Air Lift Performance ECR 6107, 39020 -15704, 39020, MN-564 User Manual

Please read these instructions completely

before proceeding with installation

Failure to read these instructions can result in mis-installation

Introduction to the RoadTamer System

What You Need to Know About RoadTamer ...................... 2

Vehicle Requirements ........................................................ 3

RoadTamer Warranty and Return Policy............................ 3

Installing the RoadTamer System

Getting Started ................................................................... 4

Inspecting Axle Spring Perch Uniformity ............................ 5

Attaching the Axle Beams .................................................. 5

Attaching the Frame Brackets ............................................ 6

Attaching and Adjusting the Panhard Rod.......................... 7

Hardware List ..................................................................... 9

*Kit Installation Diagram .................................................... 10

Installing the Rolling Lobe Air Sleeves .............................. 11

Installing the Air Lines ....................................................... 12

Reattaching the Brake Cables ........................................... 13

Final Adjustments .............................................................. 13

MN-564

(15704)

ECR 6107

by

Checking Driveline Angles

Checking Driveline Angles................................................. 14

Checking Angles in Various Conditions............................. 14

Chevy 3500 Kit No. 39020

Installation Checklist

Installation Checklist .......................................................... 15

Troubleshooting Guide

Troubleshooting Guide ...................................................... 16

Checking for Leaks ............................................................ 17

Fixing Leaks ...................................................................... 17

Maintaining and Servicing the System

Maintenance Guidelines .................................................... 18

Servicing the RoadTamer System ..................................... 18

Technical Support

1-800-248-0892

Ext. 2

1

What You Need to Know About RoadTamer

About RoadTamer

The RoadTamer suspension system and your

vehicle’s original equipment steel spring suspension

operate differently. RoadTamer allows your vehicle to

ride “on air.” It lowers air pressure for lighter loads,

meaning you will have a softer ride when you don’t

need the heavy factory springs.

RoadTamer lowers your vehicle to be approximately

level with the front suspension. The result is a vehicle

altitude very similar to that of a fully loaded vehicle.

The air management system then maintains that rear

suspension height regardless of the load you carry.

Ride Height

RoadTamer gives you optimum ride performance,

regardless of the load. RoadTamer’s air management

system will maintain the vehicle’s ride height within ½”.

You will enjoy a much more comfortable, controllable

and safer ride. The design of RoadTamer is carefully

considered to give you “The Ultimate Suspension

Upgrade.”

Vehicle Leveling, Side-to-Side

Vehicles are not always level when they are delivered

from the factory. Installing RoadTamer on your vehicle

does not correct this non-level condition. Before you

install RoadTamer, measure for vehicle levelness on

a fl at surface. After the factory springs have been

removed, use a level to verify that the axle spring

perches are level from side-to-side. If the perches

are not level, you will need to apply a wedge shim

to one side or the other to correct this condition. The

wedge shim is provided with each RoadTamer kit.

More information is provided later in the instruction

manual.

Install your RoadTamer kit and make sure the axle

is level and square with the vehicle frame. Snug, but

DO NOT TORQUE, all fasteners per the directions

provided in this installation manual. Check again to

see if the vehicle is level. If it is not close to as level

as its factory levelness, re-read the installation manual

concerning the use of the wedge shim. You may also

have to loosen all beam connecting bolts, u-bolts,

etc. Re-level the axle to the frame before re-torquing

all fasteners.

Introduction to the RoadTamer System

Driveline Angles

Driveline angles are factory-set to cancel vibrations

caused by the u-joints. RoadTamer takes this into

consideration when lowering the vehicle to a level

height. However, the factory does not set up all vehicles

to be identical. Many different axle, suspension, and

wheelbase combinations are possible. You will need to

measure the driveline angles and make a calculation

to verify that the driveline cancels correctly. See the

section Checking Driveline Angles toward the back of

the installation manual.

Technical Support

1-800-248-0892

Ext. 2

2

Vehicle Requirements

Vehicle Type

Chevy 3500

NOTE:

spacer kit # 26029 (purchased seperately) in

addition to kit # 39020. If you do not already have

spacer kit # 26029, you can purchase it by calling

Air Lift’s Customer Service Department at 800-2480892, extension 1.

For 4WD crew cab models, use driveshaft

Vehicle Years

See the application guide for specifi c years.

5th Wheel Hitch

The installation of this RoadTamer kit will fi t onto most

vehicles with a fi fth wheel hitch. Some fi fth wheel

hitches may require modifi cations to make the kit fi t

properly.

See page 5 for further instructions.

Muffl er Modifi cations

Modifi cations will need to be made to the muffl er after

the completion of this kit.

Gross Vehicle Weight Rating

(GVWR)

IMPORTANT: The installation of this kit does not

alter the GVWR or payload of the vehicle. Check

your vehicle owner’s manual and do not exceed the

maximum load listed for your vehicle.

Gross Vehicle Weight Rating - The maximum allowable

weight of the fully loaded vehicle (including passengers

and cargo). This number - along with other weight

limits, as well as tire, rim size and infl ation pressure

data - is shown on the vehicle’s Safety Compliance

Certifi cation Label.

Payload - The combined, maximum allowable weight of

cargo and pasengers that the truck is designed to carry.

It is GVWR minus the Base Curb Weight.

Introduction to the RoadTamer System

Air Lift Company recommends taking your vehicle

to a muffl er repair shop upon completion of the kit

installation.

RoadTamer Warranty and Return Policy

Air Lift Company warranties its RoadTamer

product against quality and workmanship defects

to the original retail purchaser as follows;

Main Structural components defi ned as; beams,

brackets, and links for 24 months or 24,000 miles,

whichever occurs fi rst. All other components for

12 months or 12,000 miles, whichever occurs fi rst.

Air Lift Company provides no warranty on the

vehicle’s original equipment or other aftermarket

products. This warranty does not apply to products

that have been improperly applied, installed, used

in racing applications or maintained in accordance

with installation instructions furnished with

the product. A $10.00 minimum shipping and

handling charge will apply to all warranty claims.

Before returning any defective product, you must

call Air Lift Company (800) 248-0892 ext 2 for

an RGA (Returned Goods Authorization) number.

Product failures resulting from abnormal use or

misuse are excluded from this warranty. The loss

of use of the product, loss of time, inconvenience,

commercial loss, or consequential damages is

not covered. The Air Lift Company reserves the

right to change the design of any product without

assuming any obligation to modify any product

previously manufactured. Dated proof of purchase

is required.

Technical Support

1-800-248-0892

Ext. 2

3

Getting Started

DANGER: Compressed air can cause injury and

damage to the vehicle and parts if it is not handled

properly. For your safety, do not try to infl ate the air

springs until they have been properly secured to the

vehicle.

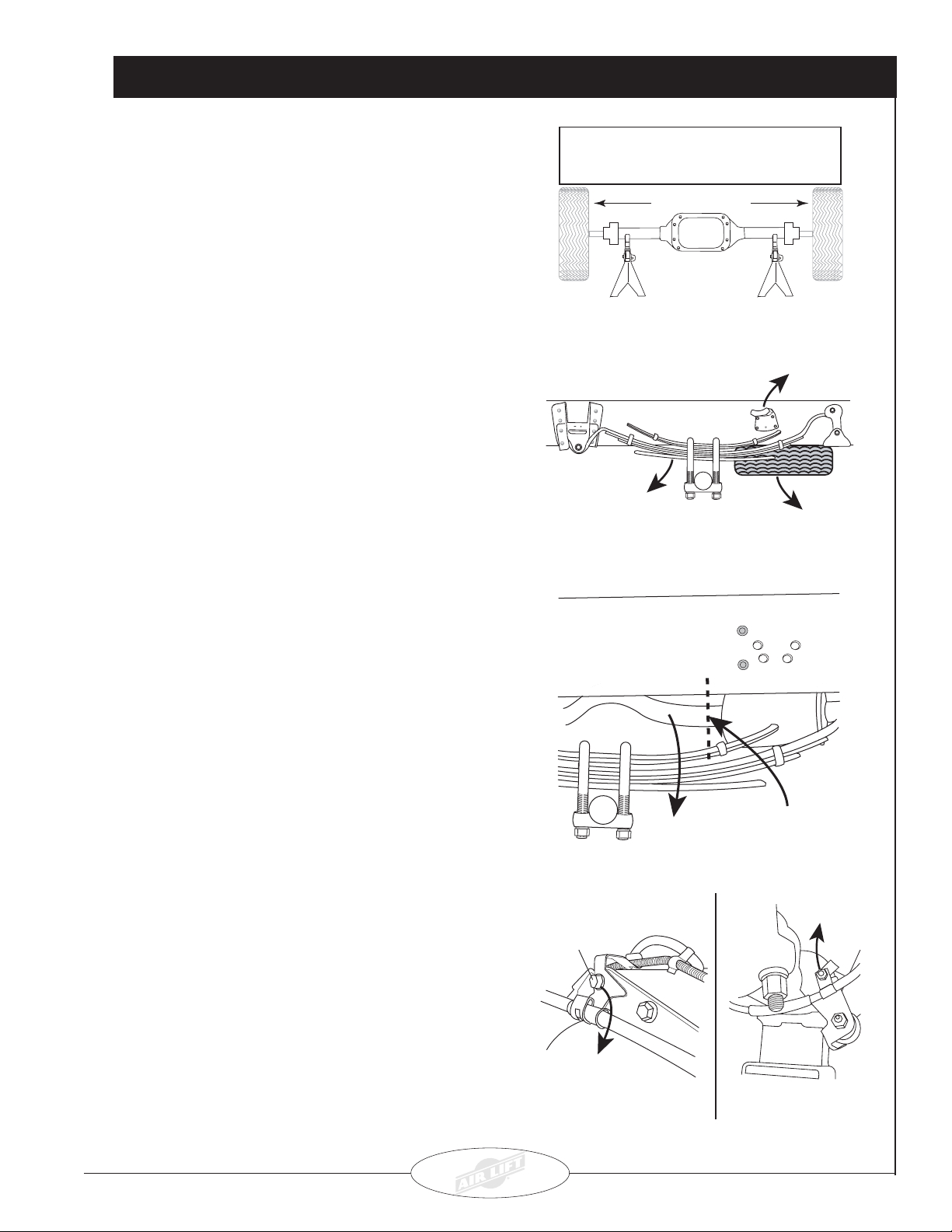

No Load in Truck

Remove Wheel Remove Wheel

IMPORTANT: Measure and record the driveline angles

in the chassis as fi rst received (Figure 21).

1. Elevate the rear of the vehicle and secure the frame

with jack stands or a frame-contact hoist. Support

the axle (Figure 1).

2. Remove the spare tire, both leaf springs, and the

rear frame contact overload brackets, if equipped,

from the frame (Figure 2).

NOTE: It will be necessary to cut the driver side

bolt out of the spring retainer because of how

the gas tank is positioned. A replacement 16

mm bolt is supplied for reinstallation. Retain

the front spring eye bolt from the passenger side

and nuts for later use.

NOTE: It may be necessary to remove the trailer

hitch in order to remove the bolts from the spring

hanger.

NOTE: After removing the factory steel springs,

check the axle spring perches for side-to-side

angle uniformity. Refer to the Inspecting Axle

Spring Perch Uniformity section for information

on installing the supplied 1° wedge shim.

Support the axle with jack

stands and raise or lower

to Normal Ride Height.

Driver-Side View

REMOVE

Leaf Spring.

Driver-Side View

Figure 1

Axle

Figure 2

REMOVE Frame

Contact Overload

Upper Bracket

if equipped.

REMOVE

Spare Tire.

Installing the RoadTamer System

3. Cut off the tailpipe behind the muffl er and remove.

Leave enough room on the muffler to install a

replacement pipe (Figure 3).

4. Remove the bolts securing the brake cables to the

rear end (Figure 4).

Technical Support

1-800-248-0892

Ext. 2

Axle

Top Rear End

Cover Bolt

Remove bolt and

discard bracket.

REMOVE

excess tailpipe.

Figure 3

Figure 4

CUT OFF tailpipe behind

muffler. Leave enough

room to attach a

replacement pipe.

Remove

Bolt

Driver Side

Emergency Brake Cable

4

Inspecting Axle Spring Perch Uniformity

1. After removing the factory steel springs, check

the axle spring perches for side-to-side angle

uniformity. Without disturbing the axle position,

place a magnetic angle protractor on one perch and

note the angle. Next, place the angle protractor on

the other perch and note the angle there as well.

A difference of less than 1° is normal and does

not require a shim. If the difference between the

two angles exceeds 1°, use the supplied 1° wedge

shim to correct the difference.

2. Place the 1° wedge shim on one axle spring perch

and re-measure the angles to verify that they equal

less than 1°. Use the centering pin to attach the

wedge to the correct beam and install the beams

as directed in the section titled Attaching the Axle

Beams. DO NOT TIGHTEN FASTENERS until you

have checked the driveline angles as instructed in

Attaching the Axle Beams

NOTE: For 4WD crew cab models, refer to the

manual provided with the driveshaft spacer kit

# 26029 (purchased seperately) at this time. You

must have this spacer kit before proceeding. If you

do not already have spacer kit # 26029, you can

purchase it by calling Air Lift’s Customer Service

Department at 800-248-0892, extension 1.

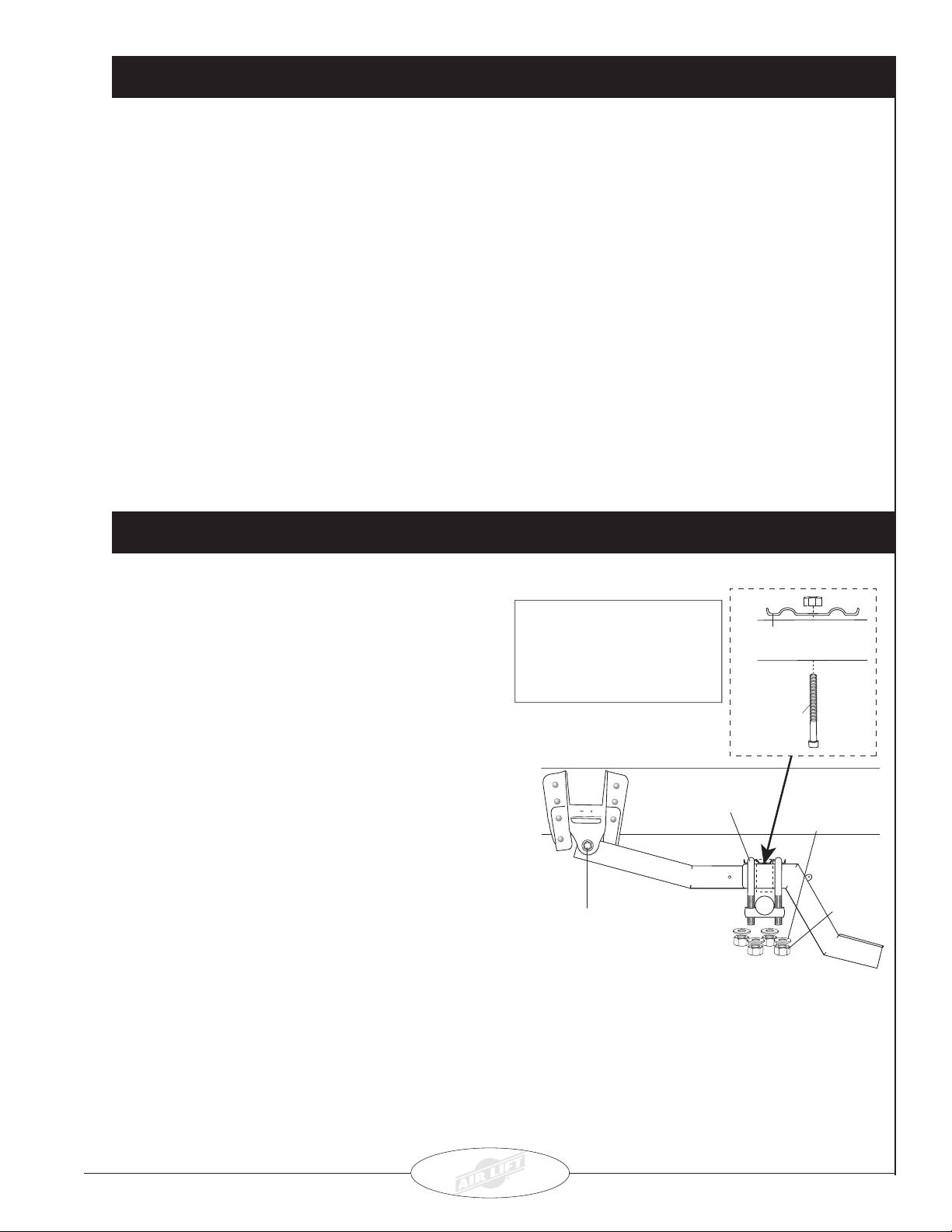

1. Attach the centering pins through each beam with

the round head facing down. Tighten the centering

pin nut securely (Figure 5).

the section dealing with that topic toward the back of

this manual.

NOTE: You must check the driveline angles for

cancellation before completing the installation

(see the Driveline Angles section toward the back

of the manual). It may be necessary to reverse the

shim and place it on the opposite side to maintain

correct driveline angles.

3. Measure from the top of each frame rail (at the rear of

the frame) to the ground. The measurement must be

made at vehicle ride height with the vehicle on level

ground and with equal tire pressures. The vehicle

levelness is acceptable if the two measurements from

side-to-side are within 3/8”. If the vehicle is not level

within 3/8”, check that the 1° shim is placed properly.

For 4WD crew cab models, refer to the manual

provided with the driveshaft spacer kit # 26029

(purchased seperately) at this time. You must

have this spacer kit before proceeding. If you

do not already have spacer kit # 26029, you can

purchase it by calling Air Lift’s Customer Service

Department at 800-248-0892, extension 1.

Driver-Side Shown

Stock Spring

Retainer

Centering

Pin

Beam

Installing the RoadTamer System

2. Attach the driver-side beam assembly to the front

spring eye hanger using the supplied 16 mm bolt

(stock bolt on passenger side) and washer and the

previously removed stock nut (Figure 5). Be sure

to index the centering pin into the spring perch in

order to properly locate the axle and the beam.

Leave loose.

NOTE: The emergency brake cable should go

over the beam assembly.

3. Attach the beam assemblies to the axle with the

hardware shown in Figure 5. Secure snugly, but

do not completely tighten at this time.

NOTE: It will be necessary to use the stock

spring retainer between the u-bolts and the

beams.

NOTE: Draw the nuts down evenly on the

retainer by using a criss-cross tightening

pattern.

Technical Support

1-800-248-0892

Ext. 2

U-bolt

A 16mm bolt and washer

are supplied for the driver

side only. Use the stock

bolt on the passenger side.

Figure 5

Axle

5

/8"

Flat

Washer

5

/8" Nut

5

Attaching the Frame Brackets

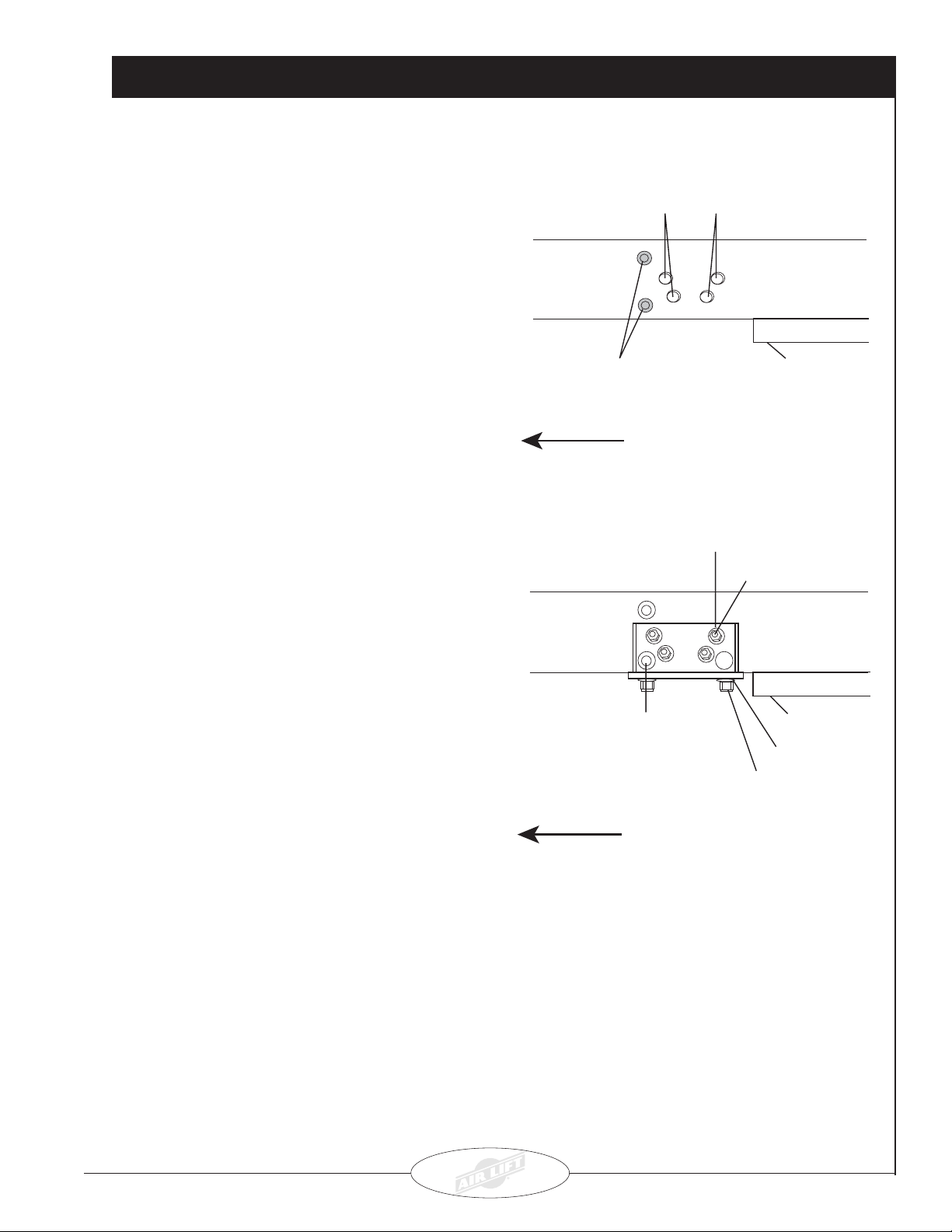

1. Install the driver-side frame bracket. Line up the

lower crossmember rivet with the lower, forward

hole in the upper bracket. Clamp the bottom of the

fl ange on the bracket to the frame fl ange using vise

grips or welding clamps.

2. a) If there are existing holes:

Line up the upper bracket holes with the

existing contact overload bracket holes in the

frame (Figure 6). Attach the bracket to the

frame with four ½” bolts, eight washers and

four nyloc nuts. Leave loose at this time.

b) If there are NO existing holes:

Drill a ½” hole using the upper bracket as a

template. Attach the bracket with one ½”

bolt, two fl at washers and one nyloc nut.

Tighten just until snug. Do not overtighten.

3. Drill two ½” holes through the frame fl ange using the

top hole in the bracket as a template. Attach the

upper bracket using two ½” bolts, four fl at washers

and two nyloc nuts. Tighten just until snug. Do not

overtighten.

Existing Frame Contact

Overload Holes

(If not equipped,

drill out to ½")

Cross Member Rivets

FORWARD

Driver-Side Shown

Figure 6

½" Flat Washer

½" Bolt

Frame

Trailer Hitch

Installing the RoadTamer System

4. Drill the remaining holes through the side, if needed,

using the bracket holes as a template. Attach the

remaining ½” hardware shown in Figure 7, starting

with the bottom ½” bolts. Torque all hardware to 107

ft.lbs.

5. Repeat steps 1-4 for the passenger side.

6. Reinstall the spare tire.

Cross member rivet

must be in forward

hole in upper bracket.

FORWARD

Frame

Trailer Hitch

½" Flat Washer

½" Bolt

Driver-Side Shown

Figure 7

Technical Support

1-800-248-0892

Ext. 2

6

Loading...

Loading...