Aiwa AZG-1 ZA8RDC, AZG-1 ZA4RNDC, AZG-1 ZA4RDC, AZG-1 YZA3RNDCM, AZG-1 YZA3RDCM Service Manual

...Page 1

AZG-1

English

SERVICE MANUAL

BASIC CD MECHANISM :ZA3:3ZG-2[E3]

CD-R/RW MECHANISM

TYPE

ZA3RDM

YZA3RDM

ZA3RNDM

YZA3RNDM

ZA3RN1DM

YKZA3RDF

YKZA3RNDF

ZA3RNM

YZA3RDCM

YZA3RNDCM

ZA4RDC

ZA4RNDC

ZA8RDC

ZA4:KSM-2131FAM

ZA8:KSM-880CAB

BASIC CD MECHANISM

3ZG-2 E3

3ZG-2 E3

3ZG-2 E3

3ZG-2 E3

3ZG-2 E3

3ZG-2 E3

3ZG-2 E3

3ZG-2 E3

3ZG-2 E3

3ZG-2 E3

KSM-2131 FAM

KSM-2131 FAM

KSM-880CAB

S/M Code No. 09-001-335-3NC

Page 2

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

CLASS 1

KLASSE 1

LUOKAN 1

KLASS 1

LASER PRODUCT

LASER PRODUKT

LASER LAITE

LASER APPARAT

This set employs laser. Therefore, be sure to follow carefully the

instructions below when servicing.

WARNING!

WHEN SERVICING, DO NOT APPROACH THE LASER EXIT

WITH THE EYE TOO CLOSELY. IN CASE IT IS NECESSARY TO

CONFIRM LASER BEAM EMISSION. BE SURE TO OBSERVE

FROM A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE OPTICAL

PICK-UP BLOCK.

Caution: Invisible laser radiation when

open and interlocks defeated avoid exposure to beam.

Advarsel:Usynling laserståling ved åbning,

når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

VAROITUS!

Laiteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyt-täjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

ATTENTION

L'utilisation de commandes, réglages ou procédures autres que

ceux spécifiés peut entraîner une dangereuse exposition aux

radiations.

ADVARSEL!

Usynlig laserståling ved åbning, når sikkerhedsafbrydereer ude

af funktion. Undgå udsættelse for stråling.

This Compact Disc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located on the rear

exterior.

VARNING!

Om apparaten används på annat sätt än vad som specificeras i

denna bruksanvising, kan användaren utsättas för osynling

laserstrålning, som överskrider gränsen för laserklass 1.

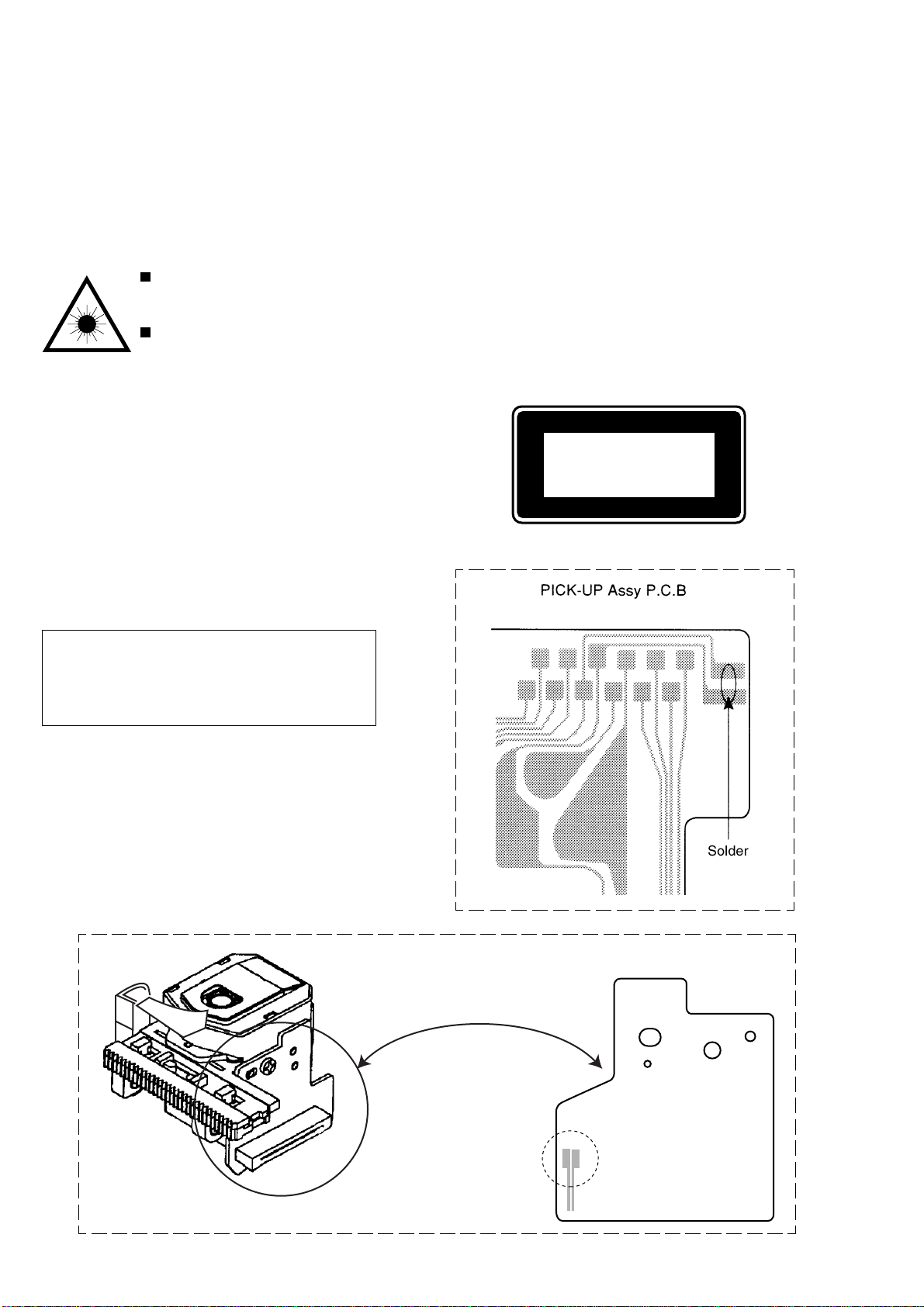

Precaution to replace Optical block

Body or clothes electrostatic potential could ruin

laser diode in the optical block. Be sure ground

body and workbench, and use care the clothes

do not touch the diode.

1) After the connection, remove solder shown in

the figure below.

ZA8 MODEL

ZA3/ZA4 MODEL (KSS-213F)

Solder

2

Page 3

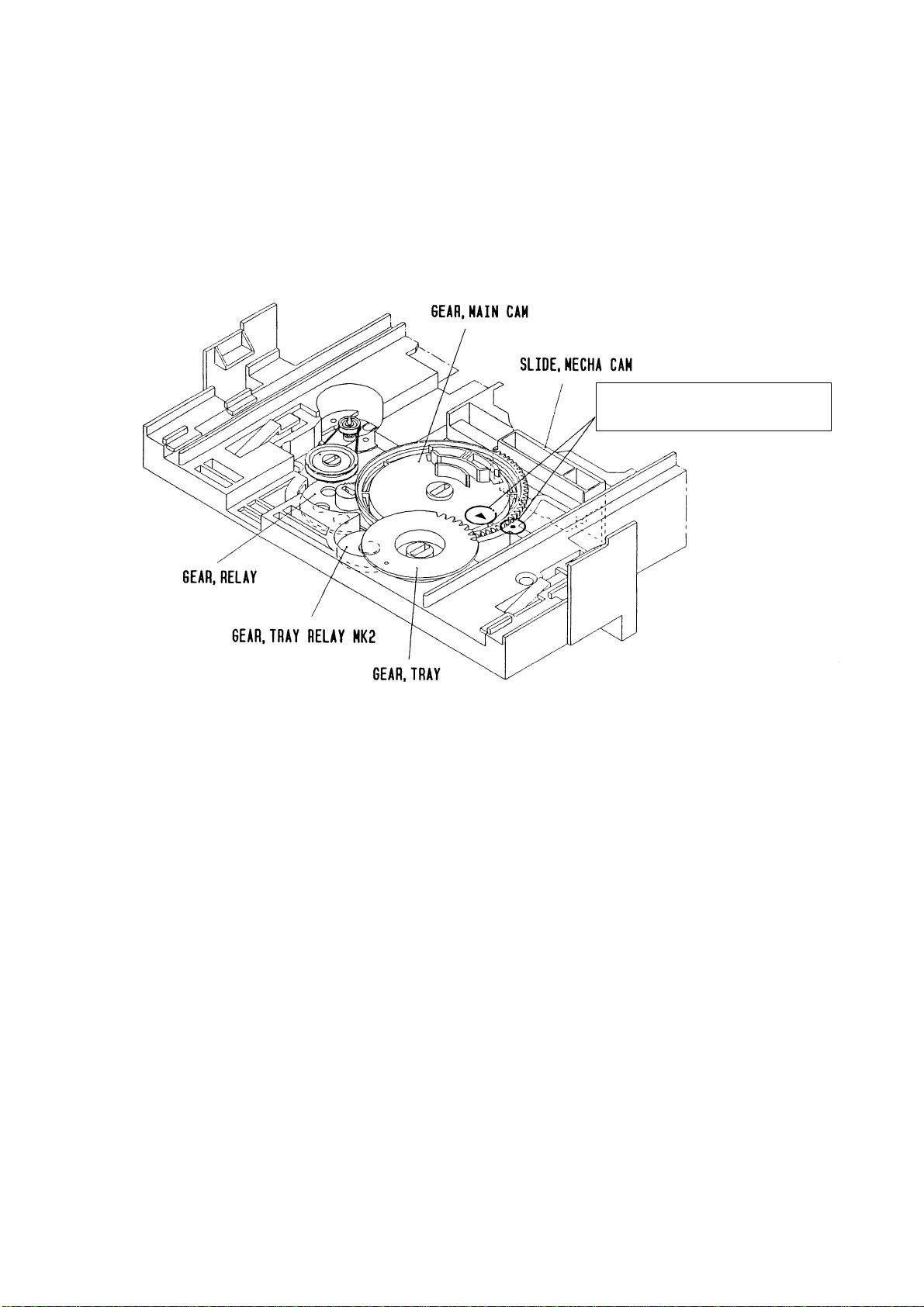

How to Adjust the Rotating Phase of the

Gear, Main Cam

1) Push down the hooking catch of the CHAS. MECH, and

remove the TRAY.

2) Align the arrow mark of the Gear, Main Cam with the black

round mark of the CHAS, MECHA as shown below.

3) Confirm that the Slide, Mech Cam is located in the right

position, then insert the TRAY gently.

Caution: If the rotating phase of the Gear, Main Cam is

incorrectly adjusted, the chucking operation and

tray movement will have malfunction.

Align the arrow 2 mark with the black

round • mark.

3

Page 4

ELECTRICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

NO.

IC

87-A20-446-010 C-IC,LA9241ML

87-017-917-080 IC,BU4066BCF

87-A21-319-010 C-IC,LC78622NE

87-A20-445-010 IC,BA5936

TRANSISTOR

87-026-609-080 TR,KTA1266GR

87-026-239-080 TR,DTC114TK (0.2W)

87-026-295-080 TR,DTC144TK

87-A30-515-080

87-A30-087-080 C-FET,2SK2158

87-026-237-080 CHIP-TR,DTC124XK

<ZA3RDM,ZA4RDC,ZA3RDF,ZA8RDC,ZA3RDCM,YZA3RDM>

87-A30-076-080 C-TR,2SC3052F

87-A30-075-080 C-TR,2SA1235F<EXCEPT ZA3RNM>

DIODE

87-020-465-080 DIODE,1SS133 (110MA)

87-020-331-080 CHIP-DIODE,DAN202K

87-A40-337-080 ZENER,MTZJ 6.8B

87-A40-313-080 C-DIODE,MC 2840

87-A40-620-080 ZENER,MTZJ6.2A

3CD C.B

C11 87-012-393-080 C-CAP,S 0.22-16 R K

C12 87-012-157-080 C-CAP,S 330P-50 CH

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C12 87-012-157-020 C-CAP,S 330P-50 CH

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM>

C13 87-016-369-080 C-CAP,S 0.033-25 B K

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C13 87-016-369-020 C-CAP,S 0.033-25 B K

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C14 87-A10-201-080 C-CAP,S0.33-16 KB

C15 87-010-213-020 C-CAP,S 0.015-25 B

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C15 87-010-213-080 C-CAP,S 0.015-50 B

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C16 87-010-992-080 C-CAP,S 0.047-25 B

C17 87-010-184-020 C-CAP,S 3300P-50 B

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C17 87-010-184-080 CHIP CAPACITOR 3300P(K)

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C18 87-A11-177-080 C-CAP,S 0.15-16 K B

C19 87-010-992-080 C-CAP,S 0.047-25 B<ZA8RDC>

C19 87-010-198-080 CAP, CHIP 0.022<EXCEPT ZA8RDC>

C20 87-010-178-020 C-CAP,S 1000P-50 B

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C20 87-010-178-080 CHIP CAP 1000P

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C21 87-012-393-080 C-CAP,S 0.22-16 R K

C22 87-016-083-080 C-CAP,S 0.15-16 RK

C23 87-010-197-020 C-CAP,S 0.01-25 B

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C23 87-010-197-080 CAP, CHIP 0.01 DM

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C24 87-010-186-020 C-CAP,S 4700P-50 B

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C24 87-010-186-080 CAP,CHIP 4700P

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C25 87-010-400-040 CAP,E 0.47-50

C26 87-010-322-080 C-CAP,S 100P-50 CH<ZA8RDC>

C26 87-010-176-020 C-CAP,S 680P-50 J SL

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C26 87-010-176-080 C-CAP,S 680P-50 SL

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA3RDCM,ZA3RNDCM>

C27 87-010-382-040 CAP,E 22-25 SME

C28 87-010-545-040 CAP,E 0.22-50 SME

C29 87-010-184-020 C-CAP,S 3300P-50 B

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

REF. NO PART NO. KANRI DESCRIPTION

C29 87-010-184-080 CHIP CAPACITOR 3300P(K)

C31 87-010-186-020 C-CAP,S 4700P-50 B

C31 87-010-186-080 CAP,CHIP 4700P

C32 87-010-315-020 C-CAP,S 27P-50 CH

C32 87-010-315-080 C-CAP,S 27P-50 CH

C33 87-016-081-080 C-CAP,S 0.1-16 RK

C35 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

C35 87-010-196-080 CHIP CAPACITOR,0.1-25

C37 87-010-405-080 CAP, ELECT 10-50V

C38 87-010-263-080 CAP, ELECT 100-10V

C39 87-010-992-080 C-CAP,S 0.047-25 B<EXCEPT ZA8RDC>

C39 87-010-197-080 CAP, CHIP 0.01 DM<ZA8RDC>

C40 87-010-401-080 CAP, ELECT 1-50V

C41 87-016-081-080 C-CAP,S 0.1-16 RK

C42 87-010-263-080 CAP, ELECT 100-10V

C43 87-010-197-020 C-CAP,S 0.01-25 B

C43 87-010-197-080 CAP, CHIP 0.01 DM

C44 87-010-263-080 CAP, ELECT 100-10V

C46 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

C46 87-010-196-080 CHIP CAPACITOR,0.1-25

C47 87-010-260-080 CAP, ELECT 47-25V

C48 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

C48 87-010-196-080 CHIP CAPACITOR,0.1-25

C49 87-010-404-080 CAP, ELECT 4.7-50V

C50 87-010-197-020 C-CAP,S 0.01-25 B

C50 87-010-197-080 CAP, CHIP 0.01 DM

C51 87-010-263-040 CAP,E 100-10

C52 87-012-156-020 C-CAP,S 220P-50 CH

C52 87-012-156-080 C-CAP,S 220P-50 CH

C53 87-010-381-080 CAP, ELECT 330-16V

C71 87-012-393-080 C-CAP,S 0.22-16 R K<ZA8RDC>

C80 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

C80 87-010-196-080 CHIP CAPACITOR,0.1-25

C101 87-016-369-020 C-CAP,S 0.033-25 B K

C101 87-016-369-080 C-CAP,S 0.033-25 B K

C102 87-016-081-080 C-CAP,S 0.1-16 RK

C103 87-010-318-080 C-CAP,S 47P-50 CH

C103 87-010-318-020 C-CAP,S 47P-50 CH

C104 87-012-154-080 C-CAP,S 150P-50 CH

C104 87-012-154-020 C-CAP,S 150P-50 J CH GRM

C105 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

C105 87-010-196-080 CHIP CAPACITOR,0.1-25

C109 87-010-197-020 C-CAP,S 0.01-25 B

C109 87-010-197-080 CAP, CHIP 0.01 DM

C111 87-010-312-080 C-CAP,S 15P-50 CH

NO.

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

<EXCEPT ZA4RNDC>

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

4

Page 5

REF. NO PART NO. KANRI DESCRIPTION

NO.

C111 87-010-312-020 C-CAP,S 15P-50 J CH

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C112 87-010-154-020 C-CAP,S 10P-50 CH

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C112 87-010-154-080 CAP CHIP 10P

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C113 87-010-178-020 C-CAP,S 1000P-50 B

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C113 87-010-178-080 CHIP CAP 1000P

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C115 87-010-404-080 CAP, ELECT 4.7-50V

C116 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C116 87-010-196-080 CHIP CAPACITOR,0.1-25

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C117 87-010-263-040 CAP,E 100-10

C118 87-010-178-020 C-CAP,S 1000P-50 B

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C118 87-010-178-080 CHIP CAP 1000P

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C119 87-010-194-080 CAP, CHIP 0.047<ZA3RN1DM>

C121 87-010-403-080 CAP, ELECT 3.3-50V

C122 87-010-403-080 CAP, ELECT 3.3-50V

C123 87-010-180-080 C-CER 1500P

C124 87-010-180-080 C-CER 1500P

C132 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C132 87-010-196-080 CHIP CAPACITOR,0.1-25

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C135 87-010-314-020 C-CAP,S 22P-50 CH

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C135 87-010-314-080 C-CAP,S 22P-50V

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C191 87-010-263-040 CAP,E 100-10

C192 87-010-178-020 C-CAP,S 1000P-50 B

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C192 87-010-178-080 CHIP CAP 1000P

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C193 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C193 87-010-196-080 CHIP CAPACITOR,0.1-25

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C201 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C201 87-010-196-080 CHIP CAPACITOR,0.1-25

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C204 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C204 87-010-196-080 CHIP CAPACITOR,0.1-25

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C205 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C205 87-010-196-080 CHIP CAPACITOR,0.1-25

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C206 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C206 87-010-196-080 CHIP CAPACITOR,0.1-25

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C207 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C207 87-010-196-080 CHIP CAPACITOR,0.1-25

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C208 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C208 87-010-196-080 CHIP CAPACITOR,0.1-25

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C211 87-010-405-040 CAP,E 10-50

C212 87-010-405-040 CAP,E 10-50

C213 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C213 87-010-196-080 CHIP CAPACITOR,0.1-25

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C251 87-010-322-020 C-CAP,S 100P-50 CH

<ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C251 87-010-322-080 C-CAP,S 100P-50 CH

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

REF. NO PART NO. KANRI DESCRIPTION

NO.

C252 87-010-322-080 C-CAP,S 100P-50 CH

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C252 87-010-322-020 C-CAP,S 100P-50 CH

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C253 87-010-322-020 C-CAP,S 100P-50 CH

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C253 87-010-322-080 C-CAP,S 100P-50 CH

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C254 87-010-322-020 C-CAP,S 100P-50 CH

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C254 87-010-322-080 C-CAP,S 100P-50 J GH GRM

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C281 87-010-382-040 CAP,E 22-25 SME

C402 87-010-197-020 C-CAP,S 0.01-25 B

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C402 87-010-197-080 CAP, CHIP 0.01 DM

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C403 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C403 87-010-196-080 CHIP CAPACITOR,0.1-25

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C404 87-010-260-040 CAP,E 47-25 SME

C405 87-010-382-080 CAP, ELECT 22-25V

C421 87-010-382-080 CAP, ELECT 22-25V

C422 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

<ZA3RN1DM,ZA3RDM,ZA3RNDM,ZA3RNM,YZA3RNDM,YZA3RDM>

C422 87-010-196-080 CHIP CAPACITOR,0.1-25

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

C901 87-010-260-080 CAP, ELECT 47-25V<EXCEPT ZA3RNM>

C902 87-010-196-020 C-CAP,S 0.1-25 Z F GRM

<ZA3RN1DM,ZA3RDM,ZA3RNDM,YZA3RNDM,YZA3RDM>

C902 87-010-196-080 CHIP CAPACITOR,0.1-25

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC,ZA3RDCM,ZA3RNDCM>

CN1 87-A60-429-010 CONN,16P H TOC-A

CN2 87-A60-081-010 CONN,06P H 9604S-06F

CN104 8A-ZA5-610-010 CONN ASSY,2P

CN201 87-099-030-010 CONN,13P 6216H

CN203 87-099-212-010 CONN,5P 6216 V

CN204 84-ZG1-648-010 CONN ASSY,6P

<ZA4RDC,ZA4RNDC,ZA8RDC>

CN204 87-099-199-010 CONN,6P 6216 H

<EXCEPT ZA4RDC,ZA4RNDC,ZA8RDC>

L11 87-005-849-080 COIL,10UH(CECS)

L101 87-005-614-080 COIL 100UH LAV35 J

L102 87-005-602-080 COIL,10UH LAV35 J

LED901 87-A40-558-010 LED,SLZ-8128A-01-A<EXCEPT ZA3RNM>

M201 87-045-383-010 MOT,M9I50T28-2

<ZA4RDC,ZA4RNDC,ZA8RDC>

M201 87-045-305-010 MOTOR, RF-500TB DC-5V (2MA)

<EXCEPT ZA4RDC,ZA4RNDC,ZA8RDC>

SFR101 87-A90-787-080 SFR,100K H HOKU

SW201 87-036-109-010 PUSH SWITCH

SW202 87-036-109-010 PUSH SWITCH

X101 87-A70-046-010 VIB,XTAL 16.934MHZ

LED C.B<ZA3RDM,ZA4RDC,ZA3RDF,ZA8RDC,ZA3RDCM,YZA3RDM>

LED302 87-A40-263-080 LED,SLH-56PCT31 GRN

<ZA3RDM,ZA4RDC,ZA3RDF,ZA8RDC,ZA3RDCM,YZA3RDM>

LED303 87-A40-268-080 LED,SLH-56DCT31 ORN

<ZA3RDM,ZA4RDC,ZA3RDF,ZA8RDC,ZA3RDCM,YZA3RDM>

T-T C.B

C401 87-A11-148-080 CAP,TC U 0.1-50 Z F

CN401 87-A60-082-010 CONN,05P H 9604S-05F

<ZA3RN1DM,ZA3RDM,ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,YZA3RDM>

CN401 86-NFZ-675-010 CONN,5P H 6216-11H

<ZA3RNDM,ZA3RNM,ZA8RDC,ZA3RDCM,ZA3RNDCM,YZA3RNDM>

M401 87-045-364-010 MOTOR(BCH3B14)

PS401 87-026-573-010 SNSR,PHOTO GP1S53V

<EXCEPT ZA3RN1DM,ZA3RDM,ZA4RDC,ZA3RDF,ZA3RNDF,YZA3RDM>

PS401 87-A90-156-010 SNSR,SG-240

<ZA3RN1DM,ZA3RDM,ZA4RDC,ZA3RDF,ZA3RNDF,YZA3RDM>

5

Page 6

REF. NO PART NO. KANRI DESCRIPTION

NO.

DRIVE C.B<EXCEPT ZA4RDC,ZA4RNDC,ZA8RDC>

M1 87-045-358-010 MOT,RF-310TA 43

<EXCEPT ZA4RDC,ZA4RNDC,ZA8RDC>

M2 87-045-356-010 MOT,RF-310TA 30

<EXCEPT ZA4RDC,ZA4RNDC,ZA8RDC>

PIN3 87-A60-086-010 CONN,6P H6216-11

<EXCEPT ZA4RDC,ZA4RNDC,ZA8RDC>

SW1 87-A90-042-010 SW,LEAF MSW-17310MVP0

<EXCEPT ZA4RDC,ZA4RNDC,ZA8RDC>

• Regarding connectors, they are not stocked as they are not the initial order items.

The connectors are available after they are supplied from connector manufacturers upon the order is received.

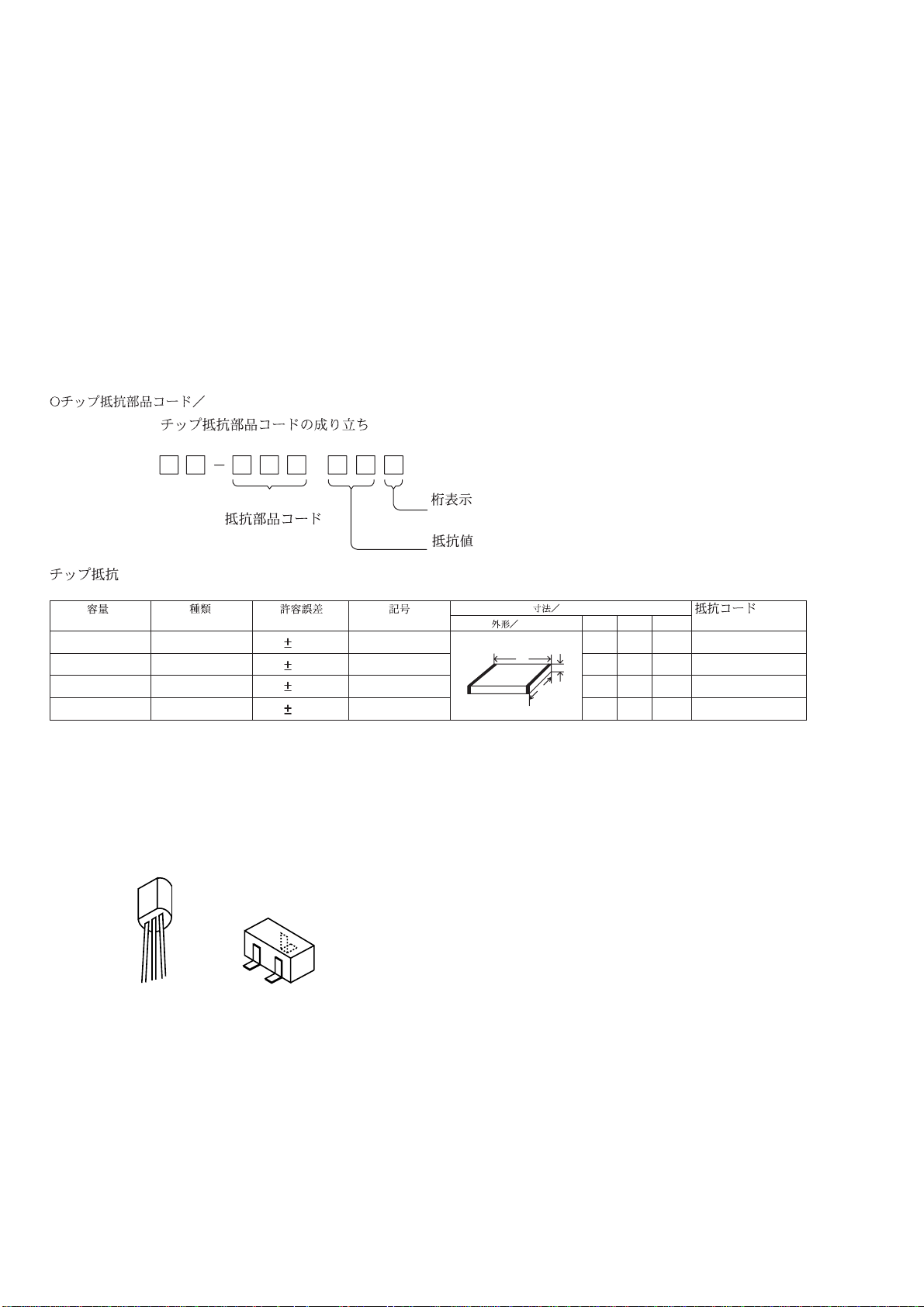

CHIP RESISTOR PART CODE

REF. NO PART NO. KANRI DESCRIPTION

NO.

MOTOR C.B<ZA4RDC,ZA4RNDC>

M2 9X-262-513-210 SLED MOTOR<ZA4RDC,ZA4RNDC>

PIN3 91-564-722-110 CONNECTOR 6P<ZA4RDC,ZA4RNDC>

SW1 91-572-085-110 LEAF SW<ZA4RDC,ZA4RNDC>

MOTOR C.B<ZA8RDC>

PIN3 91-564-722-110 CONN,PIN 6P<ZA8RDC>

SW1 91-572-085-110 LEAF SWITCH<ZA8RDC>

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

TRANSISTOR ILLUSTRATION

C

Symbol

CJ

CJ

CJ

Figure

Value of resistor

Form

L

Dimensions (mm)

t

W

0.55

Resistor Code

108

118

128

LW t

1.0 0.5 0.35 104

1.6 0.8 0.45

2 1.25 0.45

3.2

1.6

: A

: A

ECB

KTA1266

B

E

2SA1235

2SC3052

2SK2158

DTC114TK

DTC124XK

DTC144TK

6

Page 7

BLOCK DIAGRAM

EXCEPT ZA3RNM

87

Page 8

WIRING-1 (3CD/LED)

1

234567

8

ZA3 MODEL

9

TO DRIVE C.B

10

11 12 13

14

A

ZA4/ZA8 MODEL

B

C

D

E

F

G

H

I

J

K

109

Page 9

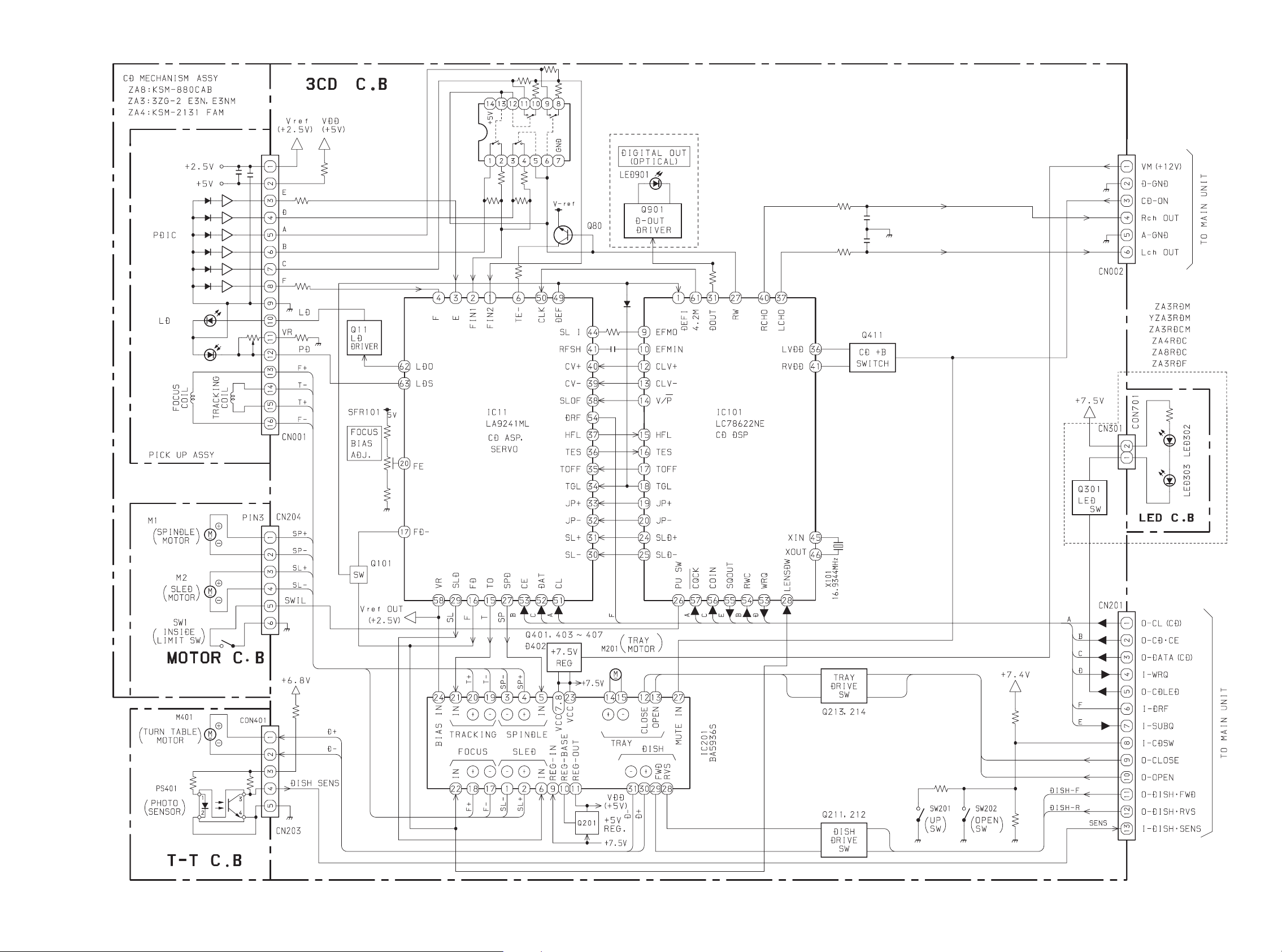

SCHEMATIC DIAGRAM

MOTOR C.B

(ZA4/ZA8)

DRIVE C.B

(ZA3)

1211

Page 10

WIRING-2 (T-T/MOTOR)

VREF

VREF

1

A

B

C

D

234567

ZA3 MODEL

ZA4 MODEL

WAVE FORM

1 IC11 Pin = (RFSH) VOLT/DIV: 0.5V

TIME/DIV: 1µS

MAX

1.7±0.1 Vp-p

0 V

EYE PATTERN

must be CLEAR and MAX

2 IC11 Pin ^ (FD) VOLT/DIV: 100mV

TIME/DIV: 1mS

VREF

4 IC11 Pin ≥ (SPD) VOLT/DIV: 100mV

TIME/DIV: 1mS

VREF

5 IC11 Pin ª (SLD) VOLT/DIV: 200mV

TIME/DIV: 2S

E

F

G

H

I

3 IC11 Pin % (TO) VOLT/DIV: 100mV

TIME/DIV: 1mS

ZA8 MODEL

IC BLOCK DIAGRAM

IC, BA5936S

J

K

1413

Page 11

TEST MODE

1. How to Activate CD Test Mode

Insert the AC plug while pressing the function CD button.

All FL display tubes will light up, and the test mode will be

activated.

3. CD Test Mode Functions

When test mode is activated, the following mode functions from No.1 to No.5 can be used by pressing the operation keys.

2. How to Cancel CD Test Mode

Either one of the following operations will cancel the CD test

mode.

• Press the function button. • Press the power switch button.

(except CD function button) • Disconnect the AC plug

Mode/No.

Start mode

No.1

Search mode

No.2

Play mode

No.3

Traverse mode

No.4

Sled mode

No.5

Operation

Activation

9 key

1 2 key

key

;

fi key

fl

FL display

All lamps light

All lamps light

Operation

• Test mode is activated.

• CD block power is ON.

• Laser diode turns always ON.

• Continual focus search

(The pickup lens repeats the fullswing up-down motion.)

* Avoid continual searches that last for

more than 10 minutes.

* NOTE 1

• Normal playback

• Focus search is continued if TOC

cannot be read. * NOTE 1

• During normal disc playback

Press once; tracking servo OFF

Press twice; tracking servo ON

* NOTE 2

• Pickup moves to the outermost track

• Pickup moves to the innermost track

* NOTE 3

(During playback, machine operates

normally.)

Contents

• FL display check (All displays light.)

• APC circuit check

• Laser current measurement

(Laser current control. Across a

resistor connected between emitter

and GND.)

FOCUS SERVO

• Check focus search waveform

• Check focus error waveform

(FOK/FZC are not monitored in the

search mode)

FOCUS SERVO/TRACKING SERVO

CLV SERVO/SLED SERVO

Check DRF

TRACKING SERVO ON/OFF

Tracking balance (traverse) check

SLED SERVO

Check SLED mechanism operation

* NOTE 1: There are cases when the tracking servo cannot be locked owing to the protection circuit being operated when heat builds up

in the driver IC if the focus search is operated continually for more than 10 minutes. In these cases the power supply should be

switched off for 10 minutes until heat has been reduced and then re-started.

* NOTE 2: Do not press the fi or fl keys when the machine is in the

after the

status has been canceled. If the fi or fl keys are pressed in the ; status, press the 9 key and return to the start mode

;

status is active. If they are pressed, playback will not be possible

;

(No.1).

* NOTE 3: When pressing the fi or fl keys, take care to avoid damage to the gears. Because the sled motor is activated when the fi or fl

keys are pressed, even when the pick-up is at the outermost or innermost track.

4. Operation Outline

The operation of each mode is carried out in the direction of the arrows from the start mode as indicated in the following illustration.

No. 2 No. 3

1 2

No. 1

Start mode

(All FLs light up.)

2

Search mode

9

9

fi

fl

No. 5 No. 4

Sled mode

;

Play mode

9

1 2

;

;

9

Traverse mode

If the DISC DIRECT PLAY button is pressed, the machine performs the same operation as the PLAY button is pressed as shown. If

the tray is opened by pressing OPEN/CLOSE button during Play mode or Traverse mode, the machine returns to the Start mode.

15

Page 12

IC DESCRIPTION

IC, LC78622NE

Pin No. Pin Name I/O Description

1

2

3

DEFI

TAI

PDO

I

Defect sense signal (DEF) input pin. (Connect to 0V when not used).

I

O

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

Phase comparator output pin to control external VCO.

4

5

6

7

8

9

10

11

12, 13

14

15

16

17

18

19, 20

21

VVSS

ISET

VVDD

FR

VSS

EFMO

EFMIN

TEST2

CLV+, CLV–

___

V/P

HFL

TES

TOFF

TGL

JP+, JP–

PCK

—

—

—

For PLL.

I

I

Digital system GND. Be sure to connect to 0V.

O

For slice level control.

I

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

O

Disc motor control output. Three level output is possible using command.

Rough servo or phase control automatic selection monitoring output pin. Rough servo

O

at H. Phase servo at L.

I

Track detect signal input pin. Schmidt input.

I

Tracking error signal input pin. Schmidt input.

O

Tracking OFF output pin.

O

Tracking gain selection output pin. Gain boost at L.

O

Track jump control signal output pin. Three level output is possible using command.

O

EFM data playback clock monitoring pin 4.3218 MHz when phase is locked in.

GND pin for built-in VCO. Be sure to connect to 0V.

Pin to which external resistor adjusting the PD0 output current.

Power supply pin for built-in VCO.

Pin for VCO frequency range adjustment.

EFM signal output pin.

EFM signal input pin.

22

23

24

25

26

27

28

29

30

31

32, 33

34

35

36

37

38

39

40

41

FSEQ

VDD

SLD+

SLD-

PUSW

RW

LENSDW

EMPH

C2F

DOUT

TEST3, TEST4

N.C.

MUTEL

LVDD

LCHO

LVSS

RVSS

RCHO

RVDD

O

—

I/O

I/O

I/O

I/O

I/O

O

O

O

—

O

—

O

—

—

O

—

Sync signal detection output pin. H when the sync signal which is detected from EFM

signal and thesync signal which is internally generated agree.

Digital system power supply pin.

The pin is controlled by the serial data

command from microprocessor. When

General purpose input/output pin 1 to 5.

De-emphasis monitor output pin. De-emphasis disc is being played back at H.

C2 flag output pin.

DIGITAL OUT output pin. (EIAJ format).

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

Not used. Set the pin to open.

L-channel mute output pin.

L-channel 1-bit DAC.

R-channel 1-bit DAC.

L-channel power supply pin.

L-channel output pin.

L-channel GND. Be sure to connect to 0V.

R-channel GND. Be sure to connect to 0V.

R-channel output pin.

R-channel power supply pin.

the pin is not used, set the pin to the input

terminal and connect to 0V, or alternately

set the pin to output terminal and leave

the pin open.

42

MUTER

O

16

R-channel mute output pin.

Page 13

Pin No. Pin Name I/O Description

43

44

45

46

47

XVDD

XOUT

XIN

XVSS

SBSY

—

Crystal oscillator power supply pin.

O

Pin to which external 16.9344 MHz crystal oscillator is connected.

I

—

Crystal oscillator GND pin. Be sure to connect to 0V.

O

Subcode block sync signal output pin.

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

EFLG

PW

SFSY

SBCK

FSX

WRQ

RWC

SQOUT

COIN

___________

CQCK

________

RES

TST11

16M

4.2M

TEST5

______

CS

TEST1

O

C1, C2, single and dual correction monitoring pin.

O

Subcode P, Q, R, S, T, U and W output pin.

O

Subcode frame sync signal output pin. Falls down when subcode enters standby.

Subcode read clock input pin. Schmidt input. (Be sure to connected to 0V when not

I

in use.)

Pin outputting the 7.35 kHz sync signal which is generated by dividing frequency of

O

crystal oscillator.

O

Subcode Q output standby output pin.

I

Read/write control input pin. Schmidt input.

O

Subcode Q output pin.

I

Command input pin from microprocessor.

I

Command input read clock or subcode read input clock from SQOUT pin

I

LC78622 reset input pin. Set this pin to L once when the main power is turned on.

O

Test signal output pin. Use this pin as open (normally L output).

O

16.9344 MHz output pin.

O

4.2336 MHz output pin.

I

Test signal input pin with built-in pull-down resistor. Be sure to connect to 0V.

Chip select signal input pin with built-in pull-down resistor. Be sure to connect to 0V

I

while it is not controlling.

I

Test signal input pin without built-in pull-down resistor. Be sure to connect to 0V.

Note: The same potential must be applied to the respective power supply terminals. (VDD, VVDD, LVDD, RVDD, XVDD)

17

Page 14

IC, LA9241ML

Pin No. Pin Name I/O Description

1

2

FIN2

FIN1

Pin to which external pickup photo diode is connected. RF signal is created by adding

I

with the FIN1 pin signal. FE signal is created by subtracting from the FIN1 pin signal.

I

Pin to which external pickup photo diode is connected.

10

11

12

13

14

15

16

17

3

4

5

6

7

8

9

E

F

TB

TE–

TE

TESI

SCI

TH

TA

TD–

TD

JP

TO

FD

FD–

Pin to which external pickup photo diode is connected. TE signal is created by

I

subtracting from the F pin signal.

I

Pin to which external pickup photo diode is connected.

I

DC component of the TE signal is input.

I

Pin to which external resistor setting the TE signal gain is connected between the TE pin.

O

TE signal output pin.

TES “Track Error Sense” comparator input pin. TE signal is passed through a band-

I

pass filter then input.

I

Shock detection signal input pin.

I

Tracking gain time constant setting pin.

O

TA amplifier output pin.

Pin to which external tracking phase compensation constants are connected between

I

the TD and VR pins.

I

Tracking phase compensation setting pin.

I

Tracking jump signal (kick pulse) amplitude setting pin.

O

Tracking control signal output pin.

O

Focusing control signal output pin.

Pin to which external focusing phase compensation constants are connected between

I

the FD and FA pins.

18

19

20

21

22

23

24

25

26

27

28

29

30, 31

32, 33

34

FA

FA–

FE

FE–

PGND

SP

SP1

SPG

SP–

SPD

SLED

SLD

SL–, SL+

JP–, JP+

TGL

—

—

Pin to which external focusing phase compensation constants are connected between

I

the FD– and FA– pins.

Pin to which external focusing phase compensation constants are connected between

I

the FA and FE pins.

O

FE signal output pin.

I

Pin to which external FE signal gain setting resistor is connected between the FE pin.

Analog signal GND.

No connection.

O

Single ended output of the CV+ and CV– pin input signal.

I

Pin to which external spindle gain setting resistor in 12 cm mode is connected.

Pin to which external spindle phase compensation constants are connected together

I

with SPD pin.

O

Spindle control signal output pin.

I

Pin to which external sled phase compensation constants are connected.

O

Sled control signal output pin.

I

Sled advance signal input pin from microprocessor.

I

Tracking jump signal input pin from DSP.

I

Tracking gain control signal input from DSP. Low gain when TGL = H.

35

TOFF

I

Tracking off control signal input pin from DSP. Off when TOFF = H.

18

Page 15

Pin No. Pin Name I/O Description

36

TES

O

Pin from which TES signal is output to DSP.

37

38

39, 40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

HFL

SLOF

CV–, CV+

RFSH

RFS–

SLC

SLI

DGND

FSC

TBC

NC

DEF

CLK

CL

DAT

CE

DRF

NC

“High Frequency Level” is used to judge whether the main beam position is on top of

O

bit or on top of mirror.

I

Sled servo off control input pin.

I

CLV error signal input pin from DSP.

O

RF output pin.

RF gain setting and EFM signal 3T compensation constant setting pin together with

I

RFSM pin.

“Slice Level Control” is the output pin which controls the RF signal data slice level by

O

DSP.

I

Input pin which control the data slice level by the DSP.

—

Digital system GND.

O

Output pin to which external focus search smoothing capacitor is connected.

I

“Tracking Balance Control” EF balance variable range setting pin.

—

No connection.

O

Disc defect detector output pin.

I

Reference clock input pin. 4.23 MHz of the DSP is input.

I

Microprocessor command clock input pin.

I

Microprocessor command data input pin.

I

Microprocessor command chip enable input pin.

O

“Detect RF” RF level detector output.

I

No connection.

56

57

58

59

60

61

62

63

64

VCC2

REF1

VR

LF2

PH1

BH1

LDO

LDS

VCC1

—

Servo system and digital system Vcc pin.

—

Pin to which external bypass capacitor for reference voltage is connected.

O

Reference voltage output pin.

I

Disc defect detector time constant setting pin.

I

Pin to which external capacitor for RF signal peak holding is connected.

I

Pin to which external capacitor for RF signal bottom holding is connected.

O

APC circuit output pin.

I

APC circuit input pin.

—

RF system Vcc pin.

19

Page 16

MECHANICAL EXPLODED VIEW 1/1

13

11

12

14

28

27

26

25

24

23

22

B

29

C

19

30

a

A

31

20

P.C .B

21

P.C.B

10

a

32

9

4

8

18

7

6

3

4

1

2

5

CUSHION,CD A

15

AZA-5 P.C.B

17

16

EXCEPT ZA4, ZA8 : 3ZG-2

ZA4 : KSM-2131FAM

ZA8 : KSM-880CAB

20

CUSHION,CD A

33 (EXCEPT ZA4, ZA8)

15

CUSHION,CD A

Page 17

MECHANICAL PARTS LIST 1/1

REF. NO PART NO. KANRI DESCRIPTION

NO.

1 84-ZG1-225-010 BELT,SQ1.0-63.3

2 84-ZG1-672-010 F-CABLE,5P 1.25 210MM WHITE N

3 87-045-364-010 MOTOR(BCH3B14)

4 84-ZG1-267-010 PULLEY,LOAD MO 8

<EXCEPT ZA3RDF,ZA3RNDF>

4 81-ZG1-212-010 PULLY,LOAD MO<ZA3RDF,ZA3RNDF>

5 84-ZG1-238-010 GEAR,WORM N

6 84-ZG1-248-010 SPR-C,WORM

7 84-ZG1-273-010 PULLEY,WORM 4

<ZA4RDC,ZA4RNDC,ZA8RDC>

7 84-ZG1-239-210 PULLY,WORM N

<EXCEPT ZA4RDC,ZA4RNDC,ZA8RDC>

8 8A-ZG1-001-010 TRAY,NO3 BLU

9 84-ZG1-291-110 HLDR,MAGNET 4 NAT

<ZA3RNDM,ZA4RNDC,ZA3RNDF,ZA3RNM,ZA3RNDCM>

9 84-ZG1-272-110 HLDR,MAGNET N 4

<ZA3RN1DM,ZA3RDM,ZA4RDC,ZA3RDF,ZA8RDC,ZA3RDCM>

10 84-ZG1-259-010 SPR-P,WORM

11 84-ZG1-221-010 GEAR,MAIN TT<ZA3RDF,ZA3RNDF>

11 84-ZG1-269-010 GEAR,MAIN TT 4

<EXCEPT ZA3RDF,ZA3RNDF>

12 84-ZG1-224-010 LEVER,TT

<ZA3RN1DM,ZA3RDM,ZA4RDC,ZA3RDF,ZA8RDC,ZA3RDCM>

12 84-ZG1-288-010 LEVER,TT NAT

<ZA3RNDM,ZA4RNDC,ZA3RNDF,ZA3RNM,ZA3RNDCM>

13 8A-ZG1-002-010 TURN TABLE,NO1 BLU

14 81-ZG1-239-010 S-SCREW,TT

15 81-ZG1-271-010 S-SCREW MECH REAR<EXCEPT ZA8RDC>

15 8A-ZG1-201-010 S-SCREW,MECH 880<ZA8RDC>

16 85-NFT-611-110 FF-CABLE 16P-1.0

17 84-ZG1-287-010 HLDR,MECHA NAT

<ZA3RNDM,ZA4RNDC,ZA3RNDF,ZA3RNM,ZA3RNDCM>

17 84-ZG1-212-210 HLDR,MECHA NO2

<ZA3RN1DM,ZA3RDM,ZA4RDC,ZA3RDF,ZA3RDCM>

17 84-ZG1-299-310 HLDR,MECHA NO3<ZA8RDC>

18 87-045-383-010 MOT,M9I50T28-2

<ZA4RDC,ZA4RNDC,ZA8RDC>

18 87-045-305-010 MOTOR, RF-500TB DC-5V (2MA)

<EXCEPT ZA4RDC,ZA4RNDC,ZA8RDC>

19 84-ZG1-211-010 SPR-E CAM S

20 84-ZG1-285-010 PLATE,MAGNET BLK<ZA3RN1DM>

20 81-ZG1-255-110 PLATE,MAGNET MK2<EXCEPT ZA3RN1DM>

REF. NO PART NO. KANRI DESCRIPTION

21 83-ZG3-604-010 RING,MAG 2

22 83-ZG3-213-010 LVR,SW

23 84-ZG1-208-210 LEVER,CAM

23 84-ZG1-266-010 LEVER,CAM 8

24 84-ZG1-205-210 GEAR,TRAY (*)

25 81-ZG1-250-110 GEAR,TRAY RELAY MK2*

25 81-ZG1-291-110 GEAR,TRAY RELAY NO3

26 84-ZG1-206-110 GEAR,RELAY

26 84-ZG1-274-010 GEAR,RELAY 8

27 84-ZG1-207-010 PULLEY,RELAY

27 84-ZG1-271-010 PULLEY,RELAY 8

28 84-ZG1-209-010 BELT,SQ1.8-117.7

29 84-ZG1-203-410 GEAR,MAIN CAM

29 84-ZG1-215-410 GEAR,MAIN CAM BLU

30 84-ZG1-011-010 REFLECTOR,CD

31 84-ZG1-216-310 SLIDE,MECHA CAM YEL

31 84-ZG1-204-310 SLIDER,MECHA CAM

32 84-ZG1-201-410 CHAS,MECHA

32 84-ZG1-232-210 CHAS,MECHA N<ZA4RDC,ZA8RDC>

32 84-ZG1-292-010 CHAS,MECHA N NAT<ZA4RNDC>

32 84-ZG1-286-010 CHAS,MECHA NAT

33 84-ZG1-630-010 CABLE FFC 6P-1.25

A 87-067-703-010 TAPPING SCREW, BVT2+3-10

B 87-067-981-010 BVT2+3-6 BLK

C 87-251-070-410 U+2.6-3<ZA4RDC,ZA4RNDC,ZA8RDC>

NO.

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC>

<EXCEPT ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC>

<ZA4RDC,ZA4RNDC,ZA8RDC>

<EXCEPT ZA4RDC,ZA4RNDC,ZA8RDC>

<ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC>

<EXCEPT ZA4RDC,ZA4RNDC,ZA3RDF,ZA3RNDF,ZA8RDC>

<EXCEPT ZA4RDC,ZA4RNDC,ZA8RDC>

<ZA4RDC,ZA4RNDC,ZA8RDC>

<ZA3RNDM,ZA4RNDC,ZA3RNDF,ZA3RNM,ZA3RNDCM>

<ZA3RN1DM,ZA3RDM,ZA4RDC,ZA3RDF,ZA8RDC,ZA3RDCM>

<ZA3RDM,ZA4RDC,ZA3RDF,ZA8RDC,ZA3RDCM>

<ZA3RN1DM,ZA3RDM,ZA4RDC,ZA3RDF,ZA8RDC,ZA3RDCM>

<ZA3RNDM,ZA4RNDC,ZA3RNDF,ZA3RNM,ZA3RNDCM>

<ZA3RN1DM,ZA3RDM,ZA3RDF,ZA3RDCM>

<ZA3RNDM,ZA3RNDF,ZA3RNM,ZA3RNDCM>

<EXCEPT ZA4RDC,ZA4RNDC,ZA8RDC>

<ZA3RDM,ZA4RDC,ZA3RDF,ZA8RDC,ZA3RDCM>

COLOR NAME TABLE

Basic color symbol Color Basic color symbol Color Basic color symbol Color

B Black C Cream D Orange

G Green H Gray L Blue

LT Transparent Blue N Gold P Pink

R Red S Silver ST Titan Silver

T Brown V Violet W White

WT Transparent White Y Yellow YT Transparent Yellow

LM Metallic Blue LL Light Blue GT Transparent Green

LD Dark Blue DT Transparent Orange

21

Page 18

CD MECHANISM EXPLODED VIEW 1/1 (3ZG-2E3)

9

7

8

2

10

6

A

A

A

A

1

5

3

SW1

4

M1

M2

P.C.B

CD MECHANISM PARTS LIST 1/1 (3ZG-2E3)

REF. NO PART NO. KANRI DESCRIPTION

NO.

1 83-ZG2-243-310 CHAS ASSY,SHT

2 83-ZG2-235-010 GEAR,A3

3 83-ZG2-205-210 GEAR,B

4 83-ZG2-236-010 GEAR,MOTOR 3

5 83-ZG2-253-110 SHAFT,SLIDE 5

6 87-A90-836-010 PICKUP,KSS-213F

7 83-ZG2-227-310 TURN TABLE,C1

8 83-ZG2-245-510 LEVER,SHUTTER(*)

9 83-ZG2-250-110 SPR-E,SHT 2

10 83-ZG2-241-110 PLATE,C2

A 87-261-032-210 V+2-3

22

Page 19

CD MECHANISM EXPLODED VIEW 1/1 (KSM-2131 FAM)

6

7

3

2

COVER

5

SPINDLE MOTOR

4

CD MECHANISM PARTS LIST 1/1 (KSM-2131 FAM)

A

1

MOTOR C.B

REF. NO PART NO. KANRI DESCRIPTION

1 9X-264-629-220 MOTOR CHASSIS ASSY(MB)(FR)

2 92-626-907-010 GEAR(A)(S)

3 87-A90-836-010 OPTICAL PICK UP KSS-213F

4 92-626-908-020 SHAFT SLED

5 92-627-003-010 GEAR(B)

6 92-646-697-020 LENS SHUTTER(F)

7 92-646-702-010 SPRIG EXTENSION

A 97-621-255-150 SCREW+P2-3

NO.

23

Page 20

CD MECHANISM EXPLODED VIEW 1/1 (KSM-880CAB)

8

6

4

5

2

7

A

9

10

11

3

P.C. B

1

CD MECHANISM PARTS LIST 1/1 (KSM-880CAB)

REF. NO PART NO. KANRI DESCRIPTION

1 91-564-722-110 CONN,PIN 6P

2 91-572-085-110 LEAF SWITCH

3 9X-264-655-010 SL MOTORR ASSY

4 M8-ZZK-C90-070 KSM-880CAB

5 92-647-416-020 SPRING EXTENSION

6 92-647-595-020 SHUTTER B

7 92-647-732-010 NS SLIDE RACK

8 92-647-742-010 SPRING COMPRESSION

9 93-321-813-110 POLI WASHER

10 92-647-407-010 GEAR A

11 92-647-408-020 GEAR B

A 93-713-786-510 SCREW,+P2-3

NO.

24

Page 21

REFERENCE NAME LIST

ELECTRICAL SECTION

DESCRIPTION REFERENCE NAME

ANT ANTENNAS

C- CHIP

C-CAP CAP, CHIP

C-CAP TN CAP, CHIP TANTALUM

C-COIL COIL, CHIP

C-DI DIODE, CHIP

C-DIODE DIODE, CHIP

C-FET FET, CHIP

C-FOTR FILTER, CHIP

C-JACK JACK, CHIP

C-LED LED, CHIP

C-RES RES, CHIP

C-SFR SFR, CHIP

C-SLIDE SW SLIDE SWITCH, CHIP

C-SW SWITCH, CHIP

C-TR TRANSISTOR, CHIP

C-VR VOLUME, CHIP

C-ZENER ZENER, CHIP

CAP, CER CAP, CERA-SOL

CAP, E CAP, ELECT

CAP, M/F CAP, FILM

CAP, TC CAP, CERA-SOL

CAP, TC-U CAP, CERA-SOL SS

CAP, TN CAP, TANTALUM

CERA FIL FILTER, CERAMIC

CF FILTER, CERAMIC

DL DELAY LINE

E/CAP CAP, ELECT

FILT FILTER

FLTR FILTER

FUSE RES RES, FUSE

MOT MOTOR

P-DIODE PHOTO DIODE

P-SNSR PHOTO SENSER

P-TR PHOTO TRANSISTOR

POLY VARI VARIABLE CAPACITOR

PPCAP CAP, PP

PT POWER TRANSFORMER

PTR, RES PTR, MELF

RC REMOTE CONTROLLER

RES NF RES, NON-FLAMMABLE

RESO RESONATOR

SHLD SHIELD

SOL SOLENOID

SPKR SPEAKER

SW, LVR SWITCH, LEVER

SW, RTRY SWITCH, ROTARY

SW, SL SWITCH, SLIDE

TC CAP CAP, CERA-SOL

THMS THERMISTOR

TR TRANSISTOR

TRIMMER CAP, TRIMMER

TUN-CAP VARIABLE CAPACITOR

VIB, CER RESONATOR, CERAMIC

VIB, XTAL RESONATOR, CRYSTAL

VR VOLUME

ZENER DIODE, ZENER

MECHANICAL SECTION

DESCRIPTION REFERENCE NAME

ADHESHIVE SHEET ADHESHIVE

AZ AZIMUTH

BAR-ANT BAR-ANTENNA

BAT BATTERY

BATT BATTERY

BRG BEARING

BTN BUTTON

CAB CABINET

CASS CASSETTE

CHAS CHASSIS

CLR COLLAR

CONT CONTROL

CRSR CURSOR

CU CUSHION

CUSH CUSHION

DIR DIRECTION

DUBB DUBBING

FL FRONT LOADING

FLY-WHL FLYWHEEL

FR FRONT

FUN FUNCTION

G-CU G-CUSHION

HDL HANDOL

HIMERON CLOTH

HINGE, BAT HINGE, BATTERY

HLDR HOLDER

HT-SINK HEAT SINK

IB INSTRUCTION BOOKLET

IDLE IDLER

IND, L-R INDICATOR, L-R

KEY, CONT KEY, CONTROL

KEY, PRGM KEY, PROGRAM

KNOB, SL KNOB, SLIDE

LBL LABEL

LID, BATT LID, BATTERY

LID, CASS LID, CASSETTE

LVR LEVER

P-SP P-SPRING

PANEL, CONT PANEL, CONTROL

PANEL, FR PANEL, FRONT

PRGM PROGRAM

PULLY, LOAD MO PULLY, LOAD MOTOR

RBN RIBBON

S- SPECIAL

SEG SEGMENT

SH SHEET

SHLD-SH SHIELD-SHEET

SL SLIDE

SP SPRING

SP-SCREW SPECIAL-SCREW

SPACER, BAT SPACER, BATTERY

SPR SPRING

SPR-P P-SPRING

SPR-PC-PUSH P-SPRING, C-PUSH

T-SP T-SPRING

TERM TERMINAL

TRIG TRIGGER

TUN TUNING

VOL VOLUME

W WASHER

WHL WHEEL

WORM-WHL WORM-WHEEL

25

Page 22

2–11, IKENOHATA 1–CHOME, TAITO-KU, TOKYO 110-8710, JAPAN TEL:03 (3827) 3111

0251431

Printed in Singapore

Loading...

Loading...