Airstream Classic 2007 Owner's Manual

OWNERS

AIRSTREAM

A TRAILERING GUIDE

MANUA

CLASSIC TRAILER

L

INTRODUCTION 2007 MODEL

The Owners Manual for your new Airstream trailer is designed to respond to the most

frequent inquiries regarding the operation, function and care of the many systems that

make modern trailering a joy.

Airstream realizes our customers possess varying degrees of expertise in the area of

repairing and maintaining the appliances in their trailer. For this reason, the service

and trouble-shooting information found in this manual is directed toward those with

average mechanical skills.

We also realize you may be more familiar in one area than you are in another. Only you

know your capabilities and limitations. We want you to use this manual, and hope you

will find the information contained in it useful, however, should you ever feel you may

be “getting in over your head” please see your dealer to have the repairs made.

A brief explanation of the operation of the appliances such as refrigerator, furnace,

water heater and others are explained in this manual. However, you will also find

the manufacturer’s information supplied in a packet included with this manual

more detailed.

All information, illustrations and specifications contained in this manual are based on

the latest product information available at the time of publication approval. If and when

new materials and production techniques are developed which can improve the quality

of its product, or material substitutions are necessary due to availability, Airstream

reserves the right to make such changes.

We have provided many important safety messages in this manual. Always read and

obey all safety messages.

WARNING indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

CAUTION indicates a potentially hazardous situation that, if not avoided,

could result in minor or moderate injury.

INTRODUCTION

manual.

Mold

CAUTION used without the safety alert symbol indicates a potentially hazardous

situation that, if not avoided, could result in property damage.

NOTE: Important information regarding the maintenance of your recreational vehicle.

(Optional)

This denotes items that may be an option on all or particular models. Additionally,

some optional items can only be included during the manufacturing phase and cannot

be added.

The inclusion of optional items does not imply or suggest the availability, application

suitability, or inclusion for any specific unit.

Important Safety Precautions

You’ll find many safety recommendations on this page and throughout this manual.

The recommendations on the next two pages are the ones we consider to be the most

important. They are covered in depth in later sections of this manual.

Do Not Allow Passengers to Ride in the Trailer During Travel

There are mold and mold spores throughout the indoor and outdoor environment. There

is no practical way to eliminate all mold and mold spores in the indoor environment; the

way to control indoor mold growth is to control moisture.

Towing and Weight Distribution

Weight distribution is an important factor when loading your travel trailer. A recreational

vehicle with the cargo distributed properly will result in efficient, trouble-free towing.

Be sure to follow the instructions in this manual.

Formaldehyde

Formaldehyde is an important chemical used widely by industry to manufacture building

materials and numerous household products. It is also a by-product of combustion

and certain other natural processes. Thus, it may be present inside the trailer with

some individuals being sensitive to it. Ventilation of the unit normally reduces the

exposure to a comfortable level.

Generator Safety

The transport of people puts their lives at risk and may be illegal. The trailer does not

have seat belts, therefore, it is not designed to carry passengers.

Reducing Fishtailing or Sway

Sway or fishtailing is the sideways action of a trailer caused by external forces.

Excessive sway of your travel trailer can lead to the rollover of the trailer and tow

vehicle resulting in serious injury or death. Be sure to follow the instructions in this

Do not operate the generator in an enclosed building or in a partly enclosed area such

as a garage. Nor should the generator be operated while sleeping. Be sure to follow

all instructions and warnings in this manual.

Lug Nut Torquing

Being sure wheel mounting nuts (lug nuts) on trailer wheels are tight and properly

torqued is an important responsibility that trailer owners and users need to be familiar

with and practice. Inadequate and/or inappropriate wheel nut torque (tightness) is

INTRODUCTION 2007 MODEL

a major reason that lug nuts loosen in service. Loose lug nuts can rapidly lead to a

wheel separation with potentially serious safety consequences. Be sure to follow the

instructions in this manual.

Appliances and Equipment

The appliances (stove, refrigerator, outdoor grills, etc.) and equipment (hot water

heater, furnace generator, etc.) typically operate on LP gas. LP gas is flammable and

is contained under high pressure. Improper use may result in a fire and/or explosion.

Be sure to follow all instructions and warnings in this manual (see page xxx) as well as

the specific owners’ manuals of the appliances and equipment.

Tire Safety

Properly maintained tires improve the steering, stopping, traction, and load-carrying

capability of your vehicle. Underinflated tires and overloaded vehicles are a major

cause of tire failure. Be sure to read the Tire Safety Manual Addendum included with

your owner’s packet.

Chemical Sensitivity; Ventilation

Chemical Sensitivity

After you first purchase your new recreational vehicle and sometimes after it has been

closed up for an extended period of time you may notice a strong odor and chemical

sensitivity. This is not a defect in your recreational vehicle. Like your home, there

are many different products used in the construction of recreational vehicles such

as carpet, linoleum, plywood, insulation, upholstery, etc. Formaldehyde is also the

by-product of combustion and numerous household products, such as some paints,

coatings and cosmetics. However, recreational vehicles are much smaller than your

home and therefore the exchange of air inside a recreational vehicle is significantly less

than a home. These products, when new or when exposed to elevated temperatures

and/or humidity, may “off-gas” different chemicals, including formaldehyde. This off-

gassing, in combination with the minimal air exchange, may cause you to experience

irritation of the eyes, nose, and throat and sometimes headache, nausea, and a variety

of asthma-like symptoms. Elderly persons and young children, as well as anyone with

a history of asthma, allergies, or lung problems, may be more susceptible to the effects

of off-gassing.

Formaldehyde

Most of the attention regarding chemical off-gassing surrounds formaldehyde.

Formaldehyde is a naturally occurring substance. It is also a key industrial chemical

used in the manufacture of the numerous consumer products which we referred

to above and used in the construction of recreational vehicles. Trace levels of

formaldehyde are also released from smoking, cooking, use of soaps and detergents

such as carpet shampoos, cosmetics, and many other household products. Some

people are very sensitive to formaldehyde while others may not have any reaction to

the same levels of formaldehyde. Amounts released decrease over time.

Ventilation

To reduce or lessen exposure to chemicals from off-gassing it is of utmost importance

that you ventilate your recreational vehicle. Ventilation should occur frequently after

purchase and at times when the temperatures and humidity are elevated. Remember

off-gassing is accelerated by heat and humidity. Open windows, exhaust vents, and

doors. Operate ceiling and/or other fans, roof air conditioners, and furnaces and use

a fan to force stale air out and bring fresh air in. Decreasing the flow of air by sealing

the recreational vehicle increases the formaldehyde level in the indoor air. Please

also follow the recommendations contained in Chapter 2 regarding tips to avoid

condensation problems. Many of the recommendations contained in Chapter 2 will

assist in avoiding exposure to chemicals that off-gas.

Do Not Smoke

Finally, we recommend that you do not smoke inside your recreational vehicle. In

addition to causing damage to your recreational vehicle, tobacco smoke releases

formaldehyde and other toxic chemicals.

INTRODUCTION

Medical Advice

If you have any questions regarding the health effects of formaldehyde, please consult

your doctor or local health department.

Warranty Exclusion

Chemical gassing is not a “Defect” in your recreational vehicle and is not covered by

the Limited Warranty. Please follow the recommendations in this manual to address

this concern.

INTRODUCTION 2007 MODEL

NOTES

TABLE OF CONTENTS

A. WARRANTY AND SERVICE

Warranty

Warranty Explanation

Service

Reporting Safety Defects

Maintenance Schedule

Maintenance Parts & Supplies

B. TOWING

Tow Vehicles

Brakes

Loading

Weighing

Hitching Up

C. CAMPING

Pre-Travel Check List

Camping Safety

Overnight Stop/Extended Stay

Slide Out Room

Leveling & Stabilizing

Hook Ups

Winter Traveling

D. EXTERIOR

Cleaning

Chassis

Power Jack

Tires

Axle and Running Gear

Electric Brakes

Tires

E. INTERIOR FURNISHINGS

AND ACCESSORIES

Fabric Care

Lounges & Tables

Features & Fixtures

Storage Areas

Smoke Alarm

Gas Detector

Fire Extinguisher

Main Door

Exterior Windows Screens

F. PLUMBING

LP (Liquid Petroleum) Gas

Water

Drainage

Winterizing

Drain and Waste

Toilet

G. ELECTRICAL

Battery

Converter

12-Volt System & Components

TV Antenna

Satellite Antenna

Solar Panel

Bathroom Exhaust

Monitor Panel

110-Volt System & Components

F. APPLIANCES

Air Conditioner

Furnace

Range/Oven

Microwave

Refrigerator

Water Heater

Roof Vent, High Volume

I. SPECIFICATIONS

WARRANTY AND SERVICE

A

WARRANTY COVERAGE

When you buy a new Airstream Travel Trailer from an authorized Airstream dealer, Airstream,

Inc., warrants the trailer from defects in material and workmanship as follows:

BASIC WARRANTY PERIOD

This warranty extends for a period of two years from the date of original retail purchase.

ITEMS COVERED

Any part of the trailer or any component equipment installed by the factory is covered

by the basic warranty except the following items, which are not covered:

• Tires

• Batteries

The tire and battery warranties will be handled by their respective service points and

according to their written policy. This limited warranty does not include failure caused

by accident, abuse, normal wear, overload or any cause not attributable to a defect

in original material or workmanship of the trailer or component equipment as installed

by the factory.

LIMITATION OF IMPLIED WARRANTIES

AIRSTREAM’S RESPONSIBILITY

The basic Airstream Limited Warranty applies for a period of two years from the

date of original purchase, and the application date of all warranties is that indicated

on the owner’s Limited Warranty. Defects in items covered under this Warranty will

be corrected without cost upon the return, at the owner’s expense, of the trailer or

defective part to an authorized Airstream dealer.

CARE AND MAINTENANCE

This warranty covers only defective material and/or workmanship; adjustments are

made at the factory prior to shipment, and rechecked by the dealer prior to delivery to

the customer. Adjustments thereafter become a customer responsibility.

Each Airstream exterior (excluding the underside and white roof) is clear coated to

prevent oxidation. This application is covered by a two-year warranty against peeling.

Prolonged exposure to salt air or industrial fall-out will permit penetration through the

coating material, causing damage to the exterior finish. Since Airstream, Inc., has no

control over these conditions, it is necessary for the owner to wash and maintain their

trailer as instructed in the Owner’s Manual.

The owner is also responsible for following all recommendations, instructions and

precautions contained in the Airstream Trailer Owner’s Manual and the individual

manuals furnished by the chassis, appliance and other manufacturers.

All warranties of merchantability and fitness for a particular purpose, whether written or

oral, expressed or implied, shall extend only for a period of two years from the date of

original purchase. There are no other warranties, which extend beyond those described

on the face hereof and which expressly excludes conditions resulting from normal

wear, accident, abuse, exposure or overload. Some states do not allow limitation on

how long an implied warranty lasts, so the above limitations may not apply to you.

INSTALLATIONS NOT COVERED

Airstream, Inc., does not accept any responsibility in connection with any of its trailers

for additional equipment or accessories installed at any dealership or other place of

business, or by any other party. Such installation of equipment or accessories by any

other party will not be covered by the terms of this warranty.

A - 1

WARRANTY AND SERVICE

IF REPAIRS ARE NEEDED

If your trailer needs repairs under the terms of the basic Airstream Limited Warranty,

you should:

1. Take your trailer to your selling dealer or other Authorized Airstream Dealer.

2. If the dealer is incapable of making the repair, request that he contact the Service

Administration Department at Airstream, Inc., for technical assistance.

3. If repairs are still not made, the customer should contact:

AIRSTREAM, INC.

419 W. Pike Street - P.O. Box 629

Jackson Center, Ohio 45334-0629

Attention: Owner Relations Department

Furnish the following information:

• The complete serial number of the trailer

• Mileage

• Date of original purchase

• Selling dealer

• Nature of service problem and steps or service, which have been performed.

(The owner may be directed to another dealer at the owner’s expense.)

DEALER REPRESENTATION EXCLUDED

The full extent of the basic Airstream Limited Warranty is set forth in detail in the

folder, and in the explanation of the basic Airstream Limited Warranty covered in the

Airstream Trailer Owner’s Manual. Airstream Inc. will not be responsible for additional

representations or implied warranties made by any of its dealers to the extent those

representations are not a part of, or are contrary to, the terms and conditions of the

basic Airstream Limited Warranty.

CONSEQUENTIAL AND INCIDENTAL DAMAGES

Airstream, Inc., will not be responsible for any consequential or incidental

expenses or damages resulting from a defect. Incidental expenses include, but

are not limited to: travel expenses, gasoline, oil, lodging, meals, telephone tolls,

and loss of work and loss of use of the trailer. Some examples of consequential

damages would be: stained curtains due to rain leaks or delaminated floor caused

by a plumbing leak. Some states do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation or exclusion may not apply to you.

WARRANTY TRANSFER

The basic Airstream Limited Warranty is transferable to subsequent owners for the

duration of the warranty period. Warranty transfer application forms are available from

your dealer or the Airstream Inc. Service Administration Department.

A

4. If, after taking the above steps, repairs are still not complete, the Airstream

owner may request the trailer be brought to the Factory Service Center at the

owner’s expense.

CHANGES IN DESIGN

Airstream Inc. reserves the right to make changes in design and improvements upon

its product without imposing my obligation upon itself to install the same upon its

products theretofore manufactured.

This warranty gives you specific legal rights, and you may also have other rights,

which vary from state to state.

A - 2

WARRANTY AND SERVICE

A

EXPLANATION OF AIRSTREAM LIMITED WARRANTY

The Airstream Limited Warranty is detailed on your warranty document.. It is filled out

by the dealer and presented to the owner during delivery of a new unit. The Limited

Warranty must be presented to a dealer to obtain warranty service. It should be kept in

the trailer during the warranty period.

EXCLUSIONS:

Normal Wear

Items such as tires, water purifier packs, curtains, upholstery, floor coverings, window,

door and vent seals will show wear or may even wear out within the two year warranty

period depending upon the amount of usage, weather, and atmospheric conditions.

Accident

We strongly urge our dealers and customers to inspect the trailer upon receipt of

delivery for any damage caused by accident while being delivered to the dealer, or

while it is on the dealer’s lot. Damage of this nature becomes the dealer or customer’s

responsibility upon acceptance of delivery, unless Airstream is notified and the person

making the delivery verifies the damage. Glass breakage, whether obviously struck or

mysterious, is always accidental and covered by most insurance policies.

Abuse

Lack of customer care and/or improper maintenance will result in early failure for which

Airstream cannot be held responsible.

Exposure

Not unlike a car, the steel parts of a trailer can and will rust if subjected to prolonged

exposure to moisture, salt air, or corrosive air-borne pollutants without repainting.

Aluminum oxidizes when unprotected under similar conditions, and refinery chemicals

of a sulfurous nature are harmful to finishes if not washed off periodically. Extremely hot

or direct sunlight will deteriorate rubber and fade curtains and upholstery. Conditions

of this nature, although they may be normal for the area, are beyond Airstream’s control

and become the responsibility of the owner.

Although it is our obligation to correct a rain or plumbing leak within the terms of

the limited warranty, it is the owner’s responsibility to use reasonable, prudent care

to minimize foreseeable secondary damage, such as a delaminated floor, stained

upholstery, carpeting, drapes etc.

Chemical Gassing

Chemical gassing is not a “Defect” in your recreational vehicle and is not covered

by the Limited Warranty. Please follow the recommendations in this manual to

address this concern.

Overload

Damage due to loading, either beyond capacity or to cause improper towing because

of improper balance, is beyond Airstream’s responsibility. The Airstream trailer is

engineered to properly handle the gross vehicle load rating on the certification label.

Load distribution has a definite effect upon the towing characteristics and attitudes of

the trailer. Level hitch installations are a necessity, and very important on a tandem axle

trailer. There are limits to the amount of load that can be safely transported depending

upon speed and road conditions, and reasonable cause to believe these factors have

been exceeded could void the Airstream warranty. For additional information on the

loading of your trailer, consult your Owner’s Manual or gross vehicle weight rating plate.

The axles used on your trailer is manufactured to a tolerance of 1-degree camber and

1/8” toe-in. These tolerances will only change if the trailer is subjected to abuse, such

A - 3

WARRANTY AND SERVICE

as dropping off a sharp berm, striking a curb, or hitting a deep hole in the road. Such

damage could be considered as resulting from an accident which risks are not covered

under the warranty. Abnormal tire wear and/or wheel alignment resulting from such

damage is not covered under the terms of the warranty.

SERVICE:

Before leaving the factory, each and every vital part of the trailer is tested for perfor-

mance. Each test is signed and certified by an inspector. After the trailer arrives on

your dealer’s lot all of these vital parts and systems are again tested. When you take

delivery of your new trailer you will receive a complete check out.

At that time a specified list of performance checks on your trailer equipment will be

conducted and any deficiencies you have experienced since taking delivery will be

corrected.

Please contact your dealer if you need service. Major service under your Airstream

Limited Warranty is available through our nationwide network of Airstream Dealer

Service Centers. An up-to-date list of Dealer Service Centers has been provided with

your new trailer. This list is current as of the date of this publication.

kindly inform him if you are unable to keep the appointment date or wish to change it.

Service may be arranged at the Factory Service Center by contacting the Service

Coordinator at :

Airstream Factory Service Center P.O. Box 629

419 W. Pike Street

Jackson Center, Ohio 45334-0629

937-596-6111

REPORTING SAFETY DEFECTS

If you believe that your vehicle has a defect, which could cause a crash or could cause

injury or death, you should immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying Airstream, Inc.

If NHTSA receives similar complaints, it may open an investigation, and if it finds that a

safety defect exists in a group of vehicles, it may order a recall and remedy campaign.

However, NHTSA cannot become involved in individual problems between you, your

dealer, or Airstream, Inc.

A

Occasionally dealerships change, or new dealers are added who may not appear on

this list. For this reason, it is suggested that you contact your local dealer from time

to time and bring your list up to date. He can also provide you with additional copies

if you need them. ALL CENTERS OPERATE ON AN APPOINTMENT BASIS FOR THE

UTMOST EFFICIENCY.

When you require service from the Airstream Factory Service Center, or a Certified

Dealer Service Center, please contact the service manager for an appointment, and

To contact NHTSA you may either call the Auto Safety Hotline toll-free at 1-888-

327-4236 (TTY 1-800-424-9153); go to www.safercar.gov; or write to: Administrator,

NHTSA, 400 Seventh St, S.W., Washington, D.C. 20590.

You can also obtain other information about motor vehicle safety from www.safercar.

gov.

A - 4

WARRANTY AND SERVICE

A

MAINTENANCE SCHEDULE

WARNING: FAILURE TO MAINTAIN YOUR COACH CAN CAUSE

PREMATURE AND UNEXPECTED PARTS BREAKAGE AND/OR ERRATIC

OPERATION THAT MAY BE HAZARDOUS.

Note: See appliance manufacturer’s literature for further information.

SUGGESTED MAINTENANCE

EVERY 1,000 MILES OR 60 DAYS

Escape Window Check operation of latches and upper hinge.

*Battery Check water level

Smoke Alarm Test and replace battery as required

Tires Check tire pressure (See Specifications)

Hitch Check for loose bolts or unusual wear.

GFI Circuit Breaker Test and record.

EVERY 5,000 MILES OR 90 DAYS

Exterior Door locks Lubricate with dry graphite

Exterior Hinges Lubricate with light household oil

LPG Hold Down Lubricate with light household oil

LPG Regulator Check bottom vent for obstructions

Main Door Striker Pocket Coat with paraffin.

Wheel Lug Nuts Torque forged aluminum wheels to 100 ft. lbs.

and steel wheels to 95 ft. lbs.

Break Away Switch Pull pin and lubricate with household oil

7-Way Plug Spray with contact cleaner.

Hitch Ball Latch Lubricate with non-detergent motor oil

Hitch Ball Lubricate with hitch ball lube or wheel bearing grease.

Range Exhaust Hood Clean fan blades and wash filter.

WARNING: WHEEL SEPARATION CAN OCCUR

1. On first trip, tighten wheel lugs at start and at 10, 25, and 50 miles.

2. Thereafter, check wheel lugs before each trip.

3. Following winter storage, check before beginning a trip.

4. Following excessive braking, inspect wheel lugs

Torque forged aluminum wheels to 100 Ft. lbs. and steel wheels to 95 ft. lbs.

Roof Vent Elevator Screws Lubricate with light household oil

Main Door Step Lubricate moving parts and check.

* As a battery ages and becomes less efficient, the water level should be checked at

more frequent levels.

A - 5

WARRANTY AND SERVICE

EVERY 10, 000 MILES OR 6 MONTHS

Brakes Inspect, adjust or replace as necessary

Wheel Bearings Clean and repack

Tires Inspect and rotate

Spare Tire Carrier Lubricate moving parts.

Seals, Windows & Door Clean with mild detergent and coat with “Slipicone”.

TV Antenna Lubricate all moving parts with silicone lubricant.

Exterior Wax

Escape Window Lubricate latches with WD-40.

LP Bottles Check tightness of center hold down rod where it

fastens to A-Frame

EVERY YEAR

Battery Clean, neutralize and coat terminals

with petroleum jelly.

A-Frame, Step Wire brush and paint frame at front and rear.

LP Bottles Have purged by LP supplier.

Seams Check and reseal exterior seams, windows,

lights and vents if necessary. Use Ten X or equivalent.

Hitch Coupler and Ball Check for wear or damage. Assure all parts

operate freely. Replace any component if

worn or damaged.

A

A - 6

A

WARRANTY AND SERVICE

PARTS AND LUBRICANTS

BULBS, EXTERIOR

Taillight LED

Back Up LED

License Plate # 53, wedge base

Hitch Light # 53, wedge base

Clearance Light # 67

Door Light # 1003

Hitch Light # 193, wedge base

Compartment Light #1141

BULBS, INTERIOR

Two-Bulb Pin Up Light #1076

3 Arm Dinette Light #921

Wall Light #1076

Reading & Ceiling Light #819

Pin Up Light #1076

WARNING: Always replace the light

bulb on an interior or exterior light fixture with

the correct bulb for that light. Failure to heed

this warning could cause fire, property damage,

personal injury, or death.

FUSES

ATC 15 & 20 Amp

Battery Cable Fuses

(Canadian approved trailers only)

SLC 50 Amp

MISCELLANEOUS

Water Hose Gaskets

Wheel Bearing Grease

Extra Hair Pin Clips for Hitch

Grease Seals & Packed Wheel Bearings

Dry Graphite

WD-40 or Equivalent Aerosol Lubricant

Oil Can with 30 Weight Non-Detergent Oil

Silicone Lubricant

Light Household Type Oil

Spray Contact Cleaner

Hitch Ball Lube (wheel bearing grease)

Sealer

C & D-Cell Batteries

Flashlight

Rain Gear

Road Hazard Signals

MAINTENANCE RECORD

DATE DEALER

SERVICE

PERFORMED

A - 7

TOWING

TOWING YOUR AIRSTREAM

TOW VEHICLE EQUIPMENT

If you plan to buy a new vehicle to tow your trailer we suggest that you include in your

purchase the towing options offered by most vehicle manufacturers. These include

such things a heavy-duty alternator and radiator, heavy-duty springs, (See Note:)

shock absorbers, transmission cooler, heavy-duty fan and flasher unit and others,

depending upon the make of the vehicle.

NOTE: Be realistic when ordering heavy duty springs. Only springs heavy enough to

support your loaded vehicle (not including trailer) are necessary. Too harsh of spring

rate will only shorten the life of the tow vehicle and trailer, and will make your journeys

less enjoyable.

Transmissions may be manual or automatic, but an automatic transmission may

prolong your tow vehicle’s life and generally does a better job of controlling engine

loads than the average driver using a manual shift.

Having adequate power is very important when considering the purchase of a new

vehicle or the trailer towing capability of your present one. American manufacturers

realize more than 30% of the vehicles they sell will be used for towing some type of

trailer. The dealers are provided with guidelines to use when helping a customer decide

on a tow vehicle. The guidelines are not just determined by the power output of the

engine. The gear ratio of the differential is also a very part of the guideline.

must be taken not to overload the front and rear ends of the trailer.

Disc Brakes

The disc brake system is a proven system that includes a ventilated rotor that fits over

the hub, combined with a caliper and mounting bracket that attach to the axle end

assembly by bolting to the standard brake flange. Major automobile manufacturers

and others have used this type of rotor installation for many years. The wheel studs

are pressed into the hub only. The rotor is a loose fit on the hub, is centered by the

wheel bolts, and is retained by the wheel, which in turn is retained by the wheel nuts.

Removal of the rotor can be accomplished with little effort once the caliper has been

removed.

Safety Information

1. Only qualified persons who are knowledgeable of brakes and brake systems should

perform brake installation, maintenance or repair on any vehicle.

2. Familiarize yourself with state laws regarding the operation of towed vehicles,

especially with regards to brake/braking requirements. Allow for extra stopping

distance that may be required when towing.

3. Immediately after each hook up, always test that the trailer brakes are operating

properly before attaining normal road speed.

B

Inspect vehicle’s hitch regularly for loose bolts or nuts, cracked welds, loose ball

mounts, worn parts, etc.

New trailerists often carry more food and other supplies than really needed. Remember

that every item you take along is one more thing to stow and adds weight to the total

load you must pull. Consolidate items in shelves, lockers, and in the refrigerator. It is

better to have one full and one empty locker, than two half empty ones. Special care

4. Make regular, periodic inspections of your trailer brakes. The inspection should

include:

a. Pads – for evidence of excessive or uneven wear.

b. Rotors – for evidence of excessive wear, scoring, excessive heat

build up, cracks, warping.

c. Actibrake Master Cylinder – proper fluid levels.

d. All bolted connections – tight

B - 1

TOWING

B

e. Calipers and Brake Lines – for evidence of brake fluid leak.

Preventive Maintenance

1. Visually check brakes before each trip. See item 4 in safety Information.

2. After each hook-up, always check trailer brake operation before attaining normal

driving speed.

3. Follow manufacturer’s recommendations with regard to use of and replacement of

brake fluid.

4. Wash down brake assembly immediately after exposure to salt water or other

corrosives.

5. Periodically, during each trip, check hub and assemblies to make sure that they are

within normal operating ranges (130°- 175° F). Do not touch brake components, as

they may be much hotter than the hub or wheel, especially after recent braking.

Actibrake Disc Brake Actuator System

and your trailer braking system in general. Unlike electric drum brakes, the ActiBrake

does not receive its power through the “blue wire”. The power to the ActiBrake is

provided through a +12 volt (normally black) wire from the tow vehicle connector.

The heart of ActiBrake is the Power Max pump. It is the highest capacity pump

available on any electric-hydraulic pump actuator.

ActiBrake is also the only electric-hydraulic actuator with the unique “Extend’ A Hold”

feature which maintains brake line pressure when the vehicle is stopped without

operating the motor. This dramatically reduces heat build-up and improves reliability

and longevity.

Filling Reservoir

The Actibrake Actuator pump is located in the A-Frame box on all models except the

25’ Front Bed which is located in the roadside underbelly compartment.

Fill the reservoir with NEW, CLEAN, “DOT 3” or “DOT 4” Brake Fluid. Never re-use

brake fluid that has been salvaged or removed from another unit. Contaminated or

dirty fluid can cause system failure and/or premature wear on the system components.

DO NOT OVER FILL the reservoir. Fill within 3/4-inch of the filler opening.

ActiBrake is part of a trailer braking system. ActiBrake is a state-of-the-art trailer brake

actuator. ActiBrake is the fastest responding, most advanced electric-hydraulic pump

actuator available.

Brake Controllers

Your trailer braking system is like a chain. It is only as good as its weakest link. This is

especially true regarding tow vehicle brake controllers. There are many marginal brake

controllers on the market, and ActiBrake will only apply the level of braking indicated

by the brake controller’s “blue wire” signal. Therefore, we urge you not to economize

on a brake controller because it will only diminish the overall performance of ActiBrake

WARNING: Use only new, clean, DOT 3 or DOT 4 brake fluid from a sealed

container. Do not fill with previously used fluid. Used fluid may absorb water or other

impurities which may cause corrosion and/or poor brake performance. This may result

in physical injury and/or property damage!

WARNING: It is critical that you verify that your breakaway system functions

properly! The breakaway battery is the trailer batteries. The breakaway switch is wired

direct to the batteries.

B - 2

TOWING

Breakaway Protection

The breakaway system is required to supply power to the ActiBrake system in the

event the trailer becomes uncoupled from the towing vehicle.

Failure to maintain adequate charge in the breakaway battery will result in the

breakaway system not functioning properly. This may result in physical injury and/or

property damage in the event of a breakaway! The breakaway battery is the trailer

batteries. The breakaway switch is wired direct to the batteries.

In THE EVENT OF AN ACCIDENTAL SEPARATION of the tow vehicle and trailer,

the BREAKAWAY SWITCH will set and lock the trailer brakes for a sufficient length

of time to stop the trailer. The switch is activated when the wire attached to it and to

the tow vehicle pulls out the small pin in the front of the unit. THIS PIN SHOULD BE

PULLED OUT, LUBRICATED WITH LIGHT HOUSEHOLD OIL AND REPLACED EVERY

90 DAYS.

To prevent corrosion within the breakaway switch, pull the switch’s pin straight forward

and spray the inside of the switch through the hole with an electric contact cleaner

(such as Spra- Kleen) and reinsert the pin. A drop of light household oil on the groove

near the base of the pin will allow the pin to operate freely. WHEN THE TRAILER IS

CONNECTED TO THE TOW CAR, THE BREAKAWAY SWITCH LOOP SHOULD BE

ATTACHED TO THE PERMANENT FRAME OF YOUR HITCH. When disconnecting

trailer from tow vehicle remove wire loop from the frame. DO NOT REMOVE THE PIN

FROM THE SWITCH FOR AN EXTENDED PERIOD OF TIME BECAUSE THIS WILL

APPLY THE TRAILER BRAKES AND POSSIBLY DAMAGE THE BRAKE MAGNETS

AND RUN THE BATTERY DOWN.

General Operation

Coupling

When coupling the trailer to the towing vehicle, always ensure the two vehicles

are properly coupled, including the safety chains and breakaway switch cable, in

accordance with the vehicle manufacturer’s instructions and trailer manufacturer’s

instructions. All coupling devices and procedures must conform to State and Federal

regulations.

Trailer Connector - Vehicle Connector

After properly coupling the trailer to the towing vehicle, plug-in the trailer connector

to the mating connector of the towing vehicle. There are two checks to ensure proper

connection has been made.

(The first time the ActiBrake is connected to a brake controller, it is necessary to engage

the manual over-ride lever of the brake controller for a period of up to 5 seconds.

During this time, Actibrake’s active synchronization system syncs-up with your brake

controller. ActiBrake stores this information in its memory so the synchronization is

necessary only at initial set-up AND whenever the trailer gets disconnected and re-

connected to the tow vehicle.)

The first check is visual, as many tow vehicle brake controllers have an indicator light.

This light will illuminate green if the electrical connection is correct. If the light does

not illuminate, there is a problem with the connection. SEE your tow vehicle brake

controller manual for complete details on verification of wiring continuity.

B

The second check requires using the manual override lever on the tow vehicle controller.

Position a second person near the ActiBrake. With the ignition switch turn on, keeping

the vehicle in Park (or not in gear with the parking brake engaged) and stationary,

move the manual override lever of the brake controller. The person near the ActiBrake

B - 3

TOWING

B

will hear the motor engage if the tow vehicle and trailer are properly connected. If the

ActiBrake does not function, immediately discontinue operation.

Determining and Setting Proper Trailer Braking Force

Become Familiar with Braking of the Coupled Tow Vehicle and Trailer.

After the system installation has been verified, the operator should take the trailer to

an empty parking lot to become familiar with the operation of the braking action of the

combined tow vehicle-trailer. Each driver has different driving habits, and each vehicle

has unique braking characteristics. Each potential driver of the coupled tow vehicle

and trailer should take some time to familiarize themselves with the response and

handling of the trailer using various settings on the tow vehicle controller. Each driver

must be familiar with the operation of the tow vehicle brake controller and understand

how to make adjustments to achieve the most desirable braking force.

Brake Controller Signal Determines Trailer Brake Pressure

Trailer braking pressure is controlled by the use of a tow vehicle brake controller. This

allows the driver to select the desired brake performance for the trailer, from the driver’s

position in the towing vehicle. Increasing or decreasing the “gain” setting of the tow

vehicle brake controller, will increase or decrease the level of brake force generated by

the ActiBrake unit. Refer to brake controller manufacturer’s manual for instructions to

properly adjust the controller settings.

activated.

NOTE: Study all material provided with your particular brake control. If you don’t

understand the information, have the installer explain the information to you or call the

manufacturer of the controller.

A BRAKE CONTROLLER installed in your tow vehicle will synchronize the trailer

brakes with your tow vehicle brakes. It is designed to apply the trailer brakes whenever

the tow vehicle brakes are applied.

ELECTRONIC CONTROLLERS are inertially activated. The controller senses

deceleration and generates an output, which reflects the inertia sensed. When you

are stationary, the controller does not apply the brakes unless the manual slide bar is

B - 4

TOWING

Which Tow vehicle Controller Is Best?

IMPORTANT

This trailer is equipped with an electric-hydraulic brake actuator. Before you plug the

trailer’s electrical connector in to your tow vehicle ensure the following:

1) Verify that an approved brake controller is properly installed in the tow vehicle, per

the brake controller manufacturer’s instructions.

2) Approved controllers are:

· Hayes Genesis

· Hayes Energize XPC

· Hayes Endeavor

· Hayes Energize III

· Tekonsha Prodigy

The list of approved controllers may change. Please contact Active Technology at

515-285-0195 during normal business hours (central time) for up to date information

on controller compatibility.

3) Verify that the 12-volt charge line (see diagram below) is energized.

4) With the tow vehicle engine running, you must have 13.5 or greater volts on the

charge line.

5) Use a reliable DC volt meter to check the voltage between the Black, 12V Charge

line and the 12V white (ground) on your tow vehicle’s 7 way connector.

B

WARNING: Use of an unapproved brake controller and/or operating your

brake system without proper charge line voltage (see above) may damage

your electric- hydraulic brake system which may result in loss of trailer braking.

WARNING: A brake controller that is not grounded per brake controller

manufacturer’s installation instructions may damage your electric-hydraulic

brake system which may result in loss of trailer braking.

For concerns or questions, call Active Technology at 515-285-0195 during normal

business hours (central time).

NOTE: Active Technology does not endorse the use of time-based tow vehicle

controllers with the ActiBrake system. The output of a time-based controller is not

proportional to the deceleration of the towing vehicle and therefore, when linked to

a time-based tow vehicle controller, ActiBrake will not generate proportional brake

pressure.

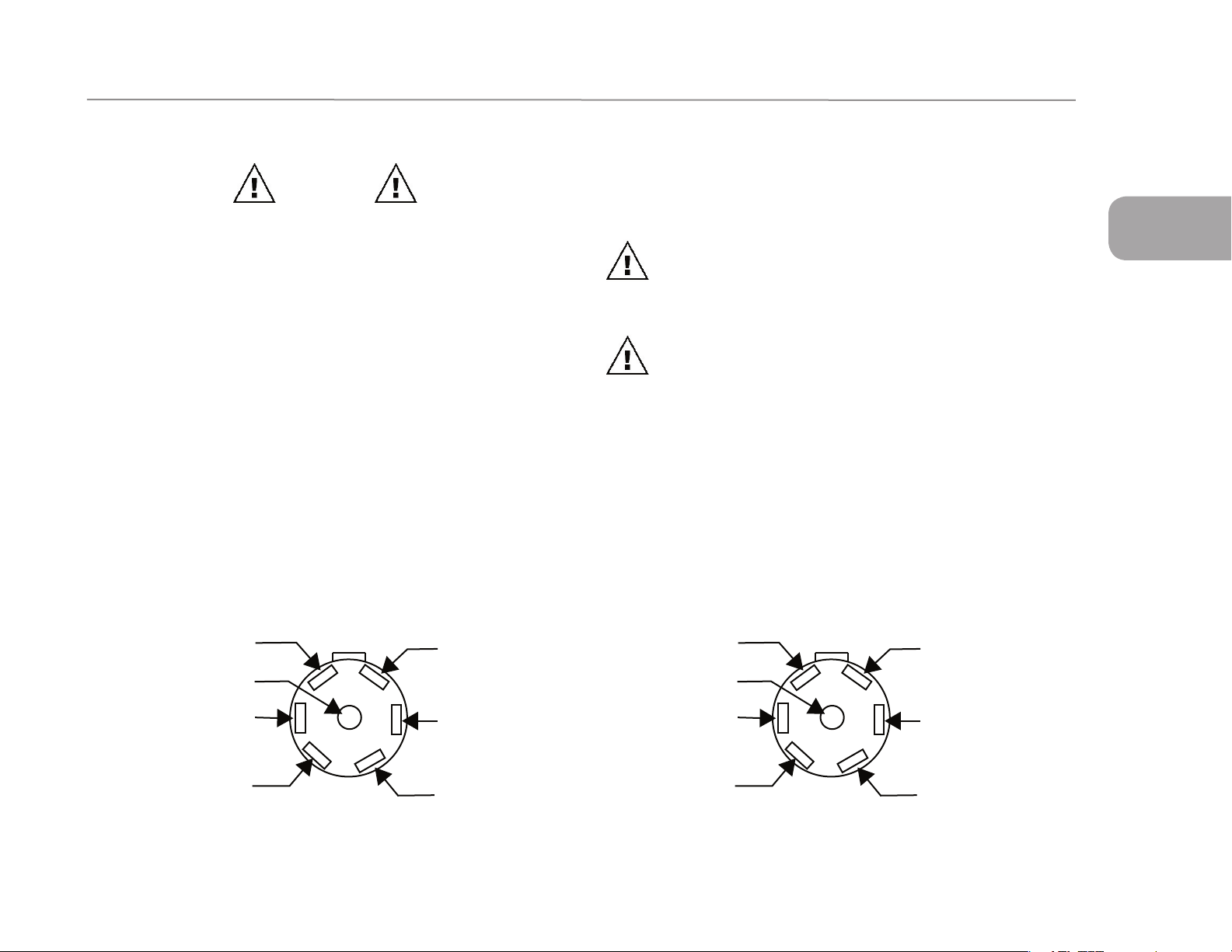

Black, 12V

Blank

Brown, Right

Turn

Blue, Brake

-

7 Way Plug-Trailer End

Clearance Lights,

Green

Turn, Red

Left

12V, White

B - 5

Clearance Lights

n

Gree

Blank

Turn, Red

Left

12V, White

7 Way Plug-Tow Vehicle End

,

Black, 12V -

Brown, Right

Turn

Blue, Brake

TOWING

B

Settings and Use of Tow vehicle Controllers

The settings of the tow vehicle controller are set by the driver. When properly set, the

braking force of the trailer will provide sufficient braking so the brakes of the towing

vehicle are not required to provide any braking force for the trailer. Variations in the

controller settings may be required for different road conditions and for changes in

trailer load. It is essential to maintain sufficient braking on the trailer on wet or slippery

road surfaces. More braking with the trailer will help prevent the possibility of a jack-

knife situation or prevent the trailer from swaying or pushing the towing vehicle. The

tow vehicle brake controller also allows for manual activation of the trailer brakes

independent of the tow vehicle, by using the manual override feature of the controller.

WARNING: It is essential that each driver read and fully understand

the tow vehicle brake controller operating manual provided by the manufacturer

of the tow vehicle brake controller. Failure to fully understand the use and

operation of the tow vehicle brake controller by each driver may cause loss of

vehicle control. This may result in physical injury and/or property damage!

DO NOT RIDE YOUR BRAKE PEDAL!

This will cause constant pressure from the ActiBrake unit to the trailer brakes, resulting

in premature wear and overheating. This may also cause damage to the ActiBrake

unit or cause damage to the internal components of the system, as well as damage to

your hydraulic brakes.

Extend’ A-Hold Feature

maintain brake line pressure until the tow vehicle brake pedal is released.

Important ! Do not remove the plastic cover of the ActiBrake. It is sealed against

moisture and other contaminant’s and to prevent tampering with internal components.

Removing this cover voids your warranty.

Replacement Parts

The internal components of the ActiBrake unit are not intended for field service. The

unit is sealed at the factory to prevent tampering with the internal components. The

ActiBrake warranty will be voided if the seal is broken. See your dealer for replacement

breakaway switches, batteries, filler cap or other items for your brake system.

Important: Brake fluid can cause damage to painted surfaces. Clean up any spills

on painted surfaces immediately.

Service and Maintenance

Visual System Check

Periodically check the complete braking system, including the brake lines and hoses,

wiring and vehicle-trailer connector plugs for damage, corrosion or leaks. Ensure

brake lines and wires are secured so they do not hang down, drag or get caught when

the trailer is in motion.

Make Sure The Breakaway Battery Is Fully Charged

In the event you are required to be stopped with the tow vehicle brake pedal depressed

for an extended period (and if the brake controller installed in your tow vehicle continues

to send a signal when your vehicle has stopped), the ActiBrake unit’s “Extend’ A Hold”

feature is activated. This Extend’ A Hold feature shuts the motor off after approximately

20 seconds and keeps your brake lines pressurized until you release the brake pedal

in the towing vehicle. The motor will re-start for a few seconds every 30 seconds to

Always check the breakaway battery to verify it is fully charged when coupling your

trailer for use. The breakaway battery is the trailer batteries. The breakaway switch is

wired direct to the batteries. The trailer systems monitor will show the batteries charge

status. Plug you shoreline into an exterior 110-volt service or running your tow vehicle

with the 7-way cord connected will charge your trailer batteries.

B - 6

TOWING

Failure to maintain proper charge in the breakaway battery will result in the breakaway

system not functioning properly. This may result in physical injury and/or property

damage in the event of a breakaway!

Charge Battery When Necessary

If battery’s charge is low, or if the trailer has been parked for a prolonged period, charge

the battery by connecting the trailer 110-volt shoreline or running the tow vehicle with

the 7-way cord connected. Use the procedure outlined above to determine if the

breakaway battery is fully charged. Always follow battery manufacturer’s maintenance

instructions.

Testing the battery in the manner outlined above confirms that the battery is charged.

However, it does NOT confirm the brakes are functioning properly. Regular inspection,

adjustment, and maintenance of the braking system is necessary to ensure proper

brake operation.

Check Brake Fluid Level

Verify brake fluid level before each use. Fluid level should be between three eights and

one half inch from the top of the filler tube. Use care to prevent contamination of the

fluid with dirt, water, or other foreign material when removing the filler cap, checking

the fluid level, or when adding fluid to the reservoir.

fluid may cause the ActiBrake system to malfunction, which may result in physical

injury and/or property damage!

See the Actibrake manual included with your owner’s packet for troubleshooting,

Active Technology

7600 Sand Drive

Fort Worth, Texas 76118

817-595-9710

www.activetech1.com

WARNING: NEVER CRAWL UNDER YOUR TRAILER UNLESS IT IS

RESTING ON PROPERLY PLACED JACK STANDS.

B

Brake Fluid Contamination

The ActiBrake reservoir is sealed to prevent contamination of the fluid during normal

operation. Should the fluid in the reservoir become contaminated, the ActiBrake and

brake system should be flushed. This procedure should ONLY be performed by a

qualified mechanic or technician. After the system has been flushed, the reservoir

must be re-filled with new “DOT 3” or “DOT 4” brake fluid and the brake lines bled as

outlined of Page 8 of the Actibrake Owner’s Manual. The use of contaminated brake

B - 7

B

TOWING

NOTES

B - 8

TOWING

LOADING

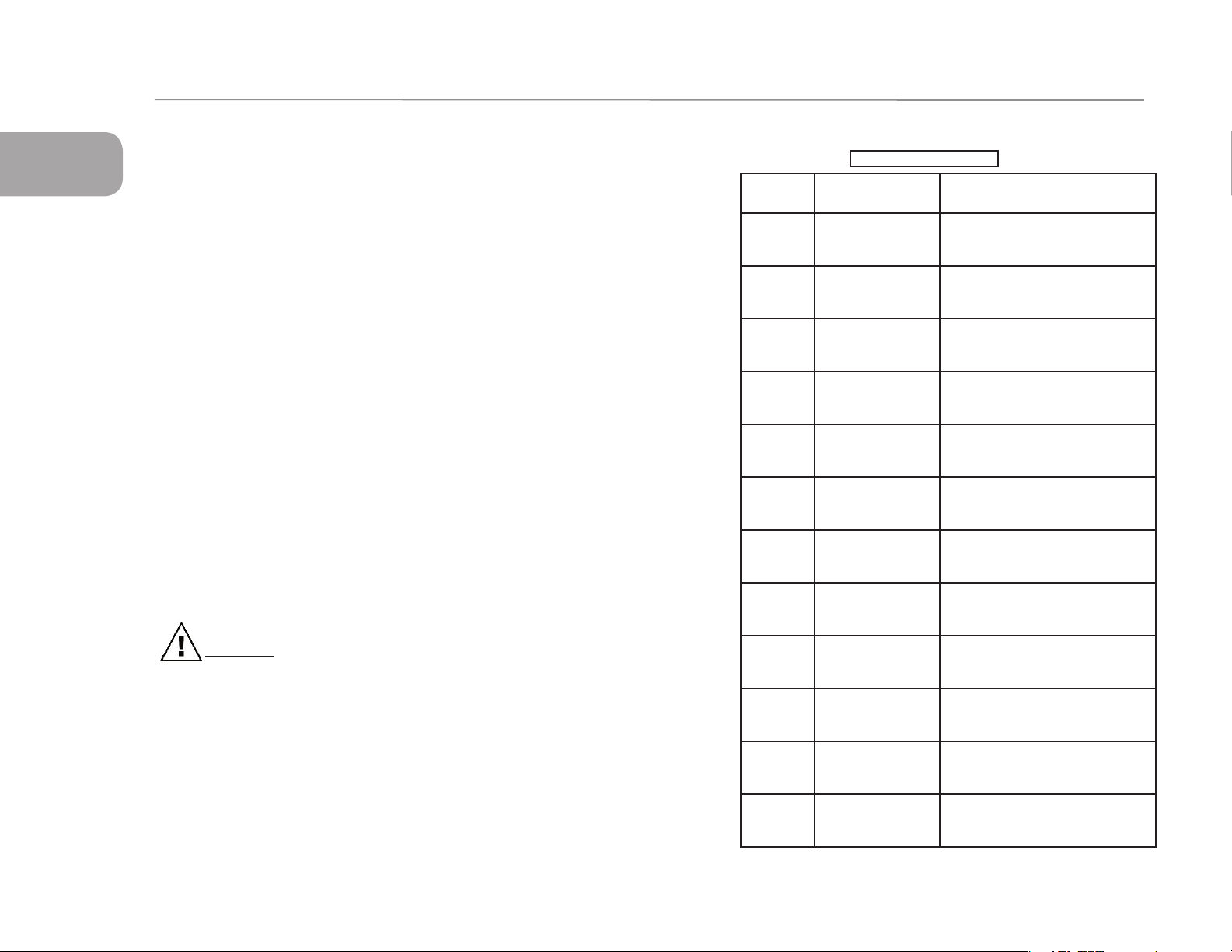

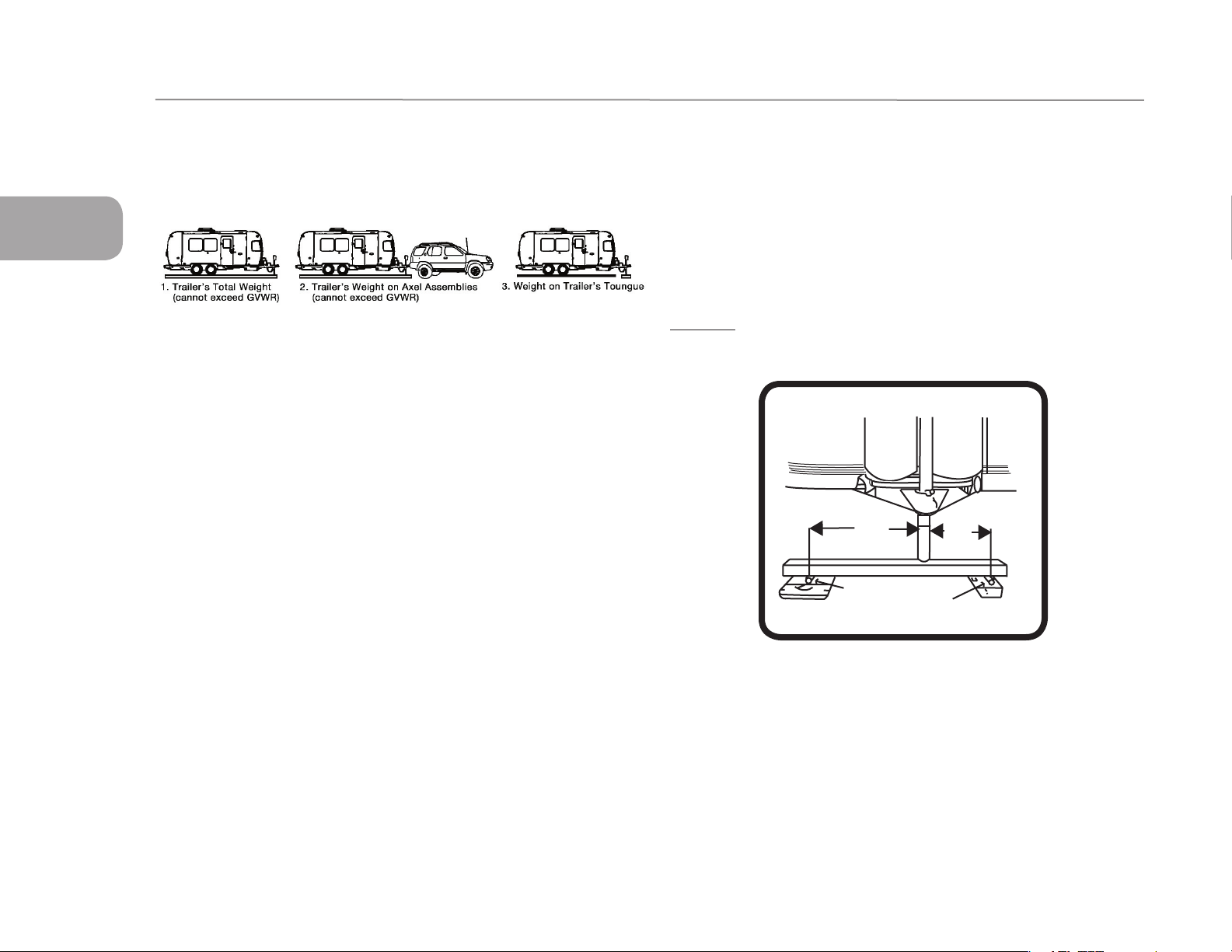

Below is a sample of the weight information chart provided in all Airstream vehicles.

This information can be found in your vehicle on the back of the first wardrobe door on

the curbside of the vehicle about 60” up from the floor.

TRAILER WEIGHT INFORMATION

VIN OR SERIAL NUMBER

GVWR (GROSS VEHICULAR WEIGHT RATING) IS THE MAXIMUM WEIGHT OF THIS TRAILER

WHEN FULLY LOADED. IT INCLUDES ALL WEIGHT AT THE TRAILER AXLE(S), AND TOUGUE

OR PIN.

UVW (UNLOADED VEHICLE WEIGHT), IS THE WEIGHT OF THIS TRAILER AS MANUFACTURED

THE FACTORY. IT INCLUDES ALL WEIGHT AT THE TRAILER AXLE (S) AND TOUGUE OR PIN.

AT

IF APPLICABLE, IT ALSO INCLUDES FULL GERNERATOR FLUIDS, INCLUDING FUEL, ENGINE

OIL, AND COOLANTS.

CCC (CARGO CARRYING CAPACITY) IS EQUAL TO GVWR MINUS EACH OF THE FOLLOWING:

UVW, FULL FRESH (POTABLE) WATER WEIGHT, (INCLUDING WATER HEATER, FULL PROPANE

WEIGHT.

CARGO CARRYING CAPACITY (CCC) COMPUTATION

GVWR.............................................................................................

MINUS UVW..................................................................................

MINUS FRESH WATER WEIGHT OF GALLONS @ 8.3 LB/GAL

MINUS PROPANE WEIGHT OF GALLONS @ 4.2 LB/GAL

*CCC FOR THIS TRAILER...........................................................

*DEALER INSTALLED EQUIPMENT WILL REDUCE CCC

POUNDS KILOGRAMS

• Gross Vehicular Weight Rating (GVWR): is the maximum permissible weight

of this trailer when fully loaded. It includes all weight at the trailer axle (s) and

tongue or pin.

• Unloaded Vehicle Weight (UVW): is the weight of this trailer as manufactured

at the factory. It includes all trailer weight at the trailer axle (s) and tongue or

pin. If applicable, it also includes full generator fluids, including fuel, engine oil,

and coolants.

• Cargo Carrying Capacity (CCC): is equal to GVWR minus each of the

following: UVW, full fresh (potable) water weight (including water heater), and

full LP-Gas weight.

• Gross Axle Weight Rating (GAWR): is the value specified as the load carrying

capacity of a single axle system, as measured at the tire-ground interfaces.

When loading heavy objects such as tools, skillets, irons, and boxes of canned

goods, etc. keep them as low as possible - preferably on the floor. Try to hold

additional weight behind the axle to a minimum.

WARNING: Never add items such as generators, heavy toolboxes or

motorcycle racks to the back of the trailer. Weight behind the axle will tend to

magnify any sway that may occur when passing trucks or in gusty wind. If a

heavy generator is mounted on the rear bumper what may have been an almost

unnoticeable sway turns into a severe sway you may not he able to control.

B

CONSULT OWNER MANUAL (S) FOR SPECIFIC WEIGHING INSTRUCTIONS

AND TOWING GUIDELINES

CD-133

CAUTION: Damage to your trailer caused by mounting heavy objects on the rear

is considered abuse, and is not covered by warranty.

B - 9

TOWING

B

WEIGHING YOUR TRAILER

The diagram shows how to weigh the trailer on scales.

The allowable personal cargo must be distributed in your trailer in such a manner that

the Gross Axle Weight Rating is not exceeded.

To determine this it is necessary to load all of your allowable personal cargo and

variable weights. Then hitch the trailer to the tow vehicle with load equalizing hitch

properly adjusted as shown on the following pages.

Place the trailer on a scale with both axles only on the scale (see 2). If the weight on

the axles exceeds the axle system GAWR then some of the personal cargo must be

redistributed forward in order to place some of this weight on the tongue.

of the jack extension. Place the scales so that another round piece can be exactly two

feet from the centerline of the jack extension in the other direction. Place a 4 x 4 on the

two round pieces and screw the jack extension down on the top of the 4 x 4 until the

tongue of the trailer is supported by it. Multiply the scale reading by three. This will be

the tongue weight of your trailer. If you exceed the capacity of the bathroom scales,

increase the two-foot dimension to three or four more feet, but always multiply the

scale reading by the total number of feet between the wood and scales.

CAUTION: Be sure trailer is level when you read scales.

2 FT.

1 Ft.

The tongue weight should be in between 10% - 15% of the trailer’s total weight, but

must not exceed 1,000 lbs. Some tow vehicle manufacturers may restrict the amount of

tongue load to a lower value. To determine tongue load, unhitch tow vehicle and place

the tongue hitch post on a scale. The trailer must be properly loaded as determined

above, with your allowable personal cargo and variable weights.

Use a scale, such as a bathroom scale, that has a lower weight limit than your tongue

load to check the tongue weight by using the following method (see illustration).

Place a piece of wood of approximately the same thickness as the bathroom scales

on the ground in line with the trailer hitch jack as shown. It should be so spaced that

a short piece of pipe or other round piece will lay exactly one foot from the centerline

B - 10

Bathroom Scale

Pipe

Pipe

Wo

od Support

TOWING

HITCHING UP

Hitching up your trailer is something that will become almost second nature with

practice. The following section includes proper hitch load distribution. Proper training

on connecting your trailer to a tow vehicle is essential for safety. Please see your dealer

or other qualified personnel for instruction on the proper hitching of your trailer.

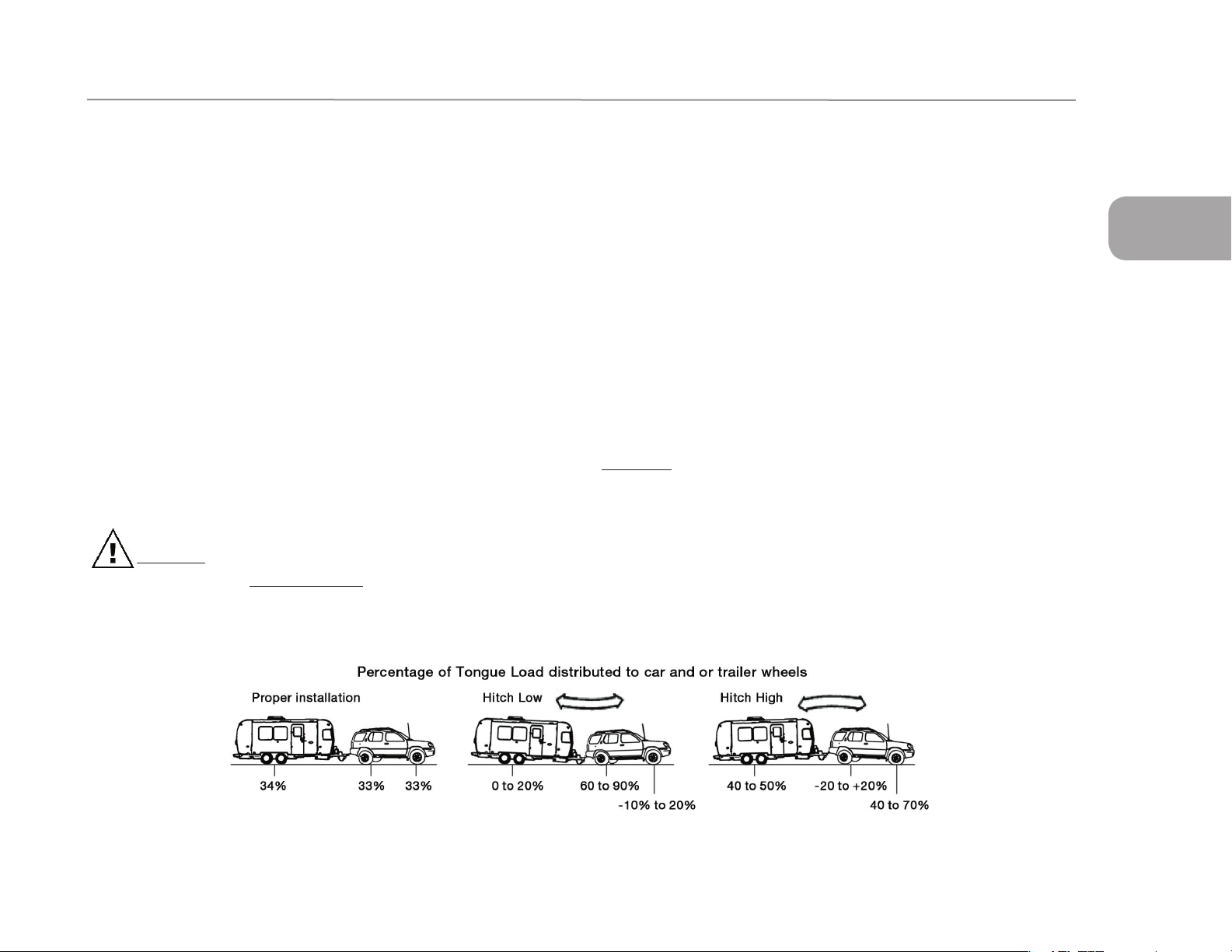

Equalizing Hitch Load Distribution

When a trailer is hitched up properly to a tow vehicle with a load equalizing hitch,

approximately 1/3 of the trailer’s tongue weight will be on the trailer’s axles and 2/3

will be transferred to the tow vehicle, 1/3 of this weight transfer will be carried by the

front wheels and 1/3 by the rear wheels of the tow vehicle (See diagram), Thus, the tire

load of each wheel on the tow vehicle will be increased by 1/6 of the trailer’s tongue

weight. The tire air pressure of the tow vehicle should be increased to compensate for

this additional weight.

WARNING: The tongue weight should he approximately 10% to 14%

of the trailer’s total weight. Under no condition should it exceed the hitch rating.

Your hitch installer should provide your hitch rating information to you.

Sway Control Device

Although Airstream has not intruded into the hitch manufacturers field of expertise and

preformed formal testing, we find the vast majority of Airstream owners purchases

sway-control devices.

B

When passed by large trucks or when exposed to sudden crosswinds the trailer will

be “pushed” and this action will be felt in the tow vehicle. It’s our understanding the

sway control devices will reduce the amount of movement and make towing more

comfortable and add some safety.

Follow the directions of the sway control manufacturer when having it installed and

using it.

CAUTION: Retract the hitch jack completely for maximum ground clearance.

Remove and stow the jack pad it in the tow vehicle’s trunk along with the leveling

jack and other gear used when stopped. NEVER TOW YOUR TRAILER WITH

THE JACK DOWN. Check that the foldaway step is up and that the main door

is completely closed and LOCKED for towing. If it is not locked the constant

vibration of travel may cause it to open with possible damage.

B - 11

TOWING

B

TOWING TIPS

We want every owner to be a safe and courteous driver. A few hours of towing

practice in a large empty supermarket lot will make pulling your trailer over the road

much easier. Line out two corners for left and right turns. You may also use these

corners to practice backing and parking.

After thoroughly inspecting your hitch, brakes, and tires you should be ready to tow.

Check traffic, signal that you are about to pull away, and start slowly. Look often in

your mirrors, and observe the action of the trailer, then carefully move into the proper

lane of traffic. Remember that the trailer wheels will not follow the path of the tow

vehicle wheels; therefore, WIDER TURNS ARE NECESSARY WHEN TURNING TO

THE LEFT OR TO THE RIGHT.

The BRAKE CONTROLLER is activated when you apply the brakes of the tow

vehicle. Your tow vehicle brakes will automatically apply the trailer brakes first when

properly adjusted. This will help keep your tow vehicle and trailer in a straight line and

make you stop as if you were driving the tow vehicle alone. If swaying or swerving

should occur, briefly operating the controller separate from the vehicle brakes may

help correct the situation. Practice this maneuver on a clear highway or deserted

parking lot. Don’t wait for an emergency then grope for the controller.

When trailering you might encounter a temporary cooling system overload during

severe conditions, such as hot days when pulling on a long grade, when slowing

down after higher speed driving, or driving long idle periods in traffic jams. If the hot

indicator light comes on, or the temperature gauge indicates overheating and you

have your air conditioner turned on, turn it off. Pull over in a safe place and put on

your emergency brake. Don’t turn off the engine. Increase the engine idle speed. Lift

the engine hood and check for fluid leaks at the radiator overflow outlet. Check to

see that all drive belts are intact and the radiator fan is turning. If you have a problem

have it fixed at the next opportunity. If there is no problem the light should go off or

temperature should come down within one minute. Proceed on the highway a little

slower. Ten minutes later resume normal driving.

WARNING: Never open a radiator cap when the tow vehicle is hot.

Check the coolant level when the vehicle is cool.

When going downhill in dry weather, down shift so that engine compression will

slow the whole rig down. Take dips and depressions in the road slowly and do not

resume normal driving speeds until you are sure that the trailer wheels are clear of

the dip.

WARNING: On slippery pavement do not use engine drag to help

slow down as this may cause the rear wheels of the tow vehicle to skid. On icy

pavement drive slowly and if you feel the tow vehicle skidding gently apply the

trailer brakes only. This will bring the tow vehicle and trailer back into a single

line. Chains do not help trailer wheels.

When driving in mud and sand let the momentum carry the rig through. Apply power

gently and use as little as possible. Stay in the tracks of the vehicle ahead and keep

the tow vehicle in the highest possible gear. If you get stuck it is best to tow out the

entire rig together without unhitching.

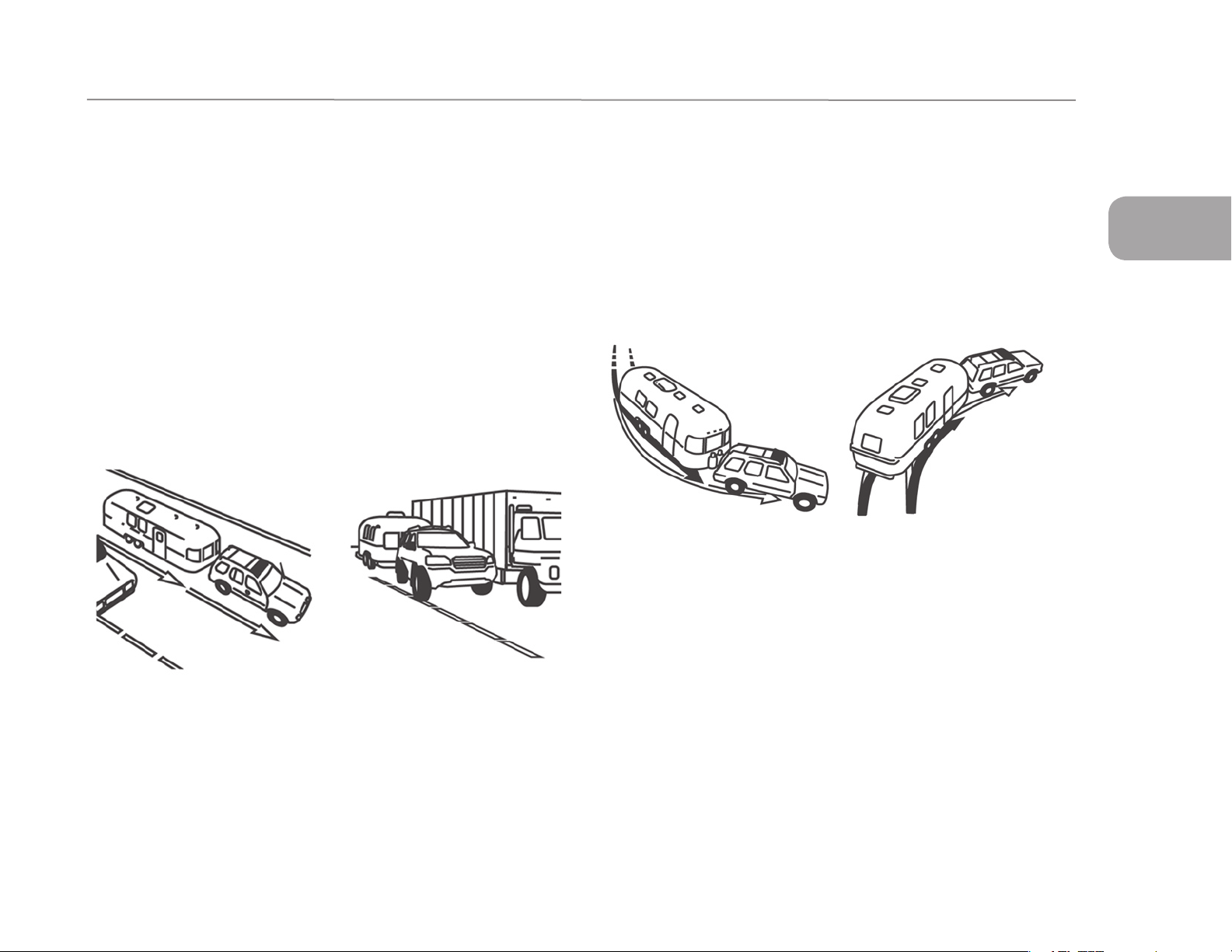

Despite the best hitch you will notice that whenever a large bus or truck overtakes

your rig the displaced air first pushes the trailer rear slightly to the right and then

affects the front. It may be necessary to steer very slightly, momentarily, toward the

bus or truck to help compensate for the sway induced by the passing-vehicle. Do not

apply the vehicle brakes, as this can tend to exaggerate the situation. You may find,

however, that briefly applying the trailer brakes with your manual control will help

eliminate sway.

On a two-lane road cars will be lining up behind you because you travel at a lower

B - 12

TOWING

speed. It is both courteous and sensible to signal, pull onto the shoulder, and let

them pass. Your trailer is designed to be towed easily at any legal speed, so if you

are not careful you may be inclined to forget it is there.

Passing

ON FREEWAYS OR EXPRESSWAYS try to pick the lane you want and stay in it.

Always maintain plenty of space between you and the car ahead, at least the length

of the tow vehicle plus trailer for every ten miles per hour. Remember that in order to

pass another vehicle you will need longer to accelerate. You must also allow for the

length of the trailer when returning to the right hand lane.

Tracking

OBSERVE THAT THE TRACKS MADE BY THE TRAILER WHEELS ARE DISTINCTLY

DIFFERENT FROM THOSE MADE BY THE TOW VEHICLE. Studying this will make it

easier for you to correct mistakes. Truck or trailer type fender or door grip rear view

mirrors are a must for maximum visibility and in most states the law requires them.

B

B - 13

TOWING

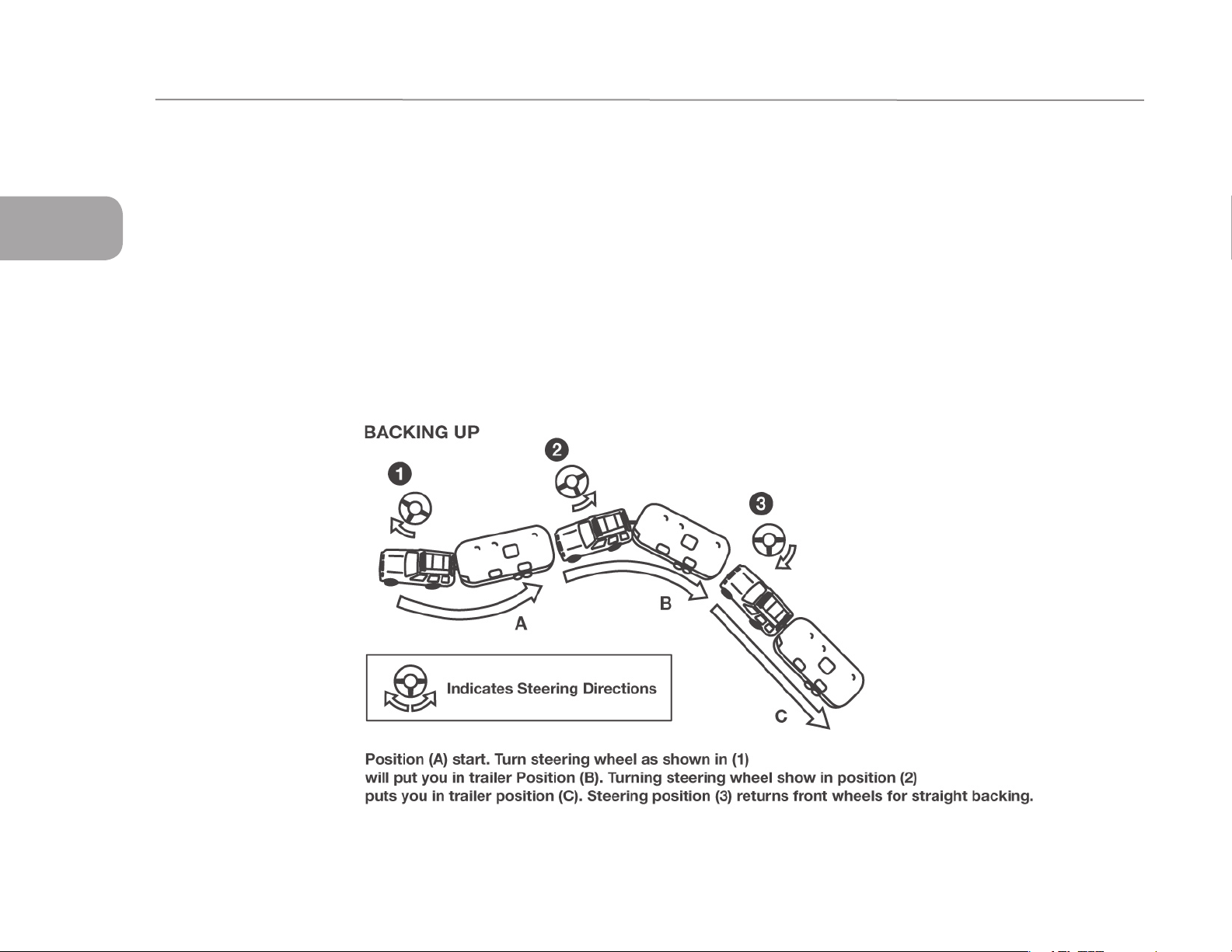

Backing Up

B

In BACKING UP the important thing to remember is to DO EVERYTHING SLOWLY

and to correct immediately if you see the trailer turning the wrong way. Concentrate

on the rear of the trailer. With your tow vehicle and trailer in a straight line back up

slowly and turn the bottom of the steering wheel in the direction you want the trailer

to go. Watch out the window or in the mirror until the rear of the trailer is pointing in

the desired direction. Your tow vehicle will be following the trailer in an arc. Straighten

the tow vehicle and trailer by turning the steering wheel more sharply, and then when

they are in line, straighten the steering wheel.

ALWAYS TRY TO BACK TO YOUR LEFT BECAUSE THE VISIBILITY IS MUCH

BETTER. (See Illustration) When you don’t make it on the first try it is usually much

easier to pull forward to your original position and start over.

If your spouse or traveling companion normally directs you when backing they should

position themselves forward of the tow vehicle so the driver can easily see them.

Their directions should always indicate to the driver the direction the rear of the trailer

should go. A little practice in a parking lot with the person giving directions can save

a lot of frustration when backing into a campsite.

B - 14

TOWING

Controlling Sway or Fishtailing

Sway or fishtailing is the sideways action of a trailer caused by external forces. It

is common for travel trailers to sway in response to strong winds or crosswinds or

when passed by or passing a semi-tractor and trailer or driving downhill.

WARNING: Excessive sway or fishtailing of your travel trailer can lead

to the rollover of the trailer and tow vehicle. Serious injury or death can occur. It is

important that you read and understand the information in this section.

Sway or fishtailing of your recreation vehicle can be controlled and is primarily

impacted by four factors:

· Equipment

· Tongue weight

· Driving

· Corrective measures

Equipment – When hitched together, the trailer and the tow vehicle must be level.

The tires of both the trailer and tow vehicle should be in good condition and inflated

to the pressure recommended as noted on the exterior of the trailer and in the

owner’s manuals of the trailer and tow vehicle.

Your trailer brakes should work in synchronization with your tow vehicle brakes.

Never use your tow vehicle or trailer brakes alone to stop the combined load. Your

brake controller must be set up according to the manufacturer’s specifications to

ensure proper synchronization between the tow vehicle and the trailer. Additionally,

you may have to make small adjustments occasionally to accommodate changing

loads and driving conditions.

Also, we recommend a friction sway damper or hitch with built-in sway control be

provided for your unit. Please consult your dealer regarding this equipment, as the

RV manufacturer does not provide sway control devices.

Tongue weight – The tongue weight should be between 10% to 15% of the total

travel trailer weight. See page xxx of this manual regarding the proper weight

distribution of your recreation vehicle.

Driving – This is the most important component. The tendency for the vehicle to

sway increases with speed therefore, obey all speed limits and reduce speed during

inclement weather or windy conditions.

Corrective measures – If sway occurs the following techniques should be used:

1. Slow down immediately, remove your foot from the accelerator. Avoid using

the tow vehicle brakes unless there is a danger of collision. Reduce speed gradu-

ally whenever possible. If you can do so safely, use the brake hand controller

(independent of the tow vehicle brakes) to gently and progressively apply the trailer

brakes. This will help to keep the vehicles aligned. Practice using the brake hand

controller on a deserted parking lot. Don’t wait until an emergency occurs before

using it. Location of the brake hand controller is important and should be made easily

accessible.

2. Steer as little as possible while maintaining control of the vehicle. Because of

natural reaction lag time, quick steering movements to counter trailer sway will actu-

ally cause increased sway and loss of control. Keep both hands on the wheel. Hold

the wheel as straight as possible until stability is regained.

3. Do not jam on the brakes or attempt to press on the accelerator to speed your way

out of the fishtailing. Both actions make the situation worse and could cause severe

injury or death.

4. Once the swaying is under control, stop as soon as possible. Check tire pres-

sures, cargo weight distribution and look for any signs of mechanical failure. Travel

at reduced speeds that permit full control until the problem can be identified and

corrected.

B

B - 15

CAMPING

SUGGESTED PRE-TRAVEL CHECK LIST

C

Interior

1. Turn off water pump switch.

2. Check battery water level.

3. Close windows and vents.

4. Lock all interior cabinet doors.

5. Latch refrigerator door.

(Seal containers first.)

6. Hold down or stack securely all loose,

hard and sharp objects.

7. Fasten sliding and foldette doors.

8. Drain toilet bowl.

9. Turn off interior lights.

10. Set table in upright position.

11. Pull up or retract step.

12. Lower blinds.

13. Secure and lock the main door.

Exterior

1. Disconnect and slow the electrical hookup

cord, the sewer hookup hose (flush out),

and the water hookup hose.

2. Turn off gas at LP tanks.

3. Retract stabilizing jacks.

4. Check Hitch: It must be properly attached.

5. Check safety chains and breakaway

switch cable.

6. Fully retract jack. Remove and

stow jack stand or wood block.

7. Check clearance and stoplights.

8. Check lug nuts.

9. Check tires for correct pressure.

10. Check that TV antenna is properly stowed.

11. Adjust tow vehicle mirrors.

12. Pull forward some 50 ft., test brakes,

and check site for forgotten objects

and cleanliness.

Home

1. Leave house key with your neighbors.

2. Valuables and important papers should

be stored in a safe place.

3. Newspaper and other deliveries

should be discontinued.

4. Ask the Post Office to hold your mail

for you.

5. Arrange with the telephone company

for discontinued or “vacation service°±.

6. Arrange care for your pets.

7. Your lawn, garden and houseplants

should be cared for.

8. Lock all windows and doors securely.

Keep shades open for a lived in look.

9. Cover all food to keep out mice and insects

10. Eliminate all fire hazards Place matches

in a tin box or glass jar.

11. Store oil, gasoline and other

flammables properly.

12. Destroy all newspapers, magazines and

oily rags.

13. Notify police.

C - 1

Loading...

Loading...