Small VRF system

for light commercial

and home use

SERVICE MANUAL

CONTENTS

1. TEST RUN

1-3 TEST RUN CONTROL................................................................................................

1-2-1 Check Items Before Power ON............................................................................

1-2-2 Check Items After Power ON...............................................................................

1-2 TEST RUN METHOD..................................................................................................

1-1 EXECUTION PROCEDURE AND EXECUTION PRECAUTIONS.............................

1-2-4 Automatic address setting procedure for indoor units..........................................

01-01

01-03

01-03

01-04

01-07

1-2-3 Automatic address setting procedure for Signal amplifiers.................................. 01-06

01-10

1-4 Field Setting And Monitor Mode List....................................................................... 01-11

2-1 INPUT / OUTPUT LIST..............................................................................................

2. OUTDOOR UNIT OPERATION CONTROL

2-2 COMPRESSOR OPERATION....................................................................................

02-01

02-02

02-02

02-03

2-2-3 Speed Range of Start,Stop,and Operation..........................................................

2-2-2 Capacity Control.................................................................................................

02-02

2-2-1 Operation / Stop Condition.................................................................................

2-5 SPECIAL OPERATION..............................................................................................

02-09

02-09

02-10

2-5-2 Pre-Heat Operation............................................................................................

2-5-1 Oil Recovery Operation......................................................................................

2-6 PROTECTIVE FUNCTION........................................................................................

02-11

02-11

2-6-1 Protective Function List......................................................................................

2-5-3 Defrost Operation Control..................................................................................

02-10

2-3 FAN CONTROL..........................................................................................................

02-05

2-4 EXPANSION VALVE CONTROL...............................................................................

02-08

02-05

02-07

2-3-3 Low noise mode..................................................................................................

02-08

2-3-4 Other Control.......................................................................................................

2-3-1 Cooling Operation...............................................................................................

02-06

2-3-2 Heating Operation...............................................................................................

1-2-5 Indoor unit connection check procedure ............................................................. 01-08

1-2-6 Test run from the outdoor unit ............................................................................ 01-09

1-2-7 Test run from the Remote controller .................................................................... 01-09

CONTENTS

3-2 MASTER CONTROL..................................................................................................

3-1-2 "AUTO" Position...................................................................................................

3-1-1 Fan Speed Setting...............................................................................................

3-1 FAN CONTROL..........................................................................................................

3. INDOOR UNIT OPERATION

3-2-1 Operation Mode Control.......................................................................................

3-2-2 Auto Changeover.................................................................................................

03-01

03-01

03-01

03-02

03-02

03-04

3-3 LOUVER CONTROL..................................................................................................

3-2-3 "COOL" Position..................................................................................................

03-05

3-2-4 "HEAT" Position..................................................................................................

03-05

03-06

3-5 DRAIN PUMP OPERATION.......................................................................................

3-4 ELECTRONIC EXPANSION VALVE CONTROL......................................................

3-6 FUNCTION..................................................................................................................

03-09

03-09

03-10

3-6-1 Auto Restart.........................................................................................................

03-10

4-1-2 Outdoor Unit Display...........................................................................................

4-1-1 Indoor Unit Display..............................................................................................

4-1 NORMAL OPERATION..............................................................................................

4. TROUBLE SHOOTING

4-2 ABNORMAL OPERATION.........................................................................................

4-2-1 Indoor Unit Display..............................................................................................

04-01

04-01

04-02

04-03

04-03

4-2-4 Remote Controller Display...................................................................................

4-2-3 Error Code List for Outdoor Unit..........................................................................

4-2-2 Outdoor Unit Display...........................................................................................

4-3 TROUBLE SHOOTING..............................................................................................

04-04

04-05

4-2-5 Error Code List for Simple and Wired Remote Controller...................................

04-07

4-2-6 Error Code List for Group Remote Controller......................................................

04-07

4-2-7 Error Code List for External Switch Controller.....................................................

04-07

+1

4-2-8 Error Code List for Signal Amplifier.....................................................................

04-07

+1

4-2-9 Error Code List for Network Convertor................................................................

04-07

+1

4-2-10 Trouble Level of System.....................................................................................

04-08

04-06

04-11

4-3-3 Trouble Shooting for Optional Parts....................................................................

4-3-2 Trouble Shooting With Error Code (OUTDOOR UNIT).......................................

4-3-1 Trouble Shooting With Error Code (INDOOR UNIT)...........................................

04-11

04-22

04-63

4-4 SERVICE PARTS INFORMATION............................................................................ 04-84

3-6-2 Icing Protection Control.......................................................................................

03-10

3-6-3 Oil Recovery Operation.......................................................................................

03-10

3-7 TIMER CONTROL......................................................................................................

03-11

3-7-1 Wireless Remote Controller................................................................................

03-11

3-7-2 Group Remote Controller..................................................................................... 03-13

3-7-3 Wired Remote Controller..................................................................................... 03-15

4-2-11 Error History Mode..............................................................................................

04-10

CONTENTS

5-2-1 Indoor Unit............................................................................................................

5-2 WIRING DIAGRAM....................................................................................................

5-1 REFRIGERANT CIRCUIT..........................................................................................

5. APPENDING DATA

5-3-1 Pressure sensor..................................................................................................

05-01

05-02

05-02

5-2-2 Outdoor Unit.........................................................................................................

05-15

5-3 CHARACTERISTICS OF SENSORS........................................................................

05-16

05-16

5-3-2 Thermistor resistance..........................................................................................

05-17

5-3-3 Saturation temperature and saturation pressure tables (R410A)........................

05-18

5-3-4 Temperature and pressure of refrigerant (Graph)...............................................

05-19

6. DISASSEMBLY PROCESS

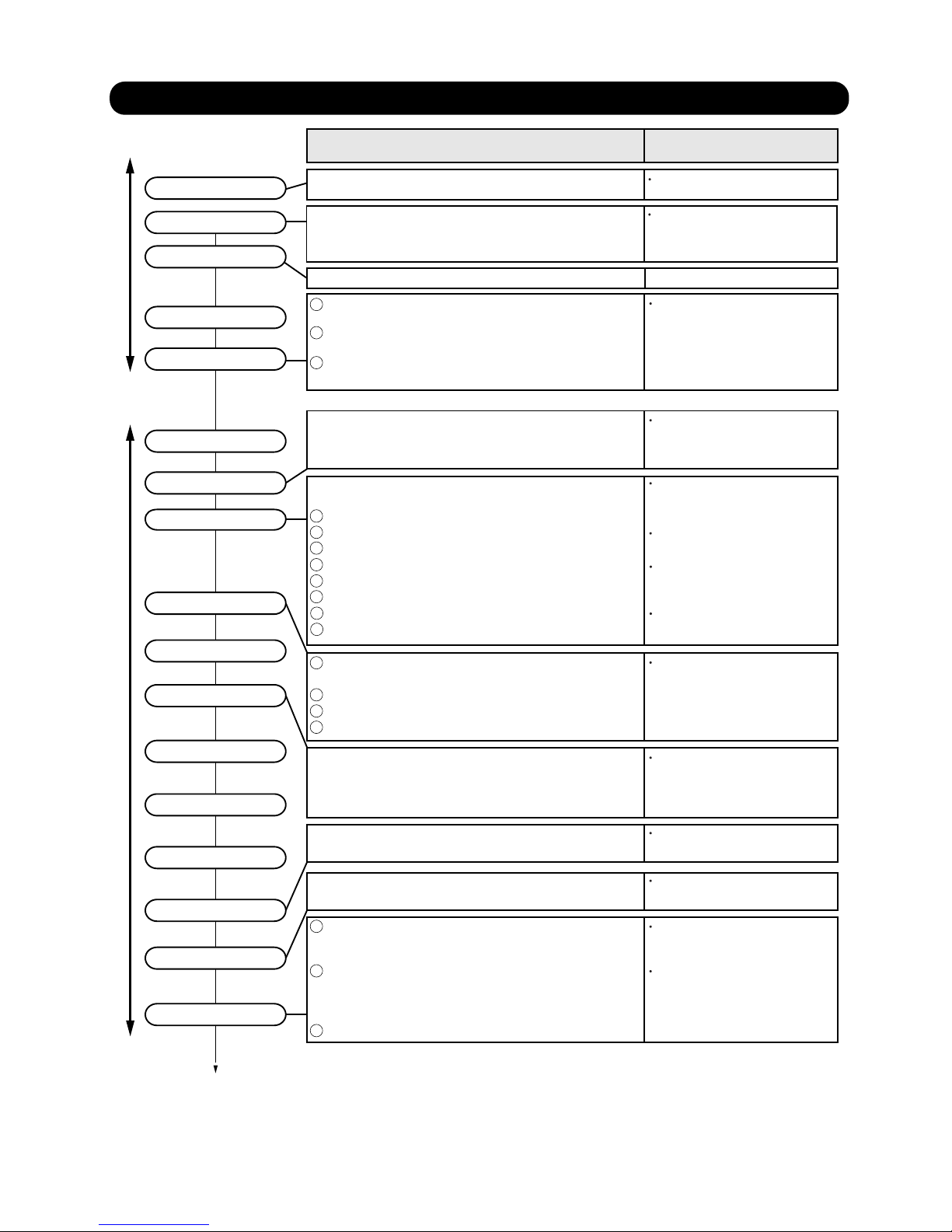

1. TEST RUN

Before execution

Execution 1/2

Location decision

Execution procedure and precautions Reason

01-01

1-1 EXECUTION PROCEDURE AND EXECUTION PRECAUTIONS

1. TEST RUN

Sleeve and insert work

Indoor unit installation

Refrigerant piping work

Drain piping work

Duct work

Heat insulation work

Electrical work

Outdoor unit foundation work

Outdoor unit installation

Refrigerant piping connection work

Air tightness test

Vacuum drying

Use new refrigerant piping of the thickness specified by the

D&T manual.

Since R410A dedicated tools are necessary, prepare them in

advance.

Absolutely avoid use of existing piping. If use of existing

piping is unavoidable, the piping must be cleaned.

Use pipe that is not dirty inside.

Confirm the design for the piping ( Diameter, Thickness )

When the pipe is left standing, protect it.

Confirm the angle of separation tube and header correctry.

Finish flaring exactly.

Confirm the width across flats dimension and shape of flare nuts.

Always blow nitrogen while brazing.

Perform flushing before connecting the equipment.

Always make the downward slope of the drain pipe 1/100 or

greater and make the horizontal length within 20m.

Use hard polyvinylchloride pipe as the drain pipe.

Support the drain pipe between 1.5 to 2.0m.

Use pipe of 1 rank up (VP30 or greater) as central piping.

Prevention of water leakage

Foreign matter, water, etc. in the

piping will cause faulty cooling and

compressor trouble.

Incorrect pipe diameter will cause

faulty cooling

Incorrect angle of separation tube or

header will be cause poor cooling or

refrigerant noise problem

Refrigerant leakage will cause low

performance and abnormal stopping

Prevention of water leakage

Prevention of water leakage

Refrigerant leakage will cause low

performance and abnormal stopping.

Refrigerant leakage will cause low

performance and abnormal stopping.

Mixing in of vacuum pump oil by

reverse flow will cause equipment

trouble.

Always use a level and keep the indoor unit level.

If the equipment is tilted toward the drain port, install it so that the tilt

is within 10mm. Excessive tilt will cause water leakage.

Select the size of the heat insulating material according to the ambient

temperature and relative humidity of the refrigerant.

Use a heat insulating material having a heat conductivity of 0.043W/

(m.k) or less.

When making flare connections always use a torque wrench and

tighten the flare nut positively to the specified torque.

Pressurize the product with nitrogen gas up to the design pressure

and conduct a 24Hr air tightness test.

Install a vacuum pump with reverse flow check mechanism or a

reverse flow check adaptor to a conventional vacuum pump and

use.

Pump down sufficiently.

Approximately 1 hour or longer after -0.10MPa reached.

Allow to stand for approximately 1 hour after stopping the vacuum

pump and confirm that the needle does not return.

Air purging using refrigerant is strictly prohibited.

1

1

1

2

3

2

3

4

5

6

1

2

3

4

2

3

Vaccuming mode

This function is used for vacuuming the indoor unit and the connection piping.

Note: For starting Vaccuming mode, the refrigerant address setting has to be finished.

When the [vacuuming mode] is set, <Push switch setting, F3:21>

EEV of connected all indoor units opens.

So, the vacuuming indoor unit and piping becomes easier.

When the vacuuming ends, please turn off the power supply for all of the indoor units and

the outdoor unit, [vacuuming mode] is released.

*

recommend the vacuuming mode

Do not install the units in the place not recommended in the installation

manual.

The performance may drop significantly

due to the protection controlling

Use of a refrigerant other than the

specified refrigerant will invite

equipment trouble

Confirmation of Refrigerant used

Preparation of execution drawings

Confirmation of installation site

Preparation before execution

Check the characteristics of the refrigerant used and grasp the

special features of the refrigerant. If refrigerant must be charged,

always charge the refrigerant specified for the product.

*Confirm the product design pressure. < R410A 4.20MPa >

Prepare the design for the system

Secure the necessary pressure

resistance.

When performing piping work, observe the following items so that the

inside of the piping is clean and air tight.

7

8

01-02

[Note] Perform in the power OFF state.

Execution 2/2

Set according to the length of the connection piping.

Set to "Standard (40 to 65m)" at the factory.

Set using the push button SW on the outdoor unit main PCB.

< Refer to the Page 01-16 Setting mode F2-00 >

Set the pipe length to be the nearest indoor unit from the outdoor unit

Set the refrigerant circuit address and indoor unit address.

Can be set by rotary SW on the indoor unit PCB ( Main PCB or Switch

PCB) or from a remote controller or from a push button SW on the

outdoor unit Main PCB < Automatic address setting,

Refer to the Page 01-07 Setting mode F3-11>

Initial setting

Gas leak test

Use an R410A dedicated leak tester to check for gas leaks.

1

2

3

Confirm the additional refrigerant amount with the installation

manual, etc.

Always take the R410A refrigerant from the cylinder liquid phase

and charge it using the gas phase.

(Do not lay a cylinder with siphon pipe on its side.)

Use an R410A dedicated gauge manifold and charging hose.

Charge refrigerant using the liquid pipe.

When the defined amount of refrigerant cannot charge using the

liquid pipe, charge refrigerant using the gas pipe while opearing

the cooling test run.

Charge refrigerant bit by bit with cautious operation of valve

for the liquid refrigerant back prevention.

If taken from the air phase, since the

composition of the refrigerant which is

charged will change, low performance

and abnormal stop will occur easily.

Prevent erroneous sealing in of

refrigerant.

A leak tester for other than R410A

cannot detect leaks.

Set the refrigerant circuit address.

ROTARY SW: REF ADX10, X1

4

Turnover & explanation of operation

Address setting for Indoor unit

Test run & adjustment

Piping length setting

Addition refrigerant charging

5

Indoor unit connection check

[Note] Perform setting by push button SW on the outdoor unit Main PCB in the power ON state

after all indoor units have stopped operation.

When setting the address of Signal amplifier, please refer to the

installation manual of the signal amplifier.

The address setting can be set by automatically from 1 outdoor unit

on the network. < Refer to the Page 01-06 Setting mode F3-10 >

Address setting for Signal Amp

- When using signal Amps -

[Note] Manual setting: Set the rotary SW on the PCB in the power OFF state.

Automatic address setting:

Perform setting by push button SW on the outdoor unit Main PCB in the

power ON state after all indoor units have stopped operation.

[Note] Perform in the power ON state after all indoor units have stopped operation

[Note] Manual setting: Set the rotary SW on the PCB in the power OFF state.

Automatic address setting:

Perform setting by push button SW on the outdoor unit Main PCB in the

power ON state after all indoor units have stopped operation.

Dual address setting No. is not

allowed in one network.

When the setting is not same as the

real piping length, the system may

not work correctly.

Dual address setting No. is not

allowed in one network.

Dual address setting No. is not

allowed in one network.

Normal operation will not be possible

without performing the indoor unit

connection check.

Before starting the system, check on the number of indoor units and

the total capacity.

< Refer to the Page 01-08 Setting mode F3-12 >

Execution procedure and precautions Reason

1

2

Confirm the DIP SW setting

SET 1: Factory setting, SET 2 : All OFF, SET 3 : All OFF,

SET 4: Factory setting

If the DIP SW setting is wrong, the sys tem may not work correctly

3

Confirm the Terminal resister setting

SET 5-4 OFF: Disable, ON: Enable

If the Terminal resister setting is wrong,

the system may detect transmission

error

If the pipe length is set as the farthest

indoor unit, the nearest operating

indoor unit may be stopped the

operation by the icing up protection

as by over cooling.

Outdoor unit: 32A ( AJ*A36,45,54LALH )

Indoor unit: 20A

Leakage current: 30mA 0.1sec or less

Install a breaker (Included with Earth Leakage Circuit Breaker) in accordance

with the related laws and regulations.

Outdoor unit: 6mm

2

2 wires + Ground 4mm

2

Indoor unit: 2.5mm2 2 wires + Ground

Outdoor unit side: AC 230V (220-240V)

Indoor unit side: AC 230V (220-240V)

Use crimp-type terminals with insulating sleeves for stranded conductor cable

Power

source

Shall be no scratches, deformation, etc. (Be careful of deformation of the front panel)

Shall be checked and entered in the check sheet.

Shall be checked and entered in the check sheet.

Connection points check & loose terminal block screws check

0.33mm2, shielded wire used (22AWG)

Connection points check & loose terminal panel screws check

Check whether or not the heat insulation material is installed without a gap.

DIP SW SET1, SET4 : Factory setting, SET2,SET3, SET5-1,2,3: ALL OFF

Terminal resistor setting SET5 - 4 OFF: Disable, ON: Enable

Check the resistance value for each network segment

Refer to the installation manual 7.7

Refrigerant circuit address setting (SET : REF AD x10 and REF AD x1)

Comparison of calculated value and value written on electrics box. Entered in check sheet.

Refer to the installation manual 8.3.2

Gas pipe: fully open

Liquid pipe: fully open

There shall be no scratches, deformation, tilting, etc.

Shall be checked and entered in the check sheet.

Shall be installed positively.

Connection points check & loose terminal panel screws check

0.33mm2, shielded wire used (22AWG)

Connection points check & loose terminal panel screws check

0.33mm

2

Connection points check & loose terminal panel screws check

Check whether or not the heat insulation material is installed without a gap.

Refrigerant circuit address (REF AD)

Indoor unit address (IU AD)

At automatic address setting, IU AD/REF AD shall be [0].

Remote controller address (RC AD)

Function setting (Remote controller custom code/ external input switching/

auxiliary heater ON-OFF)

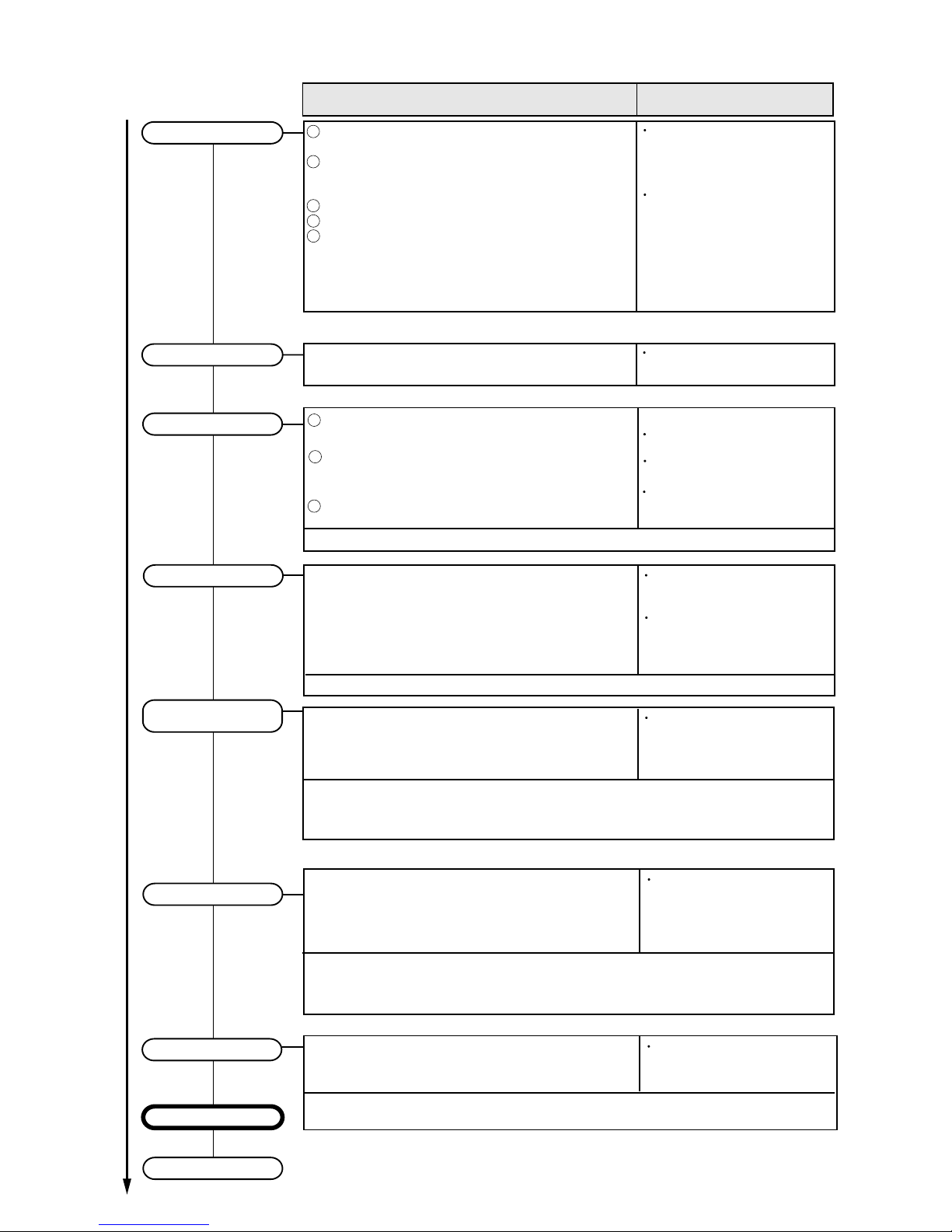

Indoor

unit

Outdoor

unit

Judgement standard

Check

Check contentsProcedure

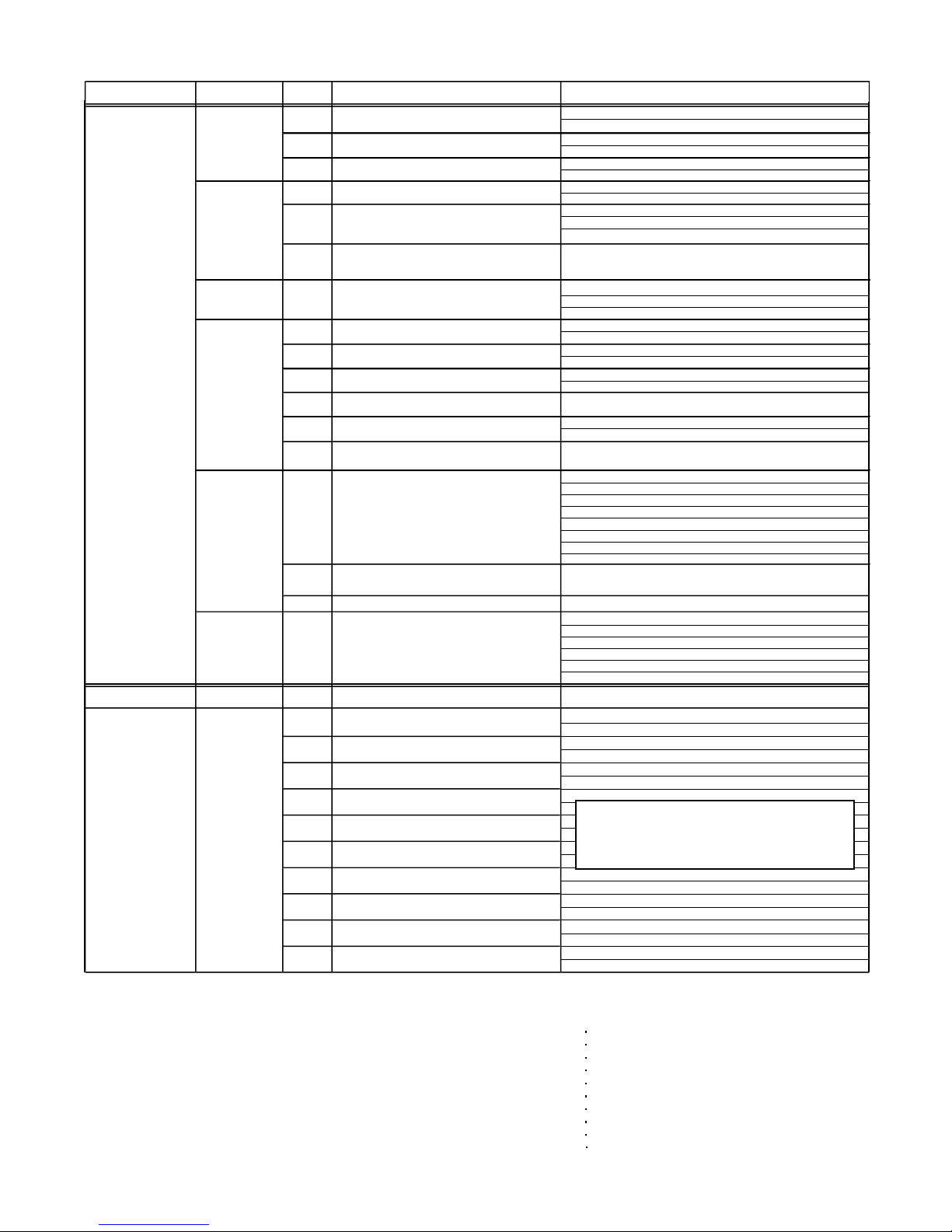

1-2 TEST RUN METHOD

1-2-1 Check Items Before Power ON

01-03

[Note] If operated with the 3-way valve closed, the oil discharged from the compressor will not be returned

and will lead to trouble.

Circuit breaker capacity

Type of power source

wiring

Supply power source

Appearance

Serial No.

Drain cap installation

Power source wiring connection

Type of communication line

Communication line connection

Type of remote controller wiring

Remote controller wiring connection

Connection piping

Rotary SW setting

DIP-SW setting

Appearance

Serial No.

Outside air temperature

Power source wiring connection

Type of communication line

Communication line connection

Connection piping

DIP-SW setting

Rotary SW setting

Additional refrigerant amount

3-way valve

Wiring on terminal blocks

Addresses shall be assigned to all indoor units / Signal amps.

Check for unset or duplicated addresses.

< For the setting, Refer to the page 01-06, 07 >

All the indoor units in the same refrigerant

circuit

shall enter the coolingtest run

state.

The outdoor units corresponding to the operation capacity of the indoor

units shall operate. < Test operation procedure, Refer to the page 01-09,10 >

Cooling

test run

All of the

indoor units

operation

(after 30 mins)

Automatic address setting

Address read

Outdoor unit circuit breaker ON

Indoor unit circuit breaker ON

Check lighting of Main PCB LED101 and 7-segment display.

Check whether or not indoor unit OPERATION and TIMER lamps flash alternately.

Address

setting/

check

There shall be no Error information on the 7-segment display on the Main PCB.

Between L - N AC230V (220-240V)

These shall be no abnormal sound or abnormal vibration.

The outdoor fan shall not make a moaning sound.

There shall be no discharge air leaking from the outdoor duct.

There shall be no pipe chattering sound or flute sound generated.

HPS: 2.7 MPa

LPS: 0.9 MPa

TH1: 81°C

TH4: 15°C

TH21: 27°C

TH22: 11°C

TH24: 13°C

Shall operate corresponding to the operation capacity of the indoor units.

Service tool used, output (CSV Excel)

Outdoor unit push button

SW operation

<On service tool>

High pressure

Low pressure

Discharge pipe temperature (outdoor unit)

Suction pipe temperature (outdoor unit)

Inlet air temperature (indoor unit)

Heat exchange inlet temperature (indoor unit)

Heat exchange outlet temperature (indoor unit)

Compressor operation

Data output

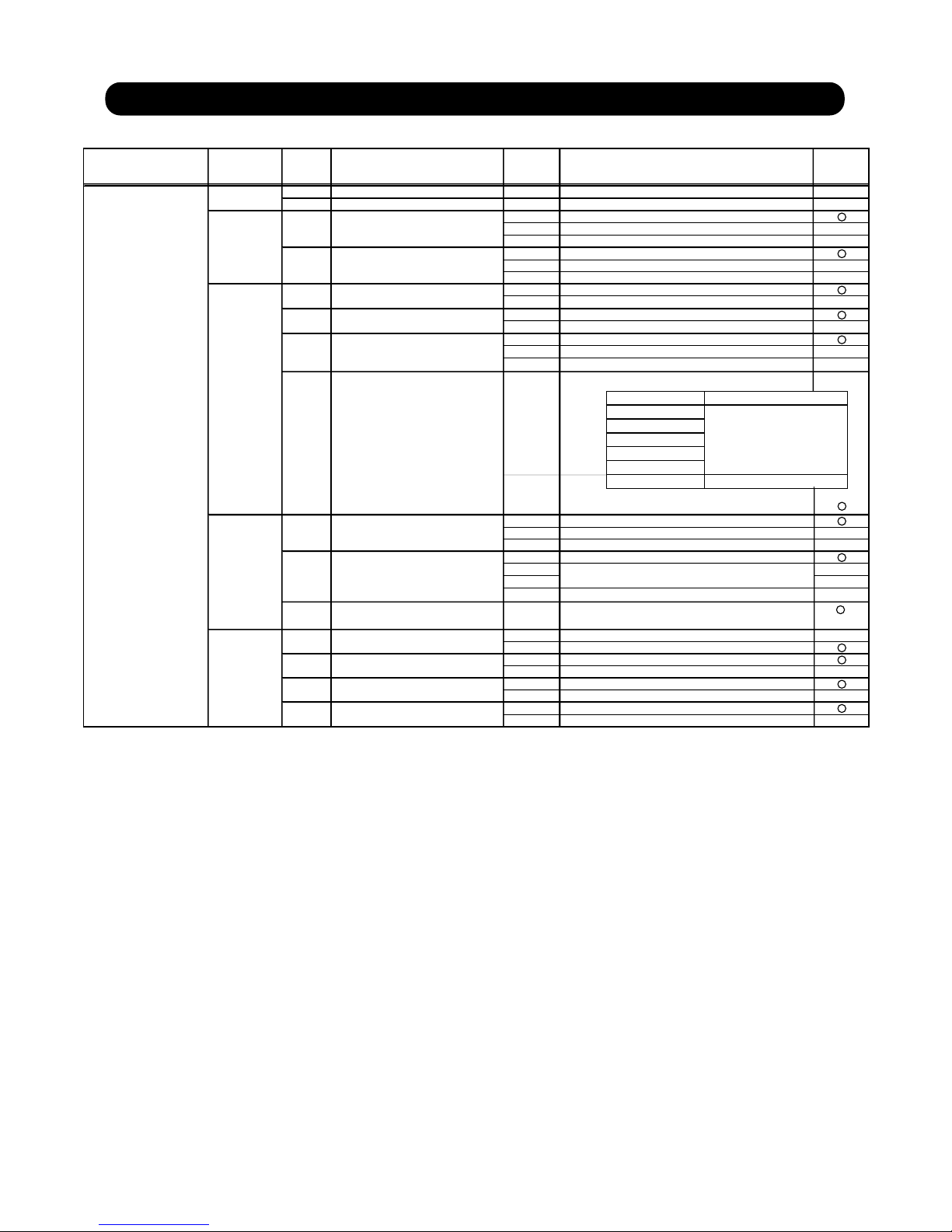

1-2-2 Check Items After Power ON

01-04

Function setting

Are the necessary functions set ?

< For the setting, Refer to the page 01-15 18 >

Outdoor unit Main

PCB push button

SW setting/check

[Note]

Cooling test run for each refrigerant circuit.

If multiple refrigerant circuits are test run at the same time, refrigerant circuit address setting errors cannot

be detected.

Judgement standard

Check

Check contentsProcedure

Power ON

Inlet air temperature and outlet air temperature difference shall be 10°C or

greater.

There shall be no abnormal sound or abnormal vibration.

There shall be no water leakage. There shall be no condensation on the drain,

cabinet, piping, and discharge port.

Shall operate according to the settings. (ON-OFF, set temperature change)

<Indoor unit service tool + actual measurement>

Outlet air temperature

Abnormal sound/abnormal vibration

Water leakage check

Remote controller operation

<Outdoor unit>

Outdoor Main PCB 7-seg. display

Operation voltage

Abnormal sound/

abnormal vibration

[Note] Turn on all indoor units power in the same refrigerant circuit address.

When the system operates with the indoor units remaining no power, it is cause of malfunction.

Indoor unit connection check

Are the number of connecting indoor units correct ?

Is the total capacity of indoor units correct ?

< For the checking, Refer to the page 01-08 >

Indoor unit

connection check

Address record

Address hold check

All the indoor units and outdoor units of the same refrigerant circuit can be

checked on the service tool.

Enter the set addresses in the check sheet.

Check whether or not the address setting is held by the service tool

after indoor/outdoor circuit breakers were turned OFF to ON.

[Note] Before connecting service tool, the address setting has to be completed.

〜

Fan operation

Louver operation (except duct)

Outlet air temperature

Abnormal sound/abnormal vibration

Water leakage check

Remote controller operation

Indoor unit

individual

operation

Shall be switched to all fan speeds in the cooling mode.

Louver shall be switched to all positions. Shall also swing.

Inlet air temperature and outlet air temperature difference shall be 10°C or

greater.

There shall be no abnormal sound or abnormal vibration.

There shall be no water leakage. There shall be no condensation on the drain,

cabinet, piping, and discharge port.

Shall operate according to the settings. (ON-OFF, set temperature change)

01-05

Judgement standard

Check

Check contentsProcedure

These are representative figures of AJYA54LALH at the standard condition. ( Indoor : 27

°C, Outdoor : 35°C )

If conditions are different from those above mentioned, the figures will be changed slightly.

It depends on following conditions.

Outdoor unit capacity

Indoor and outdoor temperature

Indoor unit capacity

Pipe length

etc

<Indoor unit service tool + actual measurement>

1. Error occured

- Check on the Error code on the Remote controller or Indoor unit or Outdoor unit or Service tool and

check the description of the Error code.

< Refer to the Trouble shooting in the Service manual.>

< Refer to the Execution of precautions 1-1 and Check item Before power ON 1-2-1>

2. No good performance without error code

- Check if the protection controlling is operating or not

Evaporator Icing up protection, High discharge temperature protection,etc.

< Refer to the part of protection controlling in the Service manual >

- Check on the refrigerant circuit

Refrigerant amount, Pipe blockage, Wrong position of separation pipes etc.

< Refer to the Execution of precautions 1-1 and Check item Before power ON 1-2-1>

< Refer to the regulation of installation in the Installation manual>

Trouble shooting on Test run operation

01-06

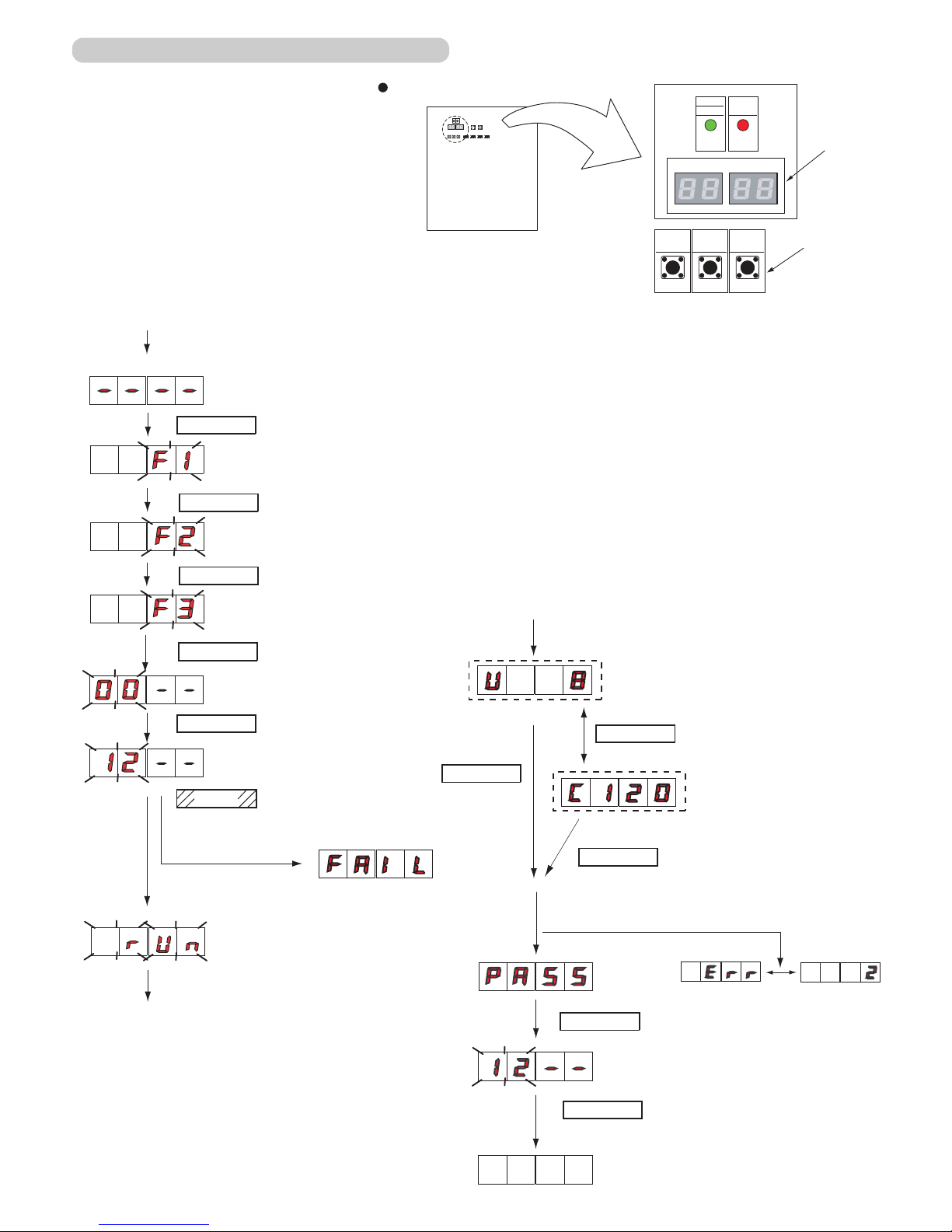

1-2-3 Automatic address setting for signal amplifiers When using signal amplifiers

When setting the address of the signal amplifier, please use the factory setting. (See the

installation manual of the signal amplifier)

When the system is normal, nothing will be displayed on the 7 segment display.

When ERROR is displayed, inspect the units.

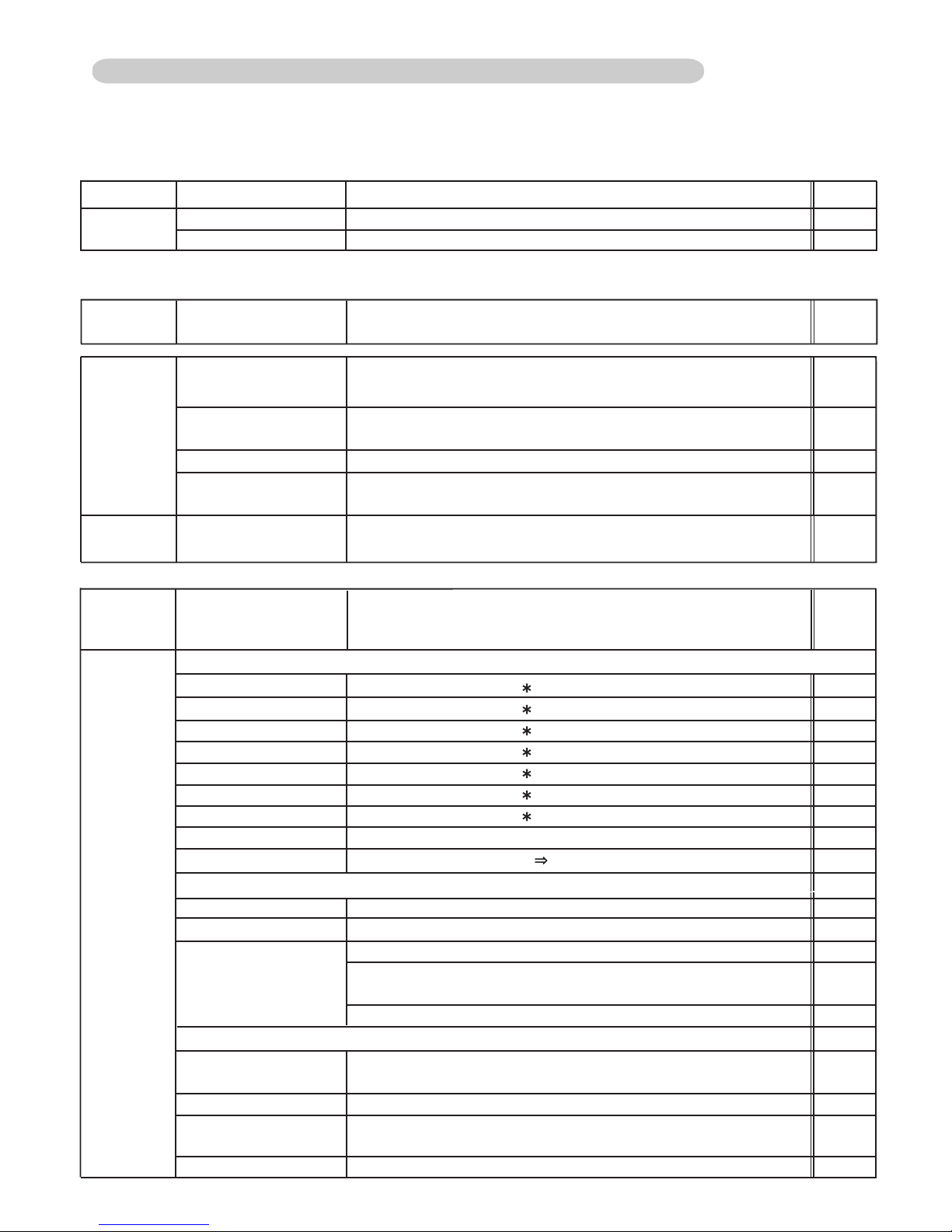

Use the “MODE/EXIT”, “SELECT”, and “ENTER” buttons on the outdoor unit Main PCB

to conÞ gure settings according to the procedures below.

1: FUNCTION Setting

First 2 digits Last 2 digits

(the display when the main power is turned on)

(When [F4] to [F9] are displayed, continue to press the "SELECT" button

until [ F3 ] is displayed)

MODE/EXIT

SELECT

SELECT

ENTER

SELECT

ENTER

Automatic address setting for

signal ampliÞ ers

Press the “SELECT” button until "10" is displayed

Press the “ENTER” button for more than 3 seconds

* Setting is complete when the number of unit is displayed

End

ENTER

MODE/EXIT

SWITCH POSITION

SW107 SW108 SW109

MODE

/EXIT

SELECT ENTER

LED101

(GREEN)

POWER

MODE

LED105 LED104

LED102

(RED)

ERROR

Push button switch

7 Segment

LED Lamp

Outdoor unit printed circuit board

*

01-07

SWITCH POSITION

SW107 SW108 SW109

MODE

/EXIT

SELECT ENTER

LED101

(GREEN)

POWER

MODE

LED105 LED104

LED102

(RED)

ERROR

Push button switch

7 Segment

LED Lamp

Outdoor unit printed circuit board

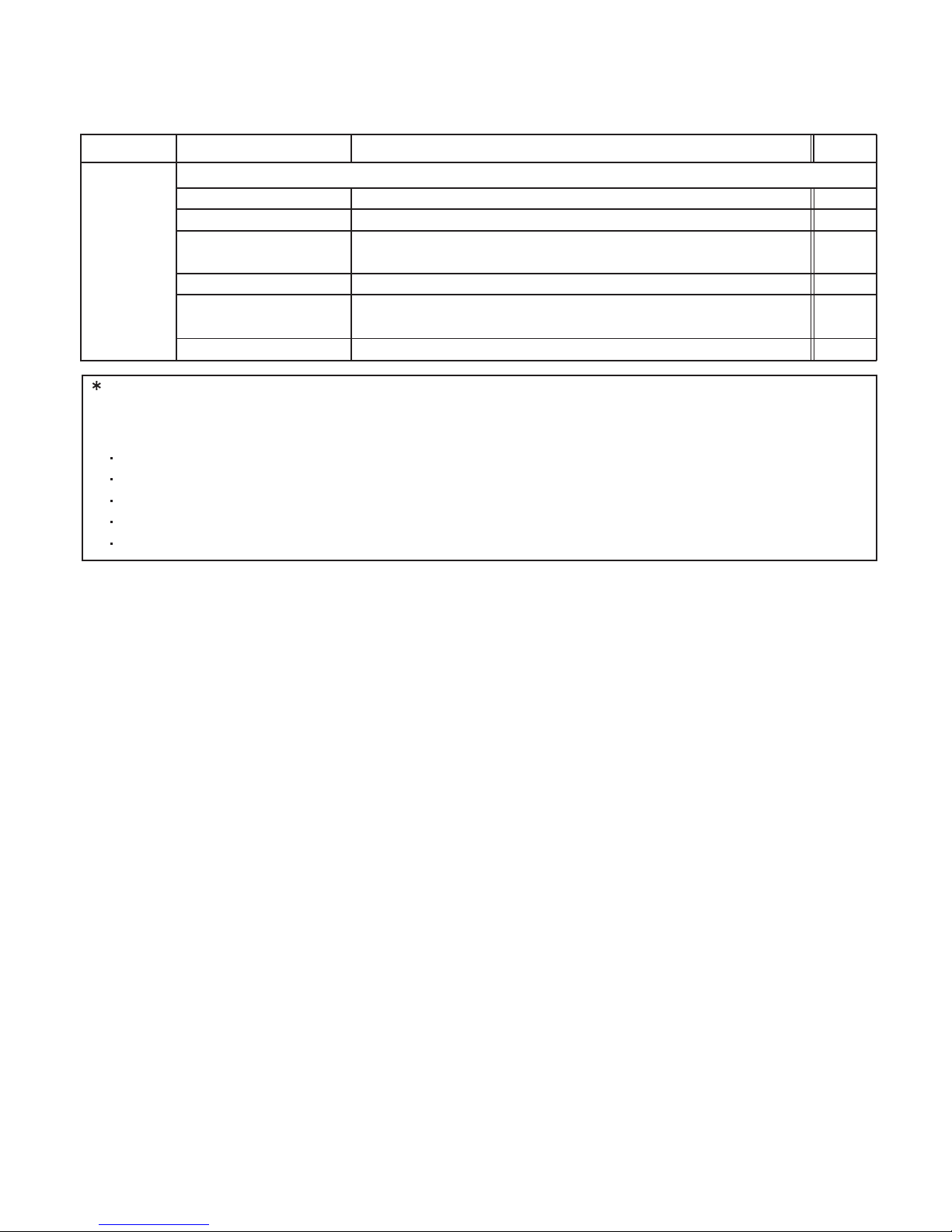

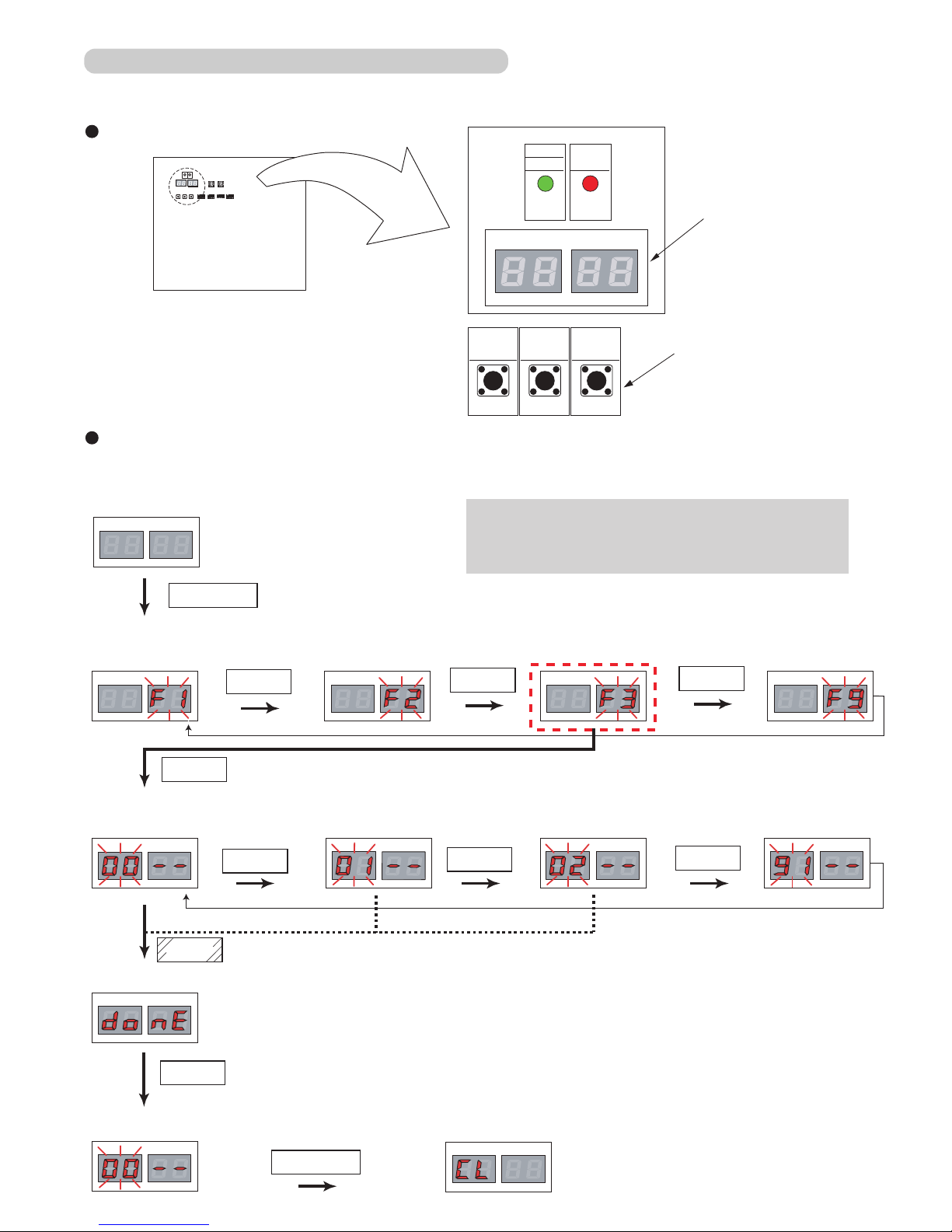

Check that the rotary switch IU AD on the indoor unit Main PCB is set to “00”.If it is not

set to “00”, it means the address of that device is not set. (Factory default is “00”).

Turn on the power of the indoor and outdoor units.

When the system is normal, nothing will be displayed on the 7 segment display.

When ERROR is displayed, inspect the units.

Use the “MODE/EXIT”, “SELECT”, and “ENTER” buttons on the outdoor unit Main PCB

to configure settings according to the procedures below .

1: FUNCTION Setting

First 2 digits Last 2 digits

(the display when the

main power is turned on)

(When [F4] to [F9] are displayed,

continue to press the “SELECT”

button until [F3] is displayed.)

MODE/EXIT

SELECT

SELECT

ENTER

1-2-4 Automatic address setting for Indoor units

It may take about 10 minutes for completing

the processing.

End

First 2 digits

Last 2 digits

Press the “SELECT” button until

“11” is displayed.

Press the “ENTER” button for more

than 3 seconds.

Automatic address setting

for indoor units

The number of indoor units with normal settings will be displayed at the first 2 digits of

the 7 segment display. The number of indoor

units with error will be displayed at the last 2

digits.

NOTE) After the “ENTER” button is pressed, the

end processing will occur for about 30 seconds.

During this period, the 7 segment will blink.

ENTER

SELECT

ENTER

Error

Found

01-08

SWITCH POSITION

SW107 SW108 SW109

MODE

/EXIT

SELECT ENTER

LED101

(GREEN)

POWER

MODE

LED105 LED104

LED102

(RED)

ERROR

Push button switch

7 Segment

LED Lamp

Outdoor unit printed circuit board

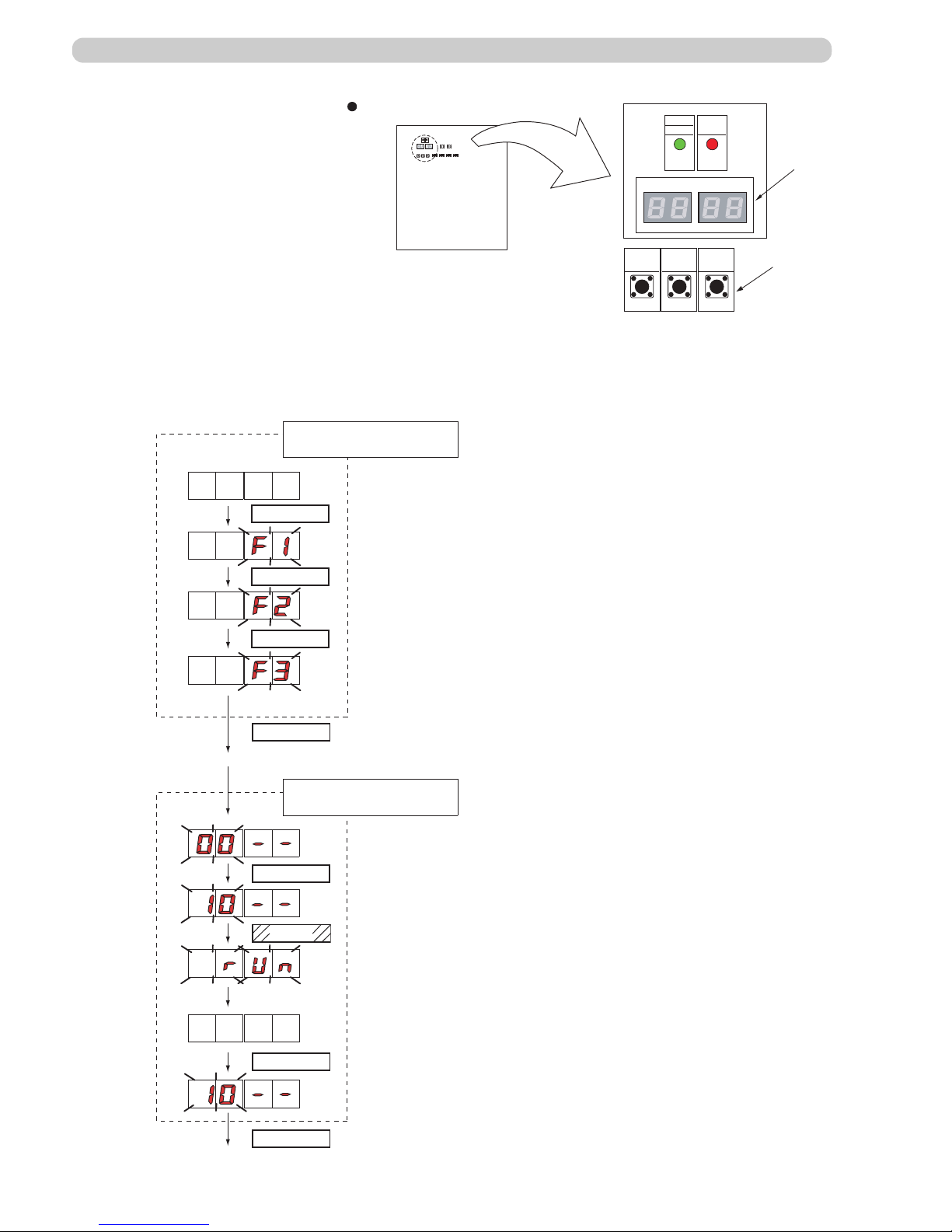

1-2-5 Indoor unit connection check

Please perform the indoor unit connection check according to following procedures.

MODE/EXIT

SELECT

SELECT

SELECT

ENTER

LED105

LED104

ENTER

Set to Function mode [F3].

(When [F4] to [F9] are displayed,

continue to press the “SELECT”

button until [F3] is displayed.)

Press the “SELECT” button until

“12” is displayed.

When indoor unit connection check

can not be performed

Turn on the power •

of indoor unit and

outdoor unit.

Press the •

“ENTER”

button for

more than 3 seconds.

This will be displayed when the •

Indoor unit connection check

starts.

MODE/EXIT

SELECT

ENTER

ENTER

ENTER

(*1)

(*2)

(*1) The number of connected

indoor units

(*2) Volume ratio of the indoor

units connection

Ex.) When 8 units are connected

Ex.) When the ratio is 120%

Please refer to the following “Error code”

for details

[ Note ] Error code

22.1: Connecting Indoor units capacity error

24.2: Connecting number of indoor unit error

26.1: Dual address number is existing

Other Error code: Refer to the Trouble shooting

When it finishes normally, nothing will be displayed on

7 segment display.

When error occurs

Confirm the number of connected indoor •

units and the volume ratio of the indoor

units connection.

Exit indoor unit connection check •

mode.

01-09

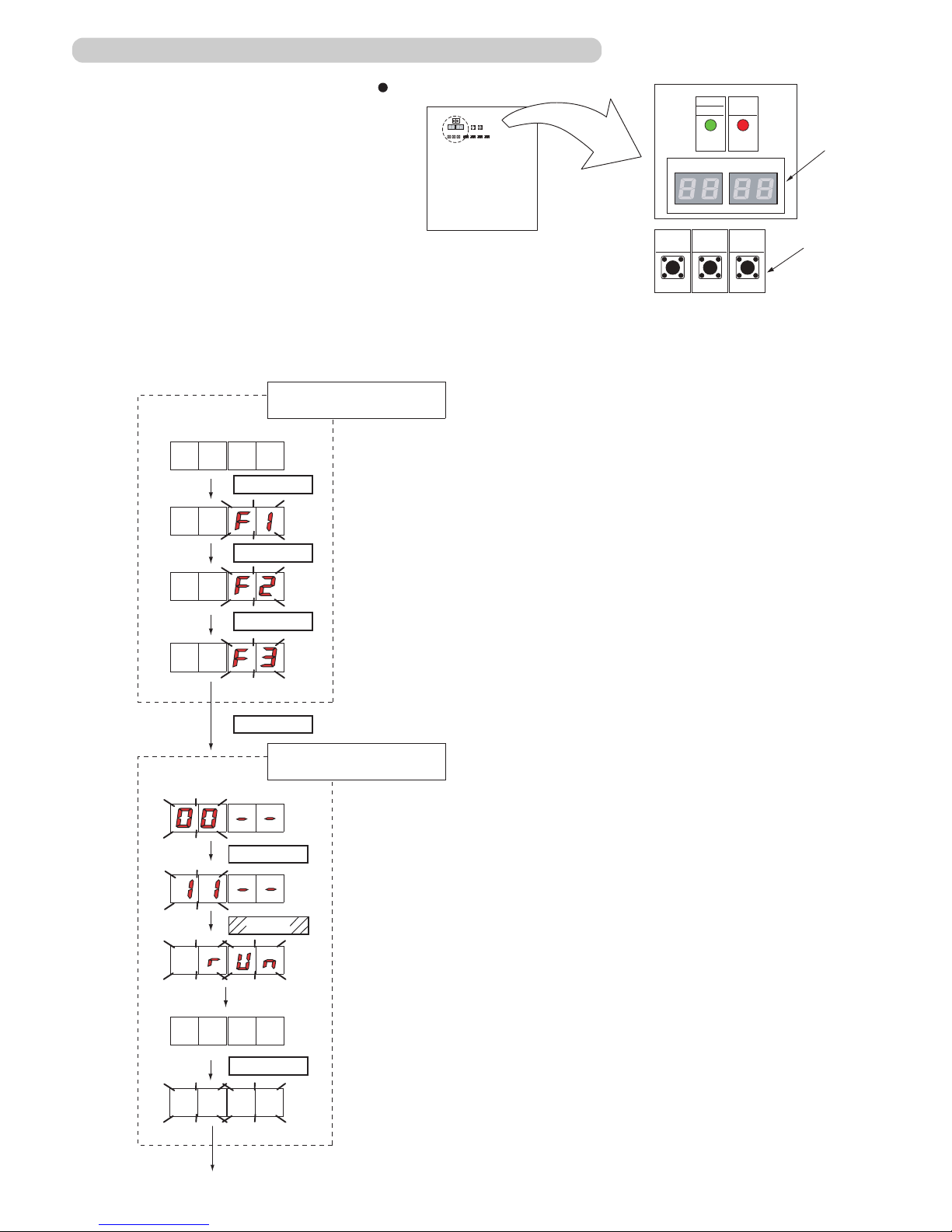

1-2-6 Test Run From Outdoor Main PCB

All the indoor units connected to the outdoor unit can be test-operated by push button setting.

LED105 LED104LED105 LED104 LED105 LED104LED105 LED104

L

ED

1

0

5

L

ED

1

0

4

LED105 LED104

LED105 LED104

[ Cooling test run ]

[ Heating test run ]

[ Test run stop ]

LED105 LED104

LED105 LED104

LED105 LED104

LED105 LED104

Press the ENTER button for at least 3 seconds.

Press the "ENTER" button or Time out ( 5 seconds)

MODE / EXIT

< Pursuance completion >

< Monitoring condition >

< Mode select condition >

< Return to mode select condition >

< Fuction select condition >

[ Function mode ]

SWITCH POSITION

SW107 SW108 SW109

MODE

/EXIT

SELECT ENTER

LED101

(GREEN)

POWER

MODE

LED105 LED104

LED102

(RED)

ERROR

Push button switch

7 Segment

LED Lamp

Outdoor unit printed circuit board

TEST RUN SETTING

[ Monitoring mode ] [ Setting mode ]

[ Error history mode ]

For a detailed description of push button operation, refer to the [D&T manual Chapter 6. SYSTEM DESIGN]

LED105 LED104

< Return to monitoring condition >

example, Normal indicate : [ Cooling mode ]

[ Central control setting

Forced reset ]

There are the following 2 methods of resetting test operation.

Automatic reset when 60 minutes has elapsed.(1)

Reset when operation stop was performed.(2)

Note

SELECT

SELECT

SELECT

SELECT

SELECT

SELECT

ENTER

ENTER

ENTER

MODE / EXIT

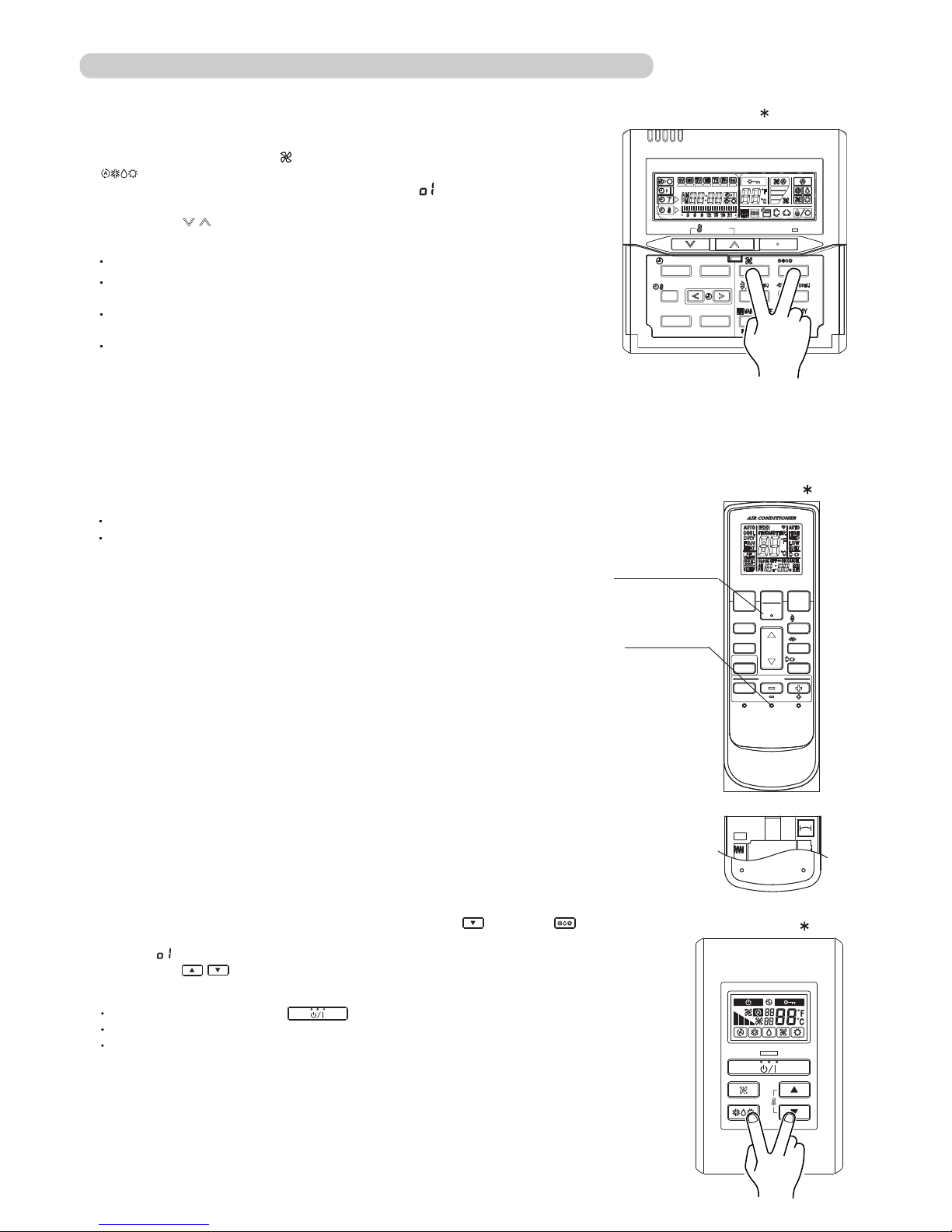

1-2-7 Test Run From Remote Controller

Press the TEST RUN button on the remote controller, while the air conditioner is running.

To end test run operation, press the remote controller START / STOP button.

When the air conditioner is being test run, the OPERATION

and TIMER lamps of indoor unit flash slowly at the same time.

START / STOP button

TEST RUN button

2. Standard wireless remote controller

Stop the indoor unit. Push the button and

button simultaneously for more than two seconds.

The air conditioner will start to conduct a test run and " " will display on

the remote controller display.

However, the , setting button does not have function,

but all other buttons, displays, and protection functions will operate.

To stop test run, push the START / STOP button of the standard wired remote

controller.

For the operation method, refer to the operating manual and perform operation

check.

Check that there are no abnormal sounds or vibration sounds during test run

operation.

Perform the test operation for 60 minutes.

1. Standard wired remote controller

UTY - LNH

UTY - RNK

button

button and

Stop the indoor and outdoor units. Push the remote controller

simultaneously for more than three seconds. The air conditioner will start to conduct a test

run and " " will display on the temperature display.

SET

However the setting button does not have function but all other buttons,

displays and protection functions will operate.

To stop test running press the button of the simple remote controller.

For the operation method refer to the operating manual and perform operation check.

Check that there are no abnormal sounds or vibration sounds during test run operation.

3. Simple remote controller

UTY - RSK

01-10

TIMER MODE

CLOCK

ADJUST

TEST

RUN

RESET

TIMER

SLEEP

FILTER RESET

SWING

SET

SET

ECONOMY

FANMODE

START

STOP

SET

TEMP.

TIMER MODE

DAY

SET BACK

CLOCK ADJUST

DAY OFF

TIMER DELETE TIMER SET

FAN MODE

SET TEMP.

START / STOP

6)

or

[ Select All (F2) ]: All of R.C.Group (Indoor units)

[ Identify Unit (F3) ] : Specific R.C.Group (Indoor unit)

Setup Menu

Indoor unit Special Setting

Test Operation

Central Controller

Setting

Indoor unit

Special setting

Indoor Unit

Set Temp. Range

Filter Sign

R.C. Prohibition

Group

Select

All

Identify

Unit

Clear

Unit

On

Select

All

Details

Off

Operation

Help

Setup

Menu

Monitor

Group

1

2

Monitor - All

UTY-DCG

On

Coll

25.0

℃

05/31 03:59

05/31 03:59

05/31 03:59

Test Operation

05/31 03:59

RCG_05

Test run operating procedure

<Monitor screen (icon)>

<Monitor screen (list)>

(1)

(1)

(2)

( * )

(1)

(1)

(2)

( * )

01-12

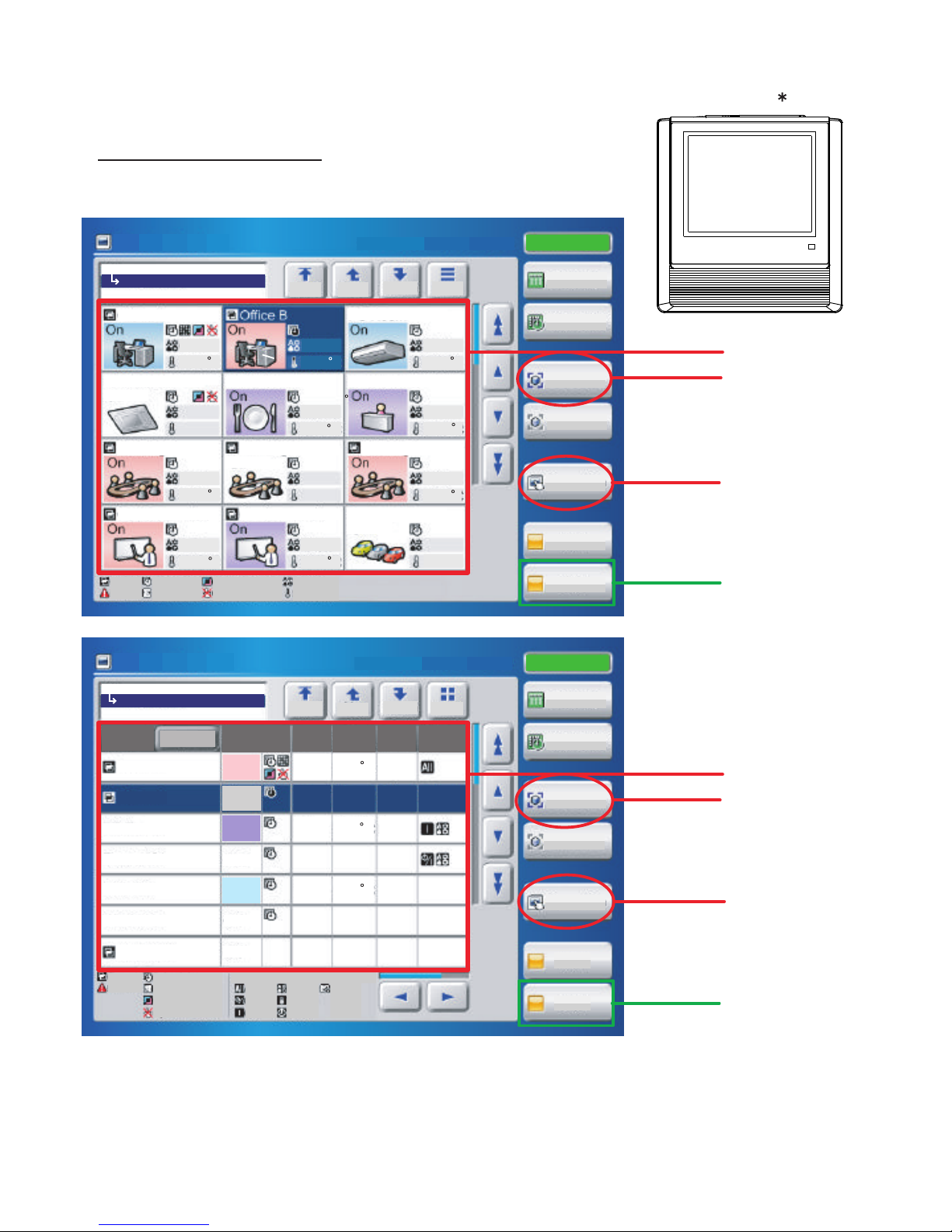

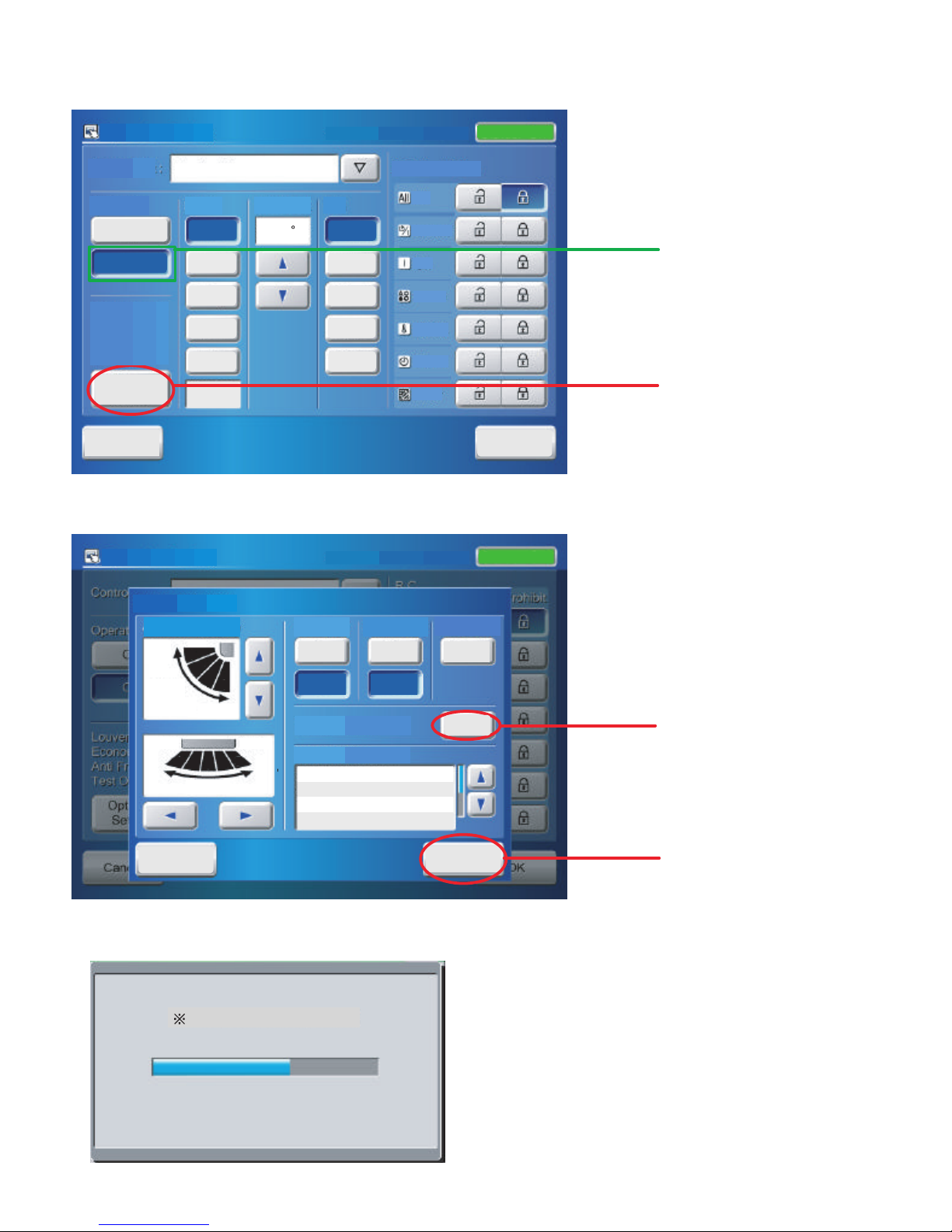

5. Touch panel controller

UTY - DTG

(1) Select the objective you want to test run.

Select the objective icon or list at the monitor screen. (Multiple selections is possible)

Select all the devices registered as objectives by pressing "Select All" on the monitor screen.

(2) After objective selection at (1), switch to the <Setting screen> by pressing "Operation".

On

C

1

On

On

On

On

On

On

On

On

Office B

Conference

A

Conference B

Meeting 1

Meeting

2

Parking lot

Meeting

3

Entrance

Restrant

Room

101

Office A

PC Room

Top Up

Down

List

Heat

Auto

Cool

26.0 C

24.0

C

Auto

22.0

C

Auto

24.0 C

21.5 C

Heat

21.5 C

21.5 C

Cool

Off

Off

Off

All

21.0

C

Heat

All

Lange Group

Lange Group

Top Up

Down

List

Office A

PC Room

Room 101

Restrant

Entrance

Meeting 1

Off

Off

Off

Mixed

Heat

Auto

Cool

24.0 C

26.0 C

Low

Auto

21.5 C

High

Office B

Mixed Mixed Mixed

Mixed

Name

Expand

Status Mode

Set

Temp

Fan

R/C

Prohibit

On

On

On

Status: On

Status: On

10/11.2008.Mar. 02:20 PM

10/11.2008.Mar. 02:20 PM

Monitor Mode

Monitor Mode

Heat

21.0

C

Off

On

Operation

Clear All

Select All

Schedule

Setting

Off

On

Operation

Clear All

Select All

Setting

Schedule

Group

Error

Schedule

Filter Sign

Op. Controlled

Op. Restricted

RC Prohibition

All

On/Off

On

Mode

Temp.

Timer

Filter

Mode

Set Temp.

Group

Error

Schedule

Filter Sign

Op.Controlled

Op.Restricted

<Setting screen>

(3) Switch to the <Details setting screen> by pressing "Optional Setting" on the setting screen.

<Details setting screen>

(4) Send (start) test run by pressing "Start" and then pressing "OK" on the details setting screen. Test run continues for 60 minutes.

During sending, the slave screen shown below is displayed. When sending is completed, the sending slave screen and details setting

screen are closed.

To interrupt test run, select the device being test run and execute an

operation stop command.

(*) At the monitor screen, test run is reset by stopping operation

of the objective devices by pressing "OFF".

(*) Or test operation is reset by stopping operation of the objective

devices by pressing "Off" of Operation and then pressing "OK"

on the setting screen.

01-13

(3)

(4)

(5)

( * )

Cancel

Off

On

OK

Transferring data. Please wait.

On

On

Reset

Cancel

Stand by (Defrost)

Stand by (Oil Recovery)

Test Operation

Start

Air Flow Direction

Economy

Anti Freeze

Filter Sign

Operation

Test

Up

Down

Swing

Swing

Left Right

Off

Off

Special State

Status: On

1

2

3

4

5

1

2

3

4

SettingOptional

Cancel

OK

On

Off

Auto

Auto

Cool

Dry

Fan

Heat

Operation

Controlled

High

Med

Low

Quiet

Meeting Room

24.0 C

operation

R/C Prohibition

Mode Set Temp. Fan

Optional

Setting

All

On/Off

Filter

Timer

Temp.

Mode

On

10/11.2008.Mar. 02:20 PM

10/11.2008.Mar. 02:20 PM

Air Flow Direction

Economy

Anti Freeze

Filter Sign

Test Operation

Control Unit :

Operation Setting

Operation Setting

OK

Status: On

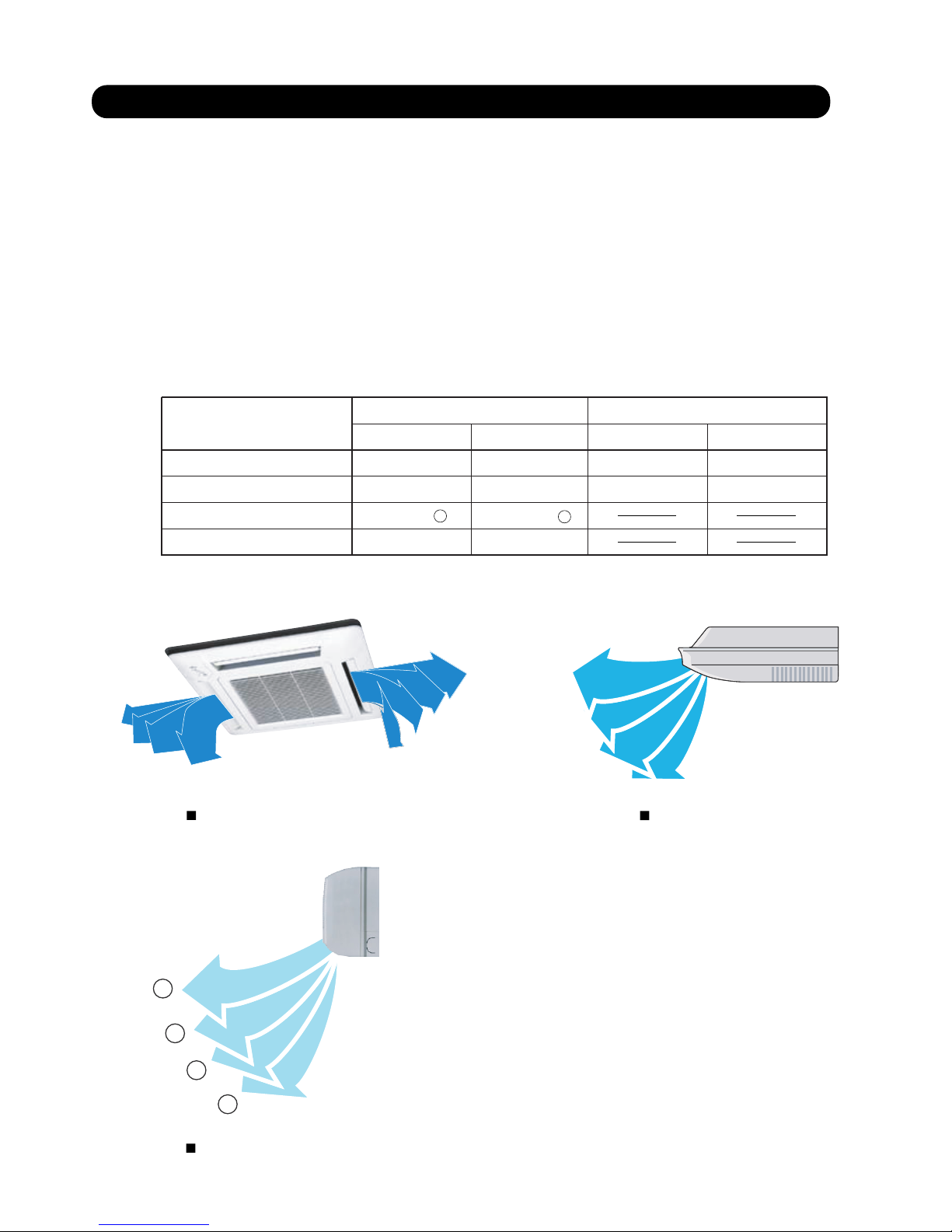

1-3 TEST RUN CONTROL

01-14

1. When the test run signal is transmitted from standard wired, wireless remote controller,

simple remote controller, transmitted network, and outdoor unit.

(1) The test run operation starts and the electric expansion valve is controlled to a maximum flow, regardless of

the temperature condition.

(2) Frost prevention operation has priority over item(1).

(3) Whether state of the indoor unit operates or stops, All units in the same refrigerant circuit will start to conduct a

test run in accordance with the operation mode set by push switch of outdoor unit ( see 1 - 2 - 3 ).

(4) After 60 minutes passes, the test run stops.

(5) Test running initialization is shown below.

Fan speed Hi Hi

Room Temperature Indication 18 30

Hi Hi

18 30

Vertical Air Direction Panel

Swing

Operating Mode

Cooling Heating Cooling Heating

OFF OFF

Position

1

Position

4

EXCEPT FOR THE DUCT MODEL DUCT TYPE

CEILING TYPE

COMPACT CASSETTE TYPE

COMPACT WALL MOUNTED TYPE

4

3

2

1

1

2

3

4

*EXAMPLE

1

2

3

4

4

3

2

1

Push switch onoutdoor

unit PCB

00 Connected number of indoor unit The number of the communicating unit is displayed

01

Software version :

[ ] [ ] [ ] [ ] [ ] displays by five items

It skips when there is no suffix

02 Software version of INV PCB

03 Software version of communication PCB

Operation of

each part

10 Rotational speed of outdoor unit fan motor The rotational speed of the outdoor unit fan motor is displayed

[ rpm ]

11 Rotational speed of INV compressor The rotational speed of the compressor is displayed

[ rps ]

12 Current value of INV compressor Current value of INV compressor is displayed

[ A ]

14 Pulse of EEV1 Pulse of EEV1 is displayed

[ pls ]

15

Pulse of EEV2 Pulse of EEV2 is displayed

[ pls ]

Time guard 20 Accumulated current time Accumulated current time is displayed

[ 10 hour ]

21 INV compressor accumulated time

[ Cooling ]

Accumulated time is displayed in the cooling operation of the

INV compressor

[ 10 hour ]

22 INV compressor accumulated time

[ Heating ]

Accumulated time is displayed in the heating operation of the

INV compressor

[ 10 hour ]

Refrigerant

cycle data 1

30 Information on Thermistor 1

( INV compressor discharge temperature )

The value of the Thermistor 1 is displayed

32

Information on Thermistor 3

( Outdoor temperature )

The value of the Thermistor 3 is displayed

33 Information on Thermistor 4

( Suction temperature )

The value of the Thermistor 4 is displayed

34

Information on Thermistor 5

( Heat-exchanger temperature )

The value of the Thermistor 5 is displayed

36

Information on Thermistor 7

( Liquid temperature 2 )

The value of the Thermistor 7 is displayed

37

Information on Thermistor 8

( Sub-cool heat-exchanger inlet temperature )

The value of the Thermistor 8 is displayed

38 Information on Thermistor 9

( Sub-cool heat-exchanger outlet temperature )

The value of the Thermistor 9 is displayed

39 Information on Thermistor 10

( INV compressor temperature )

The value of the Thermistor 10 is displayed

50

Information on pressure sensor 1

( High pressure sensor )

The value of the pressure sensor 1 is displayed

[ MPa ] or [ psi ]

51

Information on pressure sensor 2

( Low pressure sensor )

The value of the pressure sensor 2 is displayed

[ F1 ]

Monitor mode

Setting Mode

ITEM

CODE No.

Information contents

Refrigerant

cycle data 2

Device and

system

Software version of outdoor unit

Classification

01-15

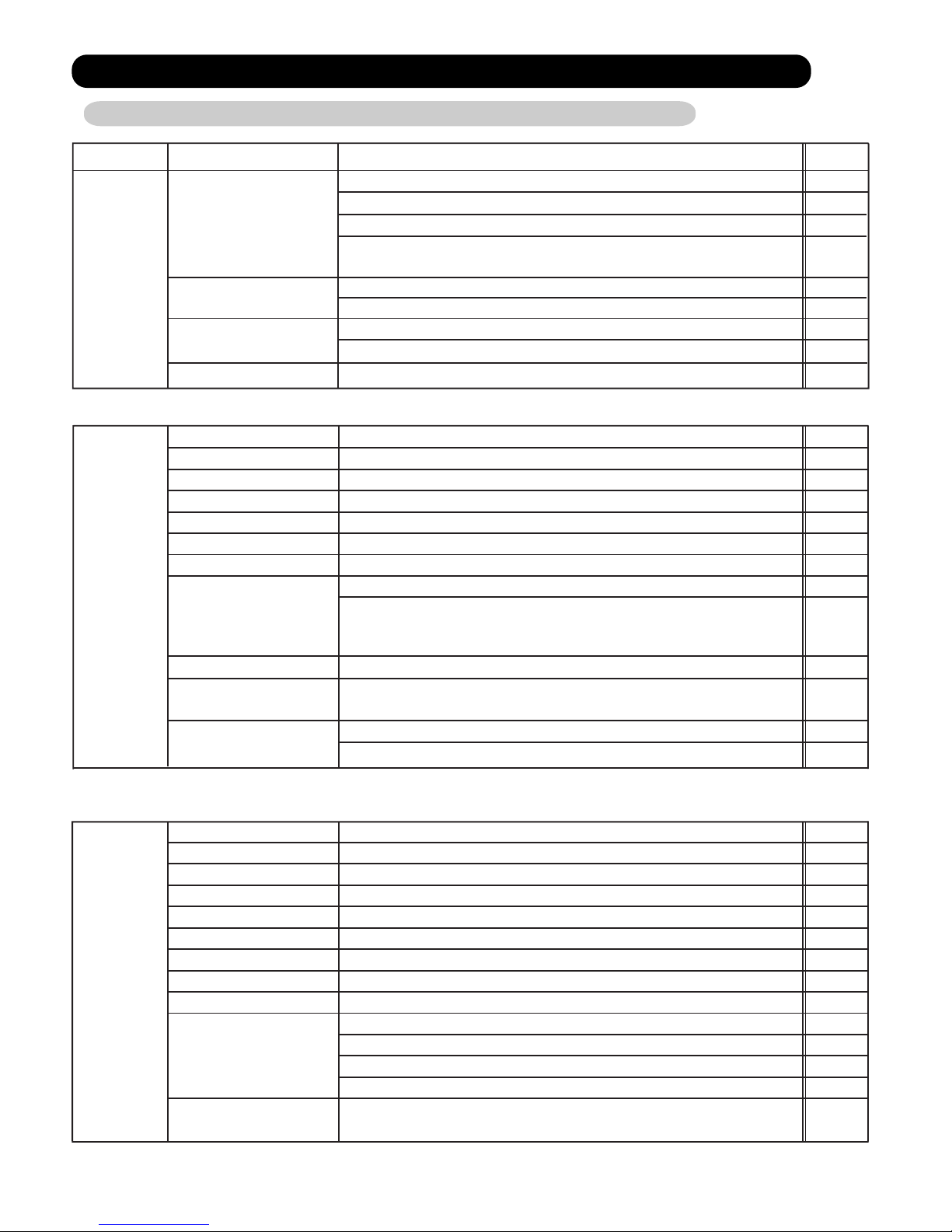

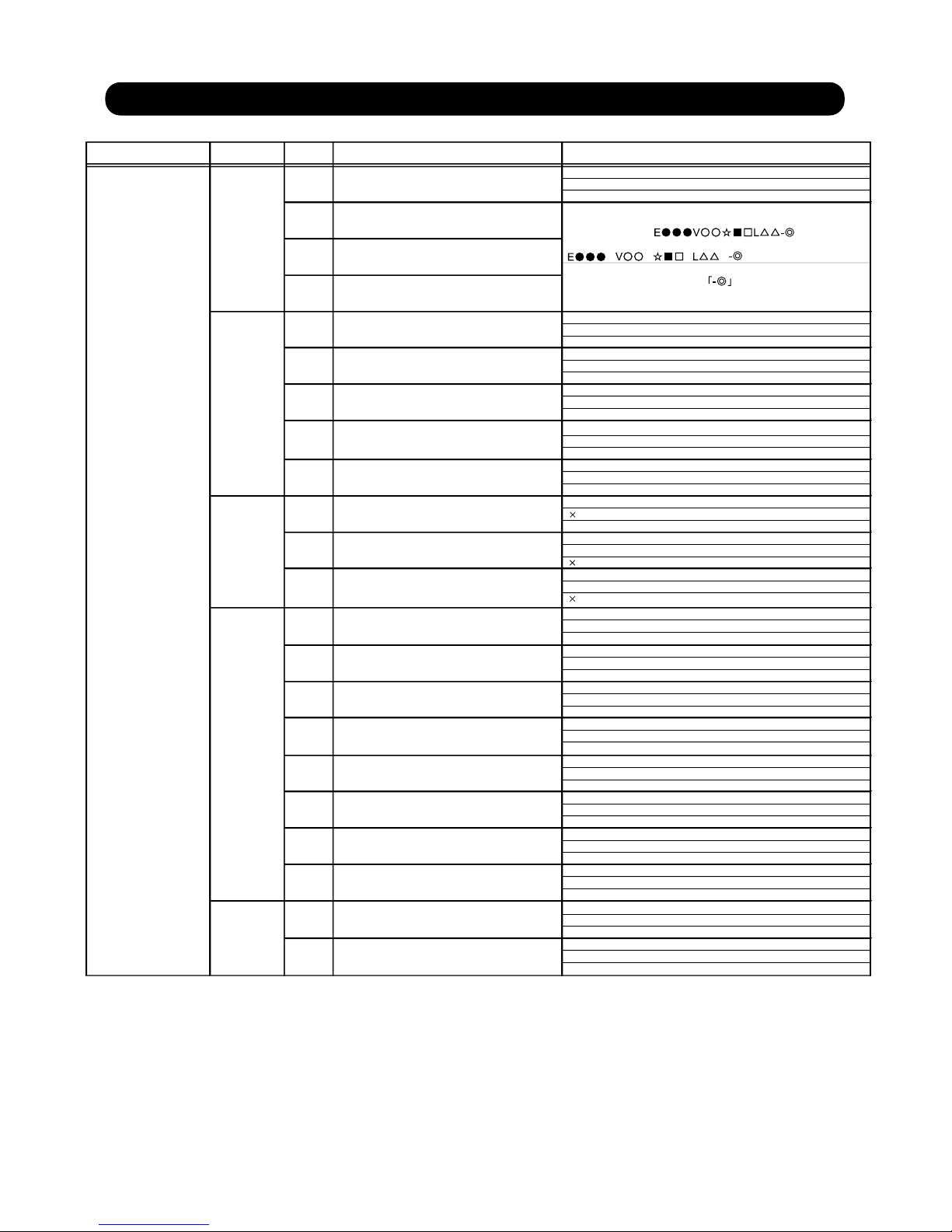

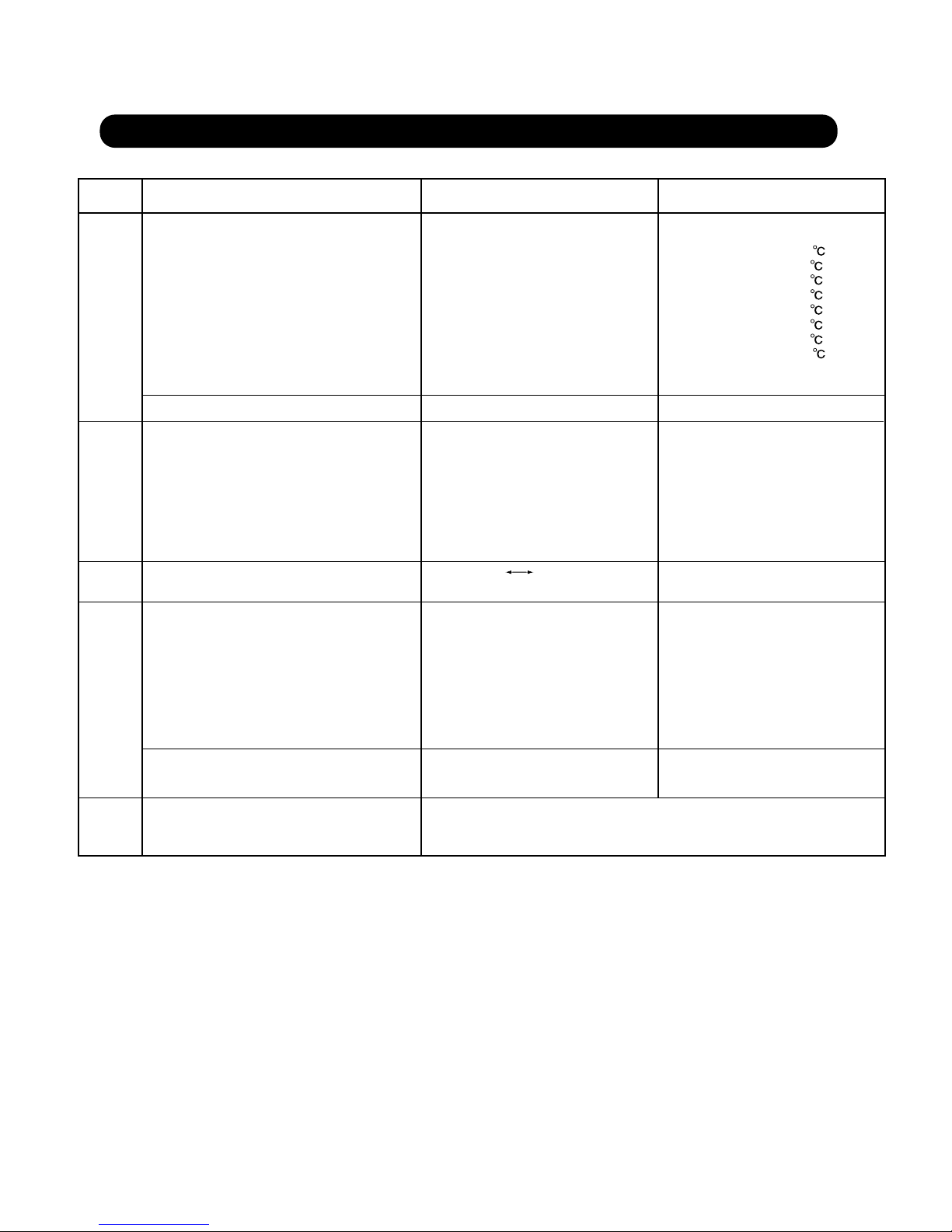

1-4 Field Setting And Monitor Mode List for Outdoor unit

[ MPa ] or [ psi ]

[°C ] or [°F ]

[°C ] or [°F ]

[°C ] or [°F ]

[°C ] or [°F ]

[°C ] or [°F ]

[°C ] or [°F ]

[°C ] or [°F ]

[°C ] or [°F ]

Setting Mode

ITEM

CODE No.

Setting Function

Default

Install 00 Pipe length setting 00 40-65m

Setting mode

01 0-40m

02 65-90m

03 90-120m

04

Correction 10

Sequential start shift

00

01

02

03

11

Cooling capacity shift 00 Normal mode

01 Save energy mode 1 (+2°C)

02 High power mode 1 (-2°C)

03 High power mode 2 (-4°C)

12

Heating capacity shift

00 Normal mode

01 Save energy mode (-2°C)

02 High power mode 1 (+2°C)

03 High power mode 2 (+4°C)

13 Defrost setting shift 00 End temperature:Normal

01 End temperature:Higher

01 Emergency stop

21 Operation mode selecting method 00 Priority given to the first command

01 Priority given to the external input of outdoor unit

02 Priority given to the master indoor unit

22

Snow falling protection fan mode

00 Normal operation

01

23

Interval setting for snow falling

00 Standard

01

02

03

24

High static pressure mode

00 Standard

01

02

28 Change of unit (Temperature) 00 Celsius(°C)

01 Fahrenheit ( F)

29 Change of unit (Pressure) 00 MPa

01 psi

Change of

Change of

function 3

30 Energy saving level setting 00 Level 1 (stop)

01 Level 2 (operated at 40% capacity)

02 Level 3 (operated at 60% capacity)

03 Level 4 (operated at 80% capacity)

04 Level 5 (operated at 100% capacity)

Low noise 40 Capacity priority setting 00 Off (quiet priority)

01 On (capacity priority)

41 Low noise mode setting

00 Off (Normal)

60

Back up operation

00 Standard

01

01 On (Low noise mode operation is always done)

42

Low noise mode operation level

00 Standard (47dB)

01

[ F2 ]

ITEM

CODE No.

Standard

20 Switching between forced stop or 00 Forced stop

Change of

function 1

emergency stop

protection fan mode

setting 1

(in low noise mode)

function 2

Classification

01-16

Push switch

on outdoor unit PCB

Setting is forbidden

Setting is forbidden

Setting is forbidden

Setting is forbidden

70

Electricity meter No. setting 1

(Set the ones digit and tens digit of the No of

the electricity meter connected to CN135.)

*3

00~99 Setting number x00~x99

00

71

Electricity meter No. setting 2

(Set the hundreds digit of the No. of the

electricity meter connected to CN135.)

*3

00~02 Setting number 0xx~2xx 00

72

Electricity meter pulse setting 1

(Set the ones digit and tens digit of the No. of

the electricity meter pulse setting connected

to CN135.)

*4

00~99 Setting number xx00~xx99 00

73

Electricity meter pulse setting 2

(Set the hundreds digit and thousands digit

of the electricity meter pulse setting connected

to CN135.)

*4

00~99 Setting number 00xx~99xx 00

Change of

function 4

*3 : When electricity meter No. is set to "000" and "201 to 299", the pulses input to CN135 become ineffective.

Available setting number is "001" to "200"

*4 : When the electricity meter pulse setting is set to "0000", the pulses input to CN135 become ineffective.

Available setting number is "0001" to "9999"

( Refer to Design & Technical Manual for details.)

( Refer to Design & Technical Manual for details.)

( Refer to Design & Technical Manual for details.)

( Refer to Design & Technical Manual for details.)

Setting is forbidden: Any of problems caused by changing these setting is not covered by the warranty.

14 Pressure equalization time shift

before defrosting start

00 No time shift

01 Shift 1 ( 30 sec.)

02 Shift 2 ( 60 sec.)

03

04

Shift 3 ( 90 sec.)

Shift 3 ( 120 sec.)

Only for solution :

Only when the refrigerant noise during Defrosting was pointed out. It is the case that the

compressor operating time in heating will be shorter.

Only for solution

04 High power mode 3 (-5°C)

03

Oil recovery

00

02

Setting is forbidden

01

25

Oil recovery Abnormal

low pressure protection control

00

01

26

27 Error code Notification

00

01

Enable

Disable

31

Heating Starting prosess

00

01

Standard

Standard

Standard

Setting is forbidden

Setting is forbidden

Setting is forbidden

Setting is forbidden

Setting is forbidden

Push switch on

outdoor unit PCB

Forced operation 00 Cooling test run

Forced thermostat-ON in Cooling.

Function mode

01 Heating test run Forced thermostat-ON in Heating.

02 Test run stop Test run is stopped.

Install and

maintenance 1

10 Signal amplifier automatic address Automatic address setting operates for signal amplifier.

11 Indoor unit automatic address

21 Vacuuming mode Vacuuming mode operatesRefer to page 01-01 for the function.

Clear 30 Error history clear All the abnormal code histories are cleared.

32 Current time clear Accumulated current time becomes [ 0 ]

33 INV compressor accumulated time clear Accumulated time of the INV compressor becomes [ 0 ]

35 Field setting all clear Return to default the all set items.

Reset 40 Abnormal reset It was displayed when abnormality occurs, and abnormal

code is reset.

This is a function that uses to clear abnormal display after the

repair is completed.

Please operate the switch after power off or power on

the outdoor unit.

Specialtyfunction 91 Foreced Central control function release

Maximum memorized indoor unit number is reset.

Setting Mode

ITEM

CODE No.

Setting Function

Install and

maintenance 2

*

Automatic address setting operates for indoor unit of same

refrigerant circuit.

[ F3 ]

01-17

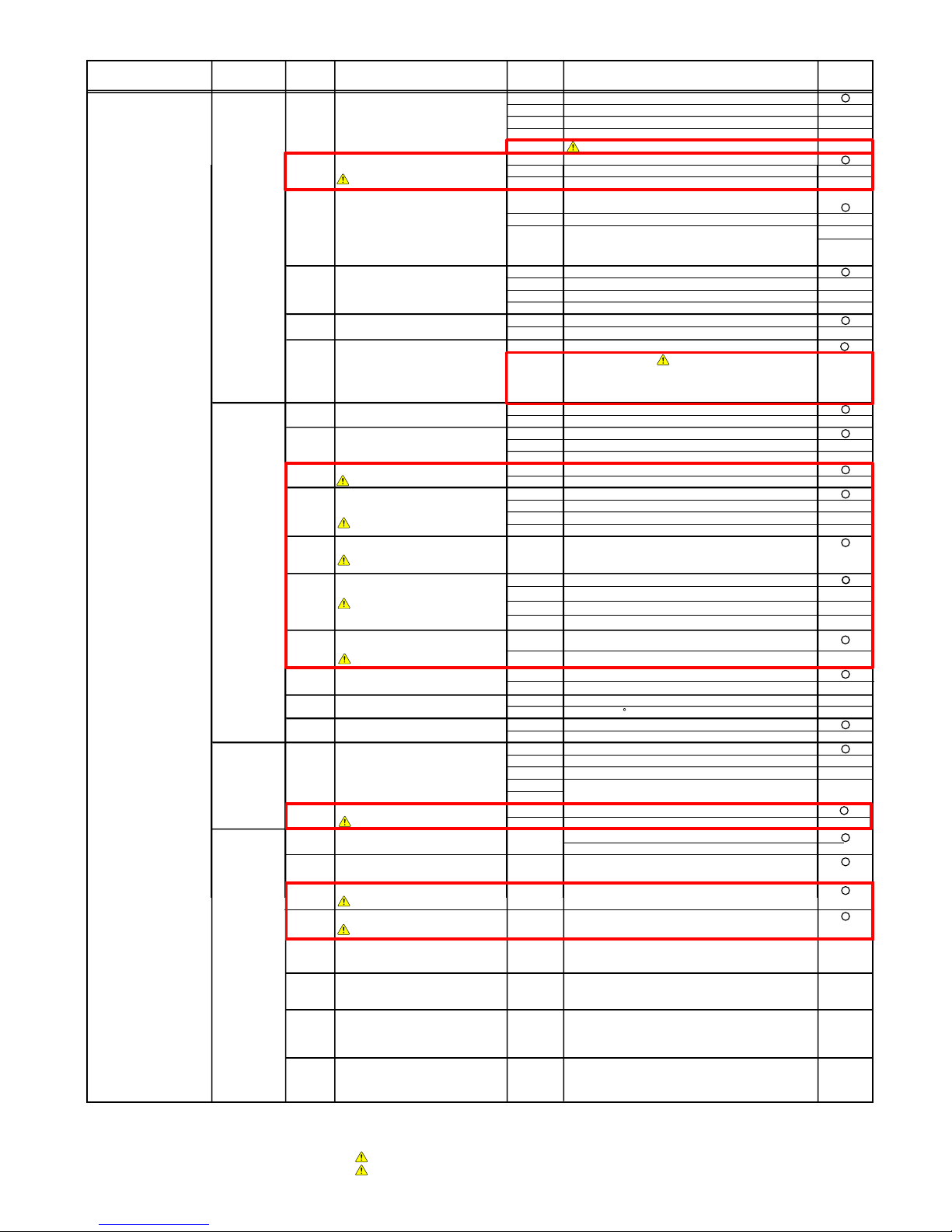

Compressor Motor Loss of Synchronization

Compressor 1 Temperature Abnormal

Inverter Compressor Start Up Error

Discharge Temperature 1 Abnormal

Low Pressure Abnormal

Current Sensor 1 Error

Trip Detection

Rush Current Limiting Resistor Temp Rise Protection

Outdoor Unit FAN motor 1 Lock Error

Outdoor Unit FAN motor 2 Lock Error

< Reset Error Item List By Abnormal Reset Setting >

*

Push switch on

outdoor unit PCB

1 time ago (Newest)

Error History Mode

2 times ago

5 times ago

Meaning of Error History Number

ITEM

CODE No.

Information contents

[ F9 ]

00

01

02

03

04

05

06

07

08

09

Error history

10 times ago (Oldest)

4 times ago

3 times ago

6 times ago

7 times ago

8 times ago

9 times ago

When the centralized control device failure, and the centralized

control setting cannot be released, this function is used.

All the limitations set with the centralized control device are

released.

Maximum memorized indoor unit number reset

41

"E14.5:Indoor unit number shortage" error is cleared.

When the error occurred, the error code is memorized up to

10 on Main PCB.

If the memorized error code becomes over 10, the oldest one

will be erased.

Refer to Chapter 4.TROUBLE SHOOTING

4-2-3 Error Code List of Outdoor unit

12

The number of indoor units and the total capacity of indoor units

of same refrigerant circuit.

Indoor unit connection check

36

Clear memorized information of "F3 - 12 "

( Indoor unit connection check )

The information of the number of indoor units and the total

capacity of indoor units are cleared.

34 Constant Speed compressor accumulated

time clear

Not in Use on J-Series

90

Foreced Normal operation release Normal operation foreced release

01-18

1-5 Field Setting / Function Setting for Indoor unit

Setting Mode

ITEM

CODE No.

Setting Function

Default

Indoor unit field setting

Address

setting by

remote controller

01 Indoor unit address 00~63 00~63 00

02 Refrigerant circuit address 00~99 00~99 00

Filter 11 Filter indicator Interval 00 Default

01

Longer

02 Shorter

13 Filter sign display 00 Enable

01 Disable

02 Display only on central remote control

Airflow 20 Ceiling airflow 00 Default

(Cassette type only) 01 High ceiling

23 Vertical airflow direction 00 Default

01 Raise

24 Horizontal swing airflow direction 00 Default

01 Left half

02 Right half

Correction

30

Cool air temperature trigger

00 Default (0°C)

01 Temperature overshoot setting (+2

°C)

02 Temperature undershoot setting (-2

°C)

31 Heat air temperature trigger 00 Default (0°C)

01 Temperature undershoot setting (-6

°C)

02 Temperature slightly undershoot setting (-4

°C)

03 Temperature overshoot setting (+4

°C)

Change of 40 Auto restart 00 Enable

01 Disable

43 Cool air prevention 00 Enable

01 Disable (Ventilation mode)

46 External control 00 Start / Stop

01 Emergency stop

47 Error report target 00 All

01 Display only for central remote control

ITEM

CODE No.

Function 1

Classification

26

32

Model name Range of static pressure

AR XD 07L ATH

0 to 90 Pa

AR XD 09 LATH

AR XD 12LATH

AR XD 14LATH

AR XD 18L ATH

AR XD 24L ATH 0 to 50 Pa

00

01

02

03

04

05

06

07

08

09

31

0 Pa

10 Pa

20 Pa

30 Pa

40 Pa

50 Pa

60 Pa

70 Pa

80 Pa

90 Pa

25 Pa

Static Pressure setting

- Slim Duct Only -

The Range of static pressure is

different from one model to other.

Temperature correction in Auto

00

01

Disable

Enable (Nonfunctional on J2 Series)

2. OUTDOOR UNIT OPERATION CONTROL

2-1 INPUT / OUTPUT LIST

2. OUTDOOR UNIT

02-01

Input / output or kind of detail Control range

Discharge pressure sensor <HIGH> Pressure sensor Measure range 0.0 to 5.0MPa

Suction pressure sensor <LOW> Pressure sensor Measure range 0.0 to 1.7MPa

Discharge temperature sensor <TH1> Themistor <Blue>

Measure range 10 to 130

Heat exchanger temperature sensor <TH5> Themistor <Pink>

Measure range -35 to 70

Sub-cool heat exchanger (inlet) sensor <TH8> Themistor <White>

Measure range -35 to 70

Sub-cool heat exchanger (outlet) sensor<TH9> Themistor <Brown>

Measure range -35 to 70

Liquid temperature sensor <TH7> Themistor <Green>

Measure range -35 to 70

Suction temperature sensor <TH4> Themistor <Red>

Measure range -35 to 70

Outdoor temperature sensor <TH3> Themistor < - >

Measure range -25 to 58

Operation current sensor

Current transformer

Rotary SW & DIP-SW & Push SW

Electronic expansion valve 1 (Main) EEV coil Operating voltage DC12V

Electronic expansion valve 2 (SC-Hex) EEV coil Operating voltage DC12V

4-way valve 4-way valve coil AC220-240V, 50/60Hz 6/5 W

Solenoid valve Comp pressure equalizing valve AC220-240V, 50Hz, 6W

Crank case heater For Inverter Compressor AC240V, 25W

Base heater Field supply AC220-240V, 35W

LON WORKS

Inverter communication

External input 1 (CN131)

(Low noise mode operation)

External input 2 (CN132)

(Cooling / Heating priority)

External input 3 (CN133)

(Outdoor unit operation peak control)

External input 4 (CN134)

(Emergency stop operation)

Dry contact input

Single LED 101

Single LED 102

LED display

Address and function setting

Display the information on operation, error and setting with single LED and

7 segment LED.

Control output: DC 0/12-24V, Max.30mA

Control output: DC 0/12-24V, Max.30mA

External output 1 (CN136) (Error display)

External output 2 (CN137) (Operation display)

ON (Error) / OFF (Normal)

ON (Operation) / OFF (Stop)

Communication

Input / Output

External

Input / Output

I

N

P

U

T

O

U

T

P

U

T

Compressor temperature sensor <TH10> Themistor < - > Measure range 10 to 130

Pressure switch

Pressure switch

Open 4.2MPa Short 3.2MPa

Fan motor 1 (Upper) DC Brushless motor

7 Segment LED

Compressor

Magnetic relay

Operation coil AC220-240V, 50Hz

Indoor unit Outdoor unit

Fan motor 2 (Lower) DC Brushless motor

2-2-1 Operation / Stop Condition

When cooling requirement capacity or heating requirement capacity from either of the indoor units in the same

refrigerant circuit is input, the compressor operates.

When all the indoor units in no "cooling requirement capacity" or "heating requirement capacity",

the compressor

is stopped.

But in the following case, the compressor operates in accordance with operation of each mode.

During 3 minute restart prevention operation

Icing protection

Failure (Refer to chapter 4, TROUBLE SHOOTING )

Under expansion valve initialization

At protective operation

Emergency stop

Defrost operation

02-02

2-2 COMPRESSOR OPERATION

2-2-2 Capacity Control

(1) Capacity of compressor operation

By the operation of DC inverter rotary compressor, the amount of required refrigerant circulation acceding to

cooling and heating load can be supplied from compressor efficiently.

DC inverter rotary compressor is able to control the amount of

required refrigerant circulation in details.

Cooling/Heating load

Capacity of

compressor operation

Total capacity

Peak cut stop operation

Oil recovery

Inverter Compressor

(2) Target low-pressure and high-pressure control

In order to make the evaporation pressure of the indoor unit at the proper pressure on a variety of operations,

capacity of the compressor will be controlled by low-pressure sensor of the outdoor unit.

In order to make the condensation pressure of the indoor unit at the proper pressure on a variety of operations,

capacity of the compressor will be controlled by high-pressure sensor of the outdoor unit.

Target low-pressure and high pressure temperature depends on system capacity, capacity of compressor operation,

pipe length, and capacity shift switch settings.

<Cooling>

<Heating>

02-03

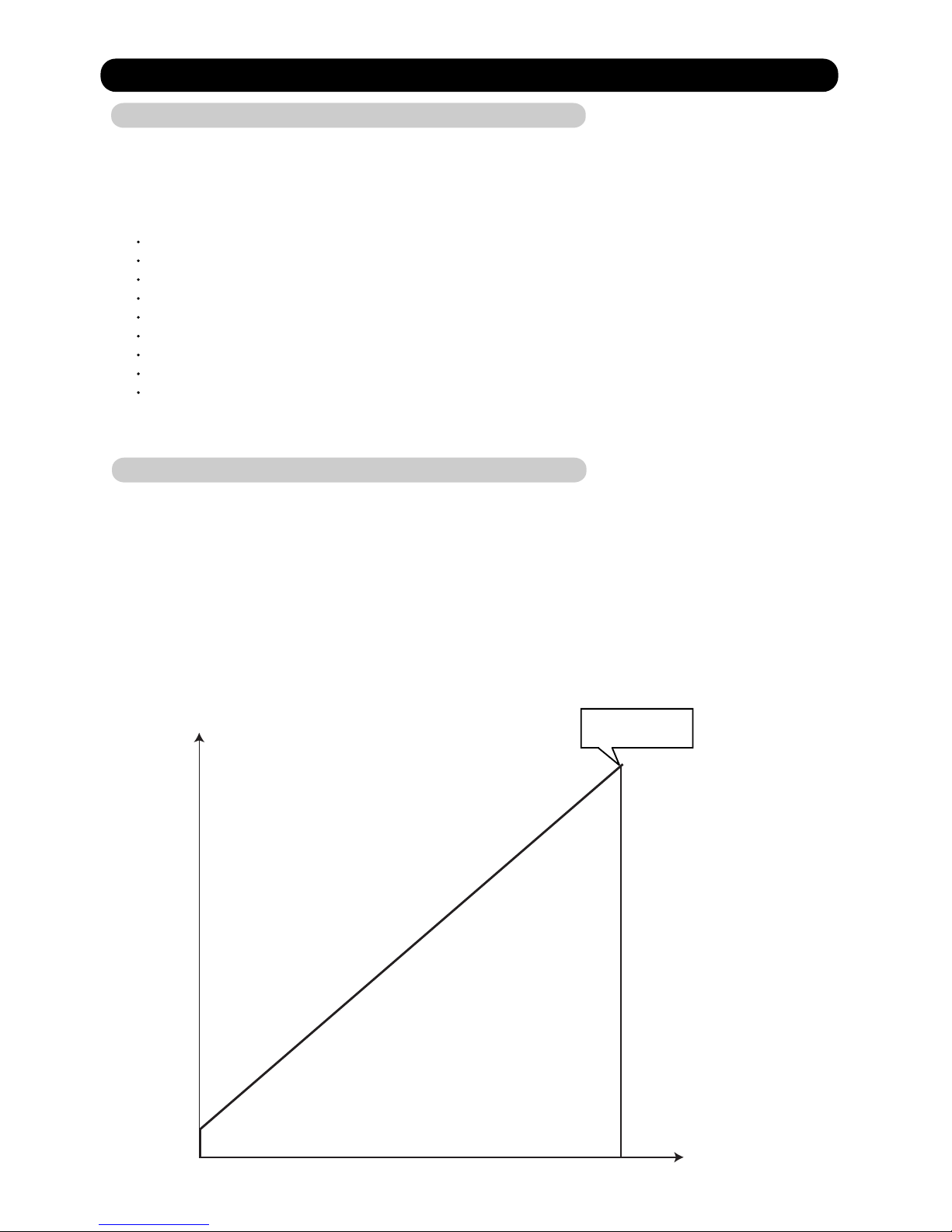

2-2-3 Speed Range of Start, Stop, And Operation

On stop mode : 0 rps

On operating mode : 20 - 100 rps

(1) Cooling starting process

For cooling operation only, the upper limit speed at starting is made 50rps and is raised in

+10rps increments every 60 seconds.

Speed

Time

0

50rps

60sec

Target speed

60sec

60sec

60rps

70rps

80rps

60sec

120sec 180sec 240sec

90rps

10rps

10rps

The compressor operates at the upper limit speed if the target speed is higher than the upper limit speed.

The compressor operates at the target speed if the target speed is lower than the upper limit speed.

60sec

10rps

02-04

Cancel conditions

Normal control

32rps fixed

(3) Limits the upper limit speed of the INV compressor according to the present high-pressure value.

(2) Heating starting process

At the start of heating, the compressor is started by the following process. Compressor start-up

to change the 4 way valve. Capacity control returns to normal control after the end of the starting process.

(target high-pressure control)

Starting process Starting process

Starting process

Starting process

3 minutes elapsed from start of process

or

High-pressure 2.63MPa

20 minutes elapsed from start of process

or

High-pressure 2.63MPa

or

Discharge SH 10 and Discharge temperature 10

[ a ] = 1.25 Low pressure value 2.125

High Pressure

3.60MPa

3.30MPa

(Maximum) 3.00MPa

Maximum speed = 80rps

Maximum speed = 90rps

Maximum speed = 95rps

Maximum speed = 100rps

[ a ]

< Starting process >

Compressor operates based on the required capacity at the start up, after that the target high-pressure

control begins.

*However, when the following condition (A) or (B) are satisfied, starting process is not performed.

< Conditions under which starting process is not performed >

(A) The compressor temperature 32 , when the room temperature reached to the setting temperature

( Thermostat - OFF controlling )

(B) The compressor temperature 32 , when the system keeps heating mode with stop condition

< Operation >

Compressor operation speed

4rps/Min

Switching conditions of step

2-3 FAN CONTROL

2-3-1 Cooling Operation

Fan step

11

10

9

8

7

6

5

4

3

2

1

0

780

700

660

660

670

590

540

540

450

410

340

340

270

250

390

0

340

0

290

0

250

0

0

0

AJ A36LALH AJ A45LALH AJ A54LALH

Fan speed (rpm)

02-05

(Conditions which lower the fan speed)

High-pressure saturation low limit of target high-pressure

saturation range and heat sink temperature 75°C

(Conditions which raise the fan speed)

High-pressure saturation upper limit of target high-pressure saturation or heat sink temperature 80°C

Fan step

7

5

2

0

Outside air temperature

sensor detected value

TAOUT 30°C

30°C TAOUT 20°C

20°C TAOUT 10°C

10°C TAOUT

The initial speed of the outdoor unit is detected by out door temperature sensor.

35 52

40.4

46.6

54

High-pressure saturation temperature

Outdoor temperature

Upper limit of target

high-pressure saturation

temp.

Low limit of target

high-pressure saturation temp.

Target high-pressure

saturation temp.

Thereafter, the high-pressure is monitoring at a

set time interval and the fan speed is changed

by the following conditions.

The fan is controlled to keep high puressure saturation temperature

within the target range as follows

780

700

660

660

670

590

540

540

450

410

340

340

270

250

390

0

340

0

290

0

250

0

0

0

780

700

700

700

670

590

540

540

450

410

340

340

270

250

390

0

340

0

290

0

250

0

0

0

Step

Upper FAN

Lower FAN

02-06

2-3-2 Heating Operation

Fan step

11

10

9

8

7

6

5

4

3

2

1

0

800

700

660

660

670

590

540

540

450

410

340

340

270

250

0

0

0

0

0

0

0

0

0

0

AJ A36LALH AJ A45LALH AJ A54LALH

Fan speed (rpm)

Switching conditions of step

Fan step

11

8

5

5

Outside air temperature

sensor detected value

TAOUT 10°C

10°C TAOUT 15°C

15°C TAOUT 20°C

20°C TAOUT

Thereafter, the high-pressure is monitoring at a set time interval and the fan speed is changed by the following conditions.

(Condition which lowers the fan speed)

High-pressure 3.30MPa and heat sink temperature 80°C

(Condition which raises the fan speed)

High-pressure saturation 3.20MPa or heat sink temperature 85°C

The initial speed of the first boot outdoor unit is detected by outdoor air temperature sensor value (TAOUT).

800

700

660

660

670

590

540

540

450

410

340

340

270

250

0

0

0

0

0

0

0

0

0

0

800

700

700

700

670

590

540

540

450

410

340

340

270

250

0

0

0

0

0

0

0

0

0

0

02-07

Capacity priority setting

Operation mode

Low noise level setting

ON

OFF

4HP

AJ*A36LALH

450

7

5HP

AJ*A45LALH

ON

ON

COOL

HEAT

«

Low noise mode and operation contents

»

( PUSH SW ) ( PUSH SW )

Normal operation

Low

capacity

Not switched for 30 minutes

after being once switched.

* Automatic switching

«

Settings and corresponding operations

»

LOW NOISE MODE

* Automatic switching

* Low capacity

Compressor capacity is low

or

High-pressure is high (high-pressure saturation 58°C) at cooling

or

Low-pressure is low (low-pressure saturation 0°C) at heating

Operation in low noise mode

When the low noise mode setting ON from PUSH SW or EXTERNAL INPUT, the outdoor unit operates in

the low noise mode as follows.

LOW NOISE MODE

The operating sound lowers from about 3 to 5 dB more than the rated value

Capacity does not become low

even when switched to low noise

mode

The operating noise is reduced by limiting the rotational speed of the compressor and fan motor

2-3-3

Low noise mode

410

40

450

7

410

45

450

7

410

52

450

7

410

60

450

7

410

60

450

7

410

60

6HP

AJ*A54LALH

Max FAN Step

Max FAN Step

Max Compressor Speed

Max Compressor Speed

Upper FAN

Lower FAN

Upper FAN

Lower FAN

Low Noise Mode

To accurately detect the outside air temperature, the fan is operated while the outdoor unit is stopped.

2-3-4 Other Control

02-08

EEV 1

EEV 2

EEV is controlled so that the system reaches closer to the target discharge temperature that is calculated from

high and low pressure.

< Cooling mode >

< Heating mode >

500 pulses basically.

Initialization

conditions

Control range

operation stop

500 pulses

55 - 500 pulses 0 pulses

0 pulses

2-4 EXPANSION VALVE CONTROL

Cooling

Heating

Operation mode

40 - 500 pulses

Cooling

Heating

When power

turned on

When operation

stopped

2-5 SPECIAL OPERATION

2-5-1 Oil Recovery Operation

Purpose of the operation

The amount of refrigerant lubricant oil which has been transported to the indoor units

and the connection pipe with the refrigerant will become large as the operation time of compressor increases.

It is necessary to recover the oil back into the outdoor unit for a certain time interval

in order to prevent compressors from damaging due to lack of lubrication oil.

During the oil recovery operation, appears on the display of wired and central remote controller,

and appears on the simple remote controller.

The operation indicators (LED) of the indoor units flash slowly.

Others

02-09

< Start condition >

Compressor accumulated operation time since last cooling oil recovery operation exceeds 3 hours (first time : 1hour)

< End condition >

30 seconds have elapsed since the start and "suction temperature - low pressure saturation temperature 5deg" or 6 minutes

have elapsed since the start.

< Operation >

COMPRESSOR: The rotation speed varies depending on the operation state.

EEV Opening (Indoor/Outdoor unit): Controlled pulse (as normal operation mode).

FAN speed (Indoor/Outdoor unit) : Controlled fan speed (as normal operation mode).

2. Oil Recovery in Heating operation

1. Oil Recovery in Cooling operation

< Start condition >

Compressor accumulated operation time since the last heating oil recovery exceeds 8 hours (first time : 1hour)

< End condition >

After 4 minutes have elapsed

< Operation >

COMPRESSOR: The rotation speed varies depending on the operation state.

EEV Opening (Indoor/Outdoor unit) : Controlled pulse (as normal operation mode)

FAN speed (Indoor/Outdoor unit) : Controlled fan speed (as normal operation mode)

02-10

2-5-3 Defrost Operation Control

Accumulated heating operation time is 40 minutes or longer

[Accumulated heating operation time is reset at the end of cooling operation or defrosting operation.]

and

an outdoor unit satisfies condition or below

Condition : "Heat exchange temperature -2°C" accumulated operating time is 180 minutes or longer

Condition : After the following all condition satisfied, "heat exchange temperature defrosting start judgment

temperature and during heat exchange liquid temperature drop" accumulated time:10minutes

(a) accumulated heating operation time 30 minutes

(b) 10 minutes have elapsed after outdoor unit starting

(c) 5 minutes have elapsed since oil recovery

* Defrosting start and end judgment temperature are determined by the outdoor temperature.

Defrosting start judgment temperature = 0.8 x outdoor temperature - 11.6 (However, -27.6°C to - 6°C)

At all outdoor units, heat exchange liquid temperature end judgment temperature

or

when 10 minutes have elapsed from the start

(When the indoor unit connection capacity is 90% or less, after 15 minutes have elapsed.)

Defrosting end judgment temperature = 0.39 x outdoor temperature + 12.7 (However, 5 to 12°C range)

If the calculated result is lower than -27.6 , the judgment temperature is defined as -27.6

If the calculated result is higher than -6 , the judgment temperature is defined as -6

2-5-2 Pre-heat Operation

This pre-heat operation protects the start up failure by preventing the refrigerant from soaking into the oil in compressor.

Crankcase heater ON: 30 minutes elapsed since installed compressors stopped

(However, ON when power turned on)

*It doesn't control according to the temperature.

If the calculated result is lower than 5 , the judgment temperature is defined as 5

If the calculated result is higher than 12 , the judgment temperature is defined as 12

OFF: Compressor starts

Outdoor temperature <2 and Compressor stop count exceed 20 times at less than 10 minutes of accumulated

heating operation time

Defrost Operation Start Condition 1

Defrost Operation Start Condition 2

Defrost Operation End Condition

2-6 PROTECTIVE FUNCTION

02-11

2-6-1 Protective Function List

Protective Function

Detect Parts

Operating Condition

Operation

Discharge Temp

Protection 1

Discharge Temp

Thermistor

Discharge Temp

Protection 2

Discharge Temp

Thermistor

High Pressure

Protection 1

High Pressure

Sensor

High Pressure

Protection 4

High Pressure

Sensor

COOL HEAT

<Starting conditions>

3 minutes have elapsed since the start of operation and

(discharge temperature 100°C or suction SH 10°C accumulated time

30 minutes)

<Reset conditions>

Discharge temperature 95°C and suctionSH 7°C

EEV of operating indoor unit gradually opened

<Starting conditions>

Cooling: Discharge temperature 95°C

Heating: Discharge temperature 102°C

<Reset conditions>

Discharge temperature 90°C

Discharge temperature 97°C

EEV2 + 30pls/30 secs

Discharge Temp

Protection 4

Discharge Temp

Thermistor

< starting condition>

Discharge temperature 105°C

<Pattern reset condition>

Discharge temperature 100°C

Compressor speed -6rps every 30 secs

Speed rise prohibited,

when discharge temperature becomes lower

than 105 , prohibit the rotational speed rise

of the compressor.

Discharge Temp

Protection 5

Discharge Temp

Thermistor

<Starting conditions>

Discharge temperature 95°C and EEV1=500pls

<Reset conditions>

2 minutes have elapsed and

(discharge temperature 90°C or EEV1 400pls)

Expansion valve of stopped indoor unit gradually

opened

(upper limit 200pls)

Discharge Temp

Protection Stop

Discharge Temp

Thermistor

<Pattern starting condition>

Discharge temperature fixed value (115°C)

<Pattern reset condition>

3 minutes have elapsed and discharge temperature 80°C

Compressor stopped

<Pattern starting condition>

Pattern generated 2 times within 40 minutes

<Pattern reset condition>

Error reset (push button SW) executed after power turned on again

Compressor stopped