4. Amount of change of jitter

The amount of change of jitter is displayed in the focus bias check mode. The displayed value has 256 steps from 00 to FF.

Example: focus bias (FB) Adjustment value™00 Jitter value™FD

RNDM RESUME

1

DSL

Tracking offset Adjustment value

* Adjustment values and jitter values are indicated in hexadecimal.

Jitter value

-13-

Page 14

WAVE FORM-1/1

1 IC301 Pin ≥ VOLT/DIV: 0.2V

RF TIME/DIV: 0.5µS

2 IC301 Pin * VOLT/DIV: 0.2V

TE TIME/DIV: 50µS

3 IC301 Pin ¡ VOLT/DIV: 0.1V

FE- TIME/DIV: 2mS

7 IC351 Pin ∞ VOLT/DIV: 0.1V

SPDO TIME/DIV: 5mS

4 IC351 Pin VOLT/DIV: 1V

XOUT TIME/DIV: 50mS

5 IC801 Pin VOLT/DIV: 1V

X1 TIME/DIV: 0.2µS

6 IC351 Pin VOLT/DIV: 2V

LRSY TIME/DIV: 5µS

52

f=16.93MHz

69

f=4.2MHz

57

f=44.1kHz

-14-

Page 15

IC BLOCK DIAGRAM-1/1

IC, BH6508FS

MUTE

4

IC, BH6554FV

POW

IN4 CN4CLK CN3

GND

IN1 CN1CT

OUT

4R

POW

GND

POW

VCC

OUT

1F

OUT

4R

POW

VCC

POW

GND

OUT

1R

OUT

3R

POW

GND

POW

VCC

OUT

2R

OUT

3F

POW

VCC

POW

GND

OUT

2F

POW

GND

IN3

VCC

VG

VREF

IN2CN2

IC, TA2120FN

IN-L IN-R

-15-

Page 16

IC DESCRIPTION-1/3 (LC78641NE-D)-1/3

Pin No. Pin Name I/O Description

1

PDO1

Internal VCD control phase comparator output pin.

O

10

11

12

13

14

15

16

17

2

3

4

5

6

7

8

9

PDO2

VVSS

PCKIST

VVDD

FR

HFL

SLCIST

SLCO

EFMIN

JITTV

JITTC

BH

PH (RFENV)

FE

TE

VREF

—

—

Internal VCD control phase comparator output pin. OFF for rough servo, ON for phase servo.

O

Internal VCD ground pin.

PDO output current adjustment resistor connection pin. (pull up)

I

Internal VCD power supply pin. (2000pF or more path controller to be inserted at a point nearer

to the pin between this pin and GND)

VCD frequency range adjustment resistor connection pin. (pull up)

I

Mirror detection signal input pin.

I

SLCO output current adjustment resistor connection pin. (pull up)

I

Control outout.

O

EFM signal input pin.

I

Jitter detection monitor pin.

O

Jitter detection adjustment pin.

O

BH signal input pin. A/D input. (Must be connected to OV when unused)

I

PH signal or RFENV signal input pin. A/D input.

I

FE signal input pin. A/D input.

I

TE signal input pin. A/D input.

I

VREF input pin. A/D input.

I

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

ADAVDD

ADAVSS

PHREF

BHREF

TBLO

TDO

FDO

SPDO

SLDO

DVREF/FG

LASER

CONT1

CONT2

CONT3

CONT4

CONT5

—

—

O

O

O

O

O

O

O

I/O

O

I/O

I/O

I/O

I/O

I/O

Servo A/D, D/A power supply pin. (2000pF or more path controller to be inserted at a point

nearer to the pin between this pin and GND)

Servo A/D, D/A ground pin.

PH reference output pin. D/A output. (Not connected)

BH reference output pin. D/A output. (Not connected)

Tracking balance output pin. D/A output.

Tracking control output pin. D/A output.

Focus control output pin. D/A output.

Spindle control output pin. D/A output.

Thread control output pin. D/A output.

Output driver VREF output pin. Input FG signal input pin. (Must be connected to OV when

unused) (Not connected)

Laser ON/OFF control pin.

General-purpose input/output pin 1. (Not connected)

General-purpose input/output pin 2. (Not connected)

General-purpose input/output pin 3. (Not connected)

General-purpose input/output pin 4.

General-purpose input/output pin 5.

34

35

36

PCK

C2F

VDD

—

EFM data playback clock monitor pin. Average 4.3218MHz when the phase is locked.

O

(Not connected)

C2 flag output pin. (Not connected)

O

Digital power supply pin. (2000pF or more path controller to be inserted at a point nearer to the

pin between this pin and GND)

-16-

Page 17

IC DESCRIPTION-1/3 (LC78641NE-D)-2/3

Pin No. Pin Name I/O Description

37

DOUT

Digital OUT output pin. (EIAJ format) (Not connected)

O

38

39

40

41

42

43

44

45

46

47

48

49

50

FSX

EFLG

TEST

EMPH

MUTEL

MUTER

LVDD

LCHO

LVSS

RVSS

RCHO

RVDD

XVDD

O

O

I/O

O

O

—

O

—

—

O

—

—

Output pin for the 7.35kHz synchronization signal divided from the crystal osillator.

(Not connected)

(Not connected)

C1 C2 error correction monitor pin. Test input pin. Must be connected to OV.

I

Emphasis pin. Which becomes an input pin after reset and can becontrolled externally.

This becomes an emphasis monitor pin under control by command. (Not connected)

L channnel mute output pin.

R channel mute output pin.

L channel power supply pin. (2000pF or more path controller to be inserted at a point

nearer to the pin between this pin and GND)

L channel output pin.

L channel ground pin, Must be connected to 0V.

R channel ground pin, Must be connected to 0V.

R channel output pin.

R channel power supply pin. (2000pF or more path controller to be inserted at a point

nearer to the pin between this pin and GND)

Crystal oscillator power supply pin. (2000pF or more path controller to be inserted at a

point nearer to the pin between this pin and GND)

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

XIN

XOUT

XVSS

ASLRCK

ASDACK

ASDFIN

LRSY

DATACK

DATA

16M

SFSY

SBSY

PW

SBCK

CE

CL

I

Connections for a 16.9344MHz crystal oscillator pin.

O

Crystal oscillator ground pin. Must be connected to 0V.

—

L/R clock input pin. (Must be connected to 0V when unused)

I

Bit clock input pin. (Must be connected to 0V when unused)

I

L/R channel data input pin. (Must be connected to 0V when unused)

I

L/R clock output pin.

O

Bit clock output pin. (Not connected)

O

L/R channel data output pin. (Not connected)

O

16.9344MHz output pin. (Not connected)

O

Subcode frame synchronization signal output pin. This signal falls when the subcode is

O

in the standby state. (Not connected)

Subcode clock synchronization signal output pin. (Not connected)

O

Subcode P, Q, R, S, T, U and W output pin. (Not connected)

O

Subcode readout clock input pin.

I

Chip enable signal input pin.

I

Data transfer clock input pin.

I

67

68

69

70

71

DI

DO

INT

WRQ

RES

Data input pin.

I

Data output pin.

O

Interruption signal output pin. (Not connected)

O

Interruption signal output pin.

O

Reset input pin. This pin must be set low briefly after power is first applied.

I

-17-

Page 18

IC DESCRIPTION-1/3 (LC78641NE-D)-3/3

Pin No. Pin Name I/O Description

72

DRF

Focus ON detect pin.

O

73

74

75

76

77

78

79

80

VDD5V

VSS

CONT6

CONT7

V/P

FSEQ

DFECT

EFMO

—

—

I/O

I/O

O

O

I/O

O

Microprocessor interface power supply. (2000pF or more path controller to be inserted

at a point nearer to the pin between this pin and GND)

Digital ground pin. Must be connected to 0V.

General-purpose input/output pin 6. (Not connected)

General-pirpose input/output pin 7. (Not connected)

Rough servo/phase control automatic switching monitor output pin. “H” for rough

servo and “L” for phase servo. (Not connected)

Synchronization signal detection output pin. Outputs a high level when the

synchronization signal detected from the EFM signal and the internally generated

synchronization signal agree. (Not connected)

Defect pin. Which becomes an input pin after reset and can be controlled externally.

This becomes the defect monitor pin under control by command. (Not connected)

EFM signal output pin. (Not connected)

-18-

Page 19

IC DESCRIPTION-2/3 (µPD789406AGC-014)-1/2

Pin No. Pin Name I/O Description

1

VDD1

—

Positive polarity power supply (except for port section).

2

3-5

6

7-10

11-26

27-30

31

32

33

34-37

38

39

40

41

42

43

44

BIAS

VLC0-VLC2

VSS1

COM0-COM3

S0-S15

P93-P90

P87

P86

P85

P84-P81

P80

AVDD

AVREF

ANI6/P66

ANI5/P65

ANI4/P64

ANI3/P63

—

—

—

—

—

Feeding the LCD drive power supply voltage.

LCD drive power supply voltage.

Ground potential (except for port section).

Common signal output from LCD controller/driver.

O

Segment signal output from LCD controller/driver.

O

P93-P90. (Signal name: COM3-COM0). COM3-COM0 relay port.

I

P87. (Signal name: TSTMOD) (Connected to Ground). L: TEST MODE.

I

P86. (Signal name: CDRW). L: CD-RW.

O

P85. (Signal name: AGON). H: AGON.

O

P84-P81. (Not connected)

O

P80. (Signal name: SHOCK) (Connected to Ground). L: Gain-up circuit operation during shock.

I

A/D comparator analog power supply.

A/D comparator reference voltage.

Signal name: OPEN. OPEN switch. Lid opens at 1 Dh or more.

I

Signal name: K-HLD. RESUME/HOLD key accepts.

I

Signal name: K-OTH. BS, FS, MODE, DSL key accepts.

I

Signal name: VDIN. Battery voltage monitoring.

I

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

ANI2/P62

ANI1/P61

ANI0/P60

AVSS

P27

P26

P25/INTP1

P24

P23/TO2

P22

P21

P20

P53

P52

P51

P50

P03

—

Signal name: RMC. Remote control key accepts.

I

Signal name: MUTLR. Zero data detection. MUTE at CDH or more.

I

Connected to Ground.

I

A/D comparator ground potential.

Signal name: DRF. Focus ON detection signal.

I

Not connected.

O

Signal name: WRQ. Interrupt signal from DSP.

I

Signal name: DO. Serial data reception from DSP.

I

Signal name: BEEP. Square wave output for BEEP sound.

O

Signal name: DI. Data output to DSP.

O

Signal name: CE. Chip enable output to DSP.

O

Signal name: CL. Serial clock output to DSP.

O

Signal name: K-STOP. H: When STOP button is pressed.

I

Signal name: K-PLAY. H: When PLAY button is pressed.

I

Signal name: ACDECT. H: AC adapter is detected.

I

Not connected.

O

Signal name: SPCON. H: Spindle stop.

O

62

63

64

65

66

67

P02

P01

P00

P47

P46

_____________

RESET

Signal name: SLCON. H: Sled stop.

O

Signal name: LSW. L: Sled inner circumference limit.

I

Signal name: APOFF. L: DC-DC CONV OFF.

O

Not connected.

O

Signal name: XRST. L: DSP reset.

O

System reset input.

I

-19-

Page 20

IC DESCRIPTION-2/3 (µPD789406AGC-014)-2/2

Pin No. Pin Name I/O Description

68

69

X2

X1

—

Terminal to connect external crystal for main system clock oscillation.

I

70

71

72

73

74

75

76

77

78

79, 80

VSS0

VDD0

XT2

XT1

IC/VPP

P45

P44

P43

P42

P41, P40

—

—

—

—

Ground potential of port section.

Positive polarity power supply for port section.

Not connected.

I

Terminal to connect external crystal for sub system clock oscillation. (Connected to Ground)

This pin is internally connected. Connect this pin directly to Vss0 or Vss1.

O

Signal name: SDBY. H: Output amplifier operates.

O

Signal name: MUTE. H: MUTE ON (Output amplifier).

O

Signal name: DSL1. L: DSL ON (Step 1).

O

Signal name: DSL2. H: DSL ON (Step 2) (When DSL1 is H).

O

Not connected.

-20-

Page 21

IC DESCRIPTION-3/3 (LA9253M)-1/1

Pin No. Pin Name I/O Description

1

FIN1

I

10

11

12

13

14

15

16

17

18

2

3

4

5

6

7

8

9

FIN2

TIN1

TIN2

REF1

VREF

LDS

LDD

GND

LDOF

ODRV

AGON

EFBL

TESO

TESI

TES

HFL

TE

—

I

Pick-up signal input.

I

I

Pin designed for reference voltage.

I

Reference voltage output.

O

APC monitor voltage input.

I

APC output.

O

GND.

Laser OFF pin. (H: ON L: OFF)

I

Speed switch pin. (H: double L: normal speed)

I

AGC ON pin. (H: ON L: OFF)

I

FE balance adjustment pin.

I

TE signal output for TES. (Not connected)

O

TE input for TES formation. (Not connected)

I

TES output. (Not connected)

O

HFL signal output.

O

TE signal output.

O

19

20

21

22

23

24

25

26

27

28

29

30

TE-

FE

FE-

RFEV

N/C

BH

PH

N/C

RF

RF-

RFSW

VCC

—

—

—

Minus input for TE gain design.

I

FE signal output.

O

Minus input for FE gain design.

I

RF envelop signal output.

O

Pin N/C.

Capasitance connection pin for RF bottom clamp.

I

Capasitance connection pin for RF gain design.

I

Pin N/C.

RF signal output.

O

Minus input for RF signal gain design.

I

Switch for equalizer design when RF has double speed.

I

Power supply.

-21-

Page 22

MECHANICAL EXPLODED VIEW-1/1

8

8

1

LCD

9

PWB

DA23L

8

10

B

12

11

2

3

4

5

7

13

6

a

A

15

14

a

-22-

Page 23

MECHANICAL PARTS LIST-1/1

REF. NO PART NO. KANRI DESCRIPTION

1 8A-HC7-007-010 WINDOW,CD

2 8A-HC7-138-010 WINDOW,DISPLAY 319

3 8A-HC7-017-110 LID ASSY,CD

4 85-HC6-205-110 SHAFT,LID(300) HK

5 8A-HC7-204-010 SPR-T,OPEN

6 8A-HC7-018-110 LEVER,OPEN

7 8A-HC7-015-310 CABI ASSY,CENTER

8 8Z-HC1-225-010 DMPR,MECHA(SP)

9 8A-HC7-201-010 GUIDE,LCD

10 8A-HC7-207-010 BAT-CONTACT,(-) (HK)

11 8A-HC7-206-010 BAT-CONTACT,(+) (HK)

12 87-HC8-205-010 BAT-CONTACT,(+)(-)

13 8A-HC7-012-010 KNOB,SL HOLD

14 8A-HC7-016-010 CABI ASSY,BOTTOM

15 88-HC6-021-010 FOOT, DIA10

A 87-067-869-010 V+1.7-8 HL BLK

B 87-067-868-010 V+1.7-4 HL BLK

NO.

-23-

Page 24

COLOR NAME TABLE

Basic color symbol Color Basic color symbol Color Basic color symbol Color

B Black C Cream D Orange

G Green H Gray L Blue

LT Transparent Blue N Gold P Pink

R Red S Silver ST Titan Silver

T Brown V Violet W White

WT Transparent White Y Yellow YT Transparent Yellow

LM Metallic Blue LL Light Blue GT Transparent Green

LD Dark Blue DT Transparent Orange GM Metallic Green

YM Metallic Yellow DM Metallic Orange PT Transparent Pink

LA Aqua Blue GL Light Green

-24-

Page 25

CD MECHANISM EXPLODED VIEW-1/1

D

D

2

4

9

A

3

5

1

7

8

C

6

B

-25-

10

Page 26

CD MECHANISM PARTS LIST-1/1

REF. NO PART NO. KANRI DESCRIPTION

1 S0-A41-A20-600 PICKUP LASER ASSY

2 SM-10A-108-001 MOTOR ASSY SPINDLE

3 S0-M10-A10-900 MOTOR SLED ASSY

4 S2-311-A12-200 CHASSIS

5 S2-511-A23-200 GEAR MIDDLE

6 S2-511-A23-100 GEAR,SCREW

7 S2-511-A23-400 GEAR,RACK

8 S2-511-A07-900 SPINDLE SCREW

9 S4-S13-A00-200 SW,LEAF

10 S2-451-A18-100 HOLDER GEAR

A SS-EXE-A04-000 SCR PAN PCS 1.4-2.2

B SS-GXE-A00-300 SPECIAL SCREW

C SS-EXE-A14-100 SPECIAL SCREW

D SS-GXE-A00-202 SPECIAL SCREW M1.7-4.0

NO.

-26-

Page 27

ACCESSORIES/PACKAGE LIST-1/1

REF. NO PART NO. KANRI DESCRIPTION

!

1 87-B30-285-110 AC ADAPTOR,AC-D603HRNC

2 87-B30-326-010 HEADPHONE,HP-M048

3 8A-HC7-944-010 IB,CCE

!

4 87-A91-017-010 PLUG,CONVERSION JT-0476

NO.

-27-

Page 28

2–11, IKENOHATA 1–CHOME, TAITO-KU, TOKYO 110-8710, JAPAN TEL:03 (3827) 3111

737004

Printed in Singapore

Loading...

Loading...