AirSep Centrox PSA Technical manual

AirSep® Corporation

Centrox

PSA Oxygen Concentrator

Instruction Manual

MN124-1 04/10 Rev. -

AirSep® Corporation x 260 Creekside Drive x Buffalo, NY 14228-2075 USA

Phone: 1-800-320-0303 x Fax: (716) 691-1255 x www.airsep.com

Ownership Data

Take a moment to note important information below about your AirSep CENTROX PSA Oxygen

Concentrator. Keep this instruction manual, along with your invoice, to serve as a permanent

record of your purchase.

PSA Oxygen Concentrator

Model Number:

Serial Number:

Invoice Date:

Start-Up Date:

AirSep Representative

Company:

Contact:

Address:

CENTROX

City/Town: State: Zip:

Country: Fax:

Telephone: Telex:

Before you attempt to install, operate, or repair the oxygen concentrator,

read and thoroughly understand this instruction manual. Improper

operation can result in severe bodily injury, damage to the system, or

poor performance.

AirSep® Corporation

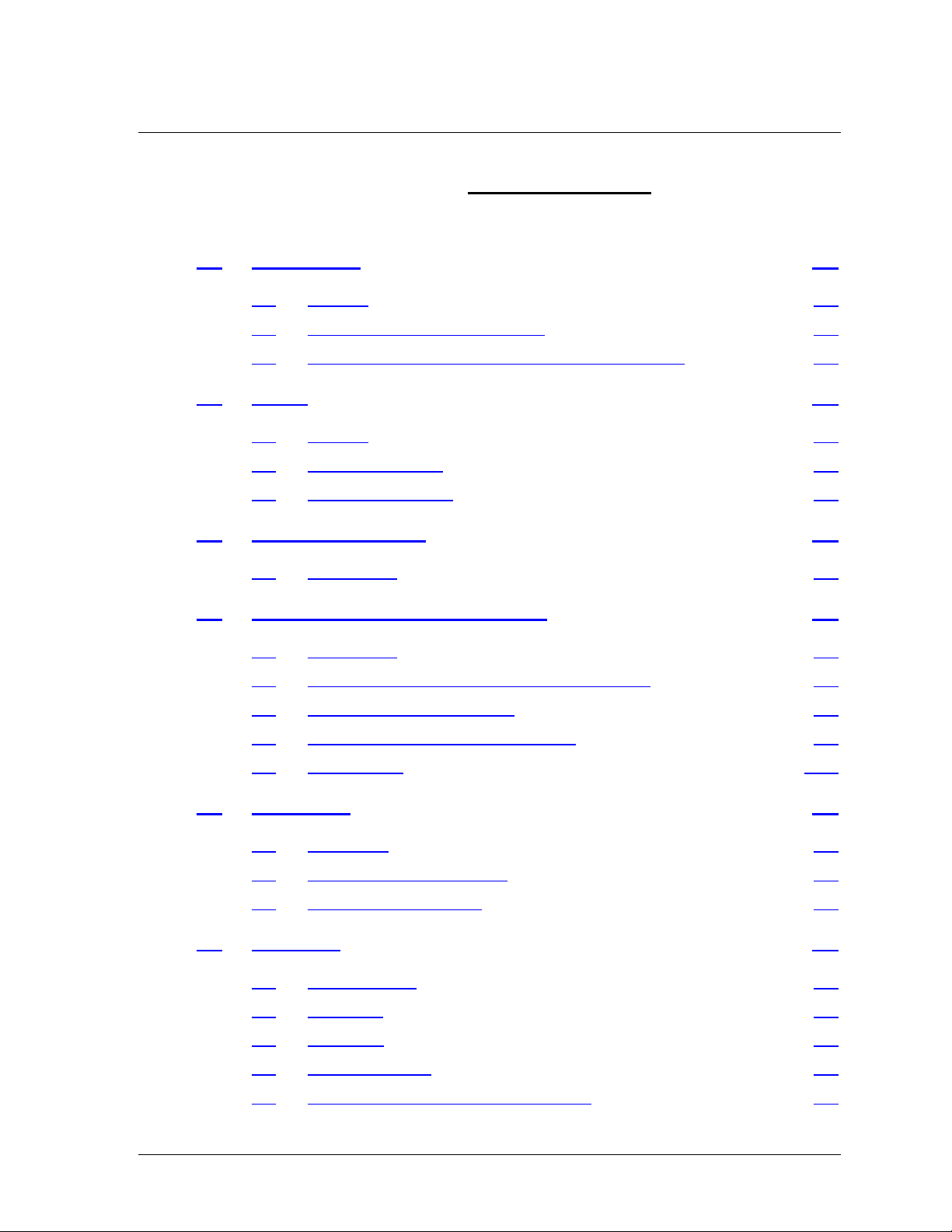

1.0 Introduction ..................................................................................... 1-1

1.1 General .............................................................................................1-1

1.2 Warnings, Cautions, and Notes ........................................................1-1

1.3 References to Controls and Indicators with Labels ..........................1-1

2.0 Safety................................................................................................ 2-1

2.1 General .............................................................................................2-1

2.2 Potential Hazards .............................................................................2-1

2.3 Safety Publications ........................................................................... 2-3

3.0 System Description ......................................................................... 3-1

3.1 Introduction .......................................................................................3-1

Table of Contents

4.0 Controls, Parts, and Connections.................................................. 4-1

4.1 Introduction .......................................................................................4-1

4.2 Oxygen Concentrator Controls and Indicators.................................. 4-1

4.3 Oxygen Concentrator Parts ..............................................................4-4

4.4 Auxiliary Kits Information (Optional) .................................................4-8

4.5 Connections....................................................................................4-10

5.0 Installation ....................................................................................... 5-1

5.1 Unpacking.........................................................................................5-1

5.2 Pre-Installation Guidelines................................................................5-3

5.3 Installation Instructions .....................................................................5-4

6.0 Operation ......................................................................................... 6-1

6.1 Initial Start-Up ...................................................................................6-1

6.2 Operation ..........................................................................................6-4

6.3 Shutdown..........................................................................................6-5

6.4 Normal Start-Up................................................................................6-5

6.5 Start-Up after an Extended Shutdown ..............................................6-5

CENTROX Instruction Manual i

AirSep® Corporation

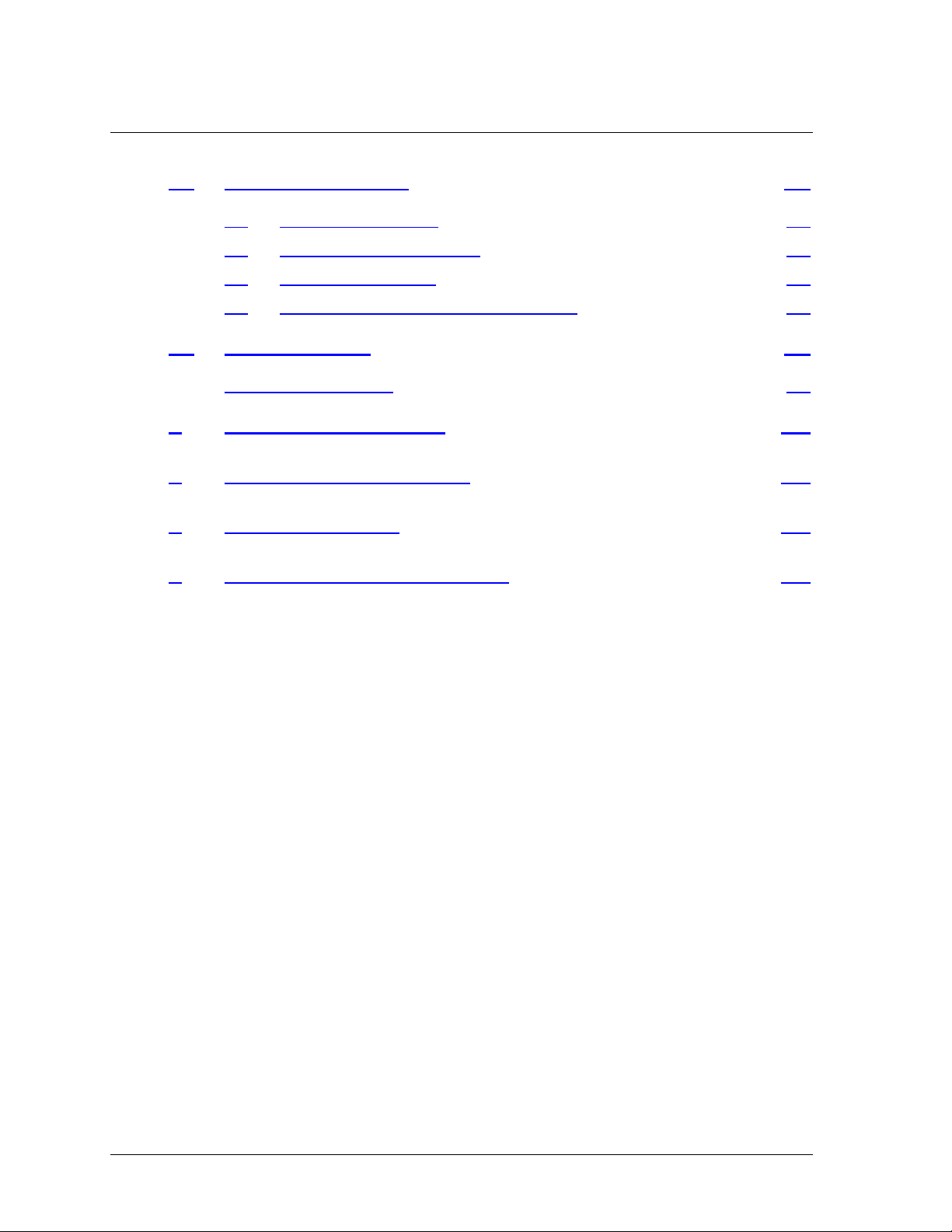

7.0 Maintenance/Service .......................................................................7-1

7.1 Weekly Maintenance ........................................................................7-2

7.2 Semi-Annual Maintenance................................................................ 7-2

7.3 Annual Maintenance......................................................................... 7-4

7.4 Pressure Switch Adjustment Procedure ........................................... 7-5

8.0 Troubleshooting ..............................................................................8-1

Troubleshooting Chart.................................................................................. 8-2

A Appendix Technical Data ............................................................... A-1

B Appendix Warranty/Returns .......................................................... B-1

C Appendix Parts List ........................................................................ C-1

D Appendix Component Literature ................................................... D-1

ii CENTROX Instruction Manual

AirSep® Corporation

Figure 3.1: CENTROX Oxygen Concentrator ........................................... 3-1

Figure 4.1: Compressor Enclosure........................................................... 4-1

Figure 4.2: PSA Enclosure Controls and Indicators .............................. 4-2

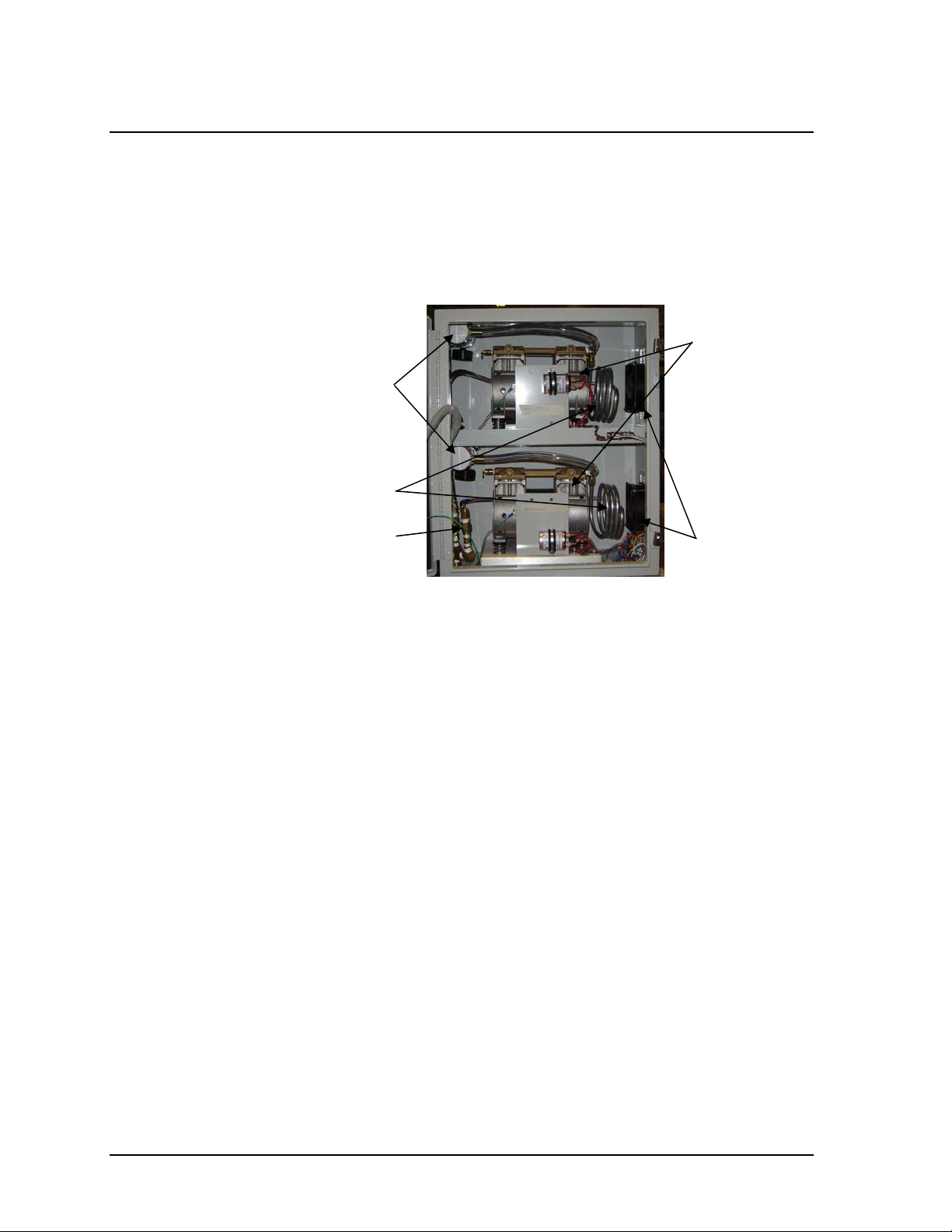

Figure 4.3: Compressor Enclosure Internal Components ...................... 4-4

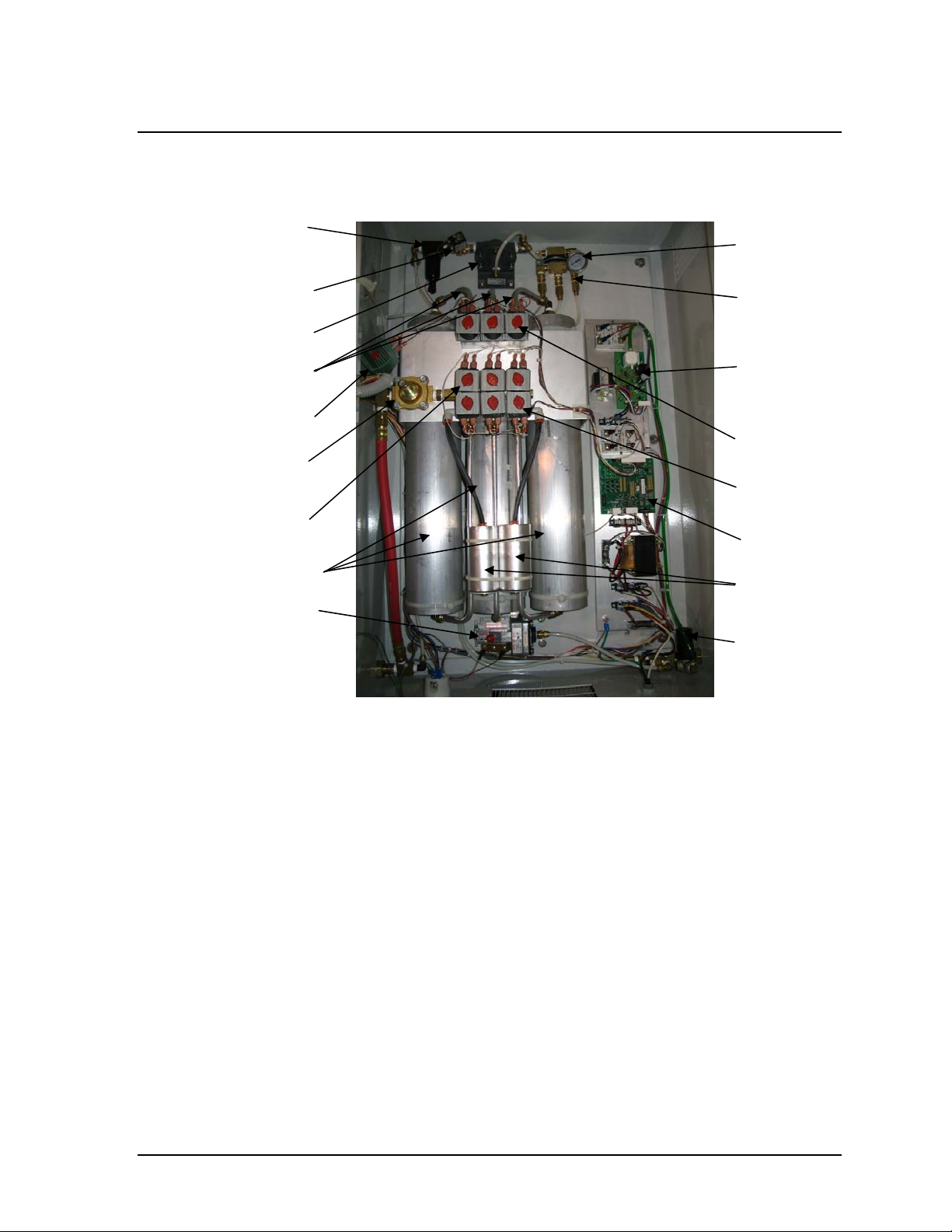

Figure 4.4: PSA Enclosure Internal Components.................................... 4-5

Figure 4.5: Oxygen Receiver ..................................................................... 4-9

Figure 5.1: General Arrangement of the CENTROX concentrator ......... 5-5

Figure 6.1: PSA Enclosure Supply Valve Assembly ............................... 6-4

List of Illustrations

Figure 7.1: Pressure Switch ...................................................................... 7-6

Figure A.1: Flow Schematic ..................................................................... A-5

Figure A.2: Wiring Schematic (120 V, 60 Hz) – PSA Enclosure............. A-6

Figure A.3: Wiring Schematic (220 V, 50 Hz) – PSA Enclosure............. A-7

Figure A.4: Wiring Schematic (120 V, 60 Hz) – Compressor Encl......... A-8

Figure A.5: Wiring Schematic (220 V, 50 Hz) – Compressor Encl......... A-9

CENTROX Instruction Manual iii

AirSep® Corporation

1.0 Introduction

1.1 General

This instruction manual provides a description of the AirSep CENTROX

Pressure Swing Adsorption (PSA) Oxygen Concentrator as well as

instructions for its installation, operation, and maintenance. Pertinent

drawings and component information are also included.

To ensure safe operation and proper system maintenance, AirSep

Corporation recommends that you keep this instruction manual readily

available for reference.

1.2 Warnings, Cautions, and Notes

As you read the instruction manual, pay special attention to the Warning,

Caution, and Note messages. They identify safety guidelines or other

important information as follows:

Provides information that can prevent severe bodily

injury or death.

Provides information that can prevent minor bodily

injury or property damage.

Provides information important enough to emphasize

or repeat.

1.3 References to Controls and Indicators with Labels

This operating manual uses uppercase characters (e.g., ON/OFF switch)

to refer to controls and indicators. Refer to section 4 for a description of

all the controls and indicators of the oxygen concentrator.

CENTROX Instruction Manual 1-1

AirSep® Corporation

yg

2.0 Safety

2.1 General

Oxygen, the most abundant of the elements, makes up about 50 percent

of the earth's crust. In its free state, it forms about one-fifth of our air by

volume. Although oxygen is classified as a non-flammable gas, it

supports combustion. As an active element, it combines directly or

indirectly with all elements except the rare gases. It is an invisible gas that

is colorless, odorless, and tasteless.

To ensure your safety, thoroughly read and familiarize yourself with this

Safety section. AirSep Corporation strongly recommends that you review

this section periodically.

2.2 Potential Hazards

Before you attempt to install, operate, or repair the CENTROX Oxygen

Concentrator, read and thoroughly understand this instruction manual.

Improper operation can result in severe bodily injury, damage to the

system, or poor performance.

It is recommended to have an alternate source of

oxygen supply if a power failure or equipment

malfunction occurs.

Take extreme care to keep all the oxygen piping and

vessel clean. To avoid a fire or an explosion, oxygen

clean all surfaces that can come in contact with oxygen.

Check all oxygen fittings/joints for leaks with an

ox

en-compatible leak-detecting solution.

CENTROX Instruction Manual 2-1

AirSep® Corporation

Oxygen vigorously accelerates the burning of

combustible materials. In an oxygen-enriched

atmosphere, many materials that do not burn in

normal air require only a slight spark or moderate

heat to set them aflame.

To avoid a fire or an explosion, keep gasoline,

kerosene, oil, grease, cotton fibers, paint, and any

other combustible material away from any part of the

CENTROX Oxygen Concentrator or optional auxiliary

oxygen receiver.

Do not smoke or use an open flame near the oxygen

concentrator or optional auxiliary oxygen receiver.

Post "NO SMOKING OR OPEN FLAMES" signs in

the area where the oxygen concentrator and optional

auxiliary oxygen receiver are located. AirSep

STRONGLY recommends that only individuals trained

and experienced in the safe handling of oxygen

operate this system.

The interior of the CENTROX Oxygen Concentrator

contains electrical parts that can produce an electrical

hazard if not handled properly. To prevent electrical

shock, read and thoroughly understand the

Troubleshooting section of this instruction manual

before you service the system.

Connect the oxygen concentrator power cord to a

properly grounded wall outlet on a circuit that cannot

be accidentally turned off. Do not use extension

cords.

To prevent fire or electrical shock, locate the oxygen

concentrator and the auxiliary oxygen receiver (if

supplied) indoors away from rain or any other type of

moisture.

2-2 CENTROX Instruction Manual

AirSep® Corporation

2.3 Safety Publications

Disconnect power before servicing oxygen generator.

This section is not a complete summary of required safety procedures.

Review the following publications for additional information on the safe

handling of oxygen:

"Installation of Bulk Oxygen Systems at Consumer Sites;" NFPA

No. 50; National Fire Protection Association; 1 Batterymarch

Park; P. O. Box 9101; Quincy, Massachusetts 02269-9101 USA.

"Oxygen;" Pamphlet G-4; Compressed Gas Association; 1725

Jefferson Davis Highway; Arlington, Virginia 22202-4102 USA.

"Cleaning Equipment For Oxygen Service," Pamphlet G-4.1;

Compressed Gas Association; 1725 Jefferson Davis Highway;

Arlington, Virginia 22202-4102 USA.

CENTROX Instruction Manual 2-3

AirSep® Corporation

3.0 System Description

3.1 Introduction

Air Contains 21 % oxygen, 78% nitrogen, 0.9% argon, and 0.1% other

gases. AirSep Oxygen Concentrator separates this small percentage of

the oxygen from the compressed air through a unique Pressure Swing

Adsorption (PSA) process.

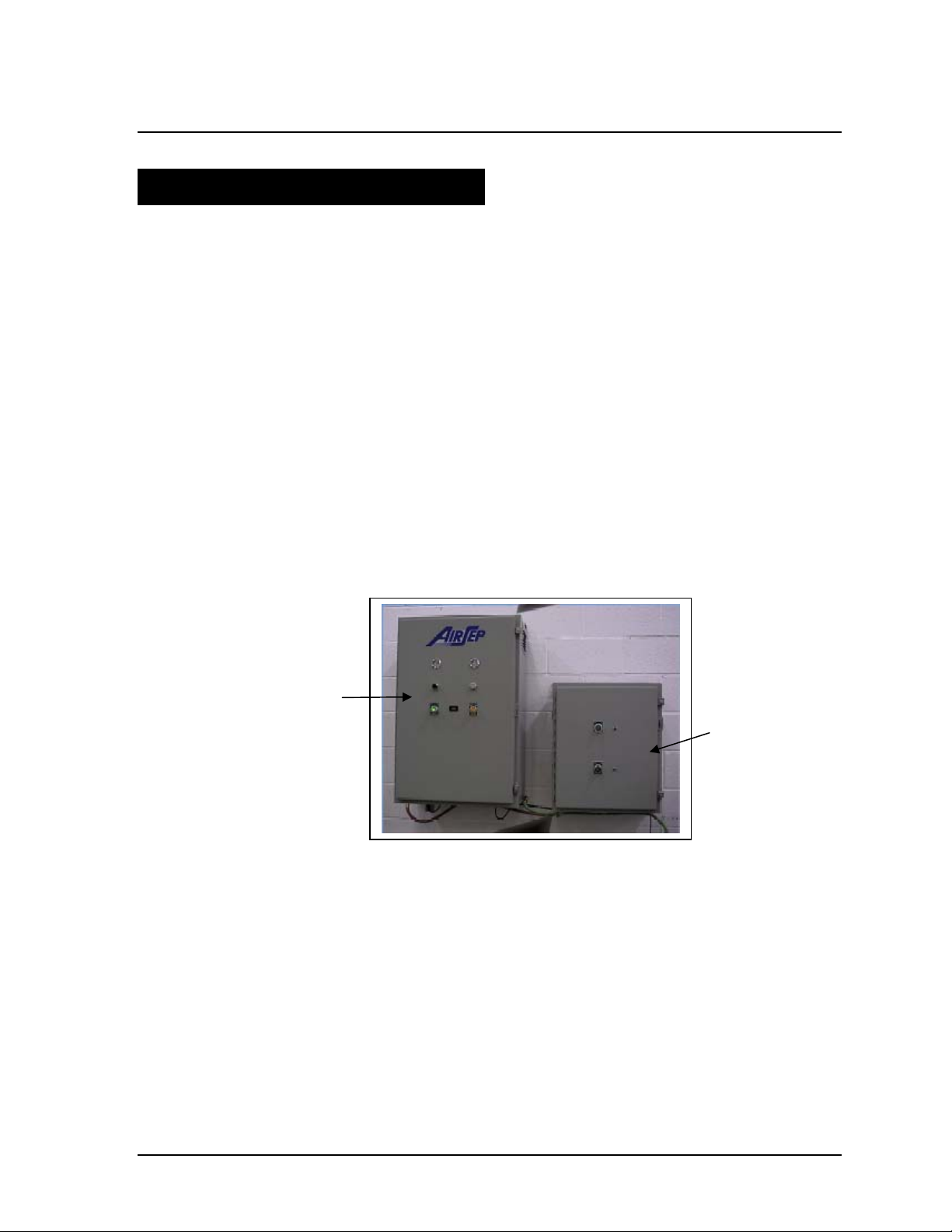

The CENTROX unit consists of two enclosures. The smaller enclosure

contains two compressors that supply air for the process. Each

compressor has a dedicated switch and circuit breaker. The cord from the

enclosure plugs into the PSA enclosure. This cord must not be plugged

into any other power supply outlet. Circuitry inside the PSA enclosure

controls the power supplied to the compressors. The power cord from the

PSA enclosure plugs into the wall. Figure 3.1 shows the two enclosures

of the CENTROX oxygen concentrator.

PSA Enclosure

The compressor enclosure (See Figure 3.1) supplies pressurized air to

the PSA enclosure (See Figure 3.1). Inside the PSA enclosure, the

pressurized air enters the feed & waste manifold (See Figure 4.4). A

series of valves in the feed & waste manifold controls the flow of air into

each of the adsorber beds (See Figure 4.4). Valves also connect the beds

to two mufflers (See Figure 4.4) that allow waste gas to be vented from

the beds. The oxygen concentrator uses in its adsorber vessels an inert

ceramic material called molecular sieve to separate compressed air into

the oxygen and the other gases. The unique properties of molecular sieve

allow it to attract, or adsorb, nitrogen physically from air under pressure.

Compressor

Figure 3.1: CENTROX Oxygen Concentrator

CENTROX Instruction Manual 3-1

AirSep® Corporation

This allows oxygen to exit the adsorbers as a product gas. Oxygen from

top of the beds then flows to the check valve assembly and then to the

product manifold (See Figure 4.4). The check valve assembly supplies

product oxygen to the flow controller. The product manifold controls the

flow of oxygen from one bed to another during various stages of the

oxygen generating process. The product oxygen then flows through the

product valve to the customer’s application. An oxygen analyzer

continuously monitors the purity of oxygen and provides an alarm in case

of low purity.

The entire oxygen generating process is completely regenerative, which

makes it both reliable and virtually maintenance-free. The molecular sieve

does not normally require replacement.

This instruction manual serves as the guidelines for CENTROX oxygen

concentrator. Refer to the illustrations, located in the Appendix A of this

instruction manual, for the detailed flow diagram and electrical schematic

of the oxygen concentrator referenced in this instruction manual.

3-2 CENTROX Instruction Manual

AirSep® Corporation

4.0 Controls, Parts, and Connections

4.1 Introduction

The section describes the various parts, controls, indicators and

connections required for the CENTROX oxygen concentrator.

4.2 Oxygen Concentrator Controls and Indicators

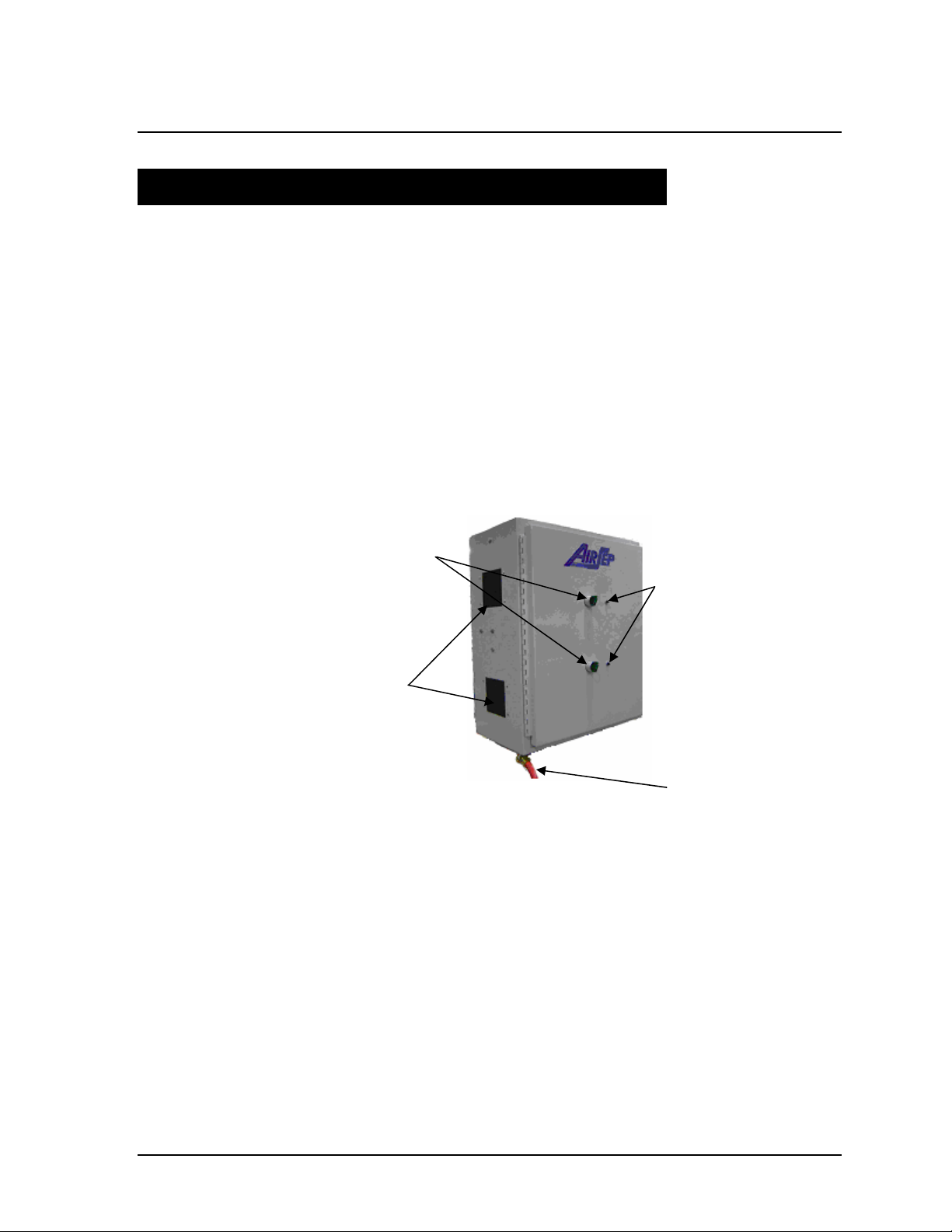

4.2.1 Compressor Enclosure

Figure 4.1 shows the compressor enclosure along with all the controls

and indicators.

On/Off

Circuit Breaker

Air Intake

Hose for

Compressed Air to

PSA Enclosure

Figure 4.1: Compressor Enclosure

ON/OFF (Power) Switch

The individual ON/OFF switches (green color) on the compressor

enclosure starts and stops the operation of the oxygen compressors.

When you supply power to the system, the green indicator light of the

switches turns on. It remains lit whether the switch is in the ON or

OFF position (See Figure 4.1).

Circuit Breaker Reset Buttons

The individual circuit breaker reset buttons on the compressor

enclosure are used to reset the compressors after an electrical

overload shutdown (See Figure 4.1).

CENTROX Instruction Manual 4-1

AirSep® Corporation

g

(

)

Air Intake Filters

Located on the left side panel, the air intake filter removes any foreign

particles from the air that enters the compressor enclosure (See

Figure 4.1).

Fuses/Circuit Breakers, if required, must be replaced

with the same type and amp rating as the original.

4.2.2 PSA Enclosure

Figure 4.2 shows the controls and indicators of the PSA enclosure.

Feed Air

Pressure Gauge

Low Purity

ht

Li

Hour Meter

Product

Pressure Gauge

Low Purity

Alarm

On/Off

Power

Figure 4.2: PSA Enclosure Controls and Indicators

Auto/Manual

Switch

ON/OFF (Power) Switch

The ON/OFF switch starts and stops the operation of the oxygen

concentrator. When you supply power to the system, the switch's

green indicator light turns on. It remains lit whether the switch is in the

ON or OFF position (See Figure 4.2).

AUTO/MANUAL Switch

The AUTO/MANUAL switch includes an yellow indicator light. In the

AUTO position, the concentrator cycles on and off to meet oxygen

demand. In the MANUAL position, the concentrator cycles

continuously. The concentrator produces oxygen only while the yellow

light is lit (See Figure 4.2).

Hour Meter

The hour meter indicates the total number of hours the concentrator

has cycled (See Figure 4.2).

4-2 CENTROX Instruction Manual

AirSep® Corporation

Low Purity Light

The unit is equipped with an oxygen sensor. If the purity supplied to

the tank is below 85 % (r 3%), the red light on the PSA enclosure will

be on (See Figure 4.2).

Low Purity Alarm

If the purity is below 85 % (r 3%) for more than 30 minutes, an

audible alarm will sound (See Figure 4.2).

The low oxygen purity alarm will sound for 4

seconds when the unit is turned on.

FEED AIR PRESSURE Gauge

The FEED AIR PRESSURE gauge indicates the pressure of the feed

air before it enters the PSA enclosure (See Figure 4.2).

PRODUCT PRESSURE Gauge

The PRODUCT PRESSURE gauge indicates the pressure of oxygen

coming out of the adsorber beds (See Figure 4.2).

CENTROX Instruction Manual 4-3

4.3 Oxygen Concentrator Parts

Figure 4.3 and Figure 4.4 shows the internal components of the CENTOX

oxygen concentrator

4.3.1 Compressor Enclosure

Resonators

Heat Exchanger

AirSep® Corporation

Compressors

Check Valve

Assembly

Figure 4.3: Compressor Enclosure Internal Components

Cabinet Fans

Compressors

The compressors compress the air entering the enclosure before it is

supplied to the PSA enclosure (See Figure 4.3).

Cabinet Fans

The cabinet fans provide internal cooling for the air compressor. Fans

also help in better circulation of the air inside the compressor

enclosure (See Figure 4.3).

Compressor Intake Filter

This filter provides additional filtration for the air as it enters the air

compressor. This filter is attached to the gray PVC pipe. The

complete assembly of the PVC pipe and the filter is called resonator

(See Figure 4.3).

Heat Exchanger

The heat exchanger coils cool the compressed air leaving the

compressor enclosure (See Figure 4.3).

Check Valve Assembly

Check Valve assembly prohibits the back flow of compressed air.

4-4 CENTROX Instruction Manual

AirSep® Corporation

r

r

4.3.2 PSA Enclosure

Coalescing Filte

Product Valve

Flow Controlle

Product

Feed Air

Dump Valve

Check Valve

Feed Valves

Adsorber Beds

Pressure Switch

Product

Pressure Gauge

Check Valve

Assembly

Oxygen

Monitor

Board

Equalization

Waste Valves

Main Circuit

Exhaust

Mufflers

Oxygen

Sample

Regulator

Figure 4.4: PSA Enclosure Internal Components

Adsorber Beds

The adsorbers contain the molecular sieve that adsorbs (attracts)

nitrogen from compressed air and allows oxygen to pass through as

product gas (See Figure 4.4).

Main Circuit Board

Main circuit board provides signal to all the valves based on the status

of the oxygen generator.

Feed Air Dump Valve

The solenoid-operated valve is used to dump the compressed feed air

for 3-5 sec at the initial start-up and 1 sec at the start of standby

mode. This removes any pressure that builds up inside the

compressor to ensure easy start-up.

Check Valve

Check Valve assembly prohibits the back flow of compressed air.

CENTROX Instruction Manual 4-5

AirSep® Corporation

Feed Valves

The automatic feed air valves control the flow of the feed air as the air

enters the adsorbers (See Figure 4.4).

Waste Valves

The automatic waste valves control the flow of waste gas as it exits

the adsorbers (See Figure 4.4).

Exhaust Mufflers

The mufflers muffle the noise produced by the waste gas that vents

through the beds (See Figure 4.4).

Product Manifold

Product manifold facilitates the oxygen flow across adsorber beds

(from top of the adsorber beds) and to the product delivery line.

Equalization Valves

The equalization valves on the product manifold controls the flow of

oxygen from one bed to another during various steps of the oxygen

generation process (See Figure 4.4).

Check Valves Assembly

The check valve assembly supplies the product oxygen to the flow

controller. See Figure 4.4.

Product Pressure Gauge

Product pressure gauge mounted on the check valve assembly (See

Figure 4.4) displays the pressure of the product oxygen.

Flow Controller

The flow controller regulates the flow of oxygen (See Figure 4.4).

Product Valve

The valve prevents the supply of oxygen when the unit is in standby

mode (Refer to section 6 for the description of different types of

mode). See Figure 4.4 for the location of the product valve.

Coalescing Filter

The coalescing filter serves as bacteria filter and removes any

bacteria present in the oxygen supply (See Figure 4.4).

Oxygen Monitor Board

The oxygen sensor monitors the purity supplied from the PSA

enclosure. If the oxygen purity decreases below the set point, low

purity light on the PSA enclosure will be on. If the problem persists for

more than 30 minutes, a low purity alarm will sound.

4-6 CENTROX Instruction Manual

AirSep® Corporation

Oxygen Sample Regulator

A regulator before the oxygen monitor board regulates the pressure to

4-5 psig to the oxygen monitor board. Refer to the section 7 for the

regulator adjustment.

Pressure Switch

When the oxygen concentrator operates in Auto mode, the pressure

switch monitors the oxygen pressure at the outlet of the oxygen

concentrator. When the pressure at the oxygen concentrator outlet

increases to the pressure switch upper setpoint, the pressure switch

circuit closes and the oxygen concentrator starts a timed shutdown

that stops the unit at the end of the shutdown sequence (After 10

additional cycles). When the pressure at the oxygen concentrator

outlet decreases to the lower setpoint of the switch, the pressure

switch opens to activate the oxygen concentrator and the oxygen

production begins. When the oxygen concentrator operates in Manual

mode, the pressure switch circuit remains open and the oxygen

concentrator cycles continuously. Refer to the appendix A of the

manual for lower and upper setpoint settings of the pressure switch.

CENTROX Instruction Manual 4-7

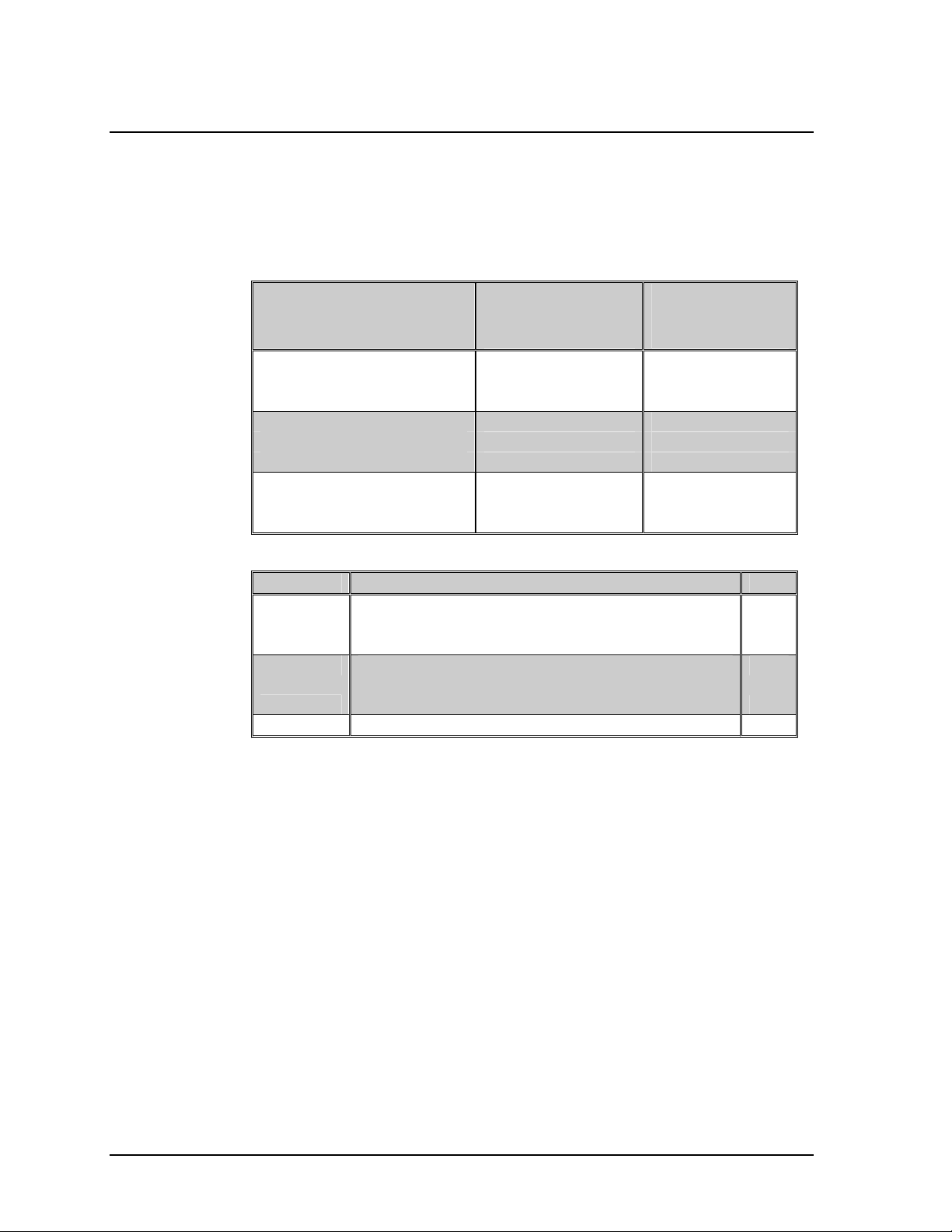

4.4 Auxiliary Kits Information (Optional)

The items discussed in this section are supplied as ordered. Listed below

are the different starter kits available as per the oxygen concentrator

ordered.

AirSep® Corporation

Unit # Kit #

(Customer

Supplied Tank)

AS074-1 120 VAC/60 Hz

AS074-2 220 VAC/50 Hz

AS074-3 220 VAC/60 Hz

KI046-1 KI046-1

TA150-1

Table 4.1: Optional Starter Kits for the Concentrator Purchased

Kit # Description

KI046-1

Primary/Secondary Ball Valve Assembly 1

Hose Assembly, Oxygen-clean, (Secondary

Hose) 1

KI470-1

Regulator-Flowmeter Assembly 1

Hose Assembly, Oxygen-clean (Main Oxygen

Outlet Hose) 1

TA150-1

60 Gallon Tank Assembly, O

Table 4.2: Description of the Parts included in the Starter Kits

KI470-1 KI470-1

KI046-1 KI046-1

KI470-1 KI470-1

KI046-1 KI046-1

KI470-1 KI470-1

Kit #

(AirSep

Supplied Tank)

TA150-1

TA150-1

Qty.

Cleaned 1

2

Please contact AirSep Corporation Sales representative for ordering the

starter kits. Below is a brief description of item included in the starter kits.

Primary Oxygen Ball Valve

The primary oxygen ball valve controls the flow of oxygen from the

oxygen concentrator to your oxygen distribution system. See Figure 5.1.

Secondary Oxygen Ball Valve

The secondary oxygen ball valve controls the flow of a backup source of

oxygen to your oxygen distribution system. This ball valve should always

be closed unless a backup source is connected to it. See Figure 5.1.

Regulator-Flowmeter Assembly

This assembly consists of a pressure regulator and a flowmeter. The

pressure regulator attaches to the outlet port of the oxygen receiver to

regulate the pressure of the oxygen. The flowmeter is used to regulate

4-8 CENTROX Instruction Manual

AirSep® Corporation

the flow of the oxygen at the outlet of the oxygen receiver. Refer to figure

5.1 for the installation location of this assembly.

Oxygen Isolation Ball Valve Assembly

The oxygen isolation ball valve stops the flow of oxygen to the oxygen

receiver during troubleshooting. The oxygen relief valve in the assembly

prevents excess pressure from building in the oxygen receiver if a system

malfunction occurs. This assembly is shipped mounted on the oxygen

receiver. See Figure 4.5.

Main Oxygen Hose

An oxygen-clean hose is provided that connects the outlet of the supply

valve assembly (Refer to section 4.5) on the oxygen concentrator to the

oxygen isolation ball valve assembly on the oxygen receiver.

Secondary Oxygen Hose

Secondary hose is provided to connect the outlet of the regulatorflowmeter assembly to the inlet of the primary oxygen ball valve. Refer to

Figure 5.1.

Oxygen Receiver

The oxygen receiver stores oxygen produced by the oxygen concentrator.

It also provides stable flow and purity for short-term surges of oxygen that

exceed the rated capacity of the oxygen concentrator.

Oxygen Outlet

Port

Oxygen

Receiver

Main Oxygen

Oxygen Isolation Ball

Valve Assembly

Hose

Figure 4.5: Oxygen Receiver

CENTROX Instruction Manual 4-9

4.5 Connections

Supply Valve Assembly

This assembly is shipped loose and must be connected to the PSA

enclosure oxygen outlet. The supply valve assembly limits the amount of

flow to the oxygen receiver during purge. Refer to Figure 5.1 and 6.1.

Power Cord

This power cord and its grounded electrical plug supply power to the

CENTROX when connected to a grounded electrical outlet.

AirSep® Corporation

4-10 CENTROX Instruction Manual

AirSep® Corporation

5.0 Installation

5.1 Unpacking

AirSep Corporation ships CENTROX Oxygen Concentrators on a wooden

skid covered with corrugated cardboard. This container includes an

accessory kit with an instruction manual and all the items necessary to

properly install the oxygen concentrator. The oxygen receiver (if supplied)

is shipped separately. Contact your AirSep Corporation’s Sales

representative for ordering the auxiliary kits supplied with the CENTROX

oxygen concentrator.

AirSep recommends that you follow these unpacking guidelines carefully

to protect yourself against loss from any damage caused during

shipment.

1. Inspect the exterior for damage. If you observe any damage, note it

on the freight bill or the express receipt before you sign it.

Failure to note exterior damage on the freight bill or

the express receipt at the time of delivery can result in

the carrier's refusal of a damage claim.

2. Carefully cut and remove any banding straps from the container. Then

remove the corrugated cardboard.

Remove the corrugated cardboard very carefully. You

may need to return the oxygen concentrator if it was

damaged during shipment

3. Remove the oxygen concentrator from the wooden skid.

4. Thoroughly inspect the oxygen concentrator interior and exterior for

damage caused during shipment. Pay special attention to the cabinet

switches, gauges, brackets, etc.

5. Remove the accessory kit and inspect the contents for damage.

6. Although the CENTROX is carefully inspected, tested, and packed, it

can be damaged during shipment due to improper handling. If you find

any concealed damage (loss or damage not found until the

CENTROX Instruction Manual 5-1

AirSep® Corporation

concentrator is unpacked), immediately call the delivery carrier and

file a concealed-damage claim. Keep ALL container material and

interior packing for the carrier's inspection.

YOU MUST MAKE A CONCEALED-DAMAGE CLAIM

WITHIN 24 HOURS OF DELIVERY. Only the

consignee can file this claim.

Follow these unpacking guidelines carefully to protect

yourself against loss from any damage caused during

shipment.

5-2 CENTROX Instruction Manual

AirSep® Corporation

5.2 Pre-Installation Guidelines

Before you install the CENTROX oxygen concentrator, and the oxygen

receiver, if supplied, refer to the Specifications section in the Appendix of

this instruction manual to determine the applicable space, and the power

requirements for your particular model.

A backup source of oxygen must be available if a

power failure or system malfunction occurs.

Make sure the area that surrounds the oxygen

concentrator is well ventilated, and provide sufficient

space around the unit [at least three feet] to allow for

cool air flow as well as to allow safe operation and

maintenance.

Locate the oxygen concentrator in an area where the

ambient air temperature remains between 4

and 44

under the AirSep Corporation Product Warranty.

Connect the oxygen concentrator power cord only to

a properly grounded electrical outlet on a circuit that

cannot be accidentally turned off. Do not use

extension cords.

Provide proper voltage to the oxygen concentrator to

prevent damage not covered under the AirSep

Product Warranty.

Do not plug in the power cord until you complete the

installation of the oxygen concentrator.

qC (112qF) to prevent damage not covered

qC (40qF)

CENTROX Instruction Manual 5-3

p

5.3 Installation Instructions

To assure proper installation and safe operation of your CENTROX PSA

Oxygen Concentrator, AirSep Corporation recommends that you review

this entire section before you attempt to install the unit.

Do not turn off power to any component unless you

are sure the medical facility does not require any

oxygen, or there is a sufficient alternative/backup

source of oxygen.

Before you attempt to install, operate, or repair the

oxygen concentrator, read and thoroughly understand

this instruction manual. Improper operation can result

in severe bodily injury, damage to the system, or poor

erformance.

AirSep® Corporation

Refer to the Figure 5.1 as you follow the installation instructions:

1. Place the oxygen concentrator near the inlet of your oxygen

distribution system.

2. Mount both the enclosures securely to a wall, ensuring that there is a

minimum of two feet between the two enclosures and minimum of

three feet between the compressor enclosure and a wall. The

compressor enclosure can be on either side of the PSA enclosure.

3. Open the compressor enclosure and remove the tie wrap from each

compressor. The tie wrap holds the compressor to a bracket support

for shipping purpose.

4. Attach the red air hose from the compressor enclosure to the fitting on

the left hand side of the PSA enclosure (See Figure 4.5 and 5.1).

The supply valve assembly at the outlet of the oxygen

concentrator has a small hole drilled in it and allows a

controlled amount of flow during purging process (See

Section 6) of the 60 gallon tank (If supplied).

5. Mount the supply valve assembly (shipped loose) at the outlet of the

PSA enclosure. Refer to Figure 5.1 and 6.1.

6. Attach the main oxygen hose from the supply valve to the inlet of the

oxygen isolation ball valve assembly at the oxygen tank (See Figure

4.5 and 5.1).

5-4 CENTROX Instruction Manual

Loading...

Loading...