Page 1

CSD-TD10/TD30

SERVICE MANUAL

Ver 1.0 2003. 07

Photo: CSD-TD30

Section

Section

US Model

AEP Model

UK Model

Australian Model

Canadian Model

Model Name Using Similar Mechanism CSD-A300

CD

CD Mechanism Type KSM-213RDM

Optical Pick-up Name KSS-213R

Model Name Using Similar Mechanism NEW

TC

Tape Transport Mechanism T ype MF-TD10

E Model

CSD-TD10/TD30

CSD-TD10

Radio section

Frequency range, antenna

FM: 87.5 - 108.0 MHz Rod antenna

US, CND, E4 model:

AM: 530/531 - 1,710/1,602 kHz (10/9 kHz step)

Ferrite bar antenna

AEP, UK model:

AM: 531/530 - 1,602/1,610 kHz (9/10 kHz step)

Ferrite bar antenna

MX model:

AM: 530/531 - 1,710/1,610 kHz (10/9 kHz step)

Ferrite bar antenna

Deck section

Track format

4 tracks, 2 channels

Frequency range

Normal tape: 50 - 12,500 Hz (JEITA)

Recording system

AC bias

Erasing system

Magnet erase

Heads

Recording/playback head (1)

Erasure head (1)

SPECIFICATIONS

CD player section

Disc

Compact disc

Scanning method

Non-contact optical scanner (semiconductor laser)

Laser diode properties

Material: GaAlAs

Wavelength: λ = 780 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW

(This output is the value measured at a distance of

200 mm from the objective lens surface on the

optical pick-up block with 7 mm aperture.)

General

Speaker

100 mm cone type (2)

Power output

AEP model:

3.4 W + 3.4 W (DIN MUSIC POWER)

2 W + 2 W (JEITA 8 ohms, T.H.D. 10% DC)

AEP, UK, E4, MX model:

1 W + 1 W (DIN 1% Rated Power)

– Continued on next page –

9-961-070-01

2003G04-1

© 2003. 07

CD STEREO RADIO CASSETTE RECORDER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

1

Page 2

CSD-TD10/TD30

Power requirements

DC 12 V using eight size C (R14) batteries

US, CND, MX model:

AC 120 V, 60 Hz

AEP, UK model:

AC 230 V, 50 Hz

E4 model:

AC 110 V - 120 V/220 - 240 V switchable, 50/60 Hz

Power consumption

US, CND model:

12 W

AEP, UK, E4, MX model:

13 W

Dimensions (W × H × D)

390 × 170 × 258.5 mm

(15 3/8 × 6 3/4 × 10 1/4 in.)

Weight (excluding batteries)

2.7 kg (5 lbs. 15 oz.)

Accessory

Remote control (1, CSD-TD30 only)

AC cord (1)

Specifications and external appearance are subject to

change without notice.

•Abbreviation

CND : Canadian model

E4 : AC 110-120V/220-240V area in E model

MX : Mexican model

TW : Taiwan model

AUS: Australian model

SP : Singapore model

KR : Korean model

AEP, UK, E, AUS model

LASER

CLASS 1

KLASSE 1

LUOKAN 1

KLASS 1

LASER

LASER

LASER

PRODUCT

PRODUKT

LAITE

APPARAT

This Compact Disc player is classified as a CLASS 1

LASER product.

The CLASS 1 LASER PRODUCT label is located on the

exterior.

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE

PART NUMBERS APPEAR AS SHO WN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

2

Page 3

TABLE OF CONTENTS

1. SERVICING NOTES......................................................... 4

2. GENERAL............................................................................ 5

3. DISASSEMBLY

3-1. CABI Rear Assy.................................................................. 7

3-2. CABI Top Assy ................................................................... 7

3-3. CD Block Assy.................................................................... 8

3-4. Main Board ......................................................................... 8

3-5. Tape Mechanism Deck ........................................................9

3-6. CASS Door Assy................................................................. 9

3-7. Display Board ................................................................... 10

3-8. HRP001, HE001, Pinch Roller Arm Assy ......................... 10

3-9. Belt, M501 ........................................................................ 11

3-10. Optical Pick-up ................................................................. 11

4. MECHANICAL ADJUSTMENTS............................... 12

5. ELECTRICAL ADJUSTMENTS

Tape Section .......................................................................... 13

Tuner Section......................................................................... 14

CD Section ............................................................................ 15

CSD-TD10/TD30

6. DIAGRAMS

6-1. IC Pin Description............................................................. 17

6-2. Block Diagram – CD Section –......................................... 19

6-3. Block Diagram – Tuner Section –..................................... 20

6-4. Block Diagram – Tape Section –....................................... 21

6-5. Circuit Boards Location .................................................... 22

6-6. Printed Wiring Board – Main Section – ............................ 23

6-7. Schematic Diagram – CD Section –.................................. 24

6-8. Schematic Diagram – Tuner Section –.............................. 25

6-9. Schematic Diagram – Tape Section – ............................... 26

6-10. Printed Wiring Board – TC Section – ............................... 27

6-11. Printed Wiring Boards

– Control, Power Supply Section – .................................. 28

6-12. Schematic Diagram – Control, Power Supply Section – .. 29

6-13. IC Block Diagrams............................................................ 30

7. EXPLODED VIEWS

7-1. Main Board Section .......................................................... 32

7-2. Cabinet Front (1) Section .................................................. 33

7-3. Cabinet Front (2) Section .................................................. 34

7-4. Chassis CD Section ........................................................... 35

7-5. Cabinet Rear Section......................................................... 36

7-6. Tape Mechanism Section .................................................. 37

7-7. CD Mechanism Section .................................................... 38

8. ELECTRICAL PARTS LIST.........................................39

3

Page 4

CSD-TD10/TD30

SECTION 1

SERVICING NOTES

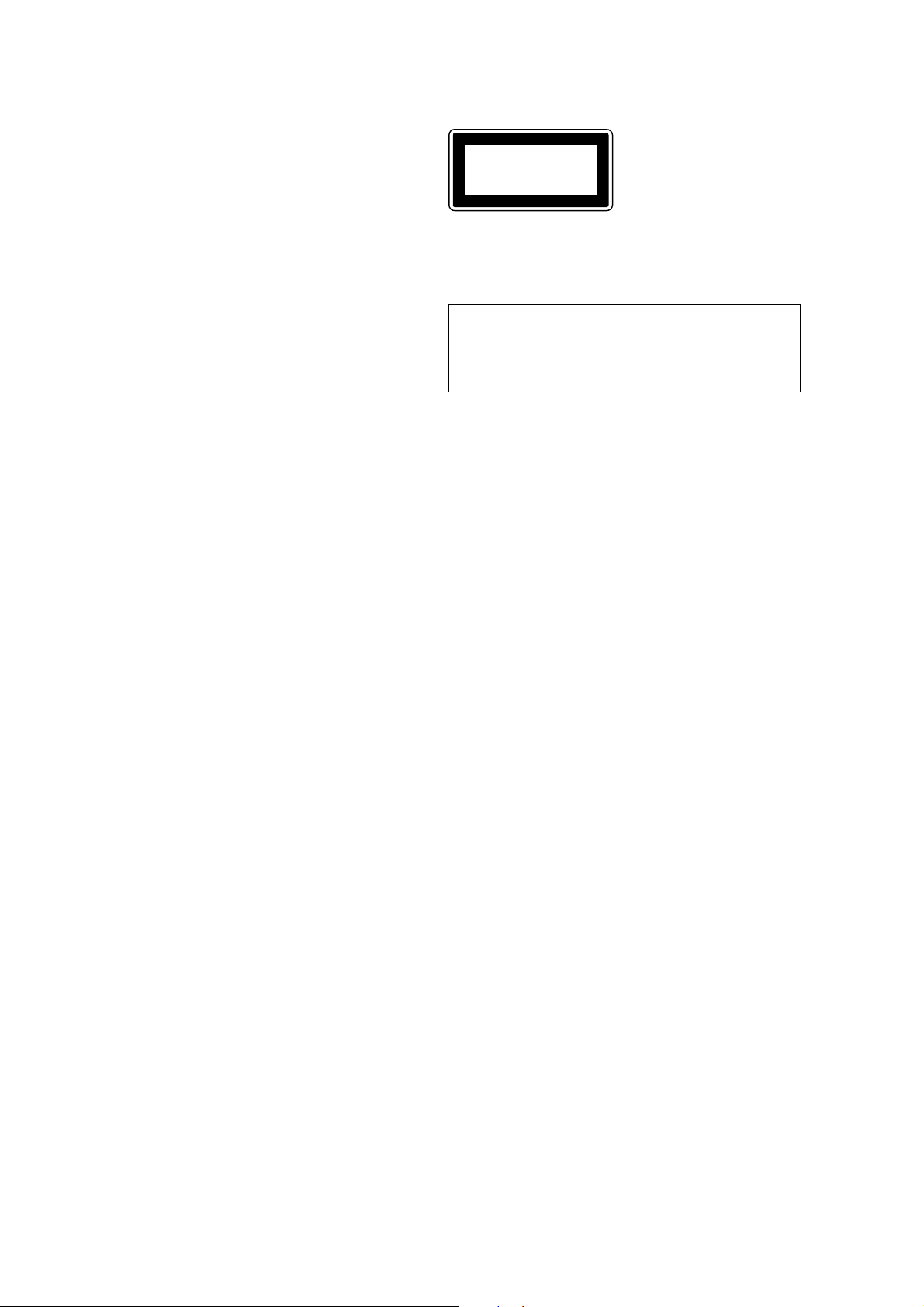

CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the lid (CD), use

Chuck Plate Jig.

• Code number of Chuck Plate Jig: X-4918-255-1

PRECAUTION TO REPLACE OPTICAL BLOCK

(KSM-213RDM)

Body or clothes electrostatic potential could ruin laser diode

in the optical block. Be sure ground body and workbench,

and use care the clothes do not touch the diode.

1) After the connection, remove solder shown in the right figure.

solder

4

Page 5

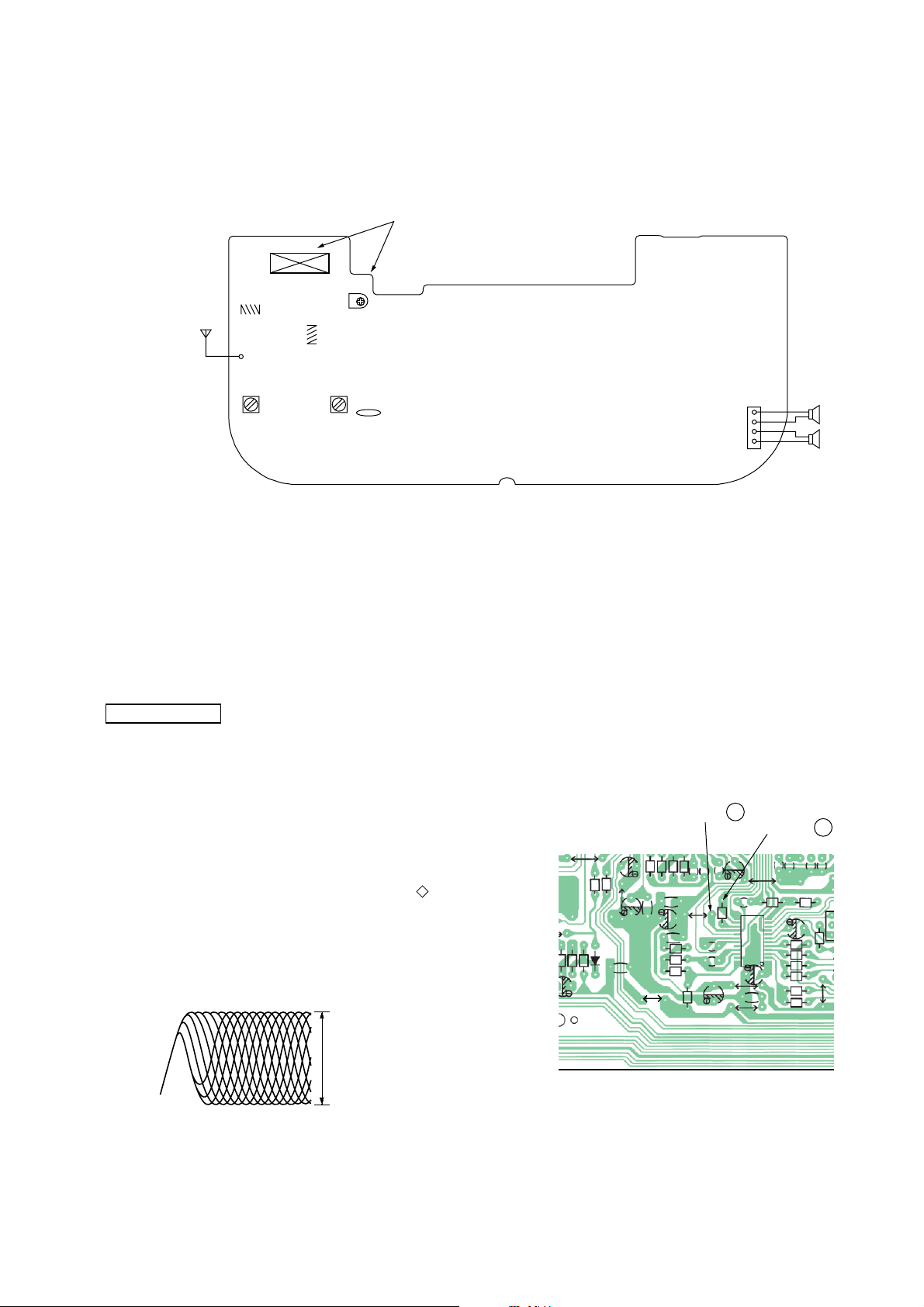

SECTION 2

GENERAL

CSD-TD10/TD30

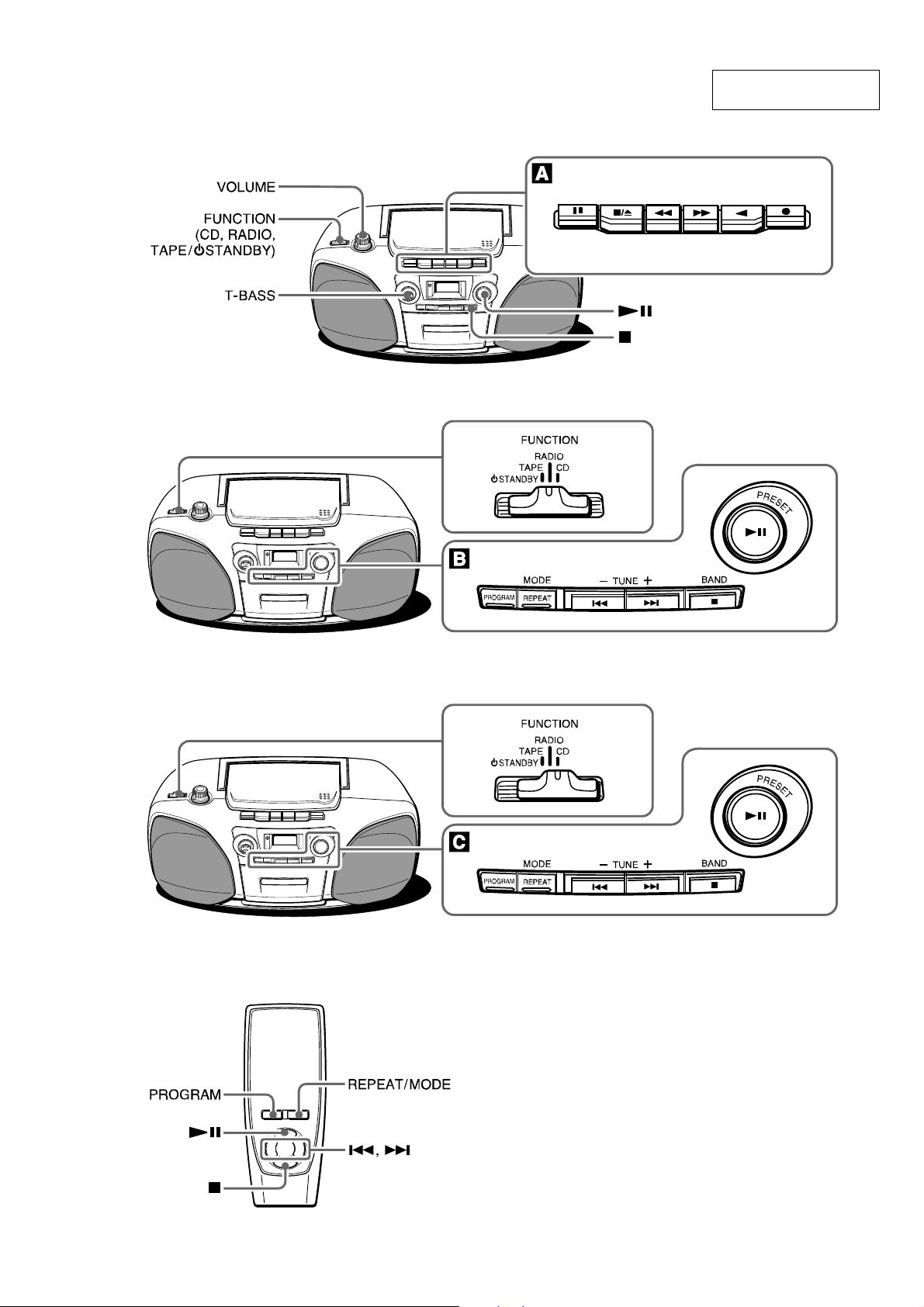

This section is extracted

from instruction manual.

PAUSE

STOP/EJECT

FF REW PLAY

REC

(CSD-TD30 only)

5

Page 6

CSD-TD10/TD30

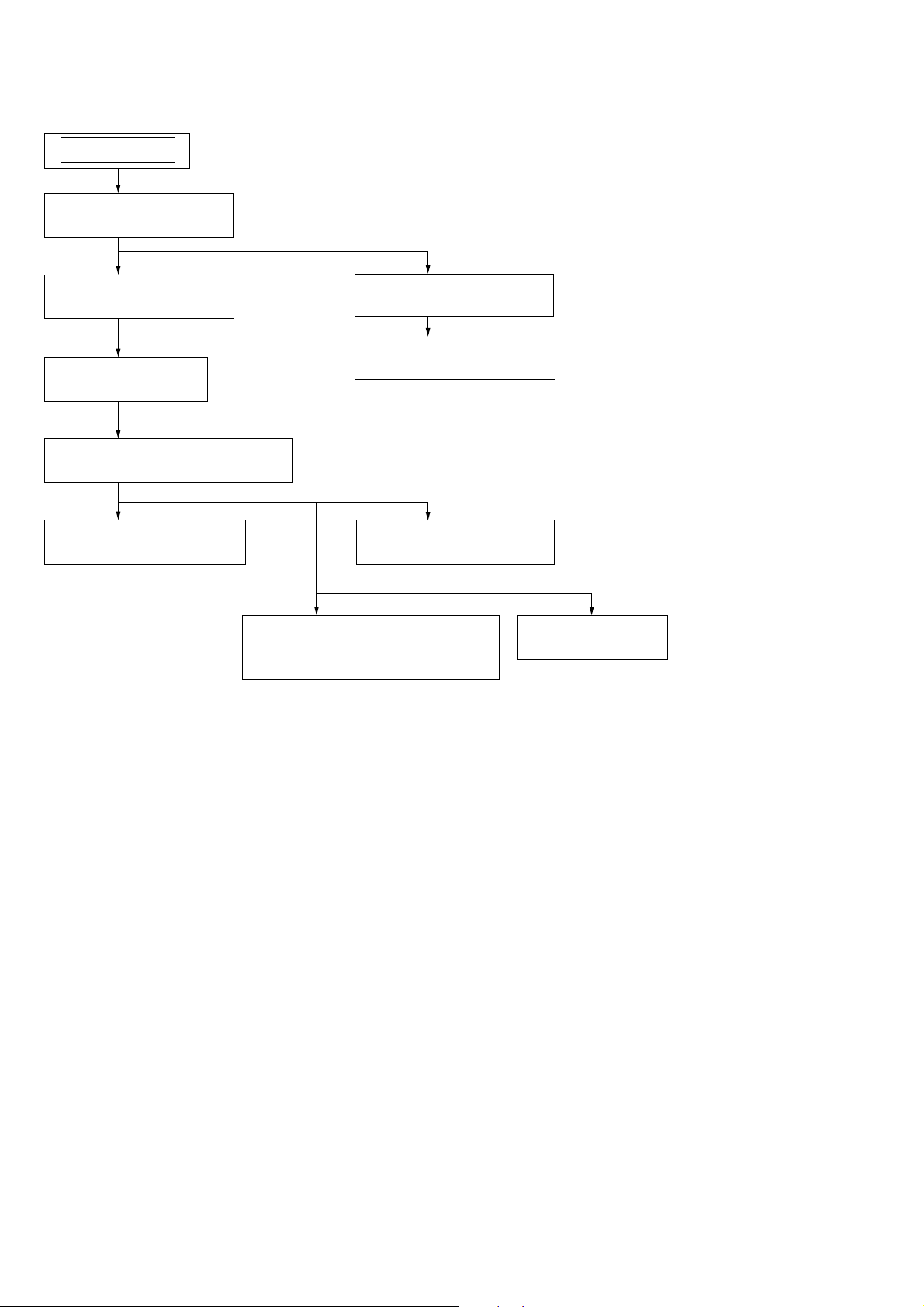

SECTION 3

DISASSEMBLY

• The equipment can be removed using the following procedure.

SET

3-1. CABI REAR ASSY

(Page 7)

3-2. CABI TOP ASSY

(Page 7)

3-4. MAIN BOARD

(Page 8)

3-5. TAPE MECHANISM DECK

(Page 9)

3-6. CASS DOOR ASSY

(Page 9)

3-8. HRP001, HE001,

3-3. CD BLOCK ASSY

(Page 8)

3-10. OPTICAL PICK-UP

(Page 11)

3-7. DISPLAY BOARD

(Page 10)

PINCH ROLLER ARM ASSY

(Page 10)

3-9. BELT, M501

(Page 11)

6

Page 7

Note : Follow the disassembly procedure in the numerical order given.

)

)

)

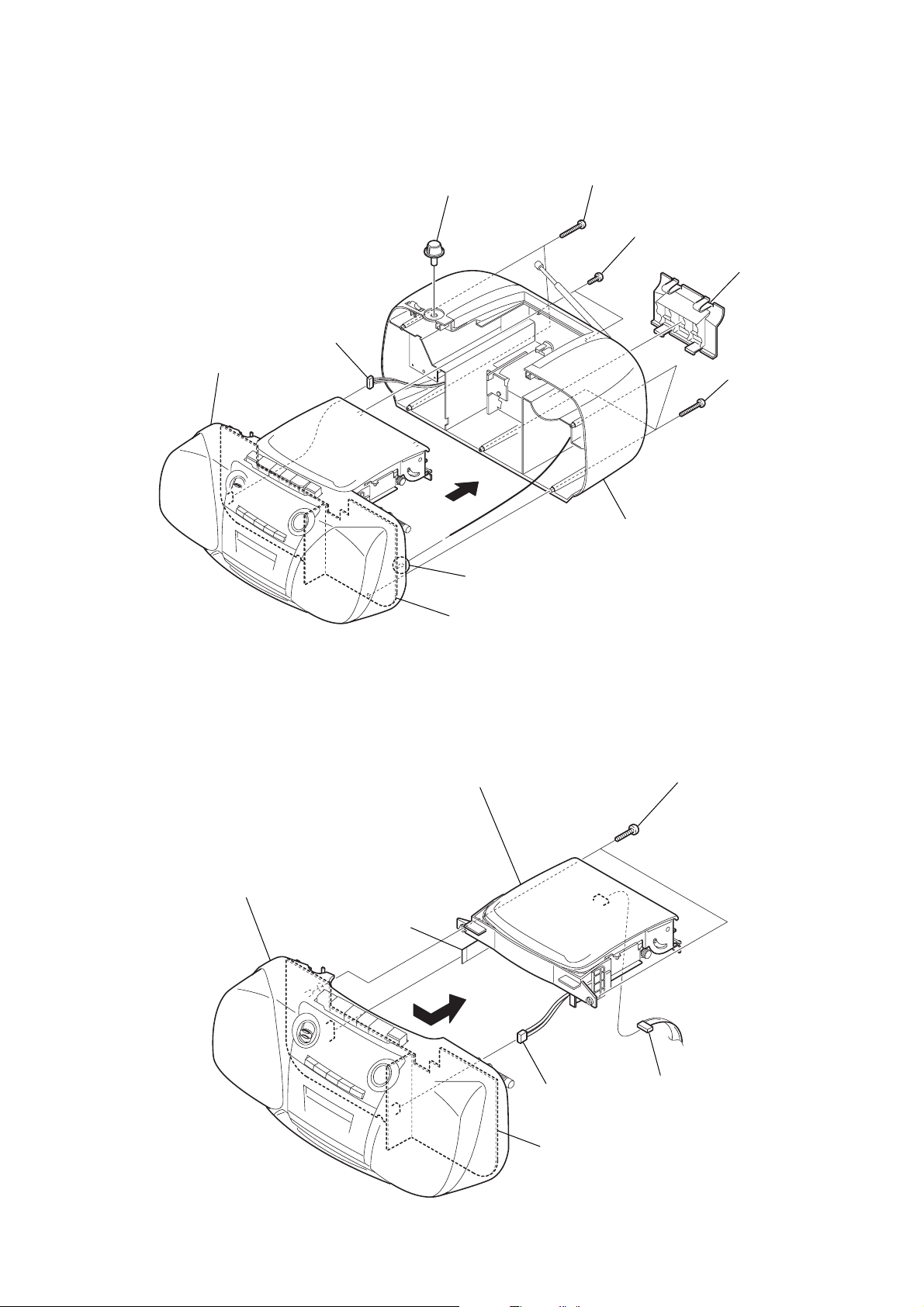

3-1. CABI REAR ASSY

1

knob RTRY VOL

7

CN851

4

two

(+

BVTP 3 x 20

screws

3

two

(+

)

screws

BVTP 3 x 10

CSD-TD10/TD30

)

2

cover (BATT

CABI front assy

3-2. CABI TOP ASSY

6

8

Removal the solder.

MAIN board

6

CABI top assy

9

CABI rear assy

4

(+

5

(+

two

screws

BVTP 3 x 10

three

screws

BVTP 3 x 20

CABI front assy

2

CN405

(flat type)

5

1

CN402

MAIN board

3

connector

7

Page 8

CSD-TD10/TD30

)

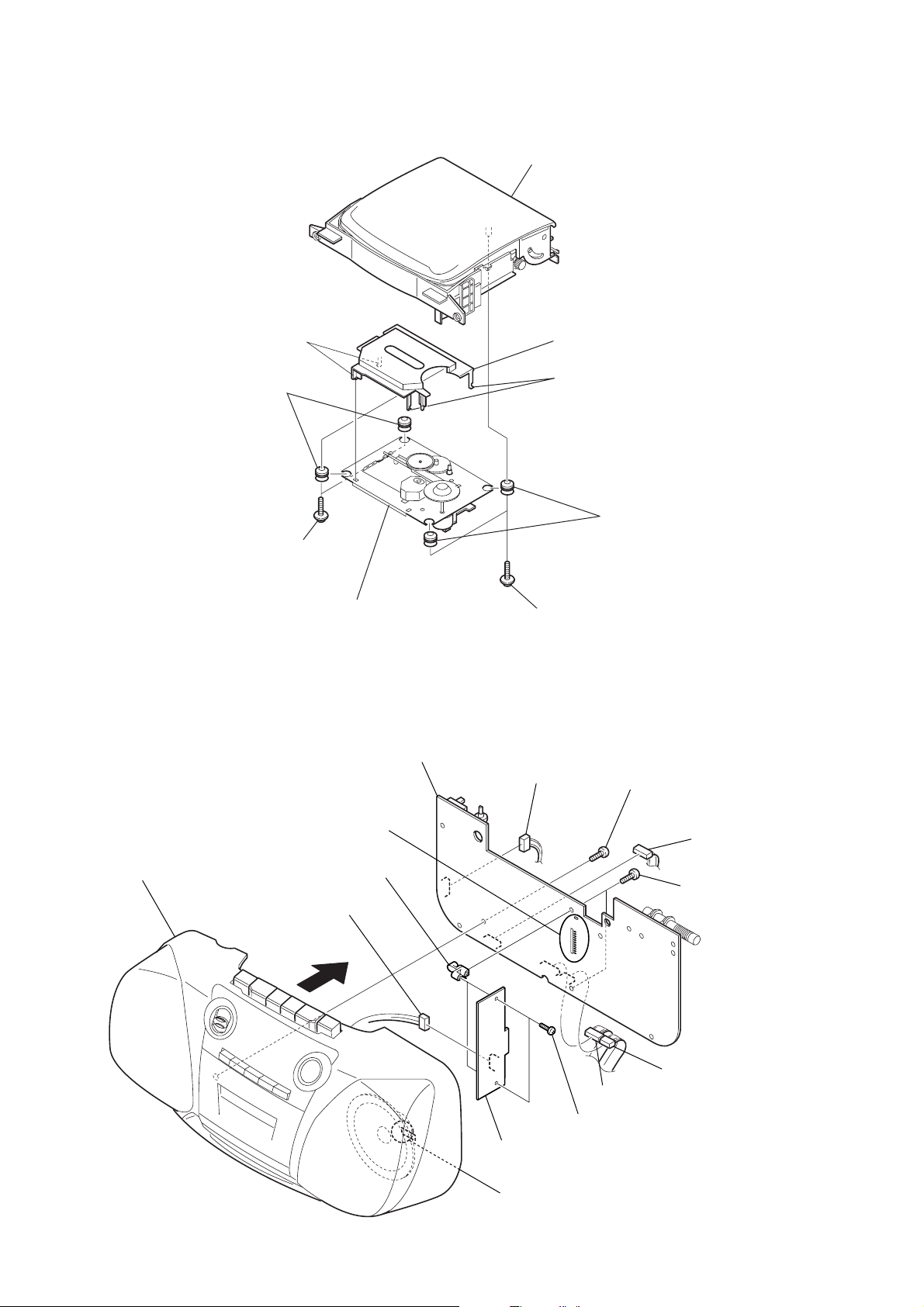

3-3. CD BLOCK ASSY

CABI top assy

4

two vibration proof rubbers

3-4. MAIN BOARD

two claws

2

two

2.6 x 16

(

screws

)

6

qa

Removal the solder.

CD block assy

6

MAIN board

1

(

1

CN801

3

CD cover

two claws

two

screws

2.6 x 16

5

two vibration proof rubbers

)

5

screw

BVTP 3 x 10

(+

2

CN501

)

qd

two

CABI front assy

holders (PWB)

9

CN301

7

qs

qf

TC board

8

Removal the solder.

(+

3

CN601

two

screws

BVTP 2.6 x 10

4

CN602

q;

two

screws

BVTP 2.6 x 10

(+

)

8

Page 9

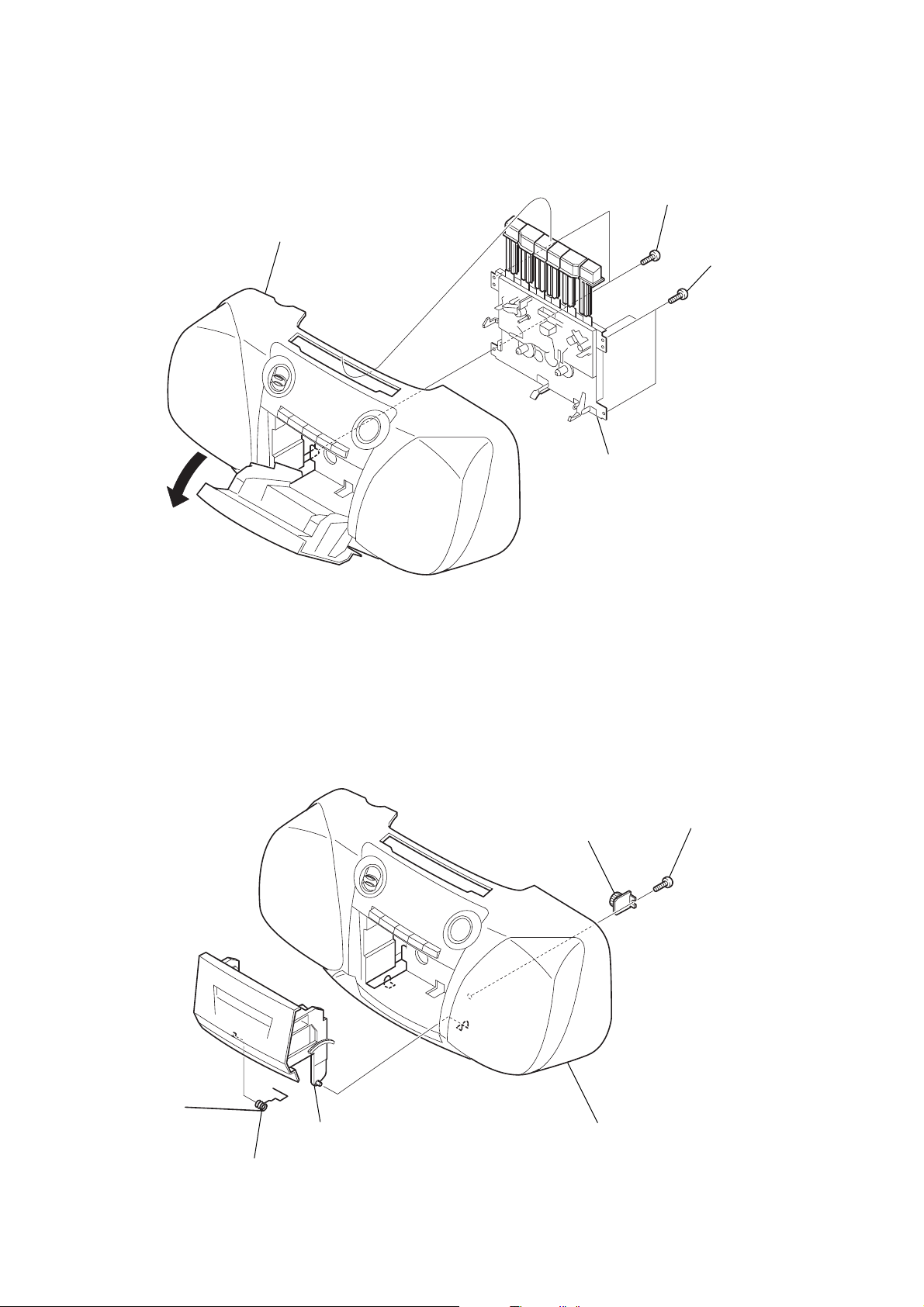

3-5. TAPE MECHANISM DECK

)

)

CABI front assy

3

two

screws

BVTP 2.6 x 10

(+

4

tape mechanism deck

CSD-TD10/TD30

)

2

two

screws

(+

BVTP 2.6 x 10

1

3-6. CASS DOOR ASSY

2

damper

1

screw

BVTP 2.6 x 10

(+

4

SPR T CASS

3

CASS door assy

CABI front assy

9

Page 10

CSD-TD10/TD30

)

y

3-7. DISPLAY BOARD

2

(+

two

screws

KTP 3 x 10

1

(+

3

DISPLAY board

)

two

screws

KTP 3 x 10

3-8. HRP001, HE001, PINCH ROLLER ARM ASSY

5

screw

(azimuth)

7

azimuth spring

2

HE001

(elase head)

claw

3

screw

(+B bind)

4

lug plate

6

HRP001 (REC play head)

1

pinch roller arm ass

10

claw

Page 11

3-9. BELT, M501

4

main belt

3

RF belt

2

1

screw

(MB)

5

two

screws

(motor coller)

motor bracket

6

M501

(motor sub assy)

CSD-TD10/TD30

3-10. OPTICAL PICK-UP

3

screw

(+

PWB tapping (M2)

5

sled shaft

6

optical pick-up

claw

1

gear (A)

4

)

2

screw

(+

PWB tapping (M2)

)

11

Page 12

CSD-TD10/TD30

SECTION 4

MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback head pinch roller

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer. (Do not bring the head magnetizer close to the erase head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the rated power

supply voltage (9V) unless otherwise noted.

Torque Measurement

Mode Torque meter Meter reading

2.95 – 6.86 mN • m

FWD CQ-102C (30 – 70 g • cm)

(0.42 – 0.97 oz • inch)

FWD

Back Tension

FF CQ-201B (more than 60 g • cm)

REW CQ-201B (more than 60 g • cm)

CQ-102C (1.5 – 5.5 g • cm)

0.15 – 0.53 mN • m

(0.021 – 0.076 oz • inch)

more than 5.88 mN • m

(more than 0.83 oz • inch)

more than 5.88 mN • m

(more than 0.83 oz • inch)

Tape Tension Measurement

Mode Tension meter Meter Reading

FWD CQ-403A

more than 100 g

(more than 3.53 oz)

12

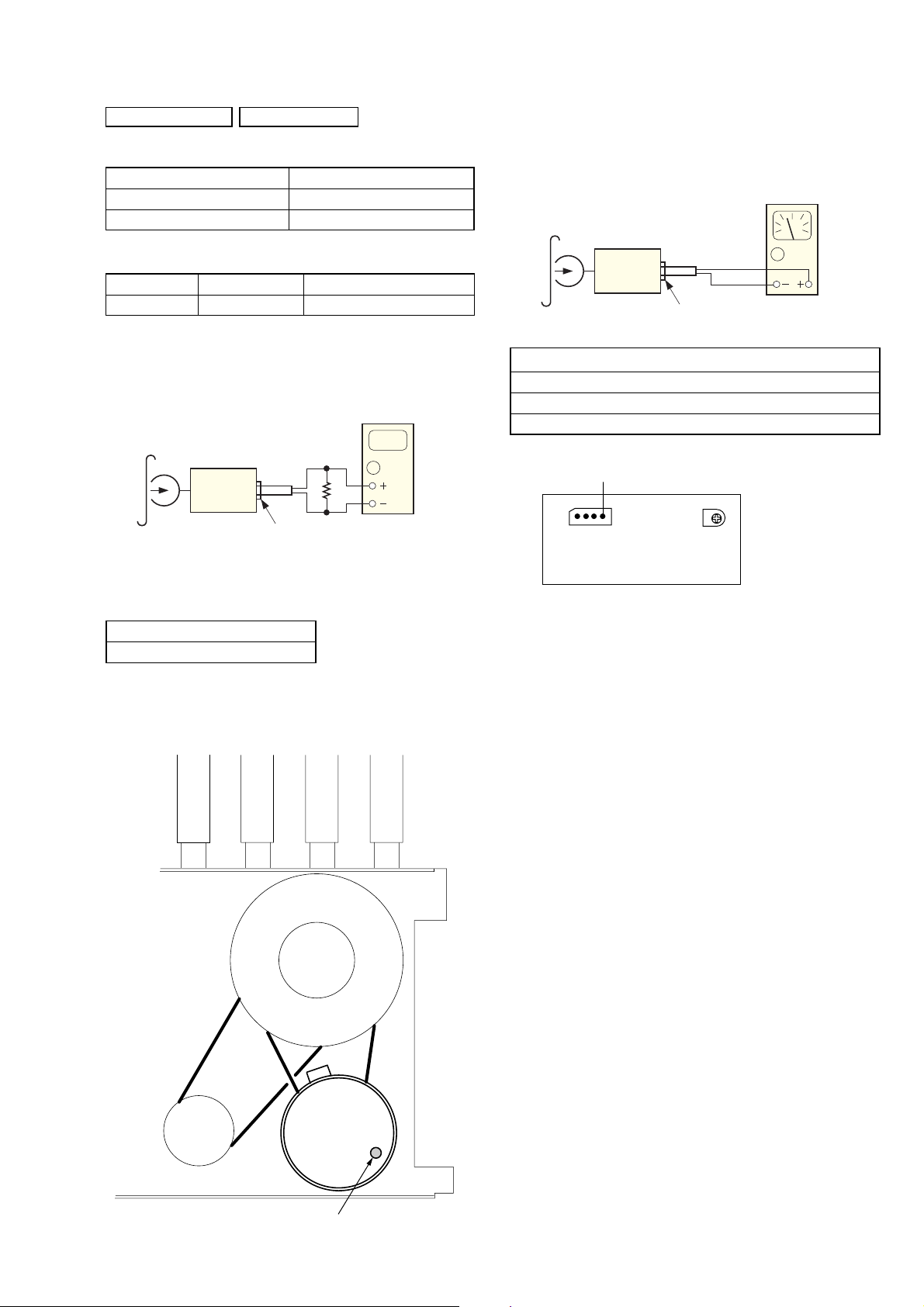

Page 13

SECTION 5

ELECTRICAL ADJUSTMENTS

CSD-TD10/TD30

TAPE SECTION 0 dB = 0.775 V

• Standard Output Level

Output terminal SPEAKER L-CH (SPK1)

load impedance 8 Ω

output signal level 0.25 V (–10 dB)

• Test T ape

Type Signal Used for

WS-48A 3 kHz, 0 dB tape speed adjustment

Tape Speed Adjustment

Procedure:

Mode: playback

test tape

WS-48A

(3 kHz, 0 dB)

set

SPEAKER, L-CH (SPK1)

Adjust so that the value on the digital frequency counter is

3,000 Hz.

Specification Value:

Digital frequency counter

2,910 to 3,090 Hz

digital frequency

counter

8

Ω

Tape Bias Frequency Adjustment

Setting:

FUNCTION button: TAPE

Mode: REC

test tape

WS-48A

(3 kHz, 0 dB)

set

TP (CN301 4pin)

frequency counter

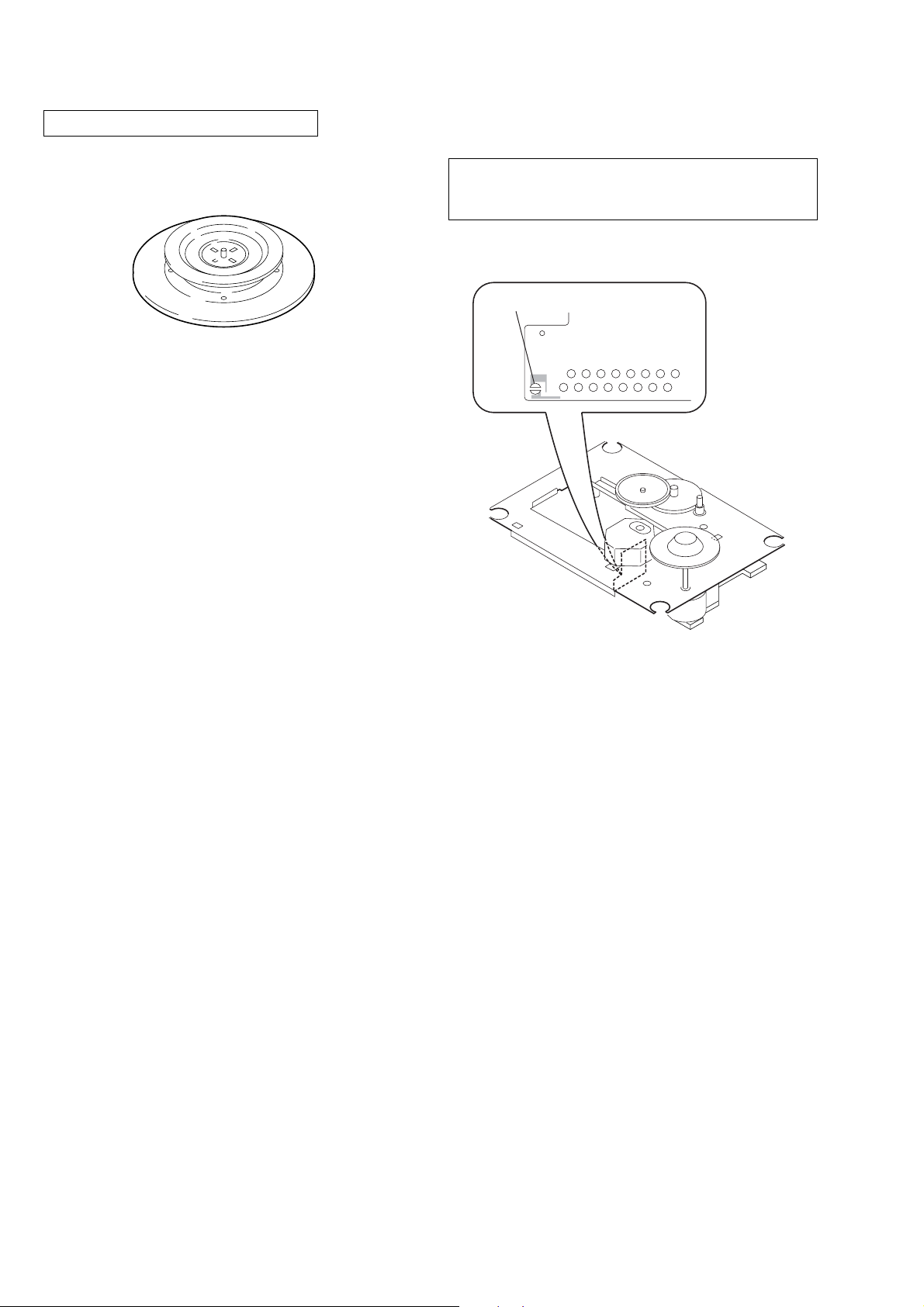

TAPE BIAS FREQUENCY ADJUSTMENT

Adjust T301 so that frequency counter reading is 60 ± 2 kHz.

T301

60 ± 2 kHz

TP

T301

CN301

– TC Board (component Side) –

Tape Bias Frequency

Adjustment

Adjust so that the frequency at the beginning and that at the end of

tape winding are between 2,940 to 3,060 Hz.

Adjustment Location:

Tape speed adjustment

control inside motor

13

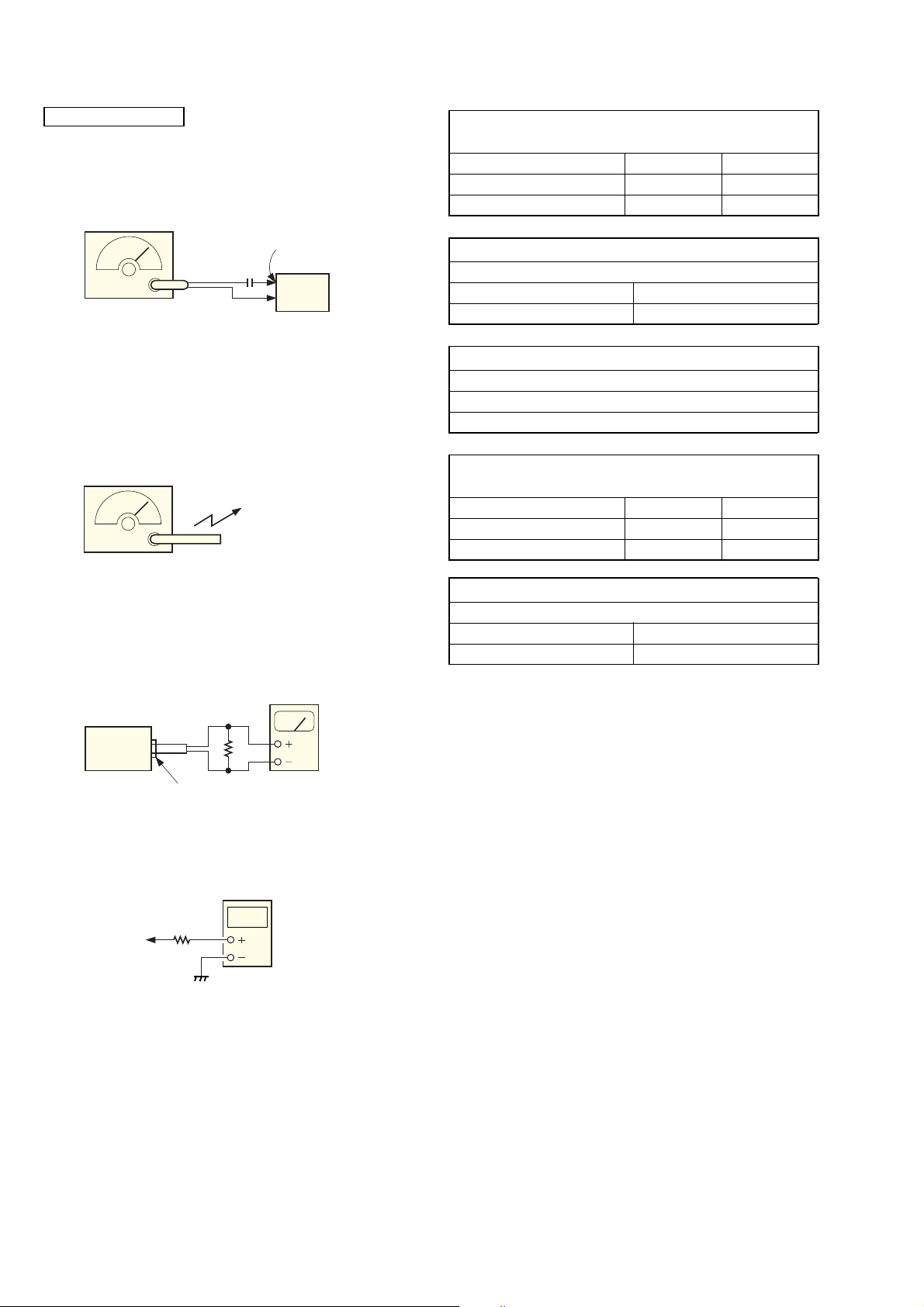

Page 14

CSD-TD10/TD30

)

T

TUNER SECTION

• FM Section

Setting:

BAND button: FM

FM RF signal

generator

FM ROD AN

0.01

µ

F

75 kHz frequency

deviation by 1 kHz signal

output level : as low as possible

• AM Section

Setting:

BAND button: AM

AM RF signal

generator

30% amplitude

modulation by

400 Hz signal

• Connecting Level Meter (FM and AM)

Put the lead-wire

antenna close to

the set.

level meter

(range: 0.5–5 V ac

8

Ω

set

FM FREQUENCY COVERAGE

ADJUSTMENT

Frequency Display 87.5 MHz 108 MHz

Reading on Digital voltmeter 2.3 ± 0.2 V 7.0 ± 0.2 V

Adjustment Part L108 <confirmation>

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L102 <confirmation>

88 MHz 108 MHz

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

L106

450 kHz

AM FREQUENCY COVERAGE

ADJUSTMENT

Frequency Display 530 kHz 1,602 kHz

Reading on Digital voltmeter 1.0 ± 0.2 V 6.7 ± 0.2 V

Adjustment Part L101 <confirmation>

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L103 TC101

600 kHz 1,400 kHz

Adjustment Location: See page 15.

set

Speaker terminal

• Connecting Digital Voltmeter (FM and AM)

digital

voltmeter

Ω

100 k

(VT)

•Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

14

Page 15

Adjustment Location:

2

13 12

24 1

C409

C455

R426

R427

R429

C840

C452

R431

JW115

JW114

C410

C453

C442

C441

R428

C419

C438

JW119

C439

JW117

R423

R424

R421

R422

R420

R419

C436

C422

R320

R848

JW201

R409

R411

R410

R412

C415

C411

C416

C414

C423

C420

C421

R414

R449

R432

R417

C468

L404

R819

R818

D808

IC402

JW138

JW122

JW187

– MAIN board (conductor side) –

IC402 pin 16

IC402 pin 14

L301

CSD-TD10/TD30

L103,TC101

AM TRACKING

ADJUSTMENT

L102

FM TRACKING

L102

TC101

— MAIN board (component side) —

ADJUSTMENT

FM ANT

L108

FM FREQUENCY

COVERAGE

ADJUTSTMENT

L106

AM IF

ADJUSTMENT

L106 L101

L101

AM FREQUENCY

C103

TP(VT)

COVERAGE

ADJUTSTMENT

CD SECTION

CD section adjustments are done automatically in this set.

In case of operation check, confirm that focus bias.

CN801

SPK

SPK1

FOCUS BIAS CHECK

1. Connect the oscilloscope between IC402 pin qf and pin qh.

2. Insert the disc (YEDS-18). (Part No. : 3-702-101-01)

3. Press the N X (CD) button.

4. Confirm that the oscilloscope waveform is as shown in the

figure below. (eye pattern)

A good eye pattern means that the diamond shape ( ) in the

center of the waveform can be clearly distinguished.

• RF signal reference waveform (eye pattern)

When observing the eye pattern, set the oscilloscope for AC range

and raise vertical sensitivity.

VOLT/DIV : 50 mV (10 : 1 probe in use)

TIME/DIV : 500 nS

RF level :

0.85 ± 0.2 Vp-p

Test Point:

15

Page 16

CSD-TD10/TD30

MEMO

16

Page 17

CSD-TD10/TD30

SECTION 6

DIAGRAMS

6-1. IC PIN DESCRIPTION

• IC601 TC94A23F-704BH (SYSTEM CONTROL)

Pin No. Pin Name I/O Pin Description

1 to 9 S1/OT5-S9/OT13 O LCD segment output: LCD601 1pin-9pin.

10 S10/OT14/ZDNET O LCD segment output: LCD601 10pin.

11 S11/OT15/CLCK O LCD segment output: LCD601 11pin.

12 S12/OT16/DATA O LCD segment output: LCD601 12pin.

13 S13/OT17/SFSY O LCD segment output: LCD601 13pin.

14 S14/OT18/LRCK O LCD segment output: LCD601 14pin.

15 P8-0/S15/BCK O Changed to the port that detects use/non-use of O-BEAT L: Use, H: Non-use.

16 P8-1/S16/AOUT O Not connected.

17 P8-2/S17/MBOV O Connecting to VDD (+5V).

18 P8-3/S18/IPF O Not connected.

19 MVDD — Controller power supply +5V.

20 MVSS — Controller power supply GND.

21 P1-0 I/O CD door switch open/close detection: “L” input at close.

22 P1-1 I/O Function CD input.

23 P1-2 I/O Function TU input.

24 P1-3 I/O Function TAPE input.

25 P3-0 I/O Not connected.

26 P3-1/ADin1 A/D-I KEY input.

27 P3-2/ADin2 A/D-I TUNER destination identification.

28 P3-3/ADin3 I/O INSIDE LIMIT switch detection.

29 P4-0/ADin4/BUZR I/O Not connected.

30 P4-1/S12 I Data input from TU IC (LC72131).

31 P4-2/SI0/SI1/SDA O Data output to TU IC (LC72131).

32 P4-3/SCK/SCL O Clock output to TU IC (LC72131).

33 P2-0/EMPH in O CE output to TU IC (LC72131).

34 P2-1/HSO in I/O Not connected.

35 P2-2/LRCK in I/O FM stereo status input: “L” input at stereo.

36 P2-3/DATA in O AM beat selector output — When AC bias is used.

37 IN1/BCK in I Not connected.

38 TESTC I Not connected.

39 OT19/HSO O Main mute output.

40 OT20/SPCK O Not connected.

41 OT21/SPDA O TU ON control signal output.

42 OT22/COPS O CD ON control signal output.

43 DOUT O DIGITAL OUT output. (Not used)

44 SBSY O Subcode block output. (Not used)

45 SBOK O Subcode Q-data CRCC judgment result output. (Not used)

46 VDD — CD section digital system power supply: +5V.

47 VSS — CD section digital system GND.

48 P2VREF — PLL system-2 VREF terminal.

49 PDO — Difference signal between EFM signal and PLCK signal is output.

50 TMAX O TMAX detection result is output.

51 LPFN I Inverted input to low-pass filter amplifier.

52 LPFO O Low-pass filter amplifier output.

53 PVREF — PLL system VREF terminal.

54 VCOF I VCO filter.

55 AVSS — Analog system GND.

56 SLCO O DAC output for generating data slice level.

57 RFI I RF signal input.

58 AVDD — Analog system power supply: 5V.

59 RFCT I RFRP signal center level input.

17

Page 18

CSD-TD10/TD30

Pin No. Pin Name I/O Pin Description

60 RFZI I RFRP zero-cross input.

61 RFRP I RF ripple signal input.

62 FEI I Focus error signal input.

63 SBAD I Sub-beam add signal input.

64 TEI I Tracking error input.

65 TEZI I Tracking error zero-cross input.

66 FOO O Focus equalizer output.

67 TRO O Tracking equalizer output.

68 VREF — Analog reference power supply: +5V.

69 RFGC O RF signal amplitude adjustment control signal output.

70 TEBC O Tracking balance control signal output.

71 FMO O Focus equalizer output.

72 DMO O Disc equalizer output.

73 2VREF — Analog reference power supply: +5V.

74 SEL O APC circuit ON/OFF signal output.

75 VDD2 — CD section digital system power supply: +5V.

76 VSS2 — CD section digital system GND.

77 XVSS — CD section crystal oscillator GND.

78 XI I CD section crystal oscillator input. (16,934MHz)

79 XO O CD section crystal oscillator output. (16,934MHz)

80 XVDD — CD section crystal oscillator power supply: +5V.

81 DVSR — R-channel DA converter GND.

82 RO O R-channel data positive polarity output.

83 DVRR — R-channel reference voltage: +5V.

84 DVDD —DA converter power supply: +5V.

85 DVRL — L-channel reference voltage: +5V.

86 LO O L-channel data positive polarity output.

87 DVSL — L-channel DA converter GND.

88 TESTM I Test mode control input. (GND)

89 IN2/(VPP) I Not connected.

90 RST I Microprocessor reset input.

91 HOLD I Hold status detection: Entering Hold at “L”.

92 INTR I Remote control input.

93 MXO O Crystal oscillator terminal for controller. (75kHz)

94 MXI I Crystal oscillator terminal for controller. (75kHz)

95 MVSS — Controller power supply: GND.

96 MVDD — Controller power supply: +5V.

97 COM1/OT1 O LCD common output: LCD601 15pin.

98 COM2/OT2 O LCD common output: LCD601 16pin.

99 COM3/OT3 O LCD common output: LCD601 17pin.

100 COM4/OT4 O LCD common output: LCD601 18pin.

18

Page 19

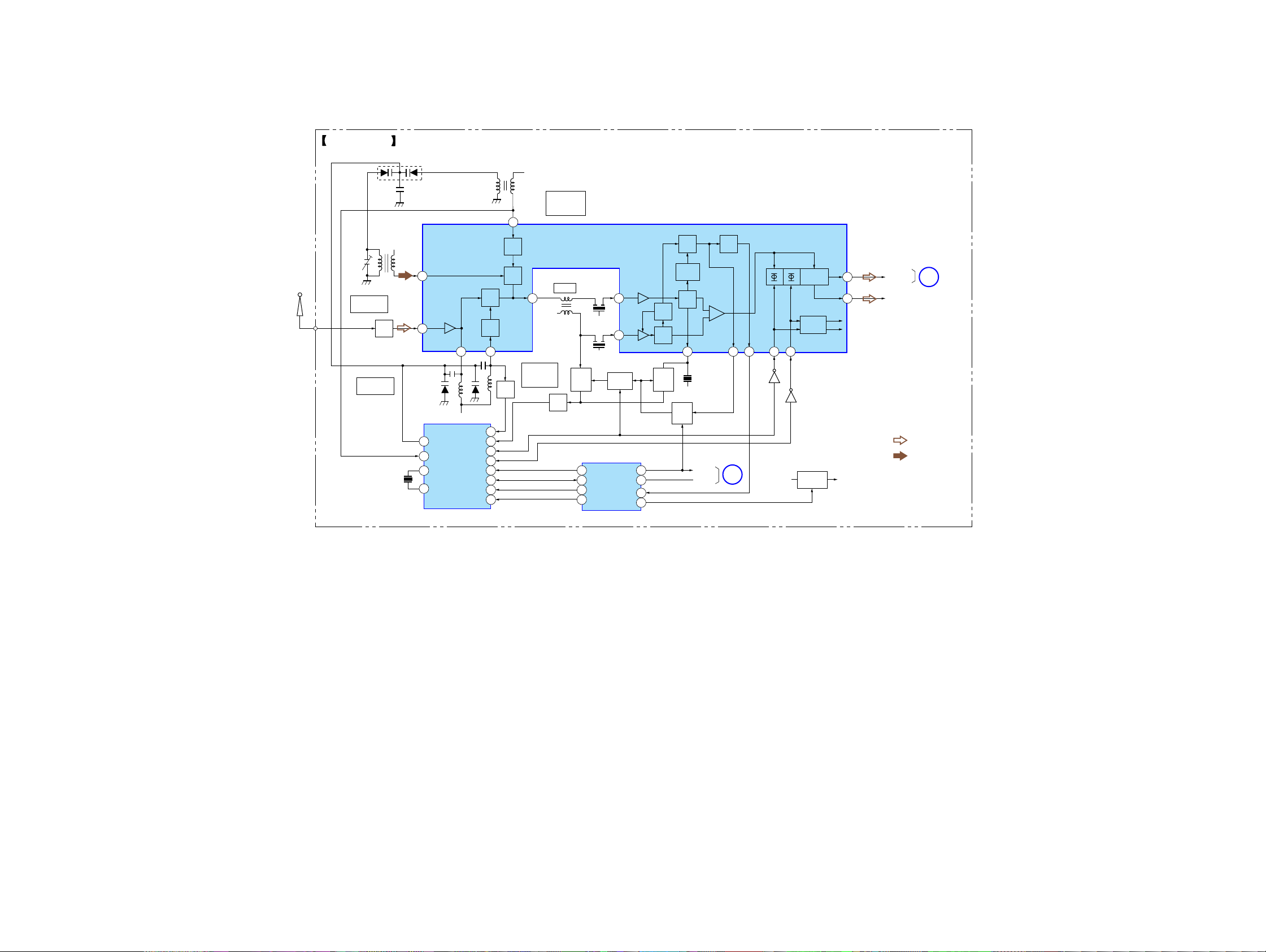

6-2. BLOCK DIAGRAM — CD SECTION —

MAIN BOARD (1/3)

CSD-TD10/TD30

M701

SPINDLE

MOTOR

M702

SLED

MOTOR

SW1

INSIDE

LIMIT

OPTICAL

PICK-UP

KSS-213R

FOCUS

TRACKING

M

M

IC402

CD RF AMP

RFGC

RFGO

RFIS

RFRP

FEO

TEB

SBAD

TEO

VRO

2VROI

20

24

4

9

5

20 69

19 57

18

17

14

9

13

12

16

VREF

2VREF

10

8

CN405

VA

5

6

7

4

3

8

12

10

13

16

14

15

1

2

3

4

5

6

5

6

7

4

3

8

12

10

13

16

14

15

CN403

1

2

3

4

5

6

VB

VC

VD

VE

VF

MD

LD

FOCUS+

FOCUS-

LASER

DRIVE

Q403

FNI

2

FP

3

TNI

5

TPI

4

MDI

6

LDO

7

MOTOR/COIL DRIVER

17

18

27

26

1

2

11

12

6

SUM

AMP

DIFF

AMP

BAL

CTL

LASER

DRIVE

DET

LASER

DRIVE

IC401

TRACKING

COIL

DRIVE

FOCUS

COIL

DRIVE

SPINDLE

MOTOR

DRIVE

SLED

MOTOR

DRIVE

LEVEL

CHECK

SUM

AMP

DIFF

AMP

GAIN

CTL

RFRP

DET

VREF

IC601 (1/2)

CPU & DSP

RFGC

DISPLAY BOARD

1-4

COM1-4

5-12

SEG0-7

1-6

SEG8-13

11

8

POWER BOARD

CNH852

1

2

LCD601

REMOTE

SENSOR

REM601

S601

T-BASS

ON

OFF

TD30

SW601

PLAY/PAUSE

RESET X

SW602

STOP/BAND x

SW602

>

SW602

.

SW602

REPEAT/MODE/

OSC

SW606

PROGRAM

E4 MODEL

SW901

VOLTAGE

SELECTOR

220-240V 110-127V

PT101

E4 MODEL

BATTERY

12V (1.5Vx 8)

EXCEPT

SKIP/

SERCH

HPOO2

AC

~

8V-VCC

16.934MHz

CD L-CH

R-CH

RESET

Q403

X401

(Page 21)

A

SW802

FUNCTION

STANDBY

RADIO

CD

8V REG

Q361,362

12V-VCC

CD8V

POWER SW

Q853,854

HOLD

Q803,804

MICON5V

(Page 21)

SW802C

SW802A

8V REG

Q851,852

12V

5V REG

B

TAPE12V

Q602

4-11

12-17

ST8W-VCC

CD8V-VCC

RA8V-VCC

TAPE12V

CN601 CN603

0-3

T-B

1-4

5-12

CN602 CN604

1-6

99

77

11

8

CN851

1

2

12V-VCC

LO

COM1

I

COM4

S1

I

S14

ADINI

INTR

CDPS

HOLD

RST

86

82

RO

87

I

100

1

I

14

26

92

42

91

90

79

XO

78

XI

RFI

RFRP

61

62

FEI

TEBC

70

63

SBAD

64

TEI

74

SEL

66

FDO

TDO

67

72

DMO

FMO

71

SW401

CD DOOR

CN402

CD 5V CD 8V

5V REG

Q404

MXO

28 94

ADIN3

21

PI-0

MXI

93

X601

75Hz

19 19

• Signal path

: CD

• Abbreviation

E4 : AC 110-120 V/220-240 V area in E model

Page 20

CSD-TD10/TD30

6-3. BLOCK DIAGRAM — TUNER SECTION —

MAIN BOARD (2/3)

FM ROD

ANT

TC101

L103,TC101

TRACKING

L103

AM

BPF

L102

FM

TRACKING

X101

4.5MHz

D101

AM RF

24

FM

RF

IN

1

23 21 12 10 111315 16

D102

L102

IC102

PLL

RA+B

20 12

A OUT

15

AM IN

22

X-OUT

1

X-IN

MW SW

IF MUTE

D103

FM IN

IF IN

L101

20

AM

OSC

AM

MIX

FM

MIX

MIX OUT

FM

OSC

FM OSC

BUF

L108

Q108

16

10

11

4

DI

6

DO

5

CL

3

CE

RA+B

L101

AM

FREQUENCY

COVERAGE

IC101

AM/FM TUNER SYSTEM

L106

AM IF

4 8

RA+B

L108

FM

FREQUENCY

COVERAGE

BUF

Q105

AM IF

AMP

Q106

31

30

32

33

CF102

RA+B

CF101

RA+B

IC601 (2/2)

S0

S12

SCK

P2-0

MW SW

Q111

CPU

7

FM

IF

IN

AM

IF

IN

OT19

P2-3

P2-2

OT21

TUN

LED

ST

LED

(Page 21)

LEVEL

AGC

AM

DET

FM IF

AMP

Q107

DET

DET

RA+B

RADIO

CTL

Q104

FM

QUAD

CF103

TUN

LEDSTLED

LPF1 LPF2

Q110

Q109

DECODE

ST/MO

FM/AM

14

RA L-CH

R-CH

C

• Signal path

: FM

(Page 21)

39

36

35

41

MUTE

BEAT

D

8V-VCC RA+B

REG

Q101-103

: AM

2020

Page 21

6-4. BLOCK DIAGRAM — TAPE SECTION —

TC BOARD MAIN BOARD (3/3)

SW301F

PB

HRP001

L CH

R CH

HE001

1

4

3

1

4

3

R-CH

REC

IC301

PRE AMP

8 7

ALC

5

SW301

REC/PB

SW301E

PB

REC

REC

PB

SW301H

C0N2CNH02 CN301 C0N1

4

33

4

(Page 20)

(Page 19)

(Page 19)

C

A

B

RA L-CH

CD L-CH

T-B

SW802B

SW802

FUNCTION

STANDBY

RADIO

CSD-TD10/TD30

VR802

AMP

Q807

Q809

CD

VOLUME

VR802A

IC801

POWER AMP

6 2

Q802

R-CH

CN801

CNH801

1

2

4

3

1

2

4

3

SPK1

(L-CH)

SPK2

(R-CH)

Q301

SW301I

PB

T301

BIAS FREQ ADJ

REC

8V-VCC

BIAS

OSC

Q302

REC PB

SW301G

MUTE

Q303

8V-VCC 8V-VCC

8V-VCC

5

8

5

5

8

5

MUTE

BEAT

D

(Page 20)

12V

TAPE 12V

CN501 CNH501

4

4

3

3

1

1

• Signal path

: CD

: FM

: TAPE PLAY

: TAPE REC

• R-ch is omitted due to same as L-ch.

4

4

3

3

1

1

SW501

(DECK SW)

M501

DECK

MOTOR

21 21

Page 22

CSD-TD10/TD30

d

6-5. CIRCUIT BOARDS LOCATION

BATT (C) board

DISPLAY board

MAIN board

POWER board

TC board

MOTOR board

BATT (A) board

BATT (C) board

BATT (B) boar

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is

printed in each block.)

Common Note on Schematic Diagrams:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• C : panel designation.

• A : B+ Line.

• H : adjustment for repair.

•Total current is measured with no cassette installed.

•Power voltage is dc 9V and fed with regulated dc power

•Voltages are taken with a VOM (Input impedance 10 M Ω).

•Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

•Abbreviation

: internal component.

Note:

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specified.

supply from battery terminal.

Voltage variations may be noted due to normal produc-

tion tolerances.

Voltage variations may be noted due to normal production tolerances.

F : FM

f : AM

E : PB

a : REC

J : CD

CND : Canadian model.

E4 : AC 110-120V/220-240V area in E model.

MX : Mexican model.

TW : Taiwan model.

AUS: Australian model.

SP : Singapore model.

KR : Korean model.

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

• Wavef orms (Mode: PLAY)

— MAIN Board —

500mV/div 0.5µsec/div

1

0.85±0.2Vp-p

IC402 ql (RFGO)

• Semiconductor Location (MAIN Board)

Ref. No. Location Ref. No. Location

D101 D-4

D102 E-3

D103 D-4

D106 C-3

D107 C-3

D108 B-4

D361 D-13

D362 D-13

D363 E-13

D604 B-5

D605 C-5

D606 B-10

D607 B-10

D608 B-9

D609 B-9

D610 C-6

D611 B-10

D808 E-6

D855 C-11

D856 C-10

IC101 D-3

IC102 B-3

IC401 D-9

IC402 E-8

IC601 C-7

IC801 C-12

L401 C-9

Q101 B-4

Q102 B-4

Q103 B-4

Q104 C-2

Q105 C-2

Q106 C-2

Q107 C-3

Q108 E-4

Q109 C-4

Q110 C-4

Q111 C-2

Q361 E-13

Q362 D-13

Q403 E-9

Q404 E-10

Q602 B-11

Q603 B-9

Q604 B-9

Q605 B-9

Q801 D-11

Q802 D-11

Q803 F-11

Q804 F-11

Q807 E-12

Q808 D-12

Q809 E-12

Q810 E-12

Q851 C-11

Q852 C-11

Q853 D-10

Q854 E-10

ZD601 B-11

Common Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• x : parts mounted on the conductor side.

f

•

• : Pattern from the side which enables seeing.

•Abbreviation

: internal component.

CND : Canadian model.

E4 : AC 110-120V/220-240V area in E model.

MX : Mexican model.

TW : Taiwan model.

AUS: Australian model.

SP : Singapore model.

KR : Korean model.

2222

Page 23

• Refer to page 22 for Circuit Boards Location and Semiconductor Location.

6-6. PRINTED WIRING BOARD — MAIN SECTION — • Refer to page 22 for Common Note on Printed Wiring Boards.

CSD-TD10/TD30

A

B

C

D

E

F

G

L103

MW COIL

1

ANT1

FM

TELESCOPIC

ANTENNA

NATURE

RED

BLK

GEN

C001

234567891011 12 13 14

(Page 28) (Page 28)

C157

R114 R117

E

C

B

Q106

C172

L109

NOTE:

CXXX

C134

L106

R112

R116

Q111

C132

L107CF101

C133

Q105

R113

R115

B

C

E

C146

C162

JW105

C135

R119 R118

CF102

C165

C129

C143

E

C

B

ECB

Q104

R121

R120

L105

Q107

C149

R124

C152

E

C

B

R125

R133

L102

R132

R134 C150

C144

C140

C171

C160

C131

C130

C110

MAIN BOARD

X101

C155

C147

1

22

D106

C139

R123

C137

C141

D102

JW101

JW102

12 13

1

IC101

BL

C109

1112

JW103

C167

CF103

JW154

JW155

24

R105

C179

C138

D107

R126

R122

C111

C176

IC102

C128

C126

C112

C190

C148

RED

C120

R149

C119

R106

C114

R108

C156

R103

C113

C163

R145

C127

R129

L108

WH

RXXX

R136

R142

R143

R144

R128

D108

Q103

C121

C117

C178

R147

R146

Q101

C125

Q110

C108

L101

RG

C115

C106

R110R111

US,CND,MX,E4

E

C

B

E

C

B

C

MODEL

C145

JW104

C124

B

E

D103

R107

C164

R109

Q108

C118

R130

C159

C

DISPLAY BOARD

CN604

B

C177

Q102

B

R131

C

E

C142

C158

JW131

JW130

R141

R137

JW147

JW151

JW166

JW152

JW153

Q109

R150

B

C123

C103

E

C122

C105

R101

R104

C104

C107

R102

C102

D101

TC101

ECB

JW199

C151

C173

C166

JW198

C324

R318

D605

C175

D604

JW150

JW107

JW105

C323

JW149

R317

L110

R622

R319

JW186

JW167

JW148

CON1

JW175

D610

10

1

R314

CN602

R606

R321

R705

JW108

R706

R322

R607

C895

US,CNDE4,MX

MODEL

JW173

JW200

R808

C828

C616

C896

C897

C894

R709

R465

C401

JW187

R819

C844

R818

R320

D808

R608

R407

R408

D

TC BOARD

CON2

(Page 27)

SW401

(CD DOOR SW)

C661

C665

C664

C663

C662

111 112

R656

R652

R653

R654

R655

CN402

R604

2

R466

1

JW181

R605

R711

R710

C405

R708

R707

C408

R848

C410

JW201

C409

C840

21

WHT

DISPLAY BOARD

CN603

A

C660

C659

C658

C657

C656

C655

C654

C653

R657

R660

R661

R662

R663

R658

R659

C893

C892

JW145

C455

R426

R427

R429

L404

R409

30

31

R411

R428

RED

JW143

R410

C453

C452

R412

50

C402

L405

JW115

IC601

51

C415

R431

C442

C441

R664

1

C411

C468

C652

100

C417

R665

C651

C416

C650

CN601

R666

C439

C454

C418

C438

R667

C649

C414

C419

C648

R668

81

80

13 12

24 1

JW119

JW117

EXCEPT E4,MX MODELEXCEPT US,CND MODEL

R669

L601

C609

C610

X601

R425

JW114

IC402

C847

C624

C460

R623

R449

R419

R420

R422

R421

R424

R423

C422

C436

C462

C608

C461

R453

JW159

C617

R405

X401

C423

C431

R413

R414

C604

R432

C603

C606

C432

C427

C426

R450

C420

R417

JW138

CNH501

R430

C421

C612

Q403

B

E

JW122

C434

D609

R462

C

1

Q605

C623

JW170

D

C433C430

C428

JW118

R463

E

B

L406

JW177

R416

R406

R451

C424

C425

L403

CN405

R452

R442

JW113

R444

16

2

R611

C607

C429

R441

15

1

4

CN501

R636

R610

D608

C407

L401

C406

JW193

15 14

IC401

28 1

C447R443

C446

C443C444

PICK UP

ASSY

KSS-213R

CD MECHANISM

KSM-213RDM

E

C

B

Q604

C403

JW192

R439

R438

R440

JW119

E

C

B

JW120

LEAF

Q603

R447

M-

M+

D607

D606

R609

R639

C622

C620

C621

C857

JW163

JW162

CN403

1

6

BCE

Q404

R475

R418

E

C

Q854

B

US,CND MODEL

SPINDLE/SLED

MOTOR,

INSIDE

LIMIT SW

D611

JW183

EXCEPT

US,CND,MX

R437

C435

C841

R849

JW110

R637

JW127

Q853

C846

JW140

JW141

R850

C821

D856

C856

R471

R168

C614

R169

L602

C602

D855

CE

JW121

B

MODEL

Q851

MX,E4

Q602

C806

R806

JW190

E

C

B

C601

ECB

JW189

JW194

JW182

Q852

R805

JW188

ZD601

R602

C613

R603

C810

R812

6

R851

R852

C808

R811

Q801 Q802

G

G

D

D

S

S

R873

R874

R804

R802

C886

C878 Q810

C888

R866

R868

R803

R865

C885

VR802

JW172

Q803

ECB

ECB

Q804

MAX MIN

VR802

VOLUME

MAX MIN

JW184

JW185

C818

R814

C819

C807 C811

C805

JW132

C802

C891

G

D

S

C801

MX,E4

MODEL

C809

R801

C812

R860

R870

R867

C890

C872

R161 JW100

C463

JW195

127

1

R856

JW197

Q808

Q877

C887

JW135

JW161

C858

IC801

C820

C817

R813

C876

R862

R864

R858

E

C

B

Q809

R869R875

G

D

S

R859

R855

B

C

E

Q807

R872

C873

C404

JW126

JW169

R470

C464

FUNCTION

CD RADIO TAPE STANDBY

C814

C874

C875

R863

R861

P1 P4

P2 P3

SW802

C813

R857

JW160

R871

C889

JW136

JW137

CN801

C815

JW123

JW124

JW128

1

4

JW134

B+

1

CN851

B-

3

JW157

JW133

C361

R361

D361

C362

ECB

Q362

D362

R363

D363

R364

R362

ECB

Q361

JW129

SW802

JW125

1-688-130- 11

C

E4,MX

MODEL

E4,MX

MODEL

POWER

BOARD

CNH852

(Page 28)

H

J

CXXX

CXXX

CXXX

RXXX

LXXX

RXXX

LXXX

CFXXX

DXXX

XXXX

SW501

(DECK SW)

WHT

WHT

BLK

RED

(DECK MOTOR)

M501

SPK1

RIGHT

SPEAKER

CNH801

14

BLK

RED

BLK

SPK2

LEFT

SPEAKER

RED

I

CXXX

23 23

Page 24

CSD-TD10/TD30

CD 402

• Refer to page 22 for Waveforms.

• Refer to page 22 for Common Note on Schematic Diagrams.

6-7. SCHEMATIC DIAGRAM — CD SECTION — • Refer to page 30 for IC Block Diagrams.

A

B

C

D

E

F

G

1

M701

M702

OPTICAL

PICK-UP

KSS-213R

234567891011121314

MAIN BOARD (1/3)

1

CD 402

IC B/D

IC401

MOTOR/COIL

DRIVER

L404

4.7µH

3.60002

0

3.5

Q404

REGULATOR

2

4.6

0

2

2.2

5.1

5.1

KTA1266GR

21222.92221.7

1

2

0.3

3.5

2.3

1.9

3.9

L405 L406

US,CND,

E4,MX

OTHER0010µH10µH

D611 L401

US,CND

00003.9

0

0

2

US,CND

MODEL

C846

EXCEPT

E4,MX

MODEL

C468

C 845

0.1

EXCEPT

E4,MX

MODEL

IC B/D

IC402

SSP

2.1

OTHER

IN4148JWIN4148

D611 L401

15µH

JW

JW

JWJWJW

IC601

C844 0.1

TC94A23F-704BH(US,CND,E4,MX)

C604

330 10V

TC94A23F-705BH(AEP,UK,AUS,KR,SP,TW)

SYSTEM CONTROL

US,CND,

MODEL

E4,MX

JW

R606

R607

JW

R320 JW

C894

ISS133

EXCEPT

US,CND

10K

MODEL

R603

US,CND,MX : 2.2

OTHER : JW

Q602

3DA8050

+5V REG

6.8K

MTZJ-T-77-6.2B

R622

JW

(Page 26)

2

3

4

(Page 25)

5

(Page 26)

MAIN

BOARD

(3/3)

MAIN

BOARD

(3/3)

(Page 26)

MAIN

BOARD

(2/3)

MAIN

BOARD

(3/3)

H

Q603,604

Q605

RESET

Q403

KTA1266GR

Q403

REGULATOR

C847

0.1

EXCEPT

35

0

85

2.2 2.3

E4,MX

MODEL

36

37

38

39

40

41

42

43

44

45

46

47

48

49

0

0

0

0

4.9

0

4.8

4.6

0.1

4.6

86

87

88

89

90

91

0 4.9

5.1 0

92

00

93

2.6 1.9

4.6

94

95

96

0 4.9

0

97

2.4 2.4

50

3.9

2.0

2

98

99

100

2.4 2.4

I

IC601 TC94A23F-704BH

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

Pin.No.

CD PLAY

Pin.No.

CD PLAY

2.4

51

2.0 1.8

2.4

2.4

0

0

0

2.4

0

0

0

0

0

0

0

0

0

5.0

0

0

0

0

4.8

0

0

0

0

0

4.6

0

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

2.0 1.5

0 1.9

2.0 4.5

22

2.9 2.1

1.7 2.1

2.1 2.1

2.0 2.0

1.1 1.9

2.0 2.0

3.9 2.3

4.6 0

76

77

02

0

78

79

80

2.3 4.3

0

81

0 2.3

34

0

0

0

82

83

84

2.2 4.4

HOLD

KTC3198GR

KTC3198GR

0303040405050606070708

01

02

00

R668

R667

R666

R665

R664

R663

C651

C652

C650

C649

0µH

L601

C653

C654

00

01

1 2 3 4 5 6 7 8 9 10 11 12

09

10

R662

R661

R660

R659

R658

R657

R656

C655

C656

02

C659

C657

C658

08

C661

C660

11

09

10

13

12

11

16

14

15

R655

R654

R653

C662

C664

C663

13

12

1 2 3 4 5 6 7 8 8 9 10 11

14

17

R652

C665

15

17

16

A B

DISPLAY BOARD

CN603

DISPLAY BOARD

CN604

(Page 29) (Page 29)

•Voltage and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : CD PLAY

2424

Page 25

• Refer to page 22 for Common Note on Schematic Diagrams.

6-8. SCHEMATIC DIAGRAM — TUNER SECTION — • Refer to page 30 for IC Block Diagrams.

CSD-TD10/TD30

A

B

C

D

E

F

1

MAIN BOARD (2/3)

L103,TC101

AM TRACKING

FM ROD ANT

L109

JW

234567891011 12 13 14

US,CND,MX,E4

MODEL

L102

FM TRACKING

IC B/D

L101

AM FREQUENCY COVERAGE FM FREQUENCY COVERAGE

4.6

4.7

0.8(0)

0.4

(1.2)

L108

4.6

4.6

4.5

(4.7)0(0.5)

1.2

1.9

R108

10 : (OTHER)

15:(US,CND,MX,E4)

4.6

TP

IC101

AM/FM TUNER SYSTEM

4.7

R120

JW

FM OSC BUFFER

3.4

JW

1.1(1)

4.6

(4.7)

4.1

Q108

4.6

3.9(4.7)

2.2

(0)

3.9(4.7)

4.6

(4.7)

Q109,110

4.7 4.7

3.9(4.7)

1.3

3.9

(4.4)

1.3

SW

4.6

(0)

3.9

(4.7)

4.6(0)

L107 JW

(US,CND,MX,E4)

ISS133

(EXCEPT US,CND,MX,E4)

4.7

7.7

IC102

PLL

MTZJ-T-77-8.2C

2.1(2.3)

2.1(2.3)

4.7 50V

0.8

6.1(3.4)

0

0

0.8

4.9

4.7

0(3.3)

4.6(4.7)

4.6(0)

IC B/D

0

4.6(0)

G

H

C001

Q105,106

IF AMP

0

0

KTC3198GR-A

0

KTC3198GR-A

0

5.4

L106

AM IF

0

0

0

0

Q104

DTA114TSA

0

LED DRIVER

LED

0

DRIVER

4.6(0)

00

SW

5.4

0

4.9

Q101~103

REGULATOR

4

BOARD

(Page 24)

MAIN

(1/3)

I

•Voltage and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : FM

(): AM

25 25

Page 26

CSD-TD10/TD30

• Refer to page 22 for Common Note on Schematic Diagrams.

6-9. SCHEMATIC DIAGRAM — TAPE SECTION — • Refer to page 31 for IC Block Diagrams.

A

B

C

D

MAIN

BOARD

(1/3)

(Page 24)

1

1

3

5

234567891011121314

MAIN BOARD (3/3)

TC BOARD

IC B/D

IC301

PRE AMP

D808

IN4148A (US,CND,E4,MX)

ISS133 (EXCEPT US,CND,E4,MX)

JW

Q803,804

MUTE

JW

Q853,854

SW

PRE AMP

0

1.8

0

1.8

0

1.8

7.6

1.8

4

4

D855,856

IN4148A (US,CND,E4,MX)

ISS133 (EXCEPT US,CND,E4,MX)

KTC3198GR-A

E4,MX

EXCEPT

E4,MX

Q851,852

REGULATOR

E4,MX

KTC3198GR

AMP

R805,806

15K (E4,MX)

8.2K (EXCEPT E4,MX)

C840

0.1

C806,807

0.47 (E4,MX)

0.1 (EXCEPT E4,MX)

AMP

E4,MX

Q809,810

MUtE

IC B/D

R811,812

100 (E4,MX)

68 (EXCEPT E4,MX)

IC801

POWER AMP

0

0.6136.8

POWER AMP

0

0.6

7.1

13.3

SPK1

(LCH)

7

13

13.2

SPK2

(RCH)

E

F

G

H

I

LCH

HRP001

RCH

HE001

MAIN

BOARD

(1/3)

(Page 24)

KTC3198GR

Q808

AMP

7

7

6

6

PB

A

REC

PB

PB

REC

D

BC

REC

PB

REC

CON2 (2/2)

TP

KTC3198GR-A

BEAT SW

F

CNH02

4

4

3

3

2

2

5

2

CON1 (2/2)

PB

REC

H

7.9(4.7)

T301

BIAS FREQ ADJ

E

7.9(0.7)

BIAS OSC

PB

REC

PB

SW301

(PB/REC)

PLAY

REC

KTC3198GR-A

MUTE

REC

G

ISS133T-77

3

3

10

10

9

9

11

2

2

CON2 (1/2)

D361,362

IN4148A (US,CND,E4,MX)

CON1 (1/2)

ISS133 (EXCEPT US,CND,E4,MX)

JW100

TAPE/

STANDBY

JW1

SW802

FUNCTION

RADIO

CD

Q361,362

+B SW

3CG9012

MTZJ-T-77-8.2A

C801,802

0.001 (E4,MX)

0.0047 (EXCEPT E4,MX)

E4,MX

EXCEPT E4,MX

E4,MX

C877,878

0.056 (E4,MX)

0.039 (EXCEPT E4,MX)

VR802

VOLUME

M501

(DECK MOTOR)

CNH501

(DECK SW)

POWER

BOARD

C

CNH852

(Page 29)

– TC BOARD –

•Voltage and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : PB

SW501

(): REC

– MAIN BOARD (3/3) –

•Voltage and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : FM

2626

Page 27

• Refer to page 22 for Circuit Boards Location.

6-10. PRINTED WIRING BOARD — TC SECTION — • Refer to page 22 for Common Note on Printed Wiring Boards.

CSD-TD10/TD30

A

B

C

D

E

1

2345678910111213

TC BOARD

C338

C339

R341

T301

Q302

R343

D302

R339

B

C

E

Q301

R395

C337

R396

B

C

E

C336

R340

VR301

1-688-131- 11

Q303

C340

R305

R323

C305

SW301

C308C307

R310

R313

R316

C311

C394

CON2

R303

G

JW75

C310

91

H

R315

JW73

JW79

R311

1

C304

IC301

R302

C306

4

JW74

CN301

10 1

C303C302

R306

R307

ABCDE F I

C314

SW301

(PB/REC)

REC PB

R301

C393

C313

R312

C315

R309

C312

C334

R304

R308

R344

JW77

C316

C335

R342

• Semiconductor

Location

Ref. No. Location

D302 D-10

D303 D-10

IC301 C-5

Q301 D-10

Q302 C-10

Q303 E-11

F

G

H

14

CNH002

WHT

RED

YWL

D

MAIN BOARD

CON1

(Page 23)

HRP001

REC/PB HEAD

HE001

ERASE HEAD

27 27

Page 28

CSD-TD10/TD30

6-11. PRINTED WIRING BOARDS — CONTROL, POWER SUPPLY SECTION — • Refer to page 22 for Common Note on Printed Wiring Boards.

• Refer to page 22 for Circuit Boards Location.

A

B

C

D

1

2345678910111213

(Page 23)

MAIN BOARD

CN601

DISPLAY BOARD

SW601

PRESET/u

R616

BAND/x

SW602

R617

18

LIQUID CRYSTAL DISPLAY PANEL

>

SW603

LCD601

R618 R619

TUNE

.

SW604

1

TD30

REM601

R620

REPEAT/MODE

SW605

JW1

PROGRAM

JW3

SW606

C611

JW2

R621

12

R615

R623

1-688-511- 11

S601

A

CN603

CN604

11

T-BASS

S601

(Page 23)

MAIN BOARD

CN602

B

RED

POWER BOARD

C604

D604

BATT-

BLK

RED

E4 MODEL

AC2

C602

C603

C606

D602

C605

B+

AC VOLTAGE

AC220-240V 110-120V

D603

SW901

1-688-126- 11

AC1

D601

B2

BATT+

B-

RST

C601

D605

CNH852

RED

1

3

C

MAIN

BOARD

CN851

(Page 23)

YEL

RED

BLK

B1

RED

E

F

G

H

PT001

EXCEPT E4 MODEL

HP002

AC ~

• Semiconductor

Location

Ref. No. Location

D601 B-11

D602 B-10

D603 B-11

BLK

RED

D604 B-10

D605 B-11

D606 B-12

BATT (A) BOARD BATT (B) BOARD

REM601 C-6

JW13

JW24

JW14

JW15

JW23

JW16

BATTERY

DC 12V

R14x8

JW19

JW22

JW20

JW17

JW21

JW18

BAT-

BAT+

I

1-688-127- 11 1-688-128- 11

2828

Page 29

6-12. SCHEMATIC DIAGRAM — CONTROL, POWER SUPPLY SECTION — • Refer to page 22 for Common Note on Schematic Diagrams.

CSD-TD10/TD30

A

B

C

D

E

1

23456789

(Page 24) (Page 24)

MAIN BOARD (1/3)

CN602

B

11

10

11223344556677889

LIQUID CRYSTAL DISPLY PANEL

MAIN BOARD (1/3)

CN601

A

9

10

11 12

S601

R615

ON

OFF

22K

C611

22

R621

50V

1.8K

2 13

REM601

RPM7138-V4

REM601

REMOTE SENSOR

TD30

S601

T-BASS

DISPLAY BOARD

PRESET/

BAND/

TUNE

REPEAT/MODE

PROGRAM

F

G

H

I

MAIN BOARD(3/3)

CN851

(Page 26)

C

POWER BOARD

1N4001B

1N4001B

1N4001B

1N4001B

1N4001B

BATT (A)

BOARD

PT001

POWER TRANSRFORMER

AC220-240V

BATT (B)

BOARD

BATTERY

DC12V R14 x 8

HP002

AC

EXCEPT E4

MODEL

E4

MODEL

SW901

AC VOLTAGE

110-120V

•Voltage and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : FM

29 29

Page 30

CSD-TD10/TD30

6-13. IC BLOCK DIAGRAMS

IC401 MM1469XH

CH4 OUT-A

SUBGND

28

1

CH1 OUT-A

CH4 OUT-B

27 26

LEVEL SHIFT

+

-

LEVEL SHIFT

2 3 4 5 6 7 98

CH1 IN-A

CH1 OUT-B

IC402 TA2109F

CH4 IN-A

25

CH1 IN-B

+

CH4 IN-B

24

+

TR-B

BIAS-IN

23

-

+

VREG-OUT

IC101 TA2111FN

FM OSC

AM RF IN

Vcc

Vcc

Vcc

MUTE

CH3 IN-B

20 19

2122

Vcc

+

+

-

GND

CH2 IN-B

CH3 OUT-B

CH3 IN-A

CH2 IN-A

CH3 OUT-A

18 17 16 15

LEVEL SHIFT

LEVEL SHIFT

12 13

CH2 OUT-A

CH2 OUT-B

OP IN +

+

SUBGND

OP IN -

-

141110

OP OUT

24 23

AM

RF AMP

FM RF IN

FM

RF AMP

RF GND

FM RF OUT

RF VCC

22 13

FM

OSC

AM

MIX

FM

MIX

AM OSC

20

AM

OSC

5431 2 6 8 9 1210 11

AGC

FM/AM

MIX OUT

AM LOW-CUT

AGC

VCC

AFC

AF BUFFER

AM

DET

AM IF

AMP

7

DET OUT

181921

AM IF IN

FM

MUTE

MPX IN

17

FM IF

FM

DET

AMP

AF

AMP

FM IF IN

LEVEL

DET

GND

LPF2

VCO

DIVIDER

ST/MONO

FM/AM

TUN

LED

TUN LED

LPF1

L-OUT

141516

DECODER

ST

LED

ST LED

R-OUT

QUAD

SBAD

FEO

FEN

VRO

RFRP

RFIS

RFGO

RFGC

AGCI

RFO

GND

RFN

180kΩ

21kΩ

24kΩ

180kΩ

180kΩ

30kΩ

20pF

20pF

30kΩ

29kΩ

24kΩ

1.74kΩ

60kΩ

60kΩ

40pF

7.67kΩ

12

TEO

20pF

10kΩ

S STATE

DET

47kΩ

SW1

LDC

1kΩ

SW3

13kΩ

SW2

680kΩ

2.12kΩ

65µA

T-T

T-T

11

TEN

10

2VRO

9

TEB

8

SEL

7

LDO

6

MDI

5

TNI

4

TPI

IC102 LC72131D

VSS

AOUT

XOUT

2122

AIN

19

20

REFERENCE

DIVIDER

PD

18

PHASE

DETECTOR

CHARGE PUMP

UNLOCK

DETECTOR

SWALLOW COUNTER

1/16, 1/17 4BITS

12BITS

PROGRAMMABLE

DRIVER

17

POWER

ON

RESET

VDD

AMIN

TUNE

NC2

FMIN

16

15 12

IFIN

13

14

1/2

20kΩ

3

20kΩ

20kΩ

20kΩ

FPI

CCB

1

XIN

INTERFACE

3

2

NC1

5

4

6

DI

CE

CL

DO

2

FNI

1

VCC

DATA SHIFT REGISTER LATCH

10

7

8

T-BASE

9

FM/SW

11

MW/SW

IF_MUTE

UNIVERSAL

COUNTER

15kΩ

10kΩ

50kΩ

36pF

15kΩ

20µA

10kΩ

10kΩ

13

14

10pF

15

7.96kΩ

10kΩ

16

21kΩ 21kΩ

50µA

17

20kΩ

12kΩ

12kΩ

18

20kΩ

19

20kΩ

PEAK

BOTTOM

20

12kΩ

23.5kΩ

21

re=130Ω

180kΩ

22

23

1.53kΩ

40pF

24

3.3kΩ

3.3kΩ

MONO/BEAT

3030

Page 31

IC801 TA8227P

NF1

IN1

6

7

IN2

4

5

8

NF2

GND

+

–

+

–

9

RIPPLE

CSD-TD10/TD30

B.S.1

OUT1

VCC2

1

2

3

12

11

10

B.S.2

OUT2

VCC1

IC301 BA3308

–

+

2

INPUT1

3

OUTPUT1

1

NF1

MUTE

–

+

ALC

6 7 8

5

4

ALC

GND

VCC

OUTPUT2

9

NF2

INPUT2

31

Page 32

CSD-TD10/TD30

NOTE:

• The mechanical parts with no reference

number in the exploded views are not supplied.

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

•Abbreviation

CND : Canadian model

E4 : AC 110-120V/220-240V area in E model

MX : Mexican model

TW : Taiwan model

AUS: Australian model

SP : Singapore model

KR : Korean model

SECTION 7

EXPLODED VIEWS

• Color Indication of Appearance Parts

Example :

KNOB, BALANCE (WHITE) ... (RED)

R

Parts Color Cabinet’s Color

• Accessories are given in the last of this parts list.

R

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque 0 sont critiques pour

la sécurité.

Ne les remplacer que par une piéce

portant le numéro spécifié.

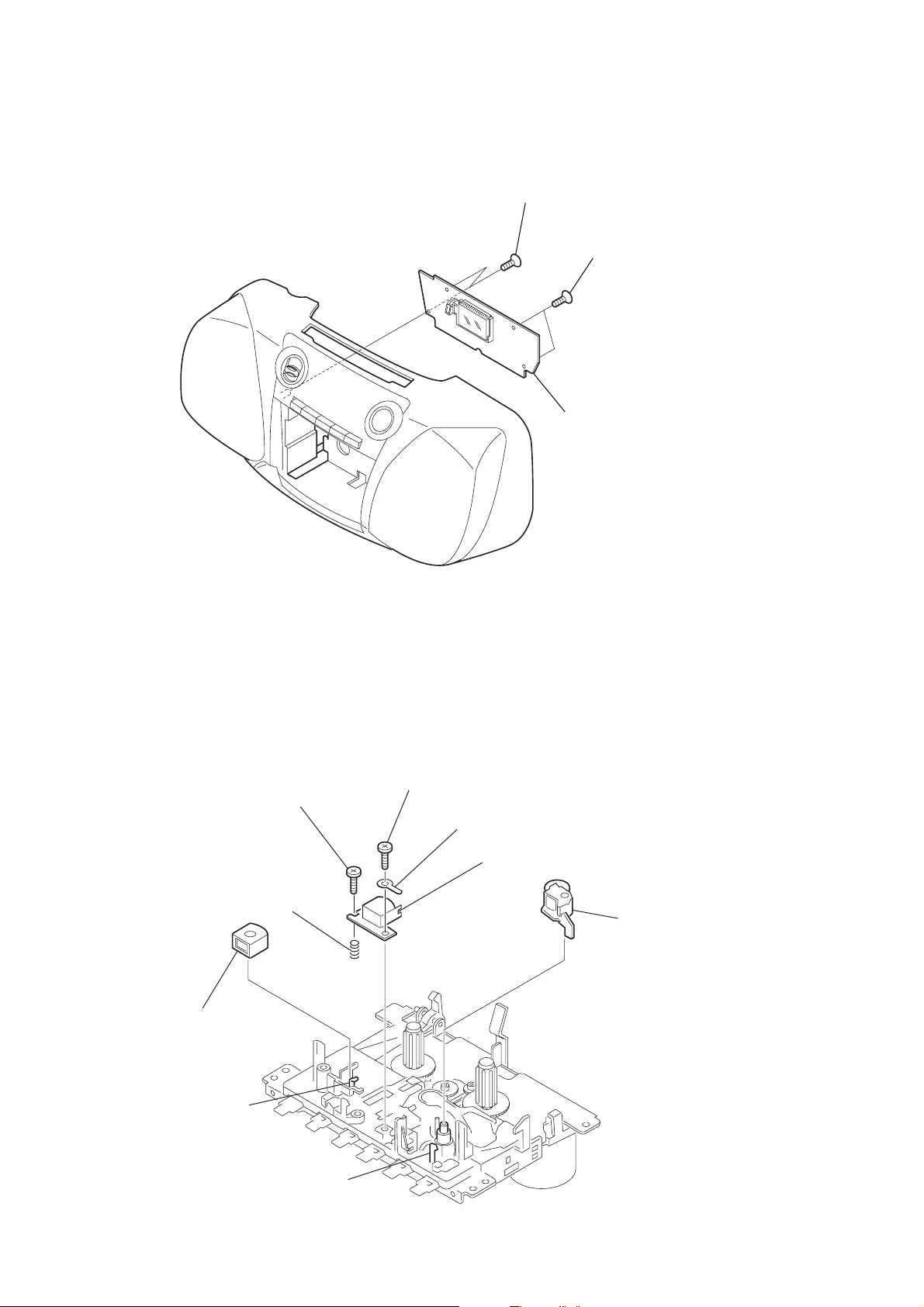

7-1. MAIN BOARD SECTION

#1

9

7

8

#2

#1

#1

#2

4

4

5

5

3

L103

6

1

Ref. No. Part No. Description Remark

* 1 A-3347-378-A MAIN BOARD, COMPLETE (US,CND)

* 1 A-3683-541-A MAIN BOARD, COMPLETE

(AEP,UK,AUS,KR,SP,TW)

* 1 A-3683-553-A MAIN BOARD, COMPLETE (E4,MX)

* 2 A-3683-550-A TC BOARD, COMPLETE

3 3-248-381-01 HLDR (PWB)

4 4-951-620-11 SCREW (2.6X10), +BVTP

5 3-249-842-01 HOLDER (FERRITE-ROD ANTENNA)

6 3-249-837-01 PAPER, SHIELD

7 3-248-385-01 KNOB SL FUNC (TITANIUM)...(TITANIUM)

7 3-248-385-11 KNOB SL FUNC (SILVER)...(SILVER,BLUE)

(EXCEPT US)

8 3-248-400-01 KNOB RTRY VOL (TITANIUM)...(TITANIUM)

8 3-248-400-11 KNOB RTRY VOL (SILVER)...(SILVER,BLUE)

32

4

2

Ref. No. Part No. Description Remark

9 3-248-398-01 COVER (BATT) (TITANIUM)...(TITANIUM) (US)

9 3-248-398-11 COVER (BATT) (SILVER)...(SILVER) (CND)

9 3-248-398-21 COVER (BATT) (SILVER)...(SILVER)

(TD10:AEP,UK,KR,SP)

9 3-248-398-31 COVER (BATT) (TITANIUM)...(TITANIUM)

(CND,E4)

9 3-248-398-41 COVER (BATT) (BLUE)...(BLUE)

9 3-248-398-51 COVER (BATT) (SILVER)...(SILVER)

(TD10:E4/TD30)

L103 1-456-299-11 ANTENNA, FERRITE-ROD (AM)

#1 7-685-647-79 SCREW +BVTP 3X10 TYPE2 N-S

#2 7-685-651-79 SCREW +BVTP 3X20 TYPE2

Page 33

7-2. CABINET FRONT (1) SECTION

CSD-TD10/TD30

SPK1

not supplied

#1

not supplied

not supplied

#1

#1

MF-TD10

52

51

not supplied

53

54

55

56

57

57

not supplied

#1

#1

#1

not supplied

SPK2

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

51 3-248-392-01 KEY CASS PAUSE (TITANIUM)...(TITANIUM)

51 3-248-392-11 KEY CASS PAUSE (SILVER)...(SILVER,BLUE)

(TD10:CND,AEP,UK,KR,SP)

51 3-248-392-21 KEY CASS PAUSE (SILVER)...(SILVER)

(TD10:E4/TD30)

52 3-248-393-01 KEY CASS STOP (TITANIUM)...(TITANIUM)

52 3-248-393-11 KEY CASS STOP (SILVER)...(SILVER,BLUE)

(TD10:CND,AEP,UK,KR,SP)

52 3-248-393-21 KEY CASS STOP (SILVER)...(SILVER)

(TD10:E4/TD30)

53 3-248-394-01 KEY CASS FF (TITANIUM)...(TITANIUM)

53 3-248-394-11 KEY CASS FF (SILVER)...(SILVER,BLUE)

(TD10:CND,AEP,UK,KR,SP)

53 3-248-394-21 KEY CASS FF (SILVER)...(SILVER)

(TD10:E4/TD30)

54 3-248-395-01 KEY CASS REW (TITANIUM)...(TITANIUM)

54 3-248-395-11 KEY CASS REW (SILVER)...(SILVER,BLUE)

(TD10:CND,AEP,UK,KR,SP)

54 3-248-395-21 KEY CASS REW (SILVER)...(SILVER)

(TD10:E4/TD30)

55 3-248-396-01 KEY CASS PLAY (TITANIUM)...(TITANIUM)

55 3-248-396-11 KEY CASS PLAY (SILVER)...(SILVER,BLUE)

(TD10:CND,AEP,UK,KR,SP)

55 3-248-396-21 KEY CASS PLAY (SILVER)...(SILVER)

(TD10:E4/TD30)

56 3-248-397-01 KEY CASS REC (TITANIUM)...(TITANIUM)

56 3-248-397-11 KEY CASS REC (SILVER)...(SILVER,BLUE)

(TD10:CND,AEP,UK,KR,SP)

56 3-248-397-21 KEY CASS REC (SILVER)...(SILVER)

(TD10:E4/TD30)

57 4-951-620-11 SCREW (2.6X10), +BVTP

SPK1 1-825-296-11 SPEAKER (10cm) (L-CH)

(TITANIUM)...(TITANIUM) (US,CND)

SPK1 1-825-296-21 SPEAKER (10cm) (L-CH)

(SILVER)...(SILVER,BLUE)

(EXCEPT US,E4,MX)

SPK1 1-825-542-11 SPEAKER (10cm) (L-CH)

(SILVER)...(SILVER) (E4,MX)

SPK1 1-825-543-11 SPEAKER (10cm) (L-CH)

(TITANIUM)...(TITANIUM) (E4)

SPK2 1-825-296-11 SPEAKER (10cm) (R-CH)

(TITANIUM)...(TITANIUM) (US,CND)

SPK2 1-825-296-21 SPEAKER (10cm) (R-CH)

(SILVER)...(SILVER,BLUE)

(EXCEPT US,E4,MX)

SPK2 1-825-542-11 SPEAKER (10cm) (R-CH)

(SILVER)...(SILVER) (E4,MX)

SPK2 1-825-543-11 SPEAKER (10cm) (R-CH)

(TITANIUM)...(TITANIUM) (E4)

#1 7-685-647-79 SCREW +BVTP 3X10 TYPE2 N-S

33

Page 34

CSD-TD10/TD30

7-3. CABINET FRONT (2) SECTION

105

104

112

102

106

LCD601

101

113

107

110

#3

109

#3

108

111

103

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

101 X-3382-795-1 CABI FRONT SUB ASSY

(TITANIUM)...(TITANIUM) (TD10:US)

101 X-3383-118-1 CABI FRONT SUB ASSY (SILVER)...(SILVER)

(CND)

101 X-3383-119-1 CABI FRONT SUB ASSY

(TITANIUM)...(TITANIUM) (TD30:US)

101 X-3383-368-1 CABI FRONT SUB ASSY

(TITANIUM)...(TITANIUM) (TD10:CND)

101 X-3383-369-1 CABI FRONT SUB ASSY (BLUE)...(BLUE)

101 X-3383-371-1 CABI FRONT SUB ASSY (SILVER)...(SILVER)

(TD10:E4/TD30)

101 X-3383-443-1 CABI FRONT SUB ASSY (SILVER)...(SILVER)

(TD10:AEP,UK,KR,SP)

101 X-3383-444-1 CABI FRONT SUB ASSY

(TITANIUM)...(TITANIUM) (TD30:E4)

102 X-3383-586-1 CASS DOOR SUB ASSY

(TITANIUM)...(TITANIUM) (TD10)

102 X-3383-587-1 CASS DOOR SUB ASSY (SILVER)...(SILVER)

(TD10:CND,AEP,UK,KR,SP)

102 X-3383-588-1 CASS DOOR SUB ASSY

(TITANIUM)...(TITANIUM) (TD30)

102 X-3383-589-1 CASS DOOR SUB ASSY (BLUE)...(BLUE)

102 X-3383-590-1 CASS DOOR SUB ASSY (SILVER)...(SILVER)

(TD10:E4/TD30)

103 3-248-375-01 SPR T CASS

104 3-248-399-01 WINDOW (DISP) (SILVER)...(SILVER,TITANIUM)

(TD10:US,CND,AEP,UK,KR,SP)

105 3-249-213-01 PANEL (LCD) (TITANIUM)...(TITANIUM) (TD10)

105 3-249-213-11 PANEL (LCD) (SILVER)...(SILVER)

(TD10:CND,AEP,UK,KR,SP)

105 3-249-213-21 PANEL (LCD) (BLUE)...(BLUE)

105 3-249-213-31 PANEL (LCD) (SILVER)...(SILVER) (TD30)

105 3-249-213-41 PANEL (LCD) (TITANIUM)...(TITANIUM) (TD30)

105 3-249-213-51 PANEL (LCD) (SILVER)...(SILVER) (E4)

* 106 A-3683-543-A DISPLAY BOARD, COMPLETE (TD10)

* 106 A-3683-555-A DISPLAY BOARD, COMPLETE (TD30)

107 3-248-402-01 HLDR (LCD)

108 3-248-374-01 KEY CONT (TITANIUM)...(TITANIUM) (TD10)

108 3-248-374-11 KEY CONT (SILVER)...(SILVER,BLUE,TITANIUM)

(EXCEPT TD10:US)

109 3-248-377-01 KNOB SL BASS (TITANIUM)...(TITANIUM)

(TD30)

109 3-248-377-11 KNOB SL BASS (SILVER)...(SILVER,BLUE)

(EXCEPT US)

109 3-248-377-21 KNOB SL BASS (TITANIUM)...(TITANIUM)

(TD10)

110 3-047-468-01 DAMPER

111 4-951-620-11 SCREW (2.6X10), +BVTP

112 3-363-898-01 CUSHION

113 3-040-916-01 FOOT (FRONT), RUBBER

LCD601 1-805-142-11 DISPLAY PANEL, LIQUID CRYSTAL

#3 7-685-247-19 SCREW +KTP 3X10 TYPE2 NON-SLIT

104 3-248-399-21 WINDOW (DISP) (BLUE)...(BLUE)

104 3-248-399-31 WINDOW (DISP) (SILVER)...(SILVER) (TD30)

104 3-248-399-41 WINDOW (DISP) (TITANIUM)...(TITANIUM)

104 3-248-399-61 WINDOW (DISP) (SILVER)...(SILVER) (E4)

34

(TD30)

Page 35

7-4. CHASSIS CD SECTION

CSD-TD10/TD30

158

154

#5

#4

151

152

157

155

165

156

151

153

151

KSM-213RDM

151

152

SW1

not supplied

(MOTOR board)

164

162

163

160

SW401

#6

161

159

#7

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

151 3-249-838-01 RUBBER, VIBRATION PROOF

152 3-916-006-01 SCREW (2.6X16)

153 3-248-388-01 COVER, CD

154 3-249-227-01 BASE (CHUCK)

155 1-471-248-11 MAGNET

156 3-249-228-01 HLDR (CHUCK)

157 3-249-229-01 PLATE (CHUCK)

158 3-248-391-01 LID (CD) (TITANIUM)...(TITANIUM) (TD10)

158 3-248-391-11 LID (CD) (SILVER)...(SILVER)

(TD10:CND,AEP,UK,KR,SP)

158 3-248-391-21 LID (CD) (BLUE)...(BLUE)

158 3-248-391-41 LID (CD) (SILVER)...(SILVER) (TD30)

158 3-248-391-51 LID (CD) (TITANIUM)...(TITANIUM) (TD30)

158 3-248-391-61 LID (CD) (SILVER)...(SILVER) (E4)

159 3-249-223-01 HLDR (CD) (LOCK)

160 3-248-389-11 SPR T CD

161 4-232-238-01 DAMPER

162 3-248-390-01 CHAS (CD) (TITANIUM)...(TITANIUM) (US,CND)

162 3-248-390-11 CHAS (CD) (SILVER)...(SILVER) (CND)

162 3-248-390-21 CHAS (CD) (BLUE)...(BLUE)

162 3-248-390-31 CHAS (CD) (SILVER)...(SILVER) (TD10:E4/TD30)

162 3-248-390-41 CHAS (CD) (TITANIUM)...(TITANIUM) (E4)

162 3-248-390-51 CHAS (CD) (SILVER)...(SILVER)

(TD10:AEP,UK,KR,SP)

163 3-249-224-01 SPR-C (LOCK)

164 3-249-222-01 LEVER (CD) (LOCK)

165 1-827-057-11 CABLE, FFC FLAT 16P

* SW1 1-572-085-21 SWITCH, LEAF (LIMIT)

SW401 1-786-487-11 SWITCH, LEAF (CD DOOR)

#4 7-685-851-04 SCREW +BVTT 2X4 (S)

#5 7-685-233-19 SCREW +KTP 2.6X6 TYPE2 NON-SLIT

#6 7-685-105-19 TPG +P 2X8, TYPE 2, NON-SLIT

#7 7-685-646-79 SCREW +BVTP 3X8 TYPE2 N-S

35

Page 36

CSD-TD10/TD30

7-5. CABINET REAR SECTION

not supplied

#2

#2

#1

208

PT001

206

209

206

212

210

SW901

HP002

#1

203

205

#1

204

#8

203

204

211

202

ANT001

207

#9

201

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

201 3-248-387-01 CABI REAR (TITANIUM)...(TITANIUM) (US,CND)

201 3-248-387-11 CABI REAR (SILVER)...(SILVER) (CND)

201 3-248-387-21 CABI REAR (SILVER)...(SILVER)

(TD10:AEP,UK,KR,SP)

201 3-248-387-31 CABI REAR (TITANIUM)...(TITANIUM) (E4)

201 3-248-387-41 CABI REAR (BLUE)...(BLUE)

201 3-248-387-51 CABI REAR (SILVER)...(SILVER) (TD10:E4/TD30)

* 202 A-3683-545-A BATT (B) BOARD, COMPLETE

203 1-688-129-11 BATT (C) BOARD

204 3-248-401-01 SPR T BATT A

* 205 A-3683-547-A BATT (A) BOARD, COMPLETE

206 4-951-620-71 SCREW (2.6)

207 3-248-386-01 ARM HANDLE (TITANIUM)...(TITANIUM)

207 3-248-386-11 ARM HANDLE (SILVER)...(SILVER)

(TD10:CND,AEP,UK,KR,SP)

207 3-248-386-21 ARM HANDLE (BLUE)...(BLUE)

207 3-248-386-31 ARM HANDLE (SILVER)...(SILVER)

(TD10:E4/TD30)

* 208 A-3683-544-A POWER BOARD, COMPLETE

209 3-250-450-01 AC (SOCKET) (COVER)

210 3-251-281-01 COVER, VOLTAGE SWITCH (EXCEPT E4)

210 3-253-687-01 COVER, VOLTAGE SWITCH (E4)

211 3-251-282-01 PLATE, VOLTAGE SWITCH (E4)

212 4-951-620-11 SCREW (2.6X10), +BVTP

ANT001 1-754-271-11 ANTENNA, TELESCOPIC (FM)

0 HP002 1-817-273-11 INLET, AC (AC -) (US,CND,MX,TW)

0 HP002 1-817-432-11 INLET (PSE27), AC (AC -)

0 PT001 1-439-616-11 TRANSFORMER, POWER (US,CND,MX,TW)

0 PT001 1-439-743-11 TRANSFORMER, POWER (AEP,UK,AUS,KR,SP)

0 PT001 1-439-744-11 TRANSFORMER, POWER (E4)

0 SW901 1-786-524-11 SWITCH, VOLTAGE SELECTION (AC VOLTAGE)

#1 7-685-647-79 SCREW +BVTP 3X10 TYPE2 N-S

#2 7-685-651-79 SCREW +BVTP 3X20 TYPE2

#8 7-623-508-01 LUG, 3

#9 7-621-773-87 SCREW +B 2.6X10

Les composants identifiés par une

marque 0 sont critiques pour

la sécurité.

Ne les remplacer que par une piéce

portant le numéro spécifié.

(AEP,UK,E4,AUS,KR,SP)

(E4)

36

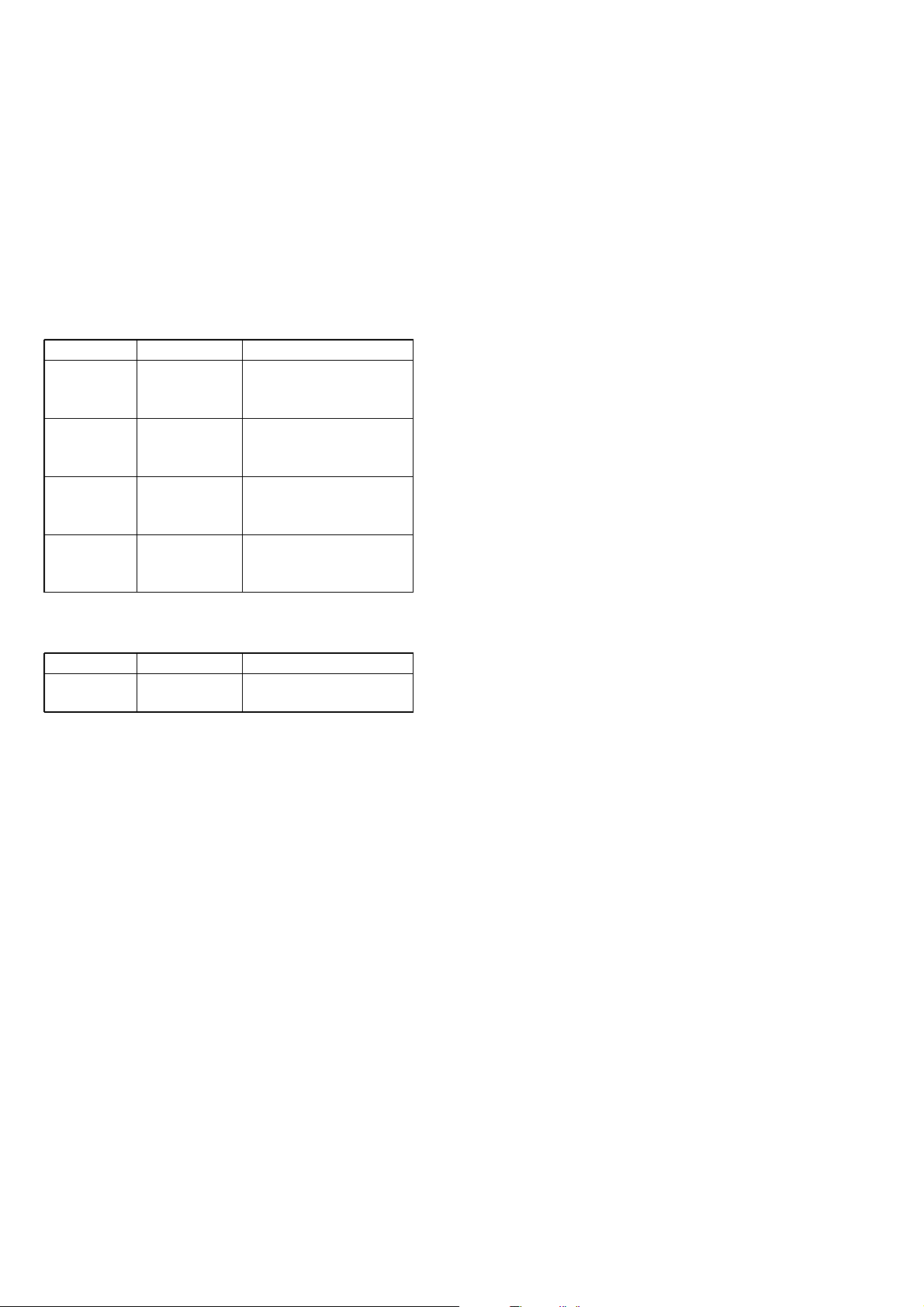

Page 37

7-6. TAPE MECHANISM SECTION

(MF-TD10)

CSD-TD10/TD30

not supplied

HE001

not supplied

not supplied

253

252

254

not supplied

HRP001

not supplied

not supplied

M501

not supplied

Ref. No. Part No. Description Remark

251 A-3172-046-A MF-TD10

252 3-257-812-01 BELT, MAIN

253 3-933-833-01 BELT, RF

254 3-933-825-01 ARM ASSY, PINCH ROLLER

251

Ref. No. Part No. Description Remark

HE001 1-500-813-11 HEAD, ERASE (ERASE)

HRP001 1-500-814-11 HEAD, REC/PLAY (REC/PB)

M501 X-3383-964-1 MOTOR SUB ASSY (CAPSTAN/REEL)

37

Page 38

CSD-TD10/TD30

7-7. CD MECHANISM SECTION

(KSM-213RDM)

303

304

301