Page 1

XP-SP910

AUB

XP-SP911

AUB

SERVICE MANUAL

COMPACT DISC PLAYER

This Service Manual is the "Revision Publishing" and replaces "Simple Manual"

(S/M Code No. 09-003-341-6T1).

BASIC CD MECHANISM : DA23L

S/M Code No. 09-003-341-6R1

REVISION

DATA

Page 2

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

This set employs laser. Therefore, be sure to follow carefully the

instructions below when servicing.

WARNING!

WHEN SERVICING, DO NOT APPROACH THE LASER EXIT

WITH THE EYE TOO CLOSELY. IN CASE IT IS NECESSARY TO

CONFIRM LASER BEAM EMISSION. BE SURE TO OBSERVE

FROM A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE OPTICAL

PICK-UP BLOCK.

Caution: Invisible laser radiation when

open and interlocks defeated avoid expo-

sure to beam.

Advarsel:Usynling laserståling ved åbning,

når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

VAROITUS!

Laiteen Käyttäminen muulla kuin tässä käyttöohjeessa mainit-

ulla tavalla saattaa altistaa käyt-täjän turvallisuusluokan 1 ylit-

tävälle näkymättömälle lasersäteilylle.

VARNING!

Om apparaten används på annat sätt än vad som specificeras i

denna bruksanvising, kan användaren utsättas för osynling

laserstrålning, som överskrider gränsen för laserklass 1.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

ATTENTION

L'utilisation de commandes, réglages ou procédures autres que

ceux spécifiés peut entraîner une dangereuse exposition aux

radiations.

ADVARSEL!

Usynlig laserståling ved åbning, når sikkerhedsafbrydereer ude

af funktion. Undgå udsættelse for stråling.

This Compact Disc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located on the rear

exterior.

CLASS 1

KLASSE 1

LUOKAN 1

KLASS 1

LASER PRODUCT

LASER PRODUKT

LASER LAITE

LASER APPARAT

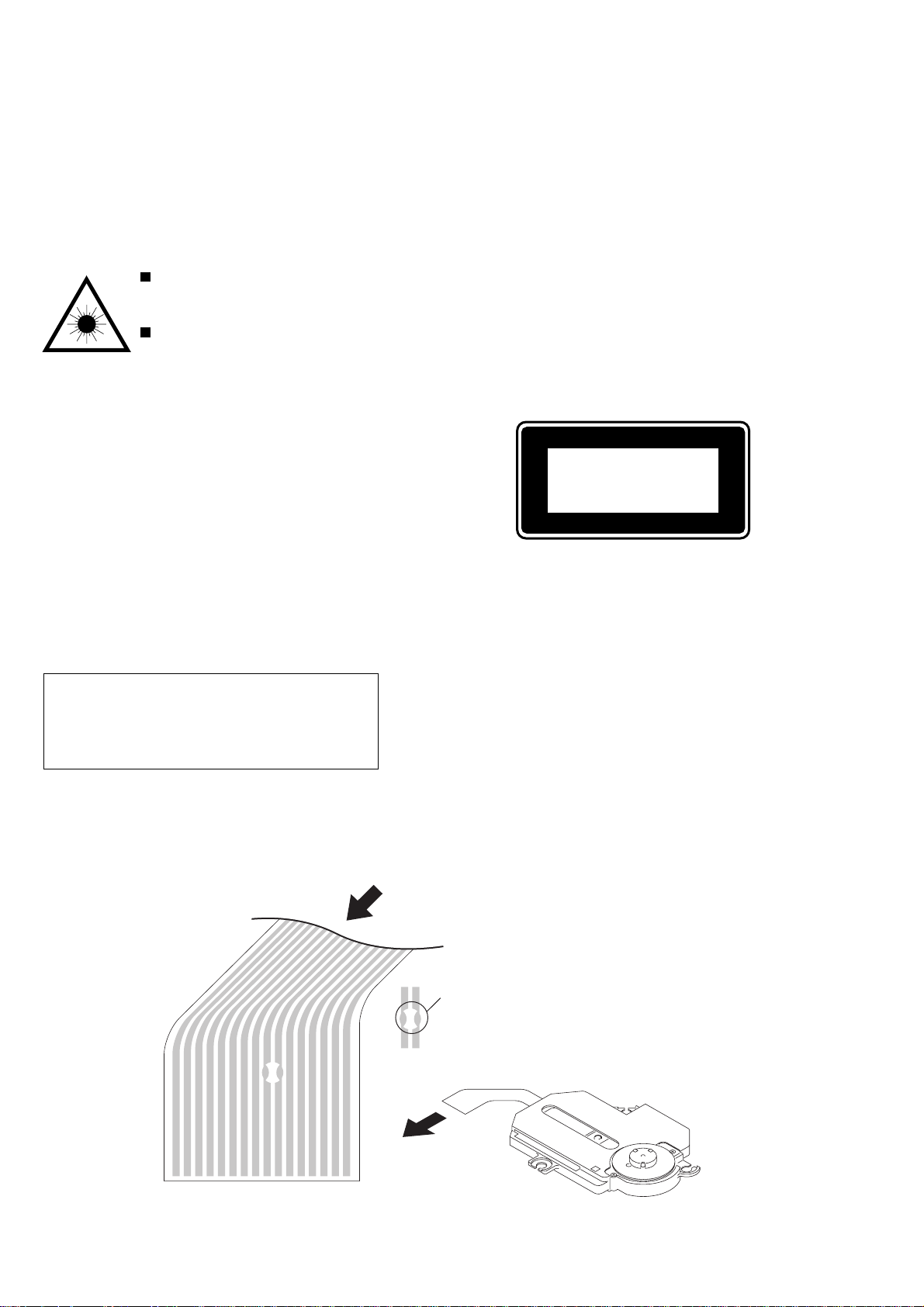

Precaution to replace Optical block

(SF-P200)

Body or clothes electrostatic potential could ruin

laser diode in the optical block. Be sure ground

body and workbench, and use care the clothes

do not touch the diode.

1) After the connection, remove solder shown in

the right figure.

:SOLDER

10 9

PICK UP ASSY

116

SF-P200

2

Page 3

SPECIFICATIONS

• Design and specifications are subject to change without notice.

ACCESSORIES LIST

REF. NO PART NO. KANRI DESCRIPTION

8A-HC3-911-010 IB,U(ESF)C2

! 87-B30-282-010 AC ADAPTOR,AC-D603UNC

87-B30-225-010 HEADPHONE,HP-M034

8A-HC3-951-010 CASE,CARRING (SP911)<1UB2,1U32>

NO.

3

Page 4

ELECTRICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

IC

87-A21-448-040 C-IC,BH6554FV

8A-HC3-610-010 C-IC,MN101C439-AC

87-A21-030-040 C-IC,S-93C46AMFN

87-A21-446-010 C-IC,MN662782RPT1

87-A21-561-040 C-IC,MSM51V17400D-SJ

87-A21-578-040 C-IC,AN8838NSB

87-A21-543-040 C-IC,NJU7012

87-A21-521-040 C-IC,BH6517FS

87-A21-085-040 C-IC,TA2120FN

TRANSISTOR

87-026-412-080 C-TR RN1305

87-A30-075-080 C-TR,2SA1235F

89-211-323-080 C-TR,2SB1132R

89-416-643-080 C-TR,2SD1664R

87-A30-076-080 C-TR,2SC3052F

89-113-695-680 C-TR,2SA1369G/H

87-A30-332-040 C-TR,CPH3106

87-A30-278-040 C-FET,2SK2980

89-115-865-080 C-TR,2SA1586GR

87-A30-336-040 C-TR,UMH4N

87-026-429-080 TR,RN2311

87-026-418-080 TR,RN1311 (0.1W)

87-A30-377-040 C-TR,2SB815B7

DIODE

87-A40-614-040 C-DIODE,SFPB-72

87-A40-469-080 C-DIODE,HSM2838CTR

87-A40-836-040 C-ZENER,HZM6.2NB1

87-A40-592-040 C-ZENER,HZM11NB2

87-A40-674-080 C-DIODE,HRC0202A

87-001-166-080 DIODE,1SS301

MAIN C.B

C101 87-012-286-080 CAP, U 0.01-25

C102 87-A11-031-080 C-CAP,E 100-16 M WX

C103 87-012-286-080 CAP, U 0.01-25

C104 87-A11-031-080 C-CAP,E 100-16 M WX

C105 87-010-831-080 C-CAP,U,0.1-16F

C201 87-012-286-080 CAP, U 0.01-25

C202 87-016-427-080 C-CAP,E 47-6.3 5.5N

C203 87-012-286-080 CAP, U 0.01-25

C204 87-016-430-080 C-CAP,E 100-6.3 5.5N

C205 87-016-421-080 C-CAP,E 10-16 5.5N

C206 87-A10-047-080 C-CAP,U 1-10 Z F

C207 83-HC3-635-080 C-CAP,E 220-6.3 WF

C208 87-016-422-080 C-CAP,E 22-6.3

C209 87-A10-260-080 C-CAP,U 0.1-16 K B

C210 87-A10-047-080 C-CAP,U 1-10 Z F

C211 87-010-787-080 CAP, U 0.022-25

C212 87-012-266-080 C-CAP,U 220P-50 B

C213 87-A11-062-080 C-CAP,S 2.2-16 Z F

C214 87-010-831-080 C-CAP,U,0.1-16F

C301 87-016-426-080 C-CAP,E 47-4 5.5N

C302 87-012-286-080 CAP, U 0.01-25

C303 87-012-273-080 C-CAP,U 820P-50 B

C304 87-010-831-080 C-CAP,U,0.1-16F

C305 87-012-286-080 CAP, U 0.01-25

C306 87-012-274-080 CHIP CAP,U 1000P-50B

C307 87-012-286-080 CAP, U 0.01-25

C309 87-016-429-080 C-CAP,E 100-4 5.5N

C310 87-012-286-080 CAP, U 0.01-25

C311 87-A10-047-080 C-CAP,U 1-10 Z F

C313 87-012-274-080 CHIP CAP,U 1000P-50B

C314 87-012-274-080 CHIP CAP,U 1000P-50B

NO.

REF. NO PART NO. KANRI DESCRIPTION

C315 87-012-274-080 CHIP CAP,U 1000P-50B

C316 87-010-831-080 C-CAP,U,0.1-16F

C317 87-012-274-080 CHIP CAP,U 1000P-50B

C318 87-012-274-080 CHIP CAP,U 1000P-50B

C319 87-012-188-080 C-CAP,U 47P-50 CH

C401 87-016-431-080 C-CAP,E 220-4 5.5N

C403 87-016-429-080 C-CAP,E 100-4 5.5N

C405 87-010-831-080 C-CAP,U,0.1-16F

C406 87-012-273-080 C-CAP,U 820P-50 B

C407 87-010-787-080 CAP, U 0.022-25

C408 87-A10-260-080 C-CAP,U 0.1-16 K B

C409 87-A10-827-080 C-CAP,U 0.47-6.3 K B

C410 87-012-286-080 CAP, U 0.01-25

C411 87-A11-062-080 C-CAP,S 2.2-16 Z F

C412 87-016-429-080 C-CAP,E 100-4 5.5N

C413 87-010-831-080 C-CAP,U,0.1-16F

C415 87-A10-047-080 C-CAP,U 1-10 Z F

C416 87-010-831-080 C-CAP,U,0.1-16F

C417 87-012-188-080 C-CAP,U 47P-50 CH

C418 87-012-164-080 C-CAP,U 2P-50 CK

C419 87-012-164-080 C-CAP,U 2P-50 CK

C420 87-010-831-080 C-CAP,U,0.1-16F

C421 87-010-831-080 C-CAP,U,0.1-16F

C422 87-010-831-080 C-CAP,U,0.1-16F

C423 87-A10-047-080 C-CAP,U 1-10 Z F

C424 87-A10-047-080 C-CAP,U 1-10 Z F

C451 87-A10-047-080 C-CAP,U 1-10 Z F

C501 87-016-429-080 C-CAP,E 100-4 5.5N

C502 87-010-831-080 C-CAP,U,0.1-16F

C504 87-010-831-080 C-CAP,U,0.1-16F

C505 87-A11-228-080 C-CAP,U 0.027-25 K B

C506 87-012-199-080 CAP 220P

C507 87-012-193-080 C-CAP,U 82P-50 CH

C508 87-012-193-080 C-CAP,U 82P-50 CH

C509 87-012-273-080 C-CAP,U 820P-50 B

C510 87-A11-241-080 C-CAP,TN 22-6.3 M F93 A

C512 87-A11-241-080 C-CAP,TN 22-6.3 M F93 A

C514 87-A11-228-080 C-CAP,U 0.027-25 K B

C515 87-A11-228-080 C-CAP,U 0.027-25 K B

C516 87-A10-260-080 C-CAP,U 0.1-16 K B

C518 87-012-176-080 C-CAP,U 15P-50 CH

C520 87-016-426-080 C-CAP,E 47-4 5.5N

C521 87-012-274-080 CHIP CAP,U 1000P-50B

C522 87-A10-047-080 C-CAP,U 1-10 Z F

C523 87-A10-047-080 C-CAP,U 1-10 Z F

C524 87-012-172-080 C-CAP,U 10P-50 CH

C601 87-016-429-080 C-CAP,E 100-4 5.5N

C602 87-012-286-080 CAP, U 0.01-25

C603 87-012-286-080 CAP, U 0.01-25

C604 87-012-286-080 CAP, U 0.01-25

C701 87-016-429-080 C-CAP,E 100-4 5.5N

C702 87-012-281-080 C-CAP,U 3900P-50 B

C703 87-012-281-080 C-CAP,U 3900P-50 B

C704 87-012-273-080 C-CAP,U 820P-50 B

C705 87-012-273-080 C-CAP,U 820P-50 B

C706 87-010-831-080 C-CAP,U,0.1-16F

C707 87-A11-062-080 C-CAP,S 2.2-16 Z F

C708 87-A11-062-080 C-CAP,S 2.2-16 Z F

C709 87-A10-047-080 C-CAP,U 1-10 Z F

C710 87-016-421-080 C-CAP,E 10-16 5.5N

C711 87-016-429-080 C-CAP,E 100-4 5.5N

C712 87-A10-353-080 C-CAP,U0.22-10KB

C713 87-A10-260-080 C-CAP,U 0.1-16 K B

C714 87-A11-062-080 C-CAP,S 2.2-16 Z F

C715 87-016-421-080 C-CAP,E 10-16 5.5N

C716 87-010-831-080 C-CAP,U,0.1-16F

C717 87-010-831-080 C-CAP,U,0.1-16F

C718 87-016-431-080 C-CAP,E 220-4 5.5N

C719 87-016-431-080 C-CAP,E 220-4 5.5N

C720 87-012-274-080 CHIP CAP,U 1000P-50B

NO.

4

Page 5

WAVEFORMS

1

IC501 Pin7 (RF O)

REF. NO PART NO. KANRI DESCRIPTION

C721 87-012-274-080 CHIP CAP,U 1000P-50B

C722 87-010-831-080 C-CAP,U,0.1-16F

C723 87-A10-047-080 C-CAP,U 1-10 Z F

CN301 87-A61-241-080 C-CONN,26P H 52437-2691

CN501 87-009-214-080 CONN,16P 52207-1690

CN601 87-099-522-080 CONN,6P ZH-SM3 V W

FB701 83-XM1-617-080 C-COIL,BK2125HM601

FB704 83-XM1-617-080 C-COIL,BK2125HM601

J101 87-A60-421-010 JACK,DC HEC3600 BLK 6

J701 85-HC5-616-010 JACK,3.5 ST W/R GRN

L201 87-A50-355-080 C-COIL,330UH LQH3C

L202 87-A50-587-080 C-COIL,68UH-CDRH5D28

L203 87-A50-355-080 C-COIL,330UH LQH3C

L301 87-A50-367-080 C-COIL, 10UH LQG21F

L302 87-A50-367-080 C-COIL, 10UH LQG21F

L401 87-A50-556-080 C-COIL, 47UH K LQH3C

L402 87-A50-440-080 C-COIL, 100UH K LQH3C34

L501 87-A50-501-080 C-COIL,10UH-FSLB2520

L502 87-A50-367-080 C-COIL, 10UH LQG21F

S301 87-A90-494-080 C-SW,SL 1-1-3 SSSS81

NO.

CHIP RESISTOR PART CODE

Chip Resistor Part Coding

88

REF. NO PART NO. KANRI DESCRIPTION

S302 87-A91-622-010 SW,MICRO PV1102

X401 87-A70-261-080 C-VIB,CER 16.93MHZ CSTCW-MX03T

LID C.B

CN801 87-A61-241-080 C-CONN,26P H 52437-2691

LCD801 8A-HC3-605-010 LCD,AHC-3

S801 87-A90-232-080 C-SW,TACT SKQRAA

S802 87-A90-232-080 C-SW,TACT SKQRAA

S803 87-A90-232-080 C-SW,TACT SKQRAA

S804 87-A90-232-080 C-SW,TACT SKQRAA

S805 87-A90-232-080 C-SW,TACT SKQRAA

S806 87-A90-232-080 C-SW,TACT SKQRAA

S807 87-A90-232-080 C-SW,TACT SKQRAA

S808 87-A90-232-080 C-SW,TACT SKQRAA

S809 87-A90-232-080 C-SW,TACT SKQRAA

NO.

IC502 Pin4 (TA O)

2

500mV/DIV

200ns/DIV

50 mV/DIV

1 ms/DIV

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

TRANSISTOR ILLUSTSRATION

C

B

E

Symbol

CJ

CJ

CJ

B C E

Figure

Value of resistor

Form

L

Dimensions (mm)

t

W

0.55

Resistor Code

108

118

128

LW t

1.0 0.5 0.35 104

1.6 0.8 0.45

2 1.25 0.45

3.2

1.6

D

G

S

: A

: A

3

IC501 Pin20 (FE O)

4

IC301 Pin10 (OSC I)

50 mV/DIV

1 ms/DIV

2SA1235

2SA1586

2SB815

2SC3052

CPH3106

RN1305

RN1311

RN2311

UMH4N

2SA1369

2SB1132

2SD1664

2SK2980

f 4.2MHz

1 V/DIV

200 ns/DIV

65

Page 6

SCHEMATIC DIAGRAM-1 (MAIN SECTION)

C417

47p

AC ADAPTOR USE

FOR SPINDLE

SPEED

WAVEFORMS

1

3

2

4

87

Page 7

1

234567

8

9

10

11 12 13

14

A

B

C

D

E

F

G

H

I

J

WIRING-1 (MAIN C.B)

1

A

B

C

D

E

F

G

H

I

J

K

L

A

B

C

D

E

F

G

H

I

J

K

L

H

II

H

2345678910 10654987321

109

Page 8

1

23456

7

A

B

C

D

E

F

G

H

I

J

SCHEMATIC DIAGRAM-2 (LID SECTION)

WIRING-2 (LID C.B)

1211

Page 9

LCD DISPLAY

13

Page 10

TEST MODE

MAIN C.B

OPEN/CLOSE

SW SHORT LAND

MAIN C.B

GND

IC501

FE

VC

TE

IC601

IC401

The servo circit of this model is designed to be adjustmentfree and the adjustment value and disc distinction (CDDA,

CD-R and CD-RW) etc. is adjusted by within the IC. Therefore the adjustment is performed each TOC reading. The

adjustment conditions within the IC of each servo can be

monitored in this test mode.

1. How to start the Test Mode

Starting method of the test mode differ depending upon

the type of disc being used. This is because the adjustment values of each servo also differ depending upon the

type of disc.

When using the CD-DA or CD-R

1) Short-circuit TEST LAND and OPEN/CLOSE SW

land.

2) Insert the AC plug to the power outlet and install the

CD-DA or CD-R disc.

3) Press the PLAY and STOP buttons in this sequence

and read the TOC.

When using the CD-RW

1) Short-circuit the TEST LAND and the OPEN/CLOSE

SW land.

2) Insert the AC plug to the power outlet and install the

CD-RW disc.

3) Pree the PLAY, STOP and DSL buttons in this sequence

and read the TOC. The LCD should display “CD-r” at

this point.

RF

TEST LAND

61

IC301

IC701

IC201

Note 3) By repeatedly pressing the DSL button the LCD

“CD-r” and “CD-d” are repeated.

When the LCD displays “CD-d” ⇒

CD-DA, CD-R is selected.

When the LCD displays “CD-r” ⇒

CD-RW is selected.

Note 4) The test mode is canceled by disconnect the AC

plug and remove the soldering of short land.

2. DISC distinction (confirmation of the FE waveform)

This mode is possible to perform a confirmation of the

disc distinction.

Confirmation method

1) Press the DSL button and select “CD-d” or “CD-r”

(Refer to Note 3))

2) Install the disc.

3) Press the MODE button.

The LCD will change as follows:

Example:

Test disc: TCD-782, DISC type select: CD-d, Judgment

value: 79, Measurement value: 44 CB

VOL

Note 1) If the TOC cannot read, “ERR” has appeared on the

LCD. The following step 2 and 3 can be verified

even if the “TOC” cannot be read.

Note 2) By repeatedly pressing the DISPLAY/ENTER but-

ton the all LCD light up and the “TOC” display are

repeated.

Judgment value

* All numerical value are displayed in HEX.

14

Measurement value

Page 11

What disc the IC has selected can be understood according to this judgment value.

The decision standard of IC is as follows.

LCD displays “CD-d” LCD displays “CD-r”

0 < Judgment value < 10 No disc No disc

10 < Judgment value < 32 CD-RW No disc

32 < Judgment value < C8 CD-DA and CD-R CD-RW

C8 < Judgment value CD-DA and CD-R

The state of the FE waveform can also be understood from to this judgment.

3. Confirmation of Sled movement

By pressing the F. SKIP of B. SKIP button continuously, it is

possible to transfer the pick-up to either the outer side or inner

side.

4. Confirmation of the RF level

Test point: RF and VC (Vref)

Test disc: TCD-782

Confirm that the RF waveform as shown below.

more than

0.8Vp-p

VOLT/DIV: 200mV

TIME/DIV: 0.5 s

5. Confirmation of Tracking balance

Test point: TE and VC (Vref)

Test disc: TCD-782

Press the DSL button while the test disc playing and confirm the

TE waveform is as is shown below.

6. Confirmation of each servo

It is possible to confirm the adjustment value of each servo by

repeatedly pressing the MODE button while the disc is playing, The switchover, sequence is as stated below.

Confirmation mode off ⇒ Focus Bias (FB) ⇒ Tracking

Balance(TB) ⇒ Tracking Gain (TG) ⇒ Tracking Error

Offset(TEO)⇒ Focus Gain (FG) ⇒ Focus Error Offset (FEO)

Confirmation mode off

Example:

Tracking Error Offset (TEO) Adjustment value: 03

VOL

Tracking Error Offset (TEO)display

Adjustment value

Adjustment value are displayed in HEX.

A

VC

B

A:B = 1:1

VOLT/DIV: 200mV

TIME/DIV: 2ms

15

Page 12

IC BLOCK DIAGRAM

IC, TA2120FN

IC, AN8838NSB

IC, BH6554FV

16

Page 13

IC DESCRIPTION

IC, MSM51V17400D

Pin No. Pin Name I/O Description

1

2

3

4

5

VCC

D0

D1

______

WE

________

RAS

—

I/O

+2.5V power supply

Data input/output

I

Write enable

I

Row address strobe

10

11

12

13

14

15

16

17

18

19

21

22

23

24

25

26

6

8

9

NC

A10

A0

A1

—

I

Not connected

Address inputs

A2

A3

VCC

VSS

—

—

+2.5V power supply

Ground

A4

A5

I

A6

Address inputs

A7

A8

O

I/O

I

Address input

Output enable

I

Column address strobe

Data input/output

A9

_____

OE

________

CAS

D2

D3

VSS

—

Ground

IC, S-93C46AMFN

Pin No. Pin Name I/O Description

1

2

3

4

5

6

7

8

VCC

NC

TEST

GND

DO

DI

SK

CS

—

—

—

—

Power supply

Not connected

Test terminal. Open (can be connected to Vcc or GND)

Ground

O

Serial data output

Serial data input

I

I

Serial clock input

Chip select input

I

17

Page 14

IC, MN662782RPT1

Pin No. Pin Name I/O Description

1

DVDD3

—

Power supply of DRAM interface (pins 2-19)

2

3

4

5

6

7

8

9

10 ~ 14

15

16 ~19

20

21

22

23

24

D0

D1

NWE

NRAS

D2

D3

NCAS0

A10

A8 ~ A4

A9

A0 ~ A3

DVSS2

DVDD2

SPOUT

TRVM

TRVP

I/O

I/O

O

O

I/O

I/O

O

O

O

O

O

—

—

O

O

O

DRAM data input/output signal 0,

DRAM data input/output signal 1

DRAM write enable signal

DRAM RAS control signal

DRAM data input/output signal 2

DRAM data input/output signal 3

DRAM CAS control signal 0

DRAM CAS control signal 1 (when two 1M/4M DRAMs are used)

DRAM address signal 10 (when 16M DRAM is used)

DRAM address signals 8 ~ 4

DRAM address signal 9

DRAM address signals 0 ~ 3

Ground of digital circuits

Power supply of digital circuits

Spindle motor drive signal output (absolute value output)

Traverse drive output (positive polarity output)

Traverse drive output (negative polarity output)

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

TRM

TRP

FOM

FOP

FBAL

TBAL

VREF

FE

TE

RFENV

OFT

NRFDET

BDO

LDON

ARF

IREF

ADPVCC

—

O

Tracking drive output (positive polarity output)

O

Tracking drive output (negative polarity output)

O

Focus drive output (positive polarity output)

O

Focus drive output (negative polarity output)

O

Focus balance adjustment output

O

Tracking balance adjustment output

Reference voltage of DA output circuits (FBAL, TBAL, DSLF2)

I

Focus error signal input (analog input)

I

Tracking error signal input (analog input)

I

RF envelope signal input (analog input)

I

Off-track signal input. H: Off-track

I

RF detection signal input. L: Detection

I

Dropout signal input. H: Dropout

O

Laser ON signal output. H: ON

I

RF signal input

I

Reference current input

I

AD reference voltage input (analog input)

42

43

44

45

46

47

48

DSLF

DSLF2

PLLF

VCOF

AVDD2

AVSS2

OUTL

—

—

O

Loop filter terminal for DSL

O

DSL unbalance current compensation

O

Loop filter terminal for PLL

O

Loop filter terminal for jitter-free VCO

Power supply of analog circuits (DSL, PLL, VCOF, AD, DA)

Ground of analog circuits (DSL, PLL, VCOF, AD, DA)

O

Lch audio output

18

Page 15

Pin No. Pin Name I/O Description

49

AVSS1

—

Ground of analog circuits (audio output circuit)

50

51

52

53

54

55

56

57

58

59

60

61

62

63

OUTR

AVDD1

FSEL

TMOD1

TMOD2

FLAG

CLVS/IPFLAG

EXT0

EXT1

EXT2

TX

MCLK

MDATA

MLD

O

—

O

O

I/O

I/O

I/O

O

Rch audio output

Ground of analog circuits (audio output circuit)

I

Noise filter on/off switching input. L: ON; H: OGG

I

Terminal mode switching input 1. Normal: L

I

Terminal mode switching input 2. Normal: L

Flag signal output

Command switching.

• Spindle servo phase sync signal output. H: CLV; L: Rough servo

• Interpolation flag signal output. H: Interpolation

Command switching • Expansion input/output port 0

• SRDATA input

Command switching • Expansion input/output port 1

• LRCK input. H: Lch audio data; L: Rch audio data

Command switching • Expansion input/output port 2

• BCLK input

Digital audio interface output signal

I

Microprocessor command clock signal input (latches data at the leading edge).

I

Microprocessor command data signal input

I

Microprocessor command load signal input. L: Load

64

65

66

67

68

69

70

71

72

73

74

BLKCK

SQCK/BCLK

SUBQ/LRCK

DMUTE/SRDATA

STAT

NRST

SPPOL

PMCK

SMCK

SUBC/SSYNC

SBCK/64FS

O

I/O

O

I/O

O

O

O

O

O

Subcode block clock signal: fBLKCK = 75 Hz (during normal playback) / CDTEXT

SYNC signal (DQSY): fDQSY = 300 Hz (during normal playback)

Command switching • External clock input for Subcode Q register

• Bit clock output for SRDATA

Command switching

• Subcode Q data output

• L/R identification signal output. H: Lch audio data; L: Rch audio data

Command switching • Muting input. H: Muting

• Serial data output

Status signals (CRC, RESY, CLVS, NTTSTOP, SQOK, FLAG6, SENSE, NFLOCK,

NTLOCK, BSSEL, SUBQ data, CDTEXT data, anti-shock read-out data)

I

Reset input. L: Reset

Spindle motor drive signal output (polarity output)

88.2 kHz clock signal output

4.2336 MHz clock signal output

Command switching • Subcode serial outputo

• Sector sync output

Command switching • Clock input for subcode serial outputo

I

• 64FS output

75

76

77

78

79

80

NCLDCK

NTEST

X1

X2

DVDD1

DVSS1

—

—

O

Subcode frame clock signal output (fCLDCK = 7.35 kHz)

I

Test terminal. Normally, H.

I

Crystal oscillator input. f = 16.9344 MHz

O

Crystal oscillator output. f = 16.9344 MHz

Power supply of digital circuits

Ground of digital circuits

19

Page 16

IC, MN101C439-AC

Pin No. Pin Name I/O Description

1

COM3

O

LCD common

10

11

12

13

14

15

16

17

18

2

3

4

5

6

7

8

9

COM2

COM1

COM0

VLC3

VLC2

VLC1

VDD

OSC2

OSC1

VSS

XI

XO

MMOD

VREF-

AN0, PA0

AN1, PA1

AN2, PA2

—

—

—

—

—

—

O

LCD common

O

LCD common

O

LCD common

LCD power

LCD power

LCD power

LCD power

O

Microcomputer main clock oscillation output.

I

Microcomputer main clock oscillation input.

GND

I

Sub clock oscillation.

O

Sub clock oscillation.

I

Connected VSS.

VSS

I

Function key input.

I

PLAY/STOP Key input.

I

AC adapter detection.

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

AN3, PA3

AN4, PA4

AN5, PA5

AN6, PA6

AN7, PA7

VREF+

TXD, SB10, P00

RXD, SB10, P01

SBT0, P02

SBO1, P03

SBI1, P04

SBT1, P05

DK, BUZZER, P06

RST, P27

RMOUT, P10

P11

TM2IO, P12

—

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I

Battery voltage detection.

I

Remote control input.

I

"DIGITAL OUT ON/OFF Input. ""L""=ON."

I

Select input of the EASS mode. Reference of A/D value table.

I

Resume/hold SW input.

VCC

Limit SW input.

Power off output of the CD servo try bar. "L" = power off.

CD-RW regeneration gain up selection output. "H" = gain up.

CD-RW regeneration gain up select output. "L" = gain up."

Power down output of H/A.

Select output of the gain up with EASS. EASS ON = "L"

BUZZER output of the headphones.

I

Microcomputer reset input.

Reset output of DSP.

STAT input of DSP.

MLD output of DSP.

36

37

38

39

40

TM3IO, P13

TM4IO, P14

IRQ0, P20

SENS, IRQ1, P21

IRQ2, P22

I/O

I/O

MDATA output of DSP.

MCLK output of DSP.

I

BLKCK input of DSP.

I

Wireless remote control sensor signal input.

I

Select input of AHC-4 or AHC-5. AHC-4 = "H". AHC-3 = "L".

20

Page 17

Pin No. Pin Name I/O Description

41

P23, IRQ3

I

Not used.

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

P40, KEY0

P41, KEY1

P42, KEY2

P43, KEY3

P44, KEY4

P45, KEY5

P46, KEY6

P47, KEY7

P50, LED0, WE

P51, LED1, RE

P52, LED2, CS

P53, SEG27, A16

P54, SEG26, A17

P60, SEG25, A0

P61, SEG24, A1

P62, SEG23, A2

P63, SEG22, A3

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

Power down output of H/A.

Select output of the gain up with EASS. EASS ON = "L".

DSL2 control output of the headphones. DSL2 = "H". DSL1/OFF ="L".

DSL on control output of the headphones. DSL ON = "H".

AUDIO MUTE outout.

Standby output of the headphones. STANDBY = "L"/POWER ON = "H".

Wireless LCD remote control output.

Power off output of power supply IC. "L" = POWER OFF.

Discharge output.

Charging output.

EEPROM CS output.

EEPROM CLOCK output.

EEPROM DATA output.

Not used.

Closing detection SW input of the cover.

FL back light control output.

PWM control output of the spindle.

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

P64, SEG21, A4

P65, SEG20, A5

P66, SEG19, A6

P67, SEG18, A7

P70, SEG17, A8

P71, SEG16, A9

P72, SEG15, A10

P73, SEG14, A11

P74, SEG13, A12

P75, SEG12, A13

P76, SEG11, A14

P77, SEG10, A15

P87, SEG9, D7

P86, SEG8, D6

P85, SEG7, D5

P84, SEG6, D4

P83, SEG5, D3

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

Output that is lighted button LED of the CAR-KIT model. "H" = Illumination.

Axis loss mode ("H" = There is not an axis loss mode.)

"L" = TEST MODE.

Select input in 10 sec or 10/40 sec with AHC-5. "H" = 10 sec. "L"=10/40 sec.

LCD segment output.

LCD segment output.

LCD segment output.

LCD segment output.

LCD segment output.

LCD segment output.

LCD segment output.

LCD segment output.

LCD segment output.

LCD segment output.

LCD segment output.

LCD segment output.

LCD segment output.

76

77

78

79

80

P82, SEG4, D2

P81, SEG3, D1

P80, SEG2, D0

SEG1

SEG0

I/O

I/O

I/O

O

O

LCD segment output.

LCD segment output.

LCD segment output.

LCD segment output.

Not used.

21

Page 18

MECHANICAL EXPLODED VIEW 1/1

1

A

A

2

C

3

LCD

4

5

6

9

5

LID C.B

E

7

C

C

B

B

B

8

LID,BATT

19

13

14

MAIN C.B

16

B

15

17

DA23L

10

10

D

10

20

21

F

18

11

C

PLATE,

BOTTOM

12

22

Page 19

MECHANICAL MAIN PARTS LIST 1/1

REF. NO PART NO. KANRI DESCRIPTION

1 8A-HC3-014-010 LID ASSY,CD<U2C2>

1 8A-HC3-018-010 LID ASSY,CD 911<1UB2,1U32>

2 8A-HC3-013-010 PLATE,LID CD B

3 8A-HC3-207-010 SPR,LID CD

4 8A-HC3-201-010 PLATE,LCD

5 8A-HC3-206-010 JOINT,LCD AHC-3

6 8A-HC3-012-010 PLATE,LID CD A

7 8A-HC3-011-010 BTN,CONT RBR

8 8A-HC3-202-010 HLDR,BTN

9 8A-HC3-015-010 CABI ASSY,CENTER

10 8Z-HC1-225-010 DMPR,MECHA(SP)

11 8Z-HC3-230-010 BAT-CONTACT,(+)(-)

12 8A-HC3-003-010 CABI,BOTTOM

13 8Z-HC3-216-010 HLDR ASSY,LOCK

14 8Z-HC3-213-010 SPR-E,LOCK

15 87-HC3-211-010 RING,KNOB RBR

16 8A-HC3-204-010 JOINT,RTRY HOLD

17 8A-HC3-010-010 KNOB,RTRY HOLD

18 8A-HC3-016-010 CAP, HP RBR

19 8A-HC3-017-010 CAP, DC RBR

20 8Z-HC7-204-010 BAT-CONTACT,(+)

21 8Z-HC7-205-010 BAT-CONTACT,(-)

A 86-HSB-226-010 S-SCREW,LID

B 87-067-869-010 V+1.7-8 HL BLK

C 87-067-732-010 TAPPING SCREW, VT1.4-3

D 88-HSA-227-010 S-SCREW,1.7-4 HL BLK

E 87-067-736-010 SCREW,1.4-2 BLK NLOCK

F 87-067-384-010 SCREWVT1.4-3.5HL

NO.

COLOR NAME TABLE

Basic color symbol Color Basic color symbol Color Basic color symbol Color

B Black C Cream D Orange

G Green H Gray L Blue

LT Transparent Blue N Gold P Pink

R Red S Silver ST Titan Silver

T Brown V Violet W White

WT Transparent White Y Yellow YT Transparent Yellow

LM Metallic Blue LL Light Blue GT Transparent Green

LD Dark Blue DT Transparent Orange

23

Page 20

MECHANISM EXPLODED VIEW 1/1

D

D

2

4

9

A

3

5

1

7

8

C

6

B

24

10

Page 21

MECHANISM MAIN PARTS LIST 1/1

REF. NO PART NO. KANRI DESCRIPTION

1 S0-A41-A20-600 PICKUP LASER ASSY

2 SM-10A-108-001 MOTOR ASSY SPINDLE

3 S0-M10-A10-900 MOTOR SLED ASSY

4 S2-311-A12-200 CHASSIS

5 S2-511-A23-200 GEAR MIDDLE

6 S2-511-A23-100 GEAR,SCREW

7 S2-511-A23-400 GEAR,RACK

8 S2-511-A07-900 SPINDLE SCREW

9 S4-S13-A00-200 SW,LEAF

10 S2-451-A18-100 HOLDER GEAR

A SS-EXE-A04-000 SCR PAN PCS 1.4-2.2

B SS-GXE-A00-300 SPECIAL SCREW

C SS-EXE-A14-100 SPECIAL SCREW

D SS-GXE-A00-202 SPECIAL SCREW M1.7-4.0

NO.

25

Page 22

2–11, IKENOHATA 1–CHOME, TAITO-KU, TOKYO 110-8710, JAPAN TEL:03 (3827) 3111

920074

Printed in Singapore

Loading...

Loading...