Aiwa XDDV-290 Service manual

XD-DV290

HRJ(N),LH(N)

SERVICE MANUAL

DVD PLAYER

This Service Manual is the “Revision Publishing” and replaces “Simple Manual”

(S/M Code No.09-99C-337-5T4)

.

BASIC DVD MECHANISM : LDM-H109

(6721R-0300A)

S/M Code No. 09-99C-337-5R3

REVISION

DATA

TABLE OF CONTENTS

SPECIFICATIONS .................................................................................................................................. 3

ACCESSORIES/PACKAGE LIST ........................................................................................................... 3

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING/

Precaution to replace Optical block......................................................................................................... 4

DISASSEMBLY INSTRUCTIONS...................................................................................................... 5-10

ELECTRICAL MAIN PARTS LIST ................................................................................................... 11-13

TRANSISTOR ILLUSTRATION ............................................................................................................ 13

BLOCK DIAGRAM-1 (OVERALL) ......................................................................................................... 14

BLOCK DIAGRAM-2 (POWER) ............................................................................................................ 15

BLOCK DIAGRAM-3 (RF/DSP/SERVO)............................................................................................... 16

BLOCK DIAGRAM-4 (AUDIO) .............................................................................................................. 17

BLOCK DIAGRAM-5 (MPEG)............................................................................................................... 18

BLOCK DIAGRAM-6 (SYSTEM CONTROL) ........................................................................................ 19

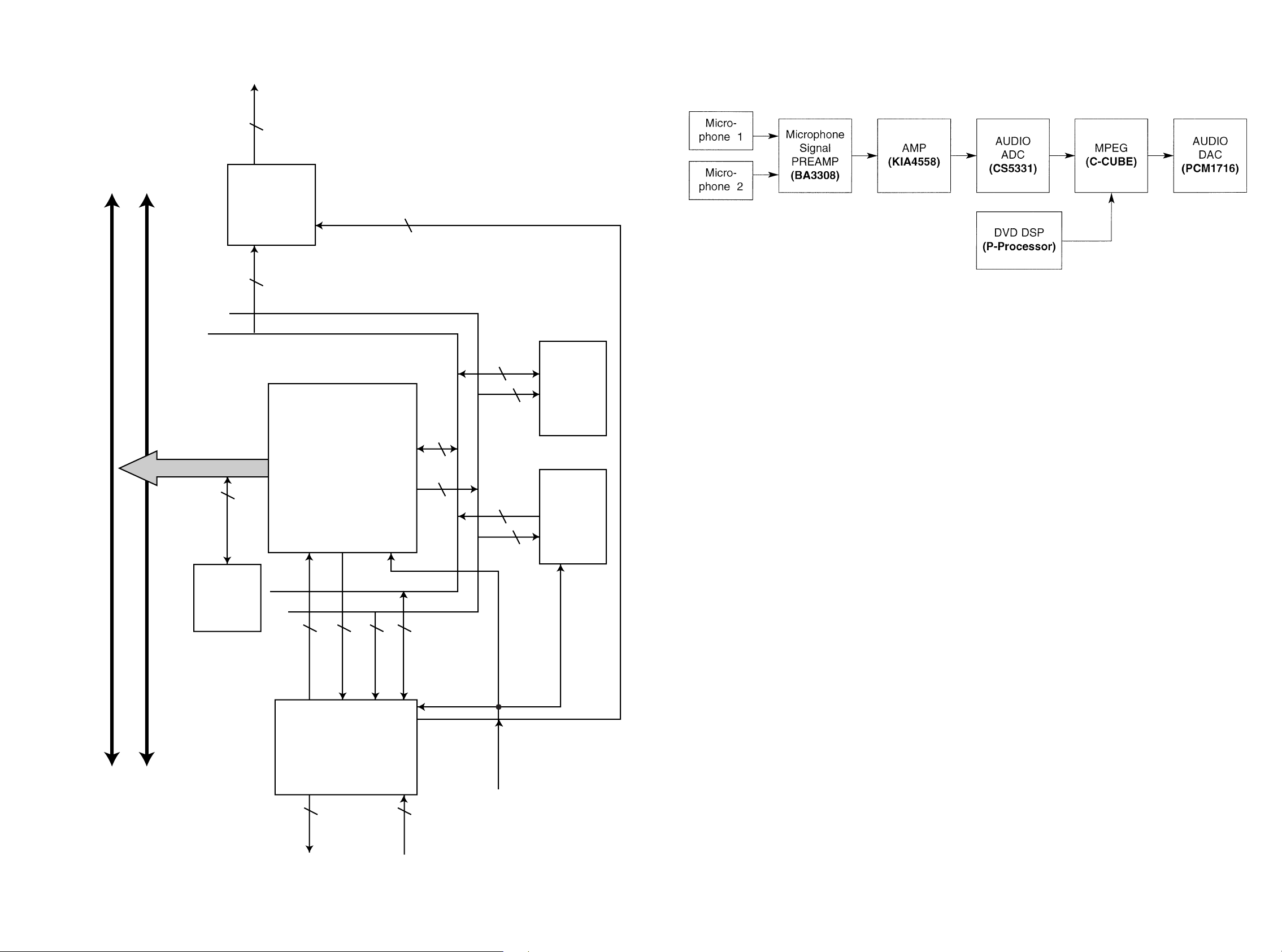

BLOCK DIAGRAM-7 (MIC) ................................................................................................................... 20

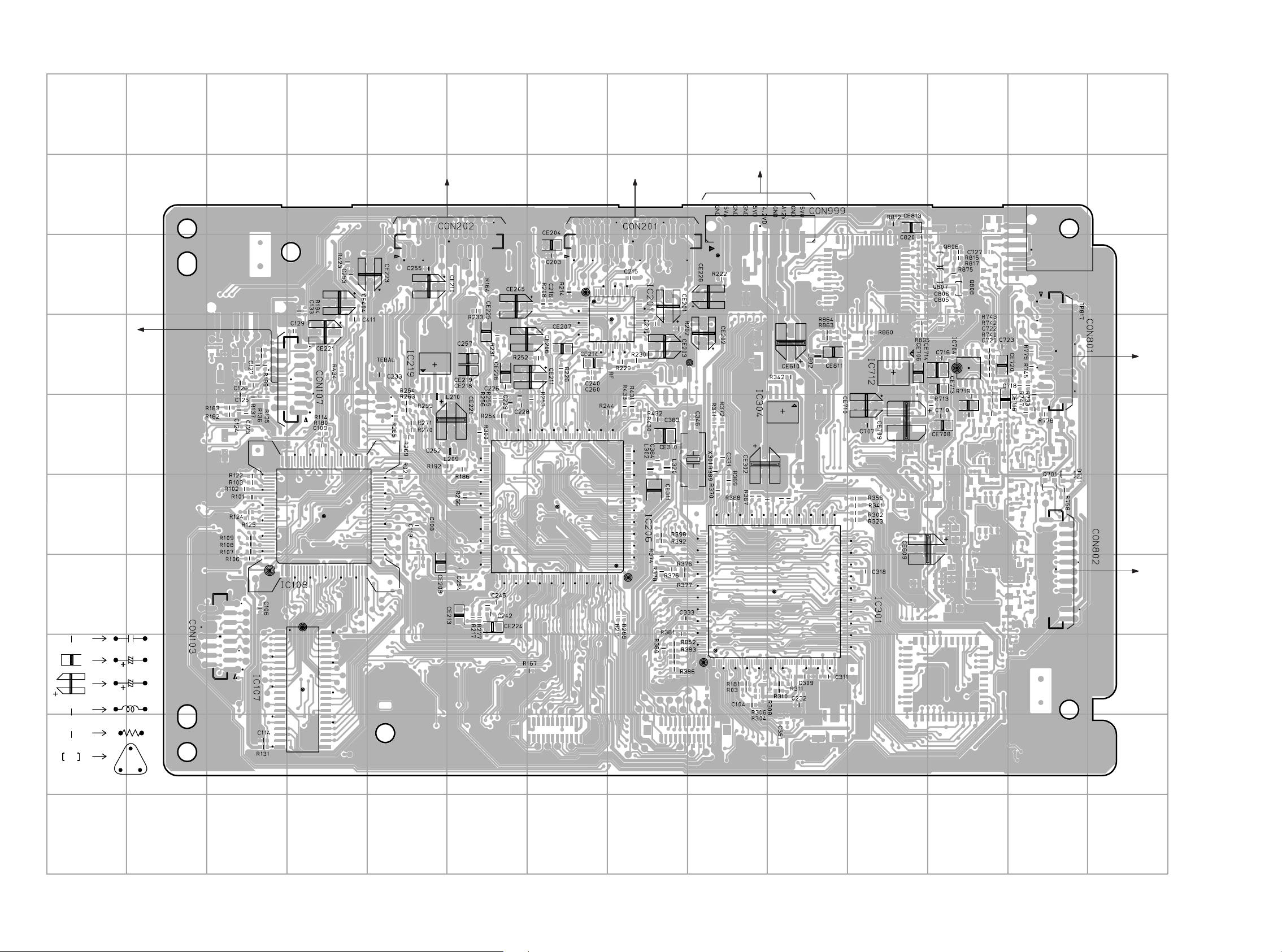

WIRING-1 (MAIN: COMPONENT SIDE) ........................................................................................ 21, 22

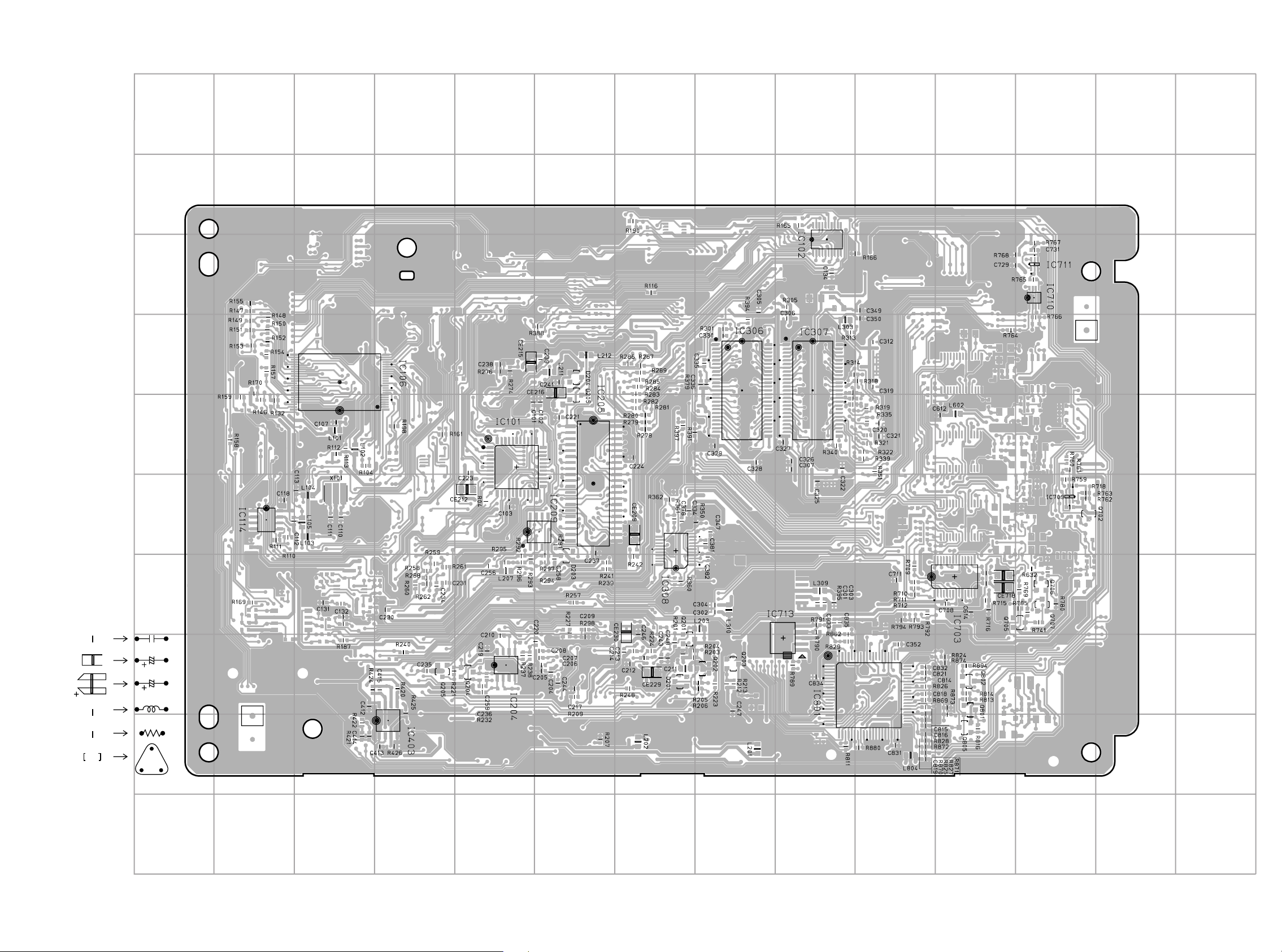

WIRING-2 (MAIN: CONDUCTOR SIDE) ........................................................................................ 23, 24

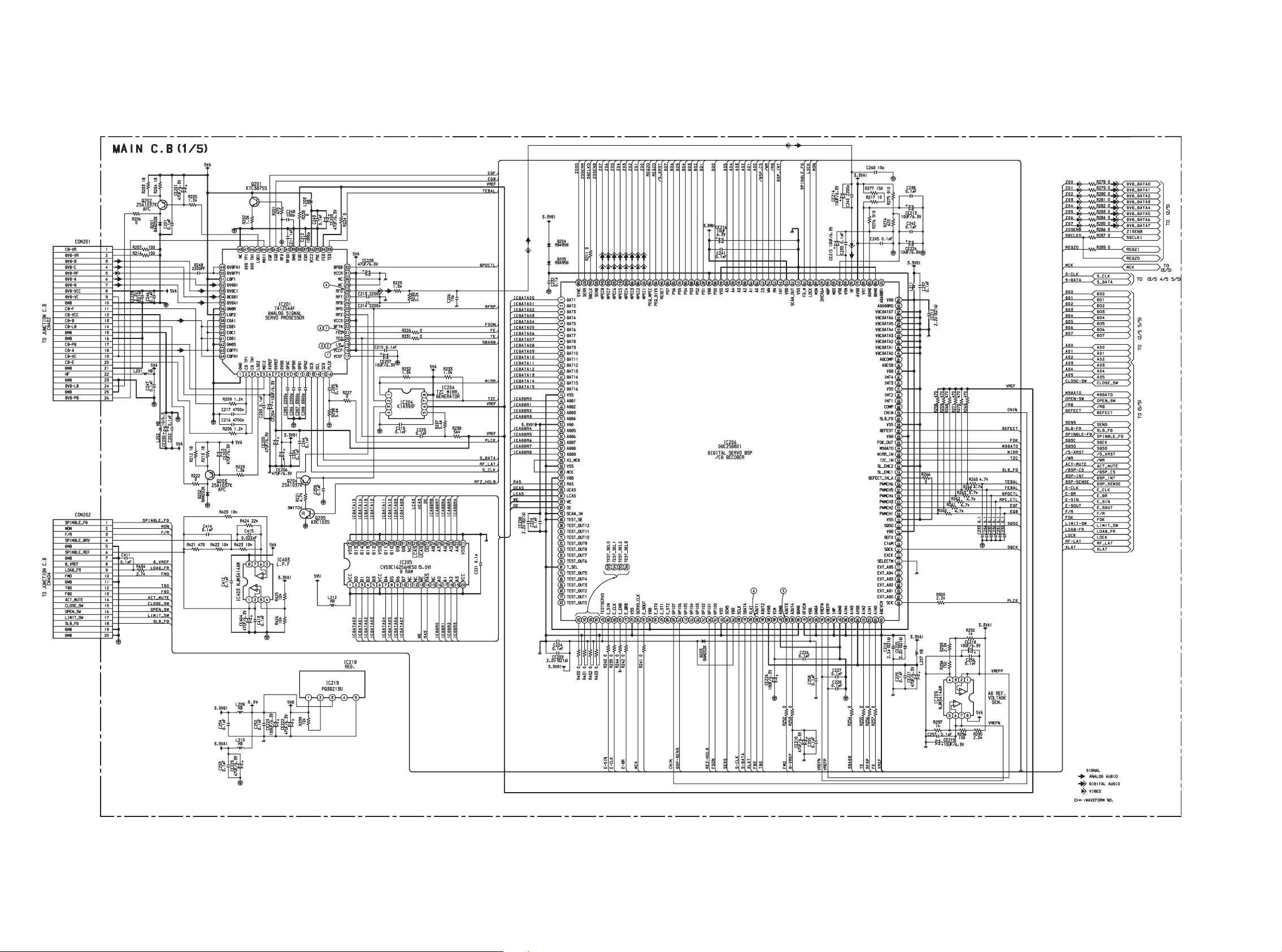

SCHEMATIC DIAGRAM-1 (MAIN 1/5)............................................................................................ 25, 26

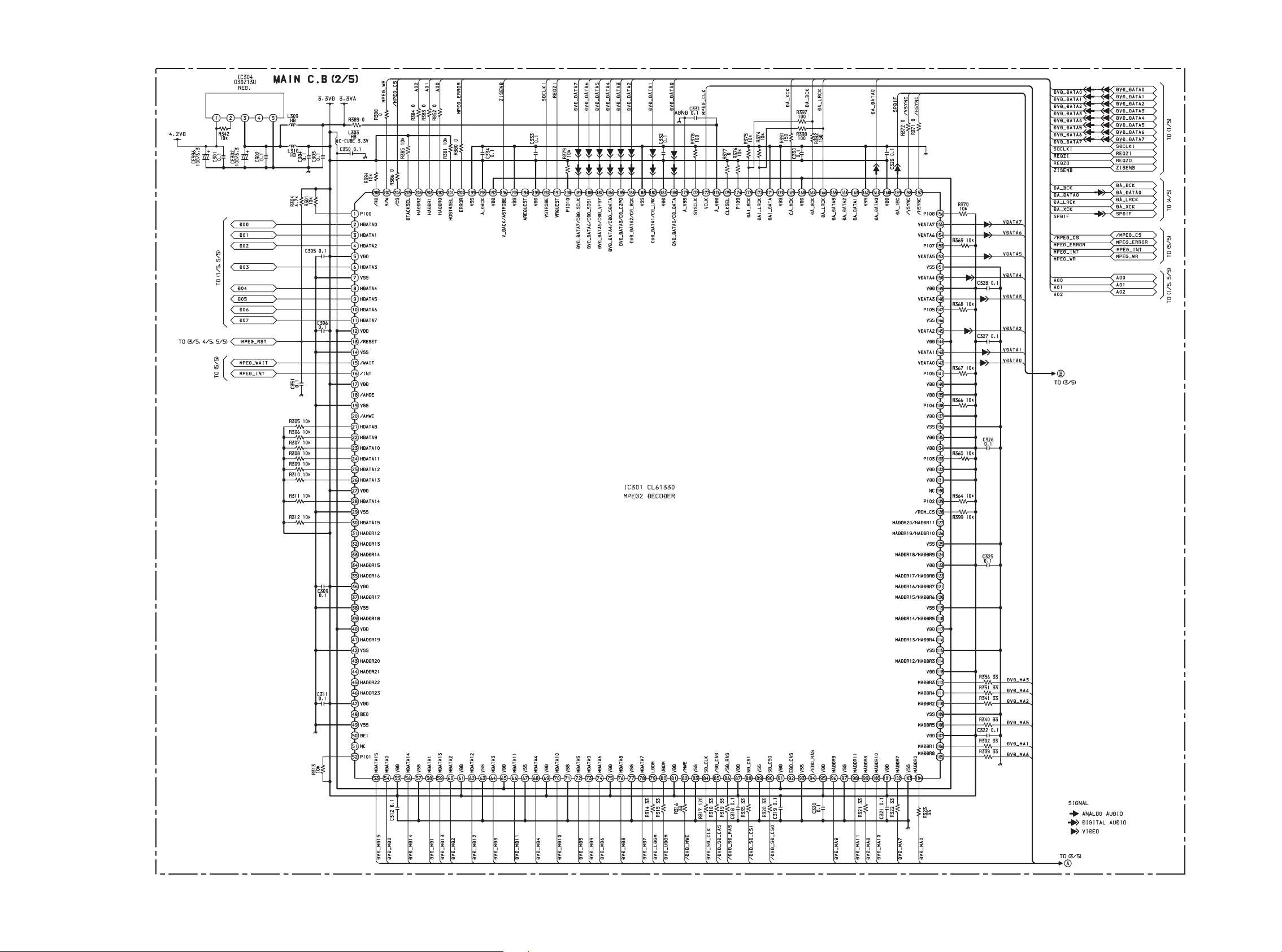

SCHEMATIC DIAGRAM-2 (MAIN 2/5)............................................................................................ 27, 28

SCHEMATIC DIAGRAM-3 (MAIN 3/5)............................................................................................ 29, 30

SCHEMATIC DIAGRAM-4 (MAIN 4/5)............................................................................................ 31, 32

SCHEMATIC DIAGRAM-5 (MAIN 5/5)............................................................................................ 33, 34

SCHEMATIC DIAGRAM-6 (JACK) ................................................................................................. 35, 36

WIRING-3 (JUNCTION/JACK)........................................................................................................ 37, 38

SCHEMATIC DIAGRAM-7 (JUNCTION) ........................................................................................ 39, 40

WIRING-4 (TIMER/KEY/POWER) .................................................................................................. 41, 42

SCHEMATIC DIAGRAM-8 (TIMER/KEY) ....................................................................................... 43, 44

SCHEMATIC DIAGRAM-9 (POWER) ............................................................................................. 45, 46

SCHEMATIC DIAGRAM-10 (MIC) .................................................................................................. 47, 48

WIRING-5 (MIC).................................................................................................................................... 49

WAVE FORM ................................................................................................................................... 50-52

TROUBLE-SHOOTING.................................................................................................................... 53-63

LCD DISPLAY....................................................................................................................................... 64

IC DESCRIPTION............................................................................................................................ 65-83

IC BLOCK DIAGRAM....................................................................................................................... 84-86

MECHANICAL EXPLODED VIEW 1/1.................................................................................................. 87

MECHANICAL PARTS LIST 1/1 ........................................................................................................... 88

MECHANISM EXPLODED VIEW 1/1 ............................................................................................. 89, 90

MECHANISM PARTS LIST 1/1............................................................................................................. 91

2

SPECIFICATIONS

DVD VIDEO PLAYER

Power supply 110~240V, 50~60Hz

Power consumtion 20W

Mass 3.5kg(7.7lbs)

External dimensions 430 x 91 x 293 (W * H * D)

Signal system NTSC

Laser Semiconductor laser, wavelength 655nm(DVD)/795nm(CD)

Frequency range (digital audio) 2Hz to 44kHz

Signal-to-noise ratio (digital audio) More than 105dB (EIAJ)

Audio dynamic range (digital audio) More than 95dB (EIAJ)

Harmonic distortion(digital audio) 0.003%

Wow and flutter Below measurable level (less than +0.001%(W.PEAK)) (EIAJ)

Operations Temperature : 5˚C(41˚F) to 35˚C(95˚F),

Operation status : Horizontal

OUTPUTS

Video outputs 1.0V(p-p), 75Ω, negative sync., RCA jack * 1

S video outputs (Y)1.0V(p-p), 75Ω, negative sync.,Mini DIN 4-pin * 1

(C)0.286V(p-p), 75Ω

Component video output (Y)1.0V(p-p), 75Ω,negative sync., RCA jack * 1

(Pb)/(Pr) 0.7V(p-p), 75Ω

Audio output(digital audio) 0.5V(p-p), 75Ω, RCA jack * 1

Audio output(optical audio) Optical connector * 1

Audio output(analog audio) 2.0Vrms (1kHz, 0dB), 330Ω, RCA jack (L, R) * 2

Design and specifications are subject to change without notice.

•

Weight and dimensions shown are approximate.

•

ACCESSORIES/PACKAGE LIST

REF. NO PART NO. KANRI DESCRIPTION

1 S8-35R-S00-09M EVNT INSTRUCTION ASSY<HR<N>>

1 S8-35R-S00-09L INSTRUCTION ASSY<LH<N>>

3 S5-640-17B-000 PLUG ASSY PHONE CORD 1WAY

4 S5-640-18B-000 PLUG ASSY PHONO CORD

5 S7-11R-2N0-13B REMOTE CONTROLLER A<LH<N>>

5 S7-11R-2N0-13C REMOTE CONTROLLER A<HR<N>>

NO.

3

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

CLASS 1

KLASSE 1

LUOKAN 1

KLASS 1

LASER PRODUCT

LASER PRODUKT

LASER LAITE

LASER APPARAT

This set employs laser. Therefore, be sure to follow carefully the

instructions below when servicing.

WARNING!

WHEN SERVICING, DO NOT APPROACH THE LASER EXIT

WITH THE EYE TOO CLOSELY. IN CASE IT IS NECESSARY TO

CONFIRM LASER BEAM EMISSION. BE SURE TO OBSERVE

FROM A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE OPTICAL

PICK-UP BLOCK.

Caution: Invisible laser radiation when

open and interlocks defeated avoid exposure to beam.

Advarsel:Usynling laserståling ved åbning,

når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

VAROITUS!

Laiteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyt-täjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

ATTENTION

L'utilisation de commandes, réglages ou procédures autres que

ceux spécifiés peut entraîner une dangereuse exposition aux

radiations.

ADVARSEL!

Usynlig laserståling ved åbning, når sikkerhedsafbrydereer ude

af funktion. Undgå udsættelse for stråling.

This Compact Disc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located on the rear

exterior.

VARNING!

Om apparaten används på annat sätt än vad som specificeras i

denna bruksanvising, kan användaren utsättas för osynling

laserstrålning, som överskrider gränsen för laserklass 1.

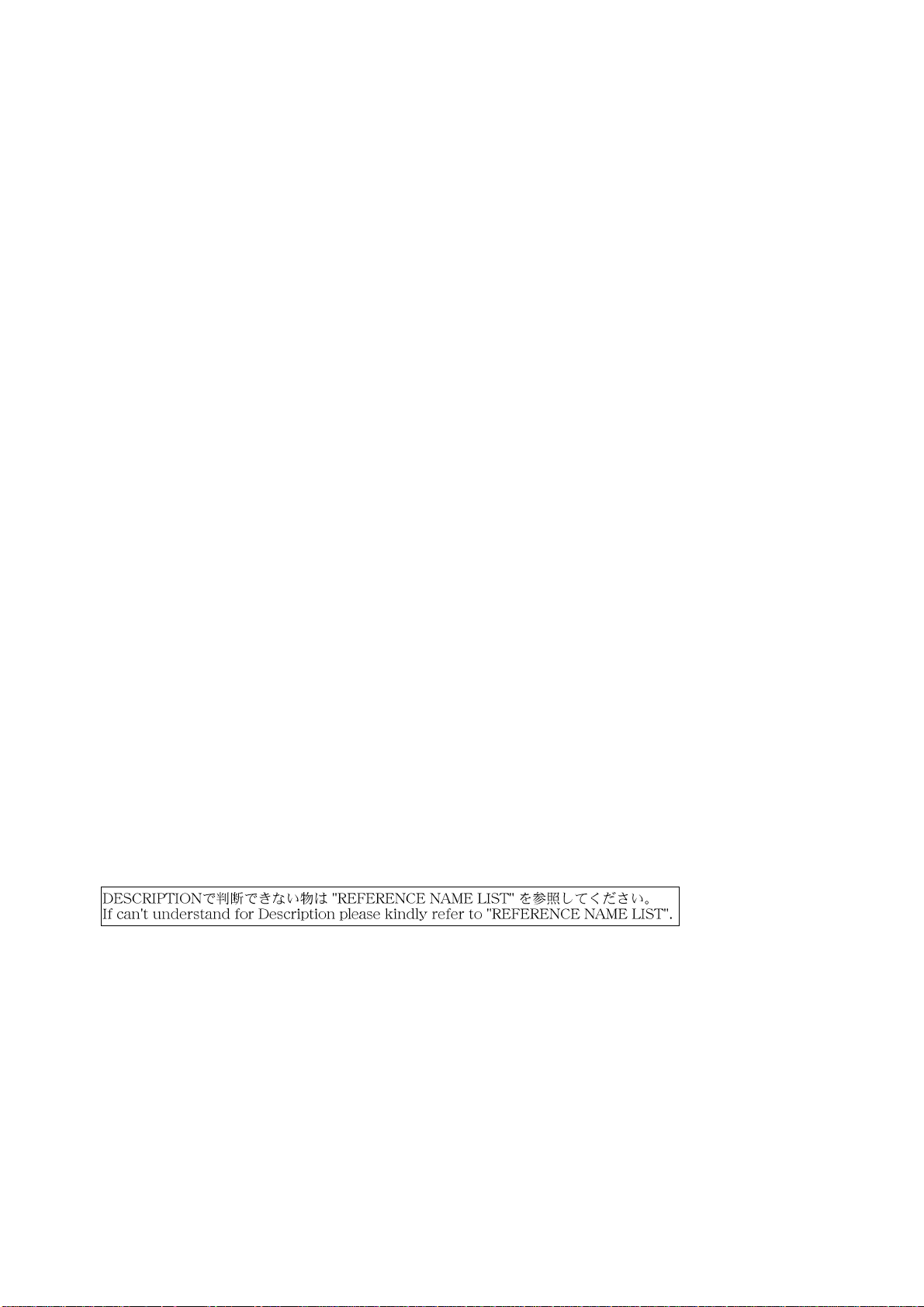

Precaution to replace Optical block

(LPC-512A)

Body or clothes electrostatic potential could ruin

laser diode in the optical block. Be sure ground

body and workbench, and use care the clothes

do not touch the diode.

1) After the connection, remove solder shown in

the right figure.

Solder

4

DISASSEMBLY INSTRUCTIONS

CAUTION BEFORE STARTING SERVICING

Electronic parts are susceptible to static electricity and may easily damaged, so do not forget to take a proper

grounding treatment as required.

Many screws are used inside the unit. To prevent missing, dropping, etc. of the screws, always use a

magnetized screw driver in servicing. Several kinds of screws are used and some of them need special

cautions. That is, take care of the tapping screws securing molded parts and fine pitch screws used to secure

metal parts. If they are used improperly, the screw holes will be easily damaged and the parts can not be

fixed.

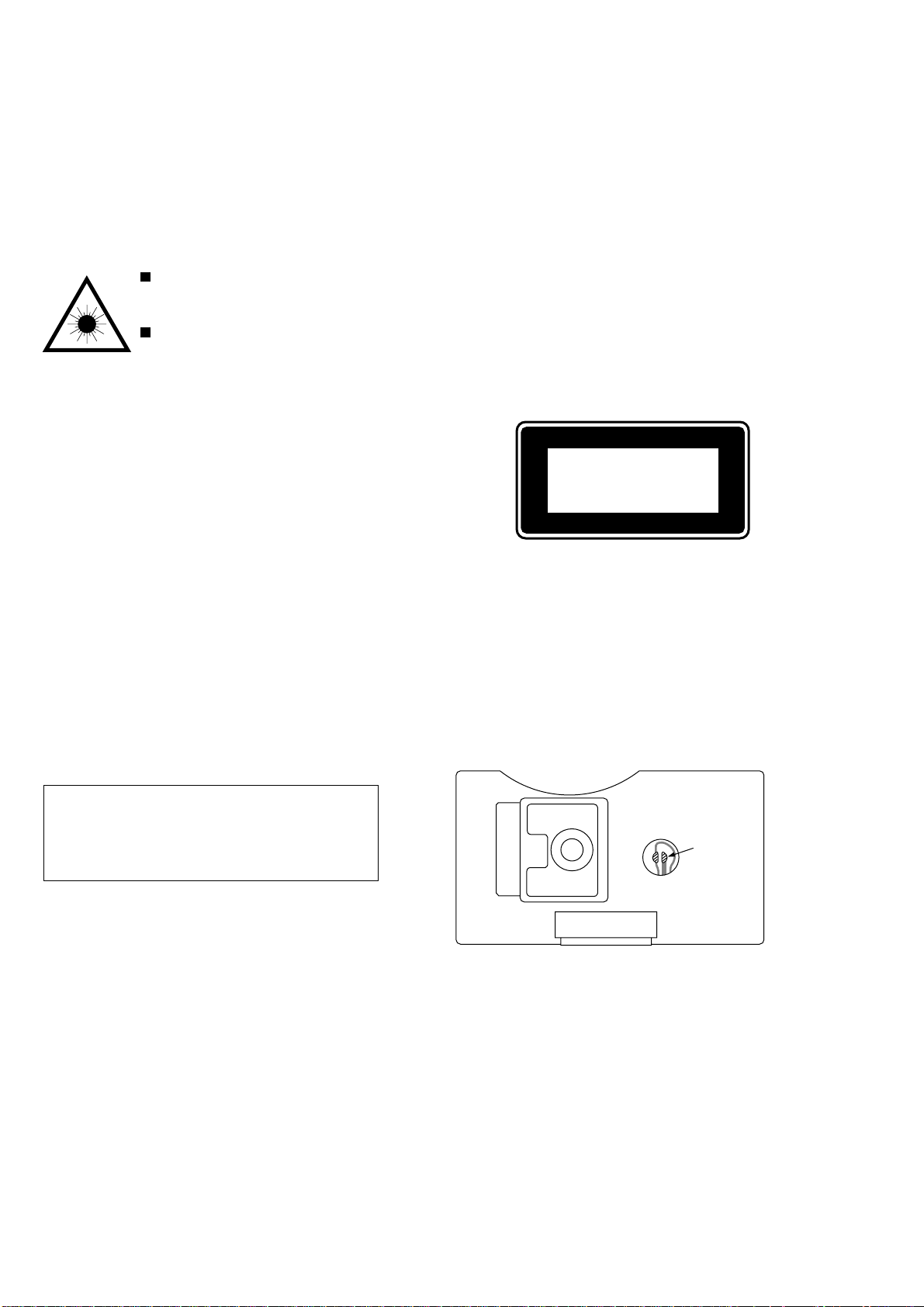

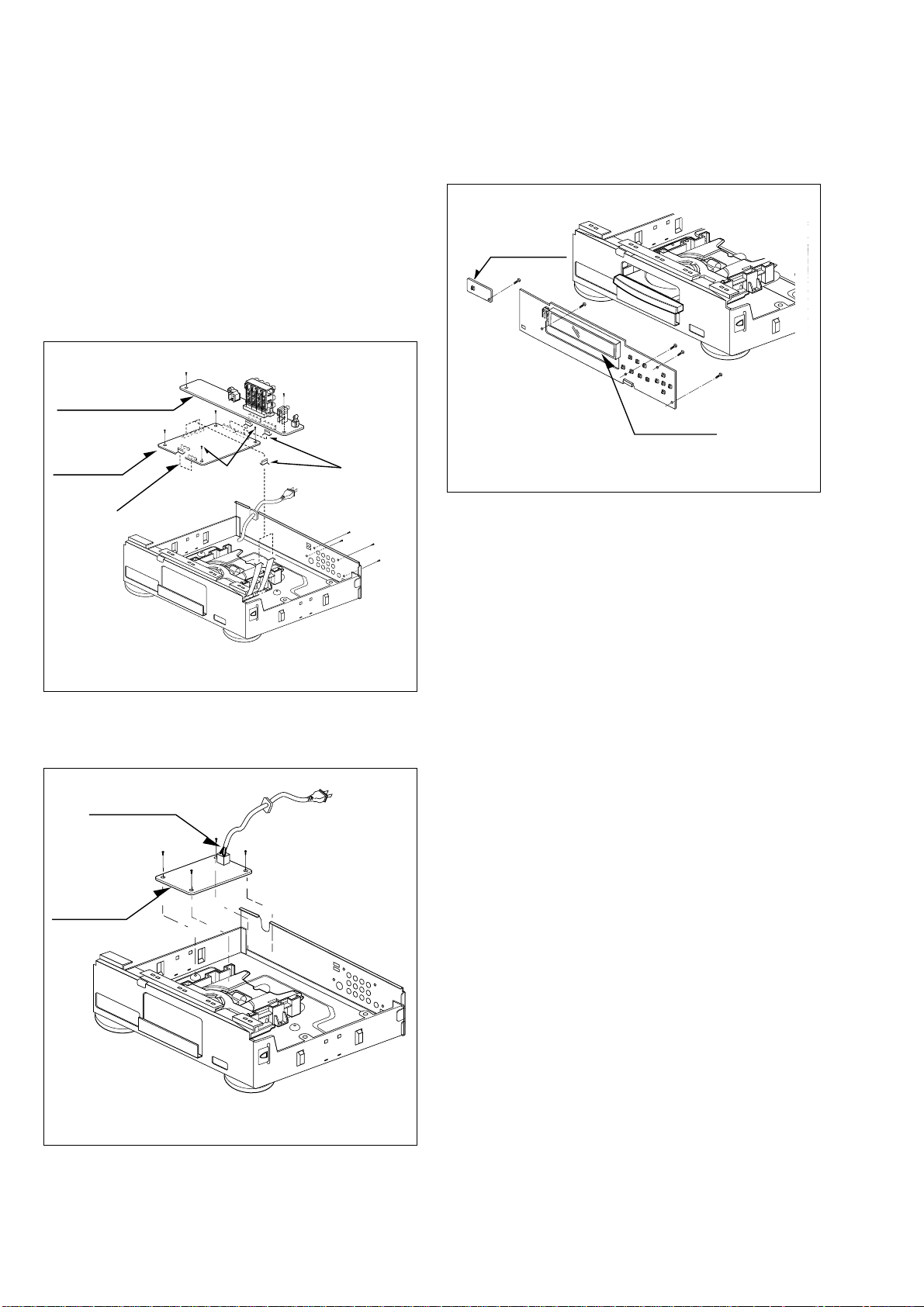

CABINET DISASSEMBLY

1. Top Case

1) Release 7 screws (A). (See Fig-1)

2) Lift the top case with holding the back of it, and remove

it in the direction of the arrow.

Top Case

(A)

(A)

(A)

(A)

(A)

3. Front Panel

1) Eject the disc tray. (See Fig-2)

2) Remove the tray door. (See Fig-2)

3) Release 2 screws (B).

4) Pull the front panel toward you while pressing 7

stoppers to disengage, and remove the front panel. (See

Fig-3)

Fig-1

2. Tray Door

1) Eject the disc tray.

2) Lift up the tray door in the direction of the arrow.

Tray Door

(A)

(A)

Stopper

(B)

Front Panel

(B)

Stopper

Fig-3

Fig-2

Disc Tray

5

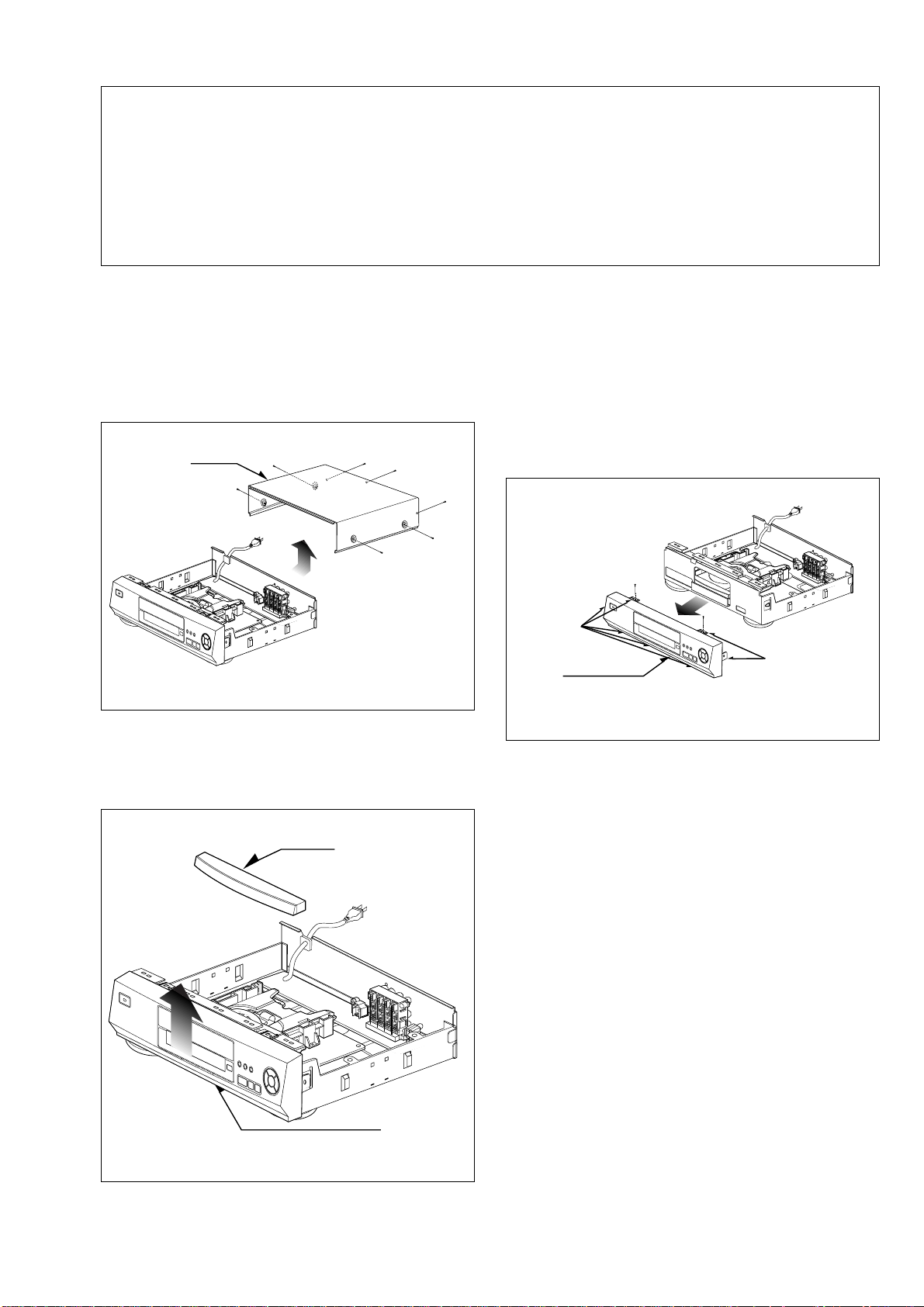

CIRCUIT BOARD DISASSEMBLY

Note: Before removing the main circuit board, be sure to

shortcircuit the laserdiode output land.

After replacing the main circuit board, open the land after

inserting the flexible connector.

(Refer to Mechanism Disassembly)

4. Main/JACK C.B

1) Remove the top case. (See Fig-1)

2) Release 10 screws (C), and take out the main/JACK

C.B. (See Fig-4)

3) Remove the flexible connectors and the connector from

main circuit board.

4) Then, remove the main JACK C.B.

(C)

(C)

JACK C.B

(C)

(C)

6. TIMER and Key C.B

1) Remove the front panel. (See Fig-3)

2) Release 5 screws (E), and remove the TIMER C.B.

Key C.B

(E)

(E)

(E)

(E)

(E)

TIMER C.B

Main C.B

Flexible

connector

5. Power C.B

1) Release 4 screws (D). (See Fig-5)

Power Code

(D)

Power C.B

(D)

(D)

(C)

Fig-4

(D)

Flexible

connector

(C)

(C)

(C)

(C)

Fig-6

Fig-5

6

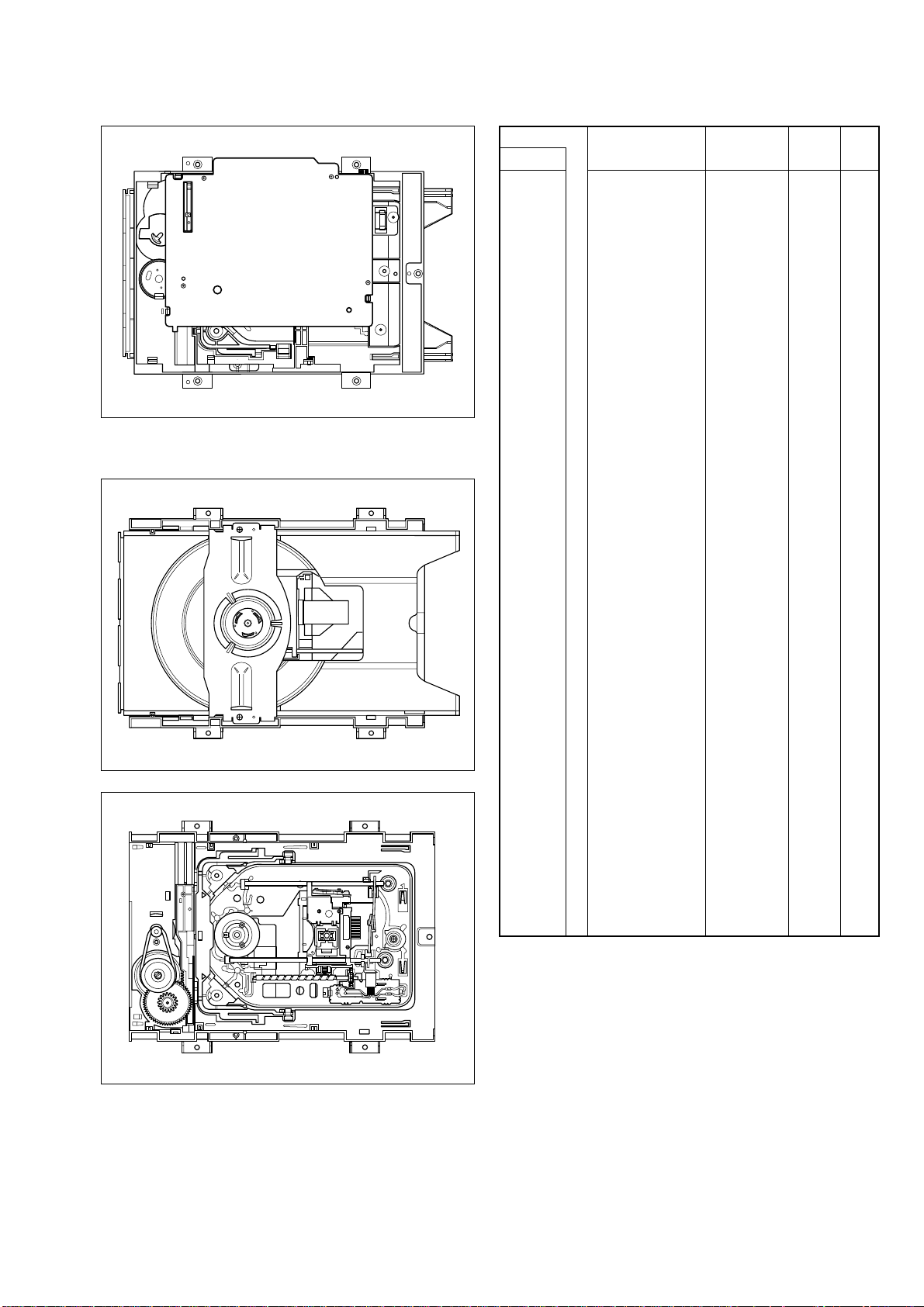

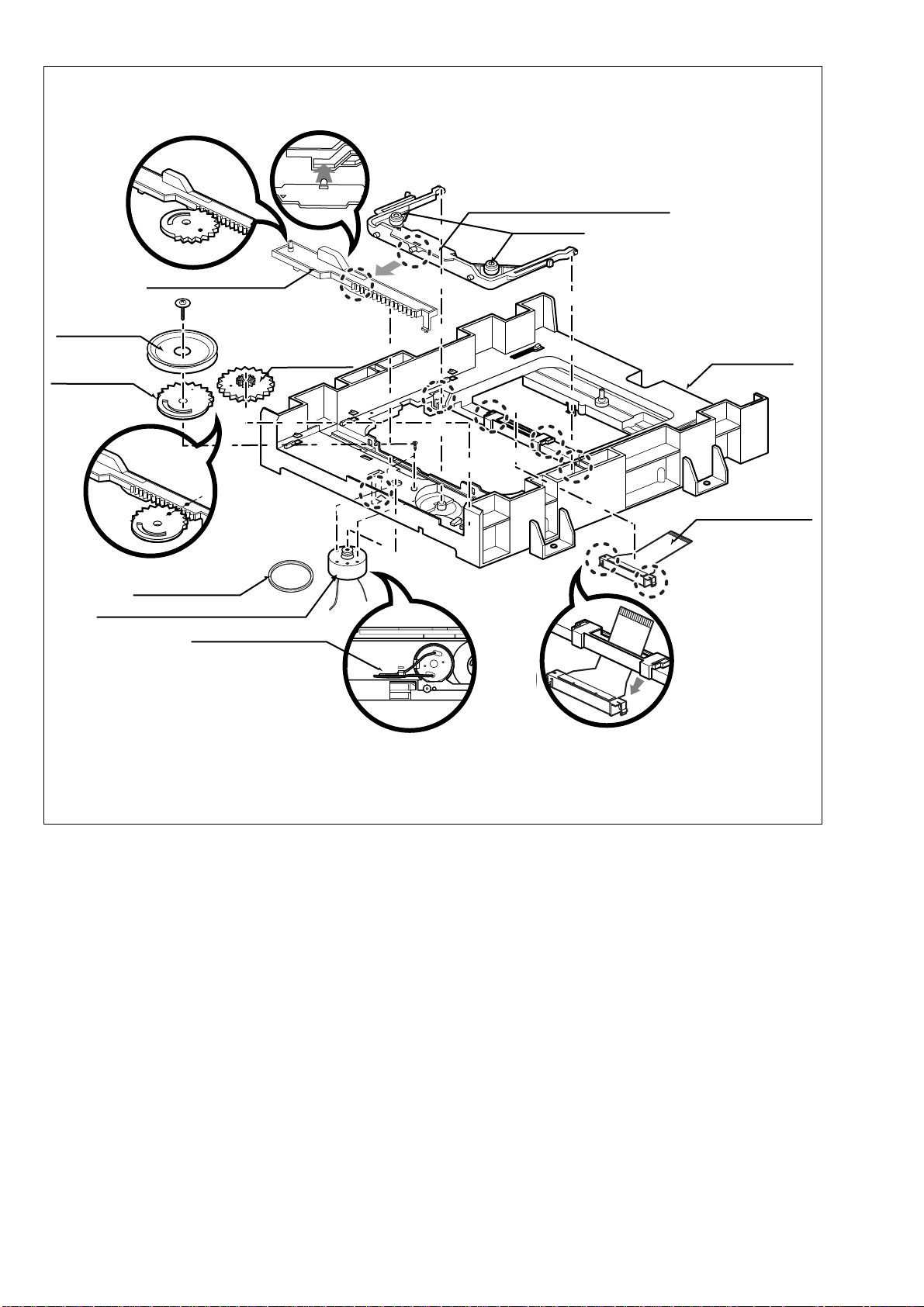

DECK MECHANISM PARTS LOCATION

• Bottom View

• Top View

Procedure

Starting No.

5

5, 6

2

2, 8

2, 8

2, 8

2, 8, 11

2, 8, 11

2, 8, 12, 13

2, 8, 12-14

2, 8, 12-14

2, 8, 12-16

2, 8, 9

2, 8, 9

2, 8, 9

2, 8, 9-20

1, 2, 8, 9

1, 2, 8, 9

2, 8, 9

2, 8, 9

2, 8

2, 8, 26

2, 8, 26, 27

2, 8, 26-28

2, 8, 26-29

1, 2, 8, 26-30

1, 2, 8, 26-31

Parts

1

Junction P.C.Board

2

Bracket Assembly Clamp

3

Bracket Clamp

4

Clamp Assembly Disk

5

Plate Clamp

6

Magnet Clamp

7

Clamp Lower

8

Tray Disk

9

Base Assembly Feed

10

Rubber R

11

Spring Skew

12

Shaft PU Main

13

Shaft PU Sub

14

Mechanism Assembly

PU Unit

15

Guide Freed PU

16

Spring Guide Feed

17

Pick up Assembly General

18

Motor (Mech.)

19

Shaft Lead Screw

20

Motor Assembly PU Freed

21

Base PU (Outsert)

22

Base Assembly Main

23

Holder Assembly Deck on

24

Frame Assembly Up/Down

25

Rubber F

26

Belt Loading

27

GearPulley

28

Gear Loading

29

Gear Emergency

30

Cam Loading

31

Motor Assembly Loading

32

Base Main

Fixing Type

4 Screws,

4 Locking Tabs

2 Screws

1 Locking Tab

1 Connector

1 Screw

1 Hook

1Screw

3Screws

2 Locking Tabs

1 Locking Tab

2 Locking Tabs

1 Screw

2 Screws

1 Locking Tab

Disassembly

Bottom

Bottom

Bottom

Bottom

Bottom

Figure

4-1

4-2

4-2

4-2

4-2

4-2

4-2

4-3

4-4

4-4

4-4

4-4

4-4

4-4

4-4

4-4

4-4

4-4

4-4

4-4

4-4

4-5

4-5

4-5

4-5

4-5

4-5

4-5

4-5

4-5

4-5

4-5

Note: When reassembling, perform the procedure in reverse order.

The “Bottom” on Disassembly column of above

Table indicates the part should be disassembled at the

Bottom side.

7

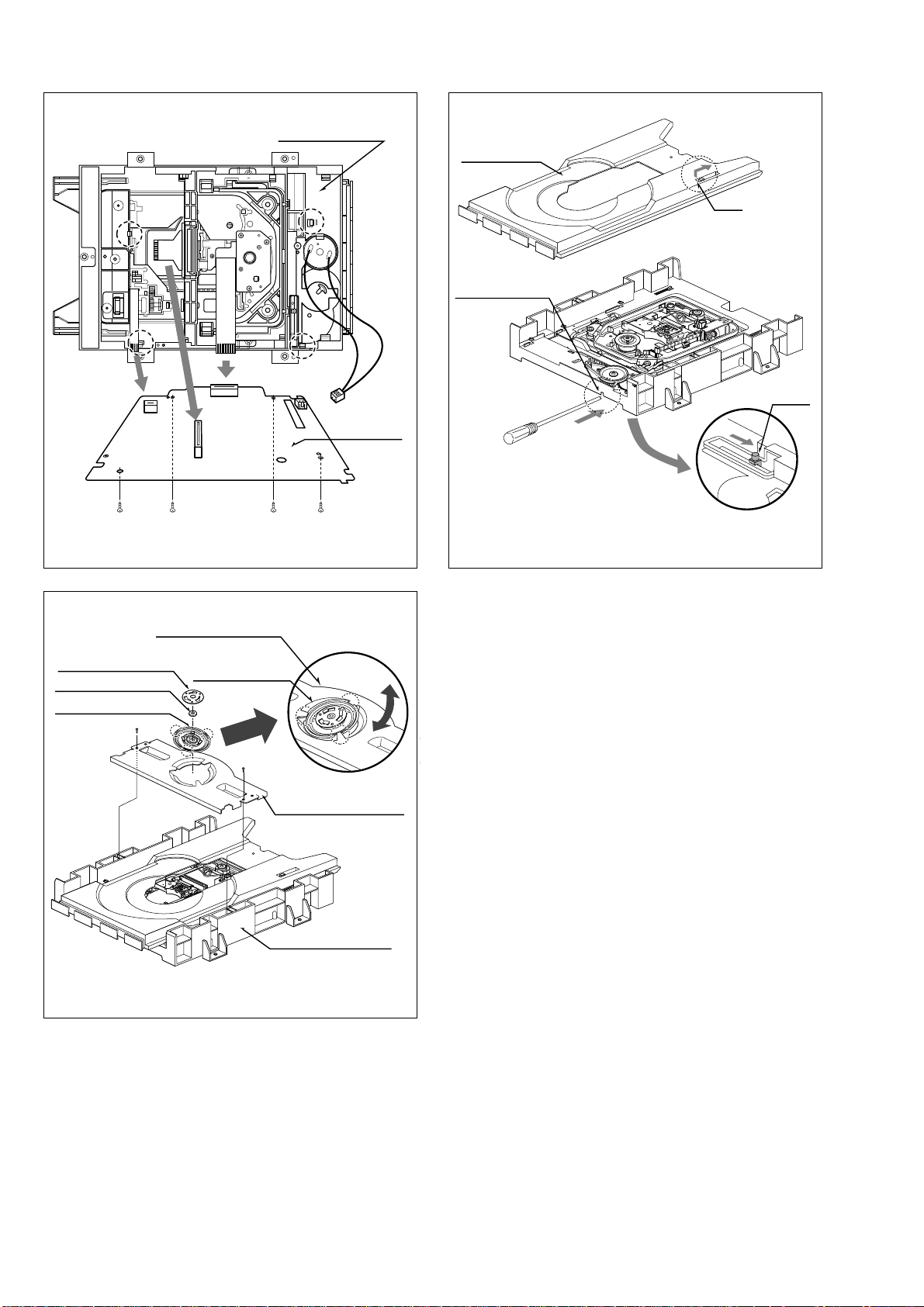

DECK MECHANISM ASSEMBLY

DECK ASSEMBLY

(L1)

(L1)

(C3)

(C2)

(C1)

(L1)

(L1)

(C4)

JUNCTION

C.B

TRAY DISK

EMERGENCY

EJECT HOLE

(A)

(B)

(L2)

(A)

LEVER

(B)

(S1)(S1) (S1)

Fig-7

BRACKET CLAMP

PLATE CLAMP

MAGNET CLAMP

CLAMP LOWER

(S2)

CLAMP

ASSEMBLY DISK

(S2)

BRACKET CLAMP

DECK ASSEMBLY

Fig-8

7. Junction C.B (Fig-7)

1) Put the Deck Assembly face down. (Bottom side)

2) Release 4 Screws (S1).

3) Unlock 4 Locking tabs (L1).

4) Lift up the Junction C.B a little to disconnect the

Connector (C1).

5) Disconnect 3 Connectors (C2, C3, C4).

(S1)

(A)

(Fig-A)

BOTTOM SIDE VIEW

Fig-9

8. Bracket Assembly Clamp (Fig-8)

1) Put the Deck Assembly on original position. (Top side)

2) Release 2 Screws (S2).

3) Lift up the Bracket Assembly Clamp.

8-1. Clamp Assembly Disk

1) Place the Clamp Assembly Disk as Fig-(A).

2) Lift up the Clamp Assembly Disk in direction of arrow

(A).

3) Separate the Clamp Assembly Disk from the Bracket

Clamp.

8-1-1. Plate Clamp

1) Turn the Plate Clamp to counterclockwise direction and

then lift up the Plate Clamp.

8-1-2. Magnet Clamp

8-1-3. Clamp Lower

8-2. Bracket Clamp

9. Tray Disk (Fig-9)

1) Insert and push a Driver in the emergency eject hole (A)

at the front side, or put the Driver on the Lever (B) of

the Gear Emergency and pull the Lever (B) in direction

of arrow (A) so that the Tray Disk is ejected about 1520mm.

2) Pull the Tray Disk until the moving is locked by the

Locking Tab (L2).

3) Unlock the Locking tab (L2) in direction of arrow (B).

4) Separate the Tray Disk completely.

8

CABLE FLEXIBLE

MOTOR ASSEMBLY PU FEED

PICK UP

ASSEMBLY GENERAL

GUIDE FEED PU

BASE PU (OUTSERT)

BASE PU (OUTSERT)

SHAFT PU SUB SHAFT PU MAIN

(C5)

SPRING

GUIDE FEED

(S4)

SPRING SKEW

(A)

(S3)

RUBBER R

(A)

(L3)

(L4)

(A)

Fig-(A)

P.C. BOARD

RED

BLACK

MOTOR

ASSEMBLY PU

FEED

MOTOR (MECH.)

(S5)

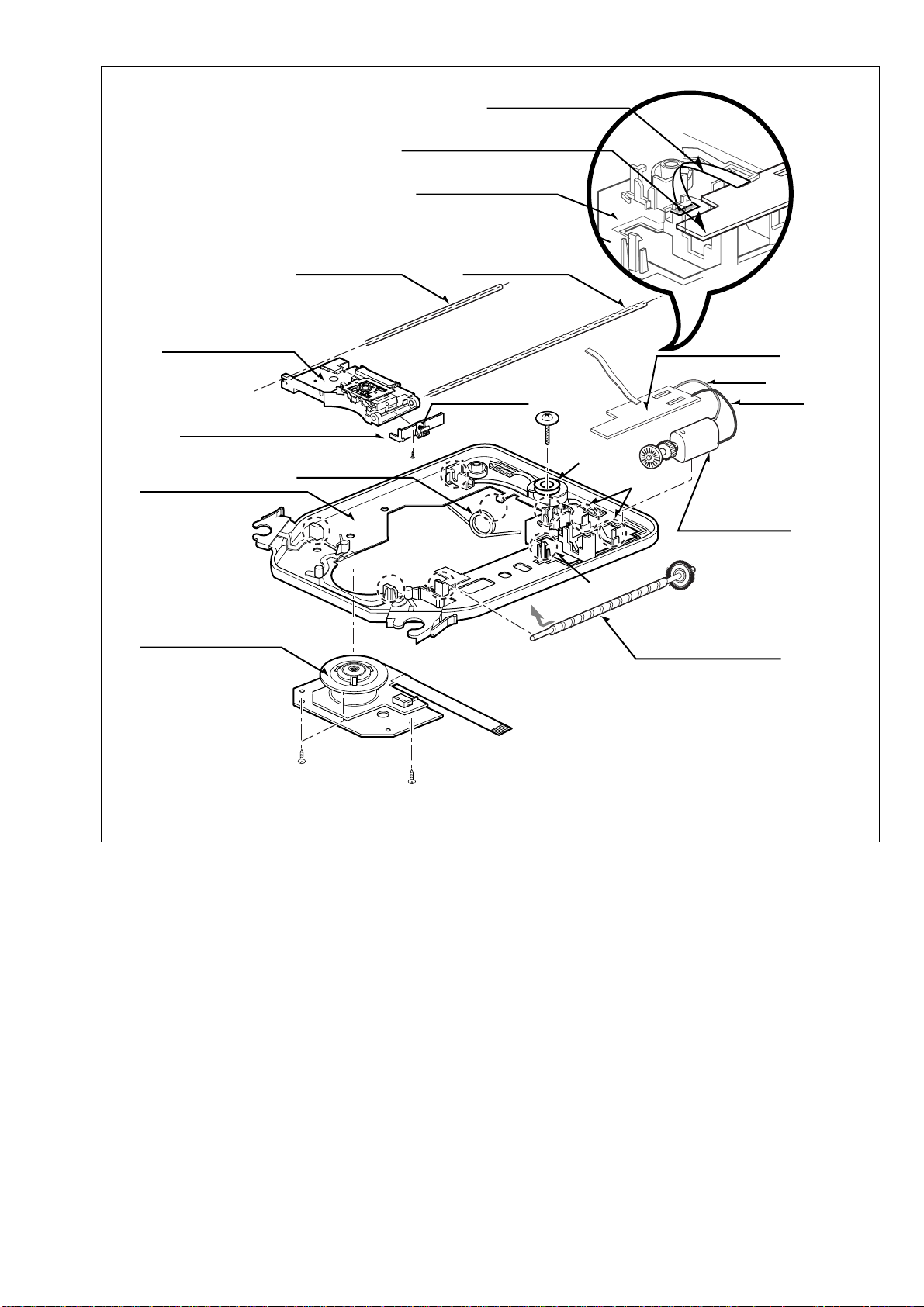

10.Base Assembly Feed (Fig-10)

1) Disconnect the Connector (C5)

2) Release the Screw (S3).

10-1. Rubber R

10-2. Spring Skew

1) Press the (A) position of the Spring Skew and unlock

the Spring Skew locking.

10-3. Shaft PU Main

10-4. Shaft PU SUB

Note: When reassembling, be careful not to change the

Shaft PU Main (Long) and the Shaft PU Sub (Short).

10-5. Mechanism Assembly PU Unit

10-5-1. Guide Feed PU

1) Release the Screw (S4) and separate the Guide Feed PU

from the Pick up Assembly General.

10-5-2. Spring Guide Feed

SHAFT LEAD SCREW

(S5)

Fig-10

10-5-3. Pick Up Assembly General

10-6. Motor (mech.)

1) Release the 3 Screws (S5) at bottom side.

2) Push down the Motor (Mech.) and separate from the

Base PU (Outsert).

10-7. Shaft Lead Screw

1) Push the Shaft Lead Screw in direction on arrow (A) a

little and lift up the Shaft Lead Screw.

10-8. Motor Assembly PU Feed.

1) Unlock the Locking tab (L3) and lift up the P.C.Board.

2) Unlock two Locking Tabs (L4) and push down the

Motor Assembly PU Feed.

3) Separate the Motor Assembly PU Feed from the Base

PU (Outsert).

Note: When reassembling, place the Motor Assembly PU

Feed as Fig-(A) and insert the Cable Flexible to the

Hole (A) of the Base PU (Outsert). (See Fig-(A))

10-9. Motor (mech.)

9

(R2)

Fig-(D)

GEAR PULLY

CAM LOADING

Fig-(C)

BELT LOADING

MOTOR ASSEMBL Y LOADING

GEAR EMERGENCY

(S6)

GEAR LOADING

CONNECTOR(2 PIN)

(R1)

(R2)

(L7)

Fig-(B)

(L6)

(R1)

(S7)

FRAME ASSEMBLY UP/DOWN

RUBBER F

(L6)

(L5)

BASE MAIN

HOLDER

ASSEMBLY

DECK ON

(L5)

11.Base Assembly Main (Fig-11)

11-1. Holder Assembly Deck On

1) Push the Locking tabs (L5) at bottom side of the Holder

Assembly Deck On in direction of arrow (A) and

separate to bottom side. (See Fig-(A))

11-2. Frame Assembly Up/Down.

1) Push the two Locking tabs (L6) and lift up the Frame

Assembly Up/Down.

Note: When reassembling, insert the Lever (R1) of the

Frame Assembly Up/Down to the Groove (R2) of the

Gear Emergency and lock the two Locking Tabs

(L6). (See Fig-(B))

11-3. Rubber F

11-4. Belt Loading

11-5. Gear Pulley

1) Release the Screw (S6) and lift up the Gear Pulley.

Fig-(E) Fig-(A)

BOTTOM SIDE VIEW

Fig-11

11-6. Gear Loading

11-7. Gear Emergency

Note: When reassembling, confirm that the Hole (A) of the

Cam Loading is aligned to the Hole (B) of the Gear

Emergency as Fig-(C).

For this alignment, place the Gear Emergency and

Cam Loading as Fig-(D), and then move the Gear

Emergency in direction of arrow (B) until these two

gears are aligned as Fig-(C).

11-8. Cam Loading

11-9. Motor Assembly Loading

1) Release two Screws (S7).

2) Unlock the Locking tab (L7) and separate the Motor

Assembly Loading to bottom side.

Note: When reassembling, confirm that the Connector (2

Pin) is aligned as Fig-(E)

(A)

10

11-10.Base Main

ELECTRICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

NO.

IC

SI-RH3-308-00A IC,BA3308<HR<N>>

SI-KE4-558-00A IC,KIA4558P<HR<N>>

SI-TI7-437-40K IC,SN74AHC374PWLE

SI-AM2-980-01A IC,AM29F800B-120EC<LH<N>>

SI-AL4-916-14A IC,AT49F1614-90TC<HR<N>>

SI-AL4-981-92B IC,AT49F8192A-90TC<LH<N>>

SI-GS7-142-60E IC,GM71C4260CJ-60

SI-MQ5-316-25A IC,V53C16256HK50

SI-HI6-417-03B IC,HD6417034AFI20

SI-AL2-402-10E IC,AT24C02N-10SC-2.7

SI-SS2-402-10A IC,KS24C021CS

SI-KE3-930-00G IC,KIA393F-EL

SI-HY2-580-10A IC,GDC25D801AA

SI-JR3-414-00C IC,NJM3414AM-TE1,3K/REEL

SI-SH3-130-00A IC,PQ3DZ13U

SI-CU3-000-00A IC,ZIVA3-PE0

SI-FA1-117-25A IC,RC1117ST-2.5

SI-SS4-161-02F IC,KM4161020CT-G7

SI-GS7-216-16C ICGM72V161621ET-7

SI-BB1-700-00A IC,PLL1700E 20P

SI-RH6-859-20A IC,BA6859AFP-E2

SI-RH5-983-20A IC,BA5983FP-E2

SI-SA8-661-12C IC,LC866112B-5N21

SI-SS7-542-00A IC,KA7542Z

87-001-196-010 IC,KIA7042P

SI-BB1-716-00A IC,PCM1716E 28P

SI-JR4-580-00B IC,NJM4580M

SI-CB5-331-00A IC,CS5331A-KS<HR<N>>

SI-SH2-050-00A IC,PQ20WZ5U 20WZ51

SI-RW8-610-00A IC,BT861

SI-SK6-153-00A IC,STR-G6153T 5P

SI-SS4-310-00A IC,KA431AZ

SI-KE4-310-00A IC,KIA431 3P

SI-SS7-808-00H IC,KA78R08 4P

TRANSISTOR

ST-R38-750-9AC CHIP KTC3875S-GR-T1

ST-R10-370-9BB C-TR,2SA1037K-Q

ST-R10-300-9AE TR,KRC103M

ST-R10-500-9AB TR,KRC105M

ST-R10-500-9AD TR,KRA105M

ST-R15-040-9BF TR,KTA1504S-Y

ST-R15-050-9AD TR,KTA1505S-Y

ST-R13-040-9BA TR,KTD1304S

ST-R11-510-0AA TR,KSB1151-Y

ST-R31-980-9AC TR,KTC3198-TP-BL

DIODE

SD-R49-500-9AA DIODE,RB495D

87-020-465-080 DIODE,1SS133

SD-D19-300-9AB C-DIODE,KDS193

SD-D01-000-9CA DIODE,EG01CW

87-A40-284-080 DIODE,ERA22-10

SD-D01-000-9AC DIODE,EU01W

87-017-352-010 DIODE,RU3YXLF-C1 100V2

SD-R10-451-0AA DIODE,B10A45V1

SD-R18-020-9AA DIODE,ERA18-02KFRB

SD-R15-402-0BA DIODE,1N5402

SD-Z51-000-9HA ZENER,MTZ5.1B 0.5W

MAIN C.B

C204 SC-H71-06C-611 C-CAP,10UF-6.3V

C207 SC-H71-06C-611 C-CAP,10UF-6.3V

C213 SC-H71-06C-611 C-CAP,10UF-6.3V

C214 SC-H71-06C-611 C-CAP,10UF-6.3V

C215 SC-H71-06C-611 C-CAP,10UF-6.3V

REF. NO PART NO. KANRI DESCRIPTION

NO.

C216 SC-H71-06C-611 C-CAP,10UF-6.3V

C218 SC-H71-06C-611 C-CAP,10UF-6.3V

C219 SC-H71-06C-611 C-CAP,10UF-6.3V

C220 SC-H81-07C-621 C-CAP,100UF-6.3V

C224 SC-H71-06C-611 C-CAP,10UF-6.3V

C226 SC-H71-06C-611 C-CAP,10UF-6.3V

C230 SC-H71-06C-611 C-CAP,10UF-6.3V

C302 SC-H81-07C-691 C-CAP,100UF-6.3V

C310 SC-H71-06F-621 C-CAP,10UF-16V

C311 SC-H71-06F-621 C-CAP,10UF-16V

C708 SC-H71-06C-611 C-CAP,10UF-6.3V

C709 SC-H82-27D-611 C-CAP,220UF-10V

C712 SC-H71-06C-611 C-CAP,10UF-6.3V

C713 SC-H71-06C-611 C-CAP,10UF-6.3V

C714 SC-H71-06F-621 C-CAP,10UF-16V

C718 SC-H71-06C-611 C-CAP,10UF-6.3V

CE201 SC-H84-76C-611 C-CAP,47UF-6.3V

CE202 SC-H84-76C-611 C-CAP,47UF-6.3V

CE203 SC-H84-76C-611 C-CAP,47UF-6.3V

CE205 SC-H84-76C-611 C-CAP,47UF-6.3V

CE206 SC-H84-76C-611 C-CAP,47UF-6.3V

CE210 SC-H84-76C-611 C-CAP,47UF-6.3V

CE211 SC-H84-76C-611 C-CAP,47UF-6.3V

CE221 SC-H84-76C-611 C-CAP,47UF-6.3V

CE223 SC-H84-76C-611 C-CAP,47UF-6.3V

CE228 SC-H84-76C-611 C-CAP,47UF-6.3V

CE609 SC-H81-07F-611 C-CAP,100UF-16V

CE610 SC-H81-07F-611 C-CAP,100UF-16V

CE710 SC-H84-76C-611 C-CAP,47UF-6.3V

CE721 SC-H84-76C-611 C-CAP,47UF-6.3V<HR<N>>

CE722 SC-H84-76C-611 C-CAP,47UF-6.3V<HR<N>>

CE723 SC-H71-05J-611 CAP,1U-35V<HR<N>>

CE724 SC-H71-05J-611 CAP,1U-35V<HR<N>>

X101 S2-12H-B20-02A CCR20.0MC6T TDK 20000000H

X301 S2-02R-427-01G C-RESO 27MHZ 20P

JUNCTION C.B

CE450 87-010-140-080 CAP,E 47-16V

CE451 87-010-140-080 CAP,E 47-16V

CE452 87-010-140-080 CAP,E 47-16V

CE453 87-010-140-080 CAP,E 47-16V

R451 SR-D01-01H-633 RES,1-1/2W

R452 SR-D01-01H-633 RES,1-1/2W

TIMER C.B

C500 SC-E22-73D-638 CAP,E 220-10V

C501 SC-E10-63F-638 CAP,E 10-16V<HR<N>>

C502 SC-E10-63F-638 CAP,E 10-16V

C506 SC-E47-63J-638 CAP,E 47UF-35V

C507 SC-E10-63F-638 CAP,E 10-16V

C512 87-010-140-080 CAP,E 47-16V

C513 87-010-140-080 CAP,E 47-16V

DIG501 S3-02H-V00-1D0 7-BT-259GK DH

LED501 SD-L32-531-9AA LED SPR325MVWT31(GRN)

RC501 S7-12R-083-8GA TSOP1238UQ1 TEMIC 8MM 37 RC

SW501 S5-562-19B-000 SW,SKHV10910B

SW502 S5-562-19B-000 SW,SKHV10910B

SW503 S5-562-19B-000 SW,SKHV10910B

SW503 S5-562-19B-000 SW,SKHV10910B

SW504 S5-562-19B-000 SW,SKHV10910B

SW505 S5-562-19B-000 SW,SKHV10910B

SW506 S5-562-19B-000 SW,SKHV10910B

SW507 S5-562-19B-000 SW,SKHV10910B

SW510 S5-562-19B-000 SW,SKHV10910B

SW511 S5-562-19B-000 SW,SKHV10910B

SW512 S5-562-19B-000 SW,SKHV10910B

SW513 S5-562-19B-000 SW,SKHV10910B

SW514 S5-562-19B-000 SW,SKHV10910B

11

REF. NO PART NO. KANRI DESCRIPTION

NO.

X501 S6-160-20P-000 CSA6.00MGU MURATA 6MHZ

JACK C.B

CV1 87-010-060-080 CAP,E 100-16V

CV10 SC-E10-86F-630 CAP,E 1000-16V

JACK1 S6-12R-L00-1A0 TOTX178 HORIZONTA JK

JACK2 S5-720-75A-000 BJP-202L BAEEN BLACK

JACK3 S6-12R-IH0-05G PJ6031MG PARK ELEC AU PLATED

JACK4 S6-12R-BH0-08A YKF51-5506 JALCO HORIZONT4P

KEY C.B

LED501 SD-L32-531-9AA LED SPR325MVWT31(GRN)

SW508 S5-562-19B-000 SW,SKHV10910B

POWER C.B

C900 87-010-408-040 CAP,E 47UF-50V

C901 S6-240-88B-000 CAP,0.1UF-250V

C902 S6-240-88B-000 CAP,0.1UF-250V

C902 S6-240-88F-000 CAP,PCX2 275V 0.1UF,M

C903 S0-2TF-H68-0M0 CAP,E 68U-400V

C905 87-016-375-010 CAP,0.01UF-630V

C906 S6-240-87B-000 CAP,100P-1KV

C907 SA-1B3-0KH-2M0 CAP,220PF-400V

C913 87-012-379-010 CAP,3300PF-400V

C916 87-010-387-010 CAP,E 470UF-25V KME

C918 87-010-112-080 CAP,E 100-16V

C919 87-010-408-040 CAP,E 47UF-50V

C921 SC-E22-76F-638 CAP,E 220UF-16V

C923 87-010-237-910 CAP,E 1000UF-16V

C924 87-010-237-910 CAP,E 1000UF-16V

C925 87-010-375-080 CAP,E 330-10V

C926 87-010-408-040 CAP,E 47UF-50V

C927 87-015-684-080 CAP,E 47-16V

C929 87-010-112-080 CAP,E 100-16V

C932 SC-E47-7CD-638 CAP,E 470UF-10V

REF. NO PART NO. KANRI DESCRIPTION

C934 SC-E47-7CD-638 CAP,E 470UF-10V

!

F901 S5-850-11T-000 FUSE,1600MA 250V

!

F902 87-001-196-010 ICP-N10 T104

!

IC903 S6-570-62B-000 SENSOR PC123Y

!

IC903 S2-309-024-040 SENSORLTV-817B PHOTO COU

!

L901 S6-161-45H-000 FILTER SHT LFS2020V4-04350

!

L901 S6-161-45J-000 FL BUJEON V-04350

L902 S6-330-88G-000 COIL,CHOCK TP 5MM

L903 S6-330-88D-000 COIL,20UH

R901 S6-140-07R-000 RES,2.7-2W

R902 SR-S10-03K-619 RES,100K-2W

R911 SR-S05-10K-619 RES,0.51-2W

R922 SR-S12-00J-619 RES,M/F 120-1W

!

T901 S6-420-23T-000 PT,SHT-023T/KSE-023T

!

V901 S6-560-04F-000 SVR681D10A SAMYANG 680V

MIC C.B <HR>

CM1 87-015-681-080 CAP,E 10-16V<HR<N>>

CM2 SC-E10-76D-638 CAP,100M-10V<HR<N>>

CM3 87-015-681-080 CAP,E 10-16V<HR<N>>

CM4 87-015-681-080 CAP,E 10-16V<HR<N>>

CM6 SC-E10-76D-638 CAP,100M-10V<HR<N>>

CM7 87-015-681-080 CAP,E 10-16V<HR<N>>

CM8 87-010-402-040 CAP,E 2.2-50V<HR<N>>

CM10 87-010-402-040 CAP,E 2.2-50V<HR<N>>

CM12 87-010-402-040 CAP,E 2.2-50V<HR<N>>

CM13 87-010-371-080 CAP,E 470-6.3V<HR<N>>

CM14 87-015-681-080 CAP,E 10-16V<HR<N>>

CM23 87-010-371-080 CAP,E 470-6.3V<HR<N>>

CM25 87-015-681-080 CAP,E 10-16V<HR<N>>

CM26 87-015-681-080 CAP,E 10-16V<HR<N>>

MJ1 S6-12R-FV0-01B HTJ-064-255GG KUNMING MIC PJK

VR1 S1-10R-RHP-03A VR,RK09K1110Z0223B 6.5-2<HR<N>>

VR2 S1-10R-RHP-03A VR,RK09K1110Z0223B 6.5-2<HR<N>>

VR3 S1-10R-RHP-03A VR,RK09K1110Z0223B 6.5-2<HR<N>>

NO.

<HR<N>>

• Regarding connectors, they are not stocked as they are not the initial order items.

The connectors are available after they are supplied from connector manufacturers upon the order is received.

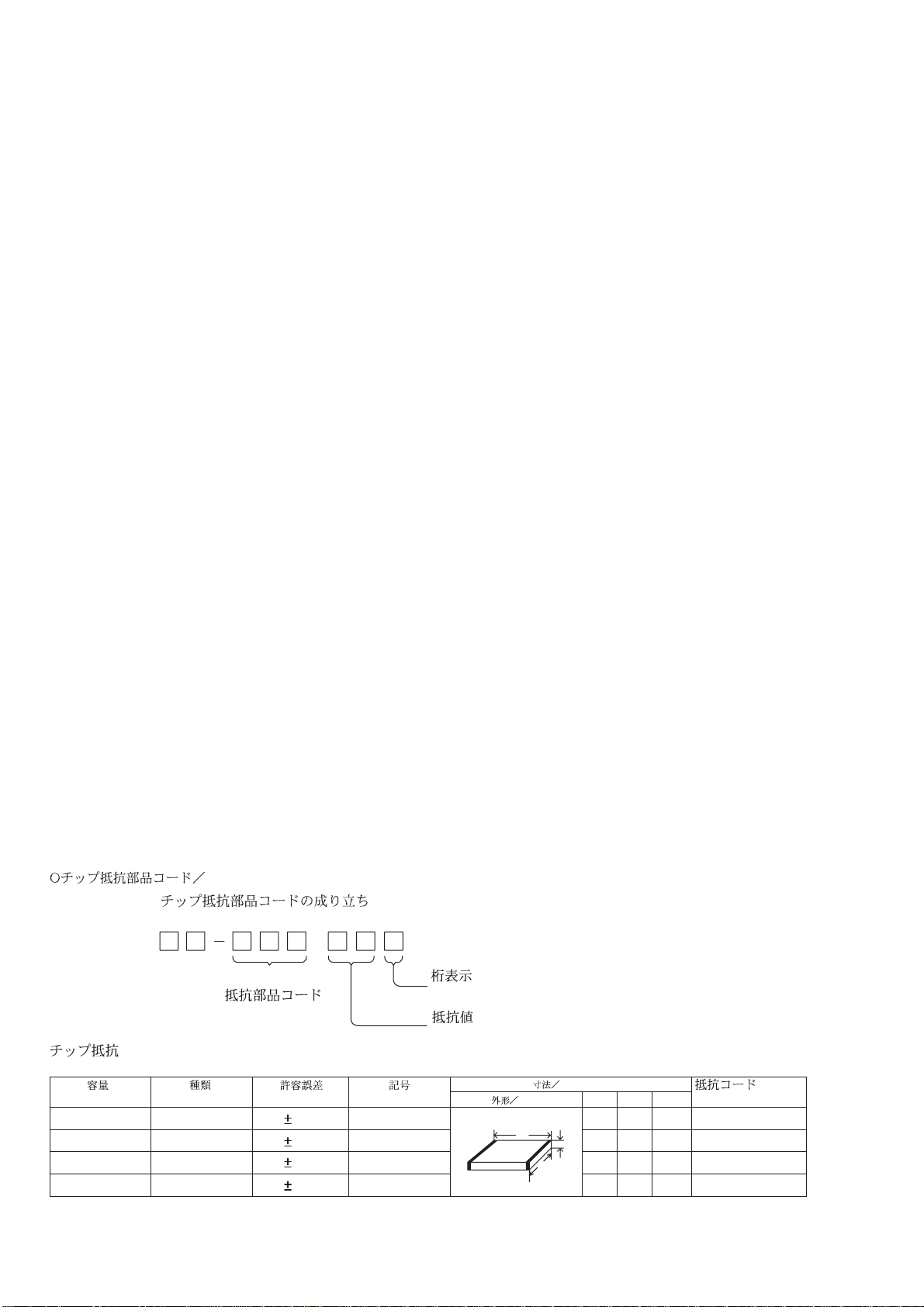

CHIP RESISTOR PART CODE

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

Symbol

Figure

Value of resistor

CJ

CJ

CJ

Form

L

W

Dimensions (mm)

LW t

1.0 0.5 0.35 104

t

1.6 0.8 0.45

2 1.25 0.45

1.6

0.55

3.2

Resistor Code

108

118

128

: A

: A

12

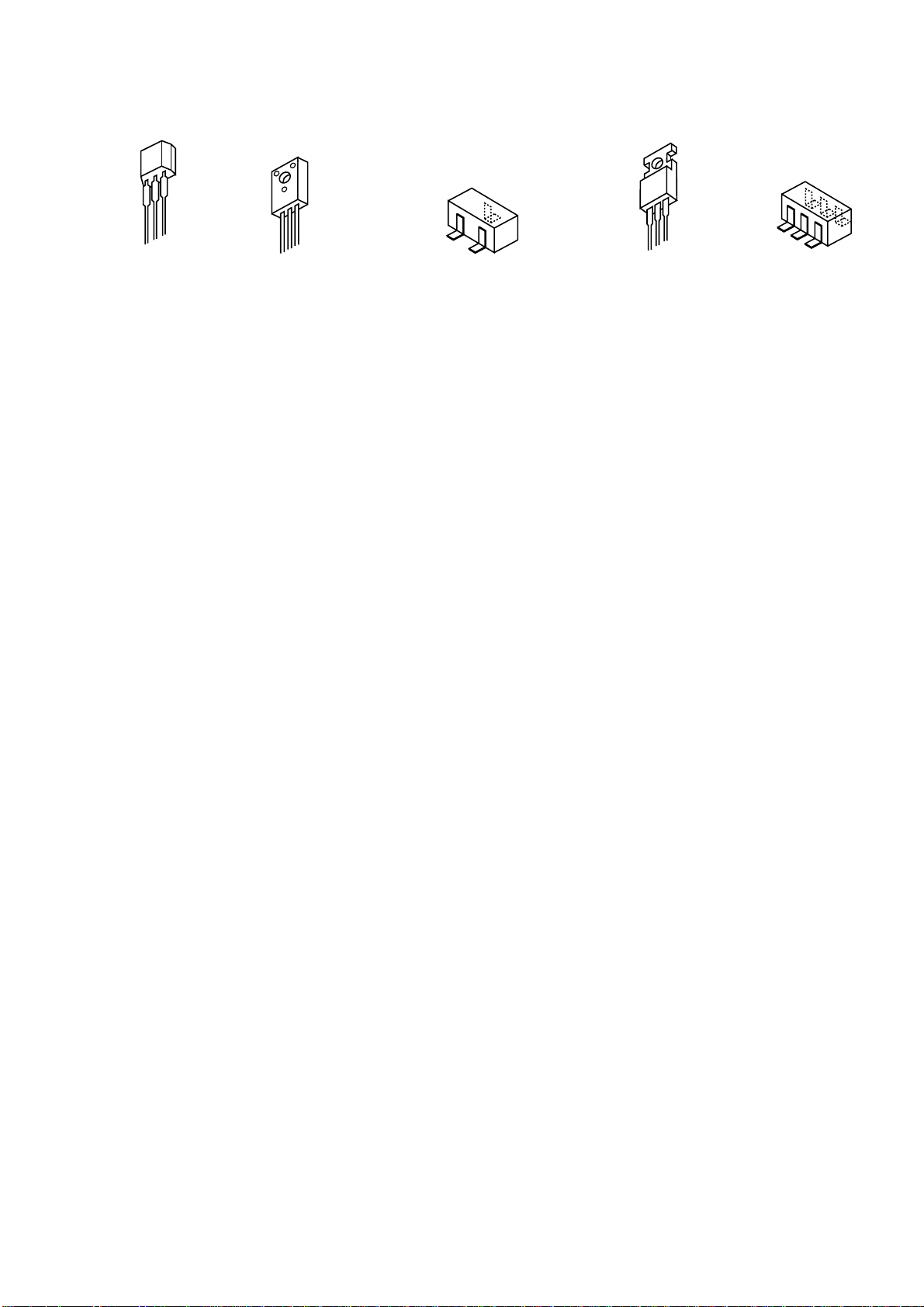

TRANSISTOR ILLUSTRATION

C

C2

B1

E1

ECB

KRA105M

KRC105M

KRC103M

ECB

KSB1151

B

E

2SA1037K

KTA1504S

KTA1505S

KTC3198

KTC3875S

KTC4419

KTD1304S

E2

BCE

B2

C1

KSE13005F UMX1N

UMZ1N

13

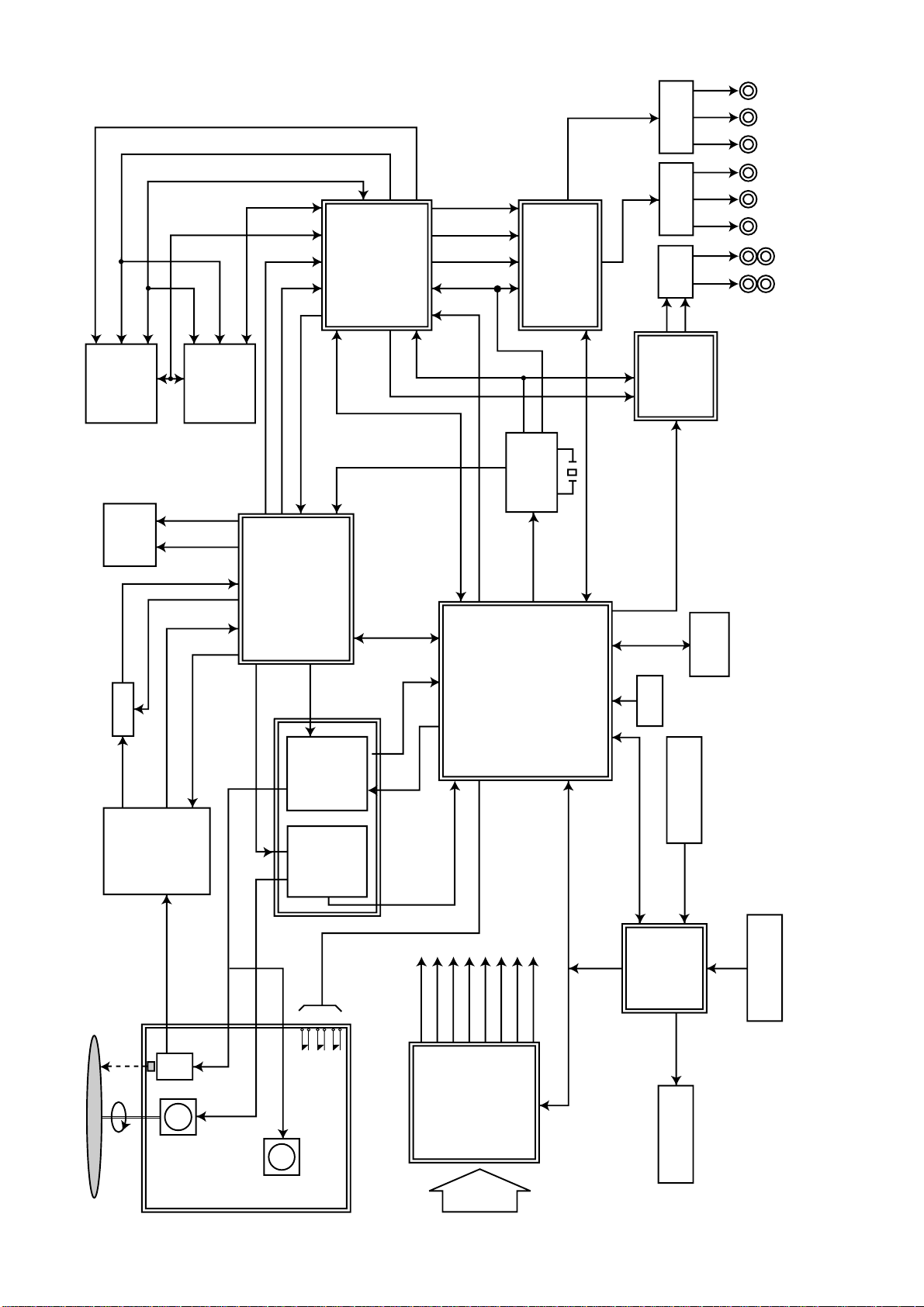

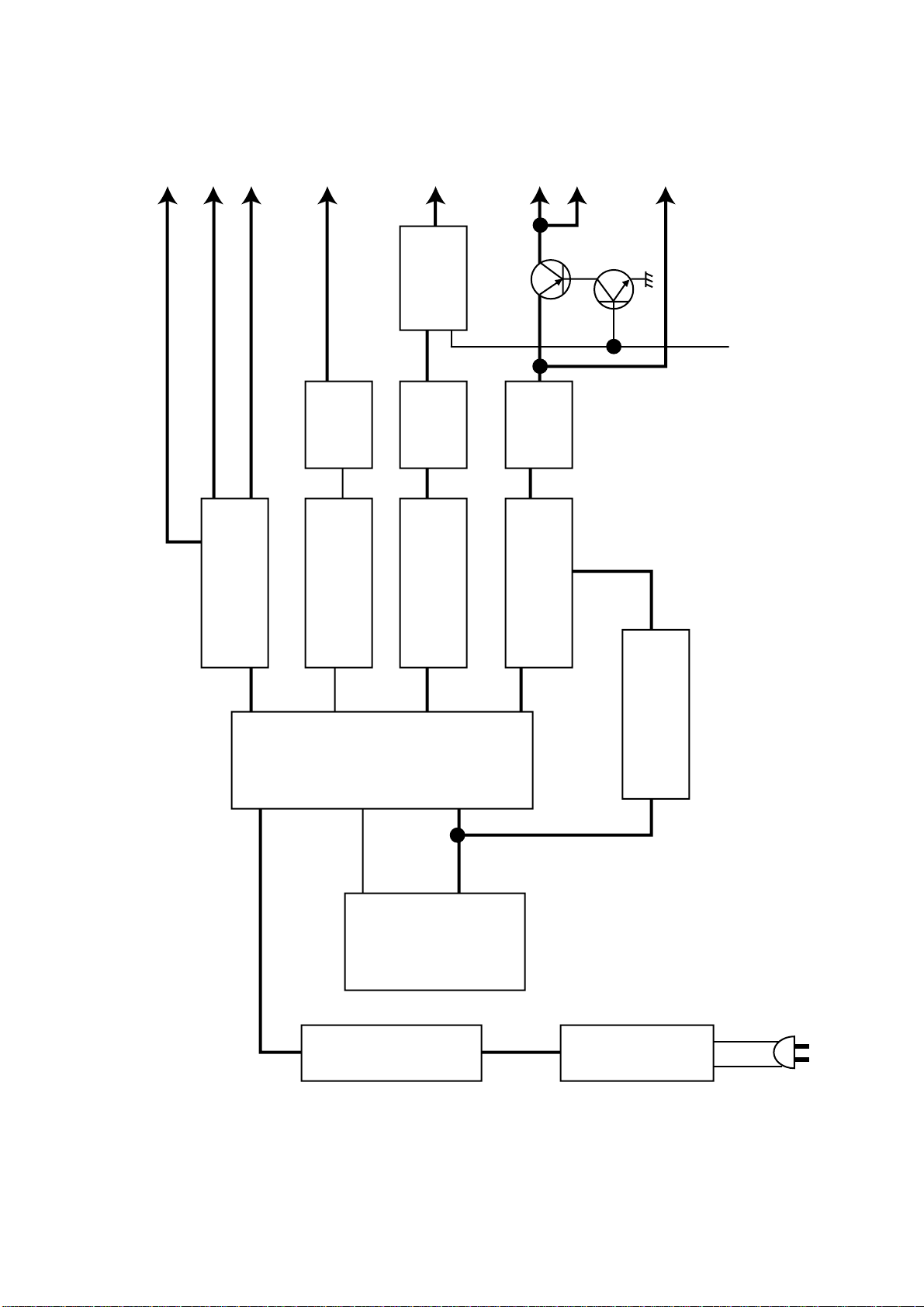

BLOCK DIAGRAM-1 (OVERALL)

M

M

POWER CONTROL

RXDO/TXDO/SCKO

LOADING DRIVE

SENS, FOK, SLD_FG,

MSDAT0,DEFECT,DSP_SENSE,

SQSO, SQCK, AO[0:5]

XLAT, S_CLK, S_DAT A, DO[0:7]

27MHz

VDATA[0:7]

Hsync

Vsync

Composite, Y , C

Component

DVD_LDQM, DVD_SD_CS1

DVD_MA[0:11]

DVD_MD[0:15]

DVD_SD_CS0,

DVD_UDQM

DVD_DATA[0:7]

SDCLKI, ZISENB

REQZI

MCK

(33.8688MHz)

DA_DATA,

DA_LRCK,

DA_BCK

DA_XCK

DVD_SD_CAS,

DVD_SD_RAS

DVD_SD_CLK

DVD_MWE

D[00:07]

A[00:02]

S_CLK, S_DATA,

DPLL_L

IIC_DATA,

IIC_CLK

MPEG RST

DAC_L0,

S_CLK

S_DATA

L

L

AUDIO

OUT

VIDEO OUT

R

Composite

CY

R

FILTER

AMP

DA_DATA,

DA_LRCK,

DA_BCK

27MHz

X-TAL

SLD_FG

SPINDLE_FG

FDO,TDO,

FMO

MON, SPINDLE_DRV

TEBAL, FEBAL,

DPOCTL, EQF, EQB

FE, TE, RFRP, SBADD, DVD/CD RF

MIRR, TZC

ICADDR[0:8]

ICDATA[00:15]

RFRP,

TE, Vref

DVD : A, B, C, D

DVD : RF

CD : A, B, E, F

spindle

Loading

focus, tracking, sled

SPINDLE

MOTOR

DISC

LOADING

MOTOR

OPEN S/W

CLOSE S/W

LIMIT S/W

DECK MECHANISM

AC 120V

60Hz

-22.5V

-27V

-21.8V

+9V

+5VA

+5VD

+5VU

AGND,GND,UGND

PICK

UP

PbPrY

FILTER

IC308

PLL1700

CLOCK

GENERATROR

IC400

BA6859FP

SPINDLE

MOTOR

DRIVER

IC401

BA5983

POWER

DRIVER

IC206

DVDSP-3301

CD/DVD DSP

DVD SERVO

DRAM

256K x 16bit

Comp.

POWER

BOARD

IC801

BT861A

NTSC/PAL

Encoder

IC703

PCM1716

AUDIO

DAC

IC108

HD6417034

IC301

ZiVA-3

MPEG A/V

Decoder

IC306

GM72V1621

1M X 16bit

SDRAM

IC307

GM72V1621

1M x 16bit

SDRAM

IC201

TA1254F

RF SIGNAL

PROCESSOR

IC500

LC866112

FL DISPLAY

KEY INPUT

REMOCON

RECEIVER

DRAM

FLASH

MEMORY

RFZ HOLD

14

TRANS

Q901

KTC4419

SWITCHING IC

LINE FILTER

RECTIFIER(FLD)

RECTIFIER(14V)

RECTIFIER(5.2V)

FEED B.

LPF

REG(8V)

F+

F-

-24V

12V

8V

D5V

A5V

U5V

PWR ON/OFF

AC110-240V

RECTIFIER(10V)

LPF

RECTIFIER

LPF

BLOCK DIAGRAM-2 (POWER)

15

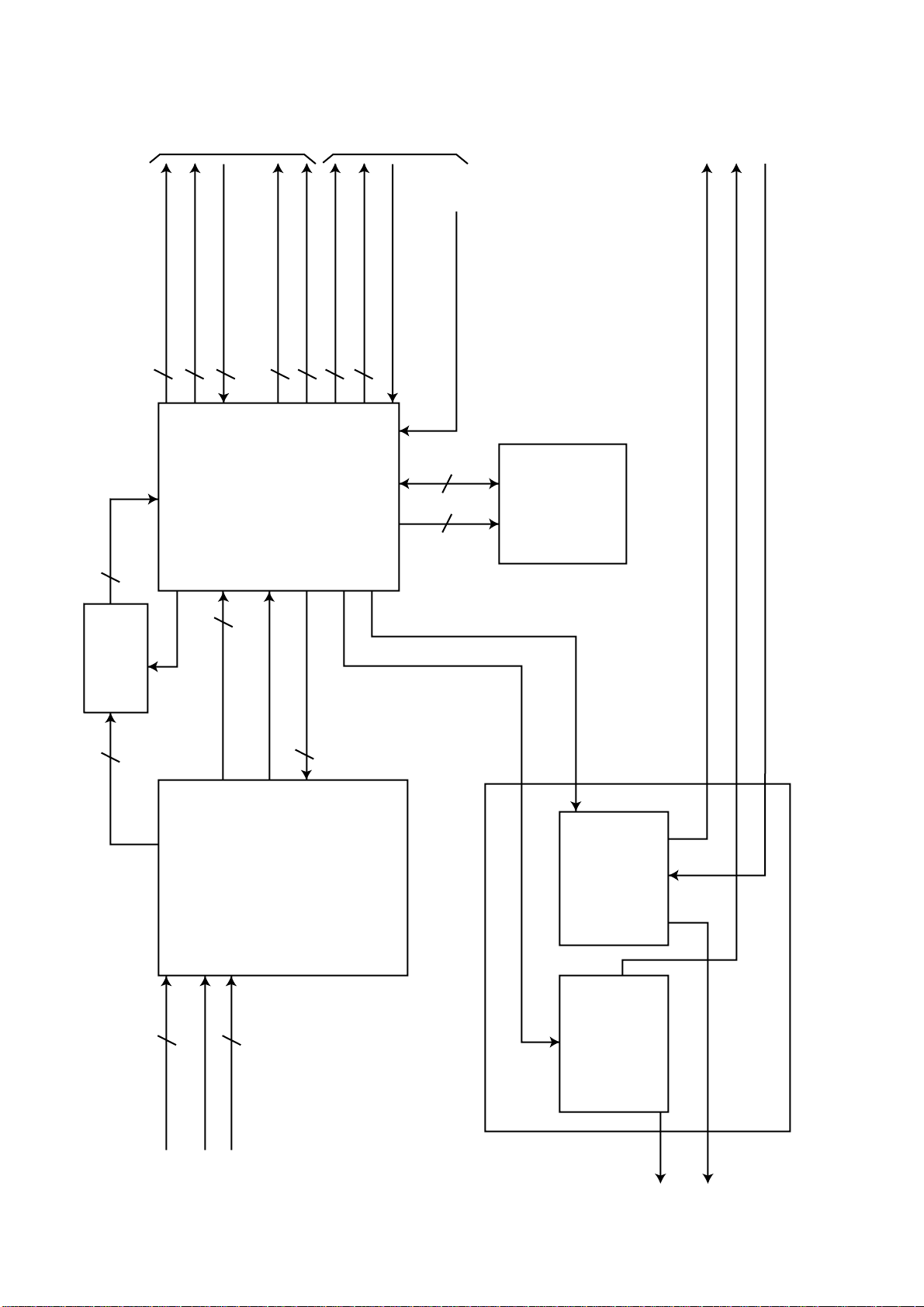

BLOCK DIAGRAM-3 (RF/DSP/SERVO)

PICK

UP

M/D

UCOM

I/F

UCOM

I/F

UCOM

I/F

MPEG

I/F

MPEG

I/F

DVD : A,B,C,D

RFRP,

TE, Vref

FE,TE,RFRP,SBADD

RFZ_HOLD

DVD/CD RF

TEBAL, FEBAL,

DPOCTL, EQF, EQB

5

4

MIRR,TZC

SENS, FOK, SLD_FG,

MSDAT O, DEFECT, DSP_SENSE

5

2

3

8

8

6

SQSO, SQCK

REQZI

XLAT,S_CLK, S_DATA

DO[0:7]

AO[0:5]

ZO[0:7]

2

SDCLKI, ZISENB

MCK (33.8688MHz)

FDO, TDO, FMO

SLD_FG

SPINDLE_FG

loading drive

focus, tracking, loading, sled

spindle

MON, SPINDLE_DRV

ICDATA[00:15]

ICADDR[0:8]

16

9

32

4

4

DVD : RF

CD : A, B, E,F

IC201

TA1254AF

RF Signal

Processor

IC206

GDC25D801

CD/DVD DSP

IC400

BA6859AFP

Spindle

Motor Driver

IC401

BA5983

Power Driver

IC205

DRAM

256K x 16bit

IC204

comp.

16

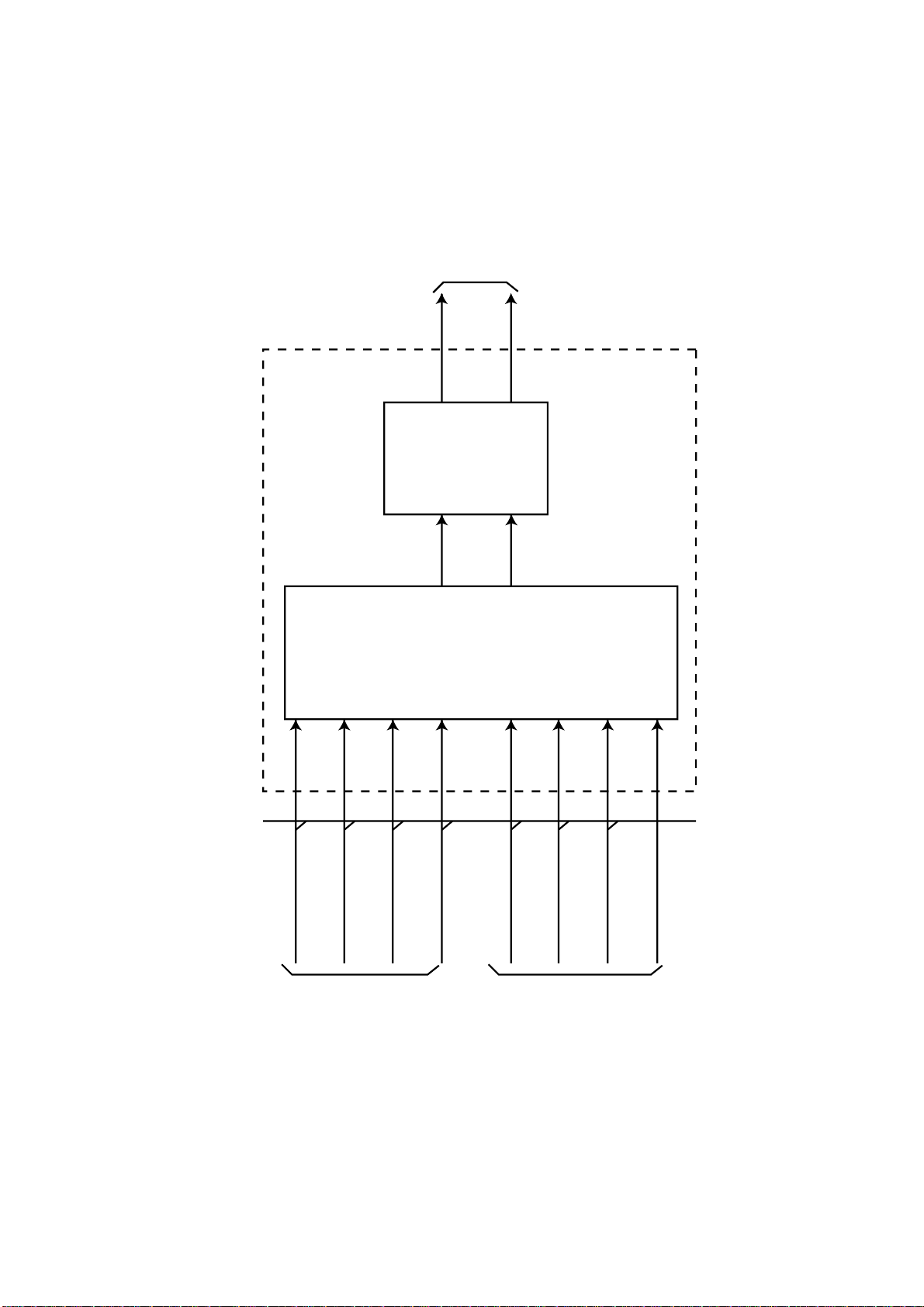

BLOCK DIAGRAM-4 (AUDIO)

µ-com I/F

(IC108)

MPEG I/F

(IC301)

TO

JACK BOARD

CH 1/2 : DOWNMIX Lt / Rt

Lt

Rt

R0

L0

MPEG_RST

S_DATA

S_CLK

DAC_L0

DA_LRCK

DA_BCK

DA_XCK

DA_DATA0

IC703

PCM1716

Audio DAC

IC704

LPF &

Buffer

NJM4580M

OP AMP

17

BLOCK DIAGRAM-5 (MPEG)

DVD_DATA[0:7]

SDCLK1,ZISENB

REQZ1

A[00:02]

D[00:07]

MPEG_ERROR

IIC_DATA, IIC_CLK

DVD_MD[0:15]

DVD_MA[0:11]

DVD_SD_CAS

DVD_SD_RAS

DVD_SD_CLK

DVD_MWE

DVD_SD_CS0, DVD_UDOM

8

4

2

8

2

2

4

16 12 2

DVD_LDOM,

DVD_SD_CSI

MCK

S_CLK, S_DATA, DPLL_L

DA_DATA[0:3]

DA_BCK

SPDIF

HSYNC, VSYNC 2

8

VDATA[0:7]

DA_XCK

MPEG_CLK

Y/C

COMPOSITE1

Pr

Pb

Y

3

DSP

I/F

µ-COM

I/F

IC301

CL61330

MPEG A/V

Decoder

IC801

BT861A

NTSC/P AL

Encoder

IC306

GM72V1621

1M x 16bit

SDRAM

IC307

GM72V1621

1M x 16bit

SDRAM

IC308

PLL1700

CLOCK

GENERATROR

27MHz

X-TAL

UCOM

I/F

VIDEO

I/F(A/V)

AUDIO

I/F(A/V)

SERVO

I/F

18

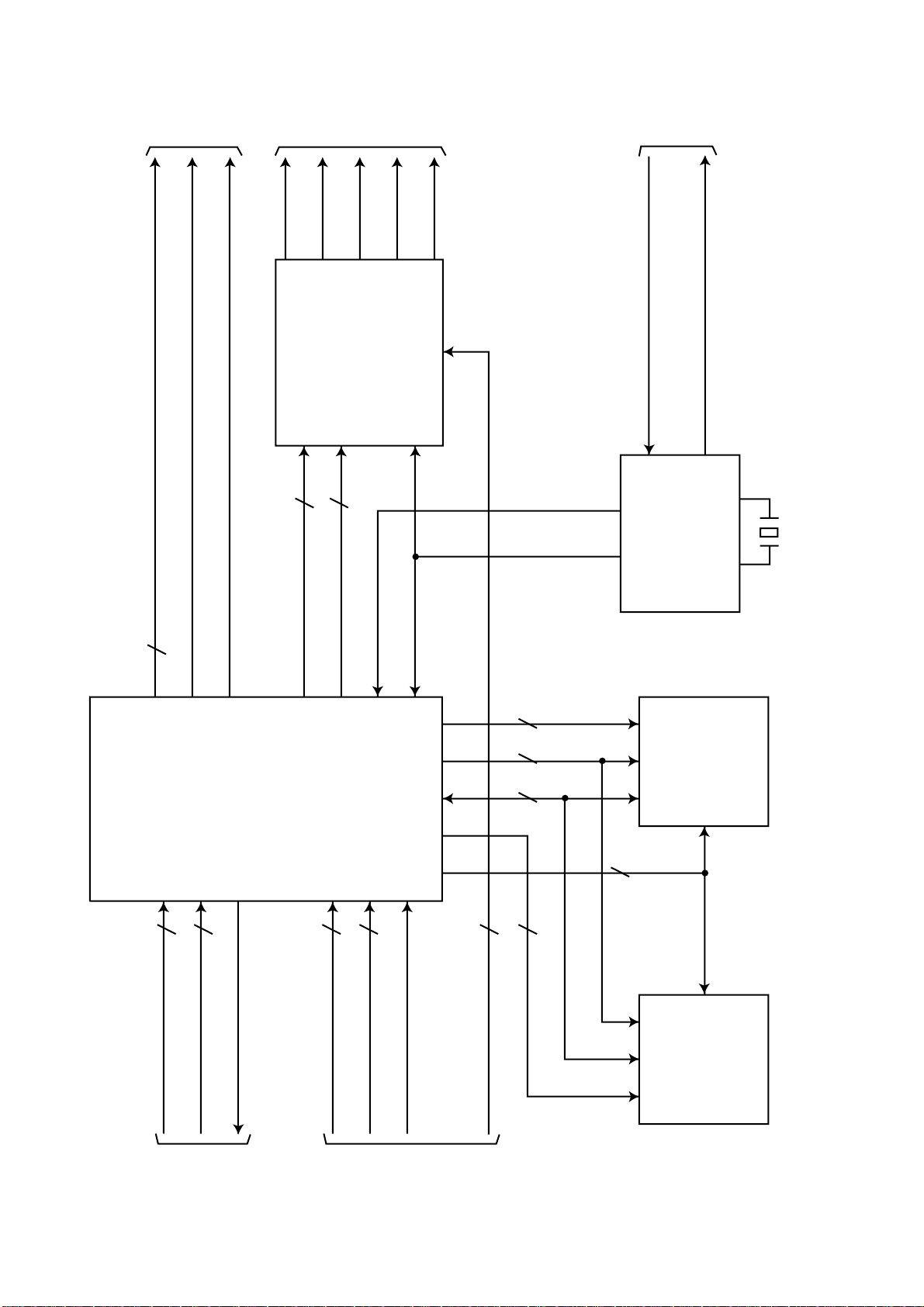

MPEG

I/F

A/V

I/F

FRONT

I/F

SERVO

I/F

DSP

I/F

D[00:07], A[00:02], IIC_CLK, IIC_DAT A, SCLK0,

MPEG_INT

ECHO, MIC_A, DISC_A, S_DATA, S_CLK

BCA_CODE, SPINDLE_FG, SLD_FG,

D[00:07], A[00:05], E_SIN, E_CLK

LOAD FR, F/R, LOCK, DEFECT , FOK,

DSP_SENSE

8

D[00:07]

EXP_W2,

/PWR_CLT

D[00:15]

D[00:15]

D[00:15]

A[01:19]

A[19:21]

/IOCS1, /WR

SENS_MCOM,

MICOM_WAIT

2

2

D[00:04]

MICOM_RESET

PWR_CTL,

SENS, LIMIT_SW,

MIC_ON, CLOSE_SW,

OPEN_SW, MPEG_WAIT,

ZISERR

MPEG_ERROR,

DAC_L0,

RF_LAT,

/DSP_CS,

/MPEG_CS,

/PP_CS

6

8

5

3

A[01:09]

19

16

9

16

16A[00:21] 22

2

MPEG_RST ,

E_DR,

/ZOOM_RST ,

/S_XRST ,

XLAT,

ACT_MUTE,

V_MUTE,

A_MUTE

8

IIC_CLK,

IIC_DATA

2

IC114

EEPROM

AT24C02

IC101

XC9536

EXPANDER

IC106

FLASH

MEMORY

512K x 16

IC102

74HC374

IC107

DRAM

256K x 16

IC108

HD6417034

MAIN µ-COM

BLOCK DIAGRAM-6 (SYSTEM CONTROL)

BLOCK DIAGRAM-7 (MIC) <HR>

1. The unit turns to KARAOKE MODE with ou-screen lyrics display and melody sound when it play backs VCD or DVD KARAOKE

DISC.

2. IF a microphone is connected at this time, MICOM recoguizes the connection and prepares the composition of external voice and

internal melody.

3. The week signal of the microphone is converted to the digital signal after voice output that has passed through PREAMP(BA3308) and

AMP(KIA4558) passes through (CS5331) that is Audio ADC(Analog to Digital convertor).

4. This digital signal enters C-CUBE that is MPEG IC and is added to the output of DVD DSP (P-Processor).

5. This mixed signal is output to AV JACK after passing through AUDIO DAC(PCM1716).

2019

WIRING-1 (MAIN: COMPONENT SIDE)

14

13 12 11 10 9 8

MAIN C.B

(COMPONENT SIDE)

CN507

TO/FROM TIMER C.B

R184

C128

15

14

R191

2

84 57

85

7

6

5

432

1

A

TO/FROM

JUNCTION C.B

CN404

TO/FROM

JUNCTION C.B

CN402

TO/FROM

POWER C.B

CON902

B

2226

11

15

1

56

105

20

19

4964

48

33

53

52

104

C227

1

16

17 32

110

25

15

R399

E

E

E

1

2

R801

CE711

1

C712

58

R729

R727

R732

21

22

E

4

R726

C715

R723

R721

C713

1

5

R787

R714

C

D

CON06

TO/FROM JACK C.B

E

NOTE

Cxxx

Lxxx

Rxxx

E

R366

R364

R365

156

157

112

1

15

14

1

2

1

C

B

E

20 21

40

29

28

156

157 208

1

208

R384

R385

1

R307

R309

R312

105

104

53

52

1

2

21

22

F

CON07

G

TO/FROM JACK C.B

H

I

J

2221

WIRING-2 (MAIN: CONDUCTOR SIDE)

1

234567

8

9

10

11 12 13

14

A

MAIN C.B

B

C

D

(CONDUCTOR SIDE)

1120

10

1

2425

1

50

1

50

13

1

46

58

4

NOTE

Cxxx

Lxxx

Rxxx

48

E

1

F

G

8

45

R188

R193

H

1

140

1

11

12 22

8

E

E

5

8

4

1

1

3444

33

23

5

8

20 21

4

1

20

5

4

C202

1011

1

E

25 26

E

E

25 26

5

1

1

20

21 40

13

46

E

C728

1528

CE712

R717

114

6180

60

41

R823

R736

E

E

E

E

R777

E

E

C

I

B

E

E

J

2423

SCHEMATIC DIAGRAM-1 (MAIN 1/5)

2625

SCHEMATIC DIAGRAM-2 (MAIN 2/5)

2827

Loading...

Loading...