Page 1

CA-DW735M

U

SERVICE MANUAL

CD CARRING

COMPONENT SYSTEM

This Service Manual is the "Revision Publishing" and replaces "Simple Manual"

(S/M Code No. 09-994-329-2T1).

BASIC TAPE MECHANISM : TN-21ZSW-1691

BASIC CD MECHANISM : 5ZG-3 D2NC

S/M Code No. 09-994-329-2R1

REVISION

DATA

Page 2

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

Solder

CD PICK-UP ASSY P.C.B

This set employs laser. Therefore, be sure to follow carefully the

instructions below when servicing.

WARNING!

WHEN SERVICING, DO NOT APPROACH THE LASER EXIT

WITH THE EYE TOO CLOSELY. IN CASE IT IS NECESSARY TO

CONFIRM LASER BEAM EMISSION. BE SURE TO OBSERVE

FROM A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE OPTICAL

PICK-UP BLOCK.

Caution: Invisible laser radiation when

open and interlocks defeated avoid exposure to beam.

Advarsel:Usynling laserståling ved åbning,

når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

VAROITUS!

Laiteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyt-täjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

VARNING!

Om apparaten används på annat sätt än vad som specificeras i

denna bruksanvising, kan användaren utsättas för osynling

laserstrålning, som överskrider gränsen för laserklass 1.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

ATTENTION

L'utilisation de commandes, réglages ou procédures autres que

ceux spécifiés peut entraîner une dangereuse exposition aux

radiations.

ADVARSEL!

Usynlig laserståling ved åbning, når sikkerhedsafbrydereer ude

af funktion. Undgå udsættelse for stråling.

This Compact Disc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located on the rear

exterior.

CLASS 1

KLASSE 1

LUOKAN 1

KLASS 1

LASER PRODUCT

LASER PRODUKT

LASER LAITE

LASER APPARAT

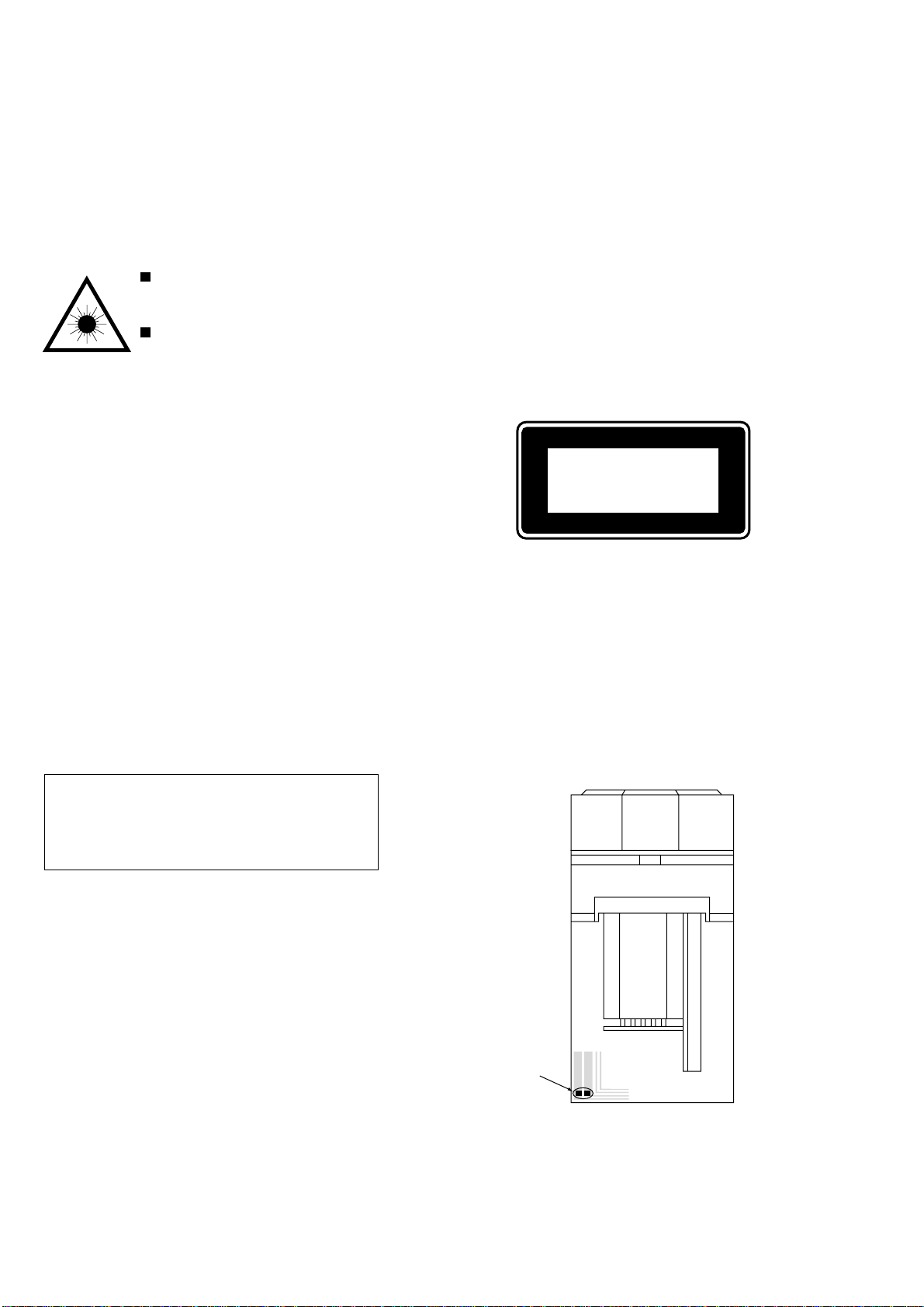

Precaution to replace Optical block

Body or clothes electrostatic potential could ruin

laser diode in the optical block. Be sure ground

body and workbench, and use care the clothes

do not touch the diode.

1) After the connection, remove solder shown in

the right figure.

2

Page 3

SPECIFICATIONS

Tuner section

FM: 87.5 - 108.0 MHz (50 kHz steps)

Antenna: FM antenna

AM: 530 - 1,710 kHz (10 kHz steps)

531 - 1,602 kHz (9 kHz steps)

Antenna: Ferrite bar antenna

Amplifier section

Power output: 5 W + 5 W (4 ohms, EIAJ)

FTC rule

4 Watts per channel, Min.

RMS at 4 ohms from 65 Hz to

15,000 Hz, with no more than 1%

distortion

Power requirements: DC 12 V using eight size D

(R20) batteries

AC 120 V, 60 Hz

Power consumption: 25 W

Cassette deck section

Track format: 4 tracks, 2 channels

Frequency response: Normal tape: 50 - 12,000 Hz (EIAJ)

Recording system: AC bias

Erasure system: Magnet erase

Motor: DC motor (1)

Heads: Deck 1

Recording/playback head (1)

Erasure head (1)

Deck 2

Playback head (1)

Common section

Dimensions (W x H x D): 274 x 301.2 x 281.6 mm

(10 7/8 x 11 7/8 x 11 1/8 in.)

Weight: 4.15 kg (9.13 lbs.)

(not including batteries)

CD player section

Disc: Compact disc

Scanning method: Non-contact optical laser

(semiconductor laser application)

Laser: Semiconductor laser

λ =780 nm

Rotation speed: Approx. 500 - 200 rpm/CLV

Error correction: Cross Interleave, Reed

Solomon code

Number of channels: 2 channels

D/A conversion: 1-bit dual

Speaker

Cabinet type: 2-way bass reflex type

Speaker: 120 mm cone type woofer

27 mm ceramic type tweeter

Impedance: 4 ohms

Allowable max. input: 10 W

Dimensions (W x H x D): 211.5 x 292 x 210.8 mm x 2

(8 3/8 x 11 1/2 x 8 3/8 in.)

Weight: 1.55 kg (3.41 lbs.) x 2

• Design and specifications are subject to change without notice.

ACCESSORIES LIST

REF. NO PART NO. KANRI DESCRIPTION

NO.

1 86-CT4-915-010 IB,U(ESF)FM

2 86-CT4-951-010 RC UNIT,RC-6AT01

! 3 87-A80-027-010 AC CORD SET,U BLK SPT2

3

Page 4

ELECTRICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

IC

87-A20-459-010 C-IC,LC78622ED

86-CT4-638-010 IC,LC867120W-5E13

87-A20-042-010 IC,BA178M05T

87-070-282-010 IC,BU2092

87-070-083-010 IC,GP1U281X

87-A20-186-010 IC,LA9240M

87-070-417-010 IC,NJM4558 DD

87-070-416-010 IC,NJU7201 L55

87-A20-157-010 IC,TA2092N

87-017-680-010 IC,TA8176SN

87-017-916-010 IC,BU4066BC

87-001-176-010 IC,TA8102P

87-002-268-010 IC,LA1851N

87-001-376-010 IC,LC7218

87-017-681-010 IC,TA8126S

87-020-828-010 IC,BA3416BL

87-017-914-010 IC,BU4094 BCP

87-017-804-010 IC,BU4052BC

87-017-947-010 IC,M62412P

87-017-564-010 IC,LC7533

87-002-848-010 IC,TA8229K

87-A20-558-040 C-IC,MM1354AJ

87-001-440-010 IC,BA15218N

TRANSISTOR

89-213-702-010 TR,2SB1370E(1.8W)

87-026-291-080 TR,DTC124XS

89-501-614-080 FET,2SK161Y

87-026-463-080 TR,2SA933SRS(0.3W)

89-319-233-080 TR,2SC1923 (0.1W)

89-112-965-080 TR,2SA1296GR(0.75W)

87-026-464-080 TR,DTC114TS (0.3W)

87-026-572-080 TR,DTA114TS

87-026-462-080 TR,2SC1740 S(RS 0.3W)

87-026-287-080 TR,DTC143ES

87-026-286-080 TR,DTA143ES

89-502-464-080 TR,2SK246Y

89-318-154-080 TR,2SC1815Y(0.4W)

87-026-214-080 TR,DTA114YS (0.3W)

89-320-011-080 TR,2SC2001K(15W)

89-322-405-680 TR,2SC2240GR/BL

89-414-683-080 TR,2SD1468S 150MHZ 0.4

89-113-187-080 TR,2SA1318TU

89-109-521-080 TR,2SA952K(0.6W)

87-026-290-080 TR,DTA124XS

DIODE

87-070-345-080 DIODE,IN4148

87-A40-156-010 DIODE,1N5392

87-017-164-080 ZENER,HZS9A2L

87-017-148-080 ZENER,HZS6A1L

87-017-139-080 ZENER,HZS15-2

MAIN C.B

C2 87-A10-131-010 CAP,CER 5P-50 K CH

C3 87-A10-136-010 CAP,CER 10P-50K CH

C4 87-A10-172-010 CAP,CER 470P-50 K B

C5 87-A10-132-010 CAP,CER 6P-50 K CH

C6 87-A10-136-010 CAP,CER 10P-50K CH

C7 87-A10-182-010 CAP,CER 0.01-50 Z F

C8 87-A10-182-010 CAP,CER 0.01-50 Z F

C10 87-A10-133-010 CAP,CER 7P-50 K CH

C11 87-A10-138-010 CAP,CER 15P-50 K CH

C12 87-A10-173-010 CAP,CER 560P-50 K B

C13 87-A10-182-010 CAP,CER 0.01-50 Z F

C15 87-A10-138-010 CAP,CER 15P-50 K CH

NO.

REF. NO PART NO. KANRI DESCRIPTION

C16 87-A10-163-010 CAP,CER 82P-50 K SL

C17 87-A10-182-010 CAP,CER 0.01-50 Z F

C18 87-A10-182-010 CAP,CER 0.01-50 Z F

C21 87-A10-176-010 CAP,CER 1000P-50 M D

C22 87-018-108-080 CAP,TC-U 20P-50 SL

C23 87-A10-170-010 CAP,CER 330P-50 K B

C24 87-A10-177-010 CAP,CER 1500P-50 M D

C31 87-A10-182-010 CAP,CER 0.01-50 Z F

C32 87-A10-182-010 CAP,CER 0.01-50 Z F

C41 87-A10-182-010 CAP,CER 0.01-50 Z F

C58 87-A10-171-010 CAP,CER 390P-50 K B

C60 87-018-173-080 CAP,TC-U 15P-50 UJ

C61 87-A10-128-010 CAP,CER 2P-50 K CH

C64 87-010-544-080 CAP, ELECT 0.1-50V

C74 87-A10-175-010 CAP,CER 820P-50 K B

C101 87-A10-182-010 CAP,CER 0.01-50 Z F

C103 87-010-248-080 CAP, ELECT 220-10V

C104 87-010-402-080 CAP, ELECT 2.2-50V

C105 87-A10-182-010 CAP,CER 0.01-50 Z F

C106 87-A10-181-010 CAP,CER 6800P-50 M D

C107 87-A10-168-010 CAP,CER 220P-50 K B

C108 87-010-401-080 CAP, ELECT 1-50V

C109 87-010-401-080 CAP, ELECT 1-50V

C110 87-010-401-080 CAP, ELECT 1-50V

C111 87-010-546-080 CAP, ELECT 0.33-50V

C113 87-010-404-080 CAP, ELECT 4.7-50V

C114 87-A10-172-010 CAP,CER 470P-50 K B

C115 87-A10-182-010 CAP,CER 0.01-50 Z F

C116 87-010-405-080 CAP, ELECT 10-50V

C117 87-A10-182-010 CAP,CER 0.01-50 Z F

C131 87-010-545-080 CAP, ELECT 0.22-50V

C132 87-010-545-080 CAP, ELECT 0.22-50V

C141 87-A10-182-010 CAP,CER 0.01-50 Z F

C142 87-010-221-080 CAP, ELECT 470-10V

C151 87-A10-157-010 CAP,CER 27P-50 K SL

C152 87-A10-157-010 CAP,CER 27P-50 K SL

C157 87-A10-176-010 CAP,CER 1000P-50 M D

C158 87-A10-176-010 CAP,CER 1000P-50 M D

C159 87-A10-182-010 CAP,CER 0.01-50 Z F

C160 87-010-263-080 CAP, ELECT 100-10V

C161 87-A10-182-010 CAP,CER 0.01-50 Z F

C162 87-A10-177-010 CAP,CER 1500P-50 M D

C163 87-A10-182-010 CAP,CER 0.01-50 Z F

C164 87-A10-163-010 CAP,CER 82P-50 K SL

C165 87-A10-182-010 CAP,CER 0.01-50 Z F

C166 87-A10-182-010 CAP,CER 0.01-50 Z F

C167 87-015-243-080 CAP,E 3.3-50 LL

C168 87-A10-182-010 CAP,CER 0.01-50 Z F

C171 87-A10-182-010 CAP,CER 0.01-50 Z F

C191 87-A10-177-010 CAP,CER 1500P-50 M D

C192 87-A10-169-010 CAP,CER 270P-50 K B

C194 87-010-263-080 CAP, ELECT 100-10V

C195 87-010-374-080 CAP, ELECT 47-10V

C301 87-018-130-080 CAP,TC-U 820P-50 B

C302 87-018-130-080 CAP,TC-U 820P-50 B

C303 87-A10-175-010 CAP,CER 820P-50 K B

C304 87-A10-175-010 CAP,CER 820P-50 K B

C305 87-010-374-080 CAP, ELECT 47-10V

C306 87-010-374-080 CAP, ELECT 47-10V

C307 87-010-382-080 CAP, ELECT 22-25V

C308 87-010-405-080 CAP, ELECT 10-50V

C309 87-010-545-080 CAP, ELECT 0.22-50V

C310 87-010-545-080 CAP, ELECT 0.22-50V

C311 87-010-248-080 CAP, ELECT 220-10V

C312 87-010-374-080 CAP, ELECT 47-10V

C315 87-010-401-080 CAP, ELECT 1-50V

C316 87-010-401-080 CAP, ELECT 1-50V

C317 87-010-382-080 CAP, ELECT 22-25V

C318 87-010-382-080 CAP, ELECT 22-25V

C319 87-010-405-080 CAP, ELECT 10-50V

NO.

4

Page 5

REF. NO PART NO. KANRI DESCRIPTION

NO.

C320 87-010-405-080 CAP, ELECT 10-50V

C321 87-A10-171-010 CAP,CER 390P-50 K B

C322 87-A10-171-010 CAP,CER 390P-50 K B

C325 87-A10-177-010 CAP,CER 1500P-50 M D

C326 87-A10-177-010 CAP,CER 1500P-50 M D

C327 87-010-404-080 CAP, ELECT 4.7-50V

C328 87-A10-176-010 CAP,CER 1000P-50 M D

C329 87-A10-178-010 CAP,CER 2200P-50 M D

C331 87-010-374-080 CAP, ELECT 47-10V

C334 87-A10-167-010 CAP,CER 180P-50 K B

C341 87-A10-170-010 CAP,CER 330P-50 K B

C342 87-A10-170-010 CAP,CER 330P-50 K B

C351 87-010-382-080 CAP, ELECT 22-25V

C451 87-A10-182-010 CAP,CER 0.01-50 Z F

C452 87-A10-170-010 CAP,CER 330P-50 K B

C481 87-A10-182-010 CAP,CER 0.01-50 Z F

C501 87-010-401-080 CAP, ELECT 1-50V

C502 87-010-401-080 CAP, ELECT 1-50V

C503 87-010-401-080 CAP, ELECT 1-50V

C504 87-010-401-080 CAP, ELECT 1-50V

C505 87-010-221-080 CAP, ELECT 470-10V

C531 87-010-401-080 CAP, ELECT 1-50V

C532 87-010-401-080 CAP, ELECT 1-50V

C539 87-010-545-080 CAP, ELECT 0.22-50V

C540 87-010-545-080 CAP, ELECT 0.22-50V

C541 87-010-260-080 CAP, ELECT 47-25V

C571 87-010-401-080 CAP, ELECT 1-50V

C572 87-010-401-080 CAP, ELECT 1-50V

C573 87-010-401-080 CAP, ELECT 1-50V

C574 87-010-401-080 CAP, ELECT 1-50V

C579 87-010-374-080 CAP, ELECT 47-10V

C580 87-010-401-080 CAP, ELECT 1-50V

C581 87-010-544-080 CAP, ELECT 0.1-50V

C582 87-010-371-080 CAP, ELECT 470-6.3V

C583 87-010-221-080 CAP, ELECT 470-10V

C591 87-010-401-080 CAP, ELECT 1-50V

C592 87-010-401-080 CAP, ELECT 1-50V

C593 87-A10-182-010 CAP,CER 0.01-50 Z F

C594 87-A10-182-010 CAP,CER 0.01-50 Z F

C605 87-A10-178-010 CAP,CER 2200P-50 M D

C606 87-A10-178-010 CAP,CER 2200P-50 M D

C607 87-010-406-080 CAP, ELECT 22-50

C608 87-010-406-080 CAP, ELECT 22-50

C609 87-010-260-080 CAP, ELECT 47-25V

C613 87-010-263-080 CAP, ELECT 100-10V

C614 87-010-263-080 CAP, ELECT 100-10V

C615 87-010-376-090 CAP 10-2200

C616 87-010-376-090 CAP 10-2200

C621 87-010-260-080 CAP, ELECT 47-25V

C622 87-010-387-080 CAP,E 470-25 SME

C625 87-010-405-080 CAP, ELECT 10-50V

C641 87-010-248-080 CAP, ELECT 220-10V

C720 87-010-405-080 CAP, ELECT 10-50V

C721 87-010-928-090 CAP,E 4700-25 SMG

C722 87-010-385-080 CAP, ELECT 220-25V

C723 87-010-248-080 CAP, ELECT 220-10V

C724 87-A10-182-010 CAP,CER 0.01-50 Z F

C726 87-010-404-080 CAP, ELECT 4.7-50V

C727 87-010-401-080 CAP, ELECT 1-50V

C728 87-010-221-080 CAP, ELECT 470-10V

C729 87-010-263-080 CAP, ELECT 100-10V

C730 87-010-248-080 CAP, ELECT 220-10V

C741 87-010-263-080 CAP, ELECT 100-10V

C831 87-010-265-080 CAP, ELECT 33-16V

C832 87-010-401-080 CAP, ELECT 1-50V

CF1 87-008-261-010 FILTER, SFE10.7MA5-A

CF101 87-008-261-010 FILTER, SFE10.7MA5-A

CN302 86-CT4-620-010 CONN ASSY,5P RPH

CN751 86-CT4-621-010 CONN ASSY,9P DECK

CN803 87-009-882-010 CONN,8P TKC-T H(F)

REF. NO PART NO. KANRI DESCRIPTION

NO.

CN804 87-009-882-010 CONN,8P TKC-T H(F)

CN901 87-A60-383-010 CONN,6P TIX-P V1

CT51 87-011-220-080 TRIMMER CAP 20P VTC

!IC602 87-001-132-010 FUSE, ICP-N38

IFT101 87-008-470-010 IFT FM (QUAD) PS

J601 87-009-216-010 JACK, DIA 3.5

J602 87-A60-217-010 TERMINAL,SPKR 4P

J801 87-099-715-010 JACK,PIN 2P

L1 87-003-133-010 COIL,0.22UH

L2 87-A50-046-010 COIL,RF FM5-1/2 TS

L3 87-006-217-010 COIL,RF FM 4-1/2TS

L4 87-005-847-080 COIL,2.2UH(CECS)

L5 87-006-217-010 COIL,RF FM 4-1/2TS

L52 87-007-301-010 COIL,OSC MW,PS

L61 86-CT4-609-010 BAR ANT,AM

L151 87-A50-073-080 COIL,4.70UH (CECS)

L152 87-A50-083-080 COIL,47UH (CECS)

L191 87-A50-094-010 COIL,OSCDC-DC 796KHZ

L192 87-A50-087-080 COIL,100UH (CECS)

L301 87-007-322-010 COIL OSC BIAS 61 KHZ

L601 87-A50-067-080 COIL,1.00UH (CECS)

L602 87-A50-067-080 COIL,1.00UH (CECS)

MFT101 87-008-460-010 FLTR,CFMT 450PS

PN301 87-A60-110-010 CONN,4P V S2M-4W

PN302 87-A60-111-010 CONN,5P V S2M 5W

PN701 87-A60-110-010 CONN,4P V S2M-4W

PN751 87-A60-037-010 CONN,9P V S2M-9W

PN801 87-099-854-010 CONN,6P S2M-6W

R607 87-022-480-080 RES,NF 2.2-1/4W J

R608 87-022-480-080 RES,NF 2.2-1/4W J

R821 87-022-480-080 RES,NF 2.2-1/4W J

R822 87-022-480-080 RES,NF 2.2-1/4W J

SFR101 87-024-173-080 SEMI-FIXED RESISTOR, 22K

SFR102 87-024-172-080 SEMI-FIXED RESISTOR, 10K

SFR751 87-024-169-080 SEMI-FIXED RESISTOR, 2.2K

SW301 87-A90-089-010 SW,SL 1-6-2

VC1 87-002-730-080 VARI-CAP,SVC203SPA

VC2 87-002-730-080 VARI-CAP,SVC203SPA

VC3 87-002-730-080 VARI-CAP,SVC203SPA

VC52 81-754-634-010 VARI-CAP, KV1260

X101 87-A70-040-010 VIB,CER457

X151 87-030-243-010 VIB X’TAL 7.2MHZ

FRONT C.B

C401 87-A10-165-010 CAP,CER 120P-50 K SL

C402 87-A10-178-010 CAP,CER 2200P-50 M D

C404 87-A10-166-010 CAP,CER 150P-50 K B

C405 87-010-401-080 CAP, ELECT 1-50V

C406 87-010-545-080 CAP, ELECT 0.22-50V

C407 87-A10-176-010 CAP,CER 1000P-50 M D

C408 87-010-401-080 CAP, ELECT 1-50V

C409 87-A10-176-010 CAP,CER 1000P-50 M D

C410 87-010-248-080 CAP, ELECT 220-10V

C411 87-010-374-080 CAP, ELECT 47-10V

C412 87-010-405-080 CAP, ELECT 10-50V

C501 87-010-248-080 CAP, ELECT 220-10V

C503 87-010-401-080 CAP, ELECT 1-50V

C504 87-010-400-080 CAP, ELECT 0.47-50V

C506 87-A10-140-010 CAP,CER 22P-50 K CH

C507 87-A10-140-010 CAP,CER 22P-50 K CH

C508 87-A10-159-010 CAP,CER 39P-50 K SL

C509 87-A10-160-010 CAP,CER 47P-50 K SL

C510 87-A10-158-010 CAP,CER 33P-50 K SL

C512 87-A10-176-010 CAP,CER 1000P-50 M D

C513 87-010-405-080 CAP, ELECT 10-50V

C517 87-010-263-080 CAP, ELECT 100-10V

C518 87-010-545-080 CAP, ELECT 0.22-50V

C519 87-A10-176-010 CAP,CER 1000P-50 M D

C520 87-A10-182-010 CAP,CER 0.01-50 Z F

5

Page 6

REF. NO PART NO. KANRI DESCRIPTION

C521 87-010-374-080 CAP, ELECT 47-10V

C522 87-010-374-080 CAP, ELECT 47-10V

CN501 87-009-878-010 CONN,6P TKC-T H (M)

CN502 87-009-879-010 CONN,8P TKC-TH(M)

CN503 87-009-879-010 CONN,8P TKC-TH(M)

CON902 86-CT4-641-010 CONN,1P PIN

D514 87-A40-162-010 LED,L-1154SRD

D519 87-A40-162-010 LED,L-1154SRD

D520 87-A40-162-010 LED,L-1154SRD

D521 87-A40-162-010 LED,L-1154SRD

D522 87-A40-162-010 LED,L-1154SRD

D523 87-A40-162-010 LED,L-1154SRD

D524 87-A40-162-010 LED,L-1154SRD

D525 87-A40-162-010 LED,L-1154SRD

D526 87-A40-162-010 LED,L-1154SRD

D527 87-A40-162-010 LED,L-1154SRD

D528 87-A40-162-010 LED,L-1154SRD

D529 87-A40-161-010 LED,L-1154SGD

D530 87-A40-161-010 LED,L-1154SGD

D531 87-A40-161-010 LED,L-1154SGD

D532 87-A40-161-010 LED,L-1154SGD

D533 87-A40-161-010 LED,L-1154SGD

D534 87-A40-161-010 LED,L-1154SGD

D535 87-A40-161-010 LED,L-1154SGD

D536 87-A40-161-010 LED,L-1154SGD

D537 87-A40-161-010 LED,L-1154SGD

D550 87-A40-161-010 LED,L-1154SGD

J401 82-NF7-630-010 JACK,3.5 MO

L401 87-A50-067-080 COIL,1.00UH (CECS)

L500 87-003-171-010 COIL,15UH TROIDAL

L501 87-005-849-080 COIL,10UH(CECS)

L502 87-003-171-010 COIL,15UH TROIDAL

LCD501 86-CT4-601-010 LCD,6CT-4

SW570 87-A90-483-080 SW,TACT TS2101

SW571 87-A90-483-080 SW,TACT TS2101

SW572 87-A90-483-080 SW,TACT TS2101

SW573 87-A90-483-080 SW,TACT TS2101

SW574 87-A90-483-080 SW,TACT TS2101

SW575 87-A90-483-080 SW,TACT TS2101

SW576 87-A90-483-080 SW,TACT TS2101

SW577 87-A90-483-080 SW,TACT TS2101

SW581 87-A90-483-080 SW,TACT TS2101

SW582 87-A90-483-080 SW,TACT TS2101

SW583 87-A90-483-080 SW,TACT TS2101

SW584 87-A90-483-080 SW,TACT TS2101

SW585 87-A90-483-080 SW,TACT TS2101

SW586 87-A90-483-080 SW,TACT TS2101

SW587 87-A90-483-080 SW,TACT TS2101

SW588 87-A90-483-080 SW,TACT TS2101

SW589 87-A90-483-080 SW,TACT TS2101

VR401 86-NFA-607-010 VR,RTRY 10K15AX1 1 V XV0121PVN

X501 87-030-273-010 VIB,XTAL 32.768K5PPM

X502 87-A70-018-080 VIB,CER 6.00MHZ MG200

CD C.B

C1 87-010-403-080 CAP, ELECT 3.3-50V

C4 87-010-248-080 CAP, ELECT 220-10V

C6 87-010-374-080 CAP, ELECT 47-10V

C9 87-010-263-080 CAP, ELECT 100-10V

C10 87-010-263-080 CAP, ELECT 100-10V

C12 87-010-401-080 CAP, ELECT 1-50V

C14 87-010-405-080 CAP, ELECT 10-50V

C16 87-010-545-080 CAP, ELECT 0.22-50V

C17 87-A10-170-010 CAP,CER 330P-50 K B

C30 87-A10-168-010 CAP,CER 220P-50 K B

C31 87-010-400-080 CAP, ELECT 0.47-50V

C32 87-010-263-080 CAP, ELECT 100-10V

C33 87-010-402-080 CAP, ELECT 2.2-50V

C36 87-010-374-080 CAP, ELECT 47-10V

NO.

C37 87-010-404-080 CAP, ELECT 4.7-50V

C40 87-A10-127-010 CAP,CER 1P-50 K CH

C42 87-A10-140-010 CAP,CER 22P-50 K CH

C48 87-A10-157-010 CAP,CER 27P-50 K SL

C50 87-A10-172-010 CAP,CER 470P-50 K B

C54 87-A10-168-010 CAP,CER 220P-50 K B

C57 87-A10-140-010 CAP,CER 22P-50 K CH

C58 87-A10-140-010 CAP,CER 22P-50 K CH

C59 87-010-263-080 CAP, ELECT 100-10V

C62 87-010-374-080 CAP, ELECT 47-10V

C63 87-010-405-080 CAP, ELECT 10-50V

C64 87-010-405-080 CAP, ELECT 10-50V

C65 87-A10-170-010 CAP,CER 330P-50 K B

C66 87-A10-170-010 CAP,CER 330P-50 K B

C68 87-010-401-080 CAP, ELECT 1-50V

C69 87-A10-166-010 CAP,CER 150P-50 K B

C76 87-A10-102-080 CAP,E 1000-10 REA

C77 87-010-263-080 CAP, ELECT 100-10V

C81 87-010-404-080 CAP, ELECT 4.7-50V

C82 87-010-221-080 CAP, ELECT 470-10V

C84 87-010-263-080 CAP, ELECT 100-10V

C89 87-010-263-080 CAP, ELECT 100-10V

CON1 86-CT4-623-010 CONN ASSY,6P CD 1

CON2 88-802-082-220 CONN ASSY,8P

CON3 88-802-092-230 CONN ASSY,9P

CON6 88-802-062-660 CONN ASSY,6P

FB1 87-008-474-080 F-BEAD,EMI BL02RN1

FB2 87-008-372-080 FILTER, EMI BL OIRNI

FB3 87-008-372-080 FILTER, EMI BL OIRNI

PIN4 87-A60-109-010 CONN,2P V S2M-2W

X1 81-592-641-080 CERALOCK 16.93MHZ

POWER C.B

!F701 87-035-488-010 FUSE,3.15A 125V D UL

!FC701 87-A90-160-080 FUSE CLAMP,FC 51F

!FC702 87-A90-160-080 FUSE CLAMP,FC 51F

DRIVE C.B

M3 87-045-356-010 MOT,RF-310A 30

PIN3 87-009-352-010 CONN,9P PH H

SW1 87-036-110-010 PUSH SWITCH

SW2 87-036-110-010 PUSH SWITCH

DOOR SW C.B

SW3 87-036-292-010 SW,LEAF LSA-1135FAU

Q-SOUND C.B

C901 87-010-382-080 CAP, ELECT 22-25V

C902 87-010-382-080 CAP, ELECT 22-25V

C907 87-010-374-080 CAP, ELECT 47-10V

C909 87-010-263-080 CAP, ELECT 100-10V

C910 87-010-405-080 CAP, ELECT 10-50V

REF. NO PART NO. KANRI DESCRIPTION

NO.

6

Page 7

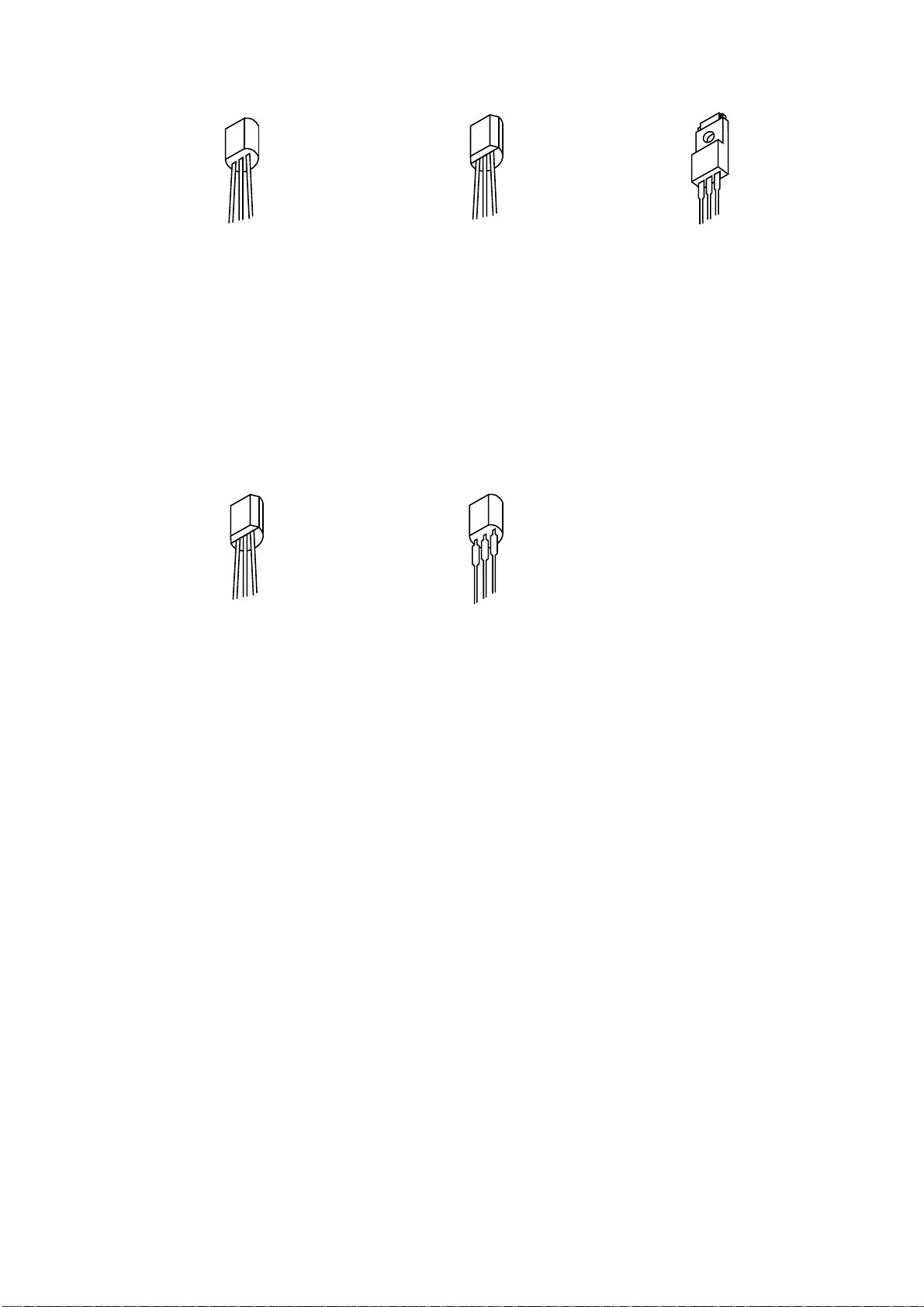

TRANSISTOR ILLUSTRATION

E C B B C E

2SA952

2SA1296

2SA1318

2SC1815

2SC1923

2SC2001

2SC2240

D S G S G D

2SK161 2SK246

E C B

2SA933S

2SC1740S

2SD1468

DTA114TS

DTA114YS

DTA124XS

DTA143ES

DTC114TS

DTC124XS

DTC143ES

2SB1370

7

Page 8

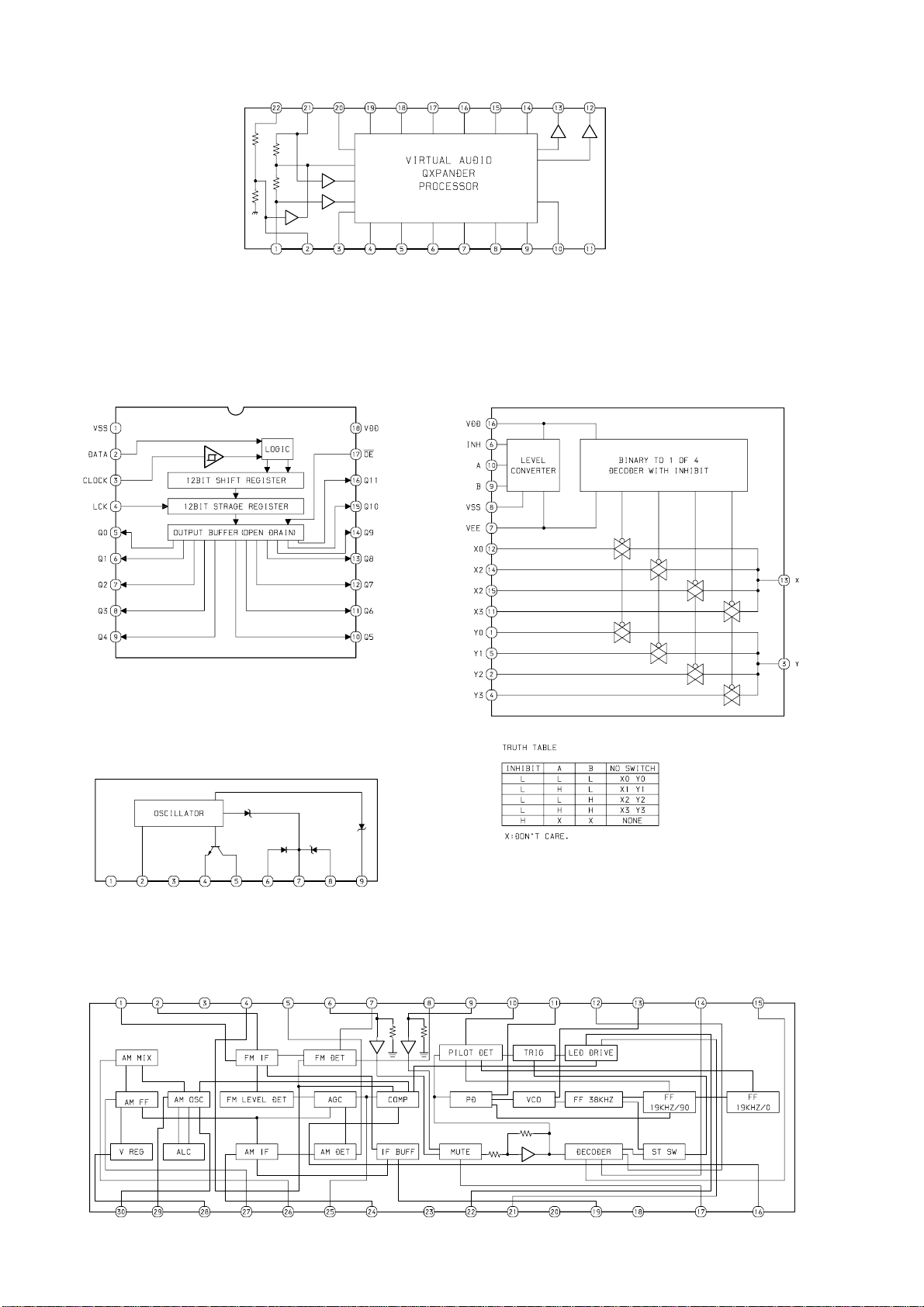

IC BLOCK DIAGRAMS

IC, MM1354AJ

IC, BU2092 IC,BU4052BC

IC, T A8162S

IC, LA1851N

8

Page 9

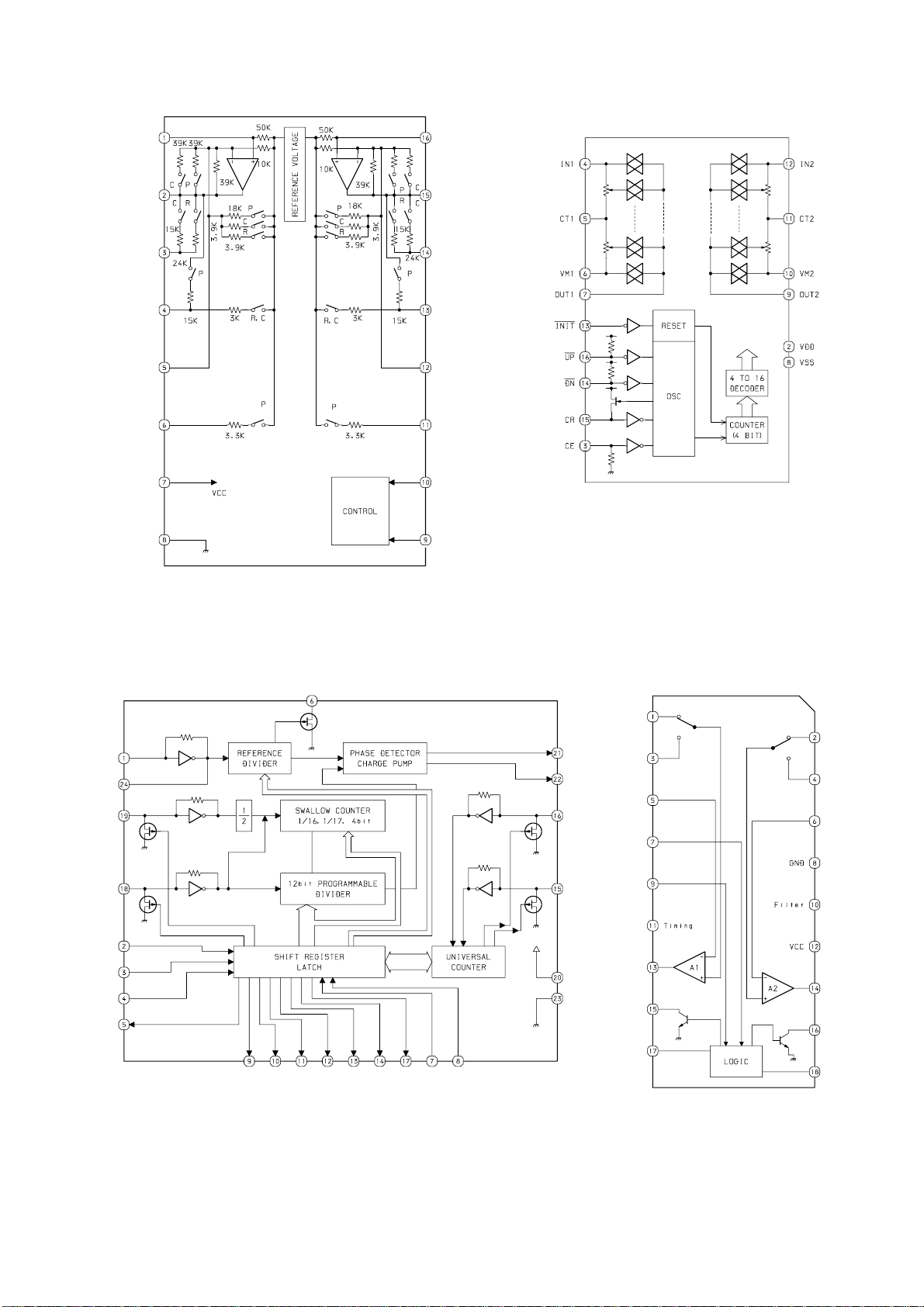

IC, M62412P IC, LC7533

IC, LC7218 IC,BA3416BL

9

Page 10

IC, TA8102P IC, TA2092N

IC, T A8176SN/F

IC, BU4094BCP

10

Page 11

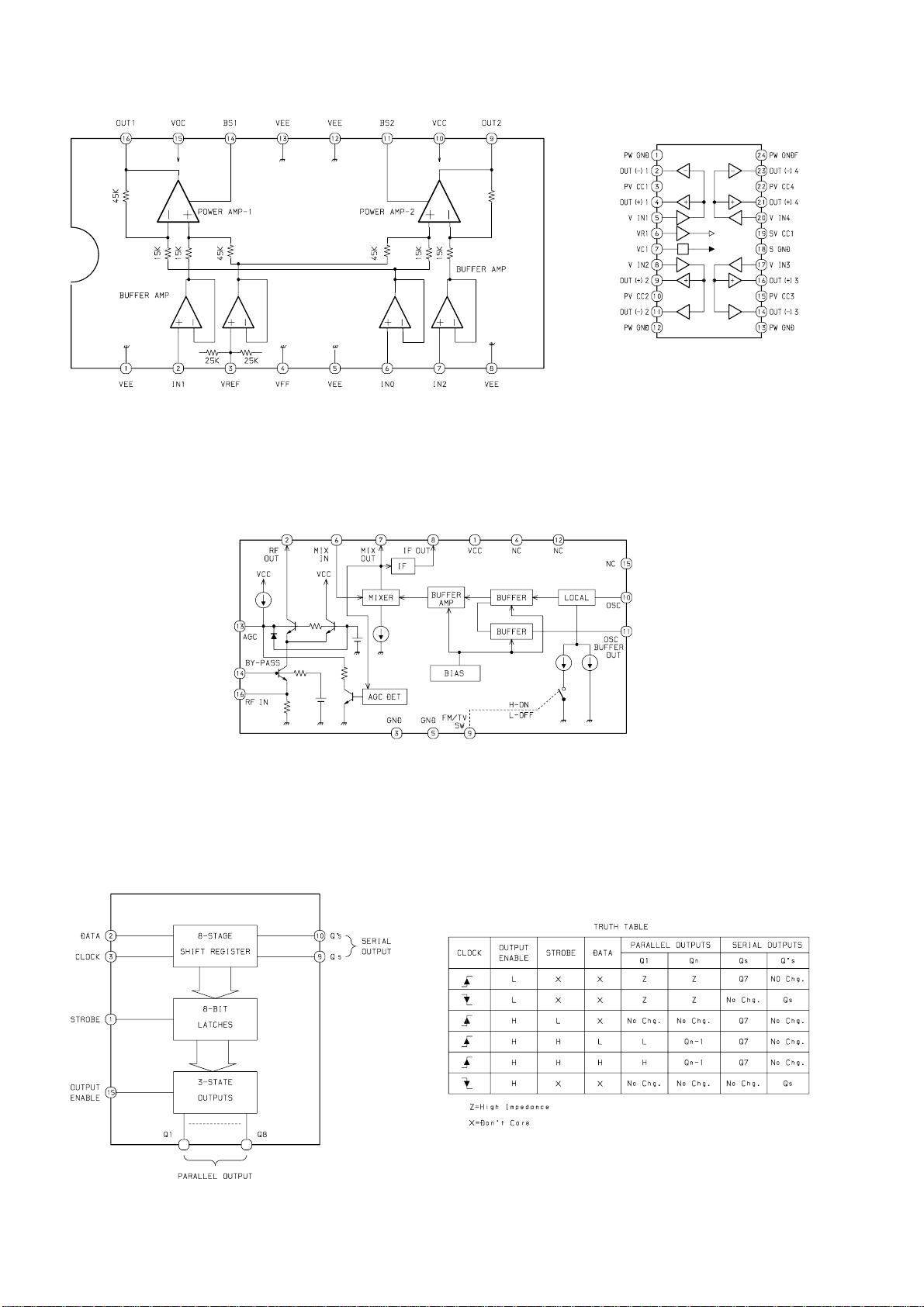

ADJUSTMENT

<TUNER SECTION>

A MAIN C.B

0

L301

R334

TP301

PN751

91

BAR ANT.

L152

SFR102

MFT101

TP1

L61

TP4

L5

IC101

R107

L52

L3

CT51

IFT101

TP3

TP2

R102

SFR101

L2

4

3

5

6

7

5

1

2

1. AM VT Adjustment

Settings: • Test point: TP1

• Adjustment location: L52

Method: Set to AM 530 kHz adjust L52 so that the test point

becomes 1.3 V ± 0.05 V.

2. AM Tracking Adjustment

L61............................................................................... 600 kHz

CT51 .......................................................................... 1400 kHz

3. FM VT Adjustment

Settings: • Test point: TP1

• Adjustment location: L5

Method: Set to FM 87.5 MHz adjust L5 so that the test point

becomes 4.0 V ± 0.3 V.

4. FM Tracking Adjustment

L2, L3 ...................................................................... 87.5 kMHz

5. DC balance/ MONO Distortion Adjustment

Settings: • Test point: TP2, TP3

• Adjustment location: IFT101

• Input level: 60 dB

Method: Set to FM 98.0 MHz and adjust IFT101 so that the

voltage between TP2 and TP3 becomes 0 V ± 0.02 V.

6. AM tuning Adjustment

Settings: • Adjustment location: SFR102

Method: Make setup for AM 1400 kHz. Adjust SFR102 so that

the machine performs Auto Stop when 50 ± 2 dB is

input.

* Confirm that TP4 is “L” at this time.

7. FM tuning Adjustment

Settings: • Adjustment location: SFR101

Method: Make setup for FM 98.0 MHz. Adjust SFR101 so that

the machine performs Auto Stop when 33 ± 2 dB is

input.

* Confirm that TP4 is “L” at this time.

<TAPE SECTION>

8. Tape Speed Adjustment (DECK1)

Settings: • Test tape: TTA-100

• Adjustment location: SFR751

Method: Play back the test tape with DECK1 and adjust SFR751

so that the output frequency is 3000 Hz. After the adjustment, check that the frequency of DECK2 is 3000

± 45 Hz.

9. Azimuth Adjustment (DECK1, DECK2)

Settings: • Test tape: TTA-320

• Adjustment location:

Head azimuth adjustment screw

Method: Play back the 10 kHz signal of test tape and adjust

screw so that the output becomes maximum.

10. Bias OSC Fequency Adjustment

Settings:• Test tape: TTA-601

• Adjustment location: L301

• Test point: TP301

Method: Set to the REC mode. Adjust L301 so that thr fre-

quency counter of the test point becomes 71.5 kHz ±

0.5 kHz

8

SFR751

RPH (DECK1)/PH(DECK2)

9

PRACTICAL SERVICE FIGURE

<RADIO SECTION>

<FM>

Frequency range: 87.5 ~ 108.0 MHz

IHF Sensitivity: 18.0 ± 5.0 dB (at 87.5 MHz)

(Distortion 3%): 19.0 ± 5.0 dB (at 98.0, 108.0 MHz)

S/N ratio: 60 ± 5.0 dB (at 98.0 MHz)

Intermediate frequency: 10.7 MHz

Stereo separation: More than 20 dB

<AM>

Frequency range: 530 ~ 1710 kHz

Sensitivity: 50 ± 5 dB (at 600 kHz)

45 ± 5 dB (at 1000 kHz)

43 ± 5 dB (at 1400 kHz)

Intermediate frequency: 450 kHz

<TAPE RECORDER SECTION>

Recording bias frequency: 71.5 ± 0.5 kHz

Erasing ratio (400 Hz, 0 dB): More than 60 dB

Distortion (T. H. D 10%): Less than 3.0% (PB)

S/N ratio: More than 40 dB (AC/DC, PB)

More than 37 dB (AC, REC/PB)

Noise (PB) Less than 1 mV/0.6 mV

(AC/DC, MIN)

Tape speed: 3000 ± 90 Hz

Wow & flutter: Less than 0.4% (JIS UN WTD)

Take-up torque: 45 ± 15 g-cm

F.F & REW torque 100 g-cm

+40

–45

1211

Page 12

BLOCK DIAGRAM-1 (TUNER SECTION)

1413

Page 13

BLOCK DIAGRAM-2 (MAIN SECTION)

1615

Page 14

SCHEMATIC DIAGRAM-1 (MAIN SECTION)

1817

Page 15

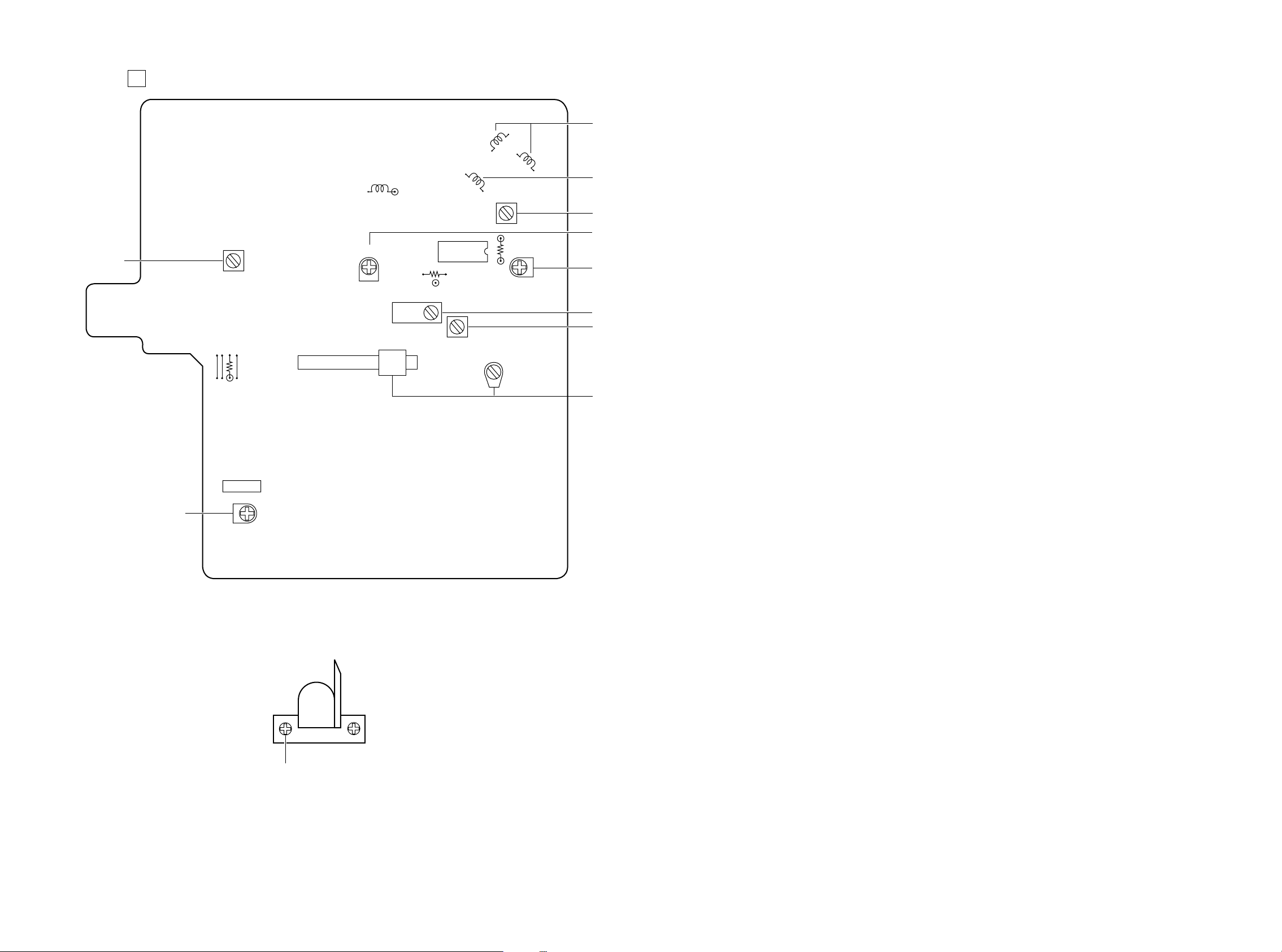

WIRING-1 (MAIN SECTION)

AC120V

60Hz

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

2019

Page 16

SCHEMATIC DIAGRAM-2 (FRONT SECTION)

2221

Page 17

WIRING-2 (FRONT SECTION)

Q SOUND

GEQ

GEQ OFF

D523

JAZZ

D524

POP

D525

ROCK

D514

Q SOUND

(GEQ)

1

A

B

234567

8

9

10

11 12 13

14

C

D

E

F

G

H

I

J

2423

Page 18

SCHEMATIC DIAGRAM-3 (CD SECTION)

2625

Page 19

WIRING-3 (CD SECTION)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

2827

Page 20

SCHEMATIC DIAGRAM-4 (Q-SOUND SETION)

IC DESCRIPTION

IC, LA9240M

Pin No. Pin Name I/O Description

1

FIN2

Pin to which external pickup photo diode is connected. RF signal is created by adding

I

with the FIN1 pin signal. FE signal is created by subtracting from the FIN1 pin signal.

10

11

12

13

14

15

16

2

3

4

5

6

7

8

9

FIN1

E

F

TB

TE–

TE

TESI

SCI

TH

TA

TD–

TD

JP

TO

FD

I

Pin to which external pickup photo diode is connected.

Pin to which external pickup photo diode is connected. TE signal is created by

I

subtracting from the F pin signal.

I

Pin to which external pickup photo diode is connected.

I

DC component of the TE signal is input.

I

Pin to which external resistor setting the TE signal gain is connected between the TE pin.

O

TE signal output pin.

TES “Track Error Sense” comparator input pin. TE signal is passed through a band-

I

pass filter then input.

I

Shock detection signal input pin.

I

Tracking gain time constant setting pin.

O

TA amplifier output pin.

Pin to which external tracking phase compensation constants are connected between

I

the TD and VR pins.

I

Tracking phase compensation setting pin.

I

Tracking jump signal (kick pulse) amplitude setting pin.

O

Tracking control signal output pin.

O

Focusing control signal output pin.

17

18

19

20

21

22

23

24

25

26

27

28

29

30, 31

FD–

FA

FA–

FE

FE–

A–GND

SP

SPI

SPG

SP–

SPD

SLEQ

SLD

SL–, SL+

—

Pin to which external focusing phase compensation constants are connected between

I

the FD and FA pins.

Pin to which external focusing phase compensation constants are connected between

I

the FD– and FA– pins.

Pin to which external focusing phase compensation constants are connected between

I

the FA and FE pins.

O

FE signal output pin.

I

Pin to which external FE signal gain setting resistor is connected between the FE pin.

Analog signal GND.

O

Single ended output of the CV+ and CV– pin input signal.

O

Single ended output of the CV+ and CV– pin input signal.

I

Pin to which external spindle gain setting resistor in 12 cm mode is connected.

Pin to which external spindle phase compensation constants are connected together

I

with SPD pin.

O

Spindle control signal output pin.

I

Pin to which external sled phase compensation constants are connected.

O

Sled control signal output pin.

I

Sled advance signal input pin from microprocessor.

32, 33

34

35

JP–, JP+

TGL

TOFF

I

Tracking jump signal input pin from DSP.

I

Tracking gain control signal input from DSP. Low gain when TGL = H.

I

Tracking off control signal input pin from DSP. Off when TOFF = H.

3029

Page 21

Pin No. Pin Name I/O Description

36

TES

O

Pin from which TES signal is output to DSP.

37

38

39, 40

41

42

43

44

45

46

47

48

49

50

51

52

HFL

SLOF

CV–, CV+

RFSM

RFS–

SLC

SLI

D–GND

FSC

TBC

NC

DEF

CLK

CL

DAT

—

—

“High Frequency Level” is used to judge whether the main beam position is on top of

O

bit or on top of mirror.

I

Sled servo off control input pin.

I

CLV error signal input pin from DSP.

O

RF output pin.

RF gain setting and EFM signal 3T compensation constant setting pin together with

I

RFSM pin.

“Slice Level Control” is the output pin which controls the RF signal data slice level by

O

DSP.

I

Input pin which control the data slice level by the DSP.

Digital system GND.

O

Output pin to which external focus search smoothing capacitor is connected.

I

“Tracking Balance Control” EF balance variable range setting pin.

No connection.

O

Disc defect detector output pin.

I

Reference clock input pin. 4.23 MHz of the DSP is input.

I

Microprocessor command clock input pin.

I

Microprocessor command data input pin.

53

54

55

56

57

58

59

60

61

62

63

64

CE

DRF

FSS

VCC2

REFI

VR

LF2

PH1

BH1

LDD

LDS

VCC1

—

—

—

I

Microprocessor command chip enable input pin.

O

“Detect RF” RF level detector output.

I

“Focus Search Select” focus search mode (± search/+ search) select pin.

Servo system and digital system Vcc pin.

Pin to which external bypass capacitor for reference voltage is connected.

O

Reference voltage output pin.

I

Disc defect detector time constant setting pin.

I

Pin to which external capacitor for RF signal peak holding is connected.

I

Pin to which external capacitor for RF signal bottom holding is connected.

O

APC circuit output pin.

I

APC circuit input pin.

RF system Vcc pin.

31

Page 22

IC, LC78622D

Pin No. Pin Name I/O Description

1

DEFI

I

Defect sense signal (DEF) input pin. (Connect to 0V when not used).

2

3

4

5

6

7

8

9

10

11

12, 13

14

15

16

17

18

TAI

PDO

VVSS

ISET

VVDD

FR

VSS

EFMO

EFMIN

TEST2

CLV+, CLK–

___

V/P

HFL

TES

TOFF

TGL

—

—

—

I

O

For PLL.

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

Phase comparator output pin to control external VCO.

GND pin for built-in VCO. Be sure to connect to 0V.

Pin to which external resistor adjusting the PD0 output current.

Power supply pin for built-in VCO.

I

Pin for VCO frequency range adjustment.

Digital system GND. Be sure to connect to 0V.

O

For slice level control.

I

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

O

Disc motor control output. Three level output is possible using command.

Rough servo or phase control automatic selection monitoring output pin. Rough servo

O

EFM signal output pin.

EFM signal input pin.

at H. Phase servo at L.

I

Track detect signal input pin. Schmidt input.

I

Tracking error signal input pin. Schmidt input.

O

Tracking OFF output pin.

O

Tracking gain selection output pin. Gain boost at L.

19, 20

21

22

23

24-28

29

30

31

32, 33

34

35

36

37

JP+, JP–

PCK

FSEQ

VDD

CONT1-CONT5

EMPH

C2F

DOUT

TEST3, TEST4

N.C.

MUTEL

LVDD

LCHO

O

O

O

—

I/O

O

O

O

—

O

—

O

Track jump control signal output pin. Three level output is possible using command.

EFM data playback clock monitoring pin 4.3218 MHz when phase is locked in.

Sync signal detection output pin. H when the sync signal which is detected from EFM

signal and thesync signal which is internally generated agree.

Digital system power supply pin.

The pin is controlled by the serial data

command from microprocessor. When

General purpose input/output pin 1 to 5.

the pin is not used, set the pin to the input

terminal and connect to 0V, or alternately

set the pin to output terminal and leave

the pin open.

De-emphasis monitor output pin. De-emphasis disc is being played back at H.

C2 flag output pin.

DIGITAL OUT output pin. (EIAJ format).

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

Not used. Set the pin to open.

L-channel mute output pin.

L-channel 1-bit DAC.

L-channel power supply pin.

L-channel output pin.

38

39

40

41

42

LVSS

RVSS

RCHO

RVDD

MUTER

—

—

—

O

R-channel 1-bit DAC.

O

L-channel GND. Be sure to connect to 0V.

R-channel GND. Be sure to connect to 0V.

R-channel output pin.

R-channel power supply pin.

R-channel mute output pin.

32

Page 23

Pin No. Pin Name I/O Description

43

XVDD

—

Crystal oscillator power supply pin.

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

XOUT

XIN

XVSS

SBSY

EFLG

PW

SFSY

SBCK

FSX

WRQ

RWC

SQOUT

COIN

___________

CQCK

________

RES

TST11

—

O

Pin to which external 16.9344 MHz crystal oscillator is connected.

I

Crystal oscillator GND pin. Be sure to connect to 0V.

O

Subcode block sync signal output pin.

O

C1, C2, single and dual correction monitoring pin.

O

Subcode P, Q, R, S, T, U and W output pin.

O

Subcode frame sync signal output pin. Falls down when subcode enters standby.

Subcode read clock input pin. Schmidt input. (Be sure to connected to 0V when not in

I

use.)

Pin outputting the 7.35 kHz sync signal which is generated by dividing frequency of

O

crystal oscillator.

O

Subcode Q output standby output pin.

I

Read/write control input pin. Schmidt input.

O

Subcode Q output pin.

I

Command input pin from microprocessor.

I

Command input read clock or subcode read input clock from SQOUT pin

I

LC78622 reset input pin. Set this pin to L once when the main power is turned on.

O

Test signal output pin. Use this pin as open (normally L output).

60

61

62

63

16M

4.2M

TEST5

______

CS

O

16.9344 MHz output pin.

O

4.2336 MHz output pin.

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

Chip select signal input pin with built-in pull-down resistor. Be sure to connect to 0V

I

while it is not controlling.

64

TEST1

Test signal input pin without built-in pull-down resistor. Be sure to connect to 0V.

I

Note: The same potential must be applied to the respective power supply terminals. (VDD, VVDD, LVDD, RVDD, XVDD)

33

Page 24

IC DESCRIPTION

IC, LC867120W-5E13

Pin No. Pin Name I/O Description

1

2, 3

4

5

6

7

8

9

10

11

12

13

14, 15

16

17

18

19

RWC

P14, P15

V. INITIAL

CKSFT

HOLD

RST

XT1

XT2

VSS1

CF1

CF2

VDD1

KEY0, KEY1

MIC LEV

DOOR

P84

WRQ

CD read, write control output

O

N. C

Volume initial output

O

Clock shift output

O

Hold input

I

Microprocessor reset

I

Connected to 32.768 kHz crystal

I

Connected to 32.768 kHz crystal

O

GND

Connected to 6 MHz ceramic lock

I

Connected to 6 MHz ceramic lock

O

Microprocessor power supply (5V)

Key A/D input

I

Mic level detection

I

CD door sw input

I

Bit input

I

CD sub code input

I

20

21

22

23

24

25

26

27

28

29

30~40

41

42

43, 44

45~60

61~63

64~67

DRF

MONO/ST

BEAT

T-BASS

HSP

INITIAL

TURDO

REC

RMT

PAO

S0~S10

VDD3

VSS3

S12, S13

S16~S31

V3~V1

COM0~COM3

CD detect RF level input

I

FM mono stereo rejection

I

BEAT sift SW output

O

T-BASS on off SW output

O

High speed dubbing selector output

O

Initial setting data

O

PLL IC tuner data input

I

Recording SW input

I

Remote control input

I

Initial setting input

I

N. C

Microprocessor power supply

GND

LCD segment output

O

LCD segment output

O

N. C

LCD common output

O

68

69

70

71

72

73

74

VSS2

VDD2

FSTB

MSTB

CLK

DATA

CDSW

GND

Microprocessor power supply (5 V)

Shift register clock output

O

Shift register data latch strobe output

O

PLL shift register data output

O

PLL shift register data output

O

CD SW output

O

34

Page 25

Pin No. Pin Name I/O Description

FL DISPLAY

75

76

77

78

79

80

PCONT

MUTE

CD MUTE

COIN

SQOUT

CQCK

O

Power supply control output

O

Main mute output

O

CD mute output

O

CD command output

I

CD sub code Q input

O

CD command clock output

3635

Page 26

MECHANICAL EXPLODED VIEW 1/1

2

3837

Page 27

MECHANICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

1 86-CT4-151-010 CABI,FR NE

2 86-CT4-011-010 WINDOW,CASS 2

3 86-CT4-157-010 BOX,CASS 2 NE

4 86-CT4-209-010 SPR-T,CASS

5 86-CT4-156-010 BOX,CASS 1 NE

6 86-CT4-010-010 WINDOW,CASS 1

7 86-CT4-161-010 WINDOW,DISP NE

8 86-CT4-159-010 WINDOW,DISC 1 NE

9 86-CT4-160-010 WINDOW,DISC 2 NE

10 86-CT4-026-010 BTN,DSL

11 86-CT4-167-010 BTN,PWR NE

12 86-CT4-168-010 BTN,Q SOUND

13 86-CT4-171-010 BTN,VOL NE

14 86-CT4-166-010 BTN,CONT NE

15 86-CT4-031-010 LENS,FUNC

16 86-CT4-165-010 BTN,FUNC NE

17 86-CT4-033-010 LENS,DISC

18 86-CT4-032-010 LENS,EQ

19 86-CT4-035-010 BADGE,AIWA 30N

20 86-CT4-172-010 KNOB,RTRY MIC NE

21 86-CT4-213-010 SPR-C,BATT B

22 86-CT4-014-010 WINDOW,CD 1

23 86-CT4-015-010 WINDOW,CD 2

24 86-CT4-158-010 BOX,CD NE

25 86-CT4-224-010 PLATE,MAGNET

26 87-036-368-010 MAGNET

27 86-CT4-210-010 SPR-T,CD 1

28 86-CT4-227-010 SPR-T,CD 2A

29 87-063-165-010 OIL-DMPR 150

30 86-CT4-164-010 BTN,CD OPEN NE

31 86-CT4-041-110 PANEL,CD

32 86-CT4-217-010 LEVER,EJECT

33 86-CT4-220-010 OIL-DMPR,GEAR

34 86-CT4-162-010 KEY,CASS 1 NE

35 86-CT4-163-010 KEY,CASS 2 NE

36 86-CT4-154-010 LID,BATT NE

37 86-CT4-155-010 HANDL,GLIP NE

38 86-CT4-216-110 PLATE,HANDLE

39 86-CT4-616-010 ANT,ROD

40 86-CT4-043-010 PLATE,VOLTAGE

NO.

REF. NO PART NO. KANRI DESCRIPTION

41 86-CT4-212-010 SPR-C,BATT A

42 86-CT4-152-010 CABI,REAR NE

43 87-A90-086-010 COVER,AC-SOCKET

! 44 87-A60-177-010 JACK AC E W/SW

! 45 86-CT4-612-010 PT,U

46 87-A90-089-010 SW,SL1-6-2

47 86-CT4-214-010 SPR-P,REC

48 86-CT4-207-010 COVER,LED

49 86-CT4-218-010 CUSHION,FOOT/PORON

50 86-CT4-206-010 GUIDE,EQ-LED

51 86-CT4-205-010 GUIDE,FUNC-LED

52 86-CT4-203-010 HLDR,ANT

53 86-CT4-222-010 HLDR,CHUCK A

54 86-CT4-223-010 HLDR,CHUCK B

55 86-CT4-208-010 HLDR,KEY-CASS

56 86-CT4-204-010 HLDR,LCD

57 86-CT4-201-010 HLDR,PCB A

58 86-CT4-202-010 HLDR,PCB B

59 86-CT4-221-010 OIL-DMPR,BRACKET

60 86-CT4-170-010 BTN,GEQ OFF

61 86-CT4-169-010 BTN,GEQ

62 86-CT4-153-010 CHAS,CD NE

63 86-CT4-620-010 CONN ASSY,5P RPH

64 86-CT4-621-010 CONN ASSY,9P DECK

65 86-CT4-641-010 CONN,1P PIN

A 87-751-097-410 SCREW 3X12

B 87-493-100-410 VWWS+3-16 BLK

C 87-661-100-410 VFT1+3-16

D 87-651-075-410 VT1 +2.6-10

E 87-623-097-410 QT1+3-12 B

F 81-CD5-204-110 SCREW,CD

G 87-067-520-010 TAPPING SCREW, VFTT+2-6

H 87-571-032-410 VIT+2-3

I 87-651-104-410 VT1+3-30

J 87-651-100-410 VT1+3-16

K 87-661-097-410 TAPPING SCREW, VFT1+3-12

L 87-067-579-010 TAPPING SCREW, BVT2+3-8

NO.

COLOR NAME TABLE

Basic color symbol Color Basic color symbol Color Basic color symbol Color

B Black C Cream D Orange

G Green H Gray L Blue

LT Transparent Blue N Gold P Pink

R Red S Silver ST Titan Silver

T Brown V Violet W White

WT Transparent White Y Yellow YT Transparent Yellow

LM Metallic Blue LL Light Blue GT Transparent Green

LD Dark Blue DT Transparent Orange

39

Page 28

TAPE MECHANSIM EXPLODED VIEW 1/2

E

47

G

12

F

LUG PLATE

48

9

8

10

13

49

21

22

23

28

25

30

51

K

32

33

34

35

11

20

50

J

L

16

c

24

2

29

a

46

44

3

14

17

18

19

31

C

45

M

4

5

15

38

39

6

7

26

36

A

b

a

1

C

40

D

D

H

27

37

40

43

42

41

B

Page 29

TAPE MECHANISM PARTS LIST 1/2

REF. NO PART NO. KANRI DESCRIPTION

1 S1-921-015-010 CHASSIS ASSY

2 S1-921-030-030 PANEL P SPRING

3 S1-921-260-050 GEAR PLATE SPRING

4 S1-921-265-020 GEAR PLATE ASSY

5 S1-921-043-090 PINCH ROLLER ARM ASY

6 S1-921-140-370 P ARM COLLER

7 S1-921-140-340 P ARM

8 S1-921-030-050 MG ARM

9 S1-921-030-4A0 HEAD BASE

10 S1-921-030-110 HEAD PANEL

11 S1-921-141-8A0 M CONTROL SPRING

12 S1-821-030-070 AZIMUTH SPRING

13 S1-921-143-010 BASE ASSY

14 S1-921-260-4A0 SENSING LEVER

15 S1-921-130-020 EJECT SLIDE LEVER

16 S1-921-141-3A0 P CONTROL SPRING

17 S1-921-140-820 PAUSE LEVER(F)

18 S1-921-140-120 PAUSE LEVER SPRING

19 S1-921-140-110 PAUSE STOPPER

20 S1-921-140-150 BUTTON LEVER SPRING(B)

21 S1-921-140-140 BUTTON LEVER SPRING(A)

22 S1-921-140-200 PR STOPPER

23 S1-921-140-090 SWITCH ACTUATOR

24 S1-821-011-590 E KICK LEVER

25 S1-921-140-080 PUSH BUTTON ACTUATOR

26 S1-921-050-060 SENSOR

27 S1-921-053-030 TAKE UP REEL ASSY

28 S1-921-140-220 REC BUTTON LEVER

29 S1-921-053-040 SUPPLY REEL ASSY

30 S1-921-140-230 PLAY BUTTON LEVER

31 S1-829-100-100 BACK TENSION SPRING

32 S1-921-140-240 REW BUTTON LEVER

33 S1-921-140-250 FF BUTTON LEVER

34 S1-921-140-260 STOP BUTTON LEVER

35 S1-921-140-610 PAUSE BUTTON LEVER

NO.

REF. NO PART NO. KANRI DESCRIPTION

NO.

36 S1-821-100-700 FF GEAR

37 S1-829-100-010 PACK SPRING

38 S1-821-100-690 RECORD SAFETY LEVER

39 S1-921-140-210 REC BUTTON LEVER SPRING

40 S1-921-260-020 CAM GEAR

41 S1-921-140-160 E ACTUATOR SPRING

42 S1-921-090-240 MAIN BBELT

43 S1-921-093-030 FLYWHEEL ASSY

44 S1-921-070-030 RF BELT

45 S1-921-073-080 RF CLUTCH ASSY

46 S1-921-140-170 P.S.LEVER SPRING

47 S6-209-100-100 E HEAD PH-K380-MS1

48 S6-201-011-110 HEAD,RP7442ES-0951

49 S6-401-011-520 LEAF SW MSW-1541F

50 S6-401-011-610 LEAF SW MSW-17820MVEI

51 S1-821-010-500 PLAY BUTTON LEVER SPRING

A S9-P33-200-320 DEL TITE SCREW M2-3

B S9-422-000-000 P WASHER CUT 1.2-3.8-0.3

C S9-679-000-000 P TAP SCREW M2-5

D S9-999-180-090 TAP SCREW M2-4.5

E S9-922-000-000 AZIMUTH SCREW M2-8

F S9-P01-200-310 SCREW,M2-3

G S9-004-000-000 SCREW M2-6

H S9-882-000-000 P WASHER 2-3.5-0.4

I S9-999-200-410 P TAP SCREW M2-3

J S9-999-030-130 P WASHER CUT 1.45-3.8-0.5

K S9-179-000-000 C TAP SCREW M2-3

L S9-999-000-030 P WASHER2.1-4-0.13

41

Page 30

TAPE MECHANSIM EXPLODED VIEW 2/2

G

1

E

2

F

LUG PLATE

52

57

22

53

23

24

21

20

11

5

12

13

M

6

7

31

30

e

A

32

33

3

4

8

a

9

10

18

J

L

19

N

14

c

54

15

16

17

34

35

36

26

27

28

29

25

46

44

H

51

B

B

e

f

50

B

d

45

f

37

B

B

46

C

38

39

42

43

48

D

c

a

56

C

d

D

K

41

40

I

49

48

55

47

42

Page 31

TAPE MECHANISM PARTS LIST 2/2

REF. NO PART NO. KANRI DESCRIPTION

1 S1-921-030-4A0 HEAD BASE

2 S1-821-030-070 AZIMUTH SPRING

3 S1-921-030-030 PANEL P SPRING

4 S1-921-260-050 GEAR PLATE SPRING

5 S1-921-265-020 GEAR PLATE ASSY

6 S1-921-140-370 P ARM COLLER

7 S1-921-140-340 P ARM

8 S1-921-030-110 HEAD PANEL

9 S1-921-143-010 BASE ASSY

10 S1-921-141-8A0 M CONTROL SPRING

11 S1-921-260-4A0 SENSING LEVER

12 S1-921-043-090 PINCH ROLLER ARM ASSY

13 S1-921-130-020 EJECT SLIDE LEVER

14 S1-921-141-3A0 P CONTROL SPRING

15 S1-921-140-820 PAUSE LEVER(F)

16 S1-921-140-120 PAUSE LEVER SPRING

17 S1-921-140-110 PAUSE STOPPER

18 S1-921-140-150 BUTTON LEVER SPRING(B)

19 S1-821-011-590 E KICK LEVER

20 S1-921-140-140 BUTTON LEVER SPRING(A)

21 S1-921-140-200 PR STOPPER

22 S1-921-140-090 SWITCH ACTUATOR

23 S1-921-140-080 PUSH BUTTON ACTUATOR

24 S1-921-140-230 PLAY BUTTON LEVER

25 S1-821-120-020 MOTOR OLLER SCREW

26 S1-921-140-240 REW BUTTON LEVER

27 S1-921-140-250 FF BUTTON LEVER

28 S1-921-140-260 STOP BUTTON LEVER

29 S1-921-140-610 PAUSE BUTTON LEVER

30 S1-821-100-700 FF GEAR

31 S1-921-050-060 SENSOR

32 S1-921-053-030 TAKE UP REEL ASSY

33 S1-829-100-010 PACK SPRING

34 S1-921-053-040 SUPPLY REEL ASSY

35 S1-829-100-100 BACK TENSION SPRING

36 S1-921-120-650 COLLER B

37 S1-921-140-170 P.S.LEVER SPRING

38 S1-921-073-080 RF CLUTCH ASSY

39 S1-921-070-030 RF BELT

40 S1-921-260-020 CAM GEAR

NO.

REF. NO PART NO. KANRI DESCRIPTION

NO.

41 S1-921-140-160 E ACTUATOR SPRING

42 S1-921-093-030 FLYWHEEL ASSY

43 S1-921-090-240 MAIN BBELT

44 S1-820-130-060 MOTOR RUBBER

45 S1-921-120-130 MOTOR PULLEY

46 S1-921-120-120 ANTI VIBR FELT MAT

47 S1-821-120-680 P KICK LEVER (A)

48 S1-821-120-230 PK COLLER SCREW A

49 S1-821-120-250 P KICK LEVER SPRING

50 S1-921-120-110 MOTOR BRACKET

51 S1-921-120-090 P KICK LEVER

52 S6-201-011-110 HEAD,RP7442ES-0951

53 S6-401-011-520 LEAF SW MSW-1541F

54 S6-401-011-610 LEAF SQ MSW-17820MVE1

55 S6-002-030-290 MOTOR EG530YD-2BH

56 S1-921-015-010 CHASSIS ASSY

57 S1-821-010-500 PLAY BUTTON LEVER SPRING

A S9-P33-200-320 DEL TITE SCREW M2-3

B S9-180-000-000 C TAP SCREW M2-4

C S9-679-000-000 P TAP SCREW M2-5

D S9-999-180-090 TAP SCREW M2-4.5

E S9-004-000-000 SCREW,M2-6

F S9-P01-200-310 SCREW,M2-3

G S9-922-000-000 AZIMUTH SCREW M2-7

H S9-182-000-000 C TAP SCREW M2-6

I S9-422-000-000 P WASHER CUT 12-3.8-0.3

J S9-999-030-130 P WASHER CUT 1.45-3.8-0.5

K S9-882-000-000 P WASHER 2-3.5-0.4

L S9-999-000-030 P WASHER 2.1-4-0.13

M S9-999-200-410 P TAP SCREW M2-3

N S9-P05-200-810 SCREW,S TAP 2-8

43

Page 32

CD MECHANISM EXPLODED VIEW

1

1

4

2

3

CHAS ASSY,

OUT-SERT

CD MECHANISM PARTS LIST 1/1

REF. NO PART NO. KANRI DESCRIPTION

NO.

1 85-ZG3-215-010 SHAFT,GUIDE

2 85-ZG3-210-010 GEAR,MOTOR

3 85-ZG3-211-010 GEAR,A

4 85-ZG3-212-010 GEAR,B

AL M8-5ZG-393-070 5ZG-3 D2

DRIVE C.B

44

Page 33

SPEAKER EXPLODED VIEW

FELT, SPKR

FELT, SPKR

6

4

7

5

3

9

FELT, SPKR

2

HLDR,WOOD

FELT, SPKR

8

1

SPEAKER PARTS LIST 1/1

REF. NO PART NO. KANRI DESCRIPTION

NO.

1 86-CT4-036-010 BADGE,AIWA

2 86-CT4-625-010 SPKR,W 120 40HM 10W 6CT-4

3 86-CT4-626-010 SPKR,T

4 86-CT4-627-010 CORD,2PSPKR

5 86-CT4-144-010 FRAME,SPKR NE

6 86-CT4-143-010 HLDR,CORD NE

7 86-CT4-110-010 CAP,SPKR

8 86-CT4-141-010 CABI,SPKR-FR NE

9 86-CT4-147-010 CABI,SPKR-REAR L NE

9 86-CT4-146-010 CABI,SPKR-REAR R NE

45

REF. NO PART NO. KANRI DESCRIPTION

NO.

A 87-661-097-410 TAPPING SCREW, VFT1+3-12

B 87-651-100-410 VT1+3-16

C 87-751-097-410 SCREW 3X12

Page 34

2–11, IKENOHATA 1–CHOME, TAITO-KU, TOKYO 110-8710, JAPAN TEL:03 (3827) 3111

920074

Printed in Singapore

Loading...

Loading...