Page 1

AirSep® Corporation

PSA Oxygen Generator

Models AS-20–1000

Instruction Manual

MN011-1 A12/02

Suggested List Price $75.00 (U.S.D.)

AirSep® Corporation • 260 Creekside Drive • Buffalo, NY 14228-2075 USA

Phone: (716) 691-0202 • Fax: (716) 691-1255

Page 2

Page 3

Ownership Data

Please take a moment to note below important information about your AirSep® Corporation

PSA Oxygen Generator. Retain this instruction manual, along with your invoice, to serve as

a permanent record of your purchase.

PSA Oxygen Generator

Model Number:

Serial Number:

Invoice Date:

Start-up Date:

AirSep Representative

Company:

Contact:

Address:

City/Town: State: Zip:

Country: Fax:

Phone: Telex:

Before you attempt to install, operate, or repair the oxygen generator,

read and thoroughly understand this instruction manual. Improper

operation can result in severe bodily injury, damage to the oxygen

generator, or poor performance.

Page 4

Page 5

AirSep® Corporation 12/02

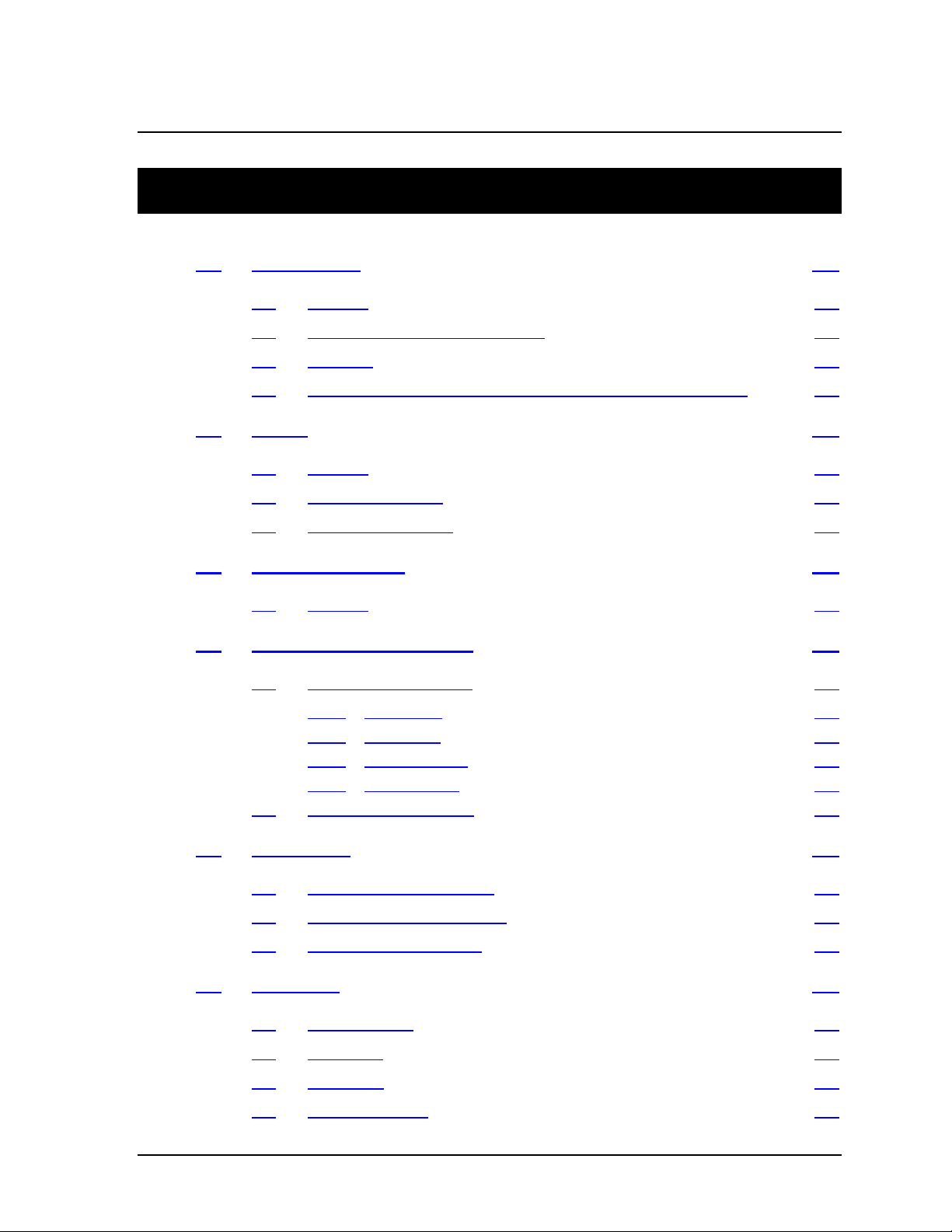

Table of Contents

1.0 Introduction ..................................................................................... 1-1

1.1 General .............................................................................................1-1

1.2 Warnings, Cautions, and Notes ........................................................1-1

1.3 Symbols ............................................................................................1-2

1.4 References to Controls and Indicators with Tags or Labels ............. 1-2

2.0

Safety................................................................................................ 2-1

2.1 General .............................................................................................2-1

2.2 Potential Hazards .............................................................................2-1

2.3 Safety Publications ...........................................................................2-3

3.0

Plant Description............................................................................. 3-1

3.1 General .............................................................................................3-1

4.0

Component Descriptions................................................................ 4-1

4.1 External Components ....................................................................... 4-1

4.1.1 Adsorbers 4-2

4.1.2 Enclosure 4-2

4.1.3 Control Panel 4-2

4.1.4 Connections 4-3

4.2 Manifold Components.......................................................................4-4

5.0

Installation ....................................................................................... 5-1

5.1 Handling and Unpacking...................................................................5-1

5.2 Pre-installation Guidelines ................................................................5-2

5.3 Installation Instructions .....................................................................5-3

6.0

Operation ......................................................................................... 6-1

6.1 Initial Start-up....................................................................................6-1

6.2 Operation ..........................................................................................6-3

6.3 Shutdown..........................................................................................6-3

6.4 Normal Start-up ................................................................................6-4

AS-20—1000 Instruction Manual table of contents - i

Page 6

04/02 AirSep® Corporation

6.5 Extended Shutdown..........................................................................6-4

6.6 Start-up after an Extended Shutdown............................................... 6-4

7.0

Maintenance..................................................................................... 7-1

7.1 Daily Monitoring ................................................................................7-1

7.2 Monthly Monitoring ...........................................................................7-1

7.3 Removing the Front Cover of the Enclosure (Not available on AS-450

— AS-1000 models) .....................................................................................7-2

7.4 Depressurizing the Filters .................................................................7-3

7.5 Changing Filter Elements .................................................................7-4

7.6 Depressurizing the Oxygen Generator ............................................. 7-5

7.7 Adjusting the Feed Air Regulator......................................................7-6

7.8 Adjusting the Pressure Switch ..........................................................7-6

8.0

Troubleshooting .............................................................................. 8-1

A

Appendix Technical Data............................................................... A-1

Specifications .............................................................................................. A-1

Operating Data ............................................................................................ A-9

Drawings.................................................................................................... A-10

Appendix Warranty/Returns .......................................................... B-1

B

Product Warranty......................................................................................... B-1

Limits of Liability .......................................................................................... B-2

Returning the Oxygen Generator or a Component for Service ................... B-2

C

Appendix Parts List........................................................................ C-1

AS-20 Parts ................................................................................................. C-2

AS-45 Parts ................................................................................................. C-3

AS-80 Parts ................................................................................................. C-4

AS-160 Parts ............................................................................................... C-5

AS-250 Parts ............................................................................................... C-6

AS-450 Parts ............................................................................................... C-7

AS-750 Parts ............................................................................................... C-8

AS-1000 Parts ............................................................................................. C-9

table of contents - ii AS-20—1000 Instruction Manual

Page 7

AirSep® Corporation 12/02

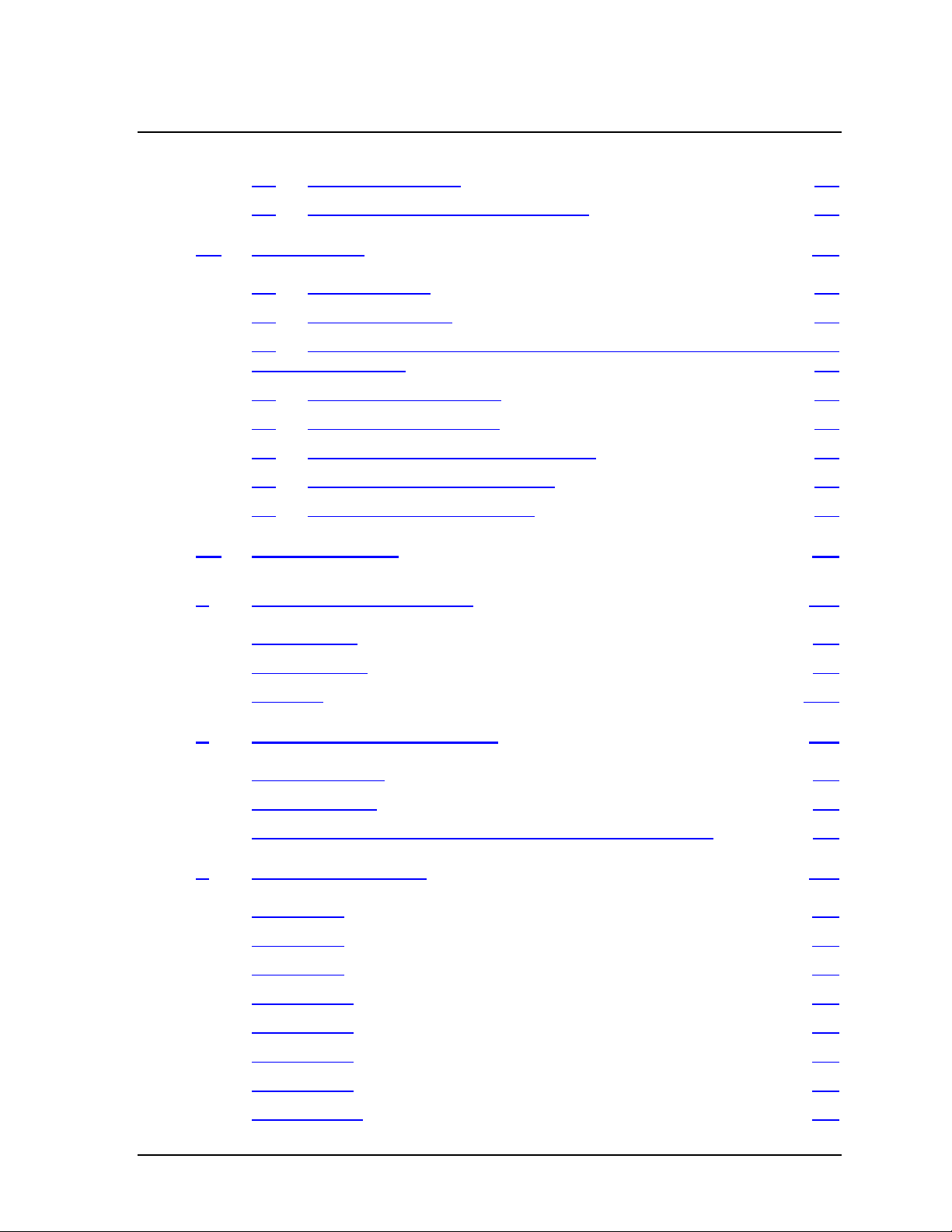

List of Illustrations

Figure 4-1 External Components — Front View ...................................... 4-1

Figure 4-2 Control Panel — AS-45 and AS-80 Models

Figure 4-3 Manifold Components — AS-160 and AS-250 Models

Figure 4-4 Manifold Components — AS-750 Model

Figure 5-1 Typical Installation Arrangement............................................ 5-3

Figure 5-2 120 Gallon Oxygen Receiver

Figure 7-1 Interior View of AS-45 and AS-80 Models

Figure 1 General Arrangement Drawing – AS-20

Figure 2 Flow Schematic – AS-20

Figure 3 Electrical Schematic – AS-20 (120V)

Figure 4 Electrical Schematic – AS-20 (220V)

Figure 5 General Arrangement Drawing – AS-45

Figure 6 General Arrangement Drawing – AS-80

......................................................... A-12

................................................... 5-5

...................................... A-13

...................................... A-13

............................ 4-3

.......... 4-4

................................ 4-5

............................. 7-3

................................ A-11

................................ A-14

................................ A-15

Figure 7 General Arrangement Drawing – AS-160

Figure 8 General Arrangement Drawing – AS-250 .............................. A-17

Figure 9 Flow Diagram – AS-45 through AS-250

Figure 10 Electrical Diagram – AS-45 through AS-250 (120V)

Figure 11 Electrical Diagram – AS-45 through AS-250 (220V)

Figure 12 General Arrangement Drawing – AS-450

Figure 13 General Arrangement Drawing – AS-750 ............................ A-21

Figure 14 Flow Diagram – AS-450 through AS-750

Figure 15 Electrical Schematic – AS-450 through AS-750 (120V) ...... A-23

AS-20—1000 Instruction Manual list of illustrations - i

.............................. A-16

................................. A-18

............ A-19

............ A-19

............................ A-20

............................. A-22

Page 8

04/02 AirSep® Corporation

Figure 16 Electrical Schematic – AS-450 through AS-750 (220V) ...... A-23

Figure 17 General Arrangement Drawing– AS-1000

Figure 18 Electrical Schematic – AS-1000 (120V)

Figure 19 Electrical Schematic – AS-1000 (220V)

Figure 20 Flow Diagram – AS-1000

........................................................ A-26

................................. A-25

................................. A-25

............................ A-24

ii - list of illustrations AS-20—1000 Instruction Manual

Page 9

AirSep® Corporation 12/02

1.0 Introduction

1.1 General

This instruction manual provides descriptions of the AirSep Corporation PSA

Oxygen Generator Models AS-20, AS-45, AS-80, AS-160, AS-250, AS-450, AS750, and AS-1000, as well as instructions for their installation, operation, and

maintenance. The Appendix of this instruction manual also includes pertinent

drawings and component literature.

To ensure safe operation and proper maintenance of the oxygen generator, AirSep

Corporation recommends that you keep this instruction manual readily available for

reference.

1.2 Warnings, Cautions, and Notes

As you read this instruction manual, pay special attention to the WARNING,

CAUTION, and NOTE messages. They identify safety guidelines or other important

information as follows:

Provides information that can prevent severe bodily injury or

death.

Cautions against the risk of electric shock.

Provides information important enough to emphasize or repeat.

AS-20—1000 Instruction Manual 1-1

Page 10

12/02 AirSep® Corporation

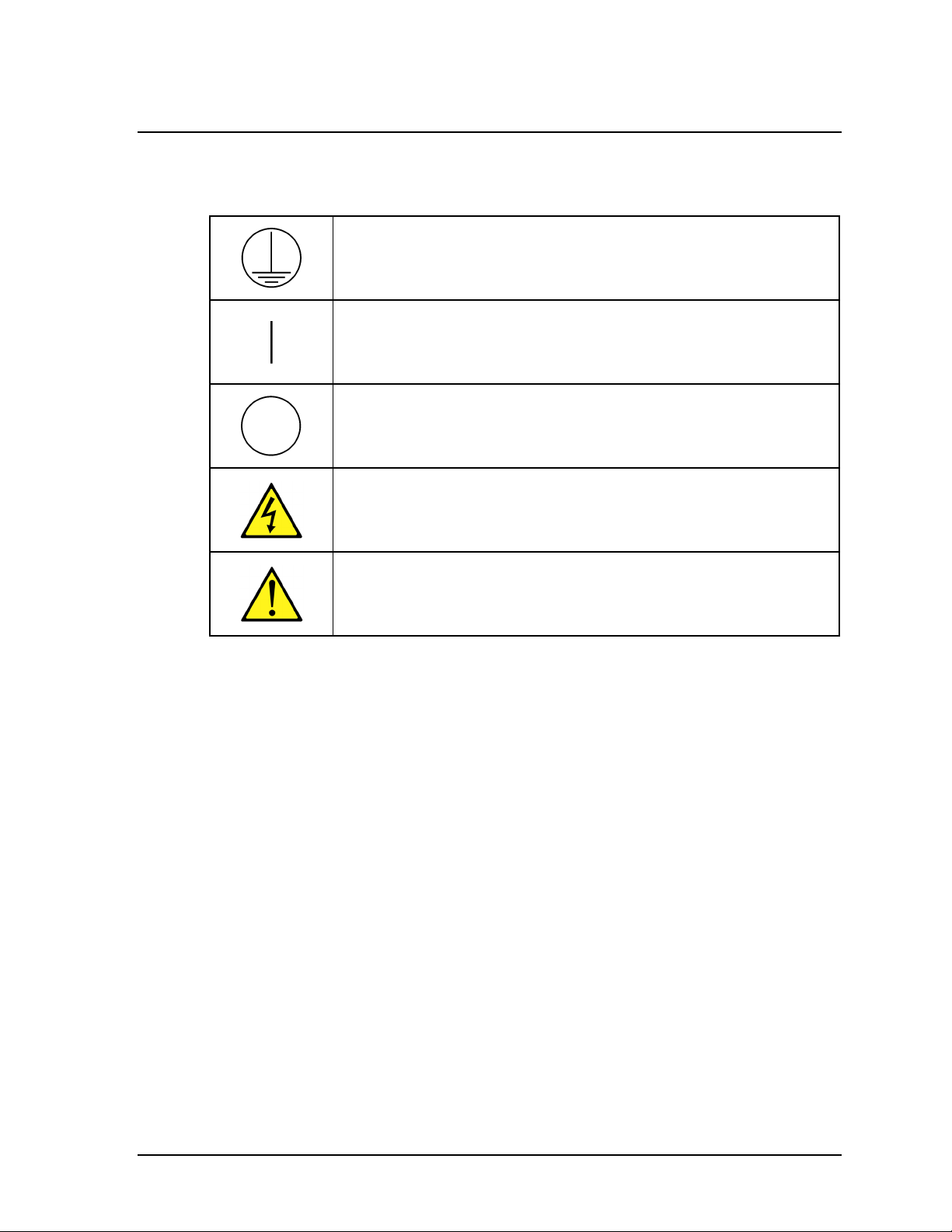

1.3 Symbols

IEC 417, No. 5019 Protective conductor terminal

IEC 417, No. 5007 On (supply)

IEC 417, No. 5008 Off (supply)

ISO 3864, No. B.3.6 Caution, risk of electric shock

ISO 3864, No. B.3.1 Caution (refer to accompanying

documents)

1.4 References to Controls and Indicators with Tags or Labels

This instruction manual uses uppercase characters (e.g., ON/OFF switch) to refer

to controls and indicators identified by tags or labels. Numbers inside parentheses

(e.g., V-2) identify manually operated flow controls (e.g., manual valves). Refer to

Chapter 4 for a description of the oxygen generator components.

1-2 AS-20—1000 Instruction Manual

Page 11

AirSep® Corporation 12/02

2.0 Safety

2.1 General

Oxygen, the most abundant of the elements, makes up approximately 50 percent

of the earth’s crust. In its free state, oxygen forms approximately one-fifth of our air by

volume. Although classified as a non-flammable gas, oxygen supports combustion.

As an active element, it combines directly or indirectly with all elements except the

rare gases. Oxygen is an invisible gas that is colorless, odorless, and tasteless.

To ensure your safety, thoroughly read and familiarize yourself with this entire

section of this instruction manual. In addition, AirSep Corporation strongly

recommends that you review this section periodically.

2.2 Potential Hazards

Oxygen vigorously accelerates the burning of combustible

materials. In an oxygen-enriched atmosphere, many materials

that do not burn in normal air require only a slight spark or

moderate heat to set them aflame.

To reduce the risk of fire or explosion, keep gasoline, kerosene,

oil, grease, cotton fibers, wood, paint, and other combustible

material away from all parts of the oxygen generator.

Do not allow smoking, open flame, or usage of electronic

devices that may generate sparks (e.g., cellular telephones)

within 15 m (50 feet) of any part of the oxygen generator.

Post “NO SMOKING OR OPEN FLAMES” signs conspicuously

near the location of the oxygen generator.

Take extreme care to keep all oxygen piping and vessels clean.

To avoid fire or explosion, oxygen clean all surfaces that can

come in contact with the product oxygen. Check all oxygen fittings

for leaks with an oxygen-compatible, leak-detecting solution.

To prevent fire or electrical shock, locate the oxygen generator

indoors, away from rain or any other type of moisture.

AS-20—1000 Instruction Manual 2-1

Page 12

12/02 AirSep® Corporation

Before you attempt to install, operate, or repair the oxygen

generator, read and thoroughly understand this instruction

manual and the component manuals located in Appendix D of

this instruction manual. Improper installation, operation, or

repairs can result in severe bodily injury, damage to the oxygen

generator, or poor performance.

The interior of the oxygen generator control cabinet contains

electrical parts that can produce an electrical shock hazard if

not handled properly. To prevent electrical shock, read and

thoroughly understand Section 8 — Troubleshooting in this

instruction manual before you service the oxygen generator.

AirSep oxygen generators are sold for use in industrial

applications only. Contact AirSep Corporation or an authorized

AirSep representative before you use this unit for any medical

application.

Disconnect power before servicing oxygen generator.

Do not disconnect protective earth:

2-2 AS-20—1000 Instruction Manual

Page 13

AirSep® Corporation 12/02

2.3 Safety Publications

The safety section of this instruction manual is not a complete summary of

required safety precautions. Review the following publications for additional

information on the safe handling of oxygen:

“Standard for Bulk Oxygen Systems at Consumer Sites;” NFPA No. 50; National

Fire Protection Association; 1 Batterymarch Park; P.O. Box 9101; Quincy,

Massachusetts 02269-9101 USA.

“Oxygen;” Pamphlet G-4; Compressed Gas Association; 1725 Jefferson Davis

Highway; Arlington, Virginia 22202-4102 USA.

“Cleaning Equipment for Oxygen Service;” Pamphlet G-4.1; Compressed Gas

Association; 1725 Jefferson Davis Highway; Arlington, Virginia 22202-4102

USA.

AS-20—1000 Instruction Manual 2-3

Page 14

Page 15

AirSep® Corporation 12/02

3.0 Plant Description

3.1 General

The AirSep Corporation PSA Oxygen Generator is a self-contained unit that utilizes

Pressure Swing Adsorption (PSA) technology to produce oxygen on site. The

oxygen generator uses compressed air as a feed gas to produce oxygen. The

compressed air flows through a filter assembly before the air enters the adsorber

vessels. A particulate filter removes condensed water, oil, dirt, scale, etc. from the

feed air, then in most models, a separate coalescing filter removes additional oil

and water vapor.

The oxygen generator uses in its adsorber vessels an inert ceramic material called

molecular sieve to separate compressed air into oxygen and other gases. The

unique properties of molecular sieve allow it to attract, or adsorb, nitrogen

physically from air under pressure. This allows oxygen to exit the adsorbers as a

product gas. The process valves on the oxygen generator then direct the oxygen to

the oxygen receiver for storage until needed by your application.

While one adsorber produces oxygen, the other depressurizes to exhaust the

waste gases it adsorbed (collected) during the oxygen production cycle. The entire

oxygen generating process is completely regenerative, which makes it both reliable

and virtually maintenance-free. The molecular sieve does not normally require

replacement when maintained and used according to this instruction manual.

Refer to the illustrations, located in Appendix A of this instruction manual, for a

detailed flow diagram, an electrical schematic, and general arrangement drawings

of all oxygen generator models referenced in this instruction manual as well as

typical cycle sequences and operating pressure levels.

AS-20—1000 Instruction Manual 3-1

Page 16

Page 17

AirSep® Corporation 12/02

A

4.0 Component Descriptions

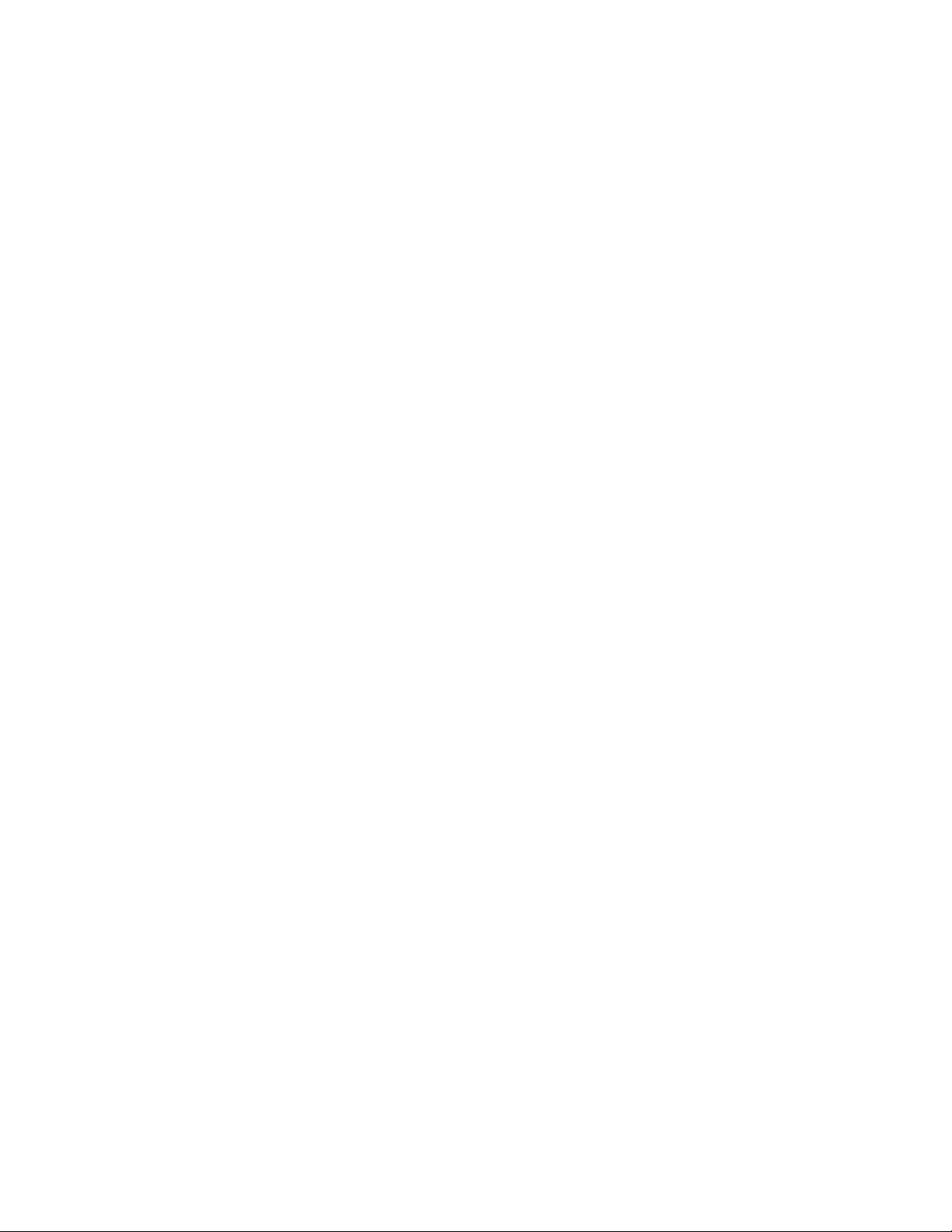

The drawings in this section illustrate the location of the main components of the

various oxygen generator models. All models include similar components unless

noted otherwise; however, the location and size of these components varies

among the different models. Refer to Appendix A of this instruction manual for

general layout drawings and specifications for all oxygen generator models

referenced in this instruction manual. In addition, the oxygen generator requires use

of an oxygen receiver to provide stable flow and purity for short-term surges of feed

oxygen above the rated capacity of the oxygen generator.

4.1 External Components

Figure 4-1 below illustrates on two models the external components viewed from

the front of the oxygen generator.

dsorbers

Control Panel

Enclosure

AS-45 Model AS-750 Model

Figure 4-1 External Components — Front View

AS-20—1000 Instruction Manual 4-1

Page 18

12/02 AirSep® Corporation

4.1.1 Adsorbers

The adsorbers, or beds, are vessels that contain the molecular sieve used to

adsorb (attract) nitrogen from compressed air and allow oxygen to pass through as

the product gas.

4.1.2 Enclosure

The enclosure protects the control system components of the unit (e.g., circuit

board, pressure switch, fuses, and transformer).

Disconnect power before opening and/or removing enclosure.

Power Cord

(U.S. units) The power cord, and its grounded plug, connects the oxygen

generator to a properly grounded electrical outlet to supply electrical power to

the oxygen generator.

(CE units) A fully qualified electrician must install the appropriate electrical

connection on the end of the power cord for a properly grounded electrical

outlet to supply electrical power to the oxygen generator.

Fuse Holder

The fuse holders contain fuses to protect the electrical components of the oxygen

generator. On the AS-450 through AS-1000 models, the fuse holders are mounted

in the control panel.

Fuses must be replaced with the same type and amp rating as

the original fuses.

4.1.3 Control Panel

The control panel on the oxygen generator contains the controls needed to operate

the oxygen generator and monitor its operation. Examples of typical control panels

are shown in figure 4-3. Not all components are available on every generator. On

the AS-450 through AS-1000 models, the gauges are mounted directly on the

manifolds and the hour meter is inside the control panel.

4-2 AS-20—1000 Instruction Manual

Page 19

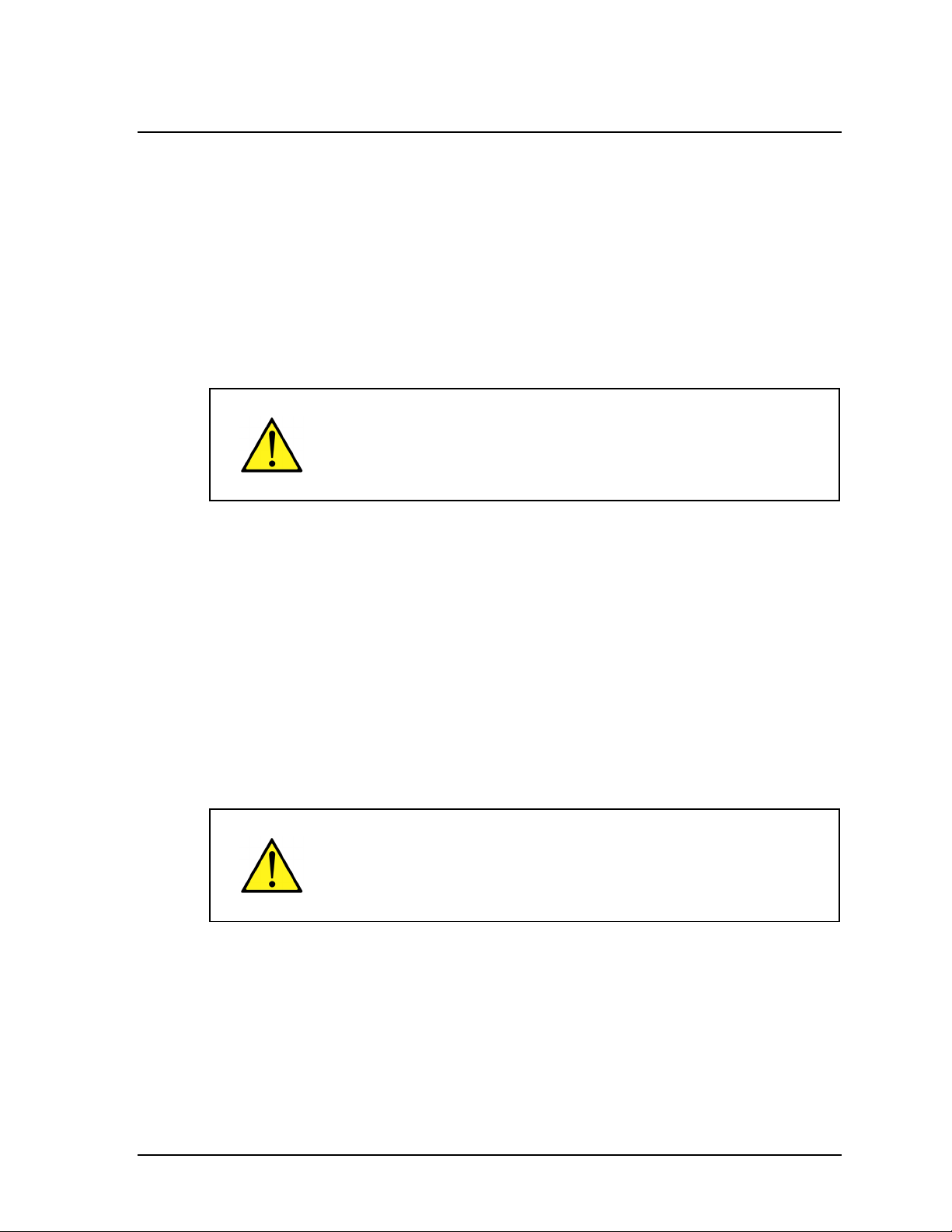

AirSep® Corporation 12/02

A

Feed Air

Pressure Gauge

On/Off Switch

Cycle Pressure

Gauge

Hour Meter

uto/Manual

Switch

Oxygen

Receiver

Pressure

Gauge

Manual Drain

Button

Figure 4-2 Control Panel — AS-45 and AS-80 Models

On/Off Switch

The l/O power switch starts and stops the operation of the unit. The green indicator

light illuminates to indicate that the oxygen generator is receiving electrical power.

Auto/Manual Switch

The AUTO/MANUAL switch selects the operating mode for the oxygen generator.

In the AUTO position, the oxygen generator cycles on and off to meet oxygen

demand. In the MANUAL position, the oxygen generator cycles continuously. The

amber indicator light on the AUTO/MANUAL switch illuminates only when the

oxygen generator produces oxygen.

Manual Drain Button

The oxygen generator uses an automatic valve to periodically drain excess

moisture extracted from the feed air. The manual drain button allows you to

operate the automatic drain valve manually at any time during operation.

Hour Meter (Not available on AS-20 model)

The hour meter indicates the total number of hours the oxygen generator cycles.

FEED AIR PRESSURE Gauge (Not available on AS-450 — AS-1000 models)

The FEED AIR PRESSURE gauge indicates the pressure of the feed air as the air

enters the generator prior to the feed air regulator.

CYCLE PRESSURE Gauge (Not available on AS-450 — AS-1000 models)

The CYCLE PRESSURE gauge indicates the pressure of the feed air before the air

enters the adsorbers. The feed air regulator controls the pressure indicated on the

CYCLE PRESSURE gauge.

ADSORBER PRESSURE Gauges (AS-450 — AS-1000 models only)

The adsorber pressure gauges indicate the pressure in the two adsorbers.

OXYGEN RECEIVER PRESSURE Gauge

The OXYGEN RECEIVER PRESSURE gauge indicates the oxygen pressure in the

oxygen receiver.

4.1.4 Connections

AS-20—1000 Instruction Manual 4-3

Page 20

12/02 AirSep® Corporation

The oxygen generator provides the connections described below.

Air Inlet

The feed air inlet provides a connection for the feed air hose from the air

compressor.

Oxygen Outlet

The oxygen outlet provides a connection for the oxygen hose to the oxygen

receiver.

Condensate Drain Outlet

The condensate drain outlet provides a connection for a hose to drain condensate

from the oxygen generator filters.

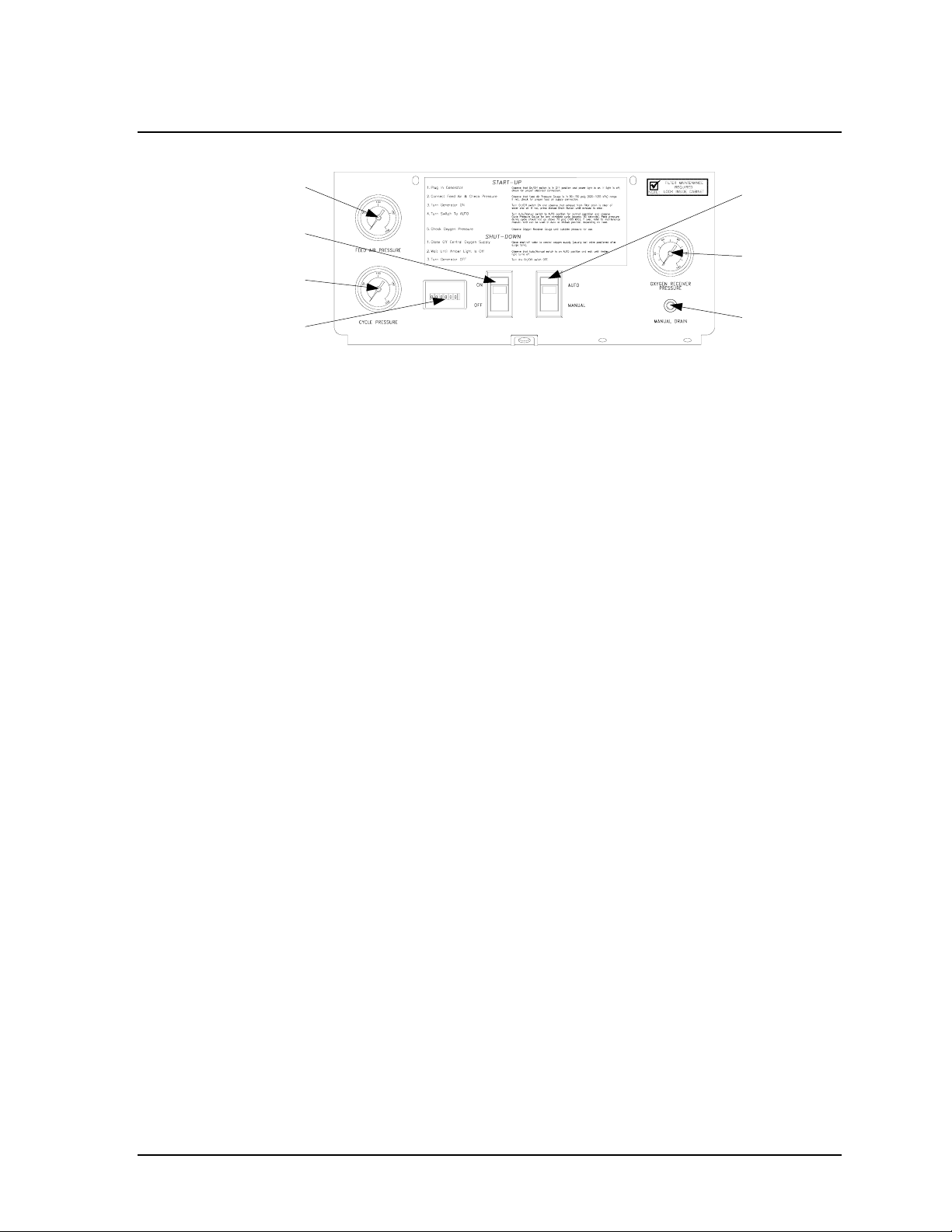

4.2 Manifold Components

Figure 4-4 below illustrates the manifold components of the oxygen generator.

The location and presence of components may vary between the various models

of generators.

Particulate Filter

Coalescing Filter

Feed Air Valves

Equalization Valves

Manual Air Inlet

Valve

Check Valves

Filter Drain Valve

Feed Air Regulator

Circuit Board

Muffler

Manual Filter outlet Valve

Waste Valves

Pressure Switch

Product Valve

Flow Controller

Figure 4-3 Manifold Components —

AS-160 and AS-250 Models

4-4 AS-20—1000 Instruction Manual

Page 21

AirSep® Corporation 12/02

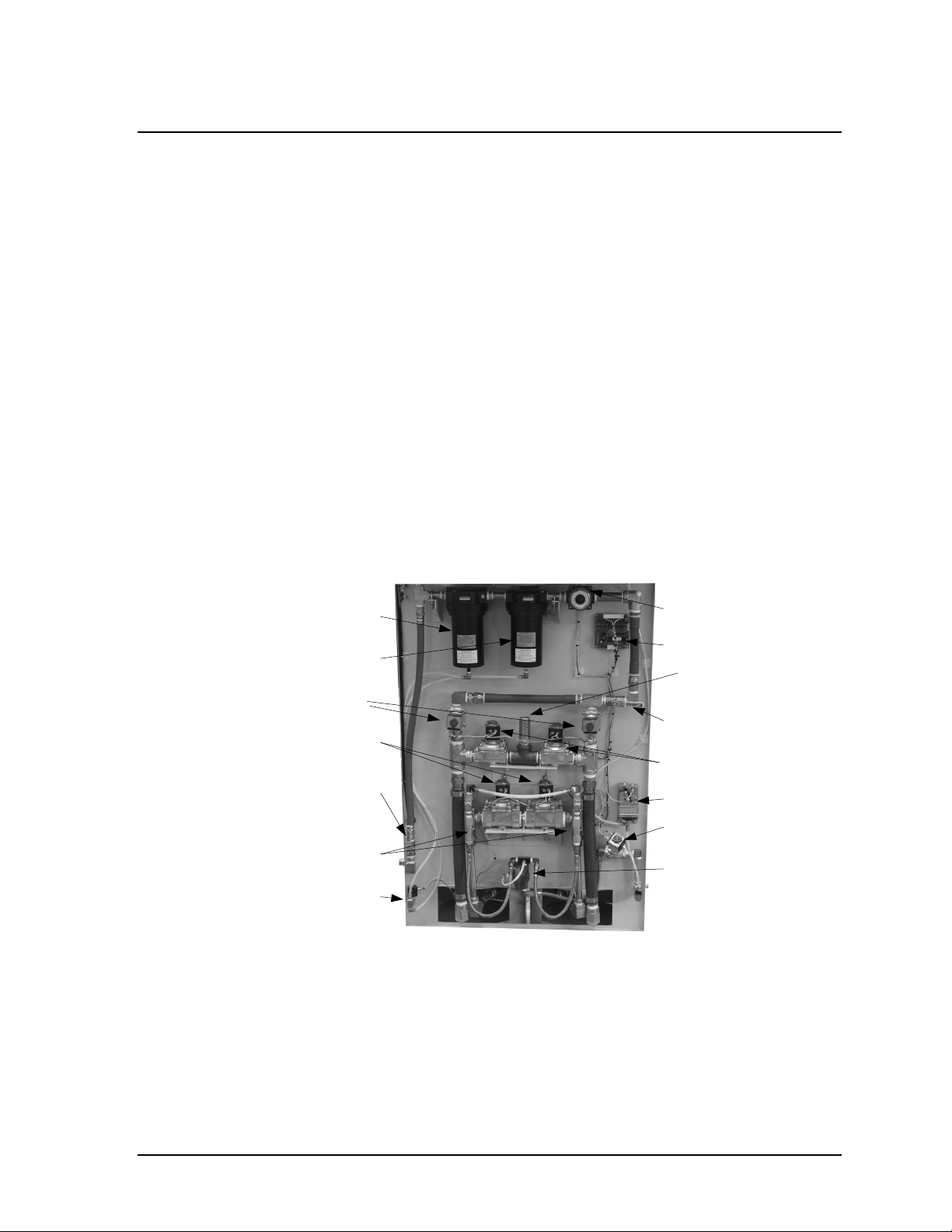

Equalization Valves

Check Valves

Manual Product Valve

Mufflers

Feed Valves

Manual Air Inlet

Particulate Filter

Figure 4-4 Manifold Components —

AS-750 Model

Automatic Equalization Valves

The automatic equalization valves enable the pressure in the adsorbers to equalize

after the product oxygen exits from one of the adsorbers.

Automatic Feed Air Valves

The automatic feed air valves control the flow of the feed air as the air enters the

adsorbers.

Automatic Product Valve

The automatic product valve controls the flow of product oxygen from the

adsorbers.

Waste Valves

Feed Air Regulator

Coalescing Filter

Automatic Waste Valves

The automatic waste valves control the flow of waste gas as it exits the adsorbers.

AS-20—1000 Instruction Manual 4-5

Page 22

12/02 AirSep® Corporation

Check Valves

The check valves ensure that product gas does not flow back into the adsorbers.

Circuit Board

The circuit board controls the cycle time and sequence of operation of the solenoid

and drain valves.

Coalescing Filter

The coalescing filter removes condensed water, oil vapor, and other contaminants

from the feed air before the air enters the adsorbers.

Feed Air Regulator

The feed air regulator is set at the AirSep Corporation factory. The feed air regulator

controls the amount of air pressure at which the oxygen generator cycles.

Filter Drain Valve

This automatic valve removes moisture from the filters through tubing connected to

an outlet at the back of the oxygen generator.

Flow Controller (Not available on AS-20 and AS-450 — AS-1000 models)

The flow controller ensures consistent flow of the delivered product oxygen.

Manual Filter Outlet Valve

This manual valve controls the flow of feed air from the feed air regulator after the

filters to the automatic feed air valves.

Manual Inlet Valve

This manual valve controls the flow of feed air from the air compressor to the filter

assembly.

Particulate Filter (Not available on AS-20 model)

The particulate filter, or prefilter, removes particulates from the feed air before the

air enters the coalescing filter and then the adsorbers.

Pressure Switch

When the oxygen generator operates in Auto mode, the pressure switch monitors

the oxygen pressure in the oxygen receiver. When the pressure in the oxygen

receiver increases to approximately 380-415 kPa (55-60 psig), the pressure switch

circuit closes and the oxygen generator starts a timed shutdown that stops the unit

at the end of the shutdown sequence. When the pressure in the oxygen receiver

decreases to approximately 310 kPa (45 psig), the pressure switch opens to

activate the oxygen generator, and oxygen production begins. When the oxygen

generator operates in Manual mode, the pressure switch circuit remains open and

the oxygen generator cycles continuously.

4-6 AS-20—1000 Instruction Manual

Page 23

AirSep® Corporation 12/02

Relief Valves (not shown)

The relief valves, one on each adsorber, ensure that the pressure in the adsorbers

does not exceed the rated maximum pressure of the adsorbers.

Transformer

The transformer provides the proper voltage for the electrical components of the

oxygen generator.

AS-20—1000 Instruction Manual 4-7

Page 24

Page 25

AirSep® Corporation 12/02

5.0 Installation

5.1 Handling and Unpacking

AirSep Corporation ships the oxygen generator on a wooden skid covered by a

container. The container also includes an accessory box containing all the

accessories for the unit and an instruction manual needed to install the unit

properly. The oxygen receiver, if supplied, is shipped on a separate skid.

To unpack the oxygen generator, follow these guidelines:

1) Inspect the shipping container, and open it immediately upon receipt.

2) If the exterior of the carton is severely damaged, note it on the freight bill

before you sign it.

You must submit a damage claim within 24 hours of receipt.

In the case of concealed or hidden damage, a claim must be

filed within 15 days of receipt. A claim can be filed only by

the consignee. The AirSep Product Warranty does not

shipping damage.

cover

3) Unpack the unit, and remove any protective wrapping and packaging. Retain

the carton and packaging to facilitate future shipping and transporting of the

unit.

4) Place the unit in an upright position, and thoroughly inspect the enclosure

and all external components (e.g., control panel) for damage.

5) Open the enclosure or control panel, and inspect the interior for loose or

damaged parts.

To prevent electrical shock, make sure the main power supply

is disconnected when you remove the enclosure, inspect the

internal components, and install the oxygen generator and

oxygen receiver.

6) Inspect all wiring to ensure that no wires are broken and no push-on

connector is off its terminal. If a wire is disconnected, reconnect the wire to

the most obvious terminal.

7) After inspecting the interior, close the enclosure or control panel on the unit.

8) Locate the instruction manual inside the accessory box. Read the entire

manual before installing and operating the unit.

AS-20—1000 Instruction Manual 5-1

Page 26

12/02 AirSep® Corporation

5.2 Pre-installation Guidelines

Before you install the oxygen generator, and oxygen receiver, if supplied, refer to

the Specifications section in Appendix A of this instruction manual to determine

applicable floor space, feed air, and power requirements for your particular model.

The oxygen generator may use feed air at specifications outside

those shown in Appendix A of this instruction manual; however,

use of such feed air may require modification of the oxygen

generator at the AirSep Corporation factory to ensure the

product oxygen meets the specifications shown in Appendix A.

Consult your sales representative to determine whether your

oxygen generator requires modifications for your application.

Locate the oxygen generator in an area where the ambient air

temperature remains between 4°C (40°F) and 44°C (111°F) to

prevent damage not covered under the AirSep Corporation

Product Warranty.

To prevent fire or electrical shock, locate the oxygen generator

away from rain or any other type of moisture.

Make sure the area that surrounds the oxygen generator is well

ventilated, and provide sufficient space around the unit [at least

one meter (three feet)] to allow for cool air flow as well as to

allow safe operation and maintenance.

AirSep oxygen generators are sold for use in industrial

applications only. Contact AirSep Corporation or an authorized

AirSep representative before you use this unit for any medical

application.

5-2 AS-20—1000 Instruction Manual

Page 27

AirSep® Corporation 12/02

Do not disconnect protective earth:

5.3 Installation Instructions

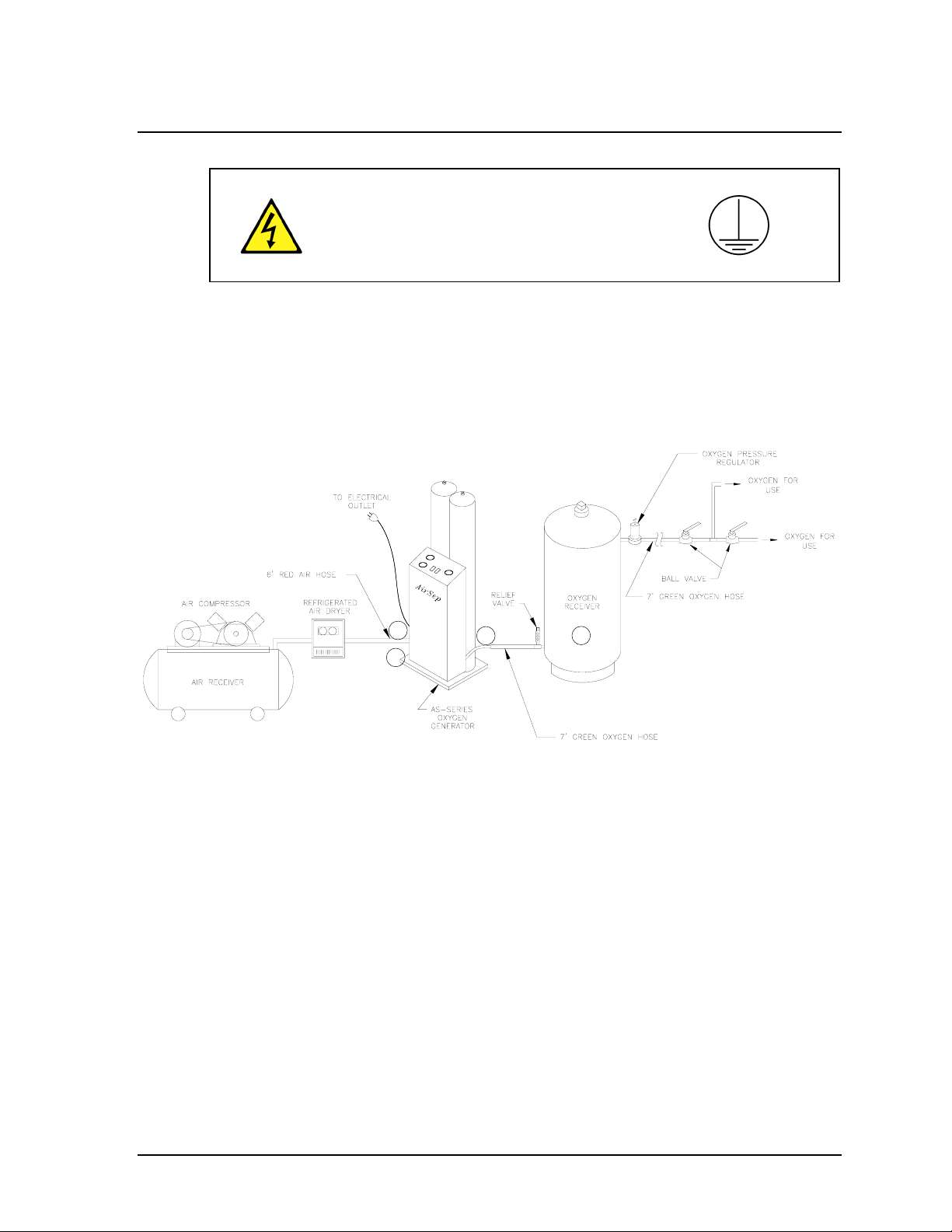

Refer to Figure 5-1 below for the recommended installation arrangement for the

oxygen generator. The numbers in the drawing correspond to the step numbers in

this section.

1

4

Figure 5-1 Typical Installation Arrangement

3

2

1) Connect the red air hose provided with the oxygen generator accessories

from the on-site air supply to the feed air inlet connection on the oxygen

generator. Refer to the Table 5.1 to determine the proper size for the feed air

inlet connection and feed air hose for your model.

AS-20—1000 Instruction Manual 5-3

Page 28

12/02 AirSep® Corporation

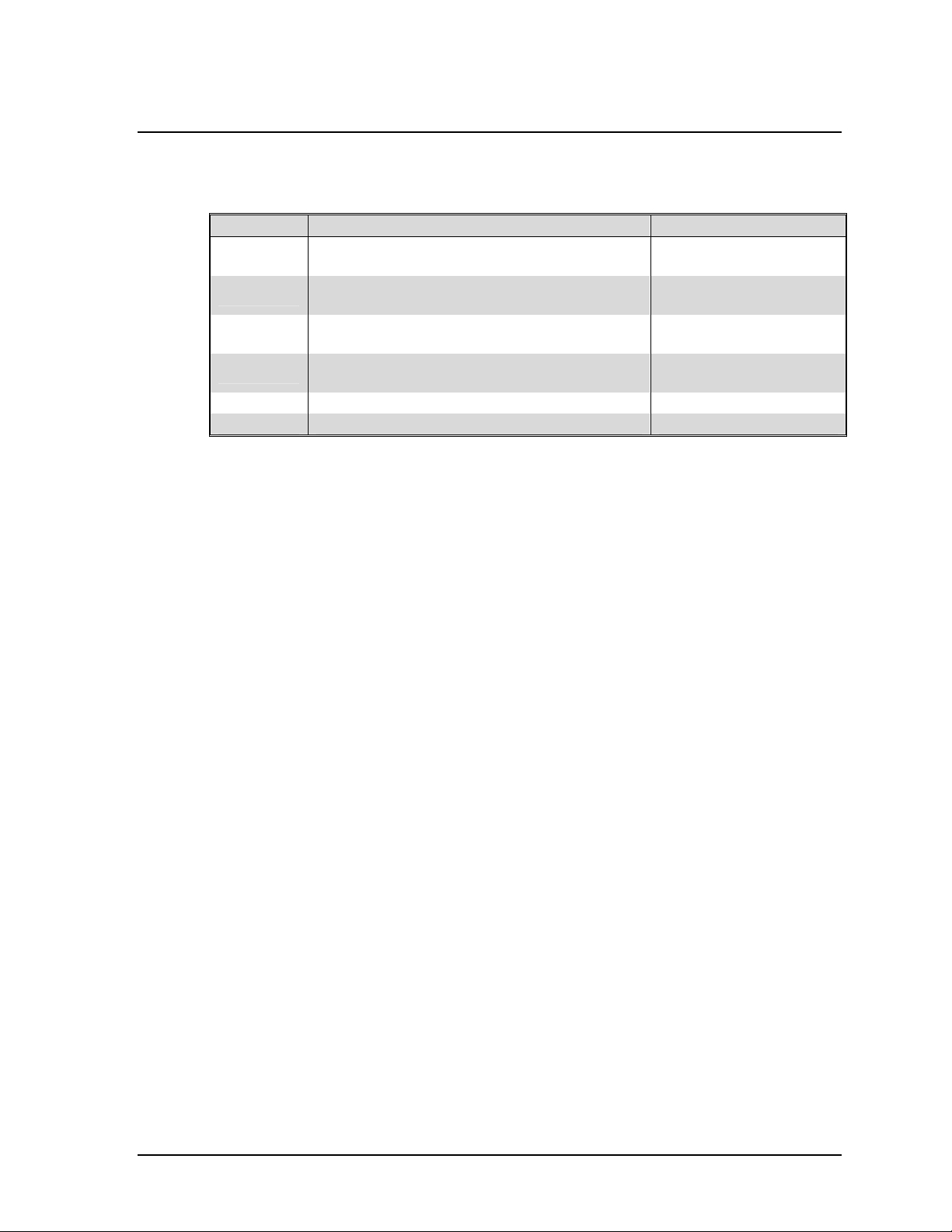

Model Feed Air Inlet Connection Size Feed Air Hose Size

AS-20,

AS-45

AS-80

AS-160,

AS-250

AS-450

AS-750 1” NPT Female fitting next to V-2 1” ID minimum

AS-1000 1” NPT Female fitting next to V-2 1” ID minimum

¼” NPT female bulkhead fitting with a ¼” NPT

male x ¼” NPSM ball-end joint adapter

¼” NPT female bulkhead fitting with a ¼” NPT

male x ⅜” NPSM ball-end joint adapter

½” NPT female bulkhead fitting with a ½” NPT

male x ¾” NPSM ball-end joint adapter

¾” NPT female bulkhead fitting with a ¾” NPT

male x ¾” NPSM ball-end joint adapter

Table 5-1 Feed Air Connection Sizes and Hose Sizes

¼” ID minimum

⅜” ID minimum

½” ID minimum

¾” ID minimum

2) Install your oxygen receiver. If AirSep Corporation provided your oxygen

receiver, assemble the receiver as follows (See Figure 5-2.):

5-4 AS-20—1000 Instruction Manual

Page 29

AirSep® Corporation 12/02

Figure 5-2 120 Gallon Oxygen Receiver

a) Connect the relief valve assembly to the oxygen inlet port on the oxygen

receiver. Tighten the connection fully.

b) Connect the hex nipple to the oxygen outlet port on the oxygen

receiver. Tighten the connection fully.

c) Connect the oxygen regulator to the hex nipple at the oxygen outlet port

on the oxygen receiver. Tighten the connection fully.

AS-20—1000 Instruction Manual 5-5

Page 30

12/02 AirSep® Corporation

Use Teflon™ tape to seal the threaded connections on the

oxygen receiver. If AirSep Corporation provided your oxygen

receiver, the threaded connections in the accessory kit were

shipped with Teflon™ tape wrapping already applied.

If AirSep Corporation did not provide your oxygen receiver, make sure your

oxygen receiver is sized properly as specified in Appendix A of this

instruction manual to meet the requirements of your oxygen generator model.

In addition, AirSep Corporation recommends that the oxygen inlet on the

oxygen receiver contain a relief valve and that the oxygen outlet on the

oxygen receiver contain a pressure regulator and pressure gauge or a

manual ball valve and pressure gauge.

3) Connect the green oxygen hose provided with the oxygen generator

accessories from the oxygen outlet connection on the oxygen generator to

the relief valve assembly at the oxygen inlet port on the oxygen receiver.

Refer to the following table to determine the proper size for the oxygen outlet

connection.

Model Oxygen Outlet Connection Size

AS-20, AS-45,

AS-80

AS-160, AS-250

AS-450

AS-750 ¾” NPT Female on tee behind PI-3

AS-1000 ¾” NPT Female on tee behind PI-3

Table 5-2 Oxygen Outlet Connection Sizes

¼” NPT female bulkhead fitting with a

¼” NPT male x B size oxygen adapter

⅜” NPT female bulkhead fitting with a

⅜” NPT male x B size oxygen adapter

⅜” NPT female bulkhead fitting with a

⅜” NPT male x C size oxygen adapter

4) Connect the ⅜” ID nylon tubing provided with the oxygen generator

accessories to the condensate outlet at the rear of the oxygen generator.

Make sure the condensate outlet and nylon tubing do not

become obstructed at any time. This may require a daily drain

system check.

5) Connect the power cord to a grounded electrical outlet. On CE units, a

qualified electrician should install the appropriate grounded electrical

connector on the end of the power cord.

5-6 AS-20—1000 Instruction Manual

Page 31

AirSep® Corporation 12/02

Provide proper voltage from a grounded outlet to the oxygen

generator. Improper voltage causes damage not covered under

the AirSep Corporation Product Warranty.

The oxygen generator is now ready for operation. Refer to Chapter 6 of this

instruction manual before you operate the oxygen generator.

AS-20—1000 Instruction Manual 5-7

Page 32

Page 33

AirSep® Corporation 12/02

6.0 Operation

When you complete installation as described in the previous section, the oxygen

generator is ready for easy start-up and operation. This section of this instruction

manual provides the procedures for start-up and shutdown of the oxygen

generator. Before you start the oxygen generator, read and thoroughly understand

any literature or instruction manuals for the air compressor that will provide the

feed air to the oxygen generator.

6.1 Initial Start-up

To start the oxygen generator for the first time or after an extended or unexpected

shutdown, follow the steps below:

1) Make sure the ON/OFF switch on the control panel is set to OFF.

2) Set the AUTO/MANUAL switch on the control panel to MANUAL.

3) Connect the grounded power cord to a grounded electrical outlet. Make sure

the power circuit cannot be turned off accidentally.

If the power is turned off unexpectedly, the unit will stop cycling.

If your application is using oxygen when the power is off, the

oxygen receiver will depressurize. Refer to Appendix A of this

instruction manual for the length of time you can expect the

oxygen receiver to repressurize.

When you connect the oxygen generator’s plug to a power circuit, the green

light on the ON/OFF switch illuminates to indicate that the oxygen generator

is receiving electrical power.

4) Provide feed air that meets the specification for your model to the oxygen

generator. Make sure the FEED AIR PRESSURE gauge on the control panel

registers pressure within the range of feed air pressures specified in

Appendix A of this instruction manual.

5) Set the ON/OFF switch on the control panel to ON.

6) For AS-450 through AS-1000 models ONLY: Close the manual product

valve (refer to Figure 4-4 for location of valve). The manual product valve on

these units has been configured to enable a predetermined amount of flow

through the valve when closed. This allows the product pressure to build up

even when the valve is closed.

AS-20—1000 Instruction Manual 6-1

Page 34

12/02 AirSep® Corporation

When you start the oxygen generator, air exhausts for 3–5

seconds from the filter drain port on the rear of the unit to remove

any condensate that may be present in the filter bowls. This

removes condensate from the feed air before the feed air enters

the adsorbers. During normal operation, air exhausts from the

filter drain for 3–5 seconds every 10 minutes.

7) Make sure the exhaust from the filter drain does not contain water or oil. If the

exhaust contains water or oil, press the manual drain button on the control

panel until the exhaust no longer contains liquid.

8) To purge oxygen at less than design purity from the oxygen receiver, while

the oxygen generator is running in manual mode, open a manual valve on the

oxygen receiver to vent gas until the gas no longer discharges from the

oxygen receiver, then fully close the manual valve.

Always vent oxygen outside. While venting oxygen, do not

allow smoking or open flame. Do not allow venting oxygen to

come in contact with clothing or hydrocarbon-based materials.

9) Allow the oxygen generator to operate until the OXYGEN RECEIVER

PRESSURE gauge on the control panel registers approximately 380–415

kPa (55-60 psig).

10) Set the AUTO/MANUAL switch on the control panel to AUTO.

When the oxygen generator cycles, i.e., it produces oxygen;

the amber light on the AUTO/MANUAL switch illuminates.

When the unit enters standby, i.e., it remains on but does not

produce oxygen; the amber light on the AUTO/MANUAL switch

shuts off.

11) For AS-450 through AS-1000 models ONLY: Open the manual product

valve

12) Observe the FEED AIR Pressure and CYCLE PRESSURE gauges on the

control panel for at least one cycle (approximately 180 seconds). As the unit

cycles, the feed air pressure should not decrease below 480 kPa (70 psig)

and the peak cycle pressure should not exceed 480 kPa (70 psig). On the

AS-450 through AS-1000 models, observe the readings on the two bed

pressure gauges.

6-2 AS-20—1000 Instruction Manual

Page 35

AirSep® Corporation 12/02

If the feed air pressure decreases below 480 kPa (70 psig) or

the peak cycle pressure exceeds 480 kPa (70 psig), refer to the

troubleshooting chapter of this instruction manual.

13) Observe the OXYGEN RECEIVER PRESSURE gauge on the control panel.

When the pressure in the oxygen receiver increases to approximately 380–

415 kPa (55–60 psig), the oxygen generator stops producing oxygen and

enters standby. When delivery of product oxygen reduces the pressure in the

oxygen receiver below 310 kPa (45 psig), the oxygen generator begins to

cycle and the amber light on the AUTO/MANUAL switch illuminates.

Under normal use, the pressure switch in the oxygen generator

does not require adjustment. If you need to adjust the pressure

switch, refer to the maintenance chapter of this instruction

manual.

14) After the oxygen receiver pressurizes, adjust the pressure regulator at the

outlet of the oxygen receiver until the pressure of the product oxygen meets

the needs of your application.

At this point, the oxygen is ready for use by your application.

6.2 Operation

The oxygen generator can be operated in auto or manual mode depending on the

requirements of your application. To use product oxygen that meets the

specifications for your model listed in Appendix A of this instruction manual, set the

AUTO/MANUAL switch to AUTO to produce oxygen only during times of oxygen

demand. To obtain maximum oxygen purity at less than maximum flow or to obtain

a delivery pressure of 345 kPa (50 psig), set the AUTO/MANUAL switch to

MANUAL to force continuous operation of the unit regardless of the pressure in the

oxygen receiver.

6.3 Shutdown

1) Stop the flow of product oxygen from the oxygen receiver to your application

by fully closing all manual valves between the outlet of the oxygen receiver

and the inlet to your application.

2) Make sure the AUTO/MANUAL switch on the control panel is set to AUTO.

3) Allow the oxygen receiver to repressurize fully. When the oxygen receiver

repressurizes, after a time delay of five cycles, the oxygen generator stops

cycling and the amber indicator light on the AUTO/MANUAL switch shuts off.

AS-20—1000 Instruction Manual 6-3

Page 36

12/02 AirSep® Corporation

Allow the oxygen generator to enter standby during shutdown

to ensure that the oxygen receiver contains oxygen at design

purity during the subsequent restart and also ensure that the

unit shuts down at the proper point in the cycle. Failure to wait

until the oxygen generator enters standby results in temporarily

reduced purity oxygen during the subsequent restart.

4) Set the ON/OFF switch on the control panel to OFF.

5) Set the AUTO/MANUAL switch on the control panel to MANUAL.

6.4 Normal Start-up

To perform a normal start-up, the oxygen generator first

requires a shutdown as described in Section 6.3 — Shutdown.

If the oxygen generator shuts down due to a power loss, follow

the procedure in Section 6.1 — Initial Start-Up to restart the

oxygen generator.

1) Provide feed air that meets the specification for your model to the oxygen

generator. Make sure the FEED AIR PRESSURE gauge on the control panel

registers pressure within the range of feed air pressures specified in

Appendix A of this instruction manual.

2) Set the ON/OFF switch on the control panel to ON.

3) Make sure the exhaust from the filter drain does not contain water or oil. If the

exhaust contains water or oil, press the manual drain button on the control

panel until the exhaust no longer contains liquid.

4) Set the AUTO/MANUAL switch on the control panel to AUTO.

6.5 Extended Shutdown

To shut down the oxygen generator for 24 hours or longer, complete all the steps

in Section 6.3 — Shutdown. In addition, perform the following steps:

1) Fully close all manual valves on the oxygen receiver to isolate the oxygen in

the oxygen receiver, to prevent the loss of pressure in the oxygen receiver

and enable a normal start-up.

2) Turn the oxygen generator off and disconnect power.

6.6 Start-up after an Extended Shutdown

After an extended shutdown or an unexpected shutdown, such as a loss of

electrical power, you must purge the oxygen receiver of any low purity oxygen

6-4 AS-20—1000 Instruction Manual

Page 37

AirSep® Corporation 12/02

before the oxygen generator can supply oxygen within purity specifications. To

purge the oxygen receiver, follow all the steps in Section 6.1 — Initial Start-Up.

AS-20—1000 Instruction Manual 6-5

Page 38

Page 39

AirSep® Corporation 12/02

7.0 Maintenance

The most important maintenance you can perform on the oxygen generator is to

make sure the automatic drain valve for the filters functions properly. Routinely

monitor the operation of this drain valve to ensure the long life of the oxygen

generator. Follow the procedures described in this section of the instruction manual

for daily, semi-annual, and annual maintenance.

Use the following chart as a guide to perform maintenance on a regular schedule:

Time Period Action

Daily Make sure automatic drain functions properly.

Monthly Inspect filters and bowls. Clean bowls or replace filters as necessary.

Six Months Replace particulate filter element.

Annually Replace coalescing filter element.

Check performance of automatic valves and actuators.

Clean and lubricate feed air regulator.

Table 7-1 Maintenance Chart

7.1 Daily Monitoring

1) Make sure the condensate outlet and tubing for the drain valve is not obstructed.

Condensate should discharge from this outlet or tubing for approximately

three to five seconds every 10 minutes when the ON/OFF switch on the control

panel is set to ON and the green indicator light on the switch illuminates.

2) Press the MANUAL DRAIN button on the control panel and observe the

discharge. The discharge should flow freely and be clear of oil and water

within five seconds.

7.2 Monthly Monitoring

Monthly monitoring requires inspection of the filters and testing the performance of

the automatic drain valve. To perform this procedure, remove the front cover of the

enclosure, depressurize the unit and remove the filter bowls as described in the

following procedures. (See Section 7.3, Removing the Front Cover of the

Enclosure, Section 7.4, Depressurizing the Filters, and Section 7.5, Changing Filter

Elements.) When the filter bowls have been removed and cleaned, perform the

following steps:

1) Inspect the filter element(s). Replace any element(s) that appear damaged or

excessively dirty.

2) Reconnect the drain tubing to the bottom of the bowls.

3) Add approximately two ounces of water to the filter bowls.

4) Re-install the filter bowls, making sure the bowls lock firmly into place.

AS-20—1000 Instruction Manual 7-1

Page 40

12/02 AirSep® Corporation

5) Slowly open fully the manual inlet valve to pressurize the filter bowls.

6) While observing the drain tubing, set the ON/OFF switch on the control panel

to ON and determine whether the automatic drain valve discharges moisture.

7) Fully close the manual inlet valve and depressurize the unit as described

below. (See Section 7.4, Depressurizing the Filters.)

8) Remove the filter bowls as described below. (See Section 7.5, Changing

Filter Elements.) Observe whether the water drained from the bowls.

If the filter bowls still contain water, refer to the troubleshooting chapter of this

instruction manual. If the bowls do not contain water, re-install the bowls,

repressurize the system, and replace the front cover of the enclosure as

described below. (See Section 7.5, Changing Filter Elements.)

7.3 Removing the Front Cover of the

Enclosure (Not available on AS-450 — AS-1000

models)

Disconnect power to the oxygen generator before removing the

front cover of the enclosure.

The front cover of the enclosure protects the components of the

unit from damage and dirt. The cover should remain on the

enclosure at all times and should only be removed for

maintenance or servicing as described in this chapter.

1) Remove the slotted screws that connect the top of the cover to the bottom of

the control panel.

2) Release the four latches on the sides of the cover by pulling the release

levers towards the front of the unit.

3) Carefully grasp the cover and slide it off the unit towards the front of the unit.

The cover is freestanding, so it can be set aside in any location.

7-2 AS-20—1000 Instruction Manual

Page 41

AirSep® Corporation 12/02

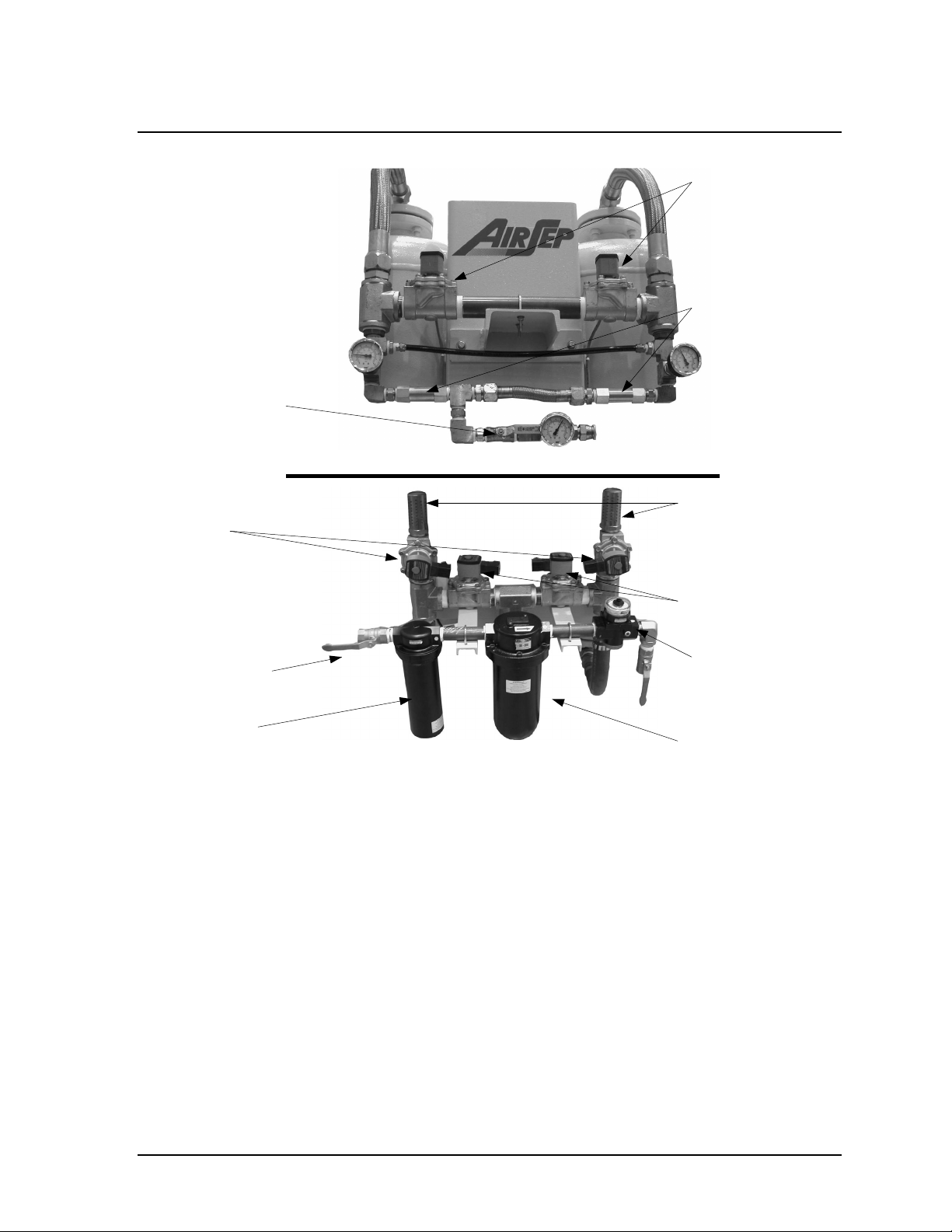

A

7.4 Depressurizing the Filters

The oxygen generator filters contain pressurized air. To

perform monthly maintenance or change filter elements safely,

fully depressurize the filter assembly as described in the

procedure in this section. To safely depressurize all oxygen

generator components, refer to the procedure described later in

this chapter. (See Section 7.6, Depressurizing the Oxygen

Generator.)

1) Make sure the AUTO/MAN switch is set to AUTO and allow the oxygen

generator to stop cycling when the oxygen receiver pressurizes fully.

2) Disconnect the oxygen generator from the power supply.

3) Remove the front cover of the enclosure, if applicable. (See Section 7.3,

Removing the Front Cover of the Enclosure.)

4) Fully close the manual inlet valve and manual filter outlet valve. (See Figure

7-1.)

Particulate filter

(not provided on

S-20 model)

Bowl Latches

Drain Tubing

Connections

Manual Inlet Valve

Coalescing Filter

Feed Air Regulator

Filter Bowls

Manual Filter

Outlet Valve

Exhaust Muffler

Pressure Switch

Figure 7-1 Interior View

of AS-45 and AS-80 Models

AS-20—1000 Instruction Manual 7-3

Page 42

12/02 AirSep® Corporation

5) Shut off the feed air supply at the air compressor or air header.

6) Re-install the front cover of the enclosure, if applicable.

7) Reconnect the oxygen generator to the power supply.

8) Press the MANUAL DRAIN button on the control panel until the CYCLE

PRESSURE gauge indicates zero pressure.

If the pressure gauge does not decrease to zero, shut down the

unit and call the AirSep Corporation Commercial Products

Division.

9) Set the ON/OFF switch on the control panel to OFF.

7.5 Changing Filter Elements

The following procedure describes how to change the filter elements for either the

particulate filter (not available on the AS-20 model) semi-annually or the coalescing

filter annually.

1) Depressurize the filter assembly and shut down the oxygen generator. (See

Section 7.4, Depressurizing the Filters.)

Do not attempt to remove the filter bowls until the filter

assembly fully depressurizes as described in Section 7.4.

2) While the unit is depressurized and the power supply is disconnected,

remove the front cover of the enclosure. (See Section 7.3, Removing the Front

Cover of the Enclosure.)

3) To remove the bowl from either filter, push down the bowl latch and rotate the

bowl slight right or left while pulling down on the bowl.

4) When the bowl is free, disconnect the drain tubing from the bottom of the

bowl.

5) Wash the bowl in warm, soapy water, then rinse the bowl.

6) Gently unscrew the old filter element and discard it.

7) If you are replacing a coalescing filter element, remove and discard the black

gasket where the top of the filter element connects to the filter housing.

8) If you are replacing a coalescing filter element, make sure a black gasket is

attached to the top of the new element.

7-4 AS-20—1000 Instruction Manual

Page 43

AirSep® Corporation 12/02

9) Taking care not to touch the filter portion of the new filter element, screw it

into the position from which the old filter was removed.

10) Reconnect the drain tubing to the bottom of the bowl.

11) Re-install the filter bowl, making sure the bowl locks firmly into place.

12) Slowly open fully the manual inlet valve and manual filter outlet valve.

13) Turn on the feed air at the air compressor or air header.

14) Re-install the front cover of the enclosure.

15) Connect the oxygen generator to the power supply.

16) Set the ON/OFF switch on the control panel to ON to operate the oxygen

generator.

7.6 Depressurizing the Oxygen Generator

The oxygen generator operates with pressurized air and

oxygen. To perform maintenance on the unit safely, fully

depressurize the oxygen generator components as described

in the procedure in this section.

1) Shut down the oxygen generator and disconnect the power supply. (See

Section 6.3, Shutdown.)

2) Remove the front cover of the enclosure. (See Section 7.3, Removing the

Front Cover of the Enclosure.)

3) Fully close the manual inlet valve. (See Figure 7-1.)

4) Re-install the front cover of the enclosure.

To fully depressurize the oxygen generator components, make

sure the manual filter outlet valve remains fully open.

5) Connect the oxygen generator to the power supply.

6) Set the ON/OFF switch to ON and set the AUTO/MAN switch to MAN.

7) Allow the unit to operate until gas no longer exhausts from the muffler and

both the FEED AIR and CYCLE PRESSURE gauges indicate zero pressure.

AS-20—1000 Instruction Manual 7-5

Page 44

12/02 AirSep® Corporation

If the pressure gauges do not decrease to zero, shut down the

unit and call the AirSep Corporation Commercial Products

Division.

8) If the unit is depressurized, power down the unit if required and proceed to

perform the maintenance.

7.7 Adjusting the Feed Air Regulator

If the feed air regulator requires adjustment, perform the following procedure. If

applicable, remove the front cover of the enclosure to gain access to the regulator.

(See Section 7.3, Removing the Front Cover of the Enclosure.)

Use extreme caution when performing this procedure since it

requires removal of the front cover of the enclosure while the

unit receives electrical power.

1) Unlock the lock nut on the adjustment knob.

2) To increase feed air pressure, rotate the knob clockwise. To decrease feed

air pressure, rotate the knob counterclockwise.

Make slight adjustments and allow the unit to run through at

least one cycle before making another adjustment. If pressure

readings remain incorrect after the cycle completes, continue

making slight adjustments and cycling the unit until the

pressure is within the manufacturer’s specifications.

7.8 Adjusting the Pressure Switch

Although preset at the AirSep Corporation factory to the pressure switch minimum

and maximum pressures specified in Appendix A of this instruction manual, the

pressure switch may require adjustment if the pressure of the oxygen in the

oxygen receiver registers outside the range specified in Appendix A. Follow the

procedures in this section to adjust the pressure switch settings when required.

7-6 AS-20—1000 Instruction Manual

Page 45

AirSep® Corporation 12/02

Use extreme caution when performing this procedure since it

requires removal of the front cover of the enclosure while the

unit receives electrical power.

Refer to Appendix D of this instruction manual for additional

information on the pressure switch.

1) Set the ON/OFF switch on the oxygen generator control panel to ON.

2) Open the front cover of the enclosure and locate the pressure switch. (See

Figure 7-1.)

Locate the two adjustment screws on top of the pressure switch. The

adjustment screw closest to the rear of the cabinet controls the high pressure

setting. The adjustment screw closest to the front of the cabinet controls the

low pressure setting. Use a ¼-inch wrench or screwdriver to make

adjustments.

The adjustment screw normally requires less than a ¼ turn.

Turn either the high or low adjustment screw ¼-turn clockwise

to increase its pressure setting. Turn either screw

counterclockwise to decrease its pressure setting.

To prevent damage to the pressure switch, do not force the

adjustment screws past their stopping points.

3) Set the AUTO/MAN switch on the oxygen generator control panel to AUTO.

AS-20—1000 Instruction Manual 7-7

Page 46

12/02 AirSep® Corporation

4) Close the oxygen outlet valve on the oxygen receiver. (This valve controls

oxygen flow from the oxygen receiver to your application.)

5) Observe the AUTO/MAN switch. When the amber indicator light on the switch

shuts off to indicate when the oxygen generator stops cycling, note the

pressure on the OXYGEN RECEIVER PRESSURE gauge. If the oxygen

generator continues to cycle and the amber indicator light remains illuminated

when the oxygen receiver pressure exceeds the pressure switch maximum

pressure of 380-415 kPa (55-60 psig), proceed to step 8. If the oxygen

generator stops cycling at approximately the pressure switch maximum

pressure, proceed to step 9. Otherwise, proceed to step 6.

6) Turn the high pressure adjustment screw ¼-turn clockwise to increase the

pressure setting.

7) Repeat step 5.

8) Turn the high pressure adjustment screw ¼-turn counterclockwise to

decrease the pressure setting.

If the oxygen generator stops cycling after five minutes,

proceed to step 9. If the oxygen generator does not stop

cycling after five minutes, repeat step 8.

9) Open the oxygen vent valve on the oxygen receiver.

10) Observe the AUTO/MAN switch on the oxygen generator control panel. When

the amber indicator light on the switch illuminates to indicate when the

oxygen generator starts to cycle, note the pressure on the OXYGEN

RECEIVER PRESSURE gauge. If the oxygen generator does not start to

cycle when the oxygen pressure in the oxygen receiver decreases below the

pressure switch minimum pressure of 310 kPa (45 psig), proceed to step 13.

If the oxygen generator starts to cycle while the oxygen pressure remains

greater than the pressure switch minimum pressure, proceed to step 11. If

the oxygen generator starts to cycle at approximately the pressure switch

minimum pressure, the pressure switch is adjusted properly. Proceed to step

14.

11) Turn the low pressure adjustment screw ¼-turn counterclockwise to decrease

the pressure setting.

12) Repeat step 10.

13) Slowly turn the low adjustment screw clockwise in ¼-turn increments until the

oxygen generator starts to cycle and the amber indicator light on the

AUTO/MAN switch illuminates.

14) Fully close the oxygen vent valve on the oxygen receiver.

7-8 AS-20—1000 Instruction Manual

Page 47

AirSep® Corporation 12/02

15) Close the front cover of the enclosure and resume normal operation of the

oxygen generator.

AS-20—1000 Instruction Manual 7-9

Page 48

Page 49

AirSep® Corporation 12/02

8.0 Troubleshooting

Use the following chart as a guide to troubleshoot the oxygen generator. For

assistance in troubleshooting or repairing the unit, or to order replacement parts,

contact the AirSep Commercial Products Service Department by telephone

Monday through Friday between 7:30 a.m. and 4:30 p.m. Eastern Time. In the

USA or Canada, call 1-800-320-0303. Outside the USA or Canada, call (716) 691-

0202. Send fax inquiries anytime to (716) 691-1255. Address written inquiries to:

AirSep Corporation, 260 Creekside Drive, Buffalo, NY 14228-2075 USA, Attention:

Commercial Products Service Department.

Problem Probable Cause Solution

Oxygen generator does not

cycle. Green light on

ON/OFF switch does not

illuminate.

Blown fuse on unit. Replace fuse in unit.

Oxygen generator operates.

Green light on ON/OFF

switch does not illuminate.

Oxygen generator does not

operate and green light on

ON/OFF switch illuminates.

AUTO/MAN switch set to

MAN and amber light on

AUTO/MAN switch does not

illuminate.

Defective ON/OFF switch. Replace switch.

Defective circuit board. Replace circuit board.

Low voltage. Check power supply.

Oxygen generator cycles

with AUTO/MAN switch set

to MAN. Amber light on

AUTO/MAN switch does not

illuminate.

Defective circuit board. Replace circuit board.

No electrical power to

control cabinet or blown

fuse on unit.

Light bulb on ON/OFF

switch burned out.

Loose or defective wire to

switch.

ON/OFF switch set to

OFF.

Loose or defective power

wire to circuit board.

Light bulb on AUTO/MAN

switch burned out.

Loose or defective wire to

switch.

Make sure unit is plugged

into wall outlet and that

wall outlet receives power.

Replace switch or replace

the bulb in AS-160 – AS-

1000.

Repair or replace wire.

Set ON/OFF switch to ON.

Repair or replace wire.

Replace switch or replace

the bulb in AS-160 – AS-

1000.

Repair or replace wire.

AS-20—1000 Instruction Manual 8-1

Page 50

12/02 AirSep® Corporation

Problem Probable Cause Solution

Oxygen generator does not

operate and green light on

ON/OFF switch illuminates.

Amber light on AUTO/MAN

switch does not illuminate

and switch set to AUTO.

Pressure of oxygen is less

than 275 kPa (40 psig).

Defective ON/OFF switch. Replace switch.

Defective pressure switch. Replace pressure switch.

Defective circuit board. Replace circuit board.

Oxygen generator operates

continuously. Amber light on

AUTO/MAN switch

illuminates and switch set to

AUTO. Pressure of oxygen

exceeds 400 kPa (58 psig).

Defective pressure switch. Replace pressure switch.

Defective circuit board. Replace circuit board.

Oxygen generator operates

continuously. Pressure of

oxygen at specified purity is

less than 275 kPa (40 psig).

ON/OFF switch set to

OFF.

Loose or defective power

wire to circuit board.

Pressure switch

improperly set.

Pressure switch

improperly set.

Loose or defective power

wire to pressure switch.

Defective AUTO/MAN

switch.

Inadequate feed air

pressure.

Inadequate cycle

pressure.

Oxygen demand exceeds

oxygen generator

capacity.

Set ON/OFF switch to ON.

Repair or replace wire.

Adjust pressure switch as

described in Chapter 7.

Adjust pressure switch as

described in Chapter 7.

Repair or replace wire.

Replace switch.

Make sure feed air valves

remain fully open and lines

are not obstructed.

Adjust or replace feed air

regulator.

Check oxygen usage or

check unit and oxygen

hoses and piping for leaks.

8-2 AS-20—1000 Instruction Manual

Page 51

AirSep® Corporation 12/02

Problem Probable Cause Solution

Oxygen purity below

specified purity (50–70%).

Momentary power loss.

Inadequate feed air.

Torn valve diaphragm.

Defective coil. Replace coil.

Defective valve. Rebuild valve.

Valve makes loud

“chattering” noise.

Dirty valve. Clean or rebuild valve.

Worn valve core. Rebuild valve.

Defective EMI filter. Replace EMI filter.

Very low oxygen output

(21–50%).

Plugged muffler. Replace muffler.

Low purity oxygen during

initial start-up.

Unit shut down for

extended period—no

pressure in oxygen system.

Valves not cycling

properly.

Improperly wired or

defective circuit board.

Solenoid valve not

functioning properly.

Check for the following

causes:

Loose or defective wire to

valve.

Defective circuit board.

(No power output to

valve.)

Valve remains energized

and open.

Worn internal parts on

valve.

Low voltage. Check power supply.

Low voltage circuit board

output.

Leaking check valves.

Contaminated molecular

sieve in adsorbers.

Start unit as described in

Chapter 6.

Start unit as described in

Chapter 6.

Vent low purity oxygen

from system as described

in Chapter 6.

Check air lines for

obstructions or adjust or

replace feed air regulator.

See valve sequence in

Appendix A.

Replace circuit board.

Identify defective valve

and rebuild valve.

Repair or replace wire.

Replace circuit board.

Replace circuit board.

Rebuild valve.

Replace circuit board.

Clean or replace check

valves.

Replace molecular sieve.

AS-20—1000 Instruction Manual 8-3

Page 52

12/02 AirSep® Corporation

Problem Probable Cause Solution

Oxygen generator outputs

particulates (dusting).

Feed air regulator leaks out

bleed orifice.

Oxygen generator relief

valves open.

Defective relief valve. Replace relief valve.

Filter drain valve remains

open. (Valve not energized.)

Filter drain valve remains

energized.

Defective circuit board. Replace circuit board.

Filter drain valve does not

energize.

Defective valve coil. Replace valve.

Filter drain valve energizes

with unit pressurized, but no

air exhausts.

Excess feed air pressure.

Feed air regulator set

above 485 kPa (70 psig).

Contaminated molecular

sieve in adsorbers.

System not cycling

properly.

Stuck feed air regulator

main valve assembly.

Defective main valve

assembly seat.

Cycle pressure exceeds

485 kPa (70 psig)

maximum.

Stuck feed air regulator

main valve assembly.

Frozen feed air regulator

main valve assembly.

Defective cycle pressure

gauge.

Valve obstructed. Clean or replace valve.

MANUAL DRAIN valve

button stuck.

Defective MANUAL DRAIN

valve button.

Loose or defective wire to

valve.

Valve core stuck in closed

position.

Defective circuit board.

(No power output to

valve.)

Drain valve obstructed or

stuck in closed position.

Drain tubing obstructed or

pinched.

Make sure maximum feed

air pressure does not

exceed 1,035 kPa (150

psig).

Adjust feed air regulator.

Contaminated molecular

sieve in adsorbers.

Check and repair or

replace faulty wiring

and/or circuit board.

Clean and lubricate main

regulator valve assembly.

Rebuild or replace

regulator.

Adjust feed air regulator.

Rebuild or replace

regulator.

Make sure ambient

temperature exceeds 4°C

(40°F).

Replace gauge and adjust

feed air regulator.

Replace button.

Replace button.

Repair or replace wire.

Replace valve.

Replace circuit board.

Clean or replace valve.

Clean or replace tubing.

8-4 AS-20—1000 Instruction Manual

Page 53

AirSep® Corporation 12/02

A Appendix Technical Data

Specifications

Data in this section refer to standard AS-20 through AS-1000 model oxygen

generators. The oxygen generators may use feed air at specifications outside

those shown; however, use of such feed air may require modification of the oxygen

generators at the AirSep Corporation factory to ensure the product oxygen meets

the design specifications. Consult your sales representative to determine whether

your oxygen generator requires modifications for your application.

AS-20

Oxygen output: 20 SCF/hr at 0–45 psig*

0.53 Nm3/hr at 0–310 kPa**

Oxygen purity: 90% minimum

Oxygen dew point: -73°C (-100°F)

Dimensions: 13 x 11 x 57 in. (W x D x H)

33 x 28 x 145 cm (W x D x H)

Approximate weight: 134 lb

61 kg

Feed Air Requirements

Flow: 5.3 SCF/min* (0.14 Nm3/min**)

Pressure: 90 psig (620 kPa) minimum

Temperature: 50°C (122°F) maximum

Power requirements: 120 VAC, 50 Hz, Single Phase, 60 W, 0.5 Amp

120 VAC, 60 Hz, Single Phase, 60 W, 0.5 Amp

240 VAC, 50 Hz, Single Phase, 60 W, 0.25 Amp

240 VAC, 60 Hz, Single Phase, 60 W, 0.25 Amp

*SCF (standard cubic foot) gas measured at 1 atmosphere and 70°F.

3

**Nm (normal cubic meters) gas measured at 1 atmosphere and 0°C.

AS-20—1000 Instruction Manual A-1

Page 54

12/02 AirSep® Corporation

AS-45

Oxygen output: 45 SCF/hr at 0–45 psig*

1.18 Nm3/hr at 0–310 kPa**

Oxygen purity: 90% minimum

Oxygen dew point: -73°C

-100°F

Dimensions: 17 x 15 x 58 in. (W x D x H)

43 x 38 x 147 cm (W x D x H)

Approximate weight: 238 lb

108 kg

Feed Air Requirements

Flow: 13.3 SCF/min*

0.35 Nm3/min**

Pressure: 90 psig minimum

620 kPa minimum

Temperature: 50°C maximum

122°F maximum

Power requirements: 120 VAC, 50 Hz, Single Phase, 60 W, 0.5 Amp

120 VAC, 60 Hz, Single Phase, 60 W, 0.5 Amp

240 VAC, 50 Hz, Single Phase, 60 W, 0.25 Amp

240 VAC, 60 Hz, Single Phase, 60 W, 0.25 Amp

*SCF (standard cubic foot) gas measured at 1 atmosphere and 70°F.

3

**Nm (normal cubic meters) gas measured at 1 atmosphere and 0°C.

A-2 AS-20—1000 Instruction Manual

Page 55

AirSep® Corporation 12/02

AS-80

Oxygen output: 80 SCF/hr at 0–45 psig*

2.10 Nm3/hr at 0–310 kPa**

Oxygen purity: 90% minimum

Oxygen dew point: -73°C

-100°F

Dimensions: 20 x 16 x 60 in. (W x D x H)

51 x 41 x 152 cm (W x D x H)

Approximate weight: 338 lb

153 kg

Feed Air Requirements

Flow: 20 SCF/min*

0.53 Nm3/min**

Pressure: 90 psig minimum

620 kPa minimum

Temperature: 50°C maximum

122°F maximum

Power requirements: 120 VAC, 50 Hz, Single Phase, 60 W, 0.5 Amp

120 VAC, 60 Hz, Single Phase, 60 W, 0.5 Amp

240 VAC, 50 Hz, Single Phase, 60 W, 0.25 Amp

240 VAC, 60 Hz, Single Phase, 60 W, 0.25 Amp

*SCF (standard cubic foot) gas measured at 1 atmosphere and 70°F.

3

**Nm (normal cubic meters) gas measured at 1 atmosphere and 0°C.

AS-20—1000 Instruction Manual A-3

Page 56

12/02 AirSep® Corporation

AS-160

Oxygen output: 160 SCF/hr at 0–45 psig*

4.21 Nm3/hr at 0–310 kPa**

Oxygen purity: 90% minimum

Oxygen dew point: -73°C

-100°F

Dimensions: 27 x 26 x 66 in. (W x D x H)

69 x 66 x 168 cm (W x D x H)

Approximate weight: 722 lb

328 kg

Feed Air Requirements

Flow: 31.0 SCF/min*

0.81 Nm3/min**

Pressure: 90 psig minimum

620 kPa minimum

Temperature: 50°C maximum

122°F maximum

Power requirements: 120 VAC, 50 Hz, Single Phase, 60 W, 0.5 Amp

120 VAC, 60 Hz, Single Phase, 60 W, 0.5 Amp

240 VAC, 50 Hz, Single Phase, 60 W, 0.25 Amp

240 VAC, 60 Hz, Single Phase, 60 W, 0.25 Amp

*SCF (standard cubic foot) gas measured at 1 atmosphere and 70°F.

3

**Nm (normal cubic meters) gas measured at 1 atmosphere and 0°C.

A-4 AS-20—1000 Instruction Manual

Page 57

AirSep® Corporation 12/02

AS-250

Oxygen output: 250 SCF/hr at 0–45 psig*

6.57 Nm3/hr at 0–310 kPa**

Oxygen purity: 90% minimum

Oxygen dew point: -73°C

-100°F

Dimensions: 31 x 28 x 76 in. (W x D x H)

79 x 71 x 193 cm (W x D x H)

Approximate weight: 1,034 lb

469 kg

Feed Air Requirements

Flow: 46.7 SCF/min*

01.23 Nm3/min**

Pressure: 90 psig minimum

620 kPa minimum

Temperature: 50°C maximum

122°F maximum

Power requirements: 120 VAC, 50 Hz, Single Phase, 60 W, 0.5 Amp

120 VAC, 60 Hz, Single Phase, 60 W, 0.5 Amp

240 VAC, 50 Hz, Single Phase, 60 W, 0.25 Amp

240 VAC, 60 Hz, Single Phase, 60 W, 0.25 Amp

*SCF (standard cubic foot) gas measured at 1 atmosphere and 70°F.

3

**Nm (normal cubic meters) gas measured at 1 atmosphere and 0°C.

AS-20—1000 Instruction Manual A-5

Page 58

12/02 AirSep® Corporation

AS-450

Oxygen output: 450 SCF/hr at 0–45 psig*

11.83 Nm3/hr at 0–310 kPa**

Oxygen purity: 90% minimum

Oxygen dew point: -73°C

-100°F

Dimensions: 42 x 34 x 79 in. (W x D x H)

107 x 86 x 201 cm (W x D x H)

Approximate weight: 1972 lb

894 kg

Feed Air Requirements

Flow: 83.3 SCF/min*

2.19 Nm3/min**

Pressure: 90 psig minimum

620 kPa minimum

Temperature: 50°C maximum

122°F maximum

Power requirements: 120 VAC, 50 Hz, Single Phase, 60 W, 0.5 Amp

120 VAC, 60 Hz, Single Phase, 60 W, 0.5 Amp

240 VAC, 50 Hz, Single Phase, 60 W, 0.25 Amp

240 VAC, 60 Hz, Single Phase, 60 W, 0.25 Amp

*SCF (standard cubic foot) gas measured at 1 atmosphere and 70°F.

3

**Nm (normal cubic meters) gas measured at 1 atmosphere and 0°C.

A-6 AS-20—1000 Instruction Manual

Page 59

AirSep® Corporation 12/02

AS-750

Oxygen output: 750 SCF/hr at 0–45 psig*

19.72 Nm3/hr at 0–310 kPa**

Oxygen purity: 90% minimum

Oxygen dew point: -73°C

-100°F

Dimensions: 58 x 40 x 100 in. (W x D x H)

147 x 102 x 254 cm (W x D x H)

Approximate weight: 2530 lb

1148 kg

Feed Air Requirements

Flow: 130 SCF/min*

3.80 Nm3/min**

Pressure: 90 psig minimum

620 kPa minimum

Temperature: 50°C maximum

122°F maximum

Power requirements: 120 VAC, 50 Hz, Single Phase, 60 W, 0.5 Amp

120 VAC, 60 Hz, Single Phase, 60 W, 0.5 Amp

240 VAC, 50 Hz, Single Phase, 60 W, 0.25 Amp

240 VAC, 60 Hz, Single Phase, 60 W, 0.25 Amp

*SCF (standard cubic foot) gas measured at 1 atmosphere and 70°F.

3

**Nm (normal cubic meters) gas measured at 1 atmosphere and 0°C.

AS-20—1000 Instruction Manual A-7

Page 60

12/02 AirSep® Corporation

AS-1000

Oxygen output: 1000 SCF/hr at 0–45 psig*

28.32 Nm3/hr at 0–310 kPa**

Oxygen purity: 90% minimum

Oxygen dew point: -73°C

-100°F

Dimensions: 62 x 40 x 106 in. (W x D x H)

158 x 102 x 270 cm (W x D x H)

Approximate weight: 3500 lb

1588 kg

Feed Air Requirements

Flow: 160 SCF/min*

4.53 Nm3/min**

Pressure: 90 psig minimum

620 kPa minimum

Temperature: 50°C maximum

122°F maximum

Power requirements: 120 VAC, 50 Hz, Single Phase, 60 W, 0.5 Amp

120 VAC, 60 Hz, Single Phase, 60 W, 0.5 Amp

240 VAC, 50 Hz, Single Phase, 60 W, 0.25 Amp

240 VAC, 60 Hz, Single Phase, 60 W, 0.25 Amp

*SCF (standard cubic foot) gas measured at 1 atmosphere and 70°F.

3

**Nm (normal cubic meters) gas measured at 1 atmosphere and 0°C.

A-8 AS-20—1000 Instruction Manual

Page 61

AirSep® Corporation 12/02

Operating Data

AS-20—1000 Instruction Manual A-9

Page 62

12/02 AirSep® Corporation

Drawings

A-10 AS-20—1000 Instruction Manual

Page 63

AirSep® Corporation 12/02

Figure 2 General Arrangement Drawing – AS-20

AS-20—1000 Instruction Manual A-11

Page 64

12/02 AirSep® Corporation

Figure 3 Flow Schematic – AS-20

A-12 AS-20—1000 Instruction Manual

Page 65

AirSep® Corporation 12/02

Figure 4 Electrical Schematic – AS-20 (120V)

Figure 5 Electrical Schematic – AS-20 (220V)

AS-20—1000 Instruction Manual A-13

Page 66

12/02 AirSep® Corporation

Figure 6 General Arrangement Drawing – AS-45

A-14 AS-20—1000 Instruction Manual

Page 67

AirSep® Corporation 12/02

Figure 7 General Arrangement Drawing – AS-80

AS-20—1000 Instruction Manual A-15

Page 68

12/02 AirSep® Corporation

Figure 8 General Arrangement Drawing – AS-160

A-16 AS-20—1000 Instruction Manual

Page 69

AirSep® Corporation 12/02

Figure 9 General Arrangement Drawing – AS-250

AS-20—1000 Instruction Manual A-17

Page 70

12/02 AirSep® Corporation

Figure 10 Flow Diagram – AS-45 through AS-250

A-18 AS-20—1000 Instruction Manual

Page 71

AirSep® Corporation 12/02

Figure 11 Electrical Diagram – AS-45 through AS-250 (120V)

Figure 12 Electrical Diagram – AS-45 through AS-250 (220V)

AS-20—1000 Instruction Manual A-19

Page 72

12/02 AirSep® Corporation

Figure 13 General Arrangement Drawing – AS-450

A-20 AS-20—1000 Instruction Manual

Page 73

AirSep® Corporation 12/02

Figure 14 General Arrangement Drawing – AS-750

AS-20—1000 Instruction Manual A-21

Page 74

12/02 AirSep® Corporation

Figure 15 Flow Diagram – AS-450 through AS-750