Page 1

CSD-MD50

EZ

SERVICE MANUAL

MD/CD STEREO

RADIO CASSETTE RECORDER

MODEL CODE : 86HR8-0117(B)

86HR8-1111(W)

86HR8-4444(L)

86HR8-8888(ST)

BASIC TAPE MECHANISM : 2ZM-1R7

BASIC MD MECHANISM : 7ZG-9B2

BASIC CD MECHANISM : 3ZG-3E2

S/M Code No. 09-994-328-4N2

DATA

Page 2

TABLE OF CONTENTS

SPECIFICATIONS .................................................................................................................................. 3

ACCESSORIES/PACKAGE LIST ........................................................................................................... 3

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING ................................................ 4

Precaution to replace Optical block......................................................................................................... 5

DISASSEMBLY INSTRUCTIONS...................................................................................................... 6-10

ELECTRICAL MAIN PARTS LIST ................................................................................................... 11-15

TRANSISTOR ILLUSTRATION ............................................................................................................ 16

FL GRID ASSIGNMENT/ANODE CONNECTION .......................................................................... 17, 18

BLOCK DIAGRAM-1 (MAIN)........................................................................................................... 19, 20

BLOCK DIAGRAM-2 (SYSTEM CONTROL) .................................................................................. 21, 22

BLOCK DIAGRAM-3 (MD) .............................................................................................................. 23, 24

WIRING-1 (MAIN) ........................................................................................................................... 25, 26

SCHEMATIC DIAGRAM-1 (TUNER) .............................................................................................. 27, 28

SCHEMATIC DIAGRAM-2 (DECK)................................................................................................. 29, 30

SCHEMATIC DIAGRAM-3 (MAIN).................................................................................................. 31, 32

WIRING-2 (SYSTEM CONTROL/CD)............................................................................................. 33, 34

SCHEMATIC DIAGRAM-4 (SYSTEM CONTROL) ......................................................................... 35, 36

WIRING-3 (FL/KEY)........................................................................................................................ 37, 38

SCHEMATIC DIAGRAM-5 (CD) ..................................................................................................... 39, 40

WIRING-4 (POWER)....................................................................................................................... 41, 42

SCHEMATIC DIAGRAM-6 (FL/KEY/POWER)................................................................................ 43, 44

WIRING-5 (MD)............................................................................................................................... 45, 46

SCHEMATIC DIAGRAM-7 (MD) ..................................................................................................... 47, 48

WIRING-6 (MECHANISM) .............................................................................................................. 49, 50

TEST MODE ....................................................................................................................................51-55

ELECTRICAL ADJUSTMENT/PRACTICAL SERVICE FIGURE ..................................................... 56-58

IC DESCRIPTION ........................................................................................................................... 59-71

IC BLOCK DIAGRAM....................................................................................................................... 72-77

MECHANICAL PARTS LIST 1/1 ........................................................................................................... 78

MECHANICAL EXPLODED VIEW 1/1............................................................................................ 79, 80

TAPE MECHANISM EXPLODED VIEW 1/1 ................................................................................... 81, 82

TAPE MECHANISM PARTS LIST 1/1 .................................................................................................. 83

CD MECHANISM EXPLODED VIEW 1/2 ............................................................................................. 84

CD MECHANISM PARTS LIST 1/2 ...................................................................................................... 85

CD MECHANISM EXPLODED VIEW 2/2 ............................................................................................. 86

CD MECHANISM PARTS LIST 2/2 ...................................................................................................... 86

MD MECHANISM EXPLODED VIEW 1/3............................................................................................. 87

MD MECHANISM PARTS LIST 1/3...................................................................................................... 87

MD MECHANISM EXPLODED VIEW 2/3............................................................................................. 88

MD MECHANISM PARTS LIST 2/3...................................................................................................... 89

MD MECHANISM EXPLODED VIEW 3/3............................................................................................. 90

MD MECHANISM PARTS LIST 3/3...................................................................................................... 91

SPRING APPLICATION POSITION .....................................................................................................92

REFERENCE NAME LIST .................................................................................................................... 93

2

Page 3

SPECIFICATIONS

Design and specifications are subject to change without

•

notice.

Dolby noise reduction manufactured under license from

•

Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol

of Dolby Laboratories Licensing Corporation.

The word “BBE” and the “BBE symbol” are trademarks

•

of BBE Sound,Inc.

Under license from BBE Sound,Inc.

are trademarks

ACCESSORIES/PACKAGE LIST

REF. NO PART NO. KANRI DESCRIPTION

1 8Z-CK4-952-010 RC UNIT,RC-ZAT04

2 8Z-CK3-906-010 IB,EZ(9L)I

3 87-006-240-010 AM LOOP ANT CON(KO)

!

4 87-A80-081-010 AC CORD SET ASSY,EZ BLK

NO.

3

Page 4

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

This set employs laser. Therefore, be sure to follow carefully the

instructions below when servicing.

WARNING!

WHEN SERVICING, DO NOT APPROACH THE LASER EXIT

WITH THE EYE TOO CLOSELY. IN CASE IT IS NECESSARY TO

CONFIRM LASER BEAM EMISSION. BE SURE TO OBSERVE

FROM A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE OPTICAL

PICK-UP BLOCK.

Caution: Invisible laser radiation when

open and interlocks defeated avoid exposure to beam.

Advarsel:Usynling laserståling ved åbning,

når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

VAROITUS!

Laiteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyt-täjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

VARNING!

Om apparaten används på annat sätt än vad som specificeras i

denna bruksanvising, kan användaren utsättas för osynling

laserstrålning, som överskrider gränsen för laserklass 1.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

ATTENTION

L'utilisation de commandes, réglages ou procédures autres que

ceux spécifiés peut entraîner une dangereuse exposition aux

radiations.

ADVARSEL!

Usynlig laserståling ved åbning, når sikkerhedsafbrydereer ude

af funktion. Undgå udsættelse for stråling.

This Compact Disc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located on the rear

exterior.

CLASS 1

KLASSE 1

LUOKAN 1

KLASS 1

LASER PRODUCT

LASER PRODUKT

LASER LAITE

LASER APPARAT

4

Page 5

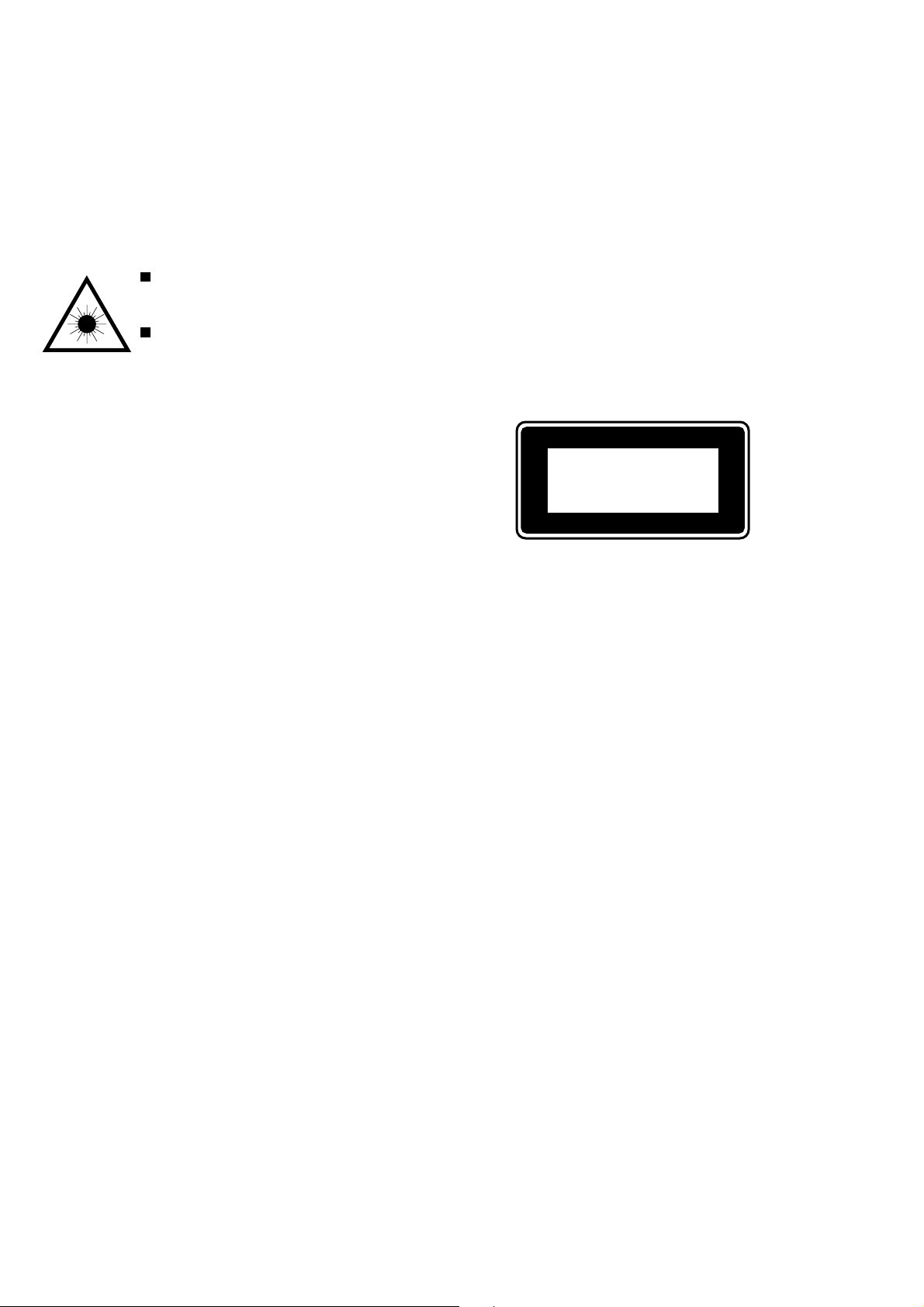

Precaution to replace Optical block

(KSS-213F)

Body or clothes electrostatic potential could ruin

laser diode in the optical block. Be sure ground

body and workbench, and use care the clothes

do not touch the diode.

1) After the connection, remove solder shown in

the right figure.

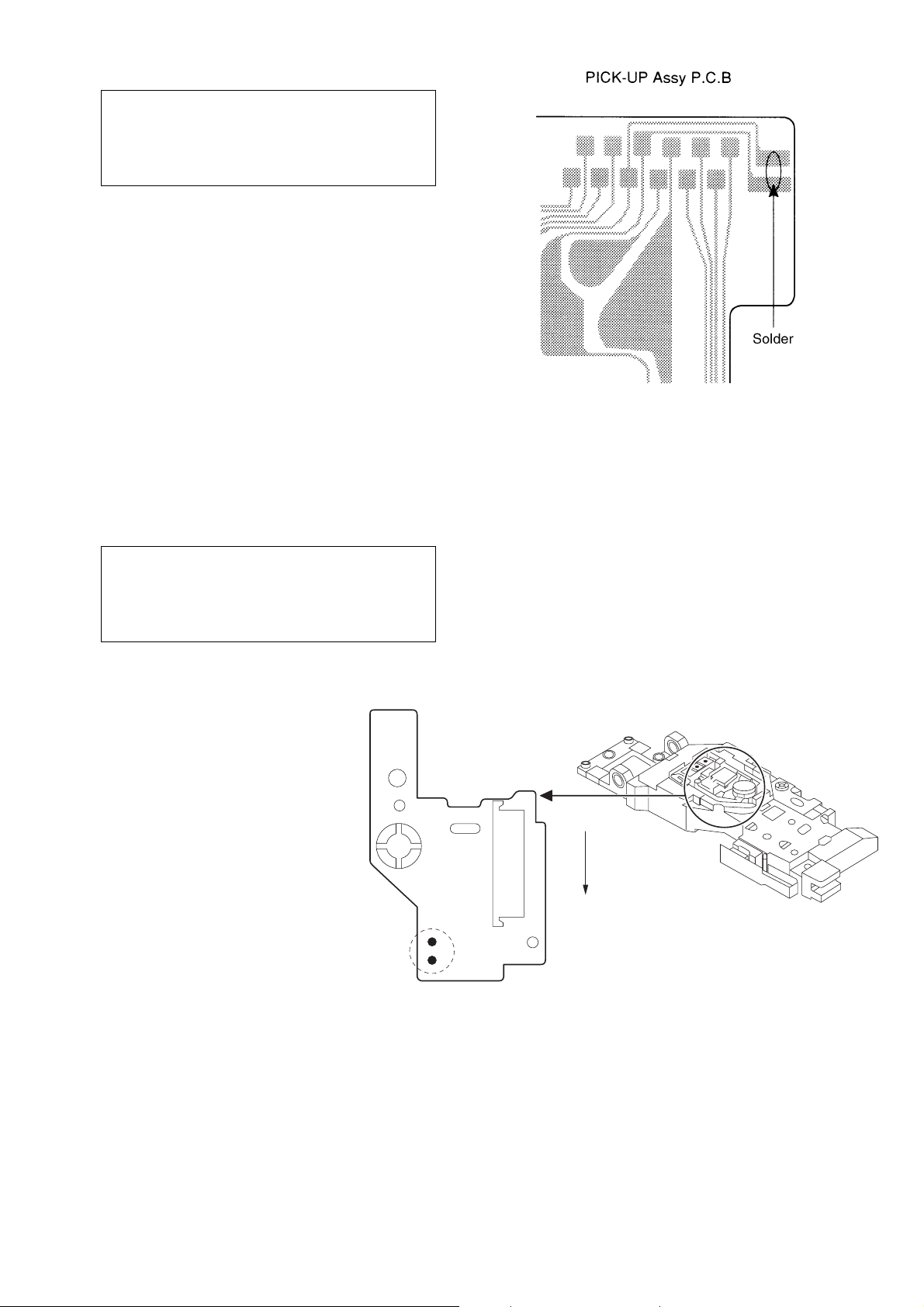

Precaution to replace Optical block

(KMS-260A)

Body or clothes electrostatic potential could ruin

laser diode in the optical block. Be sure ground

body and workbench, and use care the clothes

do not touch the diode.

1) After the connection, remove solder shown in

the right figure.

1

VEE

¡ TRK –

5

Page 6

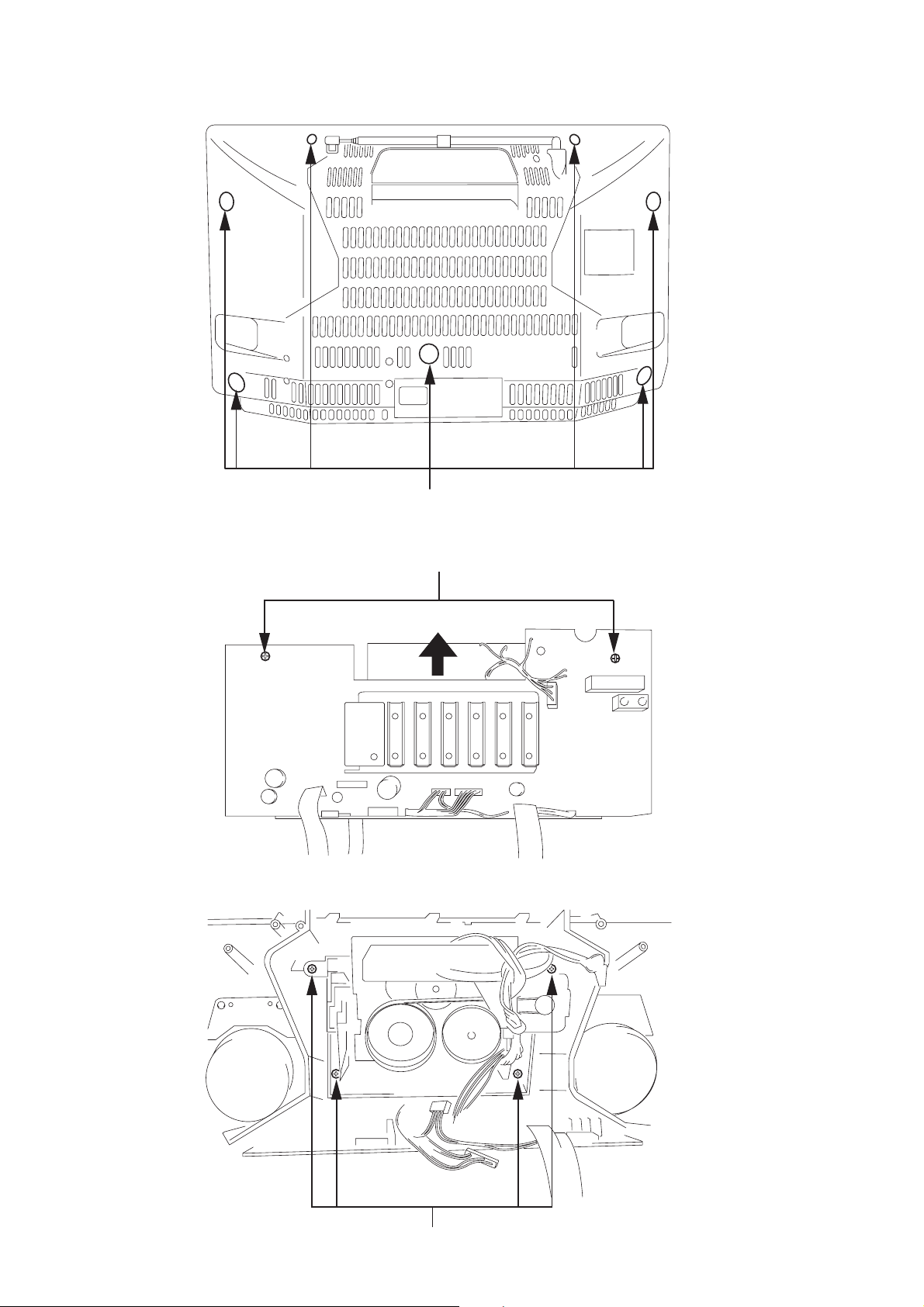

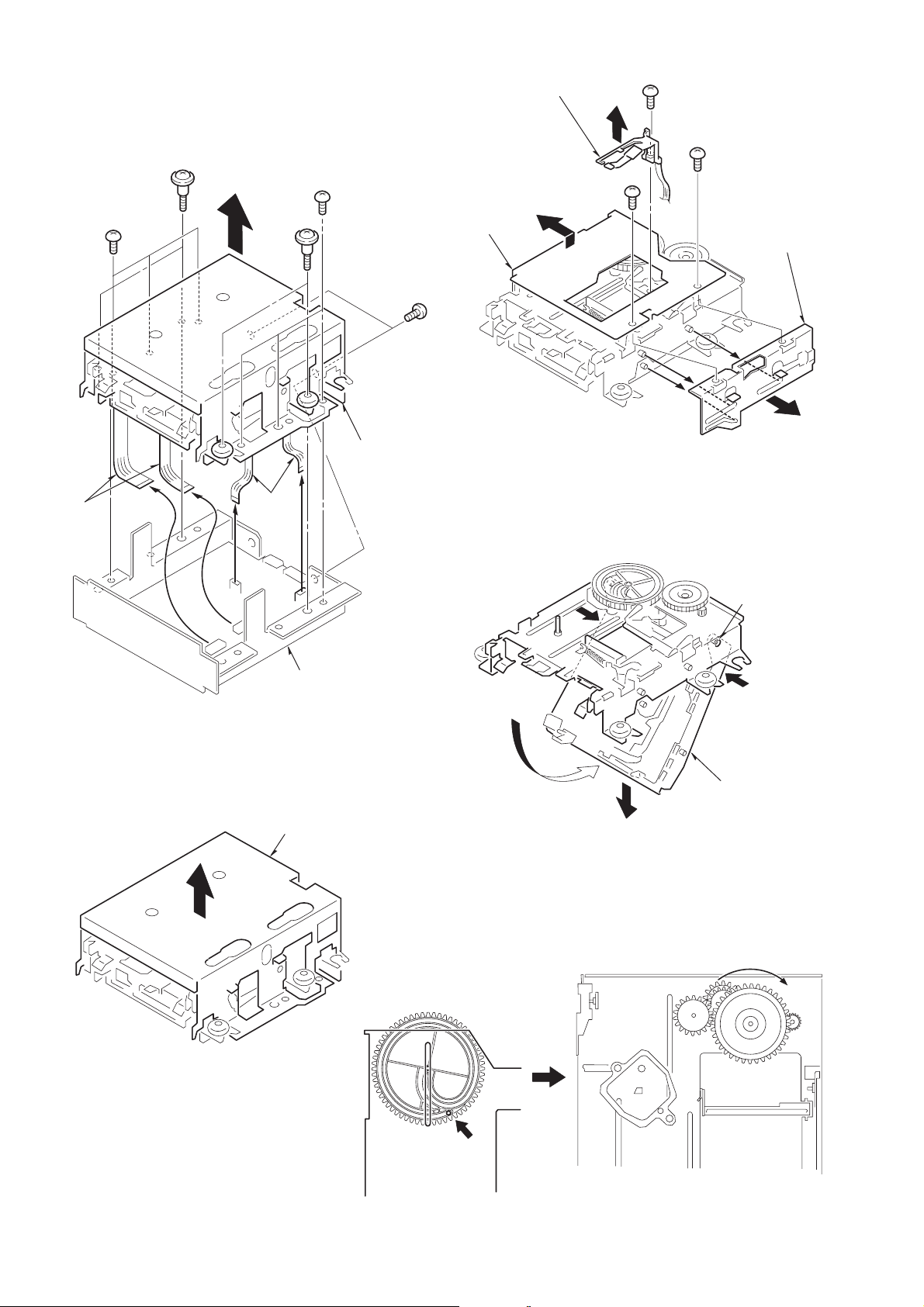

DISASSEMBLY INSTRUCTIONS

Disassembling Procedure

1. Remove the seven screws (A BVT2+3-18*7) and remove the rear cabinet.

A

2. Remove the two screws (B BVT2+3-12*2). Remove the MAIN C.B by pulling it upward.

B

3. Remove the four screws (C BVT2+3-12*4).

C

6

Page 7

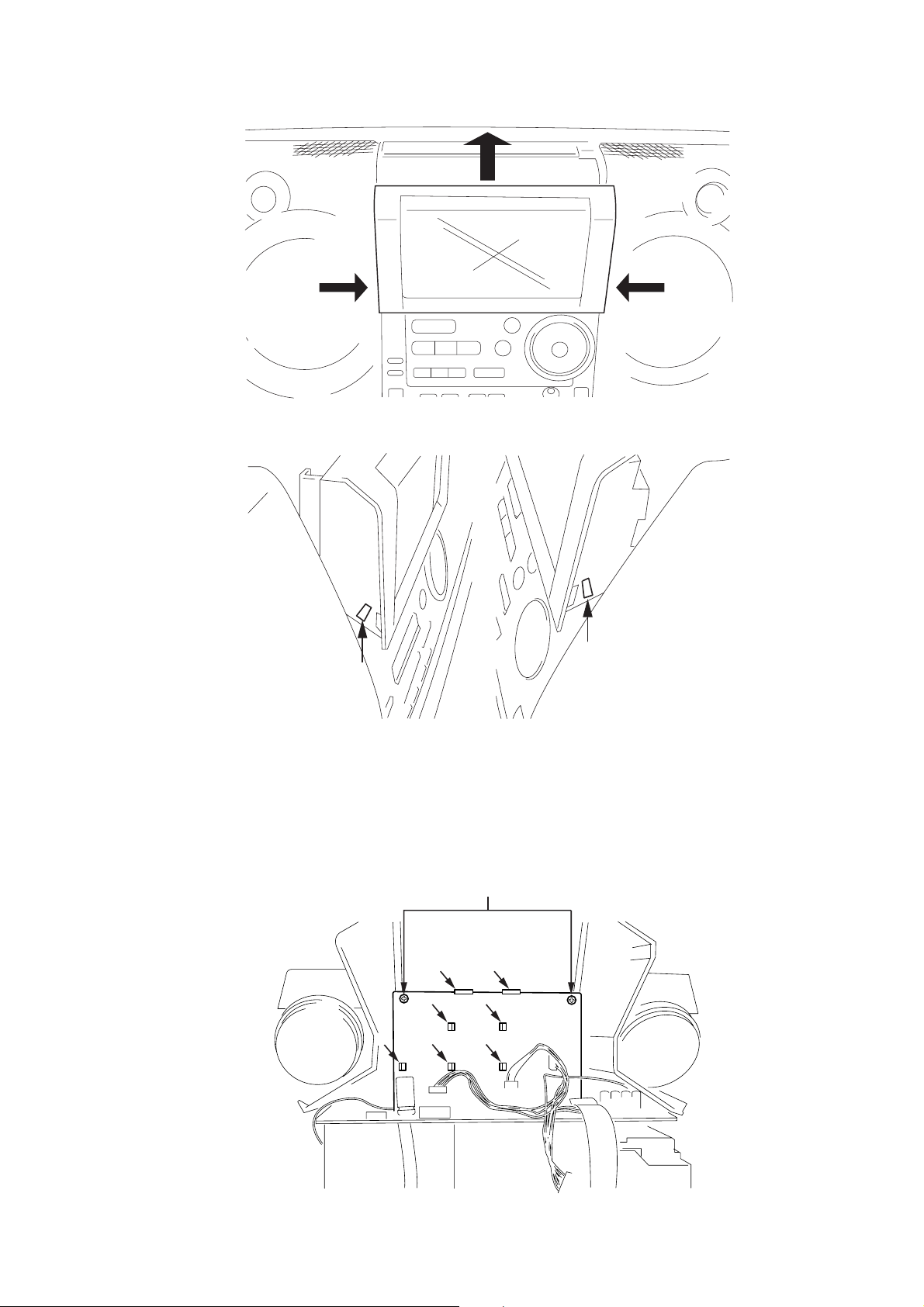

4. Open the deck lid. Release the two claws 1 and remove the PANEL DISP by pulling it upward.

11

1

1

5. Close the deck lid. Raise the deck block from the rear.

6. Remove the two screws (D BVT2+3-12*2). While raising the MAIN C.B., release the claws starting from 1 to 7, and remove

the MICOM/CD C.B.

D

4

1

23

6

7

5

7

Page 8

7. How to remove the COVER, FFC.

1) Remove the five screws (A BVT2+3-12*5) and remove the deck mechanism.

A

2) Remove the SPR T CASS from the rib and remove the BOX CASS.

3) Release the two claws of the COVER and FFC by pressing them in the direction of the arrow.

8

Page 9

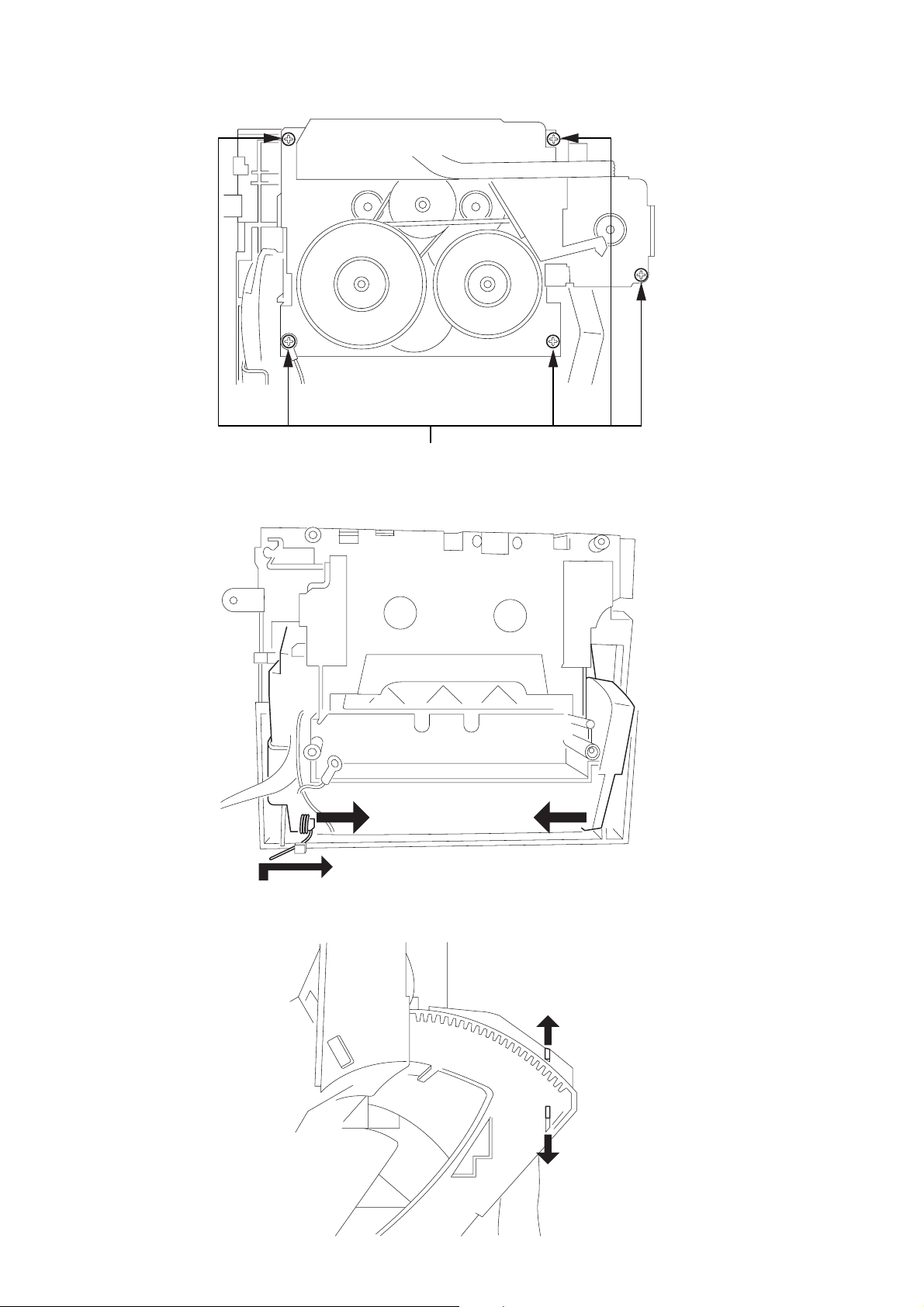

4) Raise the COVER and FFC in the direction of the arrow, and remove them.

8. How to remove FL C.B.

1) Release the two claws 2 and pull the top of the FL C.B. to the front. The FL C.B. can be removed.

9. How to remove the CD panel

1) Move the CAM SLIDE by 1 cm to the left.

2) Move down the DRIVE C.B. and establish the “un-chucking” status.

3) Press TRY, CD2 twice.

3

22

2

1

9

Page 10

10. Remove the four screws A (S-SCREW, MD) and screws B

(BVTT +3-6).

Remove the four FFCs from the connector, and remove the

MD MECHANISM in the direction of the arrow. (Fig-1)

A

B

HEAD, OWH RF325-74A

D

C

C

FFC

B

FFC

A

MD MECHANISM

PLA TE ASSY,

SIDE L

PLATE, SIDE R

B

Fig-3

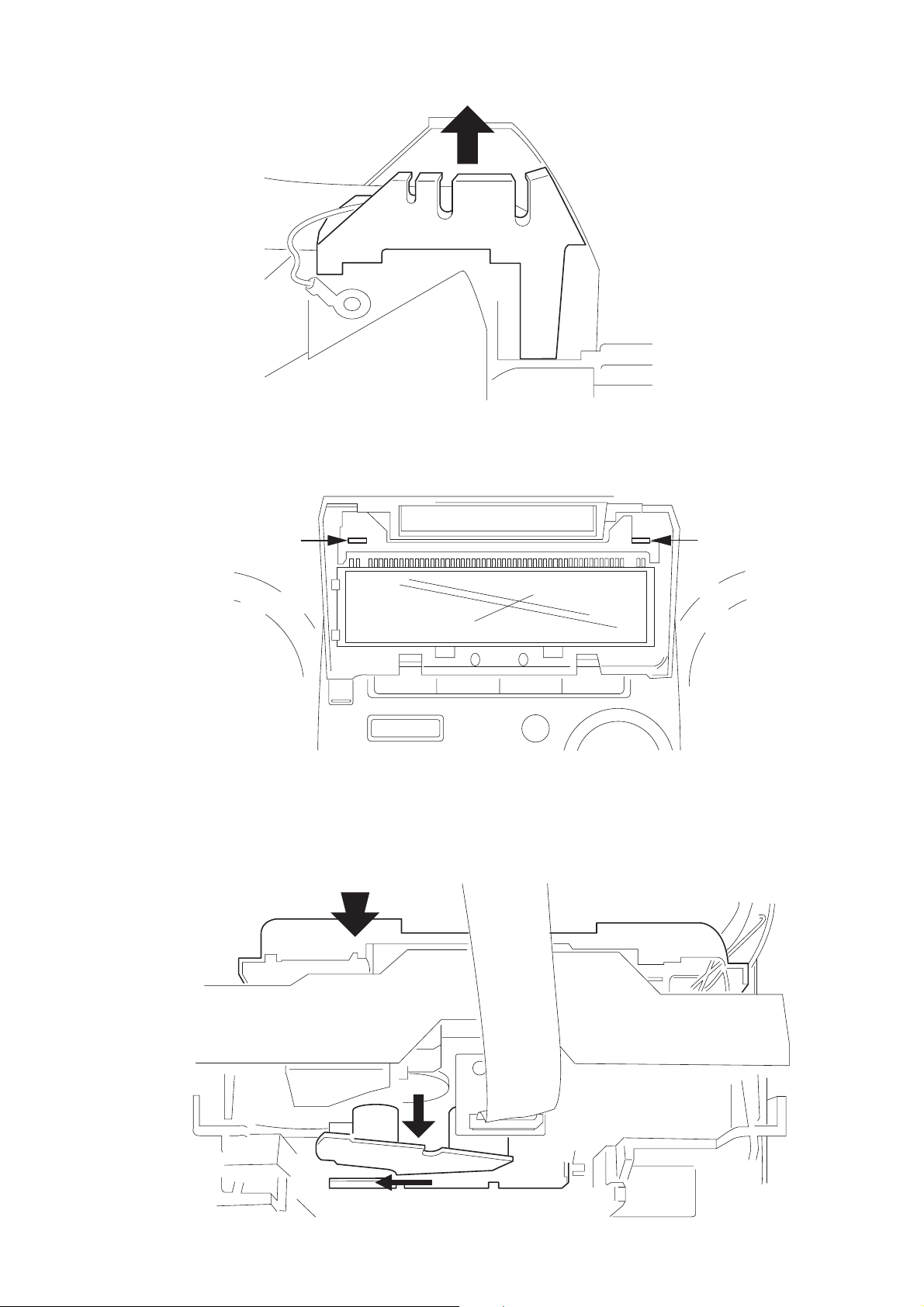

13. Open the 7ZG-3 A2 in the direction of the arrow (a), remove

the BOSS by pressing it gently in the direction of the arrow

(b), and remove the 7ZG-3 A2 in the direction of the arrow

(c). (Fig-4)

BOSS

b

HLDR, SHLD BOT

11. Remove the HIDR and SHLD TOP in the direction of the

arrow. (Fig-2)

HLDR, SHLD TOP

Fig-2

12. Remove the two screws C (VTT +2-4), and

remove the PLATE ASSY, SIDE L, PLATE, and

SIDE R in the direction of the arrow.

Remove the screw D (VW +1.7-5 w/o MFZN2C),

and remove the HEAD and OWH RF325-74A in

the direction of the arrow. (Fig-3)

Fig-1

a

c

Note During Assembling:

Rotate the gear fully in the direction of the arrow, and assemble

the main cam into the specified position as shown by the

illustration. (Fig-5)

Eject status Fully in this direction

Stud

Cover chassis

b

7ZG-3 A2

Fig-4

Fig-5

10

Page 11

ELECTRICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

NO.

IC

87-020-454-010 IC,DM6851

87-A20-707-010 C-IC,CXA2523AR

87-A20-708-010 C-IC,CXD2652AR

87-A20-709-040 C-IC,BD7910FV

87-ZG9-601-010 C-IC,CXP81952

87-ZG9-605-110 C-IC,CXP81952-521R

87-ZG9-607-010 C-IC,CXP81952M-523R

87-ZG9-608-010 C-IC,CXP81952M-547R

87-ZG9-606-040 C-IC,MN41V4400SJ-08

87-A20-755-080 C-IC,AK93C45AF

87-A20-710-040 C-IC,S-8110AMP

87-A20-711-040 C-IC,BA5970FP

87-A20-712-040 C-IC,BA6417F

87-A20-698-080 C-IC,AK4512VF

87-A21-110-040 C-IC,AK4519VF

87-017-853-040 IC,NJM2100V

87-A20-797-040 C-IC,NJU7221U30

87-A20-798-040 C-IC,NJU7221U35

87-A20-714-040 C-IC,NJM2370U33

87-A21-176-010 C-IC,LC75710NE

87-A21-218-010 IC,NJL64H380A

87-A21-211-010 IC,BA178M06T

8Z-CK3-620-010 C-IC,LC875164A-****

87-A20-976-040 C-IC,TC74HCT7007AF

87-A21-159-040 C-IC,AK93C65AF(4K)

87-A21-281-080 IC,PST9125-T

87-A20-446-010 C-IC,LA9241ML

87-A20-459-010 C-IC,LC78622ED

87-A20-445-010 IC,BA5936

87-A21-213-010 IC,BA17808T

87-A21-212-010 IC,BA17805T

87-A20-909-010 IC,LA4663

87-A21-116-040 C-IC,BH3862FS

87-A21-103-040 C-IC,MM1454XFBE

87-A20-419-010 IC,TA2068N

87-A21-210-010 IC,LC72121

87-A20-913-010 IC,LA1837NL

TRANSISTOR

89-318-155-080 TR,2SC1815 (0.4W)

87-026-447-080 TR,2SC1740S R

87-026-223-080 TR,DTC143TK

89-109-521-080 TR,2SA952 (0.6W)

87-026-610-080 TR,KTC3198GR

87-026-372-080 TR,RN1210

87-026-463-080 TR,2SA933S (0.3W)

87-026-609-080 TR,KTA1266GR

89-113-187-080 TR,2SA1318TU

87-026-245-080 TR,DTC114ES

89-406-555-080 TR,2SD655 (0.5W)

87-026-464-080 TR,DTC114TS (0.3W)

89-327-143-080 TR,2SC2714 (0.1W)

87-A30-072-080 C-TR,RT1P 144C

87-026-423-080 C-TR RN2305

89-115-884-080 CHIP -TRANSISTER 2SA1588Y

89-341-164-080 CHIP-TRANSISTOR,2SC4116 Y

87-026-412-080 C-TR RN1305

DIODE

87-017-447-010 DIODE,GBU4DL

87-070-274-080 DIODE,1N4003 SEM

87-A40-657-080 ZENER,MTZ J 13A

87-A40-488-080 DIODE,1SS244

87-A40-534-080 ZENER,MTZJ39A

87-017-090-080 ZENER,HZS5B3

87-070-136-080 ZENER,MTZJ5.1B

REF. NO PART NO. KANRI DESCRIPTION

87-020-465-080 DIODE,1SS133 (110MA)

87-A40-348-080 ZENER,MTZJ3.3A

87-A40-256-080 DIODE,RB441Q-40T-72

87-001-166-080 DIODE,1SS301

87-A40-412-040 C-DIODE,SB05-05CP

MAIN C.B

!

87-A90-505-080 FUSE CLAMP,TP00351-51

C100 87-018-205-080 CAP, CERA-SOL 0.022

C101 87-018-205-080 CAP, CERA-SOL 0.022

C102 87-018-205-080 CAP, CERA-SOL 0.022

C103 87-018-205-080 CAP, CERA-SOL 0.022

C104 87-010-892-090 CAPE6800-25SME

C105 87-010-196-080 CHIP CAPACITOR,0.1-25

C106 87-010-196-080 CHIP CAPACITOR,0.1-25

C107 87-015-997-090 CAP,E 2200-16 SME

C108 87-010-260-080 CAP, ELECT 47-25V

C109 87-010-198-080 CAP, CHIP 0.022

C110 87-010-198-080 CAP, CHIP 0.022

C111 87-010-198-080 CAP, CHIP 0.022

C112 87-010-198-080 CAP, CHIP 0.022

C113 87-010-124-090 CAP,E 4700-16

C114 87-010-196-080 CHIP CAPACITOR,0.1-25

C115 87-015-997-090 CAP,E 2200-16 SME

C116 87-010-196-080 CHIP CAPACITOR,0.1-25

C117 87-A10-944-080 CAP,E 100-100 M SMG

C118 87-018-211-080 CAP, CER 0.01-50

C120 87-010-196-080 CHIP CAPACITOR,0.1-25

C201 87-010-406-080 CAP, ELECT 22-50

C202 87-010-406-080 CAP, ELECT 22-50

C203 87-010-406-080 CAP, ELECT 22-50

C204 87-010-406-080 CAP, ELECT 22-50

C209 87-010-197-080 CAP, CHIP 0.01 DM

C211 87-010-260-080 CAP, ELECT 47-25V

C212 87-010-379-080 CAP, ELECT 22-16V

C216 87-016-279-080 CAP,E 1-50 BP

C217 87-016-279-080 CAP,E 1-50 BP

C220 87-010-401-080 CAP, ELECT 1-50V

C221 87-010-401-080 CAP, ELECT 1-50V

C222 87-010-248-080 CAP, ELECT 220-10V

C223 87-010-375-080 CAP,E 330-10 SME

C230 87-010-401-080 CAP, ELECT 1-50V

C231 87-010-401-080 CAP, ELECT 1-50V

C234 87-010-408-080 CAP, ELECT 47-50V

C235 87-010-405-080 CAP, ELECT 10-50V

C236 87-010-405-080 CAP, ELECT 10-50V

C237 87-010-263-080 CAP, ELECT 100-10V

C238 87-010-402-080 CAP, ELECT 2.2-50V

C239 87-010-402-080 CAP, ELECT 2.2-50V

C240 87-010-405-080 CAP, ELECT 10-50V

C241 87-010-405-080 CAP, ELECT 10-50V

C242 87-010-405-080 CAP, ELECT 10-50V

C243 87-010-405-080 CAP, ELECT 10-50V

C244 87-010-405-080 CAP, ELECT 10-50V

C245 87-010-405-080 CAP, ELECT 10-50V

C246 87-010-405-080 CAP, ELECT 10-50V

C247 87-010-405-080 CAP, ELECT 10-50V

C248 87-010-405-080 CAP, ELECT 10-50V

C249 87-010-405-080 CAP, ELECT 10-50V

C250 87-010-182-080 C-CAP,S 2200P-50 B

C251 87-010-182-080 C-CAP,S 2200P-50 B

C258 87-010-196-080 CHIP CAPACITOR,0.1-25

C403 87-012-156-080 C-CAP,S 220P-50 CH

C404 87-012-156-080 C-CAP,S 220P-50 CH

C409 87-010-374-080 CAP, ELECT 47-10V

C410 87-010-374-080 CAP, ELECT 47-10V

C421 87-010-405-080 CAP, ELECT 10-50V

C422 87-010-405-080 CAP, ELECT 10-50V

C429 87-010-405-080 CAP, ELECT 10-50V

NO.

11

Page 12

REF. NO PART NO. KANRI DESCRIPTION

NO.

C430 87-010-405-080 CAP, ELECT 10-50V

C431 87-010-184-080 CHIP CAPACITOR 3300P(K)

C432 87-010-184-080 CHIP CAPACITOR 3300P(K)

C433 87-010-406-080 CAP, ELECT 22-50

C434 87-010-406-080 CAP, ELECT 22-50

C435 87-012-278-080 CAP, CHIP SS 2200P BK

C436 87-012-278-080 CAP, CHIP SS 2200P BK

C437 87-010-380-080 CAP, ELECT 47-16V

C438 87-010-374-080 CAP, ELECT 47-10V

C440 87-010-248-080 CAP, ELECT 220-10V

C441 87-010-196-080 CHIP CAPACITOR,0.1-25

C442 87-010-263-080 CAP, ELECT 100-10V

C443 87-010-196-080 CHIP CAPACITOR,0.1-25

C451 87-010-183-080 C-CAP,S 2700P-50 B

C452 87-010-183-080 C-CAP,S 2700P-50 B

C453 87-010-183-080 C-CAP,S 2700P-50 B

C454 87-010-374-080 CAP, ELECT 47-10V

C455 87-010-197-080 CAP, CHIP 0.01 DM

C457 87-010-181-080 CAP,CHIP S 1800P

C458 87-010-183-080 C-CAP,S 2700P-50 B

C459 87-010-374-080 CAP, ELECT 47-10V

C470 87-010-406-080 CAP, ELECT 22-50

C471 87-010-406-080 CAP, ELECT 22-50

C701 87-010-260-080 CAP, ELECT 47-25V

C702 87-010-404-080 CAP, ELECT 4.7-50V

C703 87-012-286-080 CAP, U 0.01-25

C704 87-012-286-080 CAP, U 0.01-25

C709 87-012-195-080 C-CAP,U 100P-50CH

C710 87-012-195-080 C-CAP,U 100P-50CH

C711 87-012-195-080 C-CAP,U 100P-50CH

C712 87-012-195-080 C-CAP,U 100P-50CH

C713 87-012-286-080 CAP, U 0.01-25

C714 87-012-286-080 CAP, U 0.01-25

C717 87-012-286-080 CAP, U 0.01-25

C719 87-012-286-080 CAP, U 0.01-25

C721 87-012-176-080 CAP 15P

C722 87-012-176-080 CAP 15P

C723 87-012-274-080 CHIP CAP,U 1000P-50B

C725 87-012-274-080 CHIP CAP,U 1000P-50B

C727 87-010-196-080 CHIP CAPACITOR,0.1-25

C728 87-010-248-080 CAP, ELECT 220-10V

C729 87-012-274-080 CHIP CAP,U 1000P-50B

C755 87-012-286-080 CAP, U 0.01-25

C756 87-012-286-080 CAP, U 0.01-25

C757 87-012-188-080 C-CAP,U 47P-50 CH

C758 87-012-167-080 C-CAP,U 5P-50 CH

C760 87-010-196-080 CHIP CAPACITOR,0.1-25

C761 87-010-196-080 CHIP CAPACITOR,0.1-25

C763 87-010-829-080 CAP, U 0.047-16

C764 87-012-337-080 C-CAP,U 56P-50 CH

C765 87-012-286-080 CAP, U 0.01-25

C766 87-012-286-080 CAP, U 0.01-25

C769 87-010-408-080 CAP, ELECT 47-50V

C770 87-010-829-080 CAP, U 0.047-16

C771 87-010-265-080 CAP, ELECT 33-16V

C772 87-010-829-080 CAP, U 0.047-16

C773 87-010-196-080 CHIP CAPACITOR,0.1-25

C774 87-010-263-080 CAP, ELECT 100-10V

C775 87-010-404-080 CAP, ELECT 4.7-50V

C776 87-012-286-080 CAP, U 0.01-25

C777 87-010-400-080 CAP, ELECT 0.47-50V

C778 87-010-401-080 CAP, ELECT 1-50V

C779 87-010-401-080 CAP, ELECT 1-50V

C780 87-010-196-080 CHIP CAPACITOR,0.1-25

C781 87-010-405-080 CAP, ELECT 10-50V

C782 87-010-405-080 CAP, ELECT 10-50V

C783 87-012-286-080 CAP, U 0.01-25

C784 87-012-286-080 CAP, U 0.01-25

C785 87-010-805-080 CAP, S 1-16

C786 87-010-805-080 CAP, S 1-16

REF. NO PART NO. KANRI DESCRIPTION

C787 87-012-280-080 CAP, U 3300P-50

C788 87-012-280-080 CAP, U 3300P-50

C789 87-012-275-080 C-CAP,U 1200P-50 B

C790 87-012-275-080 C-CAP,U 1200P-50 B

C791 87-010-405-080 CAP, ELECT 10-50V

C793 87-012-273-080 C-CAP,U 820P-50 B

C794 87-010-406-080 CAP, ELECT 22-50

C795 87-010-596-080 CAP, S 0.047-16

C796 87-010-403-080 CAP, ELECT 3.3-50V

C797 87-012-278-080 CAP, CHIP SS 2200P BK

C798 87-012-278-080 CAP, CHIP SS 2200P BK

C799 87-010-829-080 CAP, U 0.047-16

C812 87-012-286-080 CAP, U 0.01-25

C814 87-012-286-080 CAP, U 0.01-25

C820 87-010-408-080 CAP, ELECT 47-50V

C821 87-012-286-080 CAP, U 0.01-25

C822 87-012-286-080 CAP, U 0.01-25

C823 87-012-286-080 CAP, U 0.01-25

C828 87-010-196-080 CHIP CAPACITOR,0.1-25

C829 87-010-196-080 CHIP CAPACITOR,0.1-25

C959 87-010-196-080 CHIP CAPACITOR,0.1-25

C960 87-010-196-080 CHIP CAPACITOR,0.1-25

C961 87-012-174-080 CAP CHIP CERA SS 12P CHJ

CF801 87-008-261-010 FILTER, SFE10.7MA5-A

CF802 87-008-261-010 FILTER, SFE10.7MA5-A

CN101 87-099-408-010 CONN,8P EH V WHT

CN201 87-A60-482-010 CONN,4P V 5267-04A-X

CN202 87-099-407-010 CONN,7P EH V WHT

CN203 87-A60-423-010 CONN,14P V TOC-B

CN204 87-099-556-010 CONN,10P TUC-P10X-B1

CN205 87-099-556-010 CONN,10P TUC-P10X-B1

CN206 87-099-670-010 CONN,9P TUC-P9X-B1

CN209 81-754-629-010 CONNECTOR, 2P

CN351 87-A60-625-010 CONN,8P V 2MM JMT

!

F101 87-035-192-010 FUSE, 4AT

!

F102 87-035-190-010 FUSE, 2AT

FFE801 A8-6ZA-19C-170 6ZA-1 YFEENC

JW102 87-008-372-080 FILTER, EMI BL OIRNI

JW105 87-008-372-080 FILTER, EMI BL OIRNI

L451 87-007-342-010 COIL,OSC 85K BIAS

L771 87-A50-266-010 COIL,FM DET-2N(TOK)

L772 87-A91-308-010 FLTR,PCFAZH- 450T (TOK)

L781 87-005-847-080 COIL,2.2UH(CECS)

L832 87-005-847-080 COIL,2.2UH(CECS)

L981 87-NF4-650-010 COIL,AM PACK 4N(TOK)

S101 87-A91-024-080 SW,TACT KSH0611BT

VR770 87-024-432-080 SFR,4.7K RH063EC

X721 87-A70-061-010 VIB,XTAL 4.500MHZ CSA-309

MICOM/CD C.B

C118 87-010-190-080 S CHIP F 0.01

C119 87-018-205-080 CAP, CERA-SOL 0.022

C120 87-018-205-080 CAP, CERA-SOL 0.022

C121 87-018-205-080 CAP, CERA-SOL 0.022

C122 87-018-205-080 CAP, CERA-SOL 0.022

C123 87-A10-011-090 CAP,E 2200-25 SMG

C124 87-010-236-080 CAP,E 1000-10 SME

C125 87-010-403-080 CAP, ELECT 3.3-50V

C301 87-012-368-080 C-CAP,S 0.1-50 F

C302 87-010-190-080 S CHIP F 0.01

C303 87-012-150-080 C-CAP,S 20P-50 CH

C304 87-012-150-080 C-CAP,S 20P-50 CH

C305 87-010-320-080 CHIP CAP 68P

C306 87-012-149-080 C-CAP,S 30P-50 CH

C307 87-010-312-080 C-CAP,S 15P-50 CH

C308 87-010-379-080 CAP, ELECT 22-16V

C309 87-012-368-080 C-CAP,S 0.1-50 F

C310 87-A10-908-010 CAP,DL 0.47F-5.5 Z FYD

C311 87-012-369-080 C-CAP,S 0.047-50F

NO.

12

Page 13

REF. NO PART NO. KANRI DESCRIPTION

NO.

C315 87-010-248-080 CAP, ELECT 220-10V

C316 87-010-178-080 CHIP CAP 1000P

C317 87-012-368-080 C-CAP,S 0.1-50 F

C321 87-012-153-080 C-CAP,S 120P-50 CH

C322 87-012-153-080 C-CAP,S 120P-50 CH

C323 87-012-153-080 C-CAP,S 120P-50 CH

C324 87-012-368-080 C-CAP,S 0.1-50 F

C325 87-012-368-080 C-CAP,S 0.1-50 F

C326 87-010-375-080 CAP, ELECT 330-10V

C327 87-010-379-080 CAP, ELECT 22-16V

C328 87-010-247-080 CAP, ELECT 100-50V

C329 87-012-369-080 C-CAP,S 0.047-50F

C330 87-010-406-080 CAP, ELECT 22-50

C331 87-010-406-080 CAP, ELECT 22-50

C355 87-010-190-080 S CHIP F 0.01

C357 87-010-405-080 CAP, ELECT 10-50V

C500 87-010-382-080 CAP, ELECT 22-25V

C501 87-010-401-080 CAP, ELECT 1-50V

C502 87-010-545-080 CAP, ELECT 0.22-50V

C503 87-012-157-080 C-CAP,S 330P-50 CH

C510 87-010-374-080 CAP, ELECT 47-10V

C511 87-010-197-080 CAP, CHIP 0.01 DM

C512 87-010-248-080 CAP, ELECT 220-10V

C514 87-010-544-080 CAP, ELECT 0.1-50V

C515 87-010-198-080 CAP, CHIP 0.022

C516 87-010-263-080 CAP, ELECT 100-10V

C518 87-010-405-080 CAP, ELECT 10-50V

C519 87-010-263-080 CAP, ELECT 100-10V

C520 87-010-197-080 CAP, CHIP 0.01 DM

C521 87-010-374-080 CAP, ELECT 47-10V

C523 87-010-176-080 C-CAP,S 680P-50 SL

C525 87-010-186-080 CAP,CHIP 4700P

C526 87-010-400-080 CAP, ELECT 0.47-50V

C527 87-012-156-080 C-CAP,S 220P-50 CH

C529 87-012-140-080 CAP 470P

C530 87-010-374-080 CAP, ELECT 47-10V

C531 87-010-401-080 CAP, ELECT 1-50V

C532 87-010-184-080 CHIP CAPACITOR 3300P(K)

C533 87-010-196-080 CHIP CAPACITOR,0.1-25

C534 87-010-221-080 CAP, ELECT 470-10V

C545 87-010-404-080 CAP, ELECT 4.7-50V

C549 87-010-314-080 C-CAP,S 22P-50V

C552 87-010-196-080 CHIP CAPACITOR,0.1-25

C554 87-012-154-080 C-CAP,S 150P-50 CH

C555 87-010-196-080 CHIP CAPACITOR,0.1-25

C556 87-010-248-080 CAP, ELECT 220-10V

C557 87-010-405-080 CAP, ELECT 10-50V

C558 87-010-405-080 CAP, ELECT 10-50V

C559 87-010-196-080 CHIP CAPACITOR,0.1-25

C560 87-010-196-080 CHIP CAPACITOR,0.1-25

C561 87-010-263-080 CAP, ELECT 100-10V

C562 87-010-314-080 C-CAP,S 22P-50V

C563 87-010-314-080 C-CAP,S 22P-50V

C564 87-010-404-080 CAP, ELECT 4.7-50V

C565 87-010-196-080 CHIP CAPACITOR,0.1-25

C566 87-010-315-080 C-CAP,S 27P-50 CH

C570 87-010-196-080 CHIP CAPACITOR,0.1-25

C571 87-010-196-080 CHIP CAPACITOR,0.1-25

C572 87-010-196-080 CHIP CAPACITOR,0.1-25

C573 87-010-196-080 CHIP CAPACITOR,0.1-25

C574 87-010-405-080 CAP, ELECT 10-50V

C575 87-010-405-080 CAP, ELECT 10-50V

C576 87-010-196-080 CHIP CAPACITOR,0.1-25

C577 87-A10-096-080 CAP,E 1000-16

C578 87-010-196-080 CHIP CAPACITOR,0.1-25

C579 87-012-156-080 C-CAP,S 220P-50 CH

C585 87-018-127-080 CAP, CER 470P-50V

C588 87-010-196-080 CHIP CAPACITOR,0.1-25

C589 87-010-196-080 CHIP CAPACITOR,0.1-25

CN301 87-099-567-010 CONN,10P TUC-P10P-B1

REF. NO PART NO. KANRI DESCRIPTION

NO.

CN302 87-099-668-010 CONN,9P TUC-P 9P-B1

CN303 87-099-567-010 CONN,10P TUC-P10P-B1

CN304 87-A60-422-010 CONN,8P V TOC-B

CN306 87-099-749-010 CONN,9P V 9604SC

CN308 87-A60-845-010 CONN,6P TRC-X06P-A2

CN309 87-A60-920-010 CONN,8P TRC-X08P-A2

CN312 87-A60-685-010 CONN,4P H WHT EH

CN500 87-A60-424-010 CONN,16P V TOC-B

CN501 87-A60-061-010 CONN,06P V 9604S-06C

CN502 87-A60-062-010 CONN,05P V 9604S-05C

CNA301 8Z-CK3-619-010 CONN ASSY,7P V WHT H.P

CNA401 8Z-CK3-616-010 CONN ASSY,9P V WHT CASS

J201 87-A60-420-010 JACK,3.5 ST (MSC)

JW213 87-003-219-010 FERRITE BEAD-BLO2RN2

JW214 87-003-219-010 FERRITE BEAD-BLO2RN2

JW238 87-003-149-080 COIL,47UH

JW284 87-003-149-080 COIL,47UH

JW285 87-003-149-080 COIL,47UH

JW286 87-003-149-080 COIL,47UH

JW238 87-003-149-080 COIL,47UH

SFR501 87-024-176-080 SEMI-FIXED RESISTOR, 100K

X301 87-030-273-010 VIB,XTAL 32.768K5PPM

X302 87-A70-070-080 VIB,CER 5.76MHZ CRHF

X501 87-A70-166-080 VIB,CER 16.93MHZ MXZ140 0.3%

KEY C.B

C318 87-018-209-080 CAP, CERA-SOL 0.1

C319 87-018-209-080 CAP, CERA-SOL 0.1

C320 87-010-374-080 CAP, ELECT 47-10V

C370 87-018-209-080 CAP, CERA-SOL 0.1

C371 87-018-209-080 CAP, CERA-SOL 0.1

CN310 87-A60-846-010 CONN,6P TRC-X06X-A2

CN311 87-A60-921-010 CONN,8P TRC-X08X-A2

D306 87-A40-664-080 LED,SEL6214S RED

D307 87-A40-664-080 LED,SEL6214S RED

D308 87-A40-664-080 LED,SEL6214S RED

D309 87-A40-664-080 LED,SEL6214S RED

D310 87-A40-664-080 LED,SEL6214S RED

S301 87-A91-024-080 SW,TACT KSH0611BT

S302 87-A91-024-080 SW,TACT KSH0611BT

S303 87-A91-024-080 SW,TACT KSH0611BT

S304 87-A91-024-080 SW,TACT KSH0611BT

S305 87-A91-024-080 SW,TACT KSH0611BT

S306 87-A91-024-080 SW,TACT KSH0611BT

S307 87-A91-024-080 SW,TACT KSH0611BT

S308 87-A91-024-080 SW,TACT KSH0611BT

S309 87-A91-024-080 SW,TACT KSH0611BT

S310 87-A91-024-080 SW,TACT KSH0611BT

S311 87-A91-024-080 SW,TACT KSH0611BT

S312 87-A91-024-080 SW,TACT KSH0611BT

S313 87-A91-024-080 SW,TACT KSH0611BT

S314 87-A91-024-080 SW,TACT KSH0611BT

S315 87-A91-024-080 SW,TACT KSH0611BT

S316 87-A91-024-080 SW,TACT KSH0611BT

S317 87-A91-024-080 SW,TACT KSH0611BT

S318 87-A91-024-080 SW,TACT KSH0611BT

S319 87-A91-024-080 SW,TACT KSH0611BT

S320 87-A91-024-080 SW,TACT KSH0611BT

S321 87-A91-024-080 SW,TACT KSH0611BT

S322 87-A91-024-080 SW,TACT KSH0611BT

S323 87-A91-024-080 SW,TACT KSH0611BT

SW301 87-A90-646-010 SW,RTRY 3-2-1 RE0131

FL C.B

C332 87-012-368-080 C-CAP,S 0.1-50 F

C333 87-012-368-080 C-CAP,S 0.1-50 F

C334 87-012-149-080 C-CAP,S 30P-50 CH

C335 87-012-369-080 C-CAP,S 0.047-50F

13

Page 14

REF. NO PART NO. KANRI DESCRIPTION

C339 87-012-156-080 C-CAP,S 220P-50 CH

C340 87-012-156-080 C-CAP,S 220P-50 CH

C341 87-012-156-080 C-CAP,S 220P-50 CH

C342 87-012-156-080 C-CAP,S 220P-50 CH

C343 87-012-156-080 C-CAP,S 220P-50 CH

C344 87-012-156-080 C-CAP,S 220P-50 CH

C345 87-012-156-080 C-CAP,S 220P-50 CH

C346 87-012-156-080 C-CAP,S 220P-50 CH

C347 87-012-156-080 C-CAP,S 220P-50 CH

C348 87-012-156-080 C-CAP,S 220P-50 CH

C349 87-012-156-080 C-CAP,S 220P-50 CH

C350 87-012-156-080 C-CAP,S 220P-50 CH

C351 87-012-156-080 C-CAP,S 220P-50 CH

C352 87-012-156-080 C-CAP,S 220P-50 CH

C353 87-012-156-080 C-CAP,S 220P-50 CH

C354 87-012-156-080 C-CAP,S 220P-50 CH

CN307 87-A60-078-010 CONN,09P H 9604S-09F

FL301 8Z-CK3-622-010 FL,16-ST-32GNK

POWER C.B

CNA100 8Z-CK3-617-010 CONN ASSY,8P V WHT POWER MAIN

!

ICF100 87-A91-276-080 FUSE,125MA 125V F 251

!

J101 87-049-784-010 AC JACK E

!

PT101 8Z-CK3-626-010 PT,ZCK-3 E

!

PT102 8Z-NF8-662-010 PT,SUB ZNF-8(E)

MD MAIN C.B

C100 87-016-296-080 C-CAP,TN 22-4SV(A)

C101 87-016-296-080 C-CAP,TN 22-4SV(A)

C102 87-012-286-080 CAP, U 0.01-25

C103 87-010-787-080 CAP, U 0.022-25

C104 87-010-662-080 C-CAP,E 22-6.3

C105 87-010-831-080 C-CAP,U,0.1-16F

C106 87-016-462-080 C-CAP,S 1-16 F

C107 87-012-195-080 C-CAP,U 100P-50CH

C108 87-012-274-080 CHIP CAP,U 1000P-50B

C109 87-016-436-080 C-CAP,TN 47-4(B2)

C111 87-016-296-080 C-CAP,TN 22-4SV(A)

C112 87-012-286-080 CAP, U 0.01-25

C113 87-012-284-080 CAP, U 6800P-50

C114 87-010-828-080 CHIP CAPACITOR,U 0.033-25F

C115 87-A10-369-080 C-CAP,S 0.47-16 K B

C116 87-012-282-080 CAP, U 4700P-50

C117 87-016-462-080 C-CAP,S 1-16 F

C118 87-012-282-080 CAP, U 4700P-50

C119 87-016-491-080 C-CAP,S 0.22-16 FZ

C120 87-010-787-080 CAP, U 0.022-25

C121 87-012-286-080 CAP, U 0.01-25

C122 87-010-829-080 CAP, U 0.047-16

C123 87-012-286-080 CAP, U 0.01-25

C124 87-010-662-080 C-CAP,E 22-6.3

C125 87-010-662-080 C-CAP,E 22-6.3

C126 87-010-831-080 C-CAP,U,0.1-16F

C201 87-010-831-080 C-CAP,U,0.1-16F

C202 87-010-831-080 C-CAP,U,0.1-16F

C203 87-010-785-080 C-CAP,U0.015-25BK

C204 87-016-461-080 C-CAP,S 0.47-16F

C205 87-010-831-080 C-CAP,U,0.1-16F

C206 87-012-270-080 CAP, U 470P-50

C207 87-016-461-080 C-CAP,S 0.47-16F

C208 87-012-286-080 CAP, U 0.01-25

C209 87-010-831-080 C-CAP,U,0.1-16F

C210 87-012-172-080 CAPACITOR CHIP U 10P CH

C211 87-012-172-080 CAPACITOR CHIP U 10P CH

C212 87-012-195-080 C-CAP,U 100P-50CH

C213 87-010-662-080 C-CAP,E 22-6.3

C214 87-012-274-080 CHIP CAP,U 1000P-50B

C217 87-012-188-080 C-CAP,U 47P-50 CH

NO.

C218 87-012-172-080 CAPACITOR CHIP U 10P CH

C219 87-016-296-080 C-CAP,TN 22-4SV(A)

C220 87-010-662-080 C-CAP,E 22-6.3

C221 87-010-831-080 C-CAP,U,0.1-16F

C222 87-016-444-080 C-CAP,TN 47-10 F95E

C223 87-010-831-080 C-CAP,U,0.1-16F

C224 87-A10-685-080 C-CAP,S 470P-100 J CH

C225 87-010-831-080 C-CAP,U,0.1-16F

C226 87-010-831-080 C-CAP,U,0.1-16F

C227 87-012-274-080 CHIP CAP,U 1000P-50B

C228 87-012-274-080 CHIP CAP,U 1000P-50B

C229 87-012-274-080 CHIP CAP,U 1000P-50B

C232 87-012-274-080 CHIP CAP,U 1000P-50B

C233 87-012-274-080 CHIP CAP,U 1000P-50B

C236 87-010-831-080 C-CAP,U,0.1-16F

C300 87-010-831-080 C-CAP,U,0.1-16F

C301 87-010-831-080 C-CAP,U,0.1-16F

C302 87-010-831-080 C-CAP,U,0.1-16F

C305 87-016-462-080 C-CAP,S 1-16 F

C307 87-010-831-080 C-CAP,U,0.1-16F

C308 87-010-831-080 C-CAP,U,0.1-16F

C311 87-010-662-080 C-CAP,E 22-6.3

C312 87-012-195-080 C-CAP,U 100P-50CH

C321 87-012-274-080 CHIP CAP,U 1000P-50B

C322 87-012-274-080 CHIP CAP,U 1000P-50B

C323 87-012-274-080 CHIP CAP,U 1000P-50B

C324 87-012-274-080 CHIP CAP,U 1000P-50B

C325 87-012-274-080 CHIP CAP,U 1000P-50B

C400 87-010-831-080 C-CAP,U,0.1-16F

C401 87-010-831-080 C-CAP,U,0.1-16F

C402 87-010-831-080 C-CAP,U,0.1-16F

C403 87-010-831-080 C-CAP,U,0.1-16F

C404 87-010-831-080 C-CAP,U,0.1-16F

C405 87-010-661-080 C-CAP,E 10-16

C406 87-010-779-080 C-CAP,E 100-6.3

C407 87-012-197-080 C-CAP,U 150P-50 CH

C408 87-012-197-080 C-CAP,U 150P-50 CH

C411 87-012-271-080 CAP, U 560P-50

C412 87-012-271-080 CAP, U 560P-50

C413 87-012-197-080 C-CAP,U 150P-50 CH

C414 87-012-197-080 C-CAP,U 150P-50 CH

C417 87-012-268-080 C-CAP,U 330P-50 B

C418 87-012-268-080 C-CAP,U 330P-50 B

C423 87-012-286-080 CAP, U 0.01-25

C424 87-012-286-080 CAP, U 0.01-25

C429 87-012-286-080 CAP, U 0.01-25

C430 87-012-286-080 CAP, U 0.01-25

C431 87-010-779-080 C-CAP,E 100-6.3

C434 87-010-831-080 C-CAP,U,0.1-16F

C501 87-010-831-080 C-CAP,U,0.1-16F

C502 87-010-831-080 C-CAP,U,0.1-16F

C503 87-010-662-080 C-CAP,E 22-6.3

C504 87-010-831-080 C-CAP,U,0.1-16F

C505 87-010-662-080 C-CAP,E 22-6.3

C506 87-010-831-080 C-CAP,U,0.1-16F

C507 87-010-661-080 C-CAP,E 10-16

C508 87-010-831-080 C-CAP,U,0.1-16F

C509 87-010-662-080 C-CAP,E 22-6.3

C510 87-010-831-080 C-CAP,U,0.1-16F

C511 87-010-661-080 C-CAP,E 10-16

C513 87-010-661-080 C-CAP,E 10-16

C514 87-010-661-080 C-CAP,E 10-16

C515 87-012-337-080 C-CAP,U 56P-50 CH

C516 87-012-337-080 C-CAP,U 56P-50 CH

C517 87-012-278-080 C-CAP,U 2200P-50 B

C518 87-012-278-080 C-CAP,U 2200P-50 B

C519 87-010-831-080 C-CAP,U,0.1-16F

C520 87-010-661-080 C-CAP,E 10-16

C521 87-010-831-080 C-CAP,U,0.1-16F

C522 87-010-661-080 C-CAP,E 10-16

REF. NO PART NO. KANRI DESCRIPTION

NO.

14

Page 15

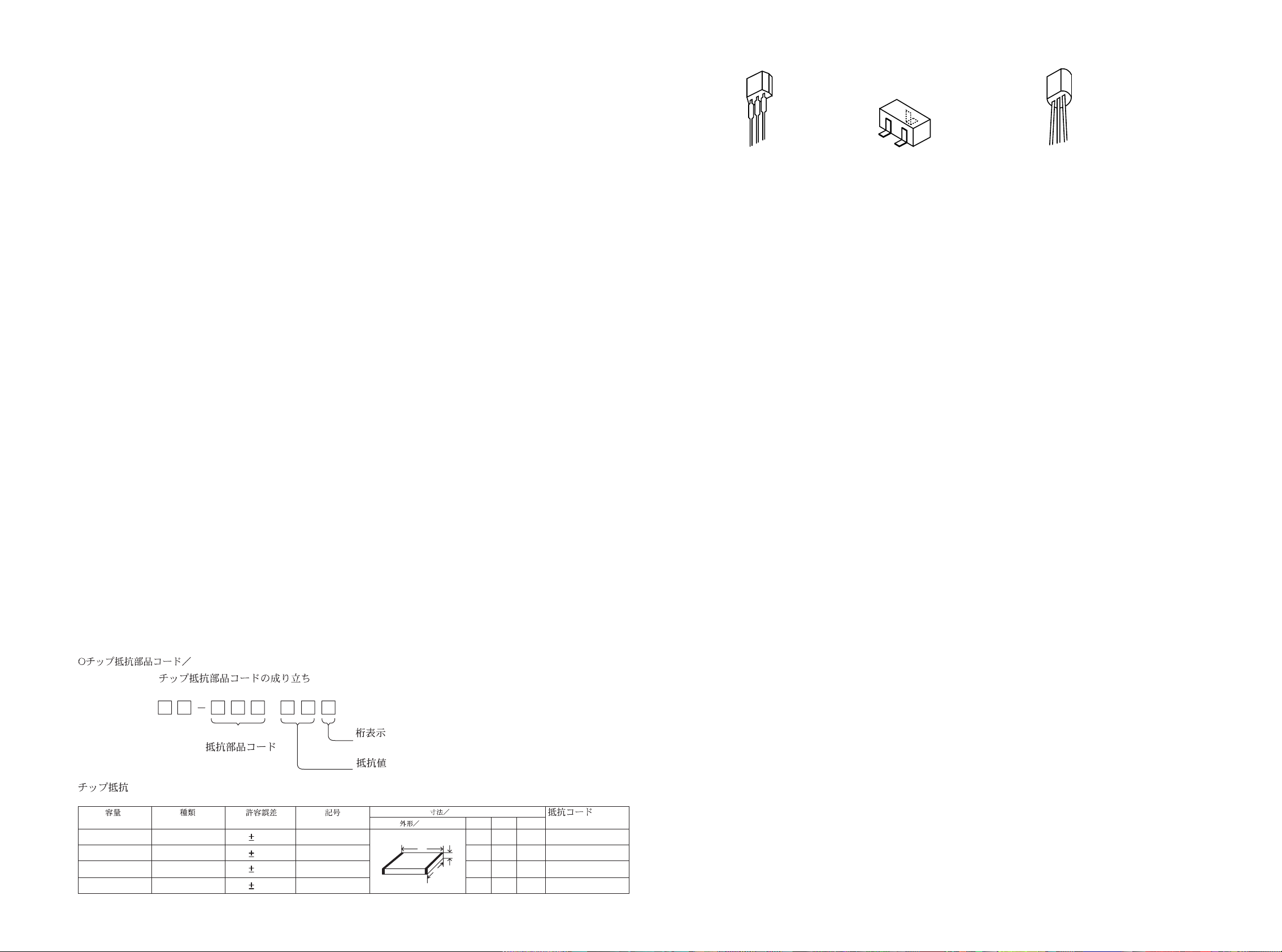

TRANSISTOR ILLUSTRATION

REF. NO PART NO. KANRI DESCRIPTION

NO.

C523 87-010-662-080 C-CAP,E 22-6.3

C524 87-010-662-080 C-CAP,E 22-6.3

C525 87-012-274-080 CHIP CAP,U 1000P-50B

C526 87-012-274-080 CHIP CAP,U 1000P-50B

C527 87-010-661-080 C-CAP,E 10-16

C528 87-010-661-080 C-CAP,E 10-16

C530 87-010-831-080 C-CAP,U,0.1-16F

C531 87-010-831-080 C-CAP,U,0.1-16F

C600 87-010-662-080 C-CAP,E 22-6.3

C601 87-010-779-080 C-CAP,E 100-6.3

C602 87-010-779-080 C-CAP,E 100-6.3

C603 87-010-662-080 C-CAP,E 22-6.3

C604 87-010-779-080 C-CAP,E 100-6.3

C605 87-012-286-080 CAP, U 0.01-25

C607 87-010-831-080 C-CAP,U,0.1-16F

C608 87-010-831-080 C-CAP,U,0.1-16F

CN400 87-A60-027-080 C-CONN,8P H WHT

CN401 87-A60-062-010 CONN,05P V 9604S-05C

FB501 87-A90-828-080 C-F-BEAD, BK1608LM182

L100 87-A50-117-080 C-COIL,10UHLQH3C

L101 87-A50-012-080 C-COIL,100UH LQH3C

L102 87-A50-117-080 C-COIL,10UHLQH3C

L103 87-A50-117-080 C-COIL,10UHLQH3C

L201 87-A50-117-080 C-COIL,10UHLQH3C

L202 87-A50-117-080 C-COIL,10UHLQH3C

L203 87-A50-116-080 C-COIL,4.7UHLQH3C

L301 87-A50-117-080 C-COIL,10UHLQH3C

L501 87-A50-116-080 C-COIL,4.7UHLQH3C

L502 87-A50-116-080 C-COIL,4.7UHLQH3C

L503 87-A50-116-080 C-COIL,4.7UHLQH3C

L504 87-005-774-080 C-COIL,4BLH

L505 87-005-774-080 C-COIL,4BLH

L611 87-A50-163-080 C-COIL,ZBFS5101-PT

L612 87-005-512-080 C-COIL,BLM21A05

L613 87-005-512-080 C-COIL,BLM21A05

L614 87-A50-163-080 C-COIL,ZBFS5101-PT

L615 87-A90-034-080 C-FLTR,EMI BLM41P750

L616 87-A50-163-080 C-COIL,ZBFS5101-PT

R423 87-025-564-080 C-RES,U M/F 47K D

R424 87-025-564-080 C-RES,U M/F 47K D

R425 87-022-583-080 C-RES,U M/F 12K D

R426 87-022-583-080 C-RES,U M/F 12K D

X200 87-A70-105-080 C-VIB,XTAL 22.5792MHZ SMD-49

X301 87-A70-100-080 C-VIB,CER 12.0MHZ PBRC-BR-A

REF. NO PART NO. KANRI DESCRIPTION

NO.

LOAD C.B

FC451 87-ZG9-604-010 FF-CABLE,5P 1.25 100MM

M450 87-A90-672-010 MOT,M25E-4

SW451 87-A90-673-010 SW,MICRO ESE11SH1C

SW452 87-A90-117-010 SW,PUSH 1-1-1 MPU1037MLB0

MECHA C.B

FC400 87-ZG9-603-010 FF-CABLE,8P 1.0 120MM

M400 87-A90-413-010 MOT,FF-110PH 9

M401 87-A90-616-010 MOT,FF-N30VA

SW400 87-A90-611-010 SW,PUSH 3-2-2 MPU20300MLB0

SW401 87-A90-612-010 SW,PUSH 2-1-1 MPU10371MLB1

CD MOTOR C.B

CON1 87-099-210-010 CONN,5P 6216 H

M1 87-045-305-010 MOTOR, RF-500TB DC-5V (2MA)

SW1 87-036-110-010 PUSH SWITCH

SW2 87-036-110-010 PUSH SWITCH

DRIVE C.B

M20 87-045-358-019 MOT,RF-310TA 43

M21 87-045-356-019 MOT,RF-310TA 30

SW1 87-A90-042-019 SW,LEAF MSW 17310 MVPO

DECK C.B

SFR1 87-024-581-010 SFR,3.3K DIA 6H KOA

SOL1 82-ZM1-618-310 SOL ASSY,27

SW2 87-A90-248-019 SW,MICRO ESE11SH2CXQ

SW3 87-A90-248-019 SW,MICRO ESE11SH2CXQ

SW5 87-A90-248-019 SW,MICRO ESE11SH2CXQ

SW6 87-A90-248-019 SW,MICRO ESE11SH2CXQ

RELAY-1 C.B

CNA400 8Z-CK3-615-010 CONN ASSY,8P V WHT DECK

2SA933S

2SC1740S

DTC114ES

DTC114TS

B

E

2SA1588

2SC2714

2SC4116

DTC143TK

C

RN1210

RN1305

RN2305

RT1P144C

E C B E C B

2SA952

2SA1318

2SC1815

2SD655

KTA1266

KTC3198

• Regarding connectors, they are not stocked as they are not the initial order items.

The connectors are available after they are supplied from connector manufacturers upon the order is received.

CHIP RESISTOR PART CODE

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

Symbol

Figure

Value of resistor

CJ

CJ

CJ

Form

L

W

Dimensions (mm)

LW t

1.0 0.5 0.35 104

t

1.6 0.8 0.45

2 1.25 0.45

1.6

0.55

3.2

Resistor Code

108

118

128

: A

: A

1615

Page 16

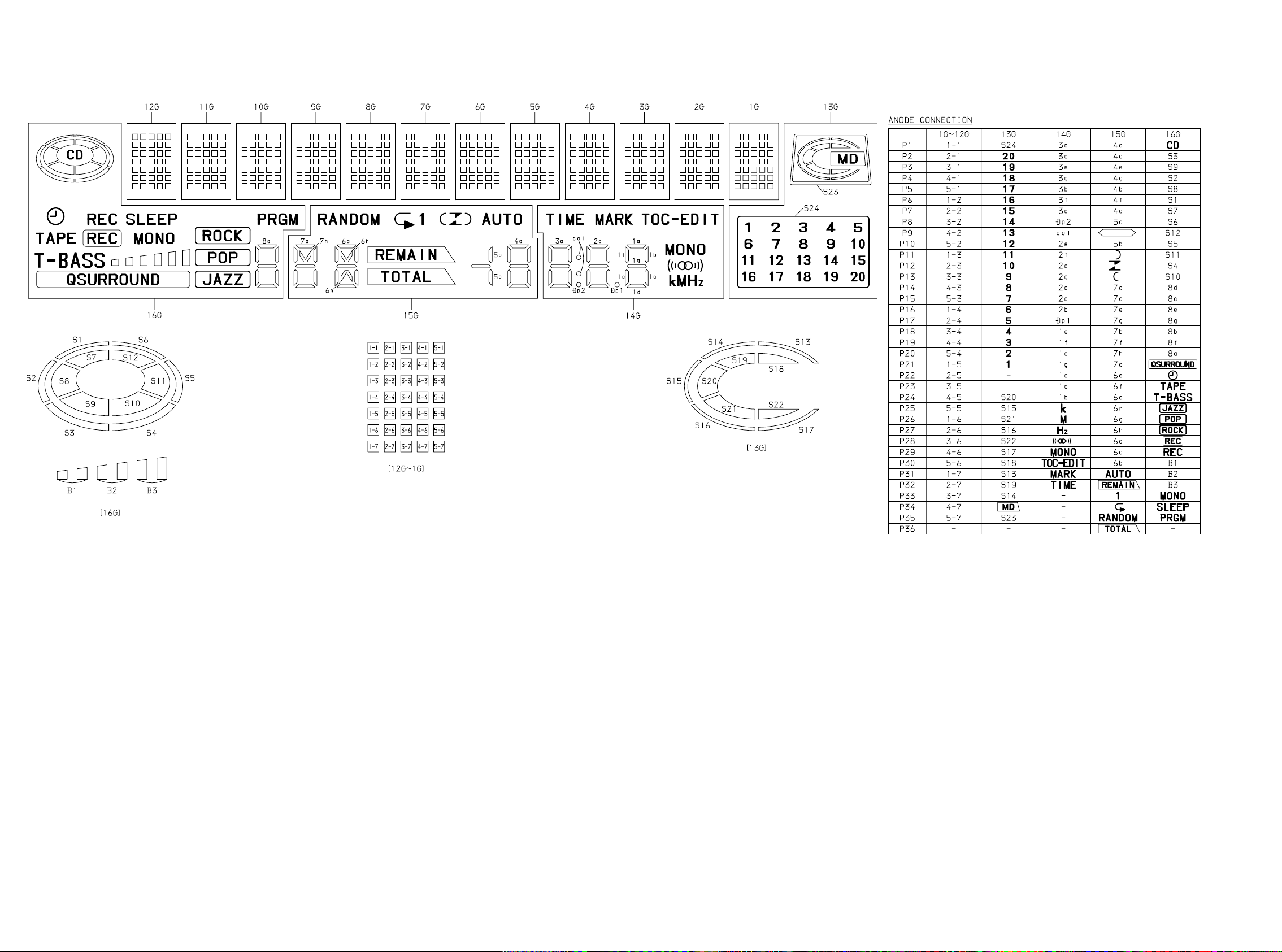

FL (16-ST-32GNK) GRID ASSIGNMENT/ANODE CONNECTION

1817

Page 17

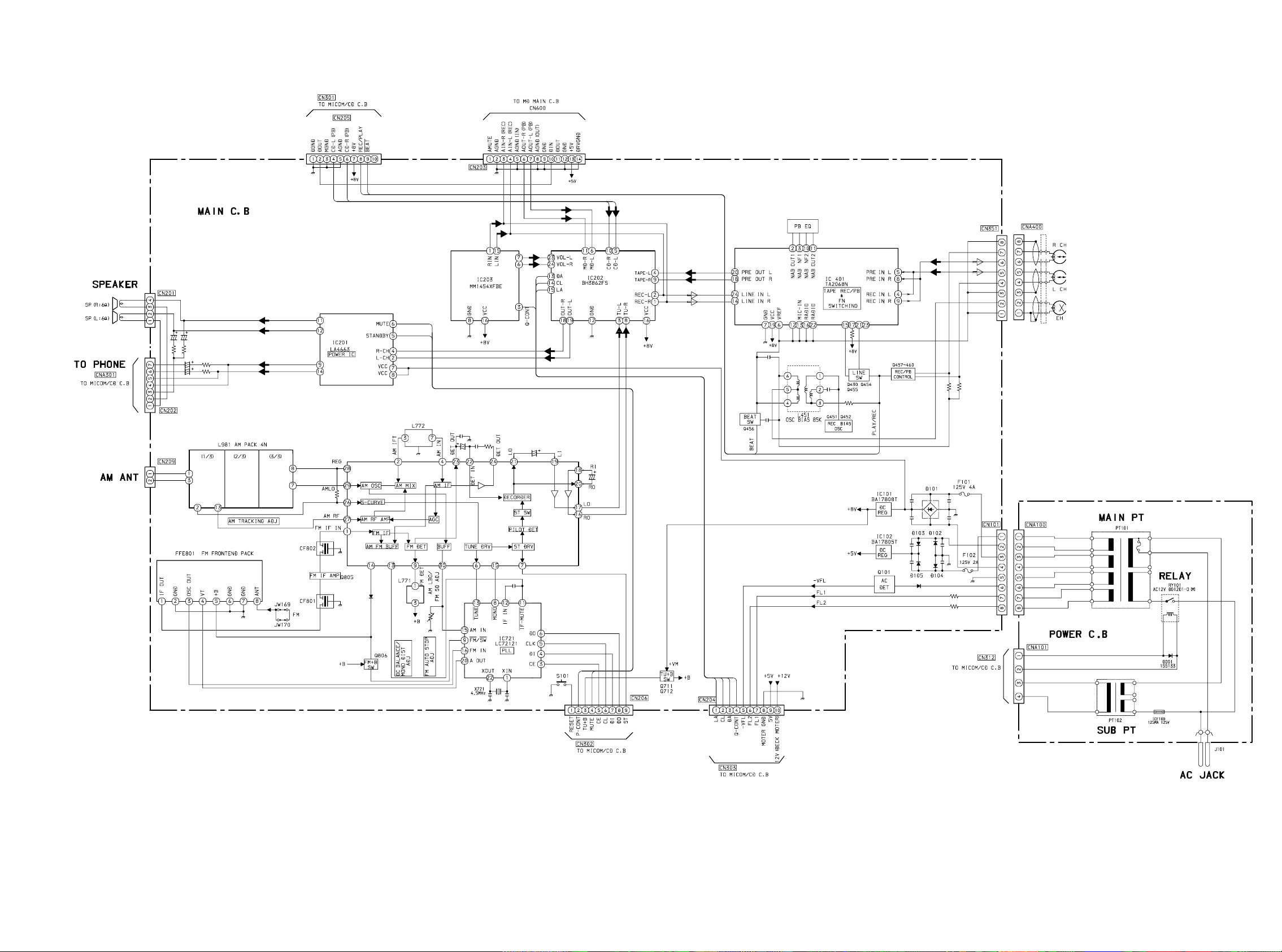

BLOCK DIAGRAM-1 (MAIN)

2019

Page 18

BLOCK DIAGRAM-2 (SYSTEM CONTROL)

2221

Page 19

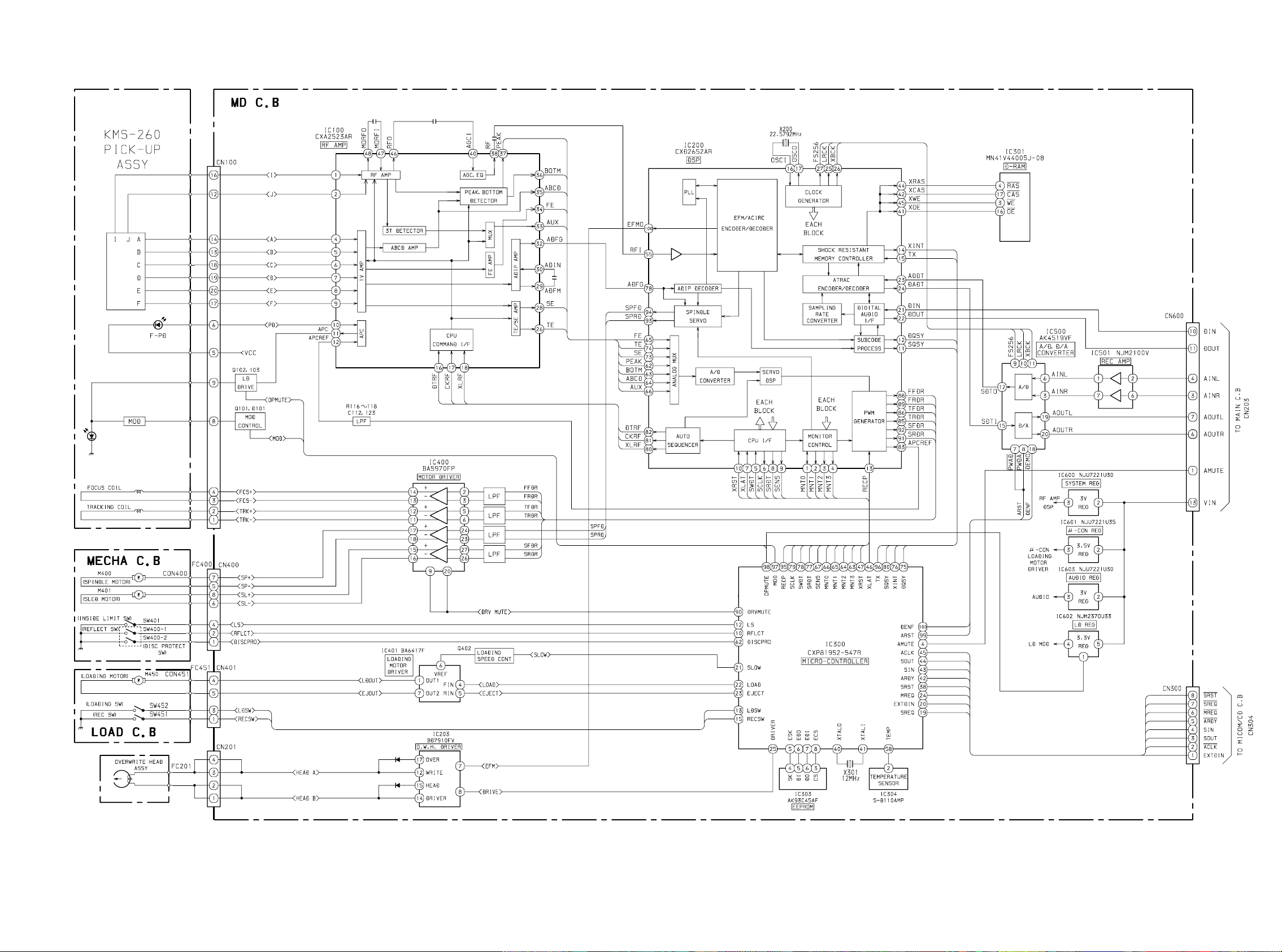

BLOCK DIAGRAM-3 (MD)

2423

Page 20

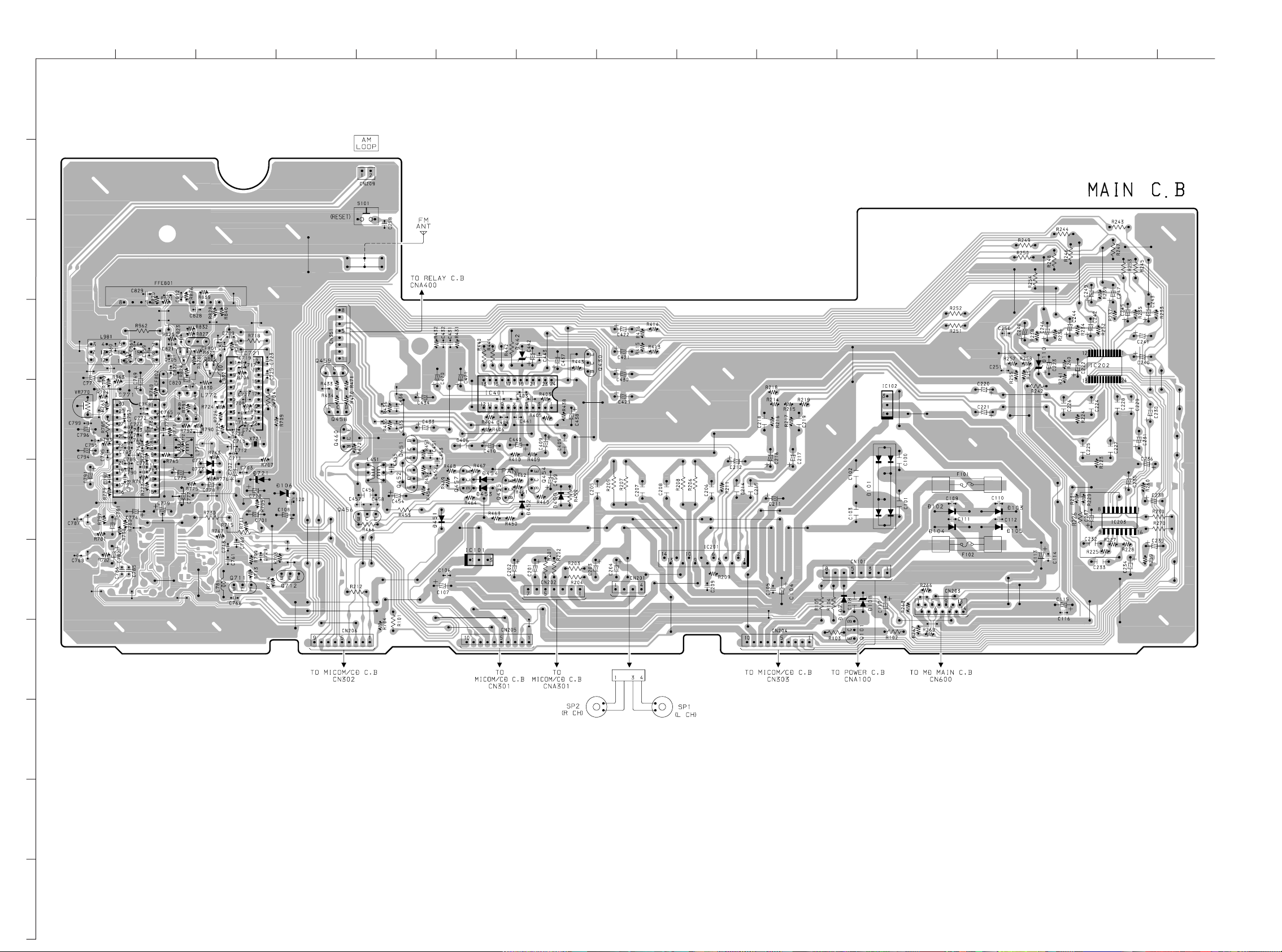

WIRING-1 (MAIN)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

K

2625

Page 21

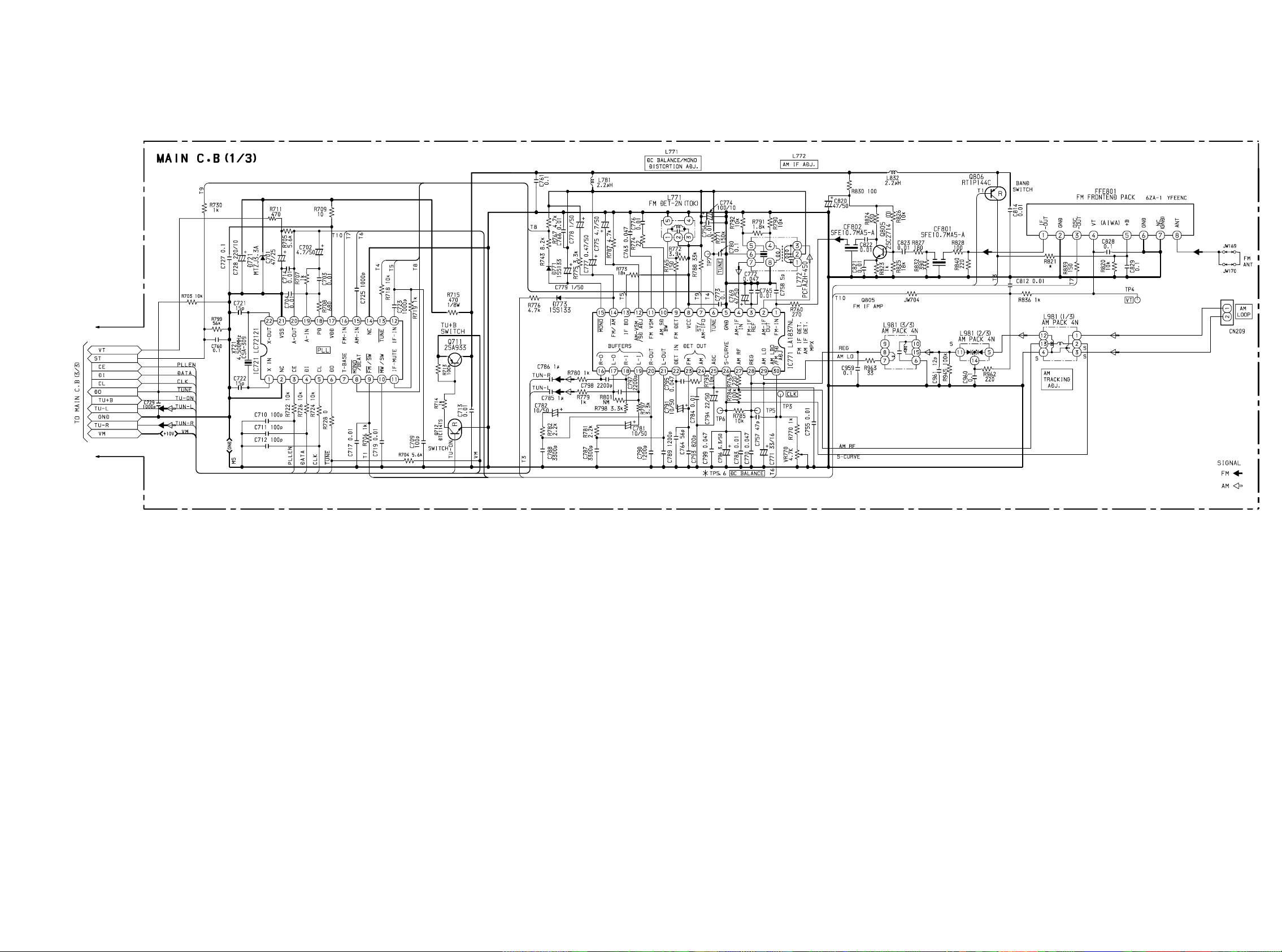

SCHEMATIC DIAGRAM-1 (TUNER)

2827

Page 22

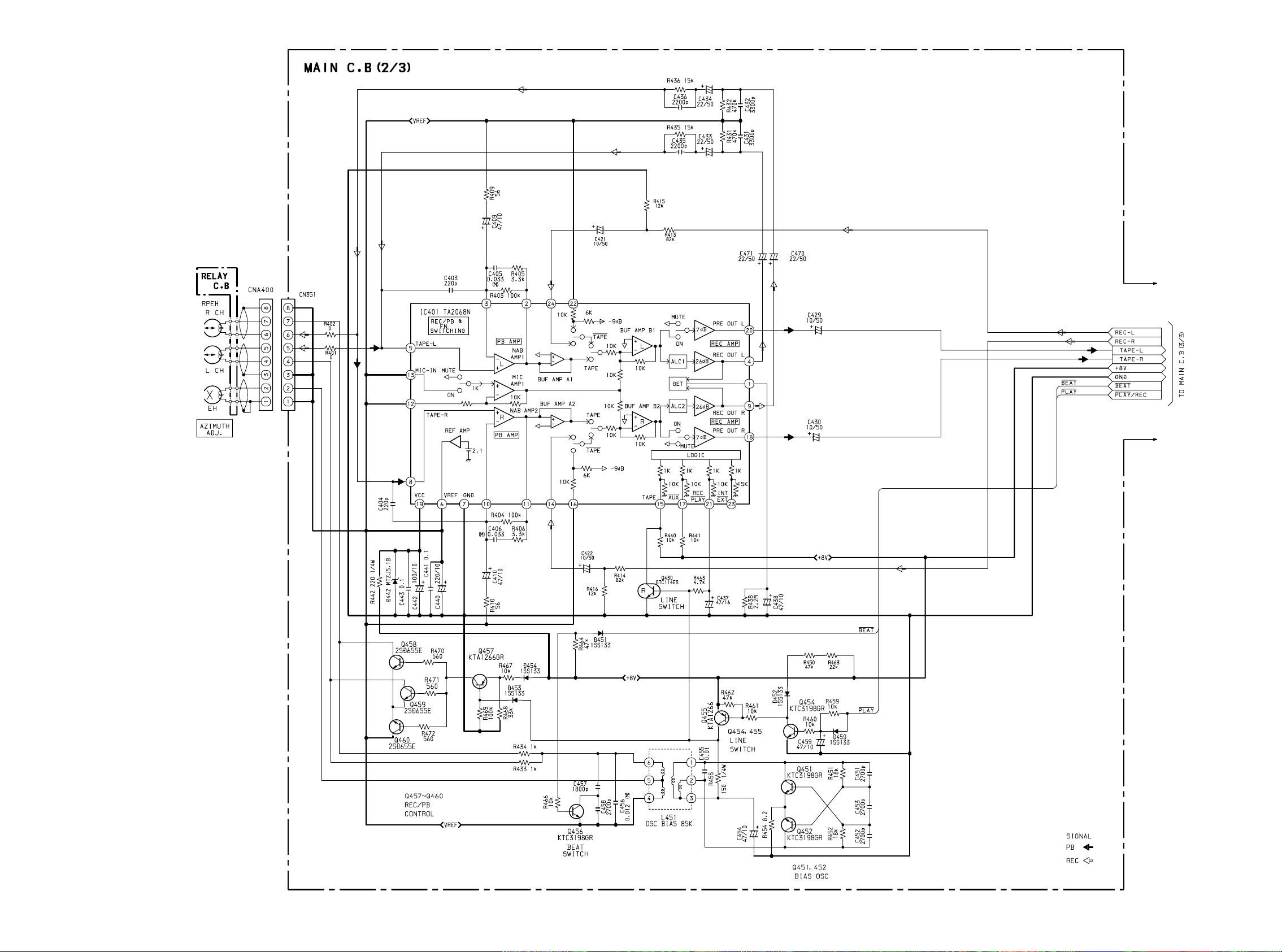

SCHEMATIC DIAGRAM-2 (DECK)

3029

Page 23

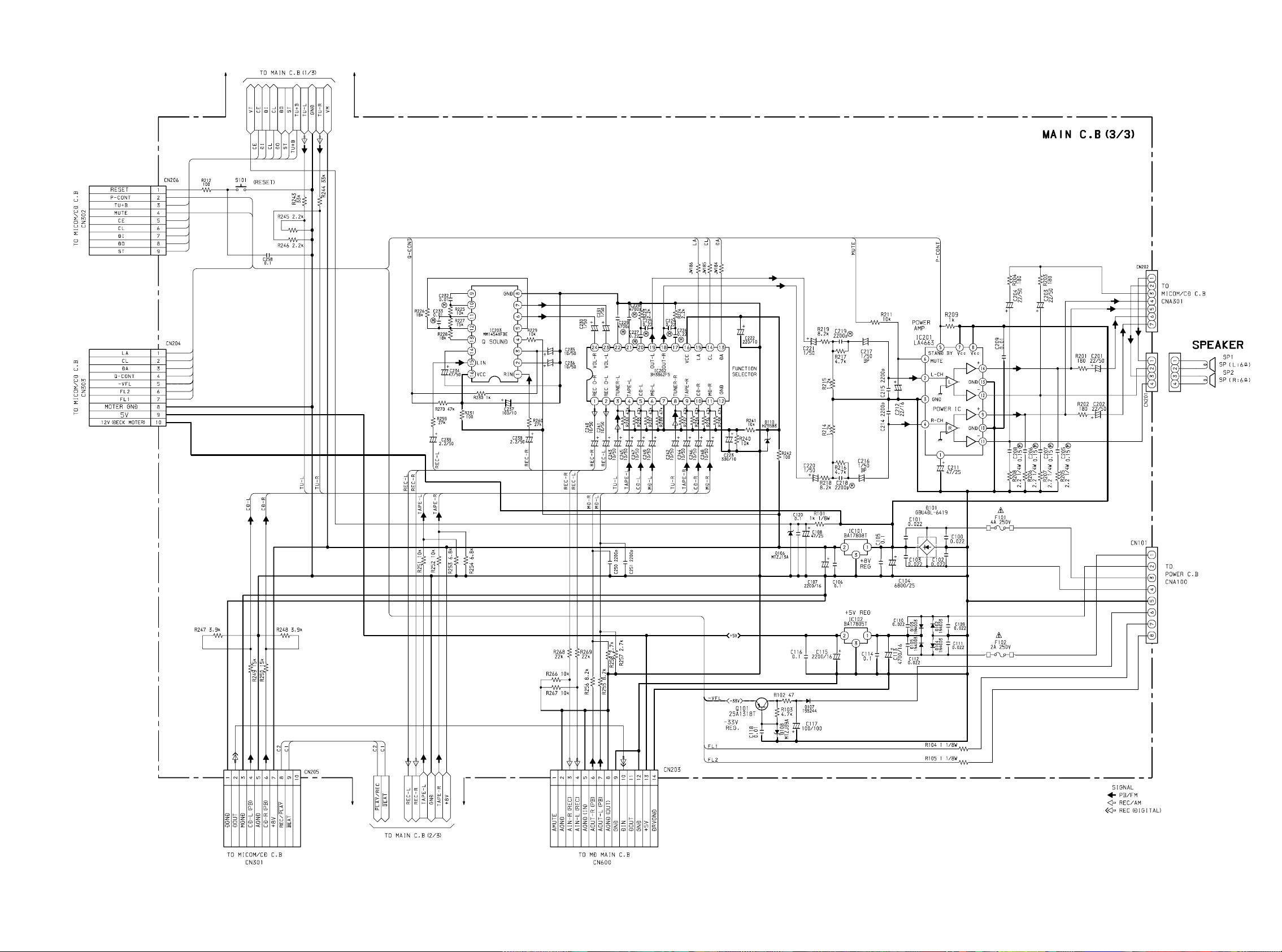

SCHEMATIC DIAGRAM-3 (MAIN)

3231

Page 24

WIRING-2 (SYSTEM CONTROL/CD)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

K

3433

Page 25

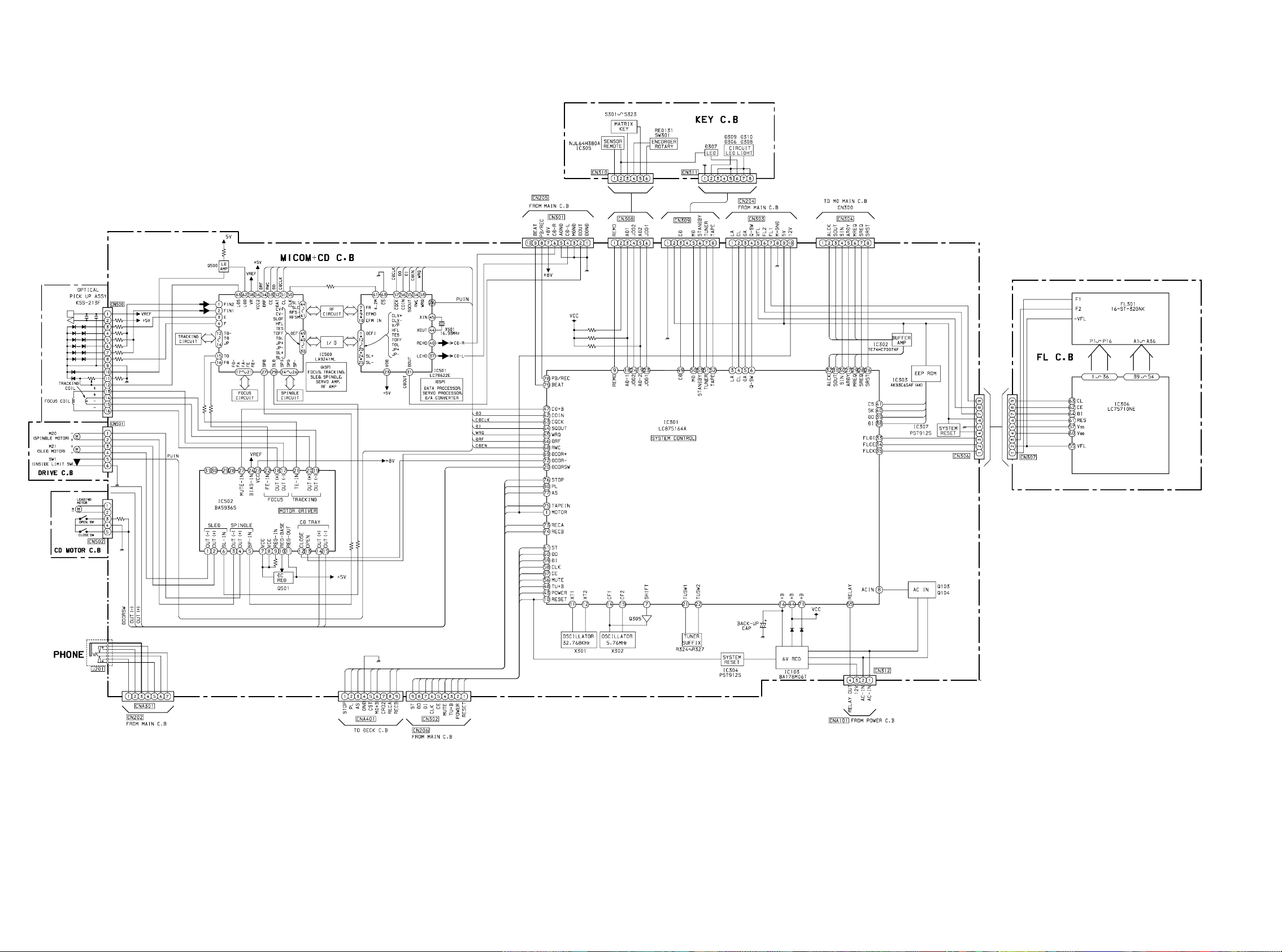

SCHEMATIC DIAGRAM-4 (SYSTEM CONTROL)

3635

Page 26

WIRING-3 (FL/KEY)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

K

3837

Page 27

SCHEMATIC DIAGRAM-5 (CD)

4039

Page 28

WIRING-4 (POWER)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

K

4241

Page 29

SCHEMATIC DIAGRAM-6 (FL/KEY/POWER)

4443

Page 30

WIRING-5 (MD)

7

654321

(COMPONENT SIDE)

A

A

B

B

C

C

D

D

1

2

3

456

7

(CONDUCTOR SIDE)

E

E

F

F

G

G

H

H

I

I

TO/FROM MAIN C.B

CN203

TO/FROM MICOM/CD C.B

CN304

J

J

4645

Page 31

SCHEMATIC DIAGRAM-7 (MD)

4847

Page 32

WIRING-6 (MECHANISM)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

TO MICOM/CD C.B

CN500

K

5049

Page 33

TEST MODE

1. CD TEST Mode

1-1. How to Active the CD TEST Mode

While pressing the CD 2 button, connect the AC power plug to the power outlet.

After the TEST mode is activated, the message “CD TEST” appears on the display and all displays on the FL tubes are turned

on.

1-2. Description of the TEST Mode Functions

Mode

Start mode

Search mode

Play mode

Traverse mode

Sled mode

Operating Control

Activating the

test mode

9

CD 2

;

6

5

FL Display

All displays

are ON

TOC READING

Track No. and

playing time are

displayed

Eye catch rotates

Track No. and

playing time are

displayed

Eye catch flashes

All displays are ON

Operation

Continuous focus search

PU lens repeats full swing

Repeats * Note

Normal playback

When the TOC READING

cannot be performed, the same

movement as the search mode is

performed

Playback pause state

Pick up moves inner

circumference

Pick up moves outer

circumference

Function

APC circuit check

Laser current measurement

Focus error waveform check

Focus servo

Tracking servo

CLV servo

Sled servo

Tracking servo OFF

Sled servo

Mechanism operation check

Note: If the focus search is continued for ten minutes or longer, CD stops working because driver IC is heated and protection circuit

works. Restart the TEST mode after turning off the power supply to cool down the heat for about ten minutes.

1-3. How to Exit the CD TEST Mode

Exit the CD TEST mode by disconnecting the AC power plug from the power outlet, or by pressing the POWER button, or by

pressing any key other than the CD function button.

2. MD TEST Mode

2-1. How to Active the MD TEST Mode

While pressing the MD 2 button, connect the AC power plug to the power outlet.

After the TEST mode is activated, waits about one second, then the message “MD TEST” appears on the display.

The MD TEST mode can be used.

Note: 1. If a machine shows any abnormal operations during the TEST mode, unplug the main AC power immediately.

2. Recording and played back are not possible during the TEST mode.

51

Page 34

2-2. How to Exit the MD TEST Mode

1) Eject the disc by pressing the “MD EJECT” button or the “VOLUME UP” button.

2) Disconnect the AC power plug from the power outlet, or press the “POWER” button.

2-3. Operation Check Mode

1) Checking activation of the TEST mode

Playback system audio circuit can be checked as follows.

• Circuit that can be checked ............. DAC, LINE AMP, HEADPHONE AMP

• Output level ..................................... 1kHz, -12dB

2) Checking status of the switches

The ON/OFF status of the respective switches on the machine and mechanism can be checked on the LCD display.

Switch Name Switch Status Display Disc in use

REC PROTECT When the WRITE PROTECT tab of a disc is closed ROCK frame is ON Disc for record and

REFRECT When high reflection disc (CD) is used POP frame is ON Disc for playback only

INNER When pick up is in the inner most circumference JAZZ frame is ON —

(LIMIT SW ON)

3) Detecting status of mechanism

Status of mechanism FL Display

Unloading status PRGM is turned on

Loading status RANDOM is turned on

Status that the over-write-head has moved down PRG and RANDOM are turned on

playback

2-4. How to Switch the Mode to the Servo Standby Mode

After the MD TEST mode has started up, the mode is switched to the servo standby mode when the 9 button is pressed,

and the message “ALL SV OFF” appears on the display. The machine can enter any other modes from the “ALL SV OFF”

mode. The machine can return from any other modes to the “ALL SV OFF” mode by pressing the 9 button.

2-5. Checking the Sled Movement

1) The laser pickup moves to the outer circumference when the 6 button is pressed while the machine is in the “ALL SV

OFF” status. Then, the message “T. SLED RVS” appears on the display.

2) The laser pickup moves to the inner circumference when the 5 button is pressed while the machine is in the “ALL SV

OFF” status. Then, the message “T. SLED RVS” appears on the display.

2-6. Checking Laser Output

1) Every passing of the “TIMER/CLOCK” button in the “ALL SV OFF” state changes output of laser power.

Laser can be operated in the following order: OFF ™ LASER READ ™ LASER 1/2 ™LASER WRITE ™ OFF.

The FL displays are as shown.

Mode FL Display

OFF ALL SV OFF

LASER READ LASER READ + T-BASS level 1

LASER 1/2 WRITE LASER 1/2 + T-BASS level 2

LASER WRITE LASER WRITE + T-BASS level 3

2) When all checks are completed, press the 9 button to show the message “ALL SV OFF” on the display.

2-7. Operation Check of OWH (Over-write-head)

The OWH can moves up or down when the “VOLUME UP” button or “VOLUME DOWN” button is pressed while the machine

is in the loading status.

“VOLUME UP” button............................ OWH moves up.

“VOLUME DOWN” button .................... OWH moves down.

Note: Don’t move down the OWH when the high reflection disc (CD) is used.

52

Page 35

2-8. Checking Servo Operation

• Checking the focus search and spindle kick: 1

1) When the MD 2 button is pressed while the machine is in the “ALL SV OFF” status without inserting a disc, focus search

and spindle kick are performed continuously.

The message “FOCUS SRCH” appears on the display.

2) After the check is completed, press the 9 button to show the message “ALL SV OFF” on the display.

• Checking the focus search and spindle kick: 2

1) When the “TUNER/BAND” button is pressed while the machine is in the “ALL SV OFF” status with a disk inserted or

without inserted, focus search and spindle kick are performed continuously .

The message “FOCUS CHECK” appears on the display.

The S curve characteristics can be checked when a disc is inserted.

2) After the check is completed, press the 9 button to show the message “ALL SV OFF” on the display.

• Checking the focus servo

1) Insert a test disc.

2) Move the laser pickup to the center of a disc using the 6 button and 5 button.

3) Press the TAPE 1 2 button, and set the servo mode of the inserted disc as follows.

MO disk (MO) ................................... Select the “SELECT GRV” display.

PIT disk (CD) .................................... Select the “SELECT PIT” display.

4) Press the MD 2 button.

When the focus servo has no problem, the messages “FOCUS SRCH” appears then “FOCUS ON!” appears on the display.

5) After the check is completed, press the 9 button to show the message “ALL SV OFF” on display.

• Checking that all servos are turned ON

1) When the “ENTER” button is pressed while the machine is in the “FOCUS ON!” status, the tracking and sled servos are

turned on and all servos start moving.

When the all servos have no problem, the message “ALL SV ON” appears on the display.

2) After the check is completed, press the 9 button to show the message “ALL SV OFF” on display.

3. ADJUSTMENT (MD)

3-1. Temperature Compensation Adjustment

Test point: Adjustment result is shown on the display

Jig: Thermometer

Adjustment method:

1) After activating the MD TEST mode, press the 9 button to display the “ALL SV OFF” .

2) Press the “DISP” button to change the display to “TEMP=$⁄⁄”.

3) Press the “EDIT” button to change the display into “TMP+**c:±## ”.

4) Place a thermometer near MD mechanism to measure the room temperature.

5) Perform adjustment by pressing the

display agree. Press the “ENTER” button.

6) After the adjustment is completed, press the 9 button to display “ALL SV OFF”.

7) When the setting is completed, display the “TMP+**c:+##” again and check the value that is calculated by adding or

subtracting the ## value to and from ** must be the room temperature.

Note: Don’t perform the above adjustment if the room temperature cannot be measured.

3-2. Laser Power Adjustment

Test point: Pick up laser output

Jig: Laser power meter

Adjustment method:

1) Press the “TIMER/CLOCK” button three times in the “ALL SV OFF” state to change the display to “LASER WRITE”.

2) Press the “EDIT” button once to display “LASER=$**”.

3) Measure the pick up laser output using the laser power meter, and perform adjustment so that the measuring value is 6.8±

0.03mW by pressing the 6 and 5 buttons. After the adjustment is completed, press the “ENTER”button.

4) Press the 9 button to display “ALL SV OFF”.

6 and 5 buttons until the thermometer reading and the value ** that is shown on the

Note: If laser output exceeds 7.0mW, the pick up may be damaged.

53

Page 36

3-3. AUTO SEQUENCE Adjustment (EFB/IVR/FOCUS AGC/TRACKING AGC adjustment)

Test disc: MDW-60. TGYS-1

When adjusting MO disc

1) Insert the test disc MDW-60.

2) Press the 9 button to display “ALL SV OFF”.

3) When the “EDIT” button is pressed, “AUTO ADJ” is displayed. When the adjustment is completed, “DONE” is displayed.

(When “FAILED” appears, it means that the adjustment has failed.)

4) Press 9 button to display “ALL SV OFF”.

Note: 1. If a test disc is dirty or has scratches, the complete adjustment may be not performed. Be sure to use a clean disc.

2. When adjusting the MO disc, the pre-recorded data on the MO disc is erased partly because WRITE POWER is on.

Use an exclusive disc for adjustment.

How to check IVR, EFB, and focus/tracking/sled gain.

1 Move the pick up to the center with

2 Press the MD 2 button to display “FOCUS ON!”.

3 Press the “ENTER” button to turn on “ALL SV ON”.

4 Press the 9 button, and press the “DISP” button twice.

Check that value of the display “IV$**: EF$ ⁄⁄” is within the specifications shown below.

“**” ............................... 13-17

“⁄⁄” ............................. 09-12

5 Repress the “DISP” button.

Check that value of the display “Gf**t##s33” is within the range shown below.

“**” ............................... 20-40

“##” ............................... 15-35

“33” ............................. 15-35

6 When the adjustment is completed, press the 9 button to display “ALL SV OFF”.

6 button and 5 button.

When adjusting PIT disc

1) Insert the test disc TGYS-1.

2) Press the 9 button to display “ALL SV OFF”.

3) When the “EDIT” button is pressed, “AUTO ADJ” is displayed. When the adjustment is completed, “DONE” is displayed.

(When the “FAILED” appears, it means that the adjustment has failed.)

4) When the adjustment is completed, press the 9 button to display “ALL SV OFF”.

How to check IVR, EFB, and focus/tracking/sled gain

Perform the same operations as the MO disc check. The data on the display must be within the following range.

“IVR” ............................ 14-19

“EFB” ........................... 09-12

“Focus gain” ................. 2A-45

“Tracking gain”............. 20-40

“Sled gain” .................... 20-40

3-4. Error Rate Check (PIT disc)

1) Insert the test disc TGYS-1.

2) Move the pick up to the center with

3) Press the “TAPE 1 2” button to display “SELECT PIT”.

4) Press MD 2 button to display “FOCUS ON!”.

5) Press the “ENTER” button to display “ALL SV ON”, and press the “DISP” button to display “Er00** 0000”.

6) Check the value of ** is “30” or less.

7) When the adjustment is completed, press the 9 button to display “ALL SV OFF”.

6 button and 5 button.

3-5. Record/Playback Error Rate Check (MO disc)

1) Insert the test disc MDW-60.

2) Move the pick up to the center with

3) Press the “TAPE 1 2” button to display “SELECT GRV”.

4) Press the “VOLUME DOWN” button to display “REC Analog”.

5) Press the MD 2 button to display “FOCUS ON!”.

6) Press the “VOLUME DOWN” button after pressing the “ENTER” button to display “ALL SV ON”.

7) When the “MD REC” button is repressed, the OWH moves. The recording starts from the 600 cluster.

Then the display changes from “ALL SV ON” to “ADR**C##S”.

8) After recording of about 15 seconds, press the 9 button to display “ALL SV OFF”.

9) Press the “VOLUME UP” button to move up the OWH.

6 button and 5 button.

54

Page 37

10) Press the MD 2 button to display “FOCUS ON!”.

11) Press the “ENTER” to display “ALL SV ON”, and press the “DISP” button to display “Er00**:0000”.

Check that the value of ### is “20” or less.

12) After the adjustment is completed, press the 9 button to display “ALL SV OFF”.

3-6. UTOC ERASE

Perform the following procedure only when the recorded disc needs to be erased.

1) Insert a disc from which UTOC is going to be erased.

2) Move the pick up to the center with

3) Press the “TAPE 1 2” button to display “SELECT GRV”.

4) Press the “MD REC” button to display “REC Analog”.

5) Press MD 2 button to display “FOCUS ON!”.

6) Press the “ENTER” button to display “ALL SV ON”.

7) When the “CD ™ MD SYNCHRO RECORDING” button is pressed, “UTOC ERASE” appears on the display and UTOC is

erased.

8) After the erasure is completed, “ALL SV OFF” appears on the display.

SERVICE JIG AND TOOLS

The following jigs and tools can be used.

6 button and 5 button.

CD Block

MD Block

Usage

CD mechanism stand

P.U. extension FFC

S.T.I G-98-50

S.T.I G-98-50

Part Name

JIG, P-CD BY TORIKOSHI

FF-CABLE, 16P 1.0 250mm

FFC, 8P-1.0

FFC, 14P-1.0

Part No.

SV-J00-018-010

87-CE1-640-010

SV-J00-043-010

SV-J00-043-010

55

Page 38

ELECTRICAL ADJUSTMENT

MAIN C.B

(CONDUCTOR SIDE)

CN201

L771

TP4

L981

L772

FFE801

IC771

TP6

3

VR770

7

TP5

MICOM/CD C.B (CONDUCTOR SIDE)

J201

SFR501

62

IC501

IC500

56

CN302

TP3

TP2

8

Page 39

SFR1

9

R.P.E HEAD

00

< TUNER SECTION >

1. AM VT Check

Settings: • Test point: TP4 (VT)

Method: Set to AM 1611kHz and check that the test

point is less than 5.6V.

2. AM IF Adjustment

Settings: • Test point: J201 (PHONES)

L772 .............................................. 450kHz

3. AM Tracking Adjustment

Settings: • Test point: J201 (PHONES)

• Adjustment location: L981

Method: Set to AM 999kHz and adjust L981 so that the

test point becomes maximum.

4. FM VT Check

Settings: • Test point: TP4 (VT)

Method: Set to FM 108.0MHz and check that the test

point is more than less than 7.3V.

5. FM Tracking Check

Settings: • Test point: J201 (PHONES)

Method: Set to FM 98.0MHz and check that the test

point is less than 20dBµV.

6. DC Balance/Mono Distortion Adjustment

Settings: • Test point: TP5, TP6

• Adjustment location: L771

• Input level: 54dB

Method: Set to FM 98.0MHz and adjust L771 so that

the voltage between TP5 and TP6 becomes

0V±0.04V.

Next, check that the distortion is less than

1.3%.

7. FM Auto Stop Adjustment

Settings: • Adjustment location: VR770

• Input level: 28dBµV

Method: Set to FM 98.0MHz and adjust VR770 so that

the level 28dBµV±3dB.

57

Page 40

< CD SECTION >

8. Tracking Balance Adjustment

Oscilloscope

(DC range)

TP2 (TB)

TP3 (VREF)

1) Connect an oscilloscope to the test points TP2 (TB) and

TP3 (VREF).

2) Turn on the power switch.

3) Insert test disc TCD-782 (YEDS-18) and press the CD

PLAY button.

4) Adjust SFR501 so that the waveform on the oscilloscope

is vertically symmetrical as shown in the figure below.

5) After the adjustment is completed, remove the connected

lead wires from the terminals.

+

–

PRACTICAL SERVICE FIGURE

< TUNER SECTION >

< FM SECTION >

IHF Sensitiviy: More than 20dB

(THD 3%) (at 88.0/98.0MHz)

More than 22dB

(at 108MHz)

Signal to noise ratio: More than 55dB

(at 98.0MHz)

Distortion: Less than 1.5%

(Input: 54dB) (at 98.0MHz)

Stereo separation: More than 20dB

(at 98.0MHz)

Intermediate frequency: 10.7MHz

< AM SECTION >

Sensitivity: 54dB±6dB (at 603kHz)

(S/N 20dB) 52dB±6dB

(at 999/1404kHz)

Signal to noise ratio: More than 36dB

(Input: 74dB) (at 999kHz)

Distortion: Less than 2.0%

(at 999kHz)

Intermediate frequency: 450kHz

A

0V

B

A = B

VOLT/DIV: 0.2V

TIME/DIV: 1mS

< DECK SECTION >

9. Tape Speed Adjustment

Settings: • Test tape: TTA-100

• Test point: CN201

• Adjustment location: SFR1

Method: Playback the test tape by adjust SFR1 so that

the frequency counter reads 3000Hz±10Hz.

Check that the counter reading in the REV

mode is within the range of ±45Hz of that in

the FWD mode.

10. Azimuth Adjustment

Settings: • Test tape: TTA-300

• Test point: J201 (PHONES)

• Adjustment location: Head azimuth

adjustment screw

Method: Playback the 10kHz signal of the test tape and

adjust the adjustment screw so that the output

becomes the -0.5dB point below the maximum

reading. The adjustment must ends with the

clockwise rotation of the adjustment screw.

Perform this adjustment in both FWD and

REV directions. Fix the adjustment screw with

adhesive agent upon completion of adjustment.

< DECK SECTION >

Tape speed: 3000Hz±60Hz

Wow & flutter: Less than 0.21%

(W.R.M.S)

Take-up torque: 30-55g-cm (FWD, REV)

F.F torque: 75-160g-cm

REW torque: 75-160g-cm

Back tension: 3±4g-cm (FWD, REV)

PB Output level: 190mV±1dB (LINE OUT)

REC/PB Output level: 190mV±2dB (LINE OUT)

Distortion (REC/PB): Less than 3%

(NORM, CrO

Noise level (PB): Less than 3.5mV

(DOLBY NR OFF, NORM)

Noise level (REC/PB): Less than 3.5mV

(DOLBY NR OFF, NORM)

Erasing ratio: More than 55dB

REC bias frequency: 85kHz

Test tape: NORMAL TTA-100

CrO2 TTA-200

2)

58

Page 41

IC DESCRIPTION

IC, CXD2652AR

Pin No. Pin Name I/O Description

1 MNT0 O Monitor output pin.

2 MNT1 O Monitor output pin.

3 MNT2 O Monitor output pin.

4 MNT3 O Monitor output pin.

5 SWDT I Data input pin for micro-processor serial interface.

6 SCLK I Shift clock input pin for micro-processor serial interface.

7 XLAT I Latch input pin for micro-processor serial interface. Shut down: Latch.

8 SRDT O Data output pin for micro-processor serial interface.

9 SENS O Output internal status according to micro-processor serial interface address.

10 XRST I Reset input pin. "L": Reset.

11 SQSY O Disc sub-code Q synchronize / ADIP synchronize output.

12 DQSY O

13 RECP I Laser power switching input pin. "H": Record power. 'L": Playback power.

14 XINT O Intrusion demand output pin. "L" setting when intrusion demand status is generated.

15 TX I Record data output enable signal input pin. "H": Enable.

16 OSCI I Crystal oscillator circuit input pin.

17 OSCO O Crystal oscillator circuit output pin. (OSCI inverted output)

18 XTSL I

19 NC – Not used. (Connected to DVDD)

20 DVSS – Digital GND.

21 DIN I Input digital audio interface signal.

22 DOUT O Output digital audio interface signal.

23 ADDT I Analog record input pin. (Connected to external A/D converter output)

24 DADT O REC monitor output pin / Output decode audio data.

25 LRCK O Output LRCK (44.1kHz) to external audio block.

26 XBCK O Output bit clock (2.8224MHz) to external audio block.

27 FS256 O Output 256Fs (11.2896MHz).

When source of the digital in is set to CD or MD, output sub-code Q synchronize of

UbitCD or MD format.

Switch input frequency of OSCI pin. (Connected to DVDD)

"H": 512Fs (22.5792MHz), "L": 1024Fs (45.158MHz).

28 DVDD – Digital power supply.

29 A03 O Output address for external DRAM.

30 A02 O Output address for external DRAM.

31 A01 O Output address for external DRAM.

32 A00 O Output address for external DRAM.

33 A10 O Output address for external DRAM. (Not used)

34 A04 O Output address for external DRAM.

35 A05 O Output address for external DRAM.

36 A06 O Output address for external DRAM.

37 A07 O Output address for external DRAM.

38 A08 O Output address for external DRAM.

39 A11 O Output address for external DRAM. (Not used.)

59

Page 42

Pin No. Pin Name I/O Description

40 DVSS – Digital GND.

41 XOE O Output enable pin for external DRAM.

42 XCAS O Output CAS for external DRAM.

43 A09 O Output address for external DRAM.

44 XRAS O Output RAS for external DRAM.

45 XWE O Write enable for external DRAM.

46 D1 I/O Data pass for external DRAM.

47 D0 I/O Data pass for external DRAM.

48 D2 I/O Data pass for external DRAM.

49 D3 I/O Data pass for external DRAM.

50 MVCI I Clock input pin for external VCO (784fs). (Connected to DVSS)

51 ASYO O Full swing output pin for playback EFM ("L" = VSS, "H" = VDD).

52 ASY1 I Input omparator slice voltage for playback EFM.

53 AVDD – Analog power supply.

54 BIAS I Input comparator bias current for playback EFM.

55 RFI I Input RF signal for playback EFM.

56 AVSS – Analog GND.

57 PDO O Output phase comparison for analog PLL of EFM decoder.

58 PCO O Output phase comparison for playback digital PLL, master PLL and record EFM PLL.

59 FILI I Input filter for playback digital PLL, master PLL and record EFM PLL.

60 FILO O Output filter for playback digital PLL, master PLL and record EFM PLL.

61 CLTV I

62 PEAK I Input peak hold signal for beam spectrum.

63 BOTM I Input bottom hold signal for beam spectrum.

64 ABCD I Input beam spectrum signal.

65 FE I Input focus error signal.

66 AUXI I Backup input 1.

67 VC I Input midpoint voltage.

68 ADIO O Monitor output pin for A/D converter input signal. (Not used)

69 AVDD – Analog power supply.

70 ADRT I Input maximum voltage of A/D converter operation range.

71 ADRB I Input minimum voltage of A/D converter operation range.

72 AVSS – Analog GND.

73 SE I Input sled error signal.

Input internal VCO control voltage for playback digital PLL, master PLL and record

EFM PLL.

74 TE I Input tracking error signal.

75 AUX2 I Backup input 2. (Connected to AVDD)

76 DCHG I Connected to the power supply of low impedance. (Connected to AVDD)

77 APC I Input error signal for laser digital APC. (Connected to AVDD)

78 ADFG I Input ADIP binary data FM signal (22.05kHz ± 1kHz).

79 FOCNT O Current setting output pin for CXA2523AR.

60

Page 43

Pin No. Pin Name I/O Description

80 XLRF O Latch output pin for CXA2523AR control. Shut down: Latch.

81 CKRF O Shift clock output pin for CXA2523AR control.

82 DTRF O Data output pin for CXA2523AR control.

83 APCREF O Reference PWM output pin for laser APC.

84 LDDR O PWM output for laser digital APC. (Not used)

85 TRDR O Tracking servo drive PWM output (–).

86 TFDR O Tracking servo drive PWM output (+).

87 DVDD – Digital power supply.

88 FFDR O Focus servo drive PWM output (+).

89 FRDR O Focus servo drive PWM output (–).

90 FS4 O Output 4Fs (176.4kHz). (Not used)

91 SRDR O Sled servo drive PWM output (–).

92 SFDR O Sled servo drive PWM output (+).

93 SPRD O Spindle servo drive PWM output. (PWM (–) or polarity)

94 SPFD O Spindle servo drive PWM output. (PWM (+) or PWM absolute value)

95 FGIN I Spindle CAV servo FG input. (Connected to DVSS.)

96 TEST 1 I Test pin. (Connected to DVSS)

97 TEST 2 I Test pin. (Connected to DVSS.)

98 TEST 3 I Test pin. (Connected to DVSS.)

99 DVSS – Digital GND.

100 EFMO O Output "L" at playback, EFM (encode data) at recording.

61

Page 44

IC, CXP81952M-547R

Pin No. Pin Name I/O Description

1 MCAS – Not used.

2 MRAS – Not used.

3 BUP – Not used.

4 AMUTE O Output AUDIO MUTE signal.

5 ESK O Serial clock output pin for EEPROM interface.

6 EDO O Serial data output pin for EEPROM interface.

7 EDI I Serial data input pin for EEPROM interface.

8 ECS O Output EEPROM chip select signal.

9 NC – Not used.

10 RFLCT I Input terminal for DISC reflection rate detection SW.

11 NC – Not used.

12 LS I Input pin for pickup inner-circumference detect switch.

13 LDSW I Loading mechanism, EJECT position detect switch input.

14 PBSW I Loading mechanism, PB position detect switch input. (Not used)

15 RECSW I Loading mechanism, REC position detect switch input.

16 ~ 17 NC – Not used.

18 ACOFF – Not used.

19 SREQ I Input system-computer send request signal for system-computer interface.

20 EXTDIN O External digital IN permit signal output.

21 SLOW O Loading mechanism speed control signal output.

22 LOAD O Loading mechanism operating-direction control signal output 1.

23 EJECT O Loading mechanism operating-direction control signal output 2.

24 MREQ O Output MD microcomputer send request signal for system-computer interface.

25 DRIVE O Output EFM driver ON/OFF signal.

26 ~ 36 NC – Not used.

37 MP – Connected to VSS.

38 SRST I Input MD microcomputer reset signal.

39 DGND – Connected to VSS.

40 XTALO O Crystal oscillator terminal 1 for system clock oscillator.

41 XTALI I Crystal oscillator terminal 2 for system clock oscillator.

42 ARDY I Input READY signal for system-computer interface.

43 SIN I Input serial data for system-computer interface.

44 SOUT O Output serial data for system-computer interface.

45 ACLK O Output serial clock for system-computer interface.

46 XLAT O Output latch signal for CXD2652AR interface.

47 XRST O Output reset signal for CXD2652AR.

48 XSTBY O Output standby signal for CXA2523AR.

49 NC – Not used.

50 AVSS – Connected to VSS.

51 AVREF – Connected to VDD.

52 AVDD – Connected to VDD.

62

Page 45

Pin No. Pin Name I/O Description

53 ~ 55 NC – Not used (PLL UP).

56 SLF – Not used (PLL UP).

57 SLR – Not used (PLL UP).

58 TEMP I S-8110AMP OUT signal input pin.

59 MAGIC – Not used (PLL UP).

60 NC – Not used (PLL UP).

61 TEST – Not used (PLL UP).

62 DISCPRO I Input pin for prevention of DISC error erase SW.

63 MNT3 I Monitor signal input pin 3 for CXD2652AR.

64 MNT2 I Monitor signal input pin 2 for CXD2652AR.

65 MNT1 I Monitor signal input pin 1 for CXD2652AR.

66 MNT0 I Monitor signal input pin 0 for CXD2652AR.

67 SENS I Input SENS signal for CXD2652AR.

68 FLG I Monitor FLAG included in SRDT of CXD2652AR interface.

69 ~ 70 NC – Not used.

71 P-CONT – Not used.

72 RFSW – Not used.

73 ~ 74 NC – Not used.

75 DQSY I Synchronize input pin for digital-in SUB-Q.

76 XINT I Status synchronize input pin for CXD2652AR.

77 SRDT I Serial data input pin for CXD2652AR interface.

78 SWDT O Serial data output pin for CXD2652AR interface.

79 SCLK O Serial clock output pin for CXD2652AR interface.

80 SQSY I SUB-Q, ADIP synchronize input.

81 ~ 83 NC – Not used.

84 TXI – Connected to VSS.

85 TXO – Open. (Not used)

86 VSS – Connected to VSS.

87 VDD – Connected to VDD.

88 NC – Connected to VDD.

89 NC – Not used.

90 DRVMUTE O Outputs MUTE signal for BA5970FP.

91 ~ 94 NC – Not used.

95 RECP O Laser power switch signal output pin.

96 TX O Output permission signal of record data output.

97 MOD O Output ON/OFF signal for high frequency modulation circuit.

98 OPMUTE O Laser MUTE signal output pin.

99 ARST O AK4516VF reset signal output pin.

100 DENF O De-emphasis ON/OFF signal output pin.

63

Page 46

IC, CXA2523AR

Pin No. Pin Name I/O Description

1 I I Input "I" RF signal converted to I-V.

2 J I Input "J" RF signal converted to I-V.

3 VC O Output voltage for VCC/2.

4 A I Input current for main beam servo signal A.

5 B I Input current for main beam servo signal B.

6 C I Input currentt for main beam servo signal C.

7 D I Input current for main beam servo signal D.

8 E I Input current for side beam servo signal E.

9 F I Input current for side beam servo signal F.

10 PD I Input beam spectrum monitor signal.

11 APC O Output laser APC.

12 APCREF I Input reference voltage for laser power setting.

13 GND – GND.

14 TEMPI I Temperature sensor connection pin. (Not used)

15 TEMPR I Temperature sensor connection pin. Output reference voltage. (Not used)

16 SWDT I Input micro-processor serial interface data.

17 SCLK I Input micro-processor serial interface shift clock.

18 XLAT I Input micro-processor serial interface latch. "L": Latch.

19 XSTBY I Standby setting pin. "H": Normal mode, "L": Standby.

20 FOCNT I Internal current setting pin.

21 VREF O Output reference voltage. (Not used)

22 EQADJ I/O EQ central frequency setting pin.

23 3TADJ I/O BPF3T central frequency setting pin.

24 VCC – Power supply pin.

25 WBLADJ I/O BPF22 central frequency setting pin.

26 TE O Output tracking error signal.

27 CSLED – LPF capacitor connection pin for SLED error signal.

28 SE O Output SLED error signal.

29 ADFM O Output ADIP FM signal.

30 ADIN I Input ADIP signal comparator.

31 ADAGC – ADIPAGC capacitor connection pin.

32 ADFG O Output ADIP2 binary data signal.

33 AUX O 13 output / Output temperature signal. Switched by serial command.

34 FE O Output focus error signal.

35 ABCD O Output beam spectrum signal for main beam servo detector.

36 BOTM O Output bottom hold signal for RF/ABCD.

37 PEAK O Output peak hold signal for RF/ABCD.

38 RF O RF equalizer output pin.

39 RF AGC – RFAGC capacitor connection pin.

40 AGCI I RFAGC input pin.

41 COMPO O User comparator output pin. (Not used)

64

Page 47

Pin No. Pin Name I/O Description

42 COMPP I User comparator non-inverted input pin. (Connected to GND)

43 ADDC I/O Capacitor connection pin for ADIP amplifier on return circuit.

44 OPO O Output pin for user operational amplifier. (Not used)

45 OPN I Non-inverted input pin for user operational amplifier.

46 RFO O RF amplifier output pin. Check point for eye pattern.

47 MORFI I Input pin where Groove RF signal is AC coupled.

48 MORFO O Output pin for Groove RF signal.

65

Page 48

IC, LA9241ML

Pin No. Pin Name I/O Description

1

2

FIN2

FIN1

Pin to which external pickup photo diode is connected. RF signal is created by adding

I

with the FIN1 pin signal. FE signal is created by subtracting from the FIN1 pin signal.

I

Pin to which external pickup photo diode is connected.

10

11

12

13

14

15

16

17

3

4

5

6

7

8

9

E

F

TB

TE–

TE

TESI

SCI

TH

TA

TD–

TD

JP

TO

FD

FD–

Pin to which external pickup photo diode is connected. TE signal is created by

I

subtracting from the F pin signal.

I

Pin to which external pickup photo diode is connected.

I

DC component of the TE signal is input.

I

Pin to which external resistor setting the TE signal gain is connected between the TE pin.

O

TE signal output pin.

TES “Track Error Sense” comparator input pin. TE signal is passed through a band-

I

pass filter then input.

I

Shock detection signal input pin.

I

Tracking gain time constant setting pin.

O

TA amplifier output pin.

Pin to which external tracking phase compensation constants are connected between

I

the TD and VR pins.

I

Tracking phase compensation setting pin.

I

Tracking jump signal (kick pulse) amplitude setting pin.

O

Tracking control signal output pin.

O

Focusing control signal output pin.

Pin to which external focusing phase compensation constants are connected between

I

the FD and FA pins.

18

19

20

21

22

23

24

25

26

27

28

29

30, 31

32, 33

34

FA

FA–

FE

FE–

AGND

NC

SP

SPG

SP–

SPD

SLEQ

SLD

SL–, SL+

JP–, JP+

TGL

—

—

Pin to which external focusing phase compensation constants are connected between

I

the FD– and FA– pins.

Pin to which external focusing phase compensation constants are connected between

I

the FA and FE pins.

O

FE signal output pin.

I

Pin to which external FE signal gain setting resistor is connected between the FE pin.

Analog signal GND.

No connection.

O

Single ended output of the CV+ and CV– pin input signal.

I

Pin to which external spindle gain setting resistor in 12 cm mode is connected.

Pin to which external spindle phase compensation constants are connected together

I

with SPD pin.

O

Spindle control signal output pin.

I

Pin to which external sled phase compensation constants are connected.

O

Sled control signal output pin.

I

Sled advance signal input pin from microprocessor.

I

Tracking jump signal input pin from DSP.

I

Tracking gain control signal input from DSP. Low gain when TGL = H.

35

TOFF

I

Tracking off control signal input pin from DSP. Off when TOFF = H.

66

Page 49

Pin No. Pin Name I/O Description

36

TES

O

Pin from which TES signal is output to DSP.

37

38

39, 40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

HFL

SLOF

CV–, CV+

RFSM

RFS–

SLC

SLI

DGND

FSC

TBC

NC

DEF

CLK

CL

DAT

CE

DRF

FSS

“High Frequency Level” is used to judge whether the main beam position is on top of

O

bit or on top of mirror.

I