Air Techniques Peri-Pro 3 User Manual

PERI-PRO III

INTRA-ORAL

FILM PROCESSOR

USER’S MANUAL

®

A6732 ISO 13485:1996

ISO 9001:2000

Air Techniques Inc.

Hicksville, NY

CONGRATULATIONS

Since 1977, more than 70,000 Peri-Pro processors have been manufactured and sold

by Air Techniques, making it the processor of choice for the dental profession. This latest

version, the Peri-Pro III, retains the same proven rollerless transport system as earlier models. This unique system carefully guides the film through the developing process without the

image surface being touched. The Peri-Pro III also offers the same slim space saving

design, with or without a daylight loader, convenient for small office spaces. Where the new

Peri-Pro III differs from previous models is in design features that make maintenance and

operation easier and faster.

The Peri-Pro III processes film, dry-to-dry and ready to read, in only 5 minutes. To

ensure the delivery of consistent film quality, a new heating pad system, located under the

tanks, maintains uniform chemistry bath temperature.

The most significant new design features of the Peri-Pro III are an external water drain

valve in the base and a refill access door built right into the cover. With these new features,

the daily maintenance task of draining and replacing the wash water is accomplished in a

few minutes without removing the processor cover. Just turn the valve to drain the water,

open the refill access door, close the valve, and refill the water tank using the Peri-Pro III

water bottle. By following the Maintenance procedures detailed in this manual, you can

depend on years of reliable service from your Peri-Pro III processor.

TABLE OF CONTENTS

IInnssttaallllaattiioonn

Key Parts Identification ...............................................................................3

Box Contains / Unpack ..............................................................................4

Install & Assemble Processor.......................................................................4-5

OOppeerraattiioonn

Operator Controls .....................................................................................5

Processing film...........................................................................................6-7

MMaaiinntteennaannccee

Daily.........................................................................................................8

Every Two Weeks........................................................................................8-9

Quarterly ..................................................................................................10

TTrroouubbllee SShhoooottiinngg

............................................................................................11-14

SSppeecciiffiiccaattiioonnss // DDiimmeennssiioonnss

.............................................................................14

AAcccceessssoorriieess

.....................................................................................................15

2

3

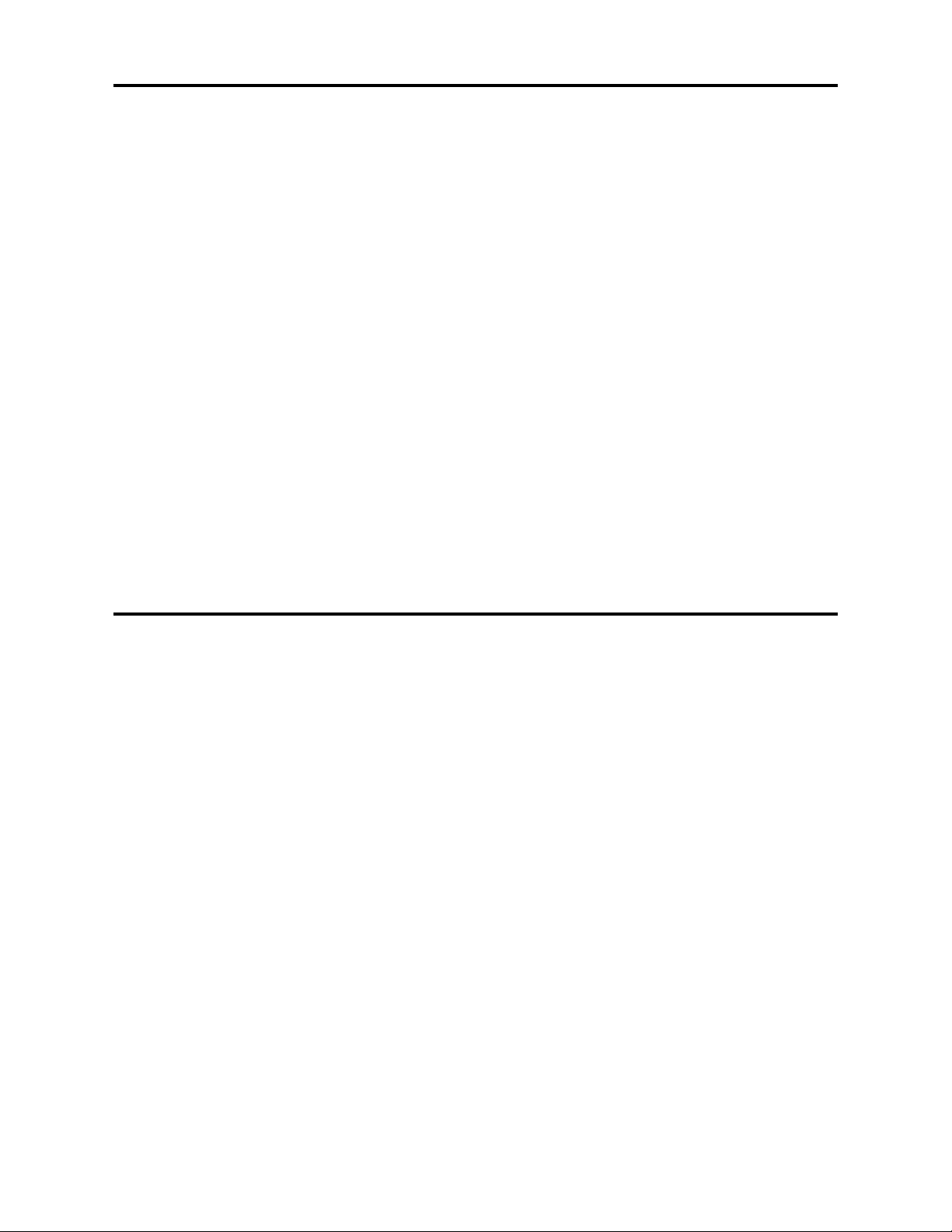

FILM INLET GRILL

FILM INLET

SHUTTER

DRAIN VALVE

KEY PARTS IDENTIFICATION

COVER

ASSEMBLY

MAINTENANCE

LABEL

OPERATOR

CONTROLS

FILM DELIVERY

RECEPTACLE

AIR OUTLET GRILL

AIR INLET GRILL

TRASH

RECEPTACLE

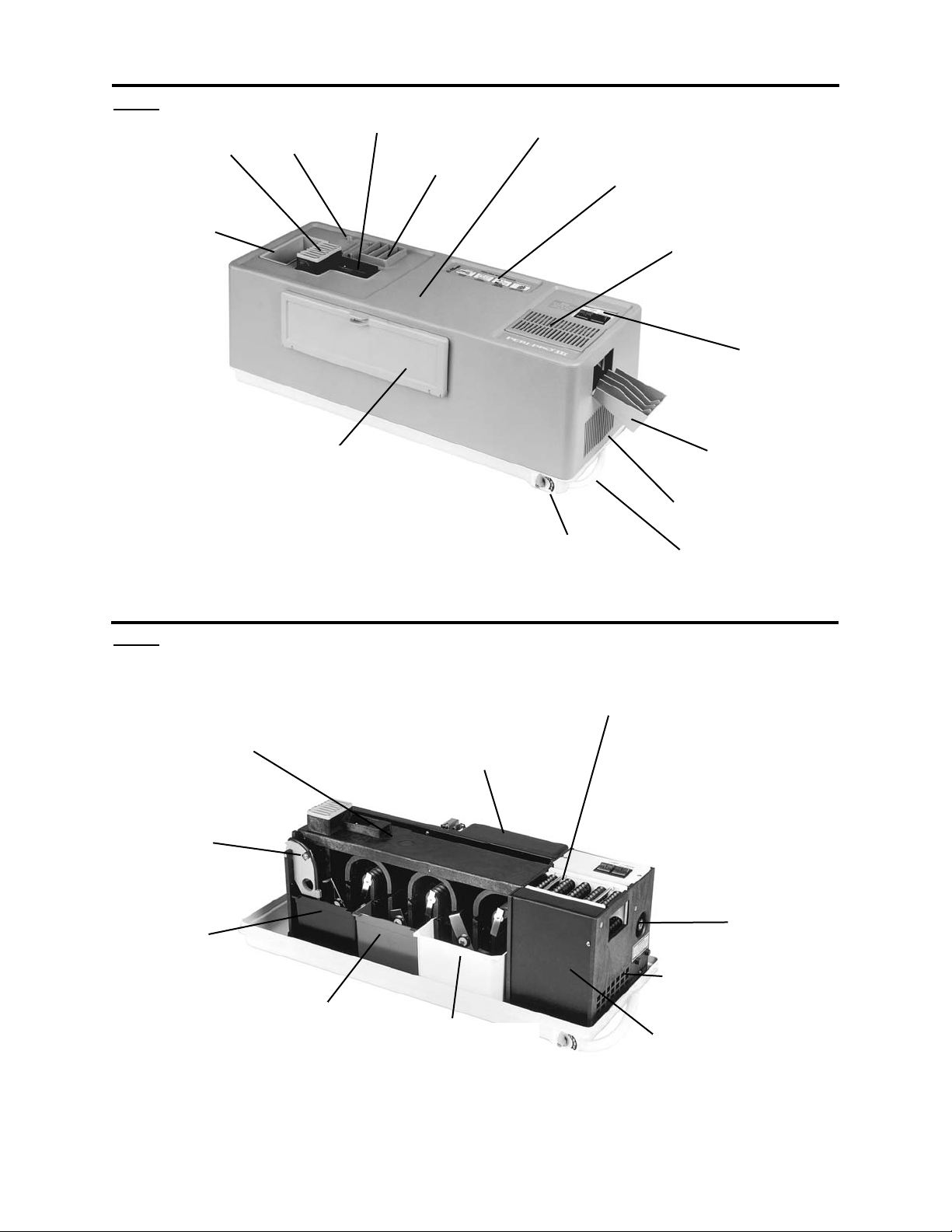

FILM TRANSPORT

DRYER TRANSPORT

DEVELOPER

TANK

(BLACK)

PCB & TRANSFORMER

COVER

5 AMP FUSE

AIR HOLES

TABS FOR

CARRIERS

FILM PACKET

STORAGE

FIG. 1

FIG

. 2

DRAIN HOSE

THERMISTOR

ARM

REFILL ACCESS

PANEL

DRYER HEATING ELEMENT

ACCESS PANEL

WASH TANK

(WHITE)

FIXER TANK

(RED)

Not shown: Grill inlet cover comes installed on the Film Inlet Grill

SHIPPING BOX CONTAINS:

Water bottle with flexible neck attachment

Peri-Pro III Processor base with cover -

NNoottee::

Grill Inlet Cover comes installed on the

Film Inlet Grill

Inside the processor:

Film transport

Chemistry tanks

((BBllaacckk ddeevveellooppeerr

ttaannkk;; rreedd ffiixxeerr ttaannkk;; wwhhiittee wwaatteerr ttaannkk))

Accessory boxes (3) containing:

## 9900885500

- 3 ea. Pedo (#0) Film Carrier

2 ea. Bite-wing Film (#3) Carrier

## 9900882255

- 3 ea. Anterior Film (#1) Carrier

1 ea. Occlusal Film (#4) Carrier

##

9900884400

- Film receptacle with 3 dividers

Literature kit: Manual, Warranty card

UNPACK

11..

Remove the water bottle and flexible neck

attachment from the cardboard packing

found at one end of the box.

22..

Place one hand on each side and underneath

the processor. Lift the processor out of the

carton and place it on a flat surface. Remove

the end caps and plastic bag.

33..

Remove the processor cover and set aside.

44..

Remove the accessory boxes and retain for

future use. Remove the top packing foam.

55..

Pull the cardboard insert out of the dryer rack

and set aside; lift the transport out (the transport cannot be removed until the cardboard

insert is removed first).

66..

Remove the shipping foam from the back wall

of the processor.

77..

Remove the foam cleaning pads from the

chemistry tanks and set aside.

88..

Do not remove the clips holding the water

drain tube to the perimeter of the base.

99..

Set the base on a flat, level, stable counter.

IImmppoorrttaanntt:: TThhee ssuurrffaaccee mmuusstt bbee ssttaabbllee ssoo tthhaatt

cchheemmiissttrryy ddo

oeess nnoott ssppllaasshh oorr ssppiillll..

INSTALLATION

INSTALL PROCESSOR

11.. FFiillll TTaannkkss

TThhee ttaannkkss ccaann bbee iinnssttaalllleedd iinn oorr rreemmoovveedd ffrroomm tthhee bbaassee oonnllyy wwhheenn tthhee ffiillmm ttrraannssppoorrtt iiss oouutt ooff tthhee

pprro

occeessssoorr.. IIff yyoouu iinnssttaalllleedd tthhee ttrraannssppoorrtt aafftteerr uunnppaacckkiinngg,, rreemmoovvee iitt nnooww..

FFoollllooww tthhee ttaannkk iinnssttaallllaattiioonn

aanndd cchheemmiissttrryy ffiilllliinngg sseeqquueennccee bbeellooww ttoo pprreevveenntt ccoonnttaammiinnaattiioonn ooff

cchheemmiissttrryy dduuee ttoo aacccciiddeennttaall ssppiilllliin

ngg oorr ssppllaasshhiinngg.. FFiixxeerr iinn tthhee ddeevveellooppeerr ttaannkk wwiillll ccaauussee

ccoonnttaammiinnaattiioonn..

PPeerrii--PPrroo cchheemmiissttrryy sshhoouulldd bbee a

att oorr bbeellooww 7755°°FF..

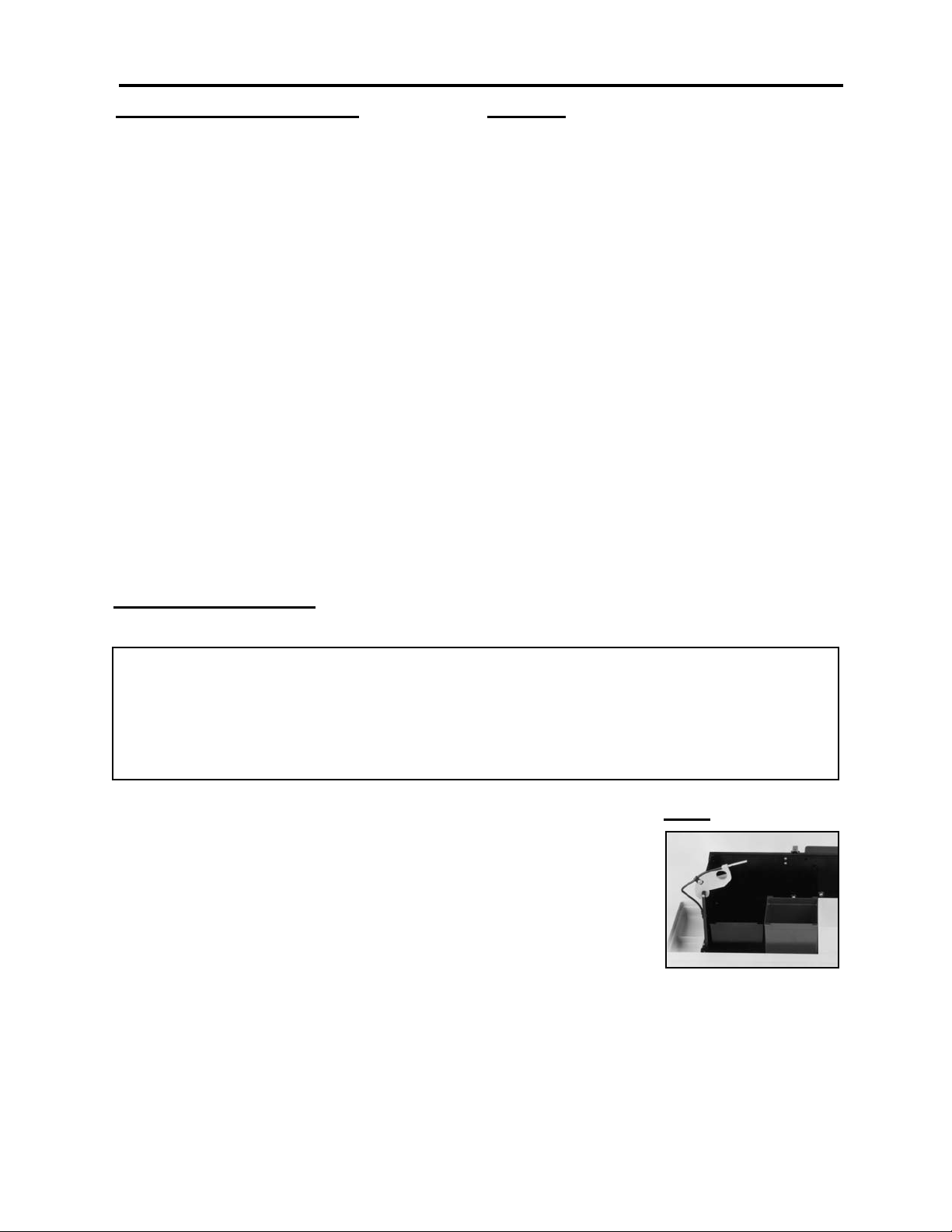

Locate the thermistor arm above and to the left of the developer

(black) tank. Carefully lift the arm up, using the finger hole, until it

locks in place. See Fig. 3.

Remove all three tanks and rinse. Note: The wash tank requires

some effort to remove the drain stem with the O-Ring from the drain

receptacle.

Install the wash tank on the right side of the base, making sure the

drain stem with the O-ring seats in the drain receptacle by pushing

down until the tank’s feet rest on the floor of the base. Fill the PeriPro III water bottle to the Fill Line (40 oz.) with room temperature

water (70° - 80°F). Attach the flexible neck to the bottle and flex into

position. Empty entire contents into the water tank.

Install the fixer tank next to the water tank, and fill with contents of the fixer bottle. Pour care-

fully to prevent splashing.

Install the developer tank on the left. Fill with the contents of the developer bottle. Lower the

thermistor arm into the tank.

If chemistry or water is accidentally spilled beneath the chemistry tanks, remove the tanks and

immediately dry the tanks, both sides of the heater plate and the depression in the base and

the area around the heater pad. Reverse the procedure to remove.

4

FIG. 3

PPOOWWEERR SSWWIITTCCHH ((AAmmbbeerr))

When the POWER switch is

turned ON it will illuminate,

indicating that there is power to

the processor and the heating

system is on. Turn the POWER

switch OFF at the end of the

day. See Fig. 6A.

TTEEMMPPEERRAATTUURREE RREEAADDYY

LLIIGGHHTT((GGrreeeenn)) // PPRROOCCEESSSS

SSWWIITTCCHH

.

When chemistry reaches its factory pre-set processing temperature of 75°F, the

RREEAADDYY

light

flashes, then remains steady,

indicating that chemistry is at

processing temperature.

Processing is initiated by turning the

PPRROOCCEESSSS

switch

OONN

.

After processing, the

PPRROOC

CEESSSS

switch is turned

OOFFFF

. The PeriPro remains ready to process

film as long as the

PPOOWWEERR

switch is left in the

OONN

position

and the green

RREEAADDYY

light is

illuminated. See Fig. 6B

RREEFFIILLLL AACCCCEESSSS DDOOOORR

Open the refill access door

when changing and refilling

water, and to check chemistry

levels at the start of the day.

This door must be closed when

processing film. It is closed

when it latches, or snaps, shut.

See Fig. 1 & 5.

FFIILLMM IINNLLEETT SSHHUUTTTTEERR

When the shutter is slid to the

right, it latches in place. Films

drop into the transport and

begin processing automatically

when the transport arms move

into position and the shutter

opens. New batches of film can

be processed every 55 seconds.

5

FIG. 6

FIG. 7

A

B

POWER

READY WHEN LIT

PROCESS

22.. AAsssseemmbbllee PPrroocceessssoorr

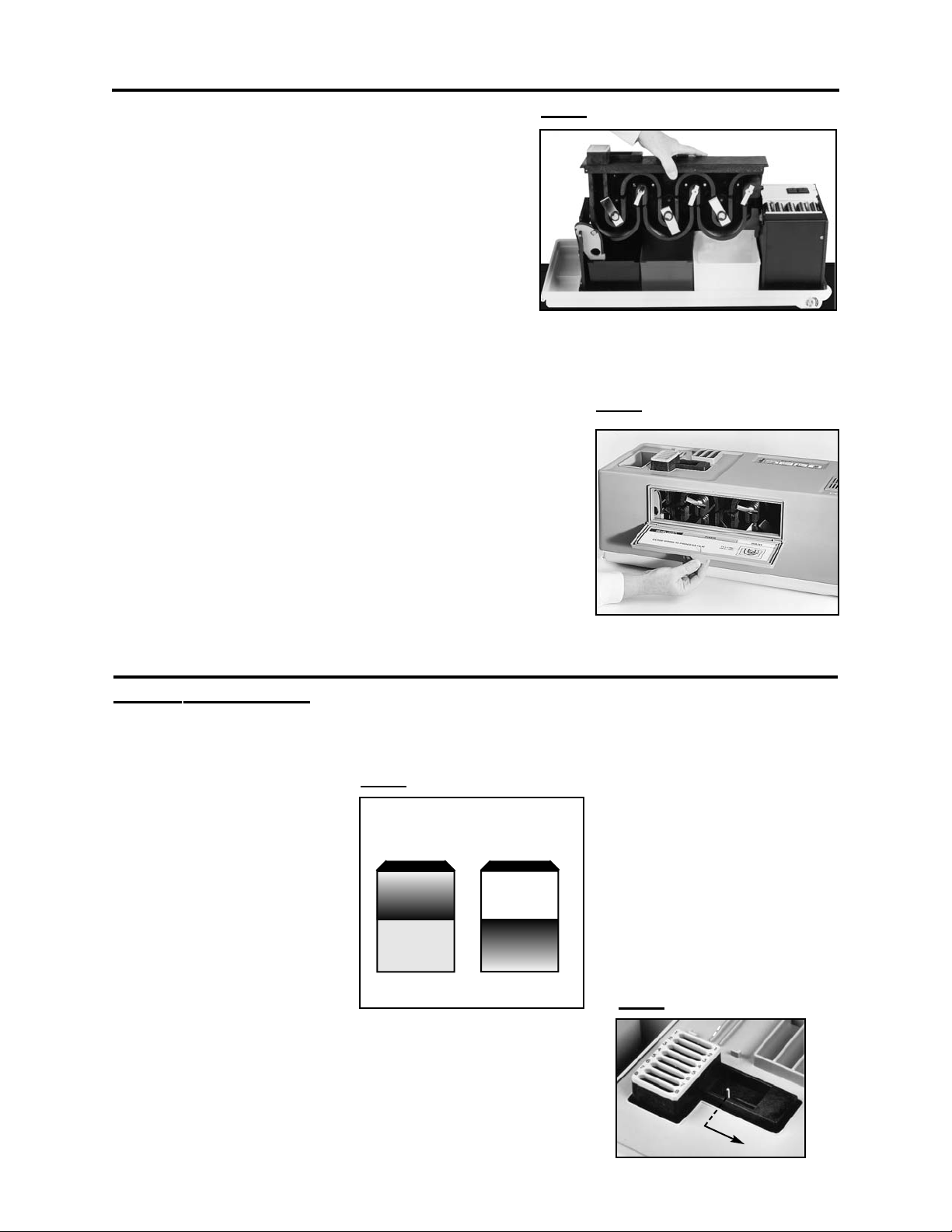

Lower the film transport straight into the tanks. The

film transport must sit squarely on the cutouts found

on the top of the vertical plates to the left and right

side of the tanks.

Note: The Transport locks the thermistor into place.

Install the film inlet grill on top of the film transport.

Note that it installs one way: track 1 to the rear and

track 8 to the front of the processor.

Remove the water drain tube from the clips that

hold it to the perimeter of the processor base and push one end of this tube onto the hose

barb part of the drain valve at the right end of the processor. Place the other end of the drain

tube into a receptacle large enough (at least 45 oz.) to hold the contents of the water tank

when it is drained.

Install the processor cover onto the base with

the refill access door in front.

Snap the film dividers (optional installation) into place in the

film delivery receptacle. Hang the film delivery receptacle on

the cutout at the dryer end of the cover.

Plug the line cord into a 115V outlet.

33.. CChheecckk OOppeerraattiioonn ooff RReeffiillll AAcccceessss DDoooorr

Open the refill access door by firmly pinching the two tabs,

then pulling the door open. There will be some resistance.

Close the panel by pushing it in until it latches (snaps) shut.

OPERATION

OPERATOR CONTROLS

INSTALLATION

FIG. 4

FIG

. 5

Loading...

Loading...