Airlux HT14A-C-H User Manual

460

HT14

448

494

450

552

863

887

577

454

567

451

208

554

455

453

452

671

765

95

802

24

38

478

0

554

455

23

479

609

609

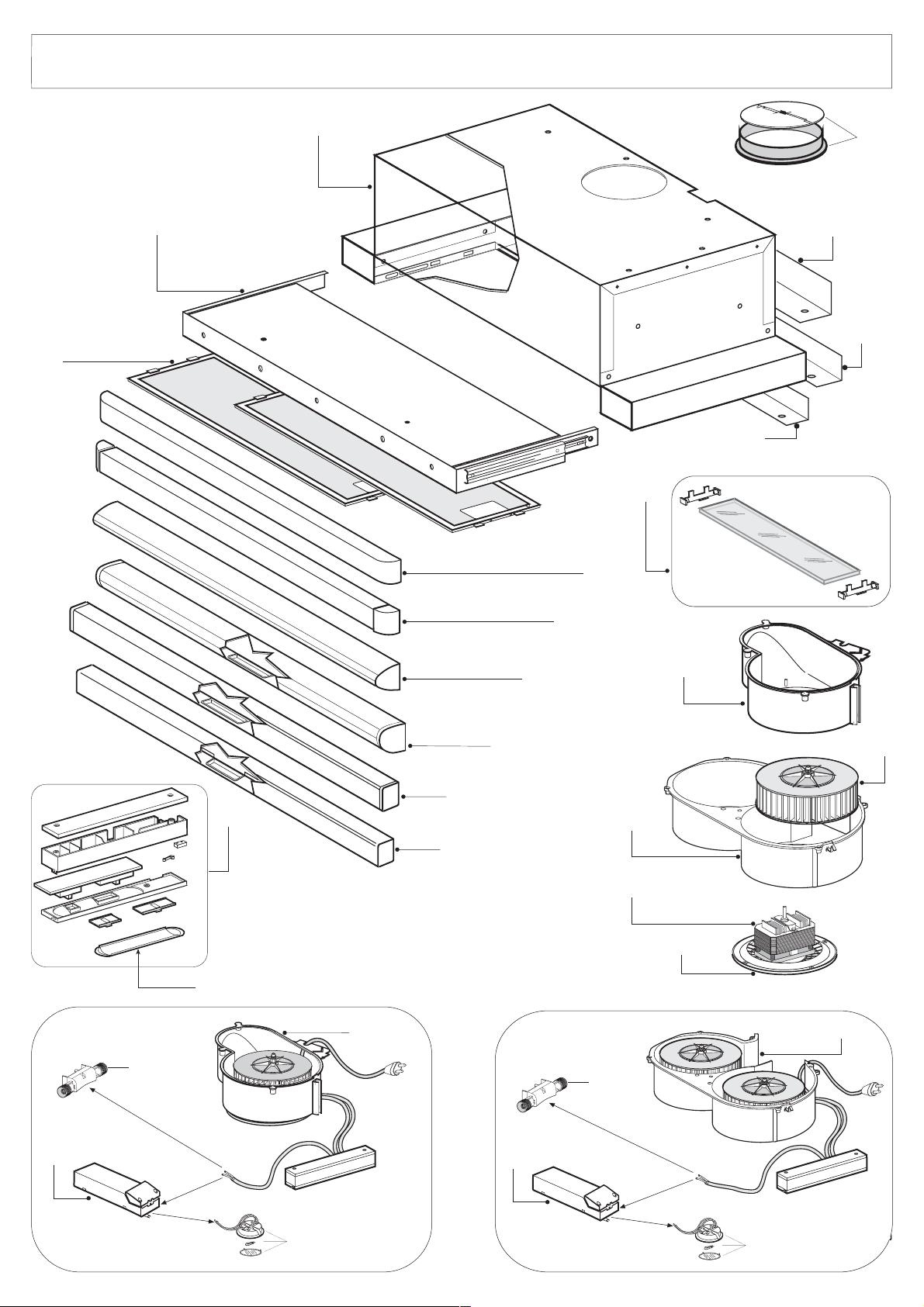

HT14A

COD. DESCRIPTION

Z00SP0023000

Z00SP0024003

Z00SP0038000

Z00SP0095000

Z00SP0448000

Z00SP045060B

Z00SP045200B

Z00SP0453000

Z00SP045400B

Z00SP0455000

Z00SP04606IB

Z00SP0479000

Z00SP0494000

Z00SP056760B

Z00SP057760B

NR.4 FAN WHEEL

NR.2 MOTORS

MOTOR SUPPORT STANDARD

CONVEYOR 2 MOTORS

FLANGE 120MM + ALUMINIUM AIR COLD VALVE

S3 WHITE SLIDING PART 60 CM

S3 WHITE CONTROL K

TRANSPARENT CONTROL COVER

GLASS COVER WITH WHITE SUPPORTS

LAMP HOLDER

S3 WHITE BODY 60CM 1/2 MT TRADIT. LAMPS

CONVEYOR IN2 S3 2 MOTORS SLIDER

ALUMINIUM PANEL SLIM3 60 CM

WELDED FRONT SLIM3 60 CM WHITE

DISTANCE PIECE S3 CM 60 WHITE

POSITION

23

24

38

95

448

450

452

453

454

455

460

479

494

567

577

HT14C

COD. DESCRIPTION

Z00SP0023000

Z00SP0024003

Z00SP0038000

Z00SP0095000

Z00SP0448000

Z00SP045060X

Z00SP045200N

Z00SP0453000

Z00SP045400N

Z00SP0455000

Z00SP04606IX

Z00SP0479000

Z00SP0494000

Z00SP056760X

Z00SP057760X

NR.4 FAN WHEEL 23

NR.2 MOTORS

MOTOR SUPPORT STANDARD

CONVEYOR 2 MOTORS

FLANGE 120MM + ALUMINIUM AIR COLD VALVE

S3 INOX SLIDING PART 60 CM

S3 BLACK CONTROL K

TRANSPARENT CONTROL COVER

GLASS COVER WITH BLACK SUPPORTS

LAMP HOLDER

S3 INOX BODY 60 CM 1/2 MT TRADIT. LAMPS

CONVEYOR IN2 S3 2 MOTORS SLIDER

ALUMINIUM PANEL SLIM3 60 CM

WELDED FRONT SLIM3 60 CM INOX

DISTANCE PIECE S3 CM 60 INOX

POSITION

24

38

95

448

450

452

453

454

455

460

479

494

567

577

HT14H

COD. DESCRIPTION

Z00SP0023000

Z00SP0024003

Z00SP0038000

Z00SP0095000

Z00SP0448000

Z00SP045060N

Z00SP045200N

Z00SP0453000

Z00SP045400N

Z00SP0455000

Z00SP0455000FA

Z00SP04606IN

Z00SP0479000

Z00SP0494000

Z00SP056760N

Z00SP057760N

NR.4 FAN WHEEL

NR.2 MOTORS

MOTOR SUPPORT STANDARD

CONVEYOR 2 MOTORS

FLANGE 120MM + ALUMINIUM AIR COLD VALVE

S3 BLACK SLIDING PART 60 CM

S3 BLACK CONTROL K

TRANSPARENT CONTROL COVER

GLASS COVER WITH BLACK SUPPORTS

LAMP HOLDER

LAMP HOLDER FRANKE IT.

S3 BLACK BODY 60CM 1/2 MT TRADIT. LAMPS

CONVEYOR IN2 S3 2 MOTORS SLIDER

ALUMINIUM PANEL SLIM3 60 CM

WELDED FRONT SLIM3 60 CM BLACK

"DISTANCE PIECE ""S3"" CM 60 BLACK

POSITION

23

24

38

95

448

450

452

453

454

455

455

460

479

494

567

577

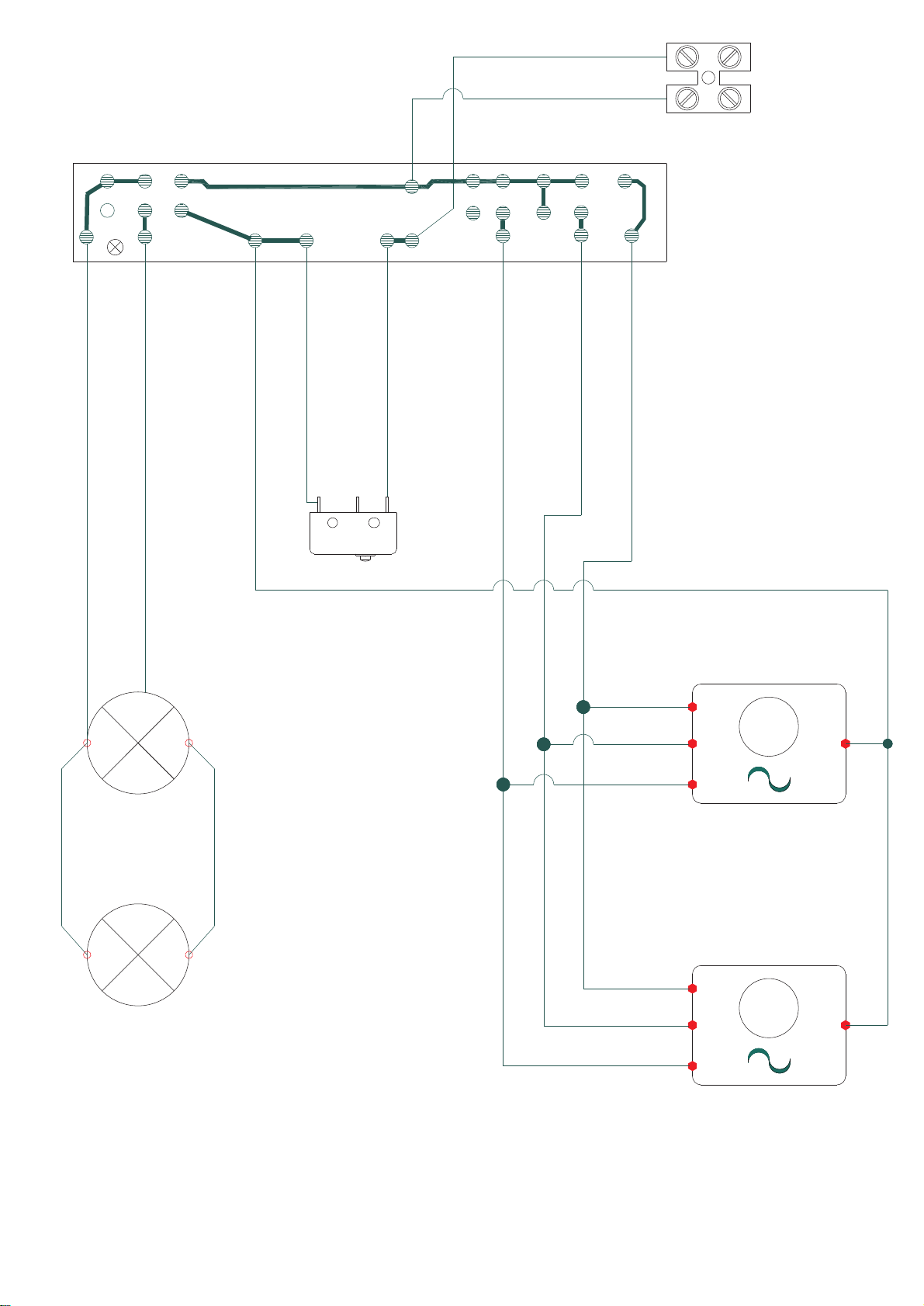

Blue

Brown

Blue

Brown

7PIASLIM3

0

S

Red

Black

L

S

Black

N

1

Black

2

White

3

Brown

Brown

Blue

White

Black

Brown

White

Black

Brown

3

2

1

M

c

Red Red

3

2

1

M

c

Instructions de montage et mode d'emploi de la hotte aspirante

Instructions on mounting and use of the cooker hood

Montagevorschrift und Gebrauchsanleitung fur die Dunstabzugshaube

Istruzioni di montaggio e d'uso della cappa aspirante-filtrante

Mod. HOTTE TIROIR

HT 12

HT 13

HT 14

HT 16

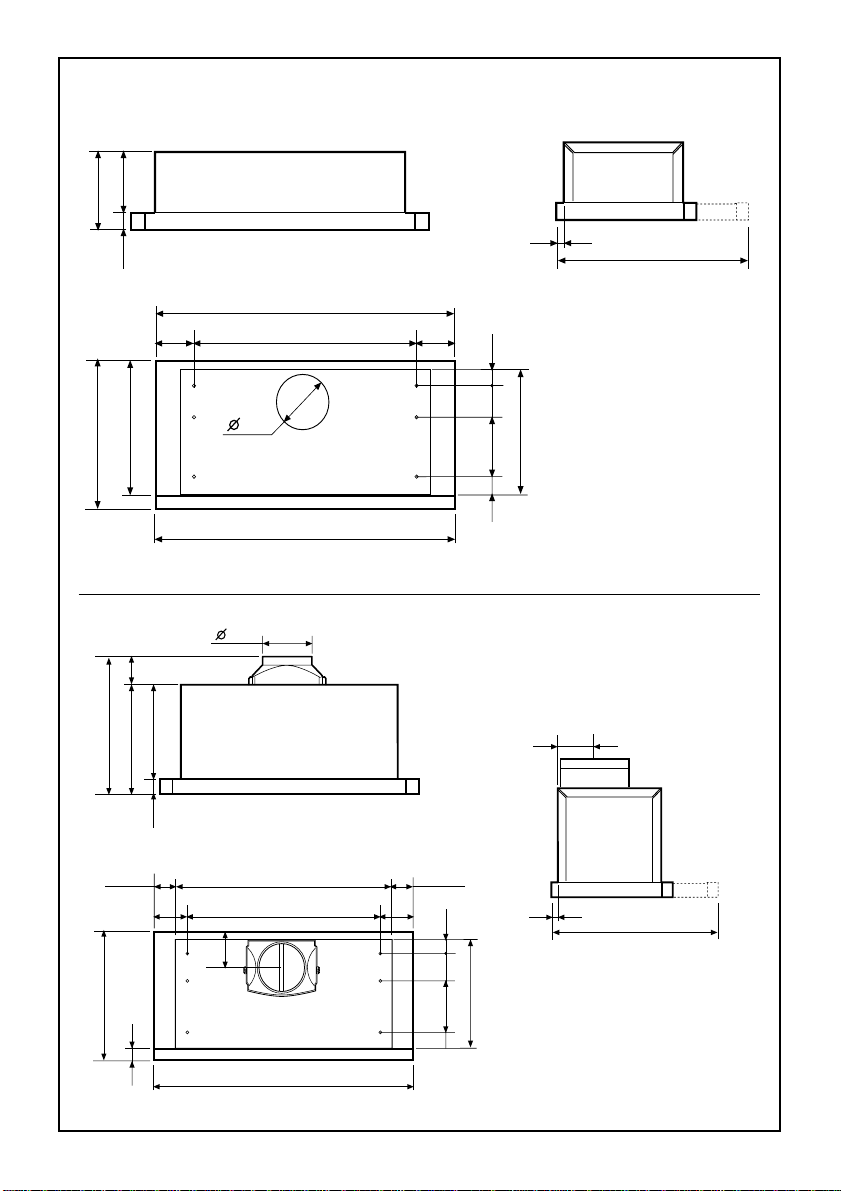

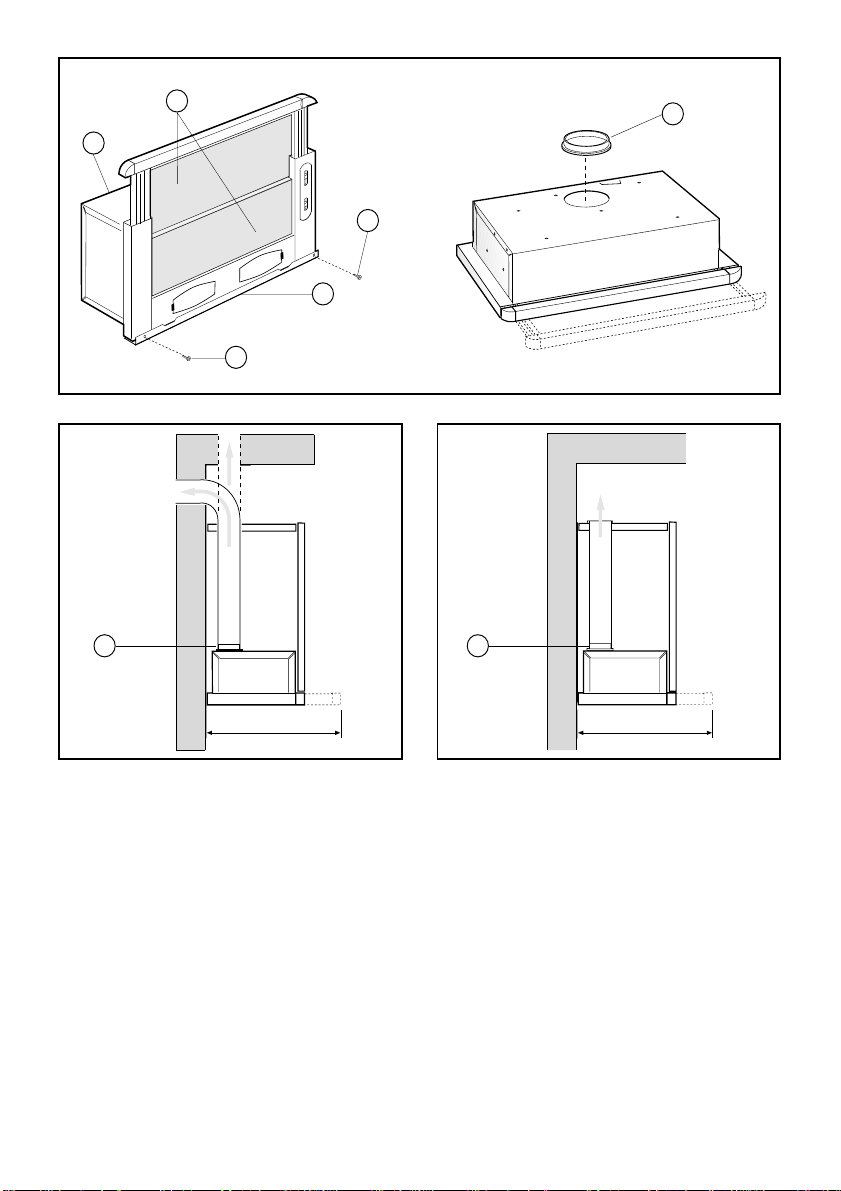

Fig.1

165

13530

290

339

270

80

259

12

440

512 / 812

469 / 76921.5 21.5

31

6513131

120

258

600 / 900

150

22930

77.5

43.5 43.5

512 / 812

469 / 76921.5 21.5

89.5

290

22

600 / 900

31

65131

258

12

440

Fig.2

G

A

P

L

P

Fig.3 Fig.4

B

B

440

B

440

2

ENGLISH

ENGLISH

GENERAL

Carefully read the following important information regarding installation

safety and maintenance. Keep this information booklet accessible for

further consultations.

The appliance has been designed as a exhausting version (external

exhaust) or as a filter version (internal air recycle) cooker hood.

SAFETY PRECAUTION

1. ake care when the cooker hood is operating simultaneously with an

open fireplace or burner that depend on the air in the environment and

are supplied by other than electrical energy, as the cooker hood remo ves

the air from the environment which a burner or fireplace need for

combustion.

The negative pressure in the environment must not exceed 4 Pa (4 x

10 -5 bar).

Provide adequate ventilation in the environment for a safe operation of

the cooker hood.

Follow the local laws applicable for external air evacuation.

2. WARNING!!

In certain circumstances electrical appliances may be a danger

hazard.

A) Do not check the status of the filters while the cooker hood

is operating

B) Do not touch the light bulbs after appliance use

C) Flambè cooking is prohibited underneath the cooker hood

D) Avoid free flame, as it is damaging for the filters and a fire

hazard

E) Constantly check food frying to avoid that the overheated oil

may become a fire hazard

F) Disconnect the electrical plug prior to any maintenance.

INSTALLATION INSTRUCTIONS

• Electric Connection

The appliance has been manufactured as a class II, therefore no earth

cable is necessary.

The connection to the mains is carried out as follows:

BROWN = L line

BLUE = N neutral

If not provided, connect a plug for the electrical load indicated on the

description label. Where a plug is provided, the cooker hood must be

installed in order that the plug is easily accessible.

An omnipolar switch with a minimum aperture of 3mm between

contacts, in line with the electrical load and local standards, must be

placed between the appliance and the network in the case of direct

connection to the electrical network.

• The appliance must be installed at a minimum height of 650 mm from

an cooker stove.

If a connection tube composed of two parts is used, the upper part must

be placed outside the lower part.

Do not connect the cooker hood exhaust to the same conductor used

to circulate hot air or for evacuating fumes from other appliances

generated by other than an electrical source.

• ATTENTION: should the lamps not work, make sure they are well

tightened.

• INSTALLA TION

The following instruction should be followed to carry out the correct

installation of the cooker hood.

1) Mounting of the cooker hood on the lower side of the cupboard.

2) Selection of the version (extraction or filtration)

Mounting the cooker hood on the lower side of the cupboard. This

appliance must be fitted to a cupboard or other suitable support. For

fixing use 4 screws suitable for the cupboard, using the hole in Fig.1.

When mounting align the front of the cooker hood to the door of the

cupboard and regulate the L wall spacer through the screws marked

P (Fig 2). The rear of the appliance must then align with the cupboard.

• EXTRACTION THROUGH AN OUTSIDE WALL

The appliance expels the fumes through an outside wall or a duct. It is

necessary to buy a telescopic pipe in accordance with the standards

in use (inflammable with diameter 120mm) and connect it to flange B

(Fig 3).

• RECIRCULA TION

To transf orm the cooker hood from the extraction v ersion to the re

circulating one ask your supplier for an activated carbon filter. The

activated carbon filter cleans the air of the room. This filter is not

washable or re-usable and must be substituted at least every 4 months.

Saturation of the activated charcoal depends on how often the appliance

is used, the type of kitchen and how regularly the grease filter is cleaned.

The filter must be fitted to the extracting group cooker hood in the

centre of the fan grille by twisting it by 90 degrees until it is gripped

securely. F or this operation remove the grill G (Fig 2). The clean air

is returned into the room through a connecting tube passing inside the

cupboard and connected to the ring B (fig 4).

USE AND MAINTENANCE

• It is recommended to operate the appliance prior to cooking.

It is recommended to leave the appliance in operation for 15 minutes

after cooking is terminated in order to completely eliminate cooking

vapours and odours.

The proper function of the cooker hood is conditioned by the regularity

of the maintenance operations, in particular, the active carbon filter.

• The anti-grease filters capture the grease particles suspended in the

air, and are therefore subject to clogging according to the frequency of

the use of the appliance.

In order to prevent fire hazard, it is recommendable to clean the filter

at a maximum of 2 months by carrying out the following instructions:

- Remove the filters from the cooker hood and wash them in a solution

of water and neutral liquid detergent, leaving to soak.

- Rinse thoroughly with warm water and leave to dry.

- The filters may also be washed in the dishwasher.

The aluminium panels may alter in colour after several washes. This

is not cause for customer complaint nor replacement of panels.

• The active carbon filters purify the air that is replaced in the

environment. The filters are not washable nor re-useable and must be

replaced at maximum every four months. The saturation of the active

carbon filter depends on the frequency of use of the appliance, by the

type of cooking and the regularity of cleaning the anti-grease filters.

• Clean the fan and other surfaces of the cooker hood regularly using

a cloth moistened with denatured alcohol or non abrasive liquid

detergent.

THE MANUFA CTURER DECLINES ALL RESPONSIBILITY FOR

EVENTUAL DAMA GES CA USED BY BREA CHING THE ABO V E

WARNINGS.

Loading...

Loading...